Free piston engine central combustion chamber tumble air intake structure

A piston engine and air intake structure technology, applied in free piston engines, internal combustion piston engines, combustion engines, etc., can solve the problems of low fuel utilization and large emissions, and achieve high fuel utilization efficiency, high combustion efficiency, and acceleration The effect of flame spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

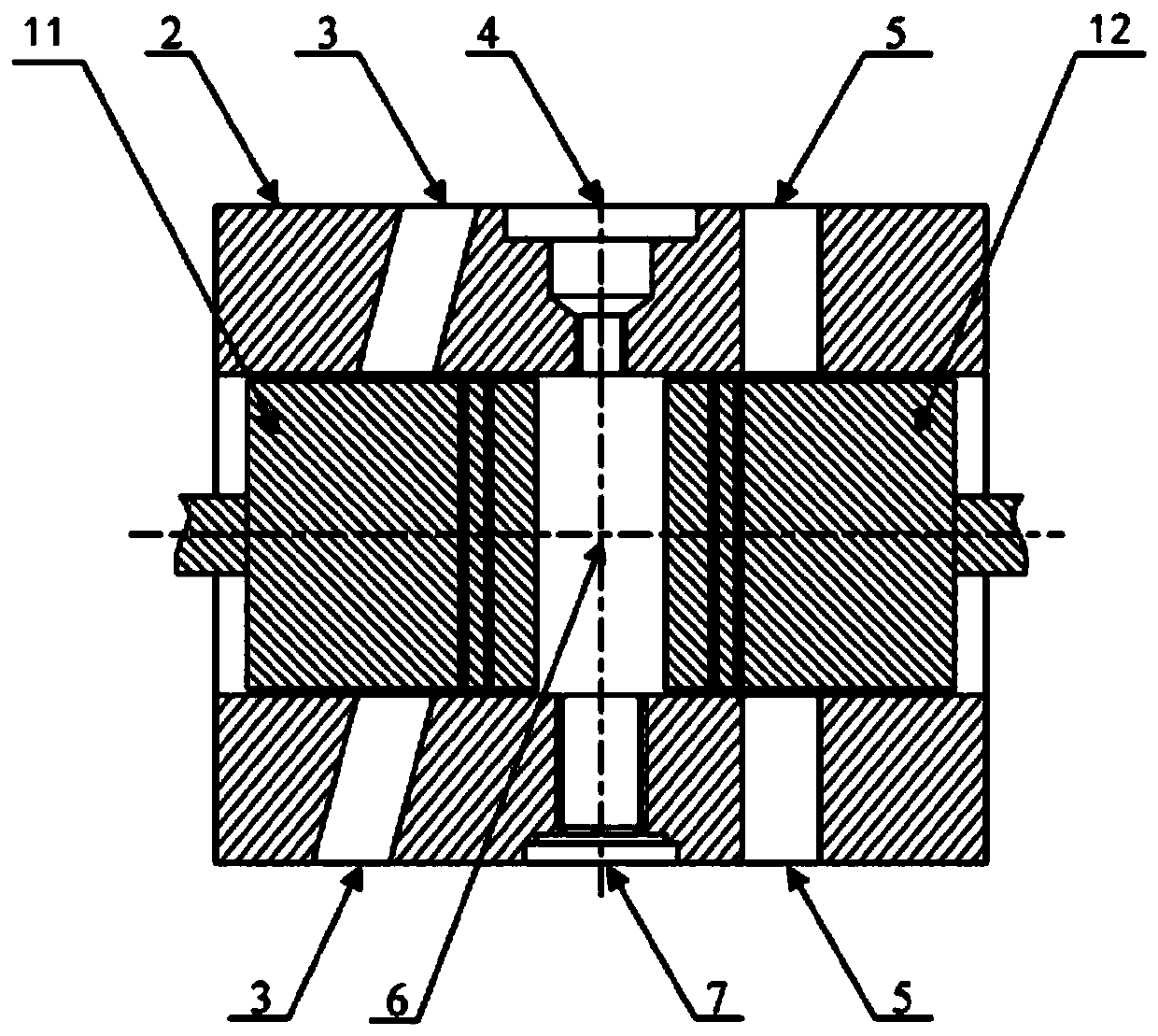

[0023] Such as Figure 1-2 As shown, a free-piston engine central combustion chamber tumble intake structure includes a cylinder block 2, the two sides of the cylinder block 2 cavity are provided with an intake piston 11 and an exhaust piston 12, and the intake piston 11 and the combustion chamber 6 between the exhaust piston 12, the top of the cylinder block 2 is provided with a fuel injector 4, and its bottom is provided with a spark plug 7;

[0024] The two sides of the fuel injector 4 and the spark plug 7 on the same vertical line are respectively provided with an intake port 3 and an exhaust port 5 .

[0025] The upper side air port of the air intake port 3 is inclined towards the direction of the fuel injector 4 , and the lower side air port is inclined towards the opposite direction of the fuel injector 4 ; the axis of the exhaust port 5 is perpendicular to the axis of the cylinder block 2 .

[0026] When the intake piston 11 and the exhaust piston 12 reach the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com