Method for producing whole eucalyptus plywood by using compound urea-formaldehyde resin against insects and mildew

A urea-formaldehyde resin and plywood technology, which is used in the joining of wooden veneers, the manufacture of veneers, and aldehyde/ketone condensation polymer adhesives, etc. Serious problems, to achieve the effect of improving aging resistance, reducing the amount of added, and white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

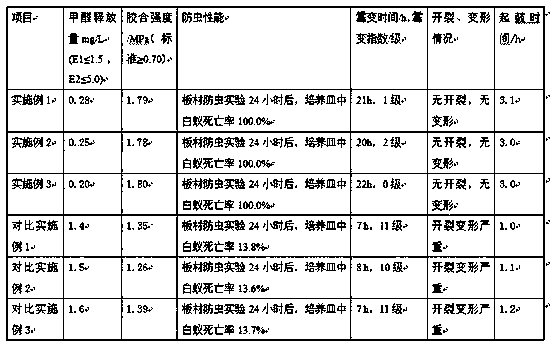

Examples

Embodiment 1

[0067] The method for producing full eucalyptus plywood by adopting the anti-insect and mildew-proof composite urea-formaldehyde resin comprises the following steps:

[0068] (1) Rotary slices of wood: Use a rotary cutter to cut eucalyptus into 1.5 mm thick slices to obtain eucalyptus veneers, and pick out unqualified boards with insect eyes, decay, and excessive defects;

[0069] (2) Veneer drying: Dry the eucalyptus veneer with a hot air stove, and control the moisture content of the veneer to be less than or equal to 10%;

[0070] (3) Gluing: Glue the eucalyptus veneer with a gluing machine, arrange 9 layers of glued eucalyptus veneer criss-cross and layered according to the wood texture structure, and glue them together to obtain a eucalyptus slab; The glue is insect-proof and mildew-proof compound urea-formaldehyde resin, and the amount of glue on one side is 200g / m 2 ;

[0071] (4) Three times of cold pressing: the eucalyptus slab is cold pressed three times at a unit ...

Embodiment 2

[0092] The method for producing full eucalyptus plywood by adopting the anti-insect and mildew-proof composite urea-formaldehyde resin comprises the following steps:

[0093] (1) Rotary slices of wood: Use a rotary cutter to cut eucalyptus into 1.5 mm thick slices to obtain eucalyptus veneers, and pick out unqualified boards with insect eyes, decay, and excessive defects;

[0094] (2) Veneer drying: Dry the eucalyptus veneer with a hot air stove, and control the moisture content of the veneer to be less than or equal to 10%;

[0095] (3) Gluing: Glue the eucalyptus veneers with a gluing machine, and arrange 11 layers of glued eucalyptus veneers in criss-cross layers according to the wood texture structure, and glue them together to obtain eucalyptus slabs; The glue is insect-proof and mildew-proof compound urea-formaldehyde resin, and the amount of glue on one side is 220g / m 2 ;

[0096] (4) Three times of cold pressing: the eucalyptus slab is cold pressed three times at a u...

Embodiment 3

[0117] The method for producing full eucalyptus plywood by adopting the anti-insect and mildew-proof composite urea-formaldehyde resin comprises the following steps:

[0118] (1) Rotary slices of wood: Use a rotary cutter to cut eucalyptus into 1.5 mm thick slices to obtain eucalyptus veneers, and pick out unqualified boards with insect eyes, decay, and excessive defects;

[0119] (2) Veneer drying: Dry the eucalyptus veneer with a hot air stove, and control the moisture content of the veneer to be less than or equal to 10%;

[0120] (3) Gluing: Glue the eucalyptus veneers with a gluing machine and arrange 13 layers of glued eucalyptus veneers criss-cross and layered according to the wood texture structure, and glue them together to get eucalyptus slabs; The glue is insect-proof and mildew-proof compound urea-formaldehyde resin, and the amount of glue on one side is 230g / m 2 ;

[0121] (4) Three times of cold pressing: the eucalyptus slab is cold pressed three times at a uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com