Flame-retardant composite urea resin and production method thereof

A urea-formaldehyde resin and flame retardant composite technology, applied in the field of adhesive production, can solve the problems of low residual formaldehyde, poor water resistance, warping and deformation of plates, etc., and achieve high bonding strength, good freeze-thaw resistance, and increased strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

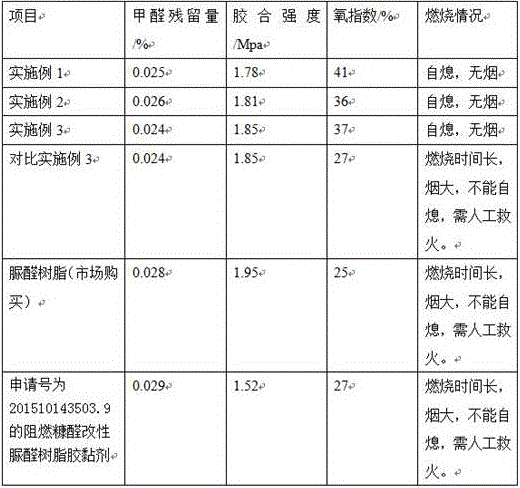

Examples

Embodiment 1

[0052] A flame-retardant composite urea-formaldehyde resin, consisting of the following raw materials in parts by weight:

[0053] 50 parts of melamine modified urea-formaldehyde resins;

[0054] 20 parts of oxidized starch;

[0055] 1 part polyvinyl alcohol;

[0056] 3 parts hydrogenated rosin;

[0057] 2 parts of propylene glycol polyoxypropylene polyvinyl ether;

[0058] 4 parts polyisocyanate;

[0059] 0.5 parts of isobutyltriethoxysilane;

[0060] 5 parts of phenolized lignin;

[0061] 100 parts of water;

[0062] Flame retardant 2.4 parts.

[0063] The flame retardant is mixed with red phosphorus masterbatch, decabromodiphenylethane and antimony trioxide, and the weight ratio of the three is 2:3:1, wherein red phosphorus masterbatch, decabromodiphenyl Ethane and antimony trioxide are 0.8, 1.2, and 0.4 parts in turn.

[0064] The red phosphorus masterbatch is the red phosphorus flame retardant masterbatch produced by Guangzhou Yinsu Flame Retardant Material Co., ...

Embodiment 2

[0068] A flame-retardant composite urea-formaldehyde resin, consisting of the following raw materials in parts by weight:

[0069] 80 parts of melamine modified urea-formaldehyde resins;

[0070] 25 parts of oxidized starch;

[0071] 2 parts polyvinyl alcohol;

[0072] 5 parts hydrogenated rosin;

[0073] 2.5 parts of propylene glycol polyoxypropylene polyvinyl ether;

[0074] 5 parts of polyisocyanate;

[0075] 3 parts of isobutyltriethoxysilane;

[0076] 8 parts of phenolized lignin;

[0077] 150 parts of water;

[0078] Flame retardant 3.6 parts.

[0079] The flame retardant is mixed with red phosphorus masterbatch, decabromodiphenylethane and antimony trioxide, and the weight ratio of the three is 2:3:1, wherein red phosphorus masterbatch, decabromodiphenyl Ethane and antimony trioxide are 1.2 parts, 1.8 parts and 0.6 parts respectively.

[0080] The red phosphorus masterbatch is the red phosphorus flame retardant masterbatch produced by Guangzhou Yinsu Flame Reta...

Embodiment 3

[0084] A flame-retardant composite urea-formaldehyde resin, consisting of the following raw materials in parts by weight:

[0085] 100 parts of melamine modified urea-formaldehyde resin;

[0086] 30 parts of oxidized starch;

[0087] 3 parts of polyvinyl alcohol;

[0088] 8 parts hydrogenated rosin;

[0089] 3 parts of propylene glycol polyoxypropylene polyvinyl ether;

[0090] 6 parts of polyisocyanate;

[0091] 5 parts of isobutyltriethoxysilane;

[0092] 10 parts of phenolized lignin;

[0093] 200 parts of water;

[0094] Flame retardant 4.8 parts.

[0095] The flame retardant is mixed with red phosphorus masterbatch, decabromodiphenylethane and antimony trioxide, and the weight ratio of the three is 2:3:1, wherein red phosphorus masterbatch, decabromodiphenyl Ethane and antimony trioxide are 1.6 parts, 2.4 parts and 0.8 parts respectively.

[0096] The red phosphorus masterbatch is the red phosphorus flame retardant masterbatch produced by Guangzhou Yinsu Flame Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com