Method for forging steel bimetallic fracture splitting connecting rod

A technology for cracking connecting rods and bimetals, which is used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., to solve the effect of bonding quality, reducing cracking deformation, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0042] A method for forging a steel bimetal cracking connecting rod specifically follows the steps:

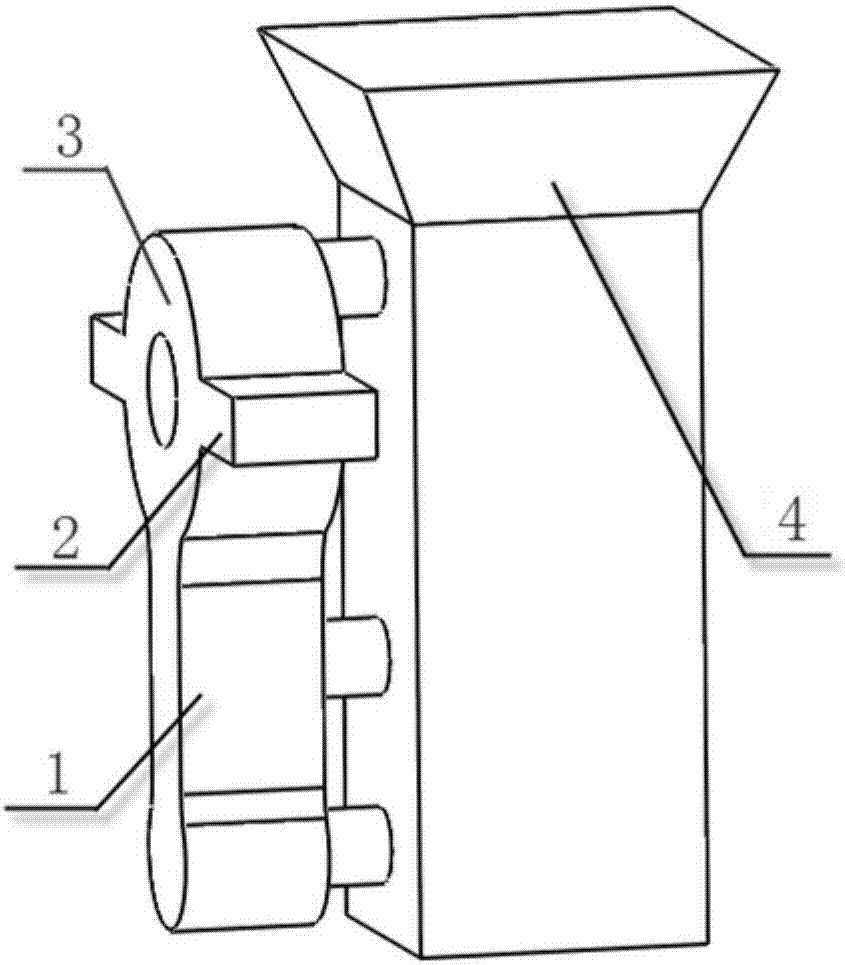

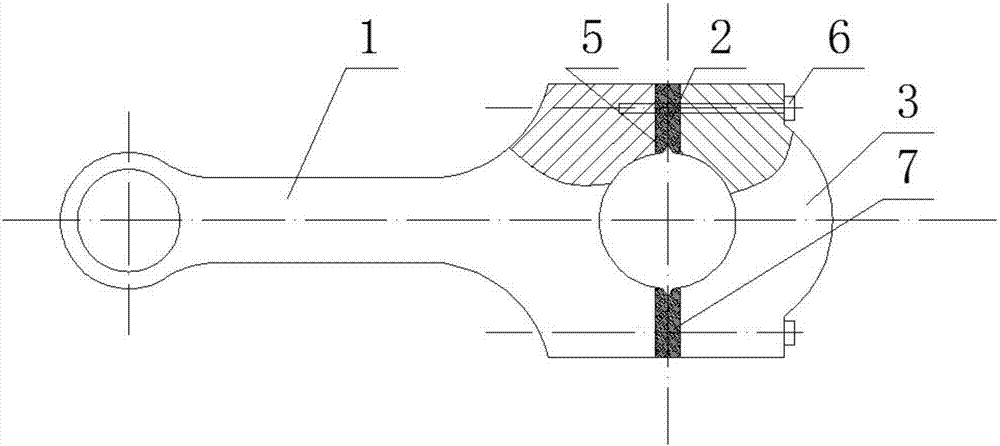

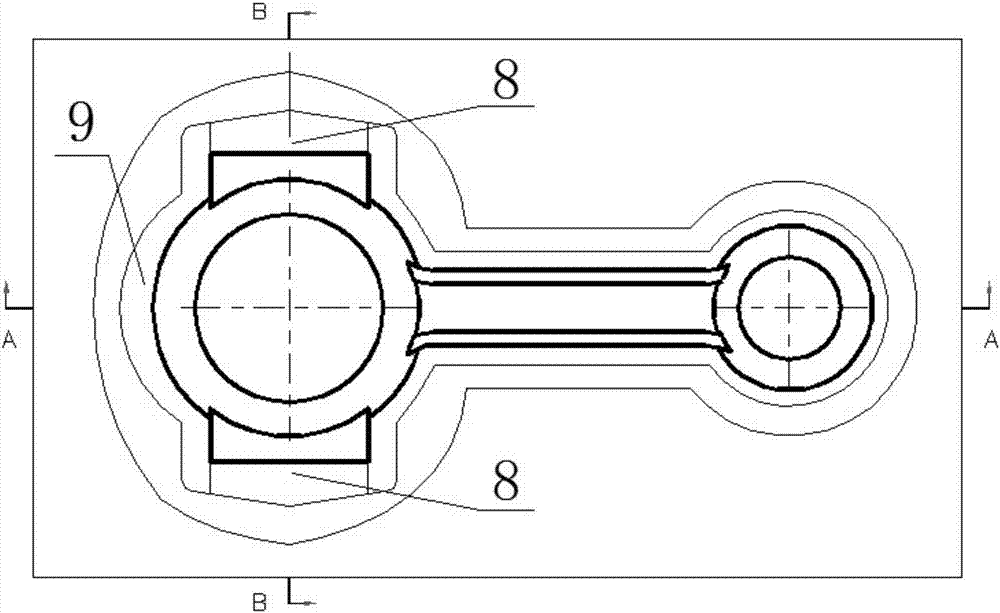

[0043] S1: The casting slab of steel bimetal cracking connecting rod is prepared by casting process, and the casting slab is composed of connecting rod body 1, cracking zone 2 and connecting rod cover 3, such as figure 1 with figure 2As shown, wherein the material of the cracking zone 2 is set as the cracking material, between the connecting rod body 1 and the connecting rod cover 3; the material of the connecting rod body 1 and the connecting rod cover 3 is set as the main body material; the The main material is medium-carbon steel or medium-carbon alloy steel; the cracked material is high-carbon alloy steel with a carbon content of 0.7% to 1.2%, and its meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com