NOx control method and device for coke oven stack gas

A technology of nitrogen oxides and control methods, which is applied to coke ovens, coke oven heating, coke oven parts, etc., can solve the problems of no very effective control methods, high operating costs, and huge investment in treatment equipment to meet environmental protection requirements. Effects of Emissions Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, a coke oven chimney exhaust gas nitrogen oxide control method includes:

[0027] A. Lay a waste gas main pipe above the coke oven waste gas switch, use the induced draft fan to draw the waste gas in the coke oven main flue, and send it into the waste gas main pipe;

[0028] B. A plurality of exhaust gas blowing mechanisms are arranged below the exhaust gas main pipe. The exhaust gas blowing mechanism includes a three-way housing, and the upper end passage of the three-way housing communicates with the exhaust gas main pipe. The three-way housings are respectively arranged downwards The left fork pipe and the right fork pipe are symmetrical to each other, the connection of the left fork pipe and the right fork pipe is provided with an exchange flap, and the exchange flap is externally connected with a rocker arm, and is linked with the coke oven exchange bar;

[0029] C. When the coke oven exchange bar pulls the damper of the exhaust gas switch, it al...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the nitrogen oxide content signal detected by the chimney gas nitrogen oxide online detection device is connected to the control system, which can automatically control the speed of the induced draft fan, thereby realizing automatic adjustment of coke oven chimney gas nitrogen. The purpose of oxide content.

Embodiment 3

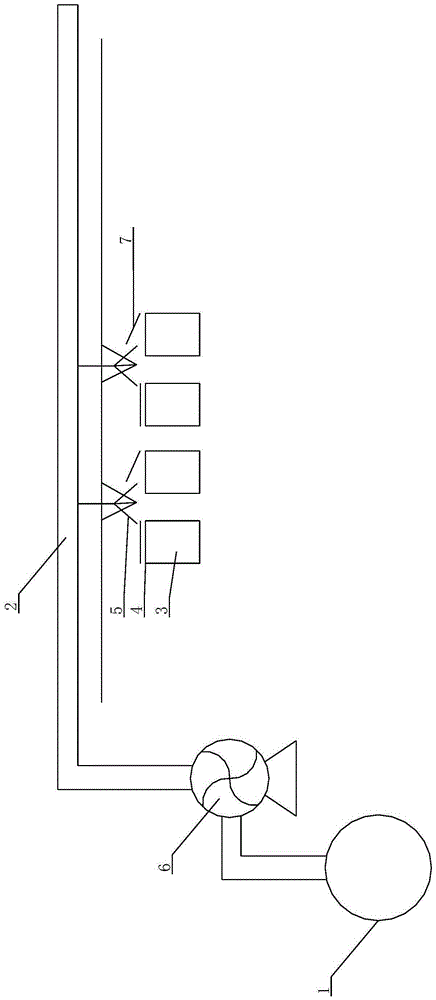

[0034] as attached figure 1 As shown, a coke oven chimney waste gas nitrogen oxide control device includes a waste gas main pipe 2 connected to the coke oven main flue 1 and a waste gas blowing mechanism 5 arranged above the damper 4 of the coke oven waste gas switch 3, the waste gas main pipe 2 and the coke oven main flue 1 is provided with an induced draft fan 6, the waste gas blowing mechanism 5 is a three-way structure, one end of the passage is connected to the waste gas main pipe 2, and the passages at the other two ends are respectively located in the adjacent two Above the damper 4 of the coke oven exhaust gas shutter 3.

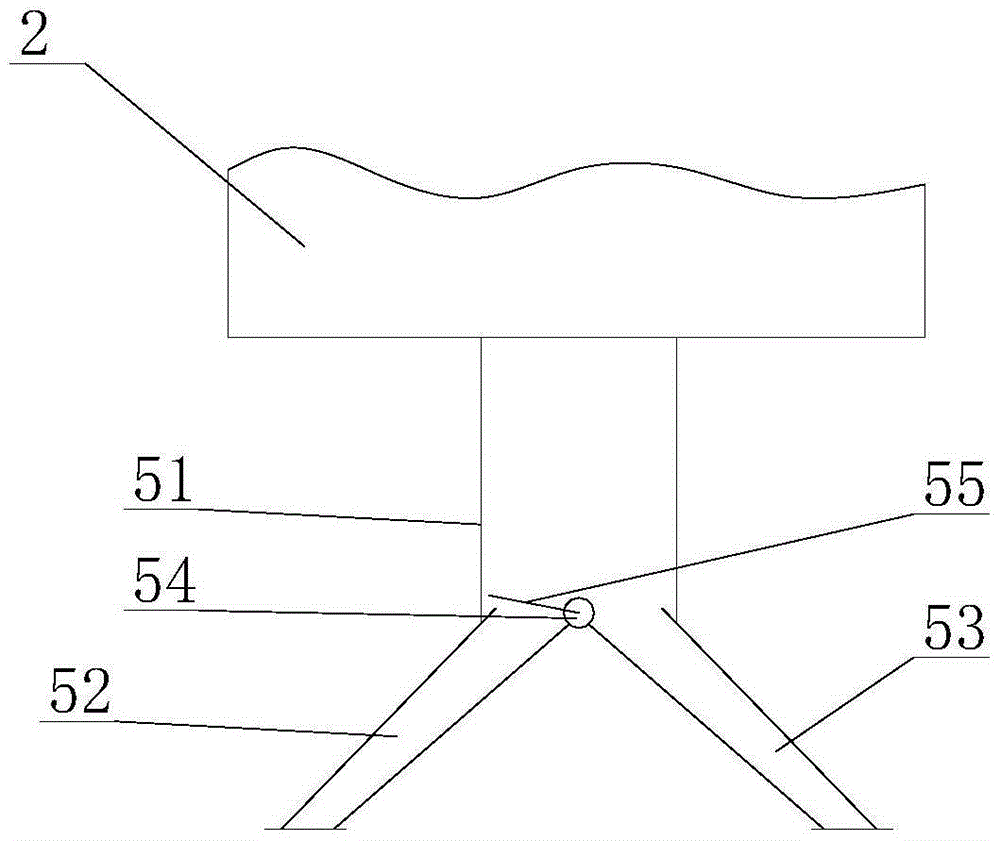

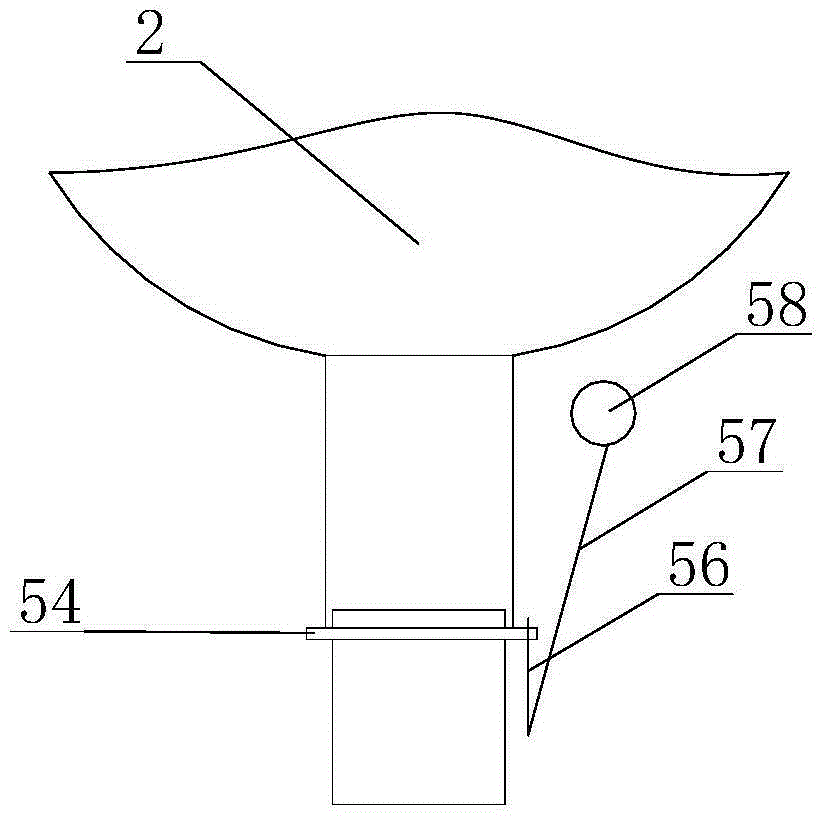

[0035] as attached figure 2 , 3 As shown, the exhaust gas blowing mechanism 5 in this embodiment includes a three-way housing 51, the upper end passage of the three-way housing 51 communicates with the exhaust gas main pipe 2, and the three-way housings 51 are respectively arranged downwards Symmetrical left fork tube 52 and right fork tube 53, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com