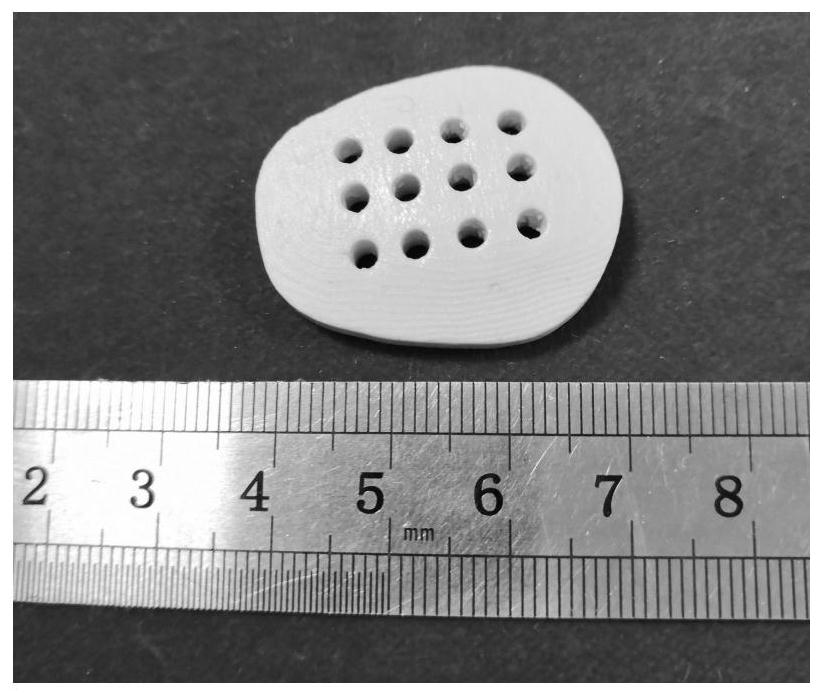

A kind of light-cured calcium silicate/β-tricalcium phosphate ceramic paste and preparation method of porous scaffold

A technology of tricalcium phosphate ceramics and light-curing molding, applied in the direction of prosthesis, tissue regeneration, additive processing, etc., can solve the problems of affecting the printing accuracy of printed parts, low printing accuracy, cracking and deformation of printed parts, etc., to improve the curing efficiency , The effect of reducing the degree of printing deformation and reducing the tendency of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1, a light-cured calcium silicate / β-tricalcium phosphate ceramic paste, according to the mass ratio, including 83% of ceramic powder, 14% of premix, 1.0% of dispersant, 0.5% of photoinitiator, Volume agent 1.0% and leveling agent 0.5%;

[0039] The ceramic powder is a mixed powder of calcium silicate and β-tricalcium phosphate, and the mass ratio of calcium silicate to β-tricalcium phosphate is 0.8:1.2; the D50 of calcium silicate and β-tricalcium phosphate is 3μm;

[0040]The premix is a mixture of bisphenol A epoxy acrylic resin, 1,6-hexanediol diacrylate and trimethylolpropane triacrylate; wherein, the bisphenol A epoxy acrylic resin accounts for the majority of the quality of the premix. 26.0%, 1,6-hexanediol diacrylate accounts for 59.0% of the premix, and trimethylolpropane triacrylate accounts for 15.0% of the premix;

[0041] Described dispersant is TEGO 685 oily wetting and dispersing agent;

[0042] Described photoinitiator is benzoin dimethyl eth...

Embodiment 2

[0061] Example 2, a light-cured calcium silicate / β-tricalcium phosphate ceramic paste, according to the mass ratio, including 81.5% of ceramic powder, 14% of premix, 1.5% of dispersant, 0.5% of photoinitiator, Volume agent 1.5% and leveling agent 1.0%;

[0062] The ceramic powder is a mixed powder of calcium silicate and β-tricalcium phosphate, the mass ratio of calcium silicate and β-tricalcium phosphate is 0.9-1.1; D50 of calcium silicate and β-tricalcium phosphate is 3 μm;

[0063] The premix is a mixture of bisphenol A epoxy acrylic resin, 1,6-hexanediol diacrylate and trimethylolpropane triacrylate; wherein, bisphenol A epoxy acrylic resin accounts for 25.0% of the mass of the premix %, 1,6-Hexanediol diacrylate accounts for 58.0% of the mass of the premix, and trimethylolpropane triacrylate accounts for 17.0% of the mass of the premix;

[0064] Described dispersant is TEGO 685 oily wetting and dispersing agent;

[0065] Described photoinitiator is benzoin dimethyl et...

Embodiment 3

[0084] Embodiment 3, a light-cured calcium silicate / β-tricalcium phosphate ceramic paste, according to the mass ratio, including 80% of ceramic powder, 15% of premix, 1.5% of dispersant, 1.0% of photoinitiator, Volume agent 1.5% and leveling agent 1.0%;

[0085] The ceramic powder is a mixed powder of calcium silicate and β-tricalcium phosphate, the mass ratio of calcium silicate and β-tricalcium phosphate is 1:1; D50 of calcium silicate and β-tricalcium phosphate is 3 μm ;

[0086] The premix is a mixture of bisphenol A epoxy acrylic resin, 1,6-hexanediol diacrylate and trimethylolpropane triacrylate; wherein, bisphenol A epoxy acrylic resin accounts for 25% of the mass of the premix. %, 1,6-Hexanediol diacrylate accounts for 59% of the mass of the premix, and trimethylolpropane triacrylate accounts for 16% of the mass of the premix;

[0087] The dispersant is TEGO 685 oily wetting and dispersing agent;

[0088] Described photoinitiator is benzoin dimethyl ether;

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com