Preparation method of superconducting and ultra-fine aluminum-magnesium alloy wires

An aluminum-magnesium alloy, ultra-fine technology, applied in the field of alloy gold wire production, can solve the problems of aluminum-magnesium alloy wire tensile performance, electrical conductivity discount, manufacturer loss, variable surface, etc., to reduce production costs and reduce deformation Effect of cracking and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

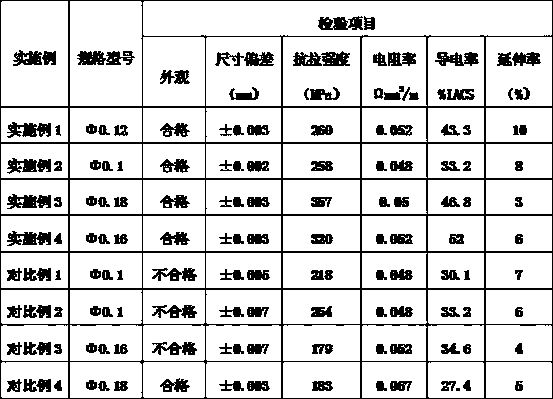

Examples

Embodiment 1

[0025] A method for preparing superconducting, ultra-fine aluminum-magnesium alloy wires, comprising the following steps:

[0026] Material preparation: accurately weigh aluminum ingots, magnesium ingots, and master alloys;

[0027] Melting: Take the aluminum ingot and put it into the melting furnace, set the temperature to be ≥ 720 for melting, and stir continuously at the same time to obtain molten aluminum; place the aluminum-chromium intermediate alloy, compounded aluminum ingot and magnesium ingot at the furnace mouth to preheat, and control the temperature at 730-740°C , gently push the aluminum-chromium intermediate alloy and compounded aluminum ingot into the aluminum liquid, and use a magnesium press to press the magnesium ingot into the aluminum liquid, and move slowly under the surface of the aluminum liquid, and finally fully stir to make the magnesium element uniform Diffusion; the input amount of compounded aluminum ingots is 5% / furnace of the total amount of alu...

Embodiment 2

[0031] A method for preparing superconducting, ultra-fine aluminum-magnesium alloy wires, comprising the following steps:

[0032] Material preparation: accurately weigh aluminum ingots, magnesium ingots, and master alloys;

[0033] Melting: Take aluminum ingots and put them into the melting furnace, set the temperature to be ≥ 720 for melting, and at the same time keep stirring to obtain molten aluminum; place aluminum-chromium intermediate alloys, waste rods, and magnesium ingots in the furnace mouth to preheat, control the temperature at 730-740°C, and put The intermediate alloy is gently pushed into the molten aluminum, and the magnesium ingot is pressed into the molten aluminum with a magnesium press, and slowly moves under the surface of the molten aluminum, and finally fully stirred to make the magnesium element diffuse evenly; the input amount of the waste rod is aluminum 3% of the total amount of ingots and magnesium ingots / furnace;

[0034] Refining: Put the degasse...

Embodiment 3

[0037] A method for preparing superconducting, ultra-fine aluminum-magnesium alloy wires, comprising the following steps:

[0038] Material preparation: accurately weigh aluminum ingots, magnesium ingots, and master alloys;

[0039] Melting: Take the aluminum ingot and put it into the melting furnace, set the temperature to be ≥ 720 for melting, and stir continuously at the same time to obtain molten aluminum; place the aluminum-chromium intermediate alloy, compounded aluminum ingot and magnesium ingot at the furnace mouth to preheat, and control the temperature at 730-740°C , gently push the intermediate alloy into the aluminum liquid, and use a magnesium press to press the magnesium ingot into the aluminum liquid, and move slowly under the surface of the aluminum liquid, and finally fully stir to make the magnesium element diffuse evenly; among them, the compounded aluminum ingot The input amount is 6% of the total amount of aluminum ingots and magnesium ingots per furnace; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com