Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

457 results about "Reflow oven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reflow oven is a machine used primarily for reflow soldering of surface mount electronic components to printed circuit boards (PCB).

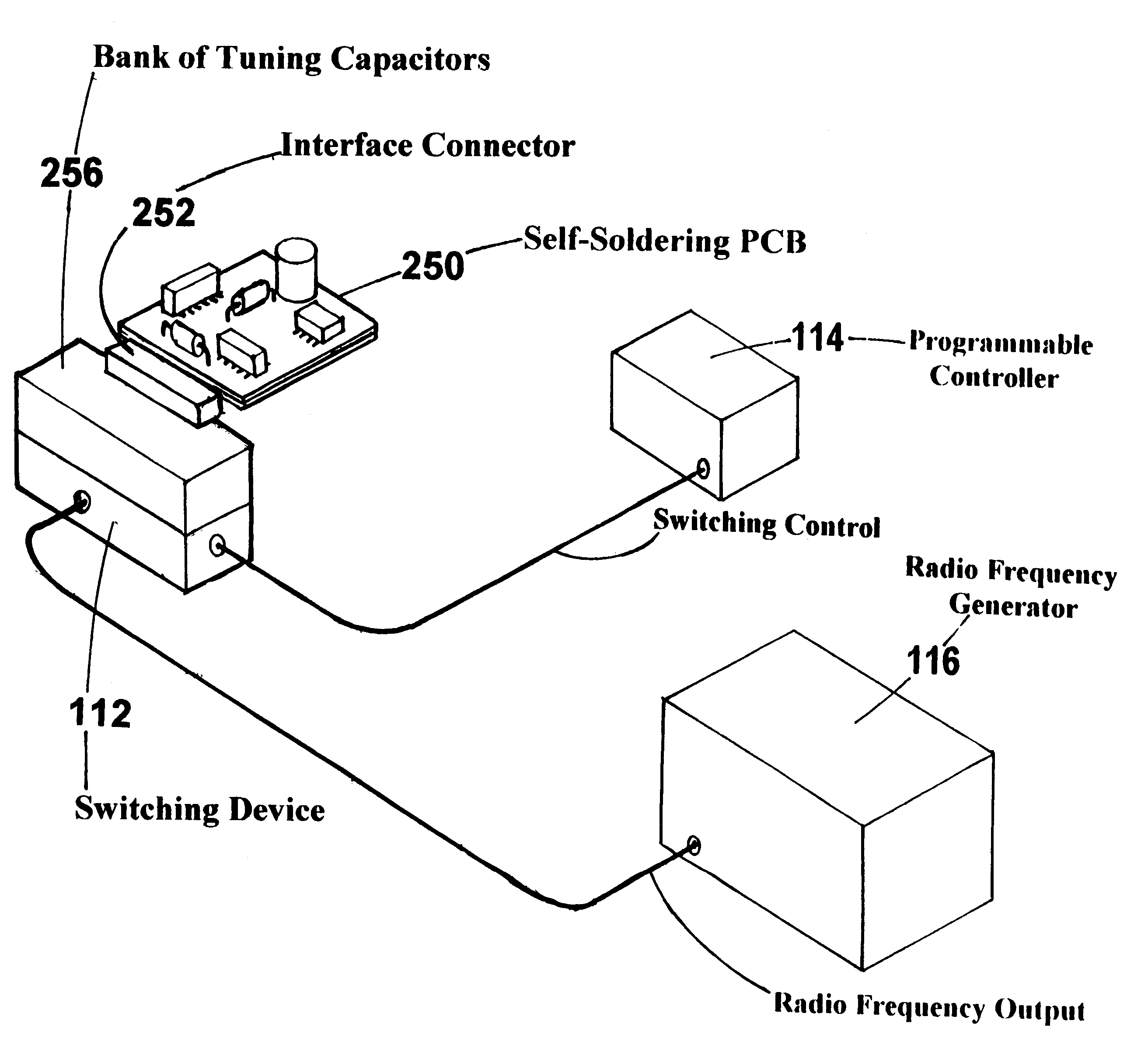

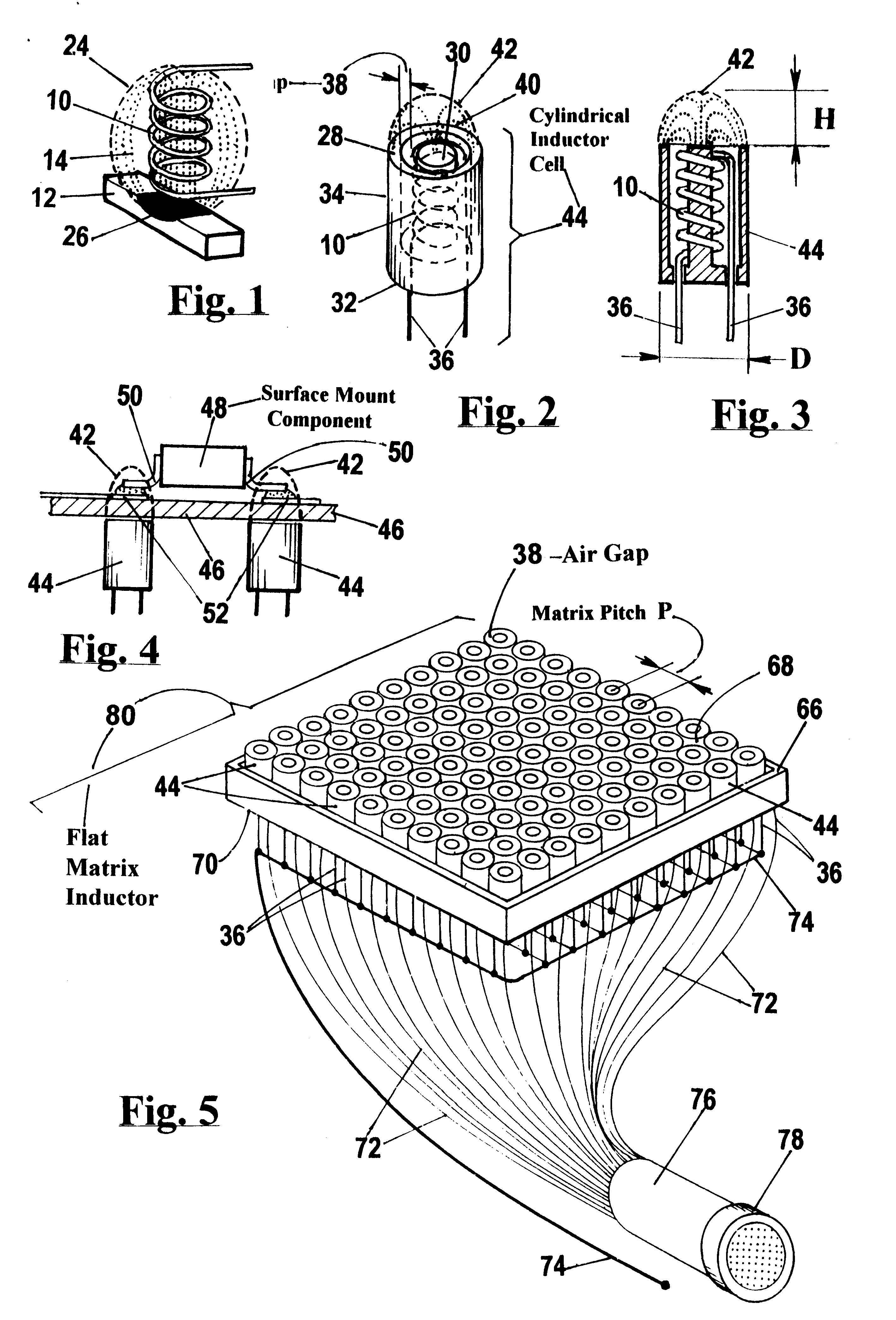

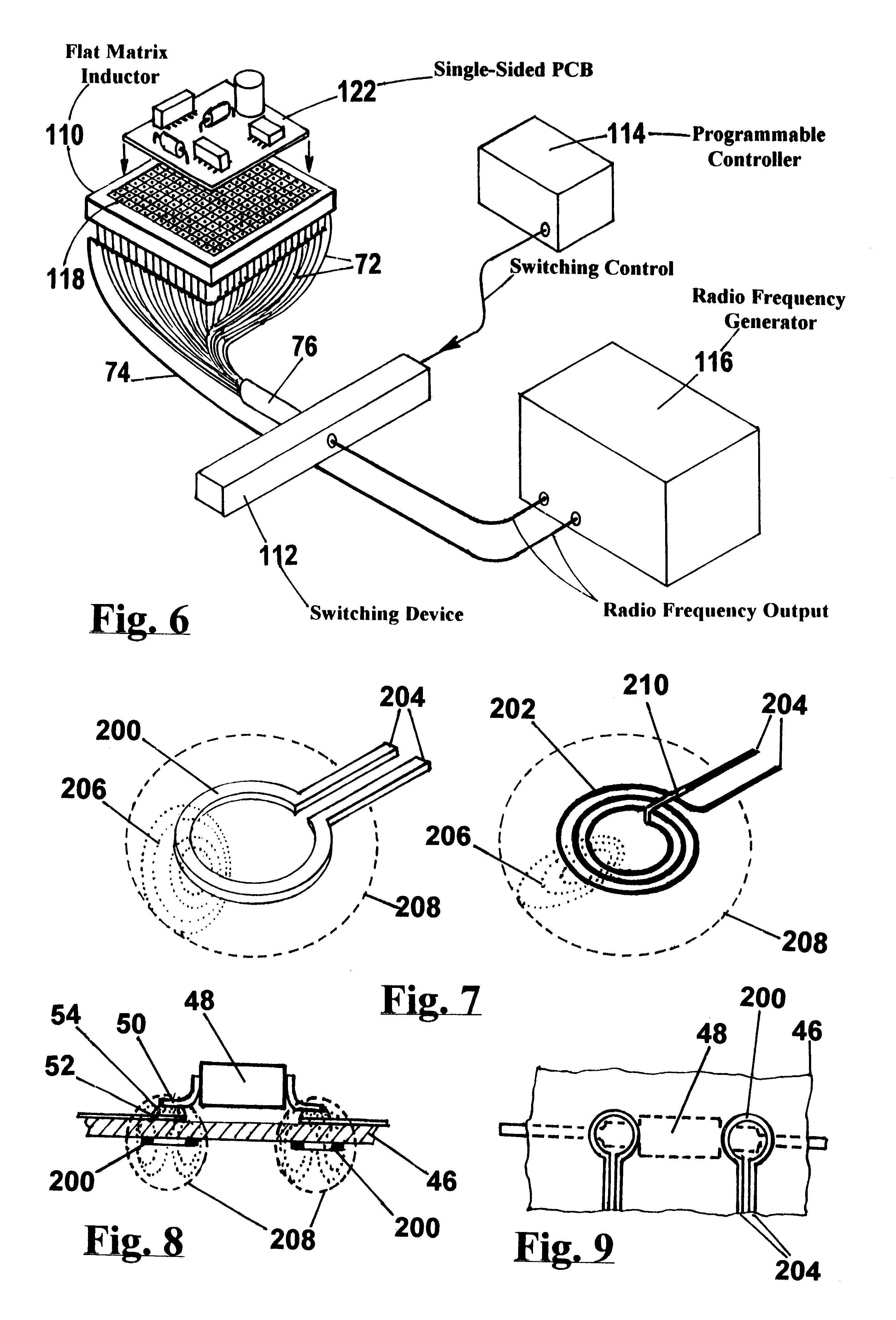

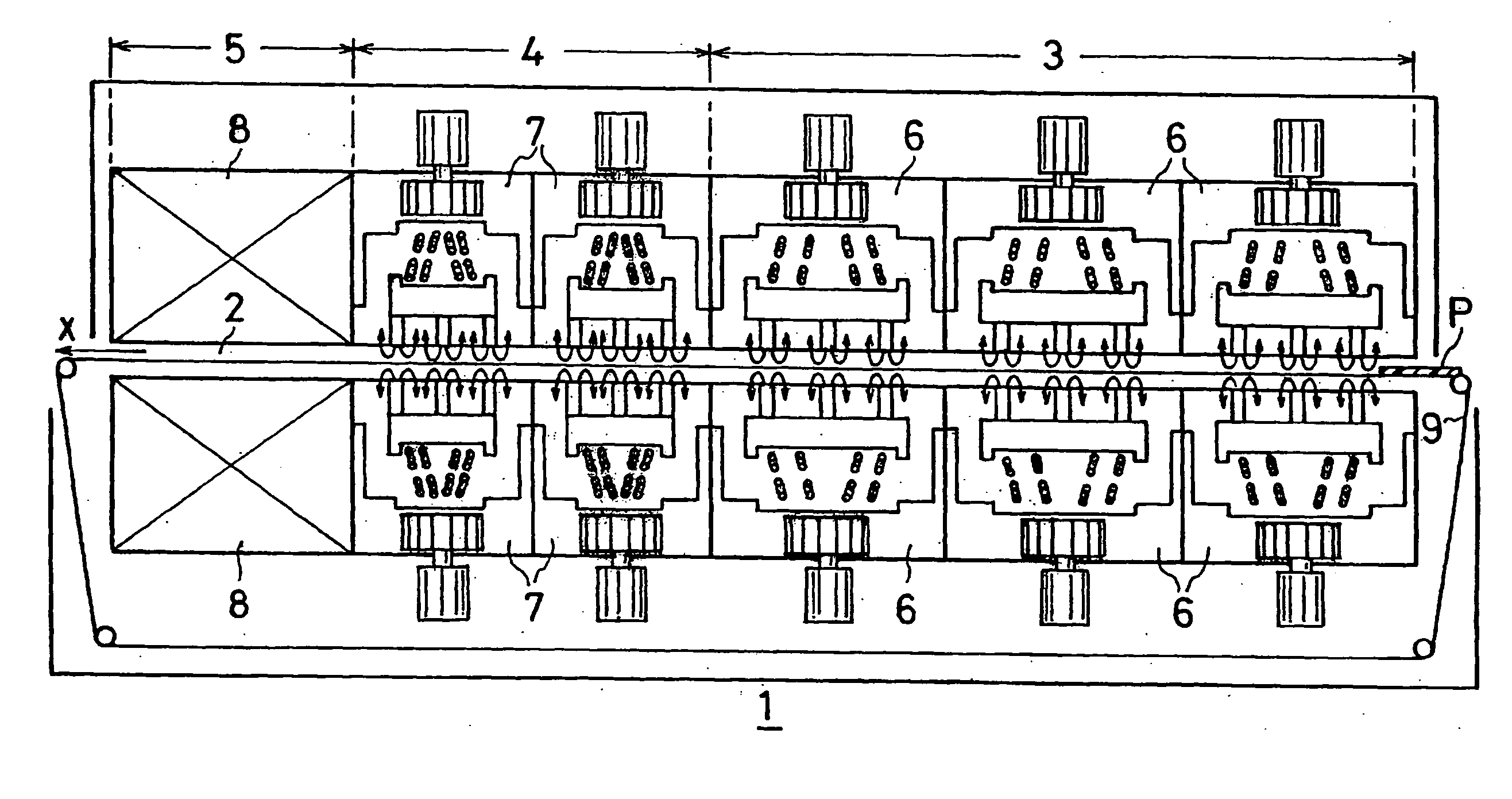

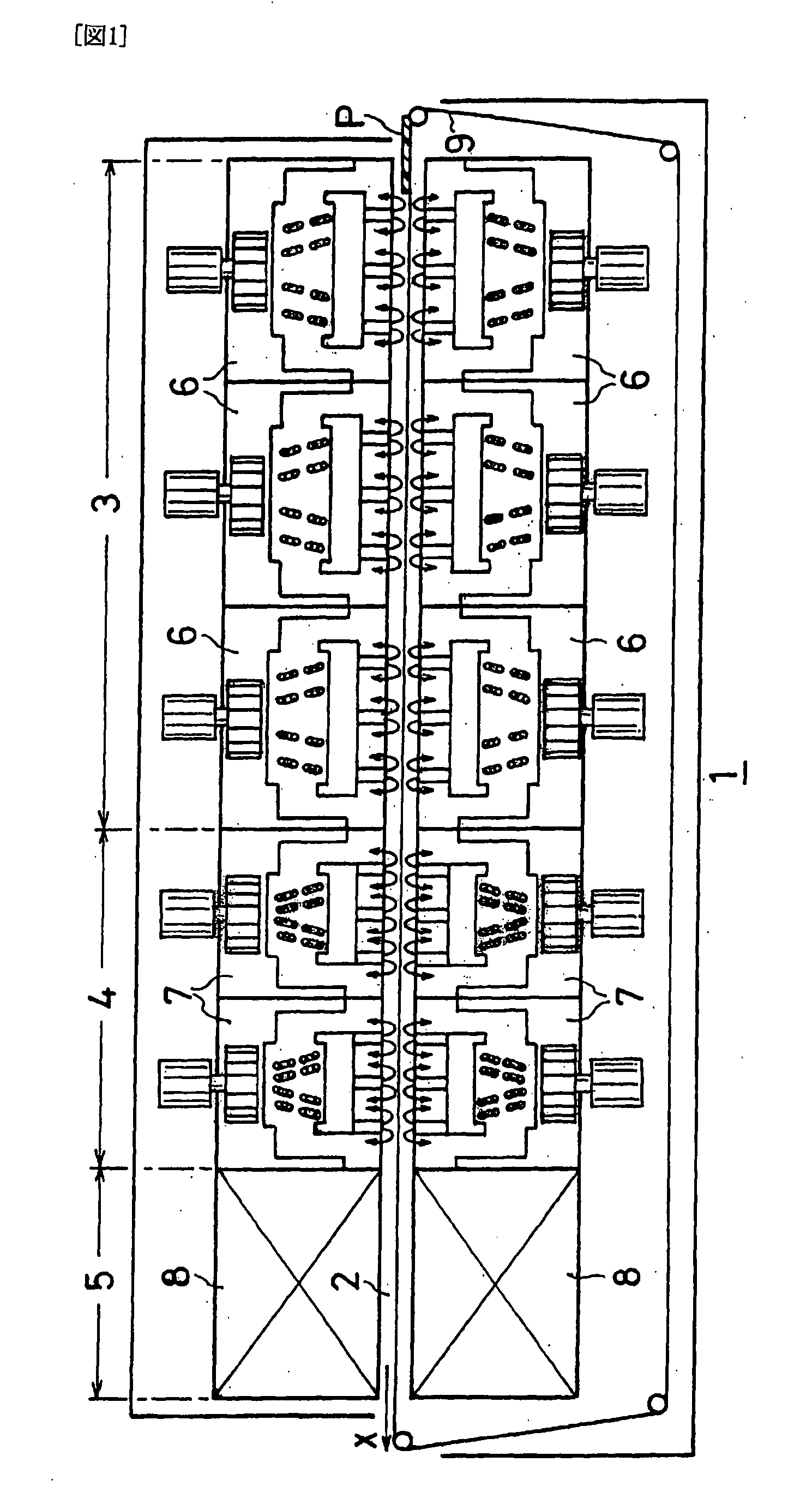

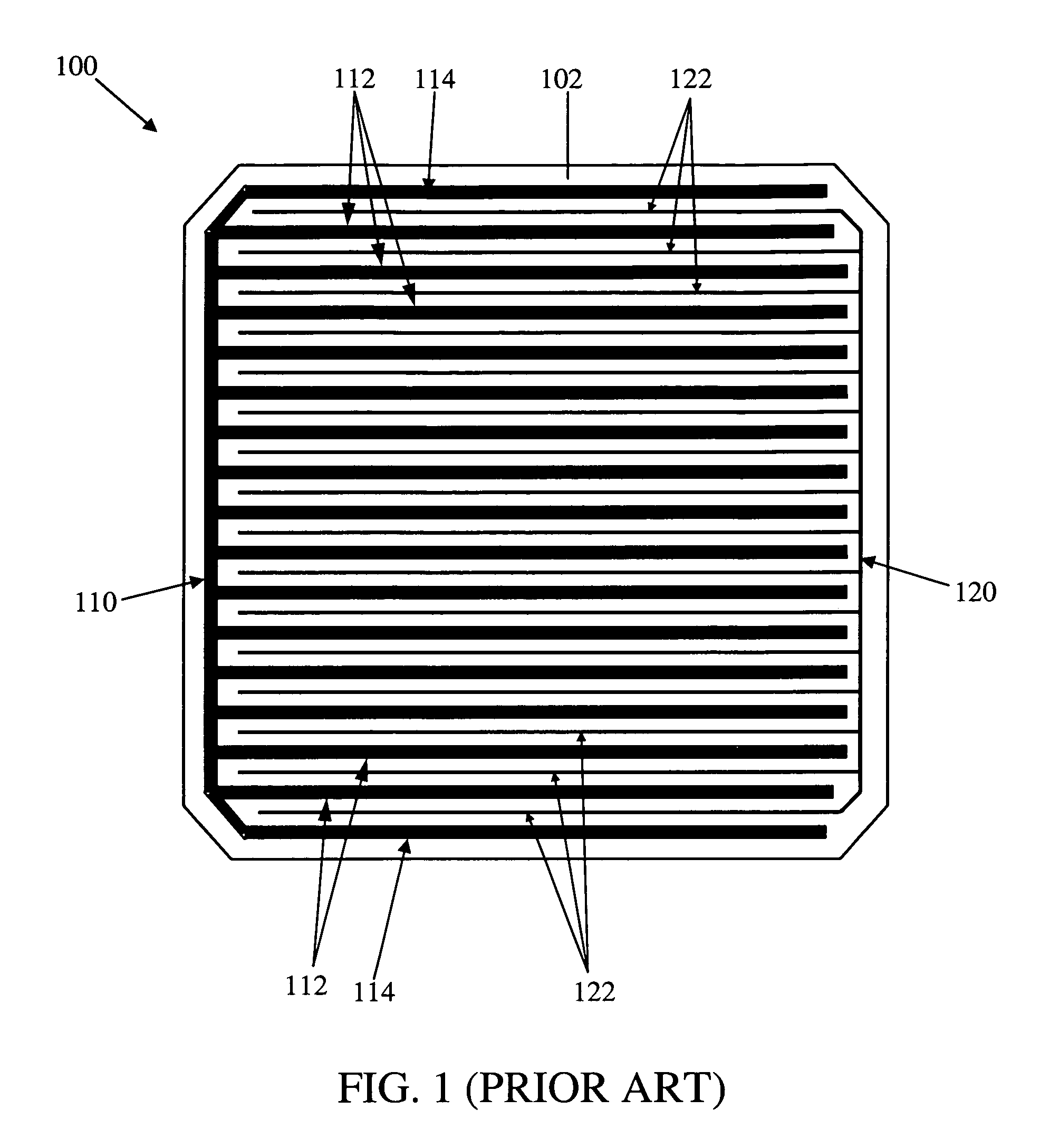

Inductive self-soldering printed circuit board

InactiveUS6229124B1Improve quality and reliabilityReduce formationPrinted circuit assemblingCoil arrangementsManufacturing technologyHeat sensitive

A new apparatus for inductively soldering surface-mount, straddle-mount and through-hole type electronic components into a self-soldering PCB (printed circuit board) in an automated fashion utilizing localized Electromagnetic Induction Heating (E.I.H.). Current manufacture technology for packaging electronic components depends on the reflow and wave soldering processes. Both processes heat up to relatively high temperatures the entire assembly, namely its PCB and all the electronic components being soldered into it. Such harsh high-temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention reflow oven and / or wave soldering equipment is not required. During a soldering operation only the leads and pads being soldered are heated but neither the body of said electronic components nor the dielectric material forming said self-soldering PCB and its interconnecting traces are heated. Because of this selectively localized inductive heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. The invention consumes about 200 times less energy than the reflow and wave soldering processes. This invention can readily be utilized to complement and / or supplement the reflow and wave soldering processes by providing selective inductive self-soldering of odd-form and / or heat-sensitive components. The invention also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a self-soldering PCB is completed. This invention also provides for a useful inductive de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

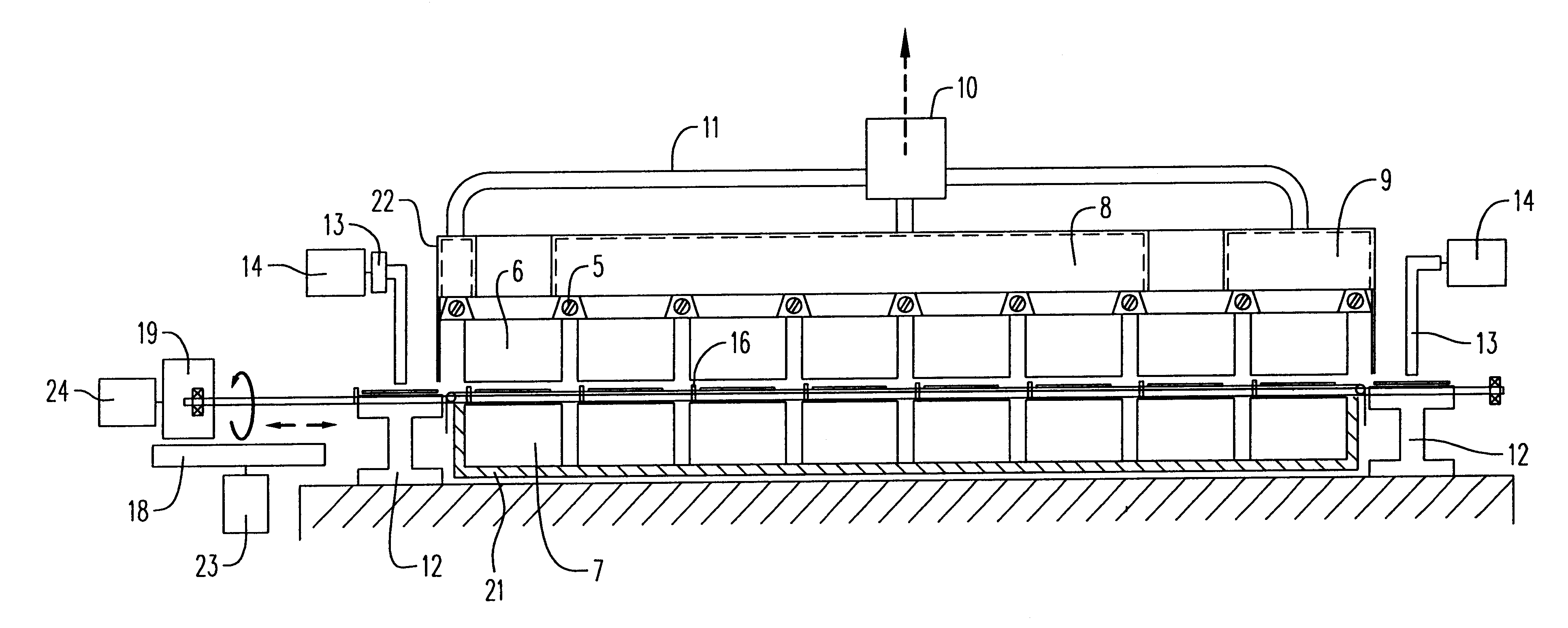

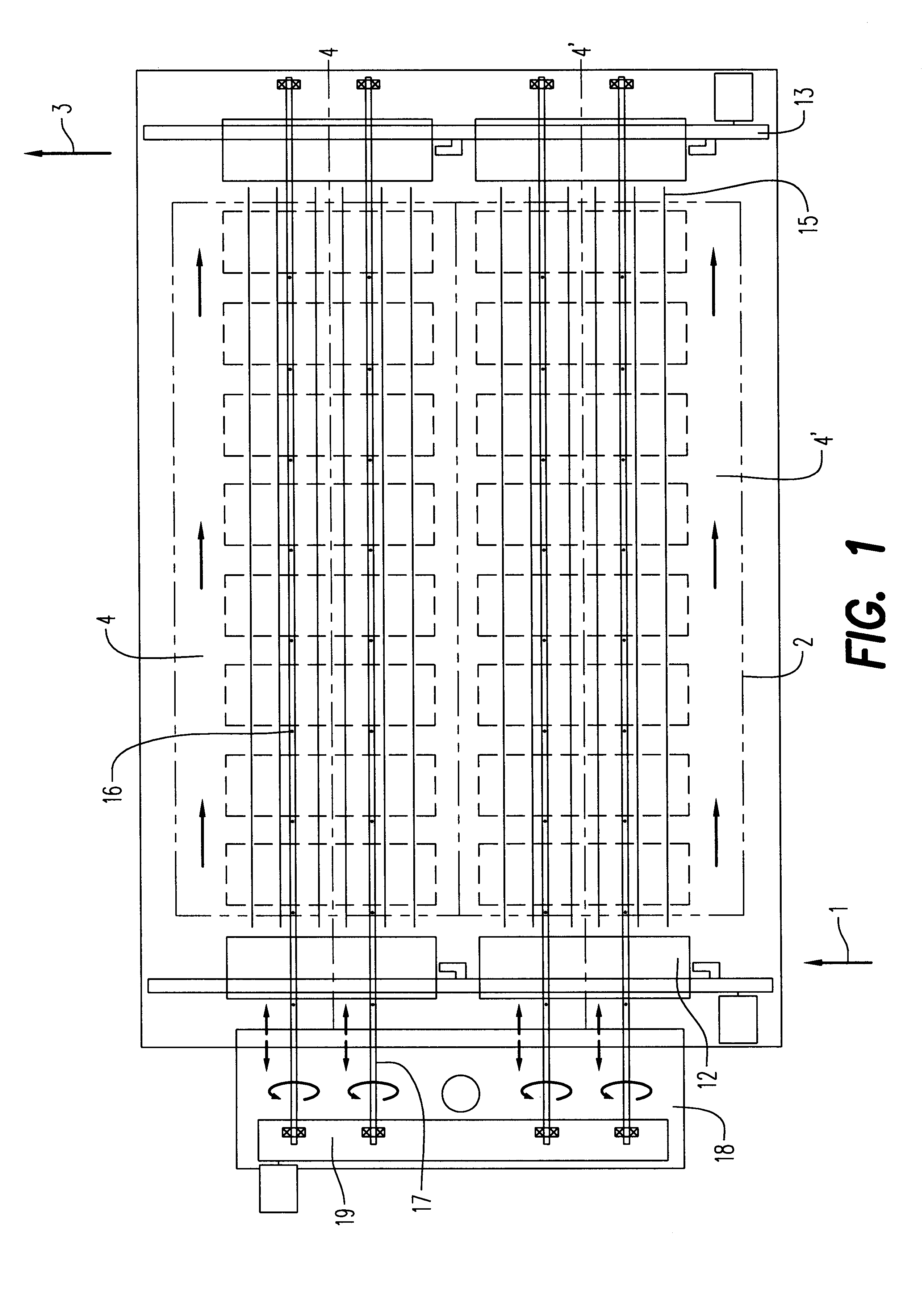

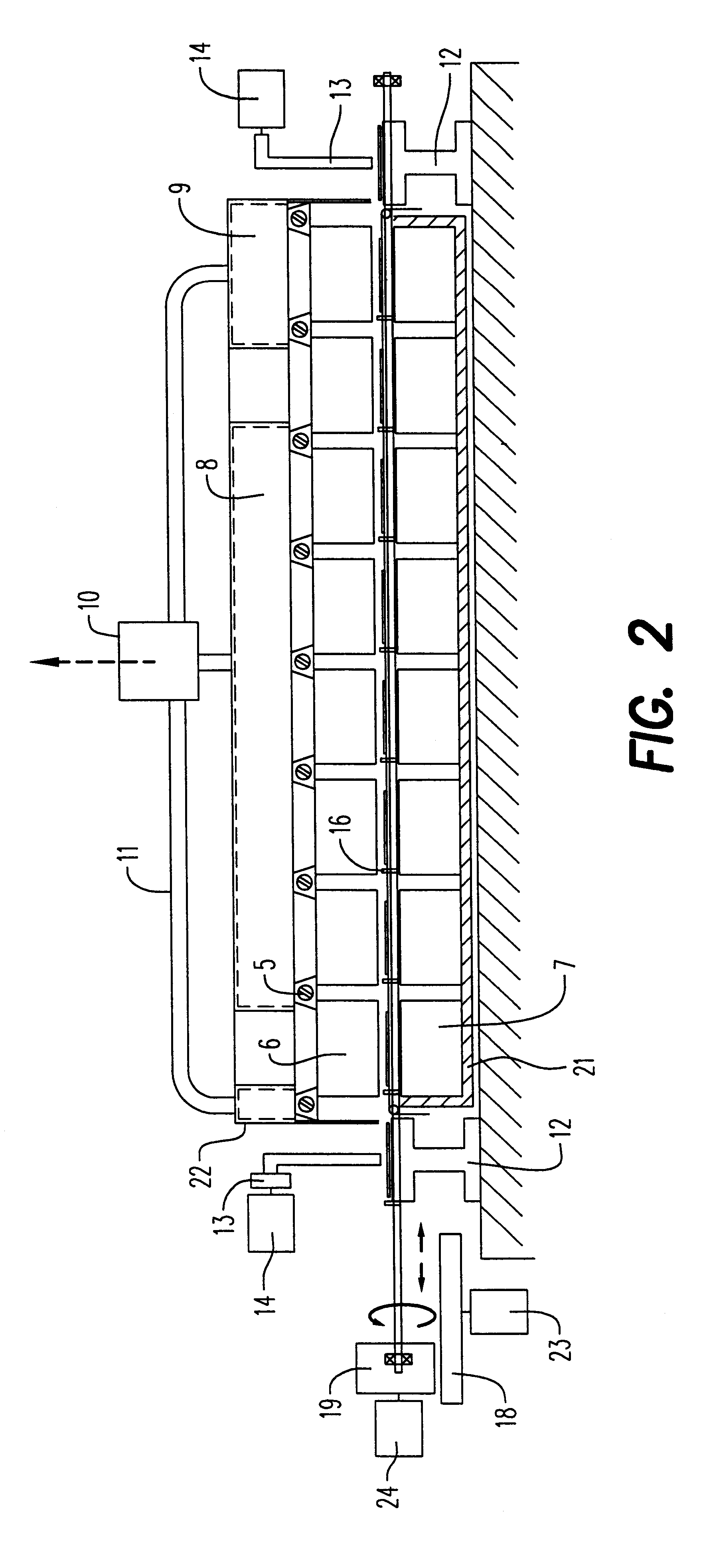

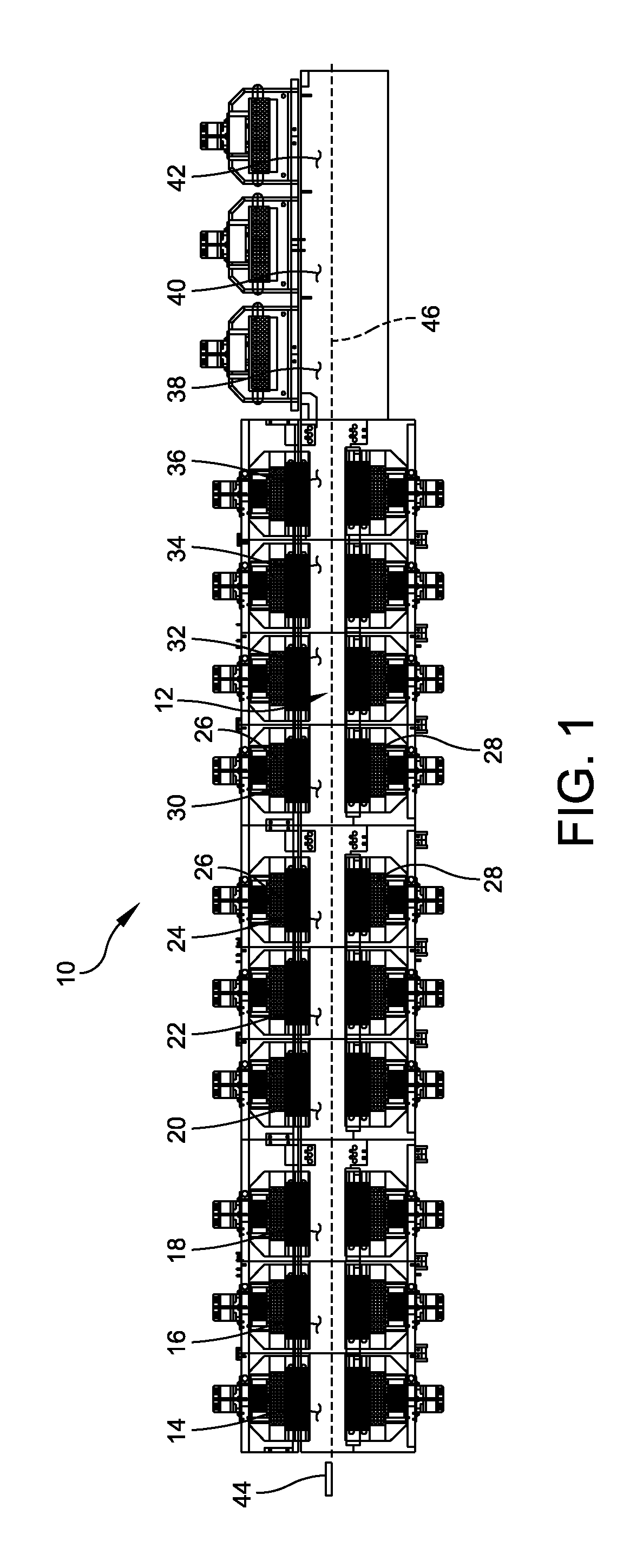

Solder reflow oven

InactiveUS6386422B1Soldering apparatusSemiconductor/solid-state device manufacturingSerpentine channelSolder ball

A solder reflow oven for the processing of ball grid array substrates bearing solder balls is described, comprising: input means for introducing substrates into the oven, a processing chamber within which the substrates are subject to a solder reflow process, and output means for discharging substrates from the oven for further processing or handling, and means for transferring the substrates through the processing chamber in a first direction towards the output means. The processing chamber comprises a plurality of heating and cooling zones arranged with a constant pitch in the first direction, and the transferring means is adapted to move the substrates in the first direction in stages, with each component moving a distance equal to the pitch between two zones in each stage, whereby the components are moved from zone to zone in stages. In addition each block of each heating zone and each block of each cooling zone is connected to a source of fresh gas, and each block of each heating zone is provided with means for heating the gas, and each block of each cooling zone is provided with means for cooling the gas, and each block is formed with a serpentine channel between the source of fresh gas and at least one opening through which the gas is discharged from the block towards a substrate.

Owner:ASM ASSEMBLY AUTOMATION LTD

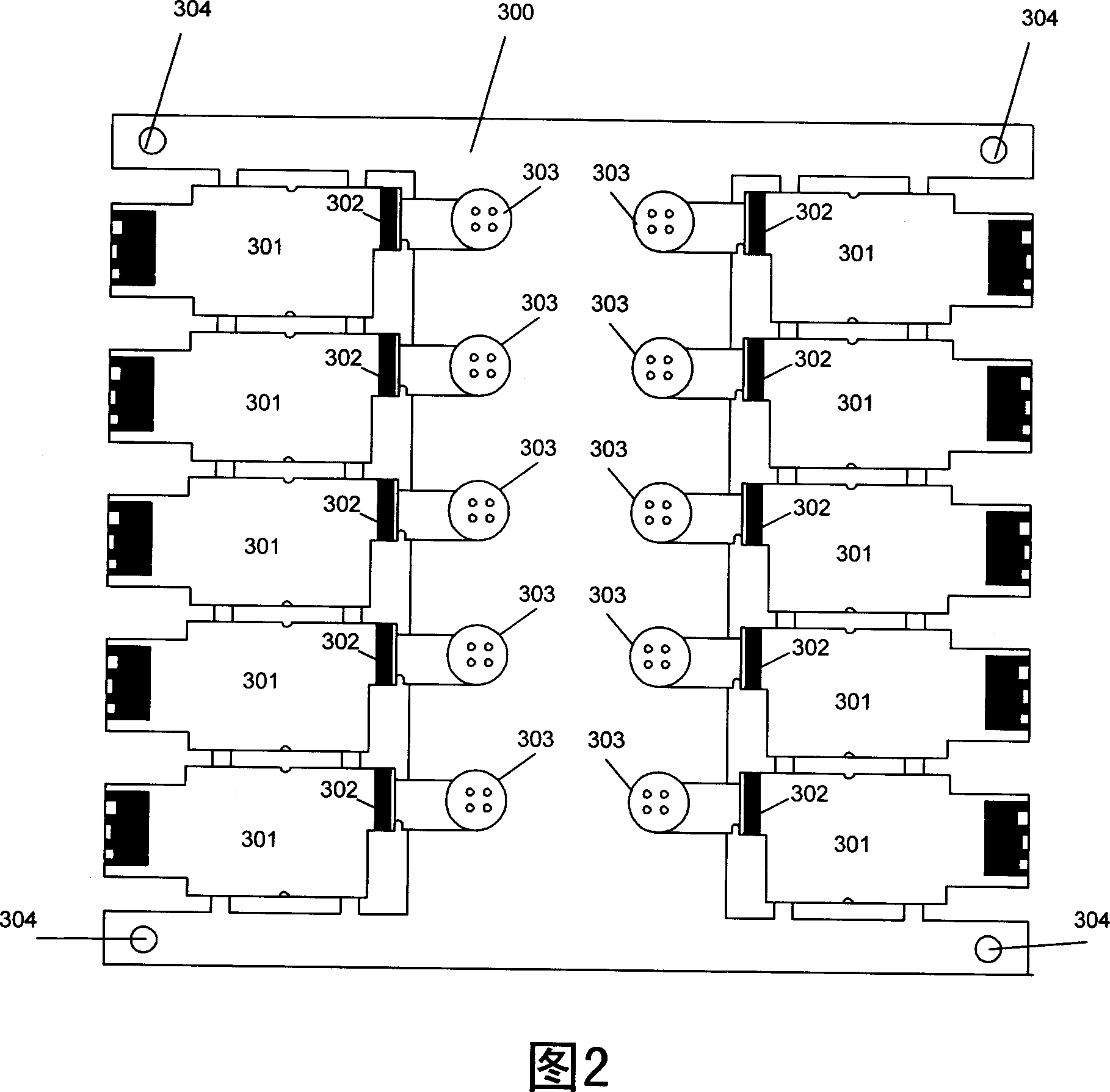

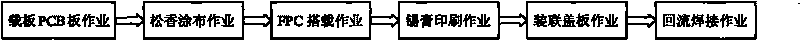

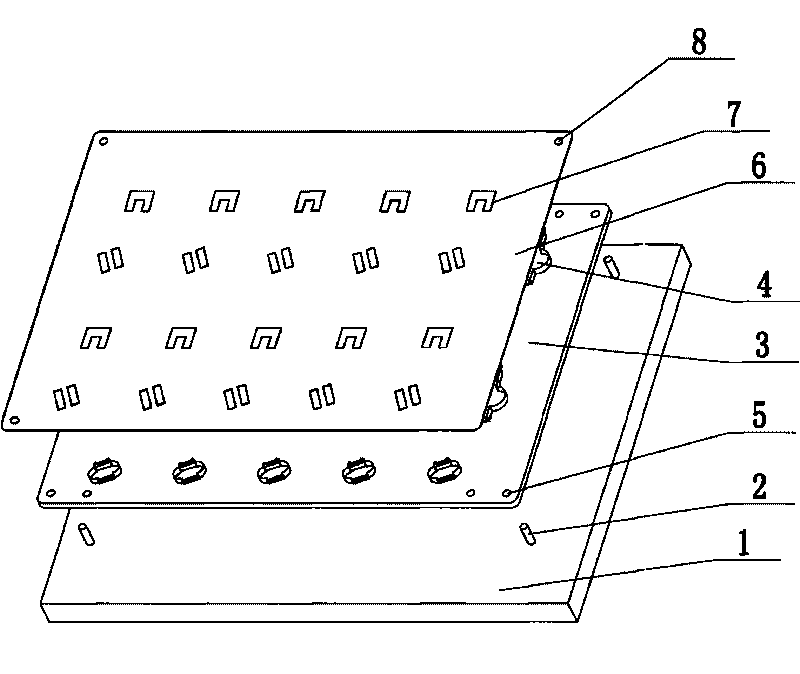

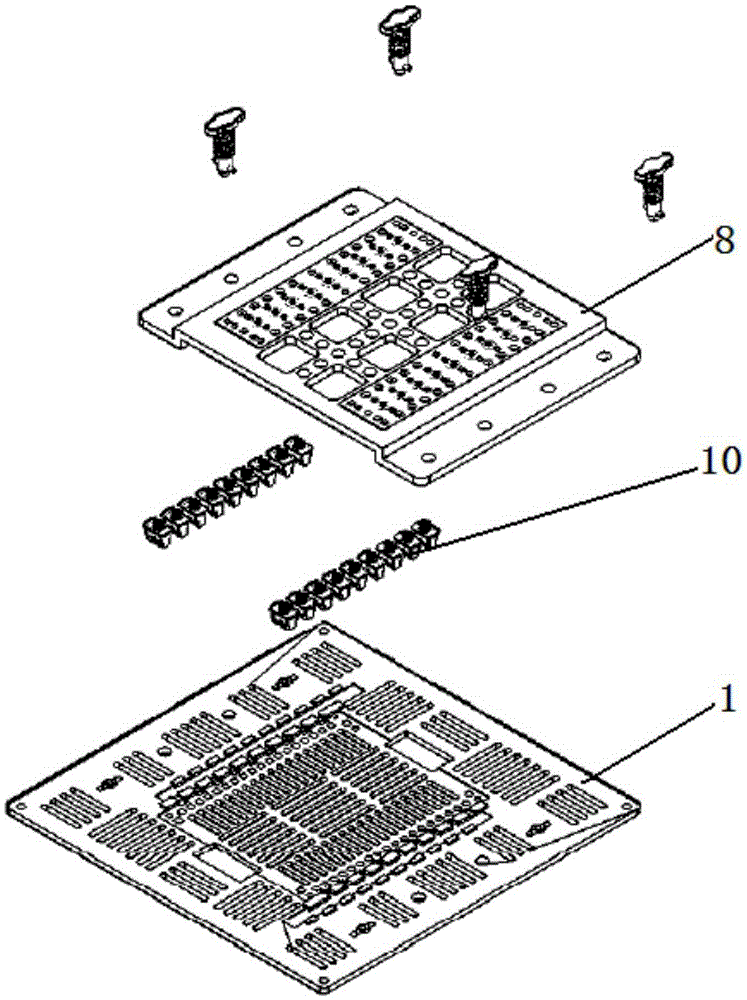

Method for welding FPC plate with PCB plate and its dedicated clamp

ActiveCN101083878AImprove consistencySmall temperature differencePrinted circuit assemblingEngineeringSolder paste

The present invention offers a method of welding FPC board and PCB board, and the special fixture for this method which includes an upper-template and an under-template. The method includes the following steps: the first step, printing solder paste onto a big-piece PCB board composed of several small-piece PCB boards; the second step, using SMT to compose components onto the PCB board; the third step, fixing the PCB board in the slot of under-template of the fixture for locating; the fourth step, aligning the solder pad zones of FPC board and PCB board; the fifth step, covering the upper-template of the fixture to the upper-surface of the PCB board, and the overlapped area of solder-pad zone is 50%-80%, the under-surface of the upper-template should must maintain horizontal, rotating the block button on the under-template to fasten the upper-template; the sixth step, sending the fastened fixture into enclosed reflow oven for refluxing weld; the seventh step, taking off the template, checking the welding state between FPC board and PCB board. As the said welding method is less in steps and simple in its special fixture, the productive efficiency is high, and the cost is low.

Owner:SHENZHEN NEOPHOTONICS TECH

Method for assembly and reflow soldering of PCB and FPC and special positioning fixture thereof

InactiveCN101720172AIncrease productivitySimplify the initial positioning methodPrinted circuit assemblingPrinted element electric connection formationEngineeringProcessing cost

The invention discloses a method for the assembly and the reflow soldering of a PCB and an FPC and a special positioning fixture thereof, which mainly solve the problems of inaccurate positioning, low efficiency of welding efficiency, difficulty for ensuring product quality and the like of manual assembly in the processes of assembling and soldering the PCB and the FPC. The method comprises the following steps: firstly, supporting, positioning and fixing the PCB by using a magnetic carrier board; secondly, carrying the FPC; next, preliminarily positioning the PCB and the FPC with a bonding agent; thirdly, printing a solder paster on a solder pad at the junction of the FPC and the PCB; and finally, pressing a magnetic cover board on the magnetic carrier board, fixing the positions of the FPC and the PCB, and performing the reflow soldering on the FPC and the PCB through a reflow oven. The method for the assembly and the reflow soldering of the PCB and the FPC and the special positioning fixture thereof have the advantages of simple operation, good reliability, great improvement on the production efficiency and the production quality of the FPC and the PCB in the processes of assembling and soldering, and processing cost reduction.

Owner:HUIZHOUSRTY INFORMATION ELECTRONICS

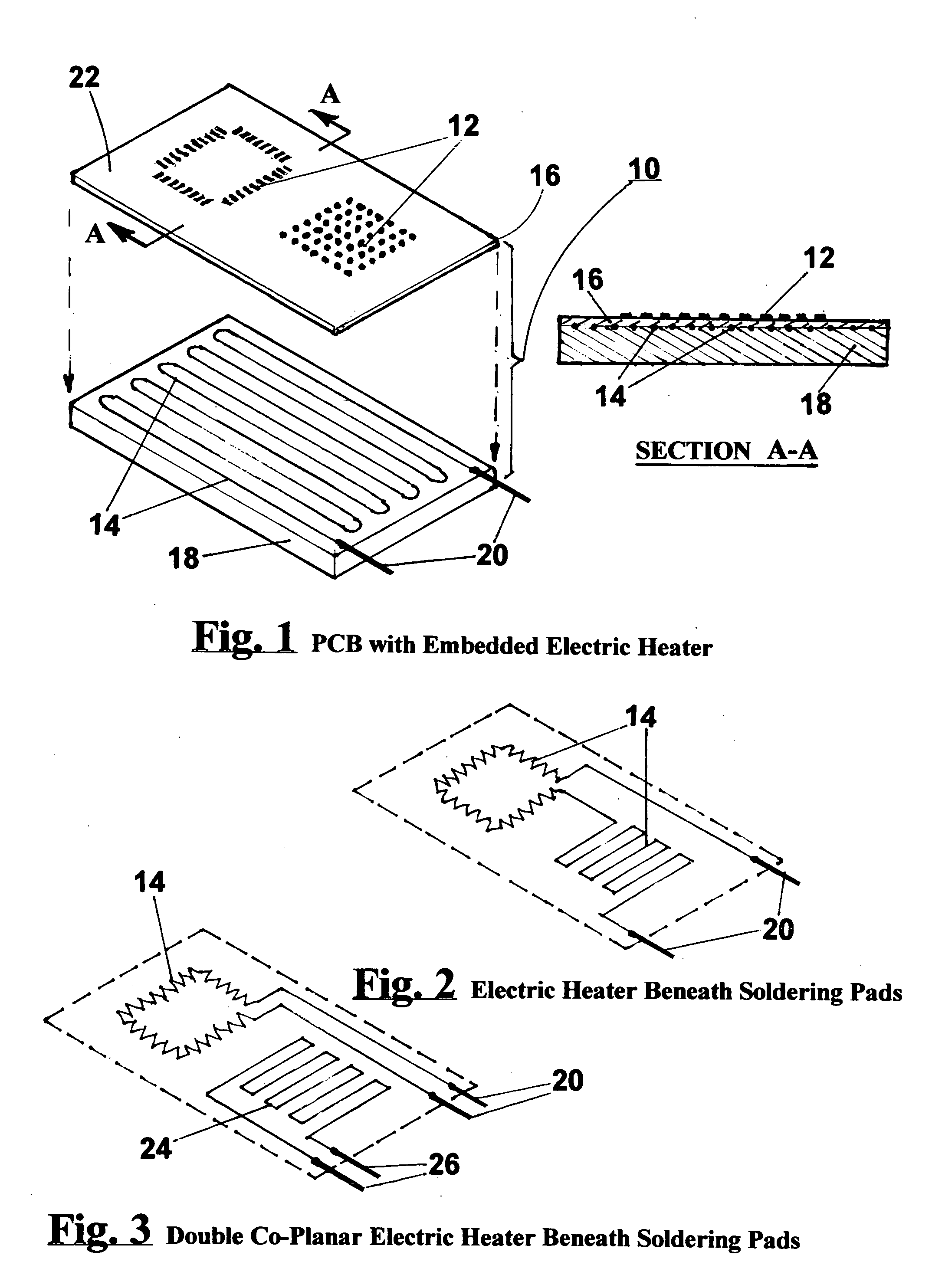

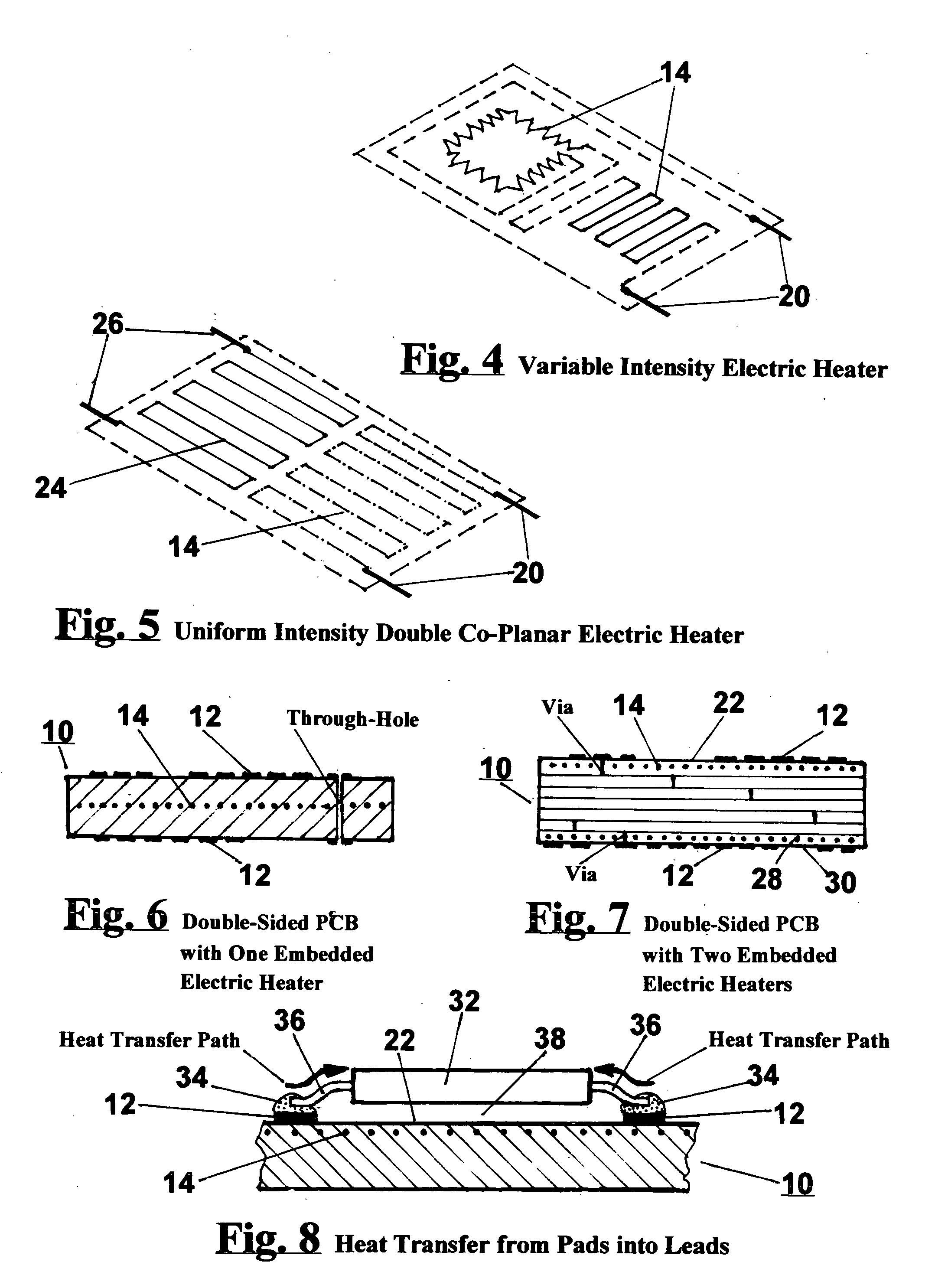

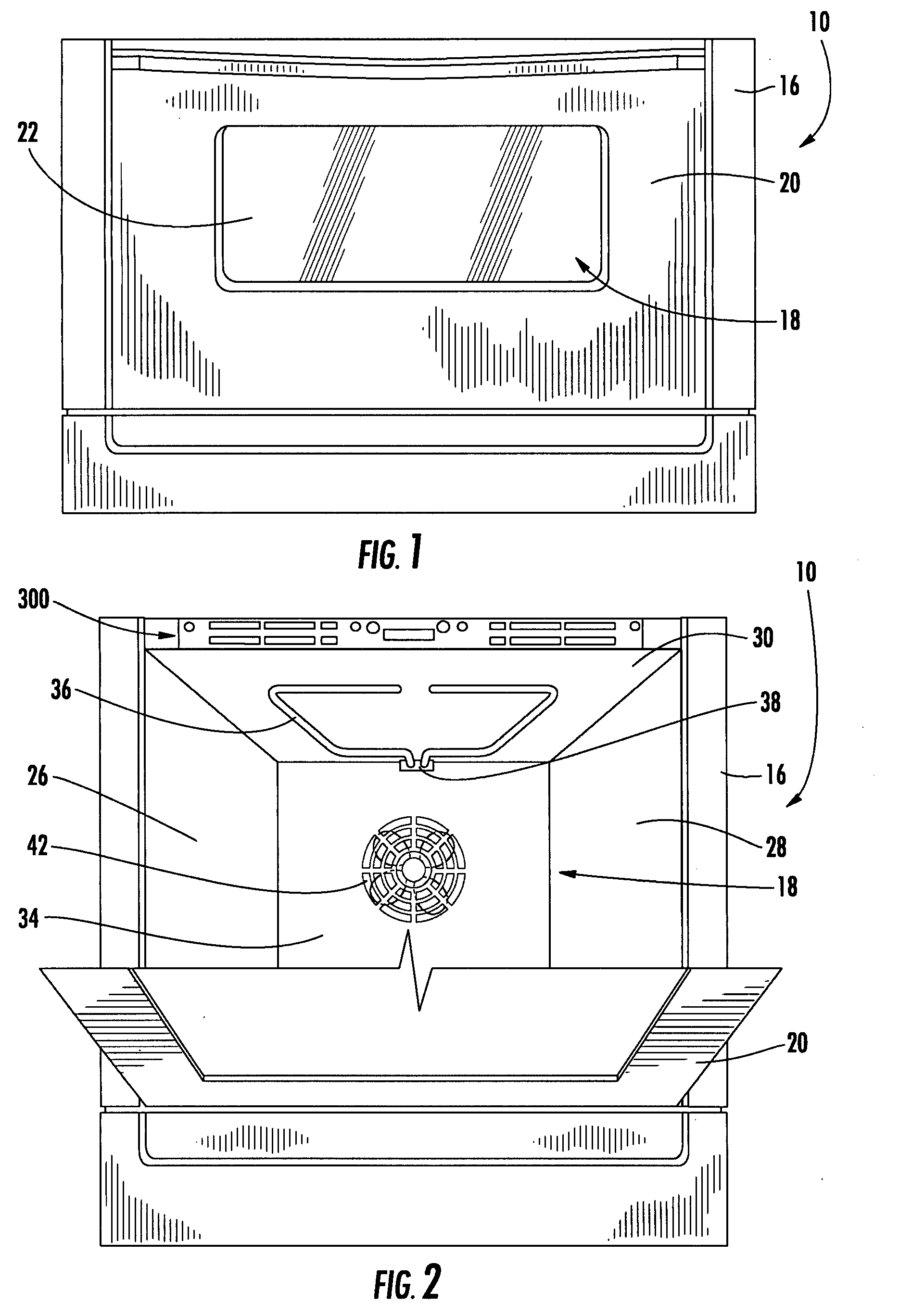

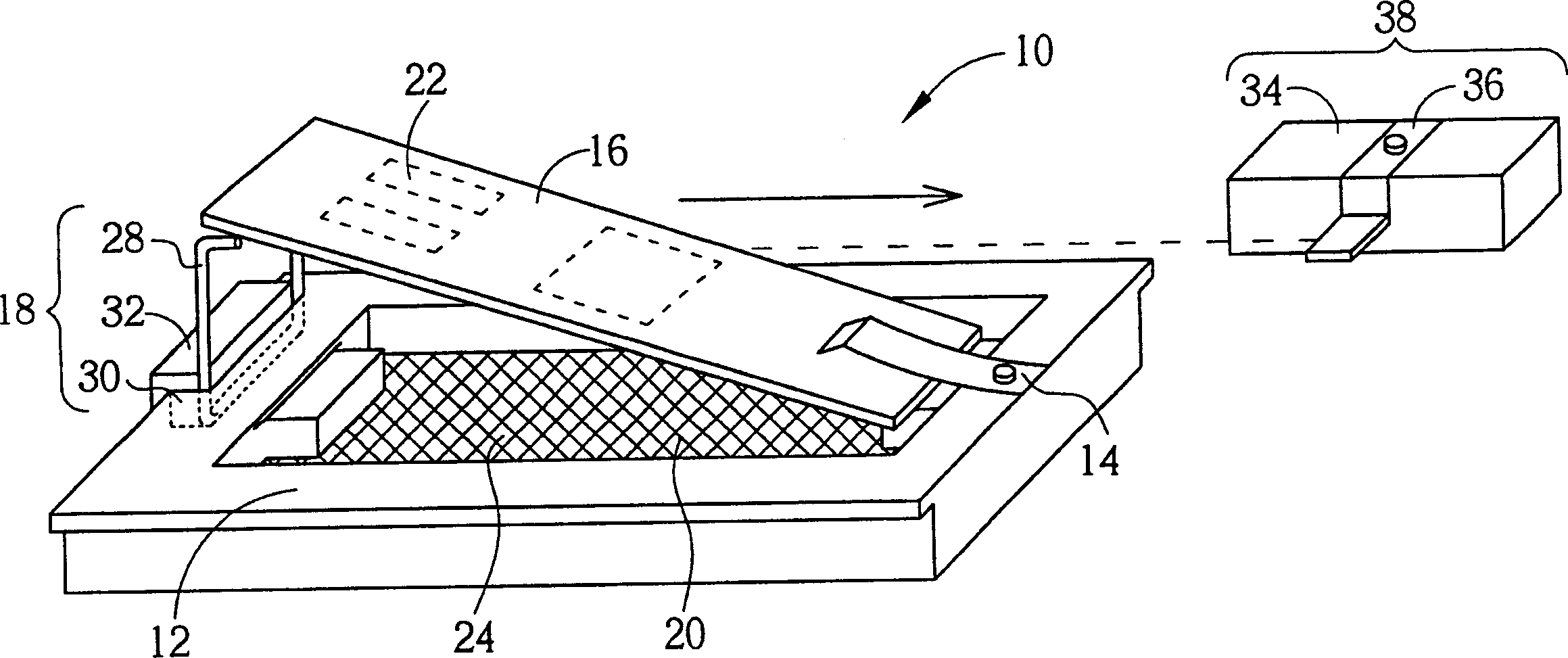

Self-reflowing printed circuit board and application methods

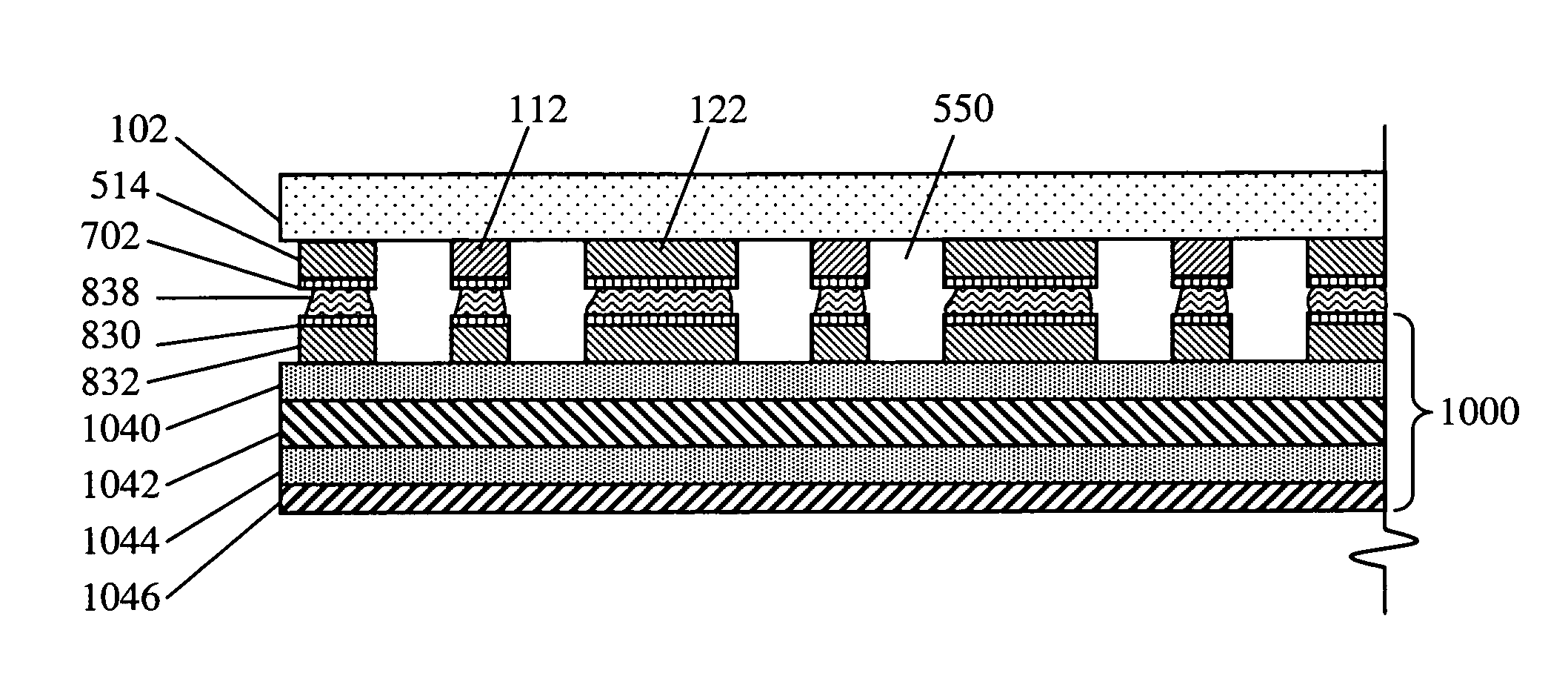

InactiveUS20060065431A1Reduce manufactured-product costLow temperature exposurePrinted circuit aspectsSolid-state devicesManufacturing cost reductionPrinted circuit board

A novel printed circuit board (PCB) 10 that incorporates embedded into its substrate an electric heater 14 is disclosed. This electric heater 14 becomes the only source of heat for simultaneously soldering components to pads 12. The PCB 10 is the key element that permits to create apparatuses and implement processes for soldering PCB assemblies without utilizing a reflow oven. Compared against the prior art this invention requires less manufacturing equipment, reduces the manufacturing cost, reduces manufacturing energy consumption and improves the quality and reliability of soldered PCB assemblies.

Owner:TRUCCO HORACIO ANDRES

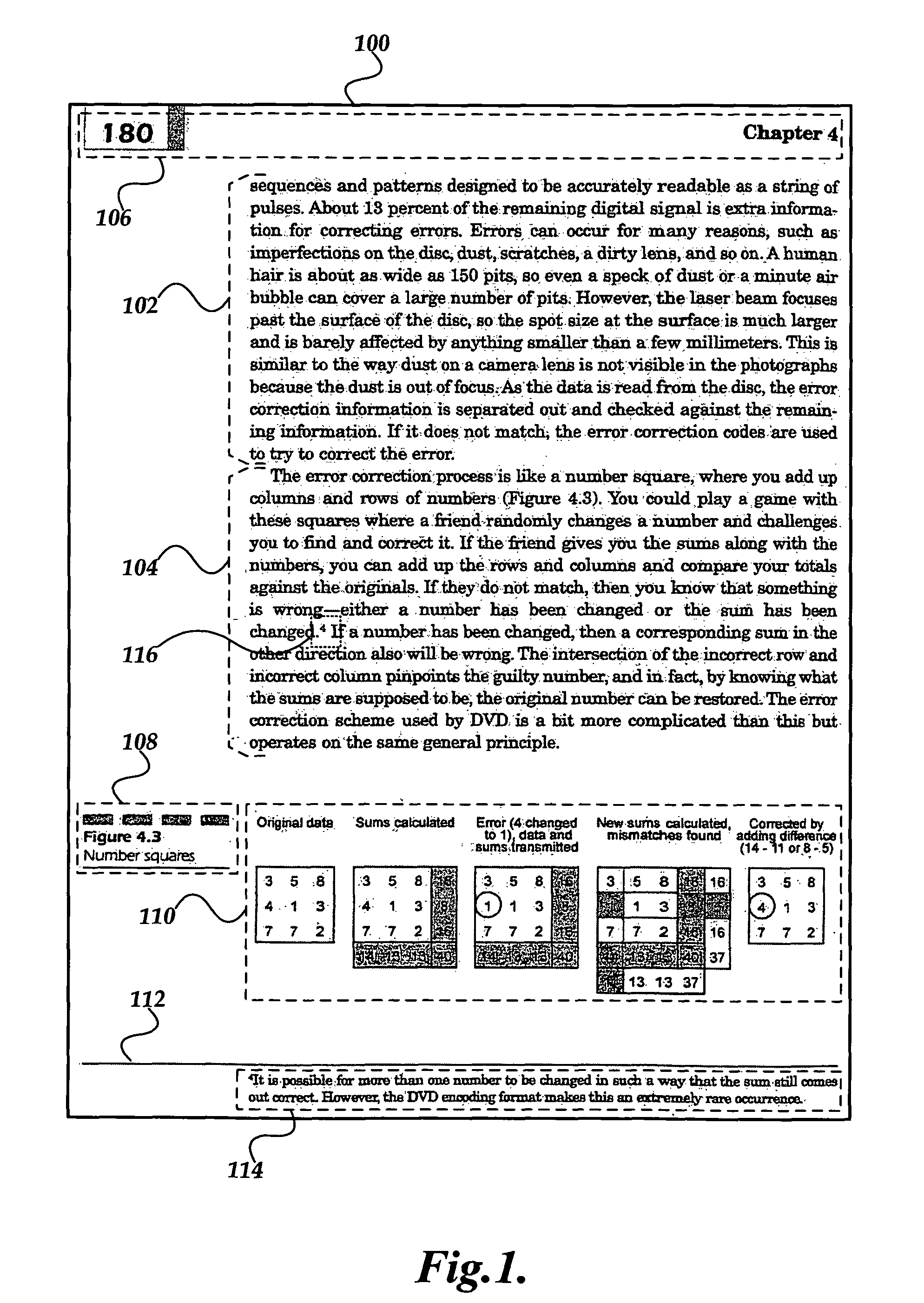

Generating reflow files from digital images for rendering on various sized displays

InactiveUS8023738B1Well formedCharacter and pattern recognitionSpecial data processing applicationsComputer graphics (images)Digital content

Processing content in a digital image into reflow content is presented. In operation, a computer system is configured to obtain a digital image from a source. The digital image comprises content including both reflow content and non-reflow content. The computer system identifies non-reflow blocks of content within the digital image and processes the digital image into reflow content, excluding the identified non-reflow blocks of content. The reflow content is copied to a digital content file or stream. The identified non-reflow blocks of content are also copied to the digital content file / stream. Information regarding the non-reflow blocks of content, such as its location in the digital image and a confidence rating, are included with the non-reflow block copied to the digital content file / stream.

Owner:AMAZON TECH INC

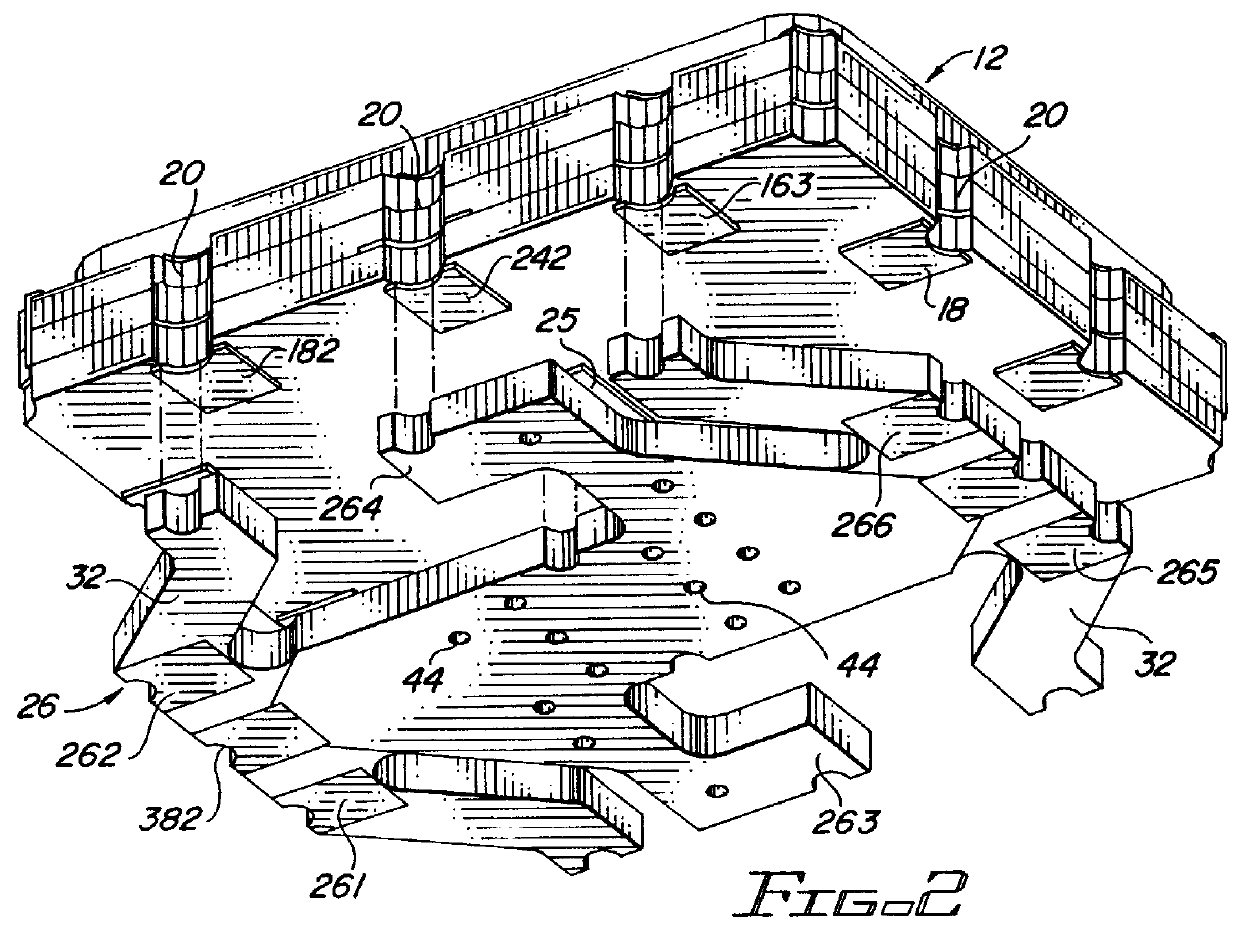

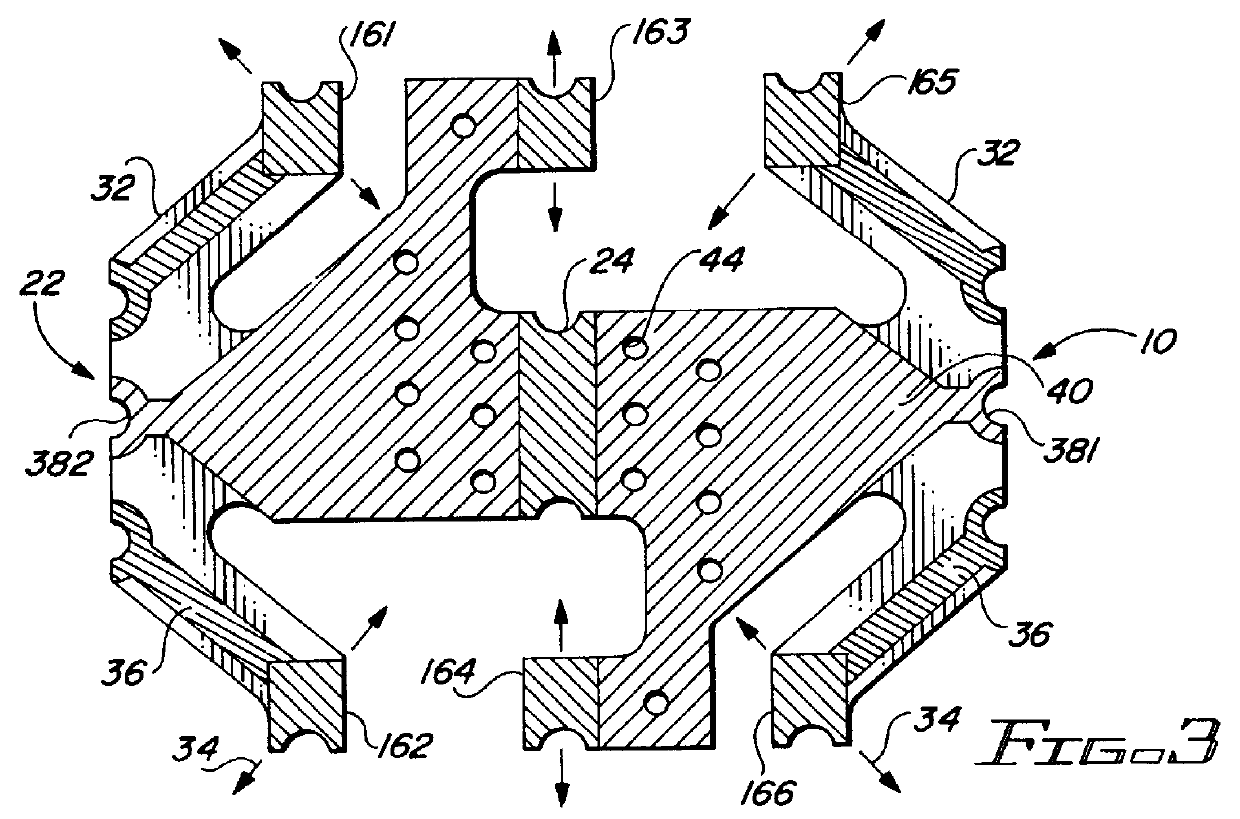

Slotted printed circuit board surface mount stress relief system

InactiveUS6011693ARelieve pressureMinimize crosstalkPiezoelectric/electrostriction/magnetostriction machinesFinal product manufactureContact padSurface mounting

A surface mounting stress relief system for mounting a surface mount package such as a leadless ceramic chip carrier on a printed circuit board includes a printed circuit board having a top layer attached to a bottom layer. The top layer includes cavities for exposing top surface portion of the bottom layer which carry a plurality of solder pads. The surface mount package is positioned on the printed circuit board for placing the package bottom surface on a top surface of the printed circuit board between the cavities while positioning package contact pads in spaced relation above corresponding preselected solder pads. A solder column extends between each of the plurality of corresponding solder pads and the selected contact pads for providing an electrical connection. The solder column is formed by applying a solder paste to the solder pads on the printed circuit board, screening a low temperature solder paste onto each of the contact pads of the surface mount package, placing a solder ball onto each pad, and attaching the solder ball to each of the contact pads of the package by passing the package through a reflow oven for reflowing the low temperature solder paste without reflowing the high temperature solder ball.

Owner:SAWTEK

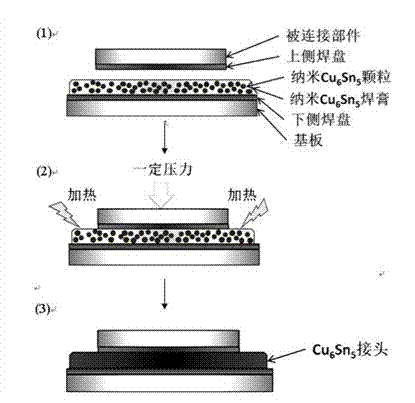

Method for preparing low-temperature interconnection/high-temperature serving joints by using nano intermetallic compound particles

ActiveCN102922071AImprove performanceStrong driving forceSolid-state devicesWelding/cutting media/materialsNanoparticleInterconnection

The invention discloses a method for preparing low-temperature interconnection / high-temperature serving joints by using nano intermetallic compound particles, which relates to a packaging and assembling interconnected method for electronic devices. The method specifically comprises the following steps: 1, placing nano intermetallic compound soldering paste on a substrate, completing a process of aligning a component to be welded, and exerting a pressure; and 2, placing the system into a reflow oven, and through the stages of preheating, heat preservation, reflowing and cooling, completing the volatilization of organic matters, the uniform sintering of nano intermetallic compound particles and the wetting and interface reaction of a pad. Because nano intermetallic compound particles are applied to the method disclosed by the invention, the great surface activity of the nano particles can provides a powerful driving force for the sintering process thereof, so that the low-temperature connection compatible with the traditional reflow soldering process and far lower than the melting point of a block thereof is realized, and then a joint with good performances is formed, therefore, the low-temperature bonding / high-temperature serving is realized on the premise of low cost, good compatibility with the traditional process, and high production efficiency.

Owner:HARBIN INST OF TECH

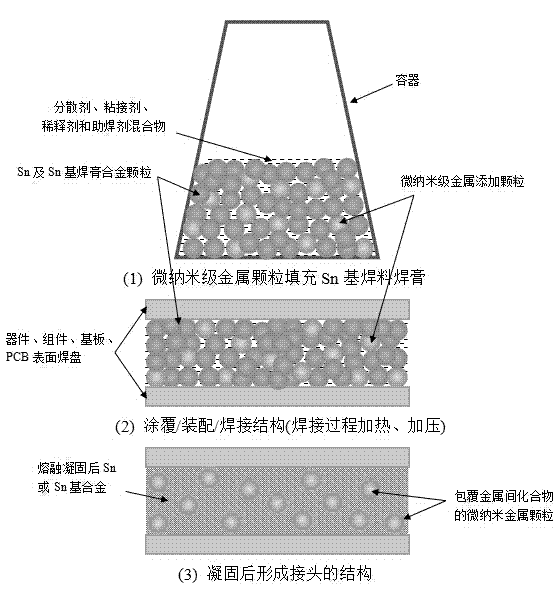

Method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles

ActiveCN104759725APlay a reinforcing roleImprove cooling effectWelding/cutting media/materialsMetal working apparatusMicro nanoBrick

The invention provides a method for achieving electronic building brick high-temperature packaging by filling Sn-based solder with micro-nano metallic particles. The method comprises the steps that the micro-nano metallic particles are prepared and mixed with a dispersing agent, a caking agent, diluent and scaling powder; a micro-nano metallic particle mixture is evenly mixed with pure Sn or Sn-based soldering paste; the Sn-based soldering paste is filled with the micro-nano metallic particles and placed on a base plate, alignment process of a part to be welded is completed, and pressure is exerted on the Sn-based soldering paste; the Sn-based soldering paste is put back in a reflow oven and experiences a preheating stage, an insulation stage, a reflowing stage and a cooling stage. According to the method for achieving electronic building brick high-temperature packaging by filling the Sn-based solder with the micro-nano metallic particles, the Sn-based solder is filled with the micro-nano metallic particles, connection and assembly of high-power devices or components can be achieved under the process condition of being compatible with traditional reflow soldering, when the devices serve at high temperature, metallic particles are formed inside a connector, excellent conductivity property and heat-conducting property are achieved, and the heat dissipation index and the electrical performance index of the electronic building brick can be significantly improved.

Owner:HARBIN INST OF TECH

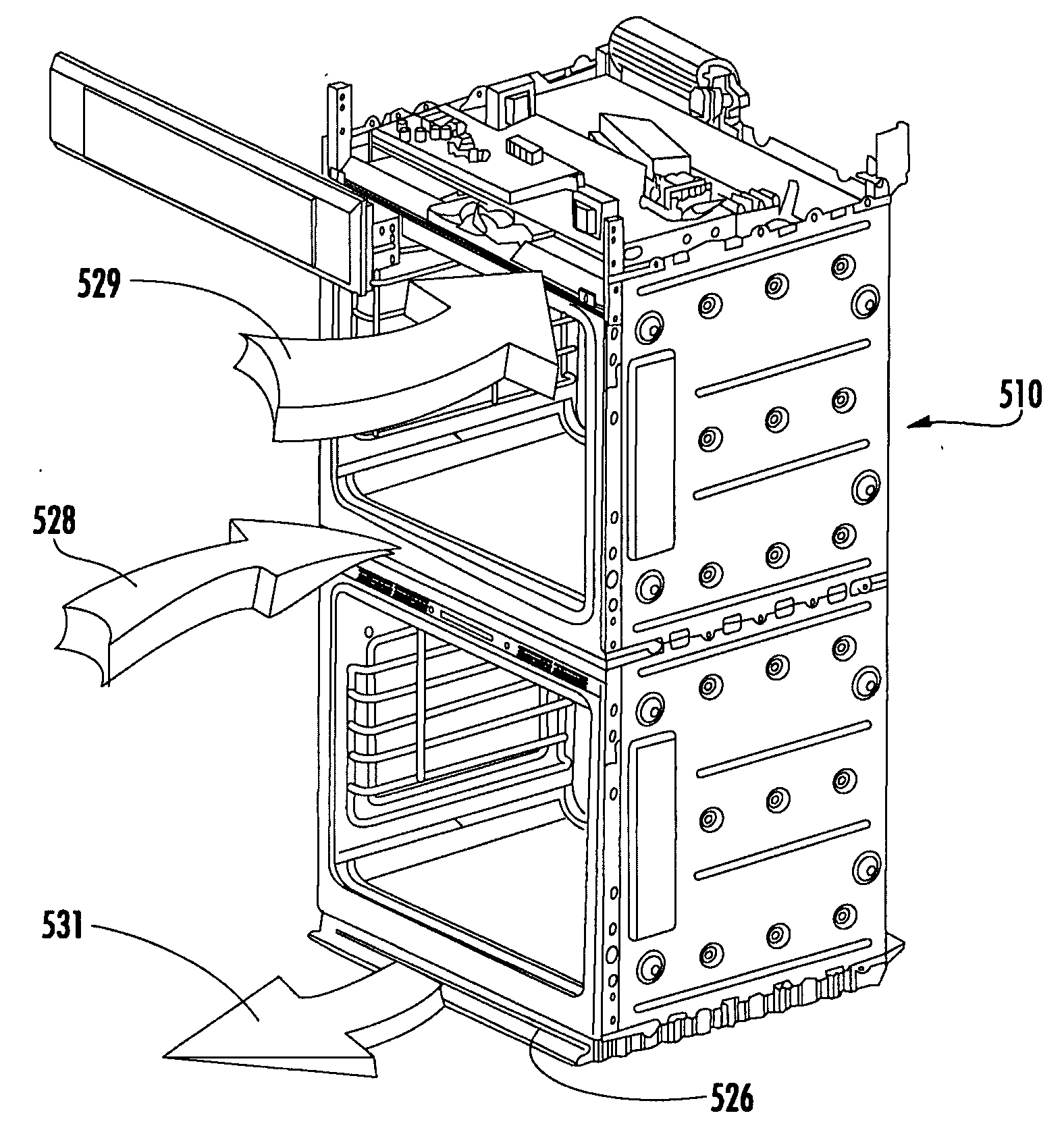

Double oven combination with an integrated cooling air and exhaust air flow arrangement

ActiveUS20080185373A1Ensure efficient flowShow cabinetsDomestic stoves or rangesConvective heatingReflow oven

A double oven combination is configured to be “built-in” an area of a household—in other words, permanently secured relative to the household area and integrated with other elements of the household area to provide a consistent decorative appearance. The double oven combination comprises an upper oven and a lower oven each of which may be a convection or non-convection oven that cooks and heats food and other substances via radiant and convective heating, and a control panel. The double oven combination has an integrated cooling air and exhaust air flow arrangement for efficiently guiding exhaust air away from the upper oven and the lower oven while at the same time effectively flowing cooling air relative to the double oven combination to promote desired cooling of the double oven combination.

Owner:BSH HOME APPLIANCES CORP

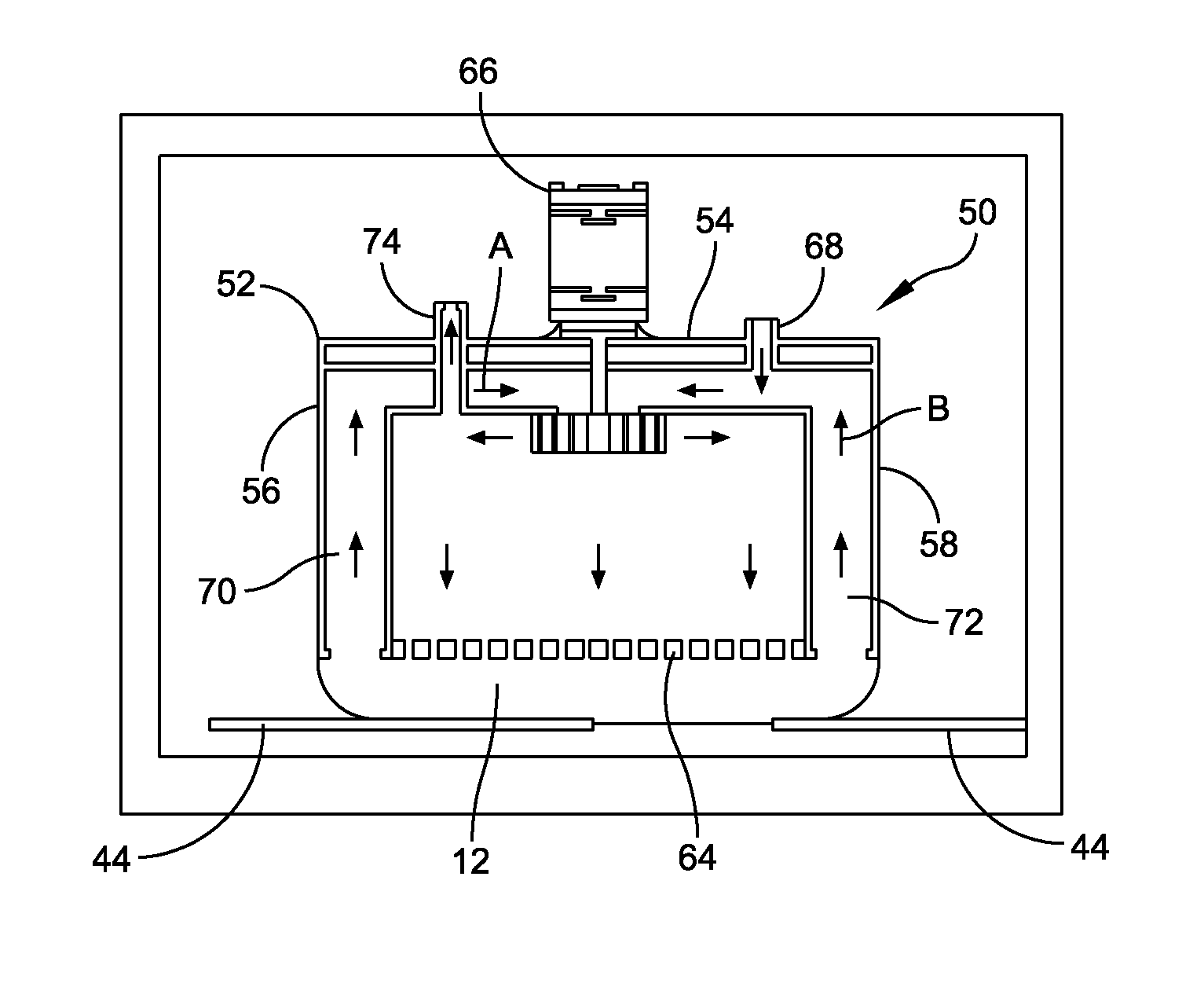

Reflow furnace

ActiveUS20090134142A1Increase the blowing speedWell formedSoldering apparatusCrucible furnacesPrinted circuit boardNozzle

The suction ports of a hot air blowing heater are arranged in a zigzag shape crossing the direction of travel of a printed circuit board, and hot air discharge nozzles project from inside or alongside the suction ports. Accordingly, in the reflow furnace according to the present invention, hot air discharged from the hot air discharge nozzles does not collide with hot air sucked into the suction ports, and turbulence does not take place.

Owner:SENJU METAL IND CO LTD

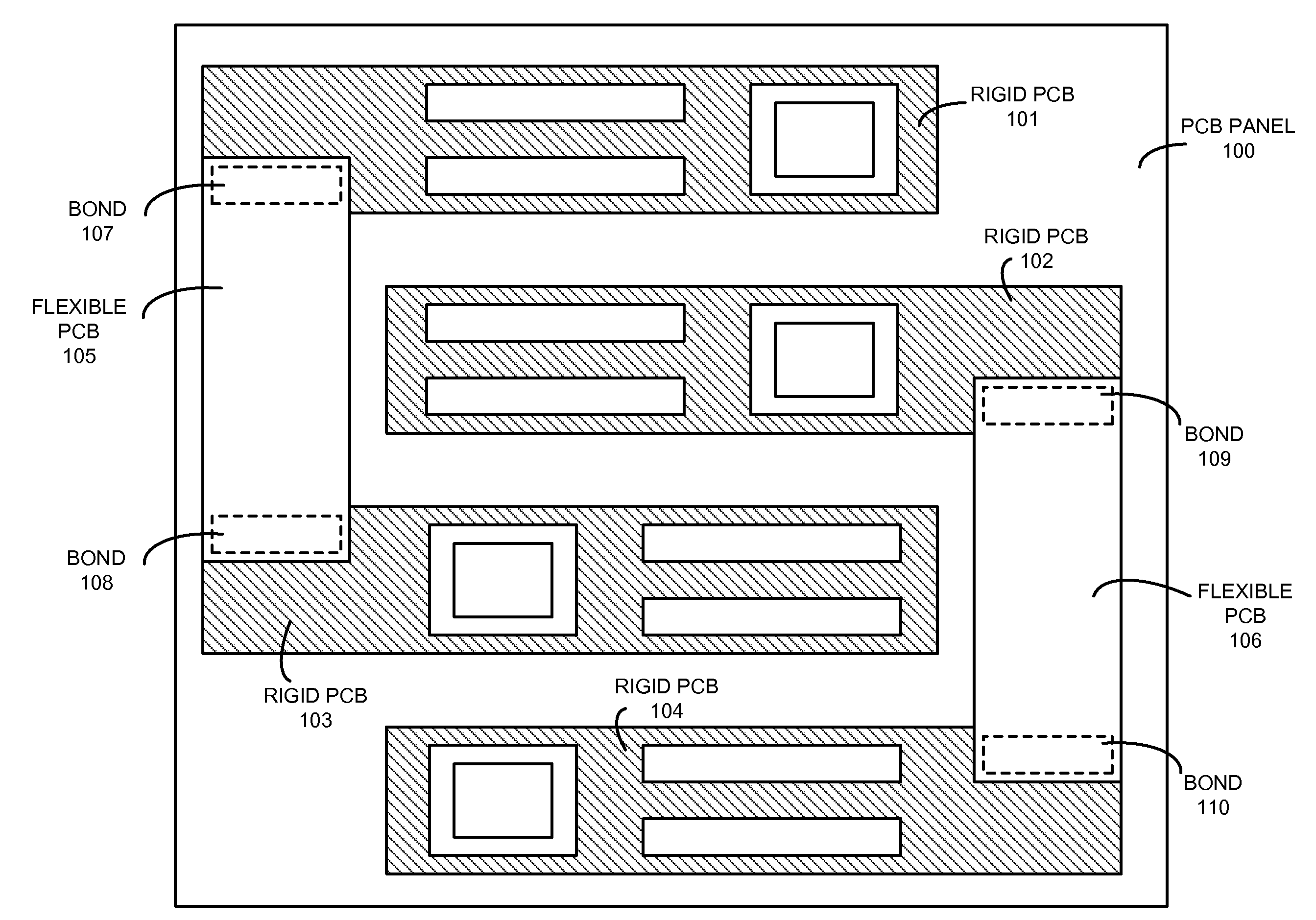

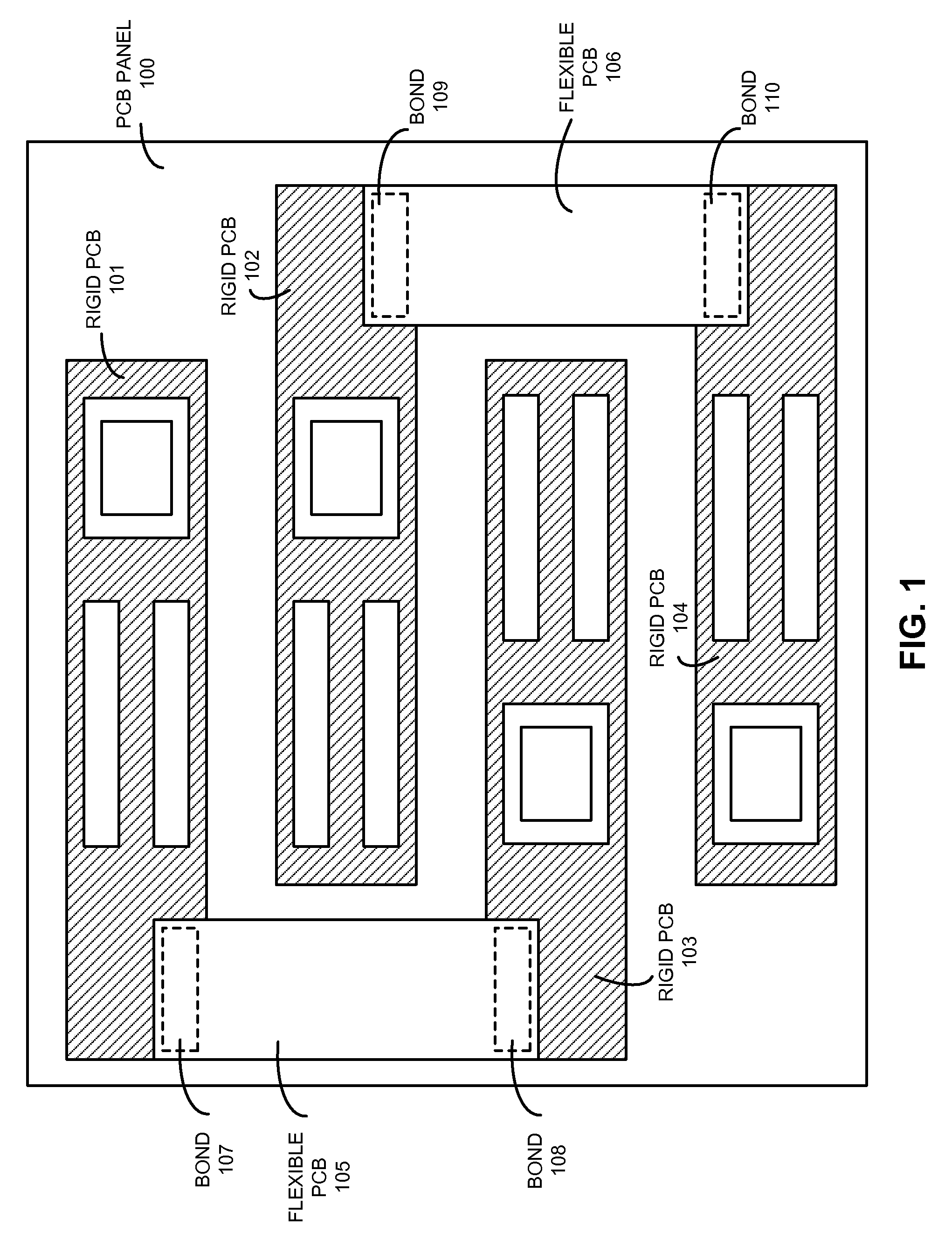

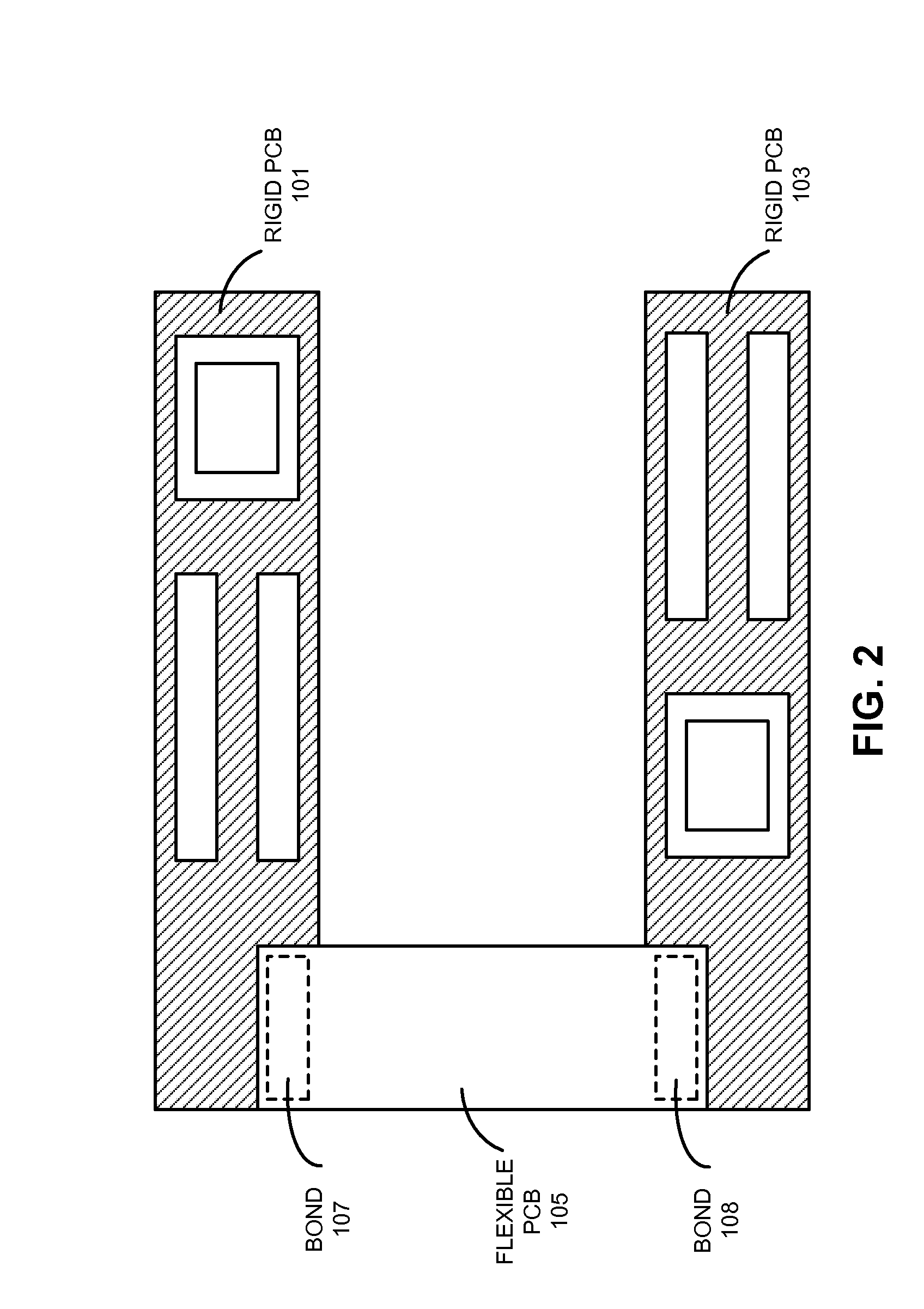

Technique for reducing wasted material on a printed circuit board panel

InactiveUS20090205200A1Minimizes amount of wasteQuantity minimizationPrinted circuit assemblingLine/current collector detailsAnisotropic conductive filmEngineering

A process for assembling a rigid-flex printed circuit board (PCB) is presented. During operation, the process receives rigid-flex PCBs that are to be coupled together, wherein a rigid-flex PCB includes flexible PCBs coupled to rigid PCBs. The process then places the PCBs onto a carrier which is configured to: align the PCBs so that bond regions located on the flexible PCBs overlap with bond regions located on corresponding flexible PCBs, and apply pressure to the overlapped bond regions. The process then sends the carrier through a reflow oven which reflows solder on the PCBs so that the components become mechanically and electrically coupled to the PCBs. The temperature profile generated by the reflow oven and the pressure applied by the carrier cures and sets an anisotropic conductive film located in the bond regions so that the overlapped flexible PCBs become mechanically and electrically coupled together.

Owner:APPLE INC

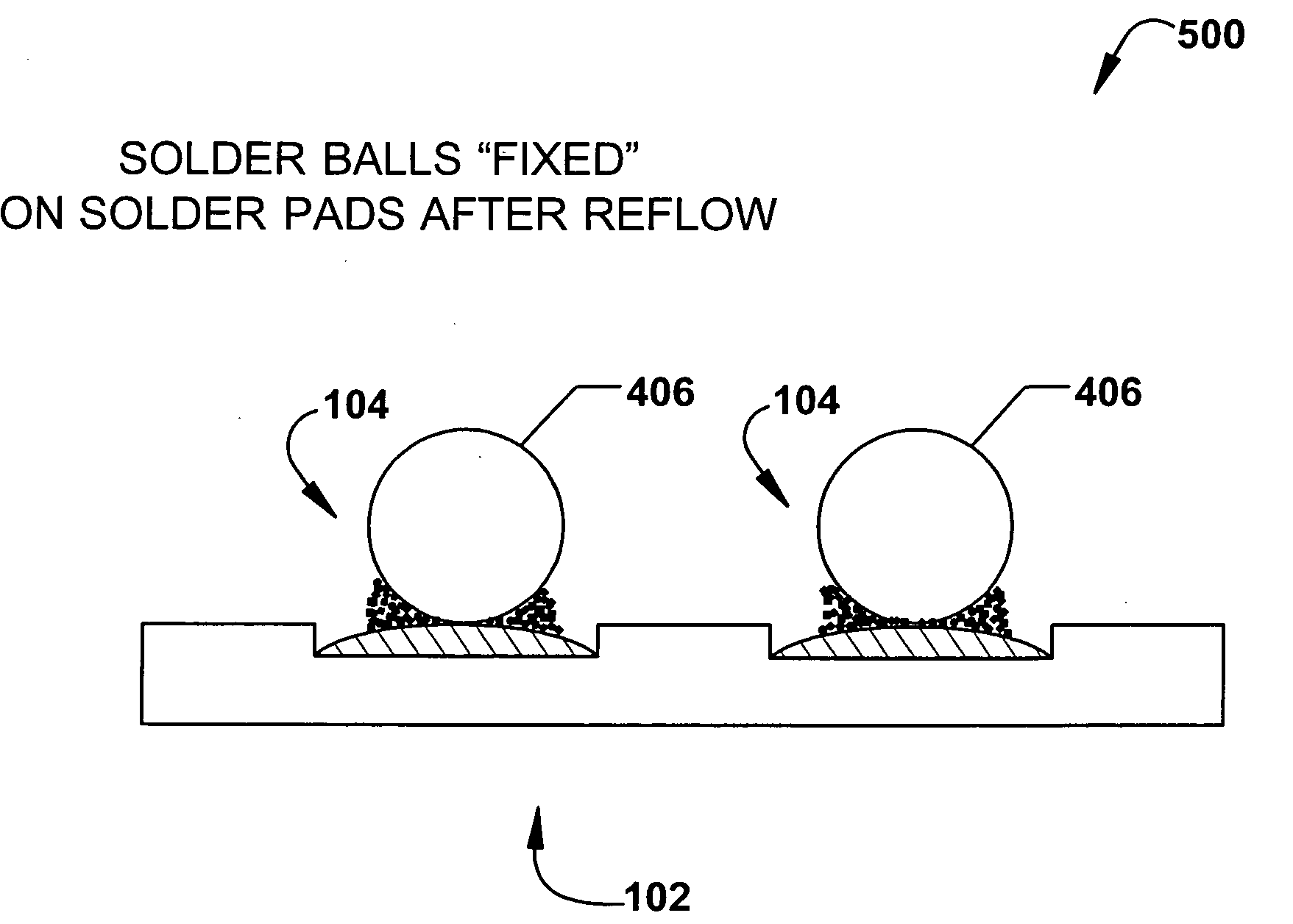

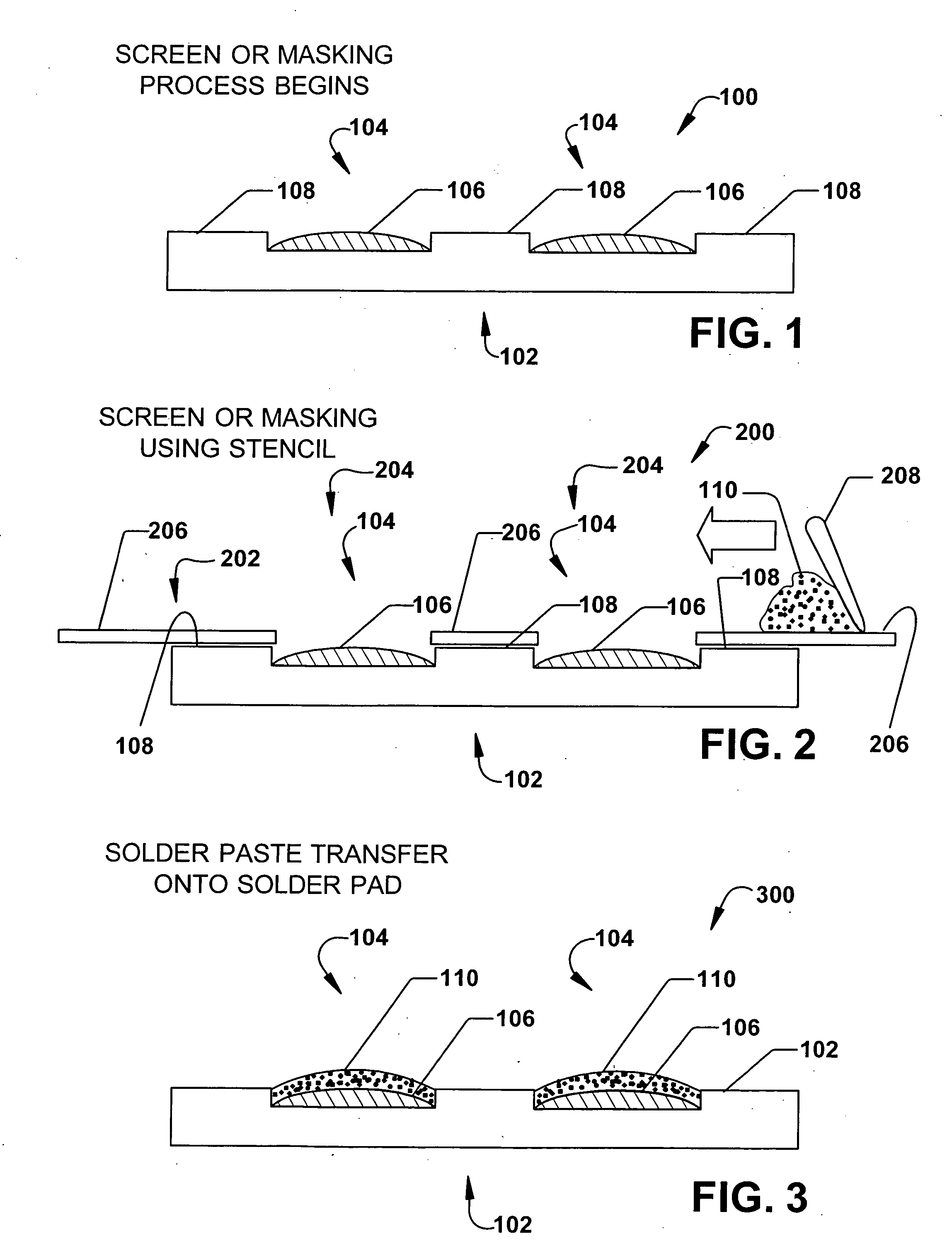

Method and apparatus for attaching solder balls to substrate

InactiveUS20070111500A1Increase productionAdvanced technologyPrinted circuit aspectsSolid-state devicesMetallurgySolder ball

A method for attaching solder balls to solder pads on a circuit board, comprising distributing an approximately uniform flat layer of solder paste with distributed solder particles on top of a flat plate employing a squeegee, picking up the solder balls from a solder ball bin utilizing a vacuum tool, dipping the solder balls into the solder paste, lifting the solder balls out of the solder paste, placing the solder balls with the solder paste proximate to the center of the solder pad, releasing the solder balls, and reflowing assembly comprising the substrate, the solder balls, the solder paste, and solder particles in a reflow oven.

Owner:TEXAS INSTR INC

Halogen-free flame-retardant high-temperature nylon

The invention relates to a halogen-free flame-retardant high-temperature nylon, which is characterized by comprising polyamide and DOPO derivatives. The halogen-free flame-retardant high-temperature nylon reaches the UL94V-0 grade in 0.8 mm burning tests, has excellent thermal stability, chemical stability, and mechanical performance, can be used as the main material to prepare surface mount devices (SMD), and meets the operating requirements of a high-temperature infrared reflow oven welding technology during the process of a surface mount technology (SMT).

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

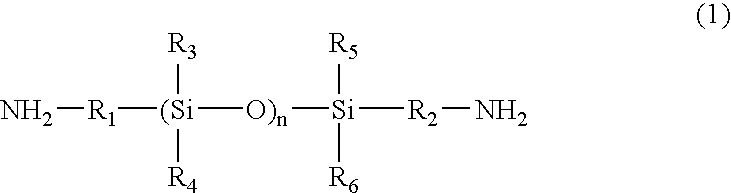

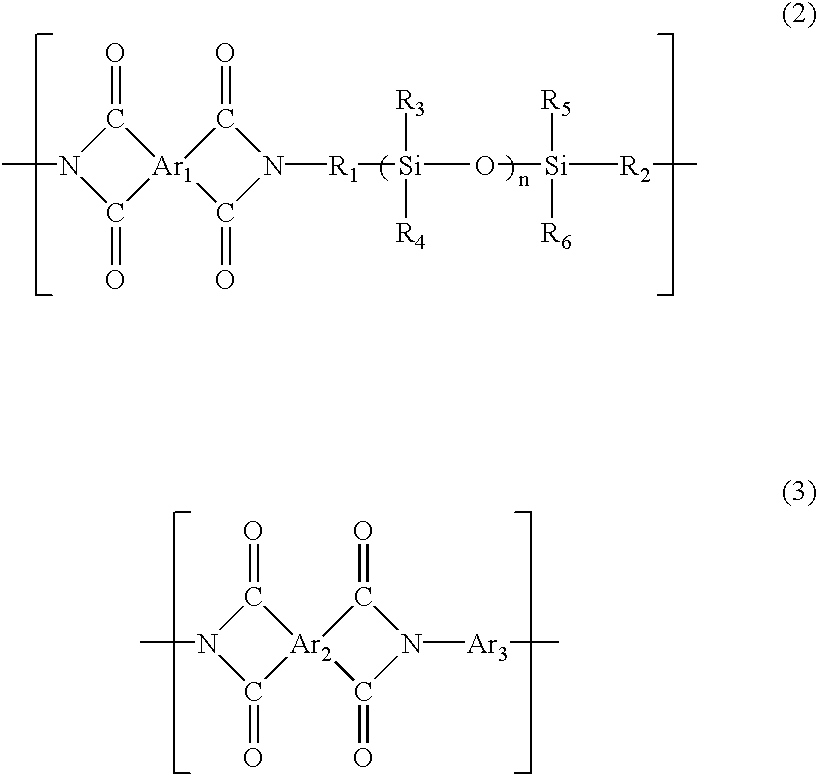

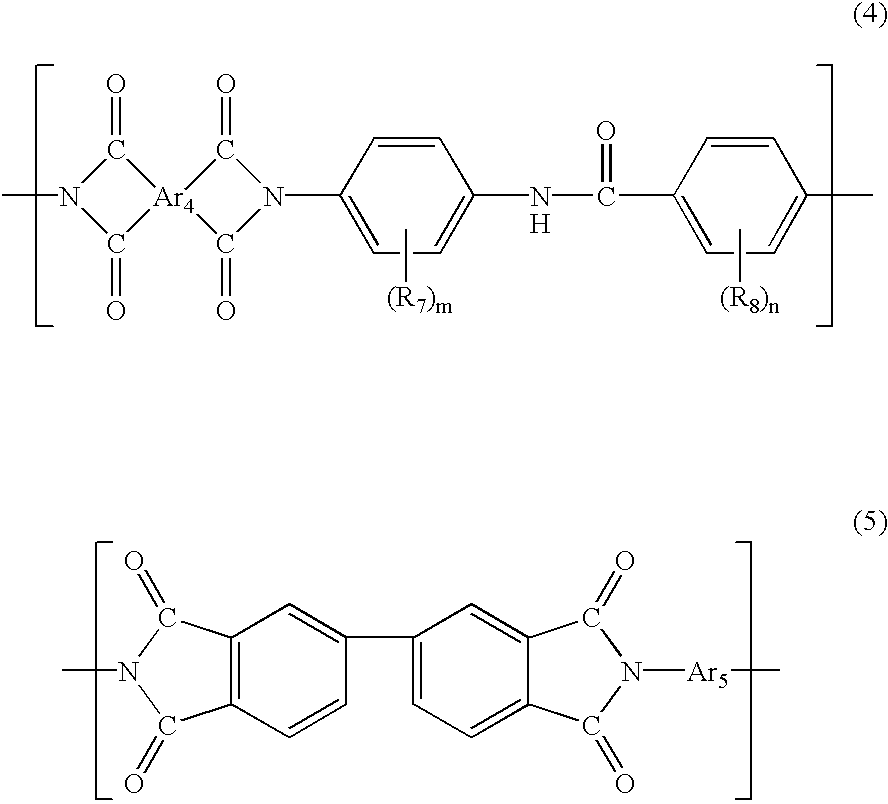

Adhesive polyimide resin and adhesive laminate

InactiveUS6887580B2Good adhesivenessIncrease freedomSemiconductor/solid-state device detailsSolid-state devicesImidePolymer science

An adhesive polyimide resin which comprises a siloxane polyimide resin obtained from (A) an aromatic tetracarboxylic dianhydride and (B) a diamine ingredient comprising (B1) a diamine having a phenolic hydroxyl group, carboxyl group, or vinyl group as a crosslinkable reactive group and (B2) a siloxanediamine and has a glass transition temperature of 50 to 250□C and a Young's modulus (storage modulus) at 250□C of 105 Pa or higher; and a laminate which comprises a substrate comprising a conductor layer and an insulating supporting layer having at least one polyimide resin layer and, disposed on a surface of the substrate, an adhesive layer comprising a layer of the adhesive polyimide resin. The adhesive polyimide resin and the laminate have satisfactory adhesion strength even after exposure to a high temperature of up to 270□C and further have excellent heat resistance in reflow ovens. They are hence suitable for use in the bonding of electronic parts.

Owner:NIPPON STEEL CHEMICAL CO LTD

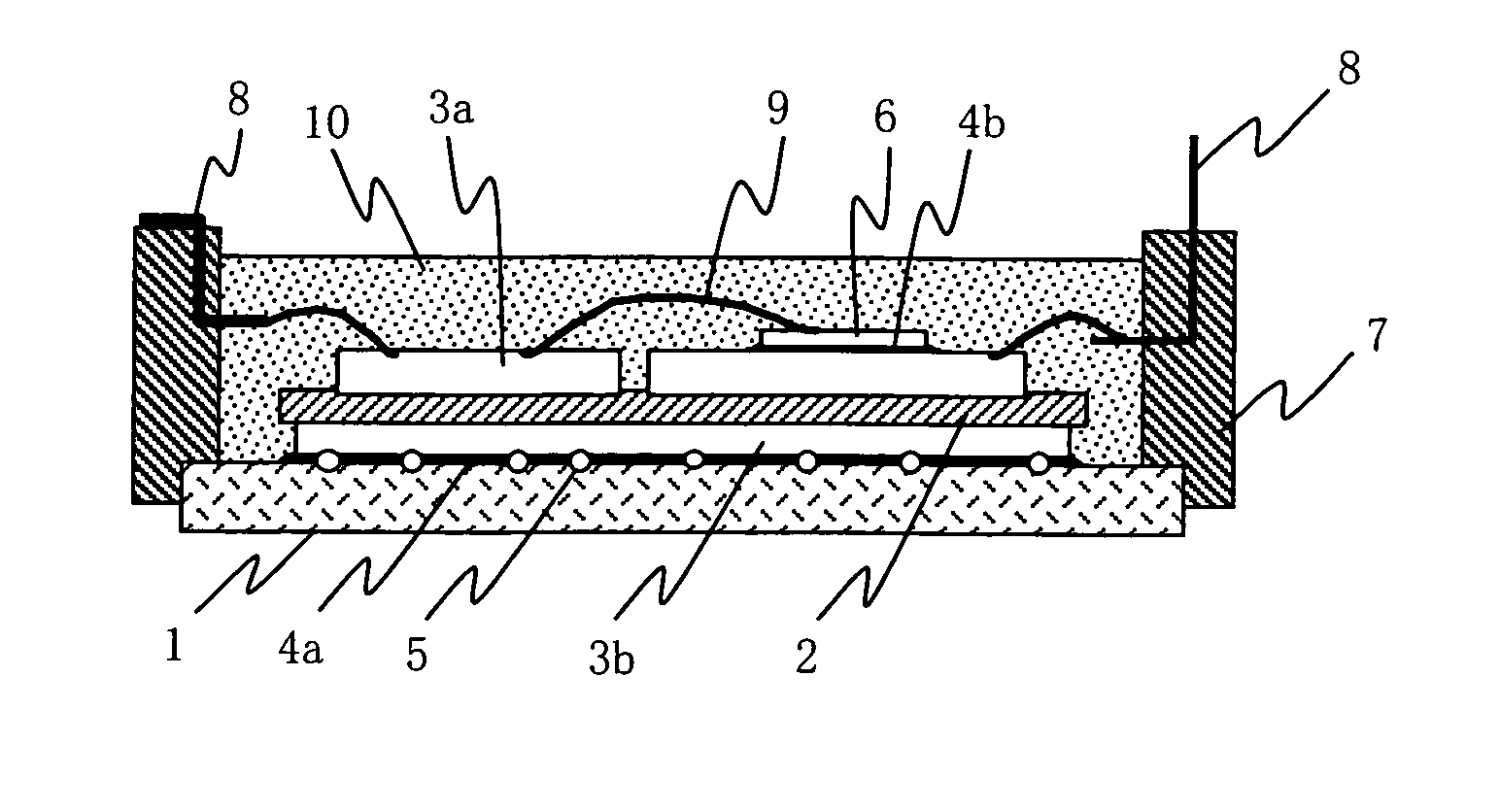

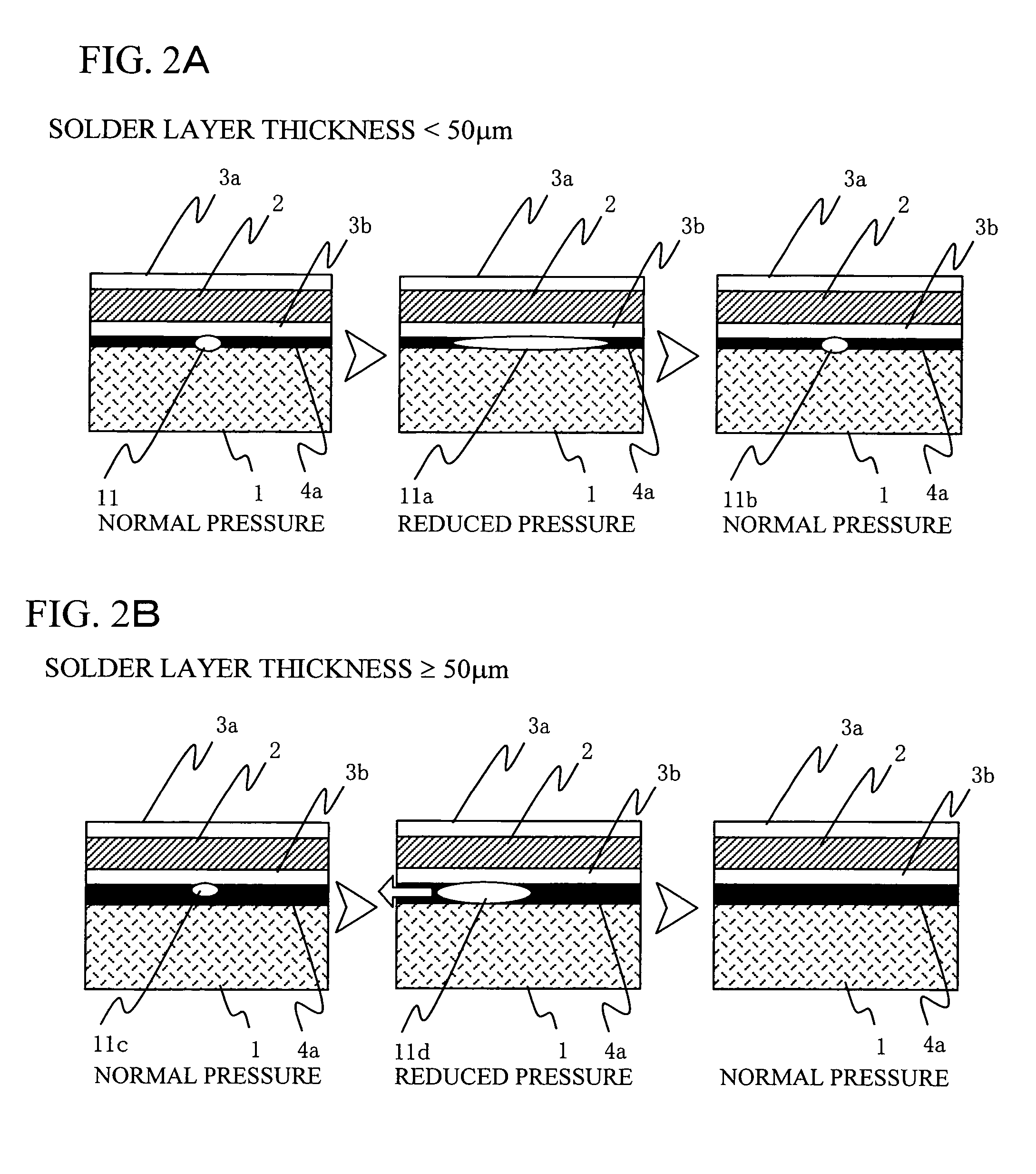

Resin encapsulated semiconductor device and the production method

ActiveUS20050221538A1Easy to moveHigh strength propertiesPrinted circuit assemblingLine/current collector detailsDevice materialSilica gel

A semiconductor device having both high strength and high thermal radiation that is capable of being applied to mounting on automobiles experiencing many thermal cycles, and a manufacturing method thereof are provided. A circuit board 1a for a resin encapsulated semiconductor module device has a configuration where a silicon nitride plate 2 with a thickness of 0.635 mm has copper plates of 1.0 mm and 0.8 mm bonded to both sides thereof via active metal. A copper plate 3a is bonded to the surface side of the silicon nitride plate 2, and a prescribed circuit pattern is formed on the copper plate 3a. Tin-silver-copper cream solder layers 4a and 4b with a thickness of 200 μm are formed at a prescribed location on the circuit pattern 3a on which a semiconductor element 6 is mounted and at a prescribed location of a base plate 1 on which the circuit board 1a is disposed. Nickel particles 5 having a maximum particle size of 100 μm and an average particle size of 70 μm are dispersed in the solder 4a on the base plate 1 of good thermal conductivity. A semiconductor element (chip) 6, the circuit board 1a, and the base plate 1 are disposed on predetermined locations. Thereafter, they are set in a reflow oven (not shown in the drawings) for reflow soldering. After the inside of the reflow oven is replaced by a nitrogen atmosphere, the reflow oven is heated to 280° C. At the time when solder is melted, the inside of the oven is decompressed to 1 Pa, nitrogen is introduced, and the reflow oven is cooled to about room temperature, thereby completing the solder bonding step. After flux is washed, an outer case 7 with an insert-molded outlet terminal 8 is adhered to the base plate 1 and a predetermined connection is conducted via an aluminum bonding wire 9. Then, silicone gel 10 is injected into a package delimited via the base plate 1 and the outer case 7, and the silicone gel 10 is heat-hardened, thereby completing a resin encapsulated semiconductor device A.

Owner:HITACHI LTD +1

Adhesive polyimide resin and adhesive laminate

InactiveCN1406262AImprove liquidityImprove heat resistanceSemiconductor/solid-state device detailsSynthetic resin layered productsVitrificationElectrical conductor

An adhesive polyimide resin which comprises a siloxane polyimide resin obtained from (A) an aromatic tetracarboxylic dianhydride and (B) a diamine ingredient comprising (B1) a diamine having a phenolic hydroxyl group, carboxyl group, or vinyl group as a crosslinkable reactive group and (B2) a siloxanediamine and has a glass transition temperature of 50 to 25 DEG C and a Young's modulus (storage modulus) at 25 DEG C of 10<5> Pa or higher; and a laminate which comprises a substrate comprising a conductor layer and an insulating supporting layer having at least one polyimide resin layer and, disposed on a surface of the substrate, an adhesive layer comprising a layer of the adhesive polyimide resin. The adhesive polyimide resin and the laminate have satisfactory adhesion strength even after exposure to a high temperature of up to 27 DEG C and further have excellent heat resistance in reflow ovens. They are hence suitable for use in the bonding of electronic parts.

Owner:NIPPON STEEL CHEMICAL CO LTD

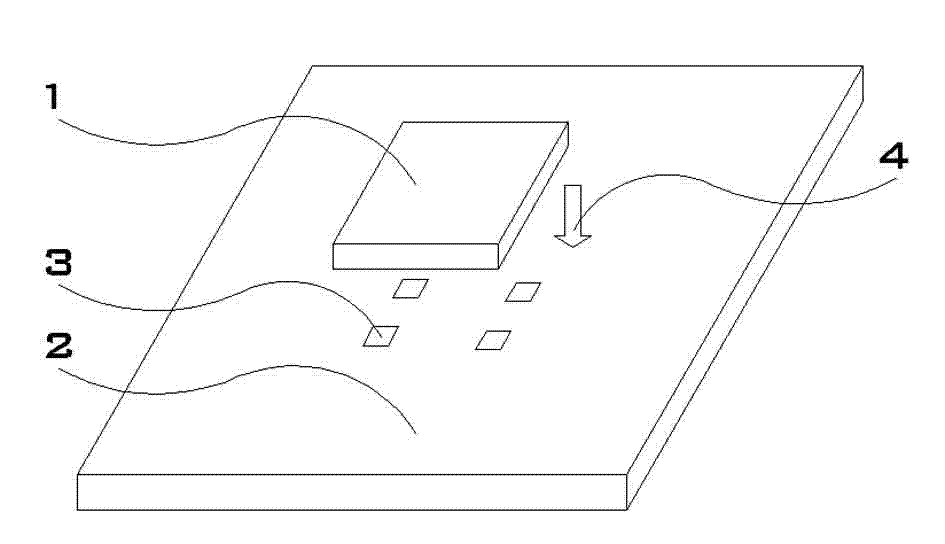

Electronic component carrier and method for shattering and loading electronic components on circuit board

An electronic element carrier is composed of a fixed frame, a clamper fixed to said fame and clamping a circuitboard on said frame, an impacter for impacting the circuitboard to separate the electronic elements from the circuitboard when the temp in a welding furnace is higher than a predefined temp, and a carrier for collecting the separated electronic elements.

Owner:HTC CORP

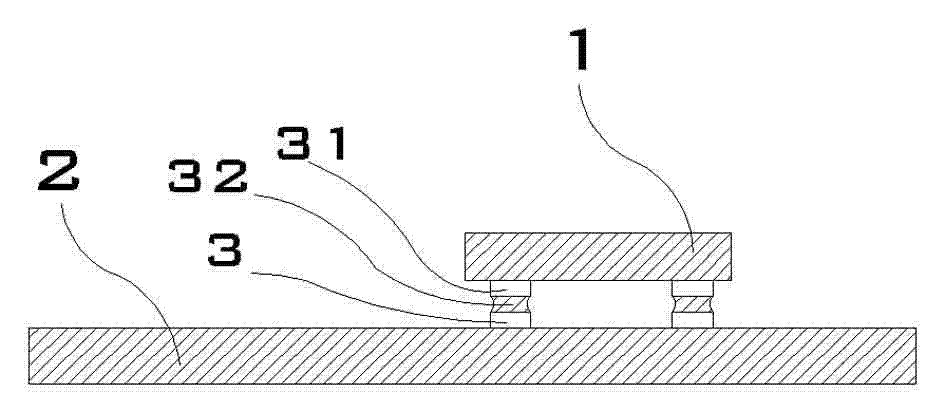

Chip welding method

InactiveCN102903646ASimple production processImprove pass ratePrinted circuit assemblingSolid-state devicesLead bondingReflow oven

The invention discloses a chip welding method. The chip welding method includes the steps of firstly, applying solder 32 to the surface of a pad 3 of a substrate 2; secondly, aligning a pad surface 31 of a chip 1 to the pad 3 of the substrate for mounting by a manipulator; thirdly, heating the chip with the chip well mounted to solidify the solder 32 by a reflow oven to complete chip welding. In certain cases, reinforcement is needed to make welding more reliable. The chip welding method is substitutive for traditional chip lead bonding and flip-chip packaging technology, production efficiency is improved, and production cost is decreased.

Owner:上海祯显电子科技有限公司

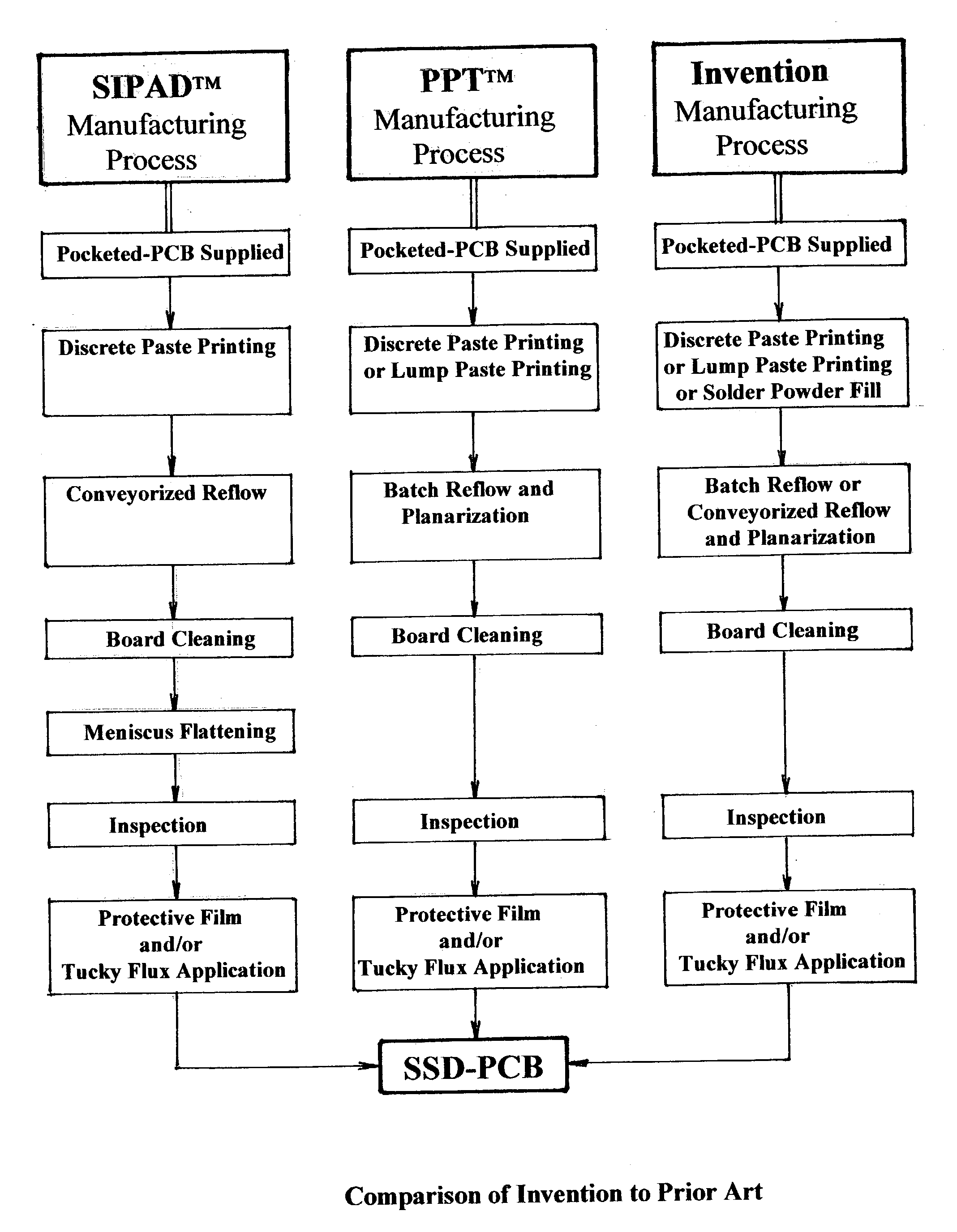

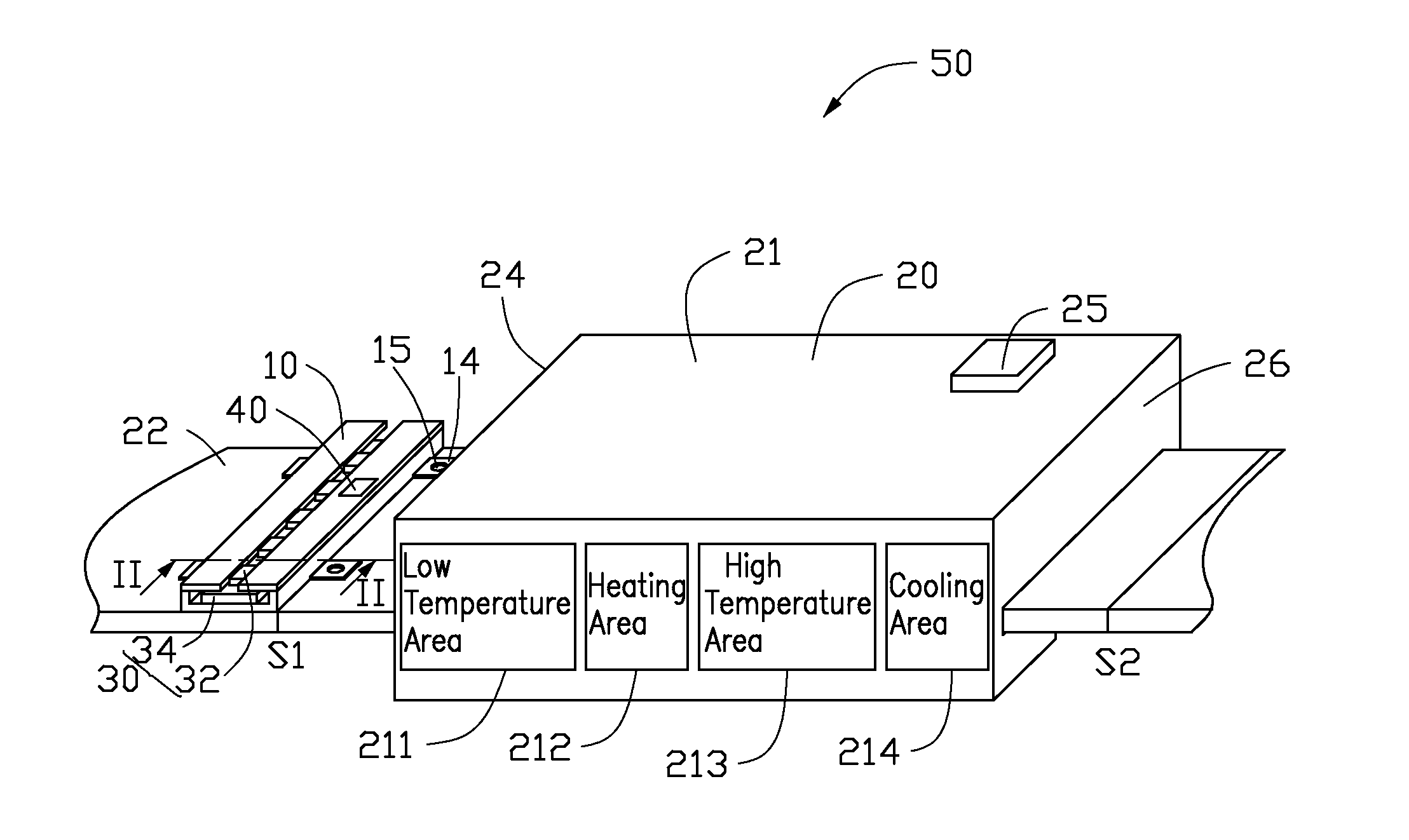

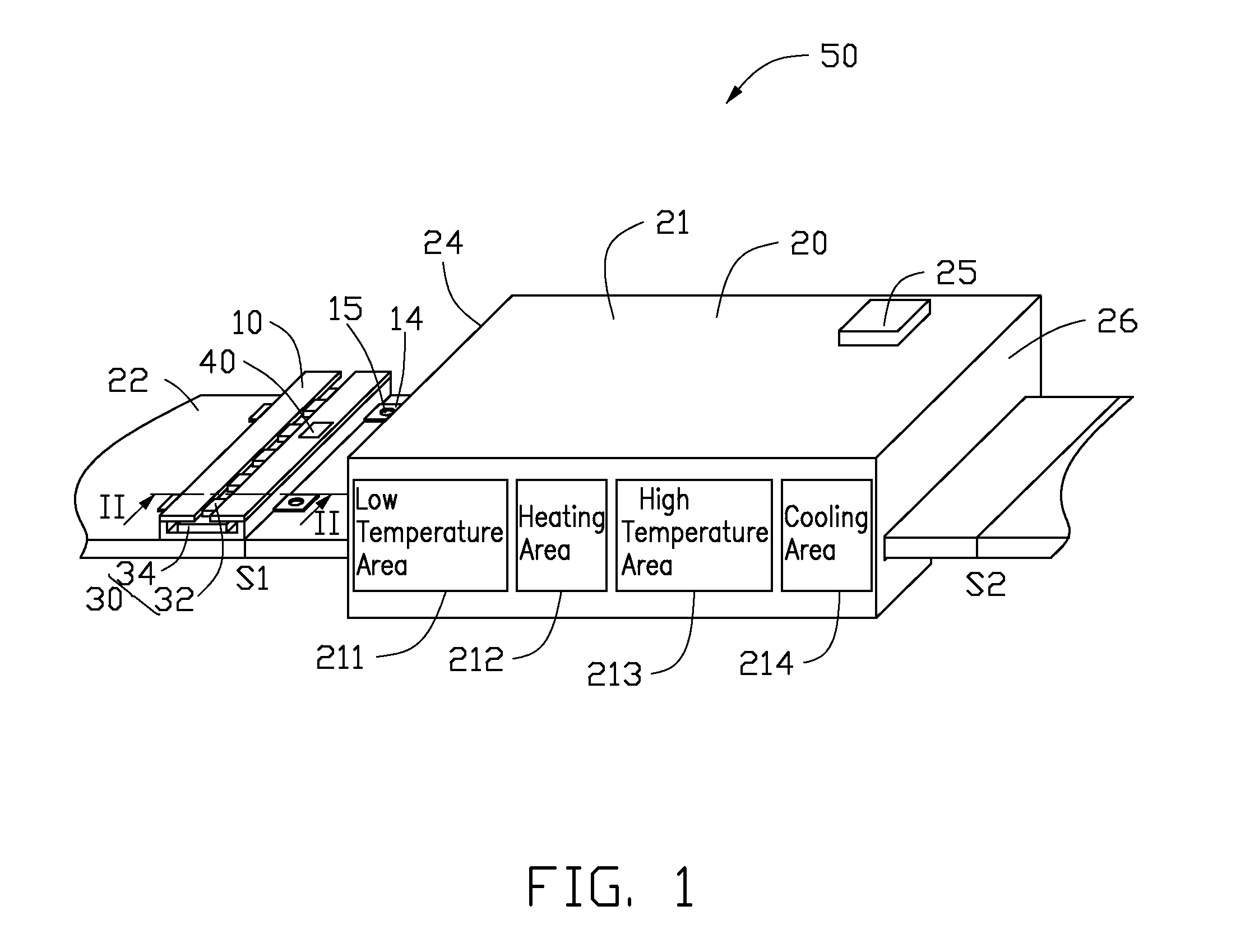

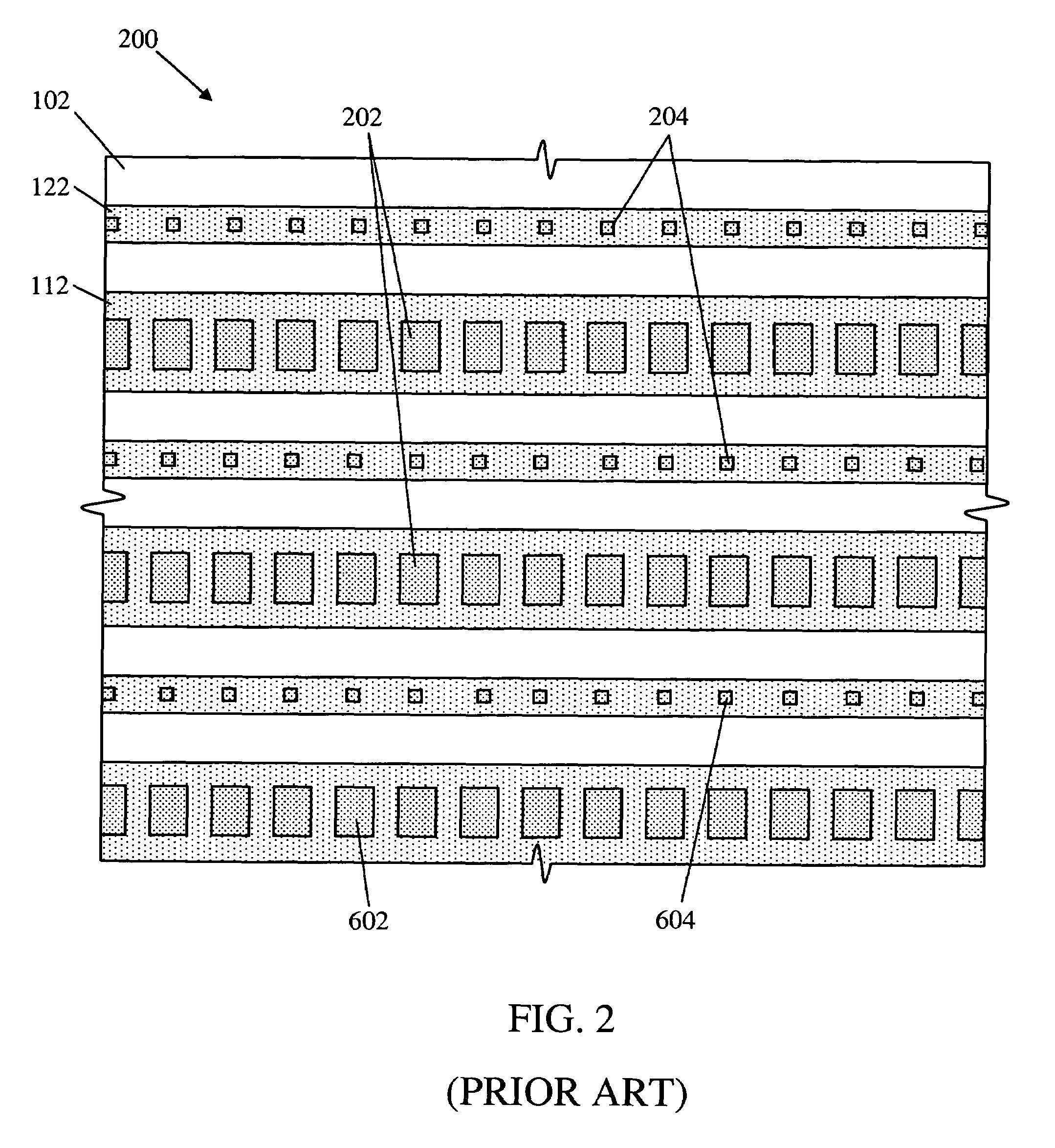

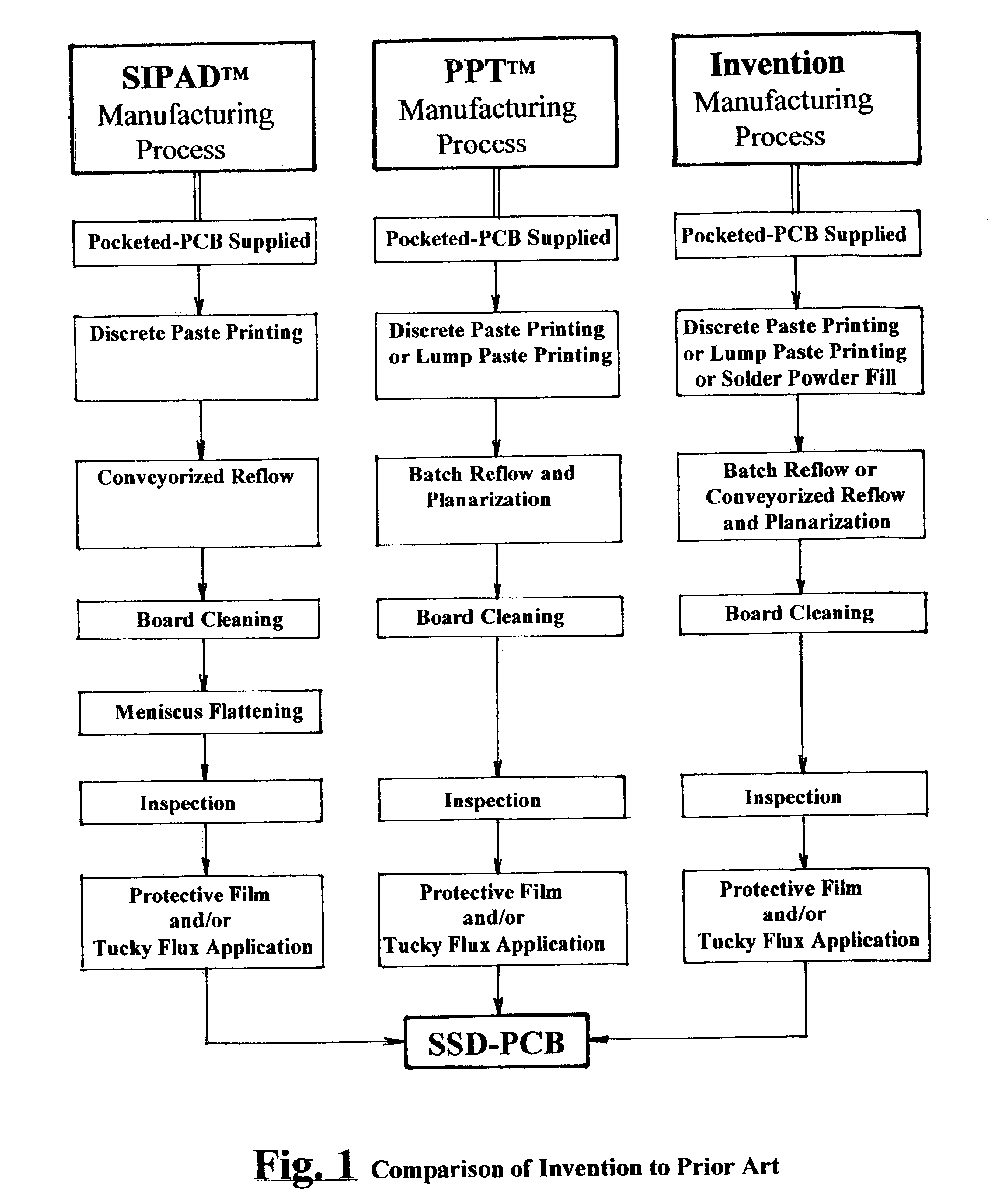

Manufacture of solid-solder-deposit PCB utilizing electrically heated wire mesh

InactiveUS20040178251A1Reduce present cost for SSD-PCBsImprove reliabilityPrinted circuit assemblingPrinted circuit aspectsAssembly lineSolder paste

A novel process and apparatus for manufacturing Solid Solder Deposit-Printed Circuit Board (SSD-PCB) by either melting solder paste or dry solder powder previously deposited on a pocketed-PCB 20. Said process and apparatus, unlike the prior art, utilize as heat source an electrically heated conveyor wire mesh 76 instead of a reflow oven. Relatively thick flat-shaped SSDs 44 metallurgically bonded over each soldering pad 24 of said pocketed-PCB 20 are formed. By itself, SSD-PCB technology provides the electronic assembly industry with ready-to-solder PCBs consequently eliminating the need to use solder paste at the assembly line. This invention, unlike the prior art for producing SSD-PCBs, can utilize dry solder powder piles 38 in conjunction with flux layers 116 deposited on top of said conveyor wire mesh 76 thereby excluding, all together, the use of paste printing equipment. Specifically my invention reduces the manufacturing cost, shortens manufacturing time, reduces manufacturing energy consumption and improves SSD-PCB's quality and reliability while requiring less manufacturing equipment than the prior art.

Owner:TRUCCO HORACIO ANDRES

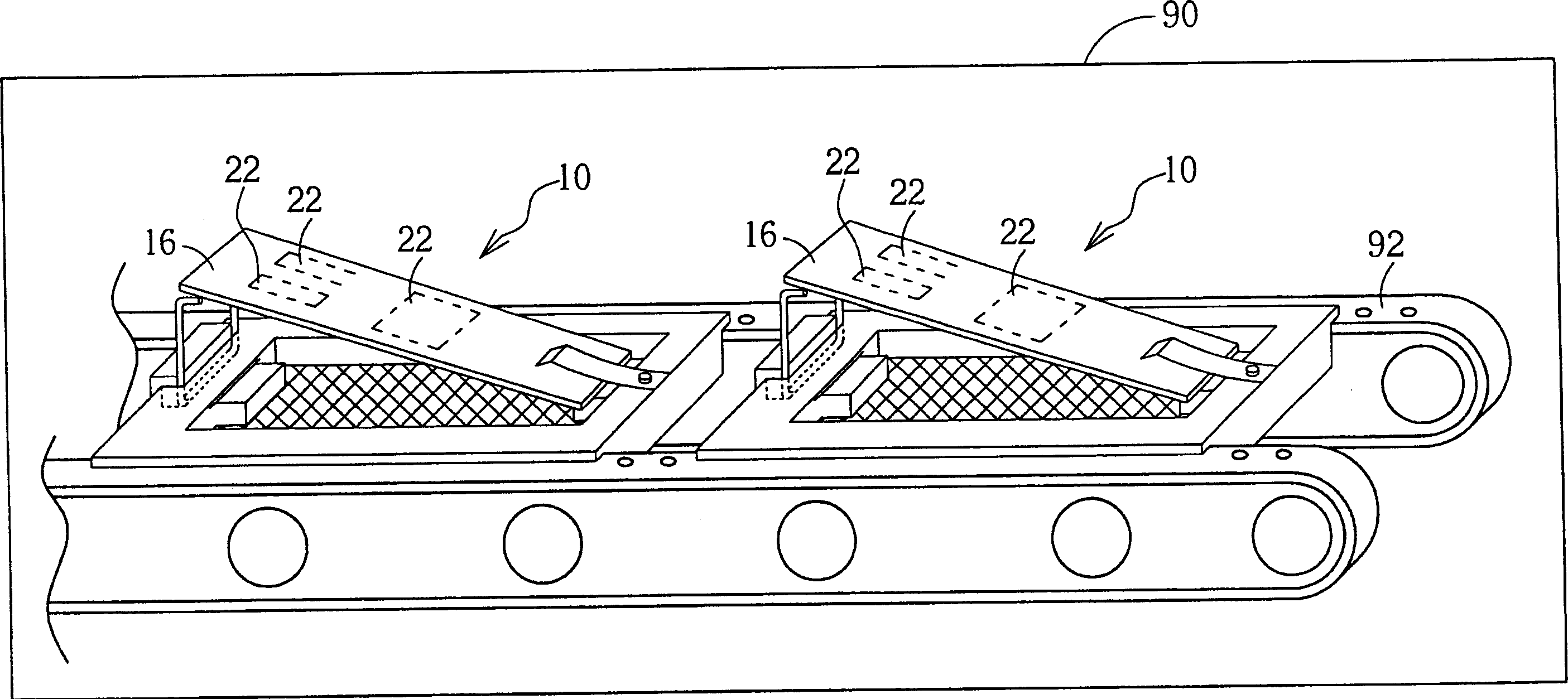

Method of manufacturing LED light bar and manufacturing equipment thereof

A manufacturing equipment for manufacturing an LED light bar includes a reflow oven and a clamping device. The LED light bar includes a printed circuit board and a plurality of LEDs arranged on the printed circuit board. The reflow oven includes a hearth box and a transmitting belt extended through the hearth box. The hearth box includes a heating area and a cooling area in an interior thereof. The clamping device is mounted on the transmitting belt. The clamping device defines a receiving space for receiving the LED light bar therein. The clamping device is changed between a clamping state for maintaining the LEDs in positions and a releasing state whereby the LED light bar can be removed from the clamping device.

Owner:HON HAI PRECISION IND CO LTD

Apparatus and method for bonding silicon wafer to conductive substrate

InactiveUS7432596B1Uniform gapFinal product manufactureSemiconductor/solid-state device detailsMelting temperatureSemiconductor

A system and method is disclosed for bonding a substrate to a semiconductor die that is prone to curling when subjected to an elevated temperature in a solder reflow oven, for example, thereby improving the electrical and mechanical bonding for large dies, wafers, chips, and photovoltaic cells. In one embodiment, the substrate is adapted to curl to the same degree as the die to form a uniform gap between the substrate and die across the boundary there between. In another embodiment, solder used to bond the die and substrate is applied such that the volume deposited varies based on the expected gap between the die and substrate when heated to the melting temperature of the solder.

Owner:CYRIUM SOLAR

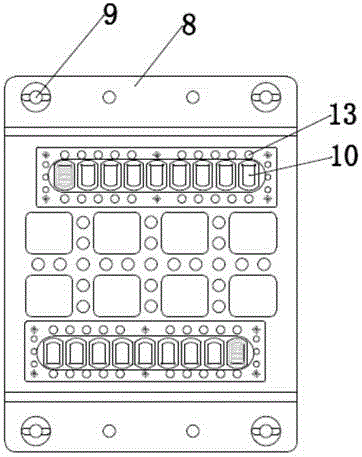

PCB and FPC welding method and surface mounting jig

ActiveCN105307420AImprove reliabilityIncrease productivityPrinted circuit assemblingPrinted circuit aspectsSurface mountingEngineering

The invention discloses a PCB and FPC welding method. The PCB and FPC welding method comprises the following steps that: PCB splicing boards are installed on a chip mounting fixture; solder paste printing or chip mounting is performed on pads of the PCB splicing boards; the chip mounting fixture with the PCB splicing boards is taken out and is flatly arranged on a board mounting base; FPCs requiring welding are arranged on the PCB splicing boards in a positioned manner through the chip mounting fixture, so that solder paste can be located between welding regions of PCBs and FPCs in each PCB splicing board; a pressing cover plate is assembled on the board mounting base, and the pressing cover plate is pressed and fixed to the chip mounting fixture and is fixed; and the assembled board mounting base, pressing cover plate and chip mounting fixture are arranged in an automatic reflow furnace, so that solder paste at attached positions of the PCBs and FPCs can be solidified through reflow soldering. The invention also provides a surface mounting jig used for the PCB and FPC welding method. The PCB and FPC welding method and the surface mounting jig of the invention have the advantages of high consistency in welding spots, high reliability, high production efficiency and no need for additional equipment investment.

Owner:广东德赛矽镨技术有限公司

Manufacture of solid-solder-deposit PCB utilizing electrically heated wire mesh

A process and apparatus for manufacturing Solid Solder Deposit-Printed Circuit Board (SSD-PCB) by melting dry solder powder previously deposited on a pocketed-PCB 20. The process and apparatus utilize as heat source an electrically heated conveyor wire mesh 76 instead of a reflow oven. This invention, unlike the prior art for producing SSD-PCB, can readily utilize dry solder powder in conjunction with flux layers 116 separately deposited on top of the conveyor wire mesh 76 thereby excluding the use of solder paste and associated paste printing equipment. Specifically the invention reduces the manufacturing cost because: shortens manufacturing time, reduces manufacturing energy consumption and requires less manufacturing equipment than prior art.

Owner:TRUCCO HORACIO ANDRES

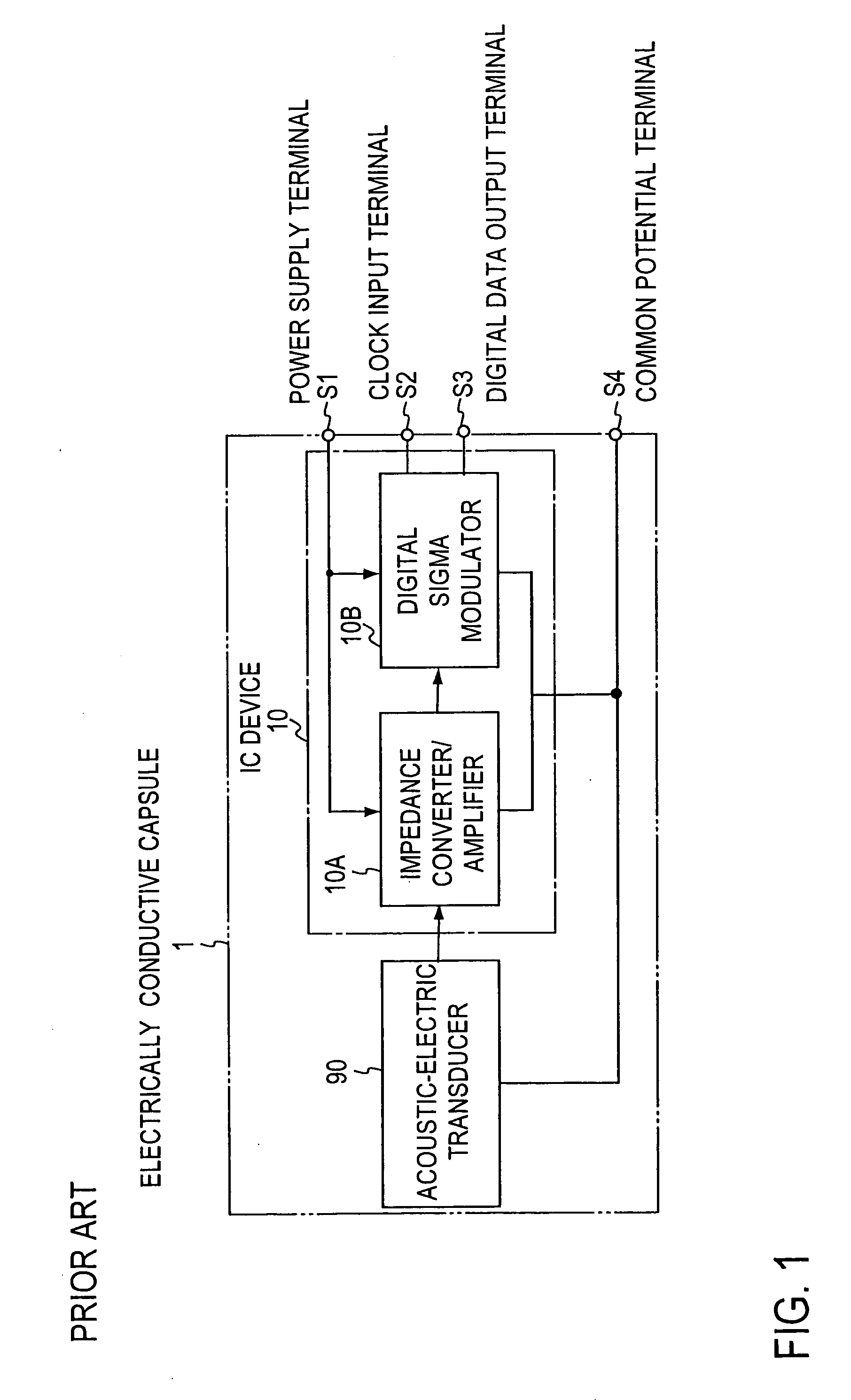

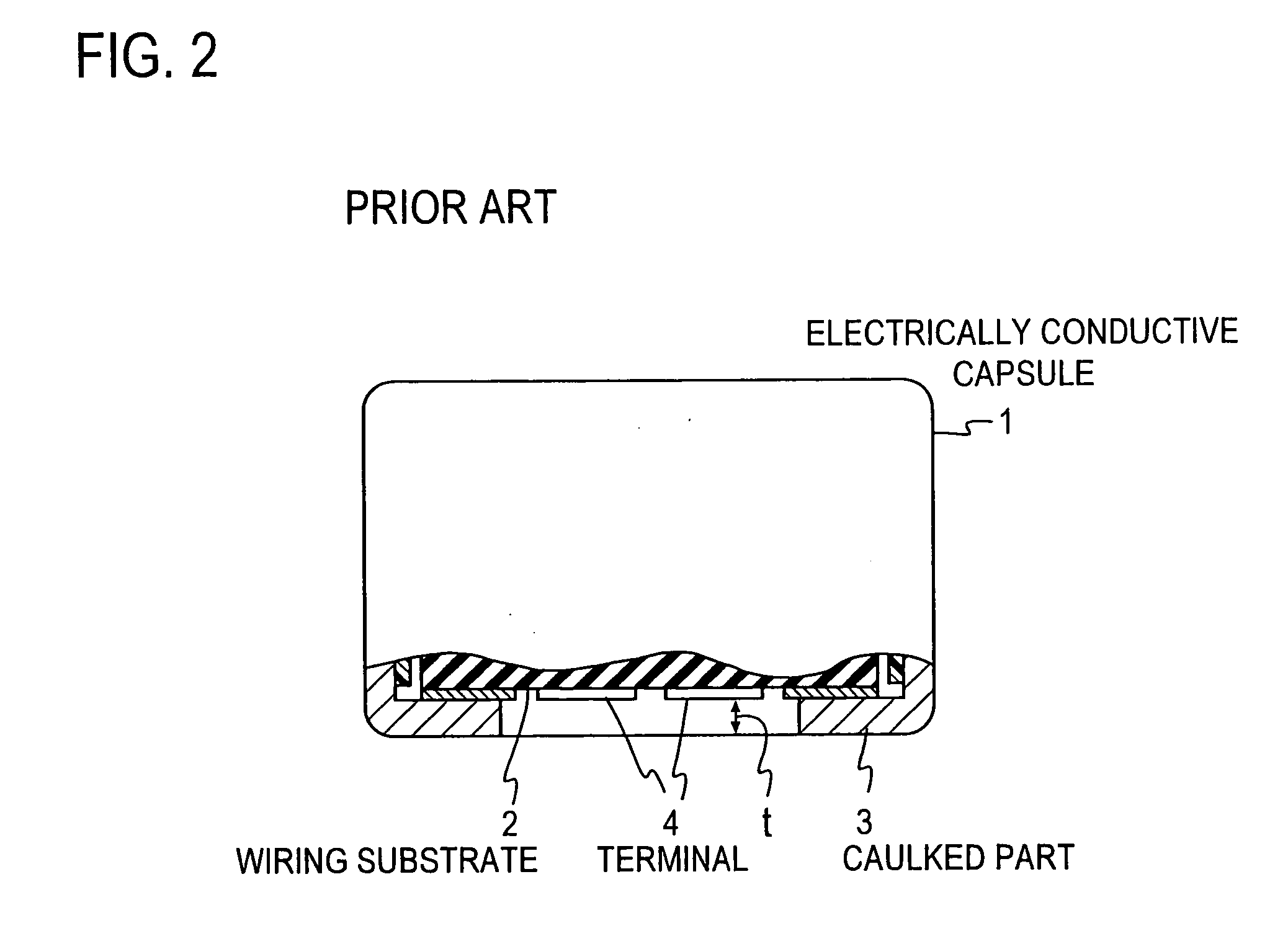

Electret condenser microphone

InactiveUS20070104339A1Improve heat resistancePiezoelectric/electrostrictive microphonesMicrophone structural associationCapacitanceEngineering

An object of the present invention is to provide a digital-output electret condenser microphone capable of being soldered on a wiring substrate of an apparatus by using a reflow furnace. An electret condenser microphone according to the present invention has an electret polymer film and a spacer that are formed of a heat-resistant material. Sound apertures are provided in a front panel of the electrically conductive capsule and / or the wiring substrate. Provided on the surface exposed in the open end of the electrically conductive capsule are multiple terminals, including at least a power supply terminal, a digital signal output terminal, and a clock input terminal. The terminals are protruded outward beyond a caulked part at the open end of the electrically conductive capsule.

Owner:HOSIDEN CORP

Reflow oven and methods of treating surfaces of the relfow oven

A reflow oven used to join electronic components to a substrate includes a chamber housing having surfaces that are in contact with heated air mixed with contaminants, including flux, and an intermediate layer selectively applied to the surfaces of the chamber housing. The reflow oven may include fabricating the intermediate layer with a foam material, including foaming polymers, e.g., epoxy, polyurethane, polyester, and silicone, or a non-foam material, including non-foaming polymers, e.g., polytetrafluoroethylene and polyimide. A method of treating surfaces of a reflow oven exposed to contaminants, including flux, is further disclosed.

Owner:ILLINOIS TOOL WORKS INC

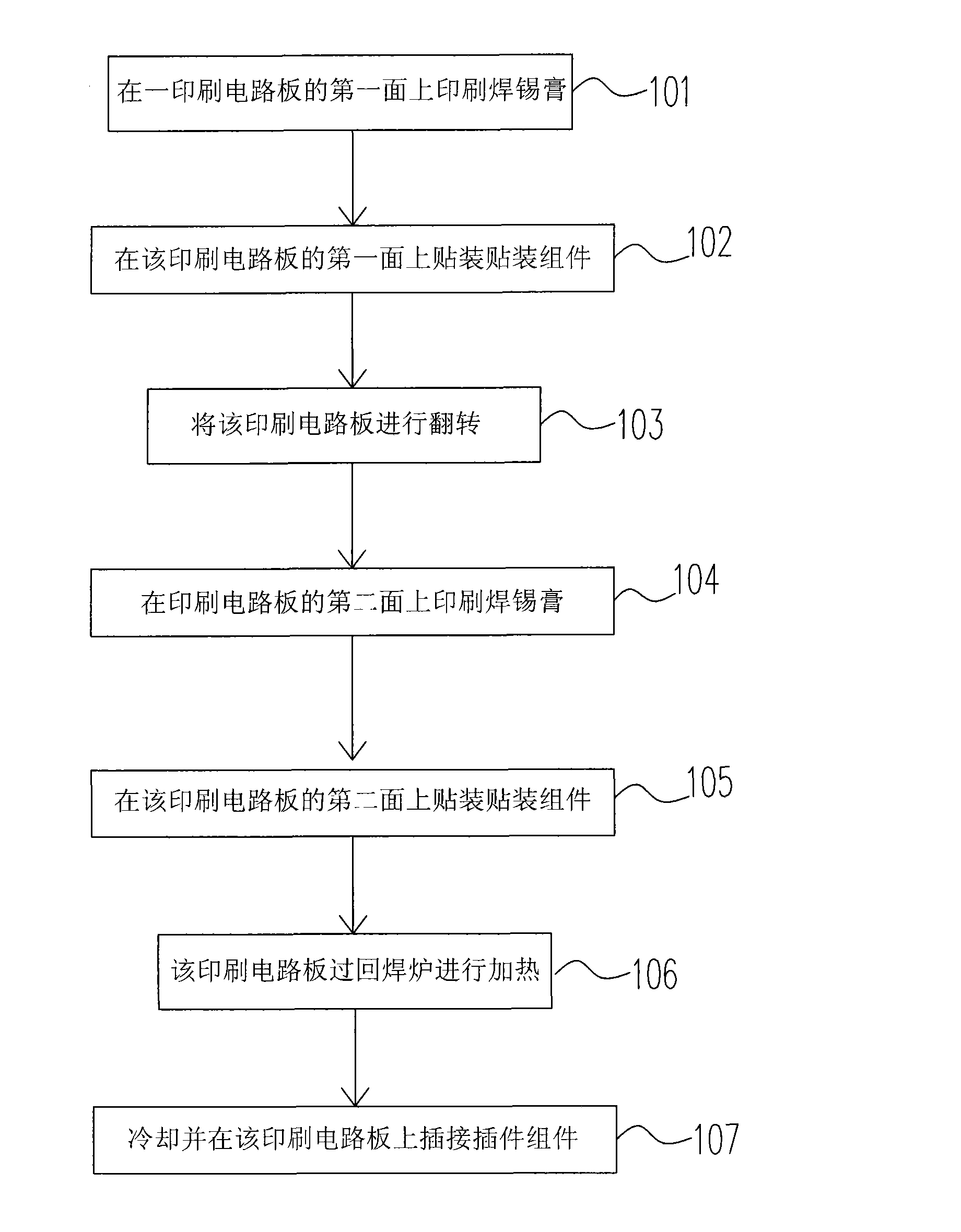

Bifacial circuit board surface assembly process

InactiveCN101528006AReduce thermal shockReduce oxidationPrinted circuit assemblingSolder pasteReflow oven

The invention provides a bifacial circuit board surface assembly process, wherein the process mainly comprises the following steps: firstly, assembling assembly parts on the first surface of a printed circuit board printed with solder paste; secondly, overturning the printed circuit board by a tilter, assembling the assembly parts on the second surface of the printed circuit board printed with the solder paste; thirdly, passing the assembled printed circuit board through a reflow oven, and welding the assembled parts on the printed circuit board; and finally, inserting plug-in assembly parts in the printed circuit board. In the bifacial circuit board surface assembly process of the invention, the printed circuit board only passes through the reflow oven once, the printed circuit board has the advantages of less heat shock, less oxygenation, no circular flow and less printed circuit board damage.

Owner:MITAC COMP (SHUN DE) LTD

Solder-reflow soldering method

InactiveCN101396751AReduces the chance of forming solder voidsEliminate Bubble ProblemsSoldering apparatusReflow ovenTin can

The invention is applicable to the field of reflow soldering, which provides a reflow soldering method comprising the following steps: a workpiece to be soldered is arranged into a reflow brazier, and processes are carried out in a preheating region, a reacting region, a reflow region and a cooling region of the reflow brazier in sequence. The ultrasonic wave is applied on the workpiece to be soldered in the reflow region to cause the workpiece to vibrate while being processed. As soldering tin in the reflow region is easy to generate bubbles and form voidages and the ultrasonic wave is applied in the reflow region to cause the workpiece to vibrate, a majority of bubbles generated by the soldering tin are eliminated, thereby effectively reducing the probability of forming soldering voidages at the soldering part, and the surface of the soldering tin can be cleaned so as to ensure that the soldering voidage ratio can be effectively controlled and the soldering performance can be improved.

Owner:BYD CO LTD

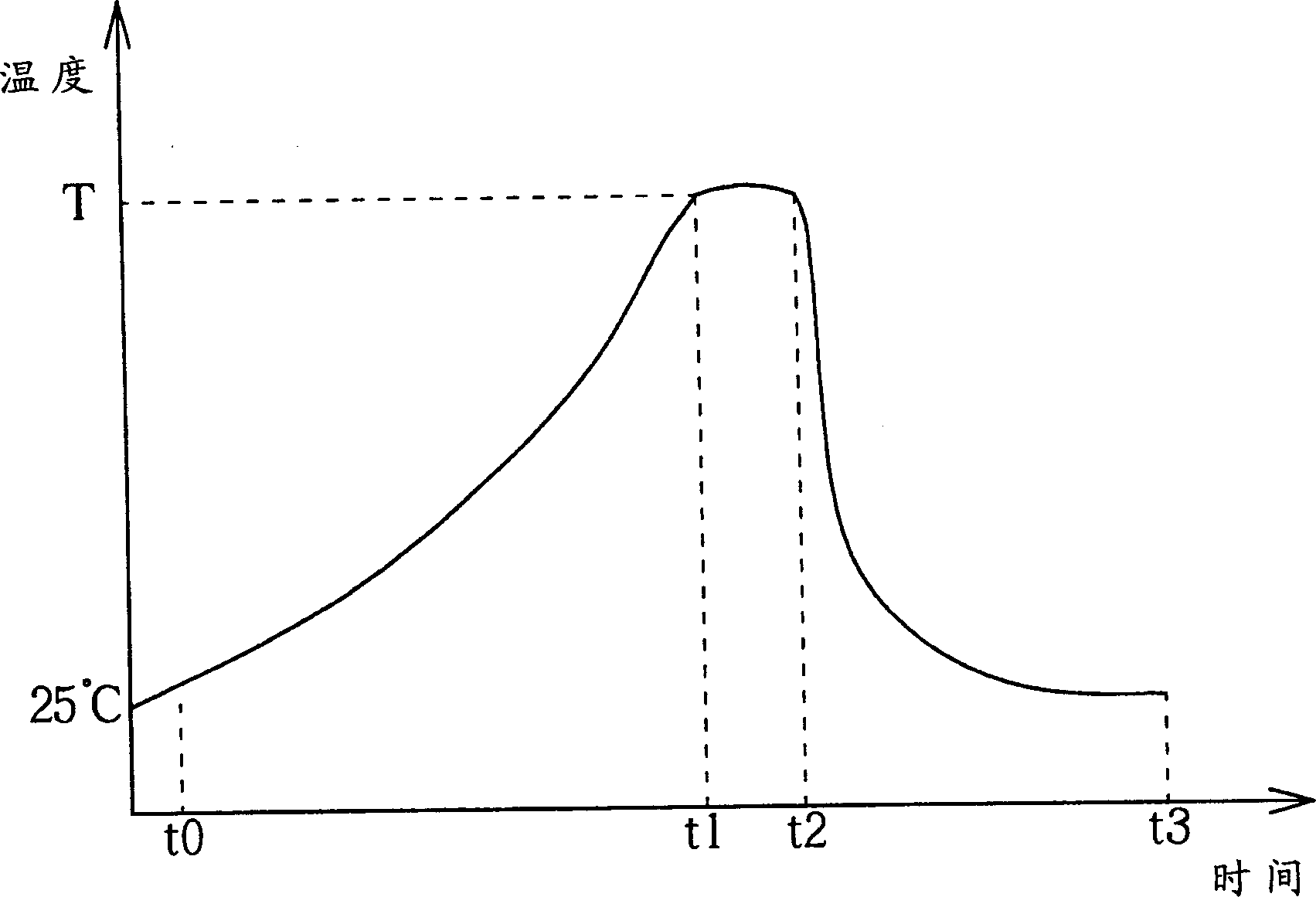

Method for creating reflow soldering ideal furnace temperature curve and application method thereof

InactiveCN108594902AImprove reflow soldering qualityIncrease productivityAuxillary controllers with auxillary heating devicesMetal working apparatusFurnace temperatureLower limit

The invention discloses a method for creating a reflow soldering ideal furnace temperature curve, comprising steps of: determining solder paste parameters; determining the size of PCBA boards, including a large board, a middle board and a small board; drawing a solder paste characteristic curve; adjusting a reflow furnace according to the solder paste characteristic curve to make the PCBA production furnace temperature meet the solder paste characteristic curve; according to the matched furnace temperature curve and a tolerance value, creating an upper limit curve and a lower limit curve of each point of the furnace temperature, and the middle belt being an ideal curve. The method for creating the reflow soldering ideal furnace temperature curve combines various parameters of the solder paste and determines the curve of each segment according to the sizes of the soldered PCBA boards, so that the furnace temperature curve of the reflow furnace does not depend on the subjective experience value of the process engineer, thereby objectively presenting the reflow soldering furnace temperature requirements, giving the reflow soldering furnace temperature standard, improving the reflow soldering quality, and finding the proper reflow furnace temperature and improving the production efficiency simply and quickly.

Owner:CHENGDU XUNSHENG ELECTRONICS TECH CO LTD

Welding method for welding columns of encapsulated integrated circuit (IC)

ActiveCN102151927ASolve the problem of micro-encapsulated air bubblesQuality improvementSoldering apparatusSemiconductor/solid-state device manufacturingMicro bubbleX-ray

The invention relates to a welding method for welding columns of an encapsulated integrated circuit (IC). The welding method is characterized by comprising the following steps: tidily arranging the welding columns in a die; forming a convex welding flux on a pad of a column base plate to be embedded; placing the welding columns and the die in the pad which corresponds to a CLGA560 circuit of the column base plate to be embedded and is provided with the convex welding flux, and transferring the pad into a reflow oven so as to complete welding; and after completion of the welding operation, washing and drying. The welding method has the advantages that by virtue of factors of the convex welding flux such as point contact, solder fusing, surface tension and the like, micro-bubbles are avoided in fusion of the welding flux and an end surface so as to obtain a high-quality welding column encapsulated device without micro-bubbles on a welded surface, which solves the problem of the encapsulated micro-bubbles on the welded surface of the welding columns, saves the step of performing X-ray or ultrasonic inspection on the device so as to ensure the welding quality in the conventional welding process, and improves welding quality and welding yield.

Owner:WUXI ZHONGWEI GAOKE ELECTRONICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com