Treatment method for reducing Cr<6+> in stainless steel acid wastewater

A treatment method, stainless steel technology, applied in the field of iron and steel, can solve the problems of stainless steel wastewater effluent exceeding the standard, affecting the operation of biochemical treatment, etc., to meet the requirements of environmental protection and discharge, and to facilitate the effect of subsequent biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

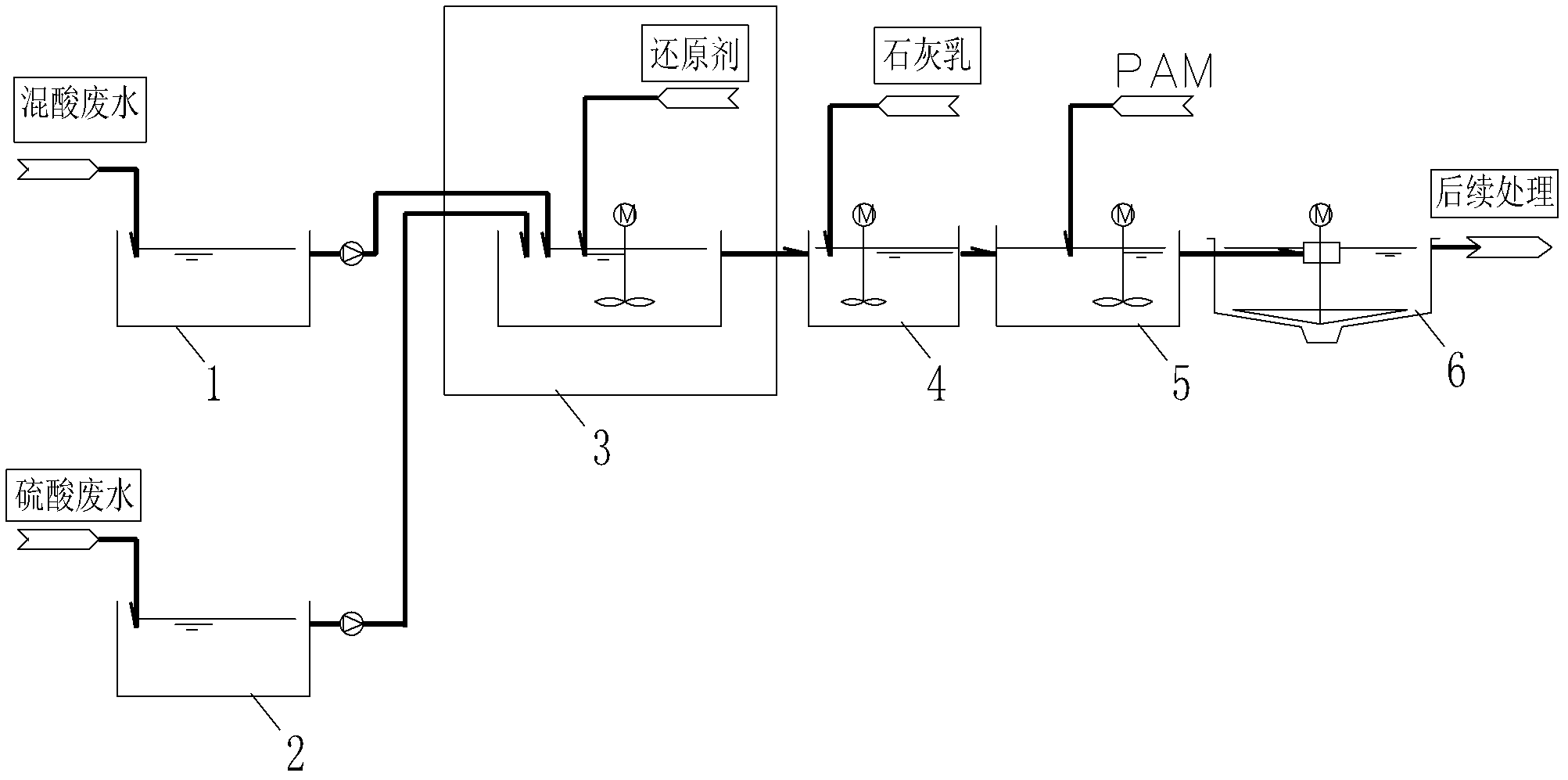

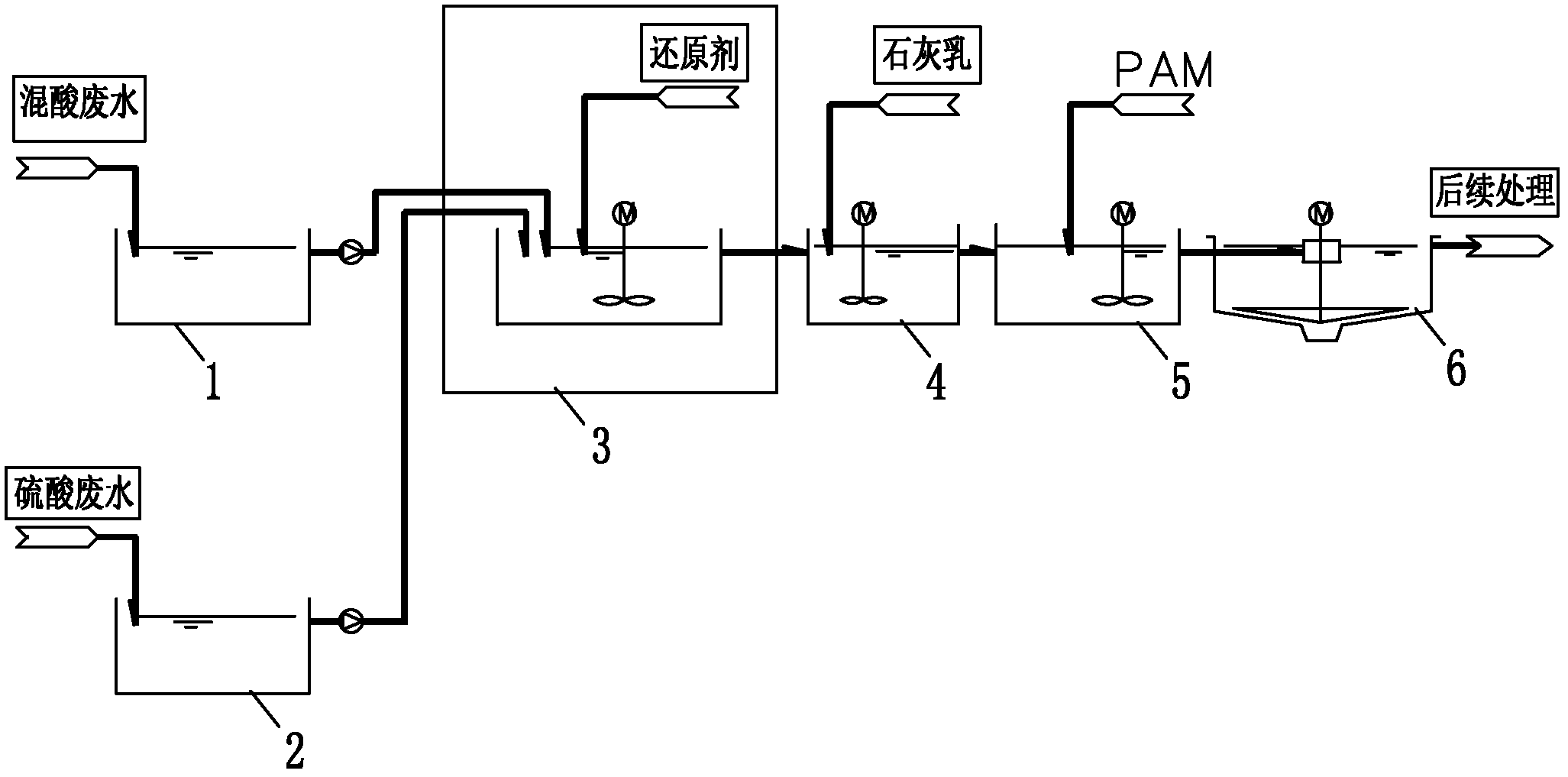

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0027] Stainless steel acid waste water provided by the invention reduces Cr 6+ The processing method, its steps include:

[0028] (1) Based on stainless steel mixed acid wastewater mixed with sulfuric acid wastewater will produce NO 2 And other toxic gases, so stainless steel mixed acid wastewater and sulfuric acid wastewater are stored separately. Then the stainless steel mixed acid wastewater stored in the mixed acid wastewater regulating tank 1 and the sulfuric acid wastewater stored in the sulfuric acid wastewater regulating tank 2 are sent into the reduction tank 3 by pumps respectively.

[0029] (2) Add a reducing agent to the waste water in the reduction tank 3 and stir it so that the Cr in the waste water 6+ Convert to Cr 3+ ;Because stainless steel mixed acid wastewater contains HF and HNO 3 , is corrosive to the electrode of the ORP dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com