High-reliability IGBT module packaging structure and processing technology

A packaging structure and reliability technology, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of chip size reduction and chip power density increase, so as to strengthen the bonding force and improve the overall thermal conductivity , The effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

[0036] The present invention proposes a high-reliability IGBT module packaging structure, which generally includes: a DBC (direct copper clad) substrate with patterned growth of 2D-hBN on the upper surface, an IGBT chip, a FRD (fast recovery diode) chip, a bottom plate, and a solder layer , bonding wires, bus bars, plastic housings, and 2D-hBN filled reinforced potting silicone.

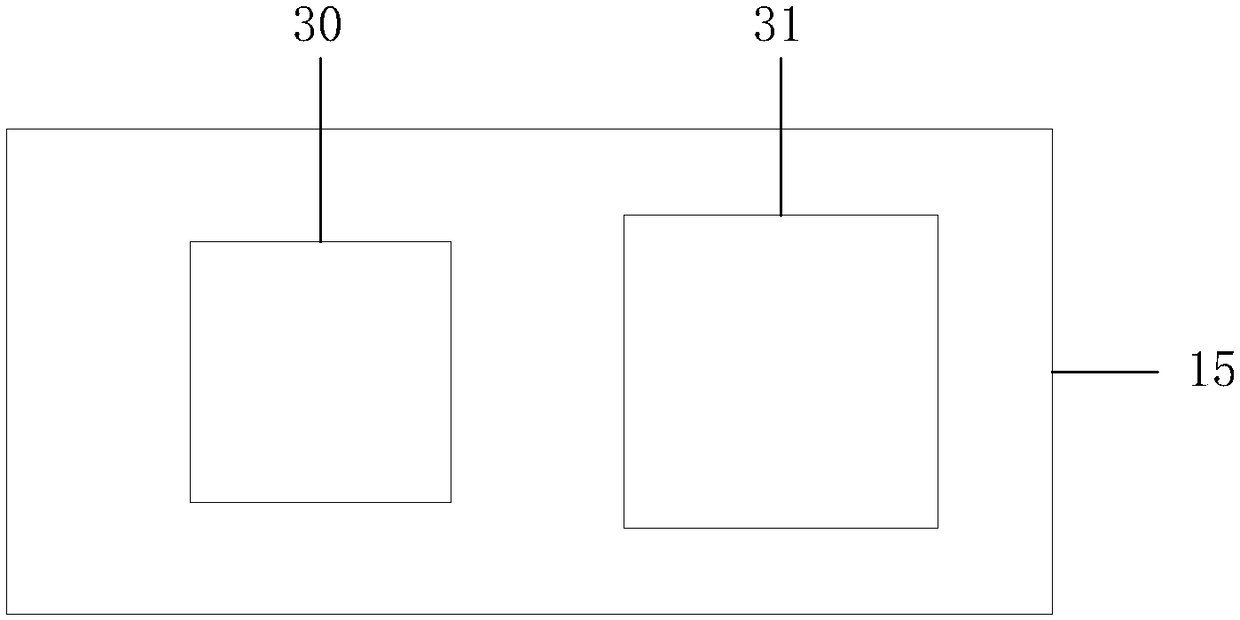

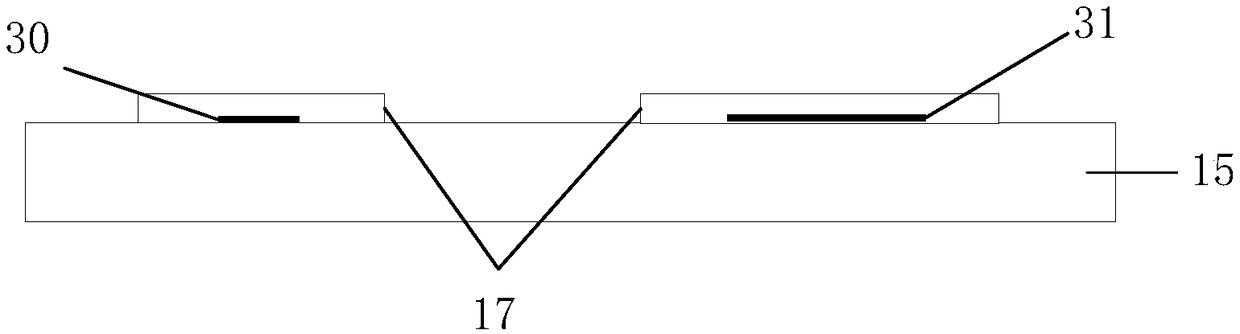

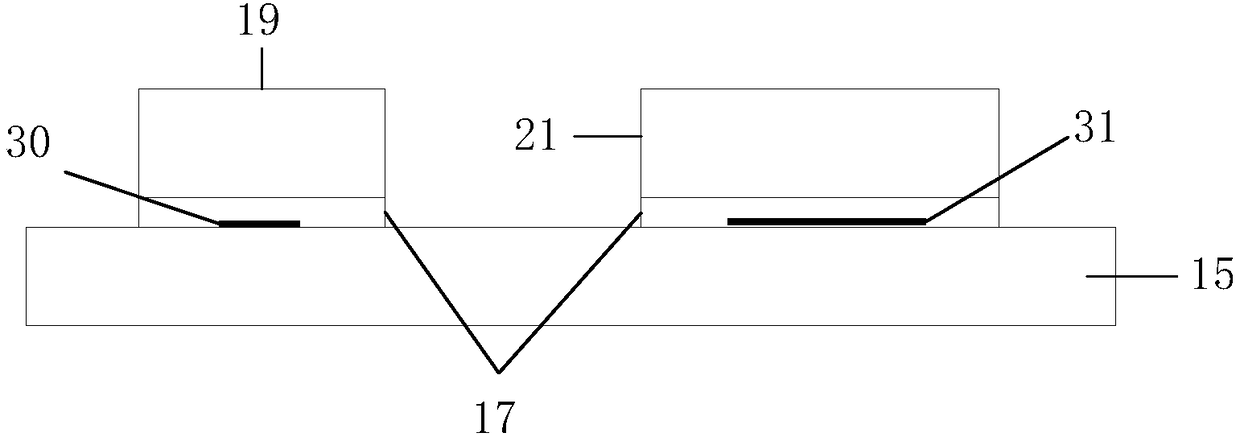

[0037] see figure 1 , in order to pattern-grow the first 2D-hBN thin film 30 on the central position of the connection area corresponding to the cathode of the FRD chip 19 on the upper surface of the DBC substrate 14 by chemical vapor deposition, and to connect the corresponding collector of the IGBT chip 21 on the upper surface of the DBC substrate 14 A second 2D-hBN thin film 31 is patterned and grown on the central position of the region. The first 2D-hBN thin film 30 and the second 2D-hB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com