Wear-resistant high-performance ceramic roller and preparation method thereof

A ceramic roller rod, high-performance technology, applied in the field of ceramic rollers, can solve the problems of poor high-temperature strength, poor wear resistance, thermal shock resistance to be improved, etc., to achieve increased strength, high production efficiency, and excellent wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

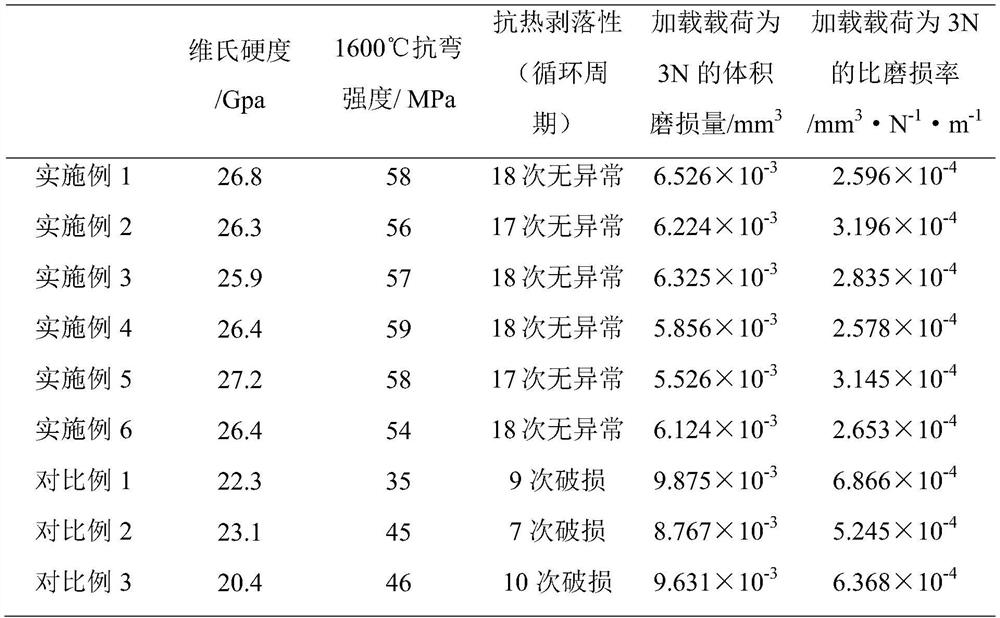

Examples

Embodiment 1

[0030] A wear-resistant high-performance ceramic roller rod and its preparation method

[0031] Wear-resistant high-performance ceramic rollers, including the following raw materials in parts by weight: fused mullite 15kg, fused alumina 20kg, sericite clay 10kg, modified zirconia sol 5kg, bauxite 5kg, silica sand 3kg , andalusite 3kg, carbon fiber 10kg, rare earth oxide 5kg, matrix oxide 15kg, binder 2kg; the particle size of the above-mentioned fused mullite 2 o 3 10kg, CaO 5kg, K 2 O3kg, MgO5kg, ZnO2kg, MoO 3 1kg.

[0032] In the present embodiment, the preparation method of the above-mentioned modified zirconia sol comprises the following steps:

[0033] (1), the ZrOCl 2 ·8H 2 After adding O into water and dispersing evenly, ZrOCl with a concentration of 30% was prepared 2 ·8H 2 O aqueous solution, the concentration of 10% ammonia solution was added to ZrOCl 2 ·8H 2 In the O aqueous solution, after stirring and dispersing evenly, add absolute ethanol for repeated w...

Embodiment 2

[0044] A wear-resistant high-performance ceramic roller rod and its preparation method

[0045] Wear-resistant high-performance ceramic roller rods, including the following raw materials in parts by weight: fused mullite 18kg, fused alumina 25kg, sericite clay 15kg, modified zirconia sol 8kg, bauxite 6kg, silica sand 4kg, red 4kg of pillar stone, 15kg of carbon fiber, 8kg of rare earth oxide, 16kg of matrix oxide, and 3kg of binder; the particle size of the above-mentioned fused mullite is 2 o 3 11kg, CaO 6kg, K 2 O3.5kg, MgO6kg, ZnO2.5kg, MoO 3 1.5kg.

[0046] In the present embodiment, the preparation method of the above-mentioned modified zirconia sol comprises the following steps:

[0047] (1), the ZrOCl 2 ·8H 2 After adding O into water and dispersing evenly, ZrOCl with a concentration of 30% was prepared 2 ·8H 2 O aqueous solution, the concentration of 10% ammonia solution was added to ZrOCl 2 ·8H 2 In the O aqueous solution, after stirring and dispersing evenly...

Embodiment 3

[0058] A wear-resistant high-performance ceramic roller rod and its preparation method

[0059] Wear-resistant high-performance ceramic rollers, including the following raw materials in parts by weight: fused mullite 18-25kg, fused alumina 30kg, sericite clay 20g, modified zirconia sol 10kg, bauxite 6.5g, silica sand 5kg, andalusite 5kg, carbon fiber 18kg, rare earth oxide 9kg, matrix oxide 17kg, binder 4kg; the particle size of the above-mentioned fused mullite 2 o 3 12kg, CaO 6kg, K 2 O4kg, MgO8kg, ZnO4kg, MoO 3 2.5kg.

[0060] In the present embodiment, the preparation method of the above-mentioned modified zirconia sol comprises the following steps:

[0061] (1), the ZrOCl 2 ·8H 2 After adding O into water and dispersing evenly, ZrOCl with a concentration of 30% was prepared 2 ·8H 2 O aqueous solution, the concentration of 10% ammonia solution was added to ZrOCl 2 ·8H 2 In the O aqueous solution, after stirring and dispersing evenly, add absolute ethanol for repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com