Electronic component carrier and method for shattering and loading electronic components on circuit board

A technology for electronic components and circuit boards, which is applied in the field of electronic component carriers, and can solve problems such as slow disassembly speed, damage to integrated circuits, and electronic components that cannot be disassembled from circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

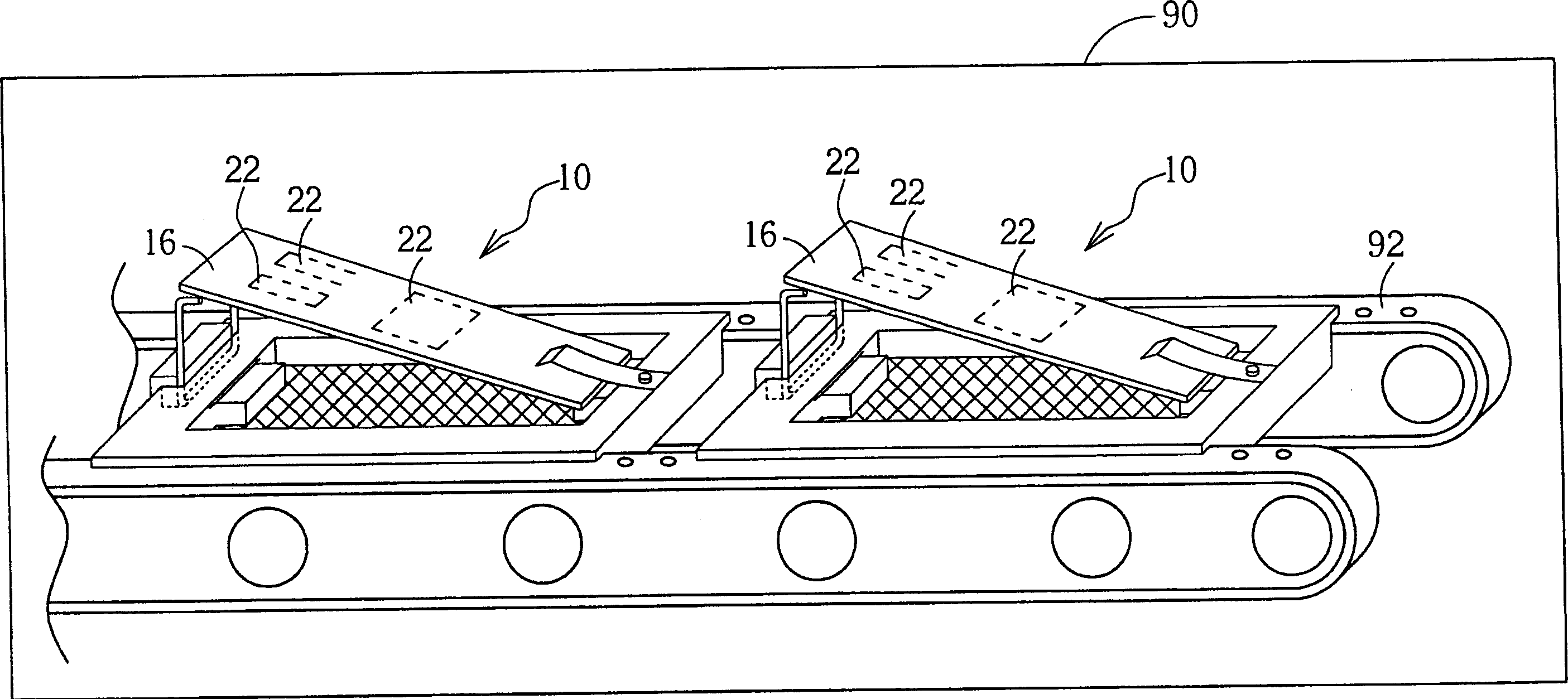

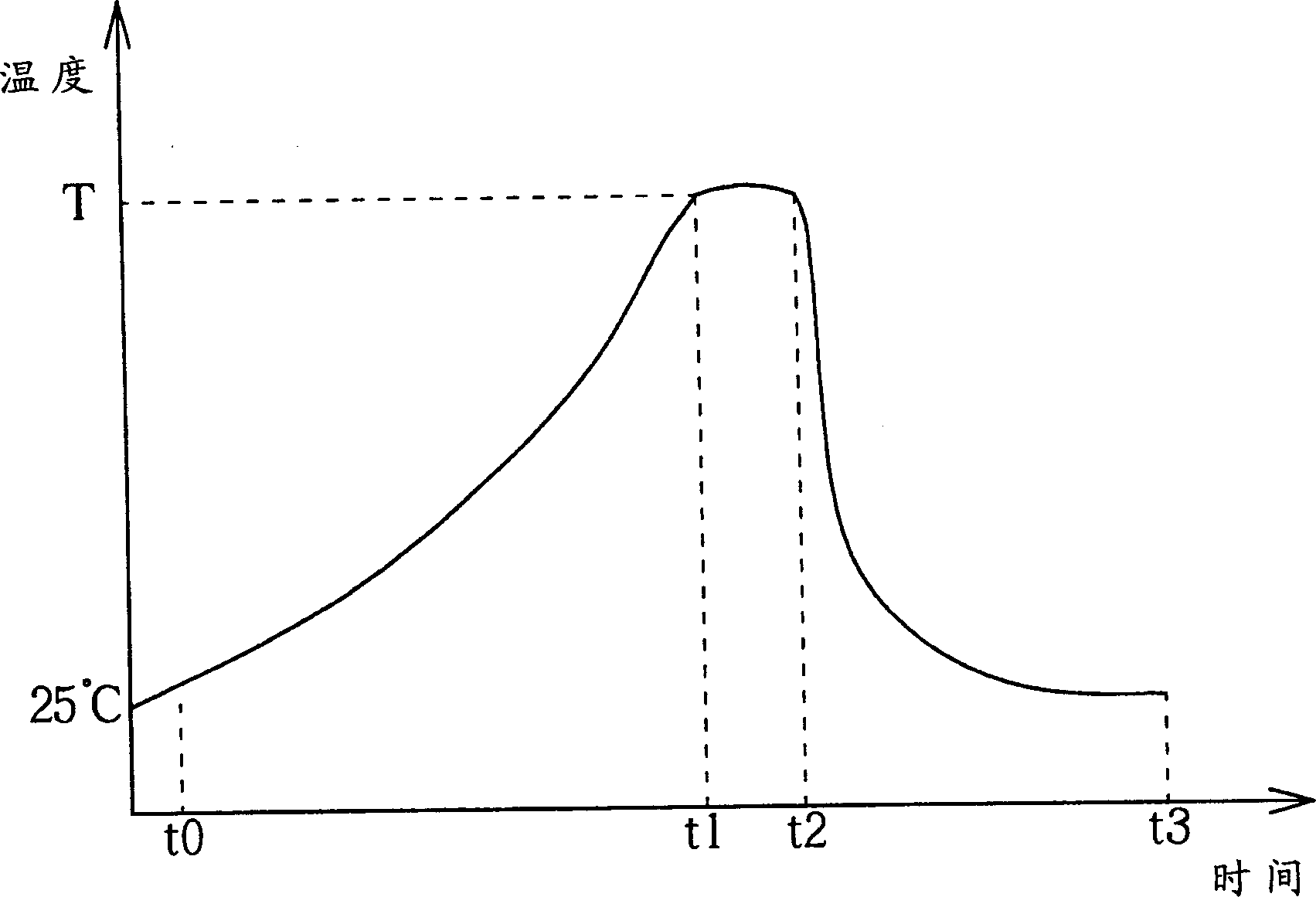

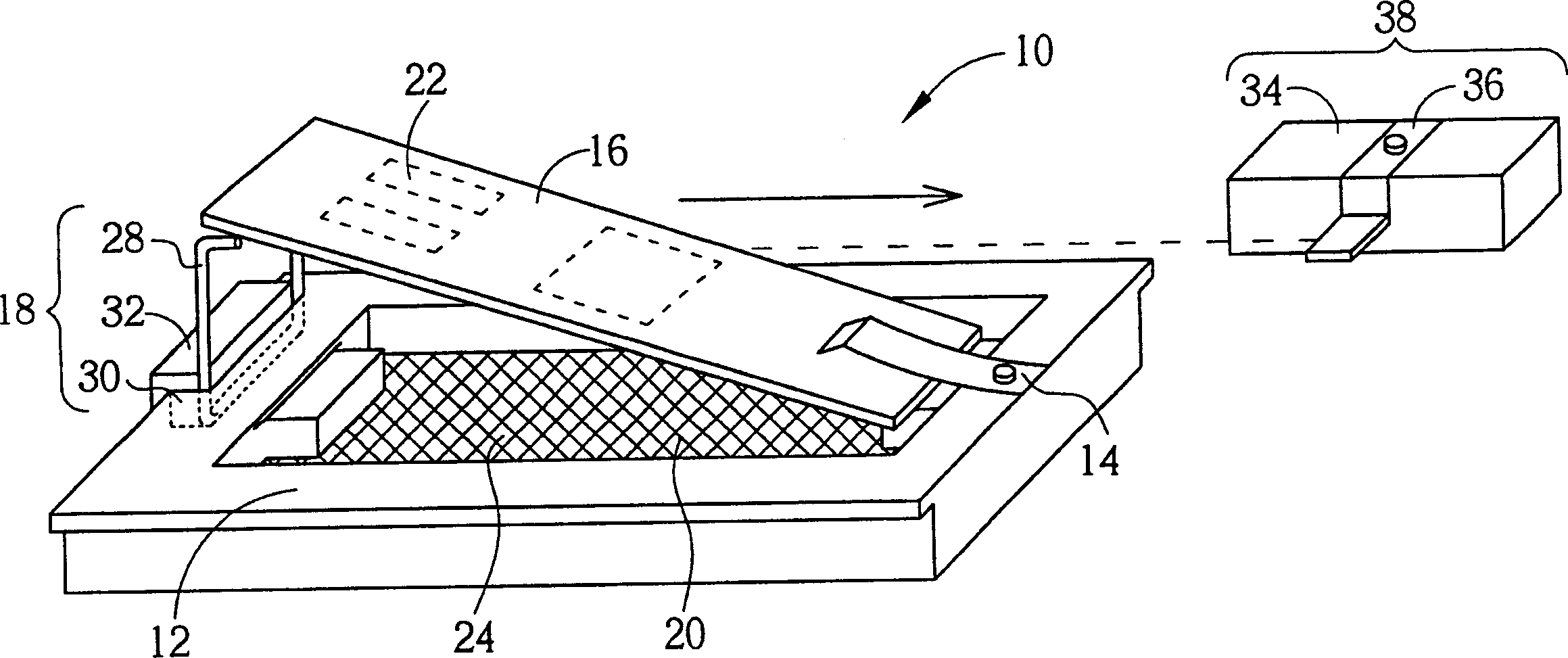

[0035] The electronic component carrier of the present invention is used in a reflow oven, please refer to figure 1 , figure 1 It is a schematic diagram of the electronic component carrier 10 in a reflow oven 90 according to the preferred embodiment of the present invention. A circuit board 16 is placed in the electronic component carrier 10, and a plurality of circuit boards ( Surfacemounting technology, SMT) is attached to the electronic components (shown in dotted lines) 22 on the circuit board 16 . The reflow oven 90 includes a trigger 38 (shown at image 3 ) and a conveying device 92 for conveying the electronic component carrier 10 . Please refer to figure 2 , figure 2 It is a temperature / time relationship diagram in the reflow oven 90, wherein the horizontal axis represents time and the vertical axis represents temperature. The reflow oven 90 is activated at time t0, and then the temperature in the reflow oven 90 will gradually increase. At time t1, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com