Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Meeting Reliability Needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

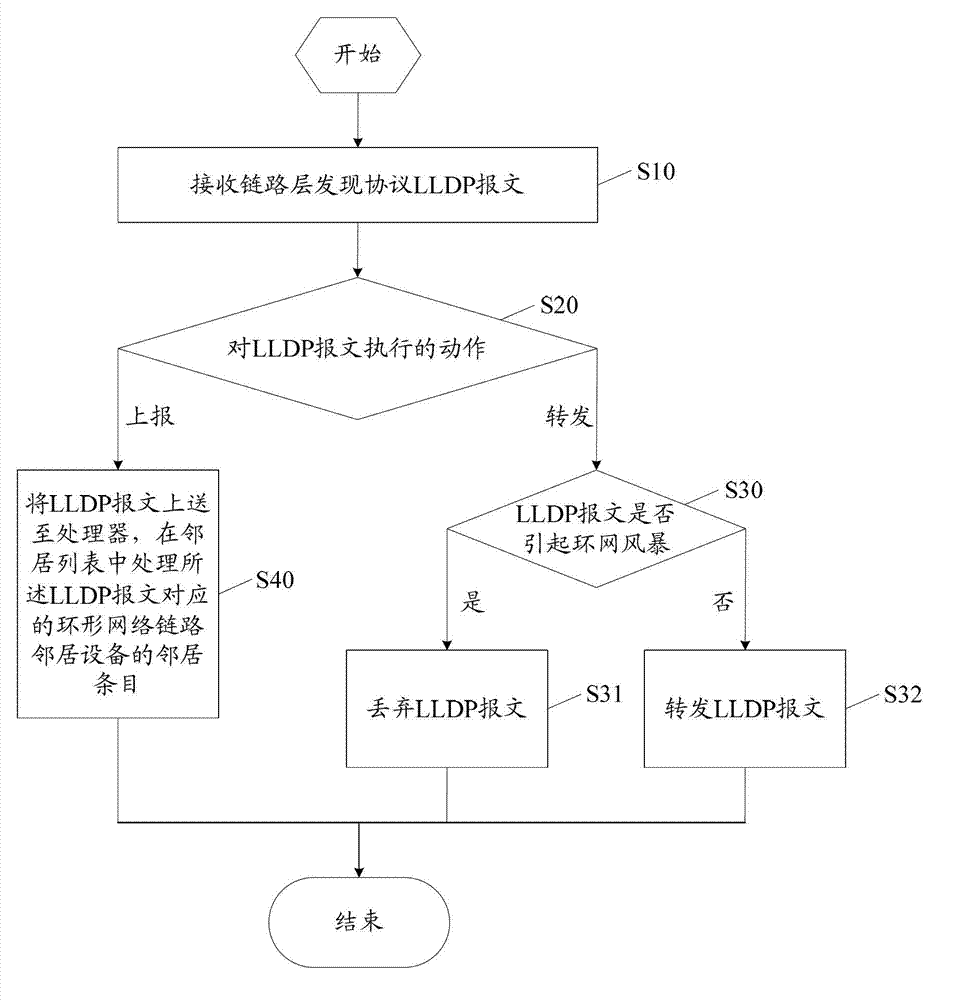

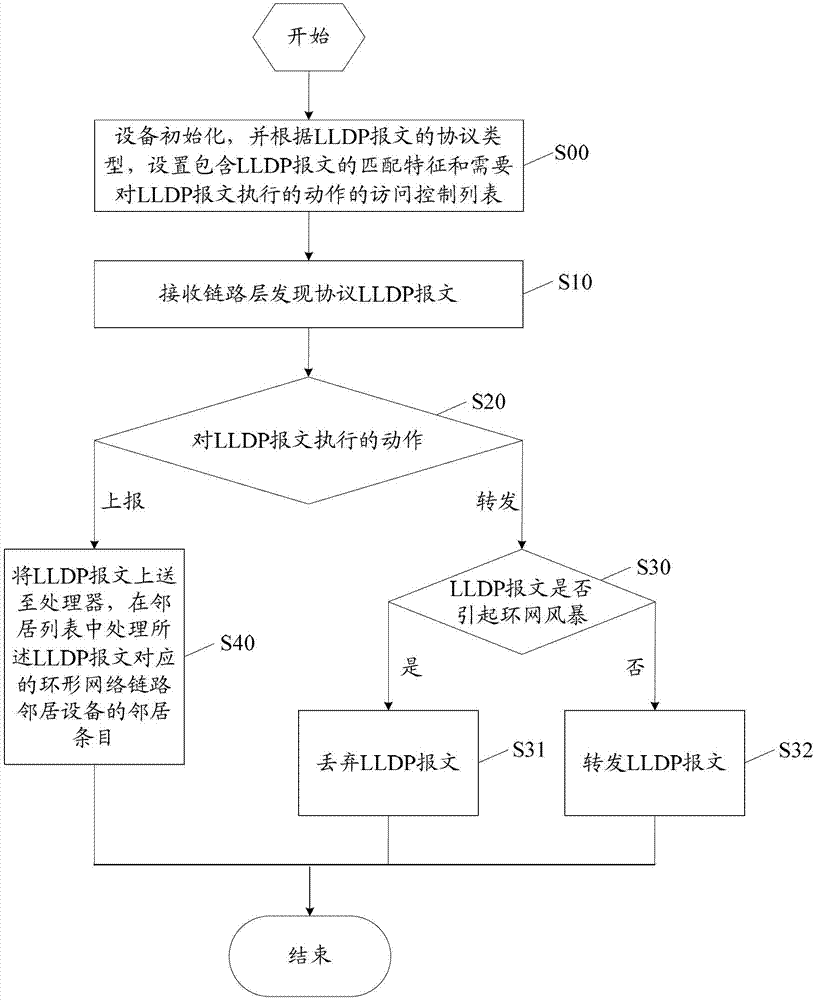

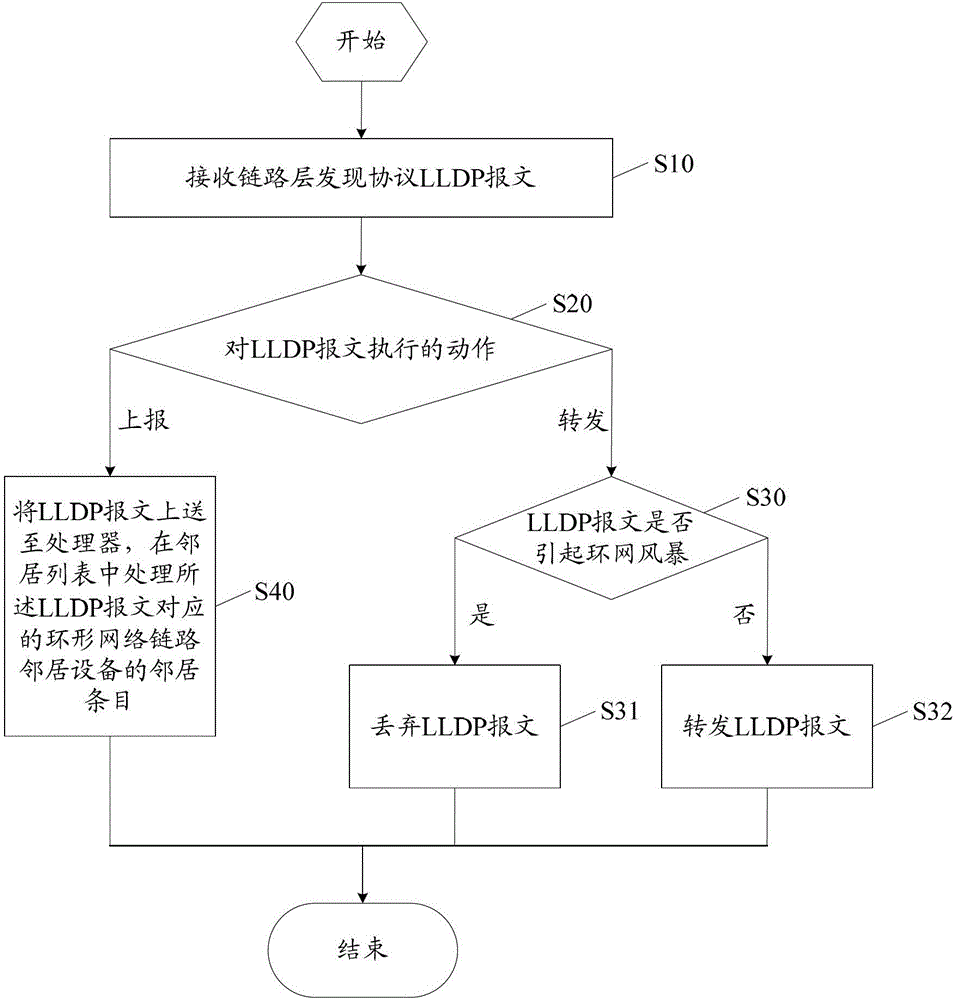

Method for monitoring ring network on basis of link layer discovery protocol and device

ActiveCN102821009AEasy to monitor and manageMeeting Reliability NeedsEnergy efficient ICTLoop networksLink Layer Discovery ProtocolDistributed computing

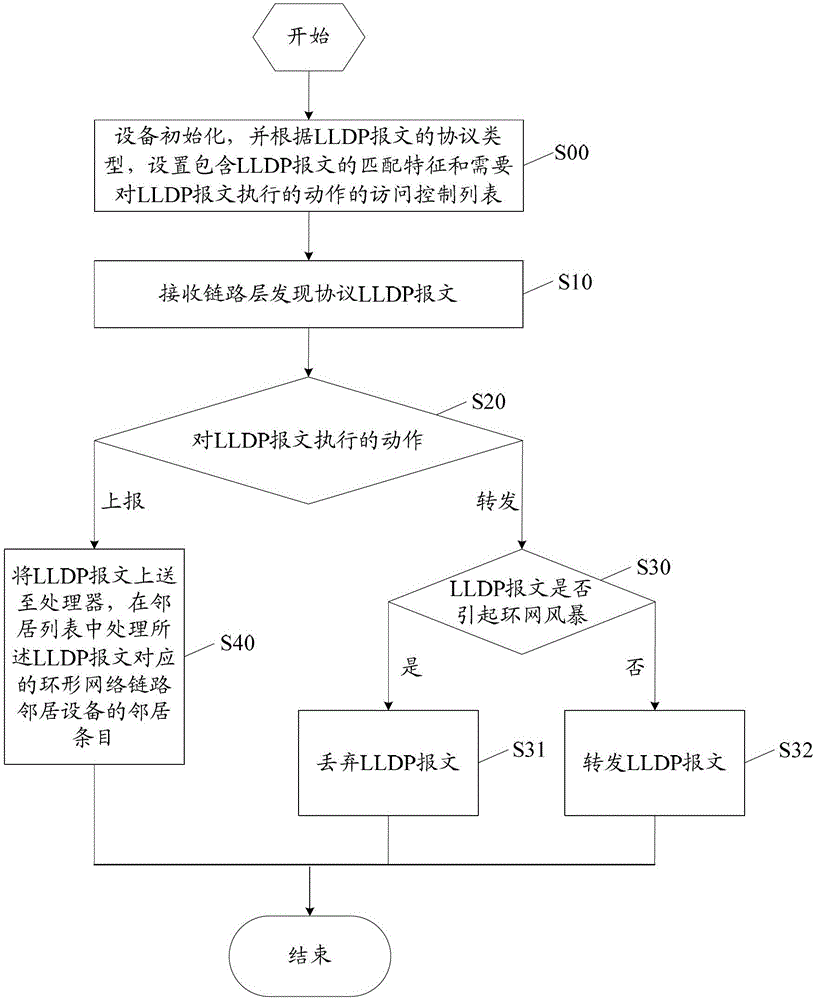

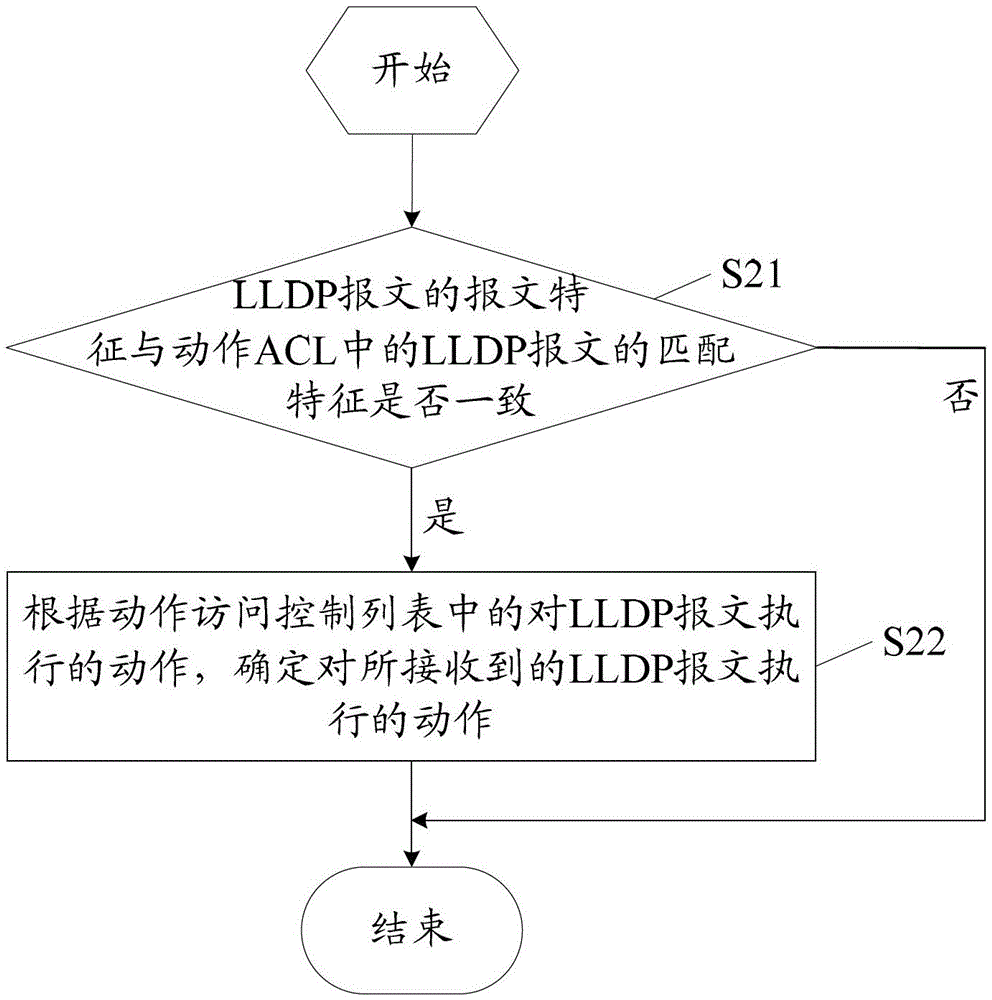

The invention discloses a method for monitoring a ring network on the basis of a link layer discovery protocol. The method comprises the following steps of: receiving a link layer discovery protocol LLDP message, and judging an action to be executed to the LLDP message according to the message characteristic of the LLDP message; when judging the forward action is to be executed to the LLDP message, judging whether the LLDP causes ring network storm, if so, discarding the LLDP message, and if not, forwarding the LLDP message; and when judging the report action is executed to the LLDP message, sending the LLDP message to a processor, and processing a neighbor item of link neighbor equipment of the ring network corresponding to the LLDP in a neighbor list. The invention also discloses a corresponding device. By the scheme disclosed by the invention, the monitoring and management of the ring network are more convenient, and the ring network storm can not be caused, so that the requirement for reliability of the ring network can be met.

Owner:ZTE CORP

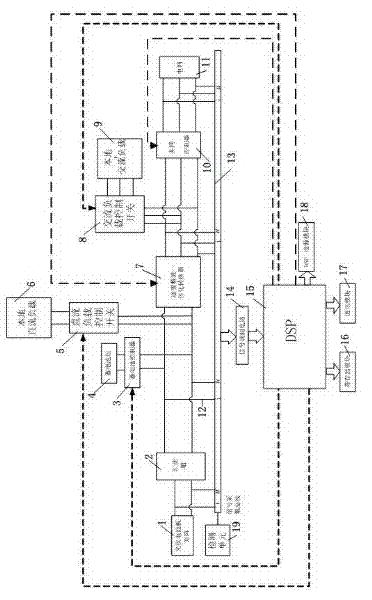

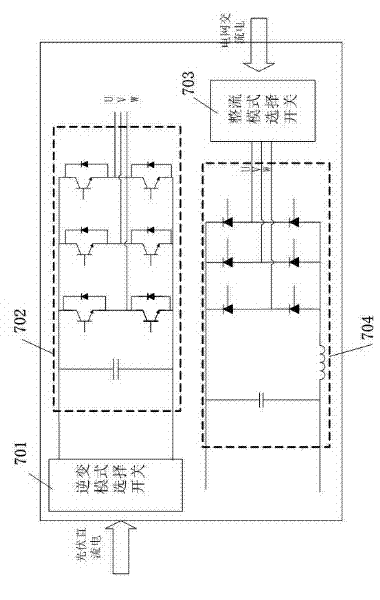

Minitype intelligent bidirectional self-adaptation grid-connected photovoltaic power generation system and control method thereof

ActiveCN102412598AOvercoming the disadvantage of execution lagIncrease profitClimate change adaptationSingle network parallel feeding arrangementsAlternating currentSignal modulation

The invention discloses a minitype intelligent bidirectional self-adaptation grid-connected photovoltaic power generation system, which comprises a photovoltaic battery board matrix and a confluence box, wherein the output end of the output end of the confluence box is connected with a storage battery controller, an inversion / rectification integrated converter and a direct-current load control switch; the storage battery controller and the direct-current load control switch are connected with a storage battery set and a local direct-current load; the output end of a converter is connected with an alternating-current load control switch and an grid-connected controller; the output end of the alternating-current load control switch is connected with a local alternating-current load; each output end is connected with a conversion module; a voltage and current sampling conversion module is connected with a signal modulation circuit; the output end of a signal modulation circuit is connected with a DSP (digital signal processor); and each control end is connected with a PWM (pulse width modulation) interface. A control method of the minitype intelligent bidirectional self-adaptation grid-connected photovoltaic power generation system comprises parameter preparation control, power generation and power supply control. The system and the method have the advantages of good reliability, convenience in installation, operation and maintenance, high stability, strong adaptivity and high solar energy utilization ratio.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +3

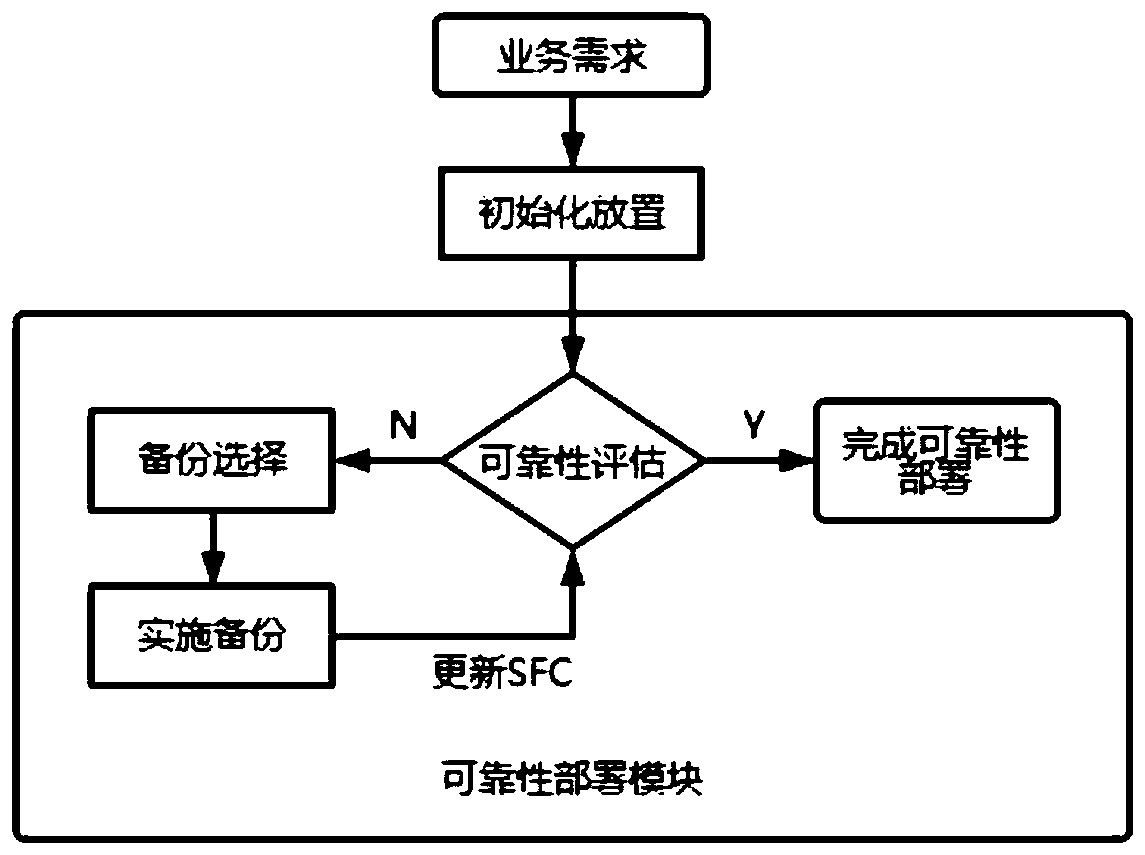

Virtual network function reliability deployment method based on backup revenue and remapping

ActiveCN110190987AImprove reliabilityMaximize Backup BenefitsNetworks interconnectionResource utilizationDependability

The invention discloses a virtual network function reliability deployment method based on backup revenue and remapping. The method comprises the following steps: firstly, introducing a dual-sharing backup mechanism, wherein the reliability of the service function chain is effectively improved, meanwhile, resource occupation of backup is reduced as much as possible, the resource utilization rate ofthe system is improved; and then providing a reasonable and efficient virtual network function remapping method for the virtual network function which is not subjected to reliability backup in the service function chain. The method provided by the invention is used for solving the problem that the reliability of the service function chain is reduced due to the fact that the virtual network function in the service function chain is subjected to backup recovery after a fault occurs and the reliability of the virtual network function is changed after remapping for the first time.

Owner:NANJING UNIV OF POSTS & TELECOMM

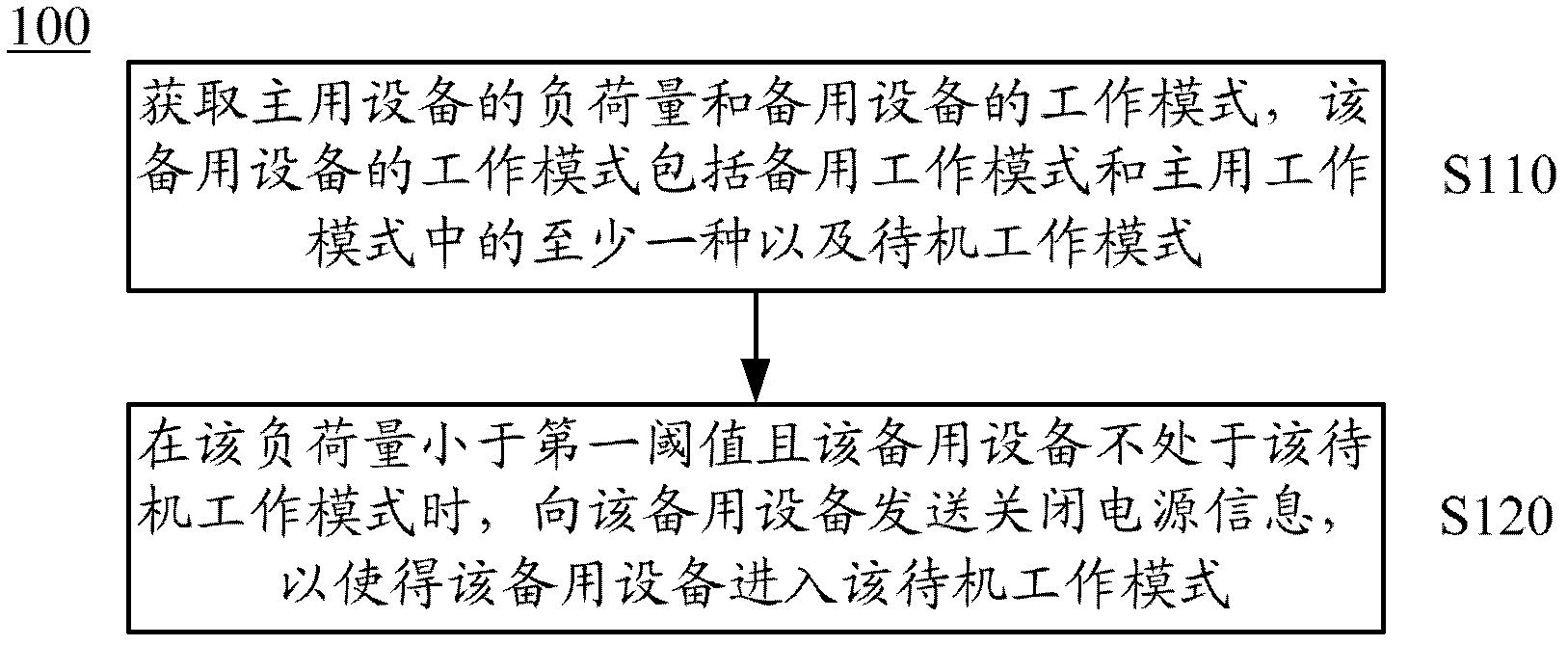

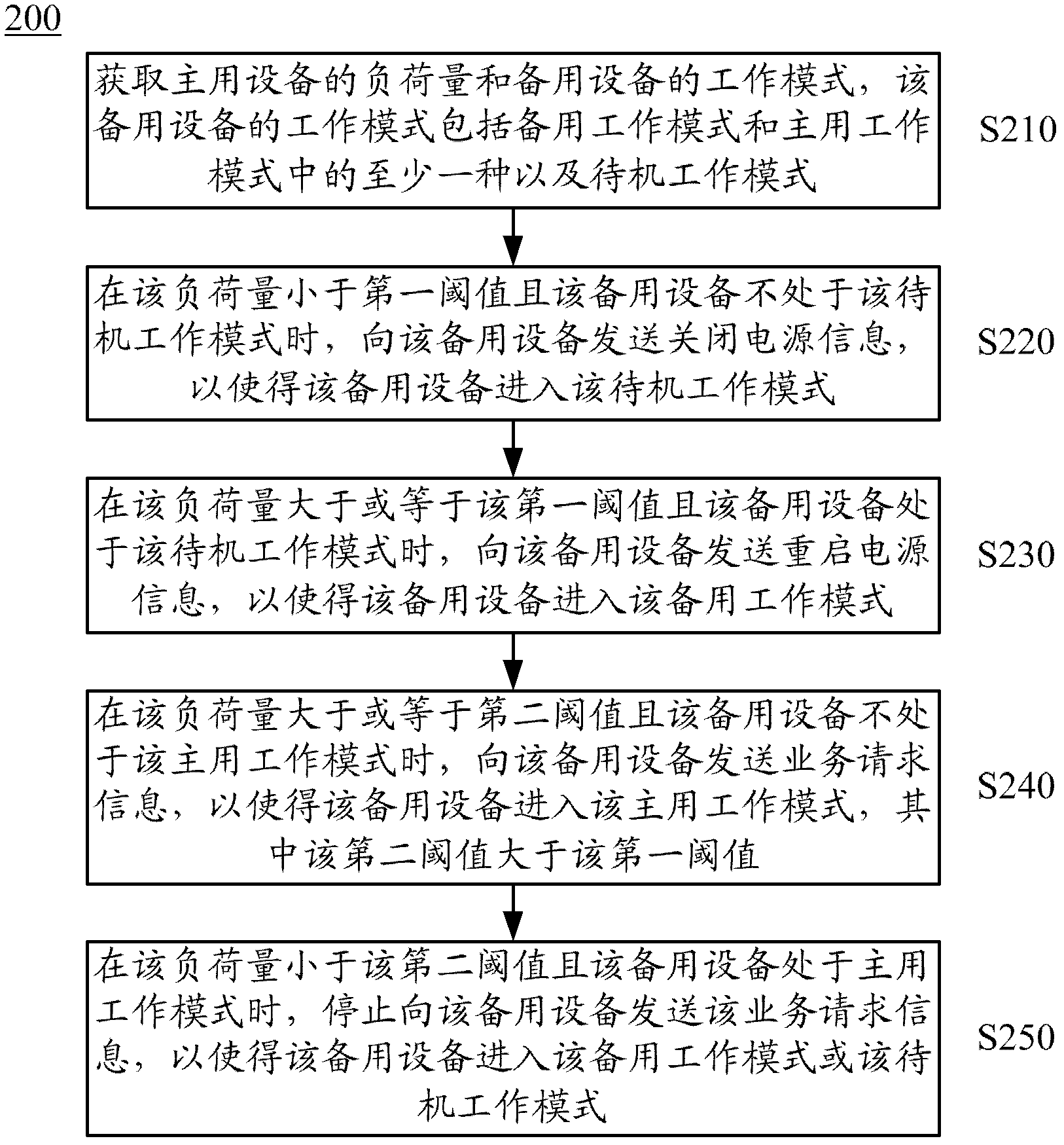

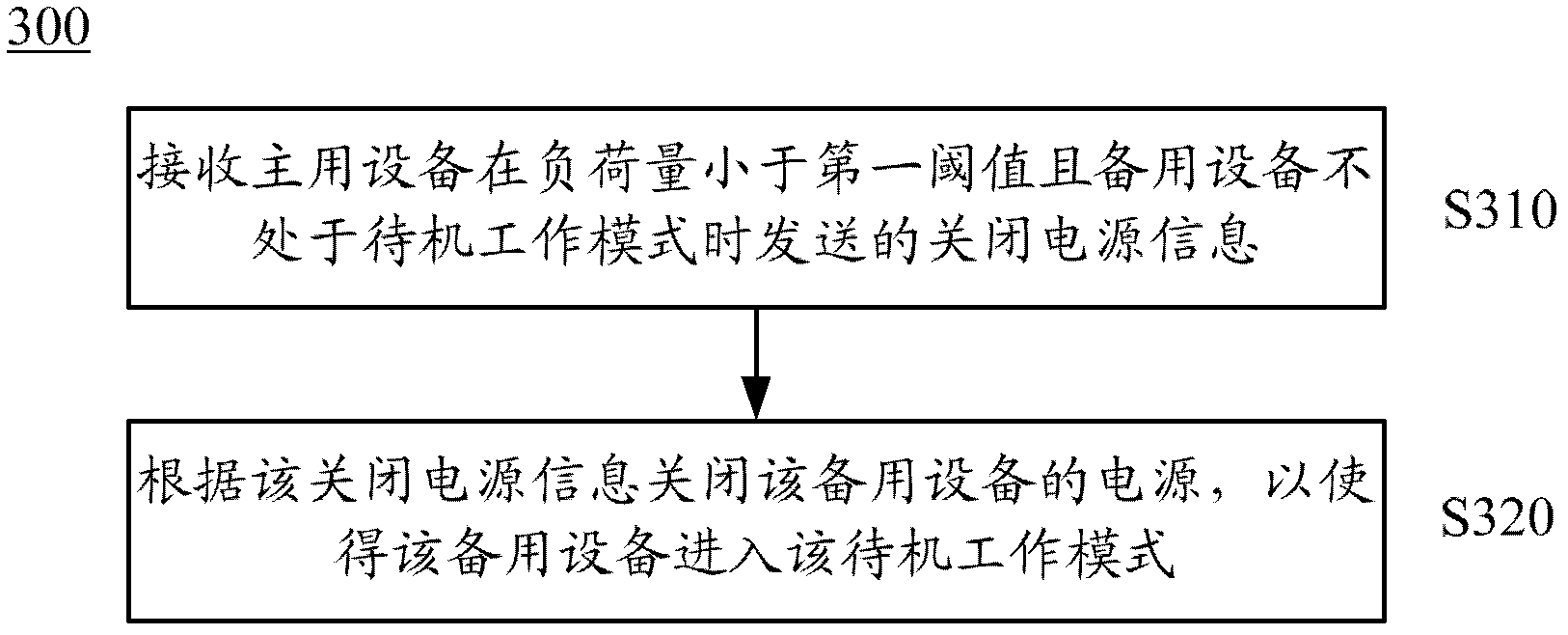

Method for controlling backup device, primary device and backup device

InactiveCN102204165AReduce energy consumptionMeeting Reliability NeedsDigital data processing detailsSubstation remote connection/disconnectionLoad capacityEmbedded system

The invention discloses a method for controlling backup device, a primary device and a backup device. The method comprises: acquiring load capacity of the primary device and the operating mode of the backup device; and sending power-off information to the backup device when the loading capacity of the primary device is less than the first threshold and the backup device is not in the standby mode, thus to make the backup device enter standby mode. The primary device comprises a first processor and a second processor while the backup device comprises a third processor and a fourth processor. In this invention embodiment, by sending the power-off information to the backup device when the loading capacity of the primary device is less than the first threshold and the backup device is not in the standby mode, the backup device enters the standby mode, thereby decreasing the power consumption of the backup device on the basis of meeting the demand for system reliability.

Owner:HUAWEI TECH CO LTD

High-reliability fast-curing filling glue

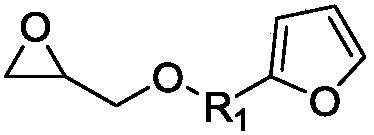

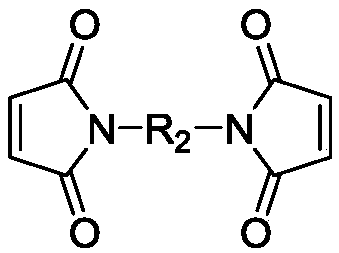

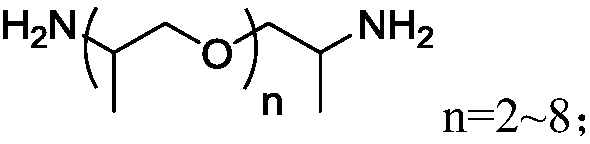

ActiveCN109401706AAchieve reworkabilityIncrease crosslink densityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention relates to filling glue and a preparation method thereof, in particular to high-reliability fast-curing filling glue. The high-reliability fast-curing filling glue is prepared from the following raw materials in percentage by weight: 10-50% of epoxy resin, 5-20% of an epoxy diluent, 5-15% of epoxy resin with capability of free radical reaction, 0-10% of an olefin monomer with capability of free radical reaction, 5-20% of a toughener, 0.5-3% of a coupling agent, 0.1-5% of a cationic initiator, 0.1-5% of a radical initiator, 0-5% of filler and 0-5% of pigment. The bottom filling glue provided by the invention can fast cure, has a high glass-transition temperature (Tg), a low expansion coefficient and good repair property, and can be mainly used for flip chip bottom filling to improve the connection reliability.

Owner:深圳广恒威科技有限公司

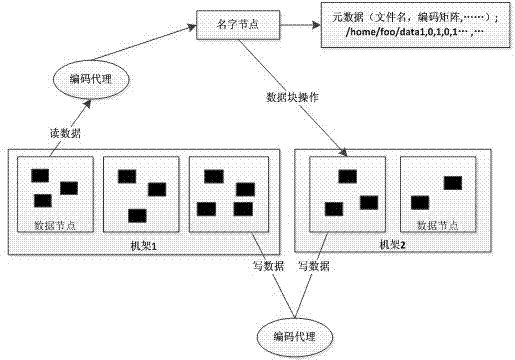

Data-center-oriented generalized network coding fault-tolerant storage platform and working method for same

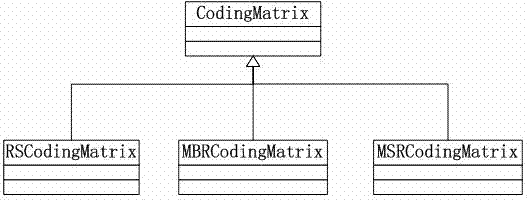

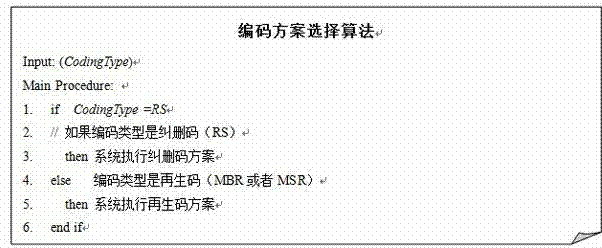

InactiveCN103544270AMeet adaptabilityIncrease diversityFile access structuresTransmissionNetwork codeEngineering

The invention discloses a data-center-oriented generalized network coding fault-tolerant storage platform and an implementation method for the same. A system mainly comprises a name node, a plurality of data nodes and a coding agent node which form the data-center-oriented distributed storage platform, and the data nodes are used for storage. The implementation method mainly includes designing a uniform processing frame on the basis of network coding; performing data coding and distributed storage processes; integrating different coding schemes; performing recovering processing. The data-center-oriented generalized network coding fault-tolerant storage platform and the implementation method have the advantages that the storage platform is data-center-oriented, the uniform processing frame on the basis of network coding is provided, and stored files are coded, so that the purpose of reducing storage redundancy of the system and a transmission bandwidth can be achieved under the condition of identical reliability of the system; the system provides integration of the different coding schemes and accordingly is extensible.

Owner:南京大学镇江高新技术研究院 +2

Link data processing method and device and computer storage medium

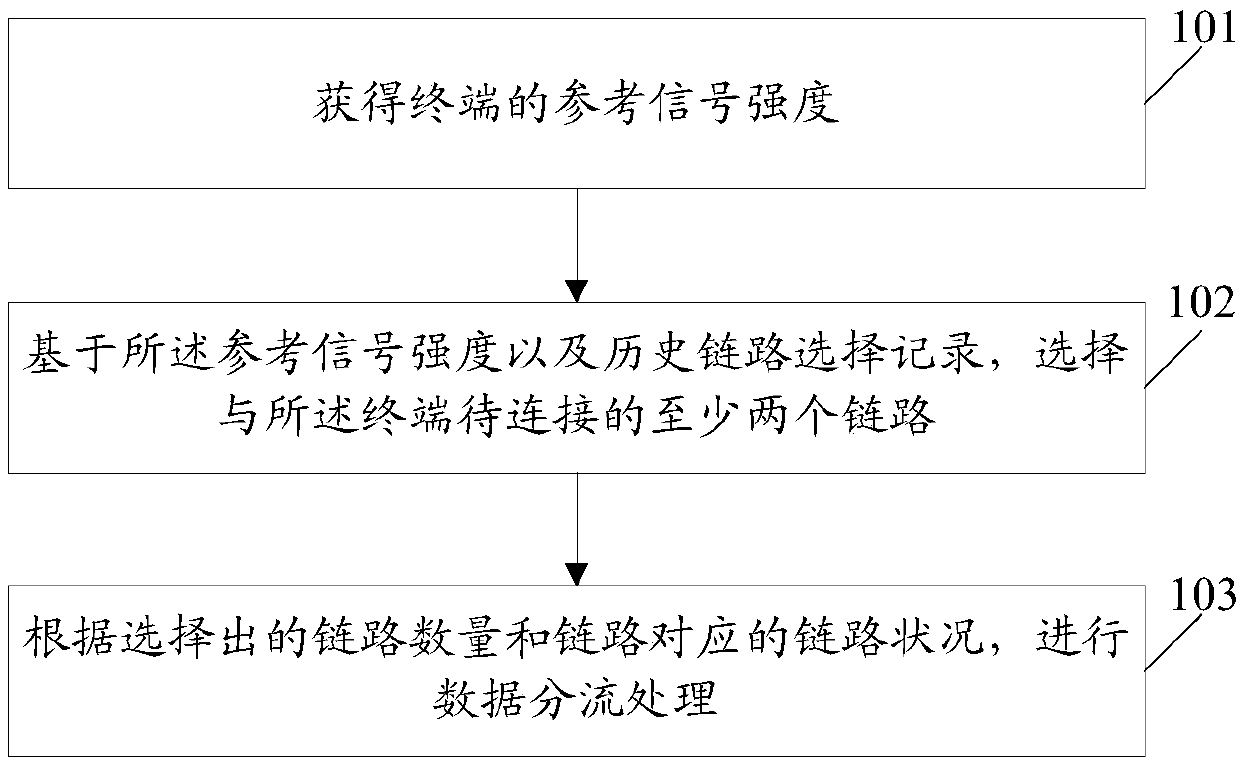

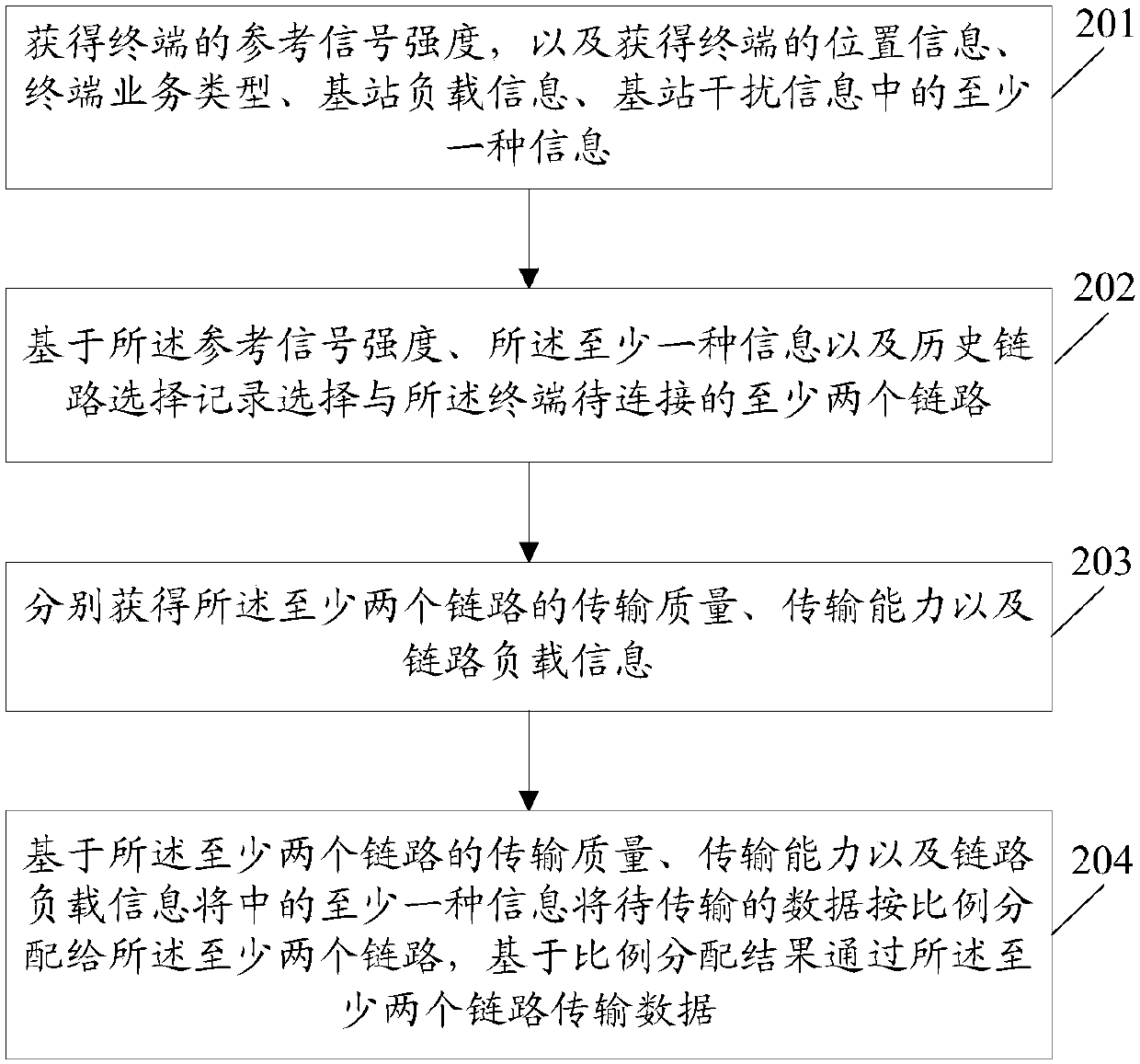

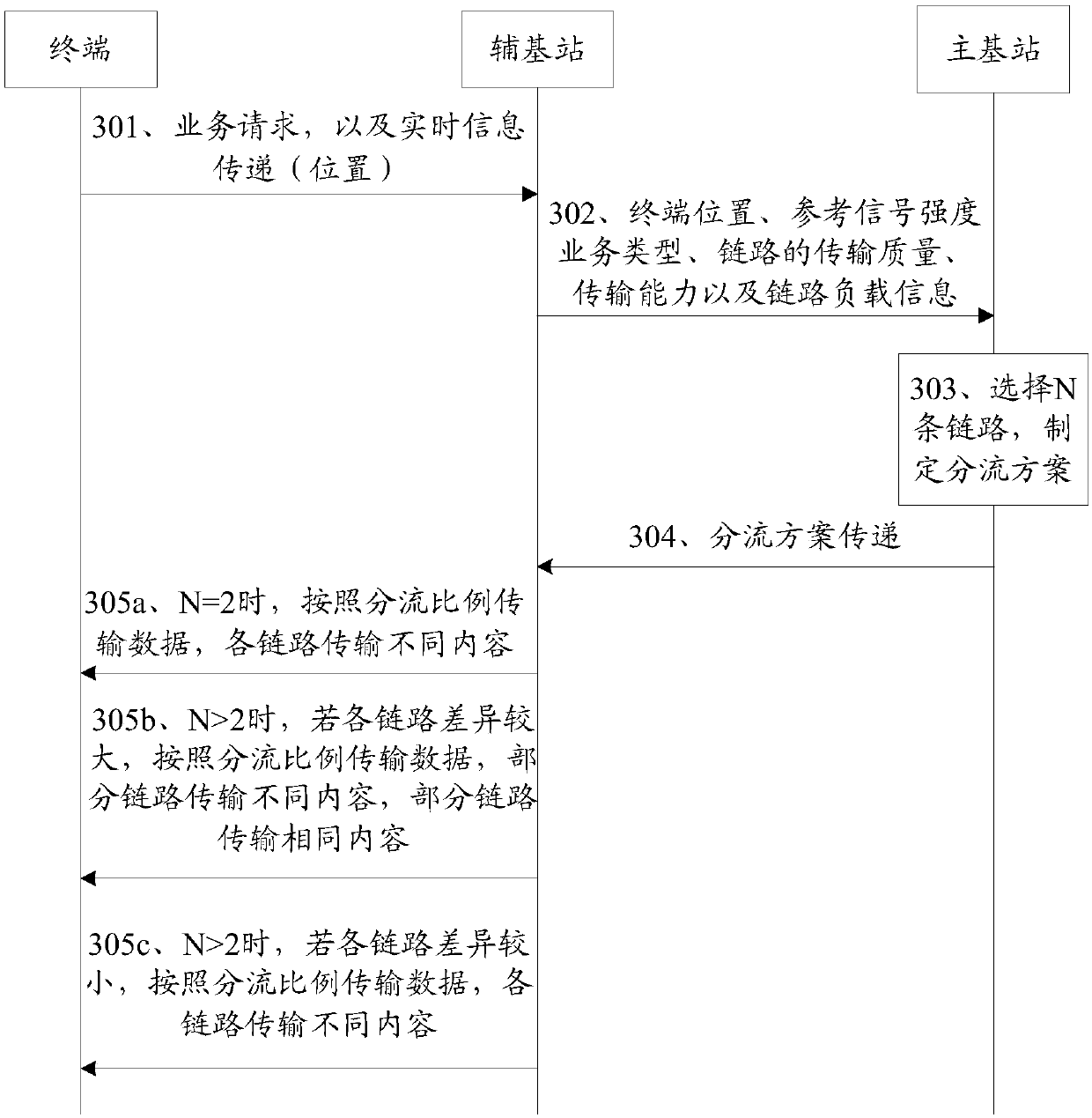

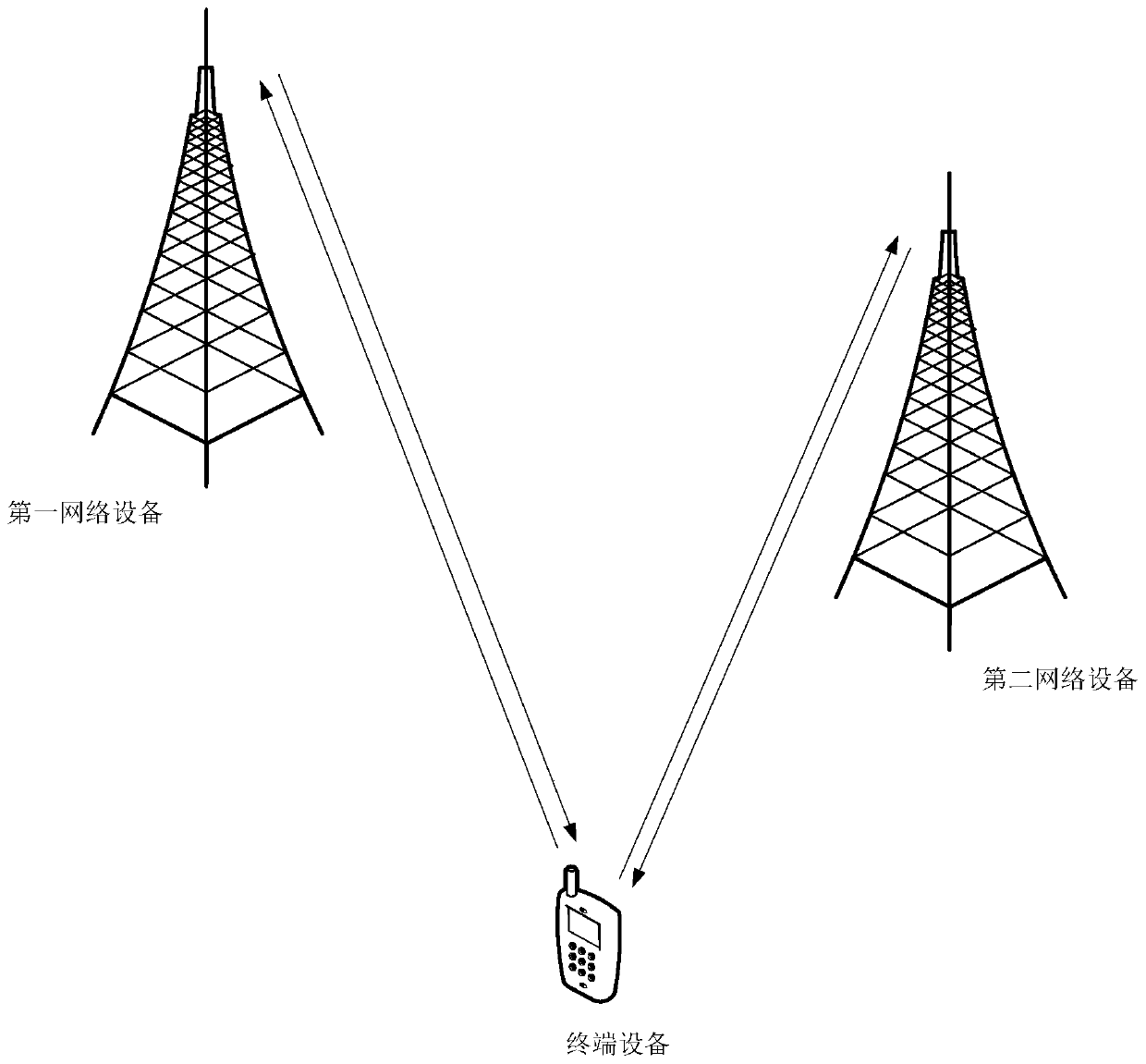

ActiveCN109729602ATake advantage ofMeeting Reliability NeedsConnection managementComputer terminalUltimate tensile strength

The embodiment of the invention discloses a link data processing method and device and a computer storage medium. The method comprises the following steps: obtaining reference signal intensity of a terminal; Selecting at least two links to be connected with the terminal based on the reference signal strength and a historical link selection record; And performing data distribution processing according to the number of the selected links and the link conditions corresponding to the links.

Owner:CHINA MOBILE COMM LTD RES INST +1

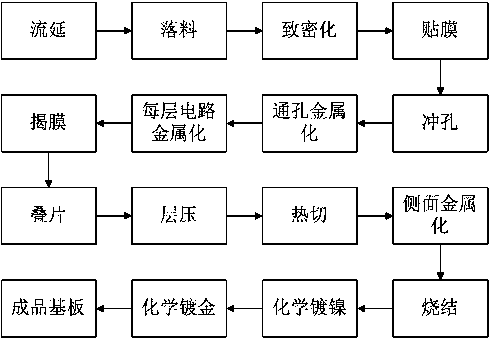

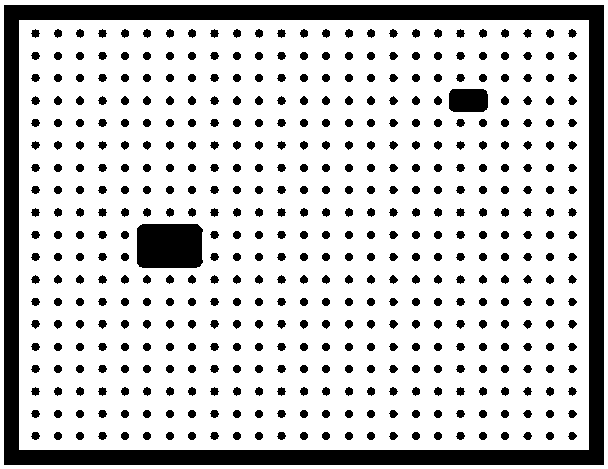

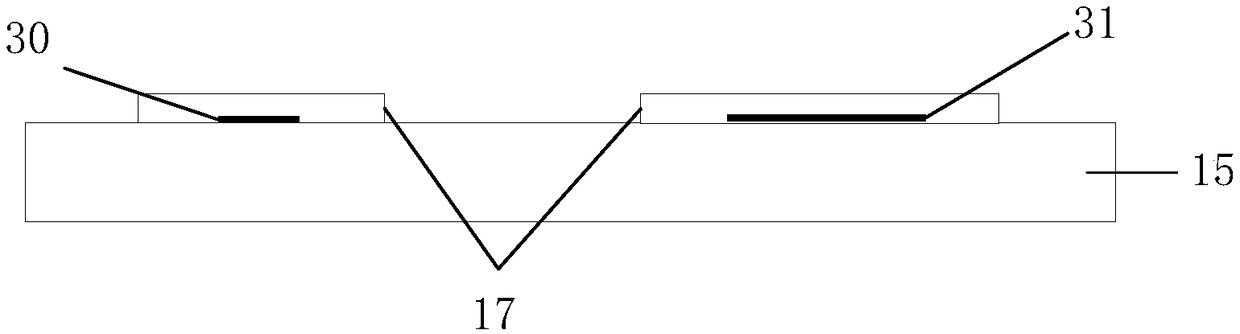

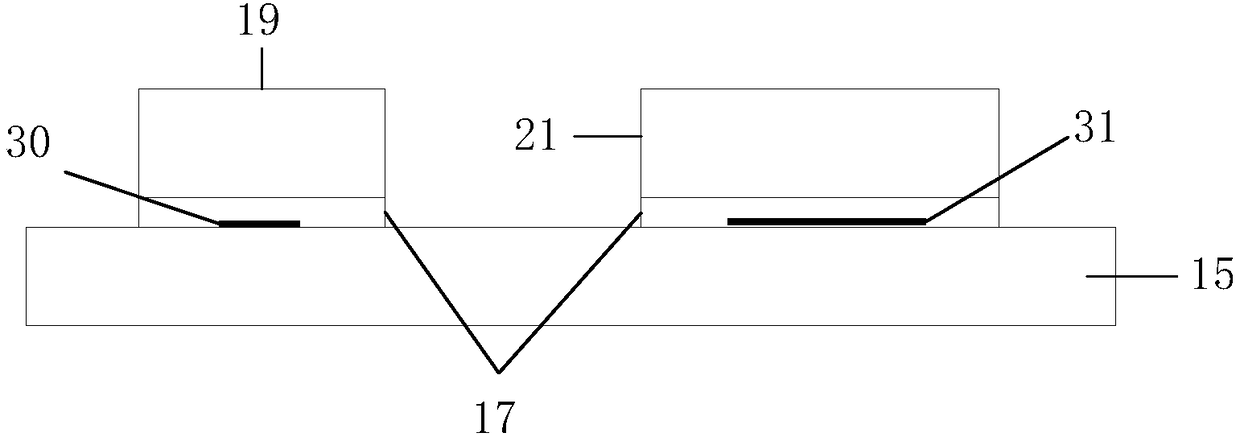

Multi-layer aluminum nitride substrate for highly integrated module level packaging, and manufacturing method thereof

InactiveCN109545771AReduce volumeSolve the heat dissipation problem of miniaturized and highly integrated module-level packagingSemiconductor/solid-state device detailsSolid-state devicesGreen tapeThermal expansion

The invention relates to a multi-layer aluminum nitride substrate for highly integrated module level packaging, and a manufacturing method thereof. The structure of the substrate comprises upper and lower surface layers, wherein the upper and lower surface layers are high-precision and high-density metalized welding pads; the side walls of the substrate are fully metalized; and the substrate is internally provided with multi-layer metalized wiring. The upper and lower surface layer metalized welding pads are welded with ball gates of a silicon-based chip; the side walls are fully metalized torealize signal shielding; the multi-layer metalized wiring inside the substrate satisfies complicated circuit signal transmission and interconnection. By utilizing a multi-layer co-firing process, aluminum nitride ceramic is selected as the ceramic base body material, tungsten is used as the metallization material, a green tape binding micro-deformation process adopted, and a tungsten metal circuit layer on the surface layer is plated by adopting chemical nickel-plating and chemical gilding processes. The multi-layer aluminum nitride substrate and the manufacturing method thereof have the advantages that the aluminium nitride substrate and the silicon-based chip are highly matched in coefficients of thermal expansion, and the reliability of ball gate welding packaging of the silicon-basedchip is realized; and the thermal conductivity of the substrate is increased to 170 W / mK, thereby being capable of meeting the high power density packaging and heat dissipation requirements of the highly integrated module.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

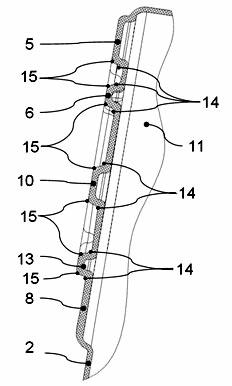

High-reliability IGBT module packaging structure and processing technology

ActiveCN108461484AFast heat conductionImprove bindingSemiconductor/solid-state device detailsSolid-state devicesIn planeHexagonal boron nitride

The invention relates to a high-reliability IGBT module packaging structure and a processing technology. The packaging structure comprises a direct copper-clad substrate, an IGBT chip, a quick recovery diode chip, a bottom plate, a soldering flux layer, a bonded lead, a bus, a plastic shell and two-dimensional layered hexagonal boron nitride filled enhanced encapsulated silica gel, wherein two-dimensional layered hexagonal boron nitride is grown on the upper surface of the direct copper-clad substrate in a graphic manner. A two-dimensional layered hexagonal boron nitride thin film is grown onthe upper surface of the direct copper-clad substrate in a graphic manner through a chemical vapor deposition method. By virtue of excellent in-plane thermal conduction performance, partial hot spot heat of the high-power IGBT module can be quickly and transversely dissipated, heat can be conducted outwardly through the direct copper-clad substrate, and the highest temperature of the module is lowered; and meanwhile, by adopting the two-dimensional layered hexagonal boron nitride filled enhanced encapsulated silica gel for encapsulating, the thermal conduction performance of the conventional silica gel is improved, and module reliability is improved effectively.

Owner:HUANGSHAN UNIV

Method for bonding metallization modification on semiconductor unpacked chip

InactiveCN106835084AMeet application needsMeeting Reliability NeedsSolid-state devicesSemiconductor/solid-state device manufacturingBiological activationAdhesion strength

The invention discloses a method for bonding metallization modification on a semiconductor unpacked chip. The method comprises the following steps: putting a deoiled semiconductor unpacked chip surface or a wafer into a mixed solution of sulfuric acid and hydrogen peroxide, performing reaction for 60-90 seconds at 30-40 DEG C, dehydrating, performing primary zinc activation, performing acid corrosion, performing secondary zinc activation, performing deposition on the surface of the unpacked chip or the wafer after secondary zinc activation so as to form an Ni layer; depositing a Pd layer on the Ni layer; depositing an Au layer on the Pd layer. By using a chemical nickel and palladium plating gold leaching process, three layers of metallization layers of nickel, palladium and gold compatible with gold thread bonding are prepared on the surface of the deoiled semiconductor unpacked chip, the adhesion strength and the stability of a membrane layer meet application requirements of packaging processes, various electric parameters of the modified chip are not greatly different from those before modification, and gold thread bonding implemented on the surface of the modified nickel, palladium and gold layer can meet high-temperature environment application and reliability requirements of long-service life application of devices.

Owner:XIAN MICROELECTRONICS TECH INST

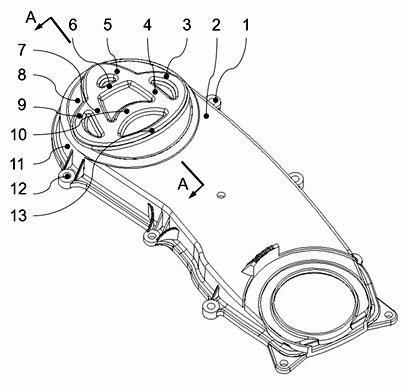

Front shell of vehicle engine

InactiveCN102121429AReduce sound pressure levelIncrease stiffnessCasingsMachines/enginesResonanceEngineering

The invention provides a front shell of a vehicle engine. A circular table board is additionally arranged on the top of the front shell and is provided with reinforcing ribs to form region segmentation, so that the rigidity of the circular table board is enhanced and noise radiation of the surface structure of the front shell is lowered. The reinforcing ribs consist of outer ring reinforcing ribs and inner ring reinforcing ribs, wherein the outer ring reinforcing ribs are connected with the side wall of the front shell; the outer ends of a part of reinforcing ribs are connected with a front shell installation point; and all reinforcing ribs are arranged in an elliptical shape and a letter 'A' shape which are mutually staggered. Due to reasonable arrangement of the reinforcing ribs, a small quantity of materials can be used, the stiffness of the front shell of the engine is enhanced, local modal frequency is improved, the local resonance and surface radiation noise are lowered, and appearance is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

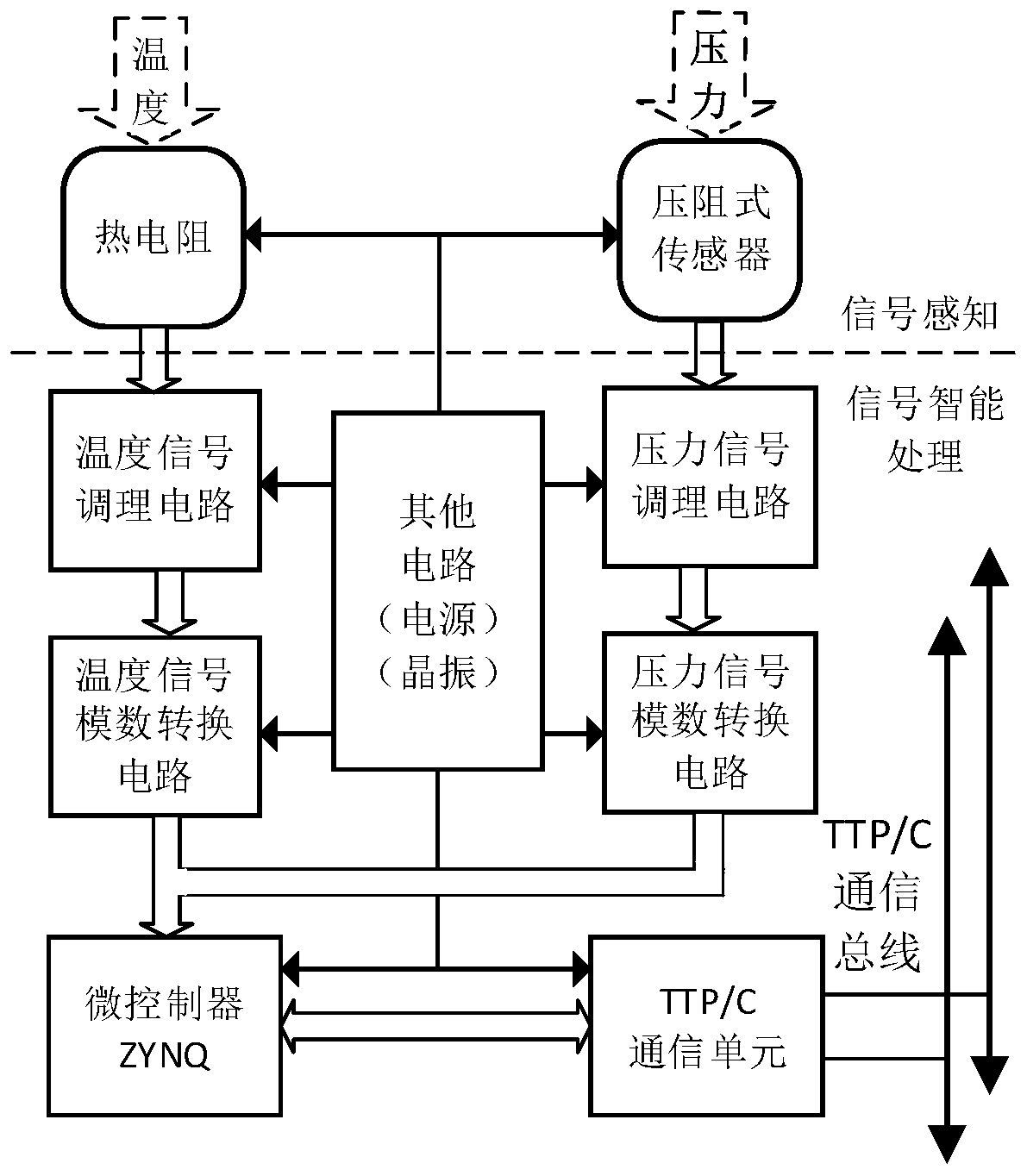

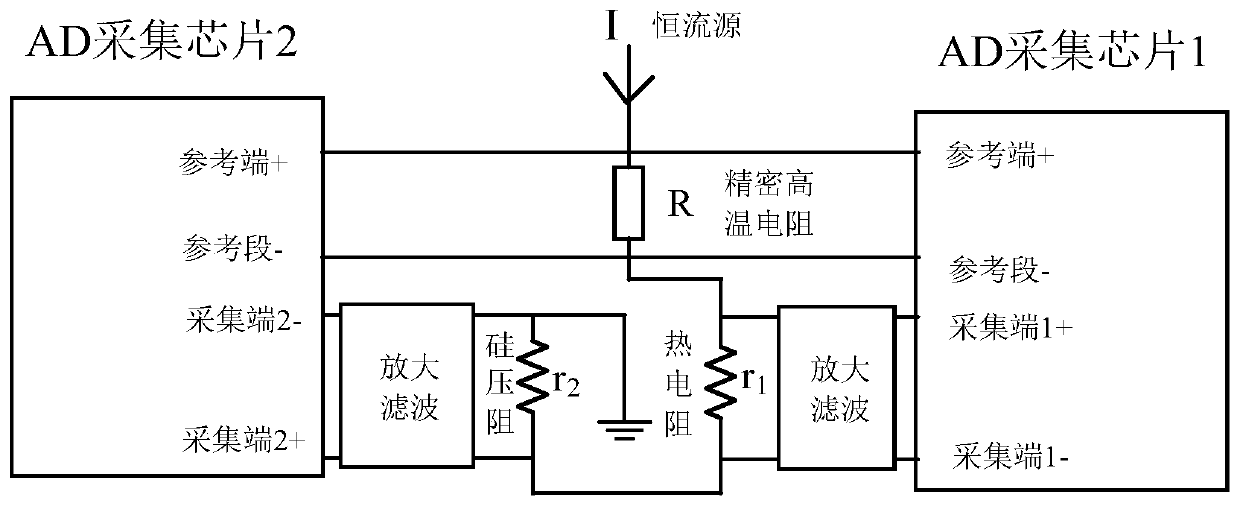

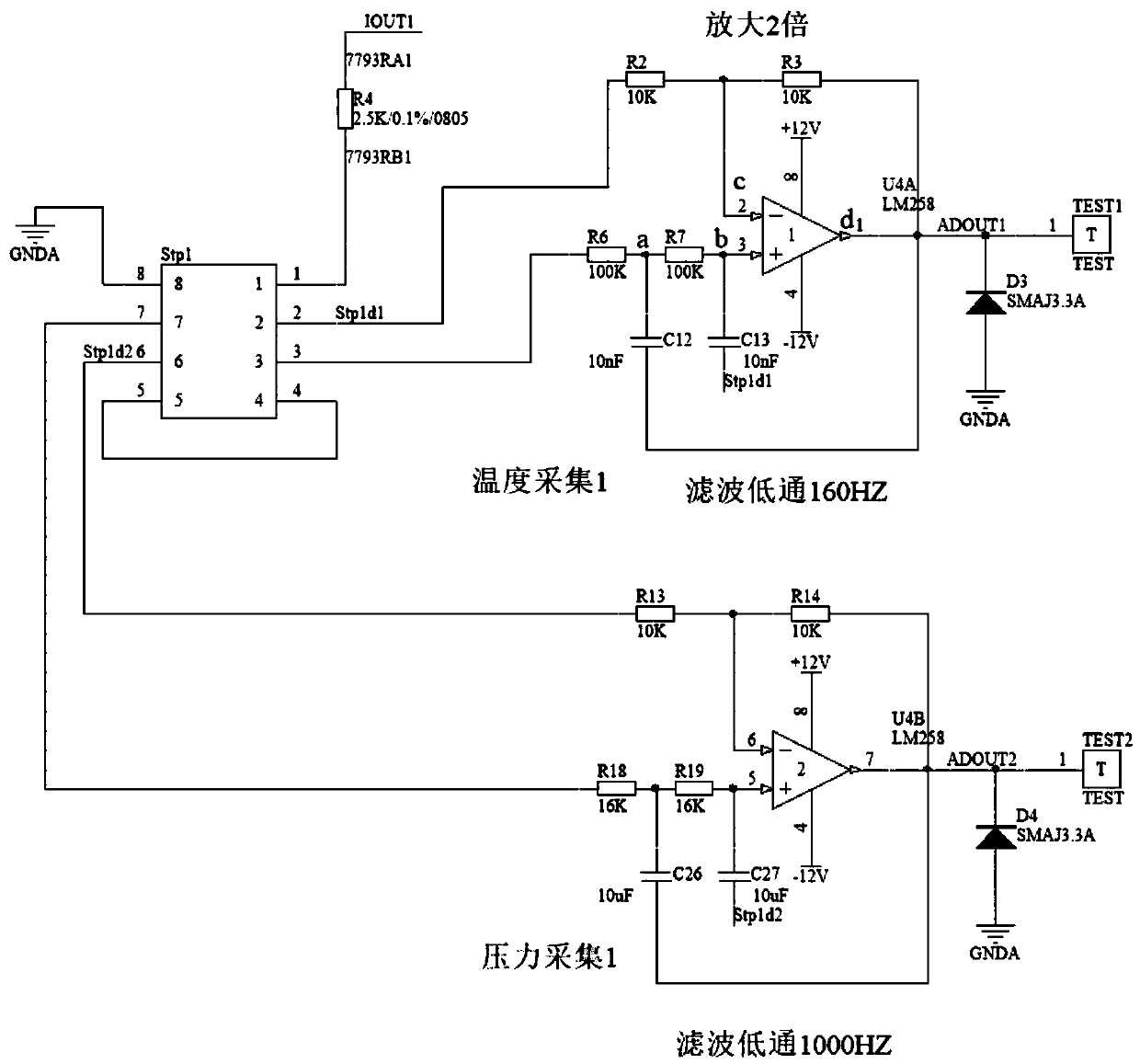

Intelligent pressure sensor system for intelligent engine distributed control

InactiveCN110895177AReduce weightReduce complexityGas turbine plantsSafety/regulatory devicesEmbedded systemDigital signal

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

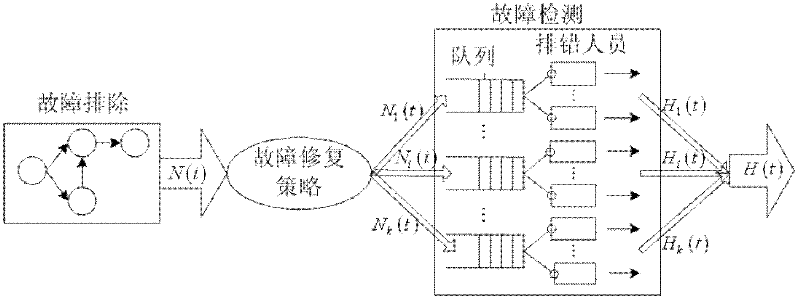

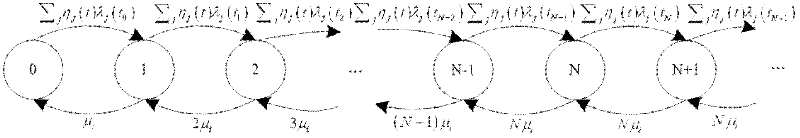

Component software reliability analysis method capable of considering limitation of debugging resources based on HFSQM (Hybrid Finite Server Queuing Model)

InactiveCN102393833AImprove reliabilityLow costSoftware testing/debuggingIntegration testingResource based

The invention discloses a component software reliability analysis method capable of considering limitation of debugging resources based on an HFSQM (Hybrid Finite Server Queuing Model), which relates to software reliability analysis methods, and overcomes the defects that infinite debugging resources are impossible in practical application and the newly detected failures have to wait in a queue when all the debugging staffs are busy. The method is realized by the following three steps of: resource allocation, failure detection and failure recovery. The resource allocation step is to allocate appropriate resources for the failures waiting for the debugging resources in the HFSQM; the failure detection process is used for executing an integration test on the entire application based on an operating profile of the component software application; and the failure recovery process is used for recovering the failures occupying the debugging resources in the HFSQM. Thus, a basis for software release and rational configuration of test resources is provided, the software can be punctually released on schedule, user demands on the reliability can be satisfied, and the total cost of the software is lowered. So, an HFSQM-based simulation method has important directive significance for component software tests and further for software marketing decisions.

Owner:HARBIN INST OF TECH

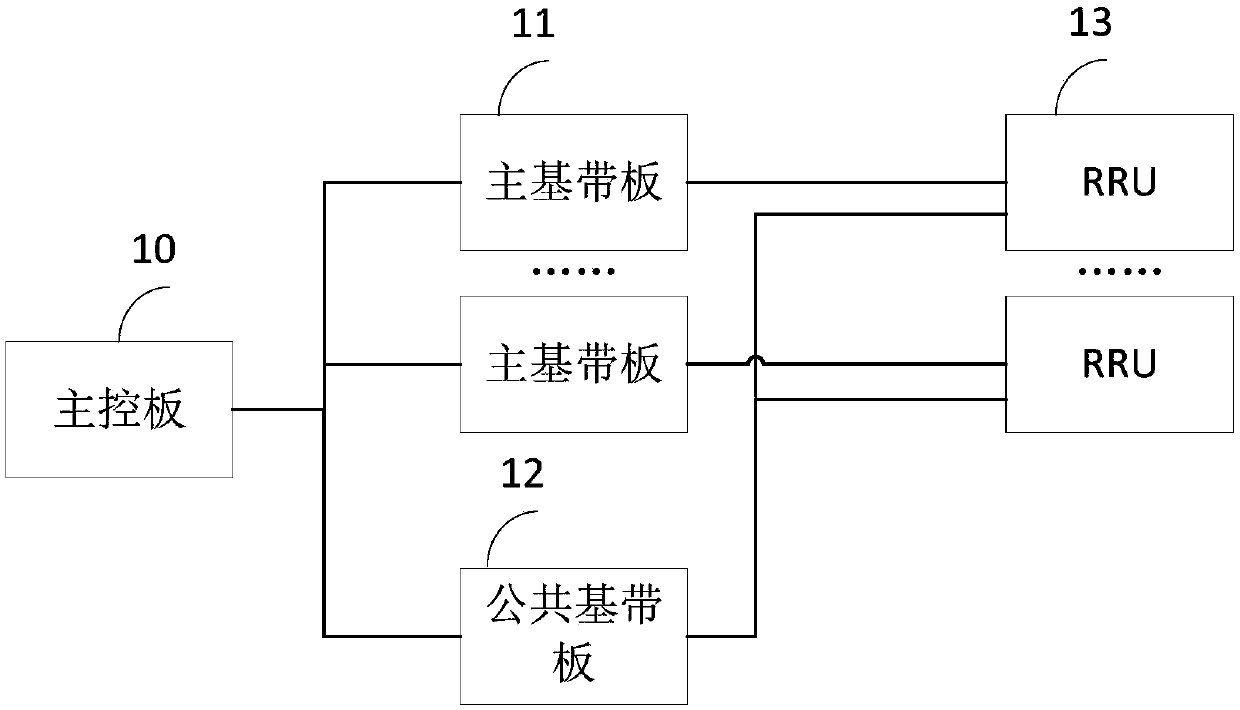

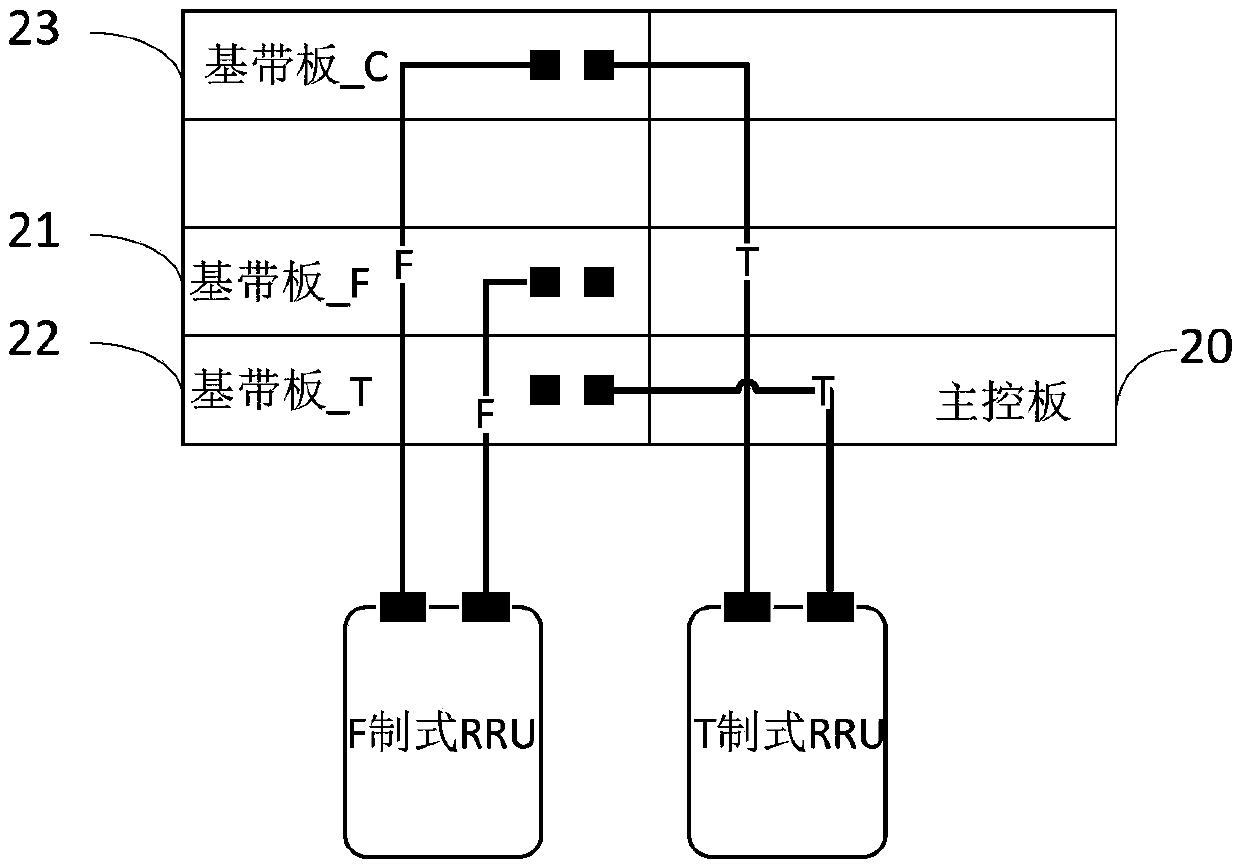

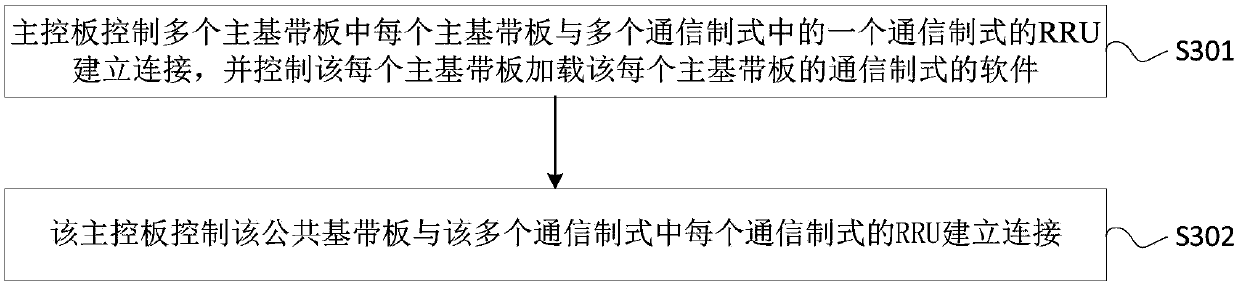

Base station configuration method and base station

PendingCN110972170AMeeting Reliability NeedsEfficient use ofWireless communicationComputer hardwareCommunications system

The embodiment of the invention provides a base station configuration method and a base station. The base station suitable for the method comprises a main control board and a plurality of baseband boards, and the plurality of baseband boards comprise a plurality of main baseband boards and a common baseband board. The method comprises the following steps: the main control board controls each mainbaseband board in the plurality of main baseband boards to establish connection with an RRU of one communication system in a plurality of communication systems, and controls each main baseband board to load software of the communication system of each main baseband board; and the main control board controls the common baseband board to establish connection with the RRU of each communication systemin the plurality of communication systems. The present invention can improve the utilization rate of baseband resources.

Owner:CHENGDU TD TECH LTD

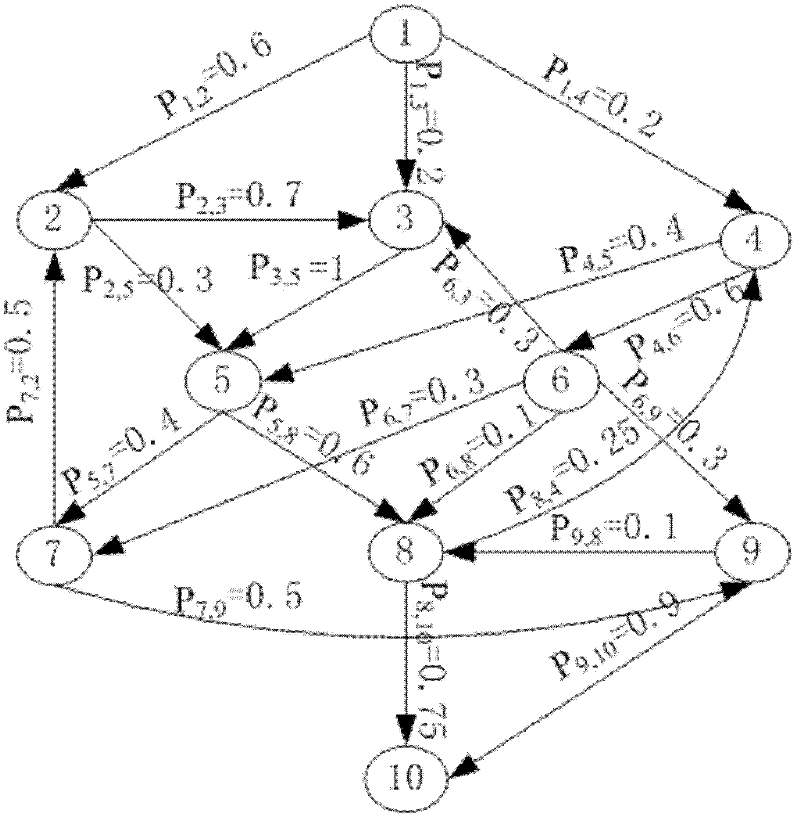

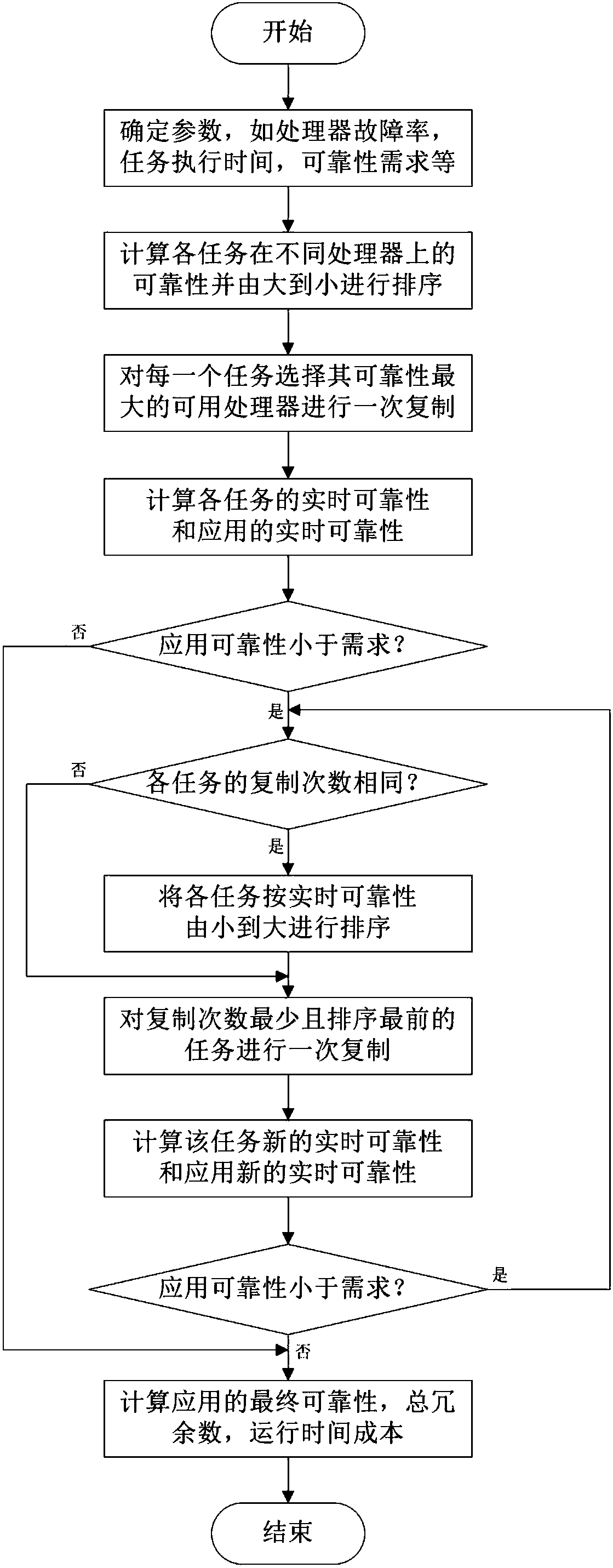

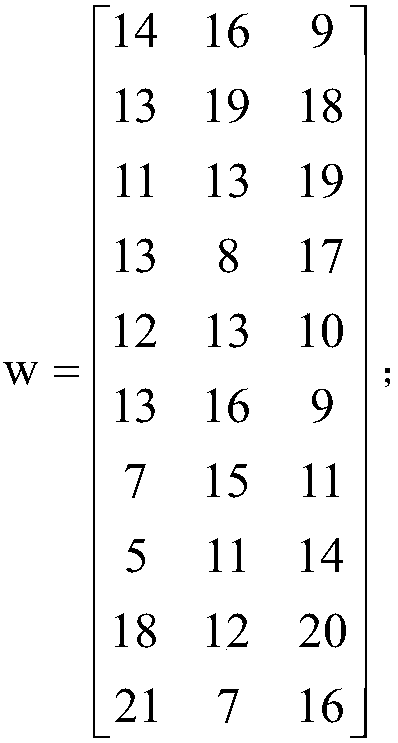

Task scheduling method for satisfying demand for reliability and used for distributed system

ActiveCN108108241AMeeting Reliability NeedsLow costProgram initiation/switchingResource allocationTime costHigh effectiveness

The invention provides a task scheduling method for satisfying the demand for reliability and used for a distributed system. The method includes the steps that first, the reliability of all tasks in application when the tasks are executed in different processors is calculated, and sequenced from high to low; then, each task is copied one time in the available processor with the highest reliability, and the real-time reliability of each task and the real-time reliability of the application are obtained; thirdly, according to the relation between the real-time reliability and the demand for reliability, the real-time reliability of all the tasks is sequenced and copied on time in sequence, the real-time reliability of the tasks and the real-time reliability of the application are updated after copying of every time, and iterated updating is repeated until the real-time reliability of the application satisfies the demand for reliability; finally, the final reliability, the total redundantnumber and the overall operation time cost of the application are determined. The task scheduling method has the advantages of being low in redundancy and high in efficiency, and is high in practicability.

Owner:XIANGTAN UNIV

Exhaust valve seat for automobile engine

InactiveCN101705850AReduce wearEasy to processMachines/enginesLift valveChemical compositionExhaust valve

The invention relates to an exhaust valve seat for an automobile engine, which is made of a material containing chemical compositions. The material comprises the following chemical compositions in percentage by weight: 0.7 to 1.4 percent of C, 3.0 to 6.6 percent of Mo, 3.0 to 6.6 percent of Cr, 5.0 to 8.5 percent of Co, 1.2 to 3.0 percent of Ni, 0.2 to 1.0 percent of V, less than or equal to 1.0 percent of Cu, and the balance of Fe. The exhaust valve seat made of the material has high crushing strength and fatigue strength and reliable quality, has lower cost than a copper-infiltrated valve seat, and meets the requirements of high-performance engines.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

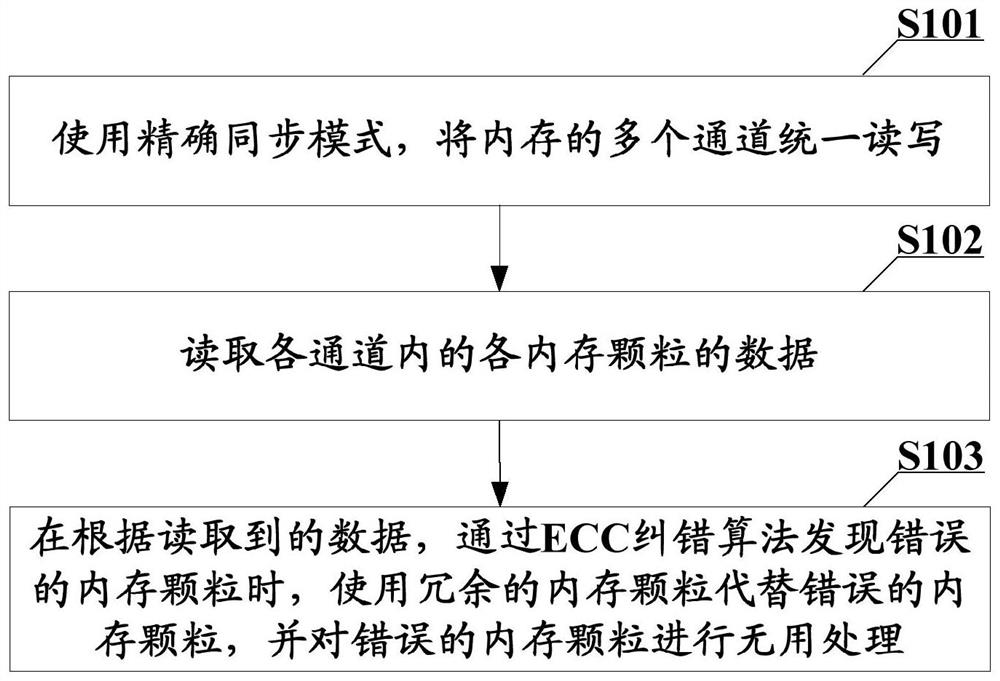

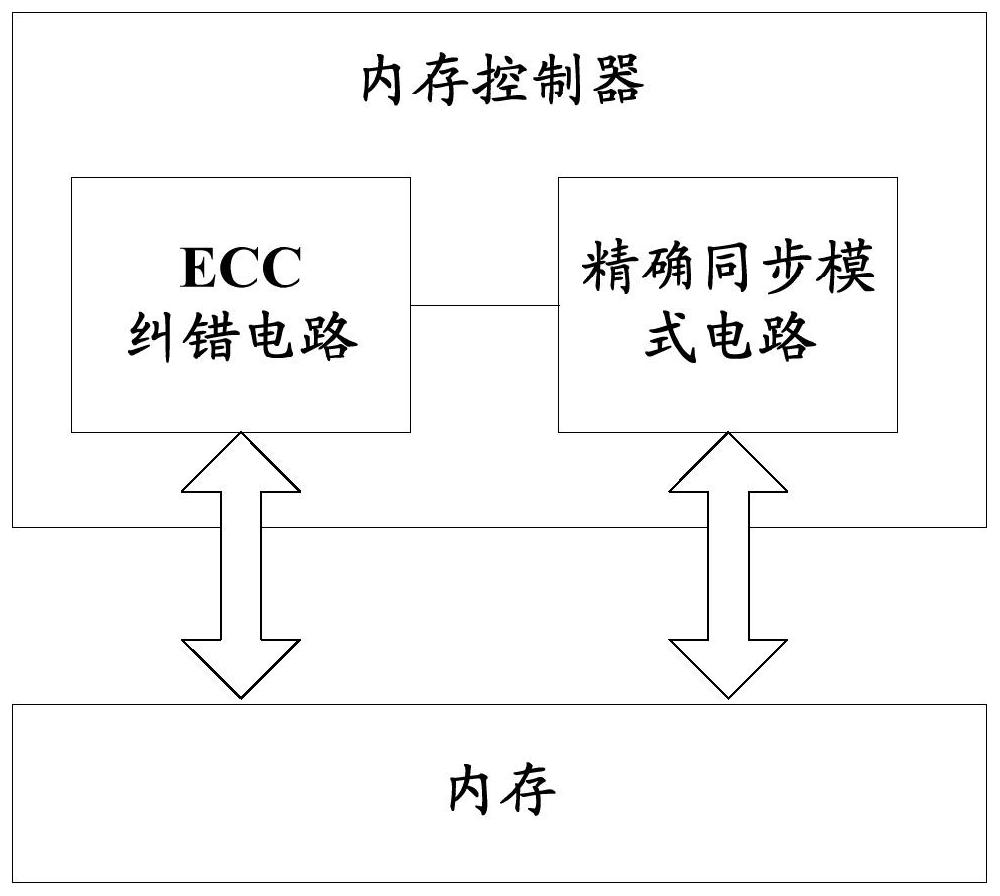

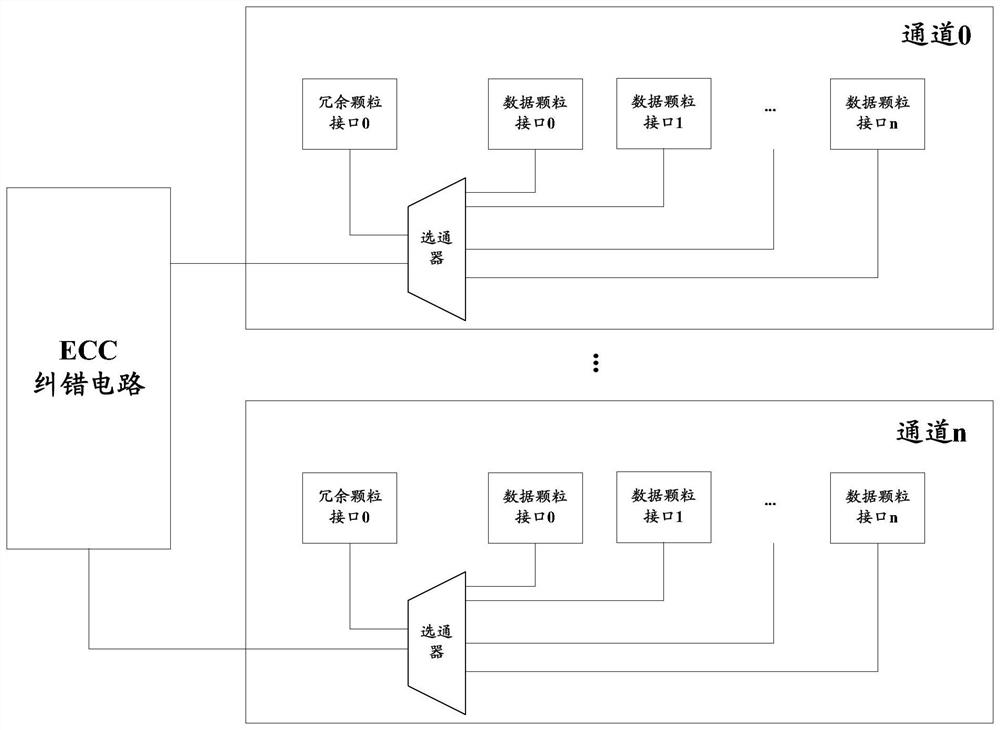

Memory error correction method, memory controller and electronic equipment

PendingCN112579342AMeeting Reliability NeedsImprove error correction performanceNon-redundant fault processingRedundant data error correctionComputer hardwareCorrection algorithm

The invention provides a memory error correction method, a memory controller and electronic equipment, and the method comprises the steps: carrying out the unified reading and writing of a plurality of channels of a memory in a precise synchronization mode, wherein the memory is a memory with a redundancy ratio greater than or equal to 1: 4; and reading data of each memory particle in each channel, when wrong memory particles are found through an ECC error correction algorithm according to the read data, replacing the wrong memory particles with redundant memory particles, and performing useless processing on the wrong memory particles. In this way, redundant memory particles are adopted to replace wrong memory particles to work, and therefore normal operation of the channel can be guaranteed. Each channel is replaced by redundant memory particles, so that error correction of a plurality of wrong memory particles can be realized in the implementation process.

Owner:HYGON INFORMATION TECH CO LTD

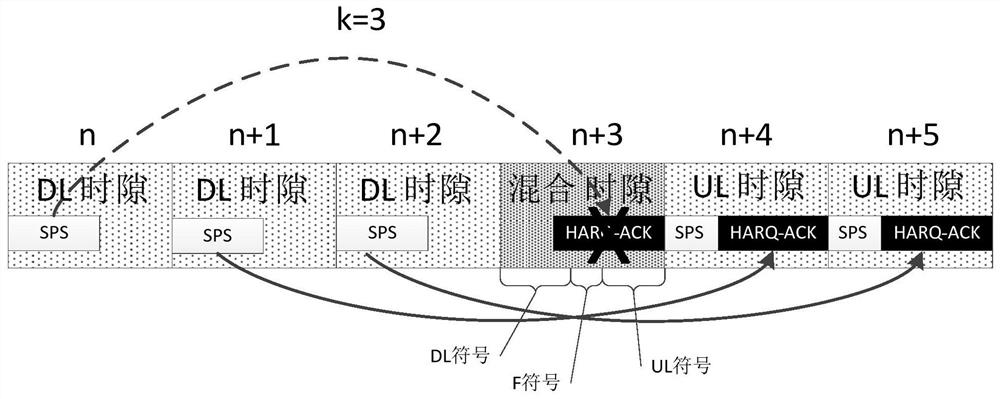

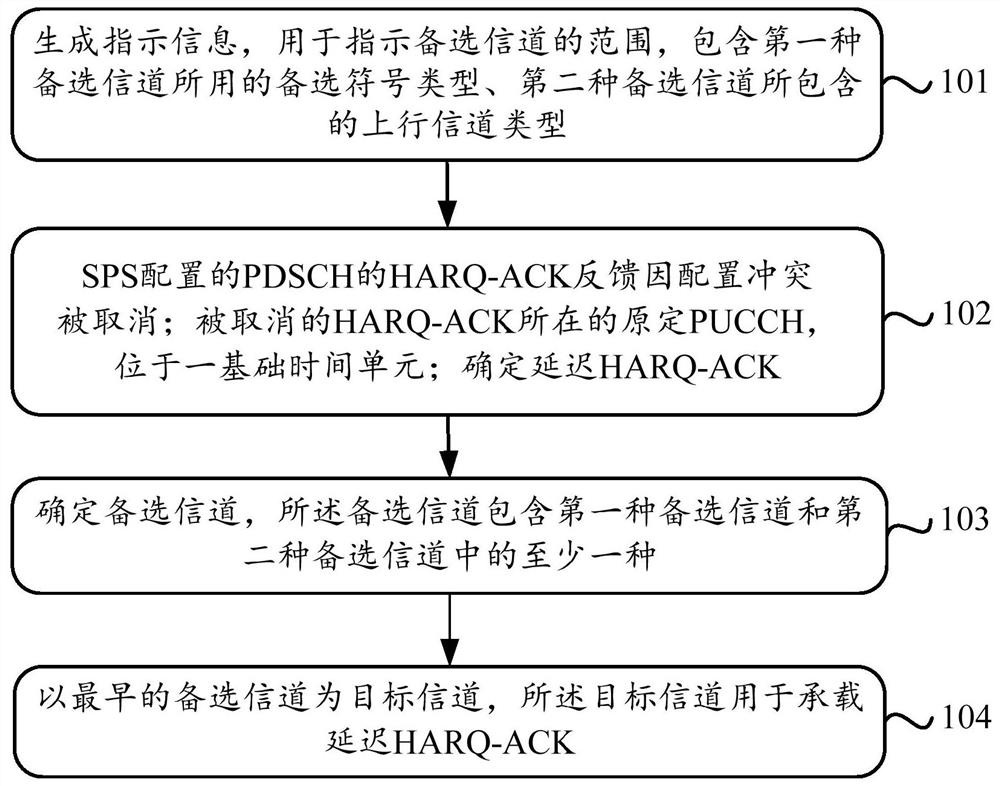

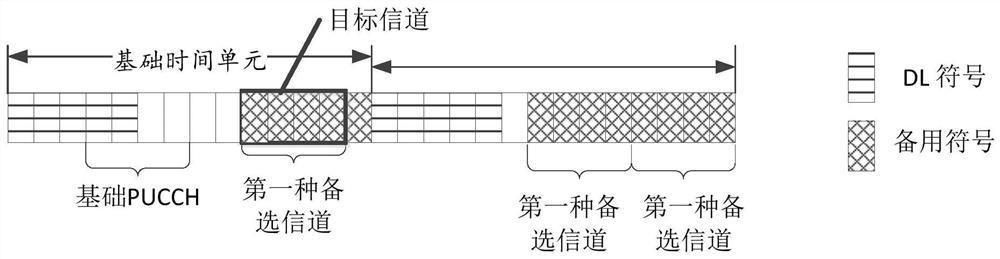

Hybrid automatic repeat request response method and device

ActiveCN112910610AMeet the delayMeeting Reliability NeedsError prevention/detection by using return channelSignal allocationChannel state informationAutomatic repeat request

The invention discloses a hybrid automatic repeat request response method, which is used for delaying the transmission of HARQ-ACK when the HARQ-ACK feedback of a PDSCH (Physical Downlink Shared Channel) configured by SPS is cancelled due to a configuration conflict, and an original PUCCH (Physical Uplink Control Channel) where the cancelled HARQ-ACK is located is located in a basic time unit. The earliest alternative channel is used as a target channel to bear delay HARQ-ACK (hybrid automatic repeat request-acknowledgement); the alternative channel comprises at least one of a first type of alternative channel and a second type of alternative channel; the first type of alternative channel is a channel formed by sequentially taking continuous N1 alternative symbols starting from a first alternative symbol in the basic time unit or a subsequent time unit; the second alternative channel is at least one of the following channels in the basic time unit or the subsequent time unit: a PUCCH (Physical Uplink Control Channel) configured to be used for transmitting HARQ-ACK (Hybrid Automatic Repeat Request Acknowledgement) and CSI (Channel State Information) of SPS (Space Point Scheduling) or a HARQ-ACK of a dynamic scheduling PDSCH (Physical Downlink Shared Channel), and a PUSCH (Physical Uplink Shared Channel) of semi-static scheduling. The invention further discloses equipment applying the method. According to the invention, the problem that the network equipment and the terminal equipment cannot communicate with each other according to the HARQ-ACK information which is transmitted in a delayed manner is solved.

Owner:CHINA ACADEMY OF INFORMATION & COMM

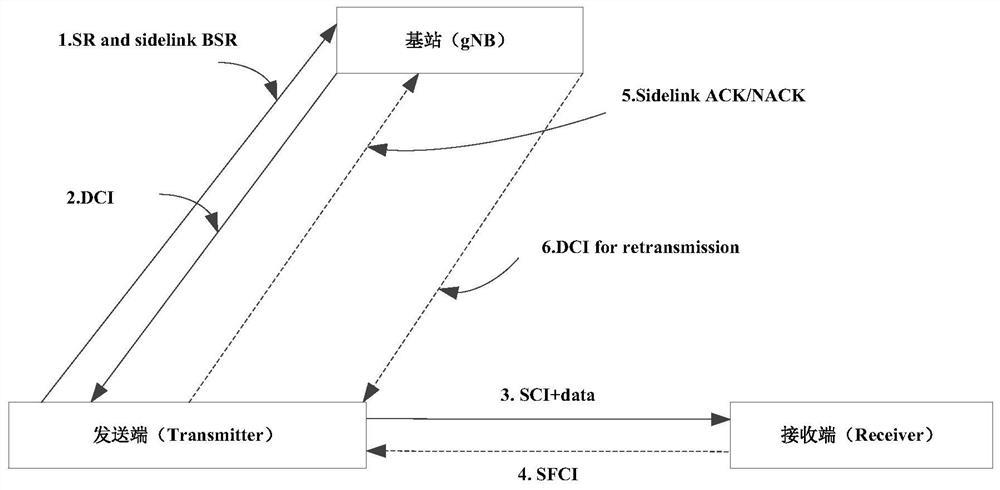

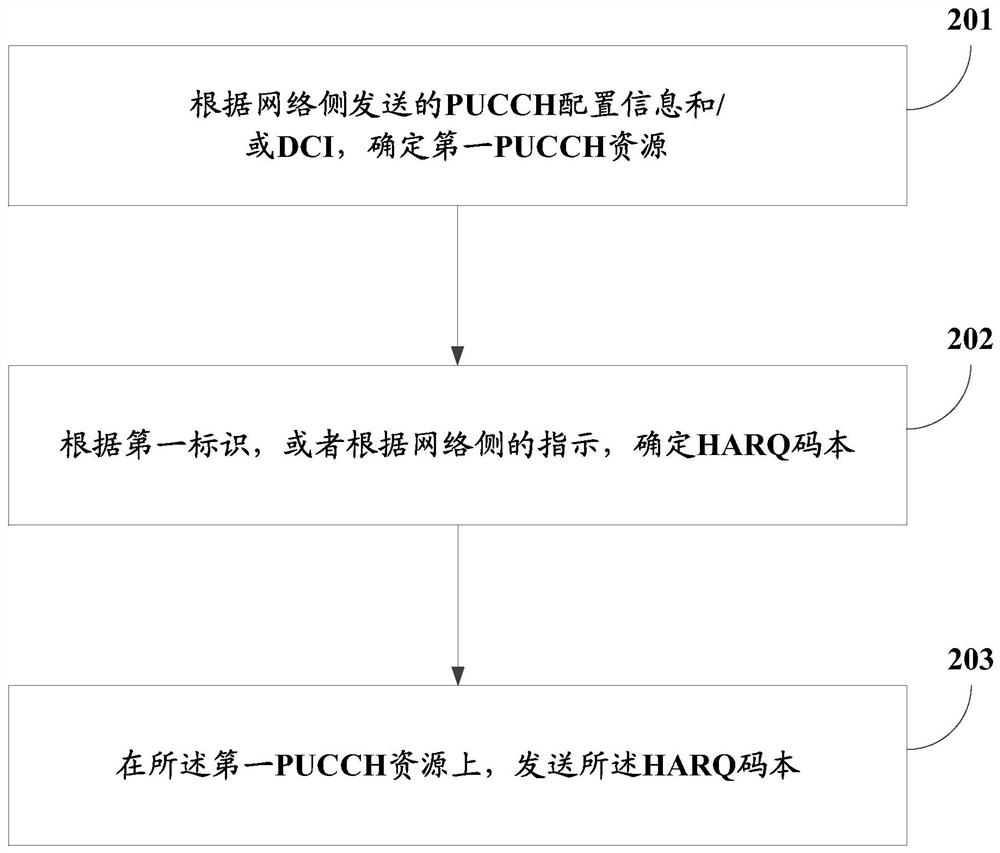

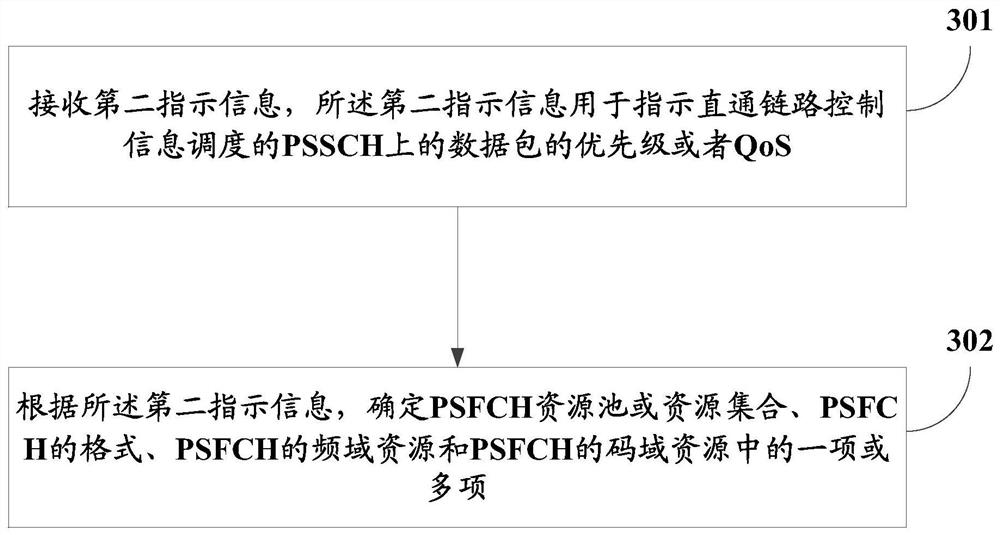

Sidelink HARQ-ACK (Hybrid Automatic Repeat Request-Acknowledgement Character) sending method, and method and equipment for determining PSFCH (Physical Single Frequency Channel) resources

InactiveCN112398594AMeeting Reliability NeedsGuaranteed LatencyError prevention/detection by using return channelSignal allocationReal-time computingData pack

Provided in embodiments of the present invention are a method for sending a sidelink HARQACK, and a method and device for determining a PSFCH resource. The method comprises steps of determining a first PUCCH resource according to PUCCH configuration information and / or DCI sent by a network side; determining an HARQ codebook according to a first identifier or according to an indication of a networkside, the first identifier being used for indicating priority information or QoS of a sidelink data packet; and sending the HARQ codebook on the first PUCCH resource. The method is advantaged in thatthe time delay of the Sidelink HARQACK of different services can be ensured, and reliability can be satisfied.

Owner:CHINA MOBILE COMM LTD RES INST +1

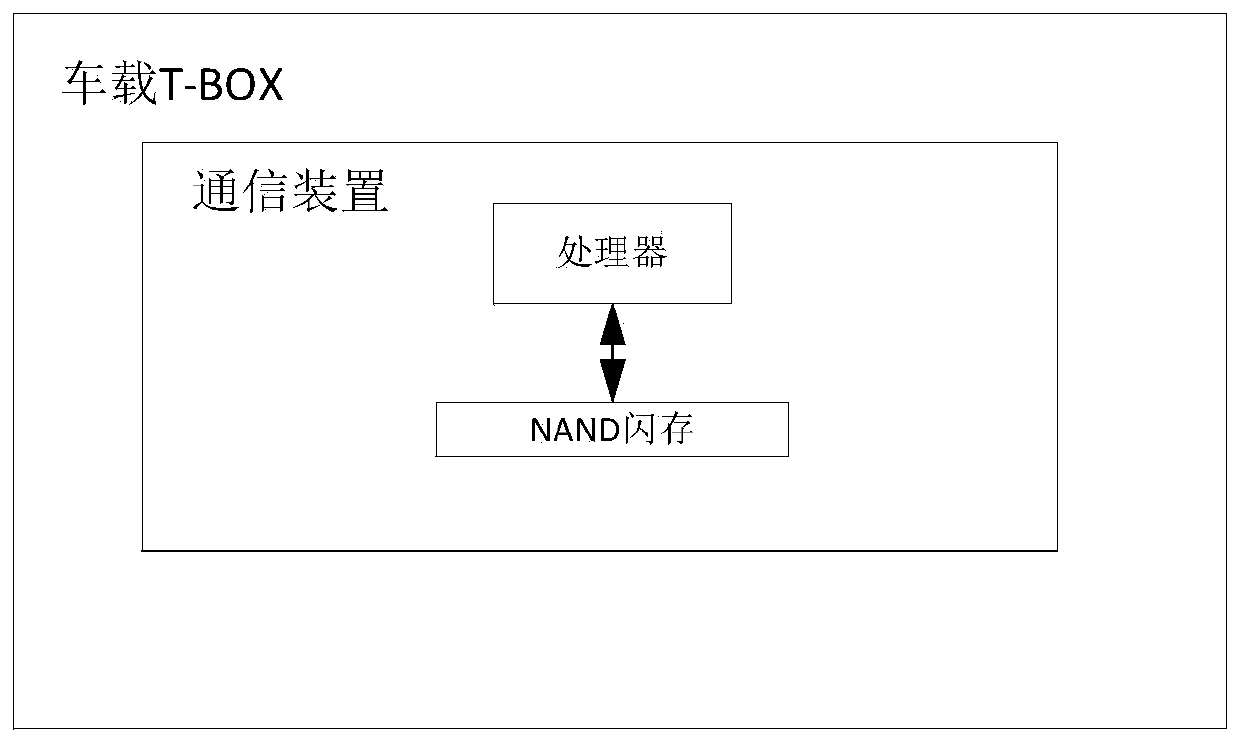

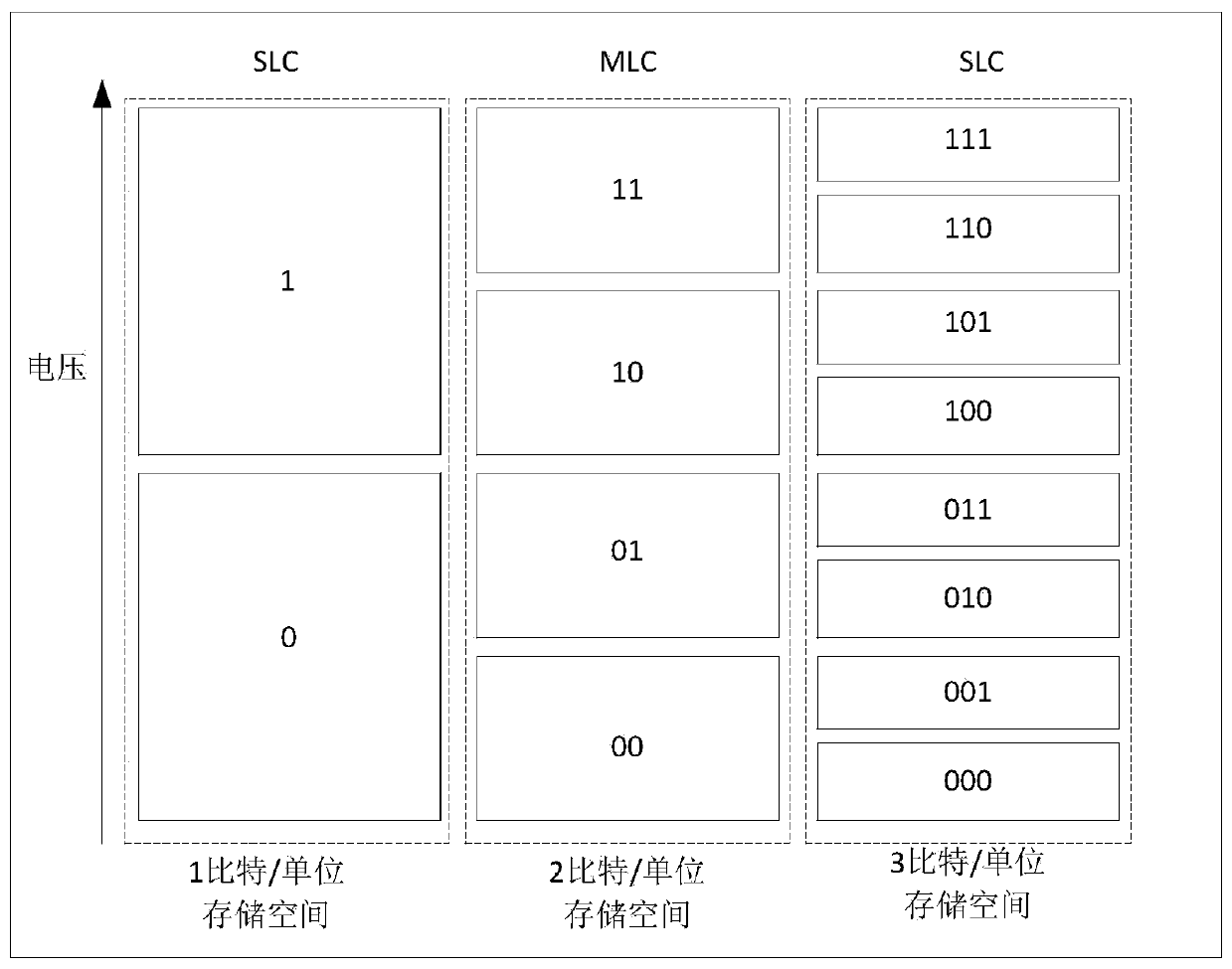

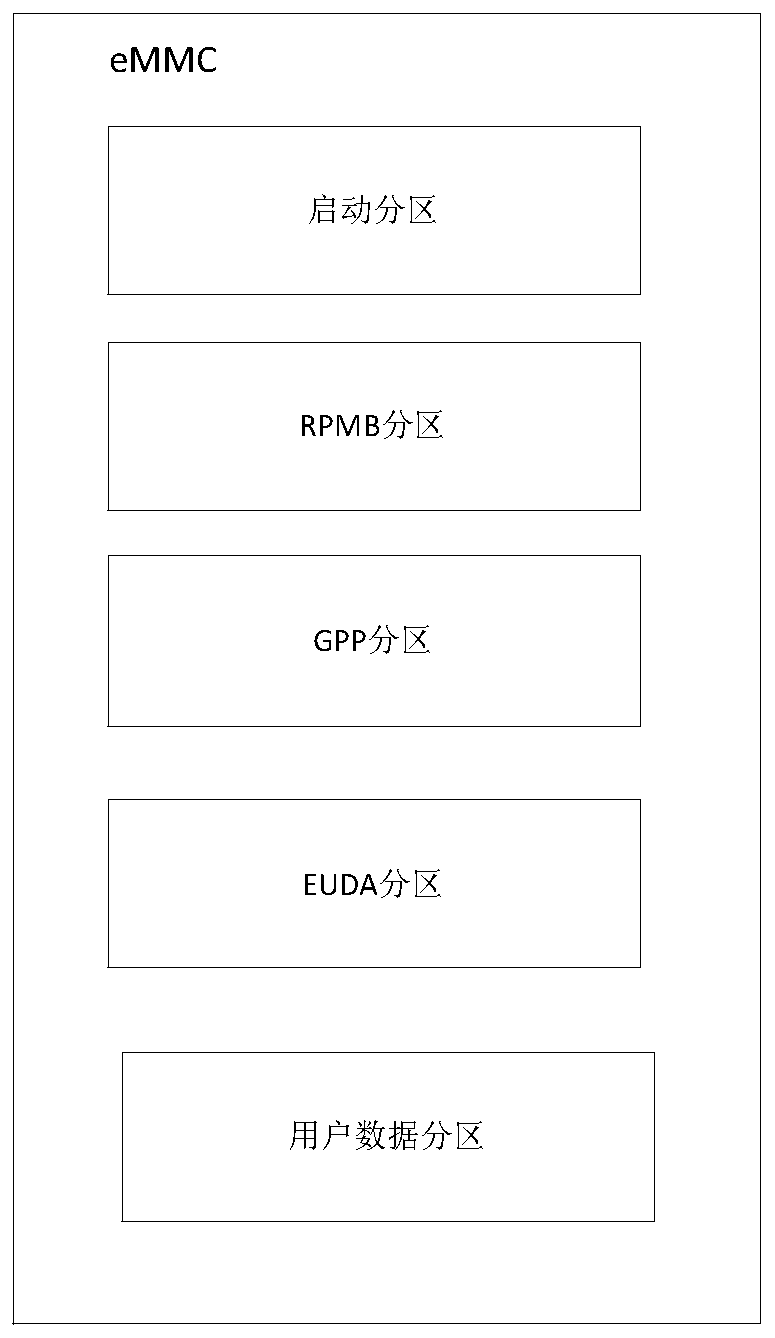

Embedded multimedia device and communication equipment for in-vehicle remote communication processor

InactiveCN110262836AImprove reliabilityAvoid problems with storage capacity limitationsData switching detailsBootstrappingIn vehicleData reliability

An embedded multimedia device and communication equipment for vehicle-mounted remote communication processor are provided. The embedded multimedia device is applied to the communication equipment of a vehicle-mounted remote communication processor T-BOX and comprises a startup disk partition, a high-reliability disk partition and a user data disk partition, and the startup disk partition stores boot program of the vehicle-mounted T-BOX in a manner of storing one bit data in each unit storage space. The high-reliability disk partition adopts mode of storing one bit of data in each unit storage space to store initialization information of hardware equipment included in the vehicle-mounted T-BOX and configuration file of the vehicle-mounted T-BOX. The user data disk partitions are used for storing data of application programs installed in the vehicle-mounted T-BOX to reduce cost of the storage module of the vehicle-mounted T-BOX on the premise of meeting high storage capacity and data reliability of the vehicle-mounted T-BOX.

Owner:HUAWEI TECH CO LTD

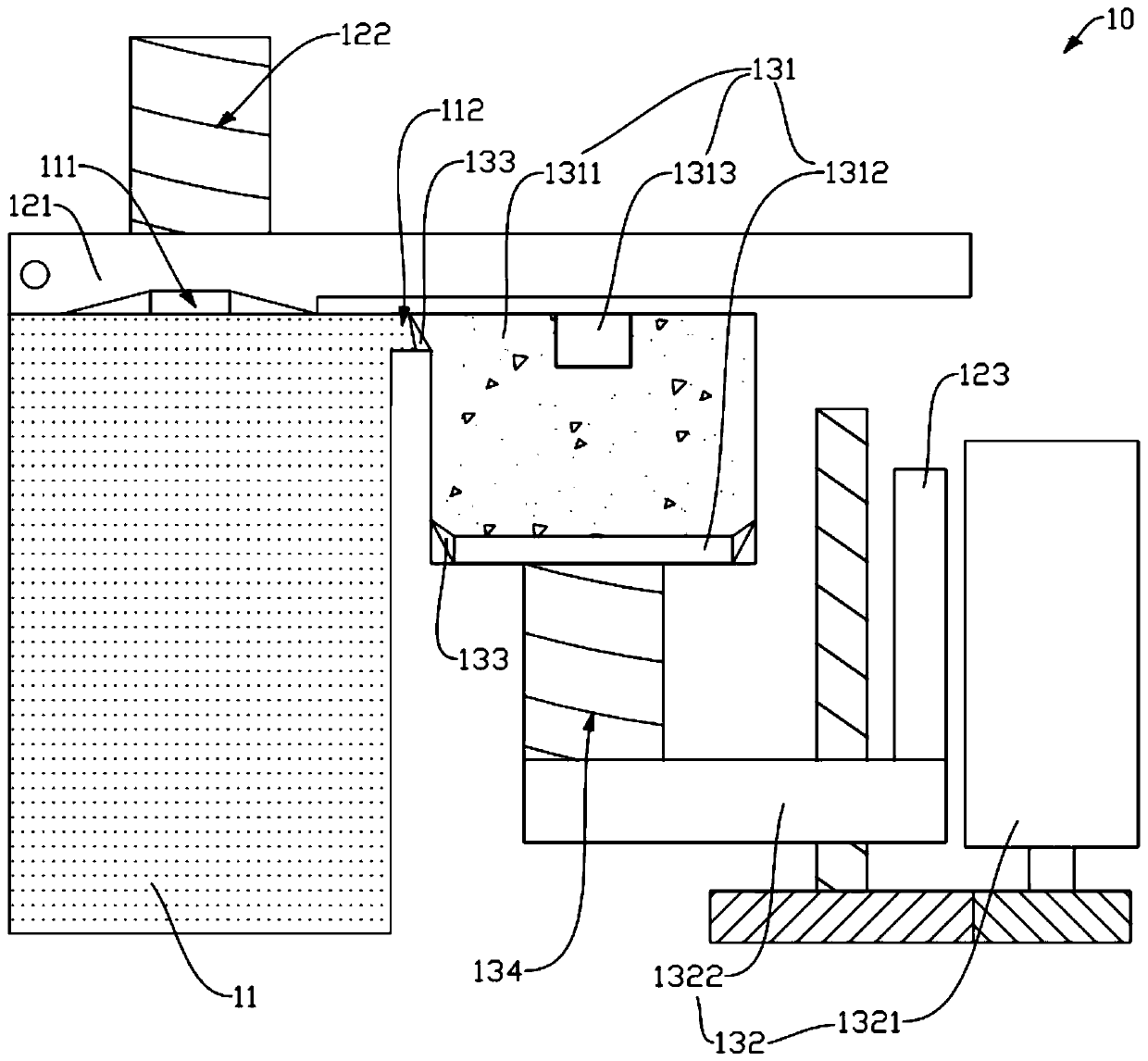

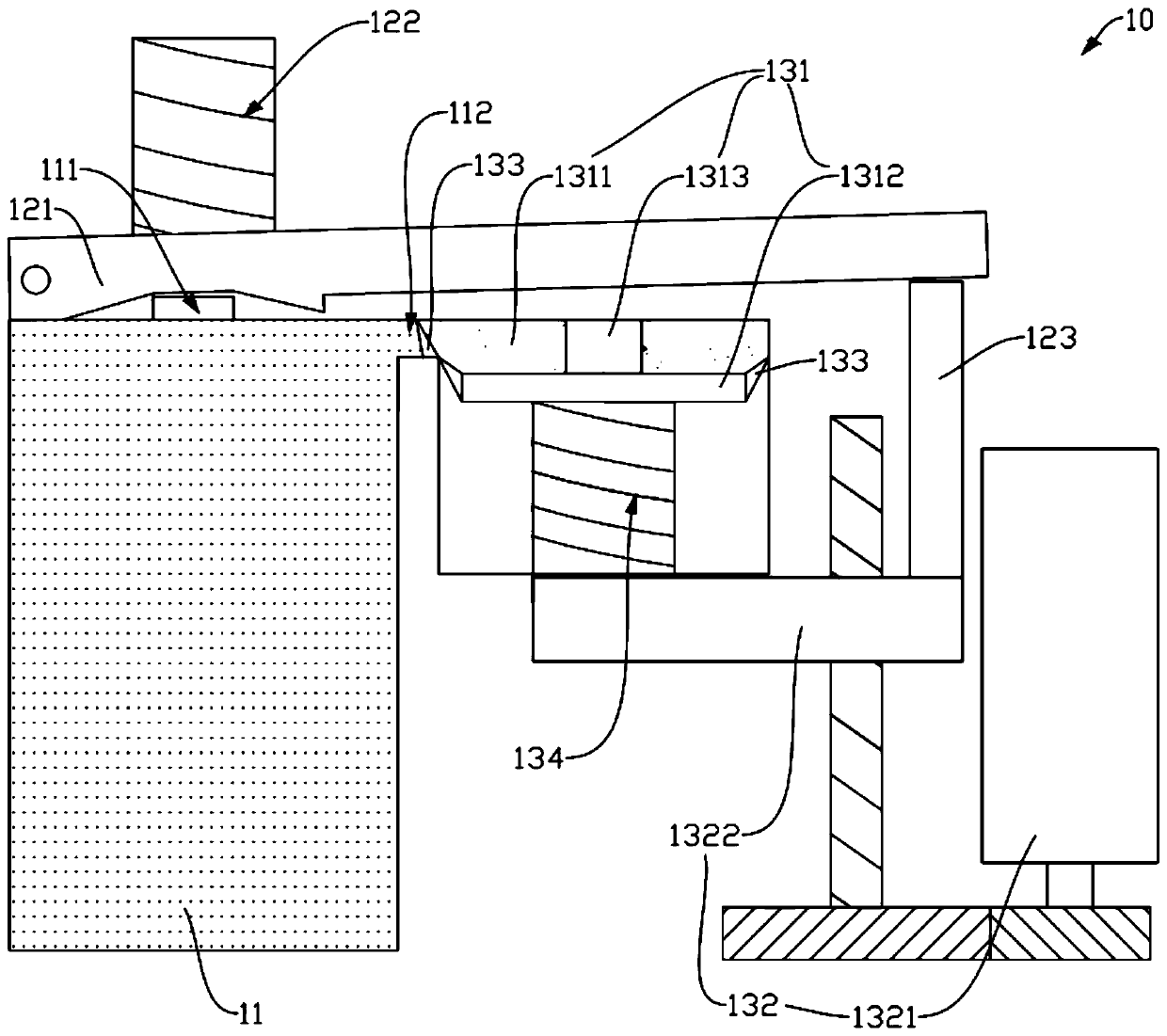

Electronic device and control method

PendingCN111556688AAvoid damageGuaranteed waterproof performanceHumidity controlHermetically-sealed casingsThermodynamicsWater vapor

The invention relates to an electronic device. The electronic device comprises a shell, a boosting device, a humidity sensor and a control device, wherein the shell comprises an inner cavity, and theboosting device, the humidity sensor and the control device are all fixed in the inner cavity; the shell is at least provided with an opening communicated with the inner cavity, and the humidity sensor is arranged corresponding to the opening; the control device is electrically connected with the boosting device and the humidity sensor, is configured to control the boosting device to inflate and boost the inner cavity when the humidity sensor monitors that the humidity of the opening exceeds a preset humidity threshold value, so that the pressure of the inner cavity is enabled to be higher than the external water vapor pressure, and water vapor is prevented from entering the inner cavity to damage the electronic device. According to the electronic device, waterproofing is achieved in an active boosting mode, the assembly, disassembly and maintenance are relatively convenient, and meanwhile, the reliability requirement for long-term use is met. The invention further relates to a controlmethod of the electronic device.

Owner:SHANGHAI TRANSSION CO LTD

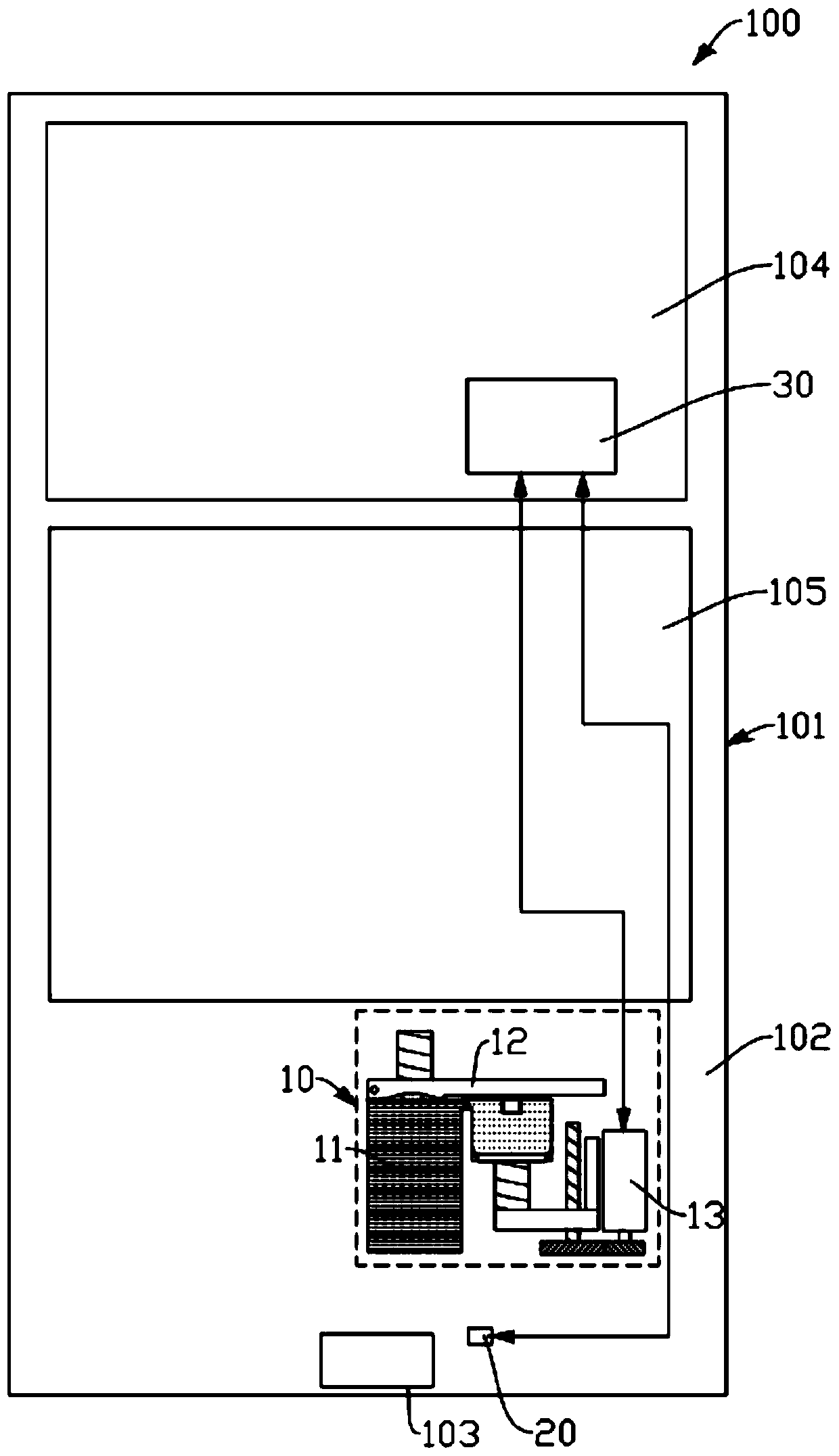

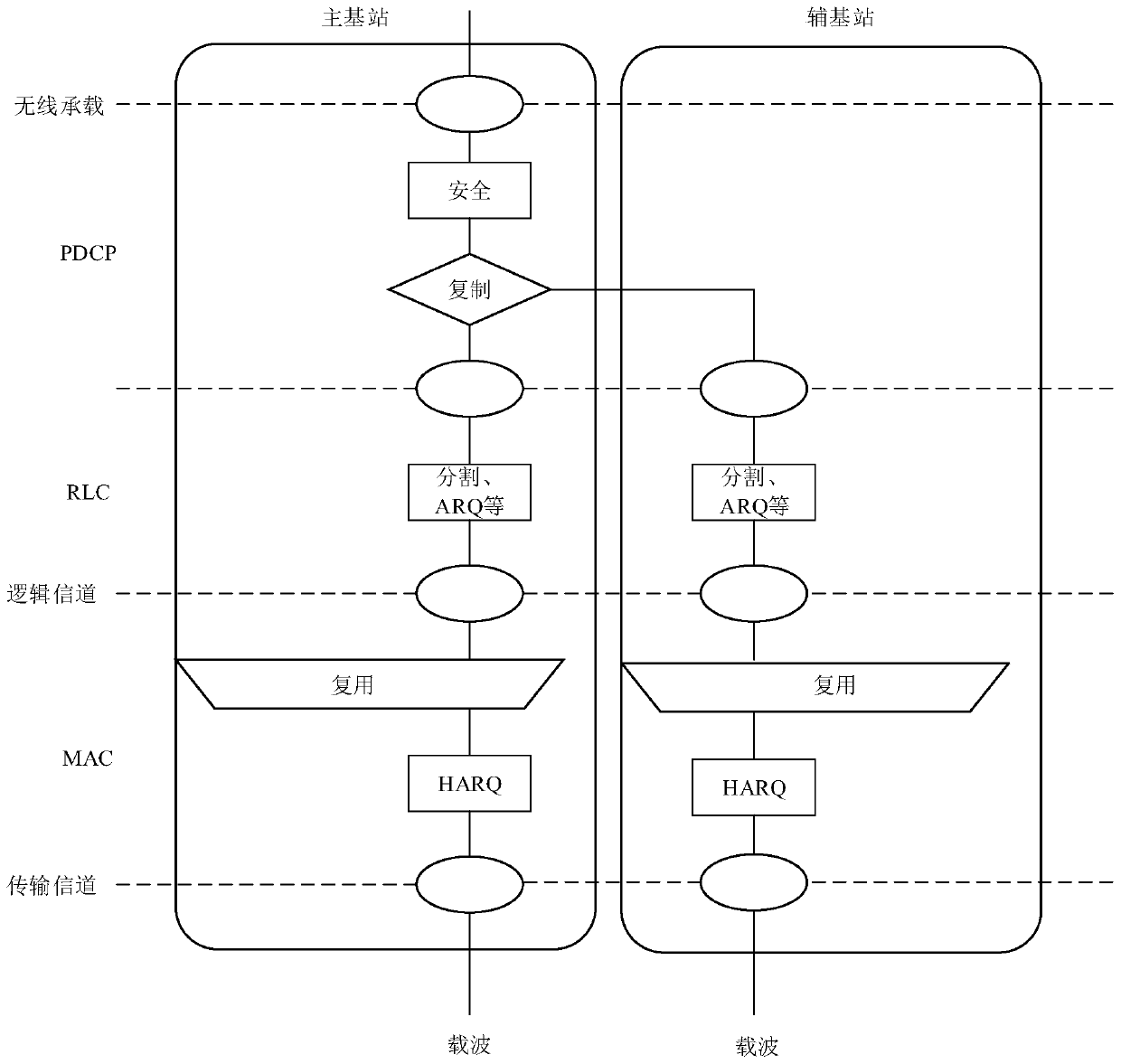

Method and device for selecting transmission mode

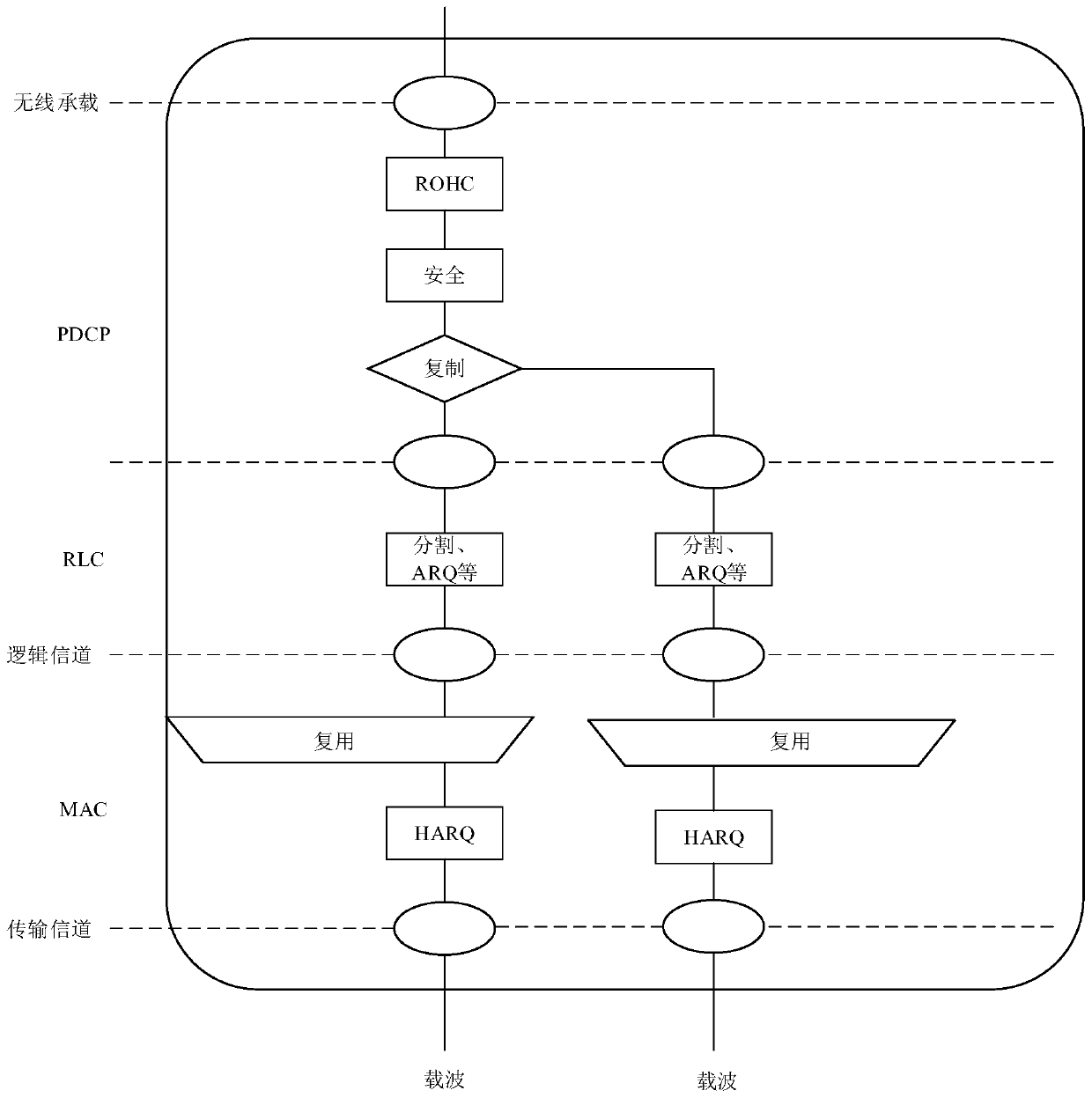

ActiveCN111404633AMeeting Reliability NeedsImprove transmission qualityError prevention/detection by using return channelConnection managementData packTerminal equipment

Provided are a method and a device for selecting a transmission mode. The method comprises: determining first indication information, the first indication information being used to indicate a changedtransmission mode, and / or being used to indicate a change of the transmission mode; and sending the first indication information to terminal device. When the data packet copied on the PDCP layer is transmitted, a plurality of transmission modes can be provided. That is to say, the repetition of the PDCP can have a plurality of modes. The transmission mode selection can be realized through the first indication information, for example, under the condition that the reliability of one repeated mode of the PDCP is not high, the other transmission mode can be selected through the first indication information, so that the reliability requirement of the service is met as much as possible, and the transmission quality of the service is improved.

Owner:HUAWEI TECH CO LTD

Pressure sensor system for compressor outlet pressure measurement

ActiveCN111473909AFacilitates temperature compensationMeeting Reliability NeedsRapid change measurementControl engineeringSignal processing

The invention discloses a pressure sensor system for compressor outlet dynamic pressure measurement. Compressor outlet pressure is collected and output as a voltage signal by a pressure sensitive device through a short measuring tube, and the voltage signal is processed by a signal processing module into a temperature compensated voltage signal to be output. A compressor outlet dynamic pressure sensor system is jointly formed based on the short measuring tube, the pressure sensitive device, the signal processing module, a pressure shell, a fixed seat and an output signal line connector. The system can reliably and accurately obtain the dynamic total pressure at high temperature, and has important significance for engine fault diagnosis.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

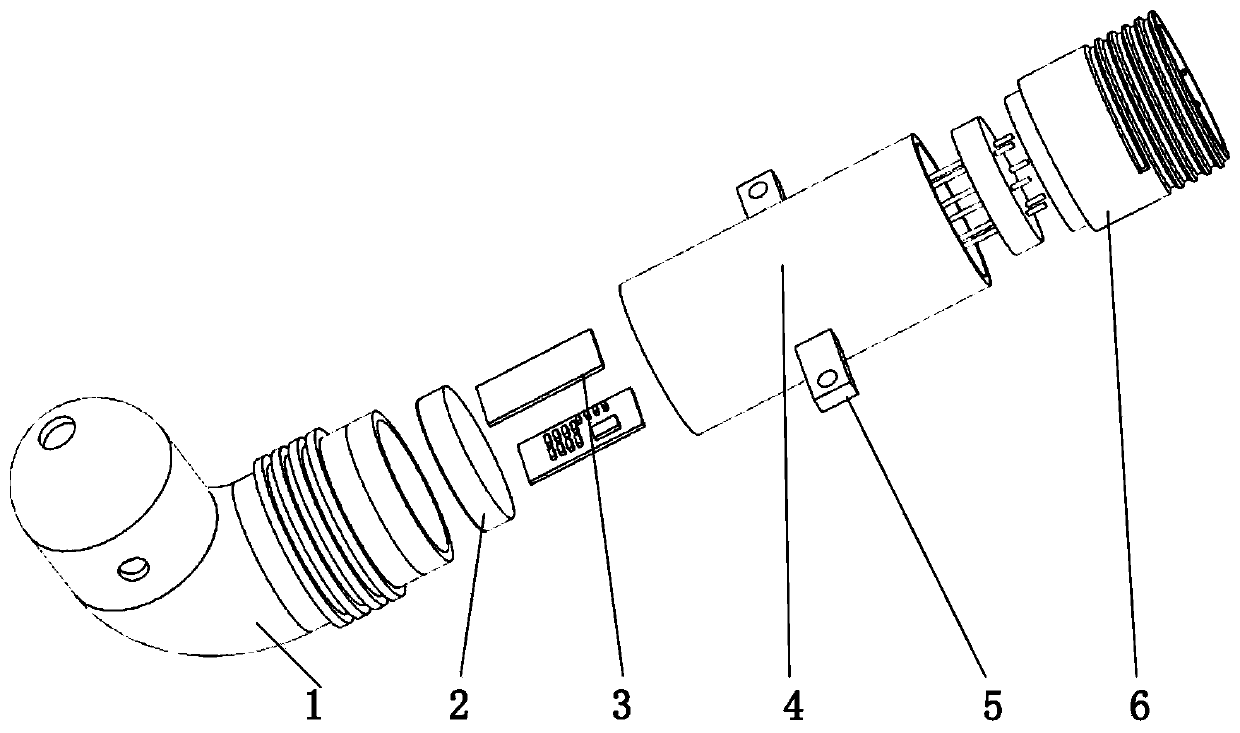

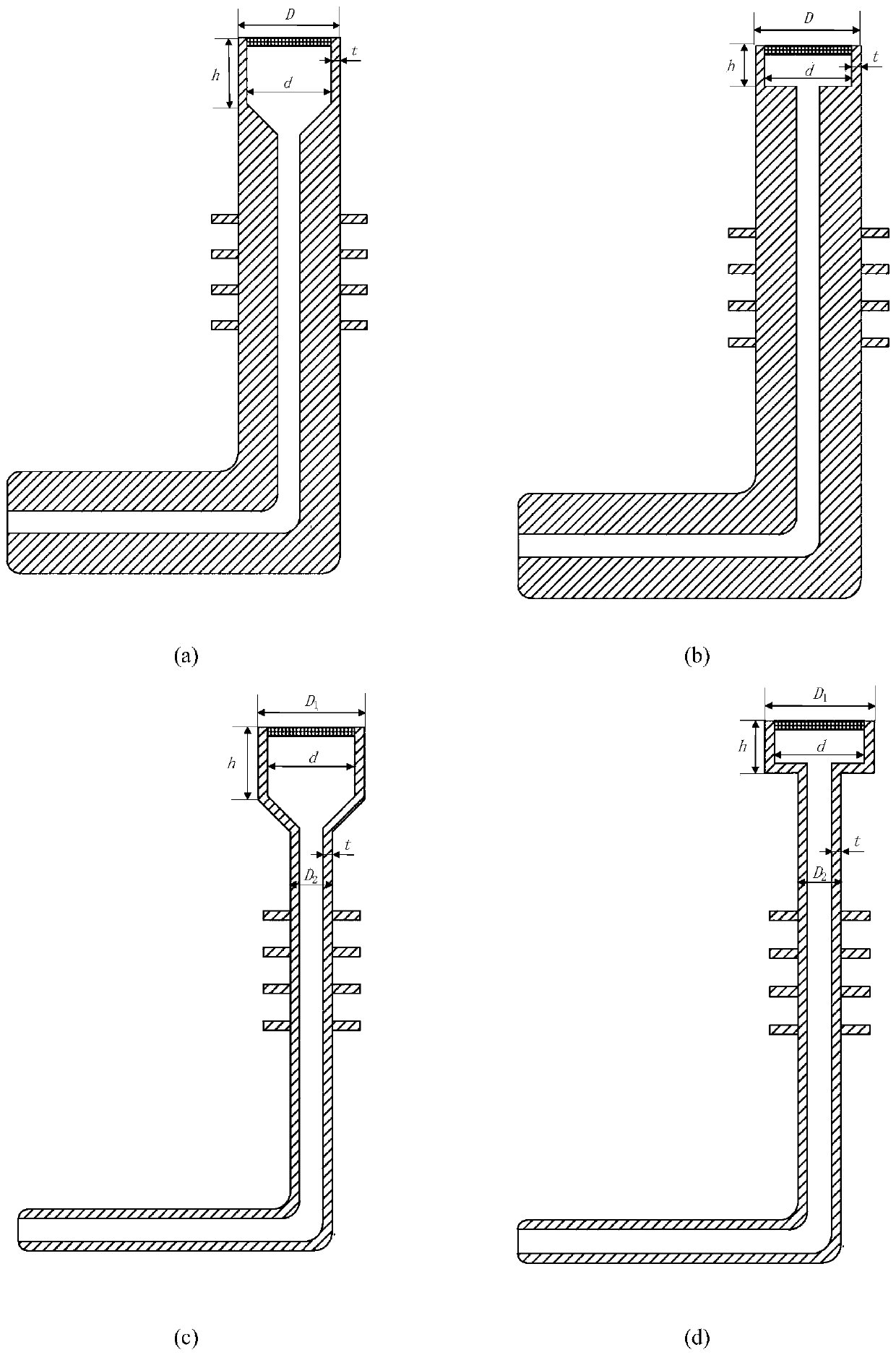

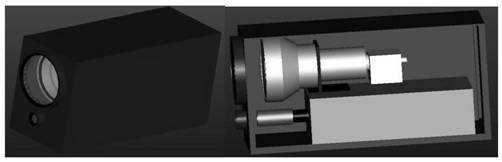

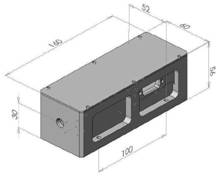

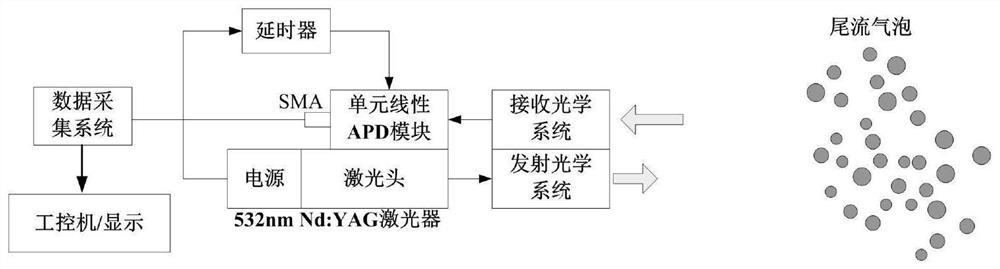

Wake flow bubble unit detection device

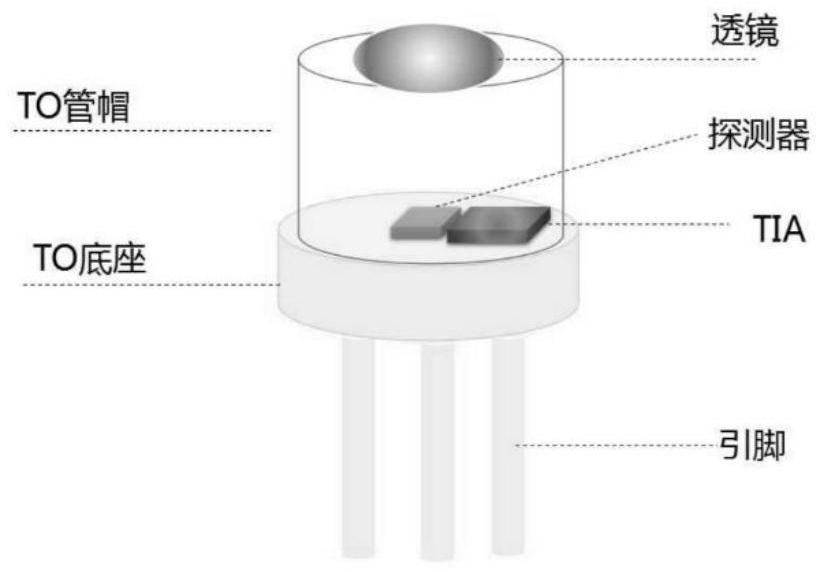

PendingCN111948668AMeet practical application needsMeeting Reliability NeedsScattering properties measurementsElectromagnetic wave reradiationLight spotData acquisition

The invention relates to a wake flow bubble unit detection device. The invention belongs to the technical field of ship wake flow bubble detection. The device comprises a receiving window, a receivinglens, a receiving detector, a box body cover plate, a box body, a laser, a transmitting lens, a transmitting window, a sealing system, a power supply system, an inclination angle mechanism, a delayer, a data acquisition system and an industrial personal computer. A laser emits pulsed light which is collimated by an emission optical system and then irradiates bubbles in wake flow, and then back scattered light is focused on a unit linear APD focal plane through a receiving optical system; the laser power supply outputs a Q-switched trigger pulse, and after a certain time delay, the trigger unit APD works, so that the laser echo and the detector work synchronously. Even if the light spot shape is expanded and distorted at the edge, the received light is basically not distorted, and the uniformity of the image surface of the detector is very high. In addition, the purpose of detecting different distances can be achieved by adjusting the position of the detector.

Owner:HARBIN INST OF TECH

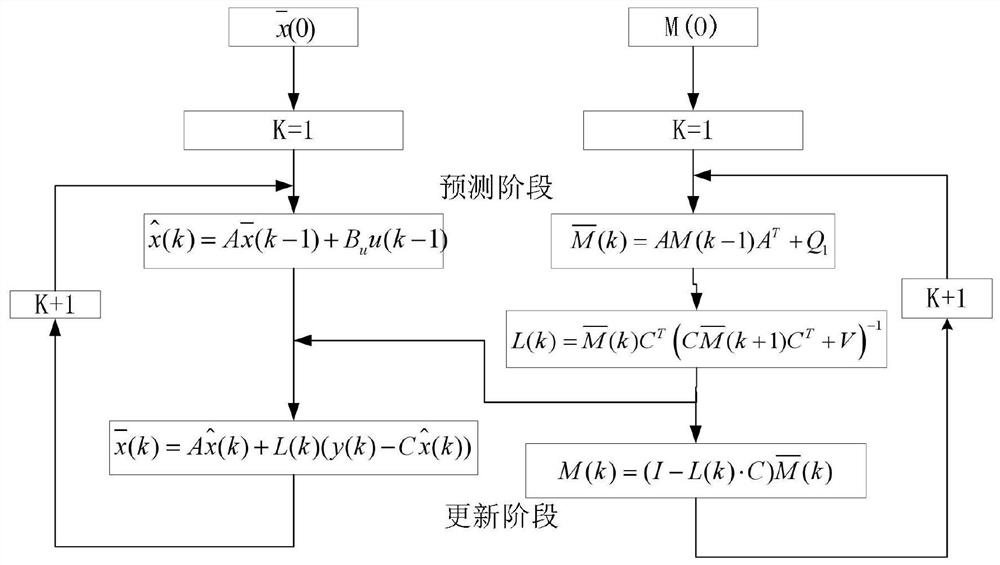

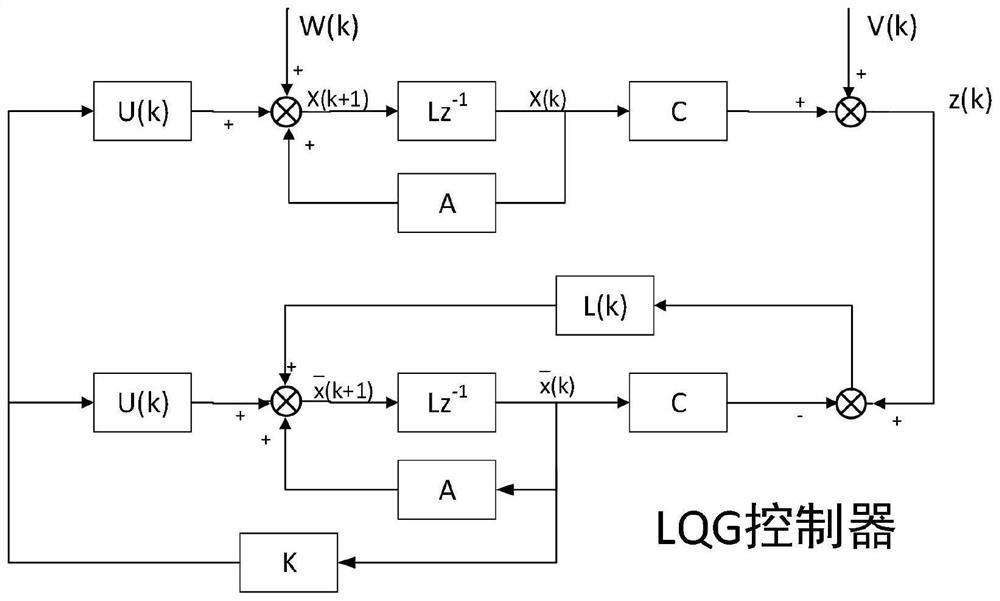

Wireless transmitting power prediction control method for reliability demand constraint of intelligent substation

ActiveCN112512110AReduce transmit powerExtended service lifePower managementParticular environment based servicesDynamic programmingReal-time computing

The invention discloses a wireless transmitting power prediction control method for reliability demand constraint of an intelligent substation, and the method comprises the steps: constructing a wireless signal propagation state space equation with state observation through the analysis of the relation among reliability, a signal-to-noise ratio and transmitting power and the utilization of a lossmodel and a Kalman filter of wireless signal propagation; performing expected signal-to-noise ratio compensation by estimating a confidence interval of signal-to-noise ratio fluctuation in real time;finally, defining a quadratic cost function taking the difference between the transmitting power and the actual signal-to-noise ratio and the expected signal-to-noise ratio as a target, and realizingoptimal control of the transmitting power through a dynamic programming algorithm. According to the invention, the problem of coordination between the transmitting power of the wireless sensor networkand the wireless communication reliability in the transformer substation environment can be solved, so that the transmitting power of the node is reduced as much as possible while the wireless communication reliability is ensured.

Owner:HEFEI UNIV OF TECH

Method for monitoring ring network on basis of link layer discovery protocol and device

ActiveCN102821009BEasy to monitorEasy to manageEnergy efficient ICTLoop networksRing networkLink Layer Discovery Protocol

Owner:ZTE CORP

Busbar cooling control method and device

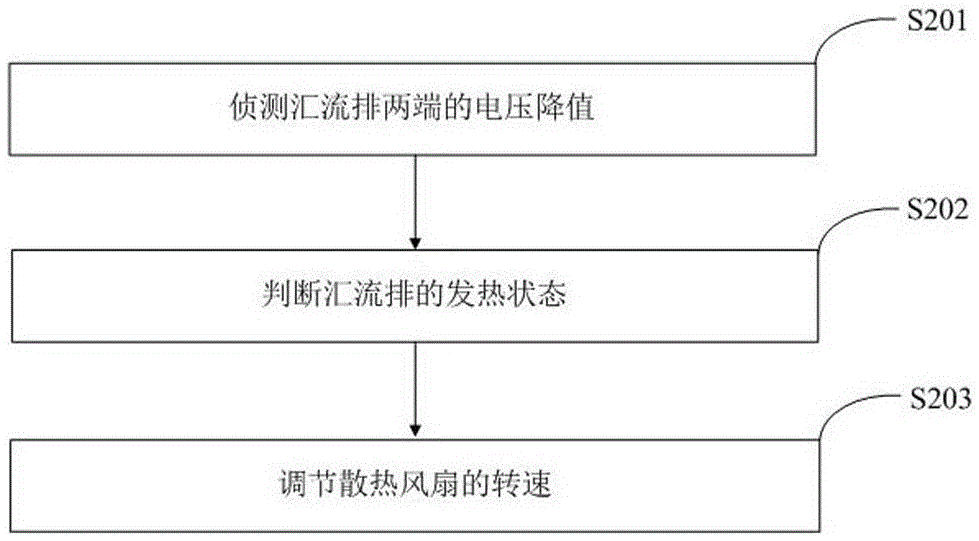

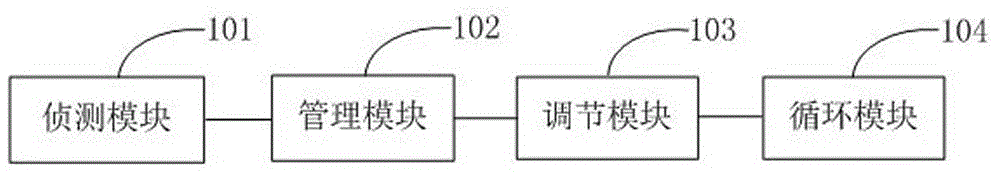

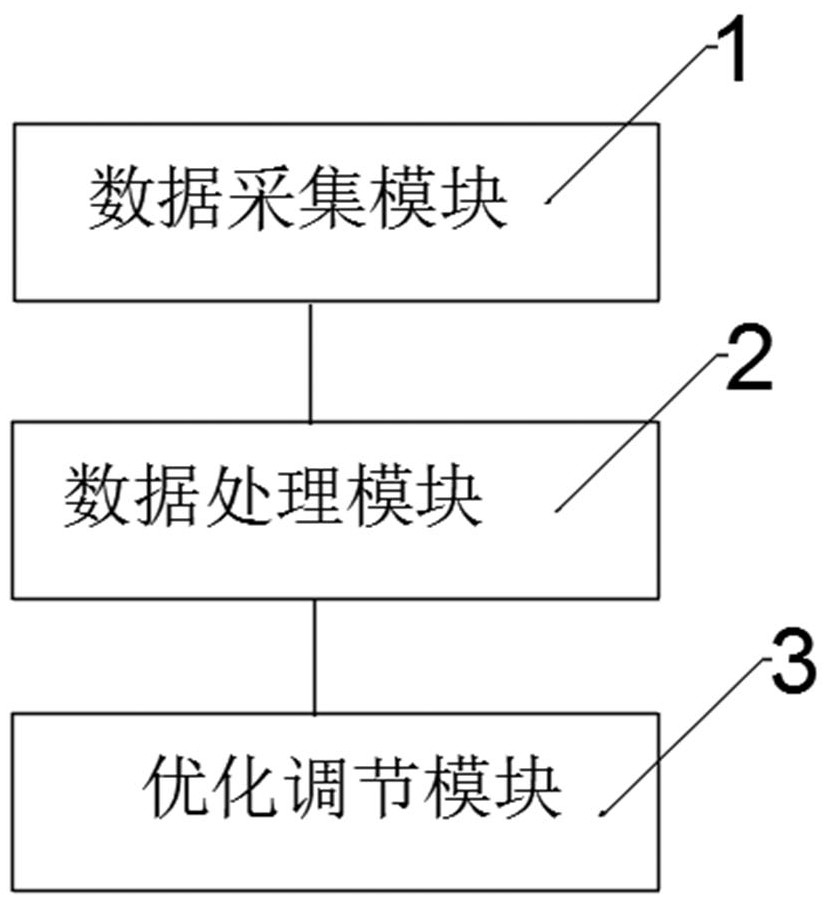

The invention relates to the technical field of cooling control and discloses a busbar cooling control method. The busbar cooling control method comprises the following steps: detecting voltage drop of two ends of a busbar; judging a thermal state of the busbar; regulating rotating speed of a cooling fan. The invention further provides a busbar cooling control device. The busbar cooling control device comprises a detection module for detecting the voltage drop of two ends of the busbar, a management module for judging the thermal state of the busbar and a regulation module for regulating the rotating speed of the cooling fan. The busbar cooling control method and device have the advantages that the problems that the temperature of the busbar is too high, the cooling state of the busbar cannot be detected precisely in real time and the rotating speed of the cooling fan cannot be regulated when the busbar is powered by a high-power power supply in the prior art are solved, one reliable cooling management method is realized, and the requirement of the system for reliability of the high-power power supply is met.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

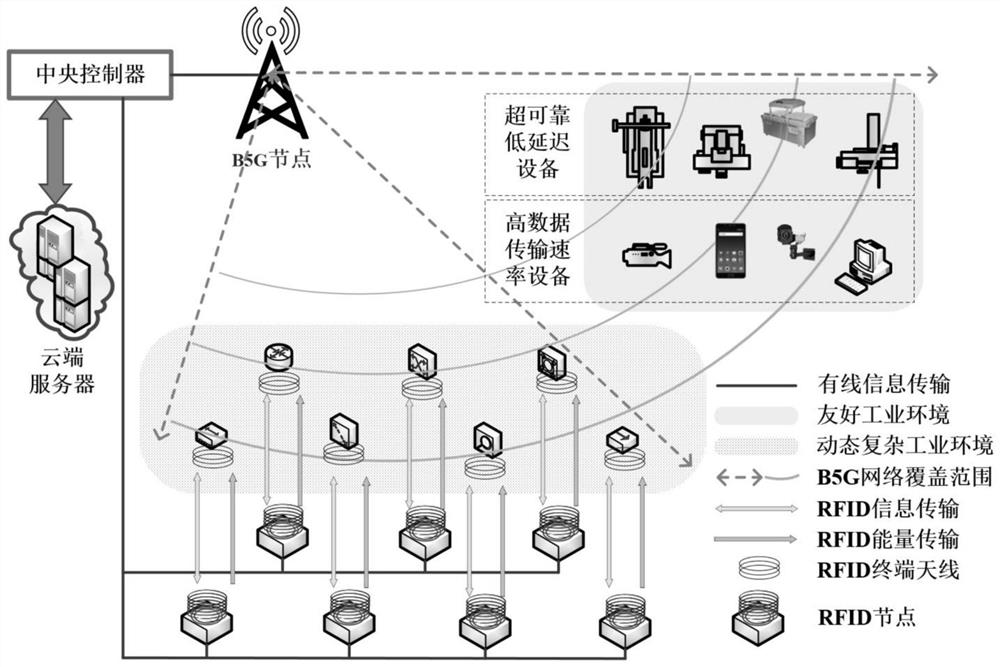

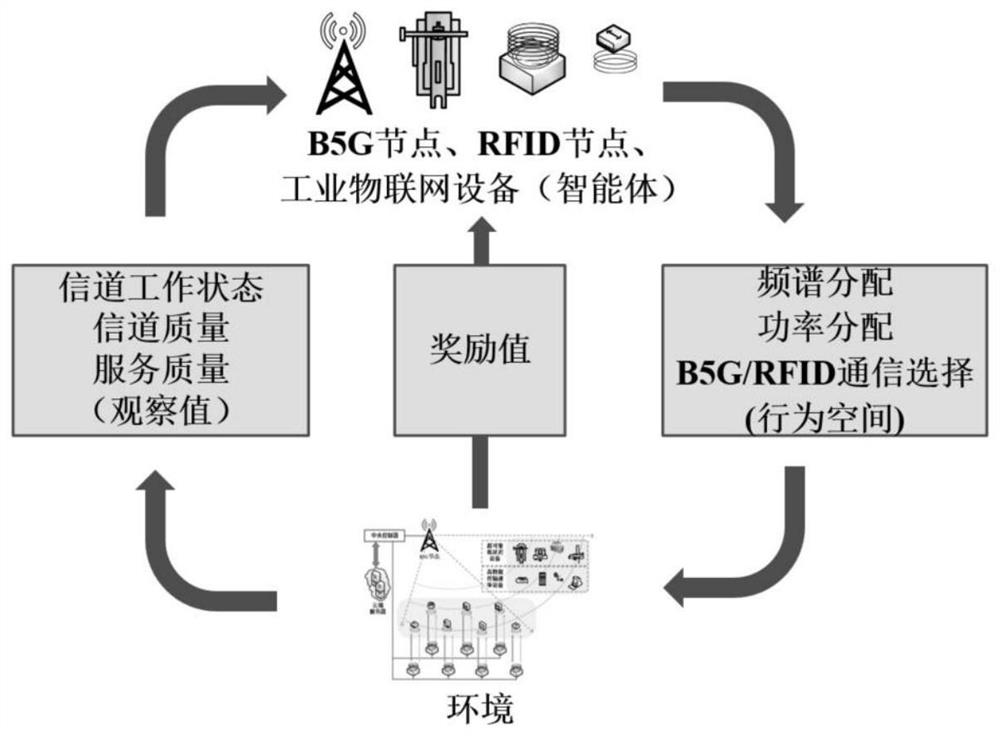

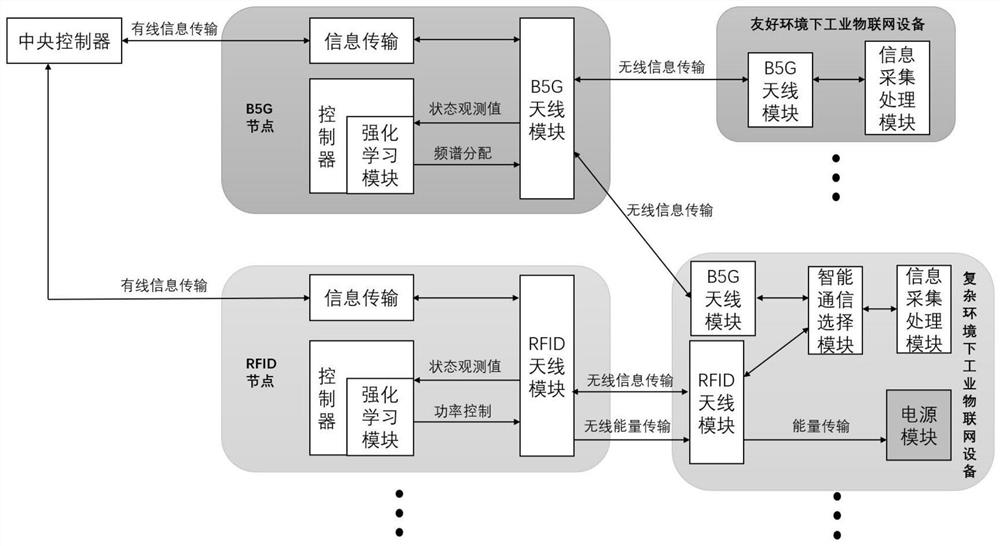

Heterogeneous B5G/RFID intelligent resource distribution system applied to industrial Internet of Things

PendingCN113938917AMeeting Reliability NeedsStable supplyCharacter and pattern recognitionTransmissionFrequency spectrumEngineering

The invention discloses a heterogeneous B5G / RFID intelligent resource allocation system applied to an industrial Internet of Things. The requirements of the industrial Internet of Things for ultra-reliability, low delay and high data transmission rate are met by utilizing an emerging B5G technology. Meanwhile, in order to solve the problems that communication of B5G industrial Internet of Things equipment in part of dynamic complex industrial scenes is easily interfered and stable power supply does not exist, the invention combines low-frequency RFID wireless energy-carrying communication with B5G wireless communication, and provides a heterogeneous B5G / RFID intelligent resource allocation system for various industrial environments. According to the system, a reinforcement learning algorithm is used for optimization, algorithm iteration is continuously carried out in an industrial Internet of Things environment, frequency spectrum optimal allocation of B5G wireless communication, power optimal control of RFID wireless energy-carrying communication and B5G / RFID communication optimal selection in a dynamic complex industrial environment are achieved respectively, optimal allocation of various resources is completed in real time, and the communication efficiency of the industrial Internet of Things is effectively improved.

Owner:BEIJING UNIV OF TECH

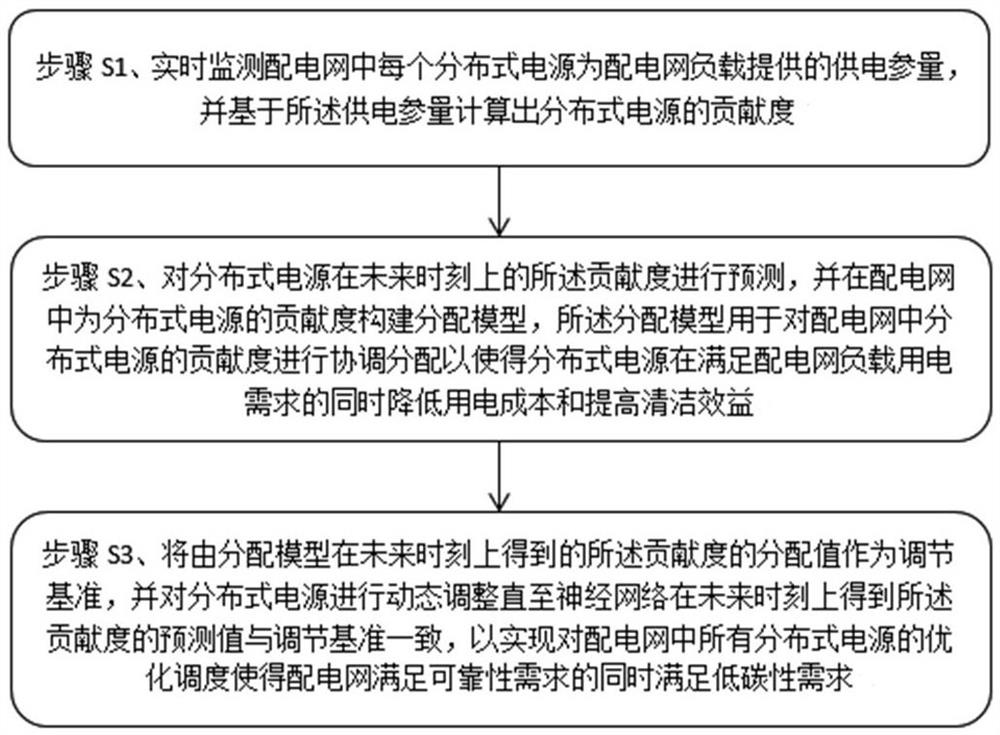

Optimization method and system for distributed prediction power grid

ActiveCN113762650AMeeting Reliability NeedsMeet the needs of low carbonForecastingResourcesPower gridEngineering

The invention discloses an optimization method and system for distributed prediction power grid. The method comprises the following steps: S1, monitoring a power supply parameter provided for a power distribution network load by each distributed power supply in a power distribution network in real time, and calculating the contribution degree of the distributed power supply based on the power supply parameter; and S2, predicting the contribution degree of the distributed power supply at the future moment, and constructing a distribution model for the contribution degree of the distributed power supply in the power distribution network, wherein the distribution model is used for carrying out coordinated distribution on the contribution degree of the distributed power supply in the power distribution network, so that the distributed power supply meets the load power demand of the power distribution network, and meanwhile, the power consumption cost is reduced and the cleaning benefit is improved. The distributed power supplies are dynamically adjusted until the predicted value of the contribution degree obtained by the neural network at the future moment is consistent with the adjustment reference, so that optimal scheduling of all the distributed power supplies in the power distribution network is realized, and the power distribution network meets the low-carbon requirement while meeting the reliability requirement.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU

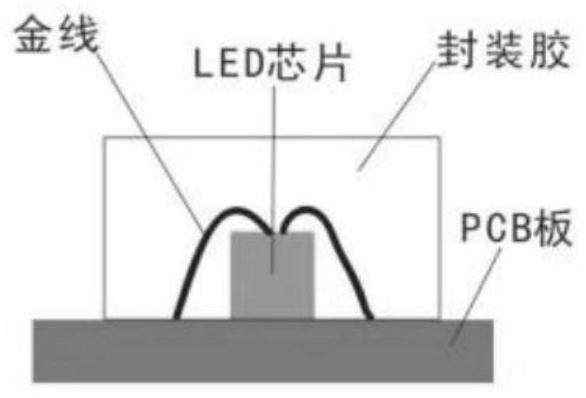

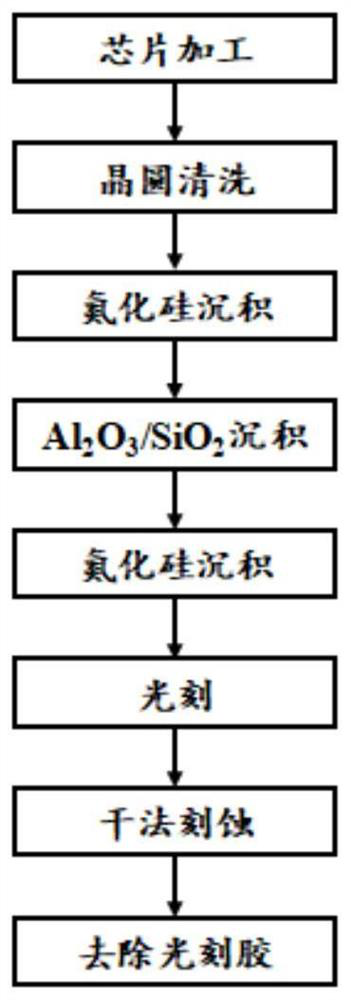

Protective layer of semiconductor photoelectric chip and production process of semiconductor

PendingCN113594266APrecise Targeted RemovalPhotoelectric performance impactLaser detailsFinal product manufactureDevice materialProtection layer

The invention discloses a protective layer of a semiconductor photoelectric chip and a production process of a semiconductor. The protective layer of the photoelectric chip comprises a first silicon nitride layer, an Al2O3 / SiO2 layer and a second silicon nitride layer from bottom to top in sequence, and a sandwich structure is presented. The process for producing the semiconductor device with the protective layer comprises the following steps of processing a chip; cleaning the wafer; depositing a first silicon nitride layer on the surface of the wafer; depositing an Al2O3 / SiO2 layer on the first silicon nitride layer; depositing a second silicon nitride layer on the Al2O3 / SiO2 layer; and producing the required semiconductor through a photoetching process, a dry etching process and photoresist removal. The protective layer with a sandwich structure fully utilizes the characteristics of different thin film layers to realize long-acting blocking of water vapor, improves the durability of the device, does not affect the electrical performance of the semiconductor device, can adjust the reflection property to light by adjusting the structure and film thickness of the protective layer, and is simple in production process, low in cost, and good in efficiency. Good application prospects are realized.

Owner:苏州鼎芯光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com