Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

407results about How to "Eliminate difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

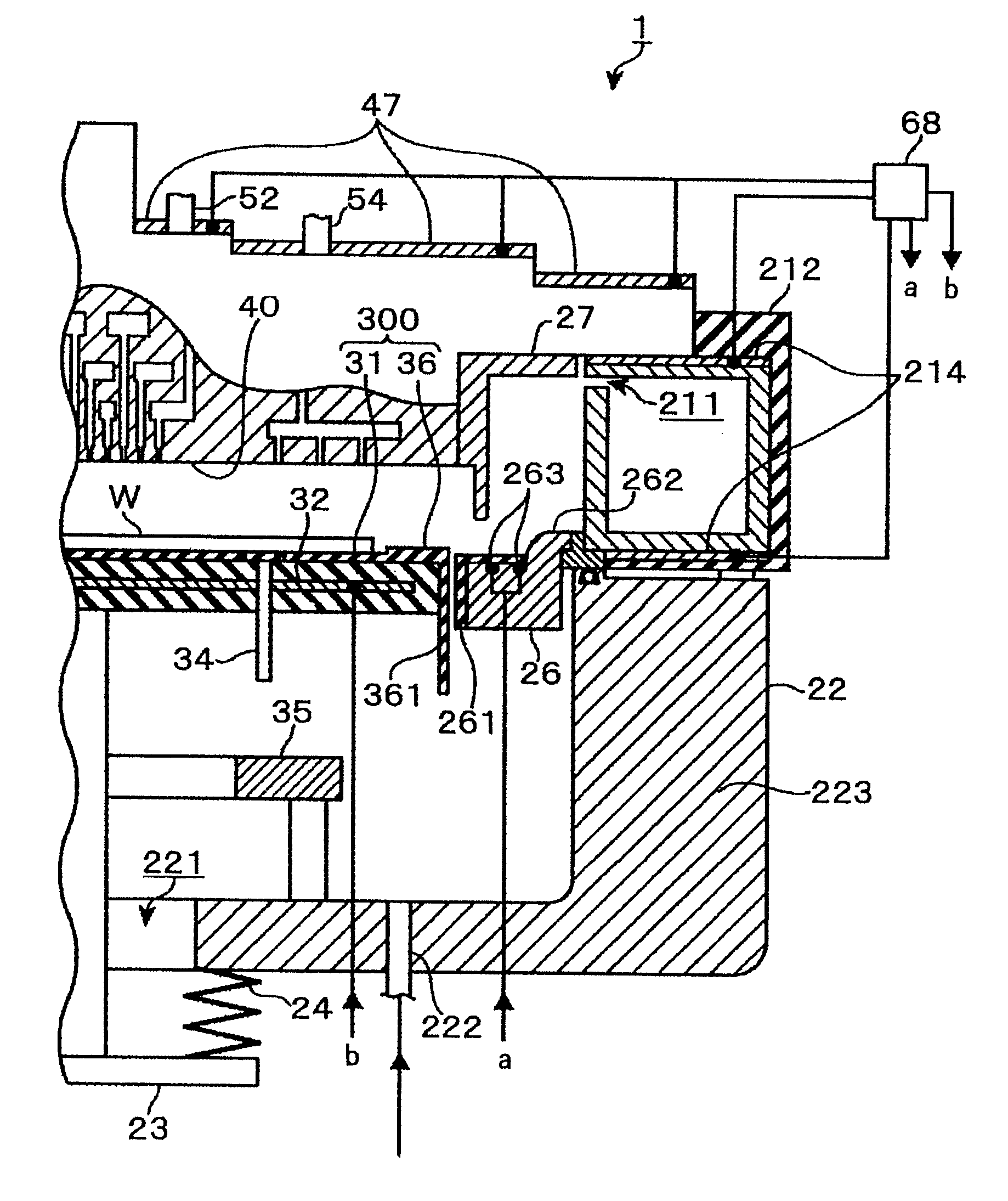

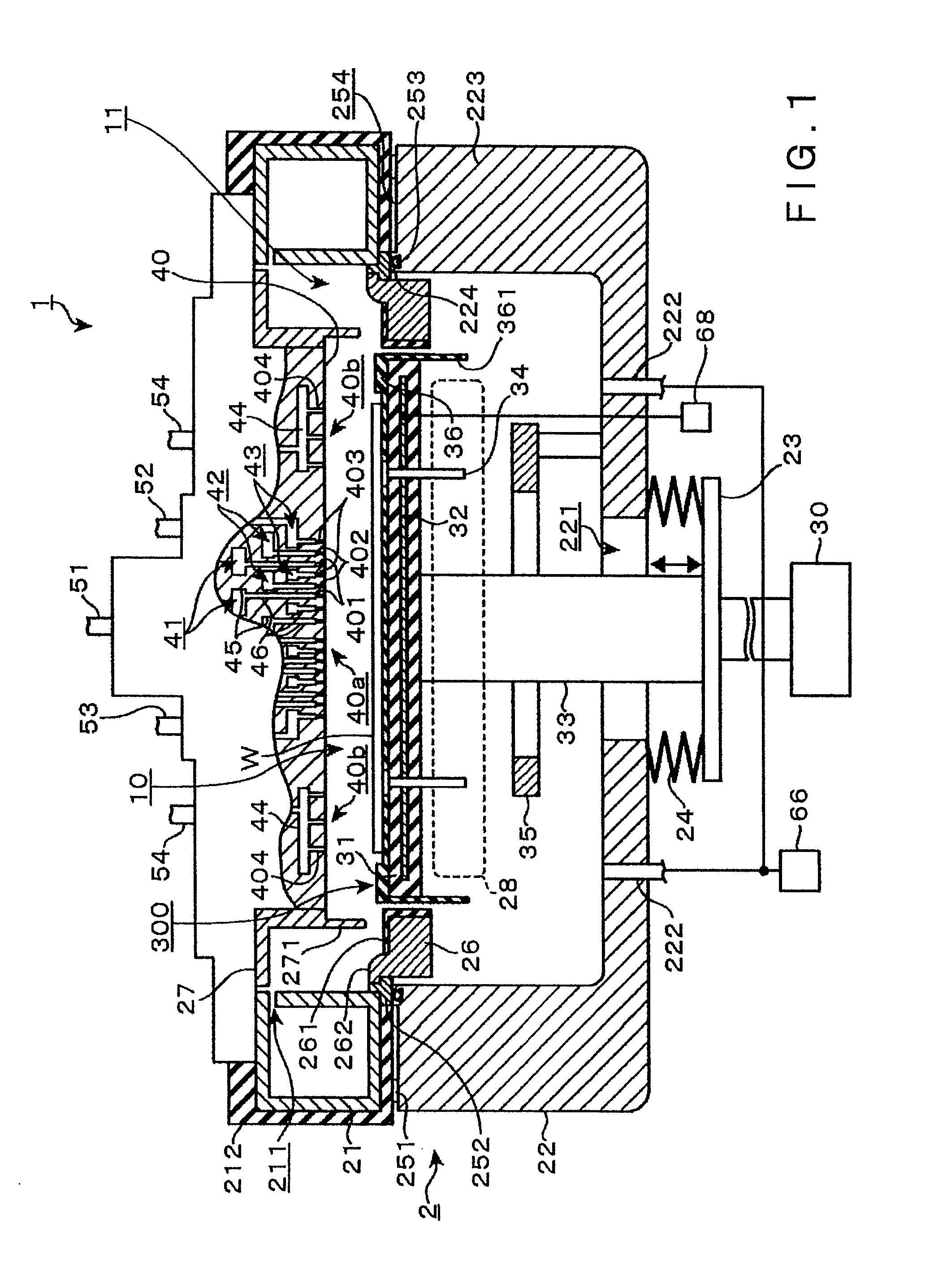

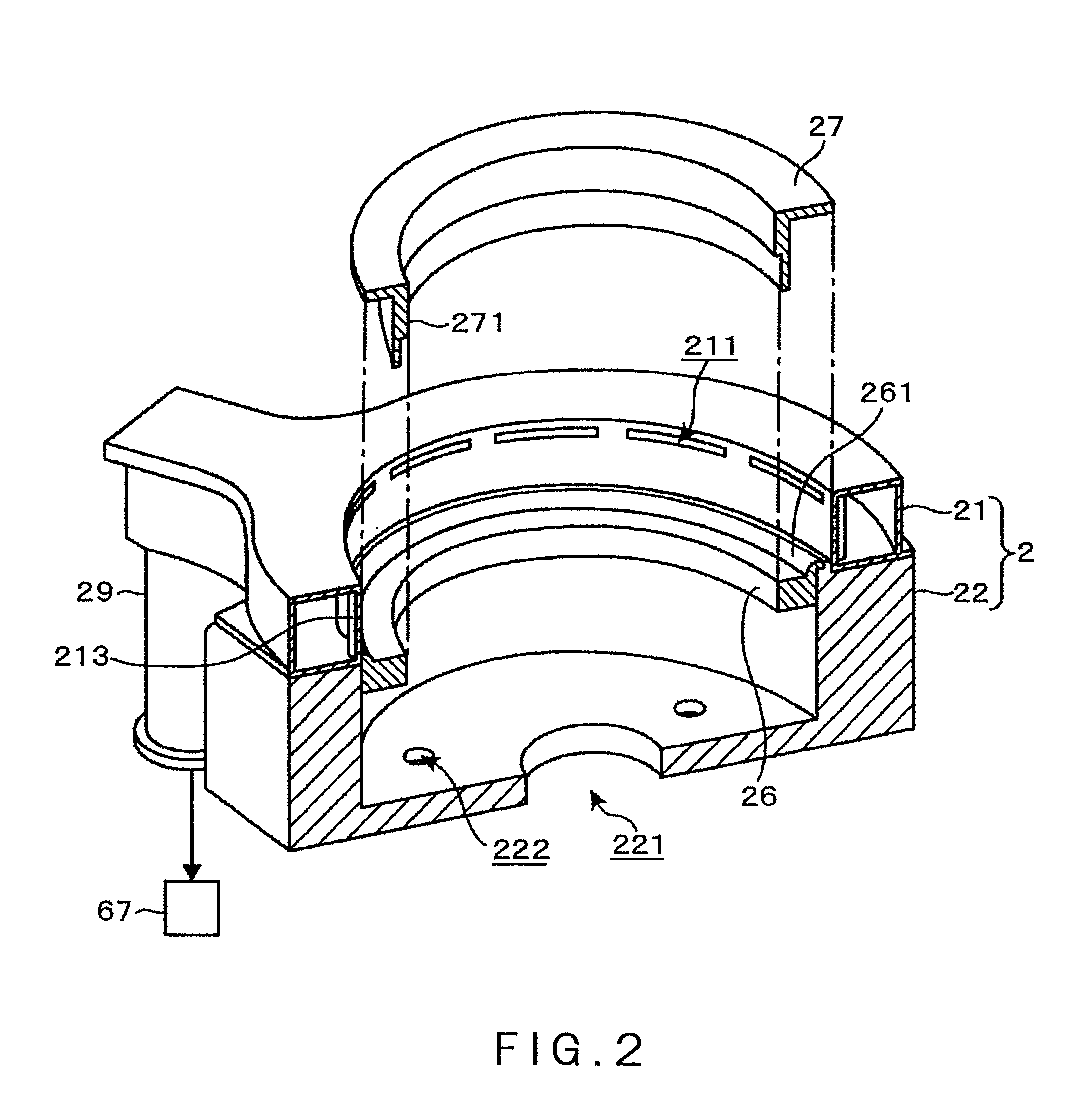

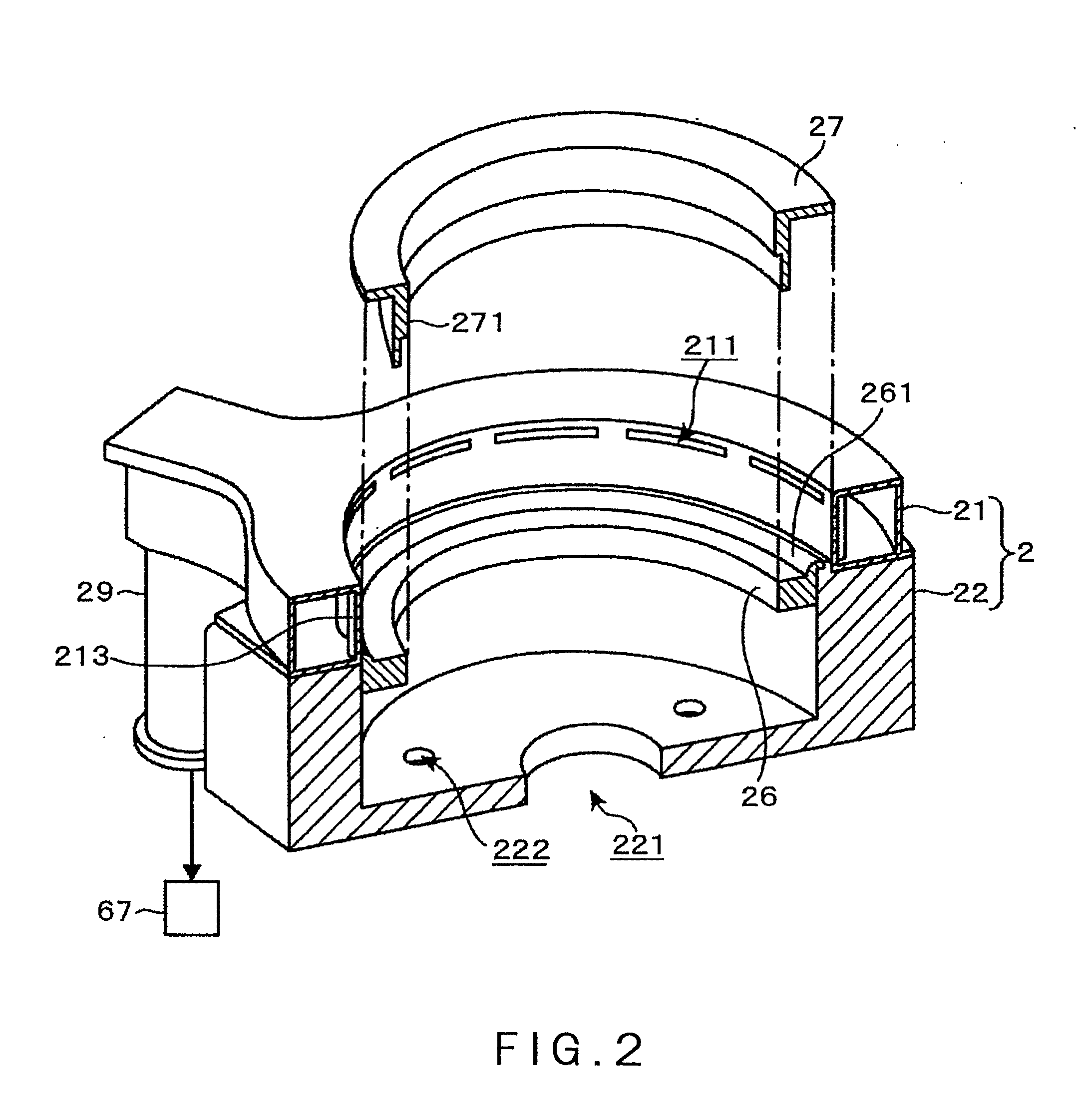

Film deposition apparatus and film deposition method

ActiveUS8506713B2Efficient solutionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

Owner:TOKYO ELECTRON LTD

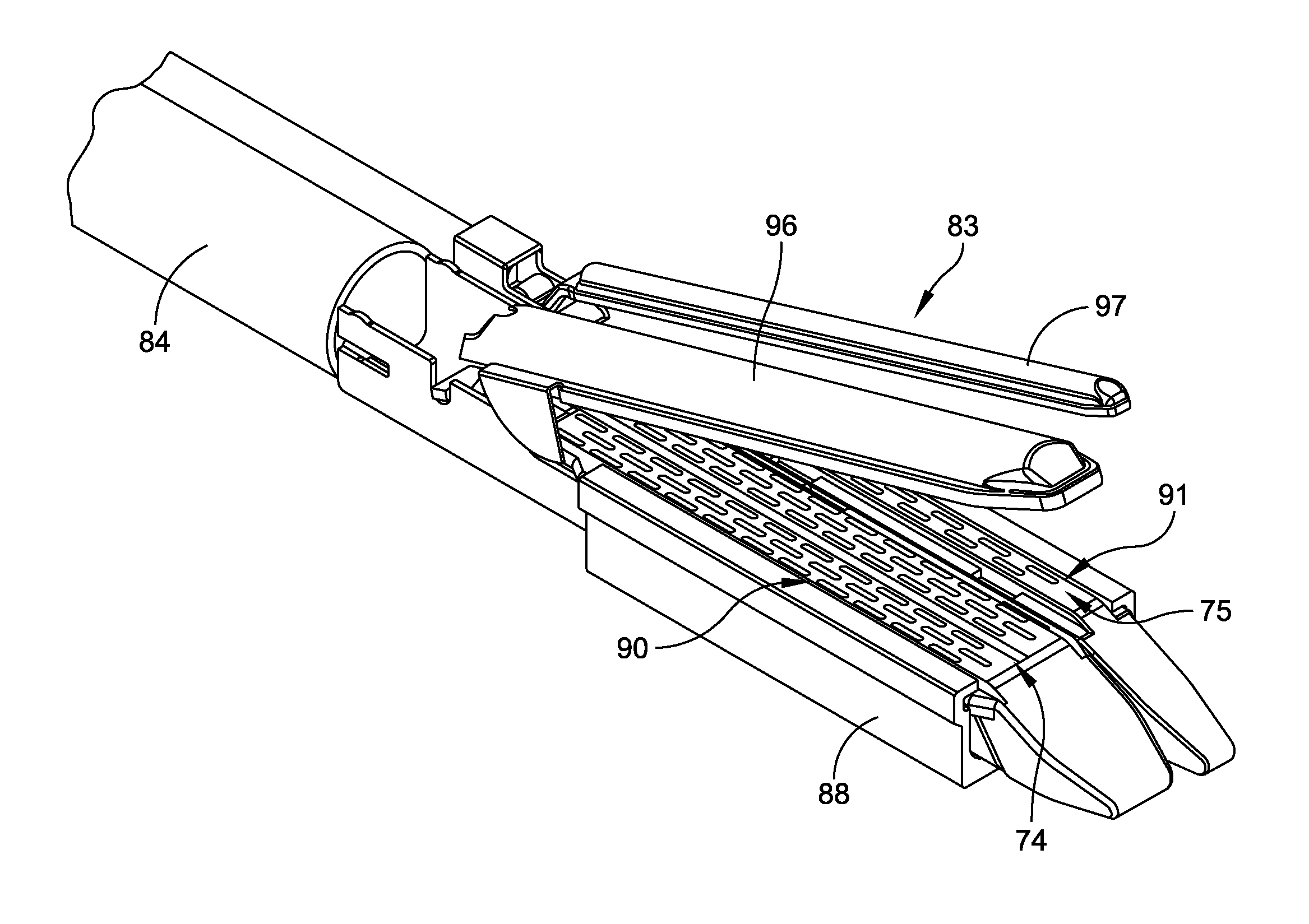

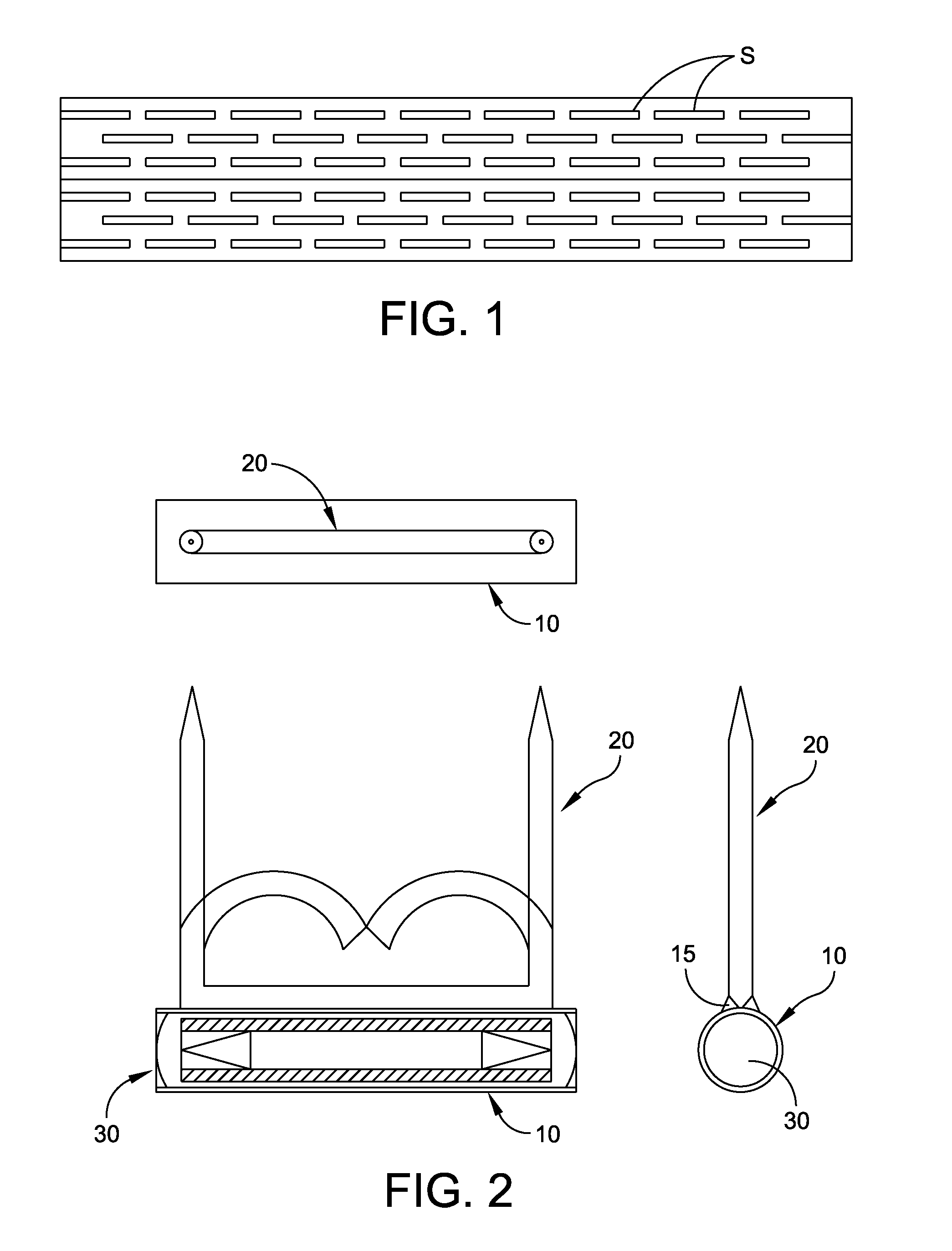

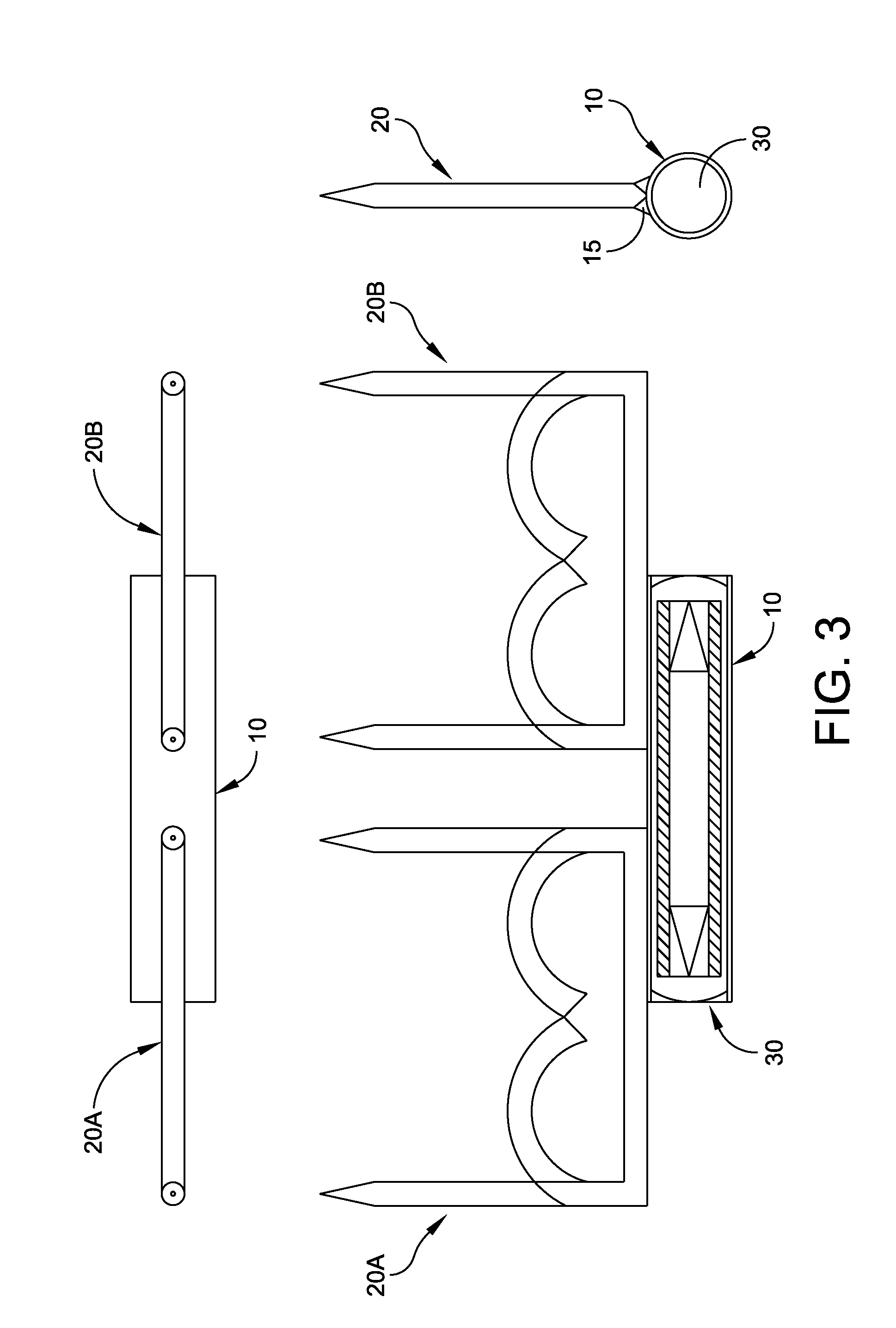

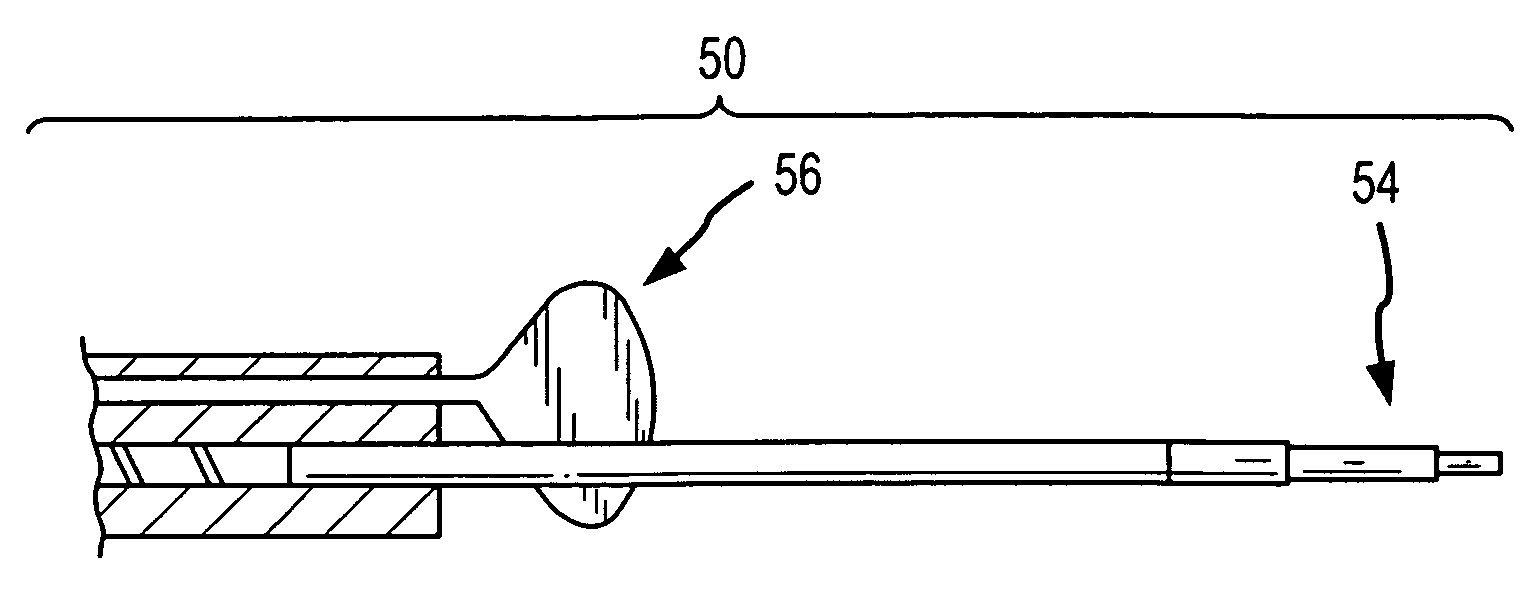

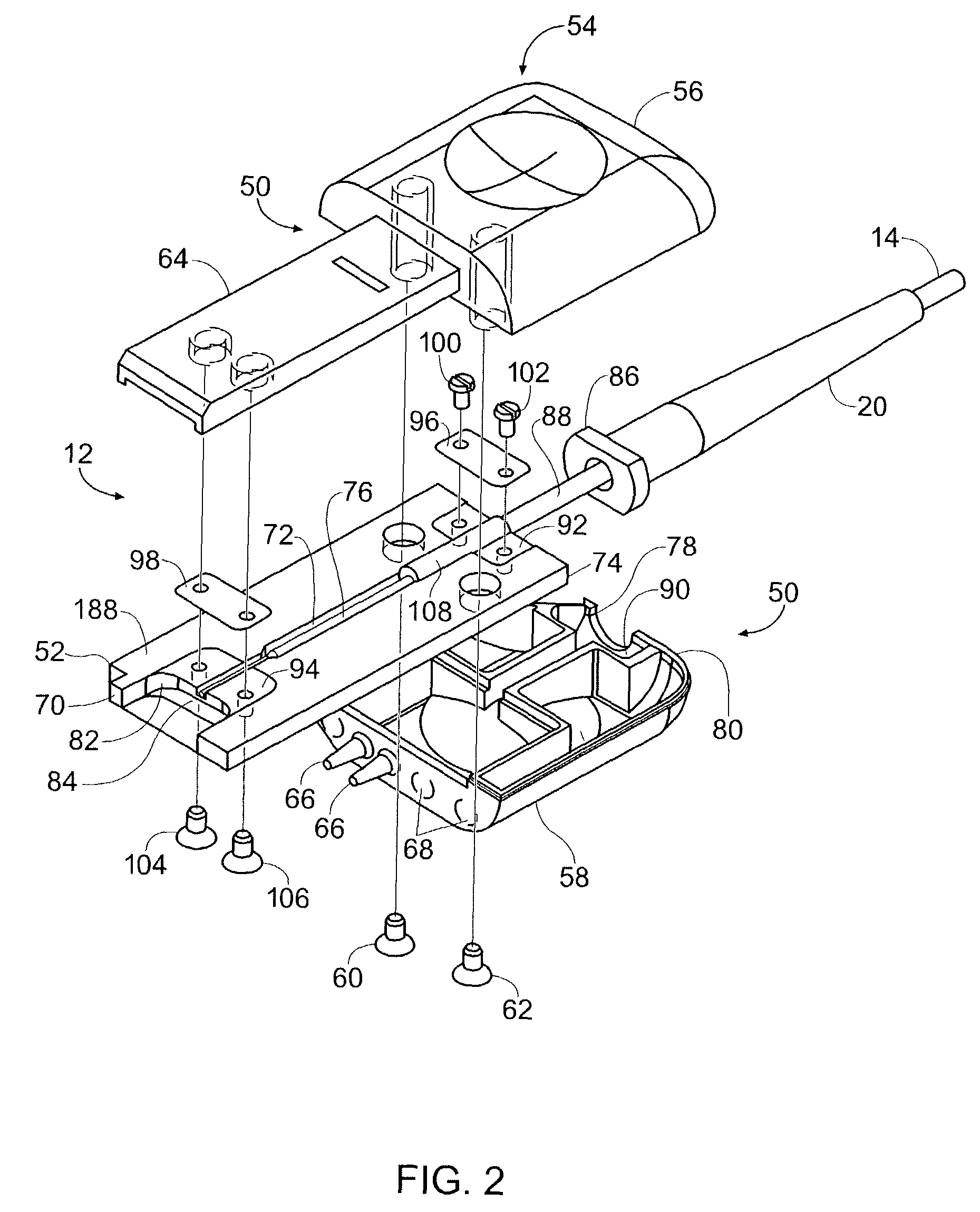

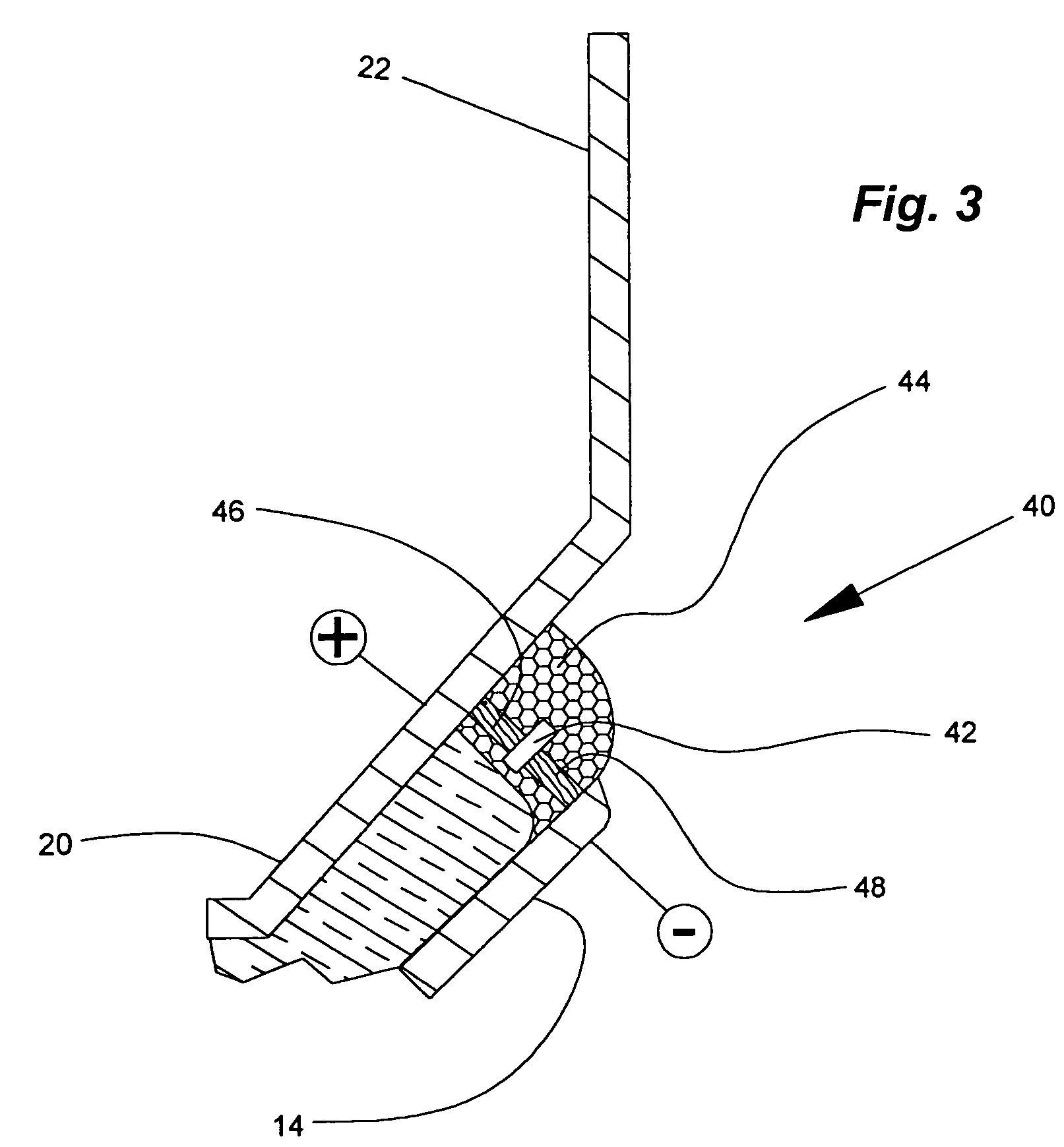

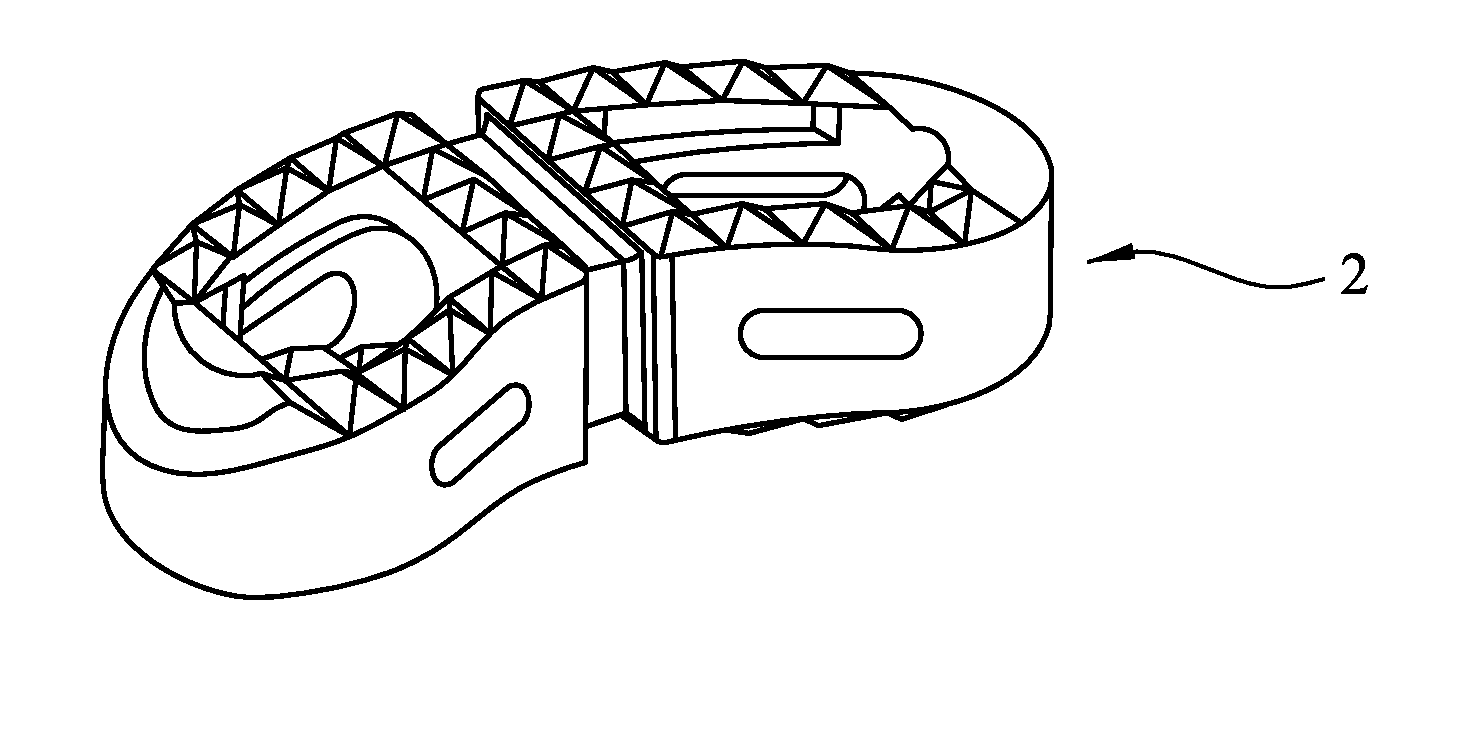

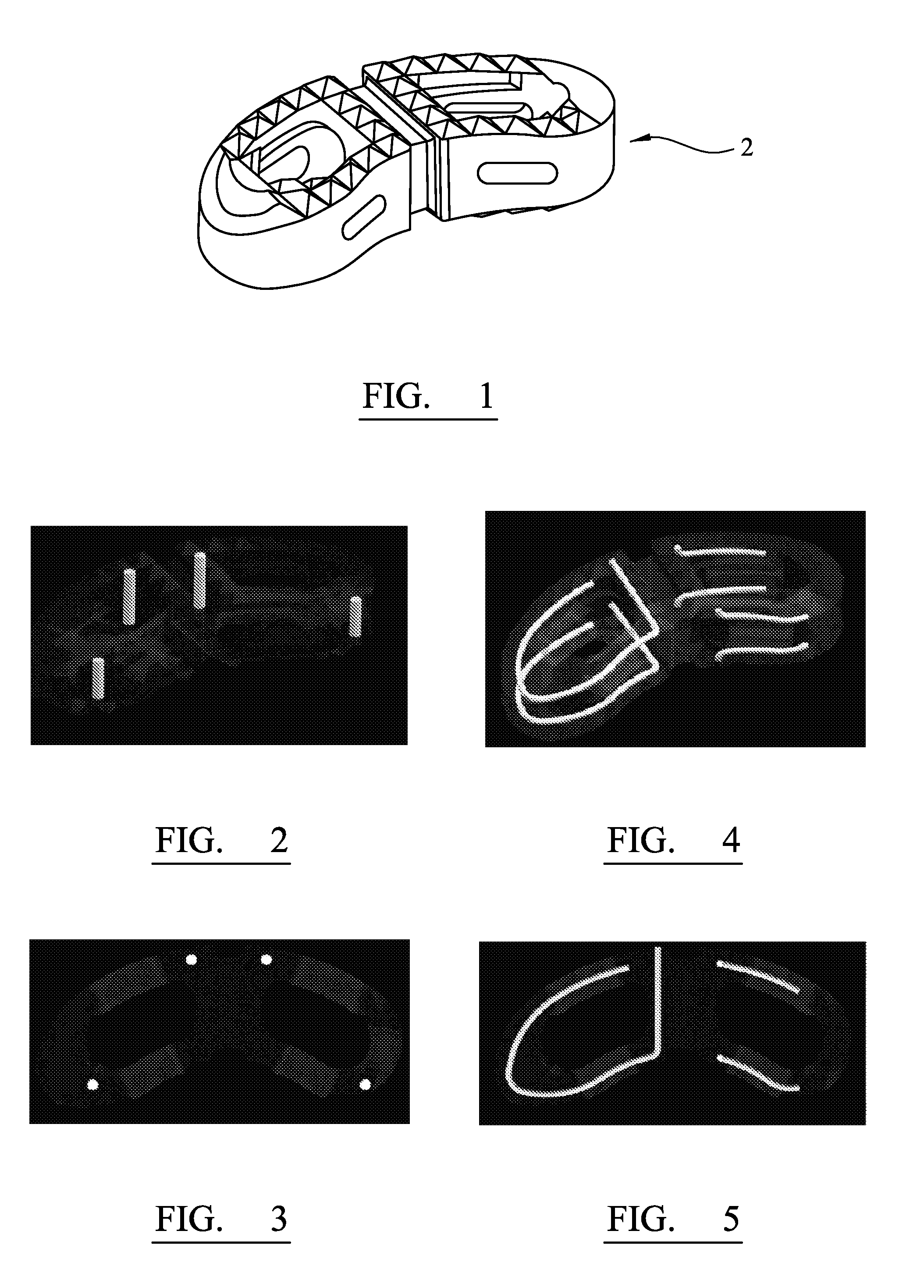

Radioactive therapeutic fastening instrument

ActiveUS8267849B2For accurate placementReduce doseSuture equipmentsStapling toolsBrachytherapyEngineering

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

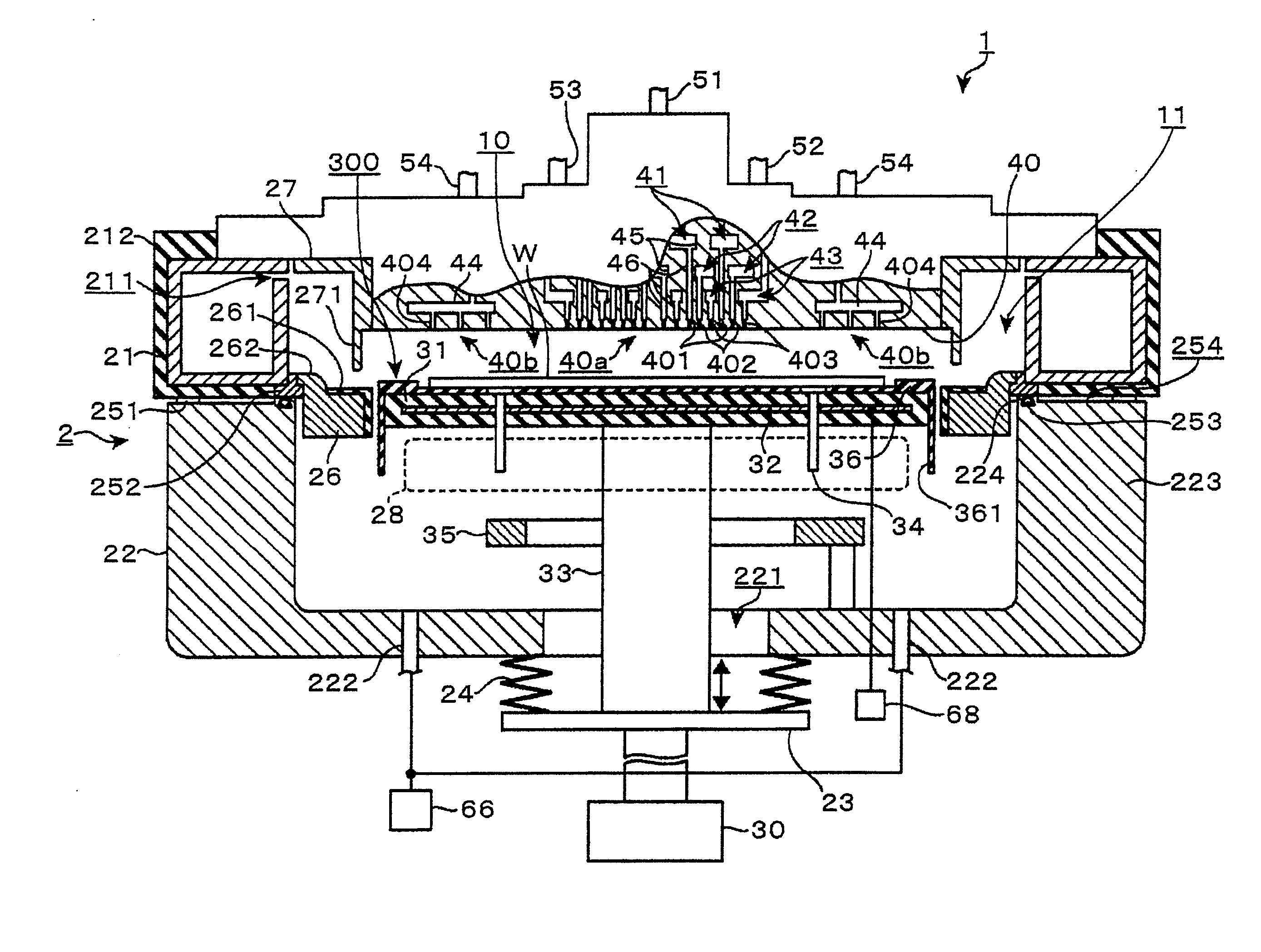

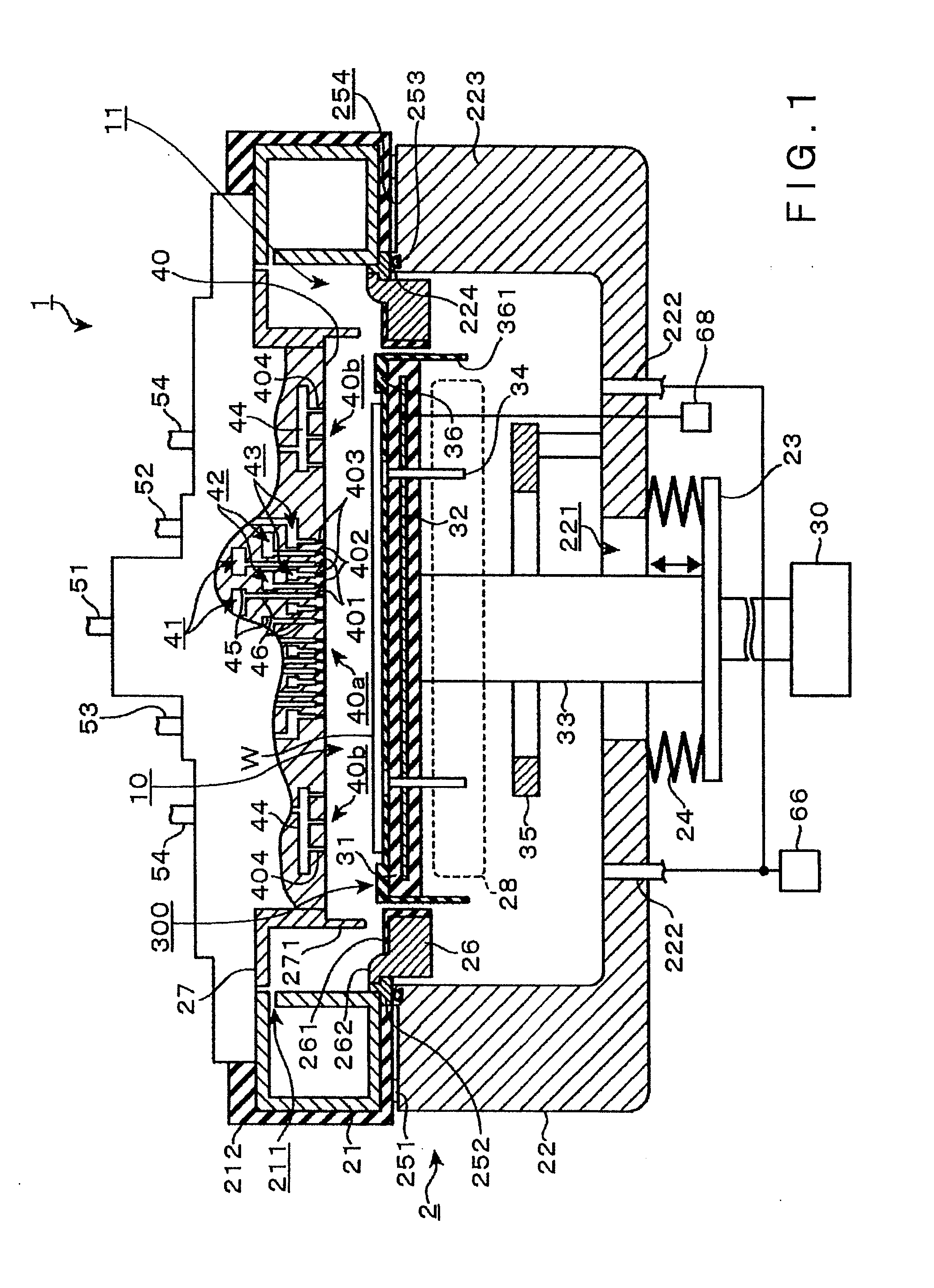

Film deposition apparatus and film deposition method

ActiveUS20100279008A1Efficient solutionHigh in-plane uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTransfer mechanism

The present invention is a film deposition apparatus configured to deposit a film on a substrate that has been loaded into a vacuum container via a transfer opening and placed on a table in the vacuum container, by supplying a process gas to the substrate from a process-gas supply part opposed to the table under a vacuum atmosphere, while heating a table surface of the table, the film deposition apparatus comprising: an elevating mechanism configured to vertically move the table between a process position at which the substrate is subjected to a film deposition process, and a transfer position at which the substrate is transferred to and from an external transfer mechanism that has entered from the transfer opening; a surrounding part configured to surround the table with a gap therebetween, when the table is located at the process position, so that the surrounding part and the table divide an inside of the vacuum container into an upper space, which is located above the table, and a lower space, which is located below the table; a vacuum exhaust conduit in communication with the upper space, through which a process atmosphere in the upper space is discharged to create a vacuum in the upper space; a heating unit configured to heat a gas contact region ranging from the upper space to the vacuum exhaust conduit, to a temperature higher than a temperature allowing adhesion of reactant; and a heat insulation part disposed between the heating unit and a lower part of the vacuum container surrounding the lower space.

Owner:TOKYO ELECTRON LTD

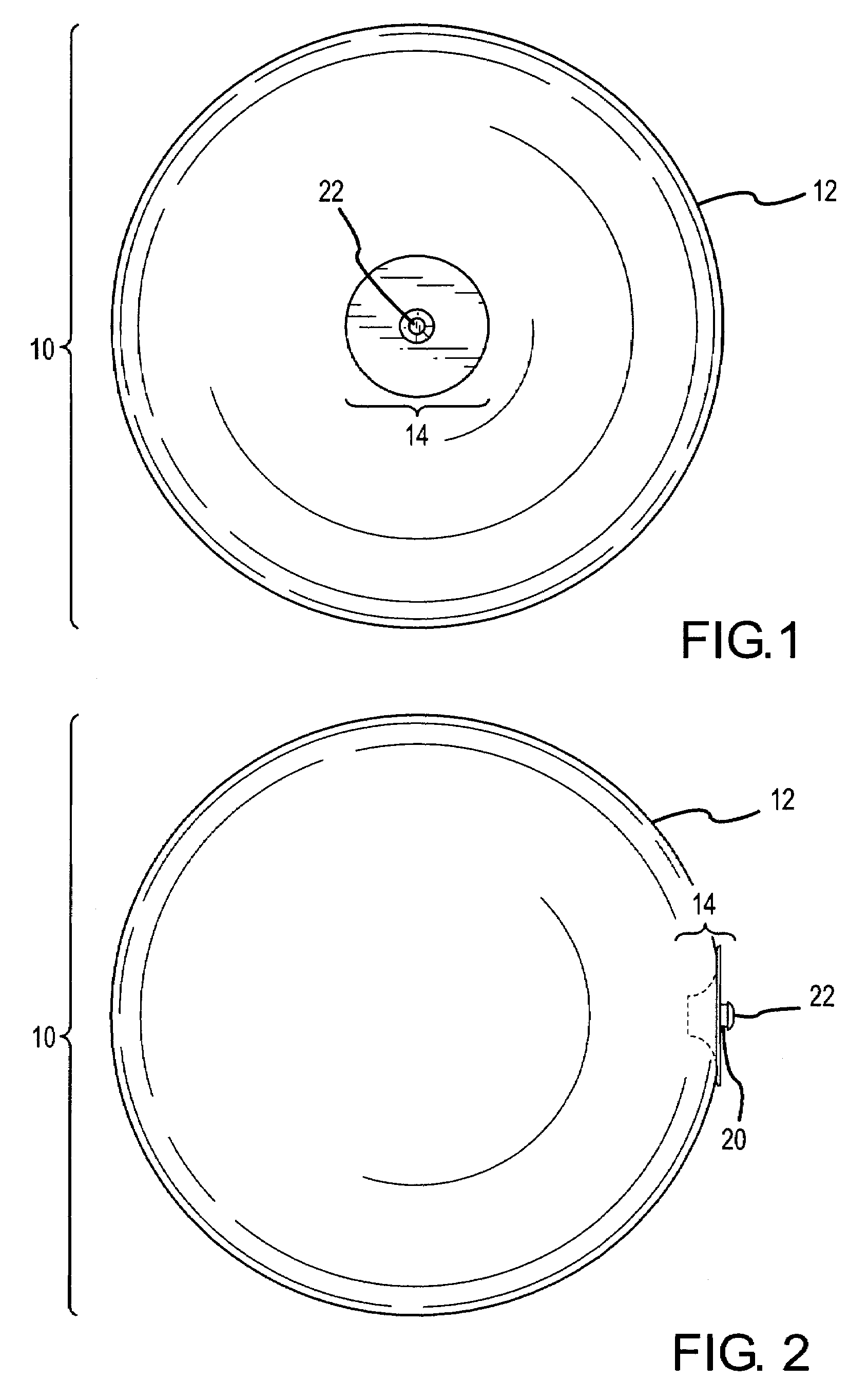

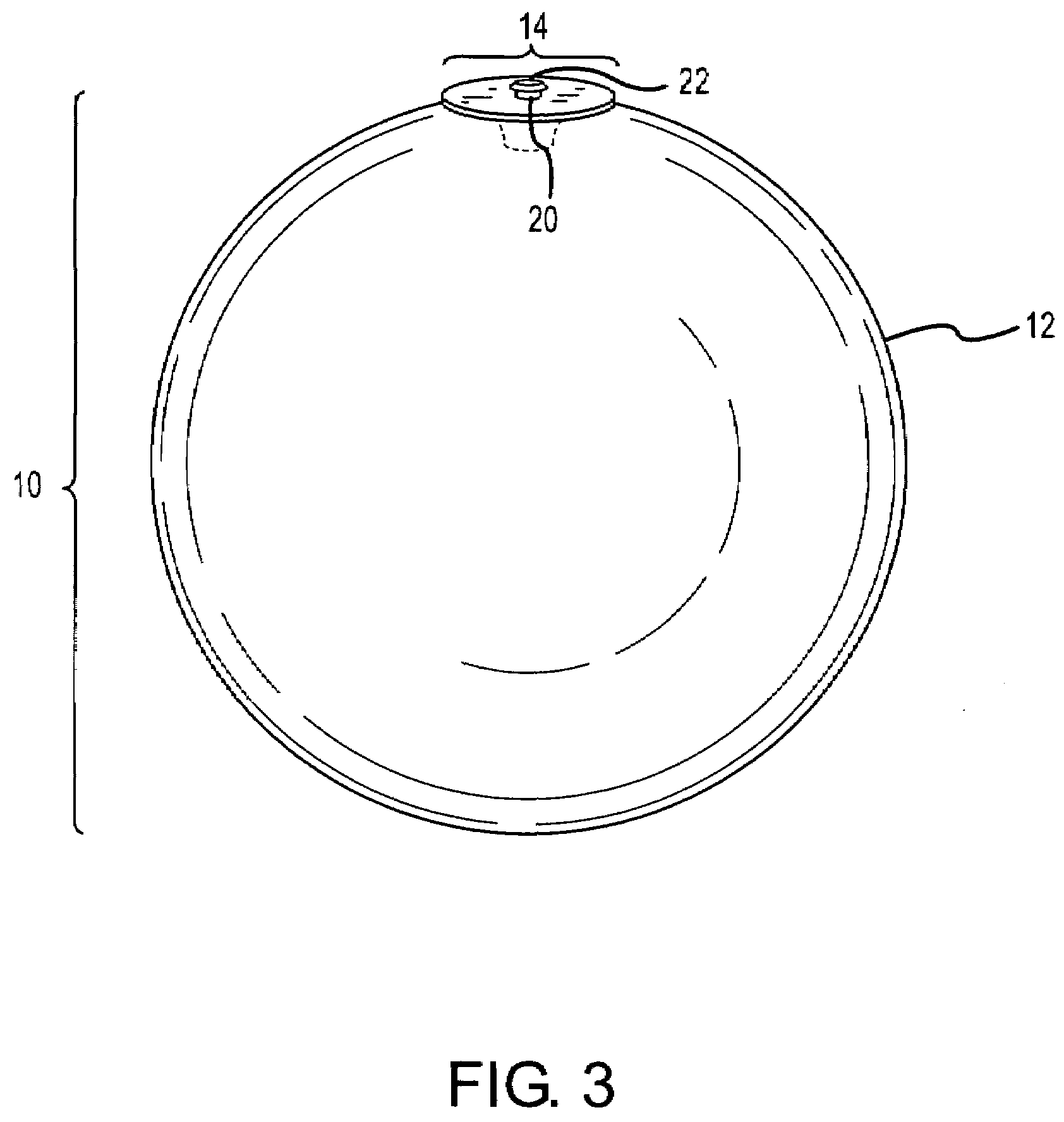

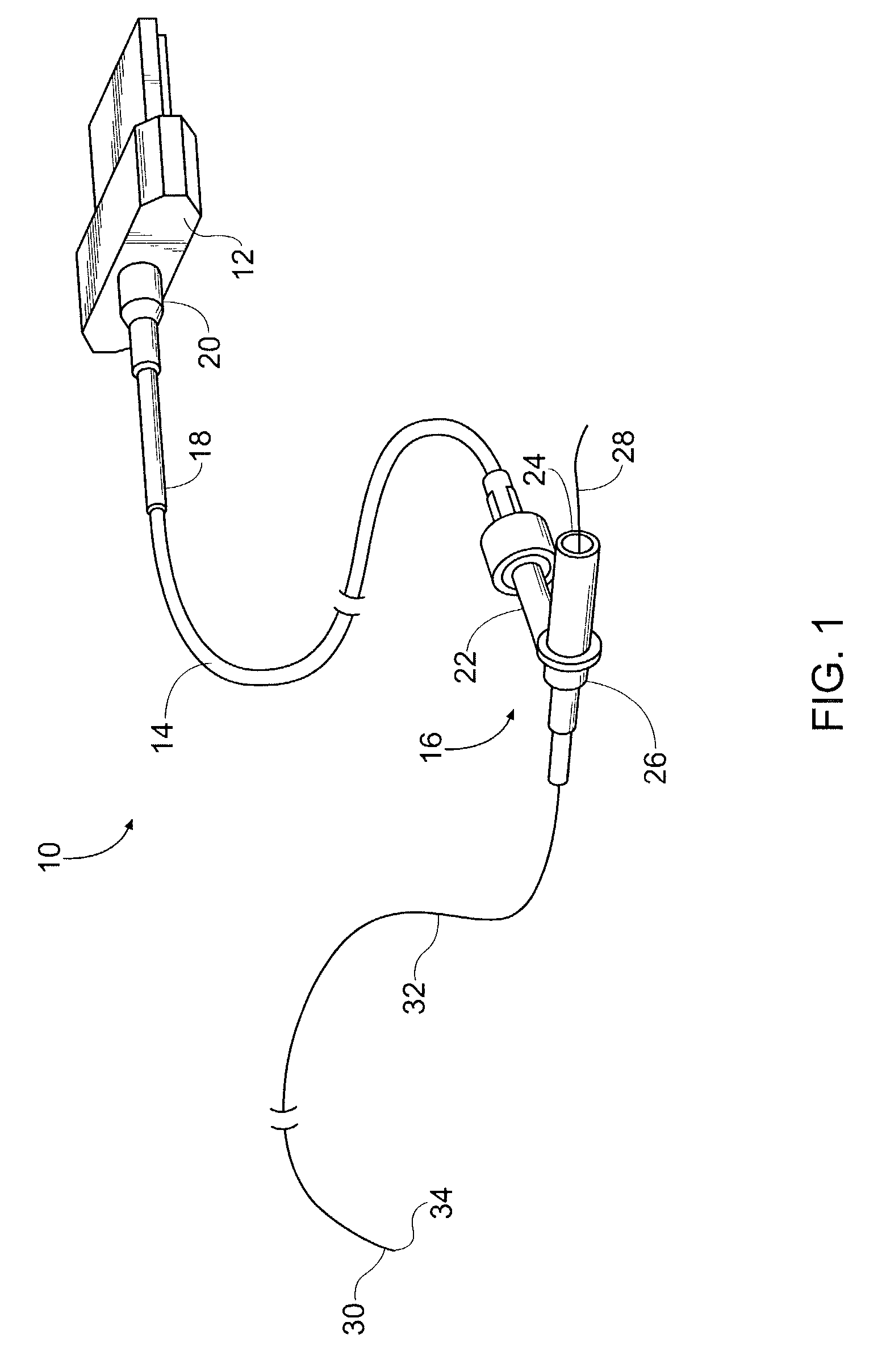

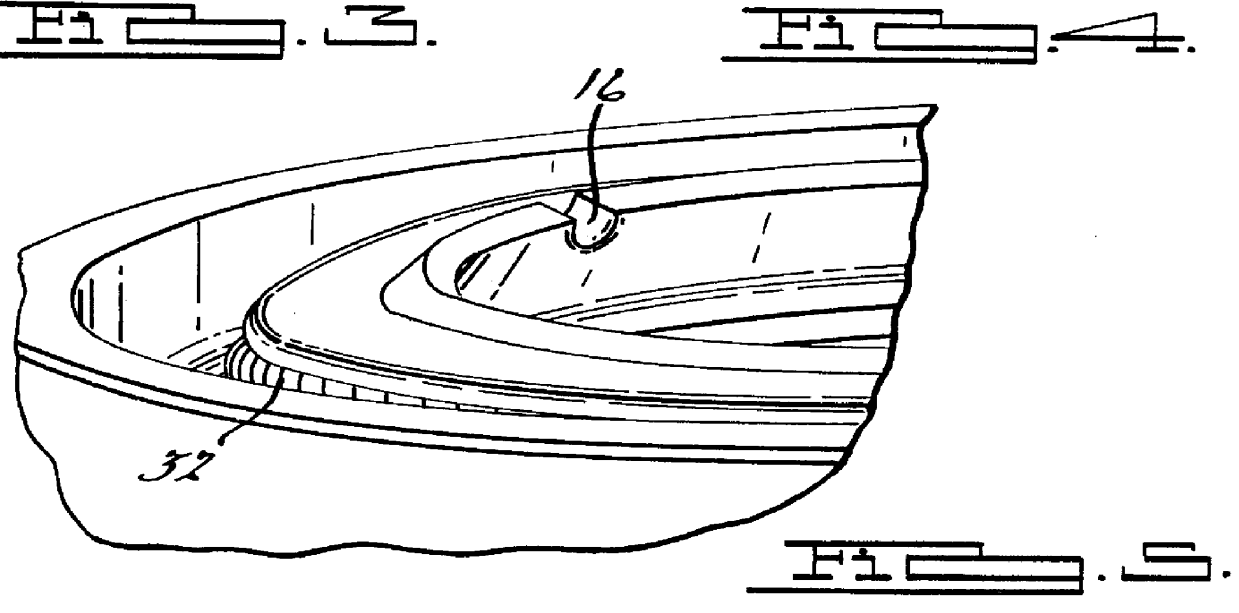

Apparatus and method for intragastric balloon with in situ adjustment means

ActiveUS20080172079A1Good for weight lossEncourage early satietySurgeryDilatorsSurgeryInstrumentation

An intragastric balloon and method of adding and / or removing fluid therefrom are disclosed. The intragastric balloon includes a shell, a grasping tab, and a self-sealing portion. A gastroscopic instrument which includes a grasping tool is inserted into the stomach of a patient and used to grasp the grasping tab located on the surface of the shell. Using the grasping tool, the intragastric balloon is securely fastened to the gastroscopic instrument. A filling instrument, such as a needle, is advanced through the self-sealing portion of the shell for the filling or deflating of the intragastric balloon. After inflation or deflation is complete, the filling instrument is then withdrawn from the balloon and the gastroscopic instrument withdrawn from the stomach.

Owner:APOLLO ENDOSURGERY INC

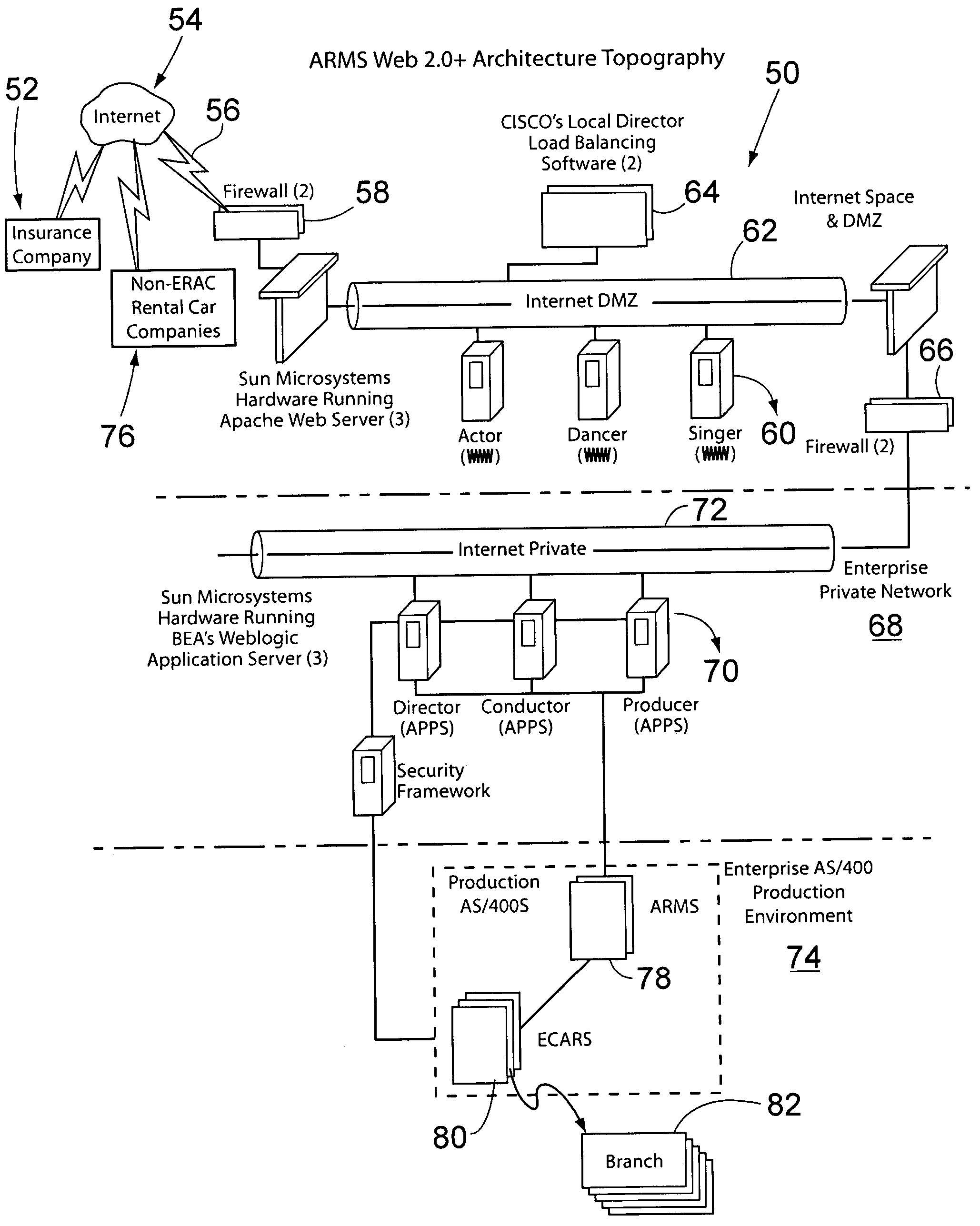

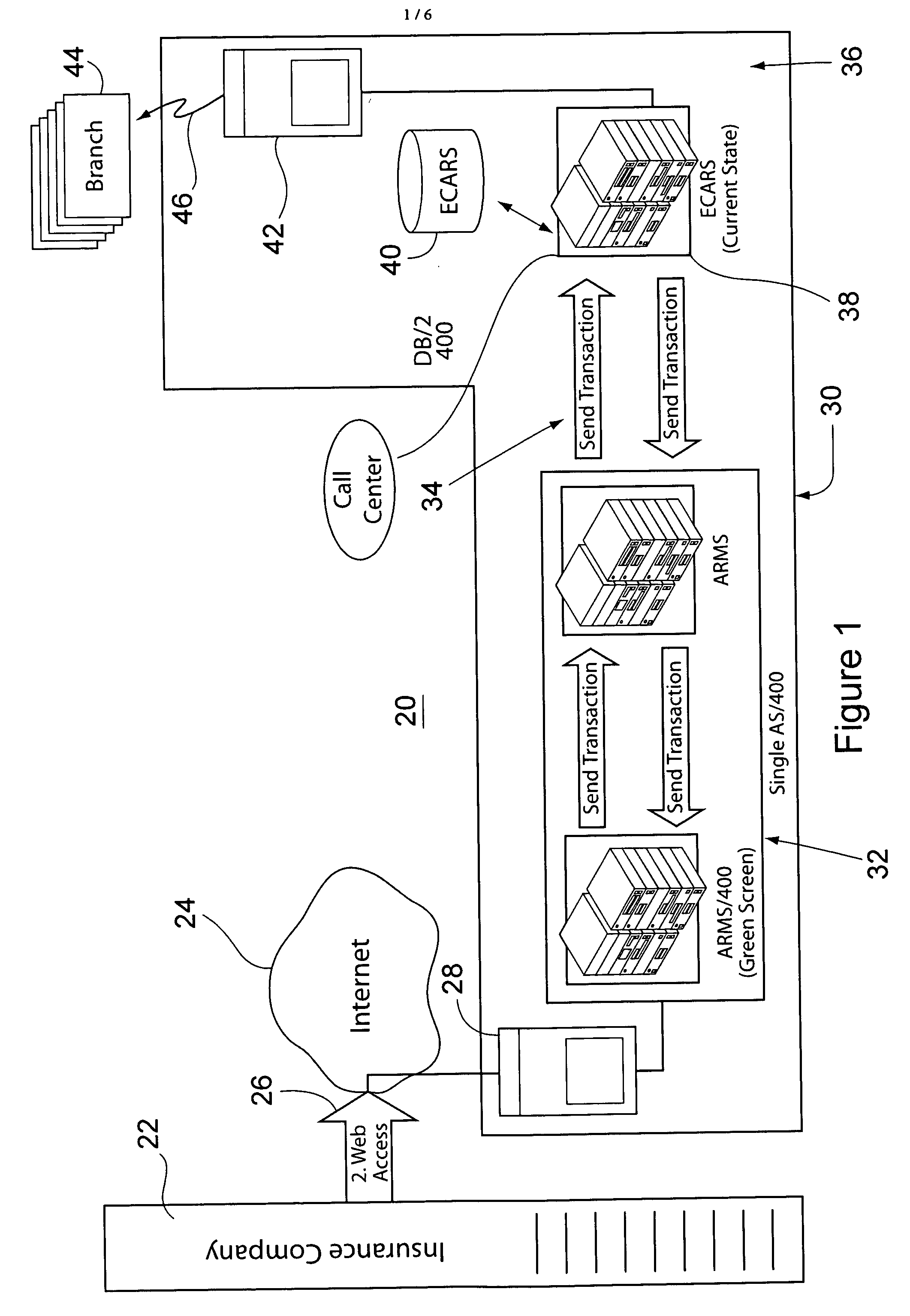

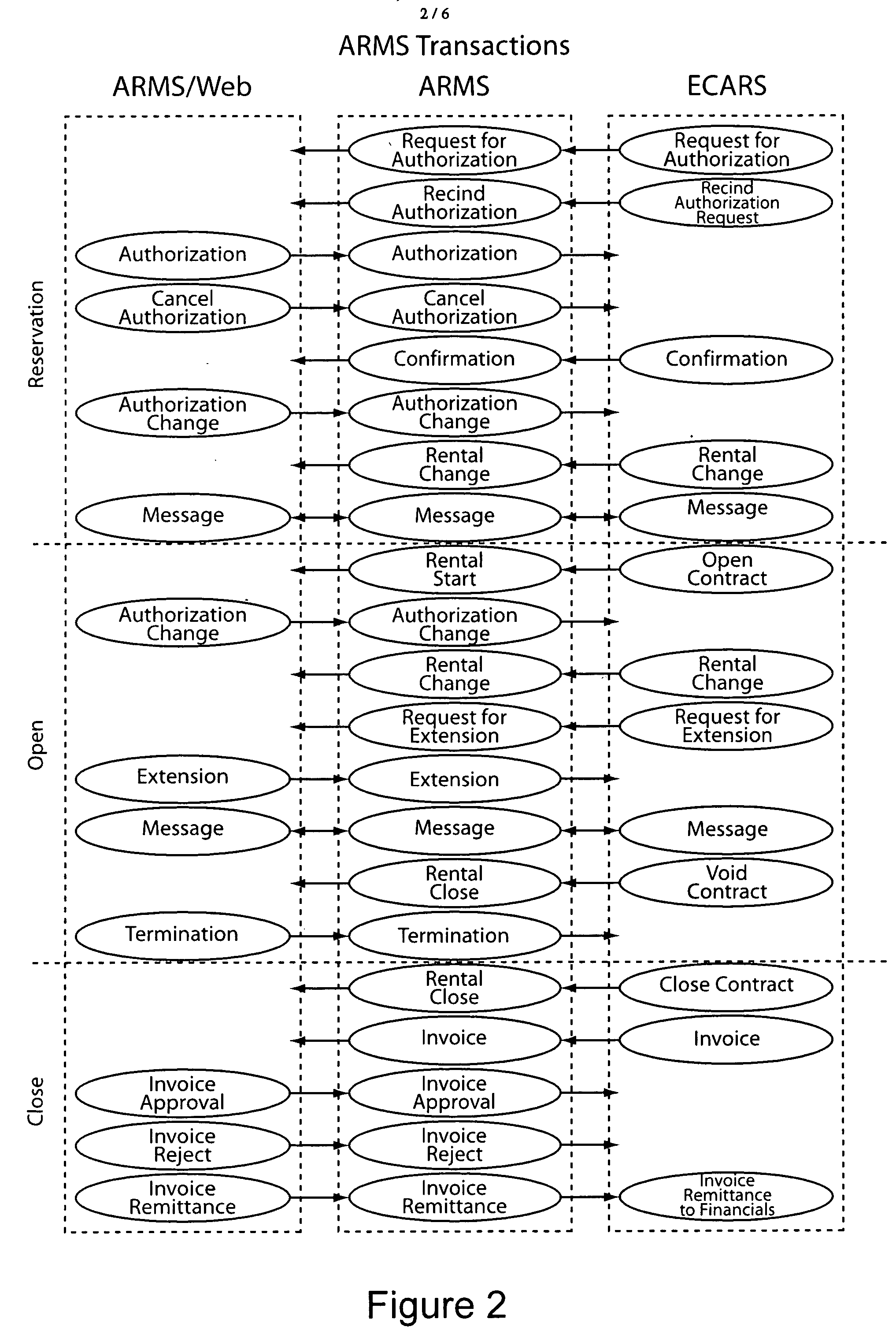

Business to business computer system for communicating and processing rental car reservations using web services

ActiveUS20050091087A1Prevent unauthorized accessCreating orderReservationsSpecial data processing applicationsSpecification documentBusiness-to-business

An Internet-enabled automatic rental vehicle transaction system, the system comprising a web service connector in communication with a rental vehicle software program, the web service connector being configured to (1) receive, via a network, a document from a computer system of an authorized purchaser of rental vehicle services on behalf of another, the document comprising a web service rental vehicle reservation request, (2) process the received document in accordance with a web service specification document to create one or more data objects having a format supported by the rental vehicle software program, and (3) communicate the one or more data objects to the rental vehicle software program, and wherein the rental vehicle software program is configured to automatically process the one or more data objects for fulfillment of the reservation request.

Owner:THE CRAWFORD GROUP

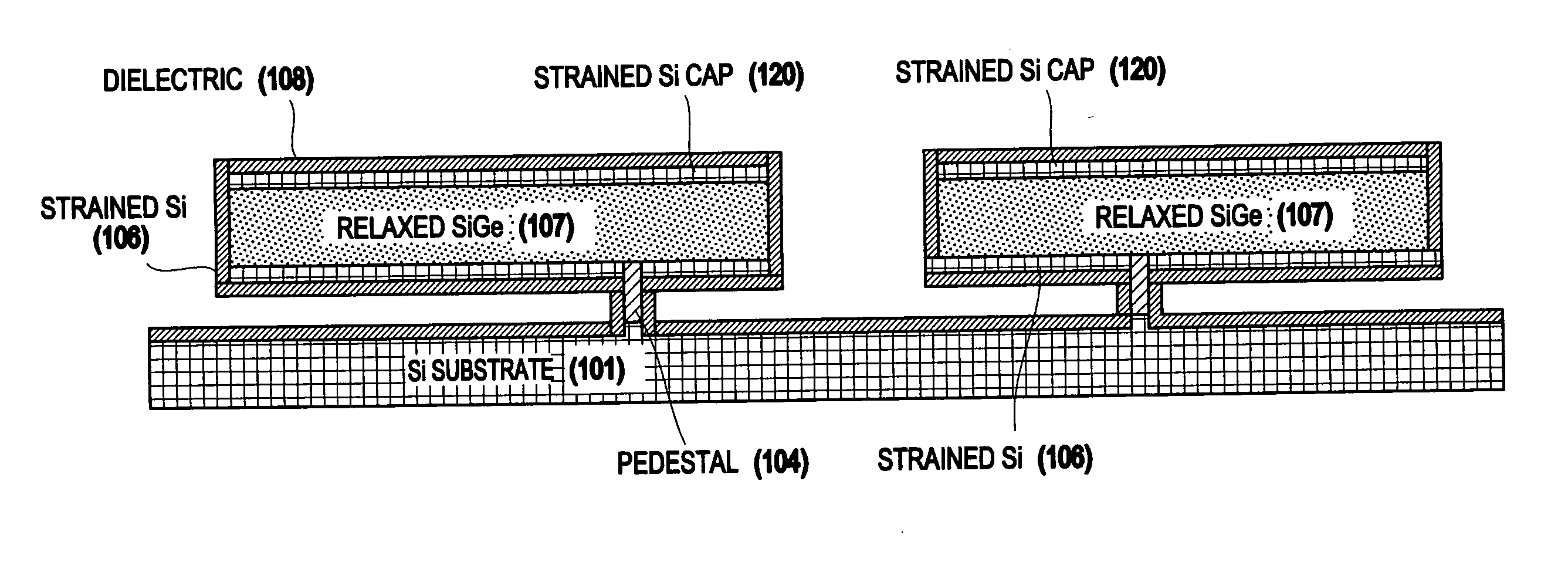

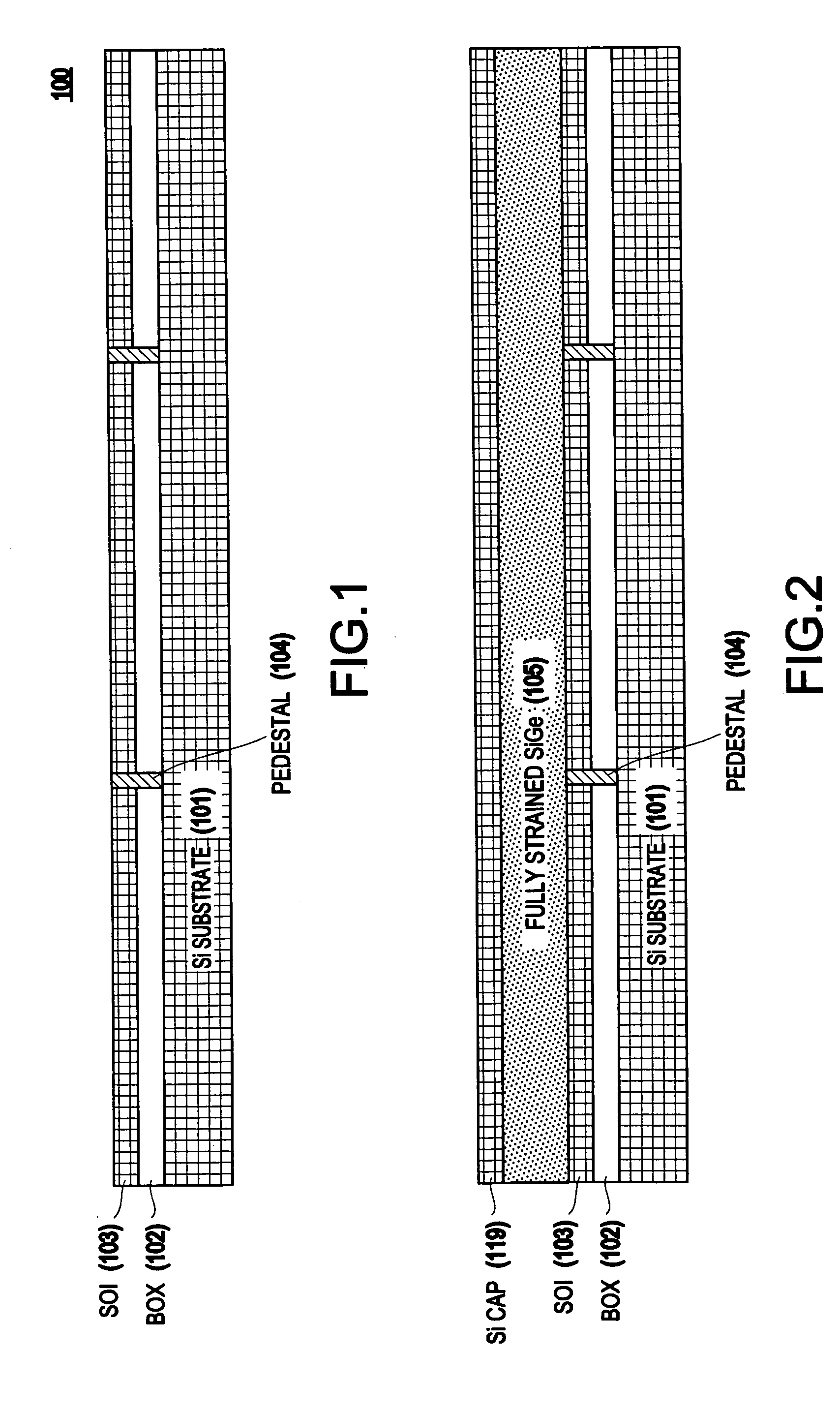

Strained-silicon-on-insulator single-and double-gate MOSFET and method for forming the same

InactiveUS20040253792A1Eliminate difficultiesSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

A method of forming a semiconductor structure (and the resulting structure), includes straining a free-standing semiconductor, and fixing the strained, free-standing semiconductor to a substrate.

Owner:IBM CORP

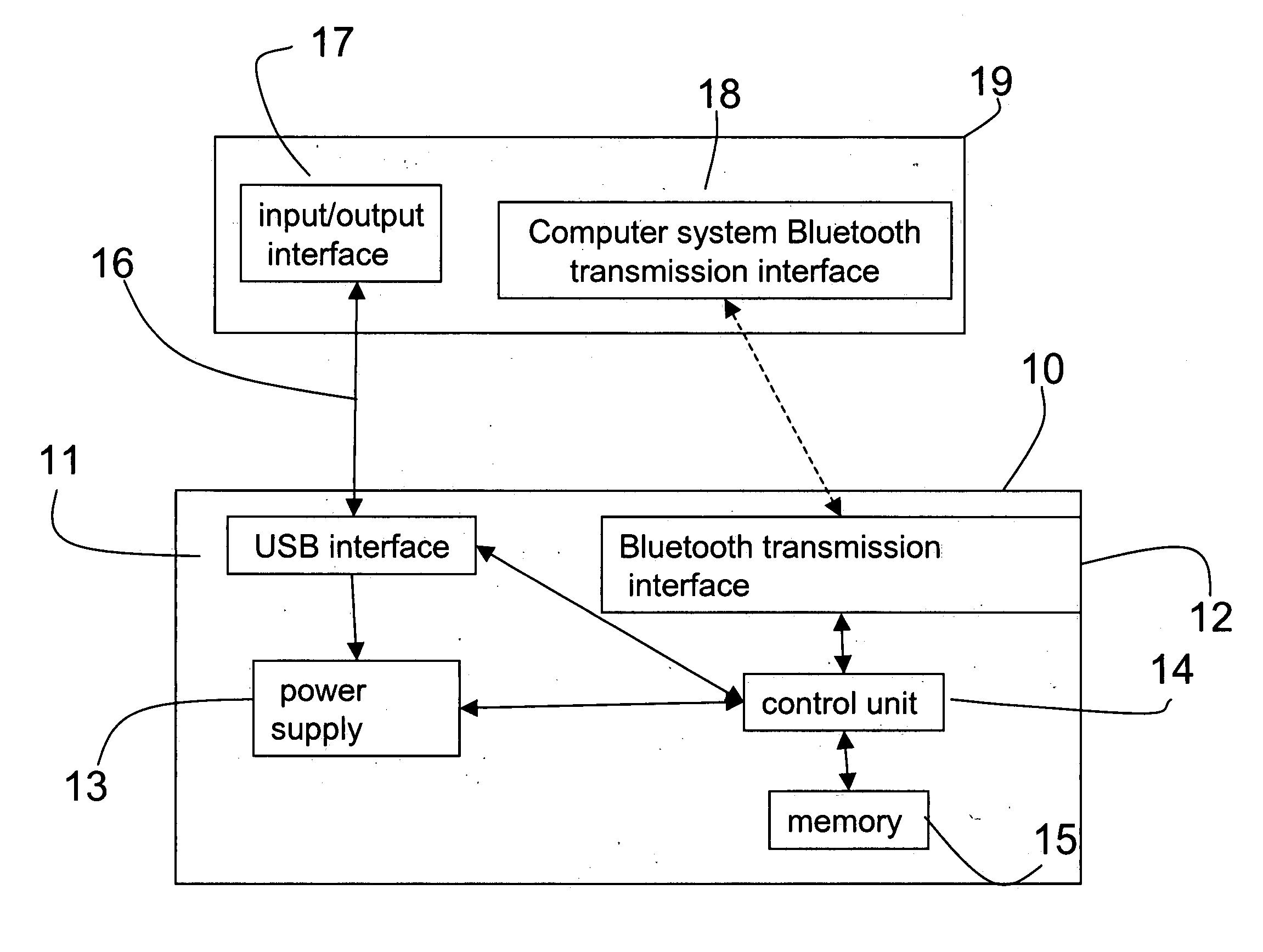

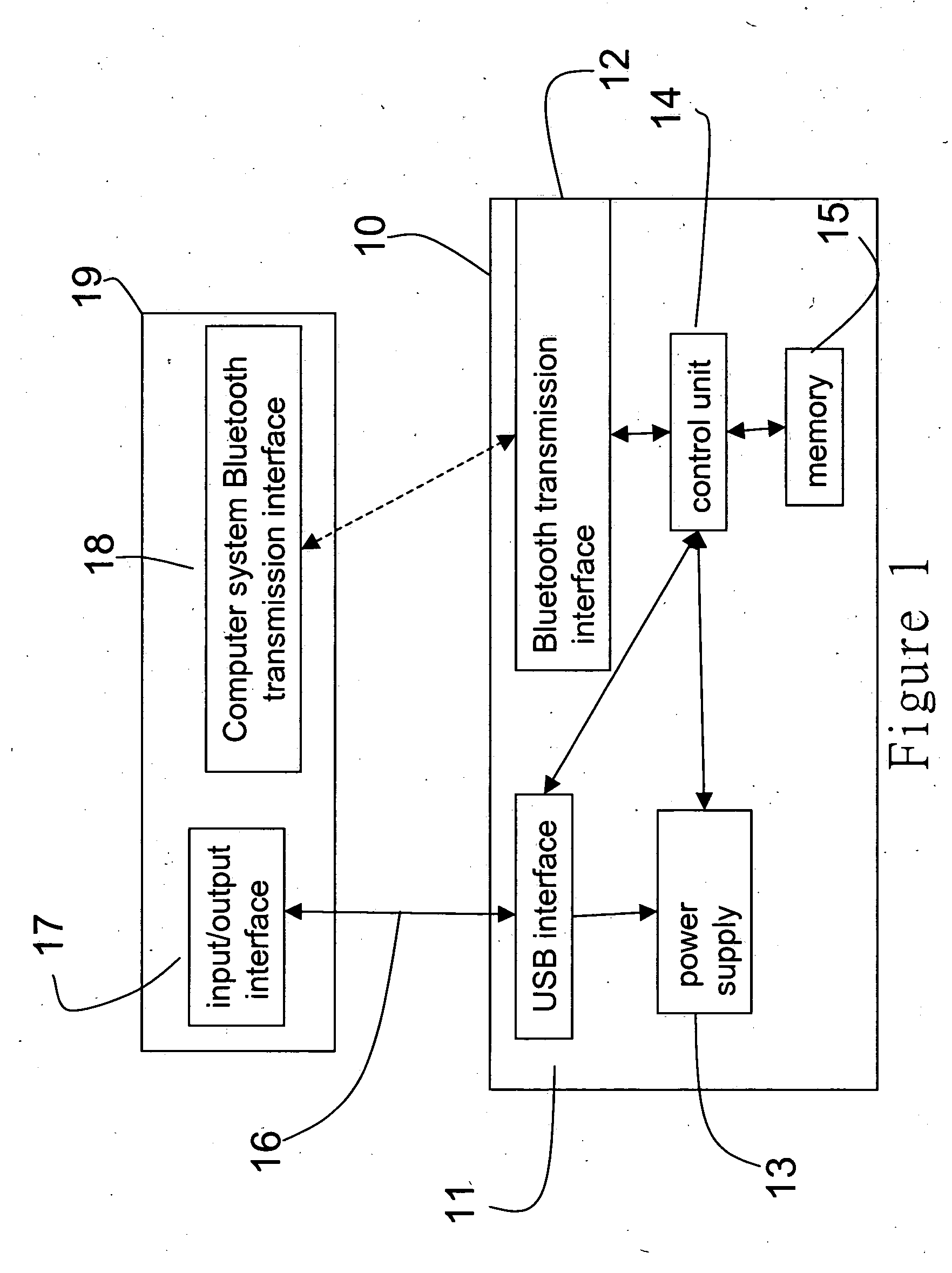

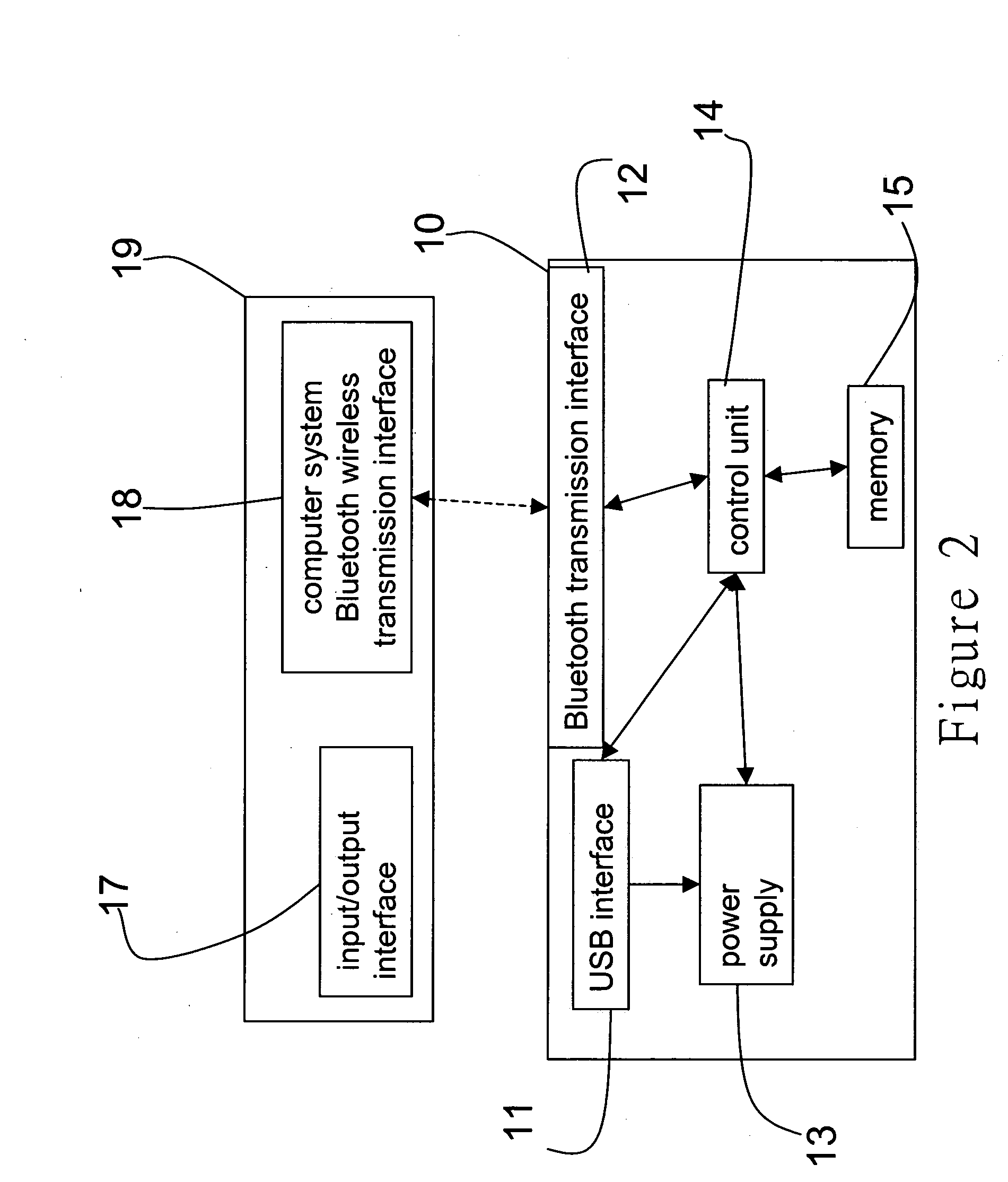

Detecting and actuating method of bluetooth devices and a control system thereof

A method of detecting and actuating of a Bluetooth device and a control system thereof is dislcosed. When the Bluetooth wireless device is used for the first time, the Bluetooth wireless device with a USB interface connects to a host system via a USB cable. After the host system is booted, the Bluetooth control program of the host system automatically detects and acquires data at a control terminal of the Bluetooth device. The Bluetooth control program further gives a Bluetooth device address to the Bluetooth device and stores the address in the Bluetooth device and the memory of the host system.

Owner:INTEGRATED SYST SOLUTION

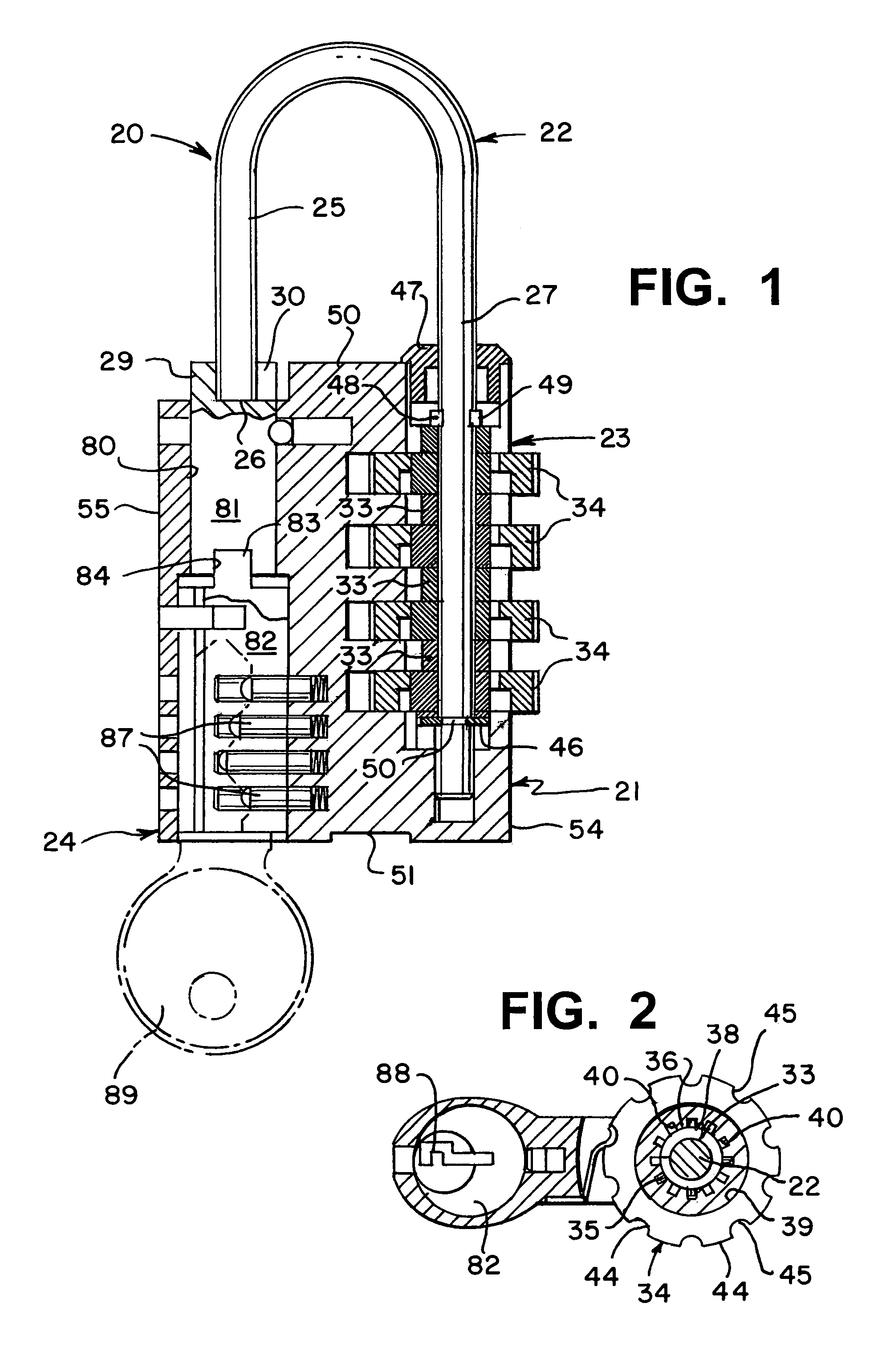

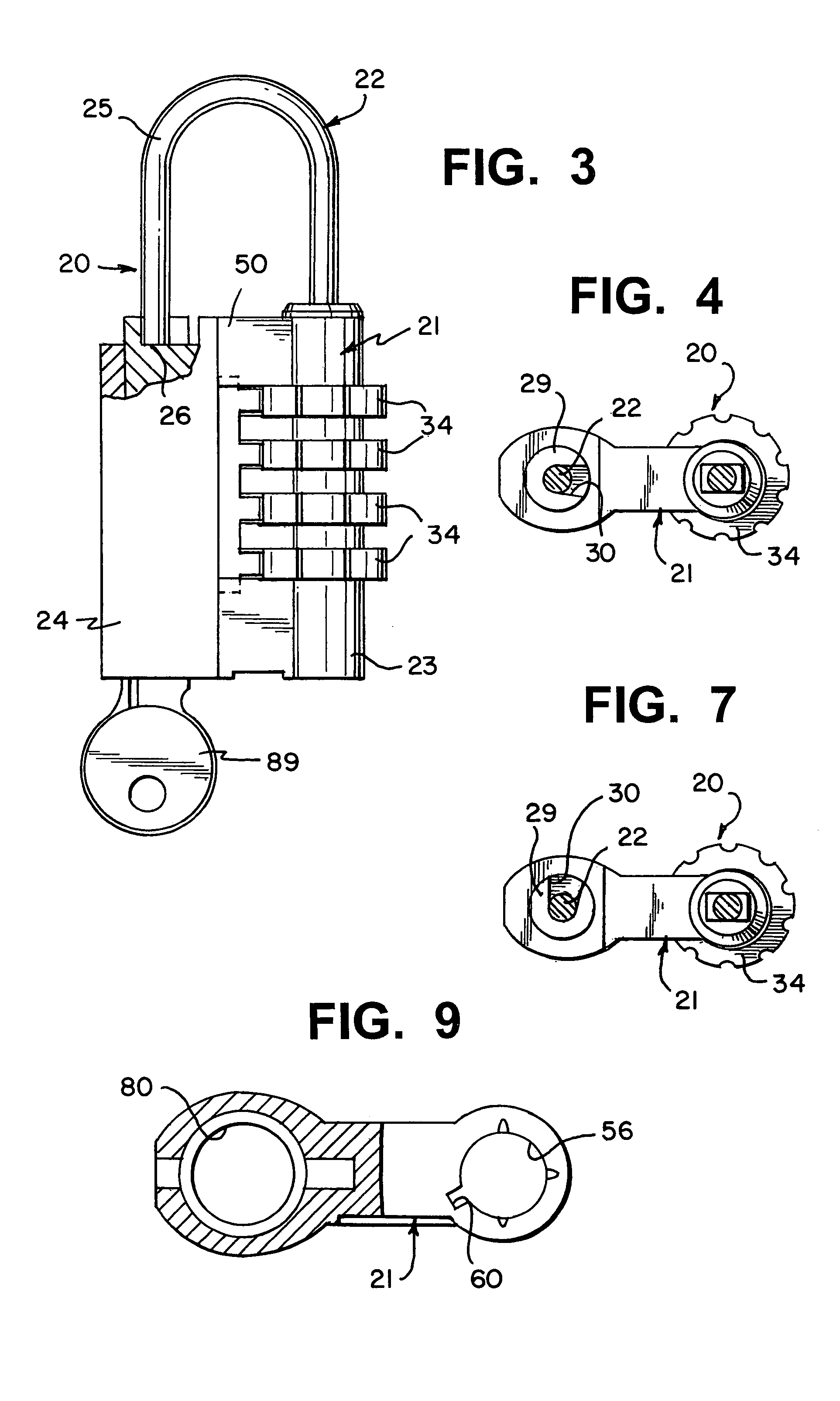

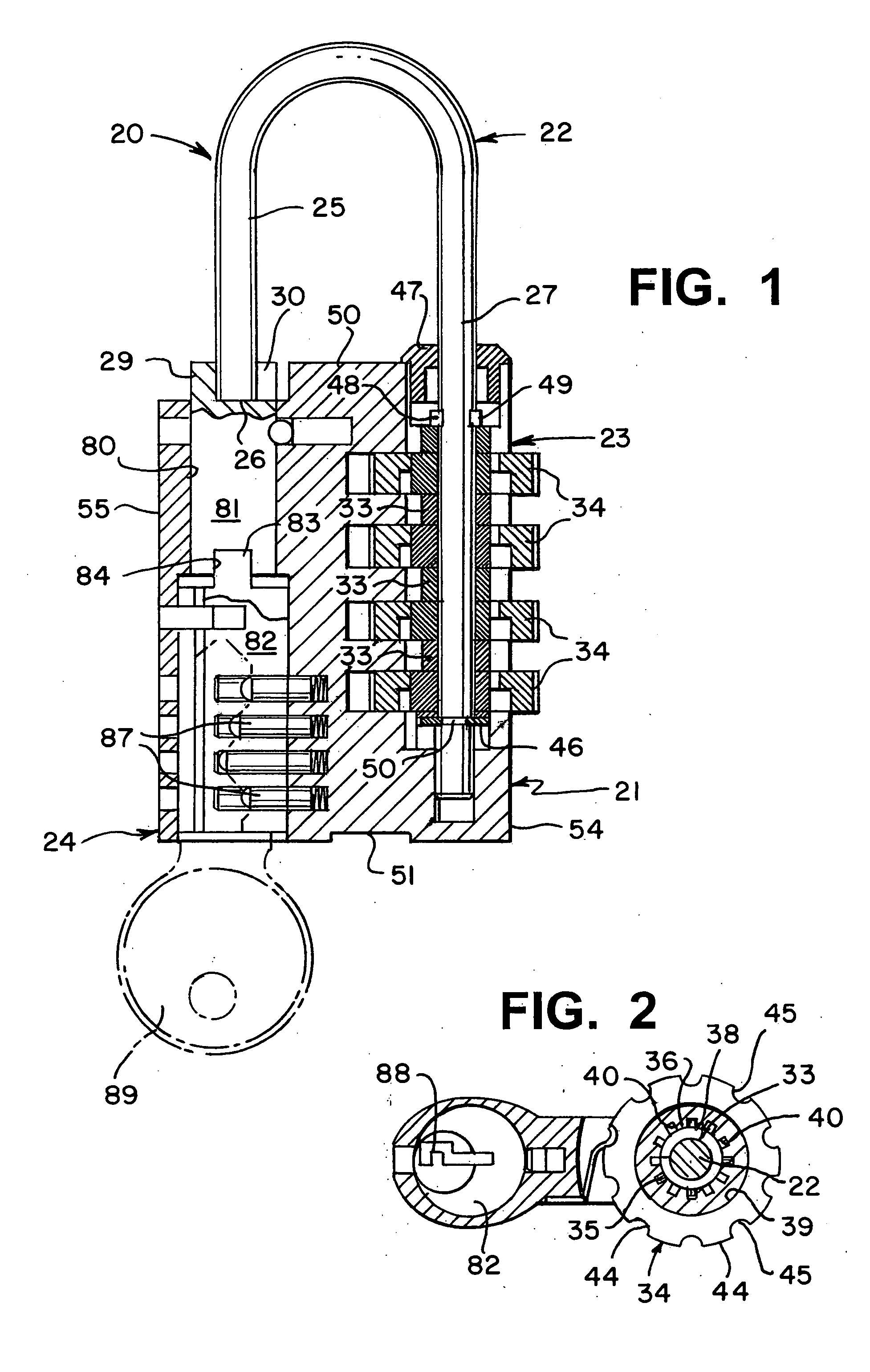

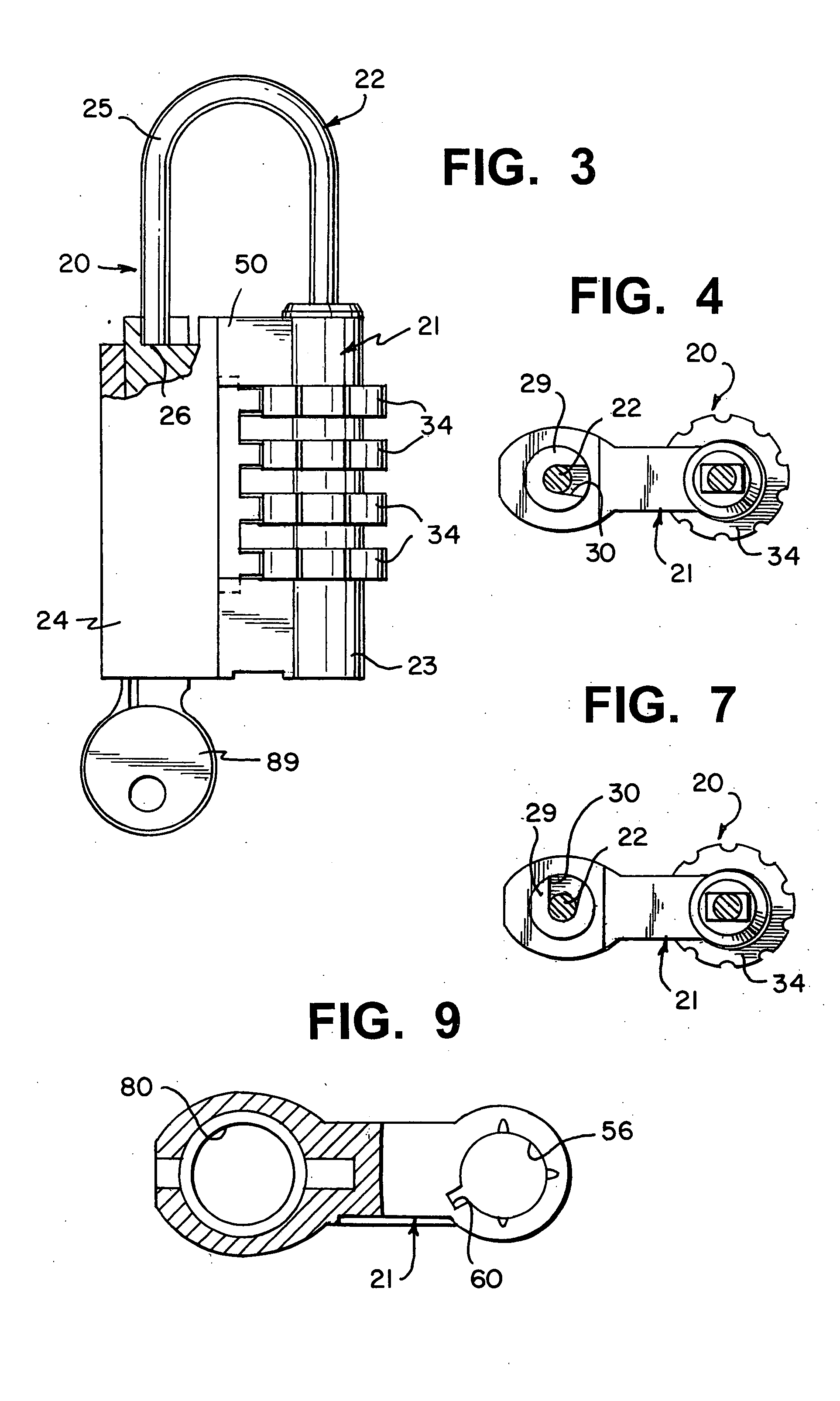

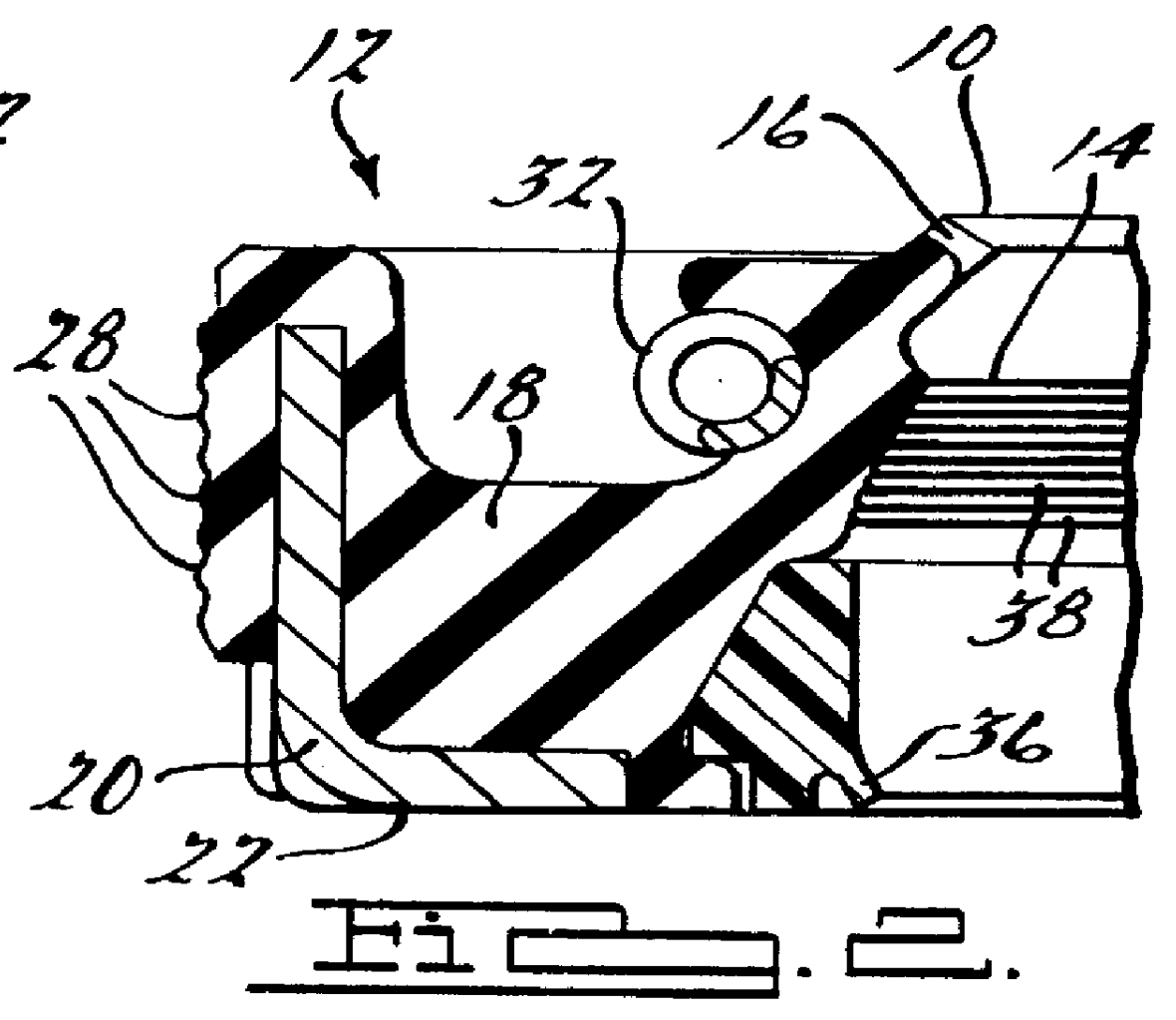

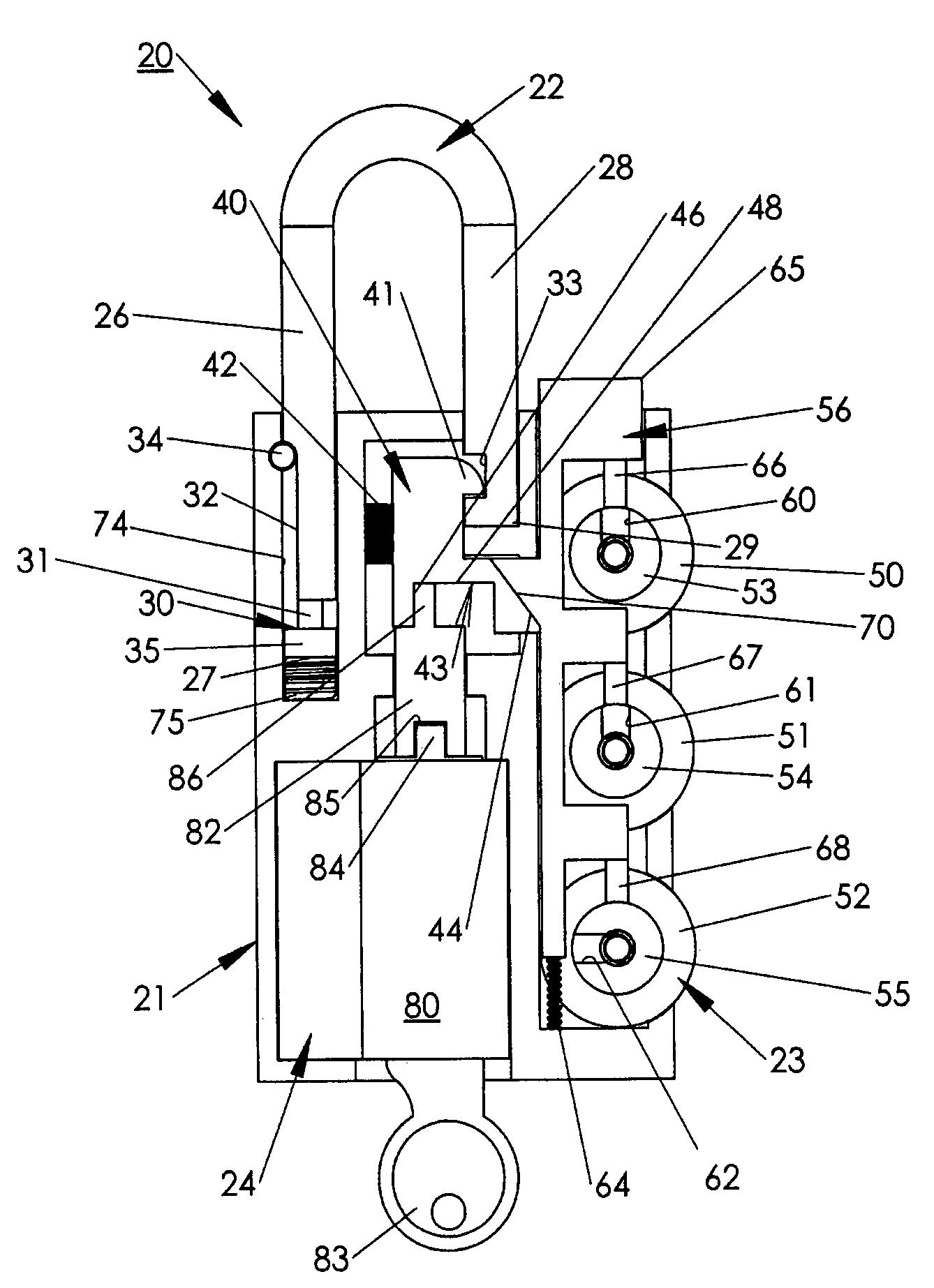

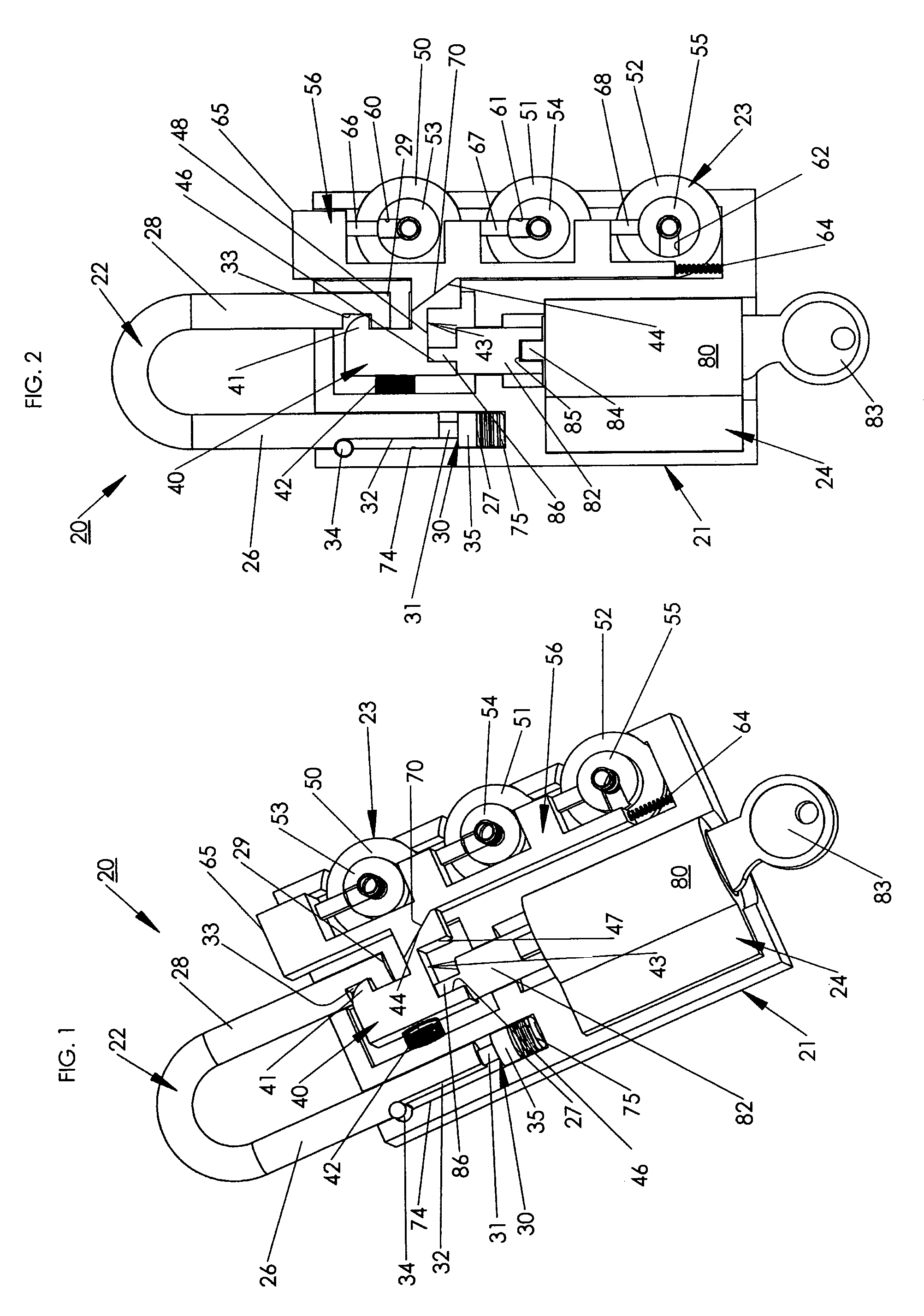

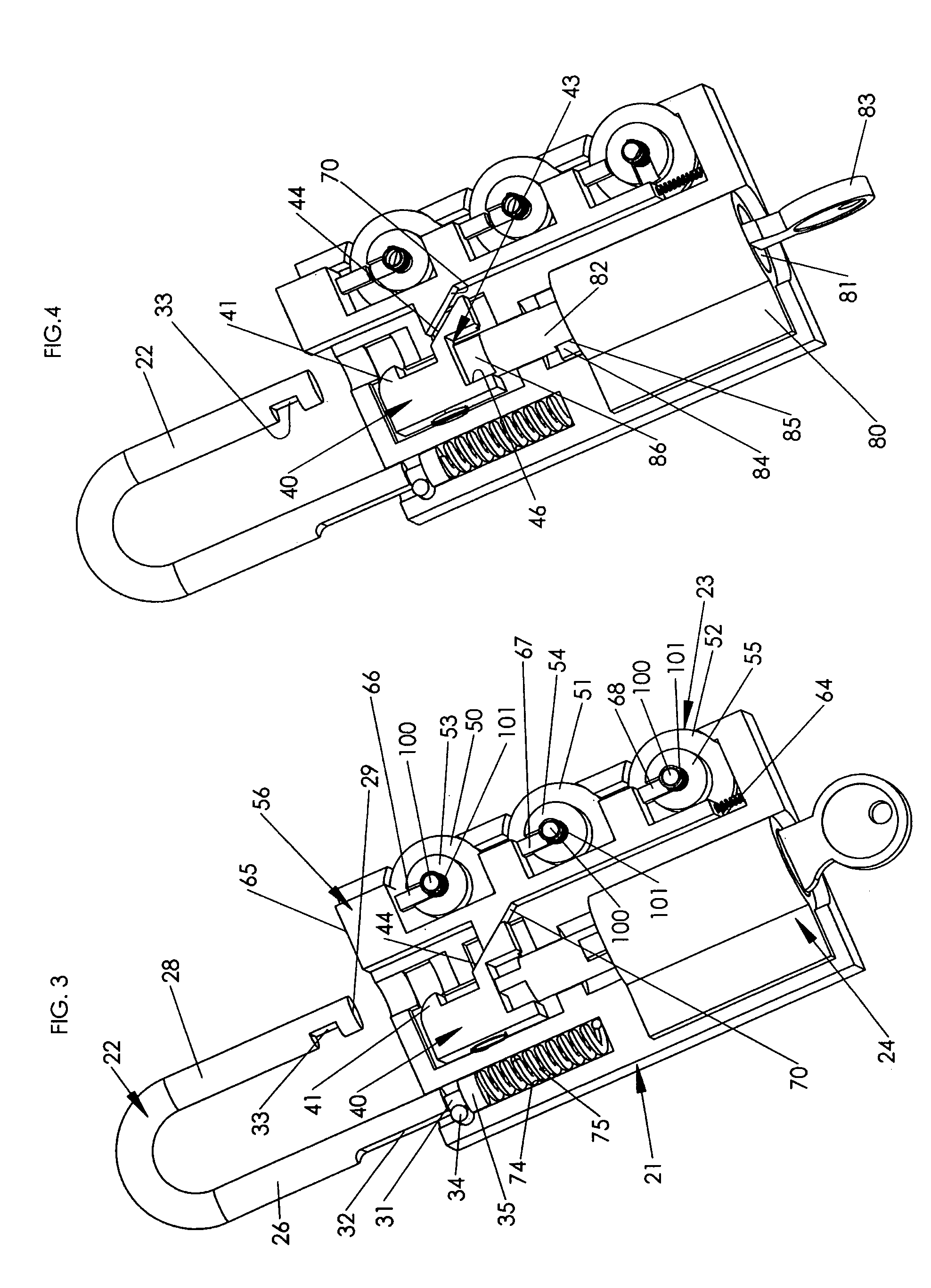

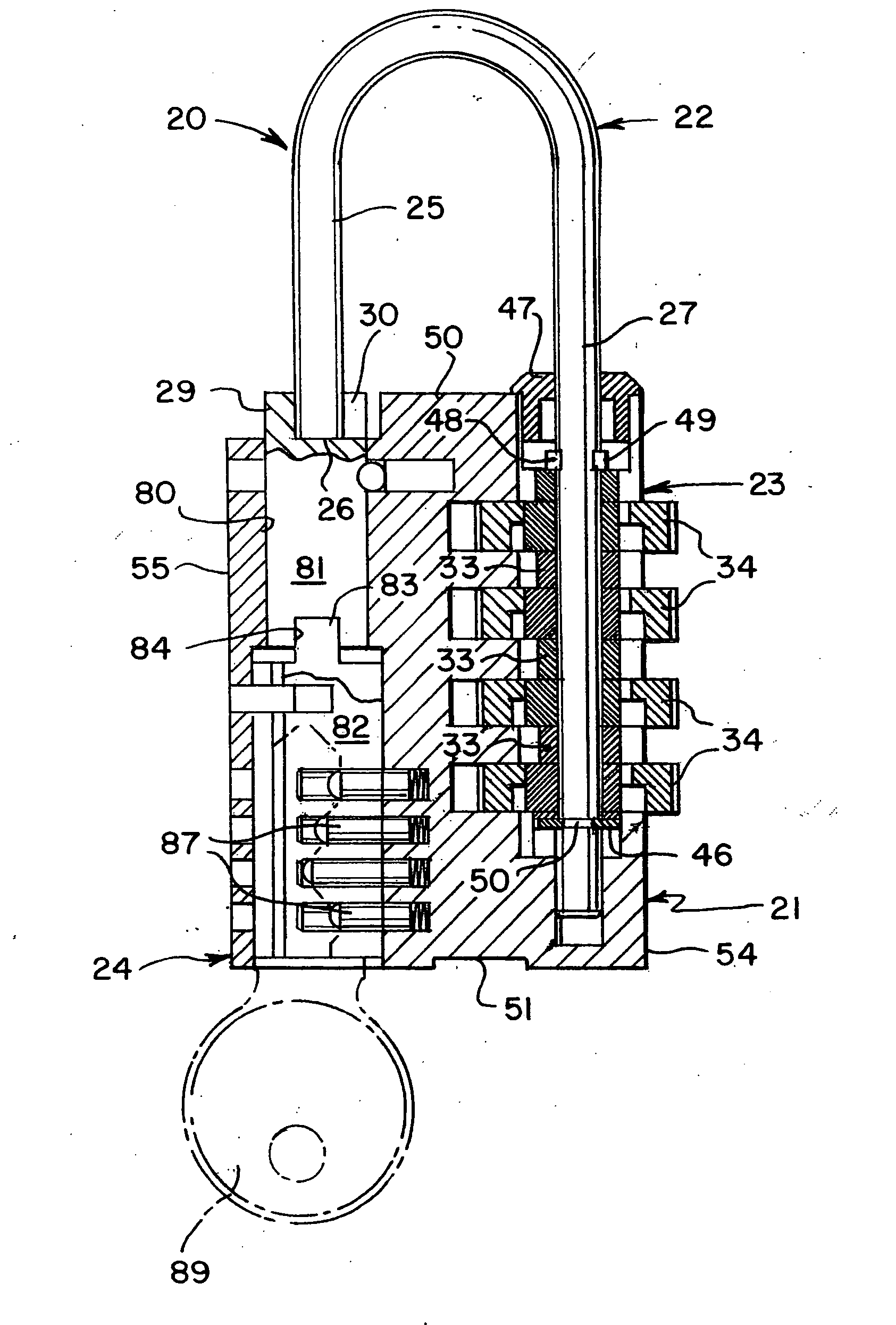

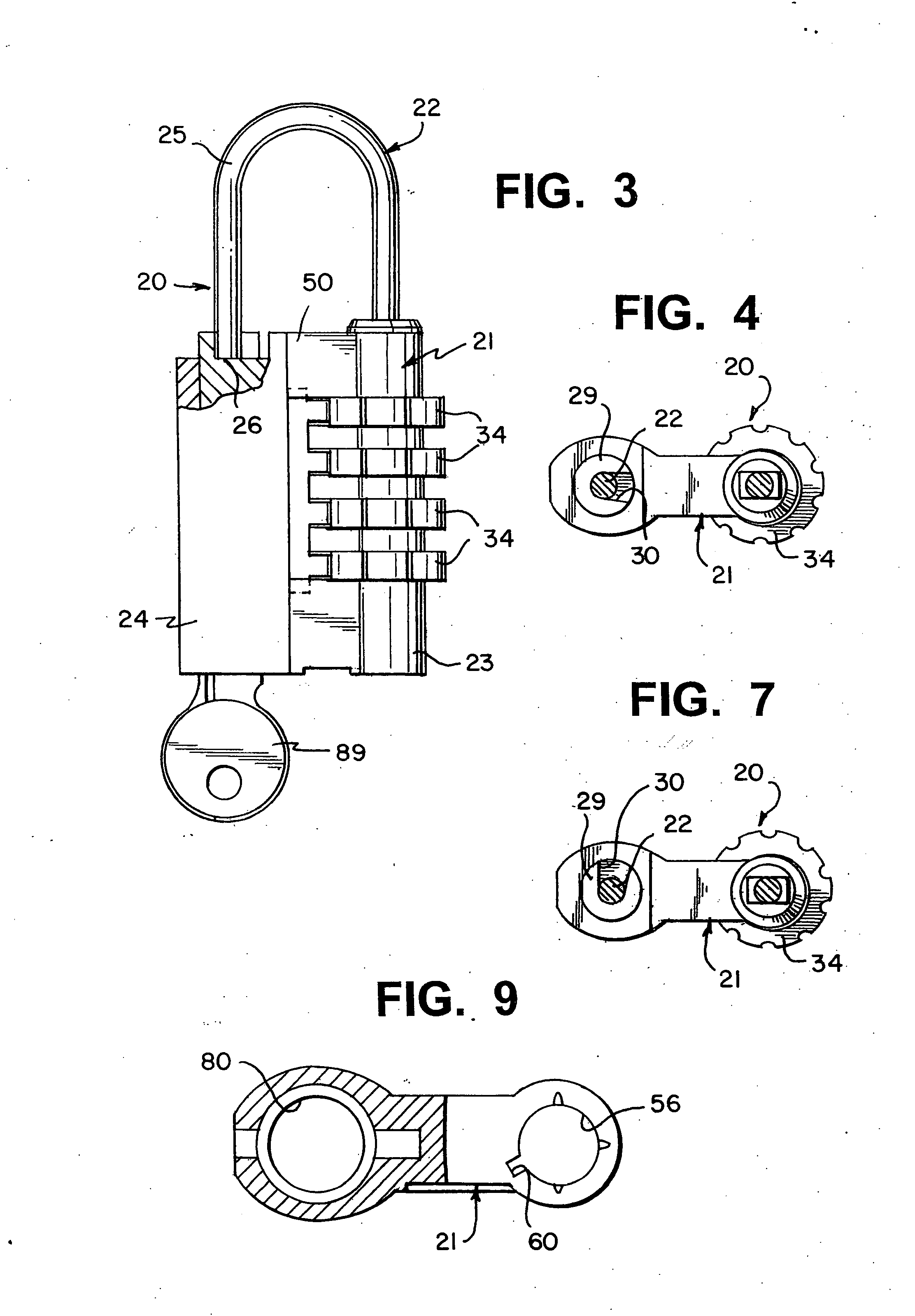

Padlock with fully integrated dual locking systems

ActiveUS7140209B2Easy to produceEliminate difficultiesPadlocksPuzzle locksShackleBuilding construction

By providing two separate and independent locking systems formed in a single padlock, with both locking systems independently enabling the single shackle to be released and / or lockingly engaged, an effective, easily produced, multi-purpose padlock is achieved. In the preferred embodiment, a single housing and shackle assembly are employed and constructed for enabling the shackle to be released from locked engagement with the housing using either a rotatable dial combination construction or a key activating tumbler construction. In this way, a dual locking and releasing padlock is achieved which virtually eliminates the difficulties typically encountered with known, prior art lock configurations.

Owner:SUN LOCK COMPANY LIMITED -THE-

Proximal coupler for optical fibers

InactiveUS7050692B2Eliminate damageMore consistent fiber packingSurgical instrument detailsSensorsFiberAdhesive

A coupler for interfacing a light source, such as a laser, and a fiber optic cable is disclosed. The coupler includes a slide mount having a channel that is adapted to receive optical fibers. The channel extends from a proximal end of the slide mount to a distal end of the slide mount. The proximal end of the slide mount is adapted to fit into an aperture of the light source and the distal end of the slide mount is adapted to transmit light to the fiber optic cable. The coupler also includes a clamp that is mounted on the slide mount adjacent to its proximal end. The clamp covers at least a portion of the channel, thereby securing the optical fibers within the channel without the use of an adhesive.

Owner:SPECTRANETICS

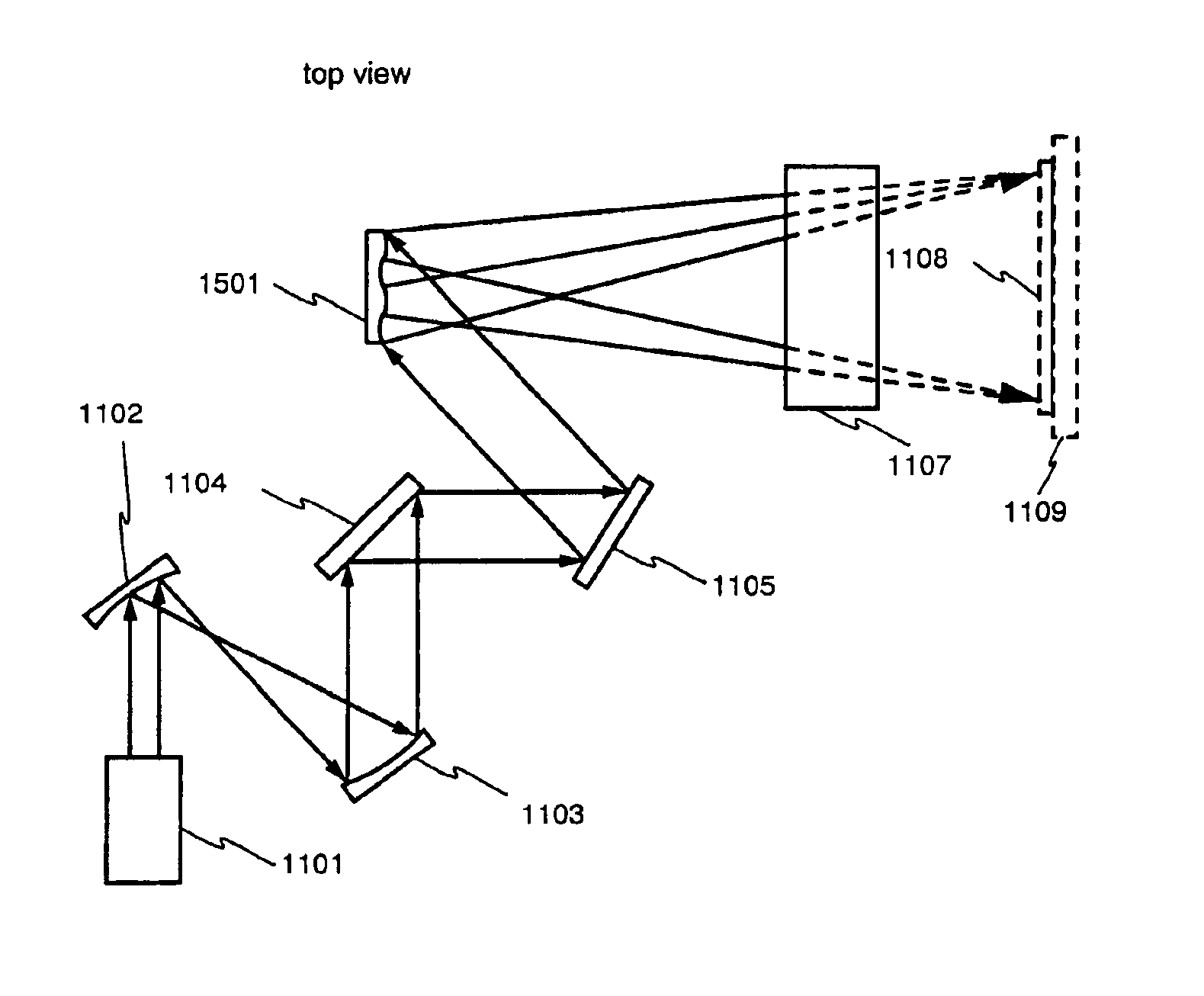

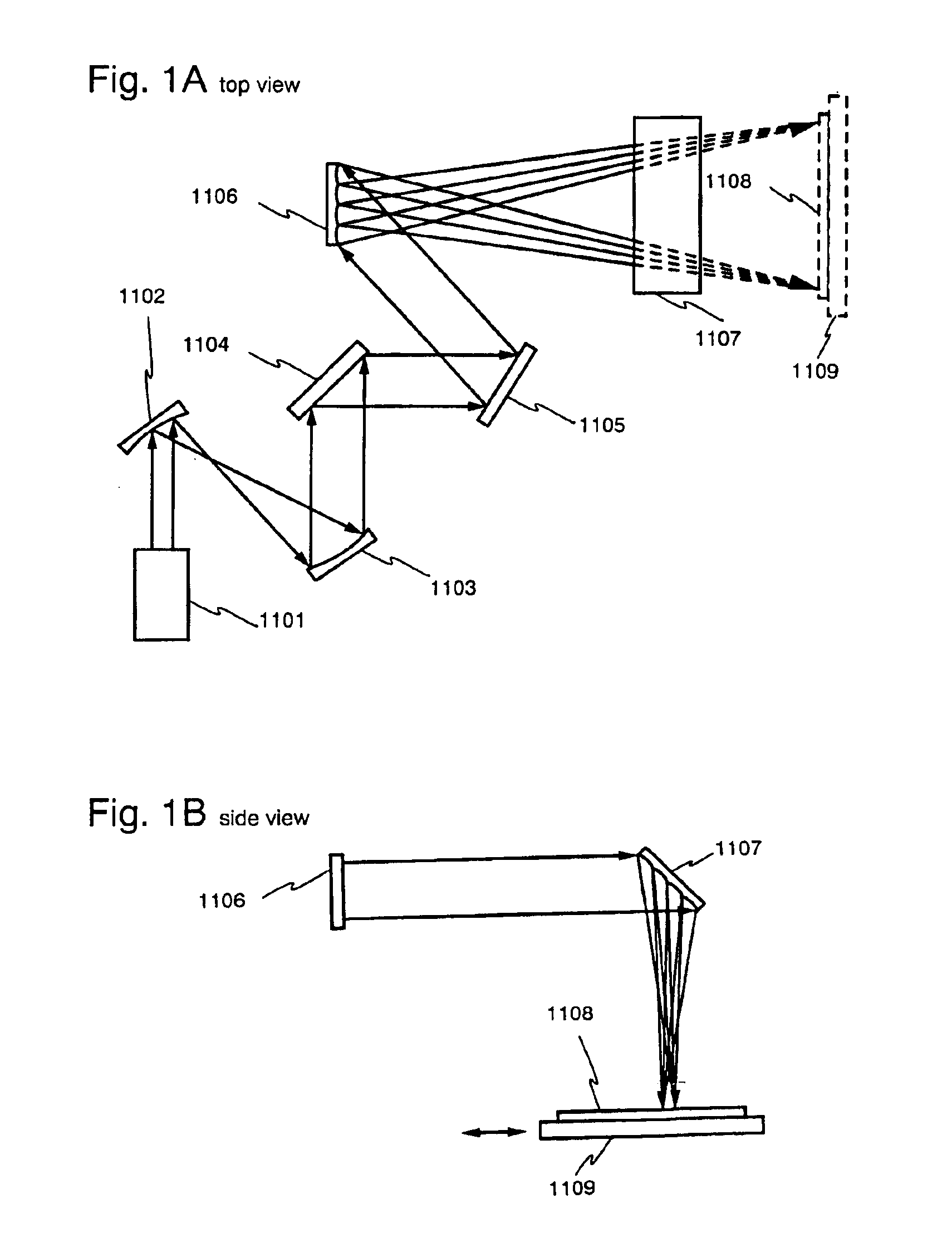

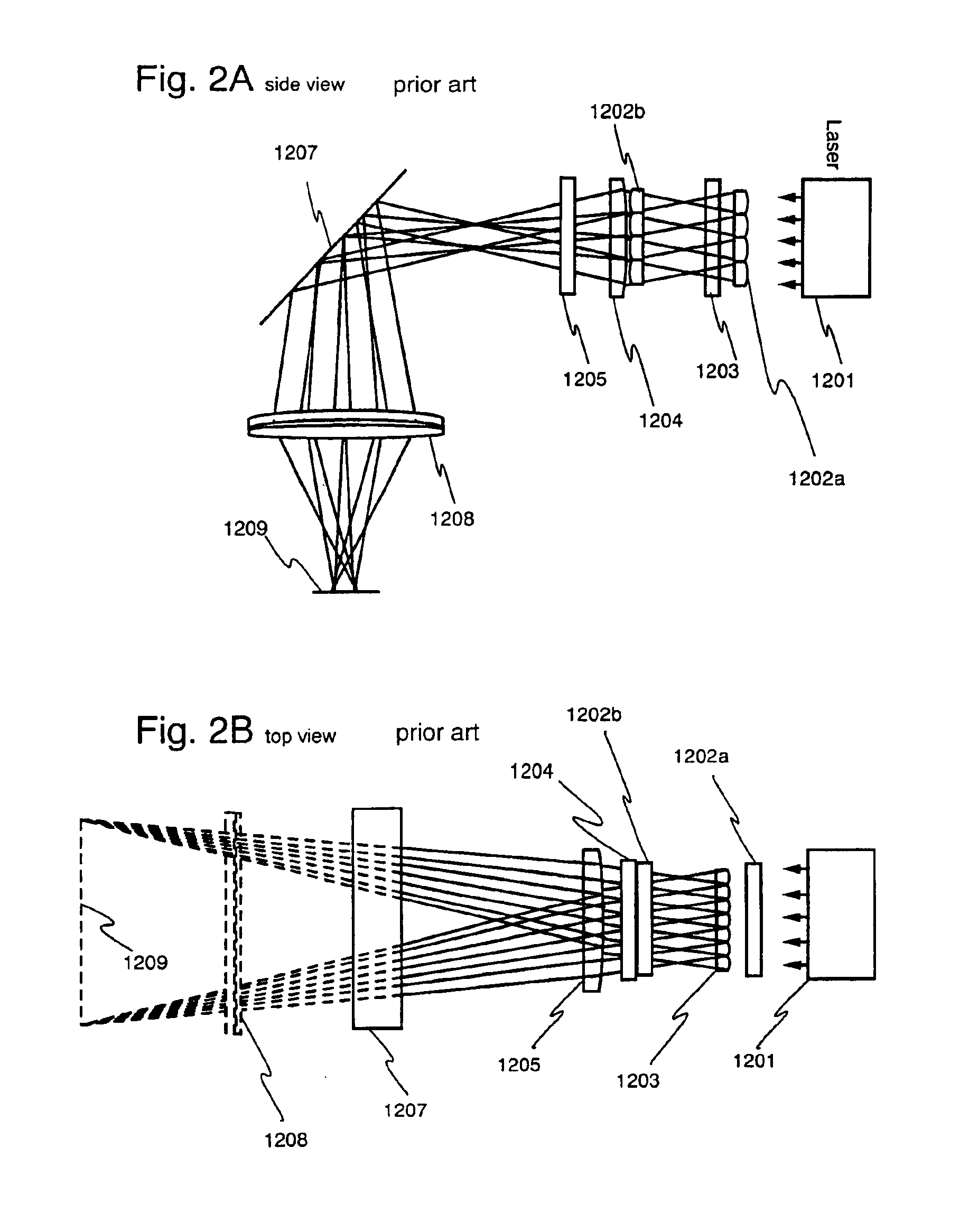

Beam homogenizer, laser irradiation apparatus, semiconductor device, and method of fabricating the semiconductor device

An optical system (in FIGS. 1A and 1B) wherein a rectilinear laser beam of homogeneous energy distribution is defined for annealing a non-single crystalline semiconductor film (a surface to-be-irradiated 1108), is constructed of reflectors (1106, 1107 etc.) easily and inexpensively without including lenses of transmission type. The rectilinear laser beam can be defined having a length of at least 600 (mm) which corresponds to the shorter latus of a large-sized substrate for mass production.

Owner:SEMICON ENERGY LAB CO LTD

Padlock with fully integrated dual locking systems

By providing two separate and independent locking systems formed in a single padlock, with both locking systems independently enabling the single shackle to be released and / or lockingly engaged, an effective, easily produced, multi-purpose padlock is achieved. In the preferred embodiment, a single housing and shackle assembly are employed and constructed for enabling the shackle to be released from locked engagement with the housing using either a rotatable dial combination construction or a key activating tumbler construction. In this way, a dual locking and releasing padlock is achieved which virtually eliminates the difficulties typically encountered with known, prior art lock configurations.

Owner:SUN LOCK COMPANY LIMITED -THE-

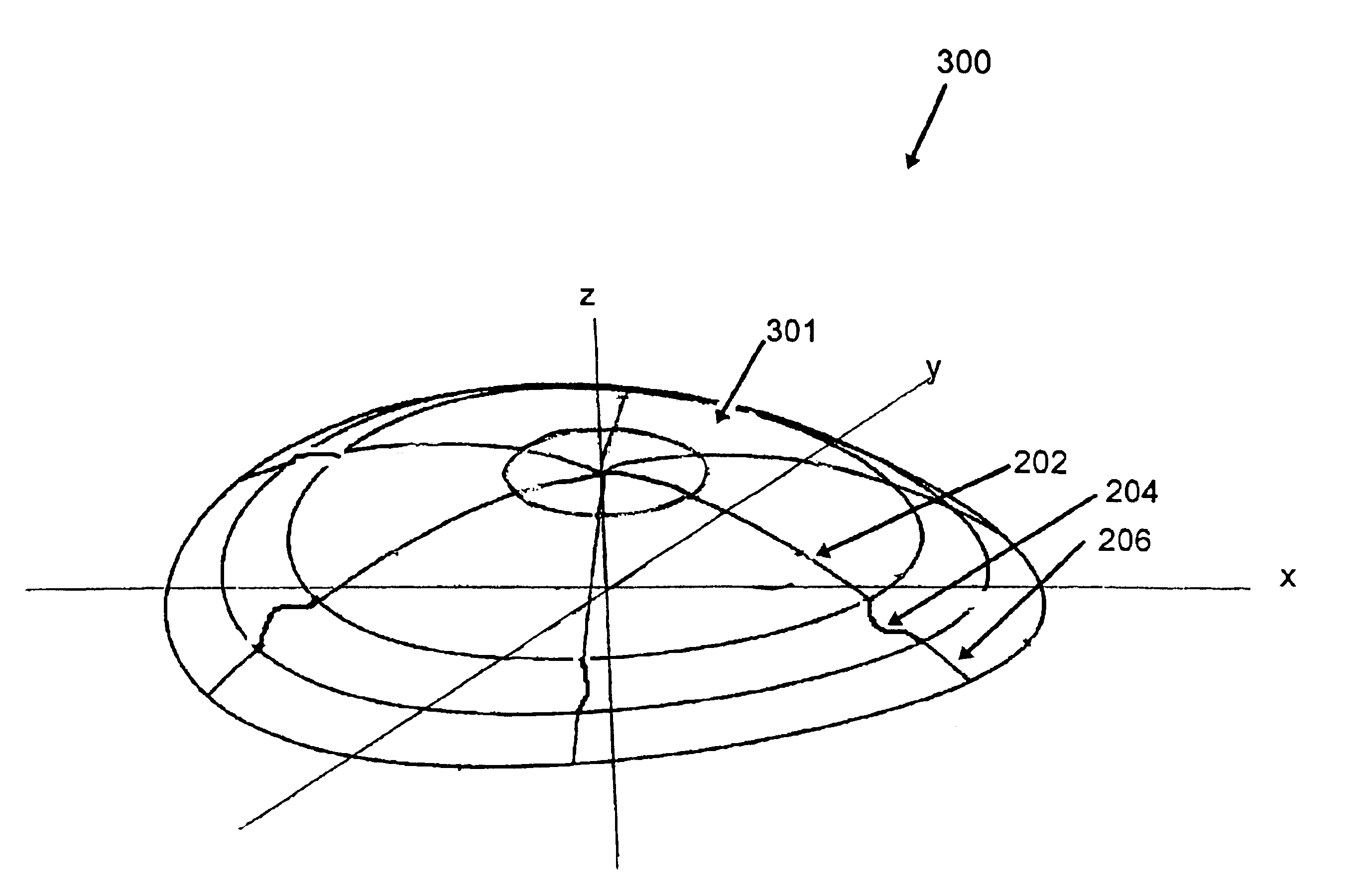

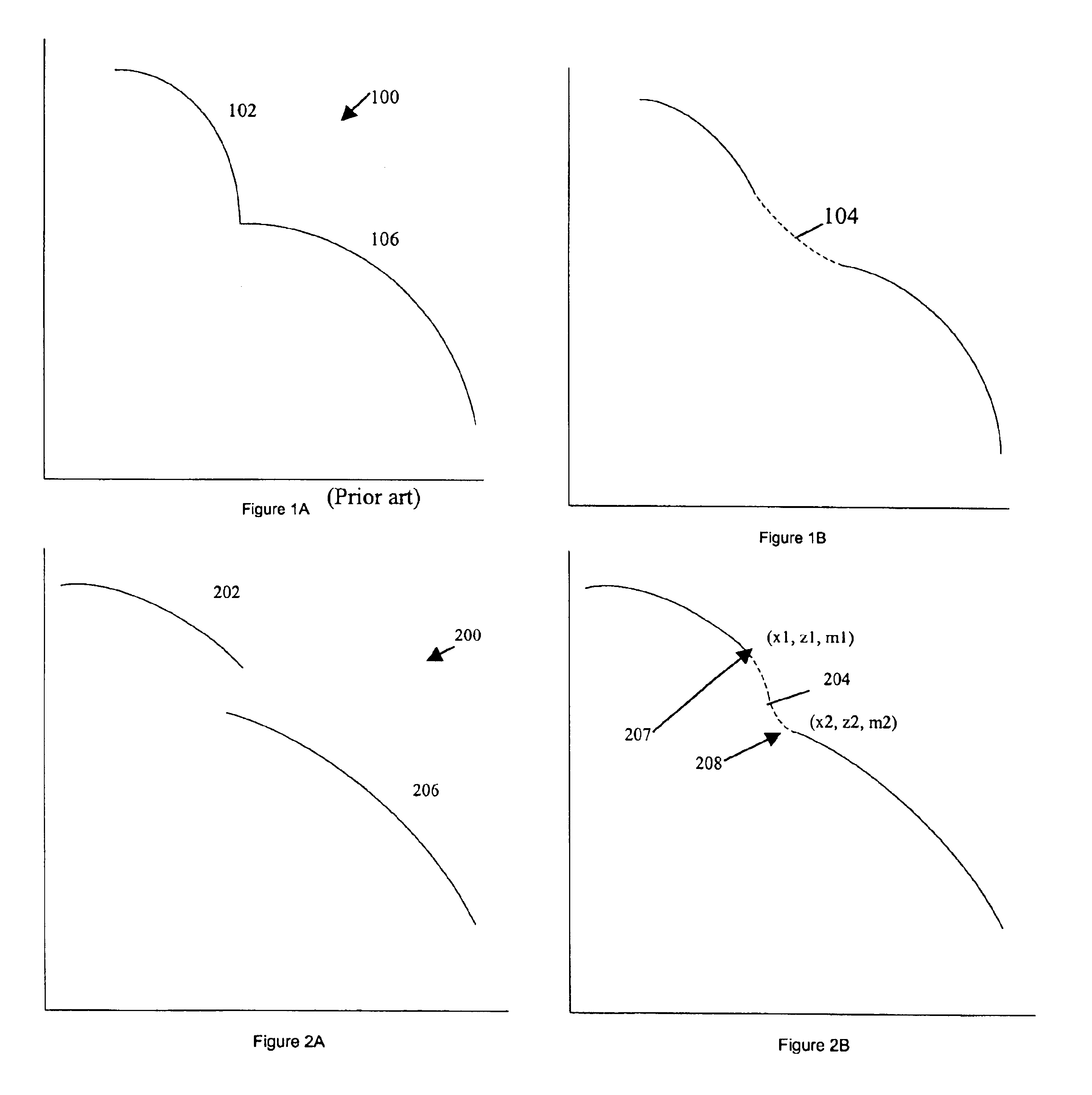

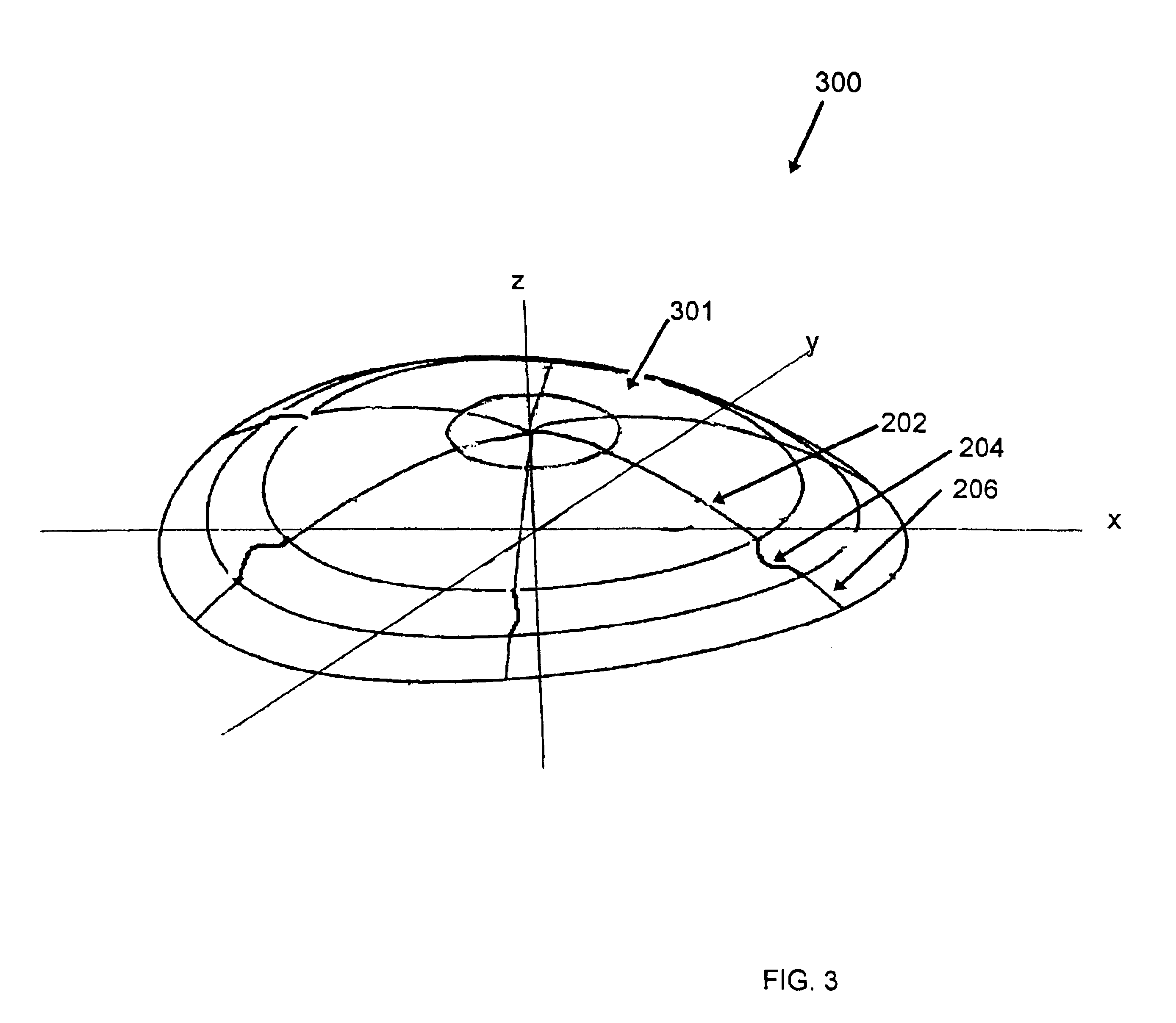

Smoothly blended optical surfaces

InactiveUS6843563B2Improve accuracyMinimum computing timeEye diagnosticsOptical partsEngineeringOptical surface

Apparatus, products, and methods are described that relate to blending various disparate optical surfaces in a smooth and continuous manner. In cross section, the two disparate surfaces are represented as meridional profiles. A blend zone profile is described by a single third-order polynomial. In the case of rotationally symmetric optics, one cross-section suffices for the description of the entire surface. In the case of non-rotationally symmetric optics, an increased number of cross-sections are necessary to produce the desired three-dimensional surface, thus meridional profiles are calculated at selected azimuthal locations to describe the full surface.

Owner:BAUSCH & LOMB INC

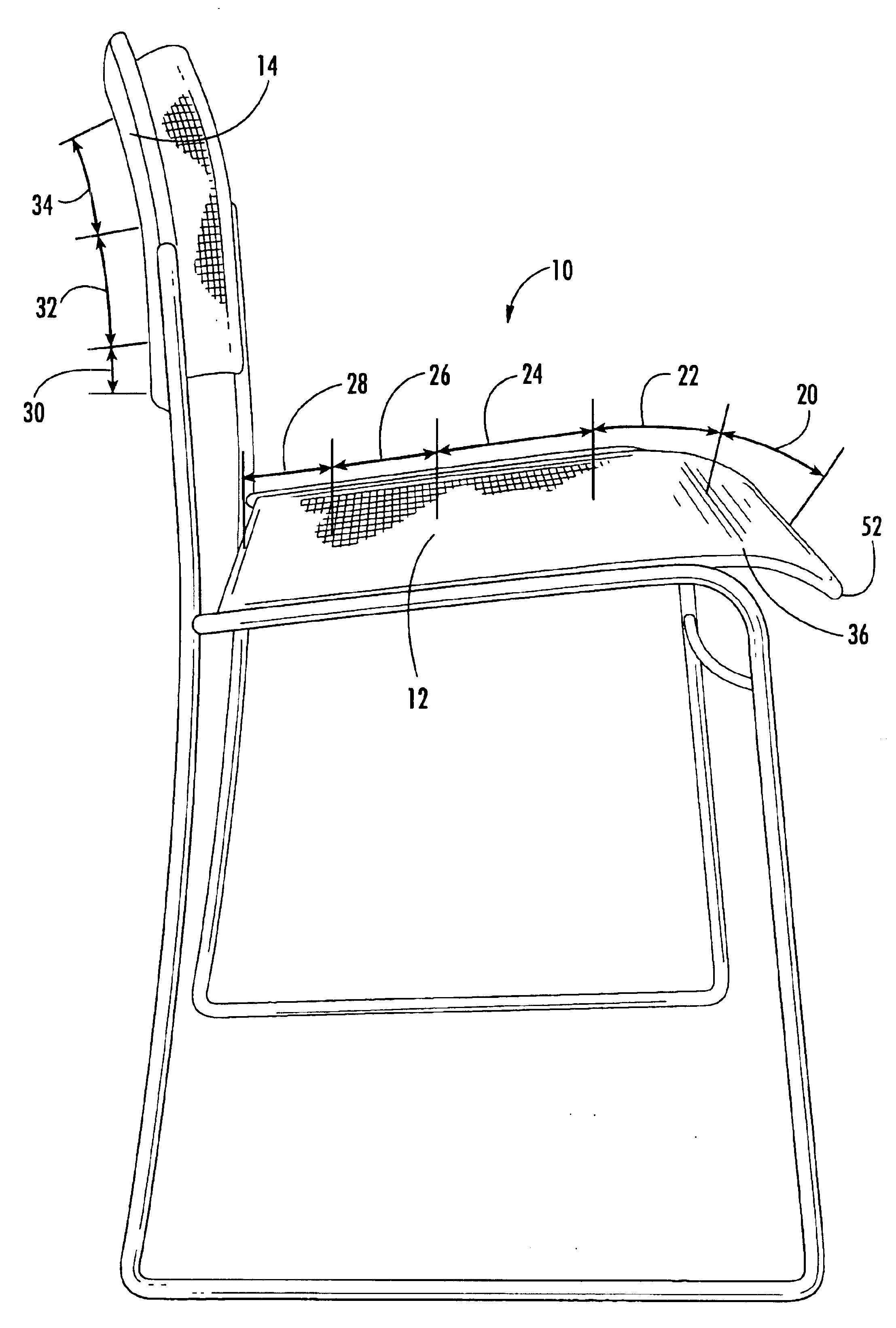

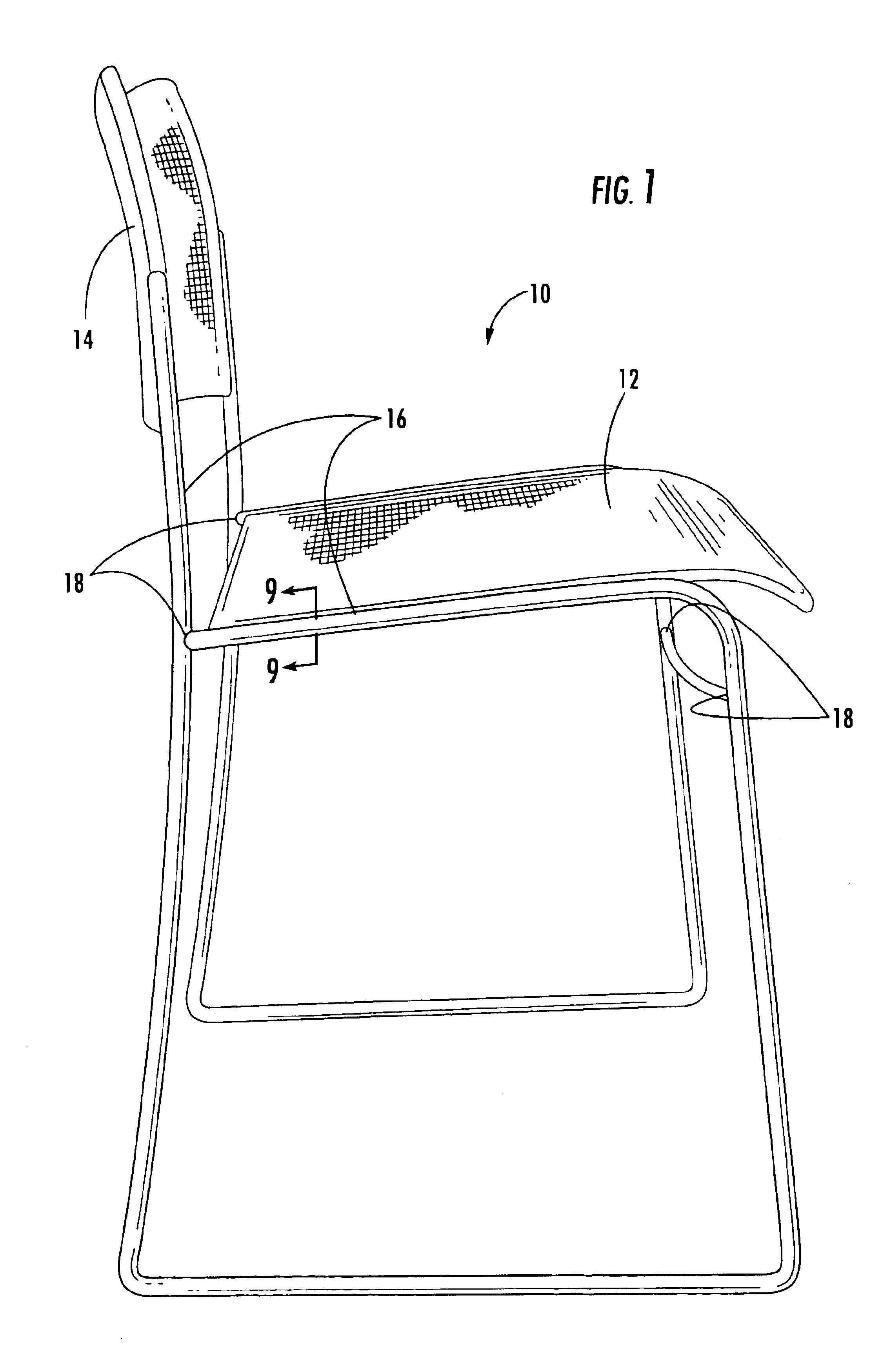

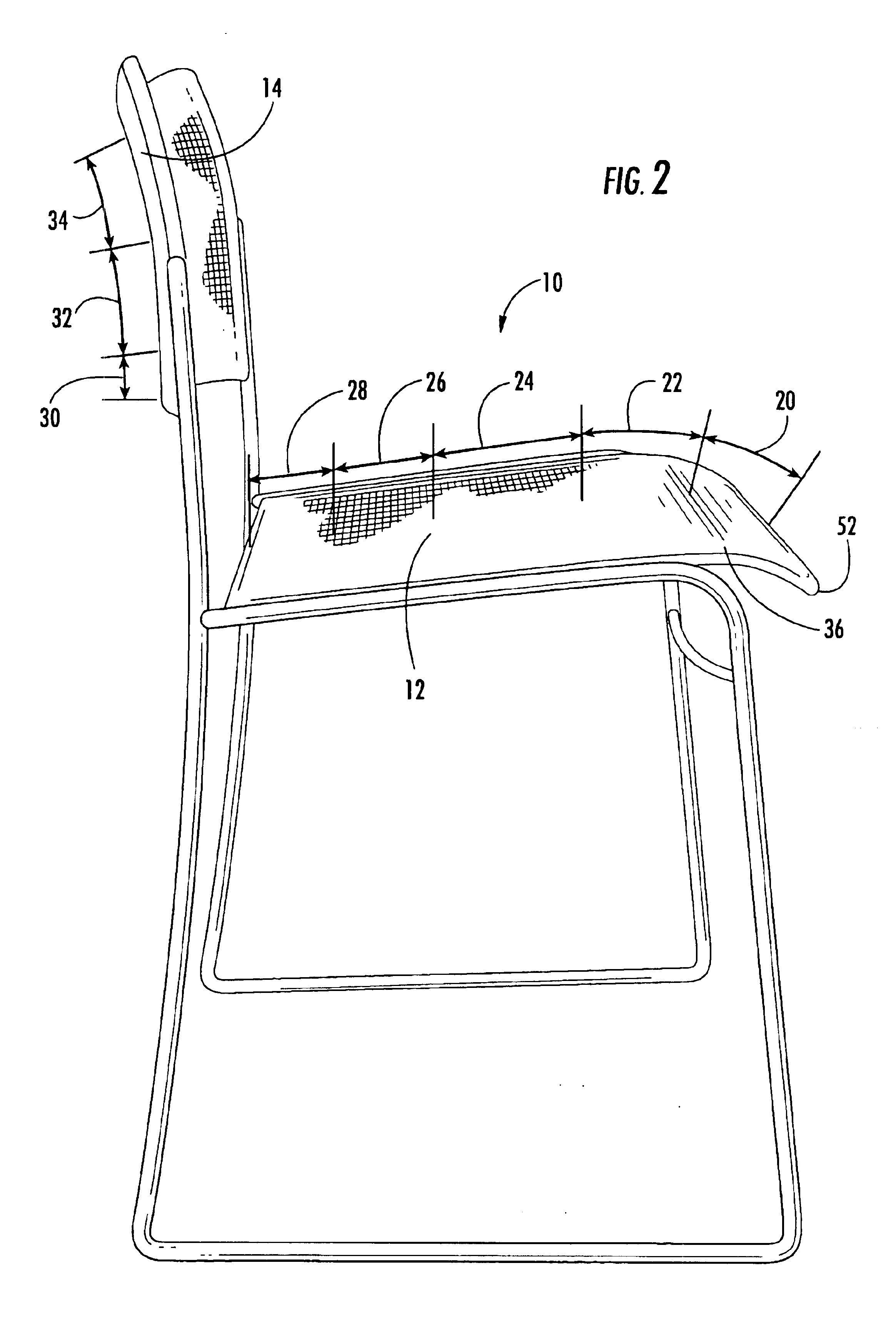

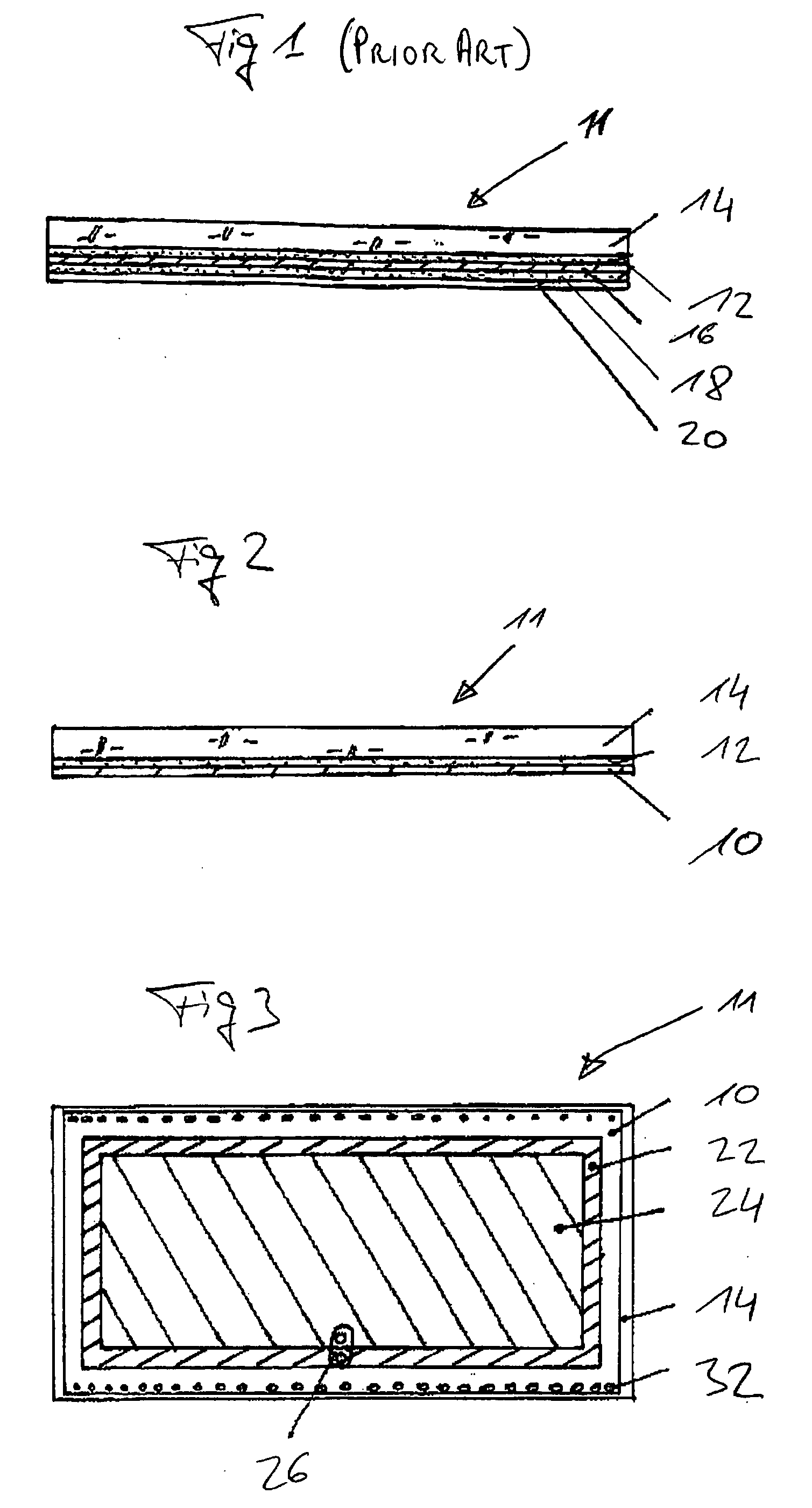

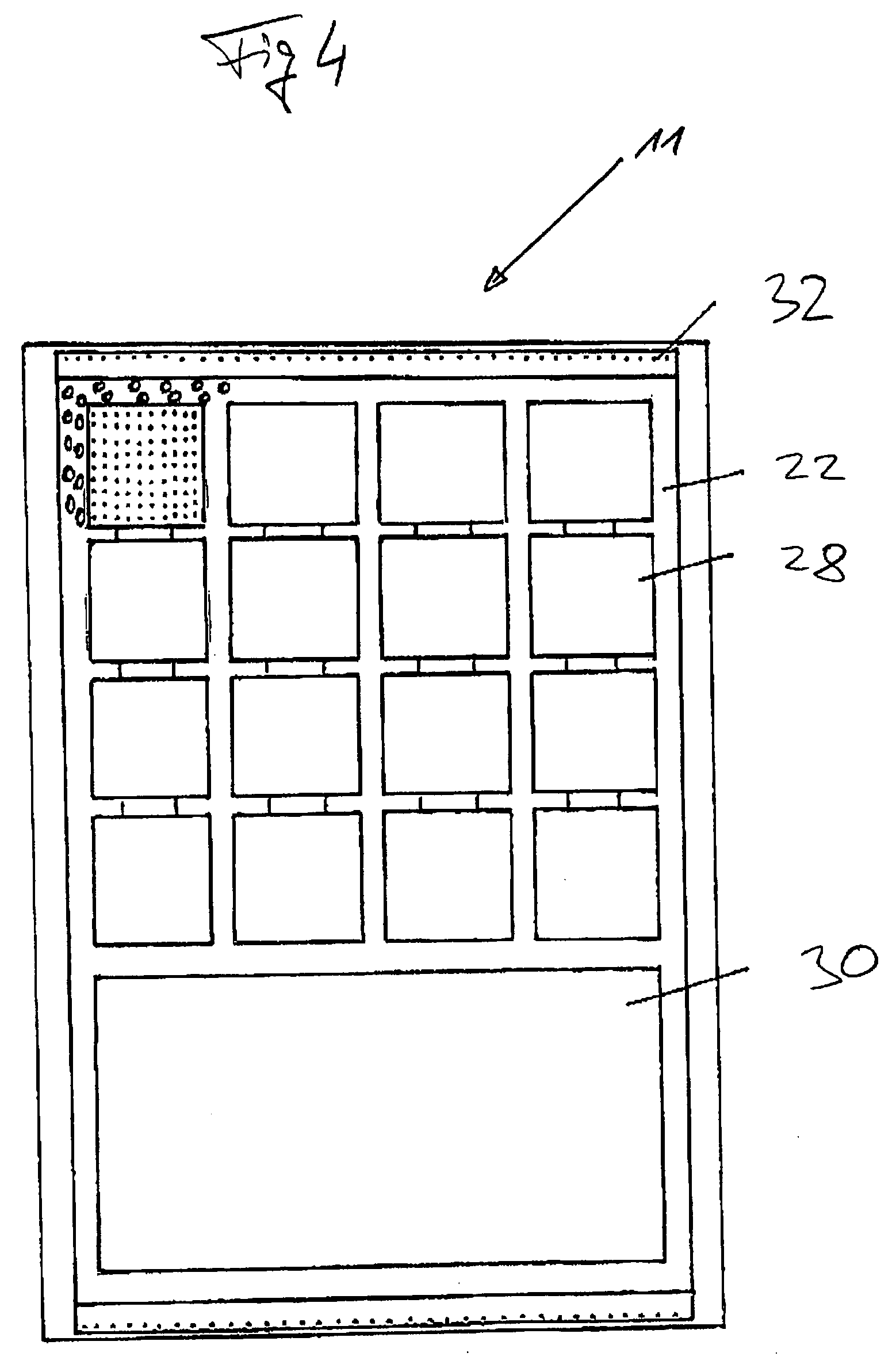

Panel

A panel having particular utility in a chair or other apparatus for receiving an occupant in a seated position includes an envelope of resilient material having an opening with a fastener for closing the envelope. An envelope support frame is substantially rigid and formed in a closed loop. The envelope support frame is positioned inside the envelope to tension the resilient material of the envelope in one or more tension zones. A fastener is closed to envelop the envelope support frame with the resilient material. The width of each tension zone when the envelope is in a its relaxed state is different than the width of each immediately adjacent tension zone.

Owner:DLR DESIGN

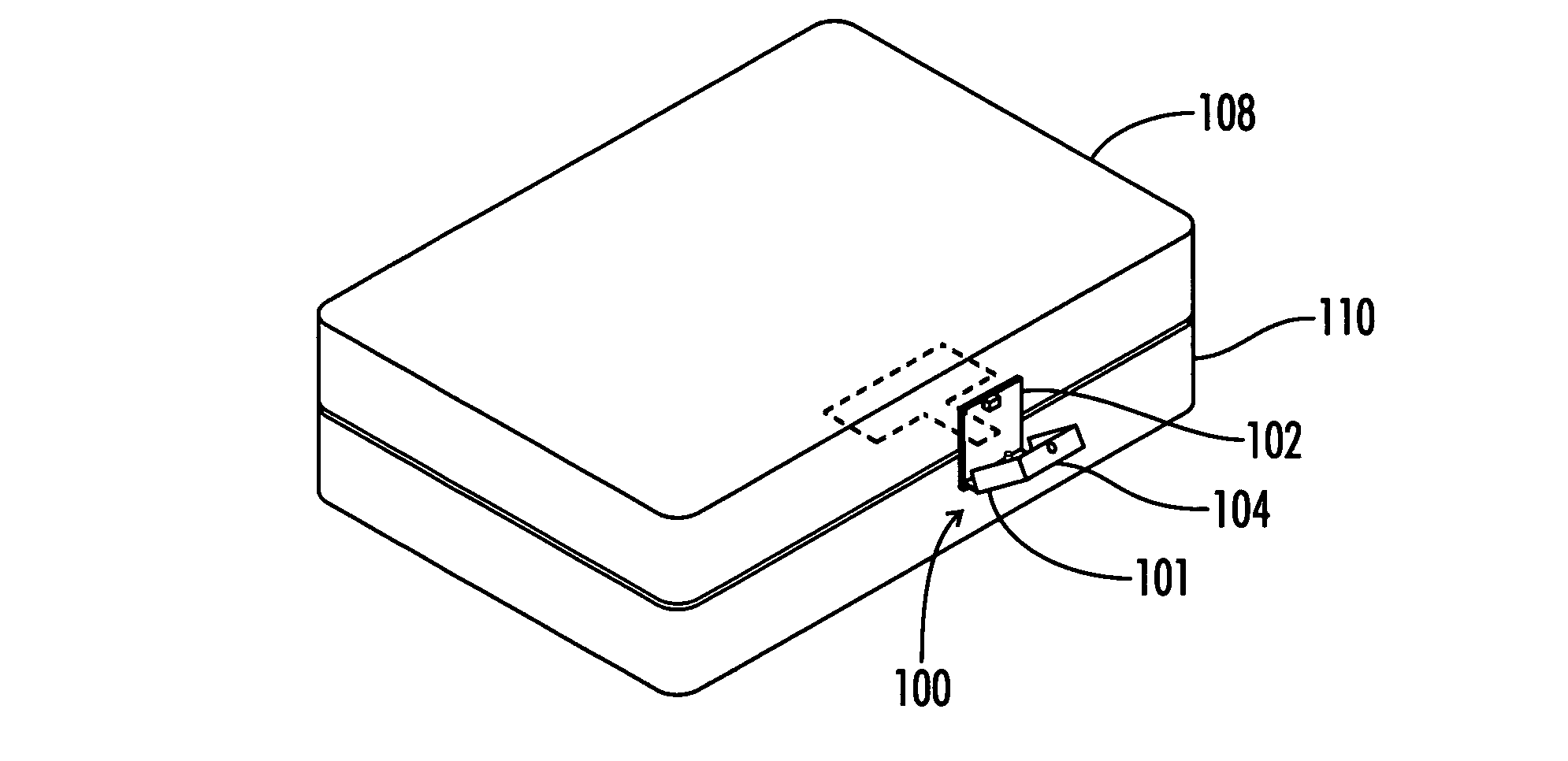

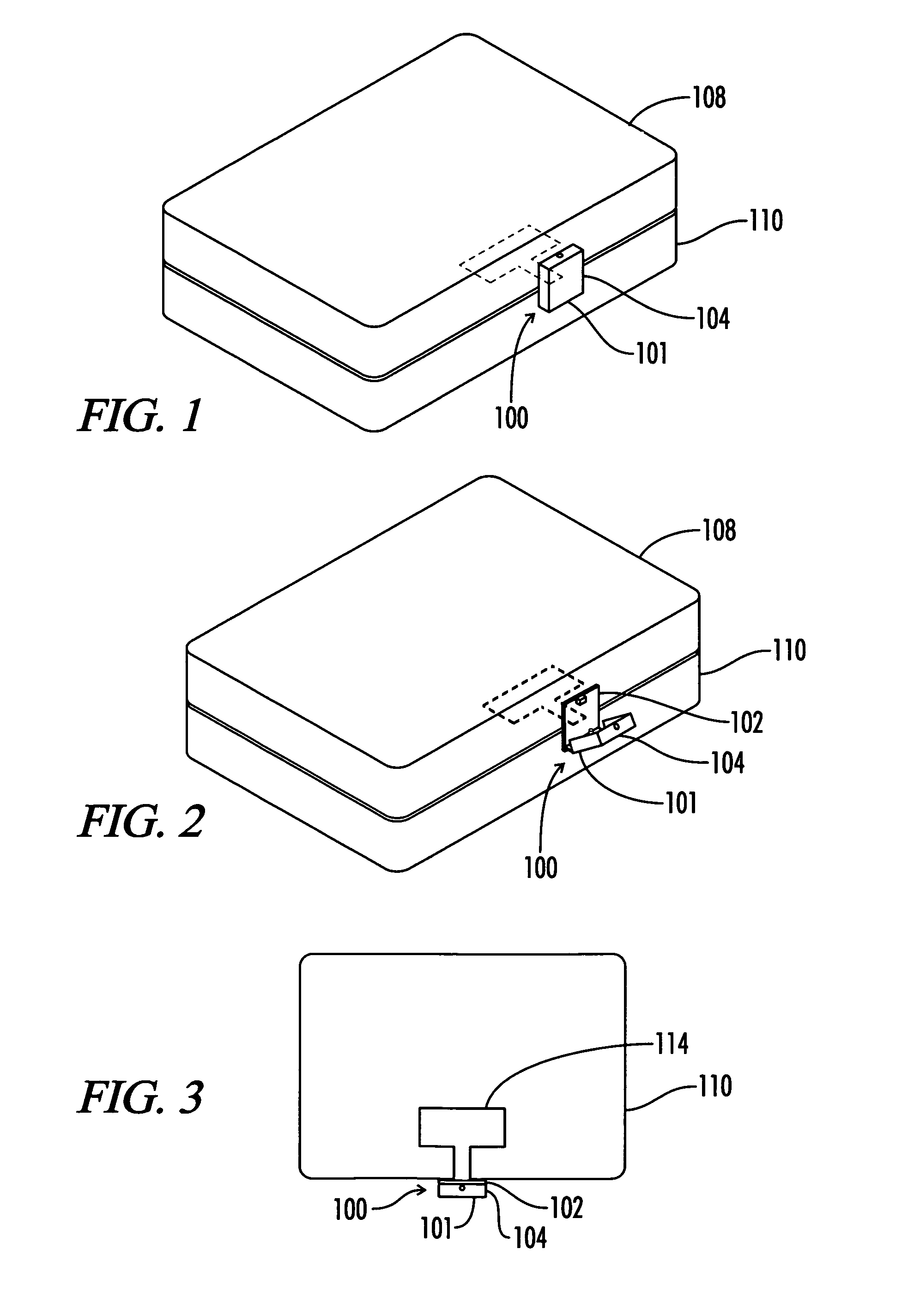

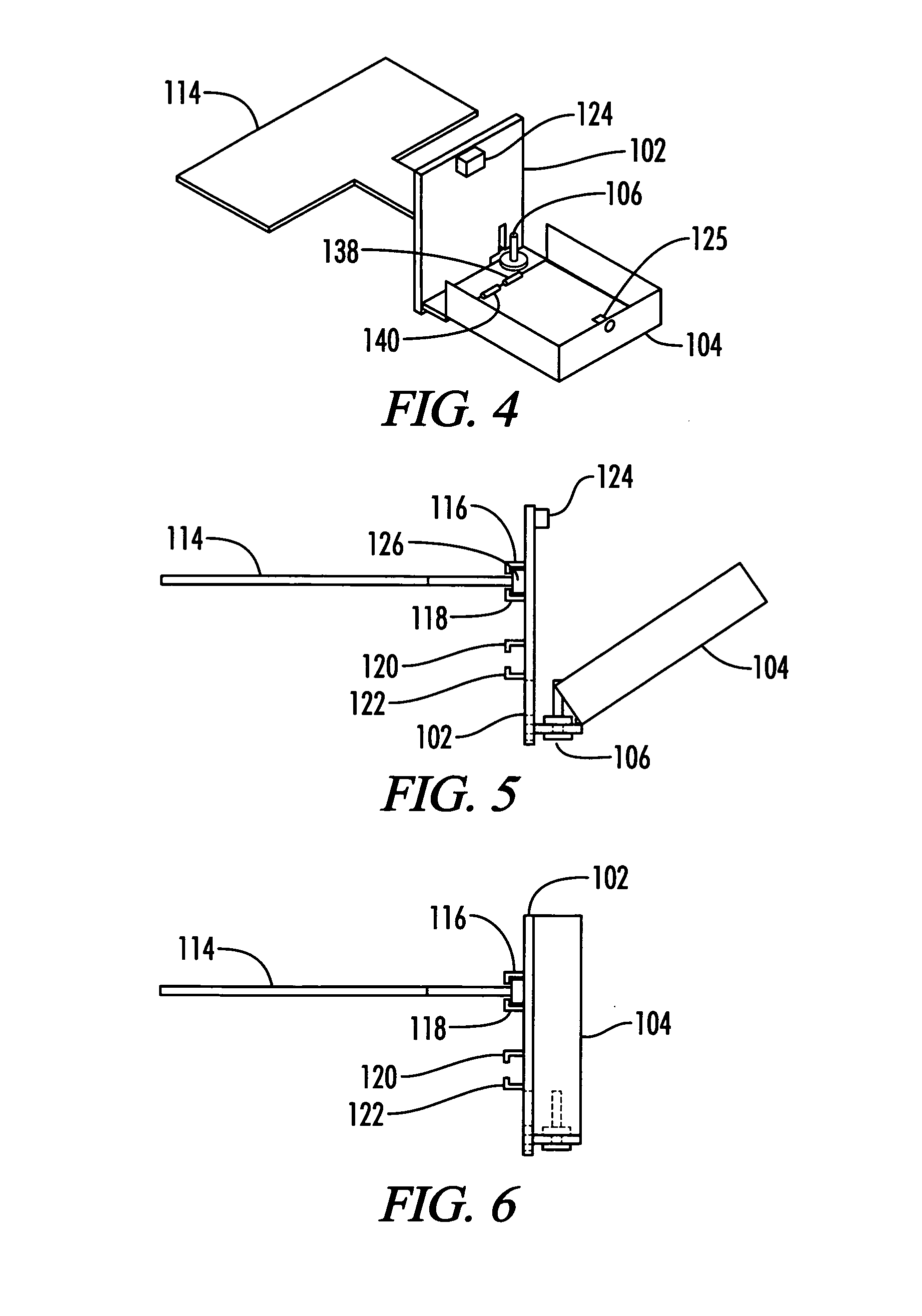

Firearm storage device

InactiveUS8074477B1Easy accessSafe storageClothing locksLocks for portable objectsEngineeringSupport surface

The present invention relates generally to a firearm storage device adapted to store at least one object, including but not limited to a firearm. A housing of the present invention attaches to a support arm located upon a lower support surface. The housing includes a mounting shell wall and a locking shell wall that pivots away from the mounting shell wall to allow access to the contents of the housing. Inside the housing, a support finger engages the interior of the barrel of a firearm to orient the firearm in a manner that provides a user with access to the grip of the firearm. The housing also locks to prevent unauthorized users from accessing the contents of the housing. The housing also releases from the support arm to allow a user to utilize the housing as a secure device to transport an object.

Owner:WEICHE CHRISTOPHER R

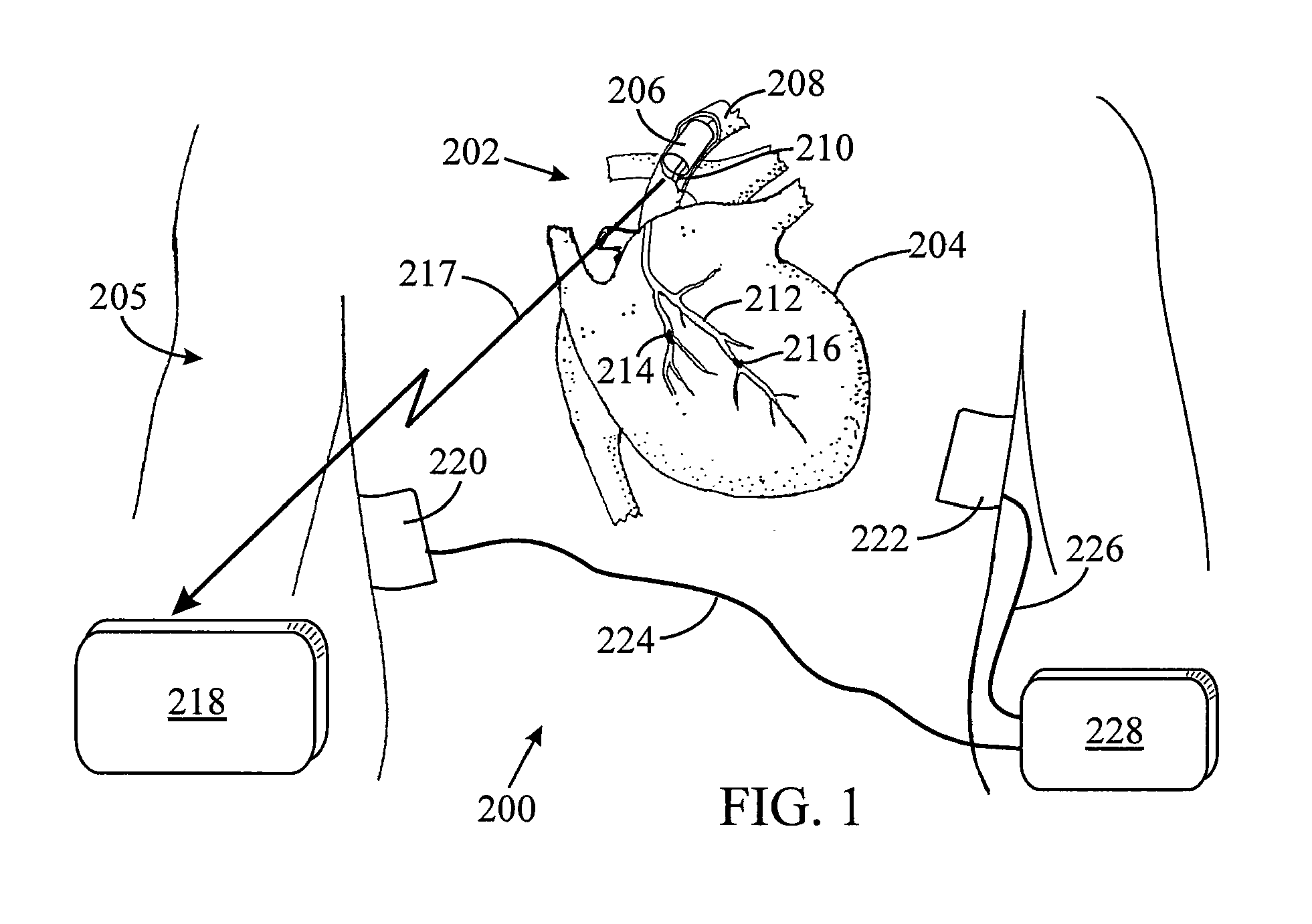

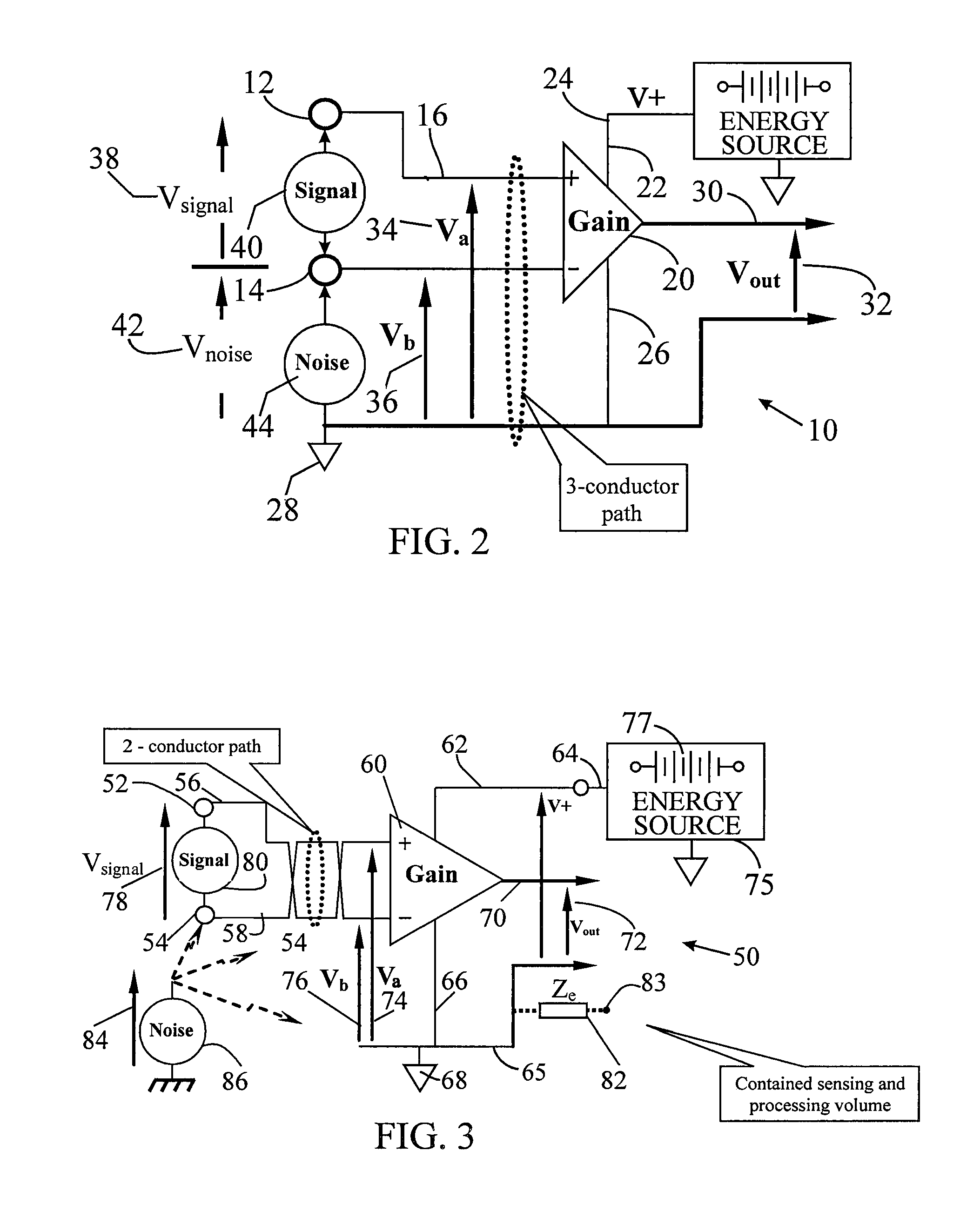

Signal sensing in an implanted apparatus with an internal reference

InactiveUS8366628B2Robust detectionPrevent pick-upElectrocardiographyAmplifier with semiconductor-devices/discharge-tubesInstrumentation amplifierElectrical conductor

An implantable apparatus for sensing biological signals from an animal includes at least two electrodes disposed at locations to sense the biological signals. The electrode locations may be internal or external to the animal. Insulated conductors couple the electrodes via a passive network of filters to an instrumentation amplifier that has an internal voltage reference. Thus a sensed biological signal is filtered and amplified to provide an amplified differential signal. A signal analysis module processes amplified differential signal to determine at least one physiological parameter of the animal. The signal analysis module may include a first derivative zero detector for signal transition detection and feature detection and analysis. The apparatus may also comprise a signal presentation module to display amplified signals and physiological parameters associated with those signals.

Owner:KENERGY INC

Fluid side contamination exclusion sealing lip for radial shaft seals

Owner:FREUDENBERG NOK GEN PARTNERSHIP

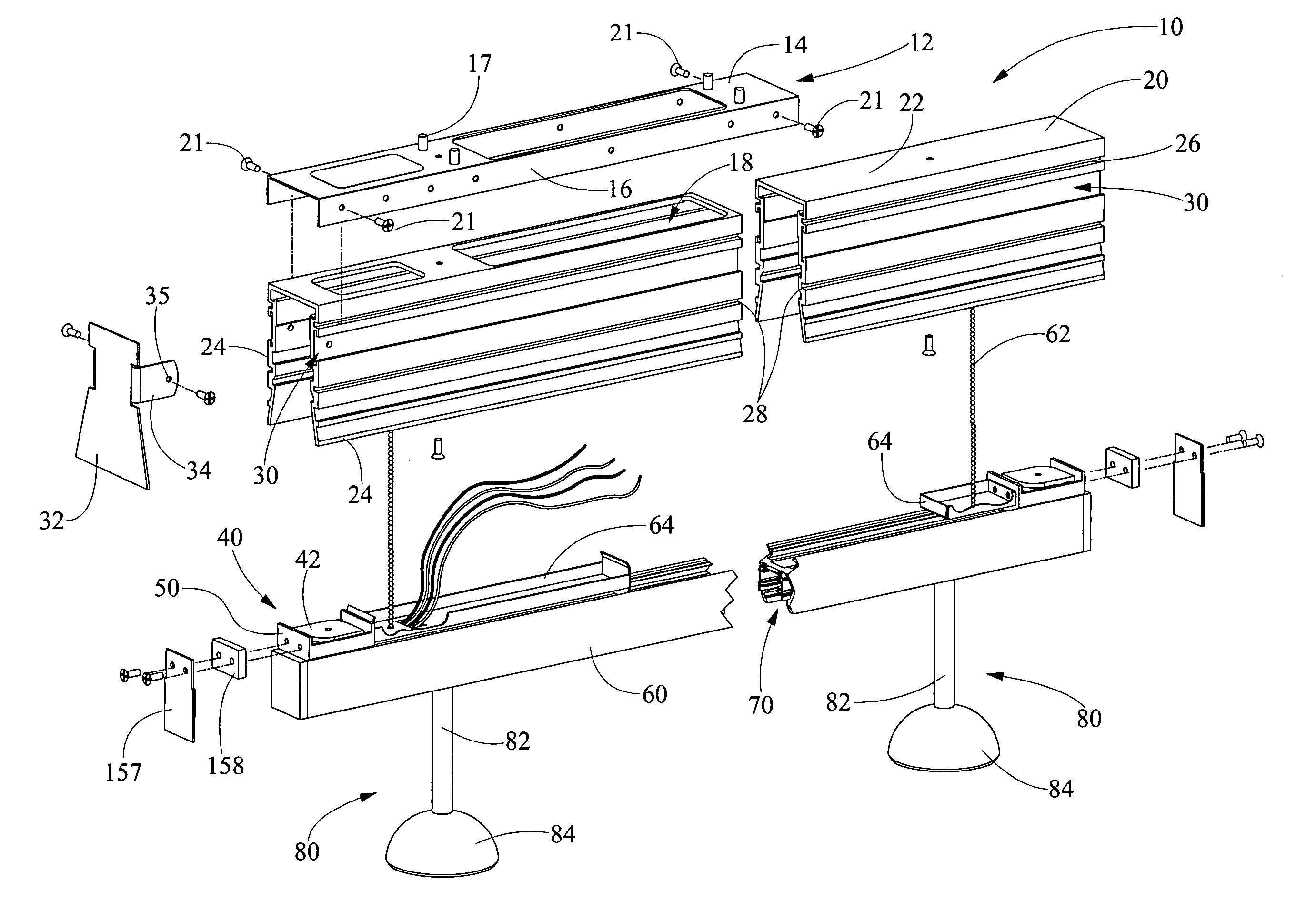

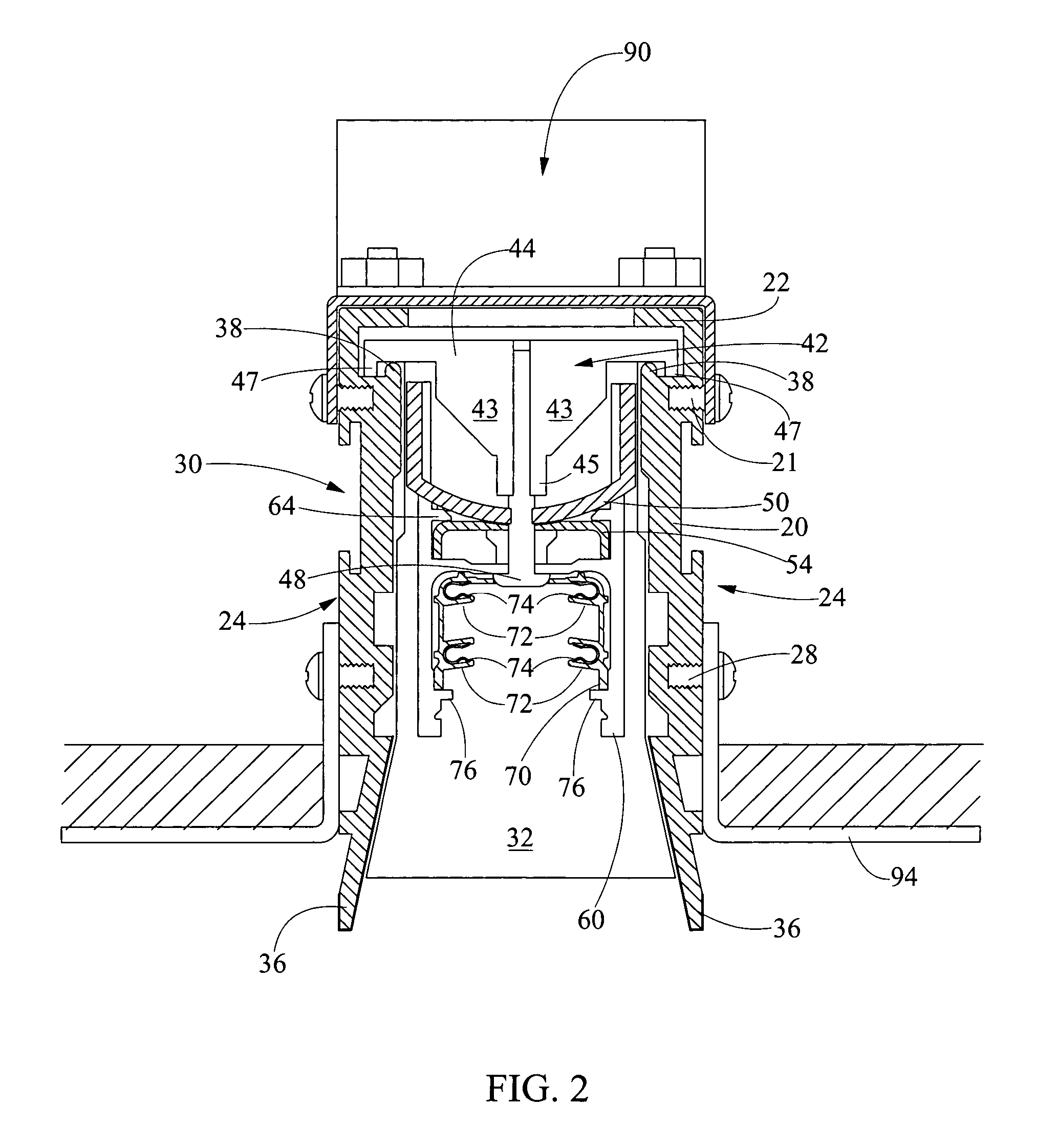

Tilt & lock air handling fixture

InactiveUS20050152132A1Eliminates oversightEliminate difficultiesCoupling device connectionsLighting support devicesLocking mechanismEngineering

Owner:PHILIPS LIGHTING NORTH AMERICA CORPORATION

Padlock with fully integrated dual locking systems

By providing two separate and independent locking systems formed in a single padlock, with both locking systems independently enabling a single shackle latching member to be controllably activated for allowing the single shackle to be released and / or lockingly engaged, an effective, easily produced, multi-purpose padlock is achieved. In the preferred embodiment, a single housing and shackle assembly are employed and constructed for enabling the shackle to be released from locked engagement with the shackle latching member by using either a rotatable dial combination construction or a key activating tumbler construction. In this way, a dual locking and releasing padlock is achieved which virtually eliminates the difficulties typically encountered with known, prior art lock configurations.

Owner:SUN LOCK COMPANY LIMITED -THE-

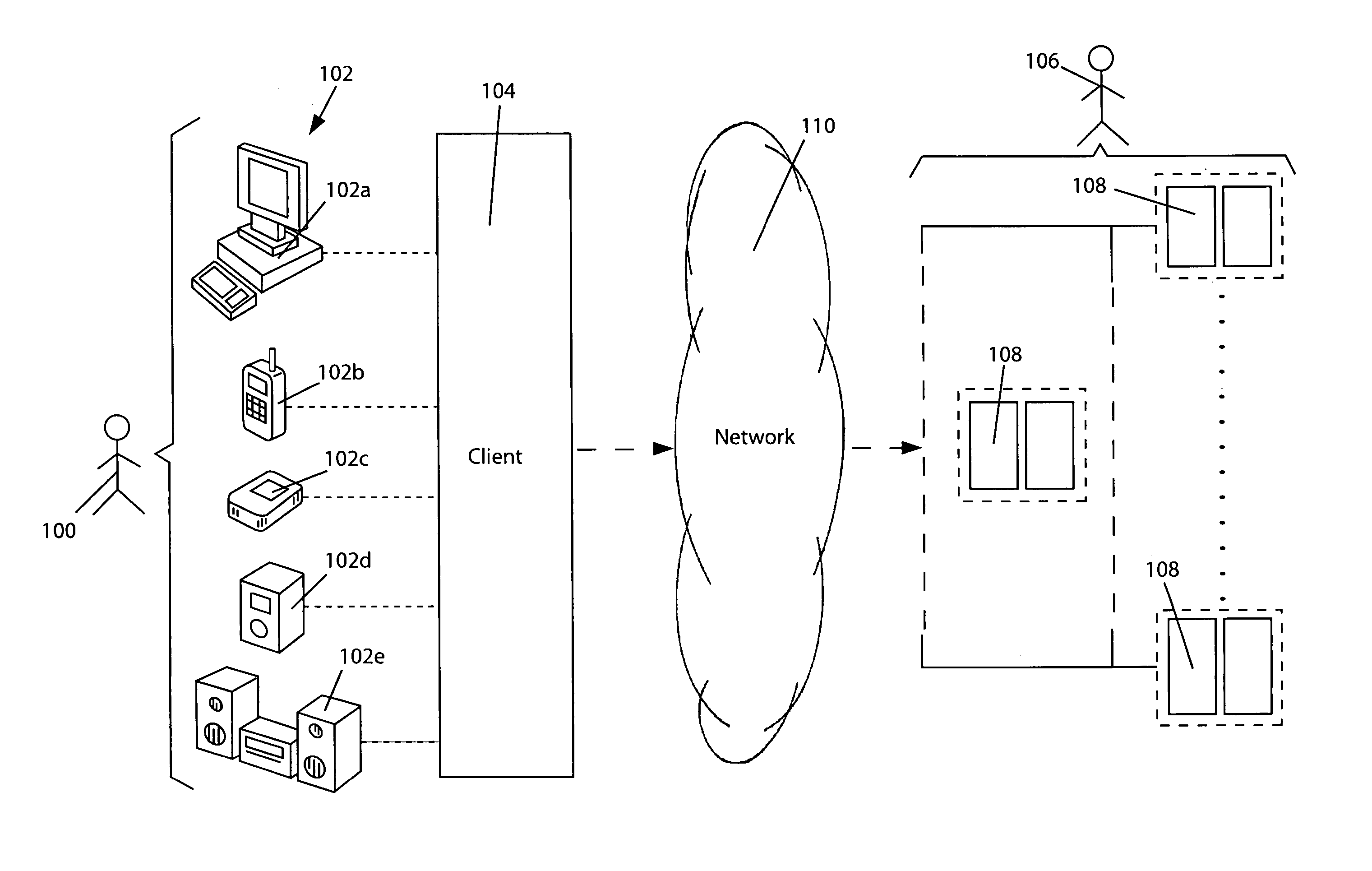

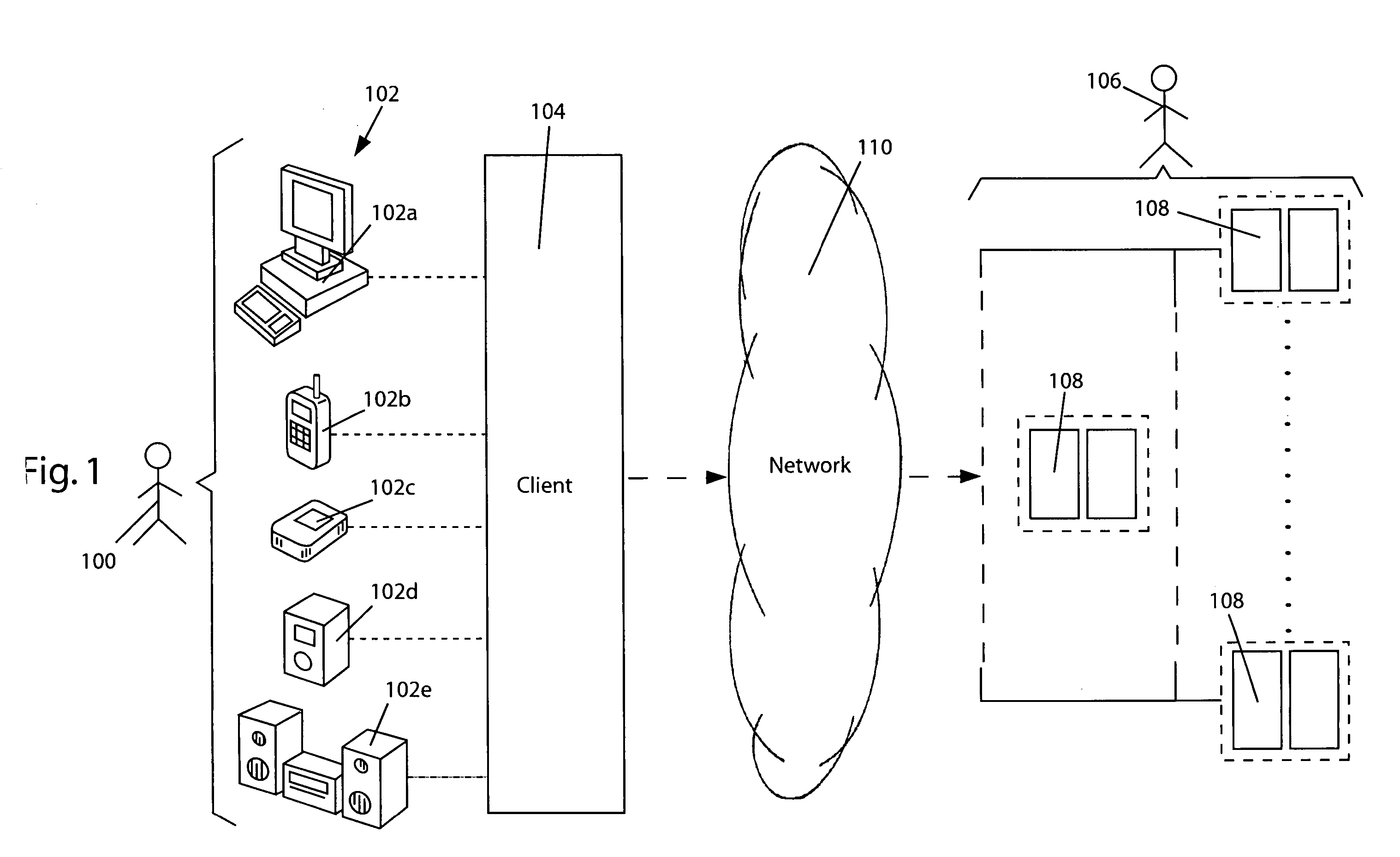

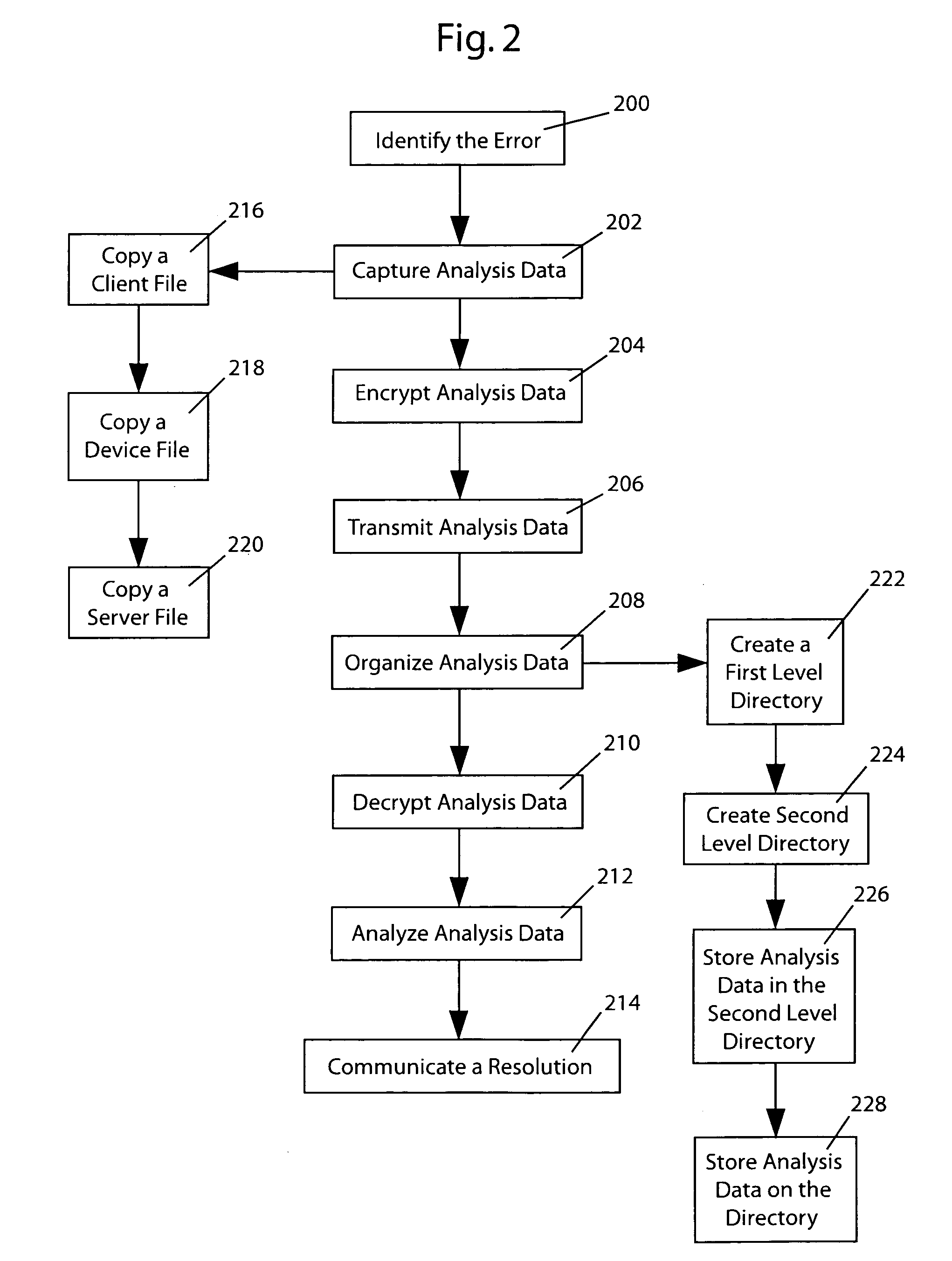

System and method for automatically uploading analysis data for customer support

ActiveUS20060212771A1Control wellReduced and no intrusionError preventionTransmission systemsProblem preventionAnalysis data

The invention enhances automatic incident control, problem control, and problem prevention using information provided by the analysis or analysis data. The burden on the part of both users and providers to resolve problems is reduced by using a method of automatic analysis data upload and intelligent problem analysis and resolution. Problems are better identified, investigated, diagnosed, recorded, classified, and tracked until affected services return to normal operation and errors trends are used to proactively prevent future problems.

Owner:MOON GLOW SERIES 82 OF ALLIED SECURITY TRUST I

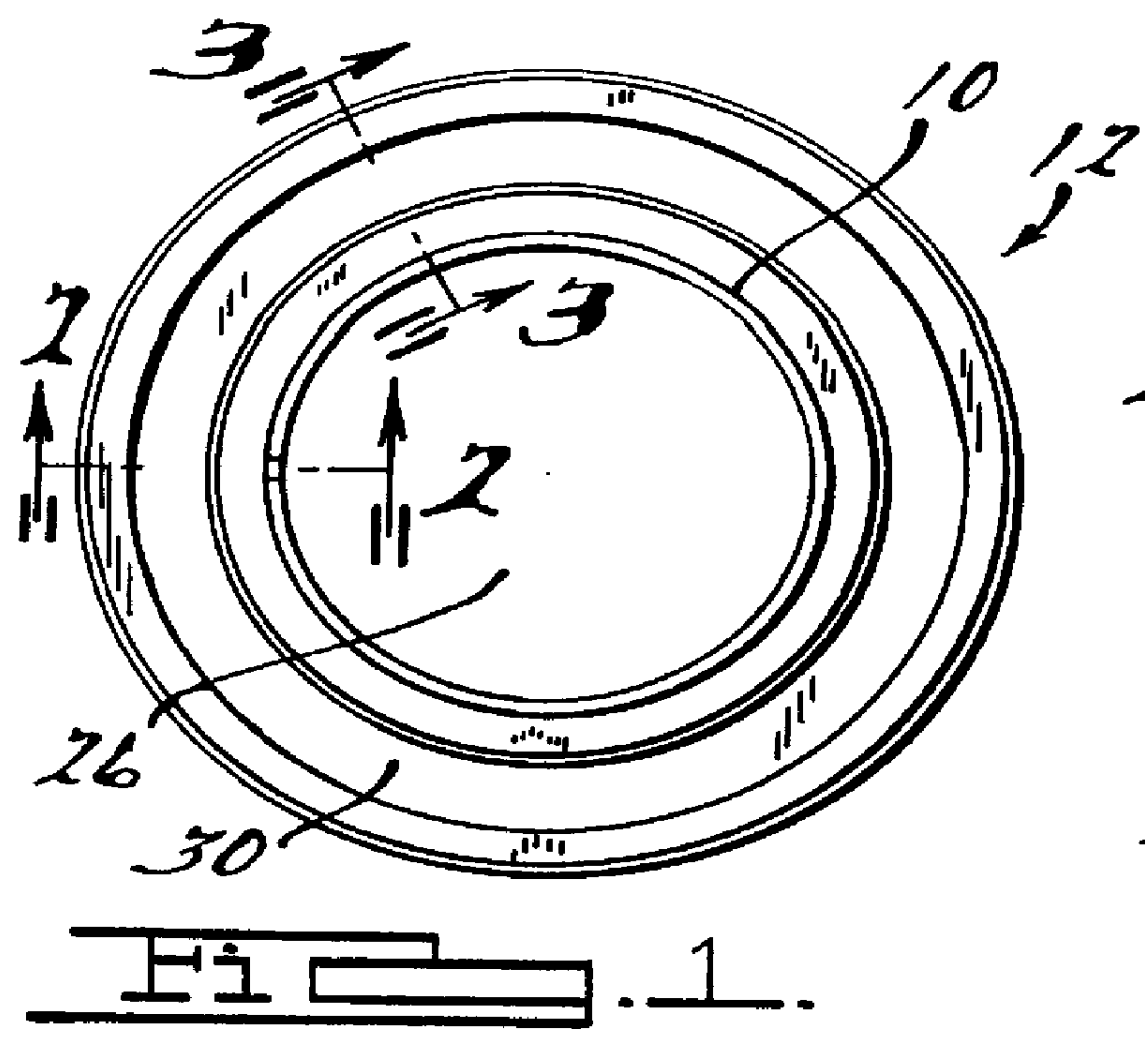

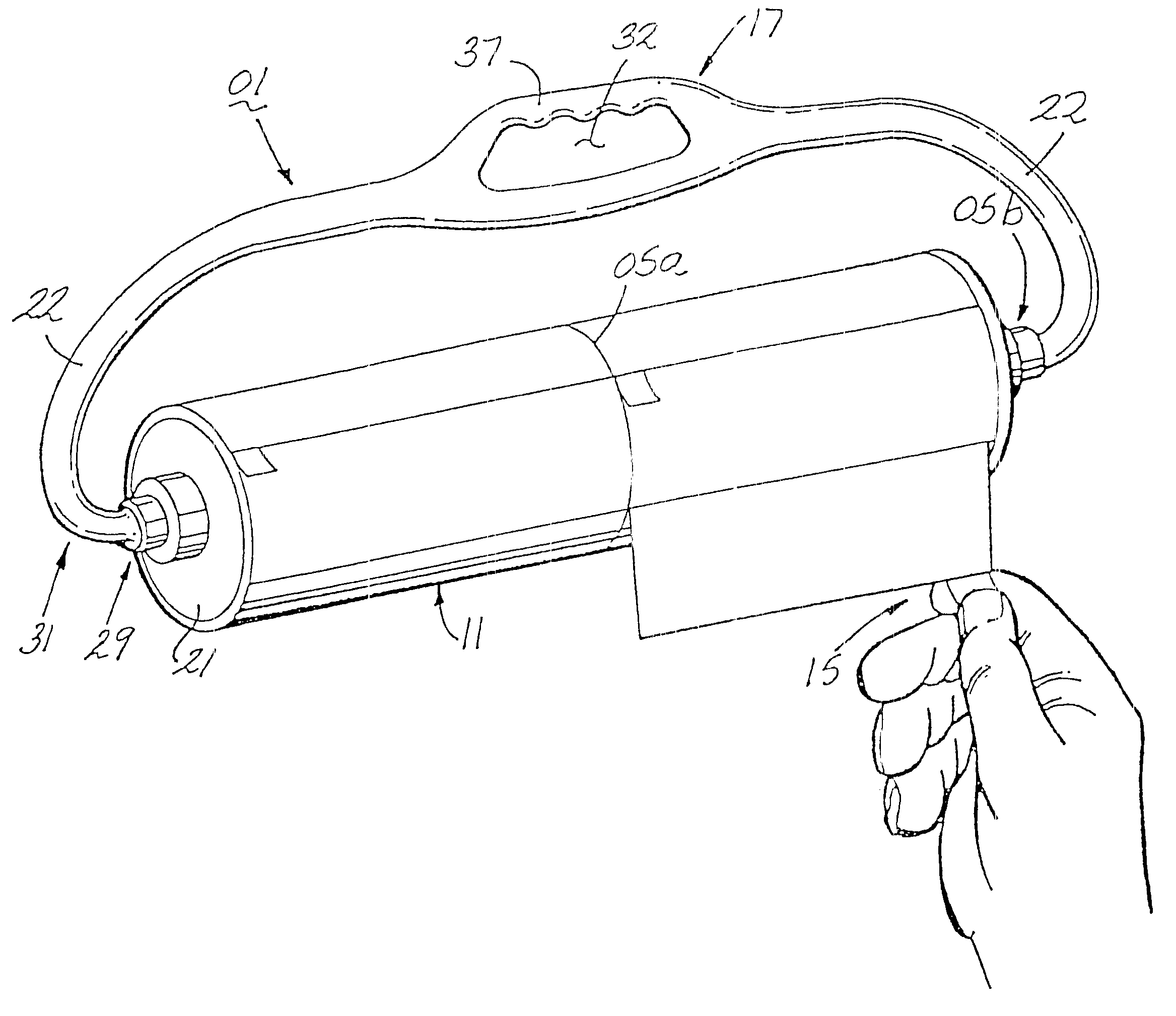

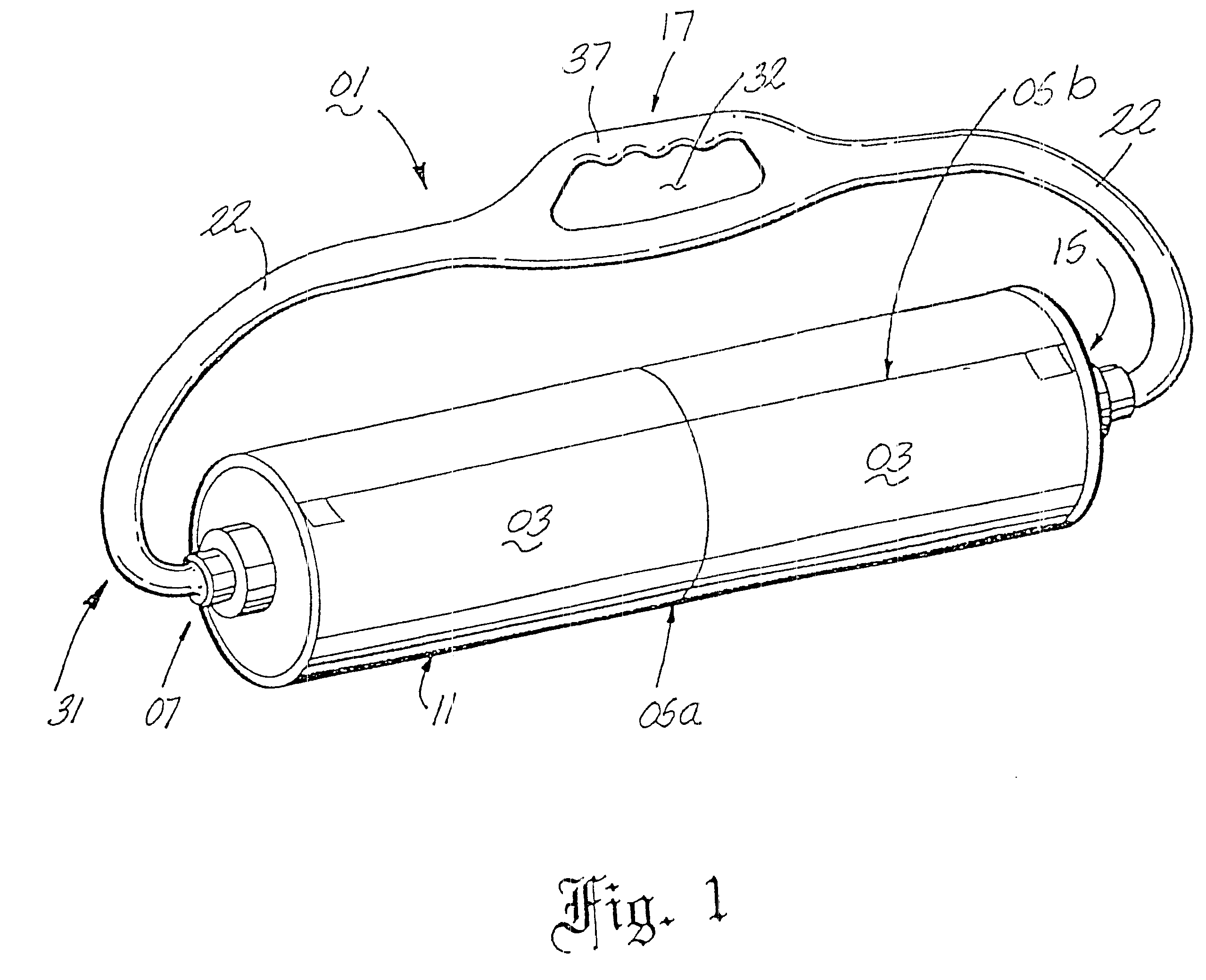

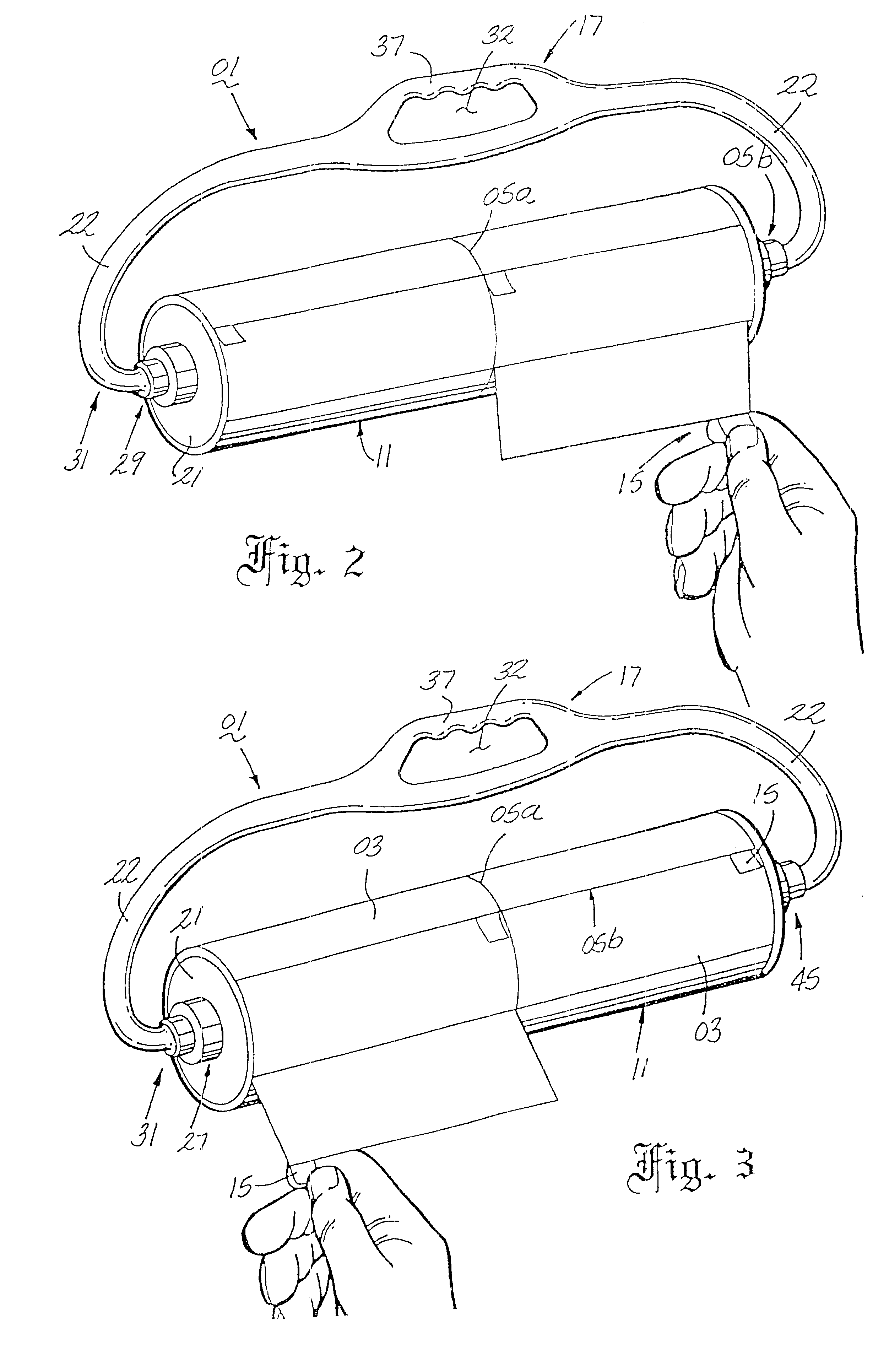

Lint roller

A micro-debris roller having outwardly facing adhesive sheets wound up on a rotatable core is disclosed. Each adhesive sheet includes an anti-bacterial or anti-allergen substance disposed on the outwardly facing surface of the sheets. Each adhesive sheet is further provided with a non-adhesive tab which cooperates with perforations formed in the adhesive sheets to facilitate easy removable of contaminated sheets.

Owner:JAFFRI RUBINA

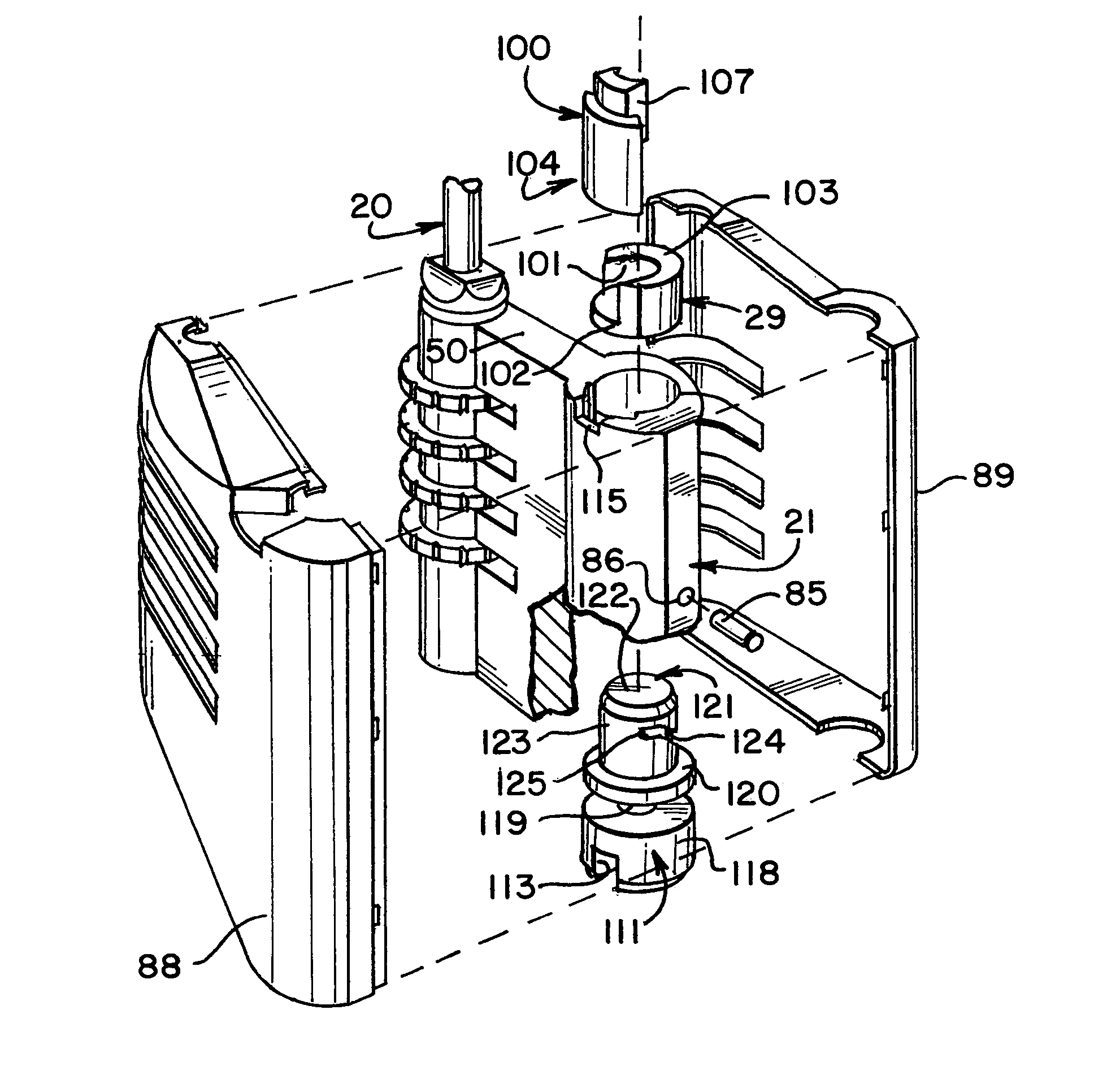

Padlock with fully integrated dual locking system with indicator/signal assembly

By providing two separate and independent locking systems formed in a single padlock, with both locking systems independently enabling the single shackle to be released and / or lockingly engaged, in combination with a signal / indicator system constructed to provide a positive notification when one of said systems is employed, an effective, easily produced, multi-purpose signal providing padlock is achieved. In the preferred embodiment, a single housing and shackle assembly are employed and constructed for enabling the shackle to be released from locked engagement with the housing using either a rotatable dial combination construction or a key activating tumbler construction. In addition, a signal / indicator is activated whenever the key controlled locking section is employed with the signal / indicator being locked in position, for resetting by only the user / owner.

Owner:SUN LOCK COMPANY LIMITED -THE-

Process for producing a cover with a glass pane and electrical function elements

InactiveUS20050001456A1Simple and reliable processEasy to manufacturePV power plantsMetal-working apparatusMobile vehicleEngineering

Owner:WEBASTO AG

Softening lotion composition, use thereof in paper making, and resulting paper product

InactiveUS6207014B1Soft and slippery feelGreat pliancyCosmetic preparationsNatural cellulose pulp/paperFiberLotion

The invention concerns in particular a composition for a softening lotion used in fiber treatment. In the invention, the lotion composition is aqueous and liquid at a temperature of at least 5° C. and comprises, as active substances: (a) one or more saturated linear fatty alcohols having at least 16 carbon atoms, and (b) one or more waxy esters having a total of at least 24 carbon atoms. The application of the invention is to the manufacture of fibrous products such as disposable absorbent paper products.

Owner:COGNIS FRANCE SA +1

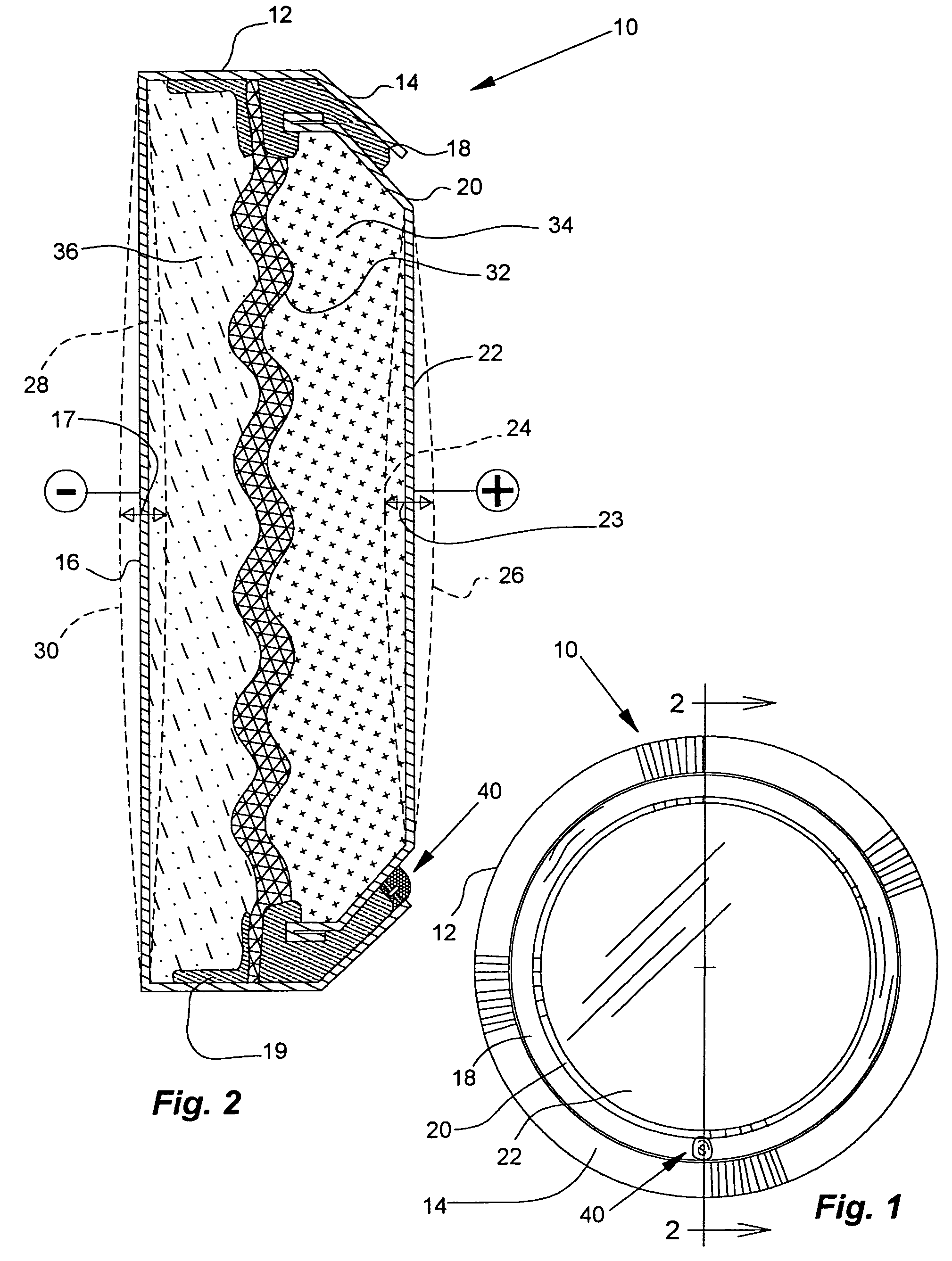

In situ rechargeable battery and charging stand

InactiveUS7705558B2Silenced acoustic feedback “ squeal ”Maximum convenienceBatteries circuit arrangementsCell seperators/membranes/diaphragms/spacersRadio frequency energyCharge current

A secondary button cell battery that is particularly suited for use in hearing aid appliances, and an associated charging station. Recharging is accomplished without direct conductive connection between the source of the energy and either the battery or its appliance. Radio frequency energy is harvested in an enclosed chamber in a charging station and applied to the recharging of the button cell. Such energy is harvested by the use of one or more energy harvesting diodes connected in parallel with the battery. Multiple diodes connected in parallel or serial may be used to adjust charging current or voltage or both. Charge control is provided by directly or indirectly detecting the level of charge on the cell. Where the associated appliance is a hearing aid, the charge level detection may be accomplished acoustically by determining the characteristics of the sound emitted by the hearing aid, and charging is accomplished with the cell within the hearing aid appliance.

Owner:DENOVO RES

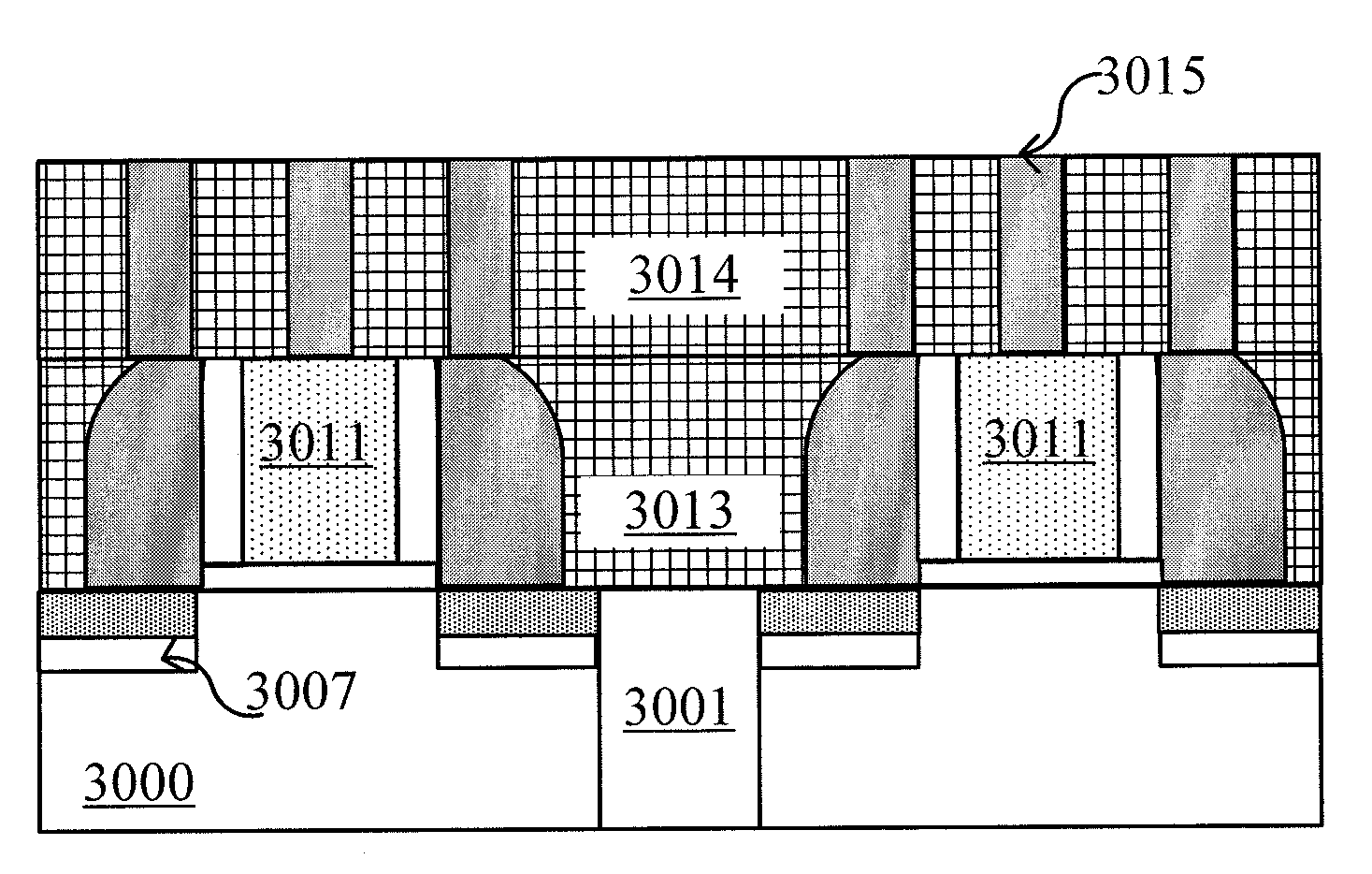

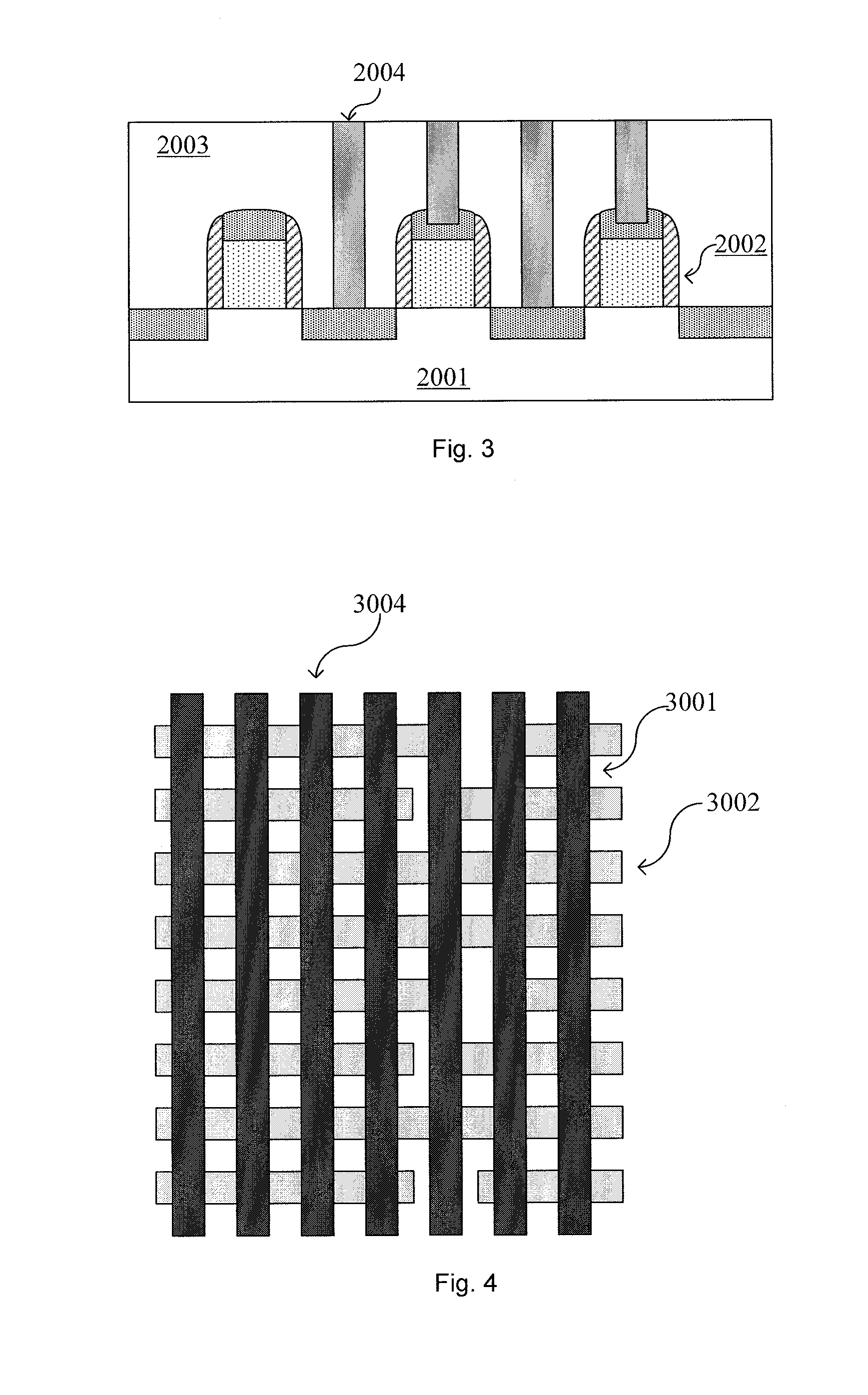

Semiconductor device structure and method for fabricating the same

ActiveUS20120025317A1Simplify formation of contactSimple formatTransistorSolid-state devicesDevice materialEngineering physics

A semiconductor device structure and a method for fabricating the same. A method for fabricating semiconductor device structure includes forming gate lines on a semiconductor substrate; forming gate sidewall spacers surrounding the gate lines; forming respective source / drain regions in the semiconductor substrate and on either side of the respective gate lines; forming conductive sidewall spacers surrounding the gate sidewall spacers; and cutting off the gate lines, the gate sidewall spacers and the conductive sidewall spacers at predetermined positions, in which the cut gate lines are electrically isolated gates, and the cut conductive sidewall spacers are electrically isolated lower contacts. The method is applicable to the manufacture of contacts in integrated circuits.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for Manufacturing a Medical Implant With a Radiopaque Marker

InactiveUS20120292814A1Eliminate difficultiesComplex shapeAdditive manufacturing apparatusSpinal implantsLiquid stateX-ray

A method of manufacturing a medical implant comprising a radiopaque marker is described. The method comprises manufacturing a medical implant using stereolithography, wherein the medical implant has an external surface that delimits an opening to a channel. A curable mixture of a biocompatible polymer and a radiopaque material is then inserted into the channel while in a liquid state and cured in the channel so that it solidifies in the channel.The combination of an implant manufactured by stereolithography and a radiopaque marker which is inserted into the channel in a liquid state enables complex internal structures to be formed in the implant for the radiopaque marker and for the marker to take on those complex forms more easily. This allows a better visualisation of the marker under X-Ray or other medical imaging technique.

Owner:MEDOS INT SARL

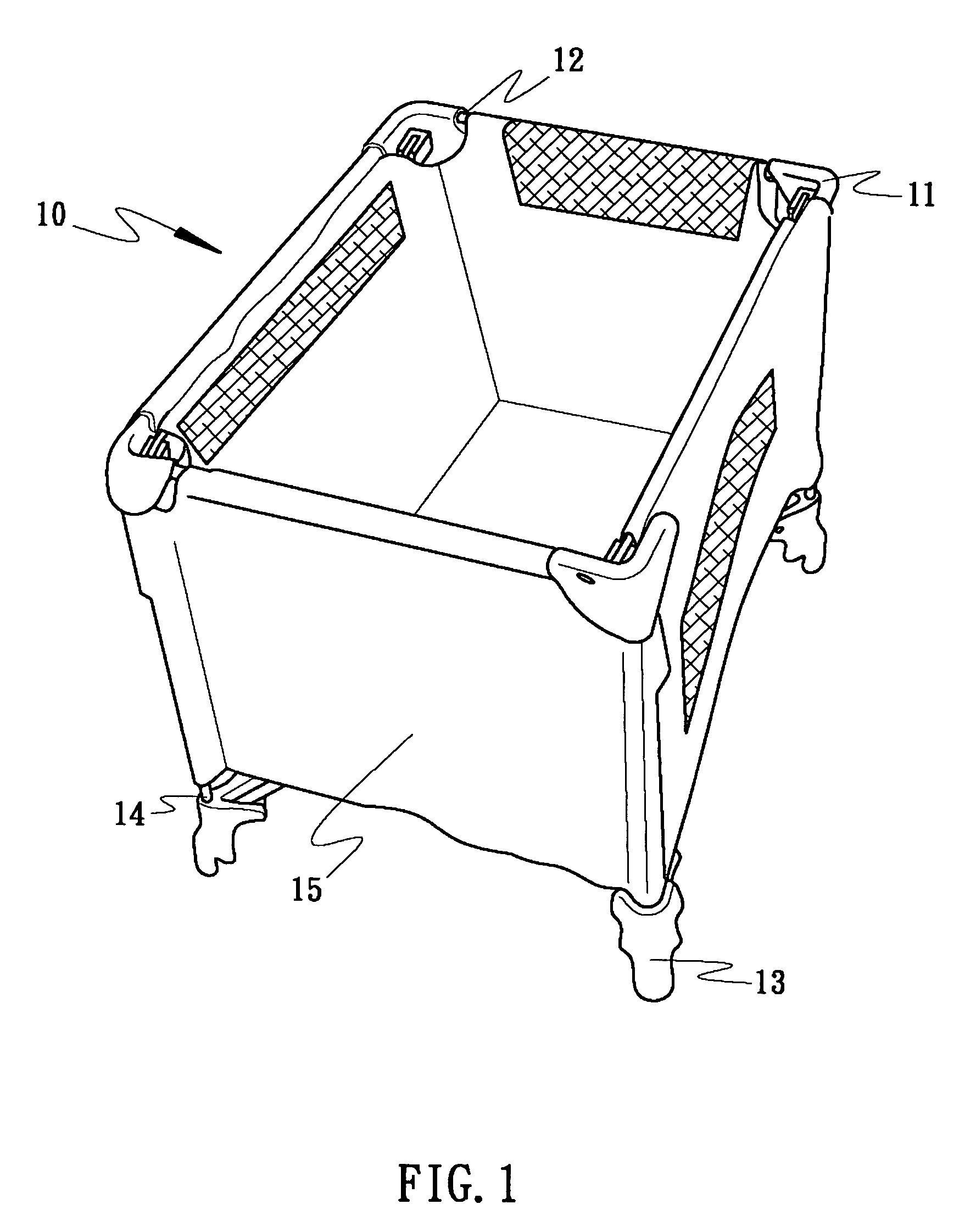

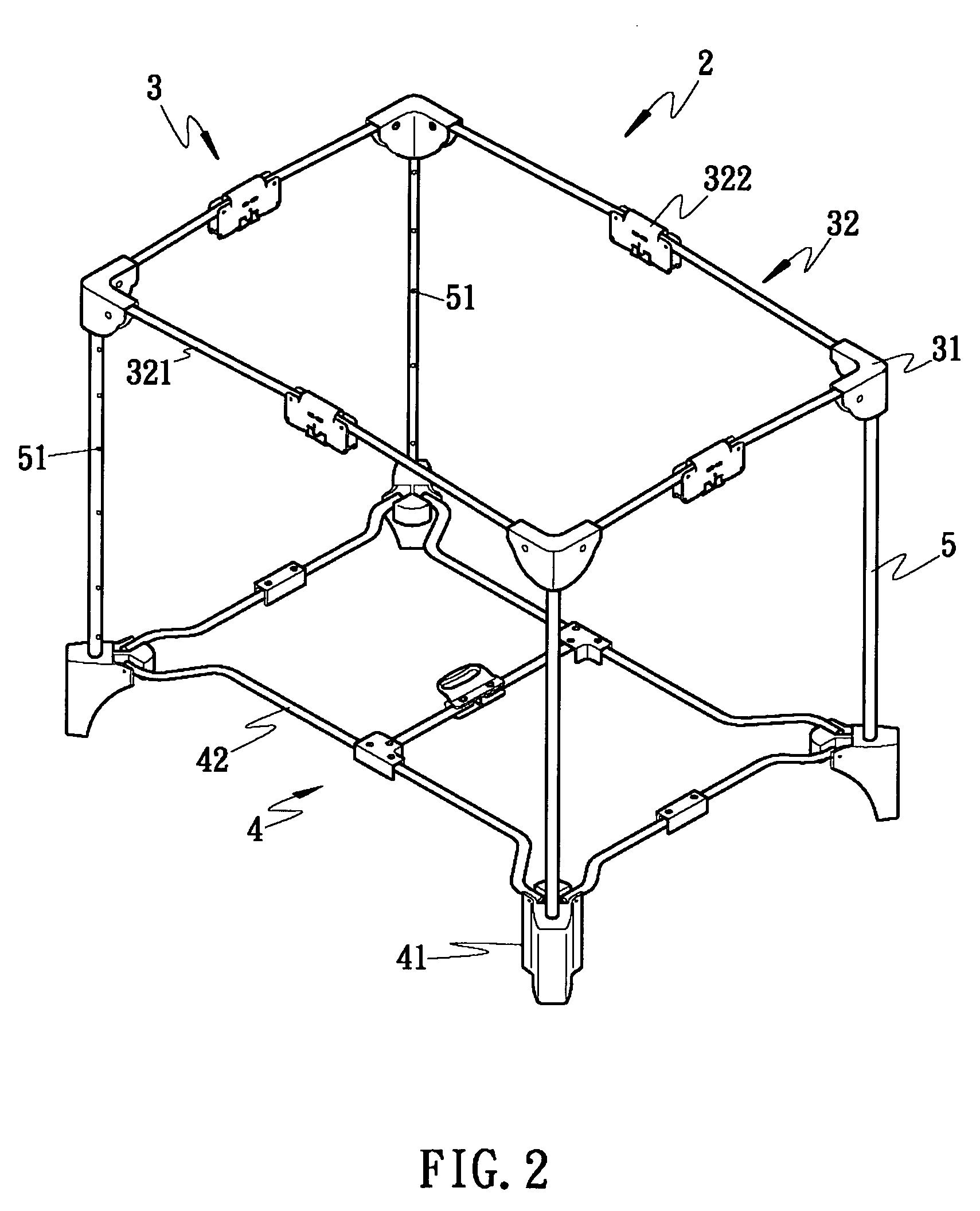

Fabric connecting structure for playyard

InactiveUS20050262629A1Easy to assemblePreventing undesired contamination of the fabric during assemblyKids bedsSofasFastenerEngineering

This invention relates to a fabric connecting structure for playyard, particularly to one where the fabric joints are caught to the inner side edges of the upstanding legs, wherein a catch portion provided to inner edges of upstanding legs of the folding frame, and a catch member provided to corresponding corners of the fabric are able to engage each other such that the fabric may either be removably retained to the upstanding legs before or after completion of the assembly so as to improve convenience during assembly and application convenience. Furthermore, the four side panels may be provided at top edges thereof and the bottom at the lower edges thereof with removable fasteners such that after completing assembly of the folding frame, the fasteners may encase over and fasten to the top folding rails and bottom folding assembly. Accordingly, this invention permits encasing of the fabric over the folding frame after completing assembly of the folding frame and prevents undesired contamination of the fabric during assembly.

Owner:LINK TREASURE

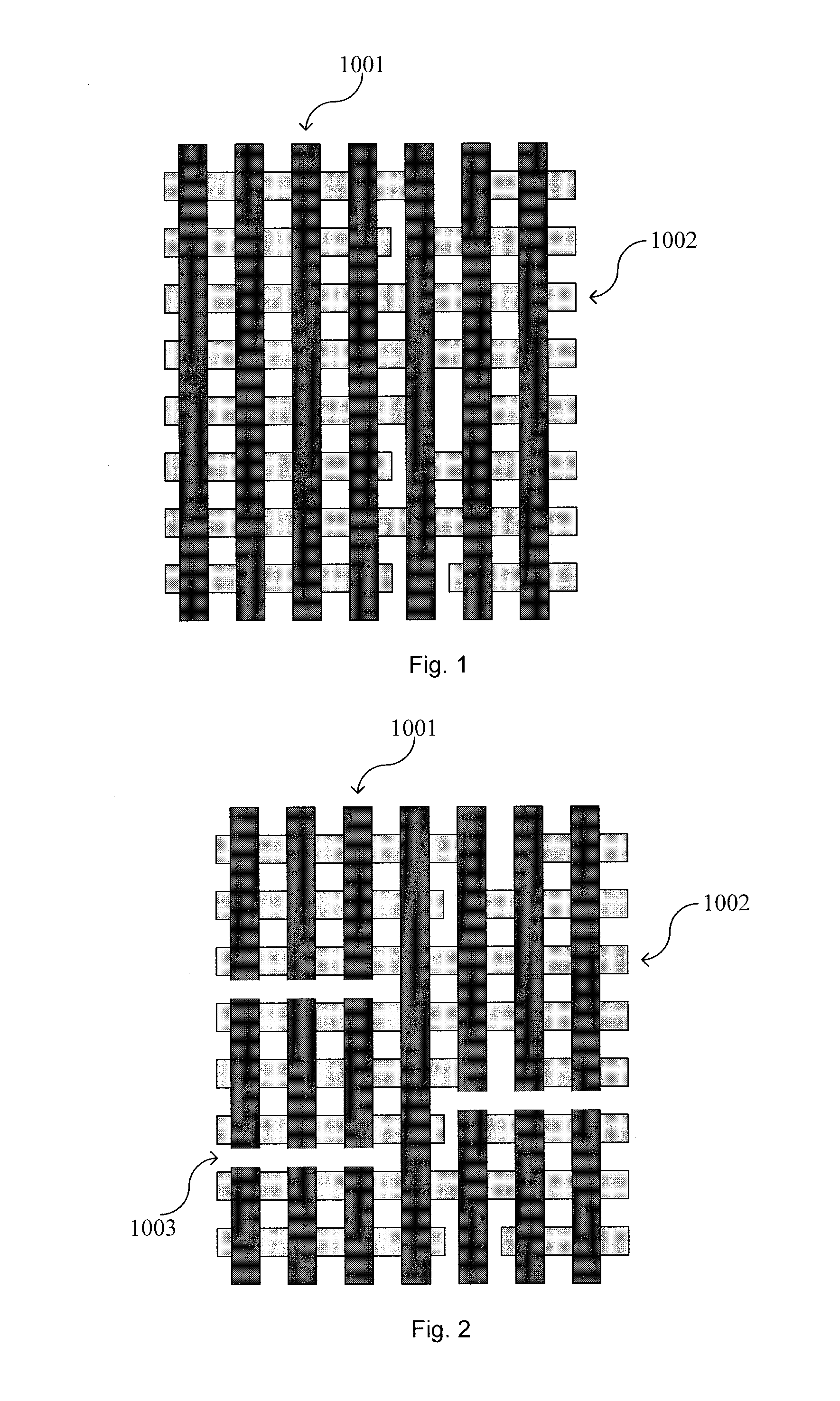

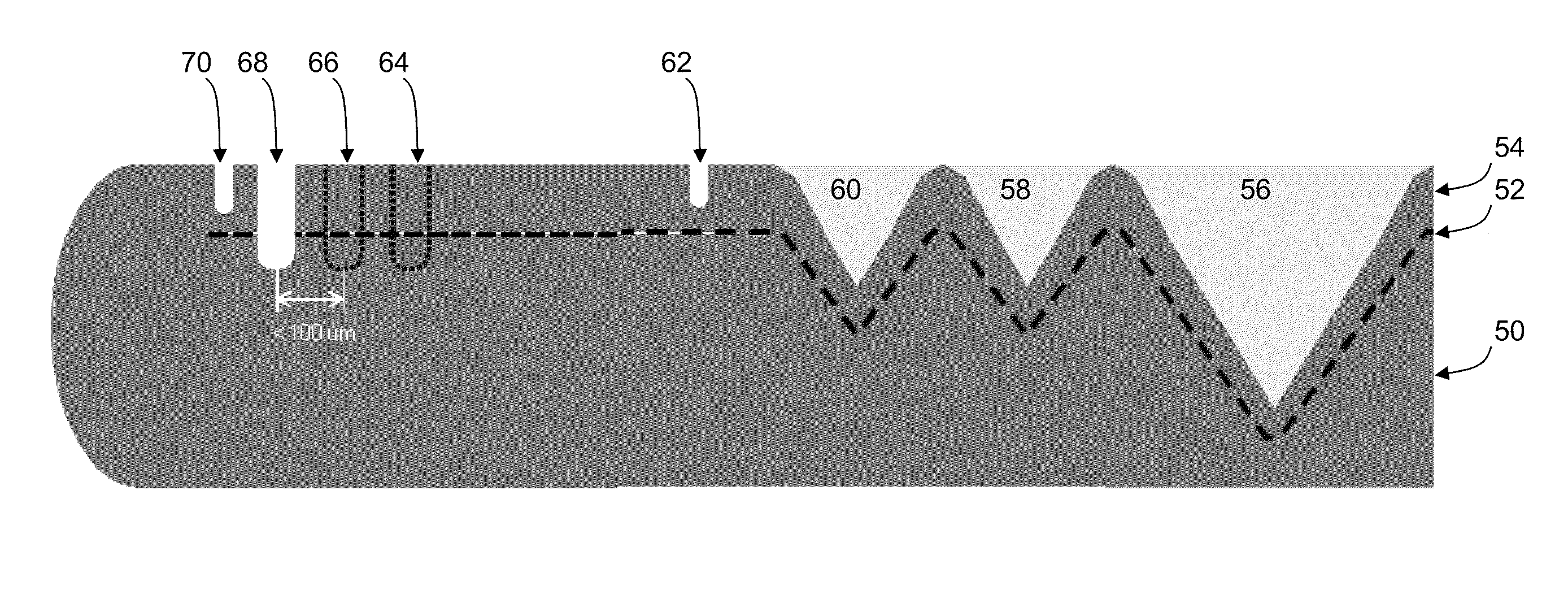

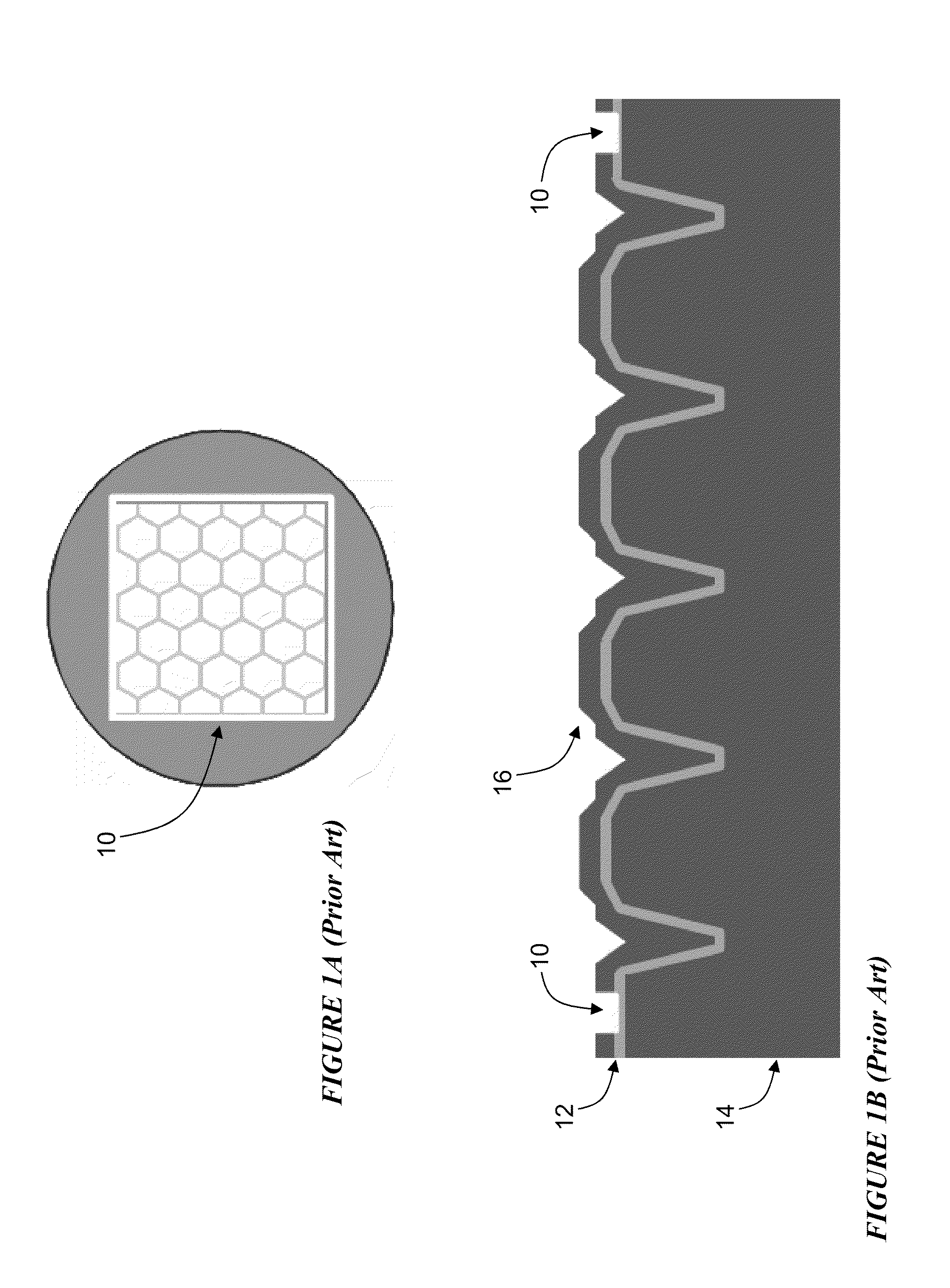

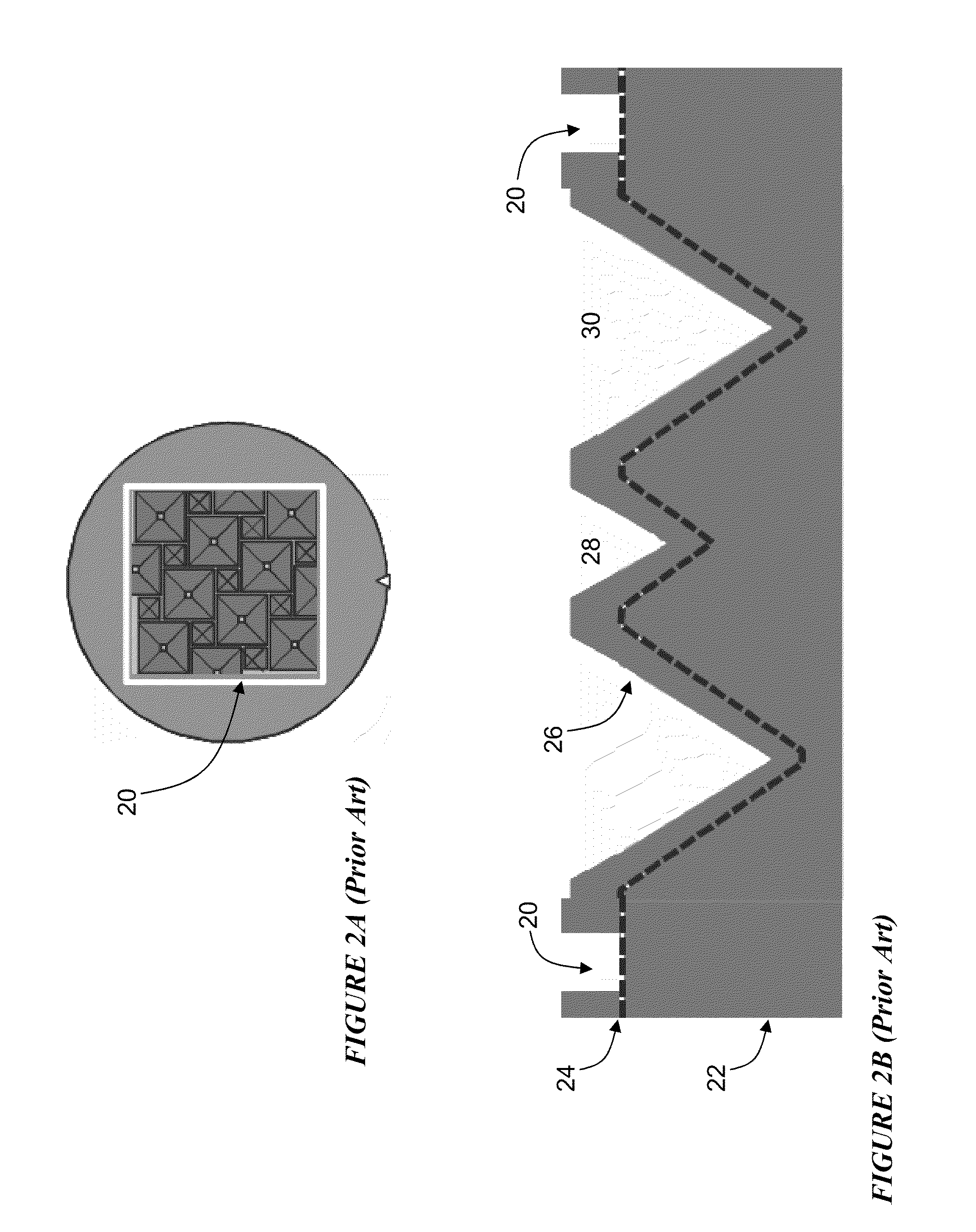

Trench Formation Method For Releasing A Thin-Film Substrate From A Reusable Semiconductor Template

ActiveUS20100203711A1Process controlEliminates and reduces disadvantage and problemFinal product manufactureSemiconductor/solid-state device manufacturingPorous semiconductorsPellicle membrane

A method is provided for fabricating a thin-film semiconductor substrate by forming a porous semiconductor layer conformally on a reusable semiconductor template and then forming a thin-film semiconductor substrate conformally on the porous semiconductor layer. An inner trench having a depth less than the thickness of the thin-film semiconductor substrate is formed on the thin-film semiconductor substrate. An outer trench providing access to the porous semiconductor layer is formed on the thin-film semiconductor substrate and is positioned between the inner trench and the edge of the thin-film semiconductor substrate. The thin-film semiconductor substrate is then released from the reusable semiconductor template.

Owner:BEAMREACH SOLAR INC

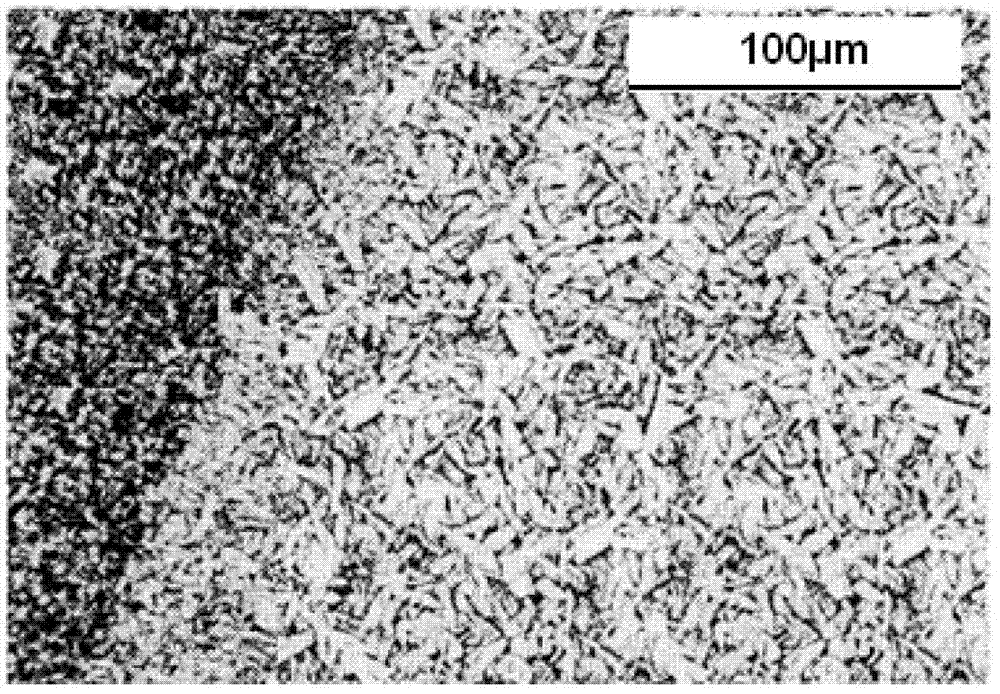

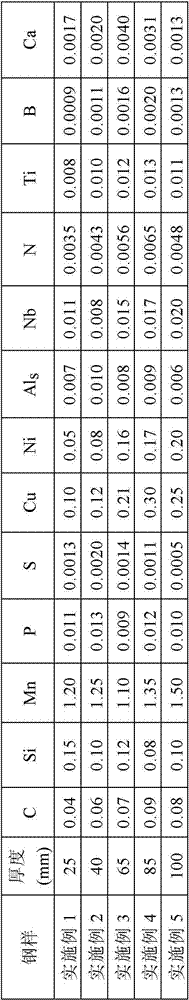

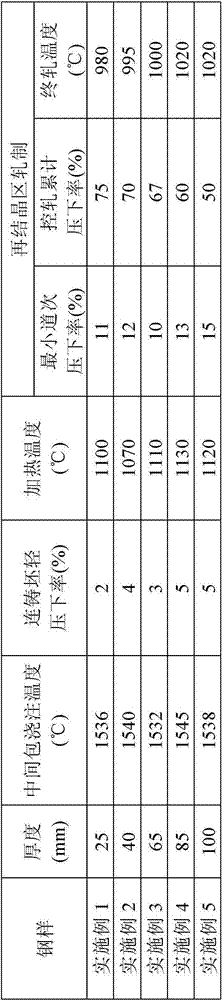

Ultra-low temperature steel in great heat input welding and manufacturing method of steel

The invention discloses ultra-low temperature steel in great heat input welding and a manufacturing method of the steel. The steel disclosed by the invention comprises the following components in percent by weight: 0.040-0.090% of C, less than or equal to 0.15% of Si, 1.10-1.50% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0020% of S, 0.10-0.30% of Cu, 0.05-0.20% of Ni, 0.008-0.020% of Nb, less than or equal to 0.010% of Als, 0.008-0.013% of Ti, 0.0035-0.0065% of N, 0.001-0.004% of Ca, 0.0008-0.0020% of B and the balance of Fe and inevitable impurities. By adopting the simple combined design of alloy elements in the steel disclosed by the invention, the TMCP (Thermal Mechanical Control Processing) technology is optimized without the requirement of adding a great number of noble elements such as Ni and Cu, the excellent patent steel plate low-temperature tenacity is acquired and simultaneously the low-temperature tenacity of the HAZ (Heat Affected Zone) during large line energy welding is also excellent; and the uniform and excellent mechanical property, good welding property and marine atmosphere corrosion resistance are acquired, so that the steel disclosed by the invention is specially applicable to wind tower structures on the sea, low-temperature pressure vessels, ocean platforms and bridges.

Owner:BAOSHAN IRON & STEEL CO LTD

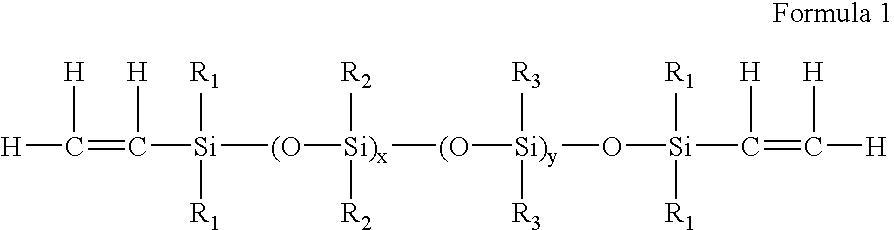

Process for the production of high refractive index polysiloxane-based polymeric compositions for use in medical devices

InactiveUS20050038219A1High refractive indexImprove homogeneityProsthesisOptical elementsPolymer scienceCorneal inlay

A process for producing polysiloxane prepolymers of improved homogeneity for use in the production of relatively high refractive index polymeric compositions is described herein. Polymeric compositions so produced are useful in the production of ophthalmic devices such as for example intraocular lenses and corneal inlays. The preferred polymeric compositions are produced through the copolymerization of one or more polysiloxane prepolymers with hydrosilane-containing polysiloxanes.

Owner:BAUSCH & LOMB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com