Planet gear and rotating cylinder engine

A planetary gear, rotating cylinder technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve problems such as complex engine structure, meet the requirements of environmental protection emissions, improve efficiency, and reduce ventilation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

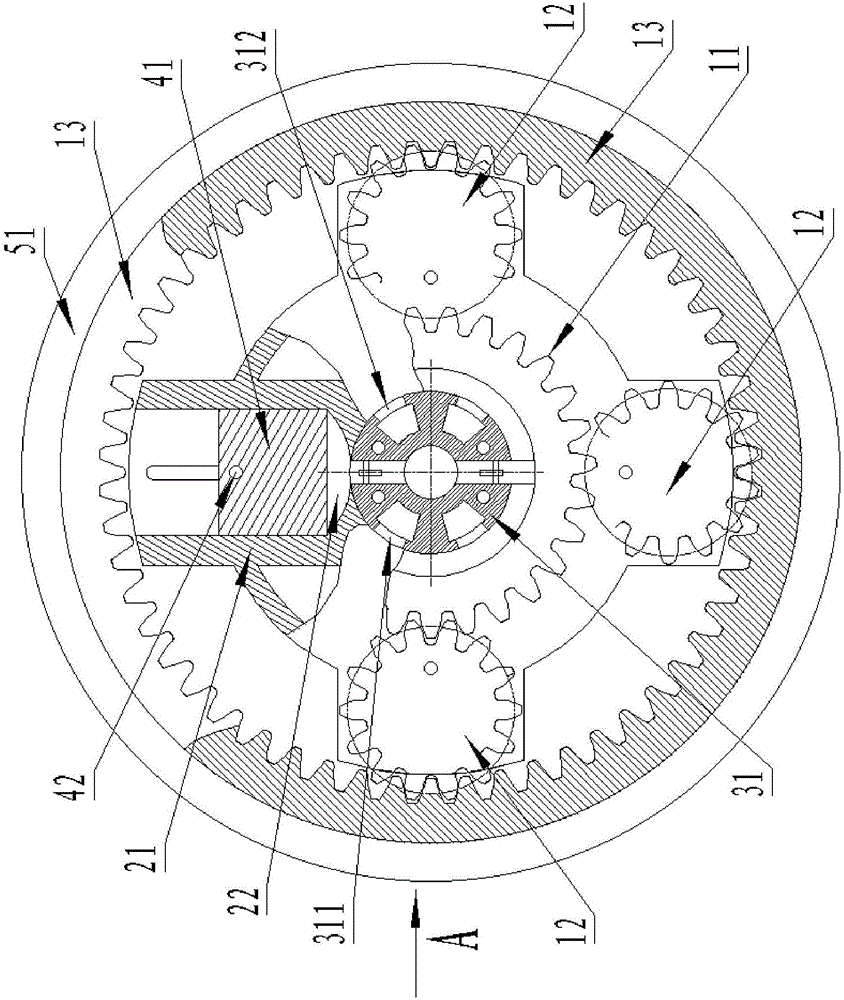

[0025] A planetary gear rotary cylinder engine comprising:

[0026] The planetary gear assembly includes a sun gear 11, a planetary gear 12 and an inner ring gear 13 connected sequentially from the inside to the outside, the sun gear 11 can rotate on its own, and the planetary gear 12 can rotate on its own and revolve around the sun gear 11;

[0027] The rotating cylinder assembly can rotate around the centerline of the sun gear 11. The rotating cylinder assembly contains a cylinder 21 corresponding to the planetary gear 12, that is, the cylinder 21 is aligned with the corresponding planetary gear 12 along the direction of the centerline of the sun gear 11. Arranged adjacently, the cylinder 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com