Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Thorough ventilation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

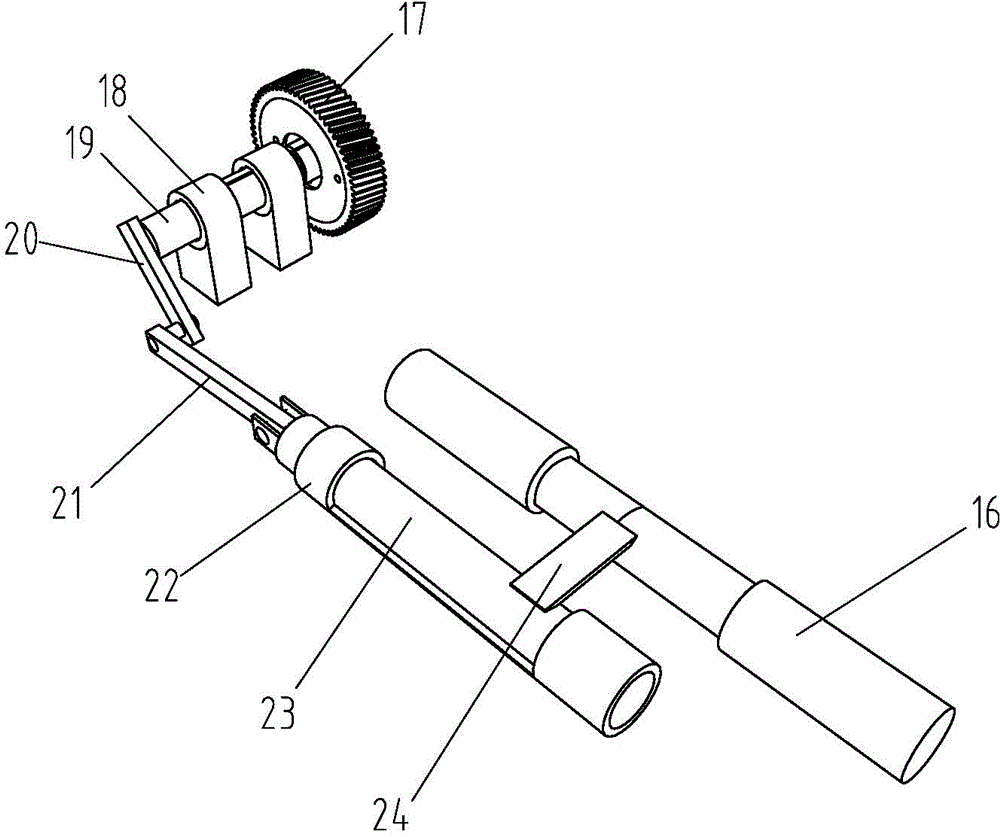

Non-crankshaft engine with air cylinder contraposition device

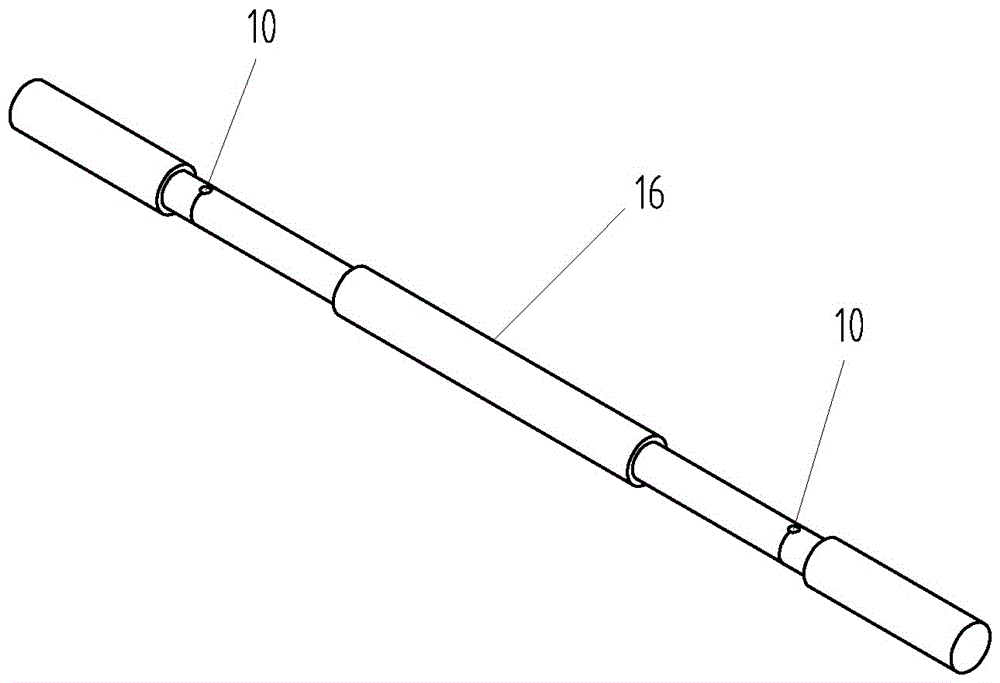

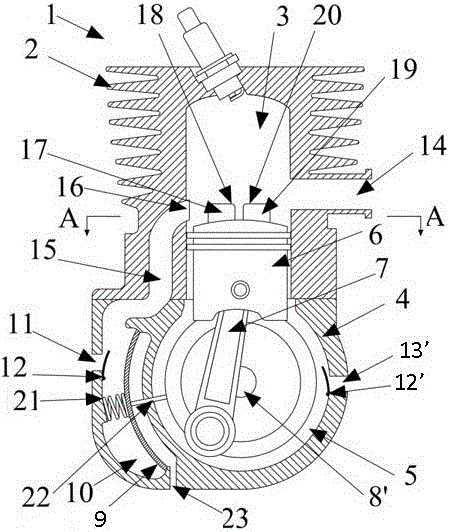

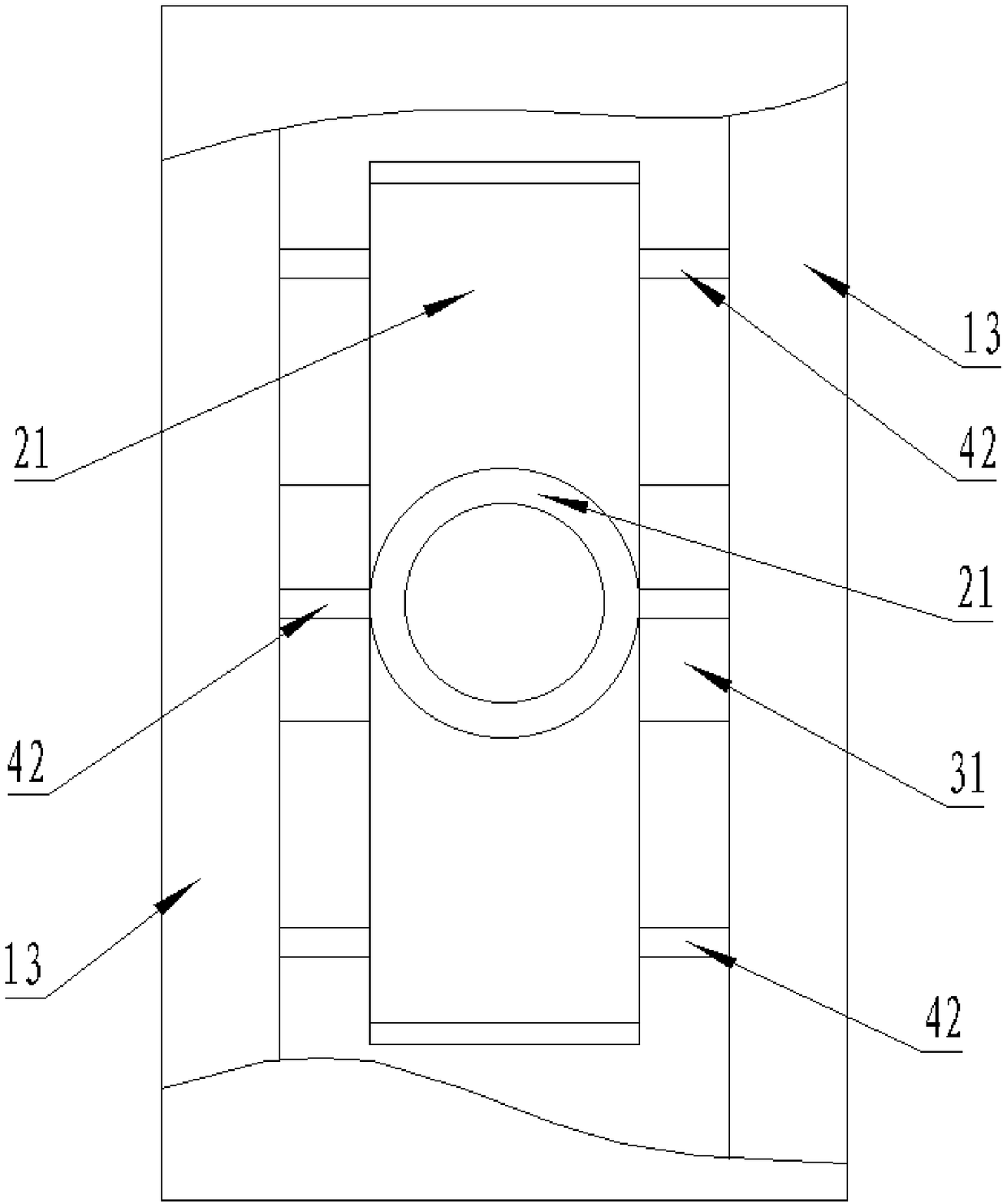

The invention provides a non-crankshaft engine with an air cylinder contraposition device. The non-crankshaft engine comprises a straight shaft, a power output gear, a crank device and the air cylinder contraposition device. The crank device comprises a connecting rod, a crank and a fixed-rail piston which is a piston conducting reciprocating motion in a fixed rail seat. One end of the connecting rod is movably hinged to the end of the fixed-rail piston, and the other end of the connecting rod is movably hinged to one end of the crank. The other end of the crank is fixedly and perpendicularly connected with one end of the straight shaft. The power output gear is fixedly installed on the straight shaft. The air cylinder contraposition device is fixedly connected with the fixed-rail piston and drives the fixed-rail piston to synchronously move with the air cylinder contraposition device. Because the crank device and the straight shaft replace a crankshaft, machining is easier, and work is more reliable. The advanced air cylinder contraposition position is adopted by the engine for drive, automatic pressurization can be achieved during acting, the displacement can be changed through electronic control, replacement of the air cylinder contraposition device is as easy as replacement of a lamp bulb, and great convenience is brought for use and maintenance.

Owner:梁廷容

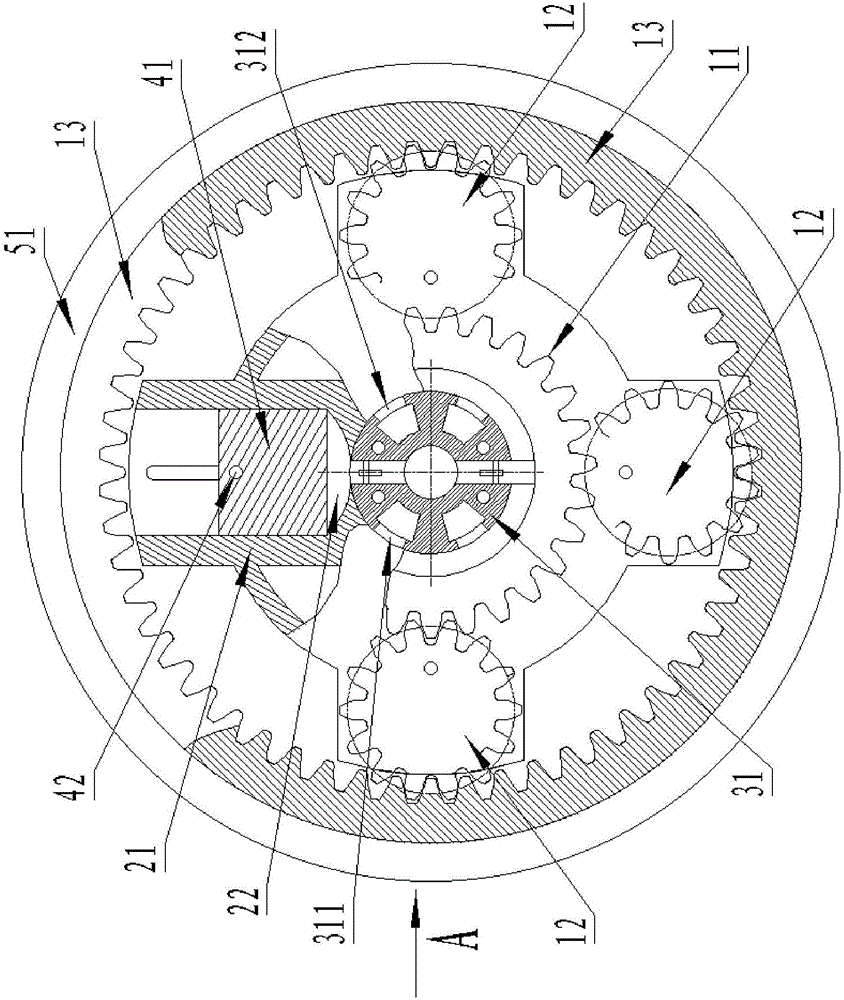

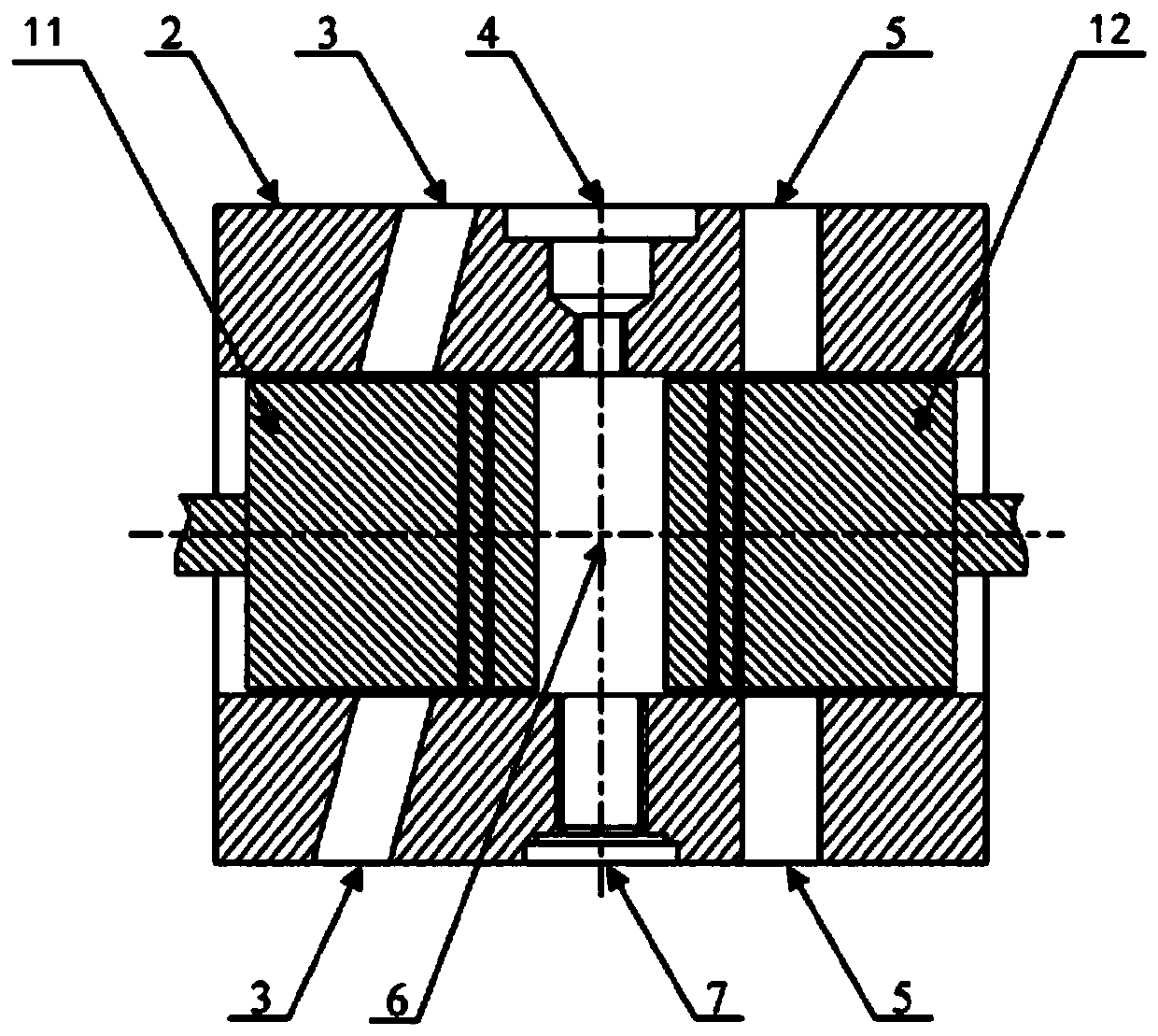

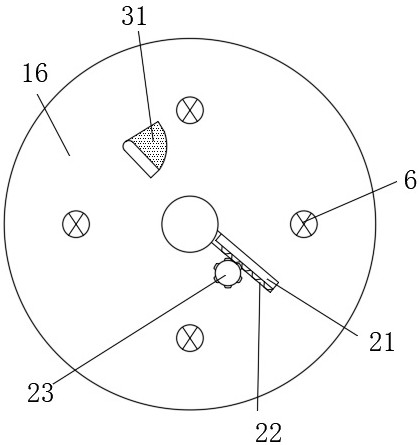

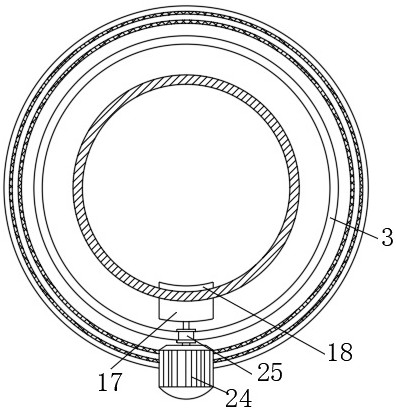

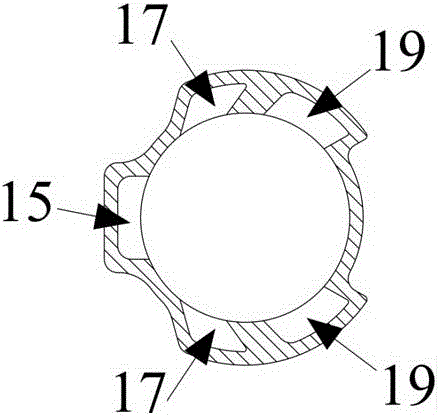

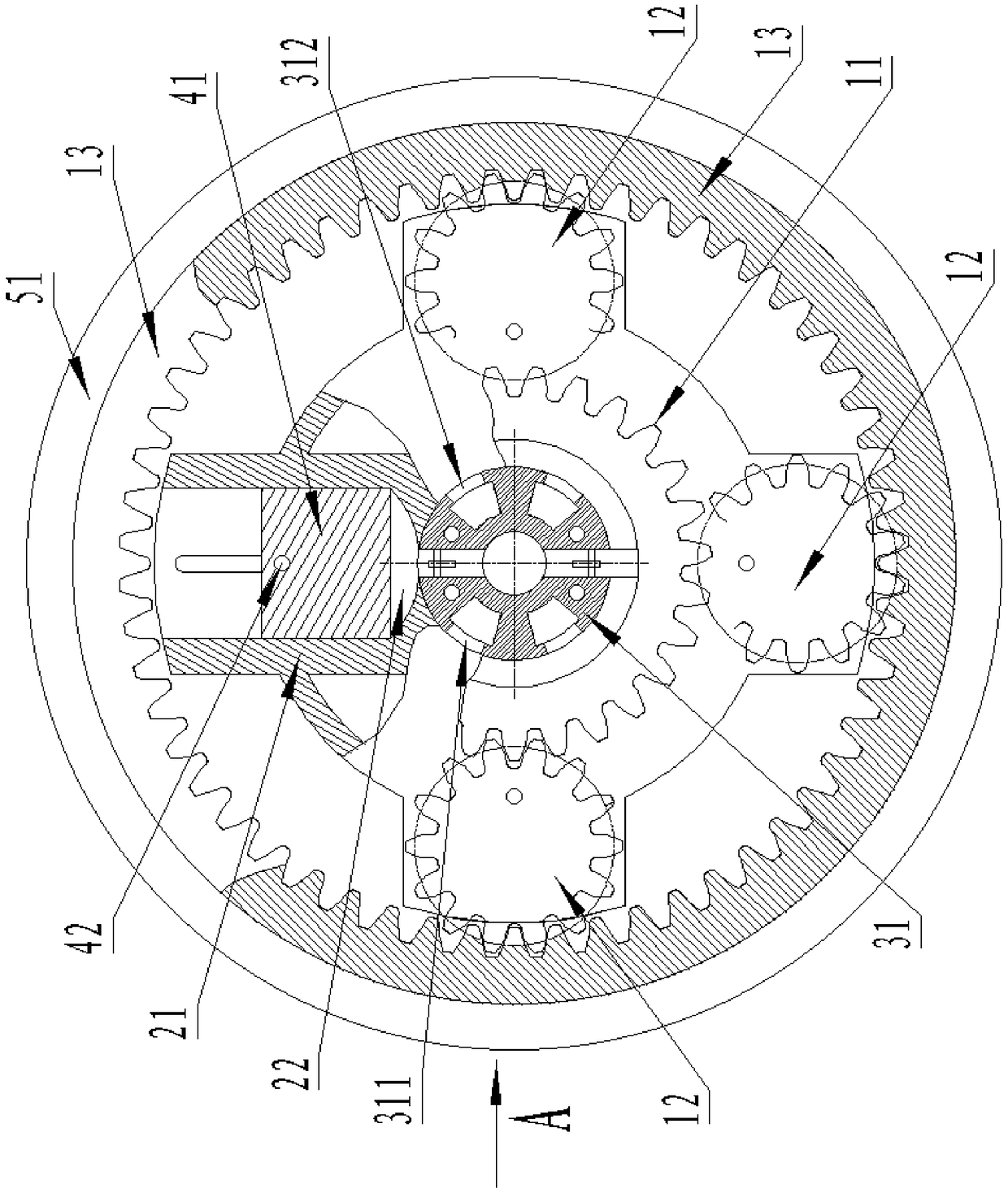

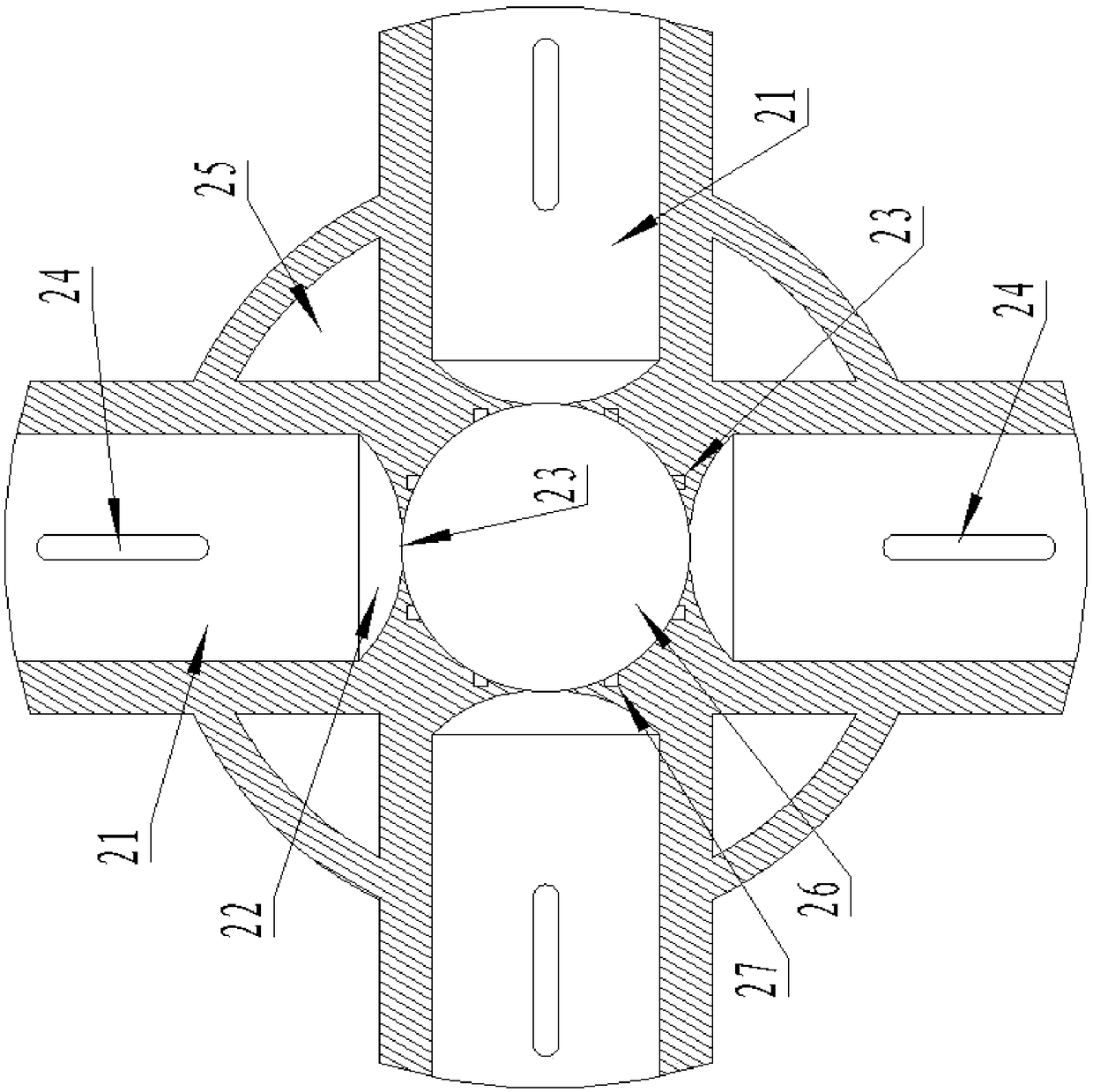

Planet gear and rotating cylinder engine

The invention provides a planet gear and rotating cylinder engine, comprising a planet gear component, a rotating cylinder component, a central distributing valve and a piston component; the rotating cylinder component in the planet gear and rotating cylinder engine rotates by centering on the central distributing valve, and a cylinder finishes a four-stroke cycle per rotation around the central distributing valve. When doing work, a piston pushes a planet gear to run along an inner gear ring and drives a sun gear to output power out. The planet gear and rotating cylinder engine has the advantages of good simplicity, good reliability, good working stability and high power.

Owner:顾永强 +1

Cylinder-cover-free engine with novel crankshaft-connecting-rod mechanism

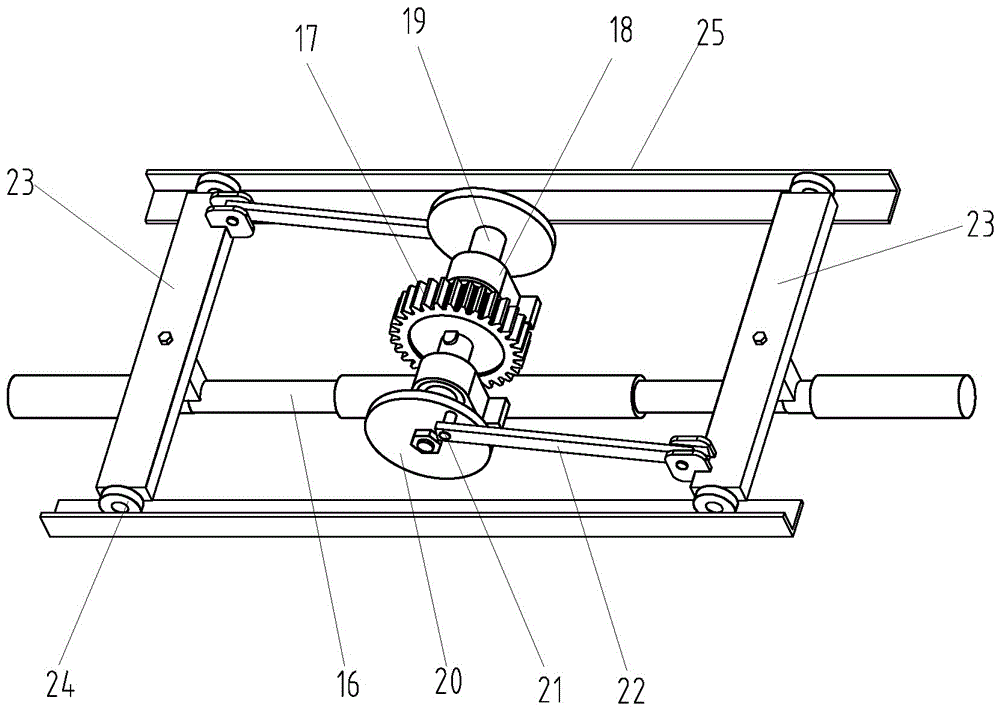

The invention provides a cylinder-cover-free engine with a novel crankshaft-connecting-rod mechanism. A power output unit of the engine comprises the novel crankshaft-connecting-rod mechanism, a power output gear and an air cylinder opposition device. The novel crankshaft-connecting-rod mechanism comprises a straight shaft, round wheels, connecting rods and fixed track plates. The two fixed track plates are driven by the air cylinder opposition device to do opening and closing reciprocating linear movement, and then the two connecting rods are driven to simultaneously conduct pushing drive and pulling drive on the round wheels at the two ends of the straight shaft correspondingly in the opposite directions, so that the two round wheels drive the straight shaft and the power output gear to rotate continuously. According to the engine, the novel crankshaft-connecting-rod mechanism which is simple in structure and reliable in operation is used for replacing conventional crankshaft-connecting-rod mechanisms with many defects, and the advanced air cylinder opposition device is adopted for driving; and an acting air cylinder of the air cylinder opposition device is not provided with a cylinder cover, automatic supercharging can be achieved while the air cylinder acts, the displacement can be flexibly changed, the fuel conversion efficiency is remarkably improved, and the two problems of lubrication and complete air exchange of conventional engines are effectively solved.

Owner:梁廷容

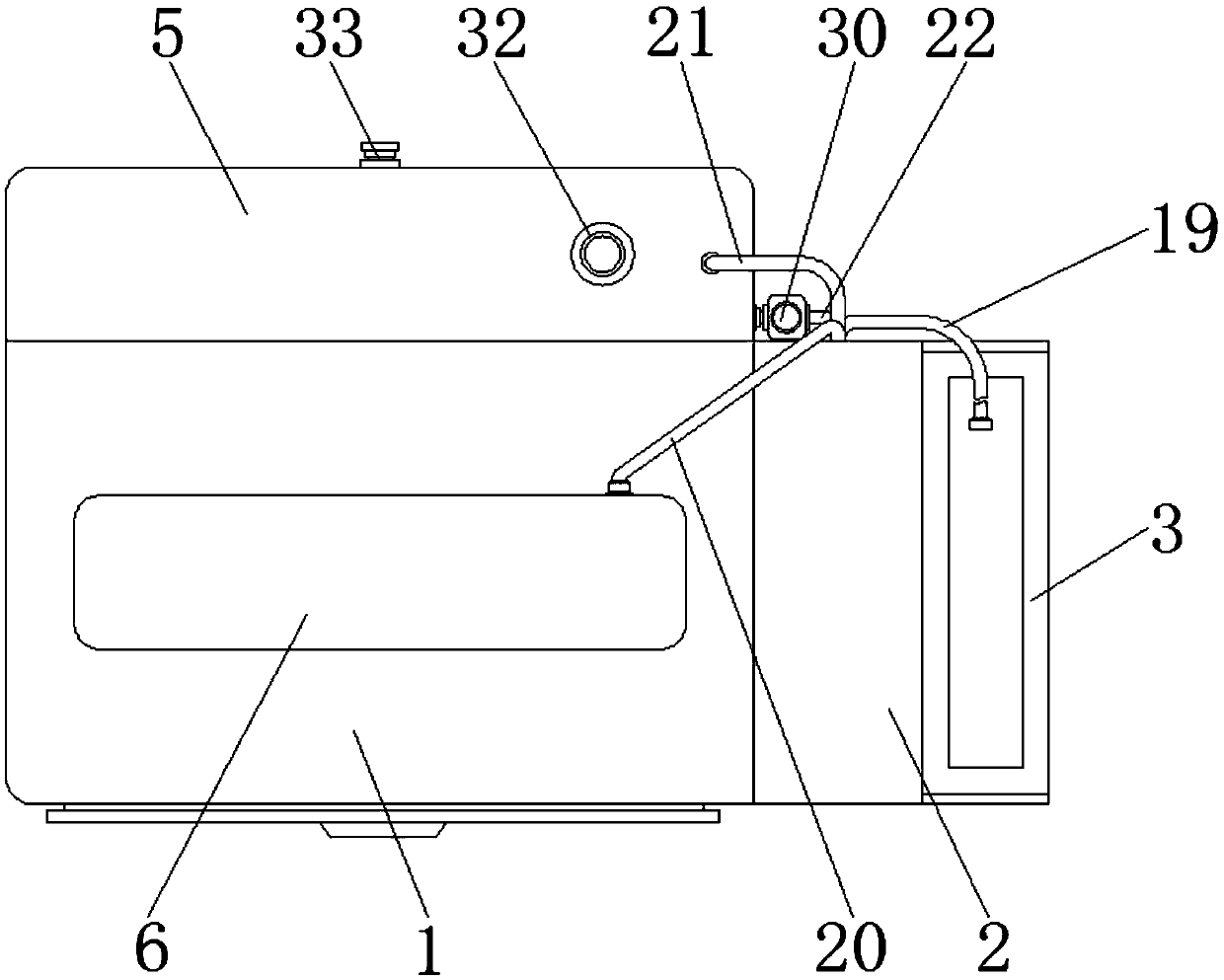

Gas composition verification device based on lightening test of aircraft fuel system

PendingCN107215481AReduce the impactImprove accuracyAircraft components testingAircraft fuel systemCapacitance

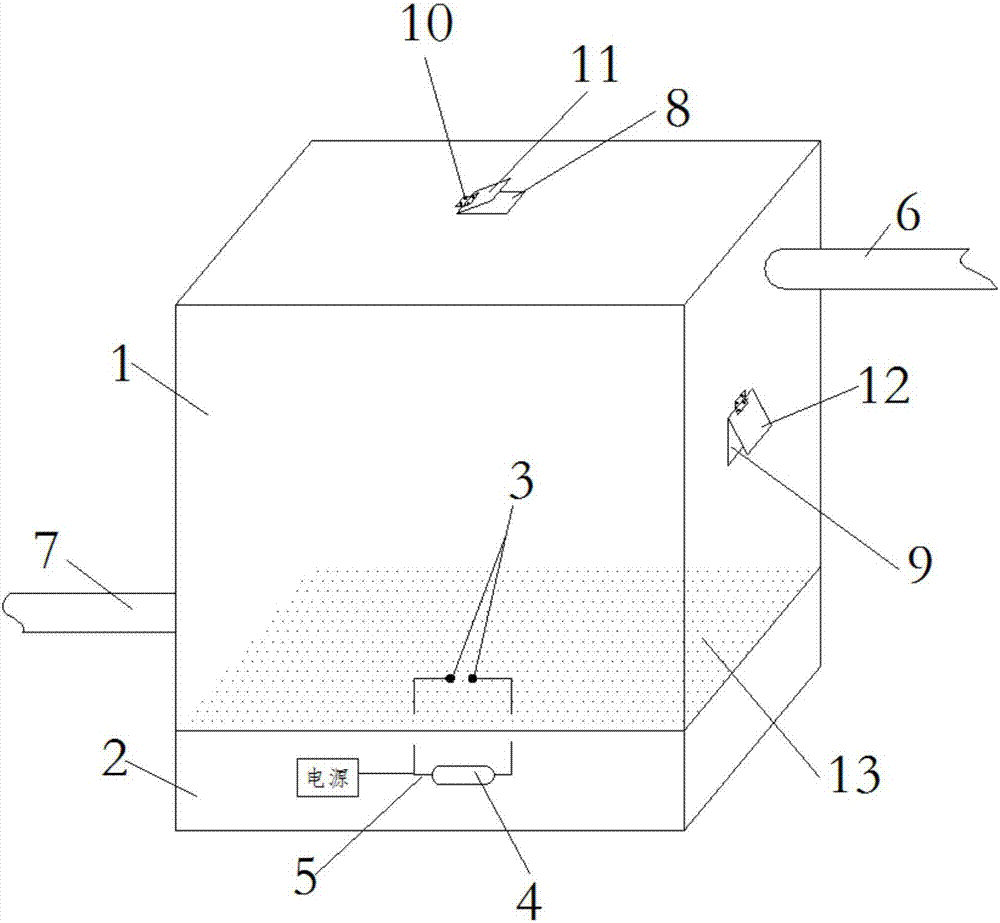

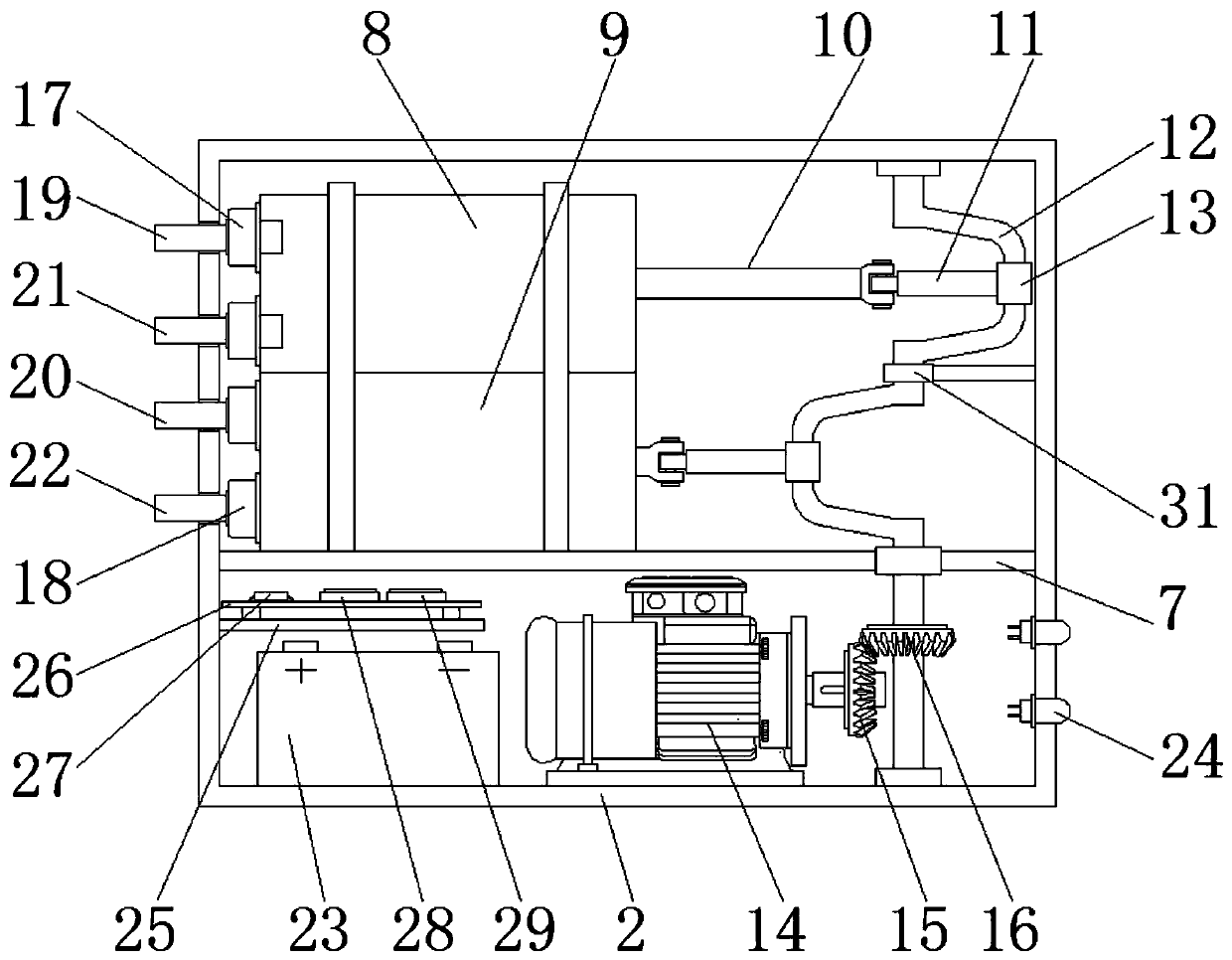

The invention discloses a gas composition verification device based on a lightening test of an aircraft fuel system. The device comprises a shell in a cubic shape, and a sampling cavity, a partition plate and an electric spark source are arranged in the shell in the vertical direction from top to bottom; pressure relief openings b are formed in every side surface on the periphery of the sampling cavity, a pressure relief opening a is formed in the upper surface of the sampling cavity, and an inflation pipe and an exhaust pipe are arranged on the side surfaces of the sampling cavity; the electric spark source comprises a power supply, discharge electrodes and a capacitor. By means of the verification device, the influence of stray capacitance on an electric spark is reduced, and the accuracy and stability of electric spark energy are improved; through the inflation pipe and the exhaust pipe, full gas change of a combustible gas in the sampling cavity is achieved, gas distribution is even, and gas leakage is unlikely to occur; pressure is relieved through the pressure relief opening a and the pressure relief openings b, so that safety of a worker and test equipment is guaranteed.

Owner:熊秀

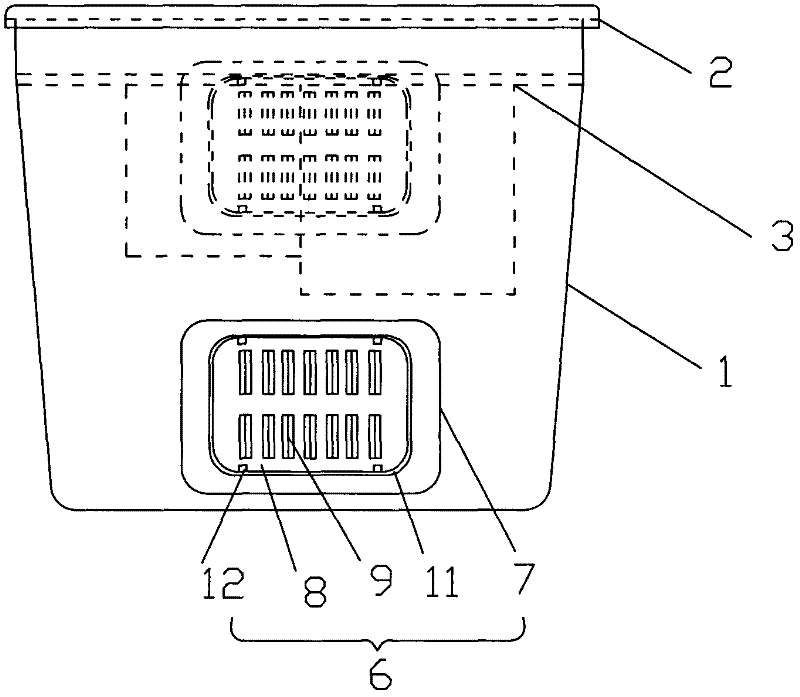

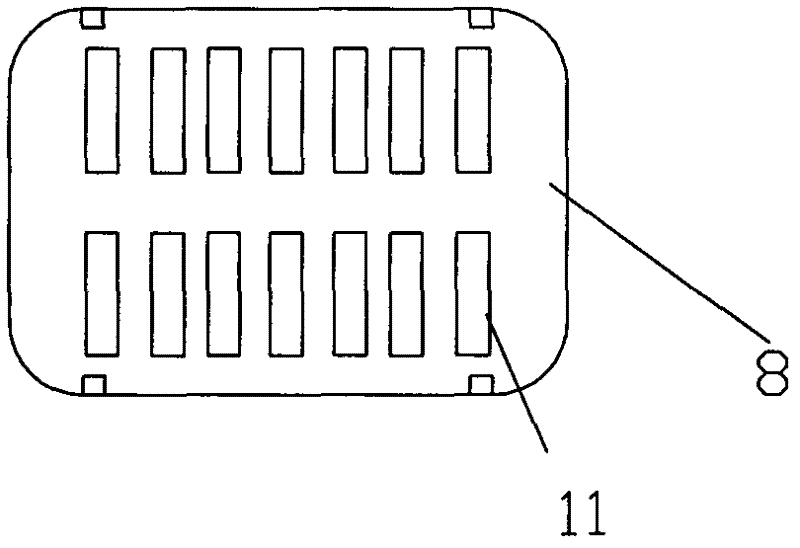

Low-power EVC mouse breeding cage box

InactiveCN102440194AImprove the living environmentThorough ventilationAnimal housingAir filtrationFresh air

The invention relates to a negative pressure type EVC mouse breeding cage box, in particular to a low-power EVC mouse breeding cage box. The low-power EVC mouse breeding cage box comprises a box body, a box cover as well as a water and food iron frame placed in the box body; an air inlet and an air outlet are formed on the two opposite side walls of the box body respectively to form a one-way air flow structure in the cage box; the air outlet and the air inlet are not at the same plane height; the air inlet is lower than the air outlet, and the box cover is integrally sealed at the upper part of the side wall of the box body. A filter is respectively mounted on the air outlet and the air inlet. According to the invention, the air inlet and the air outlet are formed on the two opposite side walls of the box body respectively to form the one-way air flow structure in the cage box; the ambient air in the negative pressure type EVC mouse breeding cage box is sucked through a fresh air entering port (air inlet) and is exhausted through the air outlet in the one-way air flow structure manner; since the air inlet and the air outlet are vertically staggered in position, air in the box body flows upwards generally; compared with the prior art, the structure has the advantages that air is exchanged with fresh air thoroughly, so that a better living environment is supplied for mice; and meanwhile, due to the adoption of the fitting method of the filters, not only is the replacement convenient, but also the air filtration effect enables the air quality in the box body to be ensured.

Owner:府志红

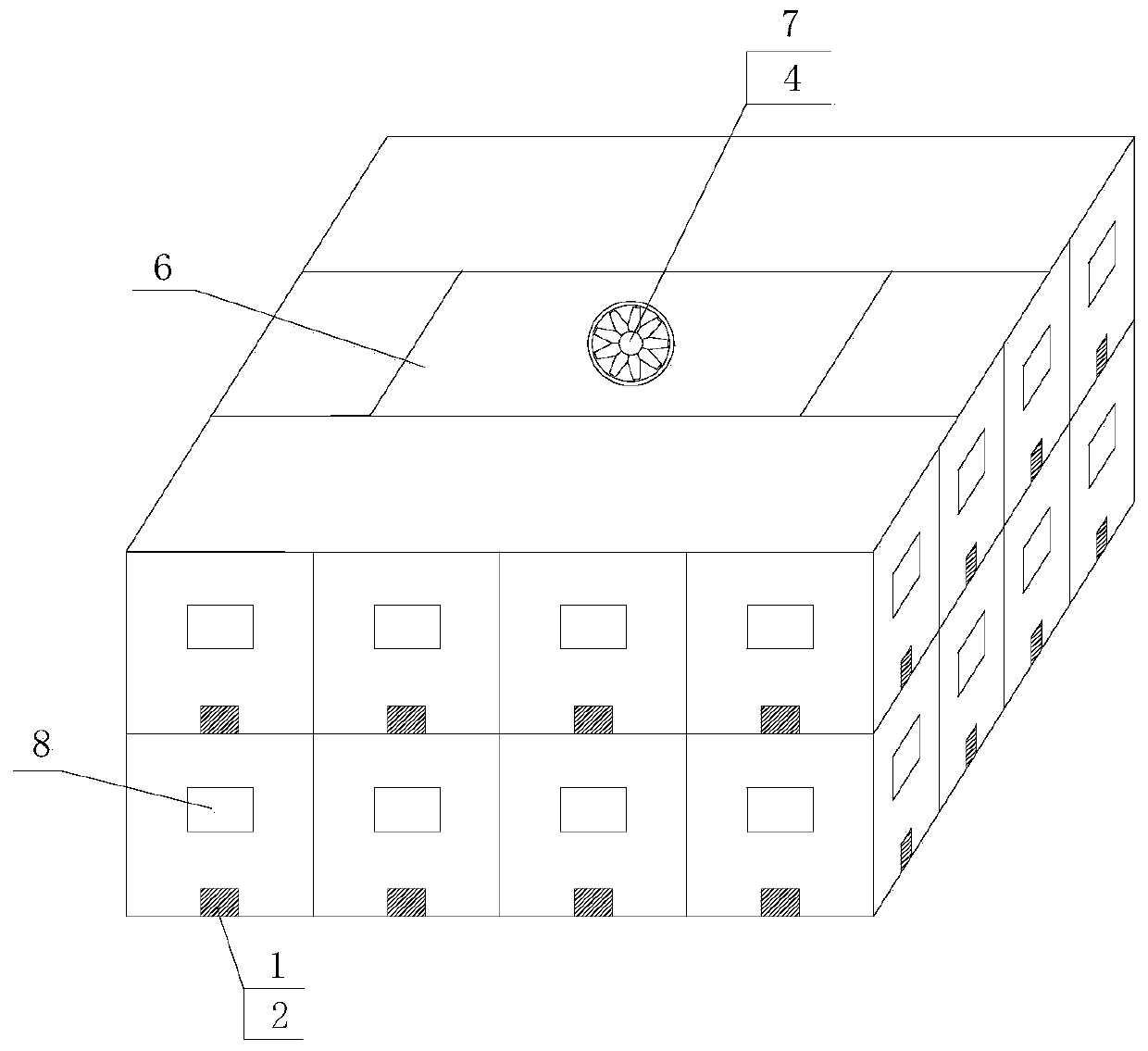

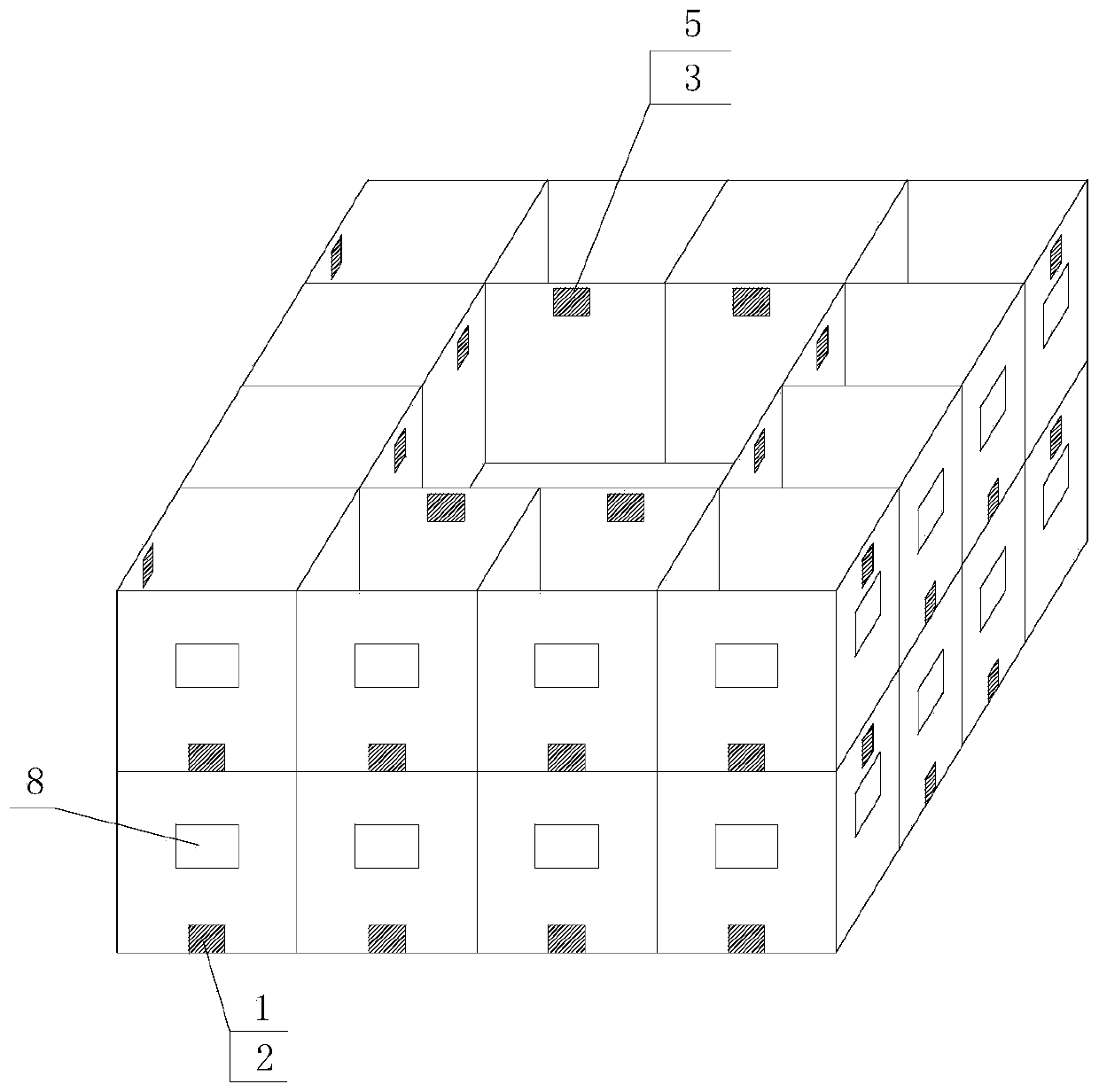

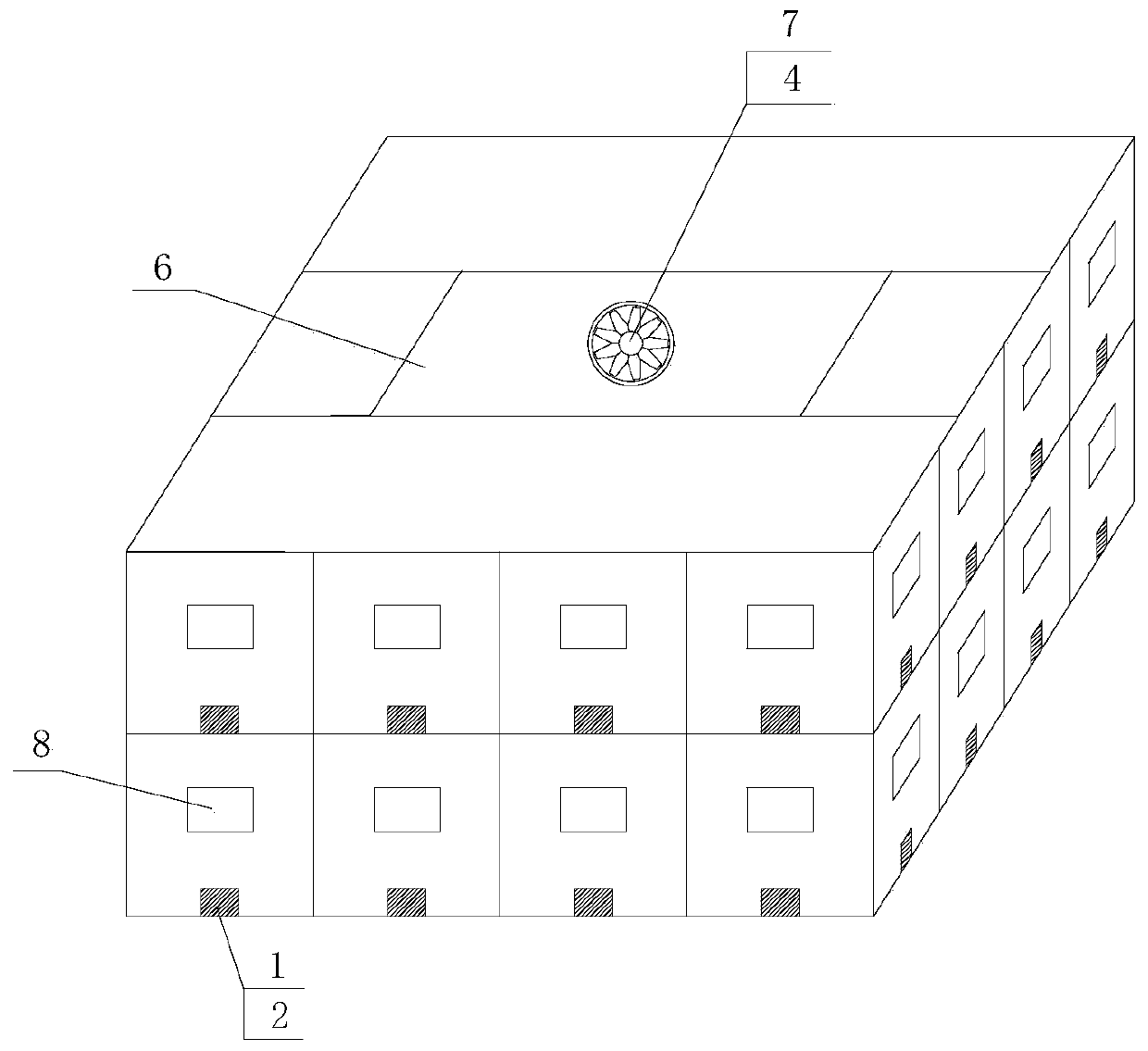

Method for improving ventilation and lighting effects of building

InactiveCN110006131AAdequate ventilationRealize ventilationLighting and heating apparatusVentilation arrangementAir purificationComputer engineering

The invention discloses a method for improving the ventilation and lighting effects of a building. The method specifically comprises the following steps: forming an air inlet port and an air outlet port in the wall of each room in the building; arranging an air purification device at each air inlet port; arranging an air exhaust device at the roof of the building; and forming a lighting window without a movable fan at the wall of each room, and arranging flow-limiting valves at the air inlet port and / or the air outlet port. According to the method, the air inlet ports and the air outlet portsare reasonably formed in the wall of the building, air is driven to enter the rooms from the air inlet ports by the air exhaust device and then is exhausted out of the rooms from the air outlet ports,so that adequate ventilation for each room is ensured; moreover, the air exhausted from the interiors of the rooms is converged into a courtyard, and uniformly exhausted from the top of the courtyardvia an air exhaust port, so that a better ventilation effect for the building is achieved; and the lighting window is a totally-enclosed window, and a movable fan window frame does not need to be arranged on the totally-enclosed window any more, so that a better lighting effect is achieved, and the effect of preventing mosquitoes and dust from entering the rooms can further be achieved.

Owner:湖南和加健养老服务有限公司

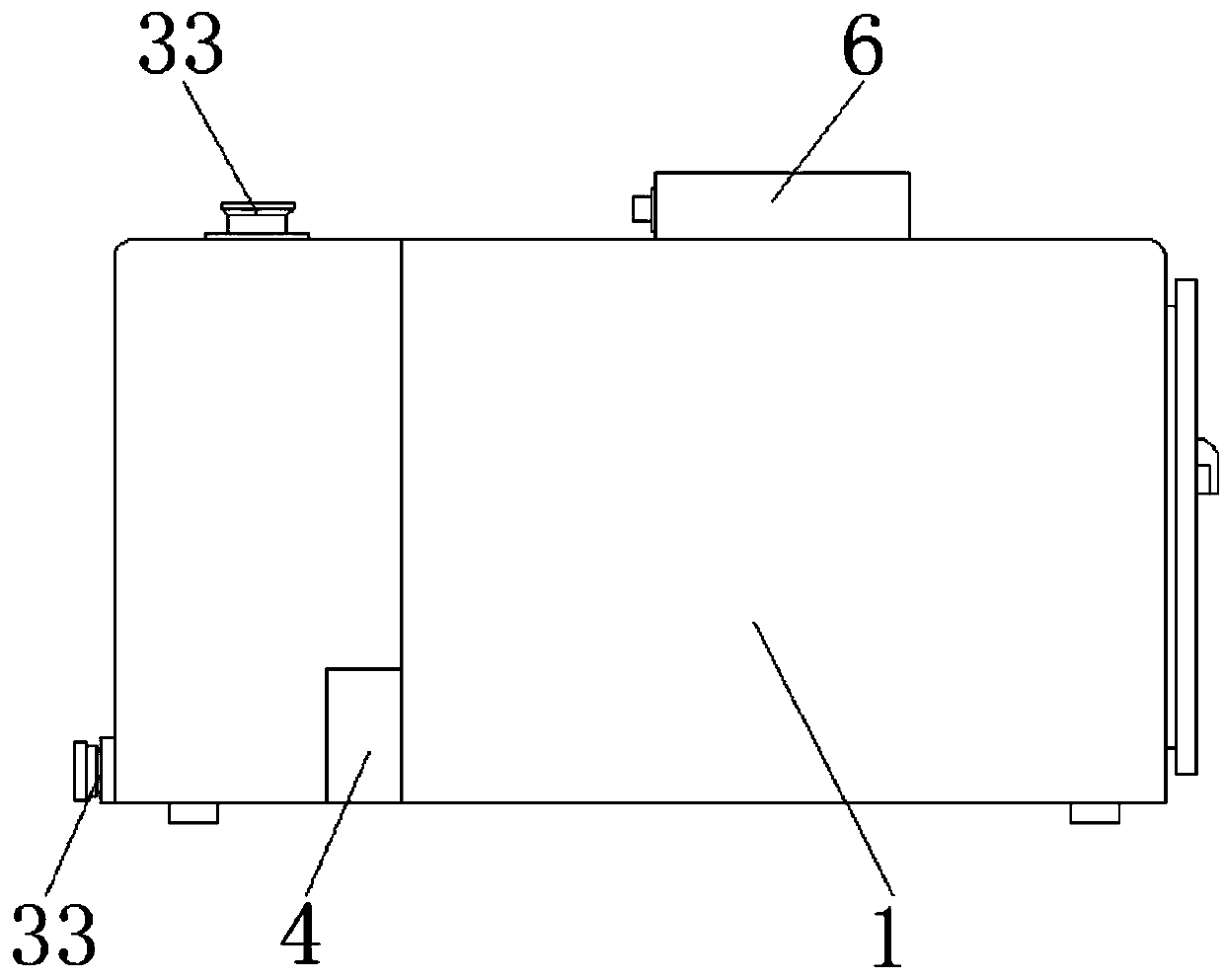

Wood modification heat treatment process and treatment equipment

InactiveCN112454576AGuaranteed dimensional stabilityReduce the influence of material colorRadiation/waves wood treatmentPressure wood treatmentCarbonizationProcess engineering

The invention discloses a wood modification heat treatment process, which comprises: placing wood blanks on a trolley at intervals, vertically stacking a plurality of layers, applying a downward pressure on the top to make the stress on each position of the wood blanks balanced and keep the wood blanks flat, and sequentially carrying out the following treatment steps: S1, replacing nitrogen gas and carrying out preheating treatment, specifically, vacuumizing in a kiln, replacing nitrogen gas, and carrying out preheating; s2, carrying out heating treatment, specifically, heating and dehumidifying the kiln; s3, carrying out deep drying treatment, specifically, completely drying the inside of the kiln; s4, carrying out vacuum microwave carbonization treatment, specifically, carrying out vacuum microwave carbonization treatment in the kiln; s5, carrying out slow cooling treatment, specifically, carrying out slow cooling d under nitrogen protection; s6, carrying out rapid cooling treatment;and S7, carrying out rewetting treatment, specifically, introducing steam into the kiln to enable the blank to reach a certain water content, and then taking out of the kiln. The invention further provides treatment equipment for the treatment process, and aims to reduce the influence of high-temperature carbonization on the color of the wood on the premise of ensuring the dimensional stability of the wood.

Owner:湖南威达尔木业科技有限公司

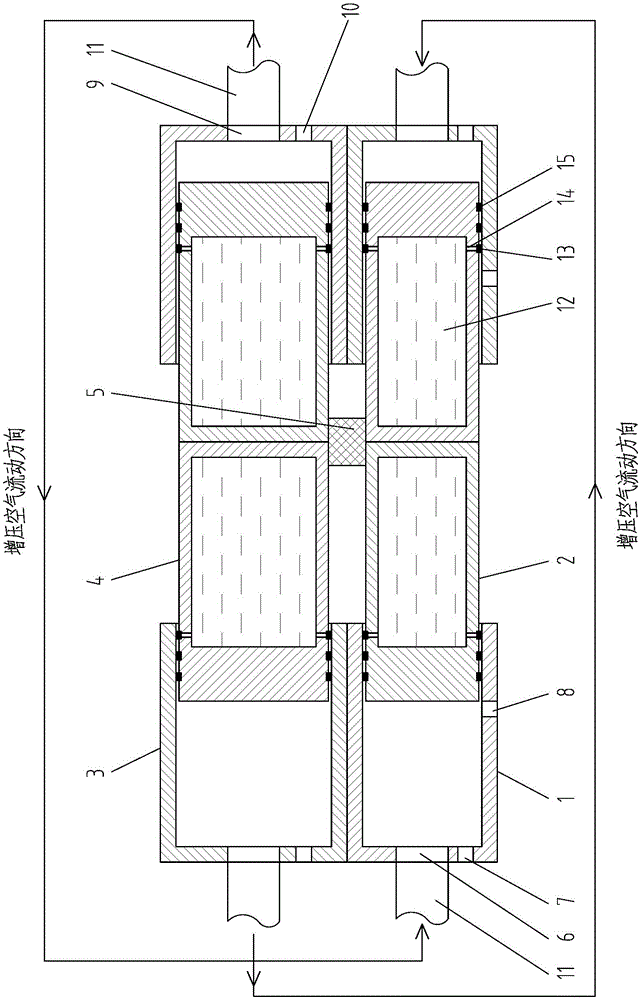

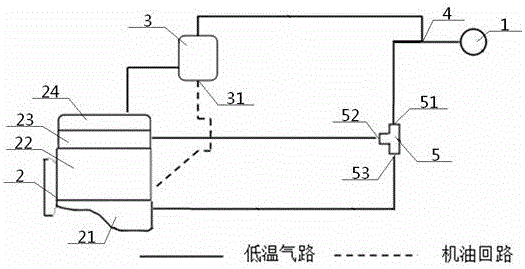

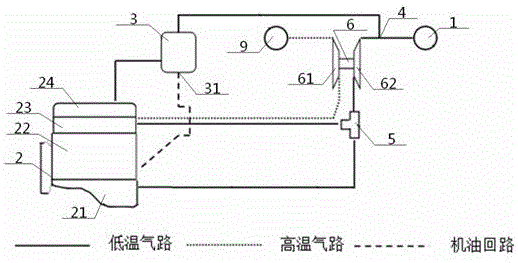

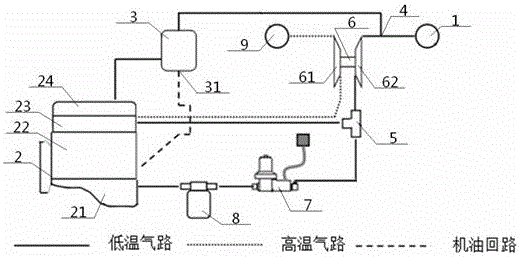

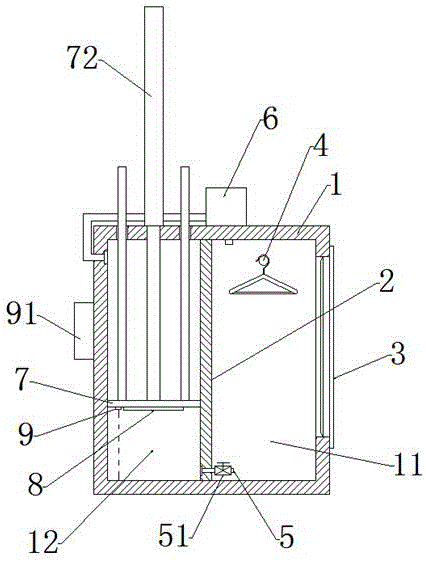

Engine local oil anti-emulsification system and using method thereof

ActiveCN106382142AAdequate ventilationSolve the oil emulsification problemOilsumpsMachines/enginesAutomotive engineeringForced induction

An engine local oil anti-emulsification system comprises an engine, a fresh air inlet, a three-way valve, a supercharger, an oil-gas separator, a solenoid valve and an air filter, wherein the engine successively comprises an oil sump, a cylinder body, a cylinder cover and a cylinder head cover which are connected with each other successively from bottom to top; after flowing out from the supercharger and the three-way valve, gas flowing out from a waste gas outlet and the fresh air inlet is divided into two parts; and one part of the gas enters the cylinder body and is combusted while the other part of the gas successively passes through the solenoid valve, the air filter, the oil sump, the cylinder body, the cylinder cover and the cylinder head cover to dilute and replace waste gas in a crank case of the engine from bottom to top. By the design, the problem of oil emulsification can be solved, gas exchange is full, furthermore, utilization rate of the gas is high, and normal running of the engine is not affected.

Owner:DONGFENG COMML VEHICLE CO LTD

Gas control system of reflow oven and method of the same

The invention discloses a gas control system of a reflow oven and a method of the same. The system comprises a reflow oven body, the right side of the reflow oven body is fixedly connected with a machine box, and the bottom of the right side of the machine box is fixedly connected with a tray; and the bottom of the back side of the reflow oven body communicates with an air suction box, a water tank is fixedly connected between the back face of the reflow oven body and the top of the air suction box; and the invention relates to the technical field of reflow ovens. According to the gas controlsystem of the reflow furnace and the method of the same, through the movement of a crankshaft, and two push rods can push a piston to move in turn through the cooperation of a fixing sleeve and a rotating rod, through the cooperation among four pipelines and four one-way valves, air in the reflow oven body can be replaced with helium gas before machining, so that oxygen can be prevented from affecting machining, air sucking and exhausting can be carried out at the same time, and the working efficiency is high; and the internal waste gas can be pumped out after the machining, use is convenientthrough a device to realized, moreover, the air sucking and the exhausting can be carried out synchronously, so that the gas exchange can be guaranteed thoroughly.

Owner:武汉倍普科技有限公司

Ventilating equipment for cleaning and maintenance of railway oil tanker

InactiveCN104061192ADoes not consume energyThorough ventilationJet pumpsMachines/enginesAir volumeTank truck

The invention relates to ventilating equipment for cleaning and maintenance of a railway oil tanker, particularly to portable ventilating equipment for cleaning and maintenance of the railway oil tanker. The ventilating equipment comprises a Venturi fan 1, a flexible air inlet pipe 2, a movable support 3, a compressed air telescopic pipeline 4 and a pneumatic booster pump 5. The ventilating equipment has the advantages as follows: the ventilating equipment is large in air volume, movable and portable; the ventilating equipment is not required to consume a large amount of compressed air and does not consume power; the ventilating equipment can extend into a tank at will and change the air outlet angle, so that no dead corner which is not easy to ventilate exists in the tank, and the ventilating operation is more comprehensive and thorough.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

Marine diesel engine high-pressure SCR ventilation pressure stabilizing system and ship

PendingCN112648048AGuaranteed cleanlinessThorough ventilationInternal combustion piston enginesExhaust apparatusFlue gasDieseling

The invention provides a marine diesel engine high-pressure SCR ventilation pressure stabilizing system and a ship. The system comprises an SCR reactor, an air inlet pipeline, an air exhaust pipeline, a bypass pipeline, a pneumatic pipeline, a first auxiliary pipeline and a second auxiliary pipeline, wherein when tail gas of a diesel engine needs to be subjected to denitrification treatment, the tail gas can enter from a flue gas inlet, sequentially passes through the air inlet pipeline, the SCR reactor and the air exhaust pipeline and is exhausted from a flue gas outlet, and the tail gas can be subjected to the denitrification treatment in the SCR reactor; and when the tail gas of the diesel engine does not need to be subjected to the denitrification treatment, the tail gas can enter the bypass pipeline from the flue gas inlet and is exhausted from the flue gas outlet, and at the moment, the tail gas in the SCR reactor and the tail gas in the air exhaust pipeline are pushed by compressed air entering from the first auxiliary pipeline and the second auxiliary pipeline to be exhausted from the flue gas outlet. According to the system, an original inlet air pipeline is omitted, a structure of the whole system is simplified, the whole system is more compact, sufficient air exchange is guaranteed, and meanwhile air consumption is reduced.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

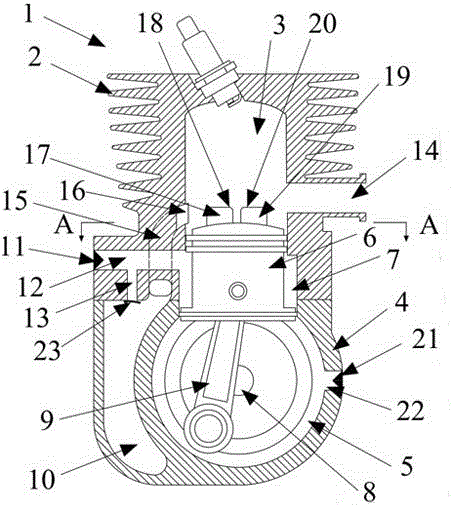

Valve actuating mechanism on engine

The invention discloses a valve actuating mechanism on an engine, which comprises a plurality of inlet valves, a plurality of exhaust valves, a first holding base, a second holding base, a first cam, a second cam, a first group of cylinders, a second group of cylinders and a push rod, wherein the inlet valves share the first cam, and the exhaust valves share the second cam. The valve actuating mechanism integrates the advantages of engine valves of four strokes and two strokes of the prior art and the existing art, and has the advantages of light weight, full air inflation, more complete ventilation as well as convenience and larger power and weight because the size of the radial engine is compact.

Owner:上海北星实业有限公司

Intelligent motor home living safety protection device

InactiveCN112406681AMonitor temperature in real timeRealize up and down movementAir-treating devicesPedestrian/occupant safety arrangementMotor homeAir exchange

The invention discloses an intelligent motor home living safety protection device, and relates to a safety protection device. The intelligent motor home living safety protection device comprises a bottom plate, a carriage is fixedly connected to the upper portion of the bottom plate, a sealing cover is fixedly connected to the upper portion of the carriage, and a first driving mechanism is fixedlyconnected to the lower portion of the middle of the sealing cover and fixedly connected with a rotating block. The rotating block is slidably connected with a first rotating rod, the right end of thefirst rotating rod is rotatably connected with a sliding rail block, the middle of the sliding rail block is slidably connected with a moving rod, the lower end of the moving rod is fixedly connectedwith an air exchange port, and the upper end of the moving rod is fixedly connected with a first sliding block. A vertical rod is fixedly connected to the lower portion of the sealing cover. A sensoris arranged above the left side of the carriage and can monitor environmental indexes such as temperature and oxygen density in the vehicle in real time, a lifting assembly is arranged below the carriage and can achieve vertical movement of a lifting plate, and when the ground surface water is too high, the lifting plate rises to avoid water seepage; and an air exchange opening moving left and right is formed below the sealing cover, so that the interior of the carriage can be fully and quickly exchanged.

Owner:山东奥斯登房车有限公司

Free piston engine central combustion chamber tumble air intake structure

PendingCN111594309AImprove mixing uniformitySimple structureInternal combustion piston enginesFree piston enginesFree-piston engineCombustion chamber

The invention discloses a free piston engine central combustion chamber tumble air intake structure. The free piston engine central combustion chamber tumble air intake structure comprises an air cylinder body, the two sides of the interior of a cavity of the air cylinder body are provided with an air intake piston and an air exhaust piston, and a combustion chamber is arranged between the air intake piston and the air exhaust piston; the top end of the air cylinder body is provided with an oil injector, the bottom of the air cylinder body is provided with a spark plug, and the two sides of the oil injector and the two sides of the spark plug located on the same plumb line with the oil injector are provided with air inlets and air outlets; and the air cylinder body of the combustion chamber is horizontally placed along the axis, and the combustion chamber is arranged in the middle of the air cylinder body. The free piston engine central combustion chamber tumble air intake structure issimple and symmetrical in structure, tumble can be organized in the cylinder to promote mixing of oil and gas, the utilization efficiency of fuel oil is high, the combustion process is smooth and steady, the output power of an engine is improved, and reduction of fuel oil consumption rate and reduction of pollution emission can be achieved at the same time.

Owner:江苏铱莱德驱动系统有限公司

Poultry house ventilation air-exchange system and poultry house ventilation air-exchange control method

PendingCN106106109AThorough ventilationImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAir exchange

The invention provides a poultry house ventilation air-exchange system which comprises an air inlet device (2), wherein the air inlet device (2) is arranged on a side wall of a poultry house. The poultry house ventilation air-exchange system is characterized by further comprising a ventilation pipeline which is communicated with the air inlet device; inside the poultry house, the ventilation pipeline extends to the part above a case along the side wall of a wall body and a roof; the ventilation pipeline comprises a guide section (3) and an air outlet section (4); an air outlet part is arranged on the pipeline wall of the air outlet section (4). The invention further relates to a poultry house ventilation air-exchange control method. By adoption of the poultry house ventilation air-exchange system, the temperature can be kept constant while ventilation and air exchange are achieved, and air can be sufficiently exchanged in the center inside the poultry house. By adoption of the poultry house ventilation air-exchange control method provided by the invention, different ventilation air exchange methods can be adopted according to different seasons and different growing stages of poultry, and thus the comfortable level of poultry can be increased.

Owner:山东益圆农牧机械科技有限公司

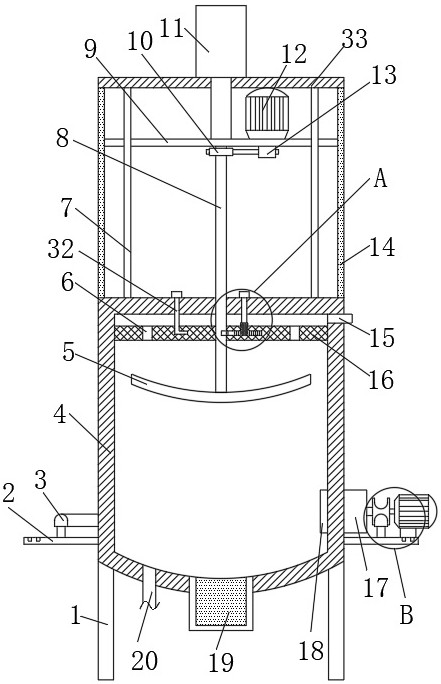

A kind of enzyme-catalyzed pharmaceutical intermediate preparation reaction kettle

ActiveCN112755951BReduce manufacturing costThorough ventilationHollow article cleaningChemical/physical/physico-chemical stationary reactorsMedicineElectric machinery

The invention provides an enzyme-catalyzed pharmaceutical intermediate preparation reaction kettle, which relates to the field of preparation of pharmaceutical intermediates. The enzyme-catalyzed pharmaceutical intermediate preparation reaction kettle includes a reaction kettle body, four one-way valves are evenly distributed on the outer periphery of the middle part of the ventilation plate, the upper part of one side wall of the reaction kettle body is provided with valves, and the rotating shaft The bottom end of the carrier ring is fixedly connected to the middle part of the stirring rod, the middle part of the upper end of the carrier ring is fixedly connected with a track, the outer side of the track is provided with two rows of slideways, the slideway is slidably connected with a sliding seat, and the second motor is The driving end is fixedly connected with a roller, and the side of the roller away from the second motor is rotatably connected with the first magnet. The setting of the ventilation plate and the one-way valve makes the ventilation rate in the reactor body high, and the first magnet drives the second magnet to move, which can quickly remove the pharmaceutical intermediates attached to the inner wall of the reactor body, which is worthy of vigorous promotion.

Owner:福建未来药业有限公司

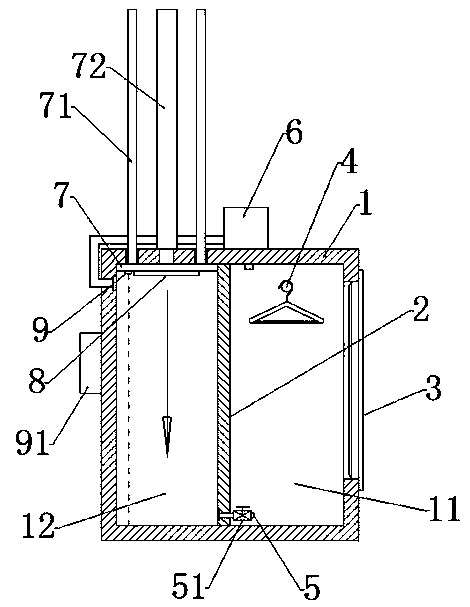

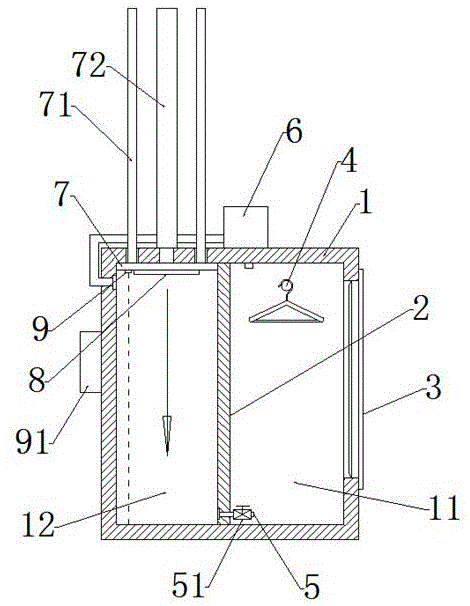

A school uniform volatile detection device

ActiveCN107525888BThorough ventilationSimple structureAnalysing gaseous mixturesData displayMagnetic valve

The invention relates to a volatile matter detection device for a school uniform. The device comprises a sealing box and a controller, wherein the inner side of the sealing box is divided into a uniform-hanging room and a detection room in equal volume through a vertical partition plate; the bottoms of the uniform-hanging room and the detection room communicate to an electromagnetic valve arranged on a pipeline through the pipeline and communicates to the upper portion through a ventilating device; a sealing door is arranged on the lateral side of the uniform-hanging room and a coat hanger is arranged inside; a sealing movable plate is arranged in the detection room through a guide structure up and down and a telescopic mechanism up and down; a distance sensor and a volatile matter detection mechanism are arranged on the lower surface of the sealing movable plate; and the volatile matter detection mechanism is connected to a volatile matter data display module. The device provided by the invention overcomes defects in the prior art, and detects the volatile matters in compressed air by means of the volatile matter detection mechanism, so that the effect of condition of volatile matters after multiple uniforms are concentrated is achieved by detecting one uniform, and the device is simple in structure, convenient to operate, low in cost and easy to popularize and use.

Owner:安徽天使服装服饰有限责任公司

A two-stroke stratified scavenging engine

ActiveCN104500212BEasy to useReduce harmful emissionsInternal combustion piston enginesRisk strokeCylinder block

Owner:JIANGSU LINHAI POWER MACHINERY GROUP

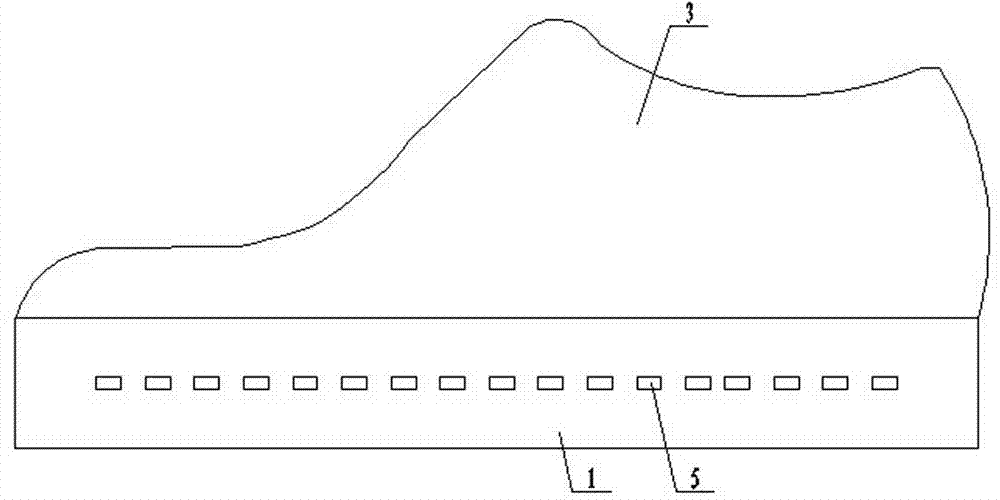

Multi-purpose ventilation shoes

The invention discloses a pair of multi-purpose ventilation shoes comfortable to wear. Each multi-purpose ventilation shoe comprises an outer sole, an inner sole and a vamp, wherein the vamp and the outer sole are glued into a whole; a ventilation cavity is formed between the outer sole and the inner sole; two sides of the outer sole are provided with a plurality of vent holes communicated with the ventilation cavity; the outer sole is provided with a plurality of guide posts; the inner sole is provided with a plurality of guide holes matched with the guide posts; the guide posts are sleeved by springs; certain ends of the springs prop against the outer sole; the other ends of the springs prop against the inner sole; the upper ends of the guide posts are provided with semicircular massage points matched with a foot.

Owner:JIANGSU QINSHENG SHOES INDAL

Structure of skylight in greenhouse

InactiveCN1299566CIncrease the opening areaAppropriate tensionClimate change adaptationGreenhouse cultivationPlastic filmEngineering

A structure of the skylight of a greenhouse capable of facilitating a stretching operation for plastic film covering the roof of the greenhouse, comprising a window receiving frame (4) having holding parts (4c) capable of holding film fixtures (11) so as to be slidably moved by the engagement thereof with a part of the film fixtures (11) disposed on a frame material (10) forming the roof of the greenhouse, characterized in that joint members (12) capable of fixing the film fixtures (11) to the frame material (10) at any positions in the slidable movement range thereof are fitted to the frame material (10).

Owner:大出武久

Multifunctional comfortable breeding shed for animal husbandry

ActiveCN114208683APromote growthThorough ventilationAnimal feeding devicesAnimal housingAnimal scienceCrop livestock

The invention relates to a breeding shed, in particular to a multifunctional comfortable breeding shed for animal husbandry. The technical problem to be solved is to provide the multifunctional comfortable breeding shed which not only can clean excrement in a livestock pen, but also can complete automatic feed throwing at the same time. According to the technical scheme, the multifunctional comfortable breeding shed for animal husbandry comprises a first wall, a framework, a feed trough, second walls and the like, the framework is fixedly connected to the top of the first wall, and the second walls are fixedly connected to the front side and the rear side of the interior of the first wall; the second wall divides the inner bottom wall of the first wall into six rectangular areas with the same size and shape, and a feed trough is formed in the middle of the other side, away from the first wall, of each rectangular area. The ceiling is made of a transparent heat-insulating material, so that the heat-insulating or light-transmitting effect can be effectively achieved, and the effect of facilitating the growth of livestock is achieved.

Owner:荣城构羊现代农业(重庆)有限公司

Volatile matter detection device for school uniform

ActiveCN107525888AThorough ventilationSimple structureAnalysing gaseous mixturesData displayEngineering

The invention relates to a volatile matter detection device for a school uniform. The device comprises a sealing box and a controller, wherein the inner side of the sealing box is divided into a uniform-hanging room and a detection room in equal volume through a vertical partition plate; the bottoms of the uniform-hanging room and the detection room communicate to an electromagnetic valve arranged on a pipeline through the pipeline and communicates to the upper portion through a ventilating device; a sealing door is arranged on the lateral side of the uniform-hanging room and a coat hanger is arranged inside; a sealing movable plate is arranged in the detection room through a guide structure up and down and a telescopic mechanism up and down; a distance sensor and a volatile matter detection mechanism are arranged on the lower surface of the sealing movable plate; and the volatile matter detection mechanism is connected to a volatile matter data display module. The device provided by the invention overcomes defects in the prior art, and detects the volatile matters in compressed air by means of the volatile matter detection mechanism, so that the effect of condition of volatile matters after multiple uniforms are concentrated is achieved by detecting one uniform, and the device is simple in structure, convenient to operate, low in cost and easy to popularize and use.

Owner:安徽天使服装服饰有限责任公司

A local engine oil anti-emulsification system and its application method

ActiveCN106382142BMeet the needs of combustionDoes not interfere with normal operationOilsumpsMachines/enginesSolenoid valveAir filter

An engine local oil anti-emulsification system comprises an engine, a fresh air inlet, a three-way valve, a supercharger, an oil-gas separator, a solenoid valve and an air filter, wherein the engine successively comprises an oil sump, a cylinder body, a cylinder cover and a cylinder head cover which are connected with each other successively from bottom to top; after flowing out from the supercharger and the three-way valve, gas flowing out from a waste gas outlet and the fresh air inlet is divided into two parts; and one part of the gas enters the cylinder body and is combusted while the other part of the gas successively passes through the solenoid valve, the air filter, the oil sump, the cylinder body, the cylinder cover and the cylinder head cover to dilute and replace waste gas in a crank case of the engine from bottom to top. By the design, the problem of oil emulsification can be solved, gas exchange is full, furthermore, utilization rate of the gas is high, and normal running of the engine is not affected.

Owner:DONGFENG COMML VEHICLE CO LTD

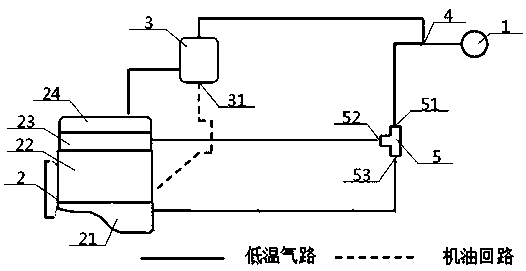

Two-stroke stratified scavenged engine

ActiveCN104500211BReduce short circuit lossReduce pollutionInternal combustion piston enginesPulp and paper industryCrankcase

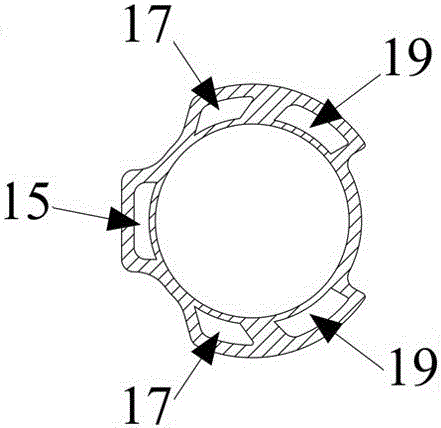

The invention discloses a two-stroke stratified scavenging engine mainly comprising an air scavenging part and a mixed gas scavenging part. The air scavenging part mainly comprises an air storage chamber (10) and an air scavenging passage (15); two ends of the air scavenging passage (15) are communicated with an air scavenging orifice (16) arranged in the inner wall of one side of a cylinder block (2) and the air storage chamber (10); the mixed gas scavenging part mainly comprises mixed gas scavenging passages (17 and 19); the mixed gas scavenging passages are hollow passages formed by the outer surface of a piston (6) and grooves arranged in the inner wall of the cylinder block (2); two ends of the mixed gas scavenging passages (17 and 19) are communicated with mixed gas scavenging orifices (18 and 20) arranged in a cylinder (3) and a crankcase (5). The technical scheme of stratified scavenging with the independent air scavenging passages is provided, short-circuit loss of fresh mixed gas is greatly reduced, and harmful emission of the engine is reduced.

Owner:JIANGSU LINHAI POWER MACHINERY GROUP

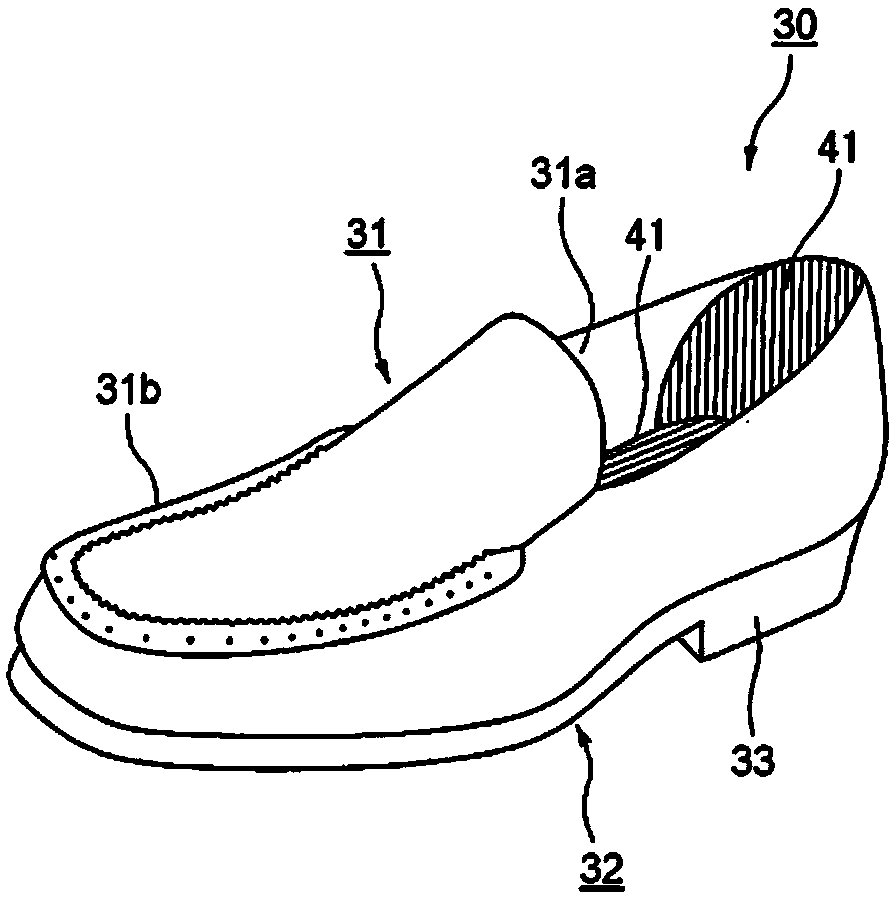

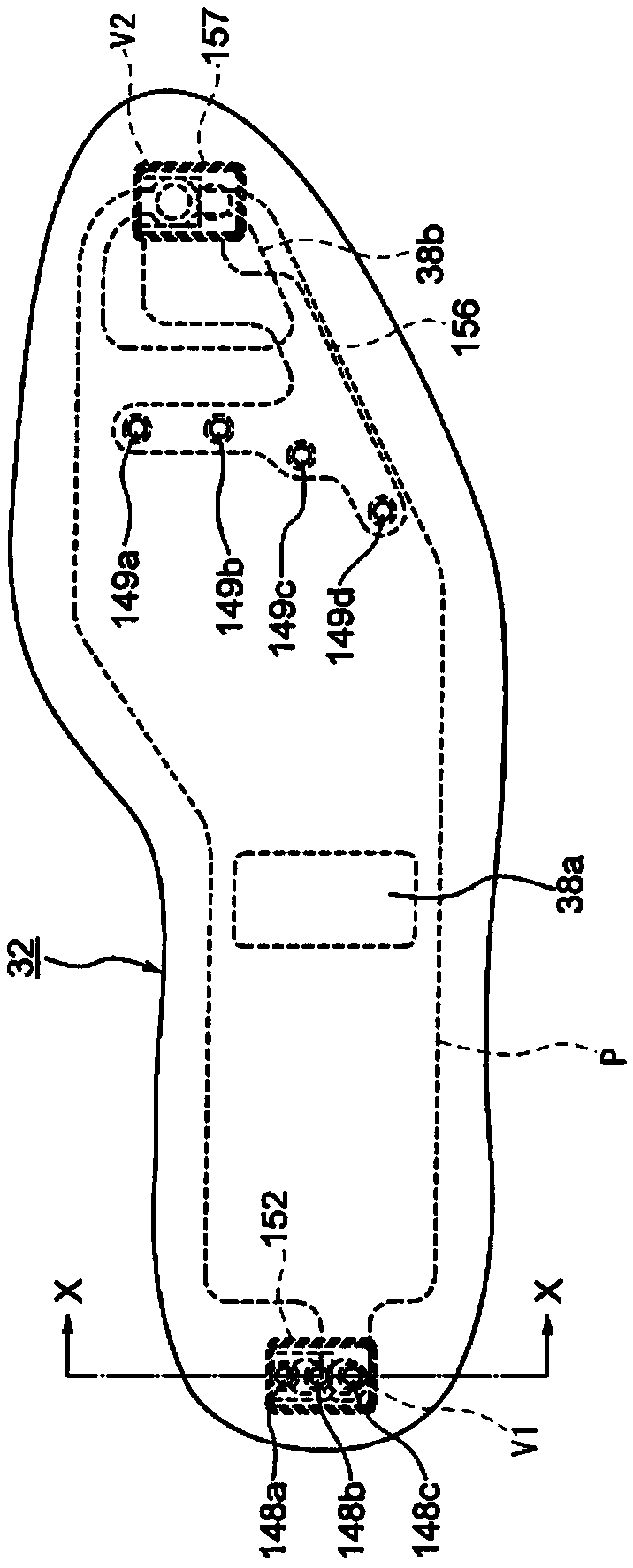

Ventilation shoe

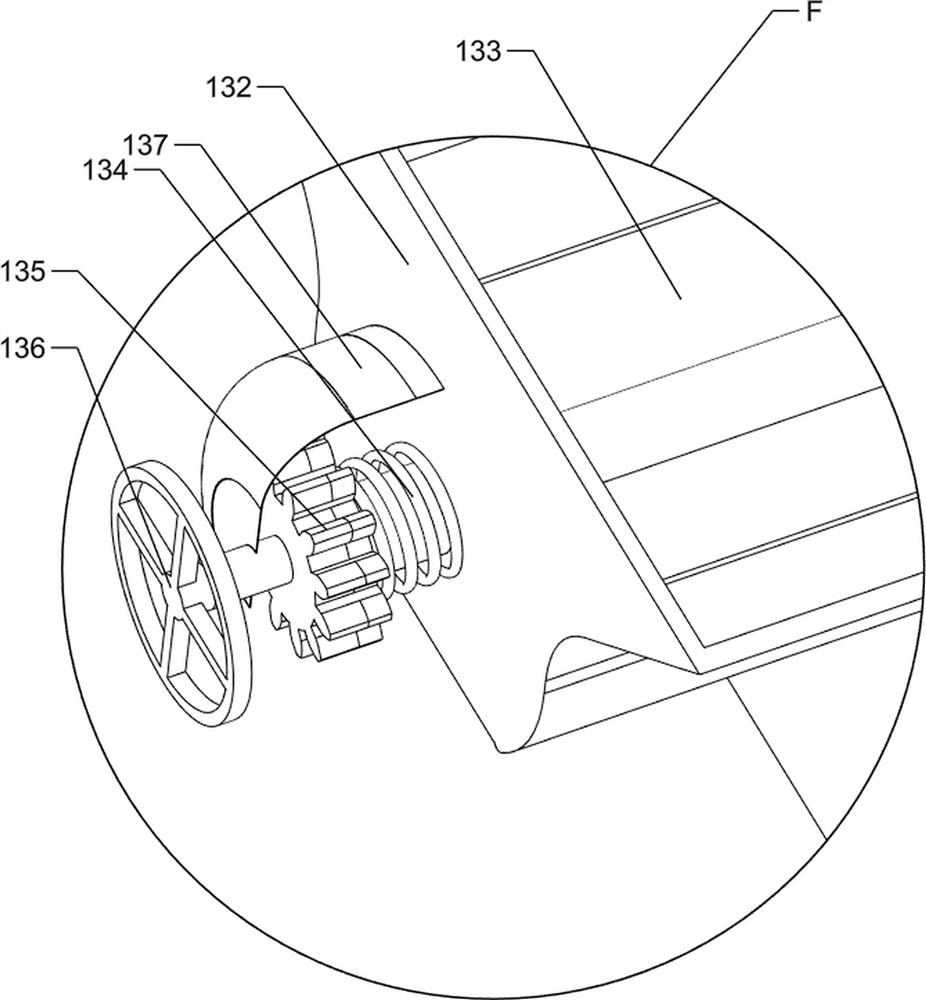

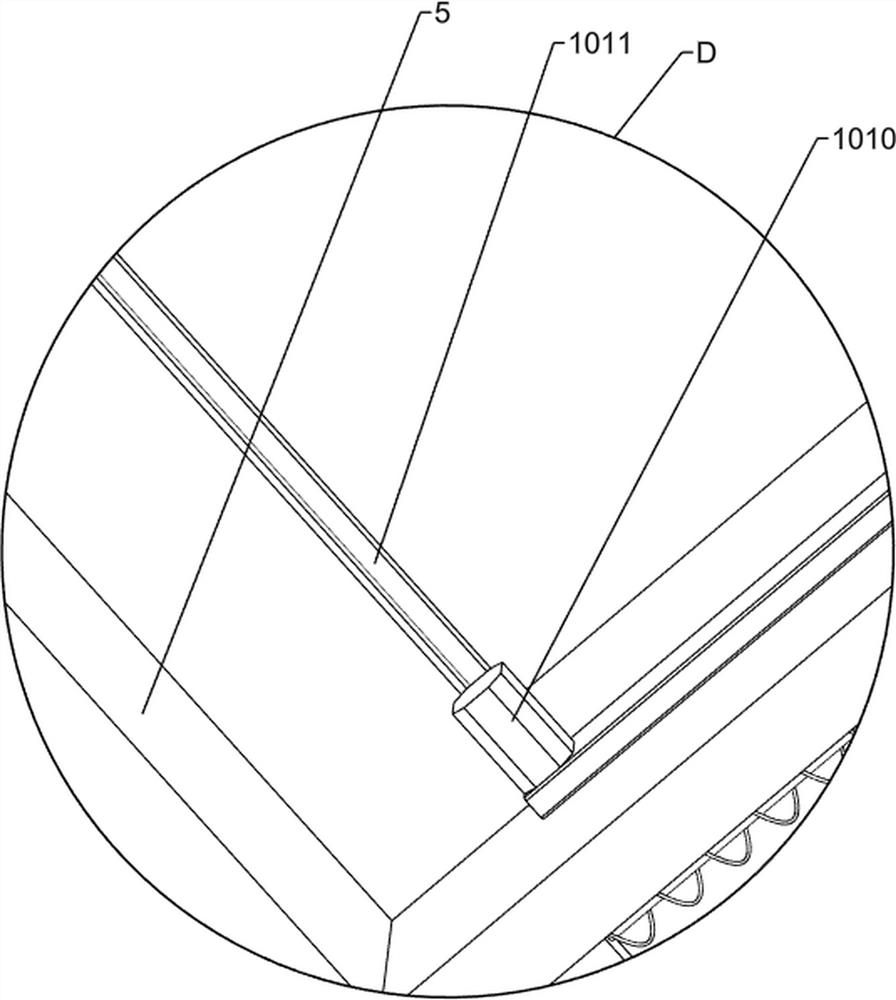

ActiveCN109068788AImprove impact resistanceEasy to manufactureSolesLayered productsPump chamberEngineering

The present invention enables downsizing of a ventilation shoe and enables sufficient ventilation of the interior of the shoe. The present invention has: an upper (31); a sole (32) obtained by stacking a plurality of sole sheets; and a ventilation device for taking air into a shoe interior (34) and discharging air outside the shoe interior (34). The ventilation device is provided with: an air intake passage (L1) for taking in air; an air discharge passage (L2) for discharging air; and a pump chamber (P) for feeding the air taken in through the air intake passage (L1) to the air discharge passage (L2). The sole (32) is configured from a plurality of sole sheets being stacked on one another, and the pump chamber (P) is formed in a flattened shape between the sole sheets, and valve installation holes (152, 157) are formed in an intermediate sole sheet that is sandwiched between other sole sheets from above and below, and check valves (V1, V2) are respectively provided in said valve installation holes (152, 157) in such a manner as to be integrated therewith via a support member.

Owner:INFOM

Ventilation system and electric locomotive

ActiveCN103569145BKeep healthyThorough ventilationRailway heating/coolingRailway transportControl theoryElectric power

The invention relates to a ventilation system and an electric locomotive. The ventilation system comprises an air suction unit, an exhaust unit and a switch circuit, wherein the air suction unit comprises a first speed regulating fan and an air suction air passage, the air suction passage is communicated with an air inlet of the first speed reducing fan, the exhaust unit comprises a second speed regulating fan and an exhaust air passage, the exhaust air passage is communicated with an air outlet of the second speed regulating fan, and the switch circuit is connected with the first speed regulating fan and the second speed regulating fan and is used for controlling the first speed regulating fan and the second speed regulating fan to synchronously work. The ventilation system provided by the invention can be applied into a cab of the electric locomotive, fresh air can be supplemented into the cab, in addition, vitiated air can be synchronously exhausted, and the sufficient ventilation of the cab is realized.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

planetary gear rotary cylinder engine

An engine having planetary gears and a rotary cylinder, comprising: a planetary gear assembly, a rotary cylinder assembly, a central air distribution valve (31) and a piston assembly. The rotary cylinder assembly rotates by using the central air distribution valve (31) as a center, while a piston (41) pushes the planetary gears (12) to move along an inner gear ring (13) and drives a sun gear (11) so as to output power. The present engine has the advantages of being simple, reliable, working stably, being high-power, and the like.

Owner:顾永强 +1

A reflow furnace gas control system

ActiveCN108672878BReduce processing stepsImprove work efficiencySoldering auxillary devicesThermodynamicsControl system

Owner:武汉倍普科技有限公司

Pig house odor treatment system

ActiveCN112535912BGuaranteed healthy growthReduce ammonia contentDispersed particle filtrationAnimal housingPork meatAtmospheric contamination

The present application relates to a pig house odor treatment system, which includes a plurality of exhaust units located on the same side of the pig house, the exhaust units are used to discharge the gas in the pig house out of the pig house; a separation unit is used to store the exhaust units The gas discharged from the wind unit; the filter unit, connected to the partition unit, used to filter the gas in the partition unit, and discharged the filtered gas to the outside; the detection unit, used to detect the ammonia gas content in the pig house , and when the ammonia gas content in the pig house exceeds the ammonia gas threshold, an exhaust command is generated; the control unit is used to receive the exhaust command, and start the exhaust unit and the filter unit after receiving the exhaust command. The application has the effects of ensuring the health of pigs, improving the quality of pork, reducing air pollution, environmental protection, saving energy and saving costs.

Owner:湖南天府生态农业有限公司

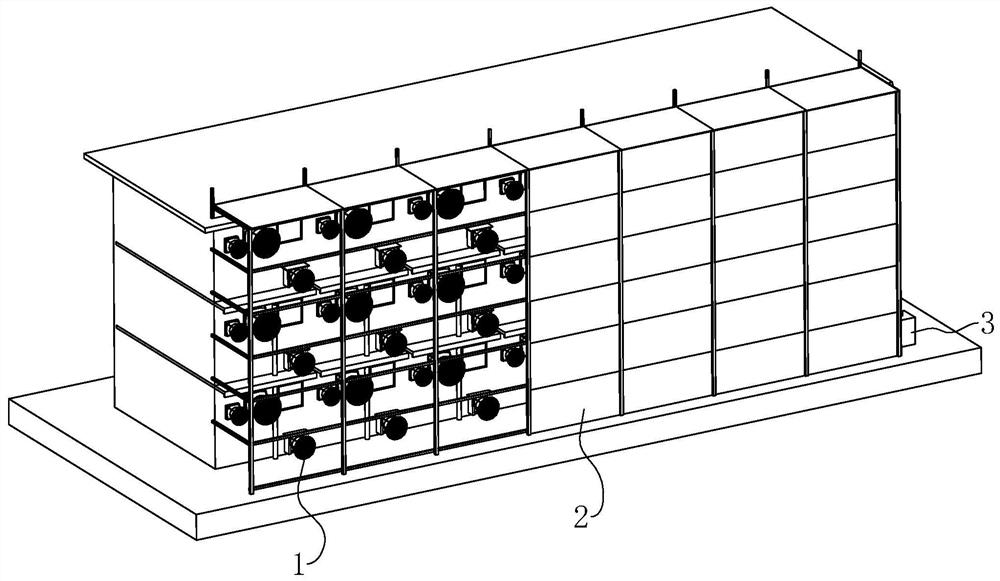

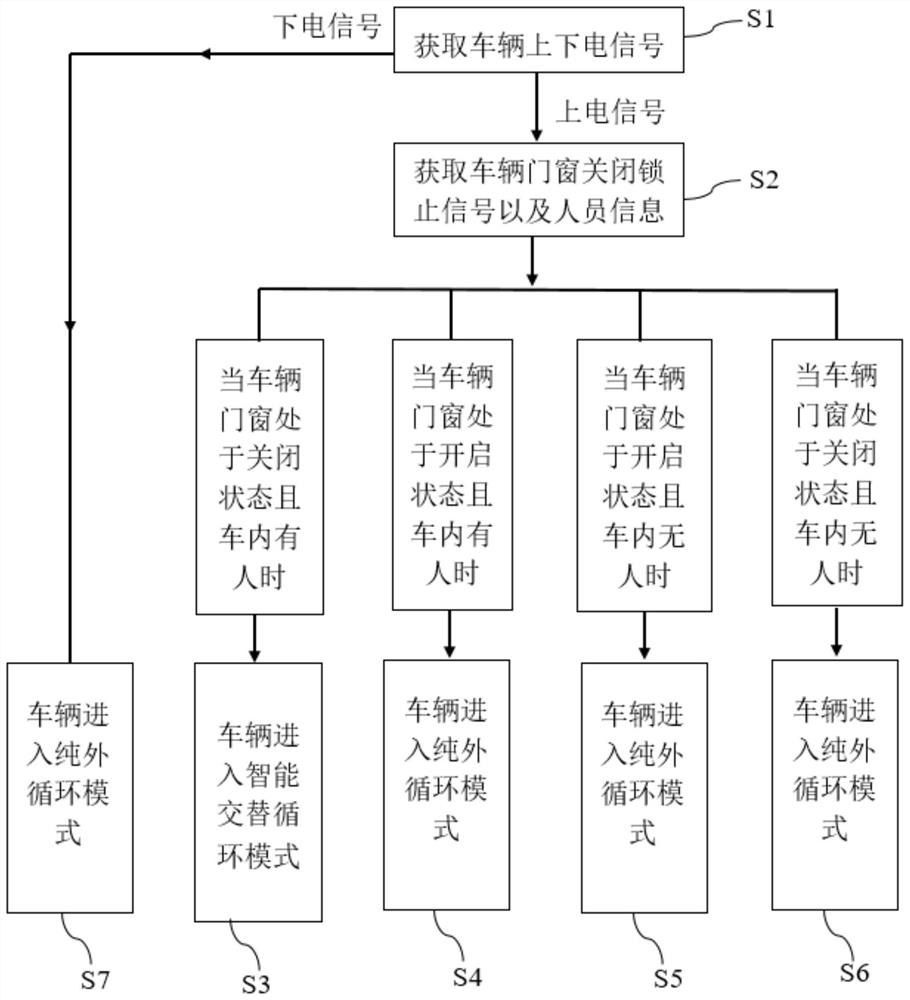

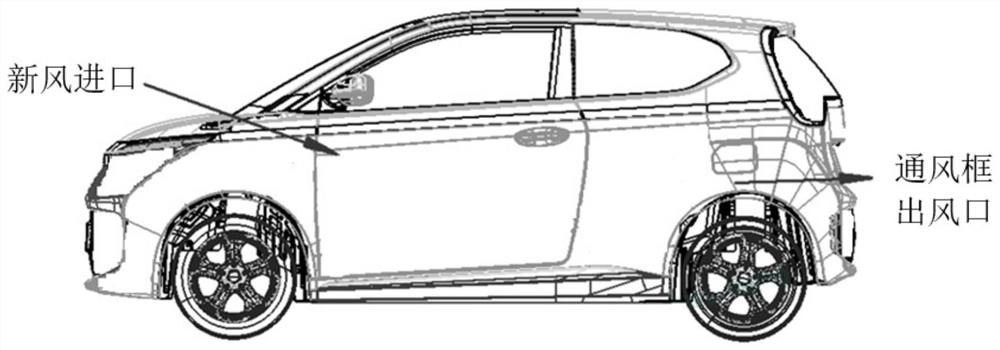

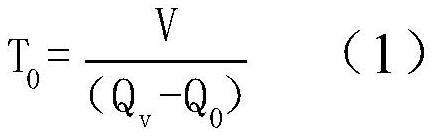

Intelligent ventilation control method of hydrogen energy automobile, terminal equipment and storage medium

ActiveCN114506191AGuaranteed fresh and healthyProtect your healthAir-treating devicesVehicle heating/cooling devicesFresh airTerminal equipment

The invention discloses an intelligent ventilation control method of a hydrogen energy automobile, terminal equipment and a storage medium. Vehicle door and window closing locking signals and personnel information are further obtained by obtaining vehicle power-on and power-off electric signals, when vehicle doors and windows are in a closed state and people exist in a vehicle, the vehicle enters an intelligent alternate circulation mode, and at the moment, the vehicle intelligently matches a ventilation frame, an air blower and an air conditioner internal and external circulation air door; active control over the air distribution form in the cab of the whole vehicle is achieved, so that short-time rapid ventilation of the cab is achieved, and the purposes of airtight NVH comfort are achieved. In the intelligent alternate circulation mode, the smaller the internal and external pressure difference of the four doors during vehicle ventilation is, the smaller the proportion of uncontrollable air leakage passing through four-door ventilation is, namely the smaller the proportion of fresh air flow short circuit is, and when the ventilation frame is used for active ventilation, the proportion of carbon dioxide in air is high, and the ventilation efficiency is high. Rapid and sufficient air exchange in the vehicle is effectively guaranteed, air in the vehicle is fresh, and the purpose of NVH comfort in the vehicle is achieved.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com