Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Moisture content is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

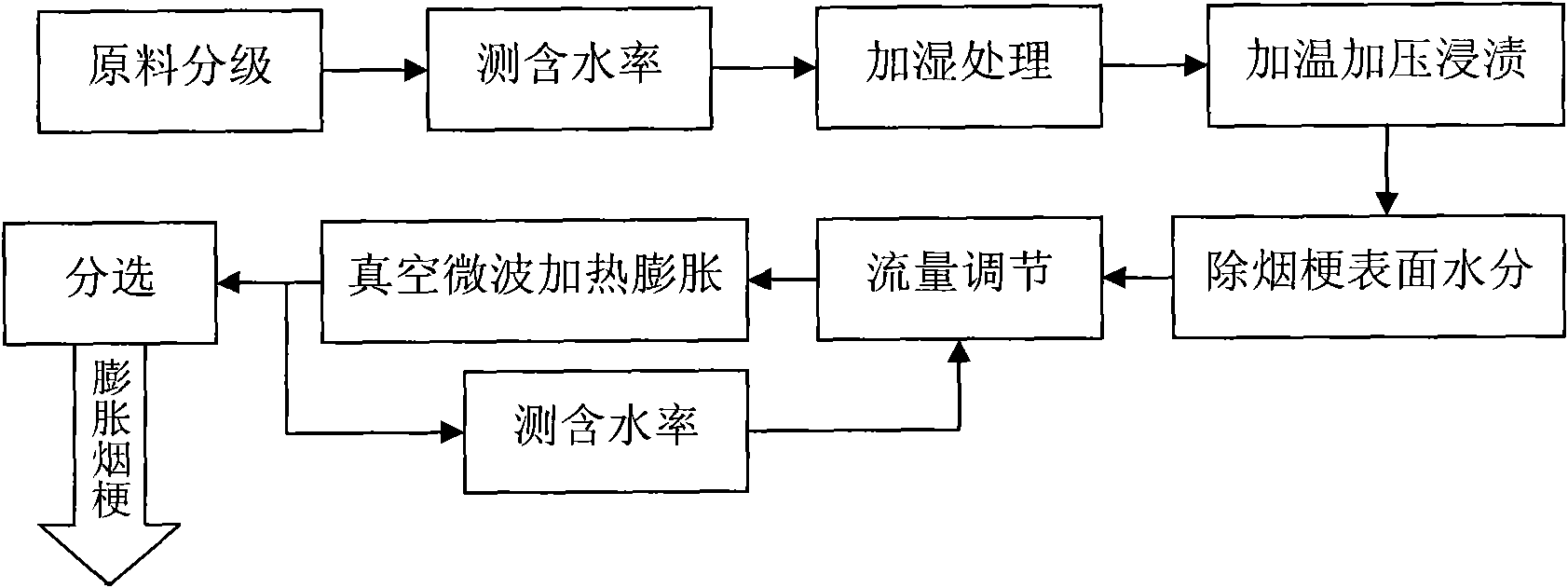

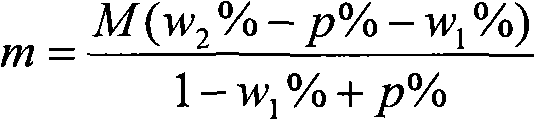

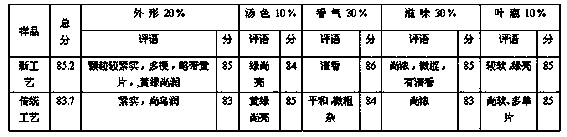

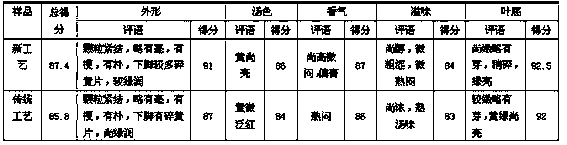

Tobacco stalk expansion method

InactiveCN101862023AUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

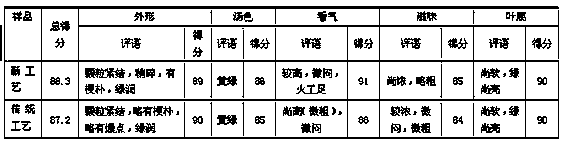

Granular green tea processing method through combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping

The invention relates to a granular green tea processing method through the combination of microwave drying of first-step roasting leaves and double-pot tea curling machine shaping, and belongs to the technical field of tea processing. The granular green tea processing method comprises the following processing steps: spreading of fresh tea leaves; deactivation; spreading for cooling; rolling; drying of first-step roasting leaves; shaping; spreading for cooling; drying; fragrance extraction. According to the granular green tea processing method through the combination of microwave drying of the first-step roasting leaves and double-pot tea curling machine shaping, the design is reasonable, and a good foundation is provided for the subsequent steps of drying of the first-step roasting leaves and shaping by reasonably restricting the conditions of spreading, deactivating, spreading for cooling and rolling; microwave heating is utilized for completing the working procedure of drying of the first-step roasting leaves, so that the water content of first-step roasting leaves is easily adjusted and controlled, the color is relatively green, and cooling treatment is not needed, so that the shaping can be directly performed; a double-pot tea curling machine is utilized for shaping, so that the shaping time is short, and the quality of a final tea product is excellent. Experiment results show that leaves collected by machines are suitable for being processed into granular green tea by adopting the granular green tea processing method provided by the invention, and the granular green tea is attractive in appearance, fresh in fragrance and pure in mouthfeel, and is popular among green tea consumers.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

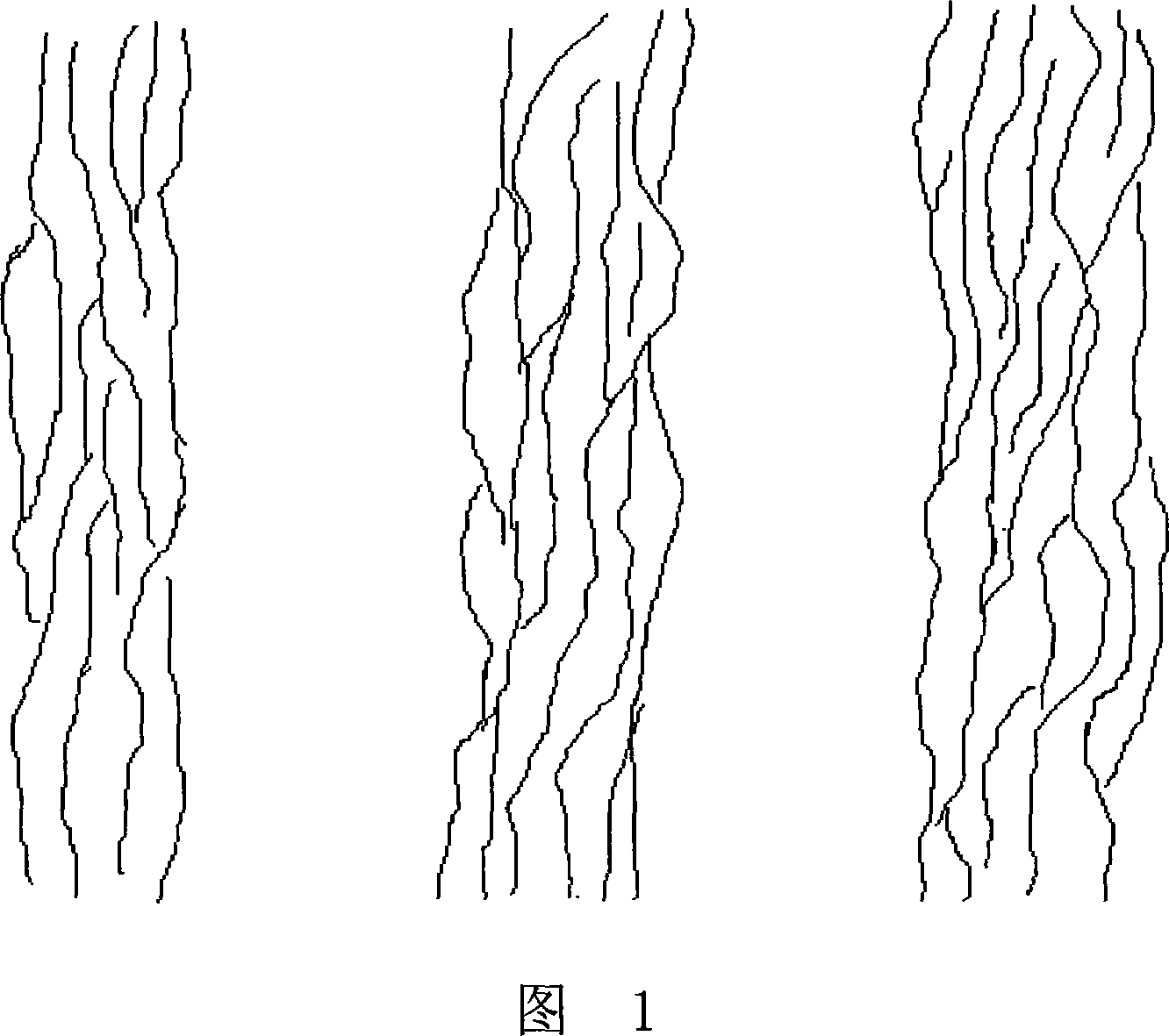

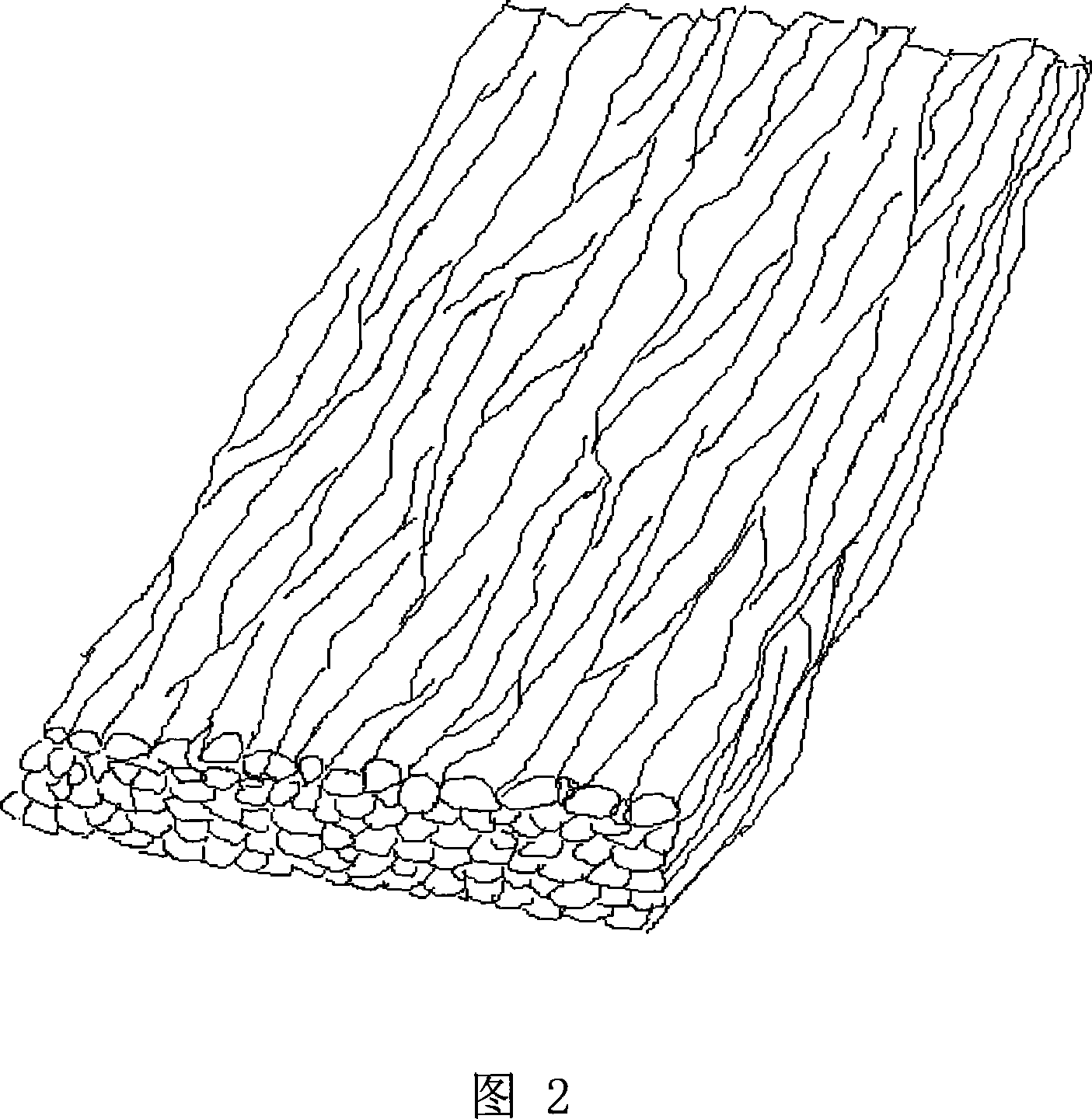

Process of producing stalk recombining material

InactiveCN101066607ASimple production processReduce energy consumptionDomestic articlesFlat articlesFiber bundleVolumetric Mass Density

The present invention discloses process of producing artificial stalk board. The material is treated through softening and rolling to form longitudinally continuous and transversely staggered fiber bundles, and the fiber bundles are glued, spread, pre-pressed and hot pressed to form artificial board with moderated density, excellent mechanical performance and good machining performance. The present invention raises the mechanical performance of artificial stalk board and develops one kind of timber substitute.

Owner:NORTHWEST A & F UNIV

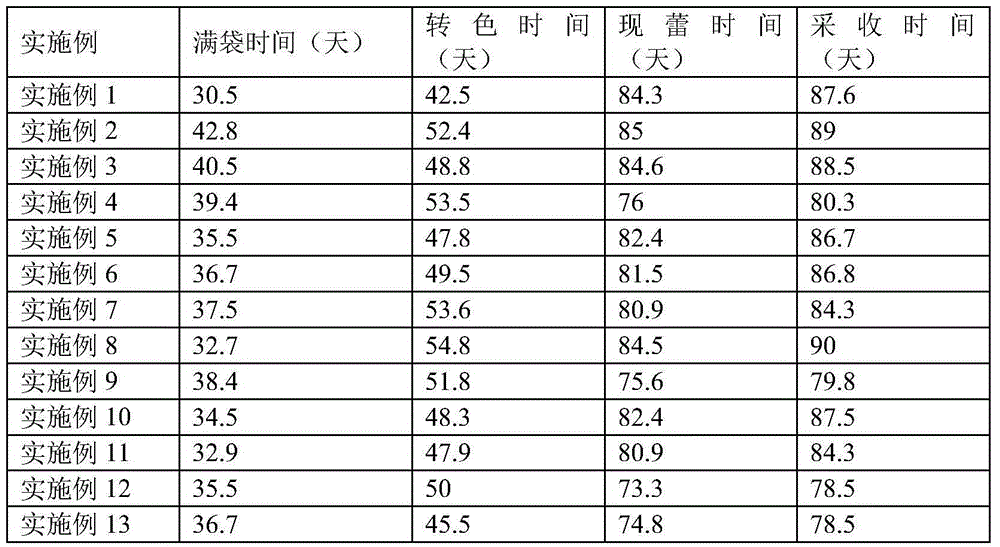

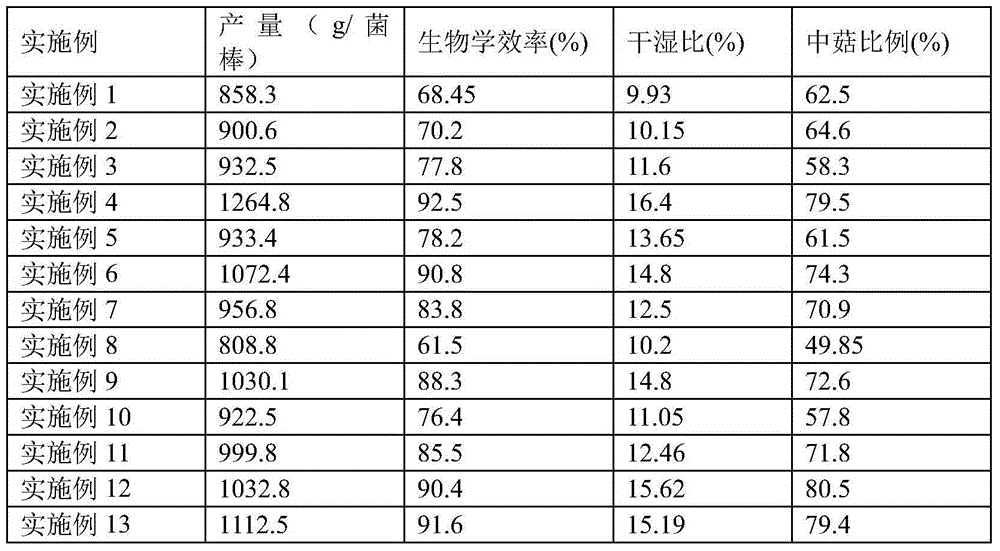

Shiitake mushroom culture medium and method of cultivating shiitake mushroom in greenhouse

The invention provides a shiitake mushroom culture medium which is composed of the raw materials of 30-80 parts of sawdust, 8-28 parts of fruit peel and / or part straw, 1-10 parts of a water-absorbing agent, 5-20 parts of soybean meal and / or bran, 0.5-2 parts of gypsum and 0.5-2.0 parts of chitosan. The invention also provides a method for cultivating shiitake mushrooms with the culture medium. The method comprises the steps of carrying out culture medium impurity-removing pretreatment, blending the culture medium with other auxiliary materials, bagging and sterilizing the culture medium, carrying out inoculation and spawn running under room temperature, realizing 30-50% coloring, allowing fruiting, and harvesting the shiitake mushrooms. With the method, the culture medium in the mushroom bag is compact and not loose. Water content is controllable, and a water retention performance is good. Shiitake mushrooms can be picked in multiple batches, and water injection is not needed. Hypha production rate is high, hypha quality is good, and contaminating microbe amount is low. Small fruiting bodies are uniformly batched, and the quality of the shiitake mushroom is high.

Owner:YICHANG DAZIRAN BIOTECH

Continuously feeding and discharging dynamic dry method anaerobic fermentation apparatus and method thereof

InactiveCN102776121ASuitable for industrializationThere is no secondary pollution problemBioreactor/fermenter combinationsBio-organic fraction processingBiogasWater content

The invention relates to a continuously feeding and discharging dynamic dry method anaerobic fermentation apparatus and a method thereof. The apparatus is characterized in that a horizontal type rotating-drum silo accommodating anaerobic fermentation materials can be remained sealed and continuously fed and discharged when rotating. Adjustments of anaerobic fermentation parameters such as premixing of raw materials and anaerobic fermentation inoculums, temperature, water content, pH value, etc. are finished at the same time. When being used in producing biogas, the apparatus is advantaged in that secondary pollution problems are not existed because of no biogas slurry; anaerobic fermentation parameters are easy to control; and that the apparatus produces the biogas uniformly and is suitable for industrialization of the biogas; Materials are remixed continuously in a reactor and in a dynamic anaerobic fermentation state, so that the apparatus has high gas yield and occupies small area.

Owner:韩迪 +1

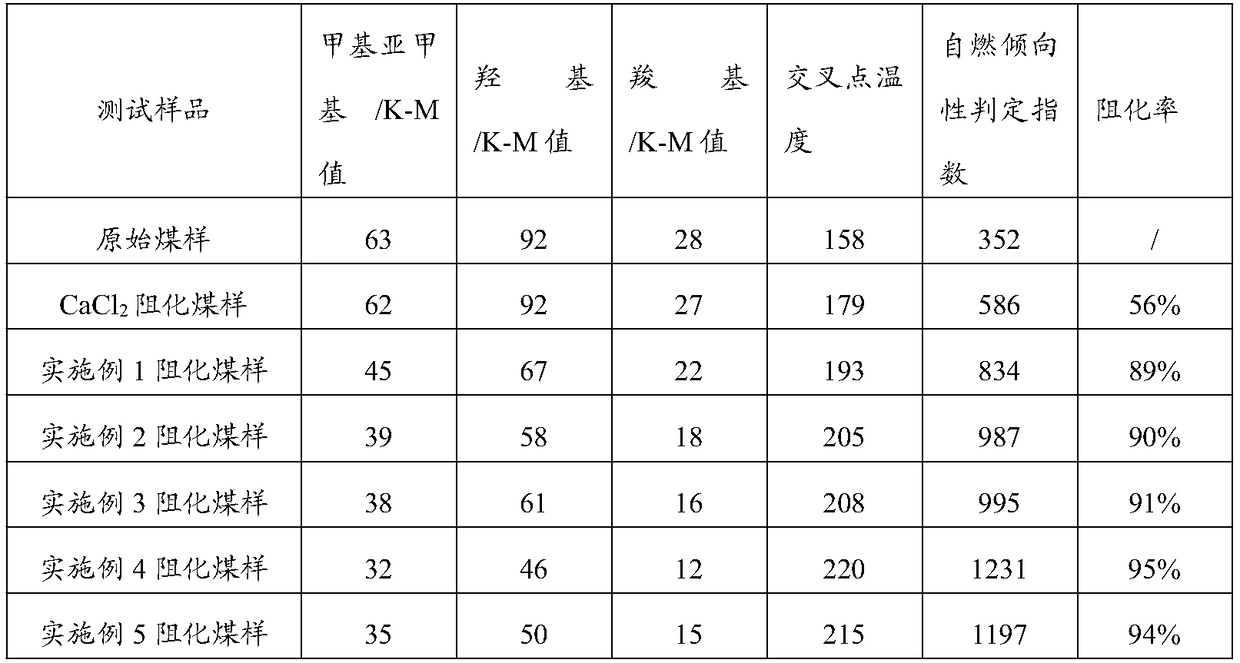

Hydrophilic-type anti-oxidation stopping agent for mines and preparation method thereof

ActiveCN108343464AEvenly distributedLong resistance lifeDust removalFire preventionAntioxidantMelatonin

The invention discloses a hydrophilic-type anti-oxidation stopping agent for mines and a preparation method thereof, and relates to the field of coal spontaneous combustion inhibition for preventing and extinguishing fire in coal mines. The hydrophilic-type anti-oxidation stopping agent for the mines is prepared from high molecular base materials, an organic antioxidant, a fire extinguishing agent, a coagulant and water as raw materials; the preparation raw materials of the high molecular base material are polyacrylic acid, sodium alginate and water; the organic antioxidant is melatonin; the fire extinguishing agent is ammonium dihydrogen phosphate; and the coagulant is ammonium bicarbonate. According to the hydrophilic-type antioxidant stopping agent, the melatonin is used as the main action component for inhibiting and blocking the chain reaction in the coal spontaneous combustion process, and water absorption and water retention performance are high, the hydrophilic-type anti-oxidation stopping agent is the first in the field of the coal spontaneous combustion stopping agent, the preparation raw materials are rich in source, the preparation cost and use cost are low, the preparation process and use process are green and environmentally friendly, the chemical blocking effect and the physical blocking effect are both achieved, the self-heating of coal can be effectively prevented, and spontaneous combustion fire areas of coal can be effectively and thoroughly controlled.

Owner:CHINA UNIV OF MINING & TECH

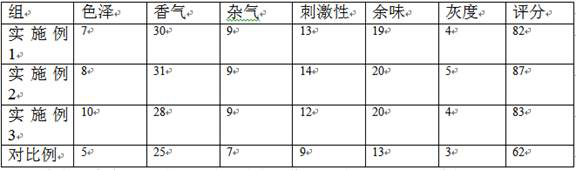

Cigar production method

ActiveCN113974195AWon't breakThere will be no mildewTobacco preparationTobacco treatmentFermentationBotany

The invention provides a cigar production method, and belongs to the technical field of cigar production and manufacturing. The method comprises the following steps: (1) soil preparation, ridging and transplanting; (2) fertilizing, irrigating and topping the tobacco plants; (3) harvesting and airing the tobacco leaves after the tobacco leaves are mature, wherein the moisture content of the aired tobacco leaves is 16-18%; (4) performing tobacco leaf moisture regaining after the tobacco leaves are graded until the water content of the moisture-regained tobacco leaves is 20%-26%; and (5) carrying out primary fermentation, alcoholization, secondary fermentation and alcoholization on the moisture-regained tobacco leaves to obtain cigar coats, cigar sleeves or cigar cores. A secondary fermentation method is adopted in the fermentation process, and differentiated fermentation is carried out according to different products in the fermentation process; the temperature range in the fermentation process is suitable, and the fermentation sufficiency can be guaranteed through temperature control during stack turning; and through the secondary fermentation, and the temperatures of the two times of fermentation are slightly different, so that the tobacco leaves are further fully fermented, the bitter taste of the cigars is eliminated, and the taste of finished cigars is adjusted.

Owner:HUBEI CHINA TOBACCO IND

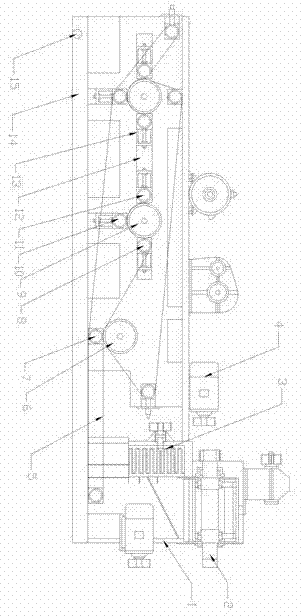

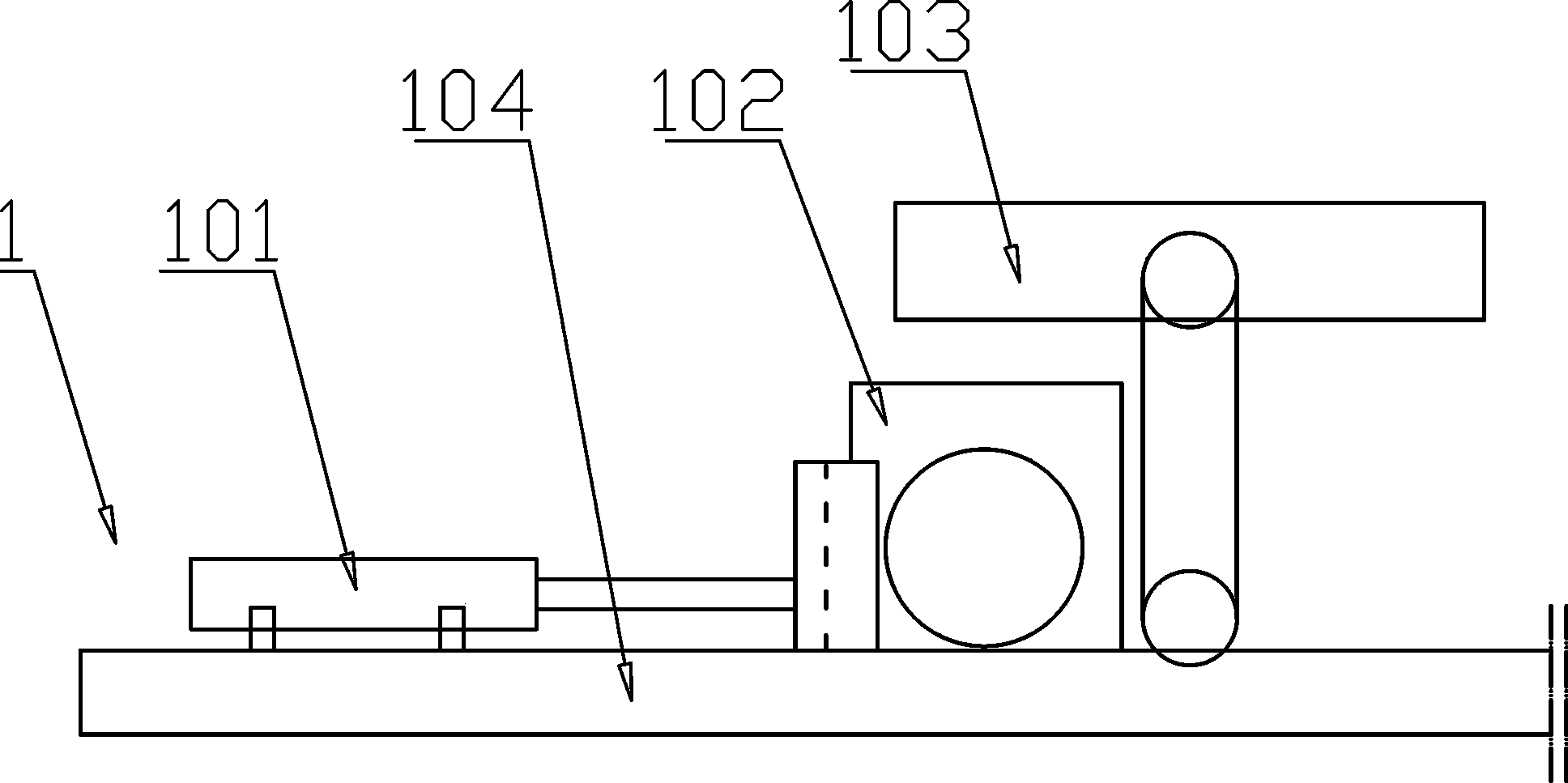

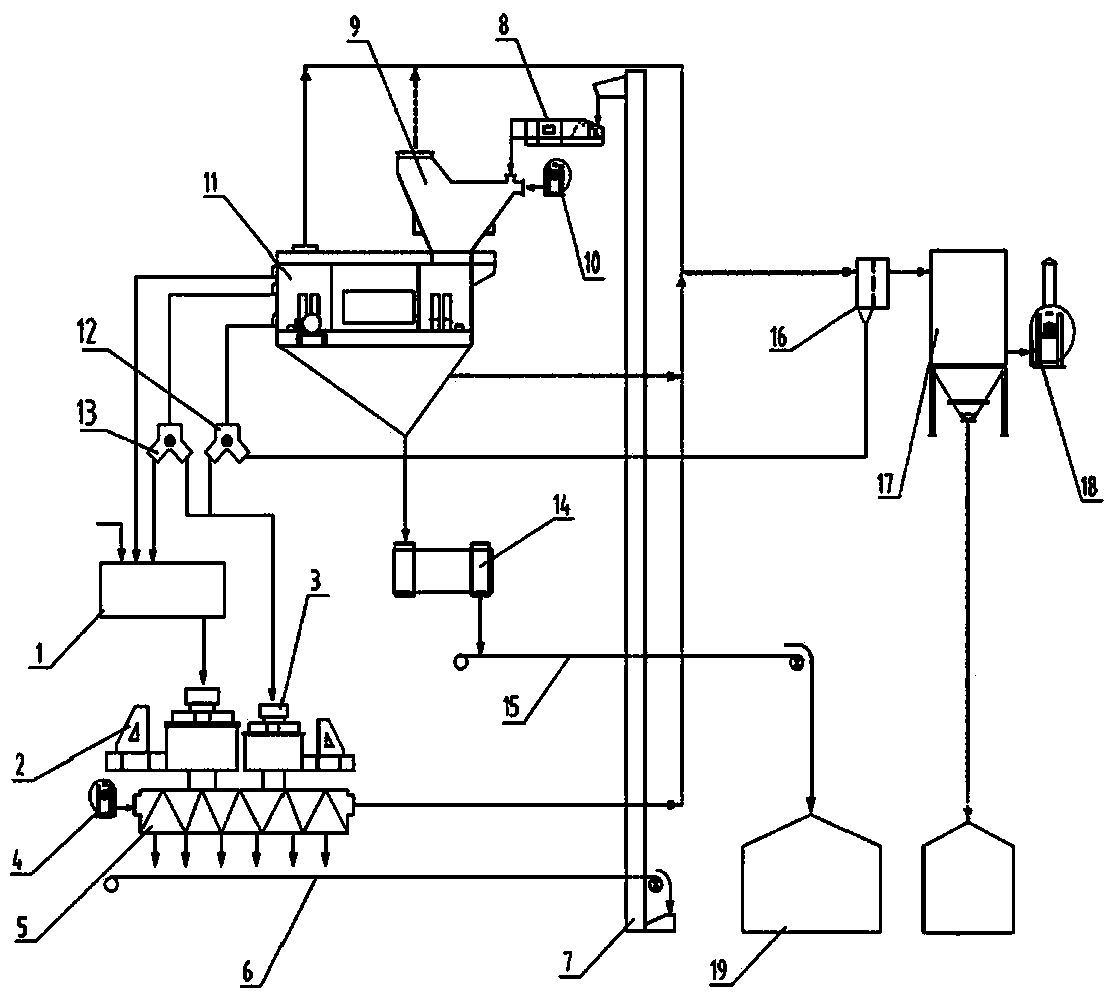

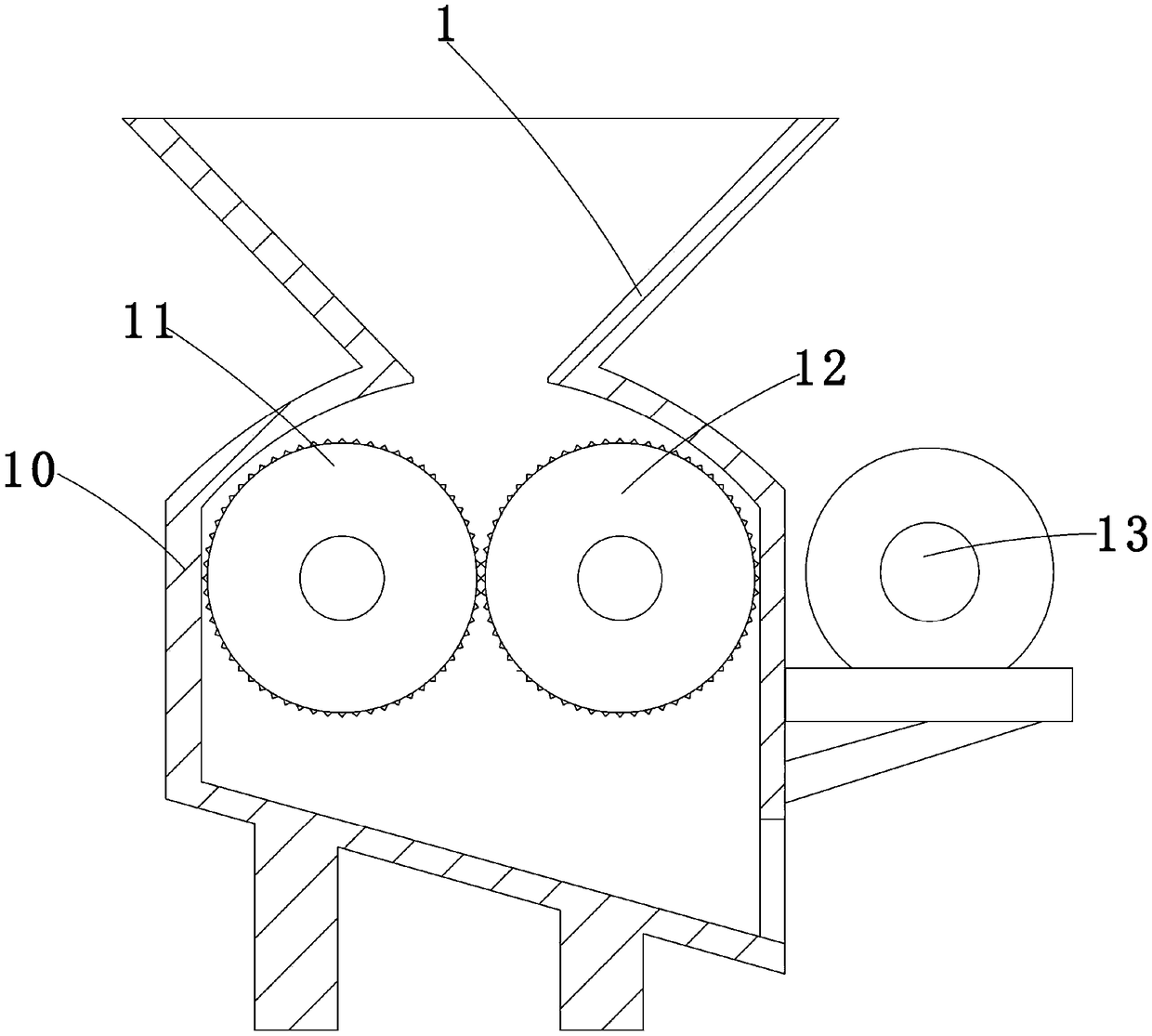

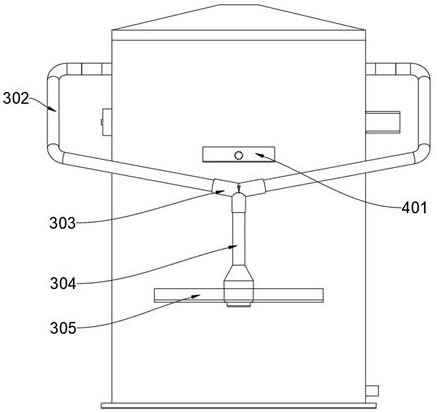

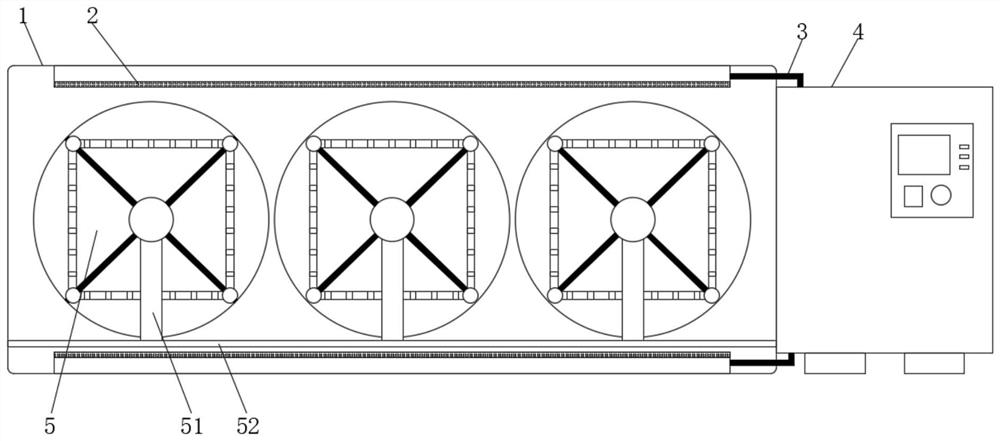

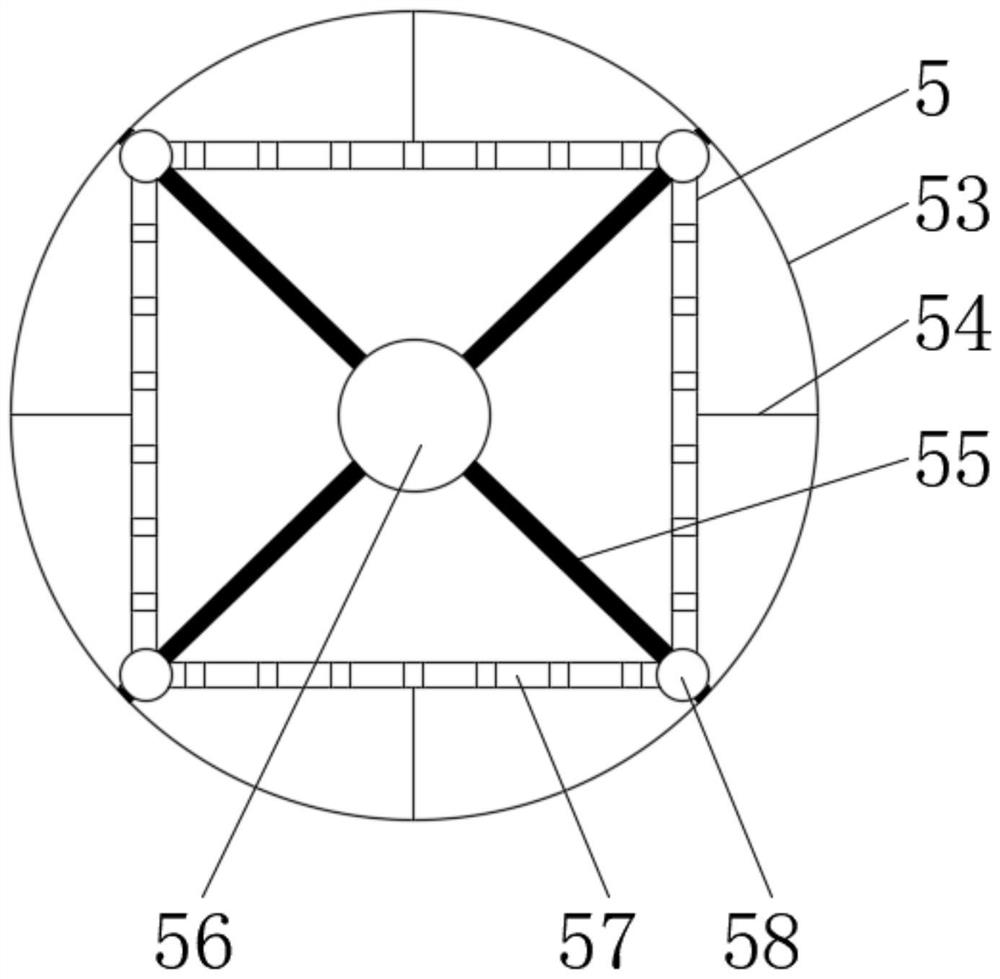

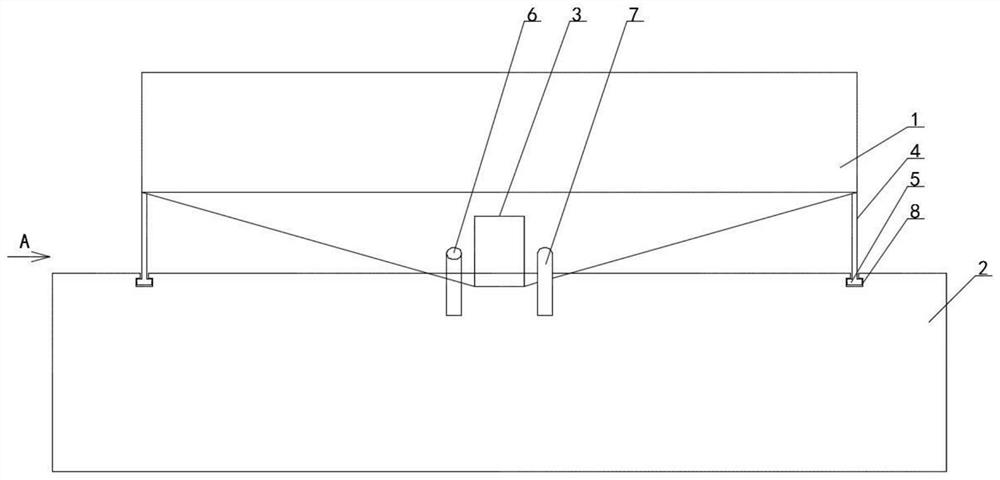

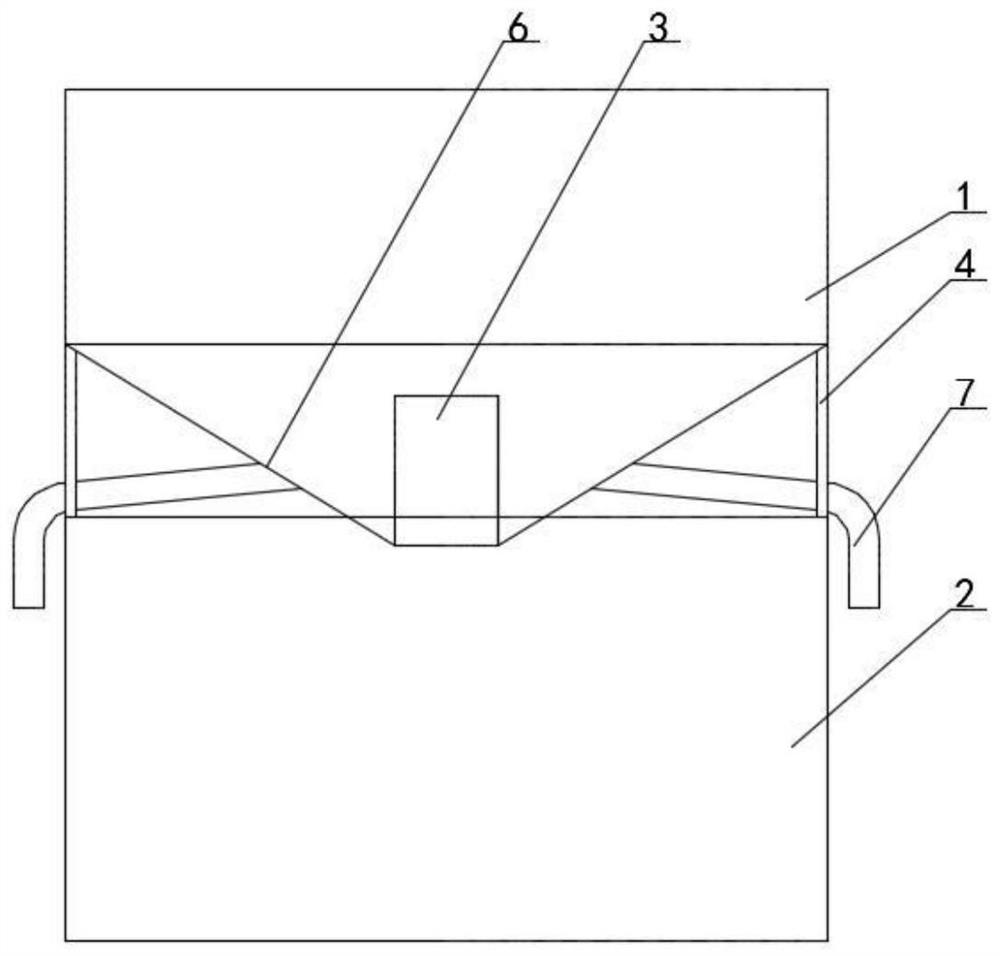

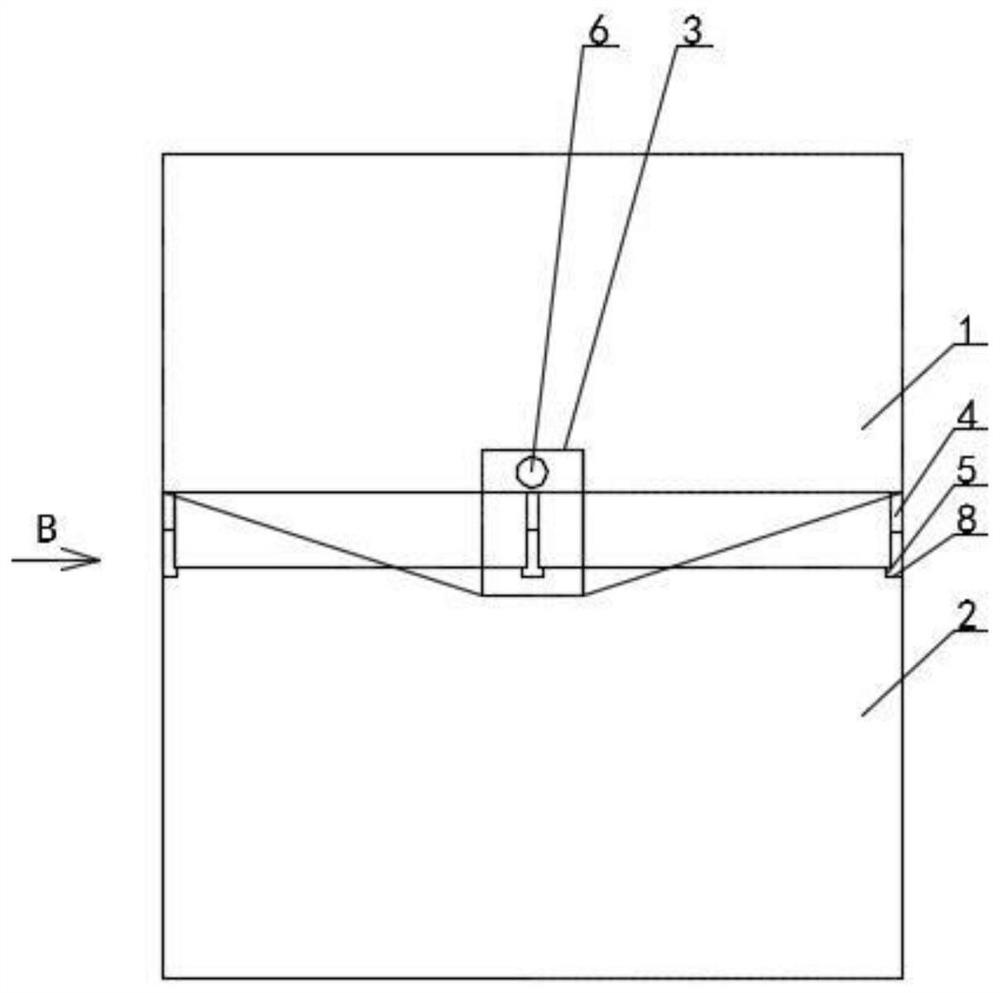

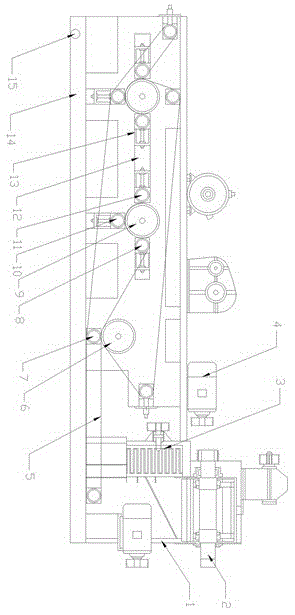

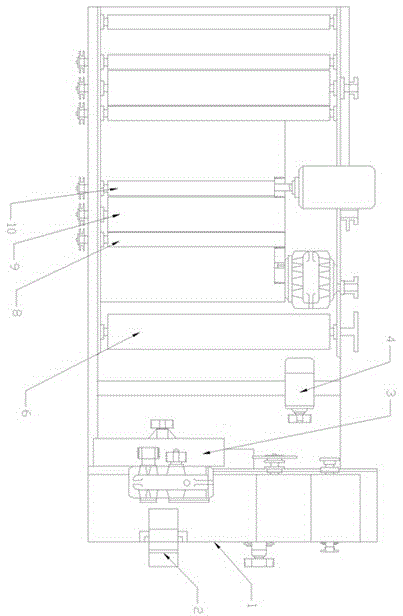

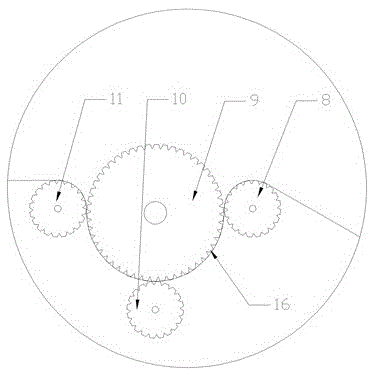

Silage processing equipment

InactiveCN104509956AControl moisture contentMoisture content is easy to controlFeeding-stuffEngineeringFodder

The invention provides silage processing equipment. The silage processing equipment comprises a rack, a conveyor belt, and a cutting device and a dispersing device which are connected in sequence, and further comprises a grinding device, wherein the grinding device comprises three compression roller wheel sets which are connected in sequence; the first compression roller wheel set is composed of an upper compression roller and a second compression roller; each of the second compression roller wheel set and the third compression roller wheel set is composed of one driving roller and three driven compression rollers, namely the driving roller driven by a motor, and the first driven compression roller, the second driven compression roller and the third driven compression roller which are located on the left and right sides and under the driving roller; the conveyor belt penetrates through a gap between the upper and lower compression rollers of the first compression roller wheel set and gaps among driving rollers of the second and third wheel sets and the driven compression rollers. The grinding device is reasonably designed and the moisture content of materials is controlled; the materials are prevented from going moldy and going bad due to bad weather; meanwhile, drying equipment is not used so that the energy consumption is reduced and the expenditure is saved. The silage processing equipment is suitable for crushing and machining silages including banana stems and leaves and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

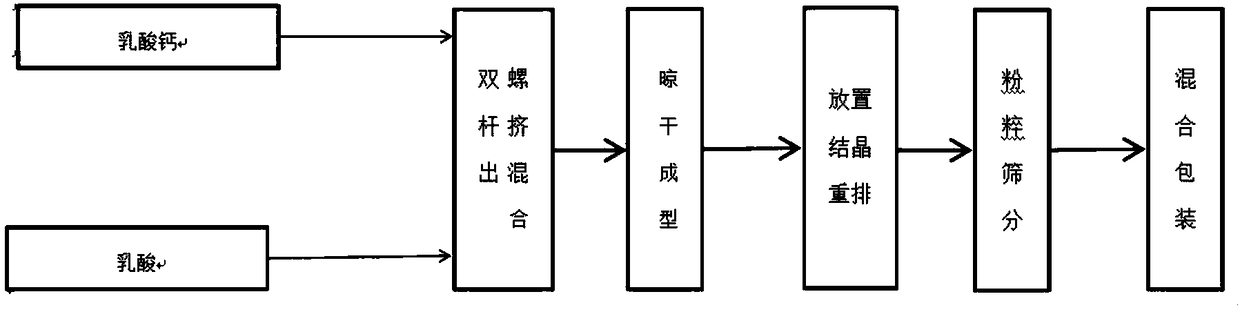

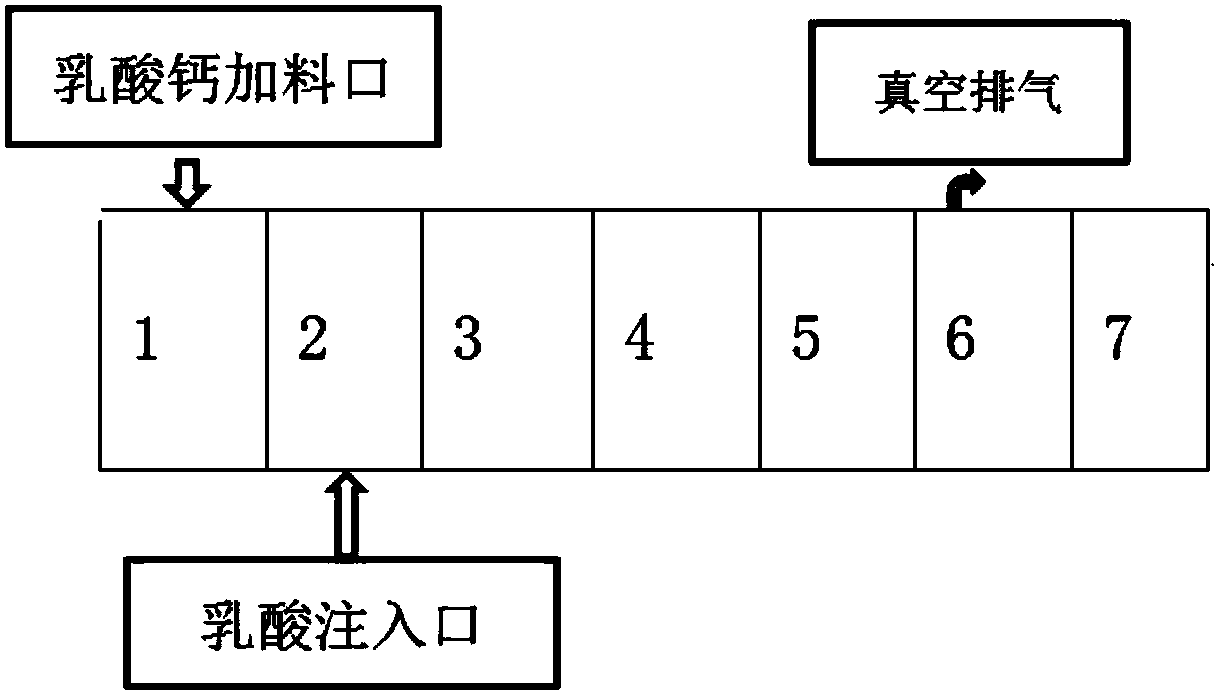

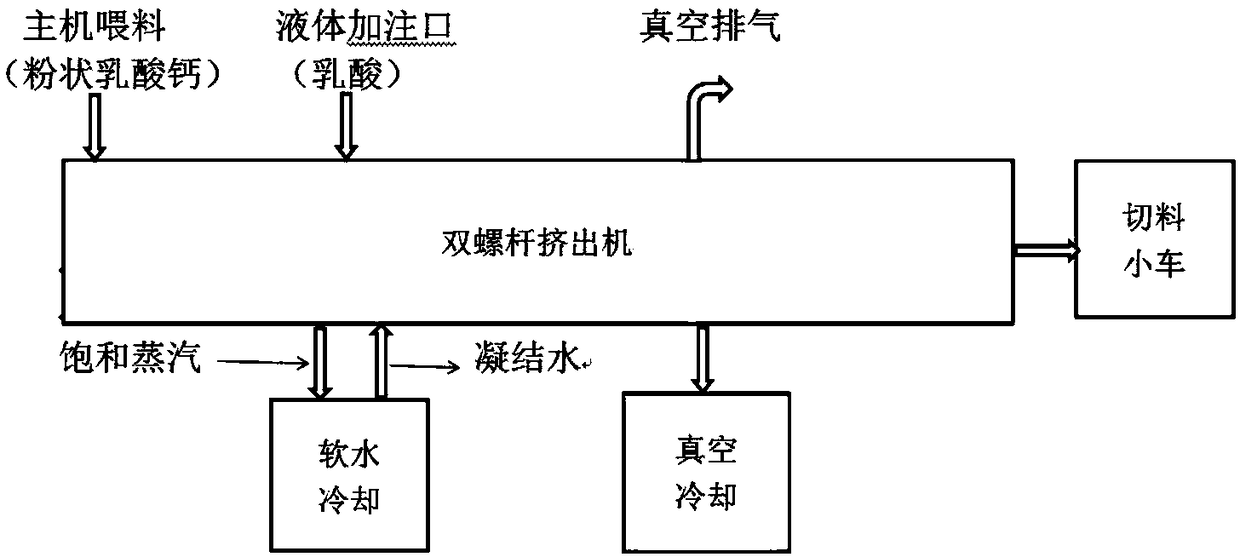

Baking-free preparation method of compounding food additive lactic acid powder through extruding and mixing of twin screw extruder

The invention relates to a baking-free preparation method of compounding food additive lactic acid powder (solid lactic acid) through extruding and mixing of a twin screw extruder. The method comprises the following steps of adding calcium lactate solid and lactic acid liquid in a twin screw extruder from different feed openings, under the effect of a screw unit assembly specially designed in theextruder, enabling the calcium lactate solid and lactic acid liquid to be in sufficient contact, mixed and transported forwards, and through working procedures of performing vacuum air extraction, performing dehydration, performing pelleting, performing airing (cooling), performing standing, performing crystallization and rearrangement, performing crushing and sieving, adding an anticaking agent,performing mixing and the like, compounding food additive lactic acid powder (solid lactic acid) products are finally made. According to the lactic acid powder obtained by the method disclosed by theinvention, the content of lactic acid of unit mass is high, much non-lactic acid foreign matter is introduced, the compounding food additive lactic acid powder (solid lactic acid) easily dissolves inwater, lactic acid substances are positioned in a molecule dissociating state, and unique and harmonious flavor of raw material products can be reflected and expressed in the application effect evaluation of goal products.

Owner:湖北壮美生物科技有限公司

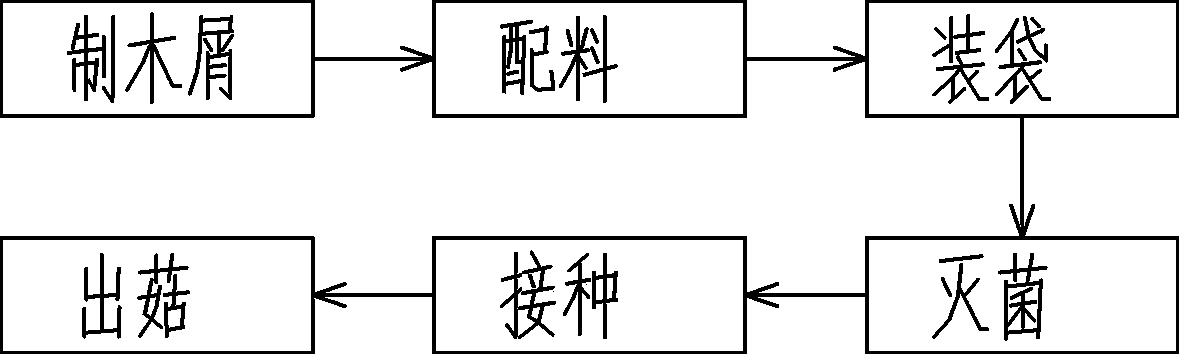

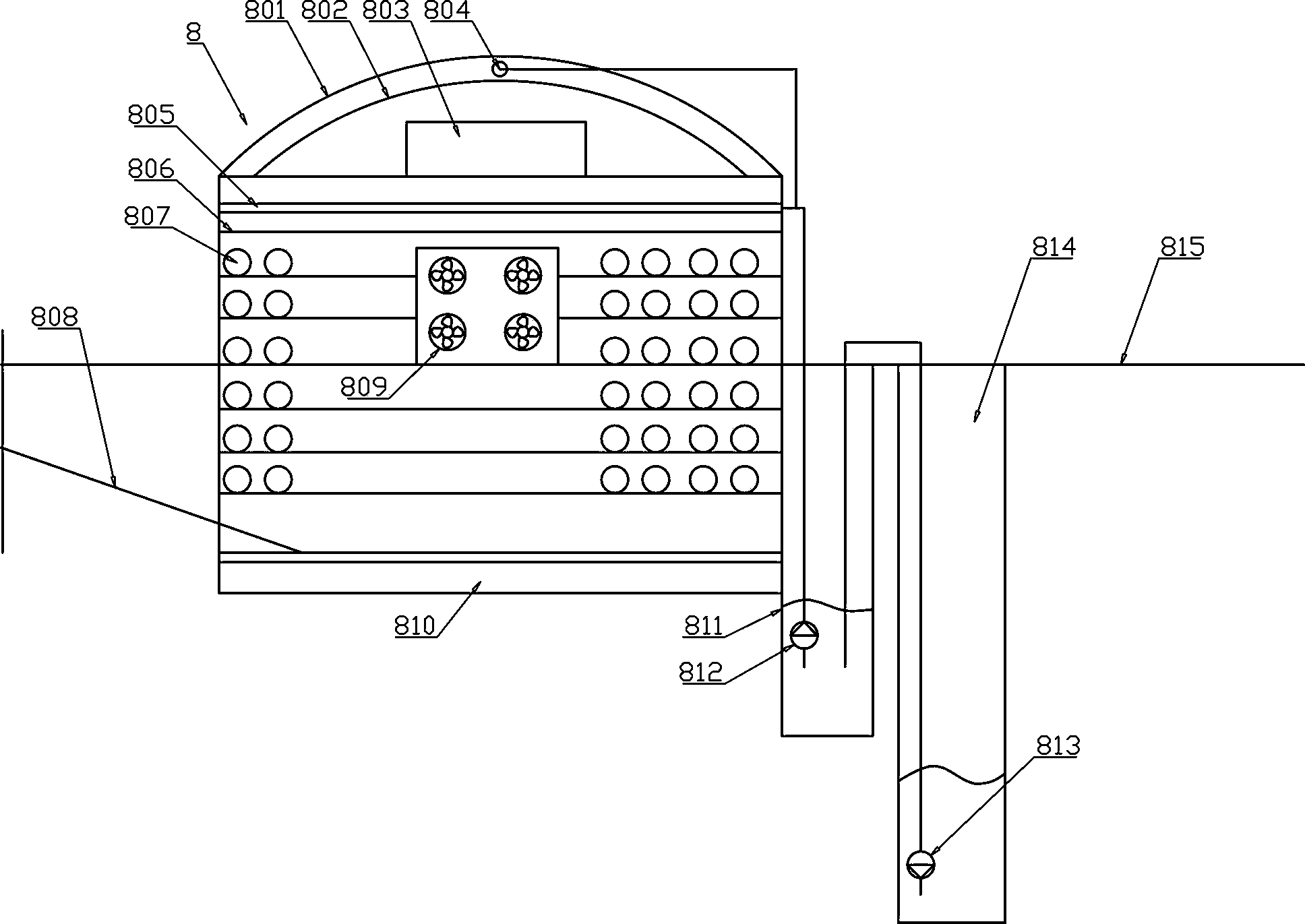

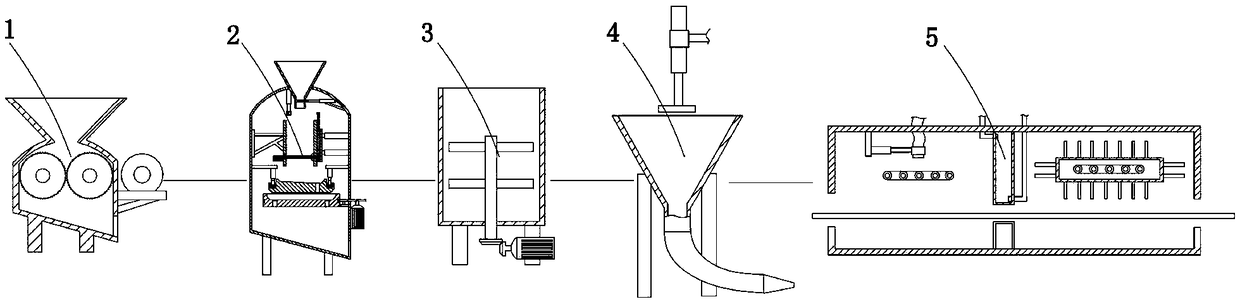

Industrialized mushroom production method and industrialized mushroom production system

ActiveCN104285673AReduce the chance of bacterial infectionEvenly in batchesCultivating equipmentsMushroom cultivationBiotechnologyMushroom

An industrialized mushroom production method comprises the following steps of making wood scraps; mixing materials; packaging the materials into bags; sterilizing the materials; feeding fungus barrels to a sterilizing chamber and sterilizing the fungus by using steam; directly feeding the fungus barrels to an inoculation workshop after the fungus barrels are sterilized; performing inoculation on the fungus barrel; and fruiting. Industrialized mushroom production is realized by the steps. The industrialized mushroom production system comprises a scrap making device, a weighing and mixing device, a fungus barrel packaging device, a sterilizing chamber, an inoculation workshop and a fruiting workshop, wherein the scrap making device is connected with the weighing and mixing device through a conveying device; the weighing and mixing device is connected with the fungus barrel packaging device through the conveying device; a first sealing door and a second sealing door are respectively arranged at two ends of the sterilizing chamber; the first sealing door is close to the fungus barrel packaging device as much as possible; and the second sealing door is directly positioned in the inoculation workshop. The probability that the fungus barrels are infected by infectious microbes is reduced in a production process, the inoculation efficiency is improved, and the labor intensity is reduced. Moreover, the utilization rate of equipment is improved, and continuous production is realized.

Owner:YICHANG DAZIRAN BIOTECH

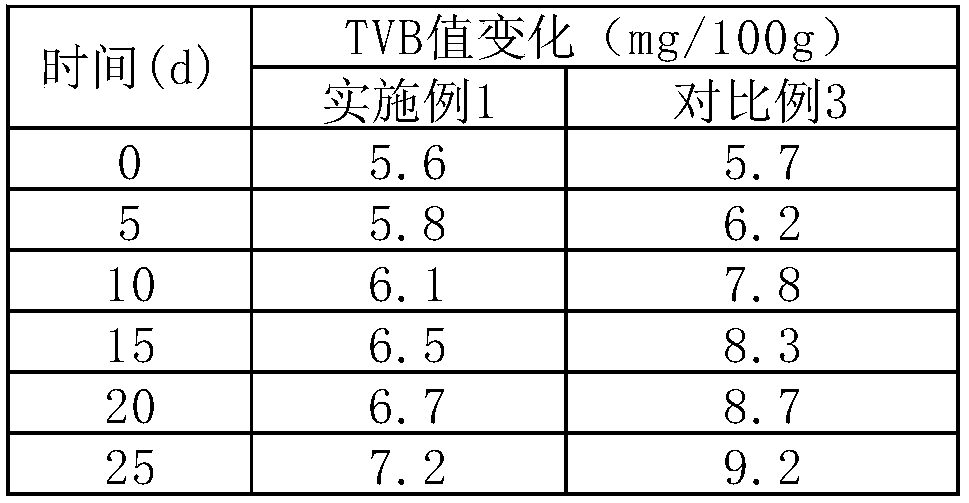

Production technology of dried antarctic krill

InactiveCN108719860AThe process steps are simpleEasy to operateFood ingredient as antioxidantClimate change adaptationFreeze-dryingAntioxidant

The invention discloses a production technology of dried antarctic krill. The production technology comprises the following steps of (1) classifying fresh antarctic krill according to the specification, thoroughly cleaning the classified antarctic krill, and performing draining; (2) adding a composite antioxidant and a composite preservative to water, and then performing uniform stirring to obtaincooling liquid; (3) adding the antarctic krill with the same specification in the step (1) to the cooking liquid, performing heating to 90-95 DEG C, and performing micro-boiling cooking for at least30min; and (4) filtering the cooked antarctic krill in the step (3), performing cooling, putting the cooled antarctic krill in a vacuum freeze drying machine, then sequentially performing vacuum prefreezing, vacuum sublimation drying and vacuum parsing drying until the moisture content is 25-30%, and then performing vacuum packing so as to obtain dried antarctic krill products. The technology of the dried antarctic krill is simple in steps, high in maneuverability and low in energy consumption, and the obtained dried antarctic krill is good in appearance and quality. The antarctic krill has certain elasticity, and is delicious and chewy in mouth feel and long in storage period.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Method for preparing L-asparaginic acid disodium

ActiveCN106117070AImprove securityQuality improvementOrganic compound preparationAmino-carboxyl compound preparationOrganic solventFreeze-drying

The invention discloses a method for preparing L-asparaginic acid disodium. The method comprises the following steps of performing a reaction at the temperature of 70-80 DEG C by using sodium carbonate or sodium hydroxide, and L-asparaginic acid as raw materials, and by using water as a solvent, after the reaction is finished, adjusting the pH value of reaction liquid to 9.0-12.0, decoloring the reaction liquid, performing filtration, performing concentration until the Baume degree of a solution is 40-45 degree Be, and reducing temperature; transferring the solution after temperature reduction is completed to a vacuum freeze drier, maintaining the pressure of the vacuum freeze drier to be 20-40Pa, performing pre-freezing at the temperature of minus 30 to minus 20 DEG C for 2-4h, and then maintaining the temperature to be at minus 25 to minus 15 DEG C for 3-5h; and drying materials after vacuum freeze-drying at the temperature of 70-80 DEG C for 3-6 hours, so as to obtain L-asparaginic acid disodium products. According to the method disclosed by the invention, an organic solvent is not used, so that the safety coefficient of production environment is increased; and the products are free from solvent residues, so that the quality of the products is improved, and the water content is easy to control.

Owner:宜兴市前成生物有限公司

Technique and device for coproducing carbide slag cement in a dry-method acetylene process

ActiveCN102746086AReduced operating requirementsStable feedingCement productionHydrocarbonsSlagCarbon dioxide

The invention provides a technique and device for coproducing carbide slag cement in a dry-method acetylene process. The device comprises a carbide crushing system, a dry-method acetylene reaction system and a cement production system. The technique is implemented in a way that: liquid carbide from a carbide furnace is sent to a seal device under the action of gravity; the seal device is provided with an air flow nozzle; pressurized carbon dioxide is introduced to crush the liquid carbide; the crushed carbide is subjected to iron removal, crushing and iron removal, and sent to a dry-method acetylene reactor again; the metered carbide with small particle sizes falls into the dry-method acetylene reactor; the second section of the partition of the dry-method acetylene reactor is provided with an opening; eolian sand or furnace slag is added; and under the action of a stirring device, the eolian sand or furnace slag and the carbide slag are discharged out of the dry-method acetylene reaction system through the outlet of the dry-method reactor, and are sent to the cement production system. The invention solves the problems of high carbide crushing cost, incomplete reaction of carbide at the dry-method acetylene station, waste of carbide resources, low acetylene yield, high blockage tendency of the reactor, complex technique and the like.

Owner:XINJIANG TIANYE GRP +3

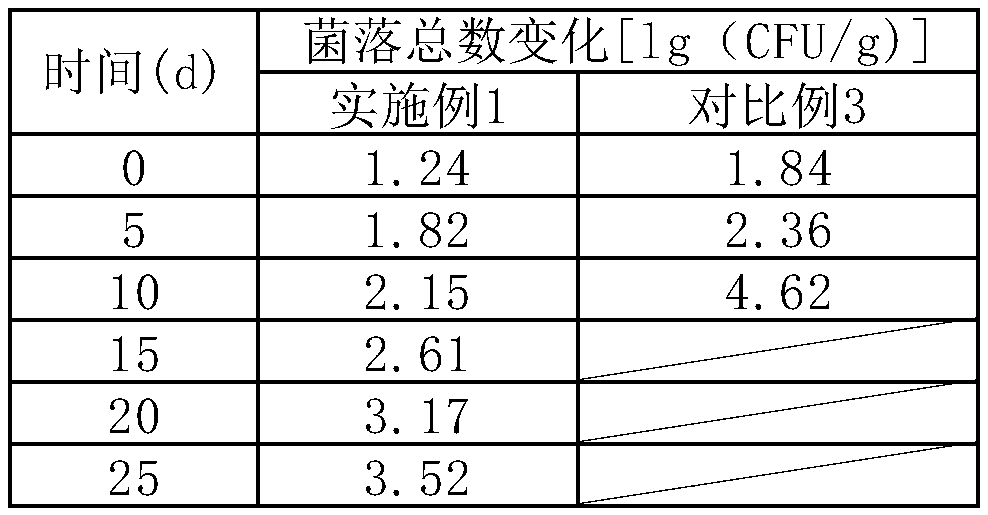

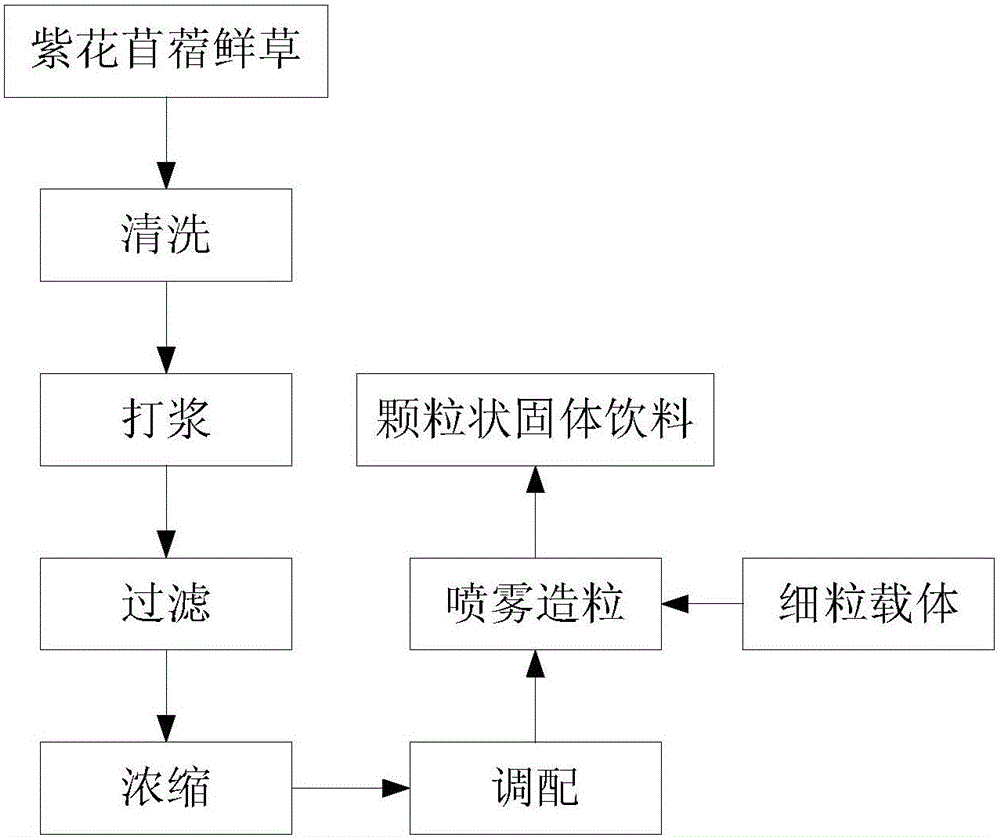

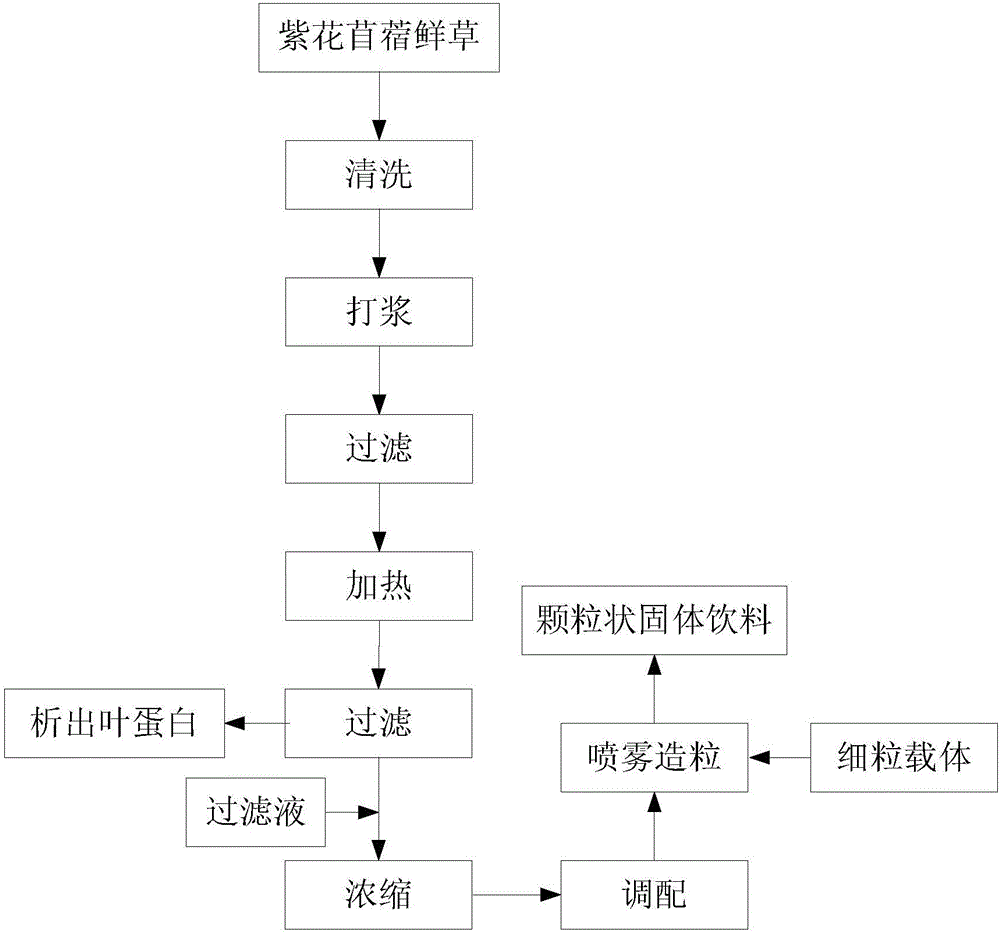

Preparation method of medicago sativa solid beverage

ActiveCN105918757AHigh extraction rateIncrease contentFood ingredientsFood shapingSpray GranulationAdditive ingredient

The invention provides a preparation method of a medicago sativa solid beverage. The preparation method comprises the following steps of cleaning fresh medicago sativa, and then sequentially performing mashing, filtering, and concentrating so as to obtain concentrated serous fluid; adding auxiliary materials to the concentrated serous fluid, and performing uniform mixing so as to obtain molding material fluid, wherein the auxiliary materials comprise cyclodextrin; and performing spraying granulation on the molding material fluid so as to obtain the granular medicago sativa solid beverage. According to the preparation method disclosed by the invention, fixation treatment is not performed on the medicago sativa, and mashing is directly performed, so that the content of nutrient components in the concentrated serous fluid are obviously increased, particularly the content of alfalfa saponin and flavone are increased, and the extraction rate of the medicago sativa is increased. A spraying granulation method is used for drying and shaping the molding material fluid, wherein the molding temperature is low, so that zero loss of effective nutrient components in the medicago sativa is guaranteed. The moisture content is easy to control, and the percentage by mass of water of the medicago sativa solid beverage provided by the invention can be well guaranteed to be 5% or below.

Owner:玉永雄

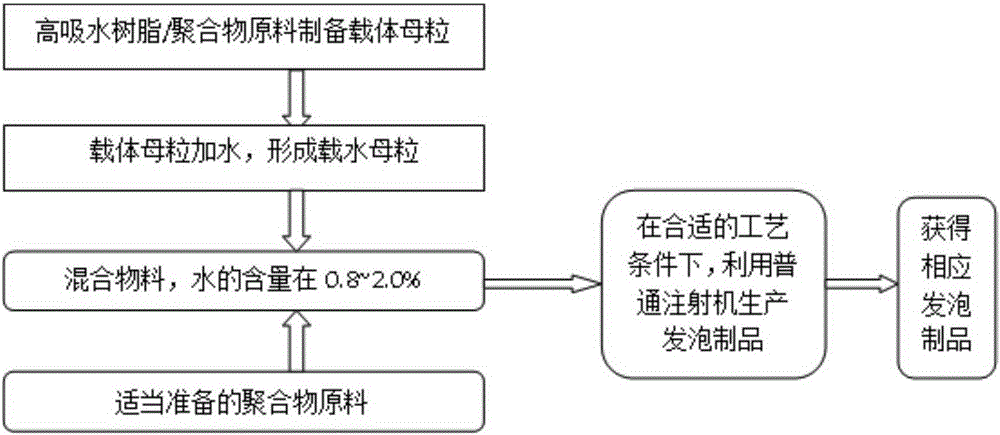

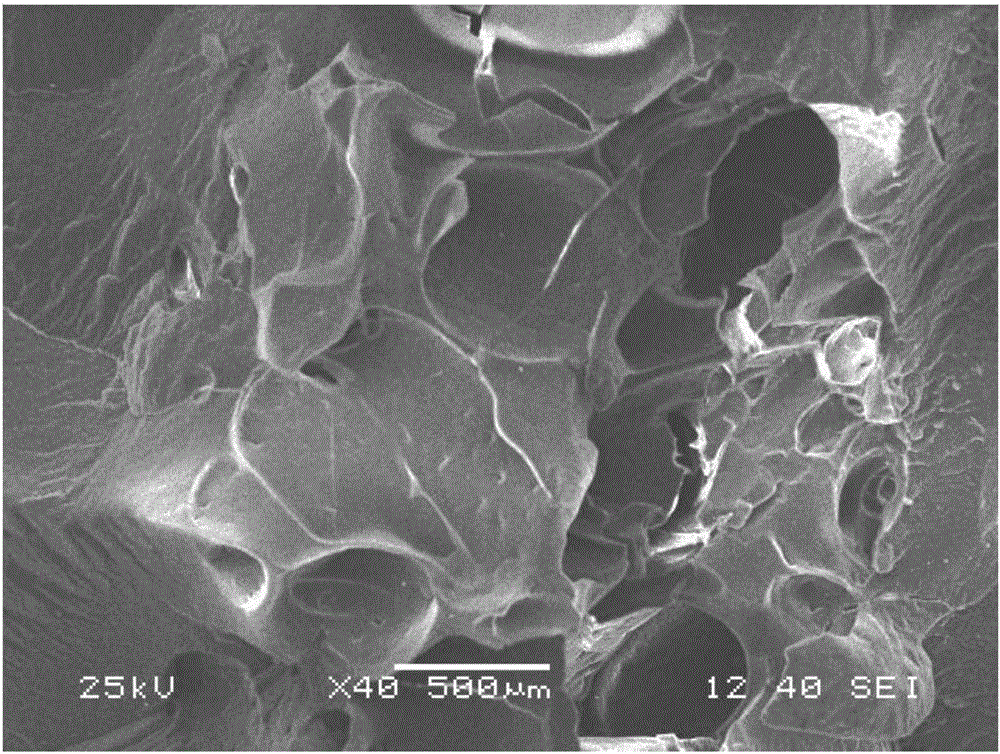

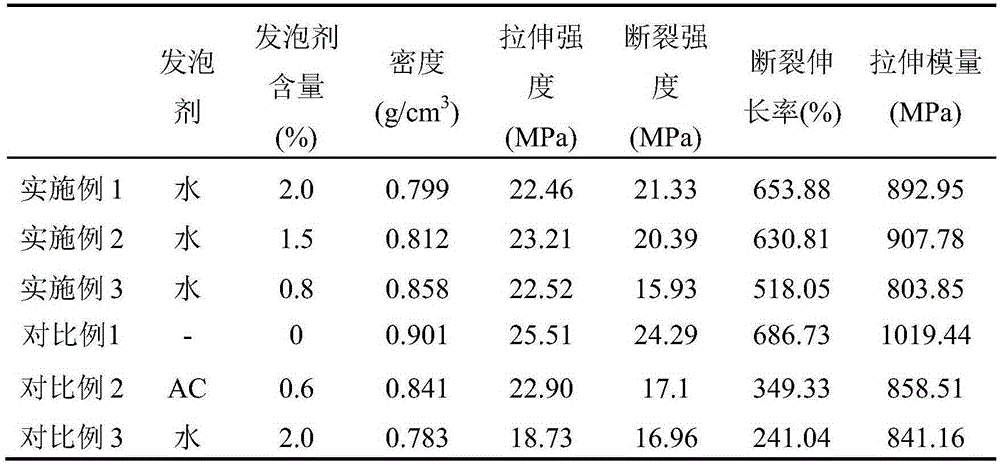

Water foaming injection method by using super absorbent resin as carrier

ActiveCN105291340AThe water absorption process is simple and fastSimple processThermoplasticPolymer science

The invention discloses a water foaming injection method by using a super absorbent resin as a carrier. The method comprises the following steps: (1) the super absorbent resin is dried; (2) a thermoplastic plastic is selected as a basal body material; and after the thermoplastic plastic is mixed with the super absorbent resin, a little water is added; (3) uniform carrier master batches are prepared through a plastic extruder; (4) the carrier master batches are dried; (5) distilled water is sprayed and added into the carrier master batches to form water-carried master batches; (6) the water-carried master batches are added in a polymer raw material to be processed for uniform mixing to prepare a second mixed material; and (7) the second mixed material is added in a plastic injector to produce a foaming injection product. In the water foaming injection method by using the super absorbent resin as the carrier provided by the invention, water is easy to obtain; the control of water quantity can be conveniently realized through the use of the high absorbent resin; the foaming degree is easy to control; the processing temperature range of applicable materials is wide; and the method has such characteristics as economy, convenience and wide applicability.

Owner:广州市科迩曼塑料科技有限公司

Environment-friendly high-quality sand making building station system

PendingCN109127086APrecise screeningCompact structureGrain treatmentsProduction rateEnvironmental resistance

The invention discloses an environment-friendly high-quality sand making building station system. A discharging port of a feeding and collecting bin is connected with a feeding port of a spill waterfall type vertical shaft through a pipeline, a discharging port of the spill waterfall type vertical shaft is connected with a feeding port of a primary powder concentrator, and a plate conveyor is placed below a discharging port of the primary powder concentrator. The system has the benefits as follows: 1, the gradation and fineness can be controlled according to demands of clients, so that different selling prices of products in different specifications can be obtained, and better economic effects can be obtained; 2, the capacity is high, finished products have superior granule shapes and thesand production rate is high; 3, the stone powder content and moisture content of sand can be controlled as required.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

Equipment for recovery processing of solid waste into home crafts

InactiveCN109093824AImprove drying efficiencyQuality improvementCeramic shaping plantsFeeding arrangmentsEconomic benefitsPulp and paper industry

The invention discloses equipment for recovery processing of solid waste into home crafts. The equipment comprises a crushing device, a grinding device, a pulping device and a drying device, wherein the crushing device is used for crushing large-block materials; the grinding device is used for grinding the crushed materials into powder particles with the particle size being 0.10-0.02 mm; the screened powder particles are placed in a material tank, water, a colorant and a binder are added, and pulping is conducted through the pulping device under the stirring condition; and the drying device heats and dries pulp injected into a mold and the mold together. The building waste is manufactured into embossment-shaped and sculpture-shaped flagstone to form the crafts, thus the equipment for recovery processing of the solid waste into the home crafts can be used for home decoration and other purposes, the utilization efficiency of the building waste can be effectively improved through the mode, and economic benefits are increased.

Owner:CITY COLLEGE WENZHOU UNIV

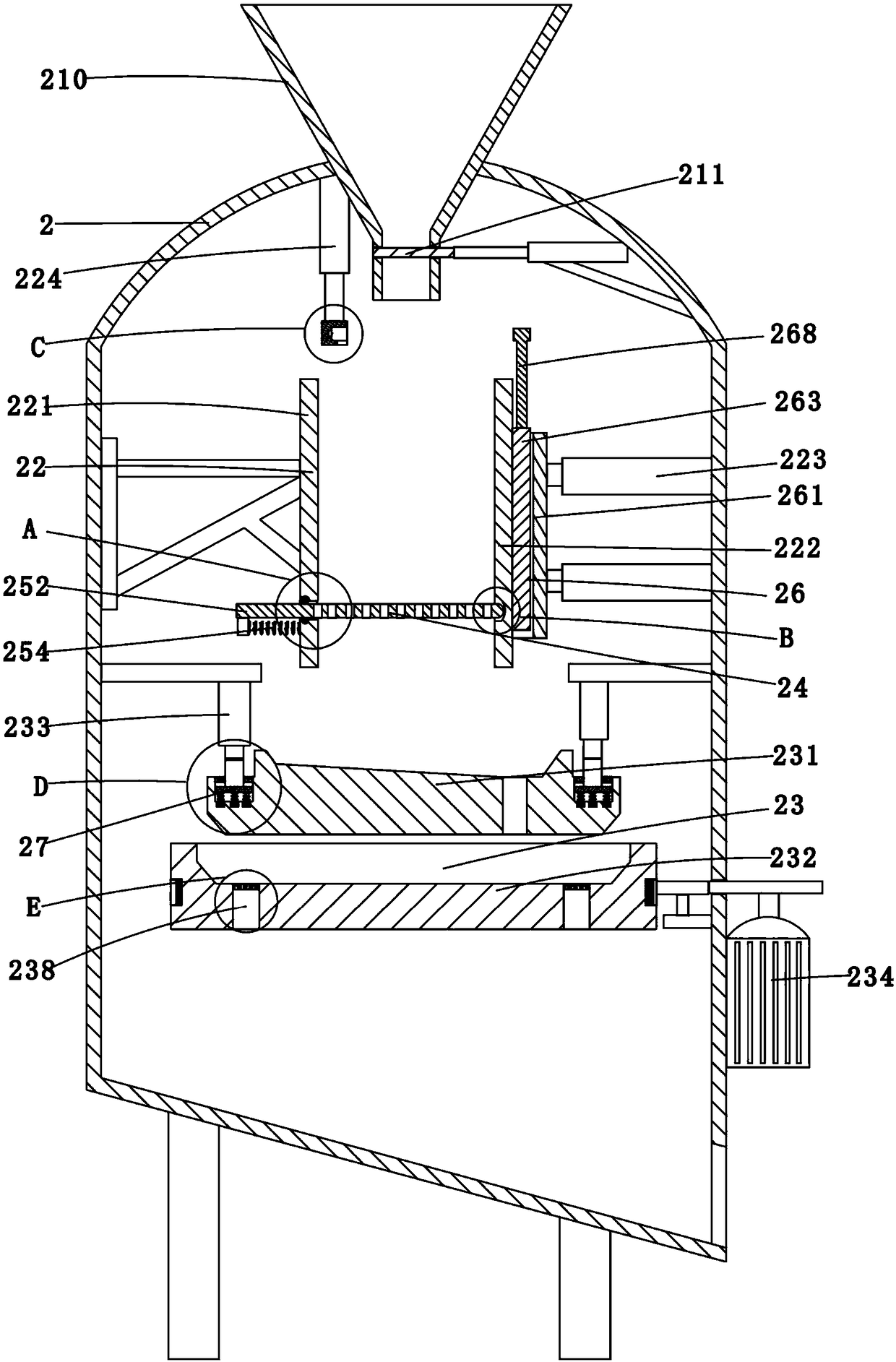

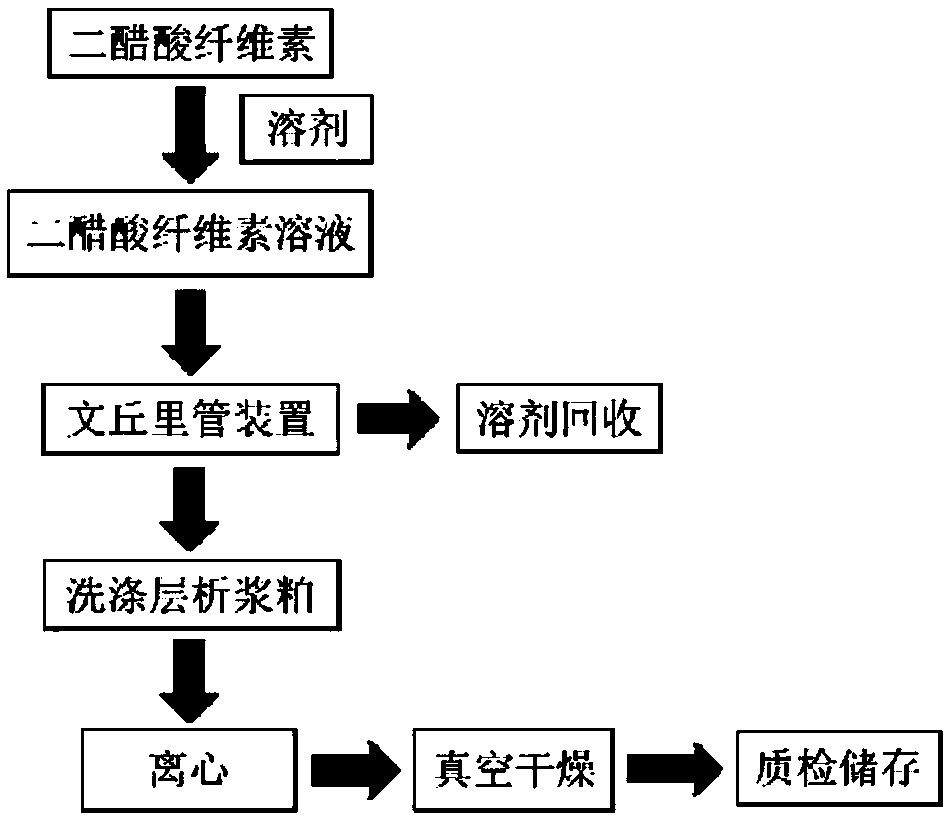

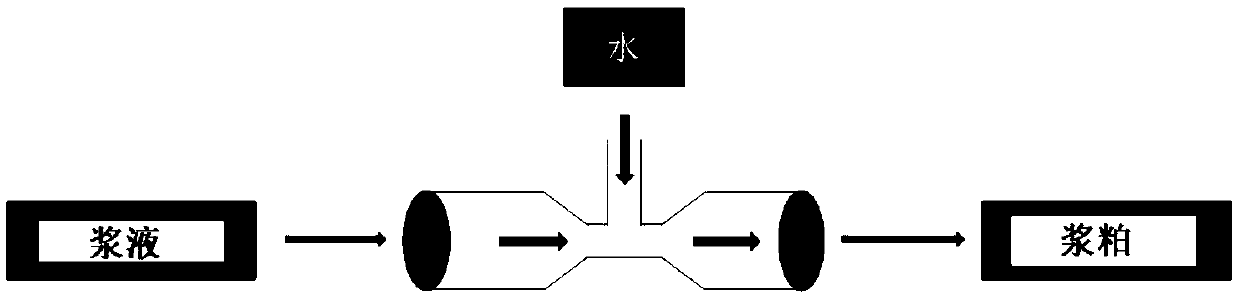

Cellulose diacetate pulp and preparing method thereof

ActiveCN109629299AIncrease productionEasy to storePulp properties modificationCellulose diacetateCellulose acetate

The invention provides cellulose diacetate pulp and a preparing method thereof. The preparing method comprises the following steps that 1, cellulose diacetate is dissolved in a solvent to form cellulose diacetate seriflux, the cellulose diacetate seriflux passes through a Venturi tube device and is injected into coagulating bath, and thus initial cellulose diacetate pulp is obtained; 2, the initial cellulose diacetate pulp is processed with water, and thus the cellulose diacetate pulp is obtained. The preparing method omits the steps such as spinning, cutting, pulping and shearing, the preparing technology is easy, compared with a conventional high polymer pulp preparing method, the prepared cellulose diacetate pulp is easy to store, the water content is easy to control, multiple components of the pulp can be mixed, operation is more convenient and easier, the cost is lower, the diameter of the finally obtained cellulose diacetate pulp becomes smaller, and the cellulose diacetate pulpis large in specific area and uniform in structure and has high practical application value.

Owner:上海展恒环保科技有限公司

Method for crushing and solidifying cohesive soil by spraying high-pressure liquid-gas mixed fluid

ActiveCN112227127AWell mixedMoisture content is easy to controlRoadwaysSoil preservationLand acquisitionSoil science

The invention discloses a method for crushing and solidifying cohesive soil by spraying a high-pressure liquid-gas mixed fluid. The method comprises the following steps: detecting the characteristicsof cohesive soil on a construction site, including detection of the water content and the clay particle content, then pre-burying a pipeline into the cohesive soil, and starting to prepare liquid-gasmixed fluid; then, applying the pressure on the liquid-gas mixed fluid, after pressing is finished, conveying the high-pressure liquid-gas mixed fluid into the cohesive soil at a certain burial depththrough a pipeline and spraying the fluid into the cohesive soil through spraying devices such as a spraying head, applying the shearing force to a soil body, cutting and crushing the soil body, and in the cutting and crushing process of the soil body through the high-pressure spraying mixed fluid, fully mixing a curing agent solution in the mixed fluid with the soil body broken particles to ensure that the soil body broken particles react with the soil body, so that the soil body is cured. According to the method, the soil body can be maintained in situ, land occupation or land acquisition isnot needed, and the method is efficient and environment-friendly.

Owner:HEBEI ROAD & BRIDGE GROUP +1

Production process of waterproof wooden door

InactiveCN110877394ALow densityReduce weightWood working apparatusProcess engineeringIndustrial engineering

The invention discloses a production process of a waterproof wooden door, and relates to the technical field of wooden doors. The production process of the waterproof wooden door includes the following steps of material selection and preparation, rough processing, finish processing, surface coating, and installation and packaging. The production process of the waterproof wooden door has the following advantages that the raw material of white pine is mainly adopted to make the wooden door, after spray steaming and heating drying under the same condition, the moisture content of the white pine can be reduced to a preset value more rapidly than that of other wood materials, the time of the whole wooden door manufacturing process can be easily shortened, and thus the production efficiency is improved; and as waterproof paint is expensive, first-layer whole-face waterborne waterproof paint is sprayed between first-layer waterborne polyurethane undercoat and second-layer waterborne polyurethane undercoat and second-layer waterborne waterproof paint is sprayed at the one-third part of the bottom, so that the waterproof effect of the bottom of the whole wooden door is greatly improved under the condition of controlling the cost, the wooden door can be used in a bathroom or other humid environments, and then the application range of the wooden door is effectively expanded.

Owner:重庆林佳建材有限公司

Wormwood raw material drying process and equipment

PendingCN113758197AGuaranteed exposureSync removalDrying gas arrangementsDrying chambers/containersProcess engineeringIndustrial engineering

The invention discloses a wormwood raw material drying process and equipment, relates to the technical field of wormwood processing, and solves the problems that manual operation is adopted in an existing wormwood drying treatment process, the drying degree is not easy to control, impurities are not convenient to automatically remove and the like. The wormwood raw material drying process and equipment comprises the following steps that firstly, wormwood is sorted, the picked wormwood is cut and removed, soil is prevented from being mixed in the wormwood, mildewed and deteriorated wormwood leaves in the wormwood is removed, the wormwood is purer, the wormwood is placed on a sorting operation table top, stems and impurities are removed, and then the selected wormwood is placed in a clean and dry container, the selected wormwood is weighed, a material state card is stuck, and the next process is turned to. According to the wormwood raw material drying process and equipment, wormwood is automatically stirred and circularly conveyed, the contact degree of the wormwood and hot dry air is effectively guaranteed, the water content is conveniently controlled, and impurities can be synchronously removed in the vibration process.

Owner:佳诺威集团股份有限公司

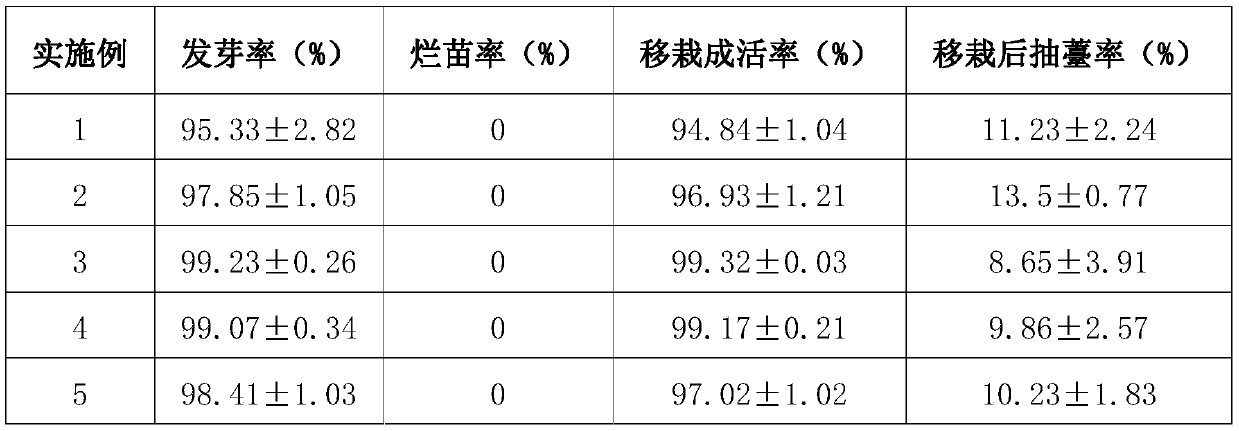

Storage method for Chinese angelica seedlings

PendingCN110810192AImprove mining efficiencyReduce labor intensityGrowth substratesCulture mediaBoltingTransplanting

The invention discloses a storage method for Chinese angelica seedlings. The storage method includes the steps of 1) seedling harvesting, 2) seedling dehydration, 3) seedling selection, 4) seedling sterilization, 5) preparation of seedling storage media, 6) seedling packing, 7) seedling warehousing, 8) seedling storage, 9) seedling removal from a warehouse, and 10) inspection. The storage method has the advantages that the efficiency is improved, and the cost is saved; through seedling treatment, diseases of stored seedlings are reduced; the storage temperature of the seedlings is controlled,and the bolting rate in transplanting is reduced; the seedlings are uniform, and mechanical transplanting is facilitated.

Owner:INST OF ECONOMIC CROPS & BEER RAW MATERIAL GANSU ACADEMY OF AGRI SCI +1

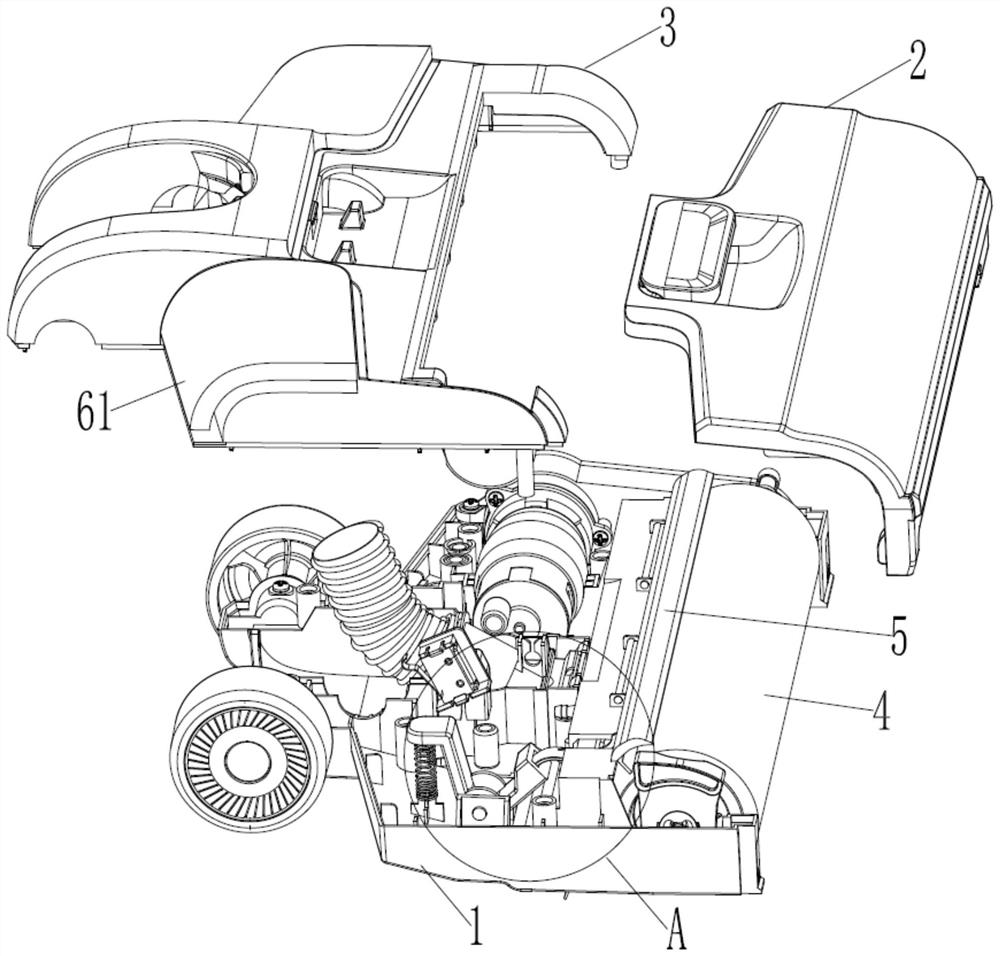

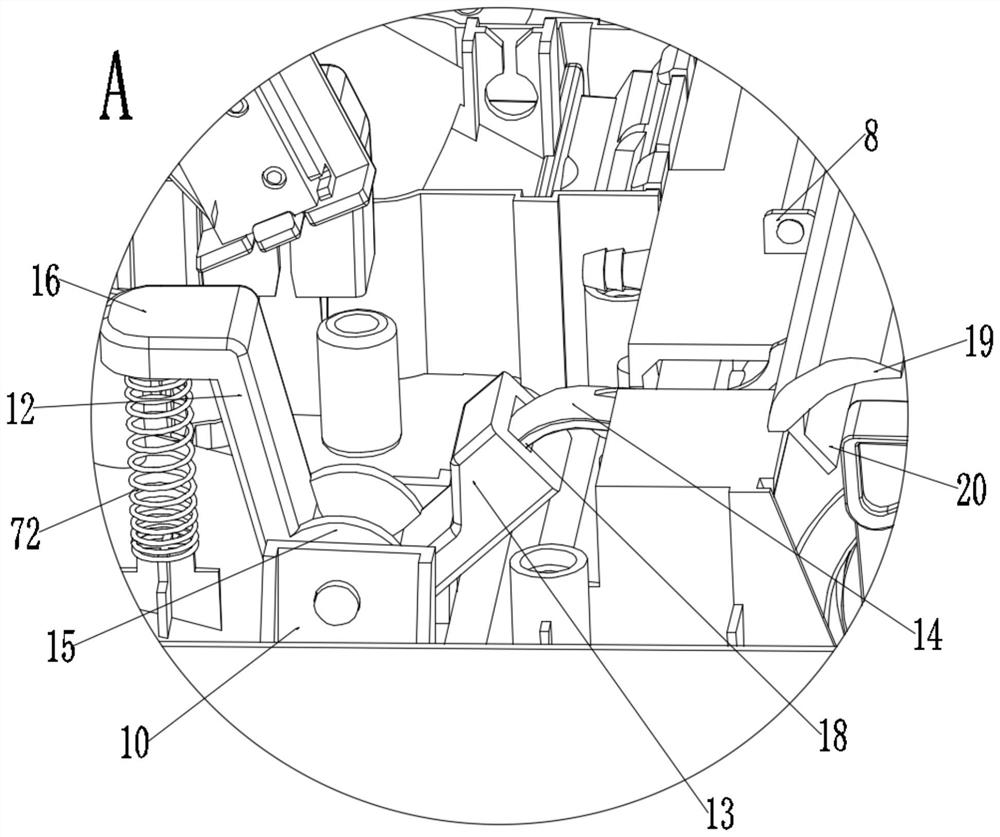

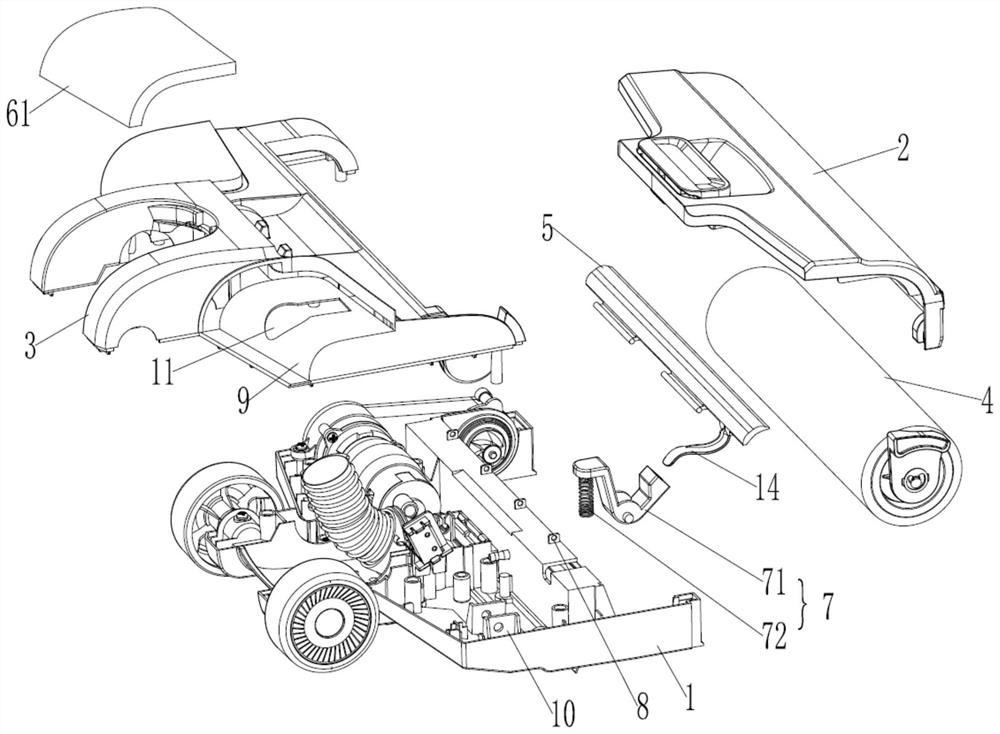

Movable scraping strip structure of floor cleaning machine

ActiveCN113509109AChange contact relationshipMoisture content is easy to controlCarpet cleanersFloor cleanersForeign matterEngineering

The invention discloses a movable scraping strip structure of a floor cleaning machine, and belongs to the technical field of floor cleaning machines, the movable scraping strip structure comprises a base, a front cover, a rear cover, a rolling brush, a scraping strip body, a treading mechanism and a scraping strip turnover mechanism, and the front cover and the rear cover are both located above the base and clamped on the base; and the edges between the front cover and the rear cover are attached, the two ends of the rolling brush are clamped to the base, the rolling brush is located below the front cover, the scraping strip body is hinged to a second supporting plate on the base, the scraping strip body abuts against the rolling brush, and the treading mechanism is arranged on the rear cover in a sliding mode. A transmission lever can be triggered to press down by treading a pedal body, and the transmission lever shifts a curved shifting strip to enable the scraping strip body to rotate, so that the contact relation between the scraping strip body and the rolling brush is changed, the water content of the surface of the rolling brush is controllable, and meanwhile foreign matter and dirt on the surface of the rolling brush can be deeply cleaned.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

Preparation method of dried yak meat

The invention relates to a preparation method of dried yak meat. The preparation method comprises following steps: meat selecting, washing, cutting, boiling and marinating, cutting in strips or blocks, drying, material blending, sterilizing, examining, and packaging. According to the preparation method, contentional baking or deep frying drying technology is changed to be stir frying, the weight ratio of oil to meat is controlled to be 1:20-23, oil temperature is controlled to be 90 to 110 DEG C, stir frying time is controlled to be 1.5 to 2h, water content after stir frying is controlled to be 10 to 15%. The mouthfeel of the obtained dried yak meat is better; the dried yak meat is more chewable, soft, and long in aftertaste lasting time.

Owner:DAZHOU HONGLONG MEAT PROD

A kind of three-step ripening and three-step aging hanging rice flour preparation method

InactiveCN104171815BReduce surface tackHigh densityFood thermal treatmentFood shapingFood additiveWheat germ

The invention discloses a Gua rice noodle preparation method including three ripening steps and three aging steps, and belongs to the grain processing technology in the technical field of processing of agricultural products. The rice noodles comprise the following raw materials in parts by weight: rice 60-80 and corn 20-40. The preparation method comprises the following steps: 1, preparing of the raw materials; 2, grinding into rice flour and corn flour respectively; 3, mixing of the rice flour and corn flour; 4, primary ripening; 5, secondary ripening; 6, third ripening until the noodles are completely ripened; 7, rapid freezing and aging; 8, moistening and aging; 9, steam aging; and 10, cutting. The preparation method has relatively short production period and no impact on environment, without any food additives. By adopting the preparation method, the rice noodles using rice and corn as the raw materials can be prepared, and other rice noodles using rice and other grains (such as millet, red rice, black rice, sorghum, oats, wheat germ, soybean, mung bean, red bean, pea, black bean, purple sweet potato, Chinese yam and potato) as the raw materials can also be prepared.

Owner:肖建平

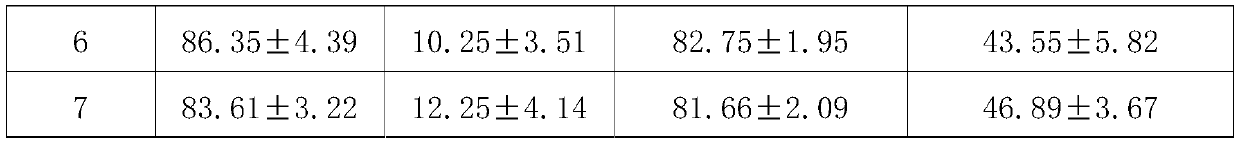

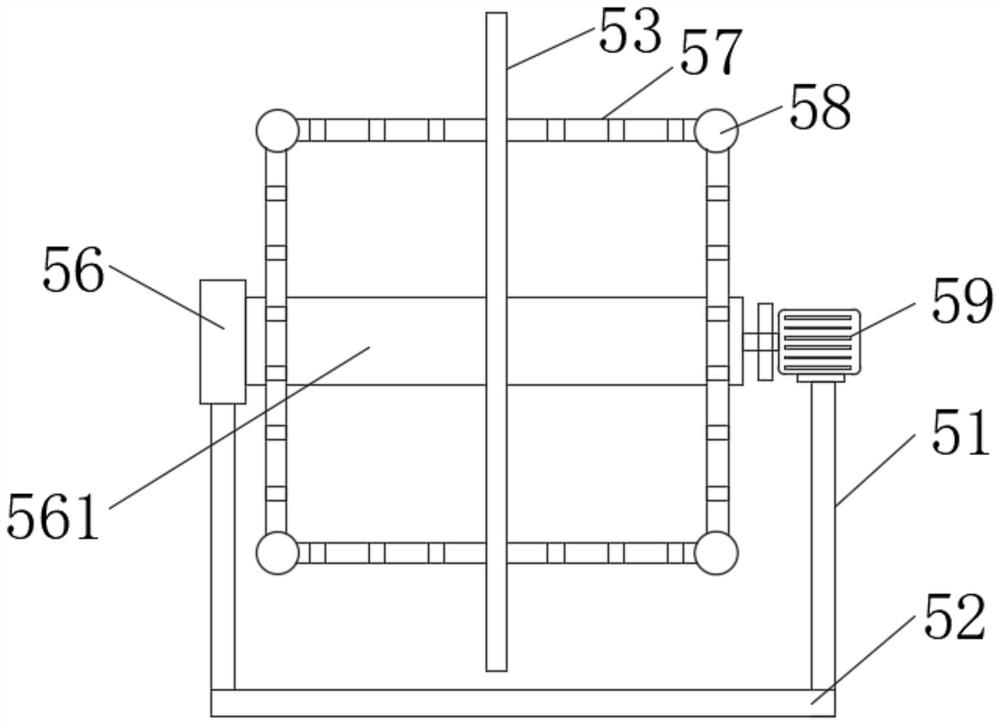

Cigar tobacco stacking fermentation device and method

PendingCN114376261AGuaranteed fermentation effectReduce labor costsTobacco treatmentBio-organic fraction processingElectric machineAgricultural engineering

The invention discloses a cigar tobacco stacking fermentation device and method.The cigar tobacco stacking fermentation device comprises a fermentation box, a hot steam nozzle, a steam pipeline, an electric control box and a stacking box, the stacking box is arranged to be of a cubic structure and comprises a latticed box body formed by splicing wood plates, and the wood plates are arranged to be of a long-strip structure; the protective ring is connected with the outer side of the stacking box through a connecting rod and is of a detachable structure; the two ends of the shaft rod penetrate through the center positions of the front face and the rear face of the stacking box and are connected, the front end of the shaft rod is connected with the rotating disc, and the rear end of the shaft rod is connected with the output end of the motor. According to the technical scheme, the electric cabinet drives the motor, the motor works to drive the shaft rod, and therefore the stacking box is driven to turn over by 180 degrees between the motor and the rotary disc, tobacco leaf pile turning is achieved, the tobacco leaf fermentation effect is guaranteed, and meanwhile the labor cost is reduced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Tobacco stalk expansion method

InactiveCN101862023BUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Lithium battery lamination processing technology

InactiveCN111600076AImprove processing qualityPromote formationLarge-sized flat cells/batteriesFinal product manufacturePhysical chemistryMaterials science

The invention discloses a lithium battery lamination processing technology, which comprises the following steps: a, stirring; b, coating; c, laminating; d, welding; e, capping; f, liquid injecting; g,pre-forming; h, molding; i, formation; and j, testing. According to the lithium battery lamination processing technology, lithium batteries can be processed and produced in batches, the humidity of aprocessing environment is conveniently controlled, the water content of positive and negative electrode materials and electrolytic solution is conveniently controlled, the processing quality of the lithium batteries is improved, and subsequent popularization and application are facilitated.

Owner:安徽五行动力新能源有限公司

Test method for simulating partial root zone irrigation through longitudinal water difference distribution

ActiveCN112913622AEasy to observePrevent inflowSelf-acting watering devicesCotton cultivationAgricultural engineeringBiology

The invention discloses a test method for simulating partial root zone irrigation through longitudinal water difference distribution, and belongs to the technical field of crop planting tests. A cotton planting method is characterized in that a special test device is used for testing, the special test device comprises an upper layer box and a lower layer box, the upper layer box and the lower layer box are open containers containing planting matrixes, the upper layer box is detachably arranged above the lower layer box, a communicating pipe is arranged at the bottom of the upper layer box, the upper end of the communicating pipe is higher than the bottom face of the upper layer box, and the lower end of the communicating pipe is not higher than the upper surfaces of the planting matrixes in the lower layer box. Compared with the prior art, the method can accurately simulate partial root zone irrigation achieved by adjusting the irrigation amount under the field under-film drip irrigation condition through the special test, and a good foundation is provided for researching the mechanism of the irrigation technology for increasing the crop water utilization rate.

Owner:SHANDONG COTTON RES CENT

A kind of silage processing equipment

InactiveCN104509956BControl moisture contentMoisture content is easy to controlFeeding-stuffElectric machineryEngineering

The invention provides silage processing equipment. The silage processing equipment comprises a rack, a conveyor belt, and a cutting device and a dispersing device which are connected in sequence, and further comprises a grinding device, wherein the grinding device comprises three compression roller wheel sets which are connected in sequence; the first compression roller wheel set is composed of an upper compression roller and a second compression roller; each of the second compression roller wheel set and the third compression roller wheel set is composed of one driving roller and three driven compression rollers, namely the driving roller driven by a motor, and the first driven compression roller, the second driven compression roller and the third driven compression roller which are located on the left and right sides and under the driving roller; the conveyor belt penetrates through a gap between the upper and lower compression rollers of the first compression roller wheel set and gaps among driving rollers of the second and third wheel sets and the driven compression rollers. The grinding device is reasonably designed and the moisture content of materials is controlled; the materials are prevented from going moldy and going bad due to bad weather; meanwhile, drying equipment is not used so that the energy consumption is reduced and the expenditure is saved. The silage processing equipment is suitable for crushing and machining silages including banana stems and leaves and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com