A kind of production method of low-aldehyde flame-retardant plywood

A production method and technology for plywood, applied in the field of plywood, can solve the problems of inability to meet processing and use requirements, increased smoke hazard, poor flame retardant effect, etc., to promote cross-linking curing, stable polymerization reaction rate, and improve water resistance. The effect of resistance and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

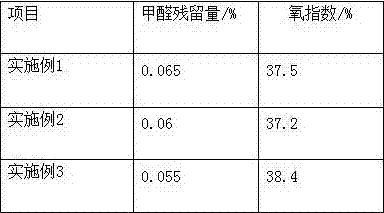

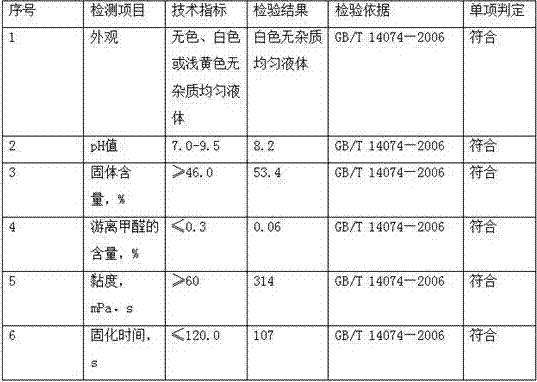

Examples

Embodiment l

[0030] A method for producing low-aldehyde flame-retardant plywood, the steps are as follows:

[0031] (1) Wood rotary blades: Rotate the eucalyptus boards with a rotary cutter to obtain veneers, and pick out the unqualified boards with insect eyes, decay, and excessive defects;

[0032] (2) Primary drying: Dry the veneer with a dryer to reduce the moisture content of the board to below 12%;

[0033] (3) Repair: Repair the defects or blemishes on the veneer including natural cracks, cracks, knots, skins and knots;

[0034] (4) Vacuum impregnation treatment: Put the obtained veneer into a vacuum pressurized tank, firstly pump the vacuum to make the relative vacuum in the vacuum pressurized tank reach -0.09~-0.12MPa, keep the vacuum pump for 65 minutes, and at the same time introduce The flame retardant solution has been prepared until the relative vacuum in the vacuum pressurized tank is 0.9 ~ 1.5Mpa, turn on the booster pump, and continue to pass the flame retardant solution ...

Embodiment 2

[0044] A method for producing low-aldehyde flame-retardant plywood, the steps are as follows:

[0045] (1) Wood rotary blades: Rotate the eucalyptus boards with a rotary cutter to obtain veneers, and pick out the unqualified boards with insect eyes, decay, and excessive defects;

[0046] (2) Primary drying: Dry the veneer with a dryer to reduce the moisture content of the board to below 12%;

[0047] (3) Repair: Repair the defects or blemishes on the veneer including natural cracks, cracks, knots, skins and knots;

[0048] (4) Vacuum impregnation treatment: Put the obtained veneer into a vacuum pressurized tank, firstly pump the vacuum to make the relative vacuum degree in the vacuum pressurized tank reach -0.09~-0.12MPa, keep it for 70min, then turn off the vacuum pump, and at the same time introduce The flame retardant solution has been prepared until the relative vacuum in the vacuum pressurized tank is 0.9 ~ 1.5Mpa, turn on the booster pump, and continue to pass the flame...

Embodiment 3

[0058] A method for producing low-aldehyde flame-retardant plywood, the steps are as follows:

[0059] (1) Wood rotary blades: Rotate the eucalyptus boards with a rotary cutter to obtain veneers, and pick out the unqualified boards with insect eyes, decay, and excessive defects;

[0060] (2) Primary drying: Dry the veneer with a dryer to reduce the moisture content of the board to below 12%;

[0061] (3) Repair: Repair the defects or blemishes on the veneer including natural cracks, cracks, knots, skins and knots;

[0062] (4) Vacuum impregnation treatment: Put the obtained veneer into a vacuum pressurized tank, firstly evacuate to make the relative vacuum in the vacuum pressurized tank reach -0.09~-0.12MPa, keep the vacuum pump for 75min, and at the same time introduce The flame retardant solution has been prepared until the relative vacuum in the vacuum pressurized tank is 0.9 ~ 1.5Mpa, turn on the booster pump, and continue to pass the flame retardant solution into the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com