Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Meet environmental emission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Harmless treating method for waste tank lining of aluminium electrolytic bath

A process for innocuously treating the used liner of aluminium electrolyzer includes such steps as proportionaly mixing it with the calcium oxide contained ore, SiO2 contained material and bitumite, heat treating in rotary kiln, adsorbing tail gas by alumina, and leaching the treated material by lime milk for secondary reaction. It can greatly decrease the contents of fluoride and cyanide in the treated dregs, which can be used to prepare cement or refractory or for building road.

Owner:中铝郑州有色金属研究院有限公司

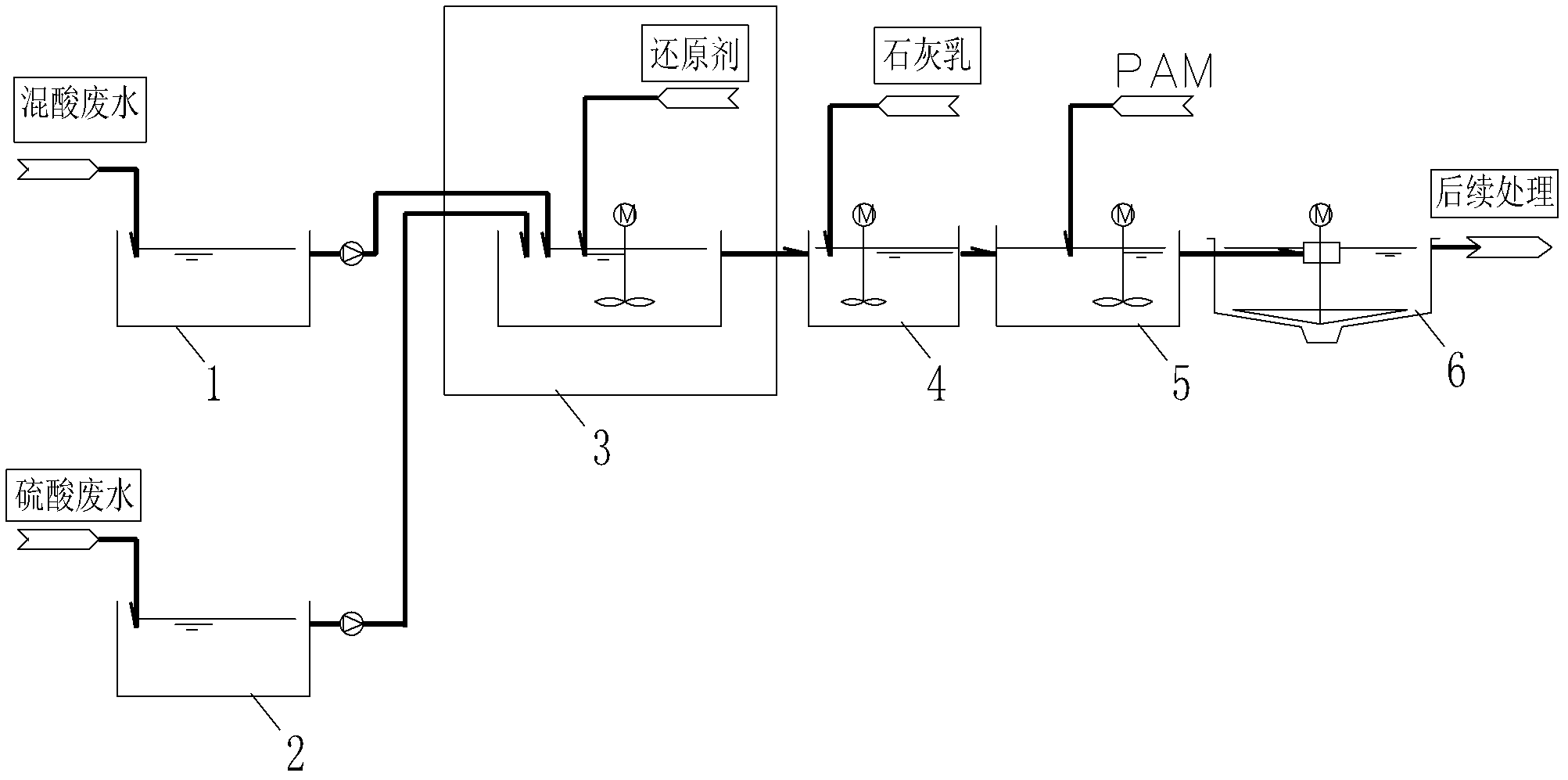

Treatment method for reducing Cr<6+> in stainless steel acid wastewater

InactiveCN102329024AMeet environmental protection requirementsFacilitate subsequent biochemical treatmentWater contaminantsMultistage water/sewage treatmentSludgeWastewater

The invention relates to a treatment method for reducing Cr<6+> in stainless steel acid wastewater. The treatment method comprises the following steps: feeding stainless steel mixed acid wastewater and sulfuric acid wastewater into a reducing pond; adding a reducing agent into the reducing pond and stirring, so that Cr<6+> in the wastewater is converted to Cr<3+> and leading effluent meeting an ORP (oxidation-reduction potential) requirement to flow into a neutralization pond; adding lime into the neutralization pond and carrying out oxygen blast aeration, so that Fe<2+> in the wastewater is oxidized to Fe<3+> and Cr(OH)3, CaF2, Fe(OH)3 and CaSO4 precipitates are formed; entering the effluent from the neutralization pond into a flocculation pond; adding 2-5 mg / l of PAM (polyacrylamide) into the flocculation pond so as to form large alum floc, and leading the effluent from the flocculation pond to flow into a precipitation pond for precipitation; and then entering the effluent after precipitation into a subsequent treatment facility so that the Cr<6+> in the effluent meets the emission requirement, and externally transporting sewage in the precipitation pond at regular intervals. The treatment method can meet environmentally-friendly requirement and is beneficial to subsequent biochemical treatment.

Owner:WISDRI ENG & RES INC LTD

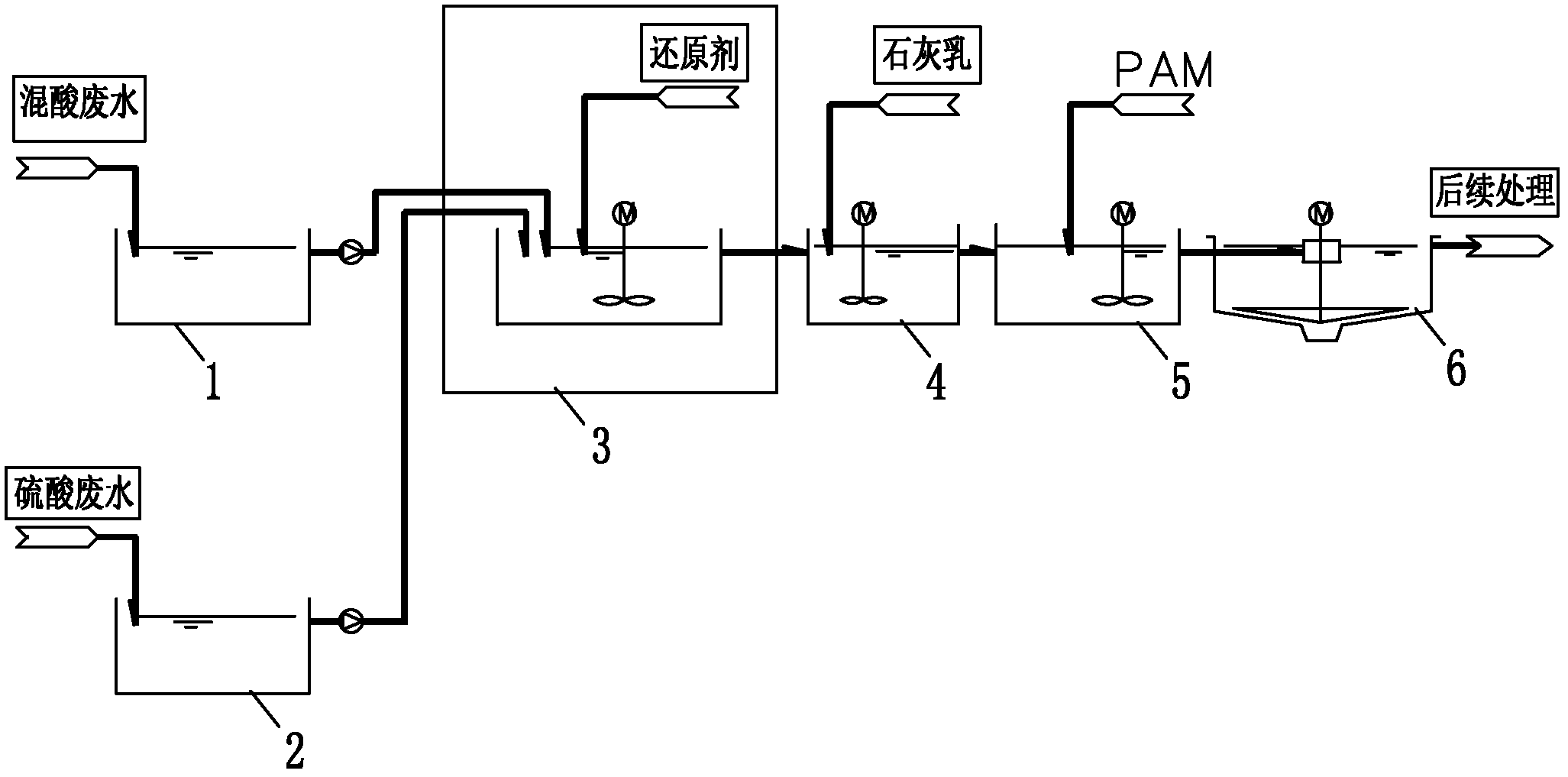

Device and method for producing sodium bisulfide by utilizing refinery dry gas

ActiveCN103754833ARaise the possibilityRealize resource utilizationSulfur compoundsResource utilizationGas composition

The invention relates to a device and method for producing sodium bisulfide by utilizing refinery dry gas. Aiming at the gas composition characteristics of the refinery dry gas, the dry gas refining desulphurization process is processed by utilizing an ultra-high gravity technology, and H2S in acid tail gas after dry gas refining desulphurization is selectively removed, so that the content of the purified H2S is over 99 percent, the purified and refined H2S is absorbed for preparing high-purity NaHS by adopting a continuous alkali liquor cycle, the concentration purity is over 42 percent, the process technology is greatly innovated, the investment is saved, secondary pollution is avoided, a process of a traditional out-dated NaHS product can be replaced, the device has a certain economic benefits and high-efficiency resource utilization rate, the H2S in the acid gas is almost recycled completely, the requirements of environment friendliness and emission are met, high social benefits are achieved, and recycling comprehensive utilization of refinery acid tail gas is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

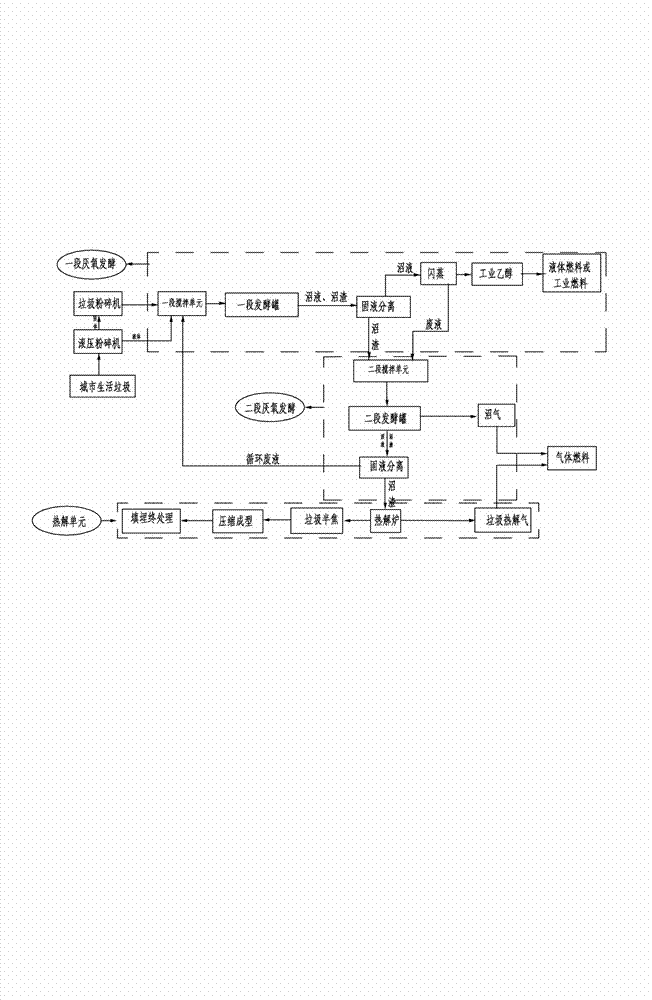

Recycling grading utilization and carbon sequestration treatment method for municipal solid waste

ActiveCN102808000ALow costReduce energy consumptionWaste processingSolid waste disposalEnvironmental engineeringCarbon sequestration

The invention belongs to the technical field of recycling grading utilization of municipal solid waste, and particularly relates to a recycling grading utilization and carbon sequestration treatment method for the municipal solid waste. The method is characterized in that a two-section anaerobic fermentation technology, a pyrolysis technology and a landfill technology are adopted in a combined way; and the method has the advantages that the municipal solid waste is innocent and is recycled, and the discharge of CO2 can be reduced by a carbon sequestration technology.

Owner:UNIV OF SCI & TECH LIAONING

Free formaldehyde eliminating agent and its prepn process

InactiveCN1526470AEliminate free formaldehydeDoes not require special environmental conditionsDispersed particle separationPhenolFORMALDEHYDE SOLUTION

The present invention is free formaldehyde eliminating agent and its preparation process. The free formaldehyde eliminating agent consists of water, stearamide, sulfuric acid, polysodium acrylate, nonyl phenol oxethyl compound, etc. and is prepared through synthesis under heating condition. When the free formaldehyde eliminating agent in 1 % is added into free formaldehyde solution of 10 ppm concentration, the free formaldehyde eliminating rate may reach 76 % in 10 min. The free formaldehyde eliminating agent is colorless, non-toxic, smell-less and suitable for use in eliminating free formaldehyde in household fitment and production of plywood and paint.

Owner:黄元銮

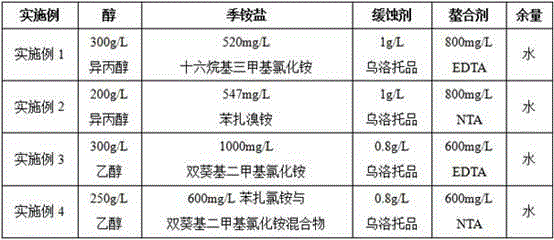

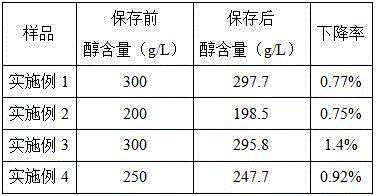

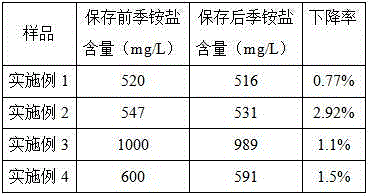

Novel disinfectant prepared from quaternary ammonium salt and alcohol

ActiveCN104521959ASynergistic bactericidal actionAvoid corrosionAntibacterial agentsBiocideSkin disinfectionDisinfectant

The invention discloses novel disinfectant prepared from quaternary ammonium salt and alcohol. The disinfectant is prepared from alcohol, quaternary ammonium salt, a corrosion inhibitor, a chelating agent and water. The novel disinfectant can be used for killing pathogenic entero becteria and staphylococcus aureus within one minute, wherein the killing log value is larger than 5; the novel disinfectant can be used for killing candida albicans and pseudomonas aeruginosa within three minutes, wherein the killing log value is larger than 5; the novel disinfectant further has an effect of killing aspergillus niger. The novel disinfectant disclosed by the invention is washing-free, has no corrosion to metal products, can be widely applied to sterilizing in the fields such as appliances and food, is free of toxic action on human bodies and animals and suitable for sterilizing the skin of the human bodies and animals, and has a long-lasting bacteriostatic action. When used for sterilizing common articles, the novel disinfectant can replace quaternary ammonium salt disinfectant to shorten the sterilization time to one minute, can take the place of alcohol and iodine disinfects when used for sterilizing the skin, can keep the antibacterial effect for a long time and can effectively protect the skin part from secondary pollution.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

High-pressure electrostatic dust collection electric field device of coal-fired unit for generating ozone and simultaneously desulfurizing and denitrating

ActiveCN102949921AEasy to collectWith the function of spark cleaningDispersed particle separationExternal electric electrostatic seperatorPower control systemClosed loop

The invention discloses a high-pressure electrostatic dust collection electric field device of a coal-fired unit for generating ozone and simultaneously desulfurizing and denitrating. The device comprises an electrostatic dust collection channel which is formed by sequentially connecting a plurality of electric fields, a neutralizing tower, a water mist spray system, a water supply device, a power control system, a spray control system and an intelligent closed-loop control system, wherein the flashover frequency of the power control system is set to be 150-10000 times / minute, the water mist spray system is arranged in the neutralizing tower, the intelligent closed-loop control system is utilized to control the power control system and the spray control system is utilized to automatically coordinated with each other, so that the high-pressure electrostatic dust collection device can be added with a denitrating function on the basis of maintaining the original electrostatic dust collecting and desulfurizing functions, and nearly no investment is required for obtaining the denitrating function. On the basis of reasonably utilizing the original equipment, the environmental protection emission requirements are satisfied, and the device has the advantages of low cost, high operation effect and obvious integral economic benefit.

Owner:XIAMEN RECH TECH

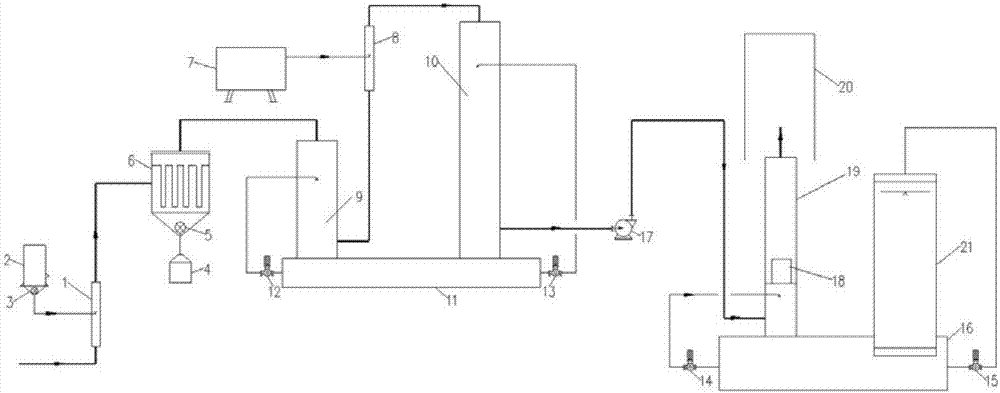

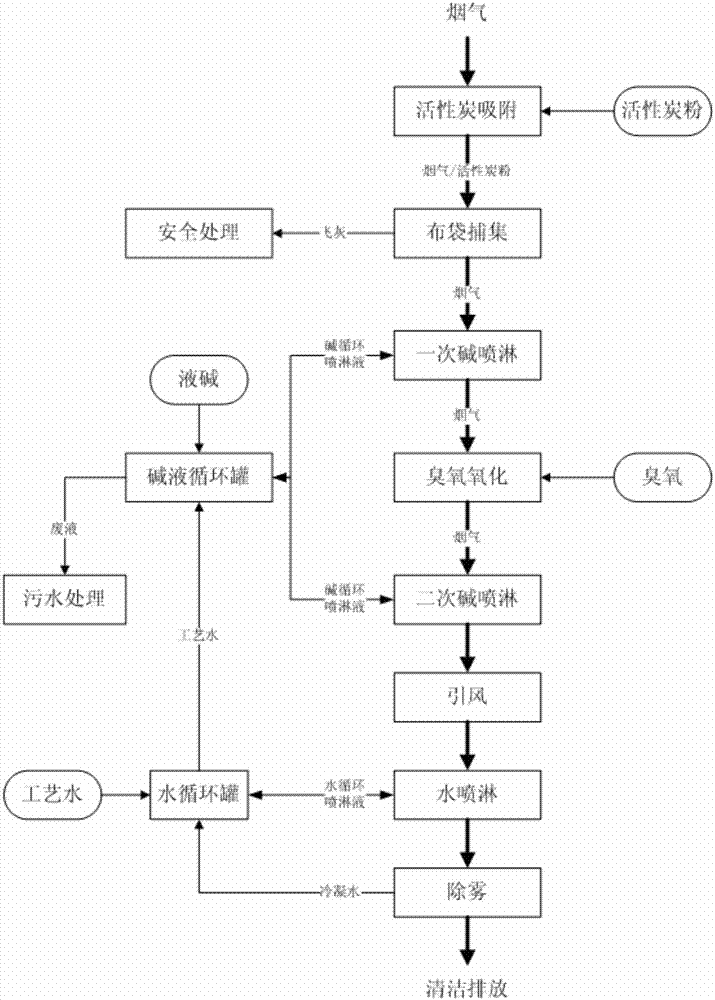

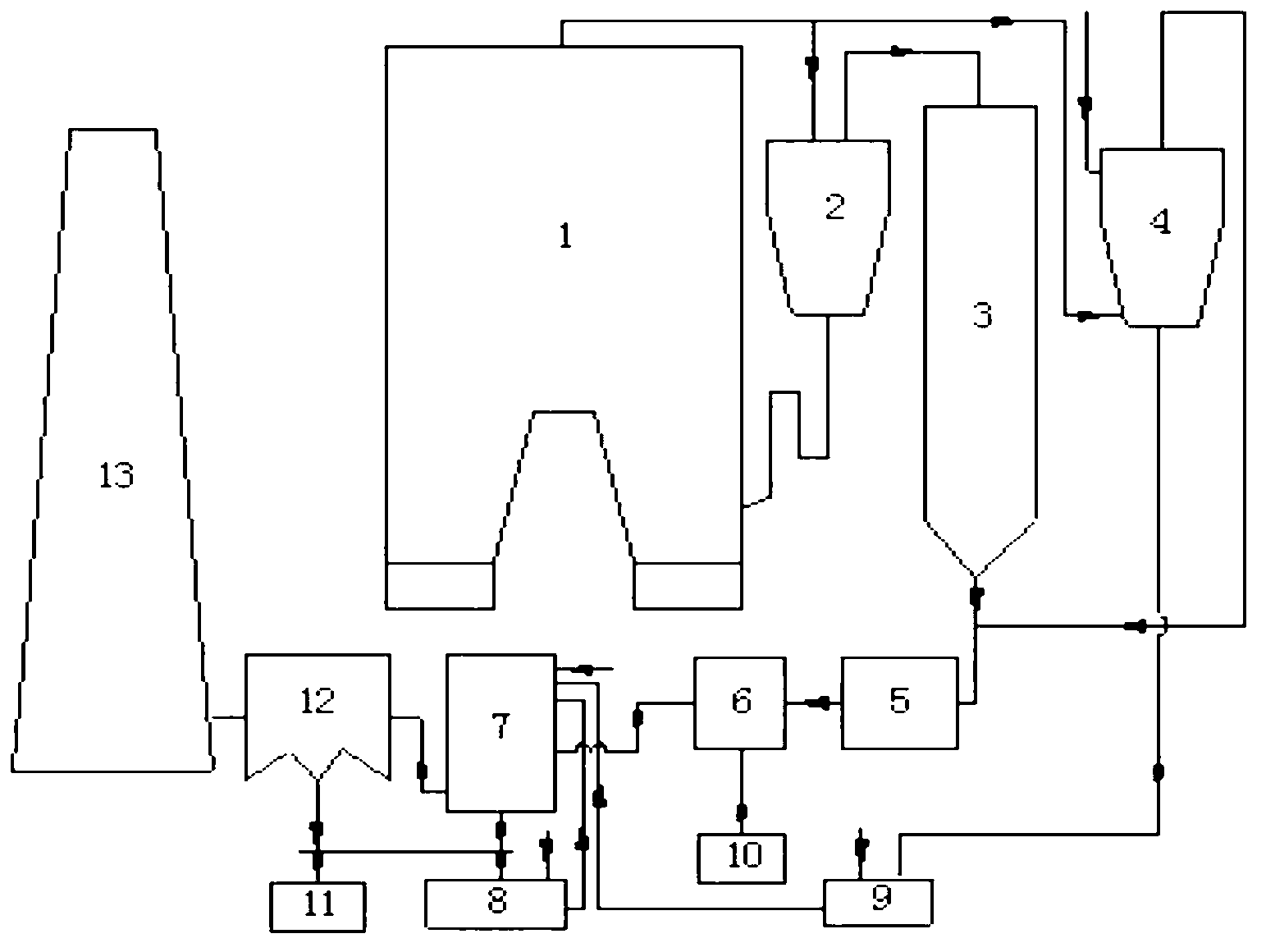

Incineration smoke gas ultralow exhaust purification treatment method and treatment system thereof

PendingCN107983126AImprove efficiencyStrong operational flexibilityDispersed particle filtrationActivated carbonPollutant

The invention discloses an incineration smoke gas ultralow exhaust purification treatment method, including treatment of sludge incineration, garbage incineration, solid waste incineration, hazardouswaste incineration smoke gas exhaust, and treatment of ceramsite kiln and cement kiln cooperated disposal waste exhaust smoke gas, and is also applicable to the treatment of exhaust smoke gas of otherindustrial kiln systems. The treatment device comprises an activated carbon powder spraying / mixing device, a cloth bag dust removing device, a primary alkali liquor spraying device, an ozone spraying / mixing device, a secondary alkali liquor spraying device, a draft fan, a water spraying device, a defogging device, a cooling tower and a chimney in sequential connection. The incineration exhaust smoke gas is connected with the activated carbon powder spraying / mixing device through a pipeline and enters the treatment device system; finally, the purified gas is exhausted through the chimney. Themethod has the beneficial effects that the operation flexibility is high; by aiming at the condition of different concentrations of contaminants in the incineration exhaust smoke gas, the addition ofreagents such as the activated carbon powder, ozone and alkali liquor and the like is regulated, so that the environment-friendly exhaust requirements can be met.

Owner:星河航天科技(天津)有限公司

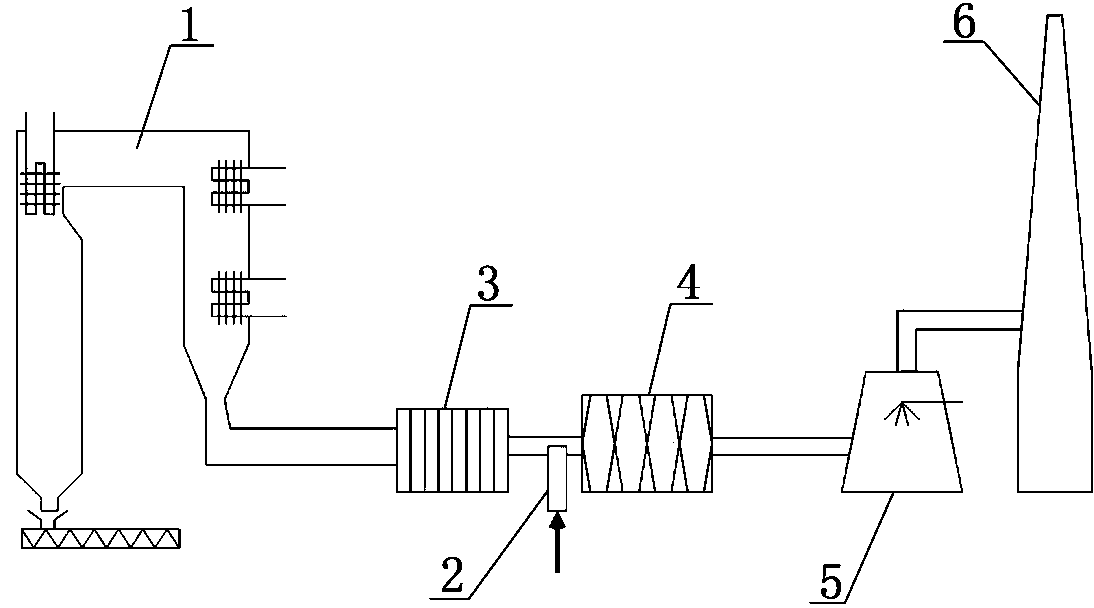

Pre-dedusting, desulfuration and denitration integrated processing device and method

PendingCN107596798AHigh catalytic efficiencyExtended service lifeDispersed particle separationIntegrated processingAir pollution

The invention belongs to the technical field of air pollution control, particularly relates to a processing device and method with pre-dedusting as well as desulfuration and denitration. The device comprises a pre-dedusting region, a desulfuration region, a buffer region and a denitration region which are connected in turn from bottom to top, wherein an air inlet connected with a flue is formed under the pre-dedusting region; an air outlet connected with a chimney is formed above the denitration region; the pre-dedusting region comprises a flue-dust retainer and a guide plate located above theflue-dust retainer; a flue-dust collecting region formed by the flue-dust retainer and the guide plate penetrates through the middle of the desulfuration region; the desulfuration region and the denitration region are connected with an ammonia gas conveying pipe and a storage silo for placing active coke; the buffer region includes a mixed ammonia cylinder wall; and the upper part, the middle part and the lower part of the mixed ammonia cylinder wall are respectively equipped with an air deflector, an ammonia spraying tube and a flow equalizing plate. This processing system is low in investment and building cost and operation cost, can switch among a desulfuration and denitration integrated mode, a desulfuration mode and a denitration mode according to components of flue, rapidly improvesflue processing amount through a parallel connection manner of reactors, so as to solve the problem that flue amount of enterprises is too large.

Owner:CISDI RES & DEV CO LTD

Preparation method of radio frequency glow discharge inductively coupled plasmas of nano powder material

ActiveCN101733405ASolve the coarse particle sizeAddress uneven distributionOxide/hydroxide preparationChemical reactionInductively coupled plasma

The invention relates to a preparation method of radio frequency glow discharge inductively coupled plasmas of a nano powder material, which comprises the following steps of: firstly, exciting and maintaining high-density radio frequency plasmas with large calibers; secondly, carrying out plasma high temperature chemical reactions to form plasma primary reactants; thirdly, condensing the plasma primary reactants into the nano powder material with high purity by adopting a two-level diffusion tube gradient shock-cooling way; and finally, collecting the nano powder material, and neutralizing the reaction tail gas. The invention achieves the continuous industrial preparation of the radio frequency plasma glow discharge nano powder material, the particle sizes and the distributions of the powder material are easy to control, the particle sizes are in normal distribution in the range of 10-50nm, the powder material is mainly in round shape and has no contamination of functional groups on the surfaces, and the purity is above 9.5%. The invention has the advantages of environment-friendliness of production process, wide application areas of products, and obvious technology values and social and economic benefits.

Owner:GUANGDONG XINGFA ALUMINUM

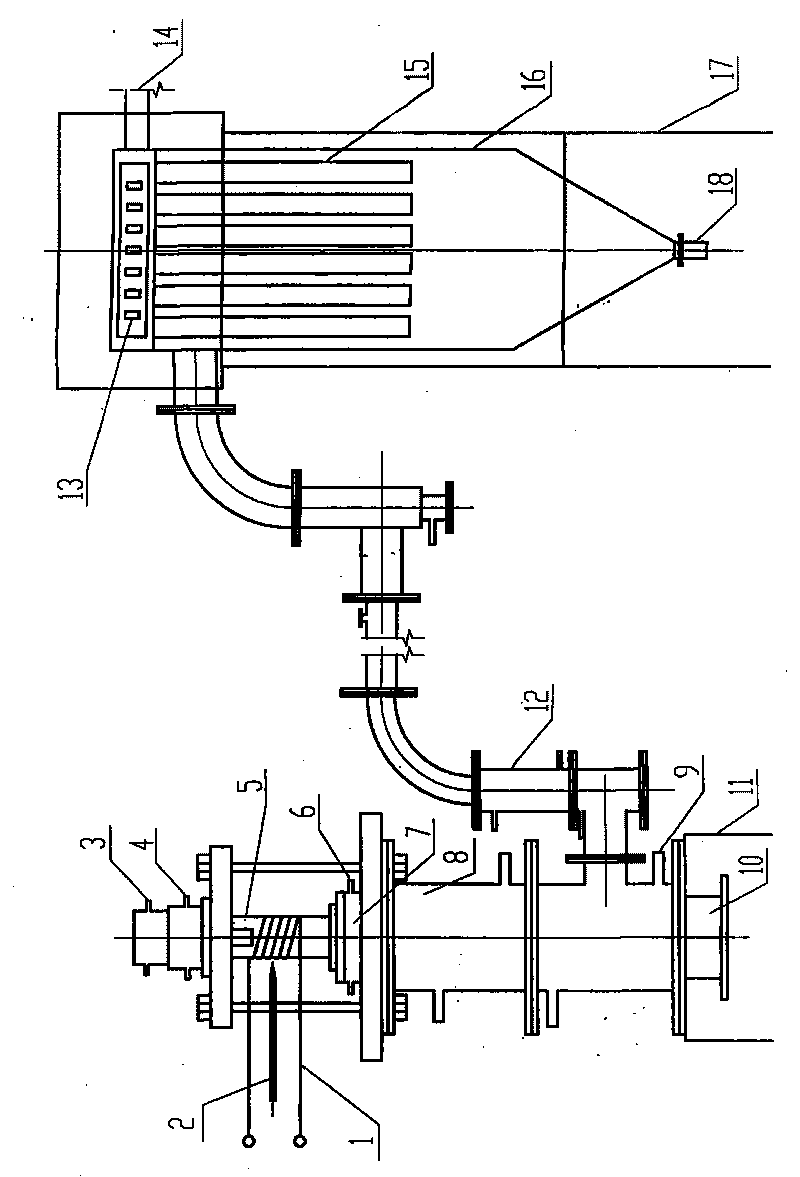

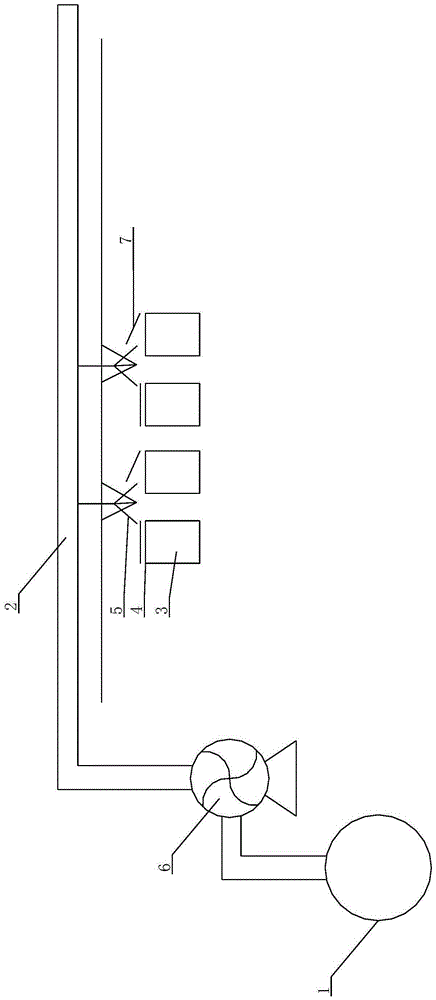

NOx control method and device for coke oven stack gas

PendingCN105199749AMeet environmental emission requirementsControl NOx contentCombustible gas coke oven heatingCoke oven detailsFlueProcess engineering

The invention relates to the technical field of coke oven equipment upgrading, in particular to a NOx control method and device for coke oven stack gas. The device comprises a stack gas main pipe communicated with a main chimney flue of a coke oven and stack gas blowing-in mechanisms arranged above dampers of coke oven stack gas shutters, wherein an induced draft fan is arranged between the stack gas main pipe and the main chimney flue of the coke oven; each stack gas blowing-in mechanism adopts a three-way turn plate switching mechanism, one channel of the mechanism is communicated with the stack gas main pipe, the other two channels are formed above the dampers of two adjacent coke oven stack gas shutters, and the stack gas blowing in direction can be changed through switching of turn plates. According to the NOx control method and device for the coke oven stack gas, the conventional coke oven production equipment is improved, so that the content of emitted NOx is controlled effectively with an air depletion method.

Owner:JINAN HONGKEXINTAI ENVIRONMENTAL PROTECTION TECH CO LTD

Spiral groove heat exchange tube

InactiveCN101033925AImprove emissions performance indicatorsImprove cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesPerformance indexEngineering

The invention relates to a kind of spiral groove heat-exchange pipe which includes stainless steel tube, and there are inward bossed spiral grooves in its surface. And the height and the width of the section shape of the stainless steel tube are unequal. In the circulation system of waste gas of automobile engine, the spiral groove whose section shape is unequal in the height and width is used in the heat-exchange tube of condenser so that making the condenser get high heat-exchange energy efficiency. Meanwhile, it's hard to accumulate filth in the tube of the inner and the outer, which greatly improves the emission performance index of automatic engine, and is satisfied with the higher requirement of environmental protection emission.

Owner:BEIJING U BRIDGE CHAOYANG

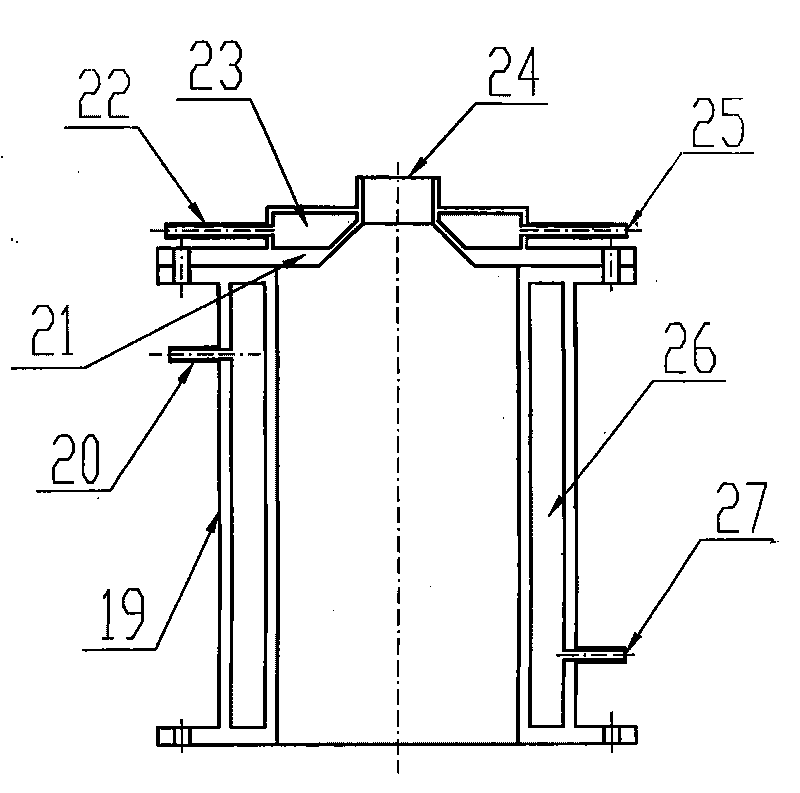

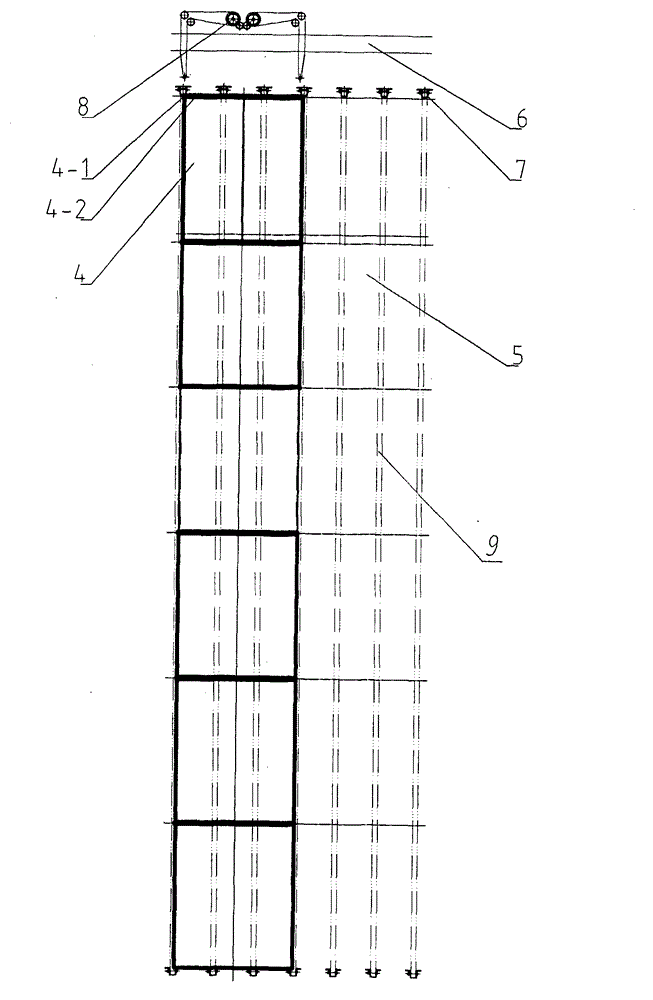

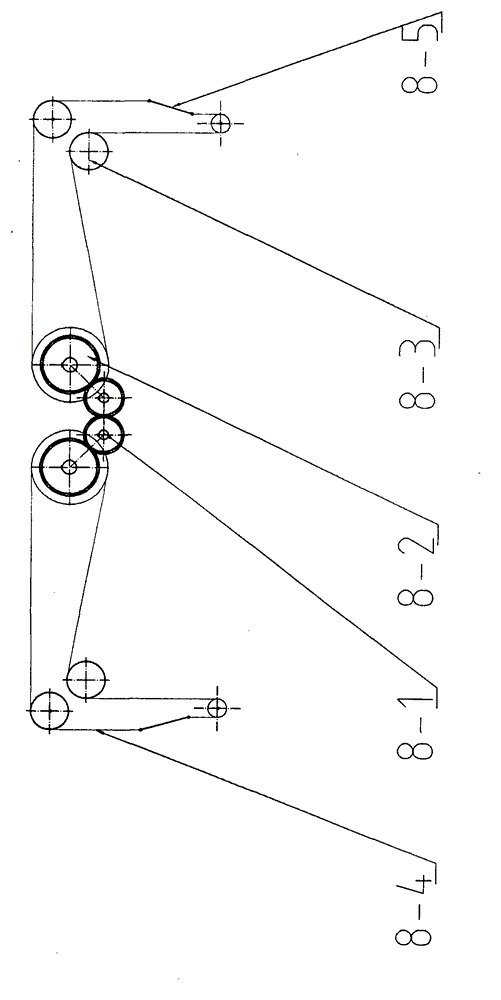

Partition-sealed deashing device of electric dust collector

InactiveCN102909135ASuppress secondary dust phenomenonEmission reductionElectrodes cleaningDischarge rateActuator

The invention relates to a partition-sealed deashing device of an electric dust collector. The partition-sealed deashing device is additionally arranged in a terminal electric field, and a sealed partition is composed of at least one or more than one electric field channel; the side of each partition is provided with a shutter sealing baffle, the opening angle of which is controlled by an electric actuator, and during operation, one of the partitions is controlled to keep deashing in a seal way, and other partitions are in opening states; and a deashing mechanism is suspended on the top of the dust collector and corresponding to the channel of each sealed partition, corresponding groups of ash scraping plates are arranged according to the amount of the electric field channels of each partition, and the ash scraping plates arranged at two sides of each electric field channel are enabled to vertically reciprocate in a way of clinging to an anode plate. Due to the adoption of a partition-sealed deashing structure, the phenomenon of secondary dust raising caused by vibration deashing of the electric dust collector is effectively suppressed, meanwhile, the problem of back corona of a conversational electric dust collector to dust with high-ratio resistance is solved, the discharging rate at an outlet is remarkably reduced, and the dust collection efficiency of the dust collector is up to over 99.9%.

Owner:北票波迪环保机械制造安装有限公司

Flue gas conditioning agent for flue gas mercury removal and composite flue gas purifying method thereof

ActiveCN103223290AImprove efficiencyReduce usageLighting and heating apparatusDispersed particle separationGas phaseSorbent

The invention discloses a flue gas conditioning agent for flue gas mercury removal and a composite flue gas purifying method thereof. The flue gas conditioning agent is ammonium bromide powder or ammonium bromide solution. The flue gas conditioning agent is put into a flue of a combustion system at 150-450 DEG C and activated by use of the temperature of the flue gas; the activated flue gas conditioning agent reinforces conversion of the elemental mercury steam to mercury oxide and particle mercury in a flue gas environment, and the activation of the flue gas conditioning agent and the oxidation and adsorption of mercury are performed at the same time; and then the flue gas mercury removal is realized by use of the existing flue gas purifying equipment of the system. According to the flue gas conditioning agent and the composite flue gas purifying method disclosed by the invention, the flue gas is subjected to trace conditioning at specific temperature, and the gas-phase oxidation or gas-solid catalytic oxidation process of the mercury steam in the flue gas environment is reinforced so as to change the state of mercury in the flue gas; and finally, the flue gas mercury removal is realized by use of the existing purifying equipment of the system. The use of an activated carbon-based adsorbent can be avoided, and the flue gas mercury removal is realized by use of the existing equipment while maintaining the reusing value of fly ash.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

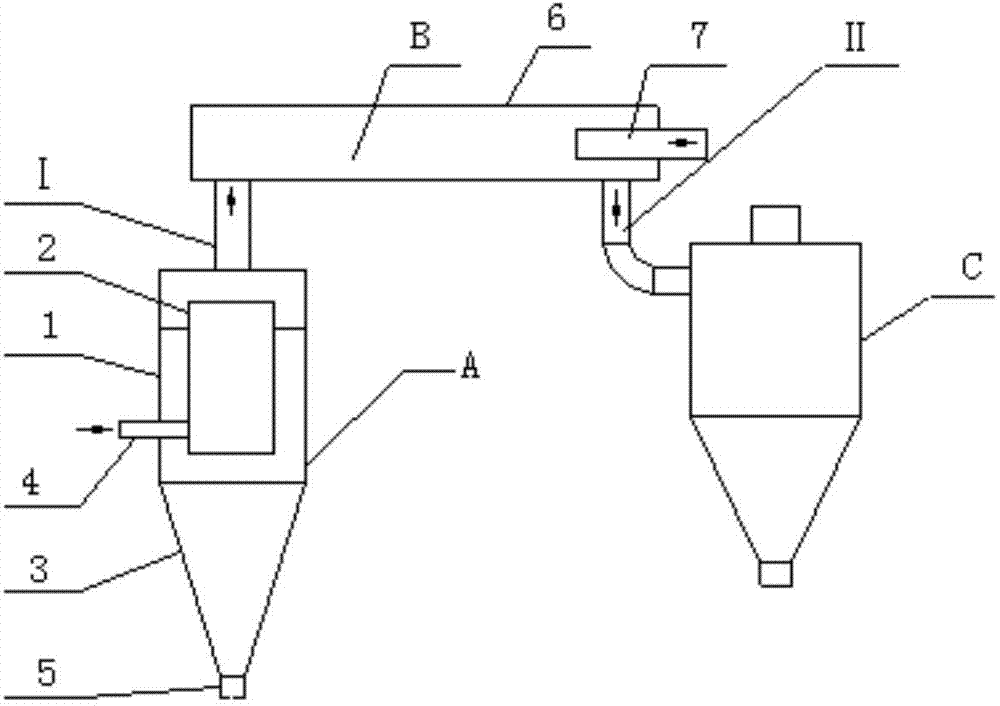

Combined dust removal device

ActiveCN104841229ASimple structureEasy to manufactureHuman health protectionCombination devicesEnvironmental resistanceIndustrial effluent

The invention belongs to the field of dust removal equipment, and discloses a combined dust removal device. The device comprises a cyclone dust collector, a horizontal re-separation segment and a dust removal bag, wherein the horizontal re-separation segment comprises a barrel; the side wall of the inlet end of the barrel is provided with a tube I; the side wall of the outlet end of the barrel is provided with a tube II; a central discharge tube is arranged at the outlet end of the barrel; the outlet of the cyclone dust collector is tangentially connected with the inlet of the barrel through the tube I; the inlet of a bag-type dust collector is tangentially connected with the outlet of the barrel through the tube II. The dust removal device provided by the invention has the advantages of small floor area, small investment, low maintenance cost, small pressure drop and long service life; the dust removing efficiency of the whole set of device can be over 99 percent, the dust removing efficiency of the device is increased, and a good dust removing effect is achieved; the combined dust removal device can meet the current environmental emission requirement, and can be widely applied to dust removal of industrial effluent gas from industrial kilns, boilers, flue gas and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Flue gas denitration transformation method for coal-fired generating unit

InactiveCN107869726AImprove denitrification efficiencyMeet environmental emission requirementsEmission preventionIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention belongs to the technical field of denitration transformation for power plants, and particularly relates to a flue gas denitration transformation method for a coal-fired generating unit.The method comprises the steps that according to the existing arrangement of the tail of a boiler, a SCR reactor is additionally arranged behind a BK shaft at the tail of the boiler, a SCR reactor isadditionally arranged above the inlet flue of an electric dust remover, and the SCR reactors are arranged in the mode of one boiler with two SCR reactors; flue gas is introduced into the SCR reactorsfrom the outlet horizontal flue of a coal economizer, NOx in the flue gas is removed under the combined action of ammonia and catalysts; and the purified flue gas subjected to the above treatment is introduced into an air preheater. According to the method, by adopting the SCR denitration process and transforming corresponding facilities of the boiler, the denitration efficiency is improved, the environment-friendly emission requirements of high standards are met, and the influence of coal burning on the environment is reduced.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

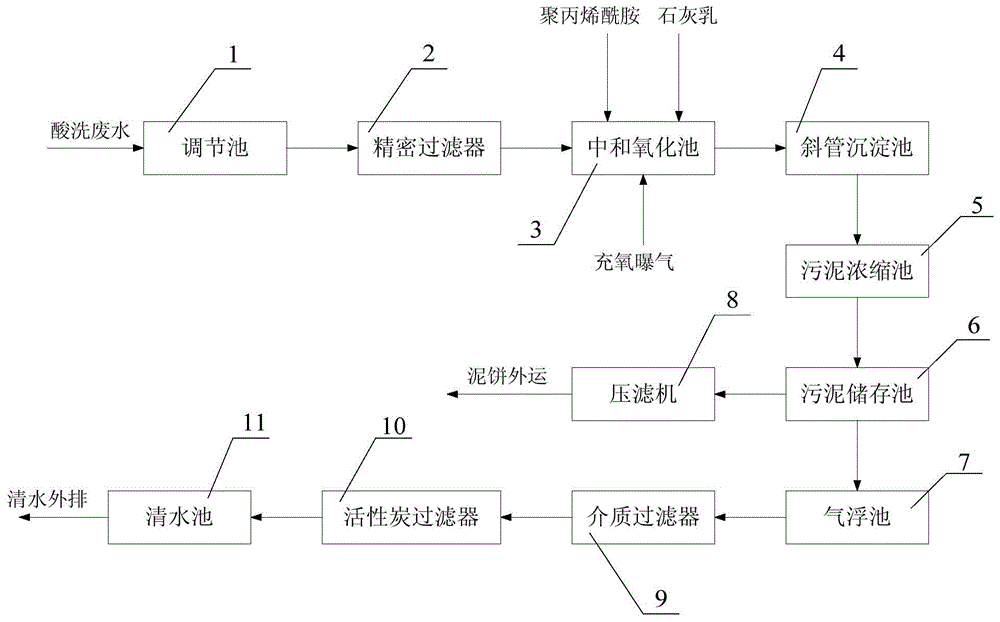

Waste liquid treatment recycling system of stainless steel pickling line

ActiveCN104891709AImprove recycling ratesSimple structureWaste water treatment from metallurgical processMultistage water/sewage treatmentSludgeActivated carbon filtration

The invention discloses a waste liquid treatment recycling system of a stainless steel pickling line. The waste liquid treatment recycling system mainly comprises a regulating reservoir, a precision filter, a neutralizing oxidation pond, an oblique pipe precipitation pond, a sludge concentration pond, a sludge storage pond, an air floatation pond, a press filter, a medium filter, an active carbon filter and a clean water pond, and is characterized in that pickling waste water flows into the regulating reservoir, the regulating reservoir is connected with the precision filter, the precision filter is connected with the neutralizing oxidation pond, the neutralizing oxidation pond is connected with the oblique pipe precipitation pond, the oblique pipe precipitation pond is connected with the sludge concentration pond, the sludge concentration pond is connected with the sludge storage pond, the sludge storage pond extends in two circuits, one circuit is connected to an external mud cake transport device by virtue of the press filter, and the other circuit is connected to a clean water discharge pipe sequentially by virtue of the air floatation pond, the medium filter, the active carbon filter and the clean water pond.

Owner:JIANGSU SERO ANTICORROSION EQUIP

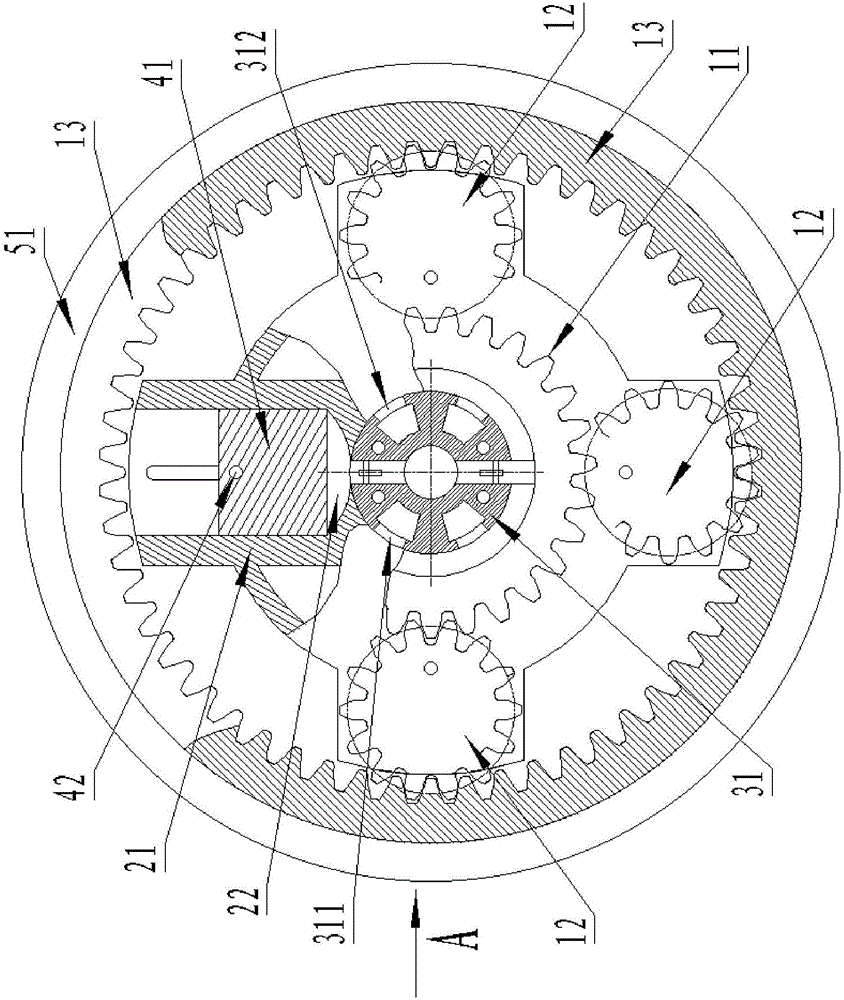

Planet gear and rotating cylinder engine

The invention provides a planet gear and rotating cylinder engine, comprising a planet gear component, a rotating cylinder component, a central distributing valve and a piston component; the rotating cylinder component in the planet gear and rotating cylinder engine rotates by centering on the central distributing valve, and a cylinder finishes a four-stroke cycle per rotation around the central distributing valve. When doing work, a piston pushes a planet gear to run along an inner gear ring and drives a sun gear to output power out. The planet gear and rotating cylinder engine has the advantages of good simplicity, good reliability, good working stability and high power.

Owner:顾永强 +1

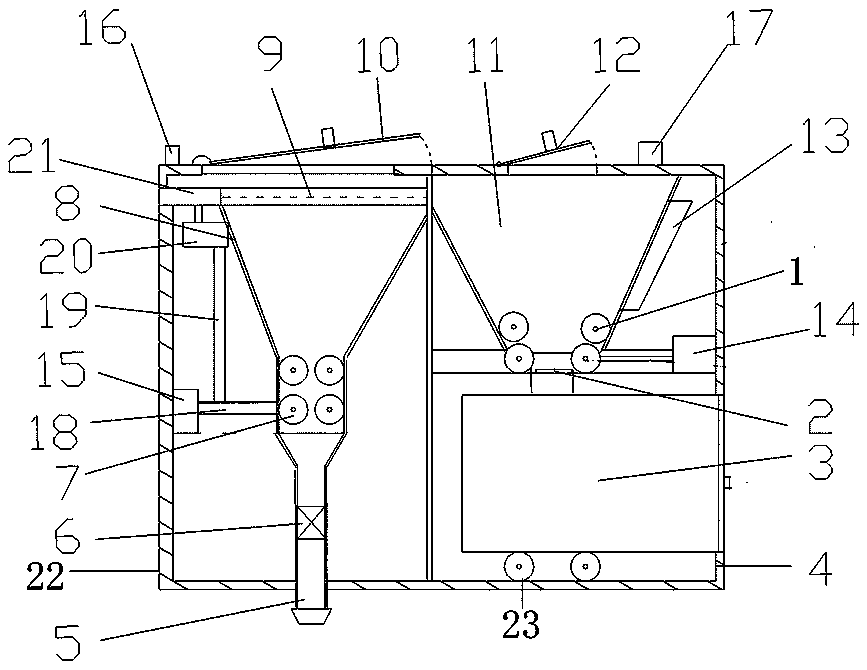

Ceramic filter tube denitration and desulfurization dust remover

The invention discloses a ceramic filter tube denitration and desulfurization dust remover. A ceramic filter tube (7) is arranged at the left inner end of a dust remover shell body (16); a middle boxbody (6) is arranged at the lower right inner end of the dust remover shell body (16); an upper box body (9) is arranged at the upper inner end of the dust remover shell body (16); an ash bucket (2) is arranged at the lower end of the dust remover shell body (16); a star-shaped ash unloading valve (15) is connected to a lower opening part of the ash bucket (2) through a flange; a venturi tube (8)is arranged at the opening part of the ceramic filter tube (7); the ceramic filter tube (7) and the venturi tube (8) are fixed on a porous plate in the upper box body (9) by utilizing a pressing platethrough bolt connection; a pulse ash cleaning device (11) and an offline valve (10) are mounted at the top of the upper box body (9); a catalyst (20) is arranged in a ceramic fiber filter tube on thesurface of the ceramic filter tube (7). The ceramic filter tube denitration and desulfurization dust remover has the advantages of novel design, simple technology, small occupied area of equipment, small equipment investment and good dust-removing, denitration and desulfurization effects.

Owner:河南绿源新星环保设备有限公司

Treatment method of oily sludge

ActiveCN105859071BReduce recycling costsHigh content of mineral elementsSludge treatment by thermal conditioningSludge treatment by pyrolysisRecovery methodOil sludge

Owner:KARAMAY AOZE IND & TRADE

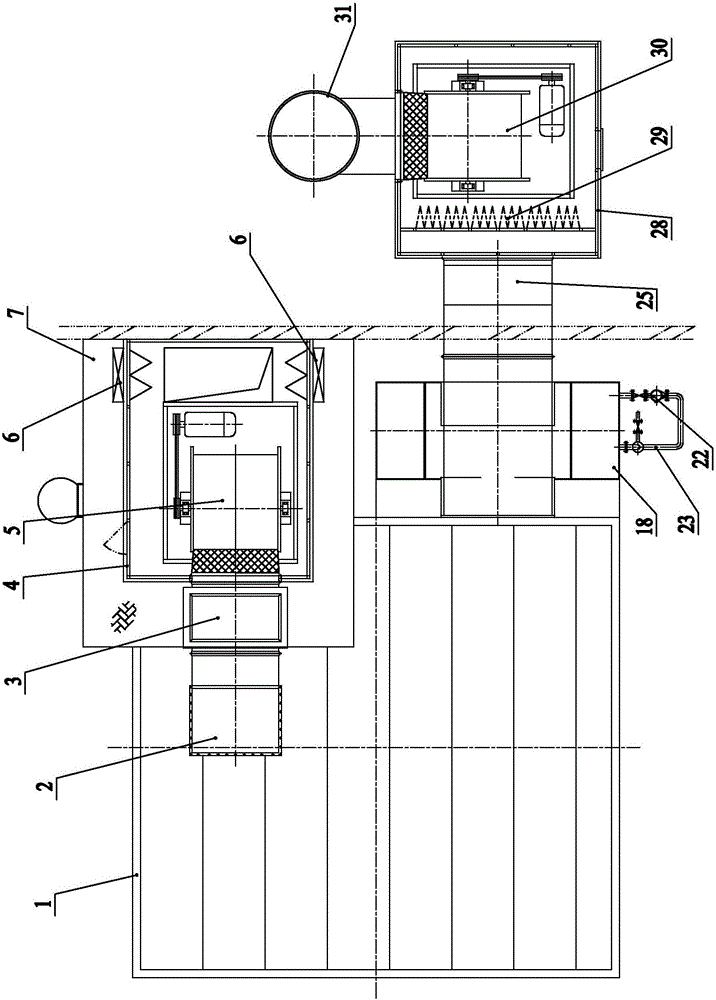

Oil spraying type multifunctional surface treatment equipment

ActiveCN105903625AImprove the operating environmentMeet environmental emission requirementsSpraying apparatusPretreated surfacesInterior spaceGrating

The invention relates to oil spraying type multifunctional surface treatment equipment. The inner space of a chamber is divided into a static pressure chamber and a spray chamber; an air outlet of a fresh hot air feeding circulating device is communicated with the static pressure chamber; the lower part of the spray chamber is communicated with an air return hole of the fresh hot air feeding circulating device through a hot air circulating return pipe; a hot air circulating feeding electric valve is mounted on the hot air circulating return pipe; a door is mounted on the front side wall of the spray chamber; three-dimensional lifting operation platforms are arranged on the left and right two sides in the spray chamber, respectively; an air drafting chamber is arranged under each of the three-dimensional lifting operation platforms; a hollow steel grating is arranged at the top of each air drafting chamber; spraying filtering cotton is arranged under each steel grating; an air outlet of each air drafting chamber is connected with an inlet of an oil spraying type paint mist purifying device through an oil-spraying paint mist purifying air-inlet electric valve via an intake pipe; an outlet of the oil-spraying paint mist purifying device is connected with an inlet of an active carbon filtering device through an exhaust pipe; a draining pipe is mounted at an outlet of the active carbon filtering device. The oil spraying type multifunctional surface treatment equipment can reduce the turnover of workpieces, can improve operation environment, can meet the environment-friendly requirement and can save investment.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

Chlorine and sulfur containing tail gas processing device and tail gas processing method thereof

InactiveCN105413435AMeet environmental emission requirementsSimple processGas treatmentDispersed particle separationThermal energyEnvironmental resistance

The invention provides a chlorine and sulfur containing tail gas processing device and a tail gas processing method thereof. The device comprises a heat exchanger, an absorbing tower, a gas-liquid separator, and an adsorption tower; wherein the heat exchanger, absorbing tower, gas-liquid separator, and adsorption tower are communicated in the air passage. The upper section of the absorbing tower adopts a water circulation treatment mode, and a circulating water pump is used to increase the pressure. The lower second of the absorbing tower adopts an alkali liquid circulation treatment mode, the pressure of alkali liquid is increased by a pump, then alkali liquid is pumped into an alkali liquid heater and is heated by the alkali liquid heater; and finally the alkali liquid is introduced to the lower section of the absorbing tower and is cyclically used. The device can recover the thermal energy of tail gas through the heat exchanger; at the same time, the high temperature tail gas, which contains high concentration corrosive mediums such as hydrogen chloride, sulfur dioxide, chlorine gas, and the like, is effectively processed through alkali liquid absorption; and the processed tail gas can reach the emission standards.

Owner:BEIJING HUAFU ENG

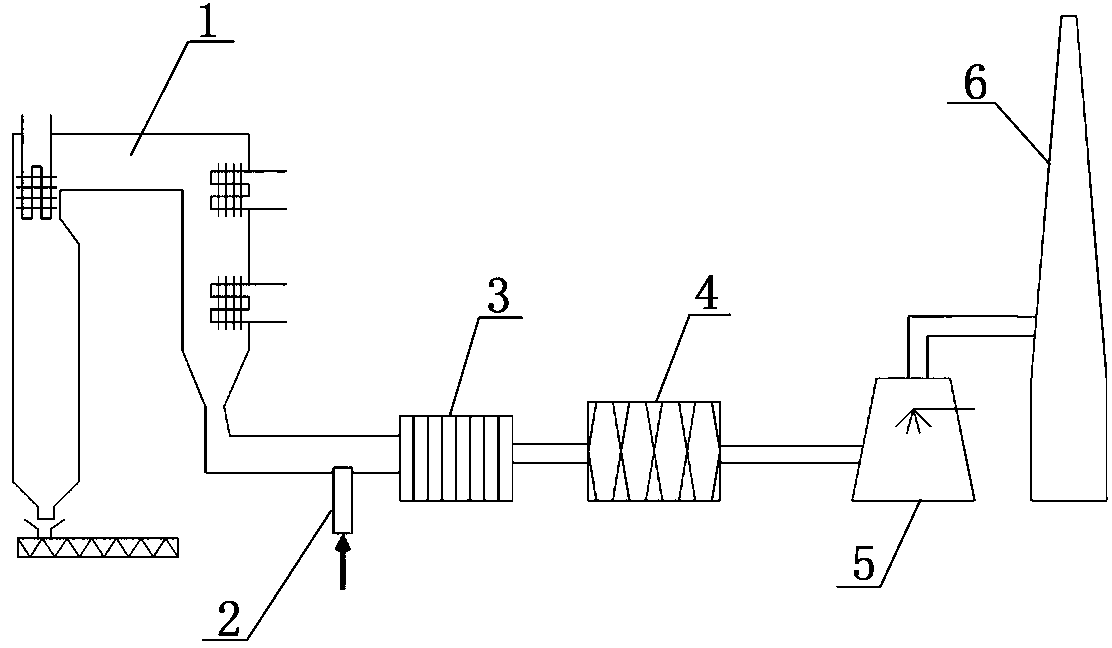

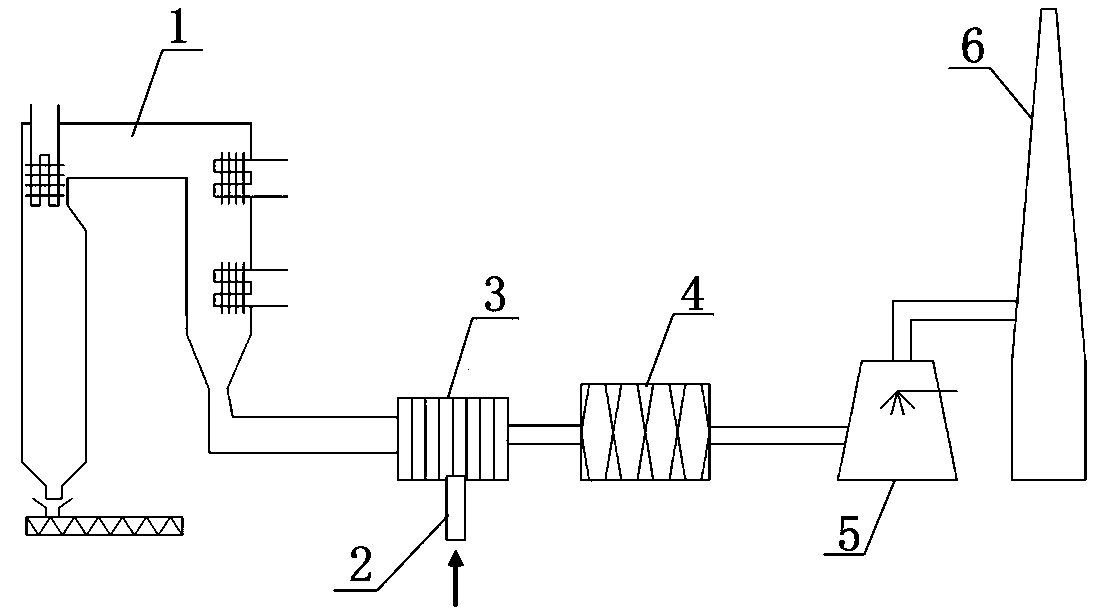

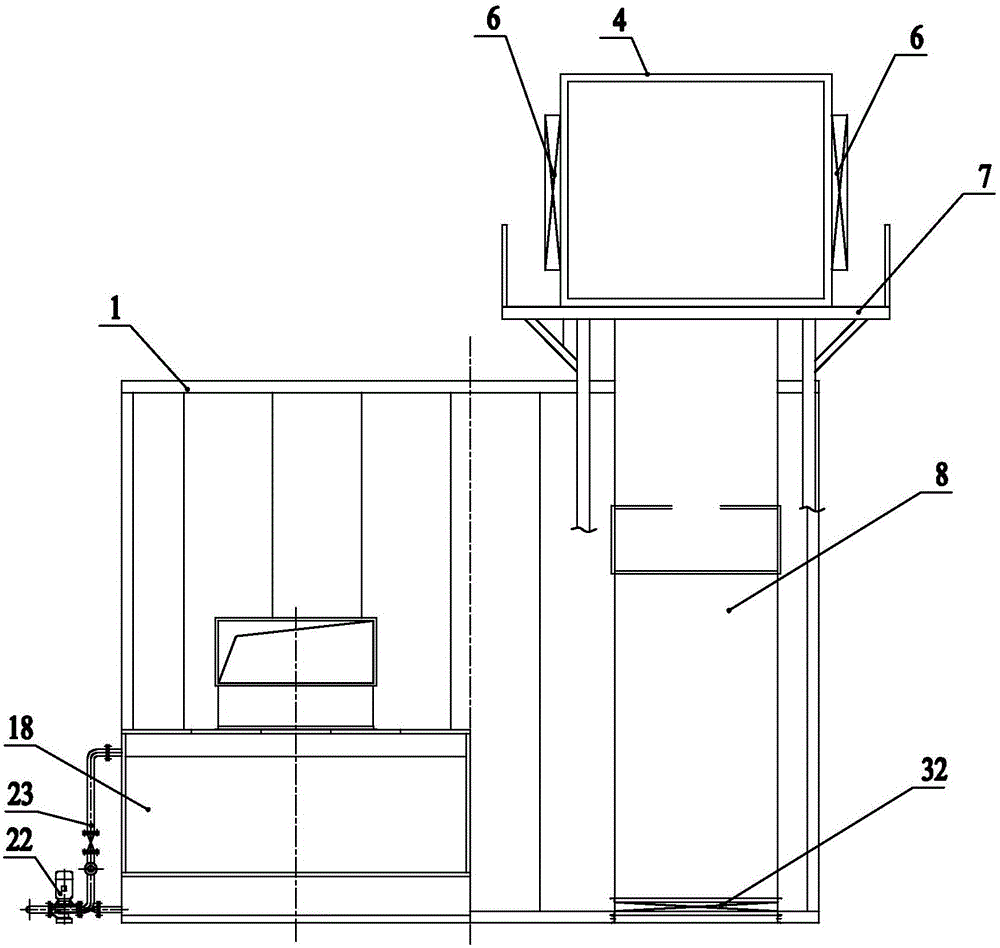

Dry-process fine continuous desulfurization device and method for CFB (Circulating Fluidized Bed) boiler

ActiveCN103239984ASimple preparation processLow investment and operating costsLighting and heating apparatusDispersed particle separationFluidized bedBaghouse

The invention relates to a dry-process fine continuous desulfurization device and method for a CFB boiler and belongs to the desulfurization field of boilers. The device consists of a furnace hearth, a cyclone separator, a tail flue path, a lime stone roaster, an air pre-heater, a preliminary dust collector, an SO2 absorber, a circulating liquid tank, a digesting tank, a dust storeroom a, a dust storeroom b, a bag dust collector and a chimney. The method is characterized in that the lime stone roaster and the cyclone separator are arranged in parallel, lime stone powder is sprayed in the roaster from the left upper part, a part of flue gas at the outlet of the furnace hearth is blown in the roaster from the left lower part; CaO decomposed after roasting is collected at the bottom of the roaster and fed to the digesting tank for semi-dry process desulfurization; and decomposed CO2 is exhausted from the top part of the roaster together with the flue gas, and then is mixed with the flue gas in front of the air pre-heater, then passes through the air pre-heater, the preliminary dust collector, the desulfurization absorber, the bag dust collector in sequence and is finally exhausted from the chimney. According to the method, the used desulfurization agent is simple in preparation process, investment and operation cost are low; and the prepared desulfurization agent CaO can satisfy use demand of the semi-dry process desulfurization in the continuous process; meanwhile, the yield of the desulfurization agent can be adjusted by controlling the adding amount of the lime stone powder according to the needs; moreover, the continuous desulfurization process combining the in-furnace dry-process desulfurization and the tail semi-dry process desulfurization can be used for improving the utilization rate and desulfurization efficiency of the desulfurization agent, so that the enterprises can operate economically and the environment-friendly emission requirements can be satisfied.

Owner:山西平朔煤矸石发电有限责任公司

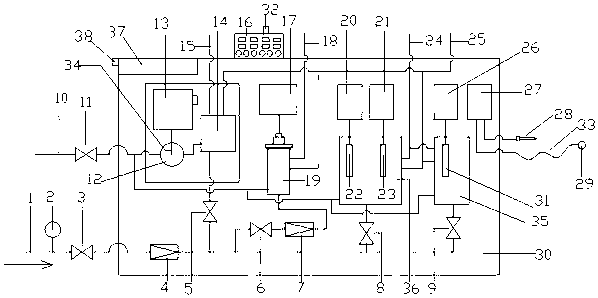

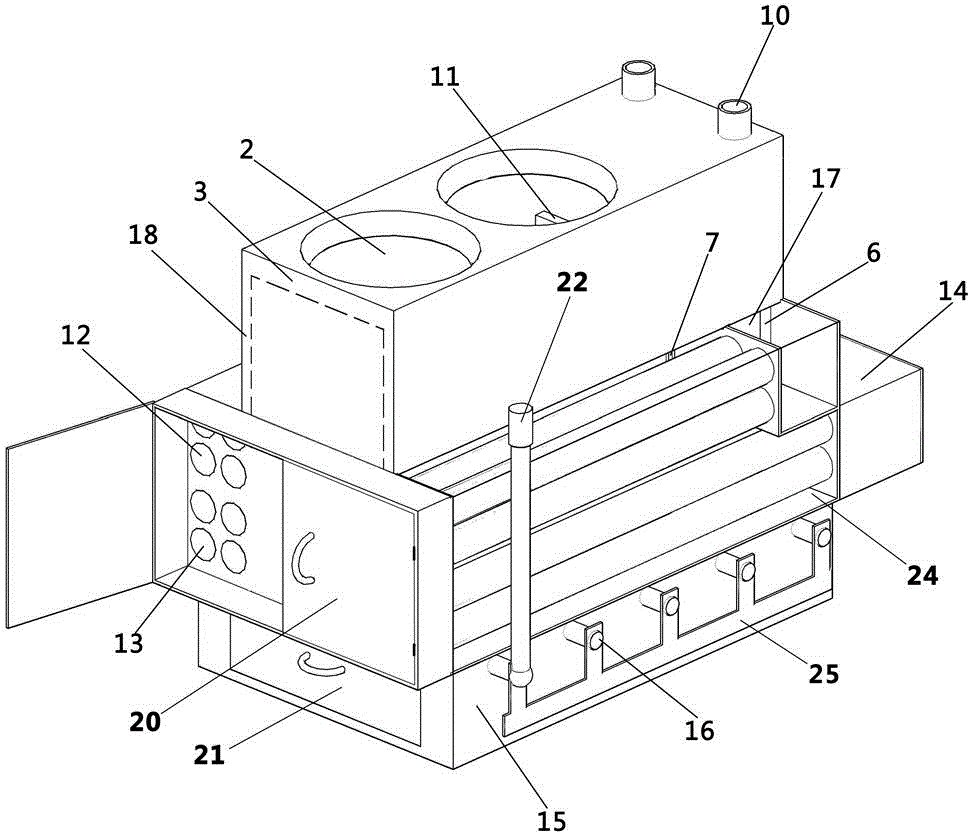

Multifunctional water quality testing equipment

InactiveCN110161199AGuaranteed accuracyMeet environmental emission requirementsMaterial resistanceTesting water hardnessPhysicsIon

The invention discloses multifunctional water quality testing equipment. The equipment includes a water inlet detection port, a flowmeter, a hardness detection sampling pipe, a hardness analyzer, a hardness detection water storage tank, a control unit, a power supply interface, a dissolved oxygen detector, a dissolved oxygen detection chamber, a conductivity tester, a PH value tester, a drainage outlet, a chloride ion detector, a temperature water level detector, a detection equipment body, a third measuring electrode, a temperature pen, a water level sensor, a water level wire harness, a hardness detection head, a chloride ion detection chamber and a conductivity detection chamber. Through the arrangement of the flowmeter, the hardness analyzer, the dissolved oxygen detector, the conductivity tester, the PH value tester, the chloride ion detector and the temperature water level detector, comprehensive detection can be performed on the flow, temperature, water level, hardness, dissolved oxygen, conductivity, PH value and chloride ion parameters of water quality, and therefore, water quality situations can be comprehensively analyzed; and through the arrangement of a cleaning waterinlet, cleaning can be performed on pipelines of the equipment, so that residual impurity components of the equipment after each detection can be clear, and the accuracy of sampling data when the equipment is used again can be ensured.

Owner:YANCHENG INST OF IND TECH

Cleaning fluid for book cleaning and preparation method thereof

InactiveCN109135947ASimple preparation processEasy to operateOrganic detergent compounding agentsNon-ionic surface-active compoundsFiberPolyvinyl alcohol

The invention discloses cleaning fluid for book cleaning and a preparation method thereof. The cleaning fluid is prepared from the following raw materials: a surfactant, chitosan grafted keratin / polyvinyl alcohol fiber powder, polyvinylpyrrolidone, carboxymethylcellulose, sodium citrate, a defoaming agent, rosemary essential oil and distilled water. The preparation method comprises the following steps: (1) treating the distilled water to prepare pretreated distilled water; (2) mixing the polyvinylpyrrolidone, the carboxymethylcellulose, the sodium citrate and the surfactant, adding the mixtureinto the pretreated distilled water, heating and stirring to dissolve the mixture, and preparing a solution A; and (3) mixing the defoaming agent, the rosemary essential oil and the chitosan graftedkeratin / polyvinyl alcohol fiber powder, adding the mixture into the solution A, heating the solution, then stirring the solution at a high speed, and cooling the product to obtain the cleaning fluid.According to the cleaning fluid prepared by the preparation method disclosed by the invention, the preparation process is simple, and the operation is convenient; the selected raw materials are pollution-free to the environment; waste fluid obtained by cleaning is convenient to treat and can meet an environmentally-friendly discharging requirement; and furthermore, the cleaning fluid is high in cleaning capacity, high in cleaning speed and long in service life.

Owner:蚌埠心里程教育科技有限公司

Domestic garbage crushing and recycling device

PendingCN109569825AEasy to handleEasy to recyclePlastic recyclingGrain treatmentsDrive shaftGear wheel

The invention provides a domestic garbage crushing and recycling device and aims to crush or recycle the domestic garbage at home and prevent environment pollution. The domestic garbage crushing and recycling device comprises a crushing box, wherein the crushing box comprises a box cover a, a motor, a crushing hopper, a water discharging pipe, crushing shafts, crushing cutters, a transmission shaft, a gear shaft, a water pipe and a water pump; the box cover a is arranged at the top of the crushing box; a crushing box control switch is mounted beside the box cover a and is connected with the motor; a circle of annular water pipe is mounted at the position, close to the box cover, in the crushing box; small water outlets are uniformly distributed on the water pipe; the crushing hopper is mounted under the water pipe; the crushing shafts are mounted at the lower part of the crushing hopper; the crushing cutters are mounted on the crushing shafts; the ends of the crushing shafts are connected with the transmission shaft; the other end of the transmission shaft is connected with the motor; the middle section of the transmission shaft is connected with the lower end of the gear shaft; the upper end of the gear shaft is connected with the water pump; the water pump is connected with the water pipe through a water inlet pipe; and the bottom of the crushing hopper is connected with thewater discharging pipe.

Owner:包头市五兴节能科技有限公司

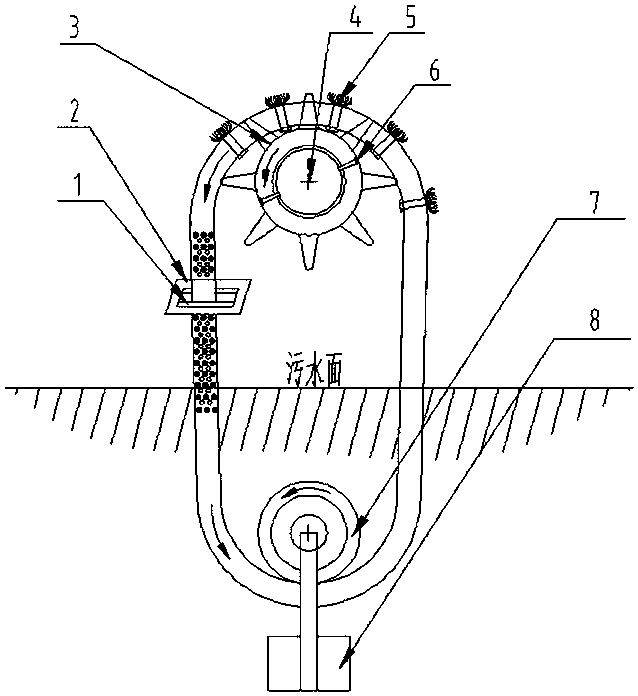

Multiple industrial sewage filtration method

InactiveCN108623026AProtect running equipmentMeet environmental emission requirementsFatty/oily/floating substances removal devicesTreatment involving filtrationFiltrationWastewater

The invention provides a multiple industrial sewage filtration method, which comprises the following steps: (1) removing heavy oil impurities from industrial wastewater in a sedimentation tank with asteel strip oil scraper; (2) installing a corrugated filter screen on a water inlet at the bottom of a long shaft pump for transporting industrial sewage, so as to prevent strip sundries overflowing from an overflow pool from entering into a transport cycle and then entering a production system through water equipment inside body; (3) installing a movable magnetic mesh grille on the periphery inner side of the overflow pool so as to control all kinds of sundries around the overflow pool to directly flow out and then enter into a reservoir; and (4) adding a plastic decontamination floating neton the surface of industrial sewage at the periphery in the sedimentation tank so as to ensure that sundries and dirty oil on the surface of industrial sewage are adsorbed by the decontamination floating net to the maximum extent and then do not enter the next cleaning process. The multiple industrial sewage filtration method can protect operating equipment in the production system, and ensure that the standard of industrial wastewater recycling again is reached and the environmental emission requirements are met.

Owner:NANJING MEISHAN METALLURGY DEV +1

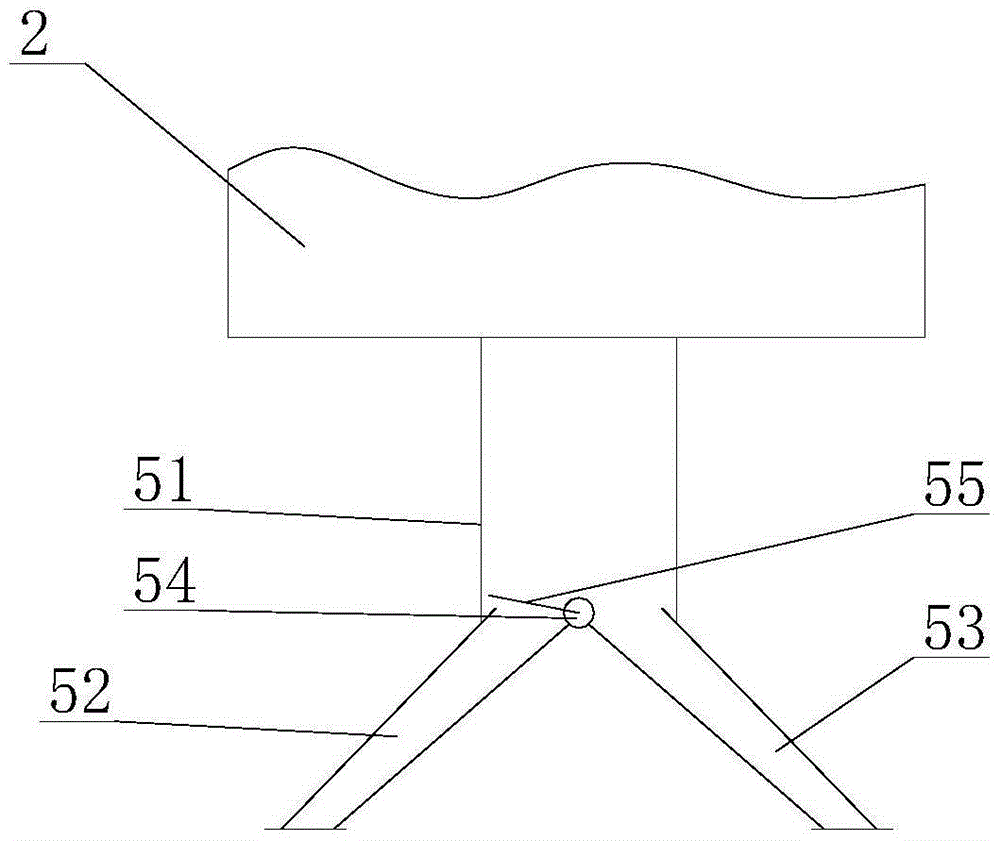

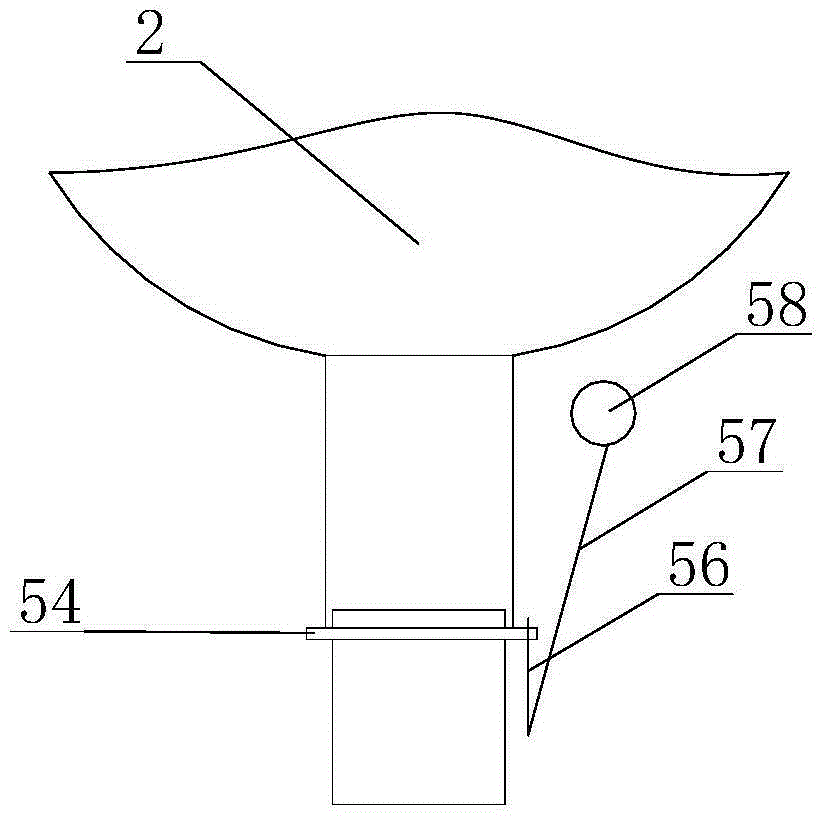

Steel slag crushing, classifying and sorting continuous treatment device and method

PendingCN111589576AImprove processing efficiencyMeet environmental emission requirementsSolid separationSlagControl system

The invention relates to a steel slag crushing, classifying and sorting continuous treatment device and method. The steel slag crushing, classifying and sorting continuous treatment device comprises afeeding system (1), a hopper (2), a longitudinal high-speed rotation crushing system (3), an iron removing system (4), an air classifying and sorting system (5), a discharging system (6), a materialbin (7), a dust collecting system (8) and a control system (9). Steel slag falls into the high-speed rotation crushing system (3) from the hopper (2), through high-speed rotation and mutual collisionbetween steel rods in the high-speed rotation crushing system (3) and the steel slag, the crushing effect is achieved, the crushed steel slag falls into the sorting system (5), and due to gravity difference, steel slag of different grain size grades are sorted out and enter the material bin (7) from respective material outlets. The whole process is collaboratively and continuously conducted, and the steel slag treatment efficiency is improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Horizontal condensation type briquette coal heating stove

ActiveCN105091338AReduce volumeRealize cross-flow condensation heat transferAir heatersSustainable buildingsCombustion chamberProcess engineering

The invention relates to a horizontal condensation type briquette coal heating stove. The horizontal condensation type briquette coal heating stove is characterized in that a combustion chamber is formed in a horizontal type stove body; a fire grate and an ash storage chamber are arranged at the lower part of the combustion chamber; a combustion chamber water sleeve which is defined by a front stove wall water sleeve layer, a side stove wall water sleeve layer and a rear stove wall water sleeve layer is arranged at the periphery of the combustion chamber; a wall-clamping water sleeve layer which is in parallel arrangement with the rear stove wall water sleeve layer is arranged in the combustion chamber; a high-temperature chamber and a smoke-gas separating cavity are arranged between the wall-clamping water sleeve layer and the rear stove wall water sleeve layer; two sides of the stove body are respectively provided with a heat exchanger; a tube plate type condenser and / or a barrier wall type condenser are / is arranged in each heat exchanger. According to the horizontal condensation type briquette coal heating stove disclosed by the invention, more than 82 percent of heat efficiency can be achieved, the horizontal condensation type briquette coal heating stove is suitable for burning smoke-free briquette coal, compared with burning of soft coal in equal amount, the horizontal condensation type briquette coal heating stove has the advantages that the emission of 86 percent of smoke, 62 percent of sulfur dioxide and 35 percent of nitrogen oxide can be reduced, and the emission reduction effect is extremely obvious.

Owner:河北盛淼安全技术工程有限公司

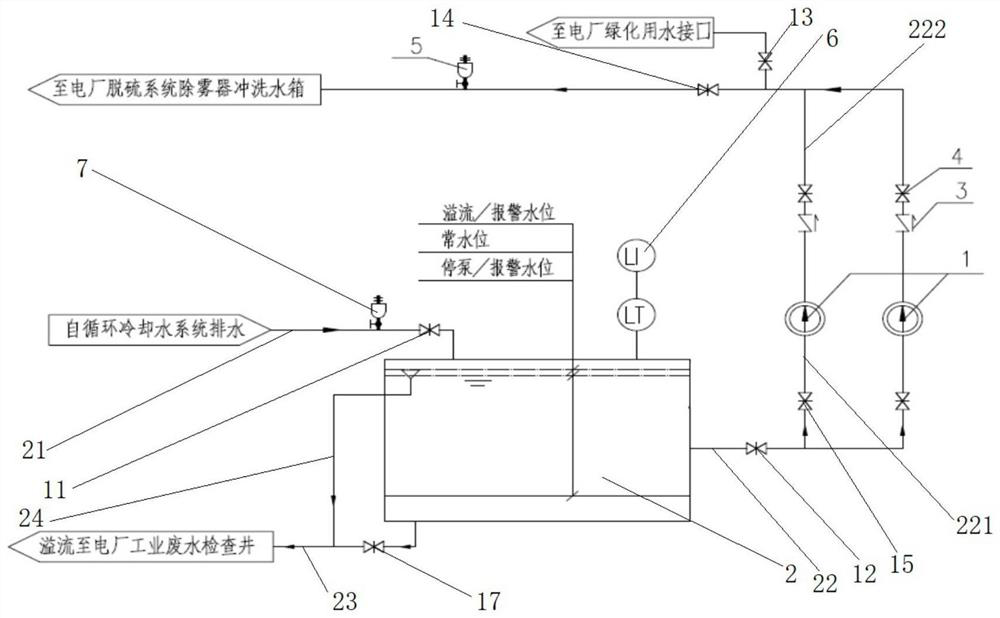

Circular cooling water draining reusing system

PendingCN111678288AReduce water consumptionGuaranteed uptimeLighting and heating apparatusCooling fluid circulationWater useProcess systems

The invention discloses a circular cooling water draining reusing system. The system comprises a collecting water tank, a water inlet of the collecting water tank is connected with a circular coolingwater draining outlet, a water outlet of the collecting water tank is connected to a flushing water tank of a water using system for greening and a demister for desulfuration, a liquidometer is arranged in the collecting water tank, and according to the circular cooling water draining reusing system, drained cooling water of a direct flowing cooling water supply system and a circular cooling watersupply system of all process systems of a carbon capture platform can be subjected to reasonable circular reuse.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com