Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Eliminate free formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

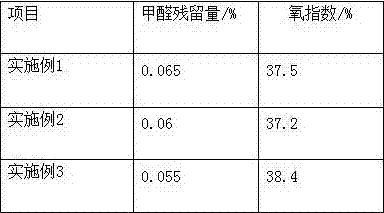

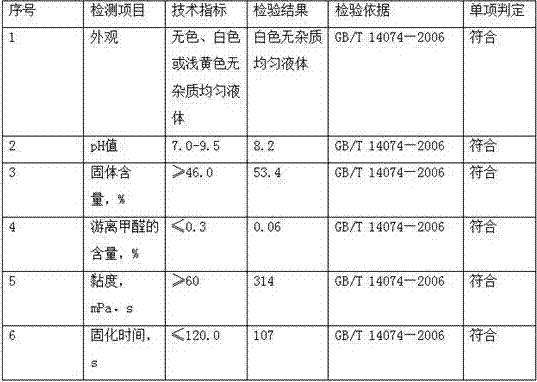

Production method for low-formaldehyde solid wood composite floor

ActiveCN105235024AAvoid gel effectLow residual formaldehydeLaminationLamination apparatusParquetinaSolid wood

The invention relates to a solid wood composite floor, in particular to a production method for a low-formaldehyde solid wood composite floor. The production method comprises the technological steps of wood plate slicing, drying, repairing, selecting, gluing, pre-pressing, hot pressing, edge cutting and sanding, and finished product obtaining. The key of the production method is that the residual amount of formaldehyde in adhesives is reduced by modifying the used urea-formaldehyde resin adhesives, so that the residual amount of the formaldehyde in the solid wood composite floor is reduced; by adopting high-quality plates and controlling process parameters in the production process, the quality of the produced solid wood composite floor is guaranteed. The content of the formaldehyde in the solid wood composite floor manufactured through the method is low, the quality of the floor is stable, and the floor is not prone to damage; the floor has the characteristics of being comfortable in foot feeling, resistant to abrasion, easy to install and clean, and high in stability.

Owner:DALIAN SHENGYU TECH DEV CO LTD

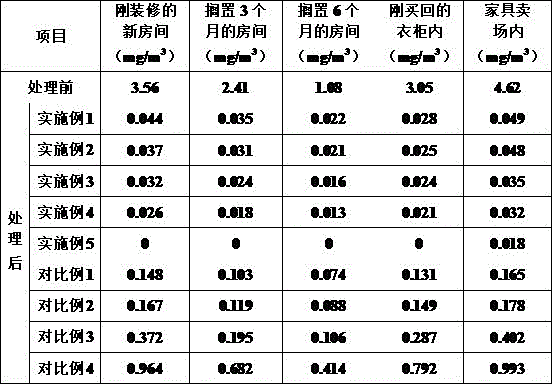

Formol collecting agent and preparing method thereof

InactiveCN1583226AEliminate free formaldehydeSolve formaldehyde pollutionLighting and heating apparatusDispersed particle separationSodium carbonateDiammonium carbonate

A formaldehyde capture for eliminating the free formaldehyde in air and decreasing the release of formaldehyde from artificial board is prepared from water, ammonium acetate, urea, sodium carbonate, sodium chloride, ammonium chloride and ammonium carbonate through proportional mixing.

Owner:王诚德

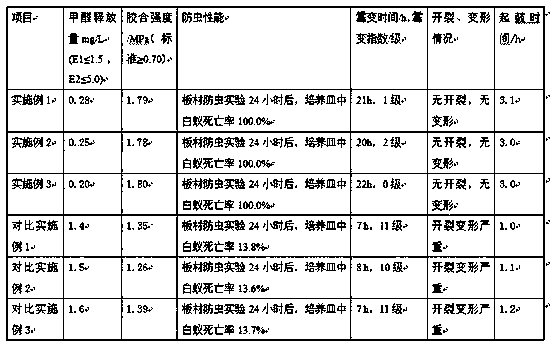

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

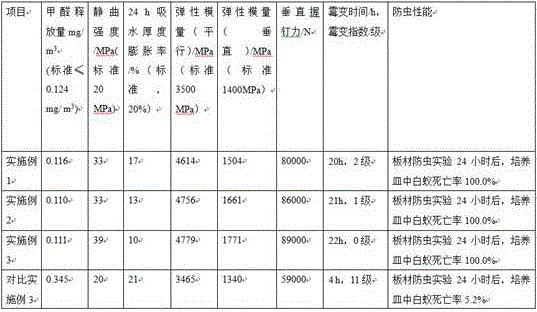

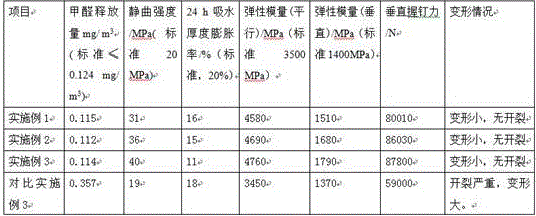

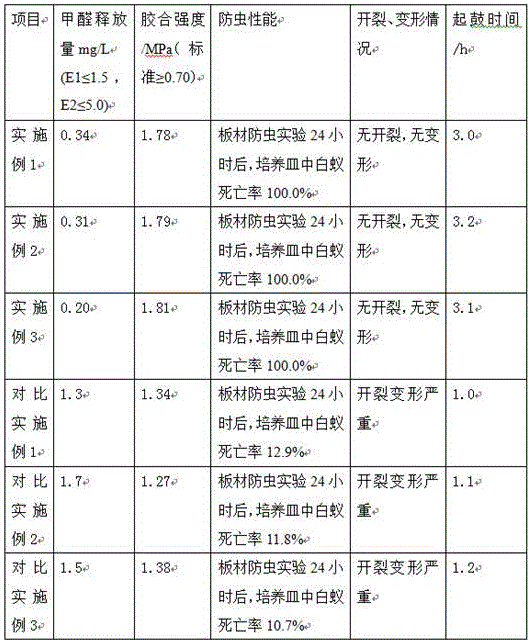

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Aloe extractive as methanal trapping agent and preparation method thereof

InactiveCN101804215AReduce releaseFully captureDispersed particle separationDeodrantsTrappingHydrolysate

The invention relates to an aloe extractive as methanal trapping agent and a preparation method thereof. The prior art has the problems of large volatility, irritant rare delicacy, secondary harm on human body and unfitness for mass use in the preparation technology of the methanal trapping agent. The invention takes natural aloe as raw material and modifies amylose in aloe gel hydrolysate on amino derivatization and then the amylose and amination collagen protein are compounded for obtaining the methanal trapping agent. Outcome of the invention contains collagen protein modified outcome, aloe protein, the amylose and the like. The amino in molecules is mainly used to eliminate the methanal, has small volatility and almost no rare delicacy and does not cause secondary hurt on human body in the use process. The invention can not only eliminate free formaldehyde in the air and reduce methanal release in man-made boards but also reduce free formaldehyde content in leather and fur. The invention has good application foreground.

Owner:爱美瑞新环保科技(武汉)有限公司

Formaldehyde scavenger and preparation method thereof

The invention belongs to the technical field of chemical preparations and particularly relates to a formaldehyde scavenger and a preparation method thereof. The formaldehyde scavenger comprises the following raw materials in parts by weight: 10-20 parts of amino acid, 10-20 parts of starch, 5-10 parts of casein, 5-10 parts of polysorbate, 10-15 parts of isoamyl alcohol, 30-50 parts of plant flower extracts, 5-10 parts of active carbon carboxymethylcellulose, 6-8 parts of a penetrant, 5-10 parts of pillared rectorite, 10-20 parts of chitosan and 80-120 parts of deionized water. The formaldehyde scavenger provided by the invention is high in absorption efficiency and capable of eliminating free formaldehyde in air, reducing the release amount of formaldehyde in a decorated product and simultaneously improving the stability of the formaldehyde in the decorated product so as to solve the problem of formaldehyde pollution caused after indoor decoration and the health of people is beneficial.

Owner:HEBEI UNIV OF ENG

Free formaldehyde eliminating agent and its prepn process

InactiveCN1526470AEliminate free formaldehydeDoes not require special environmental conditionsDispersed particle separationPhenolFORMALDEHYDE SOLUTION

The present invention is free formaldehyde eliminating agent and its preparation process. The free formaldehyde eliminating agent consists of water, stearamide, sulfuric acid, polysodium acrylate, nonyl phenol oxethyl compound, etc. and is prepared through synthesis under heating condition. When the free formaldehyde eliminating agent in 1 % is added into free formaldehyde solution of 10 ppm concentration, the free formaldehyde eliminating rate may reach 76 % in 10 min. The free formaldehyde eliminating agent is colorless, non-toxic, smell-less and suitable for use in eliminating free formaldehyde in household fitment and production of plywood and paint.

Owner:黄元銮

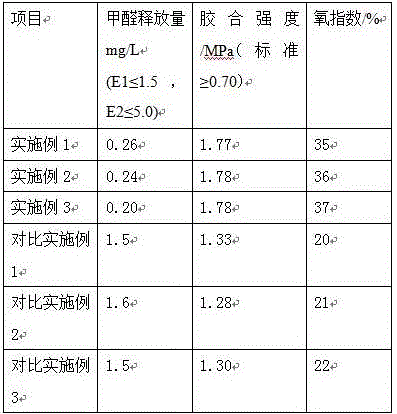

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

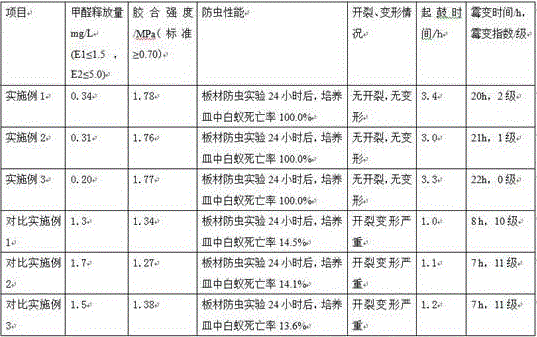

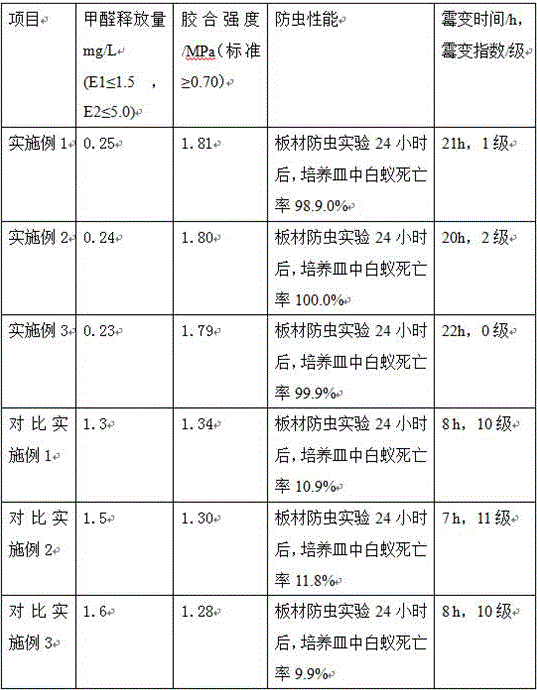

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

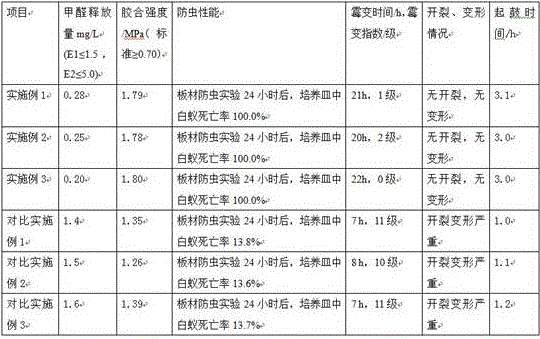

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

Method for producing high-temperature-resisting oriented particle board by using total-eucalyptus leftover material

ActiveCN106313265AWhite colorGood film formingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesParticle boardImpurity

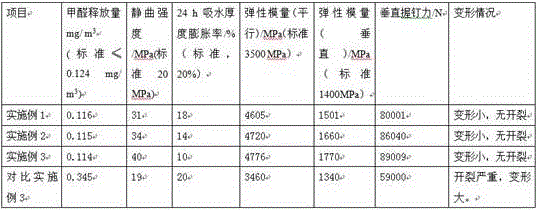

The invention provides a method for producing a high-temperature-resisting oriented particle board by using a total-eucalyptus leftover material. The method comprises the steps of material preparation, drying, debarking, impurity removing, sorting, storage, respective gluing of a surface layer and a core layer, classified paving, pre-hot-pressing molding, sanding of an overcoating and the like, wherein the surface layer is coated with an isocyanate sawdust powder composite adhesive; the core layer is coated with a high-temperature-resisting composite urea resin adhesive; the core layer wood shaving is of a three-layer structure which comprises a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer; the core layer middle layer is paved longitudinally; the core layer upper surface layer, the core layer lower surface layer and the surface layer are paved horizontally. The oriented particle board prepared by the method provided by the invention is 31MPa to 40MPa in parallel static bending intensity, 4605MPa to 4776MPa in parallel elasticity modulus, 1501MPa to 1770MPa in vertical elasticity modulus, 10% to 18% in thickness swelling rate of 24-h water absorption and as high as 89009N in vertical nail-holding power, and is good in dimensional stability and reliability. Moreover, the oriented particle board prepared by the method provided by the invention is also excellent in heat resistance.

Owner:广西横县新威林板业有限公司

Method for producing weather-resistant oriented strand board by using full-eucalyptus leftover material

ActiveCN106272865AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesOptoelectronicsImpurity

The invention provides a method for producing a weather-resistant oriented strand board by using a full-eucalyptus leftover material. The method includes material preparation, drying, peel and impurity removing, sorting storage, gluing of a surface layer and core layer, classified pavement, pre-hot pressing forming, facing sanding and other working procedures. The surface layer is coated with isocyanate sawdust powder composite adhesives, and the core layer is coated with weather-resistant composite urea-formaldehyde resin adhesives. Core layer wood shavings are divided into three layers of structures and comprise a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and a surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction is 31-40MPa, and the parallel elasticity modulus is 4580-4760MPa; and the vertical elasticity modulus is 1510-1790MPa, the 24 h thickness swelling rate of water absorption is 11%-16%, vertical nail-holding ability reaches up to 87800N, and the dimensional stability and reliability are good. Moreover, the oriented strand board prepared through the method has excellent weather resistance.

Owner:广西横县新威林板业有限公司

Method for producing antiseptic oriented strand board through full-eucalyptus leftover materials

InactiveCN106239689AWhite colorGood film formingWood veneer joiningDomestic articlesDusting powdersOptoelectronics

The invention provides a method for producing an antiseptic oriented strand board through full-eucalyptus leftover materials. The method comprises the procedures of material preparing, drying, peel and impurity removing, sorting and storing, surface layer and core layer gluing, classified paving, preheating press forming, sanding facing and the like. A surface layer is coated with an isocyanate wood dust powder composite adhesive, a core layer is coated with an antiseptic composite urea-formaldehyde resin adhesive, and core layer wood shavings are of three-layer structures including a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and the surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction ranges from 34 MPa to 38 MPa, and the parallel elasticity modulus ranges from 4,610 MPa to 4,780 MPa; and the vertical elasticity modulus ranges from 1,500 MPa to 1,774 MPa, the water absorption thickness swelling rate in 24 h ranges from 11% to 16%, and the vertical nail holding force reaches up to 89,000 N. Meanwhile, through adding of an antiseptic agent, the problem that panels are prone to suffering from corrosion of wood-destroying fungi, moulds and white ants is thoroughly solved, and the service life of the panels is prolonged.

Owner:广西横县新威林板业有限公司

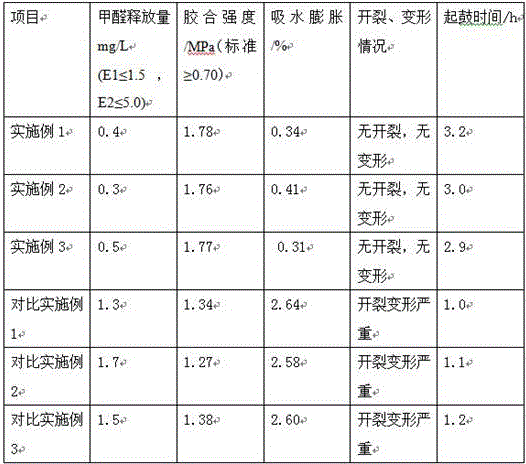

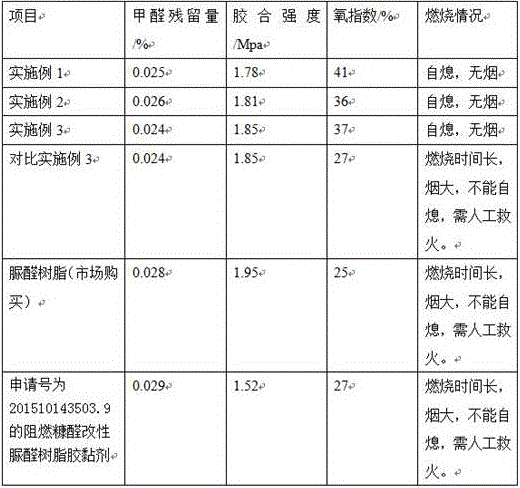

Method for producing cabinet board by adopting flame-retardant composite urea resin

InactiveCN106333530AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesBuilding materialUrea

The invention relates to home building materials, in particular to a method for producing a cabinet board by adopting flame-retardant composite urea resin. The cabinet board structurally comprises decorative paper, a cunninghamia lanceolata veneer, a shaving board and a back board from top to bottom, wherein the periphery of the cabinet board is edged with aluminium alloy; a flame-retardant composite urea resin adhesive is applied between the cunninghamia lanceolata veneer and the shaving board; a flame-retardant composite urea resin adhesive is applied between the shaving board and the back board; a flame-retardant composite urea resin adhesive is also adopted for the shaving board in the cabinet board. The cabinet board manufactured by the method has the advantages of strong water resistance, high bonding strength, low formaldehyde residue and a flame-retardant function. The shaving board in production of the cabinet board is made of waste materials and leftover materials which can not be utilized in the process of manufacturing a multilayered eucalyptus board after rotary cutting of eucalyptus boards, and the leftover materials are utilized, so that the woods can be saved and the production cost of an enterprise can be reduced.

Owner:广西横县正林木业有限公司

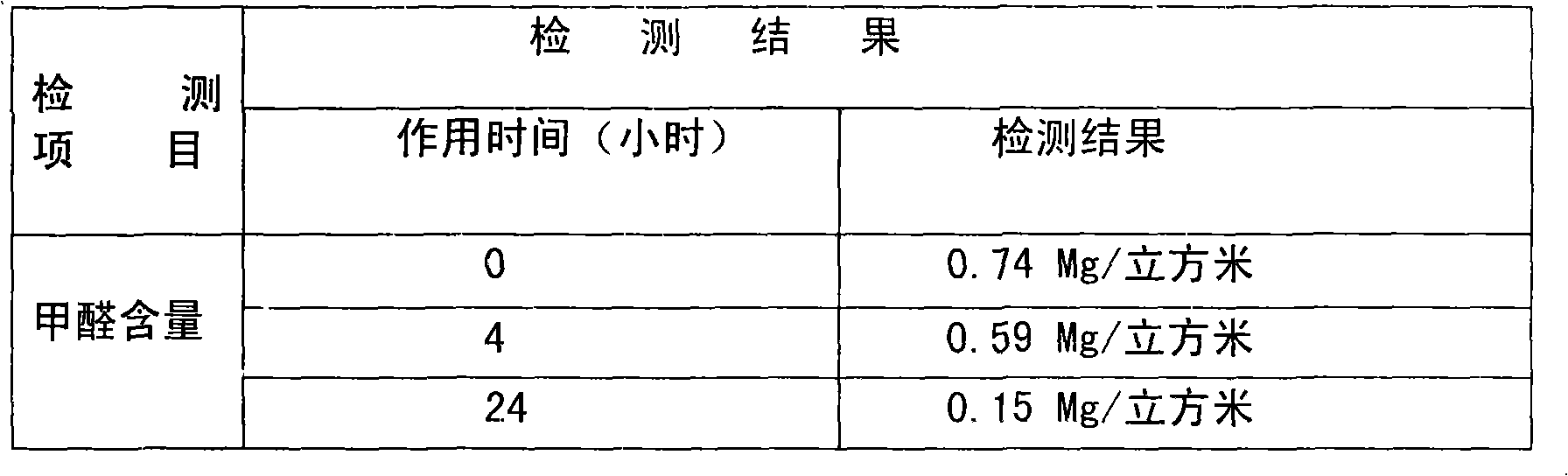

Formaldehyde remover and its preparation method

The invention relates to a formaldehyde remover and its preparation method, belonging chemical industry technical field. The formaldehyde remover is prepared from following raw materials through uniformly stirring and mixing according to the weight percentage, including: 50-85% of water; 0-12% of citric acid, 0-3% of ammonium carbonate, 0-15% of ammonium chloride; 2-10% of ammonium acetate and 3-10% of urea. The formaldehyde remover is mainly used for reducing the release amount of formaldehyde in the artificial plate, removing the formaldehyde pollution after interior decoration and protecting people body health. After spraying 35ml formaldehyde remover in each cubic meter air, the free formaldehyde concentration is lower than 0.08mg / cm3 in the indoor air, thereby the free formaldehyde content in the indoor air reaches national standard.

Owner:王诚德

Method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin

ActiveCN106335120AReduce formaldehyde contentGood gluing propertiesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerSurface layer

A method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin comprises steps as follows: rotary cutting of a board to form pieces; single plate drying; adhesive coating; three times of cold pressing; leaving to stand for reconditioning; three times of hot pressing; heat dissipation for reconditioning; fixed-thickness sanding of plate blanks; adhesive coating of base material surface layers; reconditioning and grooving; paint coating, drying and setting. The key of the production method is that melamine modified urea-formaldehyde resin is used as a main adhesive material; oxidized starch is added as a viscous compound; polyvinyl alcohol is added as a toughening agent; hydrogenated rosin is added as an anti-oxidant; polyisocyanate is added as a curing agent; isobutyltriethoxysilane is added as a bridging agent; phenolated lignin is added as a formaldehyde catching agent; an anti-insect and anti-mildew agent is added; anti-insect and anti-mildew composite urea-formaldehyde resin is prepared; and the parquet prepared from anti-insect and anti-mildew composite urea-formaldehyde resin has the advantages of being low in formaldehyde residual amount and good in anti-insect and anti-mildew effect, has the relatively high inhibition effect on breeding of Aspergillus, Trichoderma and Penicillium and has the instant killing force and the long-acting preventive effect on board powder-pest beetles.

Owner:广西横县正林木业有限公司

Method for producing particle board through anti-insect and anti-mold composite urea formaldehyde resin

ActiveCN106363760AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantPolyvinyl alcohol

The invention discloses a method for producing a particle board through anti-insect and anti-mold composite urea formaldehyde resin. The method comprises the procedures like material preparation, drying, veneer removing and grit removing, mixing glue, and hot press molding. The key of the production method is that melamine modified urea formaldehyde resin is adopted as a main material of an adhesive; oxidized starch is added as a viscous complexing agent; polyvinyl alcohol is adopted as a flexibilizer; hydrogenated rosin is adopted as an antioxidant; polyisocyanate is adopted as a curing agent; and triethoxyisobutylsilane is adopted as a bridging agent. According to the method, the anti-insect and anti-mold composite urea formaldehyde resin is prepared through adopting phenolated lignin as a formaldehyde capture agent and adding an anti-insect and anti-mold agent, and the particle board produced through the anti-insect and anti-mold composite urea formaldehyde resin has the advantages that the residual amount of formaldehyde is low and the anti-insect and anti-mold effect is good, has a quite high inhibiting effect on breeding of aspergillus, trichoderma and penicillia, and has instantaneous killing force and a long-term prevention effect on board powder-post beetles.

Owner:广西横县新威林板业有限公司

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

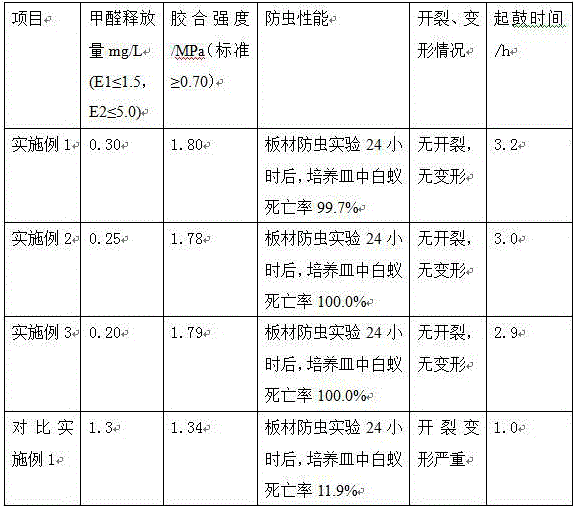

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

Method for eliminating free formaldehyde in adhesive for machining woodwork by using persulfate

InactiveCN101250382AImprove efficiencySimple methodNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEnvironmental chemistryAdhesive

The invention relates to a method for eliminating free formaldehyde in tackiness agent for processing wooden wares, which relates to a method for eliminating free formaldehyde in tackiness agent for processing wooden wares by persulfate. The method is characterized in that the method comprises the following steps: firstly, preparing persulfate into persulfate solution whose mass concentration is 17%-20%, secondly, adopting one of the following two modes, first, adding persulfate solution in tackiness agent for processing wooden wares, wherein the adding amount of presulfate is 10%-12% of the weight of tackiness agent for processing wooden wares, second, adding persulfate solution after tackiness agent polymerization reaction is finished in the process for producing tackiness agent for processing wooden wares, wherein adding amount of persulfate is 10%-12% of the tackiness agent mass after polymerization reaction in producing tackiness agent for processing wooden wares, thirdly, evenly stirring, reacting 14-16 minutes under 45 DEG C to 90 DEG C. The method of the invention has the advantages of high efficiency, innocuity, environmental protection and simple method, the content of free formaldehyde in tackiness agent after being processed is only 0.02%, which is 0.3% which is further lower than national standard.

Owner:WUHAN UNIV OF TECH

Method for adopting high-temperature-resisting composite urea resin for producing whole-eucalyptus solid wood composite floor

ActiveCN106272849AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerAntioxidant

The invention discloses a method for adopting high-temperature-resisting composite urea resin for producing a whole-eucalyptus solid wood composite floor. The method includes the steps of board rotary slicing, veneer drying, gluing, three times of cold pressing, standing maintaining, three times of hot pressing, heat dissipating maintaining, slab fixed-thickness sanding, base material surface layer gluing, maintaining grooving and paint spraying, drying and sizing. The production method is characterized in that the high-temperature-resisting composite urea resin is prepared by adopting melamine modified urea resin as the main material of an adhesive, adding oxidized starch as a viscosity complexing agent, adopting polyvinyl alcohol as a toughening agent, adopting hydrogenated rosin as an antioxidant, adopting polyisocyanate as a curing agent, adopting isobutyl triethoxy silane as a bridging agent, adopting phenolate lignin as a formaldehyde catching agent and adding high-temperature-resisting filler. The high-temperature-resisting composite urea resin prepared through the method is used for producing the whole-eucalyptus solid wood composite floor so that the whole-eucalyptus solid wood composite floor can have good heat resistance performance, no obvious crack phenomenon happens under high-temperature and high-strength ultraviolet irradiation or long-time ultraviolet irradiation, and economic losses are reduced.

Owner:广西横县正林木业有限公司

Novel and environment-friendly formaldehyde remover

InactiveCN104941408AReduce releaseAvoid pollutionDispersed particle separationChlorine dioxideAlcohol

The invention discloses a novel and environment-friendly formaldehyde remover, and belongs to the field of air purification. The remover comprises the following components by weight percent: 20-25% of chlorine dioxide, 5-10% of ammonium citrate, 15-20% of absolute ethyl alcohol, 5-10% of a penetrant and 35-55% of purified water. The remover has the benefits of solving formaldehyde pollution after indoor decoration, having a sterilizing effect, being free of pollution to the environment, safe and nontoxic, avoiding adverse side effects if human body directly touches the remover, and being beneficial to human body health.

Owner:DALIAN QUANJING ENVIRONMENT PROTECTION TECHCO

Method for producing whole eucalyptus plywood by using compound urea-formaldehyde resin against insects and mildew

ActiveCN106182218BReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAntioxidant

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

Method for producing particle board by adopting flame-retardant composite urea resin

ActiveCN106313259AWhite colorGood film formingNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryRosin

The invention discloses a method for producing particle board by adopting flame-retardant composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, hydrogenated rosin is taken as an antioxidant, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a flame retardant is also added to prepare the flame-retardant composite urea resin; the composite urea resin has the advantages of low formaldehyde residual volume and good flame retardance; by internal heat absorption reaction, the combustion temperature is reduced, so the produced particle board is low in formaldehyde residual volume and is effectively flame-resistant when a fire occurs.

Owner:广西横县新威林板业有限公司

Method for producing full-eucalyptus parquet through dampproof composite urea resin

InactiveCN106239646AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesFiberPolyvinyl alcohol

A method for producing a full-eucalyptus parquet through dampproof composite urea resin comprises the following steps of wood board sheet rotary cutting, veneer drying, gluing, three-time cold pressing, standing curing, three-time hot pressing, heat dissipation curing, slab fixed-thickness sanding, base material surface layer gluing, curing slotting and spraying drying sizing. According to the key of the production method, melamine modified urea resin is adopted as a main adhesive material, and oxidized starch is added as a sticky complexing agent; polyvinyl alcohol serves as a toughening agent; magnesium oxide serves as an anti-aging agent; hexamine and triglycidyl isocyanurate serve as a curing agent; vinyltriethoxysilane serves as a bridging fiber agent; and phenolate lignin is the dampproof composite urea resin prepared through a formaldehyde capture agent and an added dampproof agent. The composite urea resin has the beneficial effects of being low in formaldehyde residual volume and good in water resistance and dampproof performance, so that the produced full-eucalyptus parquet is low in formaldehyde residual volume and is not prone to expansion after absorbing water, arching and deformation are not likely to happen, and an abrasion resisting layer is not prone to damage.

Owner:南宁市创锦胶合板有限责任公司

Formaldehyde catching agent for indoor air purification, as well as preparation method and application of formaldehyde catching agent

InactiveCN106422726AReduce releaseImprove stabilityGas treatmentDispersed particle separationHalloysiteHigh absorption

The invention discloses a formaldehyde catching agent for indoor air purification, as well as a preparation method and an application of the formaldehyde catching agent. The formaldehyde catching agent comprises the following raw materials in parts by mass: 6-9 parts of stropanthus divericatus, 2-4 parts of wistaria wood, 0.8-1.3 parts of biotin, 3.5-5.2 parts of linoleic acid, 15-19 parts of xylitol, 3-5 parts of xanthate, 2.3-2.7 parts of modified halloysite and 68-85 parts of deionized water. The modified halloysite is prepared by drying and performing superfine grinding on halloysite, adding water for mixing, adding acetic acid for agitation, and adding terbium perchlorate for the agitation. The stropanthus divericatus and the wistaria wood after biotin treatment exert an effect together with the modified halloysite, and the agent has high absorption efficiency of formaldehyde in indoor air, and can remove free formaldehyde in the air, reduce formaldehyde release amount in a decoration product, improve formaldehyde stability in the decoration product and solve the problem of formaldehyde pollution in interior decoration.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

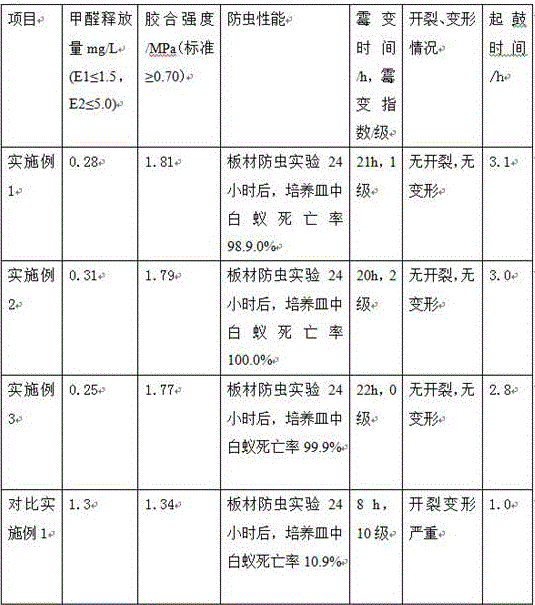

Method for producing all-eucalyptus solid wood composite floor by corrosion-resistance composite urea resins

InactiveCN106239645AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAdhesive

The invention discloses a method for producing an all-eucalyptus solid wood composite floor by corrosion-resistance composite urea resins. The method comprises the steps of: board rotary slicing-veneer drying-gluing-three times of cold pressing-standing maintenance-three times of hot pressing-cooling maintenance-blank fixed-thickness sanding-substrate surface layer gluing-maintenance grooving-paint drying shaping. The key point of the method is to adopt melamine modified urea resins as a main material of adhesive; oxide starch is added as a viscous compounding agent; polyvinyl alcohol serves as a toughening agent; hydrogenated rosin serves as antioxidant; polyisocyanate serves as a curing agent; isobutyltriethoxysilane serves as a bridging agent; phenolated lignin serves as a formaldehyde capturing agent; and a preservative is added to prepare the corrosion-resistance composite urea resins; and the solid wood composite floor produced by the corrosion-resistance composite urea resins has the advantages of low formaldehyde residual volume and good corrosion resistance, is better in resistance on wood rotting fungus, mould and termites, and prolongs the service life of the all-eucalyptus solid wood composite floor.

Owner:南宁市林润木业有限公司

Method for adopting anticorrosion composite urea resin for producing cabinet board

InactiveCN106272831ATake advantage ofSolve insufficient resourcesFlat articlesDomestic articlesWood veneerMonoboard

The invention relates to a home furnishing building material, in particular to a method for adopting anticorrosion composite urea resin for producing a cabinet board. The cabinet board structurally comprises decoration paper, a fir veneer, a chipboard and a back board in sequence from top to bottom. The periphery of the cabinet board is edged with an aluminum alloy. The part between the fir veneer and the chipboard is coated with an anticorrosion composite urea resin adhesive. The part between the chipboard and the back board is coated with an anticorrosion composite urea resin adhesive. An anticorrosion composite urea resin adhesive is also adopted in the chipboard in the cabinet board. The cabinet board manufactured through the method has high water resistance and high bonding strength and is low in formaldehyde residual volume, and meanwhile the anticorrosion function is achieved. The raw material adopted for producing the chipboard in the cabinet board is waste-leftover materials which cannot be used in the process of manufacturing a multilayer eucalyptus board after the eucalyptus board is subjected to rotary cutting, the leftover materials are utilized, wood is saved, and the production cost of an enterprise is reduced.

Owner:南宁市创锦胶合板有限责任公司

Flame-retardant composite urea resin and production method thereof

The invention discloses flame-retardant composite urea resin and a production method thereof; the flame-retardant composite urea resin is prepared from melamine-modified urea resin, oxidized starch, polyvinyl chloride, hydrogenated rosin, propanediol polyoxypropylene polyvinyl ether, polyisocyanate, isobutyltriethoxysilane, phenolated lignin, clear water, and a flame retardant; the production method comprises: placing clear water in a reactor, heating to 80-100 DEG C, adding hydrogenated rosin, isobutyltriethoxysilane and propanediol polyoxypropylene polyvinyl ether, stirring for 10-30 min, adding polyvinyl chloride and phenolated lignin and dissolving them, adding certain parts by weight of melamine-modified urea resin, oxidized starch and flame retardant, holding the temperature of 80-90 DEG C, stirring and reacting for 2-5 h, adding polyisocyanate 10-20 min before usage, and mixing and stirring well. The flame-retardant composite urea resin is good in flame retardance, acts as a main adhesive for artificial boards and can provide improved flame retardance for artificial boards.

Owner:南宁市林润木业有限公司

Method for producing cabinet board with anti-insect and anti-mold composite urea-formaldehyde resin

InactiveCN106346587AWhite colorGood film formingNon-macromolecular adhesive additivesDrying gas arrangementsParticle boardMaterials science

The invention relates to a home building material, especially a method for producing cabinet board with anti-insect and anti-mold composite urea-formaldehyde resin. The cabinet board comprises from top to bottom: decorative paper, cunninghamia lanceolata veneer, particleboard and backboard; besides, the cabinet board is surrounded by aluminum alloy trim. The contact surface between the cunninghamia lanceolata veneer and particle board is coated with anti-insect and anti-mold composite urea-formaldehyde resin adhesives, which are also applied to the contact surface between the particleboard and backboard as well as the particleboard in the cabinet board. The cabinet board manufactured according to the invention has strong water resistance, high bonding strength, littleformaldehyde residue as well as anti-insect and anti-mold functions. Raw materials used for production of the particleboard in the cabinet board are the waste and scrap materials which cannot be used for production of the multi-layer eucalyptus board after peeling the eucalyptus wood, and the home building material utilizes the scraps to save wood and reduce productioncosts of the enterprises.

Owner:南宁市创锦胶合板有限责任公司

A kind of production method of low-aldehyde flame-retardant plywood

ActiveCN105235025BImprove flame retardant performanceQuality assuranceLaminationLamination apparatusCell wallResin adhesive

The invention relates to a plywood, in particular to a production method of a low-aldehyde flame-retardant plywood. The process steps of its production include: plank rotary blade—primary drying—repair—vacuum impregnation treatment—secondary drying—gluing—prepressing—hot pressing—edge trimming and sanding. The invention uses a flame retardant solution to vacuum impregnate the veneer. After the impregnation process, the flame retardant penetrates into the cell cavity, cell wall and intercellular space of the wood to obtain a flame retardant veneer, which is used to produce plywood. The flame retardant performance of the produced plywood has been improved; by improving the urea-formaldehyde resin adhesive used, the residual amount of formaldehyde in the adhesive is reduced, thereby reducing the residual amount of formaldehyde in the plywood; The burning agent borax solution improves the flame retardancy of the urea-formaldehyde resin adhesive used. Using this adhesive to produce plywood not only reduces the residual amount of formaldehyde in the plywood but also further improves the flame retardancy of the plywood.

Owner:广州皕吉装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com