Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Play the role of color protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preserving agent for litchi and preparation method of the preserving agent for litchi

InactiveCN105166028AInhibition of reproductionGrowth inhibitionFruit and vegetables preservationSaccharumPumpkin seed

The invention provides a preserving agent for litchi and a preparation method of the preserving agent for litchi and relates to the technical field of vegetable and fruit preservation. The preserving agent comprises the following raw materials in percentages by weight: 0.5-1.2% of traditional Chinese medicine extract solution, 0.2-0.5% of sucrose ester, 0.3-0.5% of sodium chloride, 0.5-0.8% of konjak glucomannan, 0.2-0.3% of nanometer TiO2 and water accounting for all the rest percentages; the traditional Chinese medicine extract solution comprises the following raw materials in parts by weight: 5-10 parts of pumpkin seeds, 3-6 parts of pseudolaricis, 3-6 parts of radix gentianae, 2-5 parts of aloes, 2-5 parts of Chinese honey locusts and 2-5 parts of ulmus macrocarpa hance. The Chinese herbal medicines are used as raw materials of the preserving agent; the Chinese herbal medicines are used as antimicrobial substances, the konjak glucomannan is used as film-forming substance, the sucrose ester is used as emulsifier, the sodium chloride is used for sterilizing and color-protecting and the nanometer material is used as excipient, so that the preserving agent for litchi is obtained. The preserving agent for litchi is capable of preventing litchi from browning and rotting, so that commodity rate of the litchi is raised.

Owner:周建卿

Dumpling flour and production method thereof

The invention relates to a dumpling flour and a production method thereof. Complex additive is added to wheat flour which is the main raw material. The dumpling flour is produced by mixing proper amount of complex additive and the processed and ground wheat flour. The complex additive is produced by combining a guar gum, VC, CMC(thickening agent), compound enzyme agent and starch by a certain proportion, which ensures that the actions of all the components can suit well with each other. The color and luster, taste and boiling fastness of made dumplings are greatly improved by adding the complex additive to different flours. Compared with control samples, the dumpling flour has obvious advantages in color and luster, transparency of dumpling wrapper and taste, for cooked dumplings, the soup is clear and the wrapper is not broken before eating.

Owner:郑州天地人面粉实业有限公司

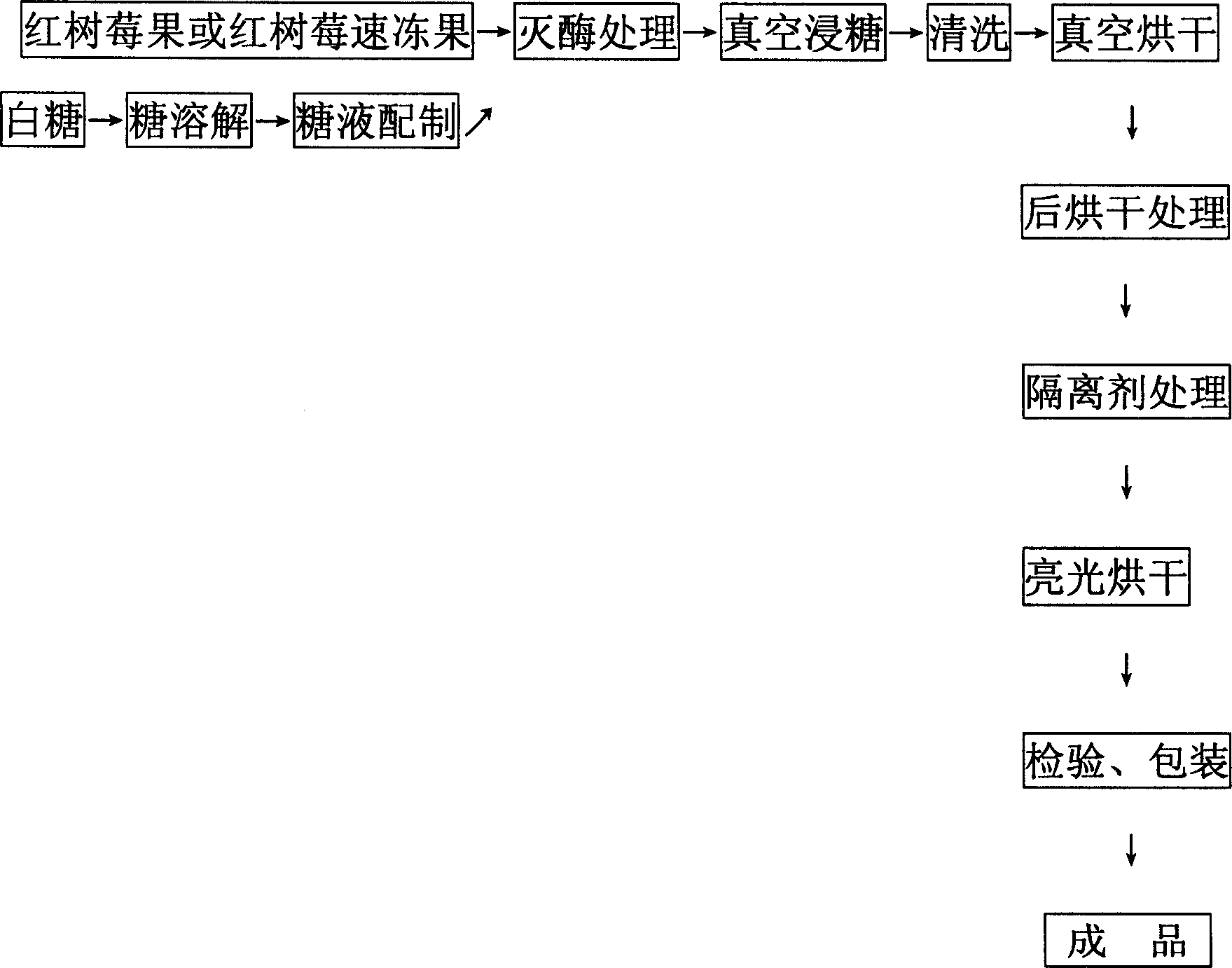

Dried fruit food with red aeterio and production thereof

InactiveCN1817165AComplete fruitBright red uniform colorConfectionerySweetmeatsMangroveAdditive ingredient

A health-care preserved mangrove raspberry fruit for removing free radicals from human body, delaying sanility and preventing and treating cancers is prepared through collecting mangrove raspberry fruits, quick freezing, deactivating enzyme, vacuum preserving in sugar, water washing, vacuum drying, treating with isolating agent, baking, examining and packing.

Owner:LIAONING TODAY AGRI

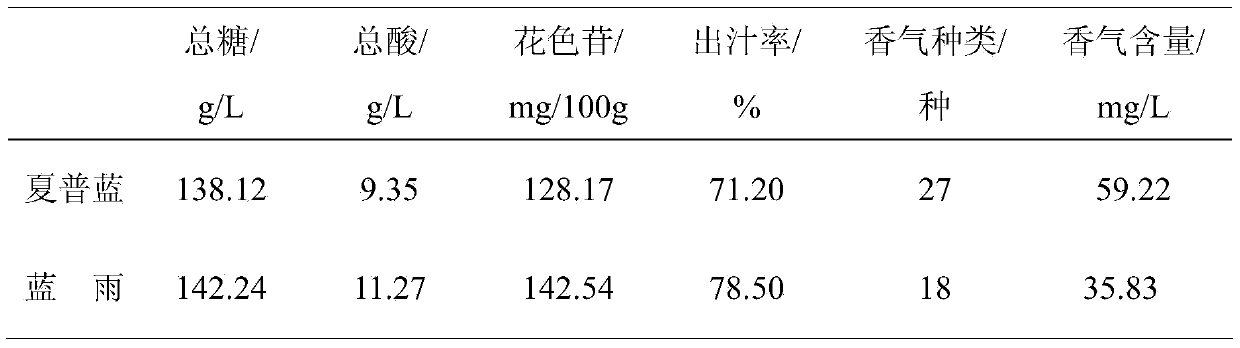

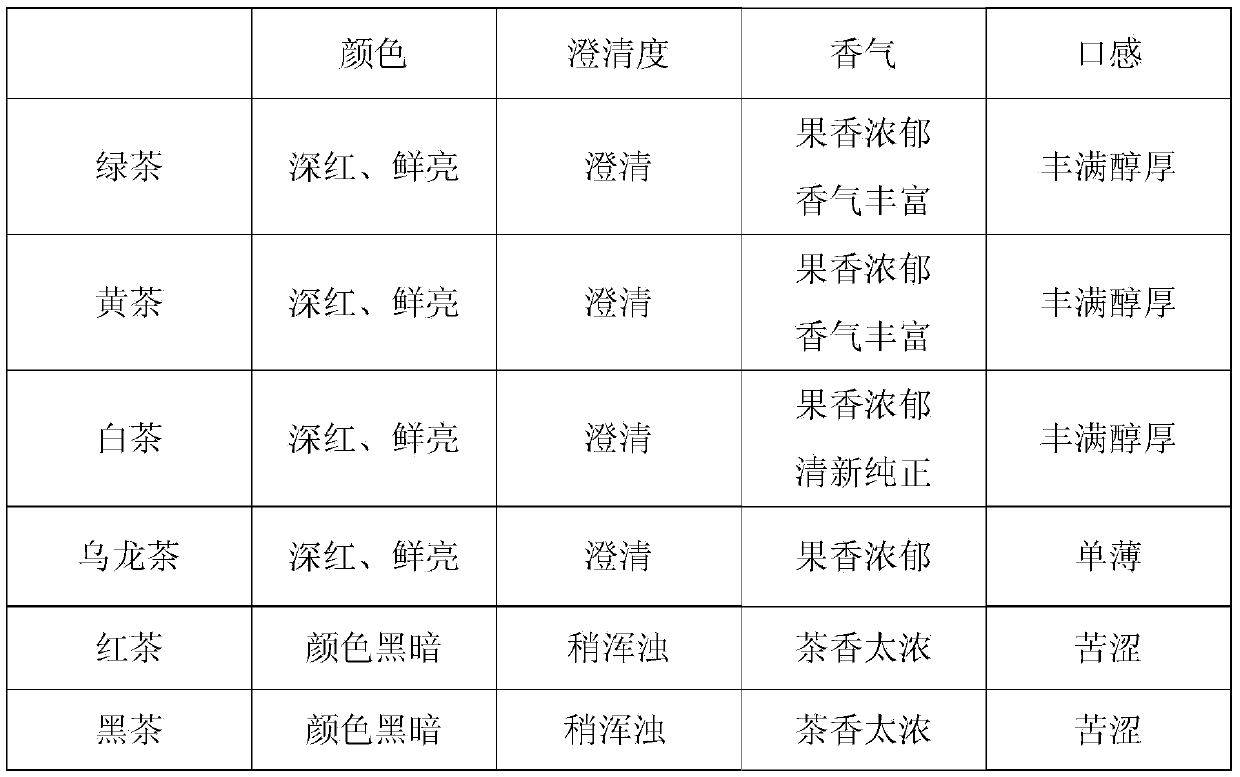

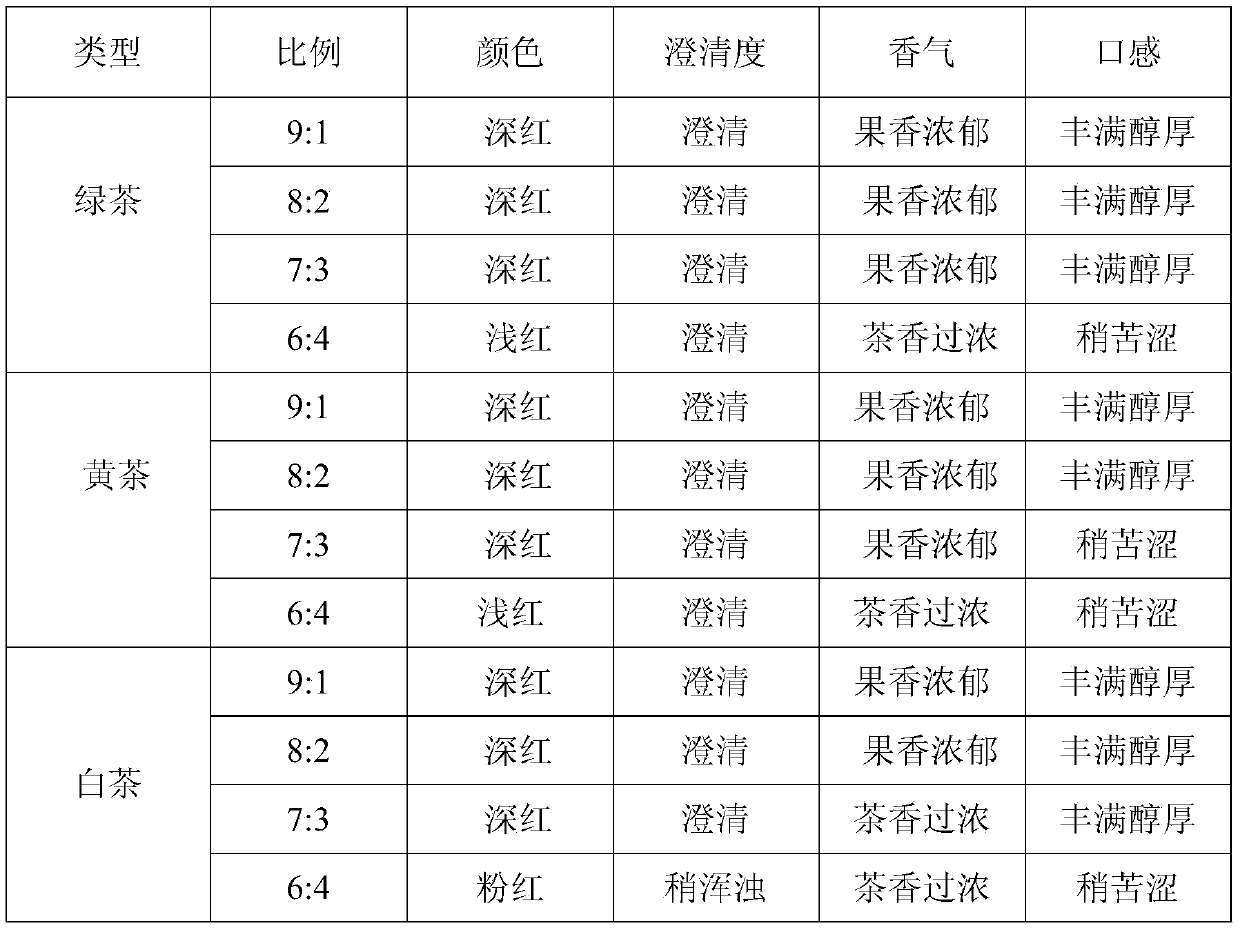

Brewing method of lower-alcohol blueberry health-care wine

ActiveCN105368631ADeep colorStrong aromaAlcoholic beverage preparationMicroorganism based processesFruit wineStable state

The invention discloses a brewing method of lower-alcohol blueberry health-care wine. The method comprises the steps of blueberry selection and processing, tea preprocessing, raw material blending, ethanol fermentation, ageing, clarification stabilizing processing and the like. The method uses an optimized blue rain variety of blueberries as raw materials, and meanwhile tea leaching liquid, prebiotics and soluble dietary fibers are added; the lower-alcohol blueberry wine is obtained through raw pulp steeping, high-temperature enzymolysis, high-temperature start, mixed-bacteria synergy and low-temperature long-time fermentation; low-temperature ageing is assisted by microwaves to accelerate wine body mature, and the quality of the fruit wine is improved; a wine body is higher in clarity and is kept in a stable state for a long period of time through clarification stabilizing processing; the taste of the wine is improved and meanwhile a health-care function is increased for the wine by adding a functional sweetener. By the adoption of the process, the high-quality lower-alcohol blueberry wine having good color, fragrance and taste and integrating nutrition and health care can be obtained.

Owner:HUANGSHAN BLUEBERRY ECOLOGICAL PARK CO LTD

Healthy tea and preparation method thereof

ActiveCN102907521AKeep the aromaGuaranteed FeaturesPre-extraction tea treatmentFood preparationDiseaseSide effect

The invention discloses healthy tea and a preparation method thereof, and aims to solve the problems that drugs and operations are mainly adopted for treating obesity and 3-high symptoms at present, yet the drug treatment takes a long period, is costly, and has side effects on the patients, the operative treatment is harmful to the patient's bodies, and the possibility of relapse after the treatment is high. The healthy tea adopts green tea as the main component and is additionally provided with the components such as tartary buckwheat, black soybean and chrysanthemum; the through the cooperation and coordination of the components, the functions of human bodies can be effectively improved, the fat accumulation can be reduced, the blood sugar, the blood pressure and the blood fat can be reduced, the functions of the intestines and stomach can be improved, the internal metabolism can be accelerated, both the both principal and secondary aspect of disease are treated, and the possibilities of the relapse of the obesity and the 3-high symptoms are reduced; and at the same time, the healthy tea has no side effect, is not harmful to the human bodies, is low in cost, and is convenient to use. Excellent effects as improving the functions and the self-immunity of human bodies and can be achieved by drinking healthy tea from a long time.

Owner:陕西雨鹤生物科技有限公司

Processing method of black pepper

The invention discloses a method for processing green pepper, including the following steps: a. the green pepper is picked in 10-30 days before the pepper is ripe, and is washed with clean water; b. pretreatment is carried out: after being picked within 4-12 hours, the washed pepper is scalded with 80-100 DEG C of hot water for 6-30 minutes, then is taken out and quickly cooled, and the water is removed by dripping; c. the pretreated pepper is placed in time in an oven for drying, the drying temperature is kept between 40-75 DEG C, until the water content drops below 12 % by drying, the pepper is taken out for cooling. The pepper processed by the invention has perfect condition, green color, strong hot taste and pure fragrance; the method has high processing efficiency, microorganism infection is not likely to occur during processing, and the finished products processed has stable quality and is easy to store.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

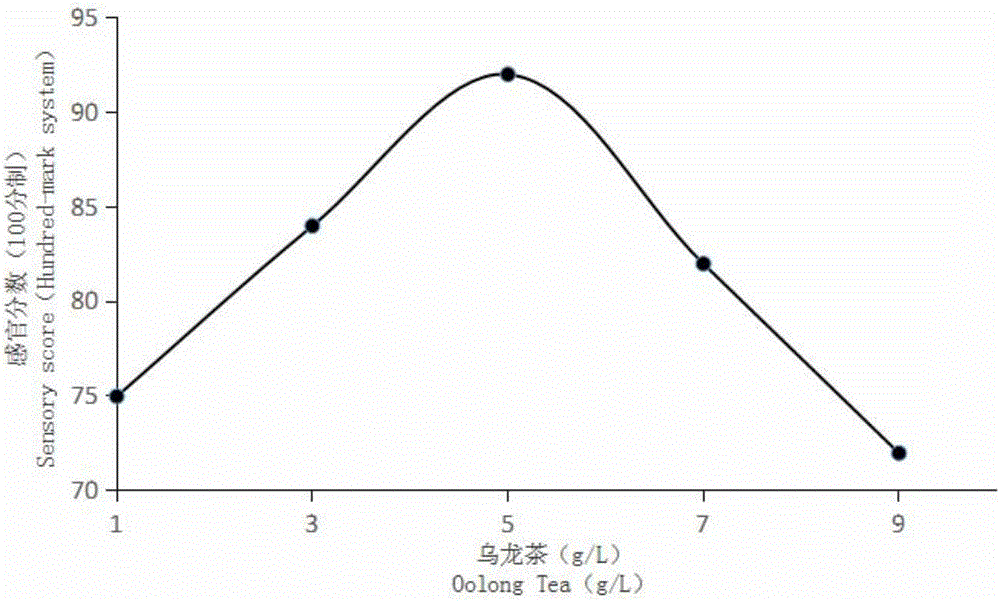

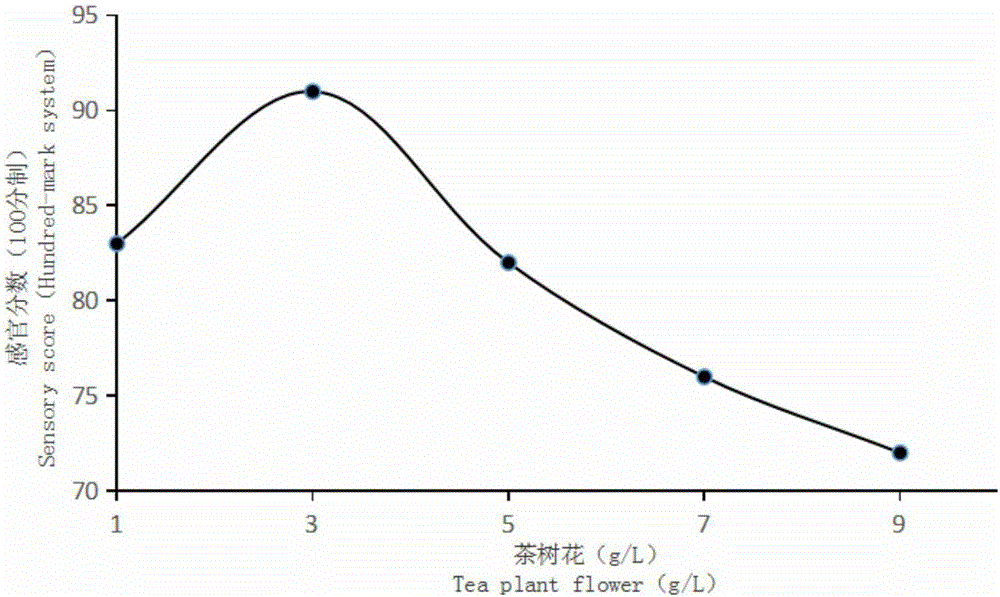

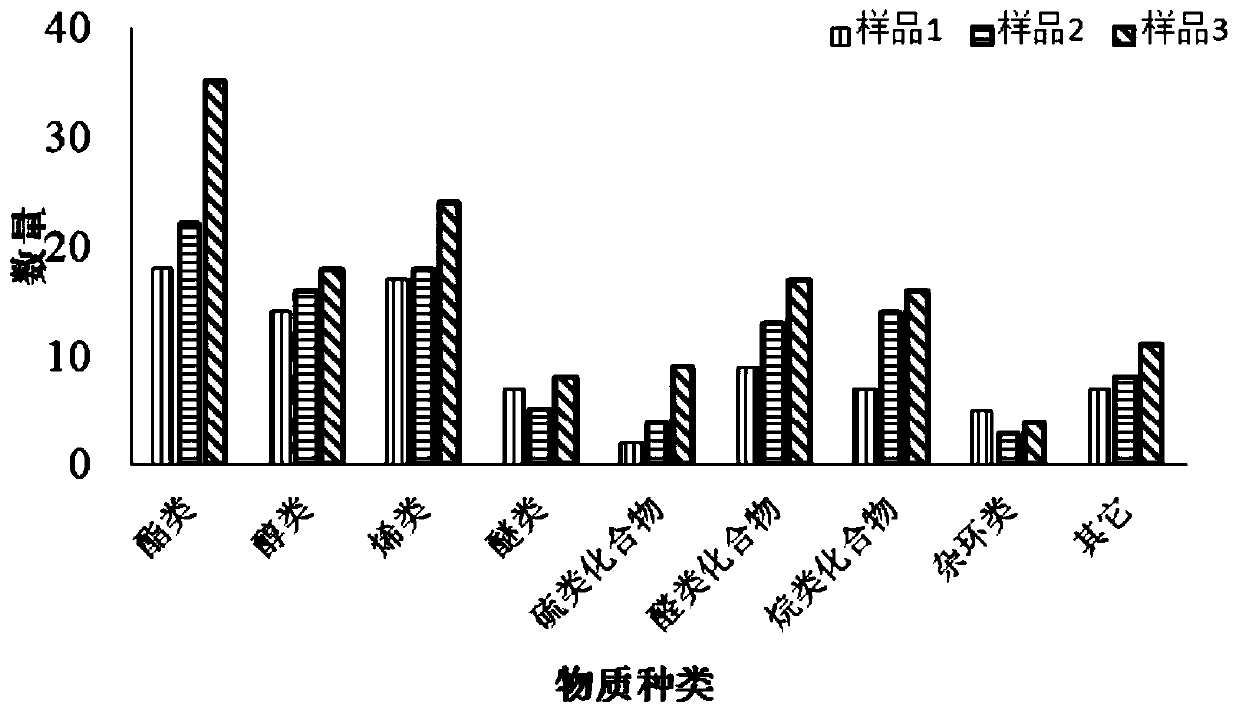

Flower and fruit oolong beverage and preparation method thereof

The invention discloses a flower and fruit oolong beverage. Each liter of the beverage comprises the following raw materials: 4 to 6 g of oolong, 2 to 4 g of tea tree flowers, 1.5 to 2.5 g of roselle, 0.5 to 1 g of rose flowers, 3 to 5 g of dried orange peel, 70 to 80 g of white granulated sugar, 0.8 to 1.2 g of citric acid and 0.05 to 0.2 g of Vc. The flower and fruit oolong beverage provided by the invention is clear and transparent, avoids impurities and precipitates during shelf life, is rose red and bright in color and luster, has oolong fragrance, flower and fruit fragrance and rose flower fragrance, slightly has the unique fragrance of the dried orange peel, and is mellow in taste, sour, sweet and delicious; the flavor and the taste of all the raw materials do not conflict with each other, but supplements each other; and the flower and fruit oolong beverage forms an oolong beverage product with new taste and good flavor, is suitable for popular taste and is quite popular with women. The flower and fruit oolong beverage provided by the invention is safe and healthy in material, has abundant various nutritional substances, has certain nutritional value and health-care effect, meets the requirements of customers on product creativity, enlarges potential consumer group and has a very good market prospect.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Industrial method for preparing pickled Chinese cabbage product by fermenting green mustard

PendingCN111000174ASlow down fermentationConducive to annual industrial productionSugar food ingredientsFruit and vegetables preservationBiotechnologySalt water

The invention belongs to the field of food, particularly relates to a pickle preparation technology in the field of food, and particularly relates to an industrial method for preparing a pickled Chinese cabbage product by fermenting green mustard. The method comprises the steps of 1) raw material selection and pretreatment; 2) quickly starting fermentation for the first time, and carrying out sand-sealed fermentation for 15 to 30 days; (3) carrying out second-round storage and shallow fermentation, and carrying out sand-sealed fermentation for 90 to 120 days again; and (4) carrying out third-round aroma enhancement fermentation for 10 to 15 days to obtain the fermented pickled Chinese cabbages. According to the method, through three rounds of fermentation, vegetable salting water is recycled; spices and other auxiliary materials are added, so that vegetables are more mature in fermentation and better in flavor; by recycling the vegetable salting water, the utilization efficiency and benefit of water can be improved; more nutrient substances are provided for later fermentation; the special flavor is achieved; the salting degree is reduced; resource waste is avoided; and the production cost is saved.

Owner:SICHUAN DONGPO CHINESE PAOCAI IND TECH RES INST

Preparation method of purple sweet potato powder

InactiveCN106579144AGood effectPlay the role of color protectionFood ingredient functionsChemistryExodermis

The invention discloses a preparation method of purple sweet potato powder. The preparation method includes the following specific steps: 1, washing, wherein purple sweet potatoes are washed with clean water; 2, peel removing, wherein the peel of the purple sweet potatoes are removed completely with a bamboo knife; 3, slicing, wherein the peeled purple sweet potato in the step 2 is sliced with a vegetable slicer into purple sweet potato slices; 4, color protection, wherein the purple sweet potato slices are placed in a sodium chloride solution with the concentration of 0.6% for 5-8 min, and the solution is slightly stirred with a stirring rod; 5, drying, wherein the purple sweet potato slices are placed in a drying oven; 6, crushing, wherein the purple sweet potato slices dried in the step 5 is crushed in a hammer piece type crusher, the fineness of the crushed purple sweet potato is 50-100 meshes, and the purple sweet potato powder is prepared; 7, packaging, wherein the purple sweet potato powder obtained after crushing in the step 6 is packaged into a bag. The obtained purple sweet potato powder has the advantages of being healthy, safe, and good in color protection effect.

Owner:周梦倩

Winged prickly ash-flavored seasoned bamboo shoot slices and preparation method thereof

The present invention relates to the technical field of bamboo shoot product processing, and especially relates to winged prickly ash-flavored seasoned bamboo shoot slices and a preparation method thereof. The winged prickly ash-flavored seasoned bamboo shoot slices in the invention are prepared from the following raw materials in parts by weight: 100 parts of bamboo shoot slices, 10-13 parts of thick broad-bean sauce, 2-2.5 parts of winged prickly ash oil, 0.3-0.4 part of beef powder, 0.15-0.2 part of yeast powder, 0.15-0.2 part of flavor peptide, 0.3-0.4 part of I+G (disodium inosine 5'-monophosphate and disodium guanosine 5'-monophosphate), 1-1.5 parts of sodium glutamate, 0.3-0.4 part of white granulated sugar, 0.03-0.05 part of potassium sorbate, 0.03-0.05 part of sodium dehydroacetate and 0.01-0.02 part of disodium ethylenediamine tetraacetate. With the above components, the winged prickly ash-flavored seasoned bamboo shoot slices which are prepared by the steps of raw material pretreatment, first-time color-protection and brittleness-keeping treatment, second-time color-protection and brittleness-keeping treatment, stirring and packaging and sterilization treatment have thecharacteristics of a unique flavor, good taste and luster, high nutrient component content and high safety quality.

Owner:成都吉食道食品有限公司

Pigment-free chicken sausage with vegetable flavor and tremella

The invention discloses a pigment-free chicken sausage with vegetable flavor and tremella. The sausage is prepared from the following raw materials by weight ratio: 20 to 25 grams of sugar, 30 to 40 grams of salt, 30 to 40 grams of dried tremella, 2 to 4 grams of papain, 20 to 25 grams of peach blossom wine and 50 to 60 grams of freeze-dried vegetable powder in every 1000 grams of chicken meat. The components of the sausage are reasonable in proportion, so that the sausage has mellow taste and tender meat, and is fragrant.

Owner:牛岷

Method for making fermented type chilli sauce

InactiveCN108669519AShorten fermentation timeReduce productionFood ingredient as mouthfeel improving agentNon enzymaticAgar

The invention provides a method for making fermented type chilli sauce. The method comprises the following steps: a, preparing pure bacterium fermentation liquor; b, preparing fruit pulp; c, performing enzymolysis on the fruit pulp to obtain an enzymolysis liquid; d, preparing filtrate from the enzymolysis liquid; e, preparing agar liquid from the filtrate; f, crushing fresh red chillies by usinga crushing machine, heating to 30-35 DEG C, further putting the agar liquid and the pure bacterium fermentation liquor into chilli pieces, and uniformly stirring to obtain a mixture; g, at a room temperature, after the mixture is cured, putting the mixture into a fermentation tank, and fermenting for 6-7 days at 30-35 DEG C. By adopting the method, the chilli sauce fermentation time can be shortened, and the amount of nitrite can be effectively reduced; meanwhile, the chilli sauce has a very high eating value, and is capable of blocking formation routes of the nitrite; due to adoption of an anti-softening agent, a chilli sauce hardening effect can be improved; non-enzymatic browning can be alleviated while a function of protecting the color of the chilli sauce is performed.

Owner:QIANNAN NORMAL UNIV FOR NATTIES +1

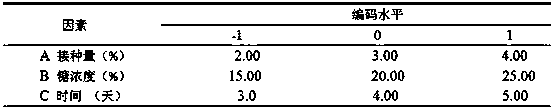

Preparation technology for high antioxidant activity zizyphus mauritiana enzymes

The preparation technology includes taking zizyphus mauritiana as a raw material, blending the zizyphus mauritiana and syrup with a ratio being 1 : 2 after boiling, color protecting and sterilization,inoculating microzyme, lactobacillus bulgaricus and streptococcus thermophilus to perform constant temperature incubation for 4 d, and performing clarification, filtering, disinfection and other technologies so that a high antioxidant activity zizyphus mauritiana enzyme stock solution can be prepared. Prepared zizyphus mauritiana enzymes have characteristics of strong in fragrance, smooth and fine in juice and mellow in taste; the zizyphus mauritiana enzymes can effectively adjust human body metabolism and maintain the balance of human intestinal flora; and the zizyphus mauritiana enzymes arerich in vitamin C, flavone, polyphenol, SOD, polypeptide and other antioxidant active substances which can delay aging and enhancing human immune functions.

Owner:山西师范大学

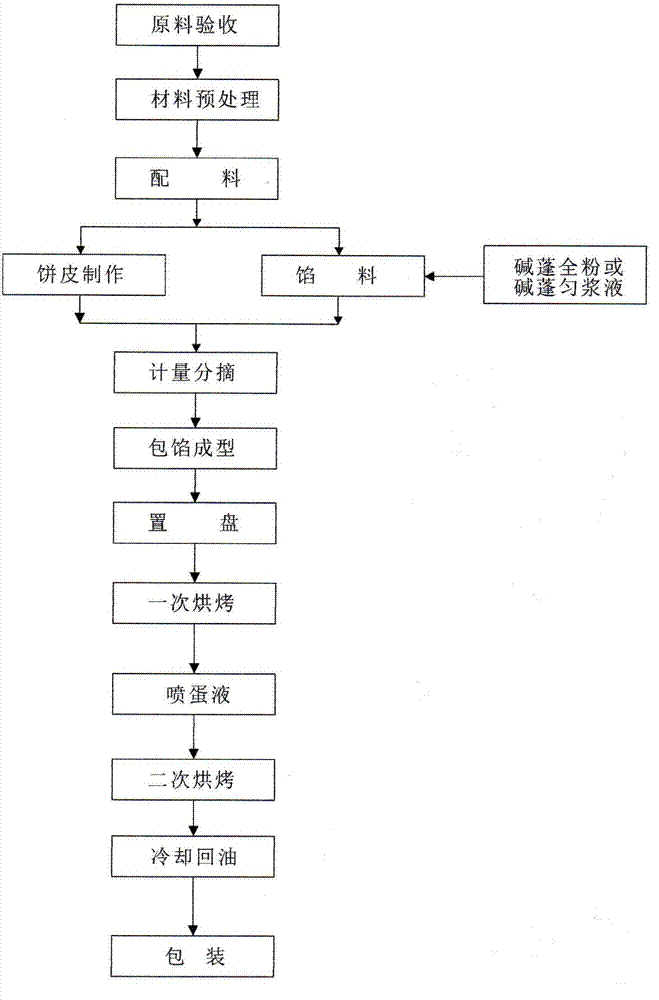

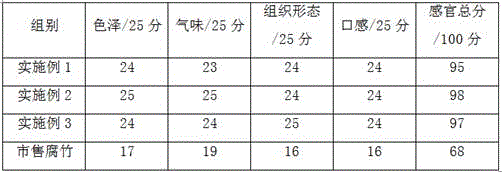

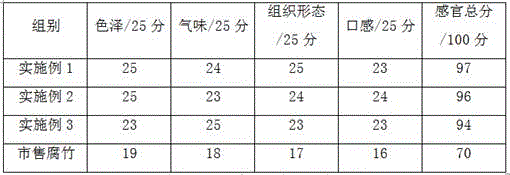

Healthy mooncake containing common seepweed herbs and preparation method of healthy mooncake

PendingCN107372725ARetain nutrientsReduce digestion and absorptionModified nutritive productsBiotechnologyTraditional medicine

The invention discloses a healthy mooncake containing common seepweed herbs and a preparation method of the healthy mooncake, and relates to a mooncake. 2.5-3.5 parts by weight of common seepweed herb powder or common seepweed herb homogenate is added into mooncake fillings. Extremely green common seepweed herbs are acquired by elaborate modern processing, natural probiotic functional factors of the common seepweed herbs are reserved, the natural common seepweed herb powder or common seepweed herb homogenate is added into the mooncake fillings, a traditional mooncake achieves unique healthy functions of reducing blood glucose, cholesterol and blood pressure, resisting cancers, protecting livers and benefiting health and long life by the aid of the green common seepweed herbs, and nutritional components of the mooncake are added.

Owner:碱蓬先创科技(盘锦)有限公司

Quality-improved and yield-increased yam bean curd sticks

InactiveCN106720414AIncrease profitAlleviate protein lossCheese manufactureFood sciencePeptideSodium bicarbonate

The invention discloses quality-improved and yield-increased yam bean curd sticks, and belongs to the field of food processing. The bean curd sticks are bean products prepared by carrying out steeping, grinding into thick liquid, boiling, tearing off of bean curd sticks and drying on the following raw materials in percentage by weight: 65 to 90 percent of soybeans, 10 to 25 percent of yam beans and 3 to 15 percent of an edible conditioner. The edible conditioner is prepared from moringa leaves, shaddock peels, peanut peptides, flax seed meal, citronella leaves, citric acid, polyglycerol fatty acid ester, isomaltulose, sodium bicarbonate and olive oil. The bean curd sticks disclosed by the invention are high in glossiness, uniform in branch and high in water reabsorbing capacity, taste soft and unique, are pleasant to the palate, and have a lasting aftertaste. The processing technology of the yam bean curd sticks is simple in step and high in yield; an obtained product is high in quality and relatively low in production cost.

Owner:陈劲

Korea-lily drink and preparation method thereof

The invention belongs to the field of processing production of drinks and specifically discloses a Korea-lily drink and a preparation method thereof. The Korea-lily drink is processed by only adding sucrose and a small amount of citric acid to natural Korea-lily which is taken as a main material. The method comprises the following steps of: firstly, blanching the washed fresh Korea-lily in boiling water for 2-3 minutes, then juicing and filtering the blanched Korea-lily, performing static settlement and siphon filtering on the Korea-lily to obtain pellucid filtrate, adding a right amount of softened water, sucrose and citric acid into the pellucid filtrate for seasoning, and finally, filling, sterilizing and cooling the filtrate. Compared with the prior art, the formula and the preparation method provided by the invention have the advantages of simple preparation process, low cost, high material utilizing rate, stable quality of products, and the like, and can be popularized to living and enterprise production. Moreover, by giving full play to the color, aroma and taste of a plurality of raw materials, the Korea-lily drink is rich in nutrient and has a very good tonic effect. As a novel Korea-lily tonic product, the Korea-lily drink provided by the invention fills up the blank of the market.

Owner:DALIAN NATIONALITIES UNIVERSITY

Water chestnut dried bean curd stick being rich in dietary fibers and preparation method thereof

The invention discloses water chestnut dried bean curd stick being rich in dietary fibers and belongs to the field of food processing. The water chestnut dried bean curd stick includes, by weight, 80-100 parts of black soybean, 50-70 parts of water chestnuts, 10-15 parts of peas, 15-30 parts of peanuts, 20-35 parts of yam bean, 15-25 parts of Tartary buckwheat extraction liquid, 15-20 parts of buckwheat, 20-40 parts of milled oat rice with embryo, 12-25 parts of lotus roots, 10-20 parts of kelp powder, 5-10 parts of lemon juice, 3-9 parts of cactus powder, 2-8 parts of trehalose, 0.1-0.5 parts of locust bean gum, 0.2-0.4 parts of polyglycerol fatty acid ester, and 0.03-0.08 parts of sodium citrate. The dried bean curd stick has abundant nutrients, contains dietary fibers, is low-calorie and is low in fat and sugar. Through optimization of preparation process, the water chestnut dried bean curd stick has dietary therapy effect on various people and is especially suitable for people requiring weight control and diabetic patients in early stage.

Owner:陈劲

High dietary fiber vine tea green juice powder and preparation method thereof

InactiveCN108740192AKeep active ingredientsEfficient use ofTea substituesAcute hyperglycaemiaAdditive ingredient

The invention discloses high dietary fiber vine tea green juice powder and a preparation method thereof. The powder is prepared from the following raw materials in parts by weight: 8-10 parts of vinetea, 5-7 parts of strigose hydrangea juvenile leaves, 3-5 parts of mulberry leaves, 3-5 parts of chlorella, 1-3 parts of burdock, 1-2 parts of lotus leaves, 1-2 parts of sugar alcohol and 1-2 parts ofbamboo salt. The preparation method comprises the following steps: pre-treating the raw materials, performing secondary squeezing for the vine tea, strigose hydrangea juvenile leaves, mulberry leaves, chlorella and lotus leaves to obtain green juice, and performing drying and grinding to obtain a crude product green juice powder; directly drying and grinding the burdock to obtain burdock powder,mixing the burdock powder with the crude product green juice to obtain green juice powder, adding the bamboo salt and sugar alcohol into the green juice powder, performing uniform mixing and sterilizing to obtain the high dietary fiber vine tea green juice powder. The preparation method is simple, the green juice powder is rich in flavones, rubusosides and other active ingredients having remarkable effects for reducing blood glucose, blood pressure and blood fat, has rich dietary fibers, and is an ideal solid drink for the group with hypertension, hyperglycemia and hyperlipidemia.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

White sesame seed and needle mushroom cookies with effects of benefiting liver and nourishing hair and preparation method thereof

InactiveCN106417535AShorten face-to-face timeImproves touch and glossDough treatmentBakery productsPeppermintsFlavor

The invention discloses white sesame seed and needle mushroom cookies with the effects of benefiting the liver and nourishing hair. The cookies are prepared from, by weight, 300-320 parts of low-gluten flour, 120-130 parts of fresh needle mushrooms, 6-7 parts of olive oil, 20-23 parts of white sesame seeds, 9-10 parts of peppermint candy, 14-16 parts of water chestnuts, 65-70 parts of butter, 90-95 parts of white granulated sugar, 4-4.5 parts of salt and a proper amount of citric acid, sodium isoascorbate, sodium pyrosulfite, sodium carboxymethylcellulose, soya bean lecithin and water. The needle mushroom cookies have rich raw materials, the main material is reasonably matched with multiple auxiliary materials such as the olive oil and the white sesame seeds, and the prepared finished cookies are higher in nutritional value. In the processing process, the needle mushrooms are subjected to color protection, the needle mushrooms are evenly dried gradually, and the certain stability and special flavor of the needle mushrooms are kept; the cookies have the effects of benefiting the liver and nourishing hair after being eaten, and are suitable for a wide range of people.

Owner:钱毅

Yoghourt and needle mushroom biscuit for enhancing immunity and preparation method thereof

InactiveCN106359496APlay an emulsifying roleReduce cholesterolDough treatmentBakery productsFlavorGluten

The invention discloses a yoghourt and needle mushroom biscuit for enhancing immunity. The yoghourt and needle mushroom biscuit is prepared from the following materials in parts by weight: 300-320 parts of low-gluten flour, 120-130 parts of fresh needle mushroom, 18-20 parts of buckwheat sprout, 16-19 parts of yoghourt, 26-30 parts of pine nut, 3-4 parts of cattail root, 65-70 butter, 90-95 parts of white granulated sugar, 4-4.5 parts of salt, citric acid, sodium isoascorbate, sodium pyrosulfite, sodium carboxymethylcellulose, soya bean lecithin, and a proper amount of water. The needle mushroom biscuit has rich materials, the main material is reasonably matched and processed with multiple auxiliary materials like yoghourt and pine nut, the prepared finished product of biscuit is rich in nutrient, the color of the needle mushroom is protected in the processing process, the needle mushroom is evenly dried gradually, certain stability and the special flavor of the needle mushroom are kept, and if taken for a long period of time, the needle mushroom biscuit has the effects of life cultivation and health preservation, and plays a role of enhancing immunity.

Owner:胡王振

Preserved turnip food and preparation method thereof

The invention provides a preserved turnip food and a preparation method thereof. The preserved turnip food is prepared from the following raw materials in parts by weight: a turnip product and seasoning juice, wherein the seasoning juice including 5-30 parts of saccharides, 50-100 parts of licorice juice, 5-7 parts of lemon pulp, 0-5 parts of pericarpium citri reticulatae, 0-0.3 part of saffron crocus, 0-5 parts of ginseng fruits and 0-5 parts of mint leaves; the mass ratio of the turnip product to the seasoning juice is 1 to (1-3); and the turnip product is prepared from turnip through blanching, pickling and dehydration. The preparation method comprises the following steps: blanching, pickling, dehydration, seasoning and concentration. The final product has strong fragrance, sour, sweet and delicious taste and good color, flavor and taste; furthermore, the salt content is less than or equal to 3wt, the sugar content is less than or equal to 20wt, and the salt content and the sugar content are relatively low, so that the turnip preserved food is nutrient and healthy; and meanwhile, the preserved turnip food is convenient to eat and is suitable for being eaten by the majority of people in various places.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

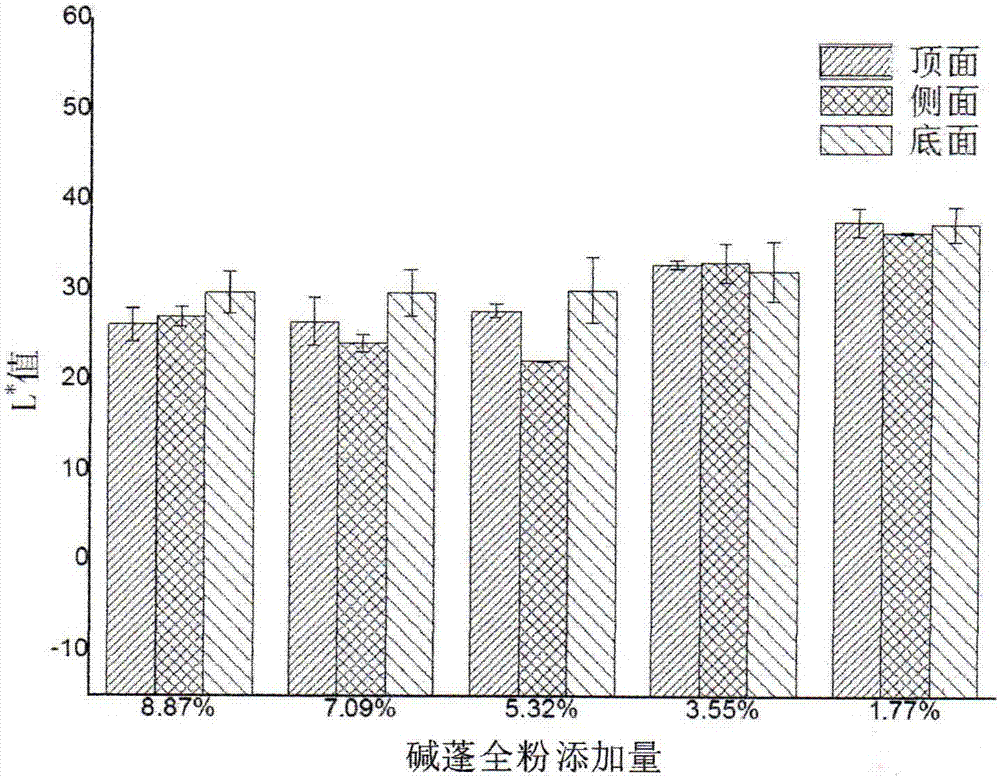

Low-oil high-quality suaeda salsa health-care moon cakes

ActiveCN107494673AReduced fat additionShorten oil return timeDough treatmentModified nutritive productsVegetable oilGluten

The invention provides low-oil high-quality suaeda salsa health-care moon cakes, and relates to moon cakes. The cake crusts of the moon cakes consist of the following components in parts by weight: 48-56 parts of low-gluten flour, 2.3-11 parts of whole suaeda salsa powder, 29-37 parts of invert sugar syrup, 3-11 parts of vegetable oil and 0.6-0.8 part of detergent granules. According to the low-oil high-quality suaeda salsa health-care moon cakes disclosed by the invention, through careful modern processing, extremely green suaeda salsa is obtained, natural probiotic functional factors of the suaeda salsa are reserved, the natural whole suaeda salsa powder is added to the cake crusts of the moon cakes, the high-oil abuse of conventional moon cakes is changed, the addition quantity of oil and fat in the cake crusts is reduced by 30-72%, besides, low oil and high quality are uniquely given to the conventional moon cakes through the green suaeda salsa, based on low oil, the original mouth feel and the original characteristics of the moon cakes are guaranteed, and the moon cakes have health-care effects and conform to the pursuit of people at the large health era.

Owner:福建一品居生物科技有限公司

Lotus dried beancurd sticks with increased brightness value and increased yield and preparation method

InactiveCN106509152AImprove toughnessHigh strengthOther dairy technologyCheese manufactureLemon juiceOligosaccharide

The invention discloses lotus dried beancurd sticks with increased brightness value and increased yield and a preparation method, and belongs to the field of food processing. The dried beancurd sticks disclosed by the invention are bean products which are made from the following raw materials in parts by weight of 80-100 parts of soybeans, 15-25 parts of wheat germs,30-50 parts of lotus flowers, 15-20 parts of lotus leaves, 10-20 parts of a purple cabbage extract, 10-15 parts of lemon juice, 8-15 parts of dried scallop powder and 10-20 parts of an edible adjusting agent through the steps of performing soaking, performing grinding to obtain pulp, cooking the pulp, uncovering pulp skin to obtain dried beancurd sticks, and performing drying, wherein the edible adjusting agent is prepared from the following raw materials of citronella leaves, inulin, pomelo peel, horseradish tree leaves, dried emblic leafflower fruits, linseed meal, fumaric acid, malt oligosaccharide, propylene glycol fatty acid ester, disodium hydrogen phosphate and tea oil. The prepared dried beancurd sticks disclosed by the invention are good in lustrousness, uniform in strips, good in rehydration properties, pliable, tough and unique in mouth feel, delicately fragrant and refreshing to eat, and long in aftertaste; and a processing technology of the dried beancurd sticks is simple in steps, the production yield is high, the quality of obtained products is high, and the production cost is low.

Owner:覃金晖

Walnut-flavored flammulina velutipes biscuits with effects of moistening dryness and tonifying deficiency and making method of biscuits

InactiveCN106106673APlay an emulsifying roleReduce cholesterolDough treatmentBakery productsGlutenSodium erythorbate

The invention discloses walnut-flavored flammulina velutipes biscuits with effects of moistening dryness and tonifying deficiency. The biscuits are made from, by weight, 300-320 parts of low-gluten flour, 120-130 parts of fresh flammulina velutipes, 15-18 parts of red grapes, 23-26 parts of walnut powder, 5-6 parts of goose livers, 3-4 parts of honeysuckle flowers, 65-70 parts of butter, 90-95 parts of white granulated sugar, 4-4.5 parts of salt and an appropriate amount of citric acid, sodium erythorbate, sodium pyrosulfite, sodium carboxymethylcellulose, soybean lecithin and water. According to the flammulina velutipes biscuits, the raw materials are rich, the main material is reasonably matched with multiple auxiliary materials such as the walnut powder and the goose livers to be process, and therefore the made finished biscuits contain more nutrient elements; color protecting operation is conducted on the flammulina velutipes in the processing process, gradual and uniform drying is adopted, therefore, the certain stability of the biscuits is kept, the unique flavor of the biscuits is kept, and the effects of moistening dryness and tonifying deficiency are achieved if the biscuits are eaten.

Owner:许文静

High-dietary fiber ampelopsis grossedentata green juice powder and preparation method thereof

InactiveCN109549051ASweet and blandHas heat-clearing and detoxifying effectsSugar food ingredientsFood homogenisationAdditive ingredientAlcohol sugars

The invention discloses a high-dietary fiber ampelopsis grossedentata green juice powder and a preparation method thereof. The raw materials are as follows: 8-10 parts of ampelopsis grossedentata, 5-7parts of leaves of strigose hydrangea, 3-5 parts of mulberry leaves, 3-5 parts of chlorella, 1-3 parts of great burdock achene, 1-2 parts of lotus leaves, 1-2 parts of sugar alcohol, and 1-2 parts ofbamboo salt. The preparation method comprises the following steps: first pretreating raw materials, then subjecting the ampelopsis grossedentata, the leaves of strigose hydrangea, the mulberry leaves, the chlorella and the lotus leaves to secondary juicing to obtain green juice, and performing drying and pulverizing to obtain a crude green juice powder; and directly drying and crushing the greatburdock achene to obtain a great burdock achene powder, mixing the great burdock achene powder with the crude green juice powder, then adding the bamboo salt and the sugar alcohol, and performing uniform mixing and sterilization to obtain the high-dietary fiber ampelopsis grossedentata green juice powder. The preparation method of the invention is simple, and the prepared green juice powder not only contains rich in active ingredients such as flavonoids and catechins which have significant effects on lowering blood sugar, lowering blood pressure and lowering blood fat, but also contains rich dietary fibers, and is an ideal solid drink for people with three highs (high blood pressure, high blood fat and high blood sugar).

Owner:湖北仙芝堂生物科技有限公司

Body-building and brain-strengthening fish roe and enoki mushroom biscuit and preparation method thereof

InactiveCN106509021APlay an emulsifying roleReduce cholesterolDough treatmentModified nutritive productsCelluloseGrape seed

The invention discloses a body-building and brain-strengthening fish roe and enoki mushroom biscuit which is prepared from the following raw materials in parts by weight: 300-320 parts of low-gluten flour, 120-130 parts of fresh enoki mushroom, 10-13 parts of grape seeds, 20-23 parts of grenadine juice, 7-9 parts of lanatechead saussurea herb with flower, 14-16 parts of fish roes, 65-70 parts of butter, 90-95 parts of white granulated sugar, 4-4.5 parts of salt, and a proper amount of citric acid, sodium isoascorbate, sodium metabisulfite, sodium cellulose glycolate, soya bean lecithin, and water. The enoki mushroom biscuit is rich in raw materials; main raw materials and various auxiliary materials such as grape seeds and fish roes are reasonably collocated and processed, so that the prepared finished product biscuit is relatively high in nutritional value. In addition, during a processing process, a color protection operation is adopted for enoki mushrooms, and gradual and uniform drying is adopted for the enoki mushrooms, so that certain stability of the enoki mushrooms is kept, and special flavor of the enoki mushrooms is also kept; after being eaten, the body-building and brain-strengthening fish roe and enoki mushroom biscuit has a health-preserving efficacy and is capable of building body and strengthening the brain.

Owner:胡王振

Eriosema chinense dried beancurd sticks rich in dietary fibers and processing method

The invention discloses eriosema chinense dried beancurd sticks rich in dietary fibers and a processing method, and belongs to the field of food processing. The eriosema chinense dried beancurd sticks are made from the following raw materials in parts by weight: 90-115 parts of soybeans, 45-70 parts of pachyrhizus erosus powder, 10-20 parts of green peas, 10-15 parts of red beans, 9-18 parts of a tartarian buckwheat extract, 7-15 parts of okra powder, 8-20 parts of pomelo peel powder, 15-25 parts of oat plumule rice, 10-15 parts of konjaku flour, 8-16 parts of dried scallop powder, 10-15 parts of lemon juice, 6-12 parts of inulin, 5-10 parts of galactooligosaccharide, 2-5 parts of glucomannan, 0.5-1.5 parts of VC palmitate and 0.2-0.8 part of potassium polyphosphate. The dried beancurd sticks disclosed by the invention are rich in nutrition and contain dietary fibers, low-calorie low-fat low-sugar dried beancurd sticks and a technology of the dried beancurd sticks are optimized, requirements of various crowds are met, the dietetic therapy effects are achieved, and the dried beancurd sticks are particularly suitable for people needing to control body weight and patients suffering from initial stage diabetes to eat.

Owner:覃金晖

Preparation method of crisp fruit and vegetable chips without adding color retention agent

InactiveCN109105809AHas antibacterial propertiesProtect colorFood freezingFood dryingForeign matterFreeze-drying

The invention relates to the field of food processing, in particular to a preparation method of crisp fruit and vegetable chips without adding a color retention agent. The preparation method comprisesthe following steps: washing raw materials, i.e., washing the raw materials by utilizing a high-pressure washing machine, and removing silt and foreign matters on the surfaces of the raw materials; screening i.e., removing uneatable parts in the raw materials, grading the raw materials and selecting qualified raw materials, and spraying low-temperature water in a screening process; carrying out secondary washing, i.e., putting the raw materials into a bubble washing machine and washing, and then putting the raw materials into a long water flowing tank; sterilizing, i.e., conveying the raw materials into a sterilization tank through the long water flowing tank and carrying out sterilization treatment; carrying out film coating, i.e., carrying out oxygen isolation treatment on the sterilized raw materials on a conveyor belt, and then putting the raw materials into a film coating solution and carrying out film coating; carrying out air drying, i.e., treating the film-coated raw materialson the conveyor belt and treating through an air drying machine to carry out rapid air drying and water removal; carrying out freeze-drying, i.e., putting the water-removed raw materials into a vacuum freeze-drying box and carrying out freeze-drying treatment. According to a color retention technology provided by the invention, any color retention agent is not added; contact between the raw materials and oxygen gas is reduced in a whole conveying process of the raw materials, and the fruit and vegetable raw materials are effectively prevented from changing color in a processing process.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

A kind of brewing method of low-alcohol blueberry health wine

ActiveCN105368631BDeep colorStrong aromaAlcoholic beverage preparationMicroorganism based processesHydrolysisHigh heat

The invention discloses a brewing method of low-alcohol blueberry health wine. The method comprises the steps of selecting and processing blueberries, tea pretreatment, raw material blending, ethanol fermentation, aging, clarification and stabilization treatment and the like. The method uses the blueberry of the preferred Blue Rain variety as the raw material, and simultaneously adds tea extract, prebiotics and soluble dietary fiber; through impregnation of the original pulp, high-temperature enzymatic hydrolysis, high-temperature start-up, mixed bacteria synergy, and low-temperature long-term fermentation to obtain low-temperature Alcoholic blueberry wine; Microwave-assisted aging at low temperature accelerates wine body maturation and improves fruit wine quality; Through clarification and stabilization treatment, the wine body obtains higher clarity and maintains a stable state for a long time; Improves the taste of the wine by adding functional sweeteners, Increase its health care function at the same time. According to this process, a high-quality, low-alcohol blueberry fruit wine with good color, aroma and taste, which integrates nutrition and health care can be obtained.

Owner:HUANGSHAN BLUEBERRY ECOLOGICAL PARK CO LTD

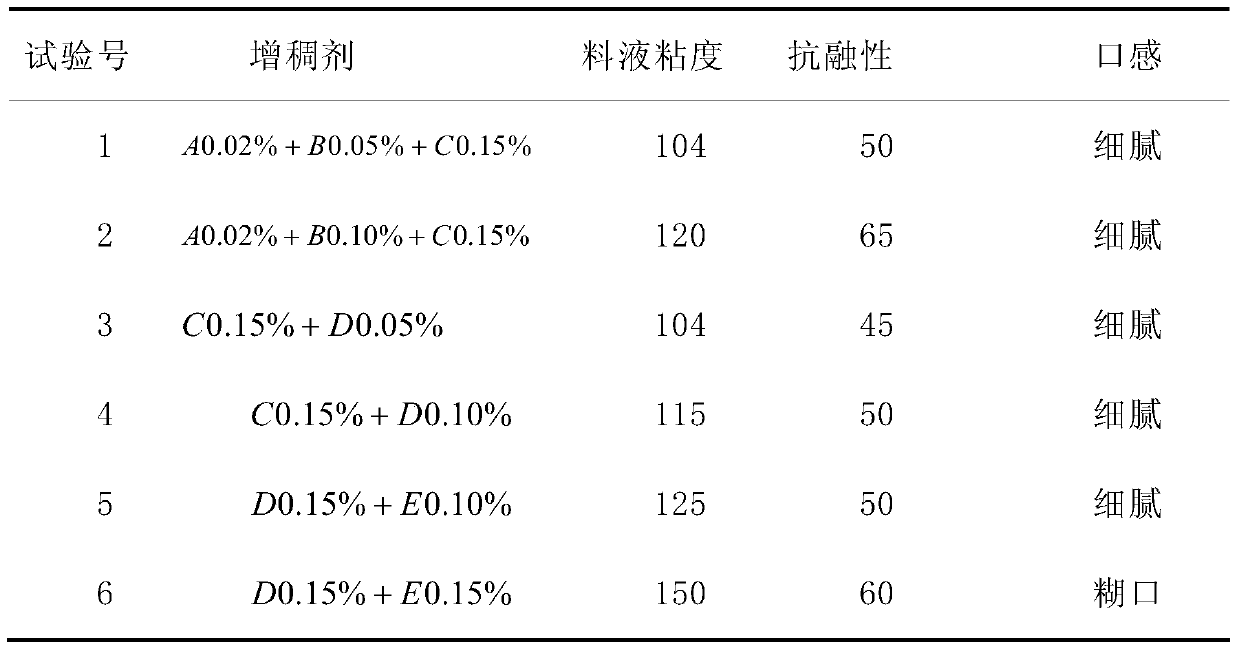

A kind of Hericium erinaceus tofu ice cream and preparation method thereof

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com