Intelligent pressure sensor system for intelligent engine distributed control

A pressure sensor, distributed control technology, applied to engine components, machines/engines, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

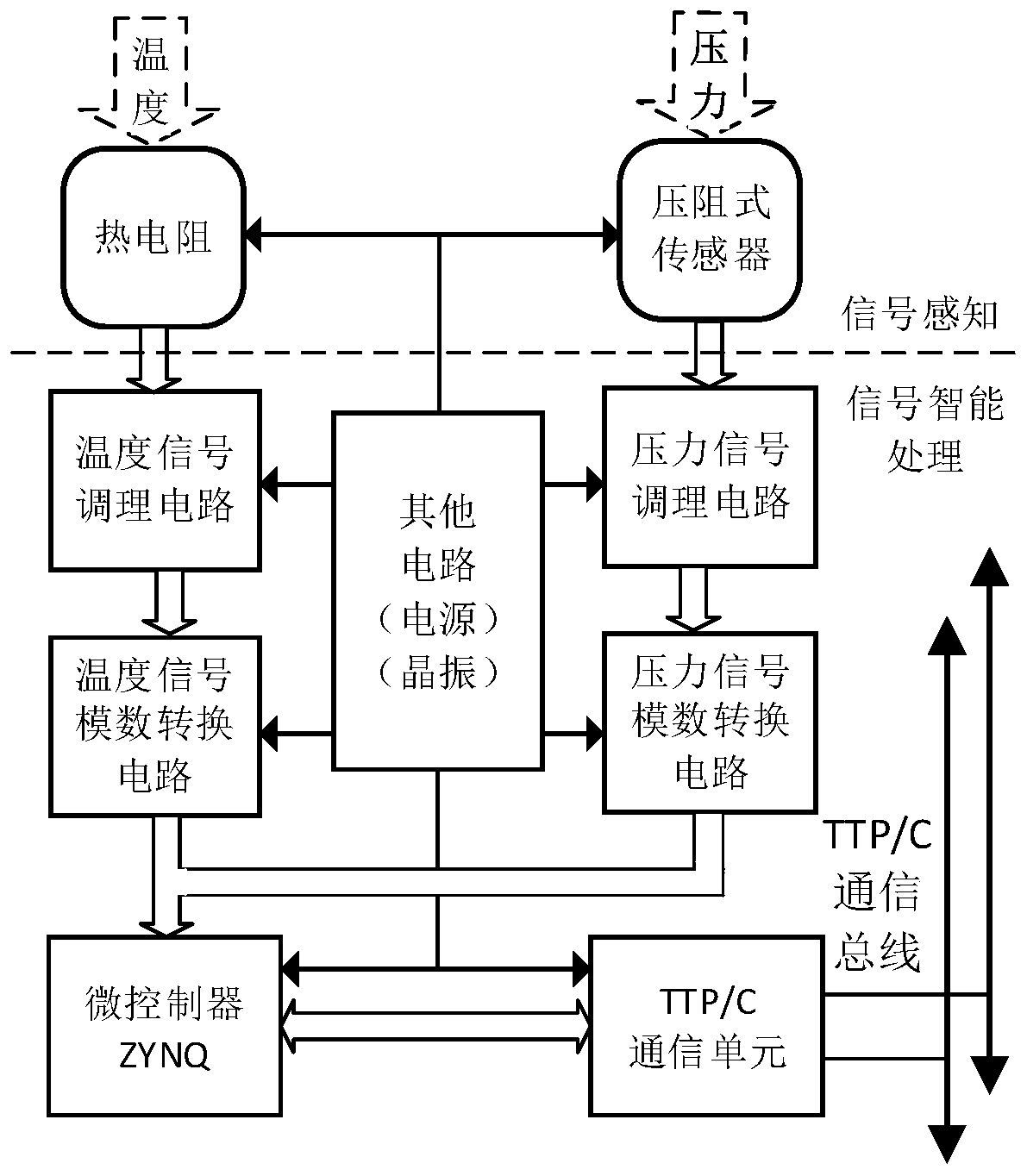

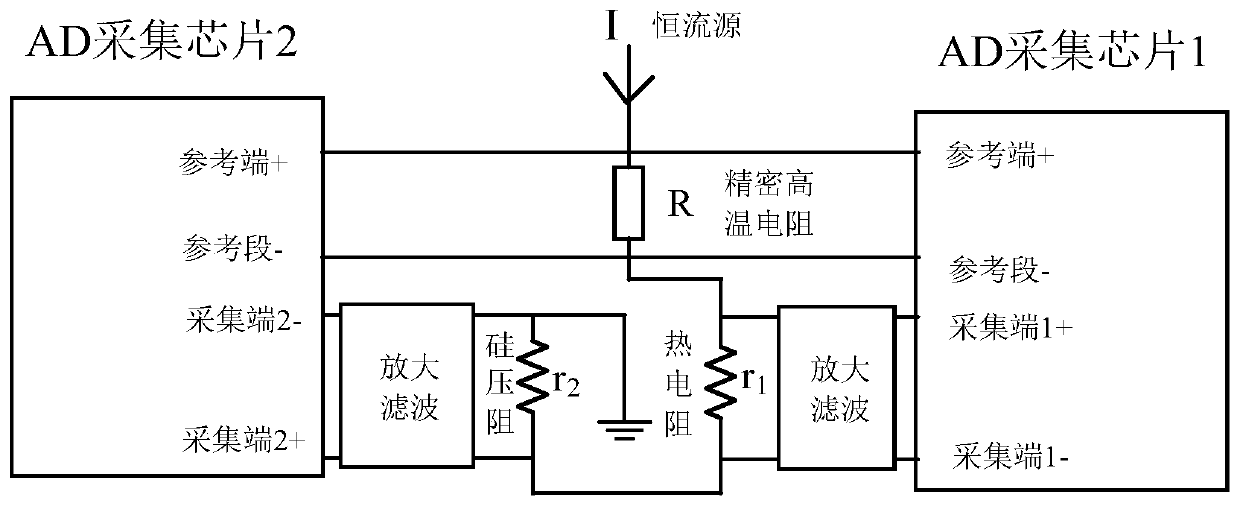

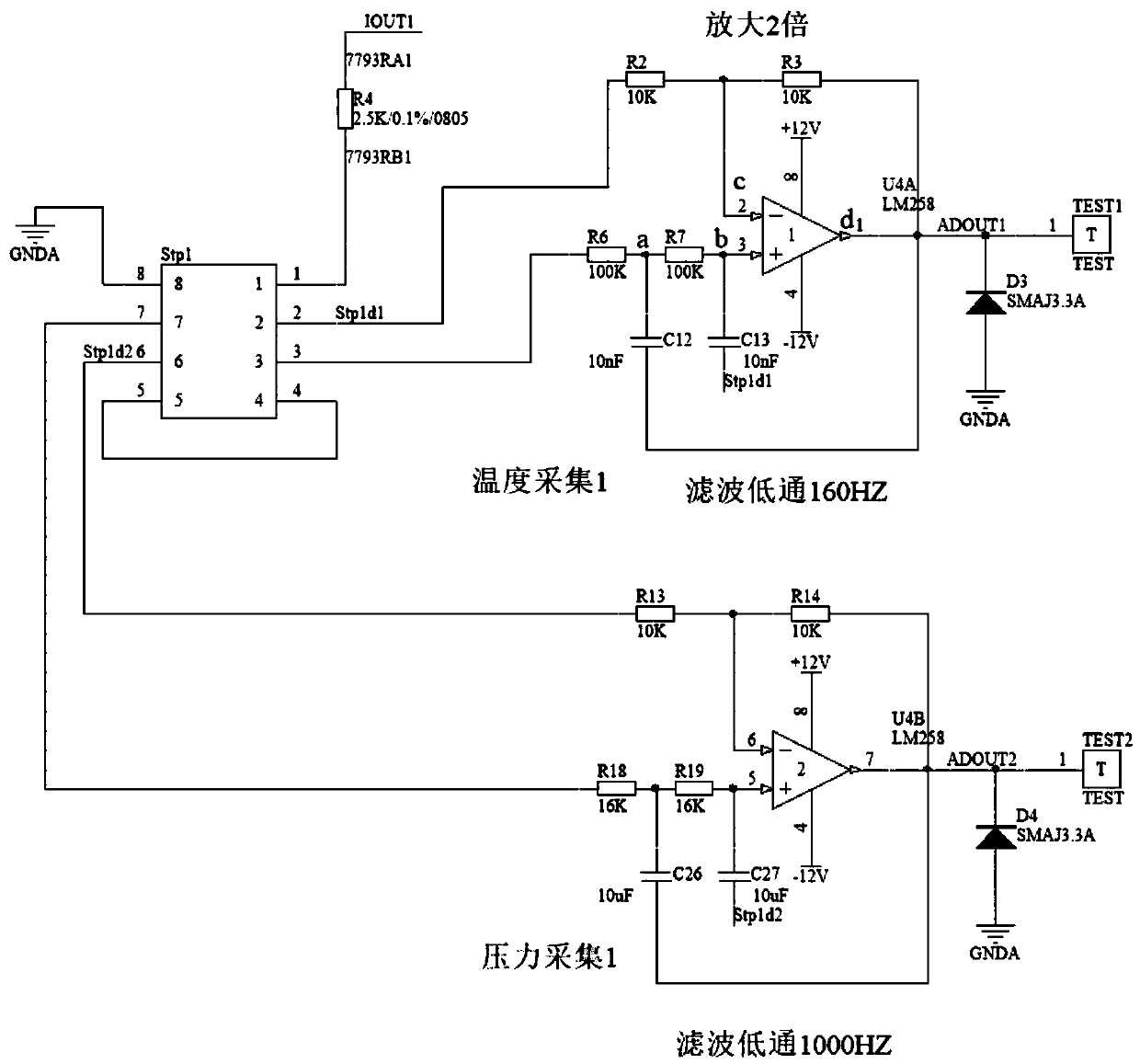

[0055] figure 1 It is the overall structure of the aero-engine intelligent pressure sensor. Combined with the distributed control system of the aero-engine, multiple functional units such as the signal processing unit of the intelligent pressure sensor, the intelligent calculation unit of the intelligent pressure sensor, the TTP / C communication unit of the intelligent pressure sensor and other circuits of the intelligent pressure sensor are designed respectively. In the hardware part, a second-order active filter is designed to filter and amplify the collected sensor signals. The AD7793 chip of ADI Company is used to collect the dual temperature sensor channels. The TTP / C bus controller adopts the AS8202NF chip provided by TTTech Company. The hardware part is mainly designed for the peripheral circuit of the TTP protocol controller, includi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com