Dried fruit food with red aeterio and production thereof

A technology of red tree berries and preserved berries, which is applied in confectionary, confectionary industry, food science, etc., can solve the problems of backward processing technology, reduce pectin exudation, improve the state of fruit body adhesion, and change the state of fruit body The effect of disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

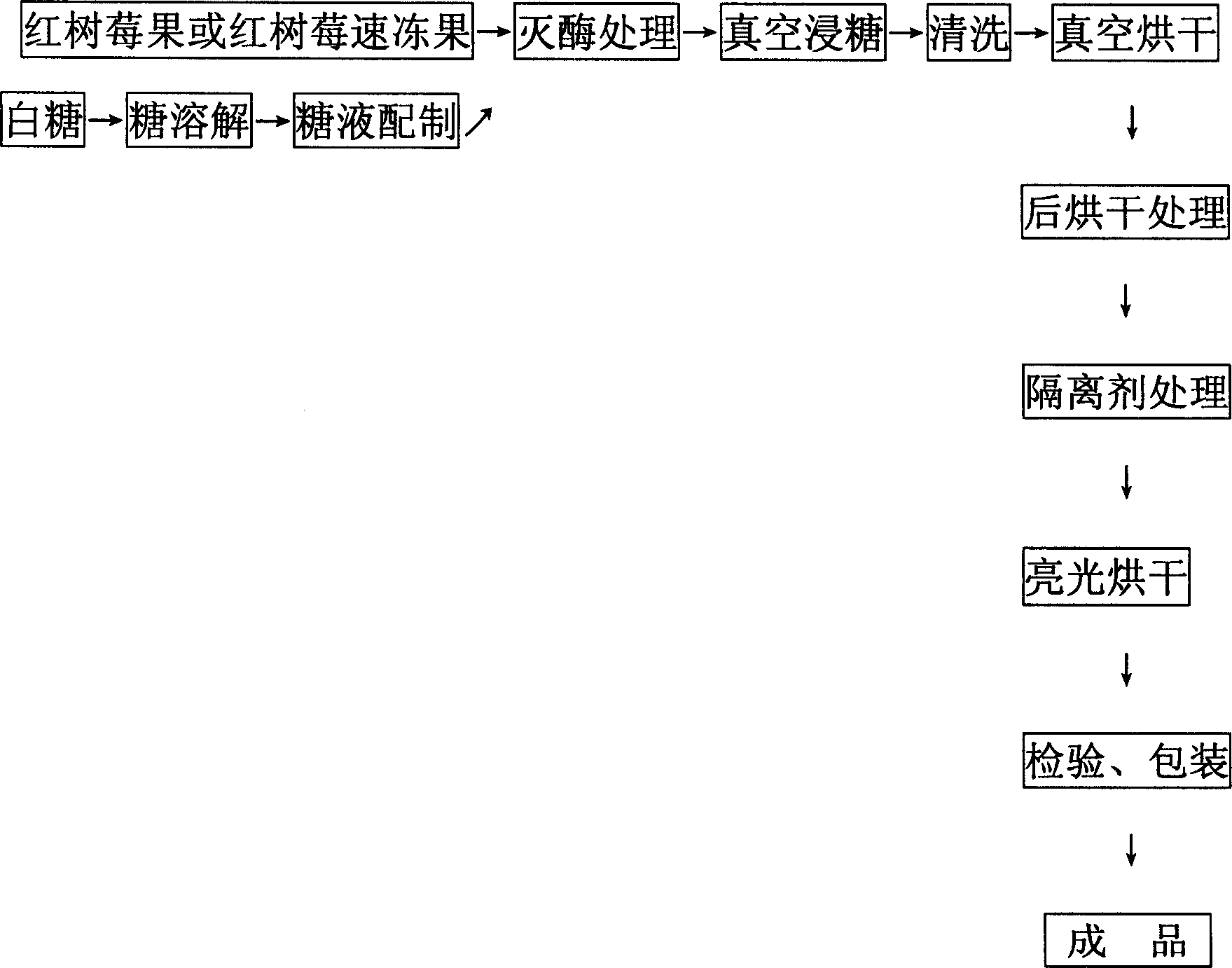

Method used

Image

Examples

Embodiment 1

[0047] 1. Select 300g of red raspberry fresh fruit with small seeds, complete fruit shape and uniform bright red color. Weigh out 1000g of white sugar and melt it in a sugar pot. Adjust the concentration of the sugar solution to 60% (w / v) with water. Calcium chloride is added to 0.6g, vitamin C is added to 0.2g;

[0048] 2. Put the fresh red raspberry fruit into the stainless steel mesh, add the red raspberry fruit into the hot sugar solution while it is hot, soak the surface of the red raspberry with the sugar solution, keep the temperature at 75-85°C, and wait for 5 ~10 minutes. Carry out enzymatic treatment;

[0049] 3. Carry out vacuum dipping of red raspberry berries after deenzyme removal. The vacuum degree is kept within the range of 0.1-0.12 MPa for 100-120 minutes.

[0050] 4. The sugar concentration of the red berry after dipping in sugar is 50% (w / v); the surface of the red berry after the vacuum immersion treatment is cleaned with sugar solution, the water tempe...

Embodiment 2

[0057] 1. Select 100kg of red raspberry quick-frozen fruit with small seeds, complete fruit shape, and bright red uniform color. Weigh 100kg of white sugar and melt it in a sugar pot. Adjust the concentration of the sugar solution to 65% (w / v) with water. Add calcium chloride to 1 / 1000g, add vitamin C to 0.4 / 1000g;

[0058] 2. Put the red raspberry quick-frozen fruit into the stainless steel screen in stages, add the red raspberry quick-frozen fruit into the hot sugar solution, and use the sugar solution to soak the surface of the red raspberry. The water in the berries is continuously leached, which dilutes the concentration of the sugar solution. White sugar should be added at any time to keep the sucrose concentration at 60-65%, and the temperature at 75-85°C for 5-10 minutes. Carry out enzymatic treatment;

[0059] 3. Carry out vacuum dipping of red raspberry berries after deenzyme removal. The vacuum degree is kept within the range of 0.1-0.12 MPa for 100-120 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com