Method for adopting anticorrosion composite urea resin for producing cabinet board

A composite urea-formaldehyde resin and cabinet technology, which is applied in applications, household components, household appliances, etc., can solve the problems of reducing formaldehyde content and having no anti-corrosion effect, and achieve high bonding strength, increased glue solid content, and improved water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

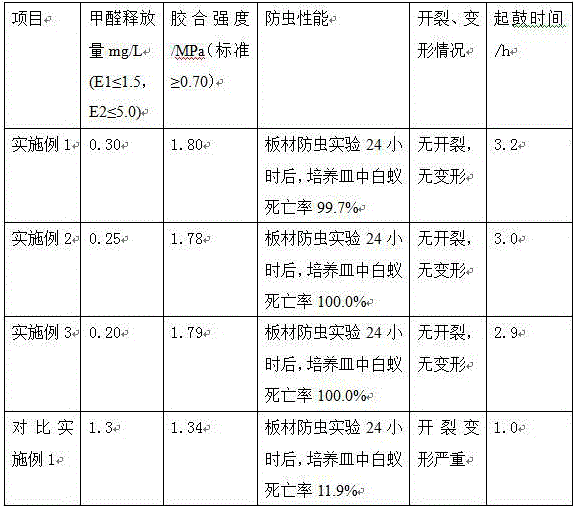

Embodiment 1

[0065] A method for producing cabinet boards using anti-corrosion compound urea-formaldehyde resin, the cabinet boards have the following structure from top to bottom: decorative paper, fir veneer, particle board, and back board; the cabinet boards are surrounded by aluminum alloy borders; Anti-corrosion compound urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and anti-corrosion compound urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and the anti-corrosion compound urea-formaldehyde resin adhesive is used for the particle board in the cabinet board; , Chinese fir veneer and backboard are respectively glued and covered with particleboard and decorated.

[0066] The preparation process of described particle board is:

[0067] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary cutting eucalyptus boards are sent to...

Embodiment 2

[0093] A method for producing cabinet boards using anti-corrosion compound urea-formaldehyde resin, the cabinet boards have the following structure from top to bottom: decorative paper, fir veneer, particle board, and back board; the cabinet boards are surrounded by aluminum alloy borders; Anti-corrosion compound urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and anti-corrosion compound urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and the anti-corrosion compound urea-formaldehyde resin adhesive is used for the particle board in the cabinet board; , Chinese fir veneer and backboard are respectively glued and covered with particleboard and decorated.

[0094] The preparation process of described particle board is:

[0095] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary cutting eucalyptus boards are sent to...

Embodiment 3

[0121] A method for producing cabinet boards using anti-corrosion compound urea-formaldehyde resin, the cabinet boards have the following structure from top to bottom: decorative paper, fir veneer, particle board, and back board; the cabinet boards are surrounded by aluminum alloy borders; Anti-corrosion compound urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and anti-corrosion compound urea-formaldehyde resin adhesive is applied between the particle board and the backboard, and the anti-corrosion compound urea-formaldehyde resin adhesive is used for the particle board in the cabinet board; , Chinese fir veneer and backboard are respectively glued and covered with particleboard and decorated.

[0122] The preparation process of described particle board is:

[0123] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary cutting eucalyptus boards are sent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com