Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Improve quality and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

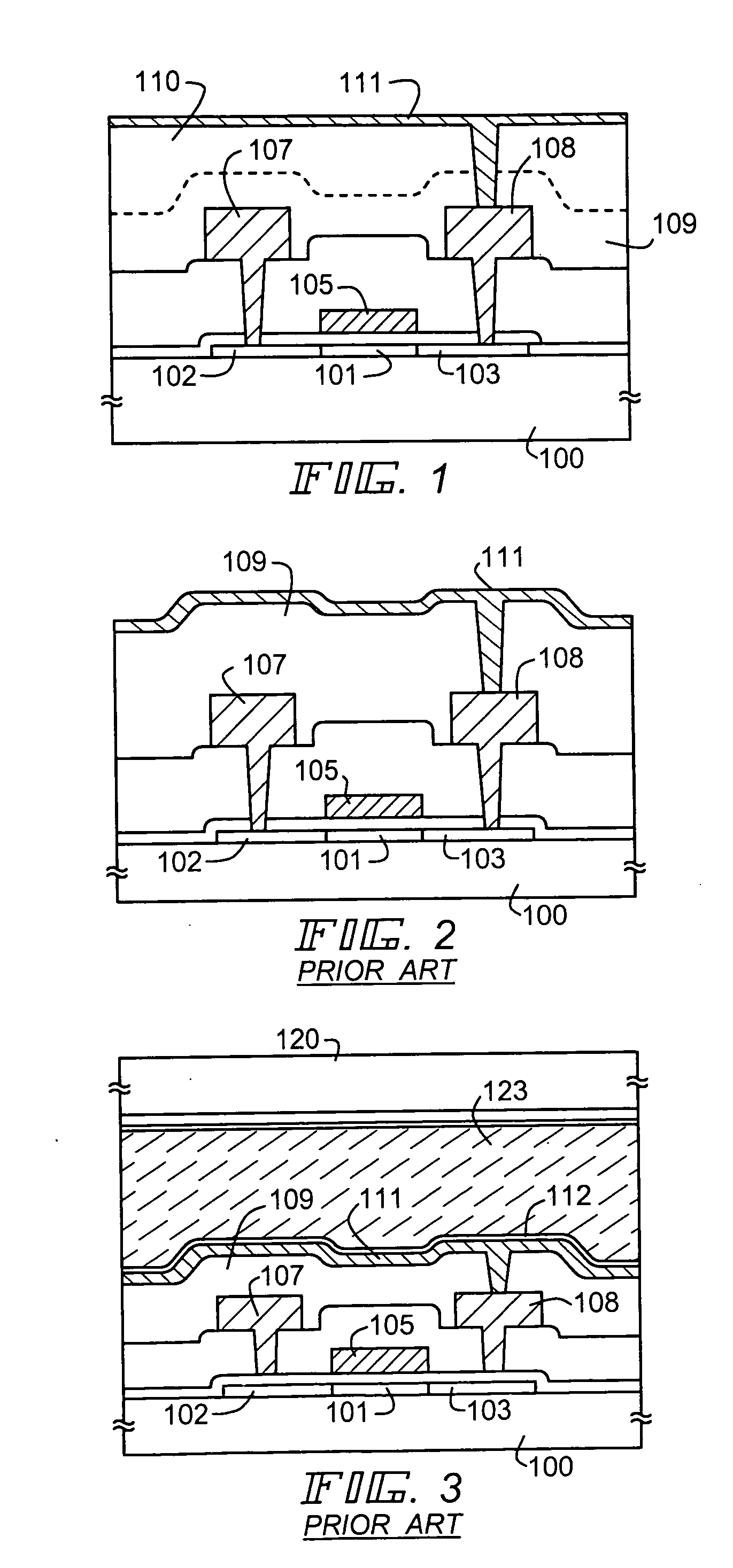

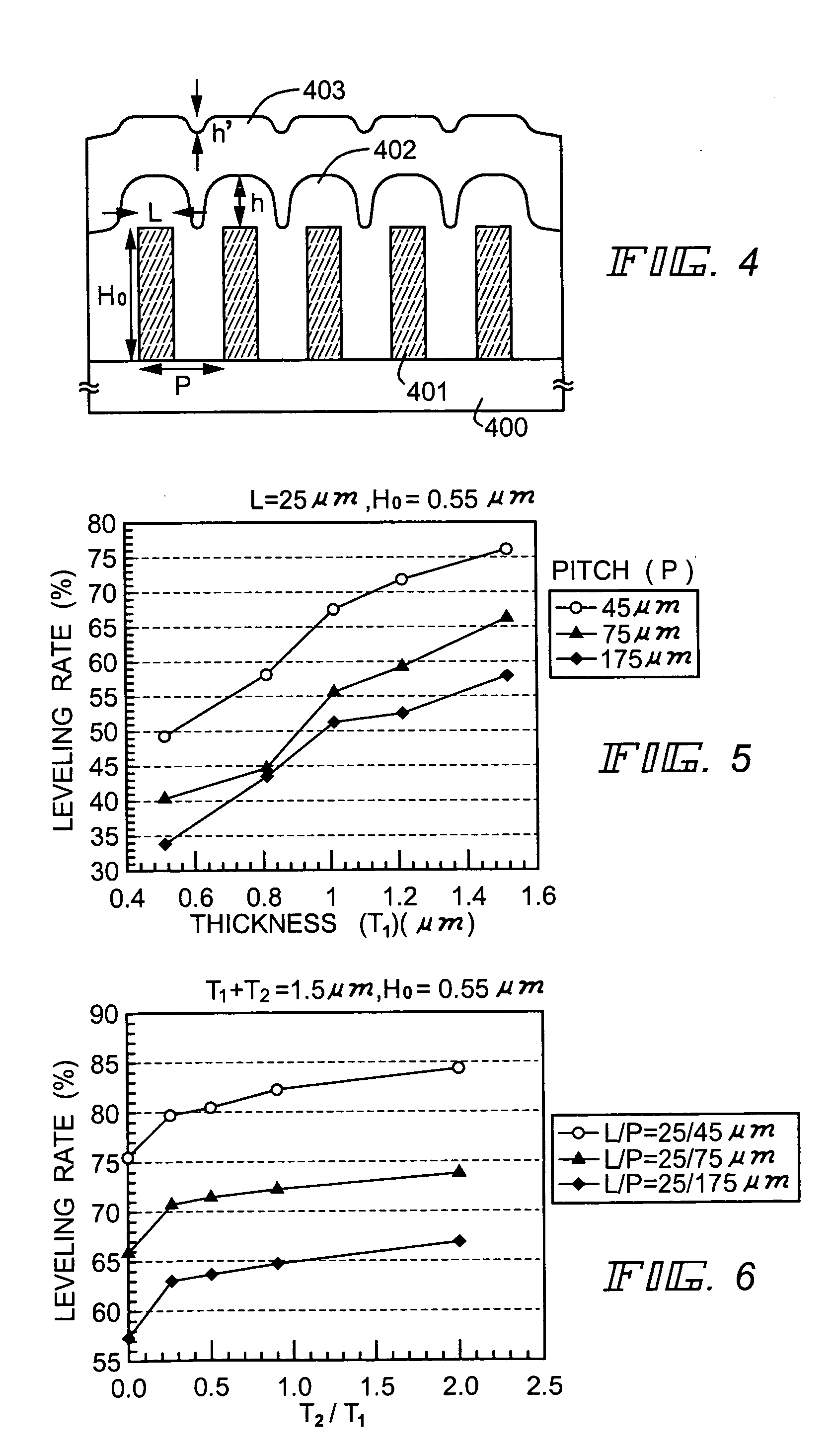

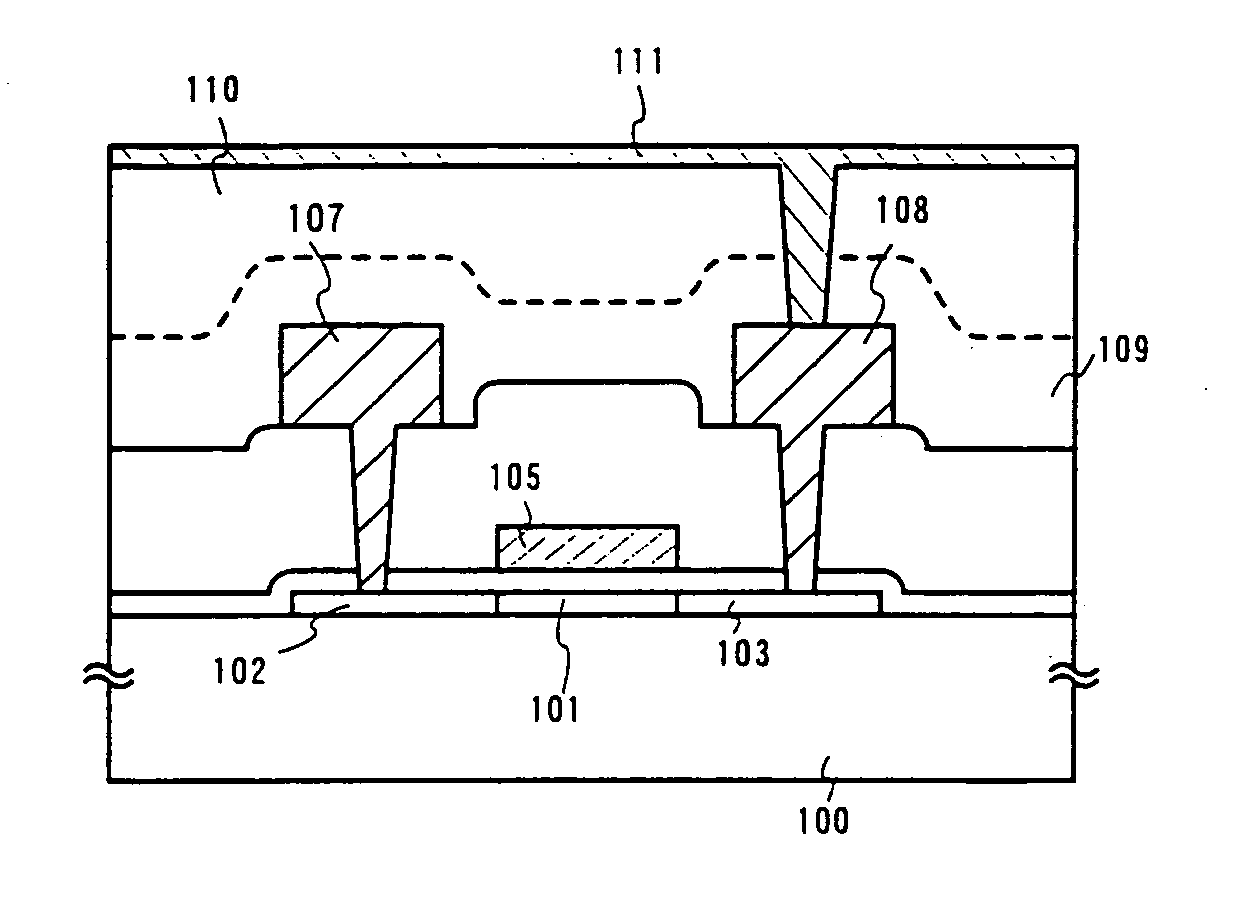

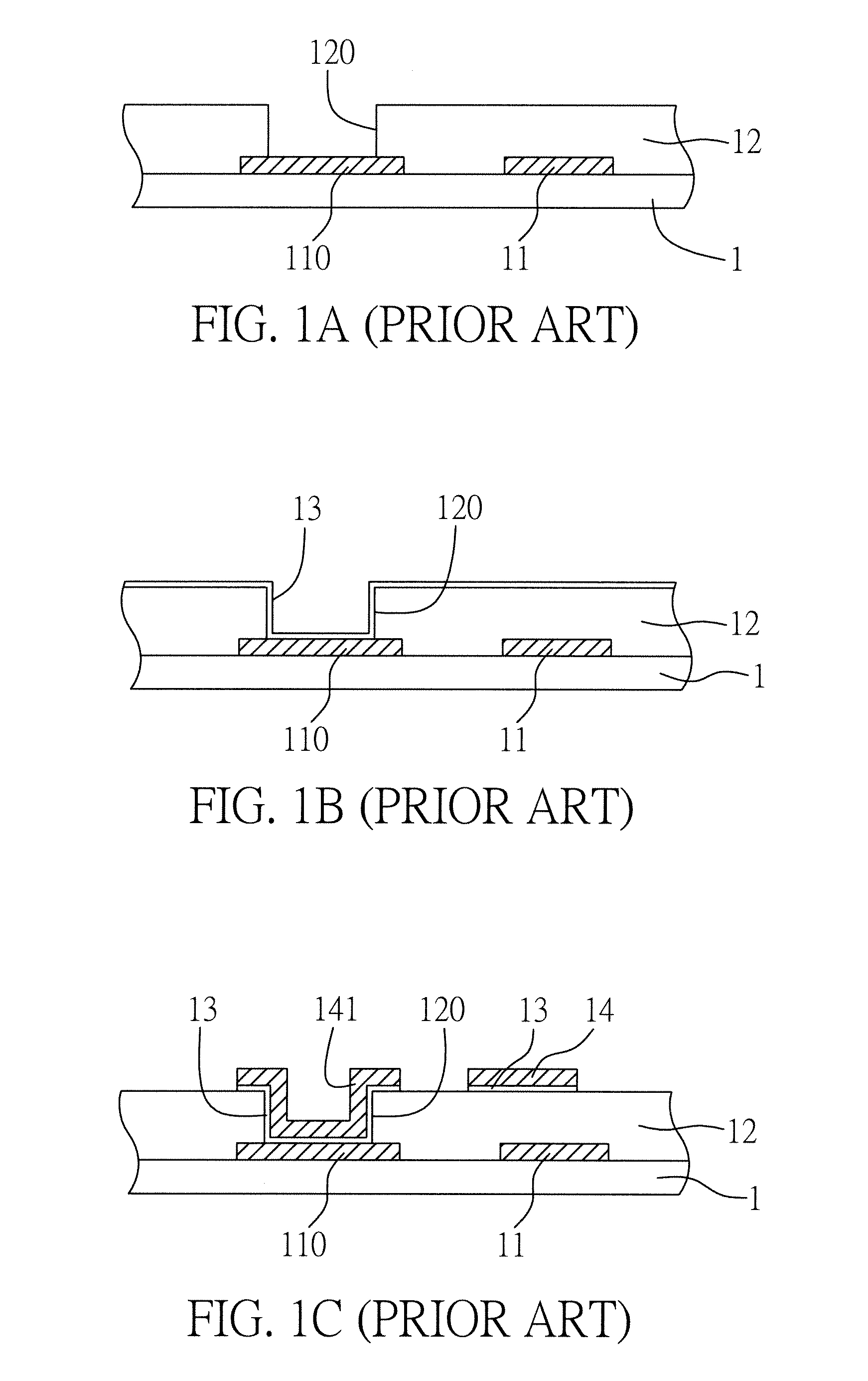

Method of fabricating display device

InactiveUS20050042798A1Highly reliable wiringUniform imagingSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDisplay device

The present invention improves the reliability of wirings, facilitates the orientation control of liquid crystal, or improves a reflectance of a reflective liquid crystal display device. In the case where a plurality of leveling films are laminated, a first leveling film is formed to have a thickness smaller than that of a second leveling film, thereby realizing a higher leveling rate. Therefore, unevenness of the surface due to level differences is reduced, and it becomes possible to attain the above objects.

Owner:SEMICON ENERGY LAB CO LTD

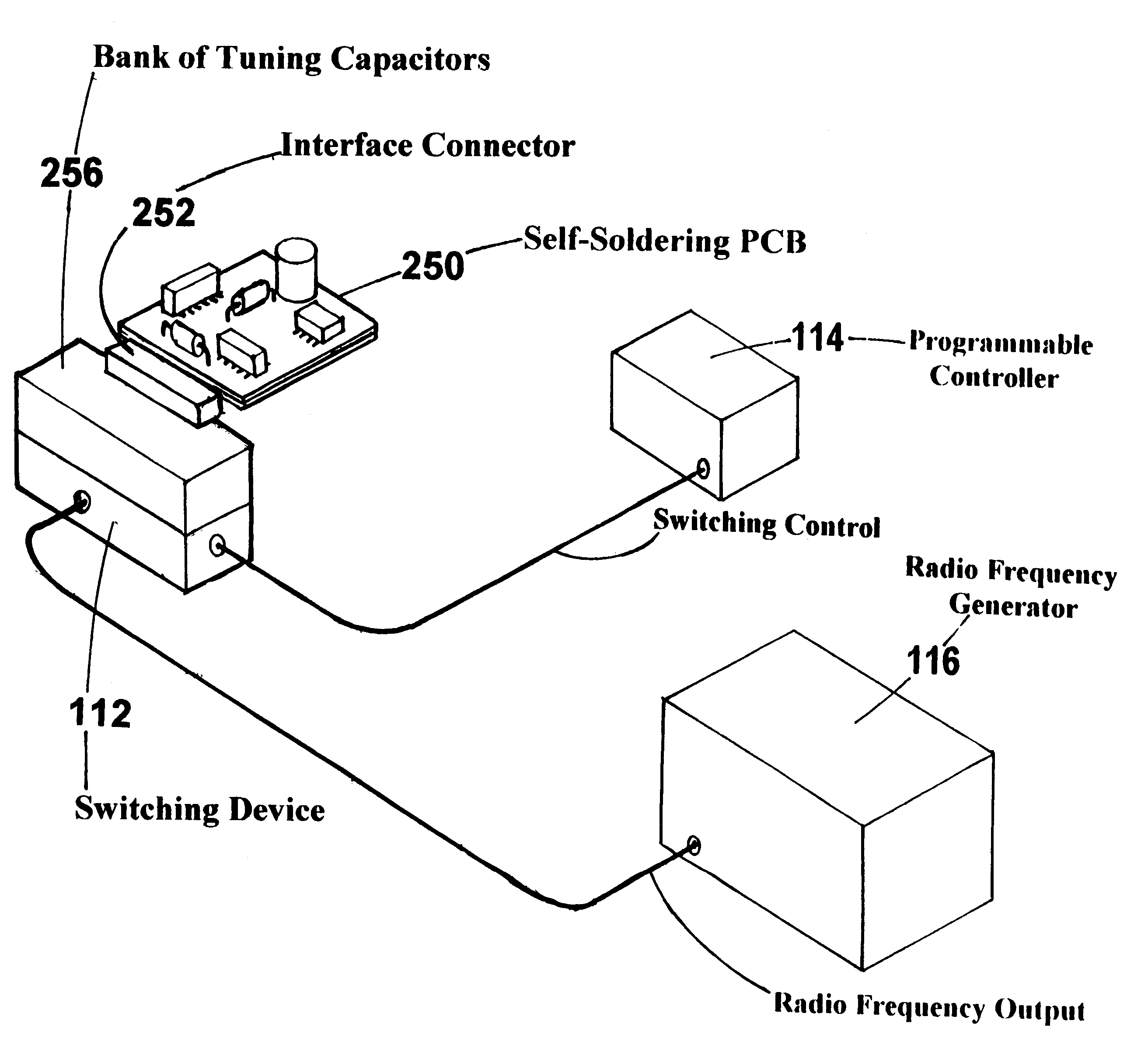

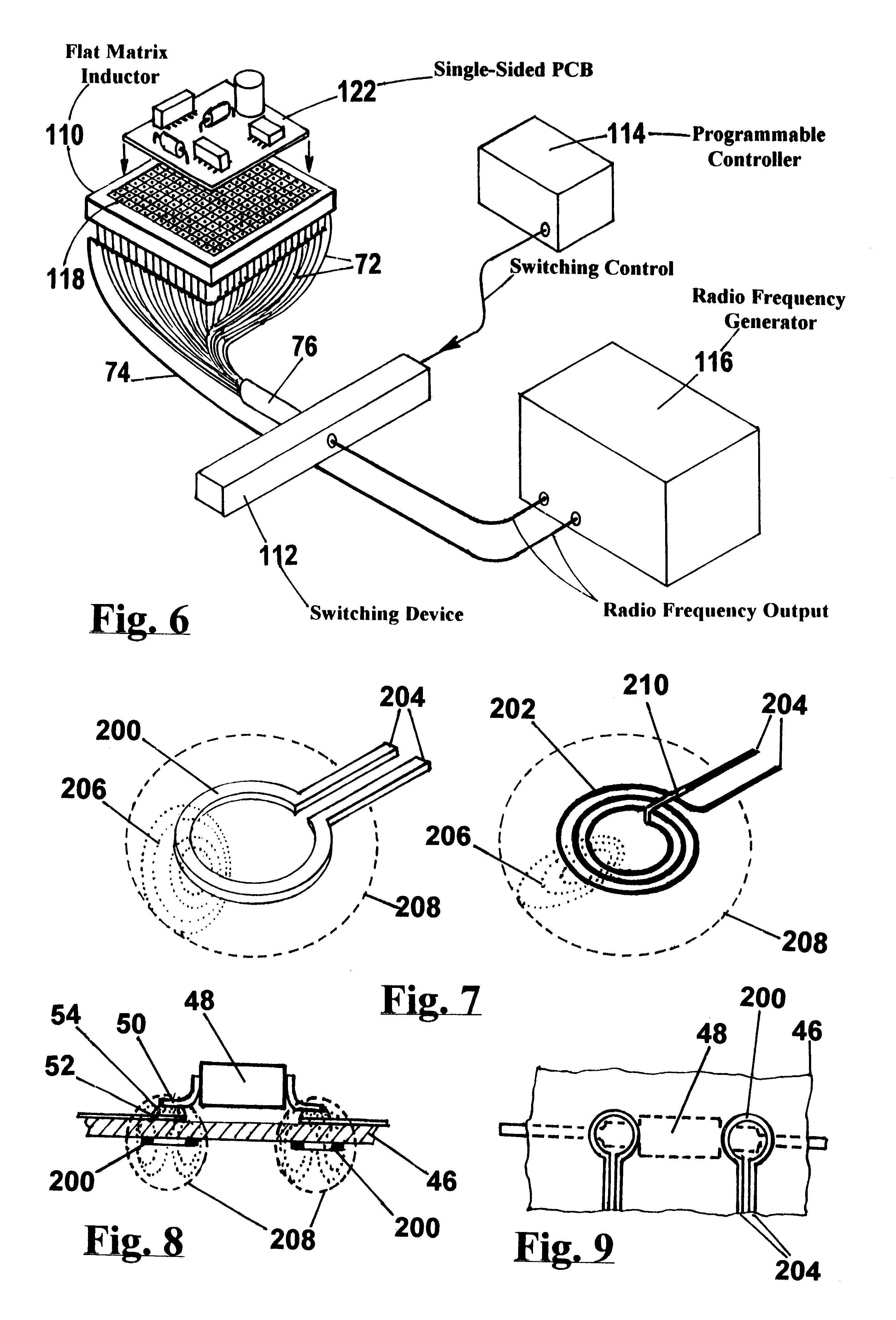

Inductive self-soldering printed circuit board

InactiveUS6229124B1Improve quality and reliabilityReduce formationPrinted circuit assemblingCoil arrangementsManufacturing technologyHeat sensitive

A new apparatus for inductively soldering surface-mount, straddle-mount and through-hole type electronic components into a self-soldering PCB (printed circuit board) in an automated fashion utilizing localized Electromagnetic Induction Heating (E.I.H.). Current manufacture technology for packaging electronic components depends on the reflow and wave soldering processes. Both processes heat up to relatively high temperatures the entire assembly, namely its PCB and all the electronic components being soldered into it. Such harsh high-temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention reflow oven and / or wave soldering equipment is not required. During a soldering operation only the leads and pads being soldered are heated but neither the body of said electronic components nor the dielectric material forming said self-soldering PCB and its interconnecting traces are heated. Because of this selectively localized inductive heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. The invention consumes about 200 times less energy than the reflow and wave soldering processes. This invention can readily be utilized to complement and / or supplement the reflow and wave soldering processes by providing selective inductive self-soldering of odd-form and / or heat-sensitive components. The invention also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a self-soldering PCB is completed. This invention also provides for a useful inductive de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

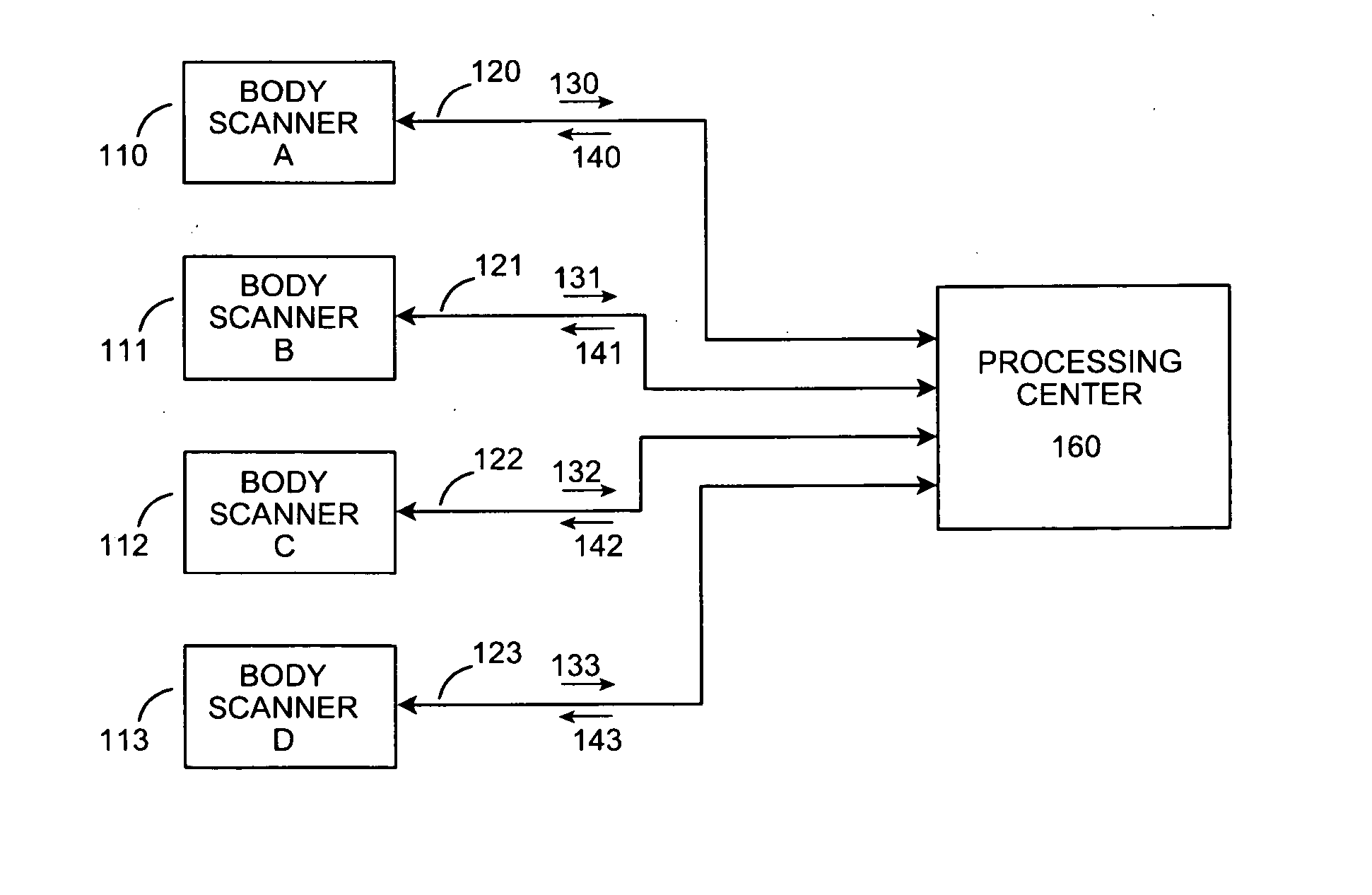

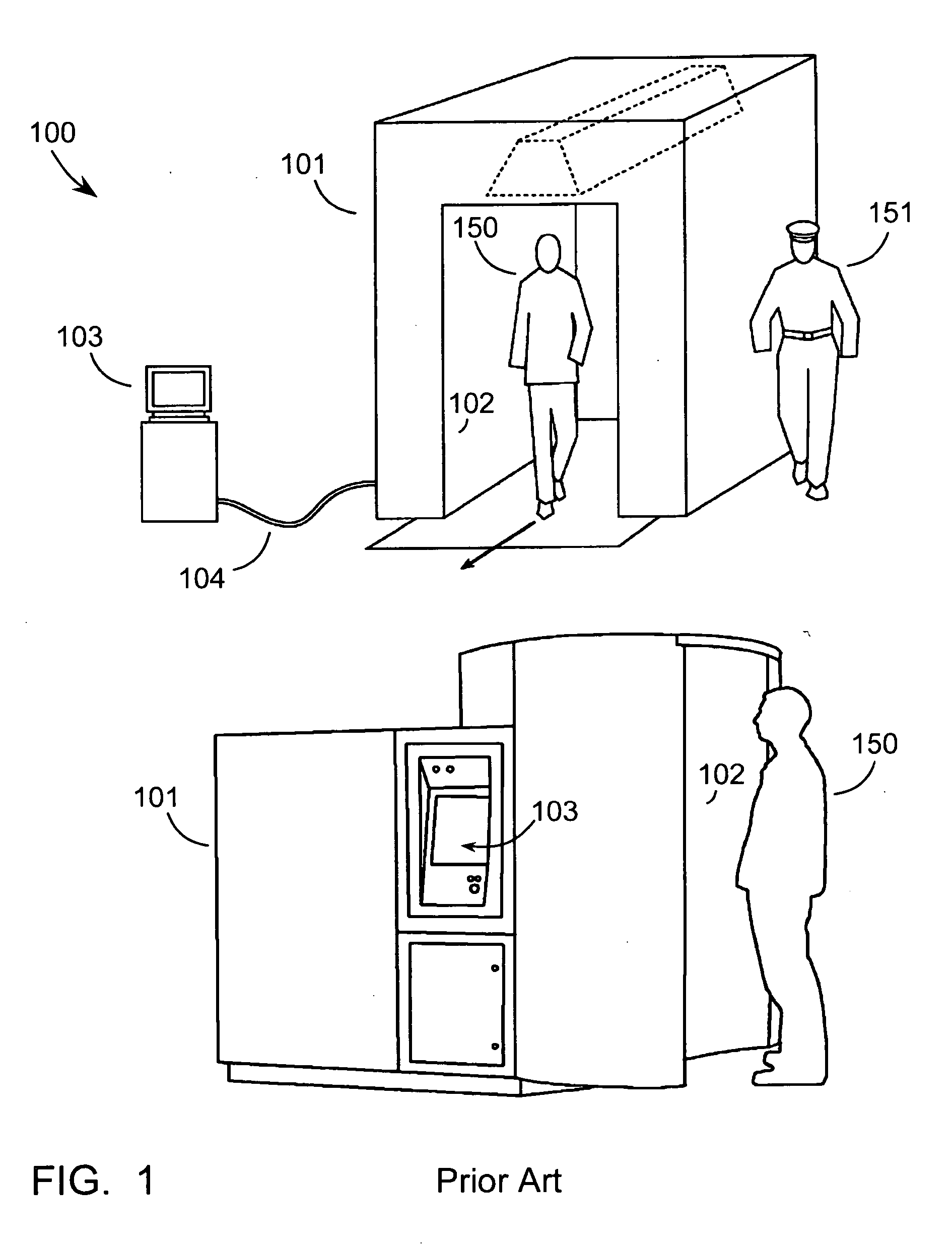

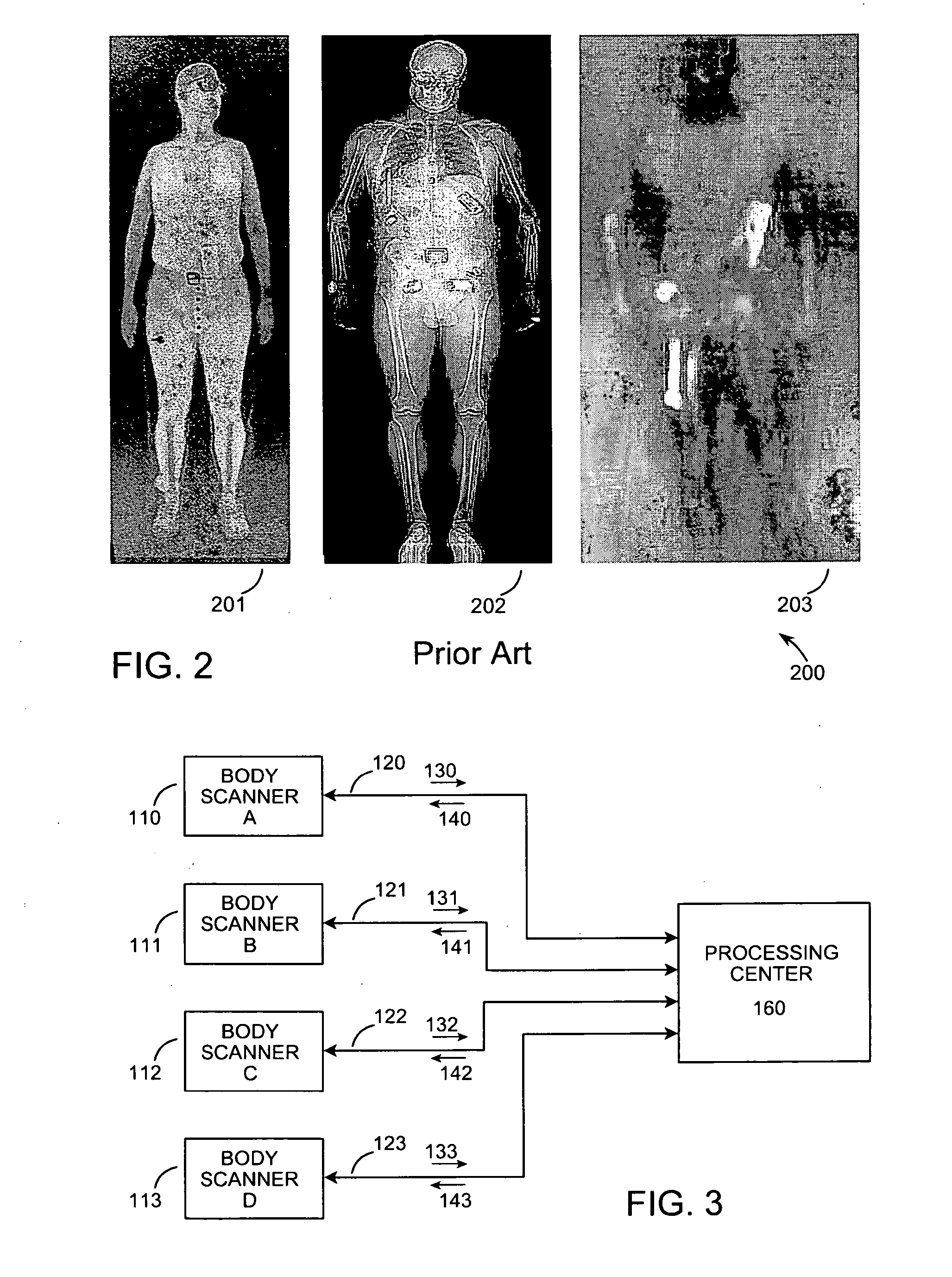

Weapon detection processing

InactiveUS20070235652A1Reduce manpowerEliminate embarrassmentMaterial analysis by optical meansX/gamma/cosmic radiation measurmentBody scannerRadiant energy

A radiant energy imaging system is used to create an electronic image of a person entering a security controlled area to detect weapons or contraband concealed under their clothing. The electronic image is electronically transmitted to a processing center where it is evaluated by a human and / or software algorithms for the presence of concealed objects. The resulting evaluation, consisting of digitally represented information, is electronically transmitted back to the examination site. In one embodiment this processed data is displayed as a graphical outline of the concealed objects superimposed on an optical image of the person. In another embodiment, the processed data is used to control a personnel barrier controlling access into the security controlled area. In another embodiment a network allocation server selectively routes the electronic images from two or more body scanners to two or more processing centers.

Owner:SMITH STEVEN WINN

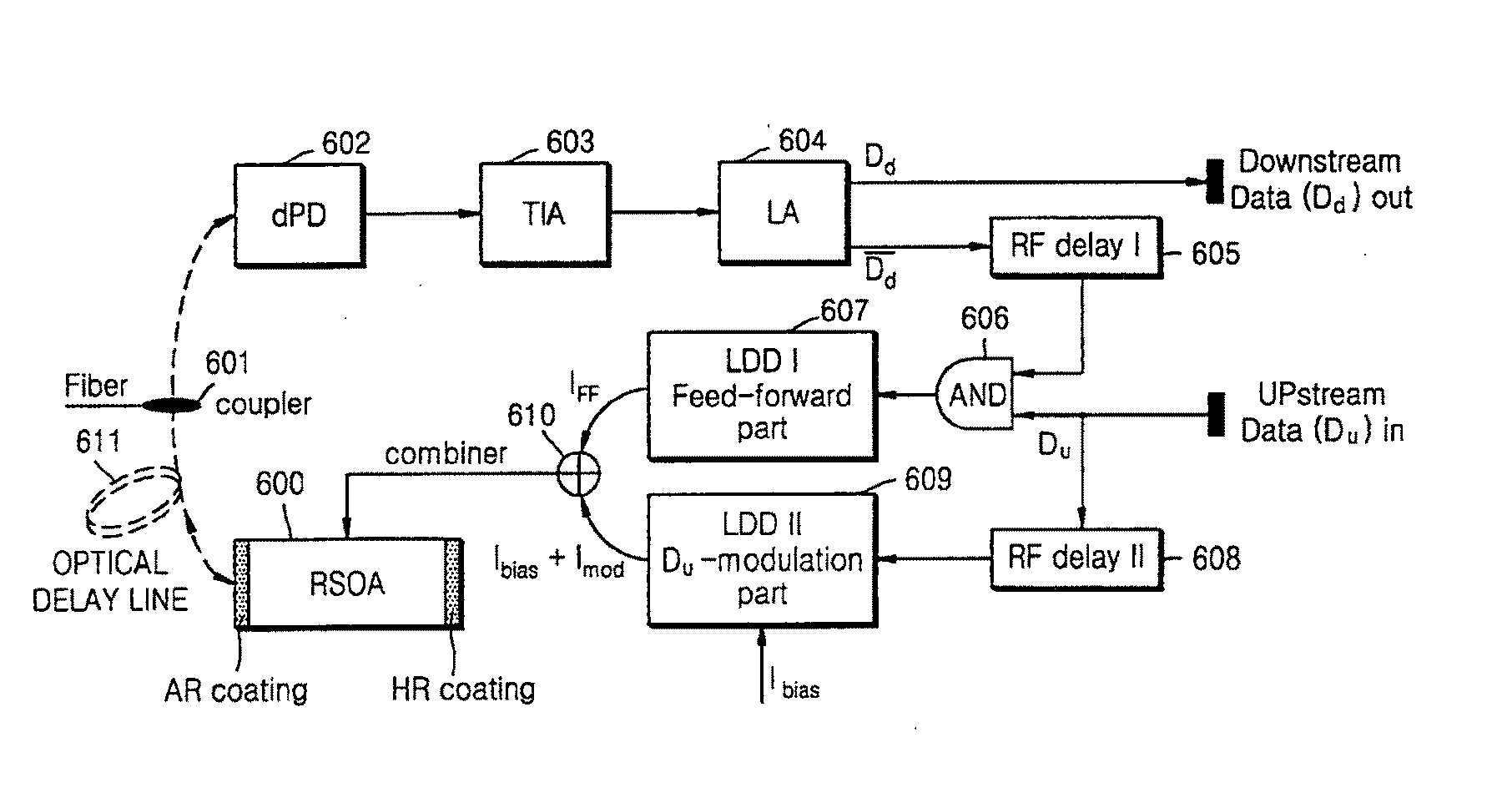

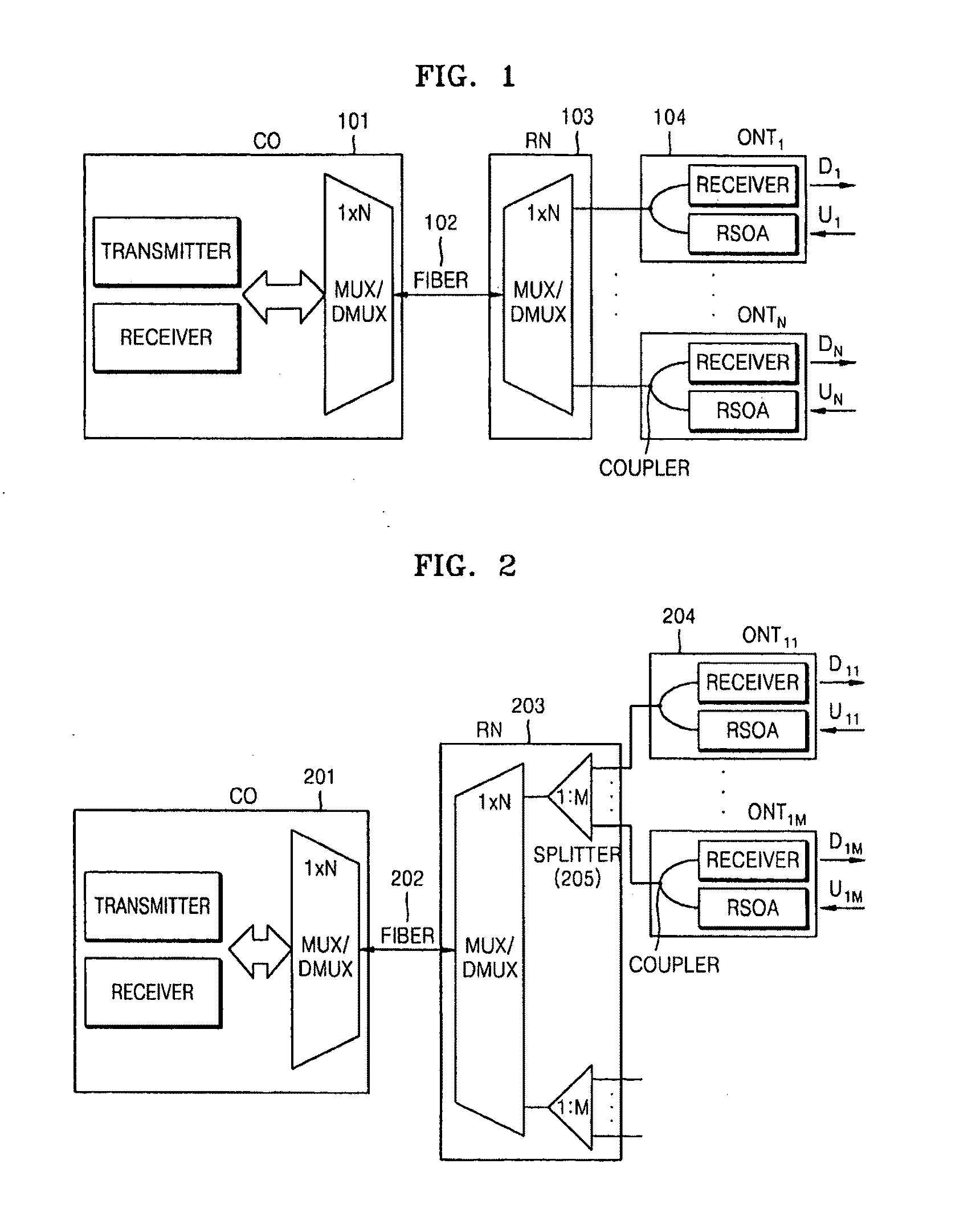

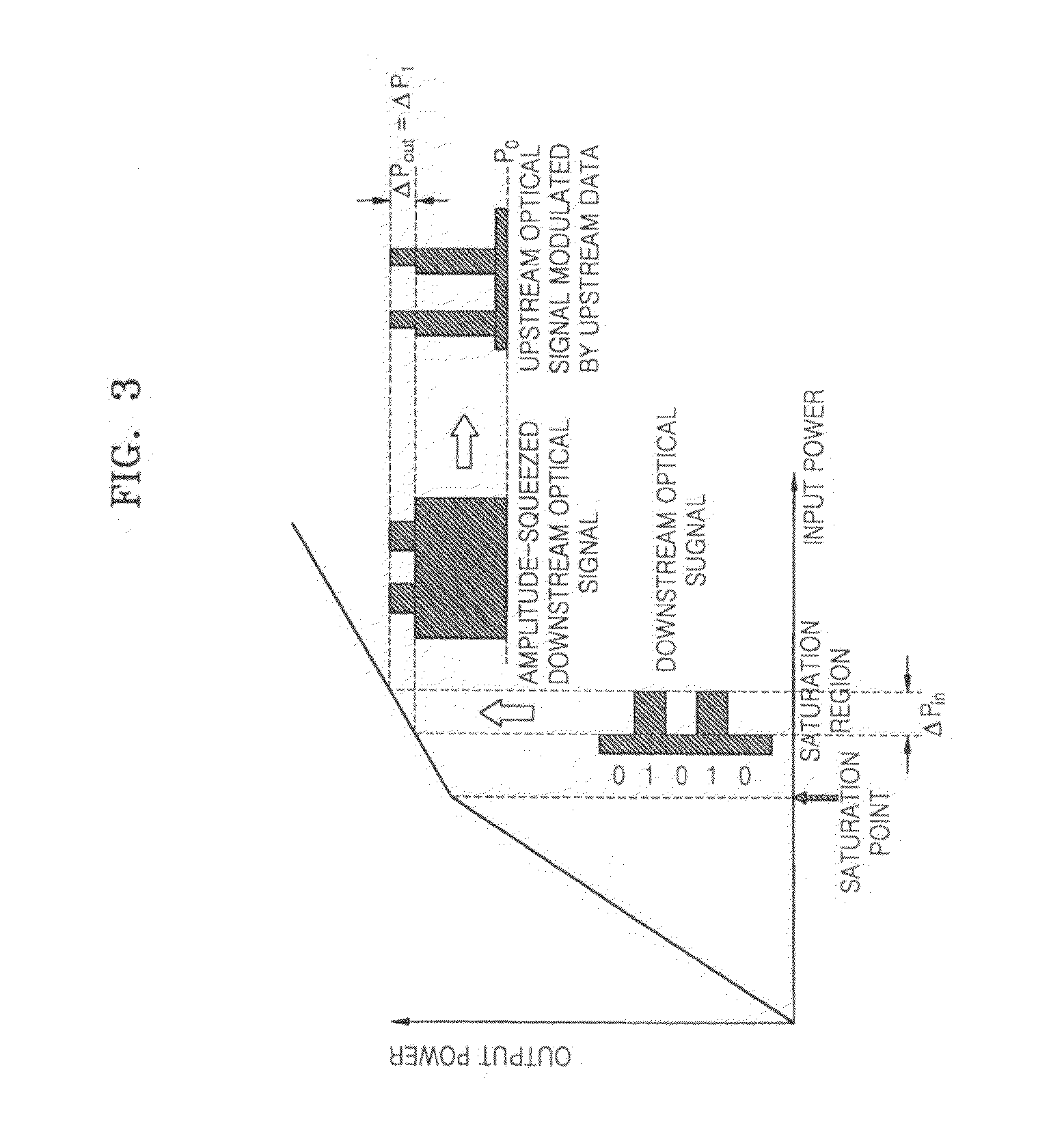

Apparatus and method for olt and onu for wavelength agnostic wavelength-division multiplexed passive optical networks

ActiveUS20110026923A1Lowering in extinction ratioPossible to transmitLaser detailsWavelength-division multiplex systemsComputer terminalLength wave

In a Wavelength-Division-Multiplexed Passive Optical Network (WDM-PON) utilizing a conventional downstream optical signal reusing method, there is an inventory problem that different optical transmitter types need to be provided for the operation, management, replacement, etc. of a system. A WDM-PON system according to the present invention, includes: a seed light (SL) unit generating a seed light whose wavelength intervals and center wavelengths are adjusted using at least one seed light source; an optical line terminal (OLT) receiving the wavelength-multiplexed seed light from the seed light unit, transmitting a downstream optical signal to a subscriber of the WDM-PON, and receiving a upstream optical signal from the subscriber; and an optical network unit (ONU) receiving the downstream optical signal from the OLT, flattening and modulating the downstream optical signal with upstream data so that the downstream optical signal is reused for carrying upstream data. It is possible to improve the quality and reliability of downstream transmission by sufficiently increasing an extinction ratio, and improve the quality and reliability of upstream transmission by sufficiently flattening an input downstream optical signal in a semiconductor optical amplifier.

Owner:ELECTRONICS & TELECOMM RES INST

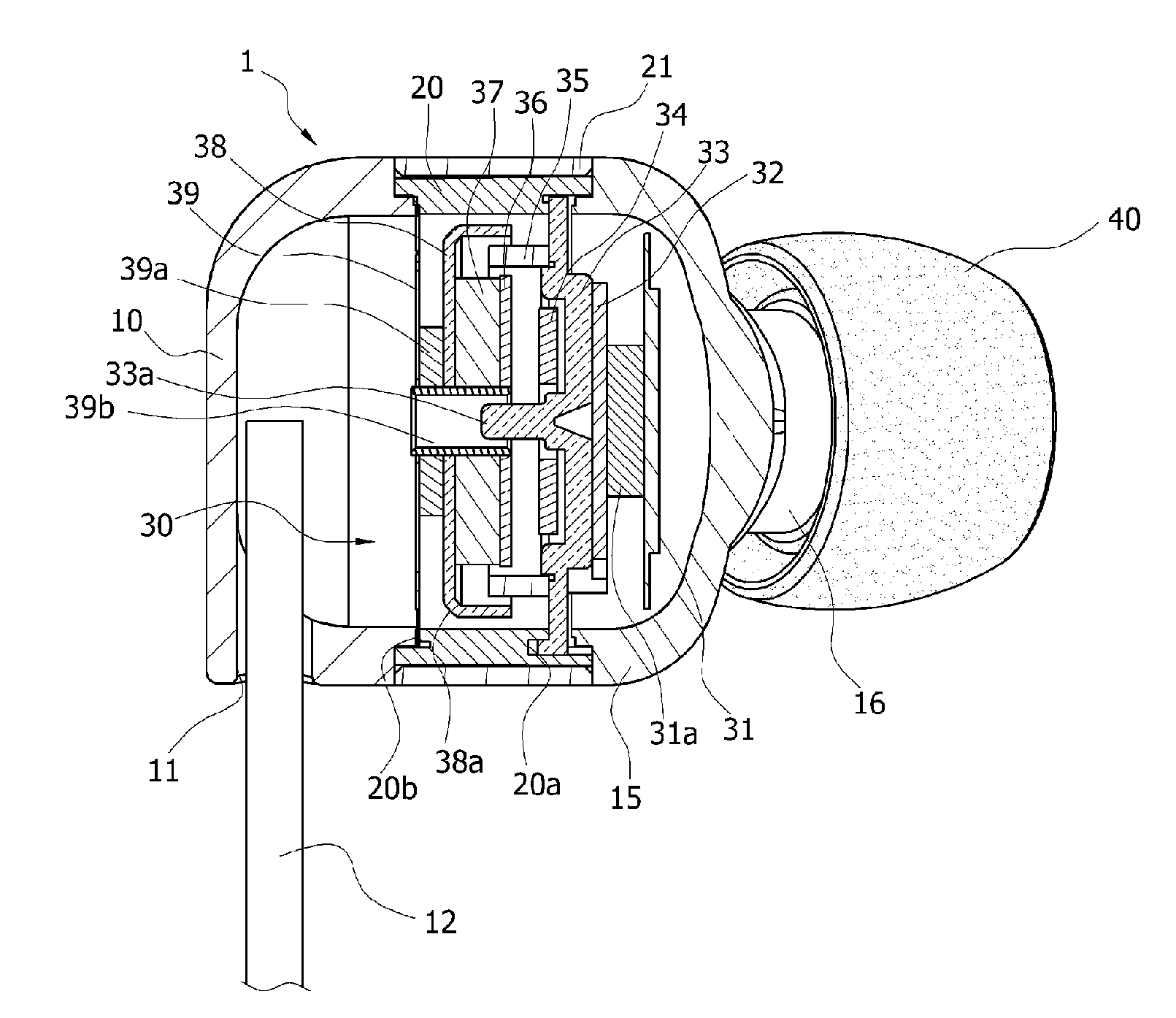

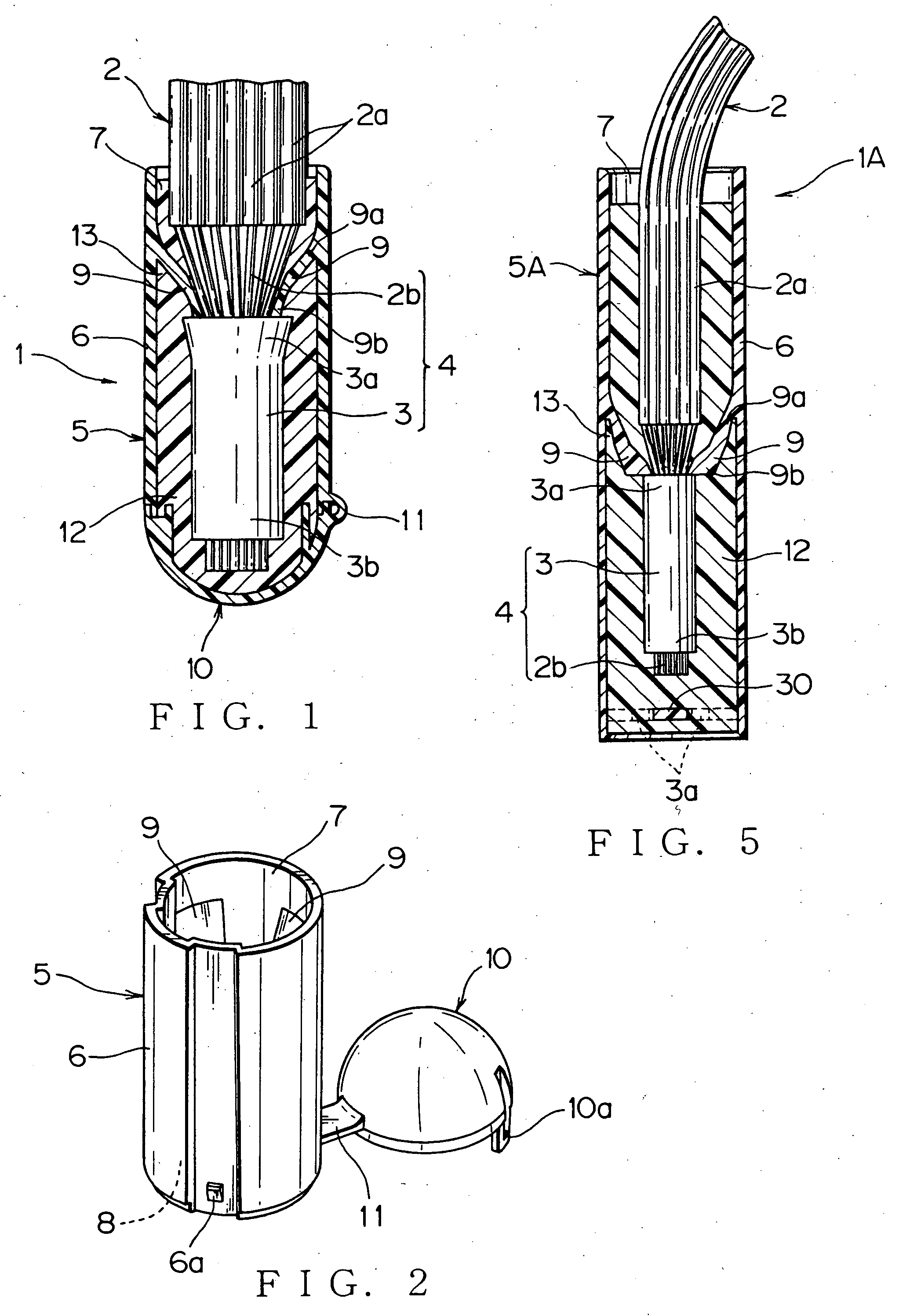

Dual earphone using both bone conduction and air conduction

InactiveUS8447061B2Quality improvementImprove reliabilityBone conduction transducer hearing devicesIntra aural earpiecesEngineeringHeadphones

Disclosed is an earphone set using both bone conduction and air conduction. The earphone set includes: a dual earphone which allows a user to selectively hear sounds from the front or rear side of the earphone set; a case cover provided at an end of the dual earphone; a cylindrical reinforcing frame assembled on one side of the case cover; a finishing ring mounted on the outer peripheral surface of the cylindrical reinforcing frame; a top cover assembled on one side of the cylindrical reinforcing frame and the finishing ring and having an extension projection at one side thereof; a rubber ear cap assembled at a front end of the extension projection to be inserted into an ear hole of a user; and a bone conduction vibrator provided inside the dual earphone.

Owner:VONIA CORP

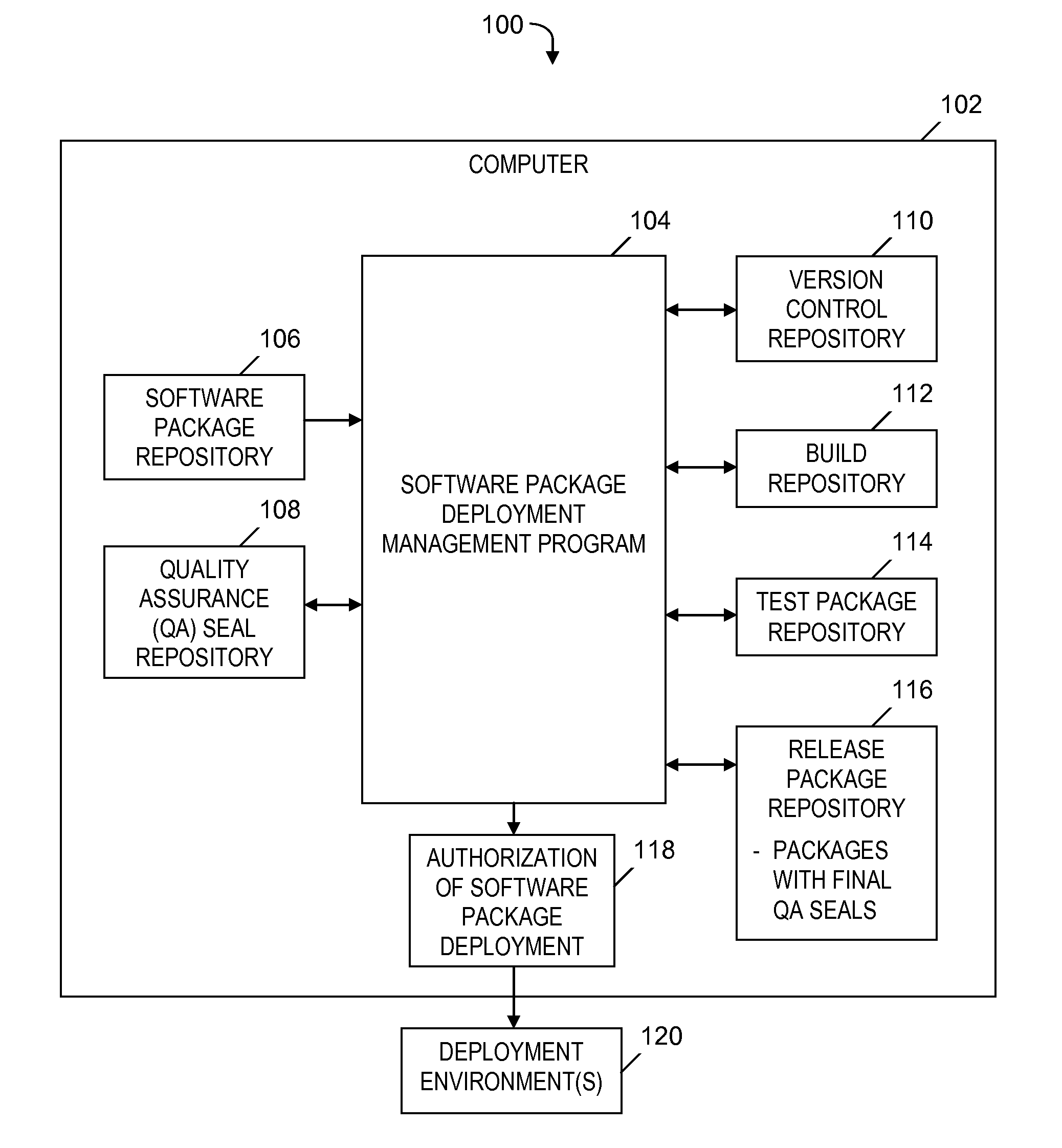

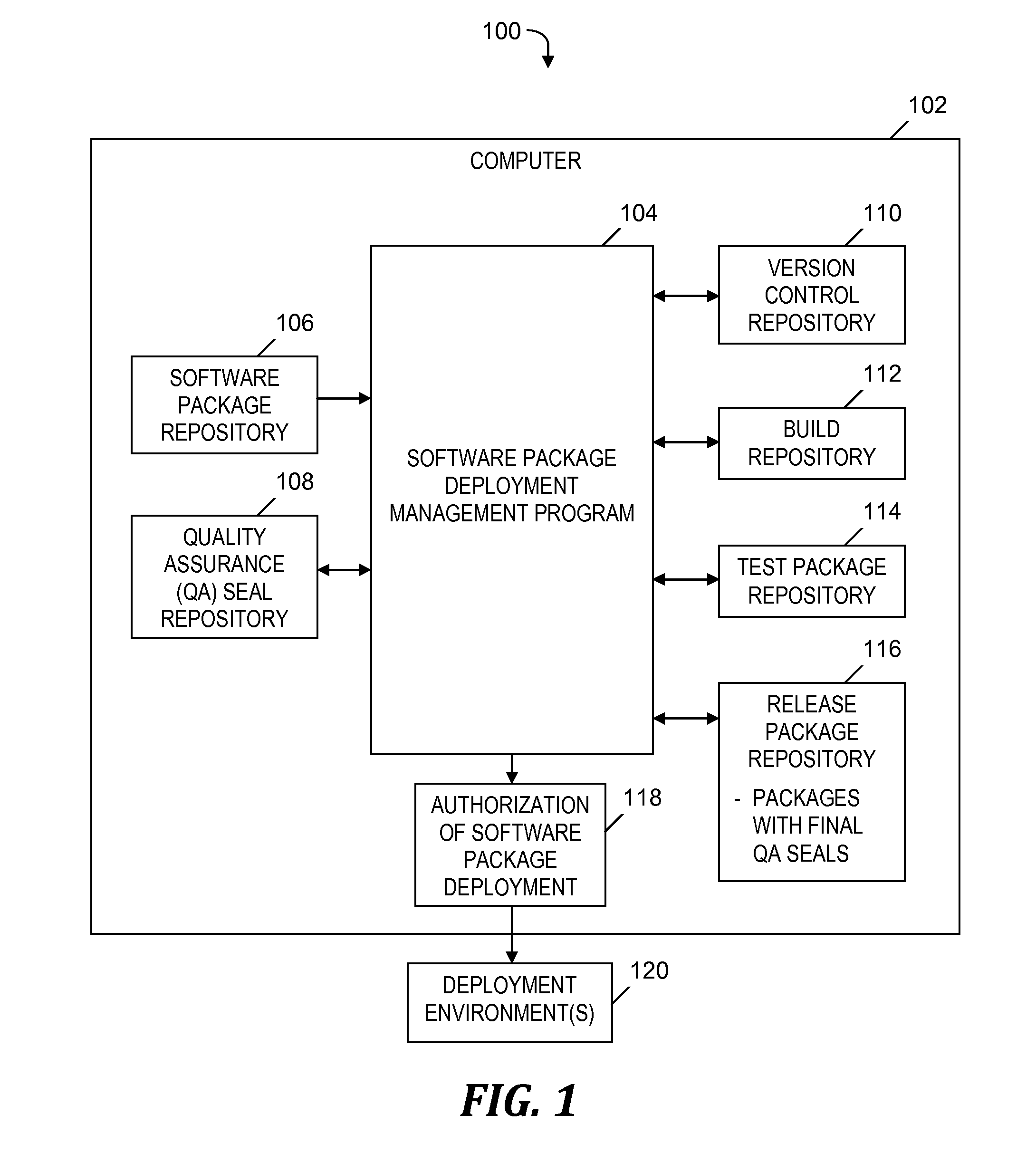

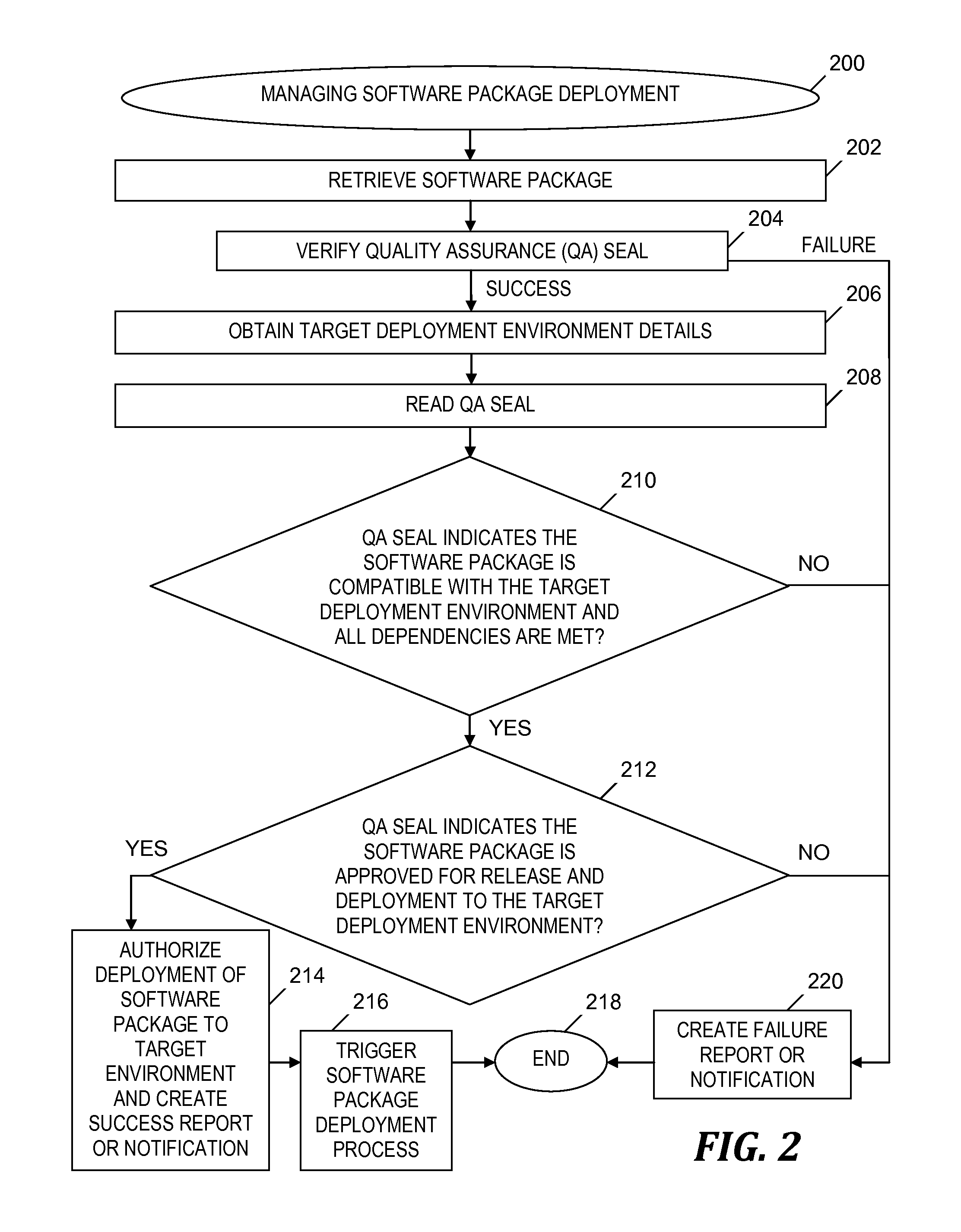

Seal-based regulation for software deployment management

InactiveUS20150199188A1Easy to solveQuality improvementVersion controlComputer security arrangementsQuality assuranceSoftware dependencies

An approach is provided for managing a deployment of a software package. A retrieved quality assurance (QA) seal corresponding to a software package is verified. A target deployment environment (TDE) is obtained. The QA seal is read to obtain first and second profiles, and metadata, which specify a deployment environment, hardware and software dependencies required in the deployment, and an approval for a release of the software package to the specified deployment environment, respectively. Based on a determination that the TDE matches the specified deployment environment, the QA seal indicates the software package is compatible with the TDE. The dependencies are determined to be satisfied. Based on the software package being compatible with the TDE, the dependencies being satisfied, and the specified approval for the release of the software package, a notification of an authorization of the deployment of the software package to the TDE is generated.

Owner:IBM CORP

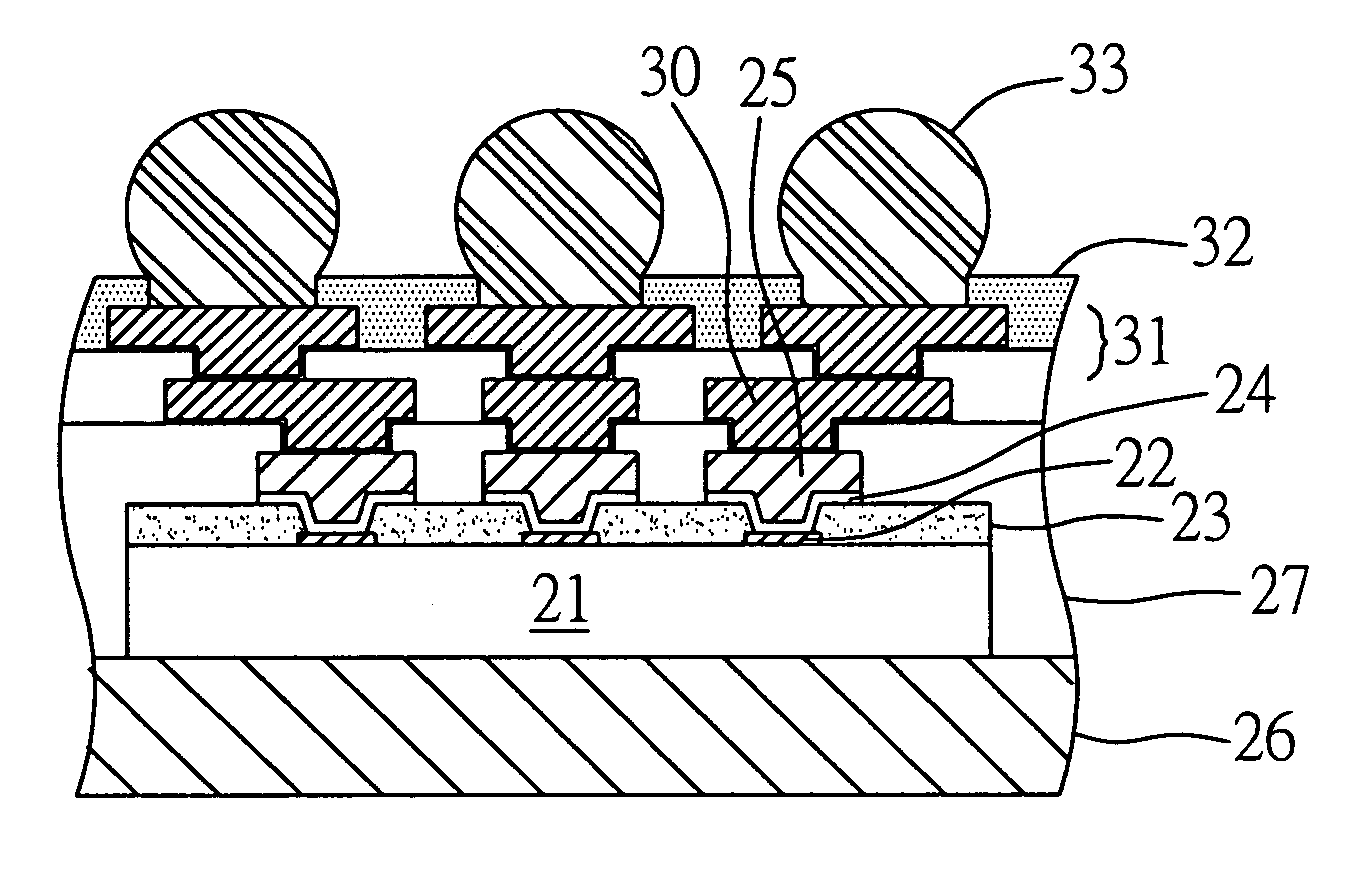

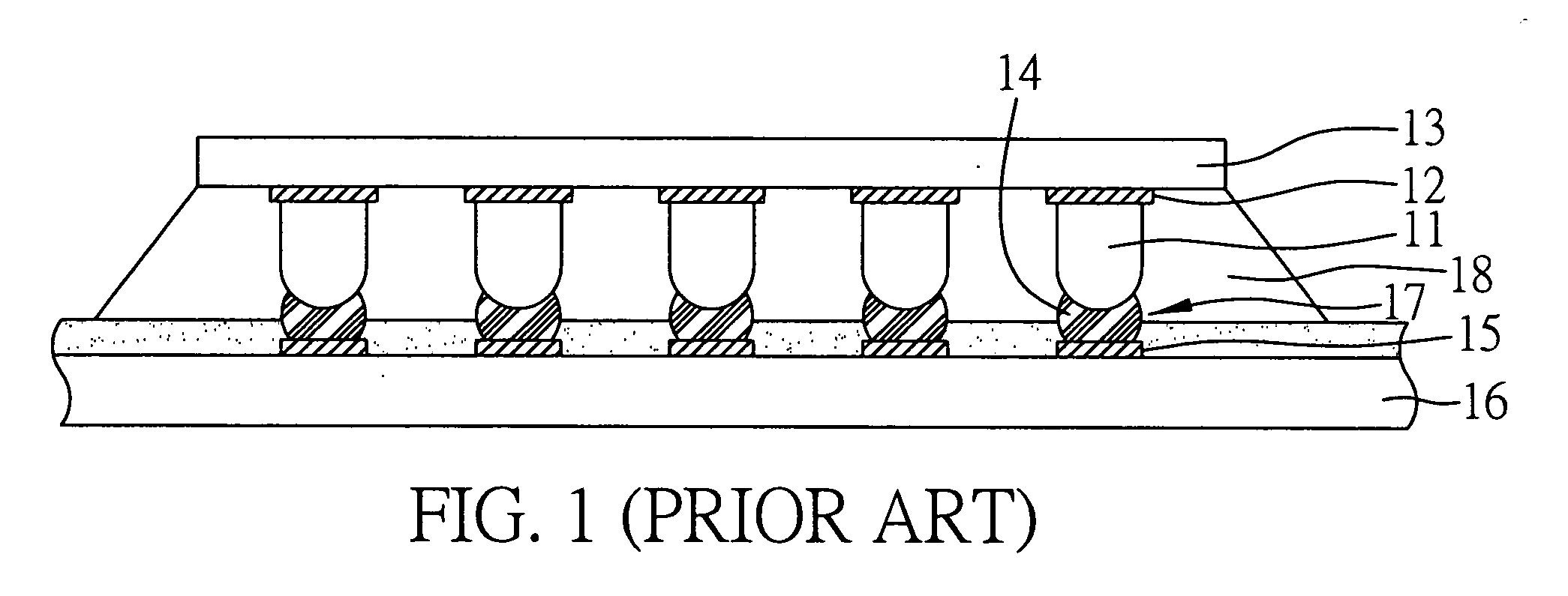

Semiconductor electrical connection structure and method of fabricating the same

InactiveUS20060073638A1Not easily oxidizedImprove utilizationSemiconductor/solid-state device detailsSolid-state devicesResistElectrical connection

A semiconductor electrical connection structure and a method of fabricating the same are provided. A wafer formed with a plurality of gold bumps thereon is divided into a plurality of individual chips. A carrier is prepared, and at least one of the chips is mounted on the carrier via a non-active surface of the chip. An insulating layer is applied on the carrier mounted with the chip, and formed with a plurality of openings using a laser drilling, photo imaging or plasma etching technique to expose the gold bumps via the openings. A conductive layer is formed on the insulating layer and in the openings. A pattered resist layer is applied on the conductive layer to define openings for electroplating. A circuit structure is electroplated in the openings of the resist layer so as to allow the chip to be electrically connected to an external device via the circuit structure.

Owner:PHOENIX PRECISION TECH CORP

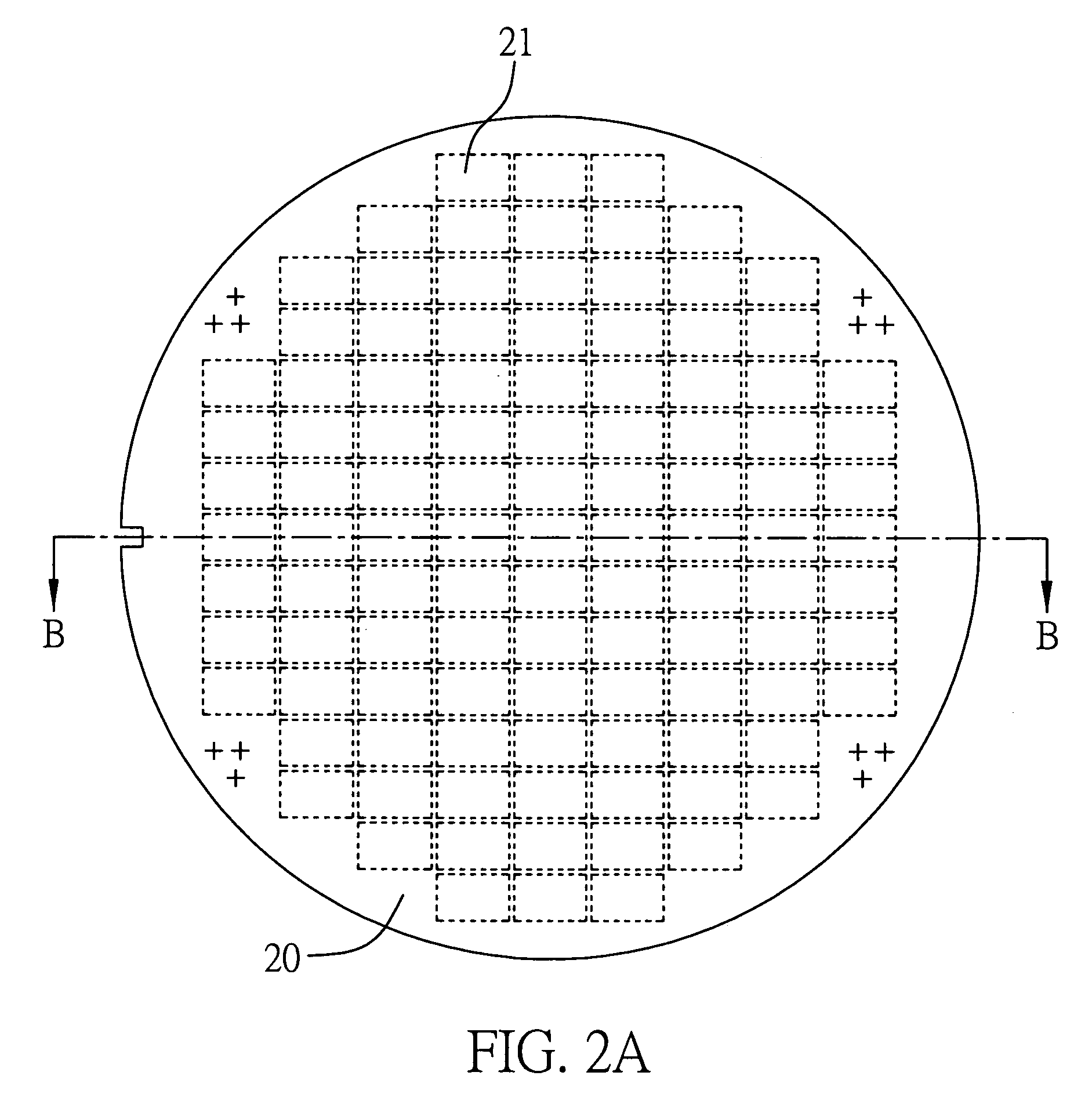

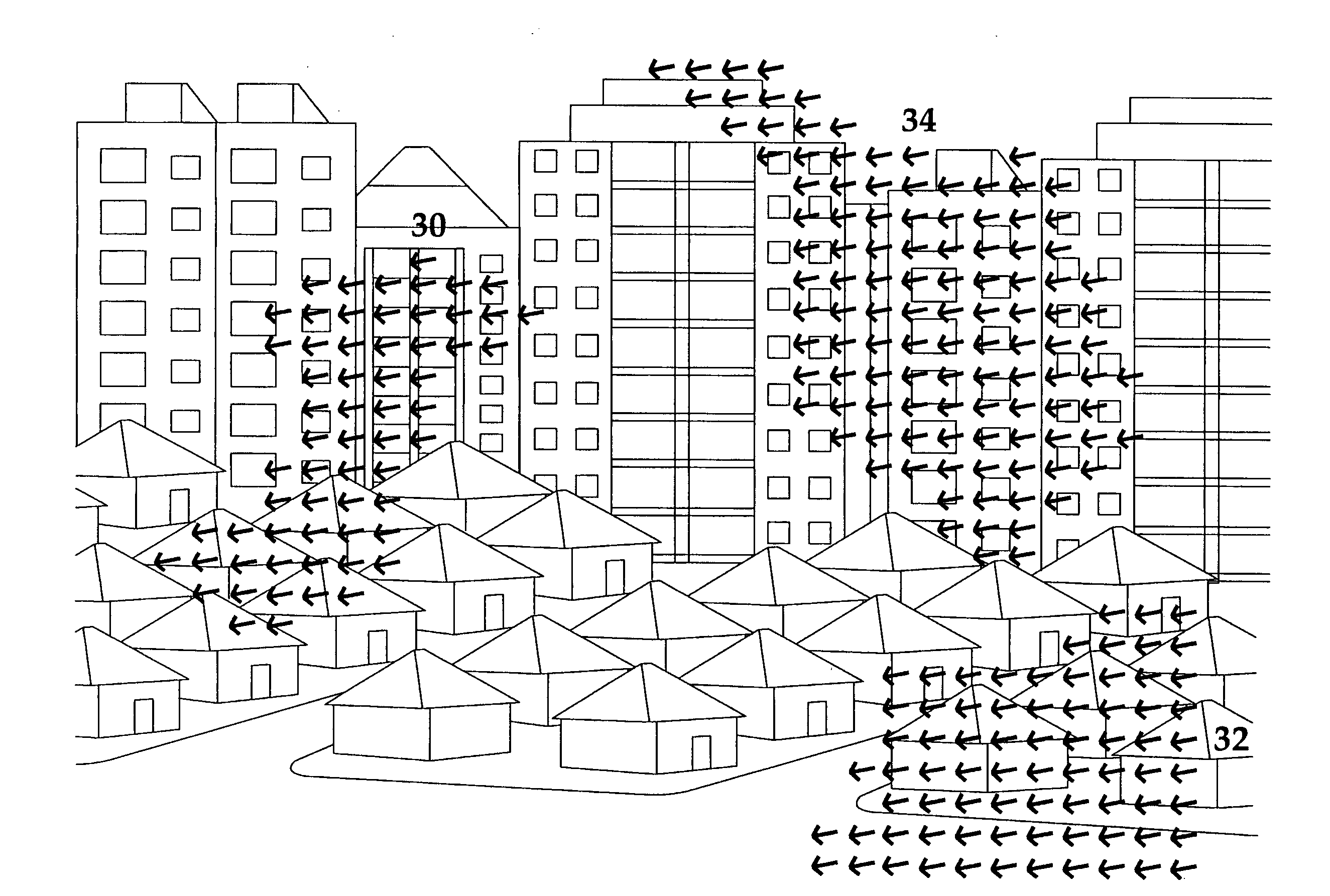

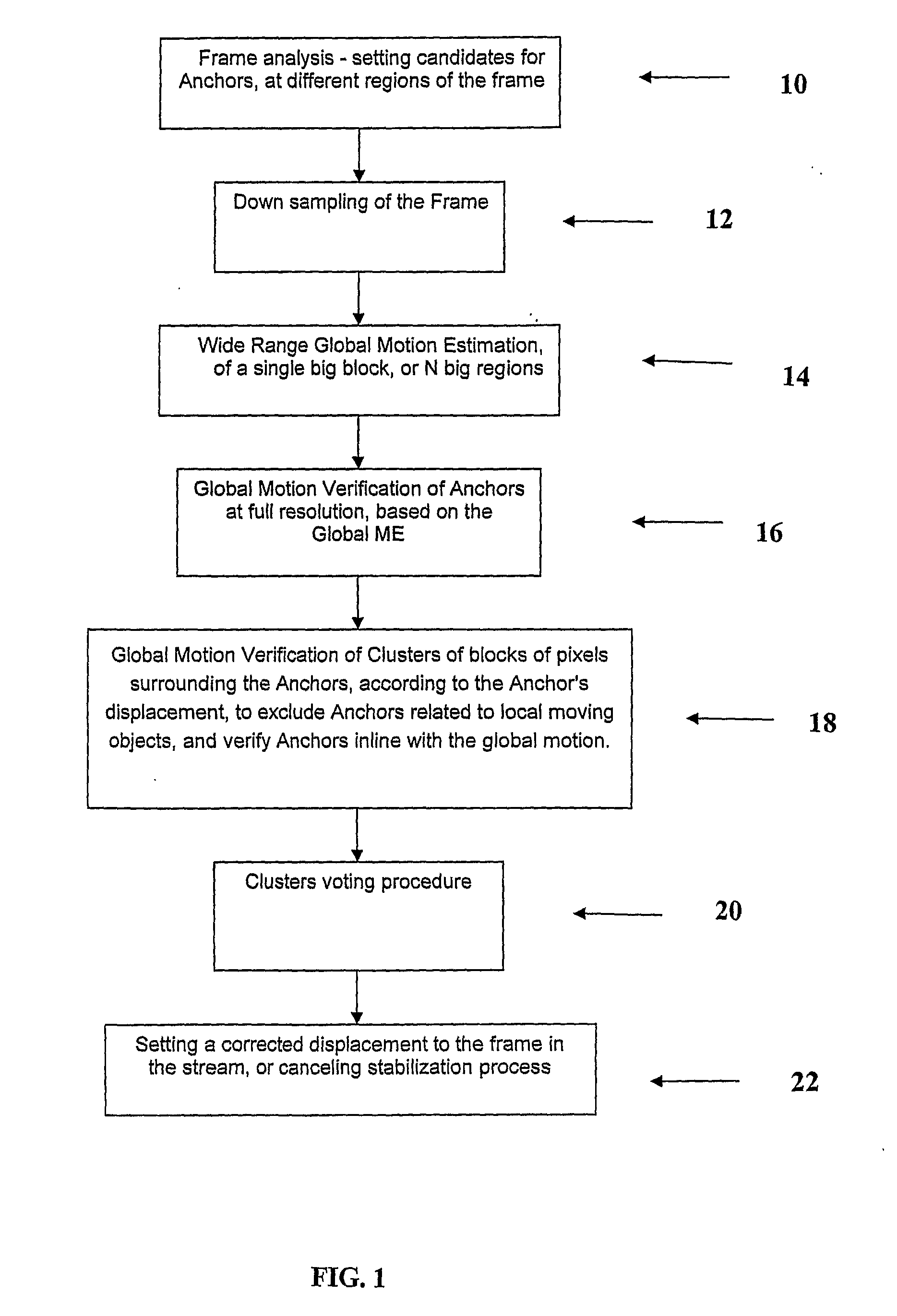

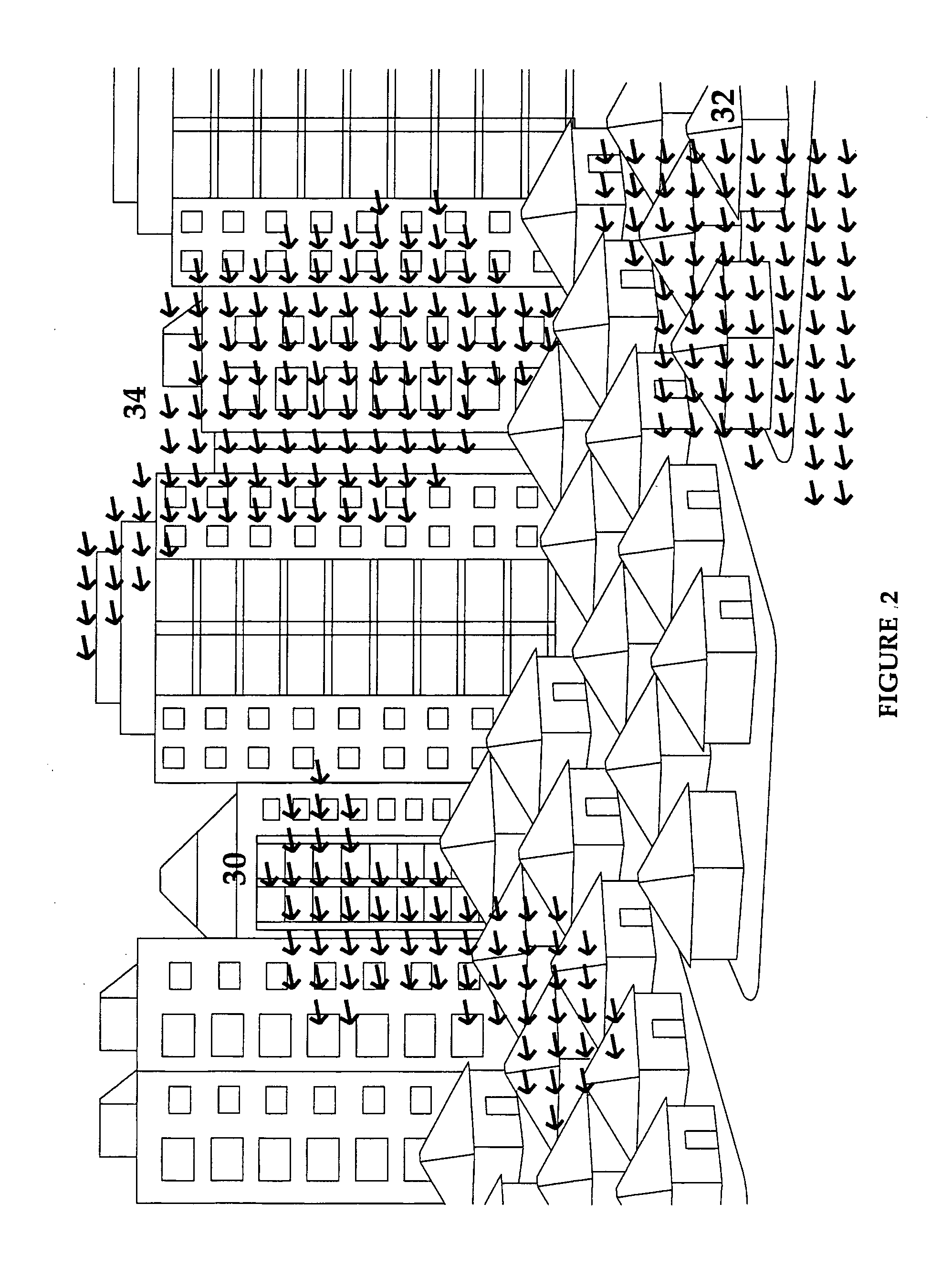

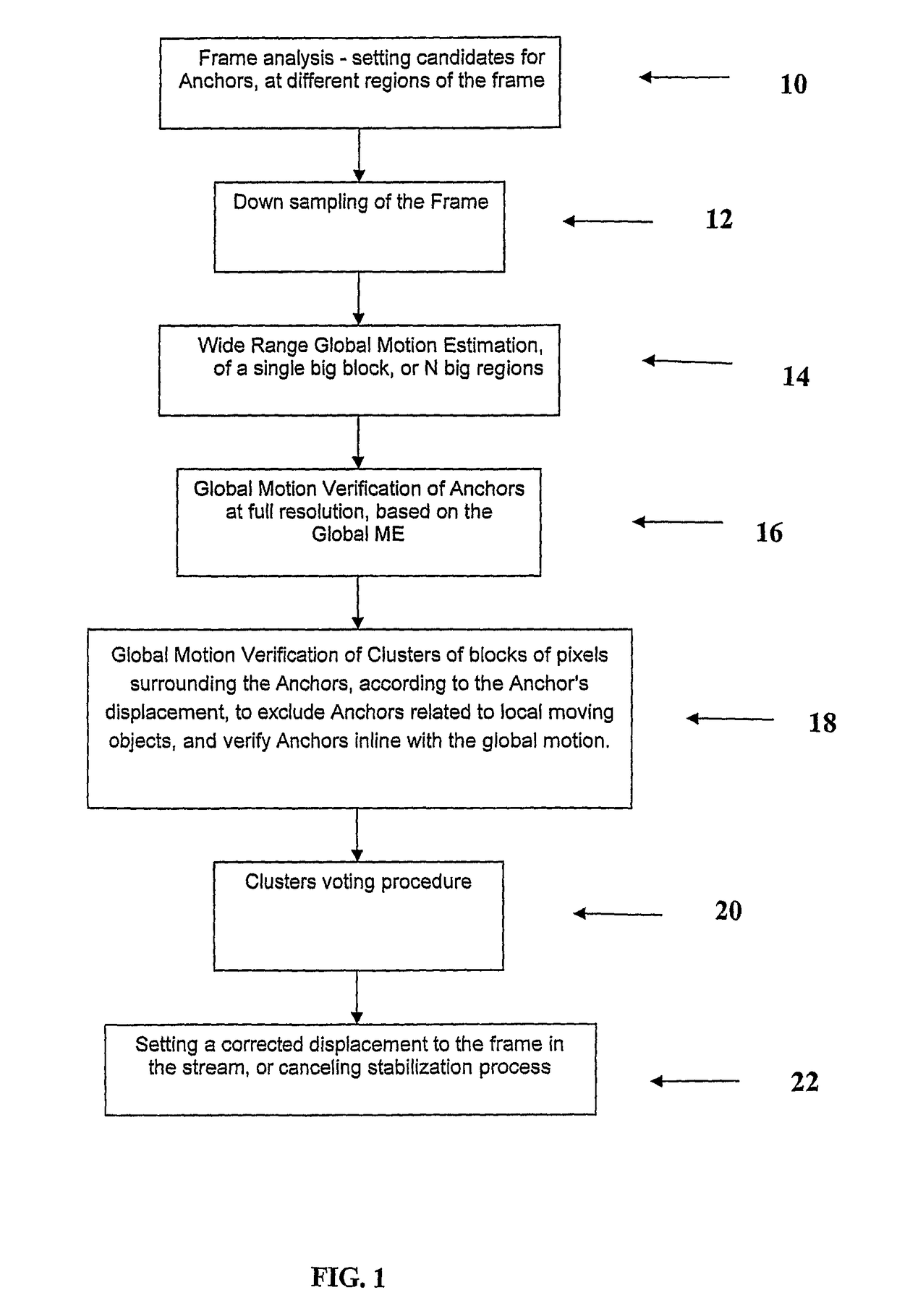

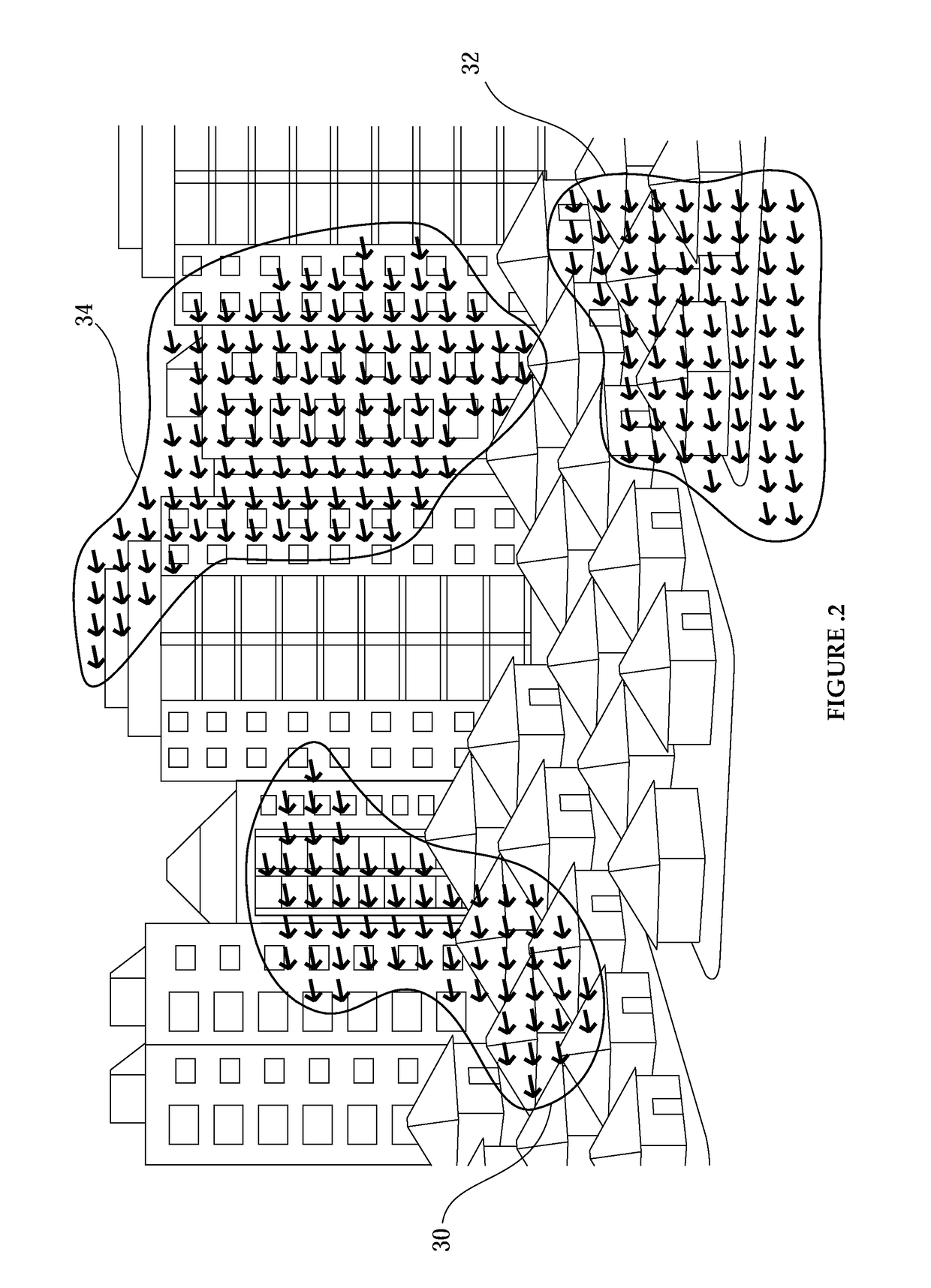

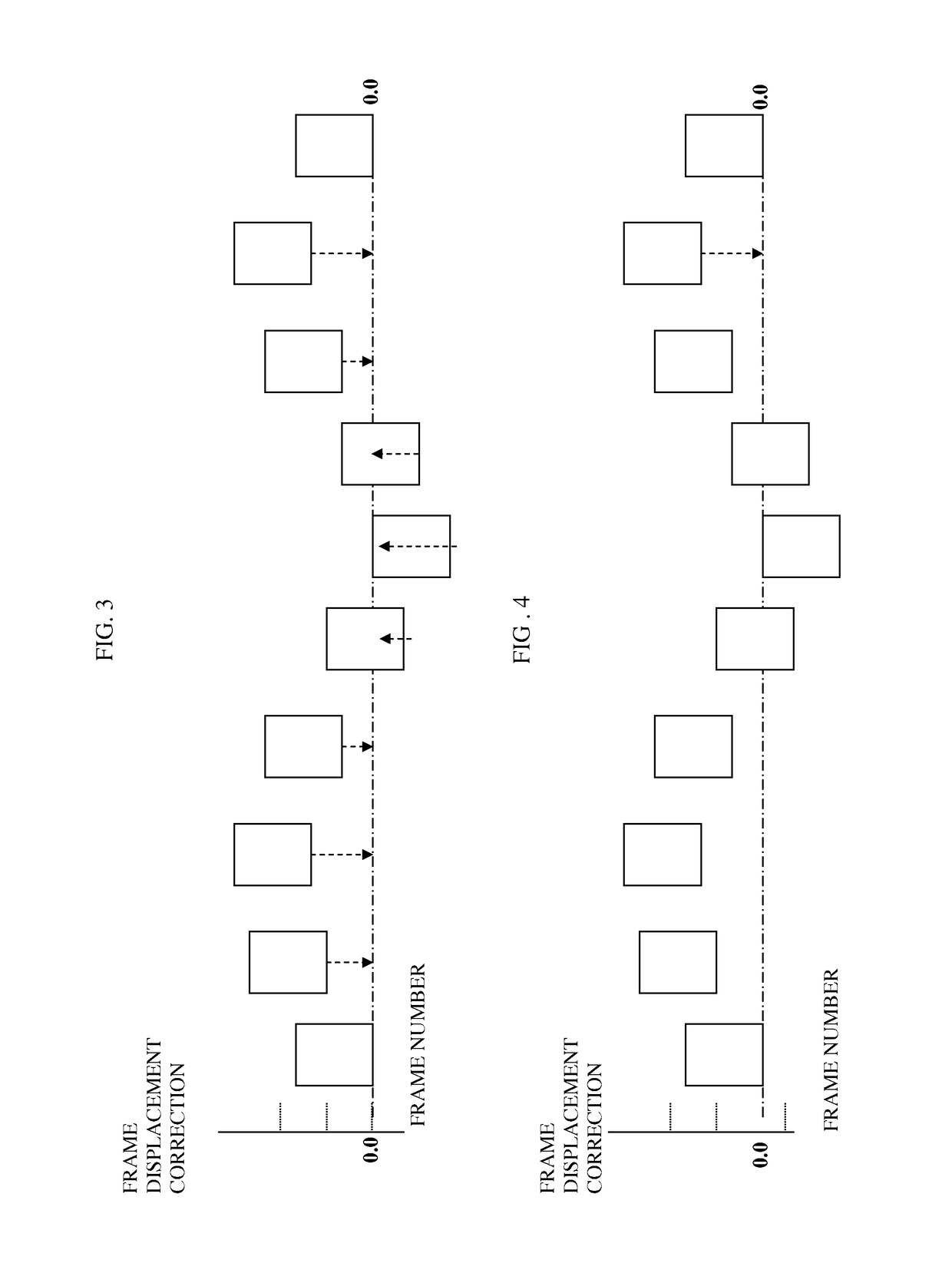

Image stabilizer

InactiveUS20090256918A1Smooth effectLess memoryTelevision system detailsImage analysisPattern recognitionDigital video

A method for digital video image stabilization, the method including: estimating, from at least one portion of a frame, global frame displacement between an initial reference digital video frame and a current frame in a video sequence of frames; verifying, for the entire frame, the validity of the estimated frame displacement; and compensating for the estimated frame displacement by aligning at least one frame in the sequence with respect to the initial reference frame; wherein the step of aligning includes producing a corrected motion vector for the frame to be aligned and displacing the frame within the video frames sequence in accordance with the corrected motion vector.

Owner:HUMAN MONITORING

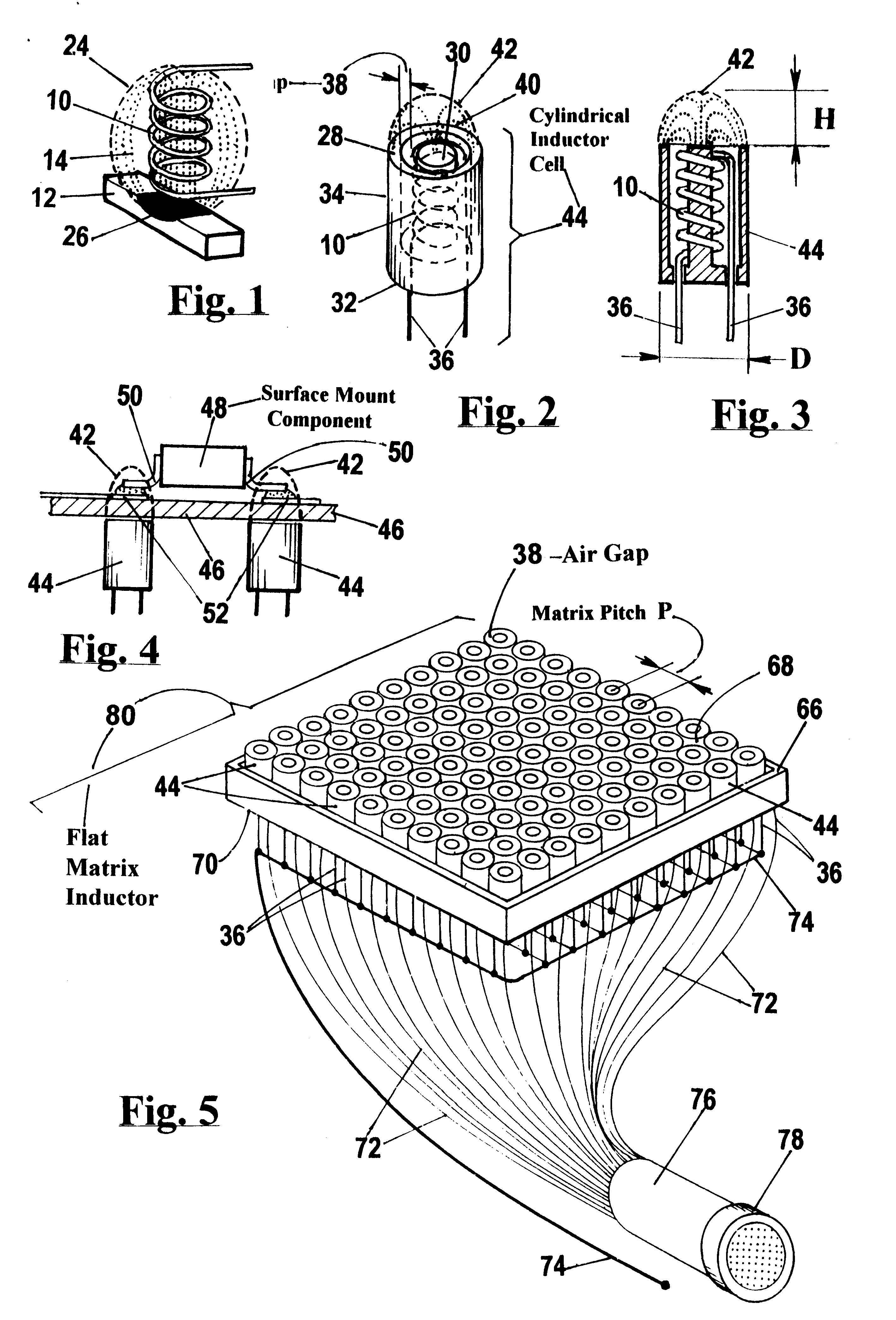

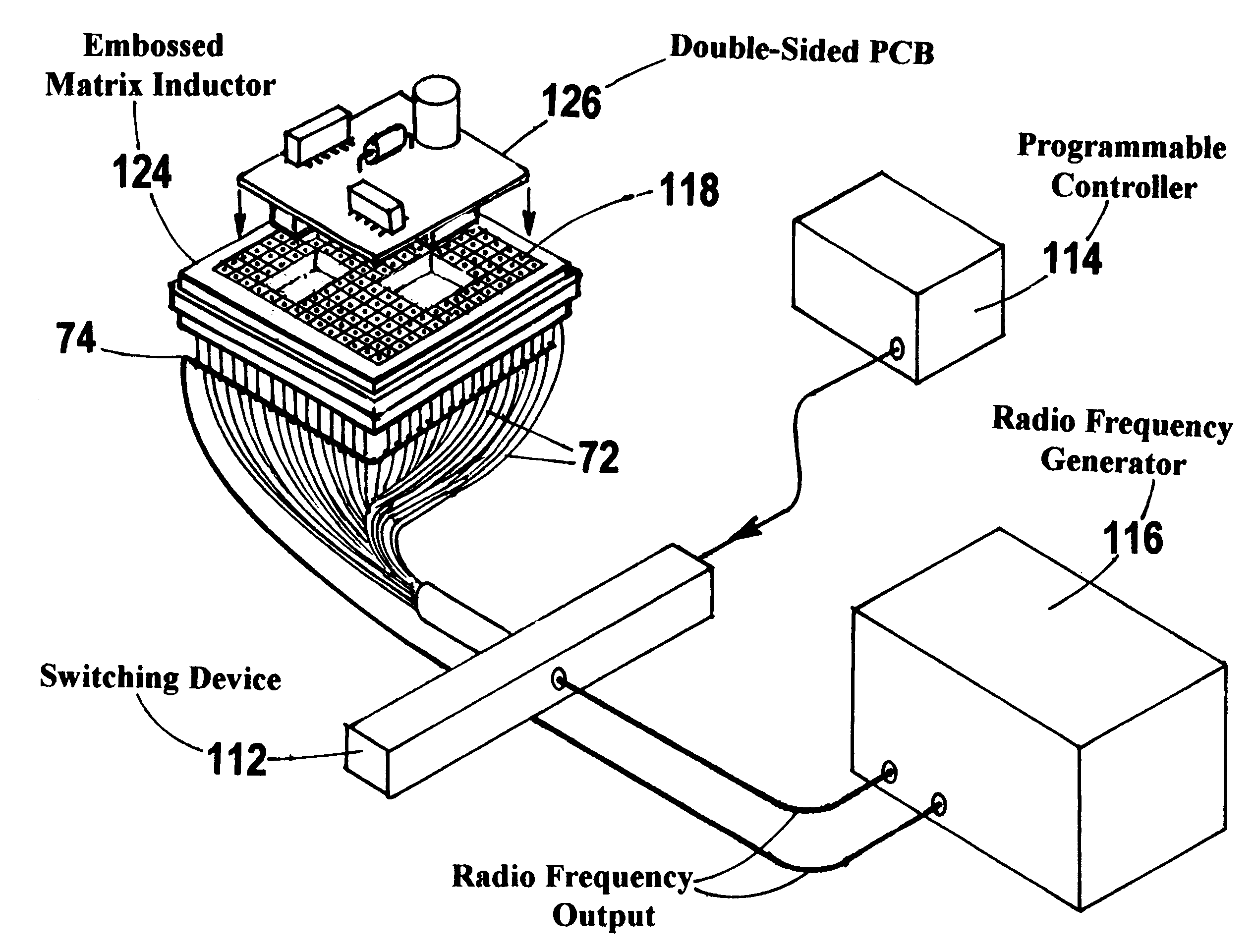

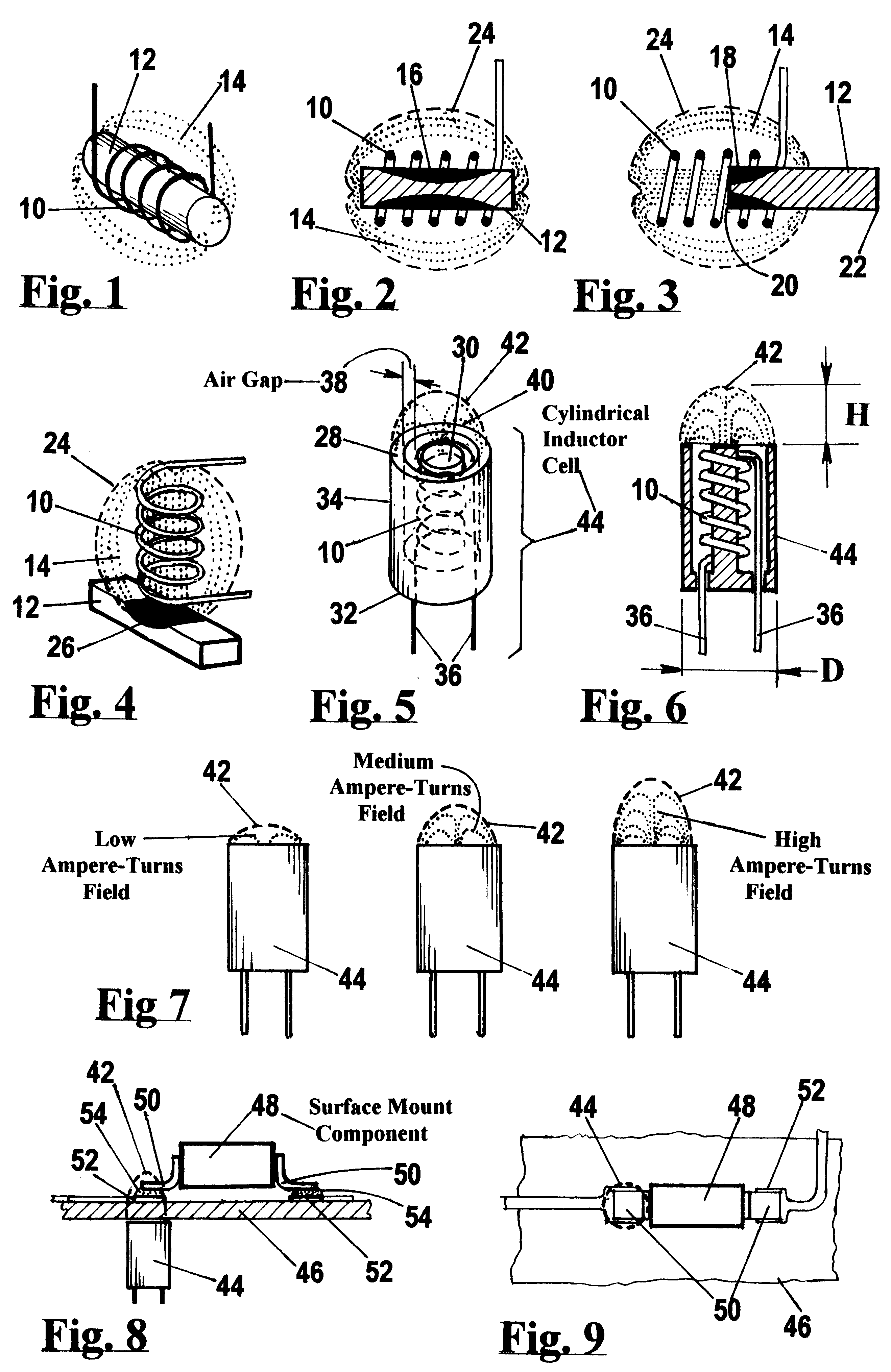

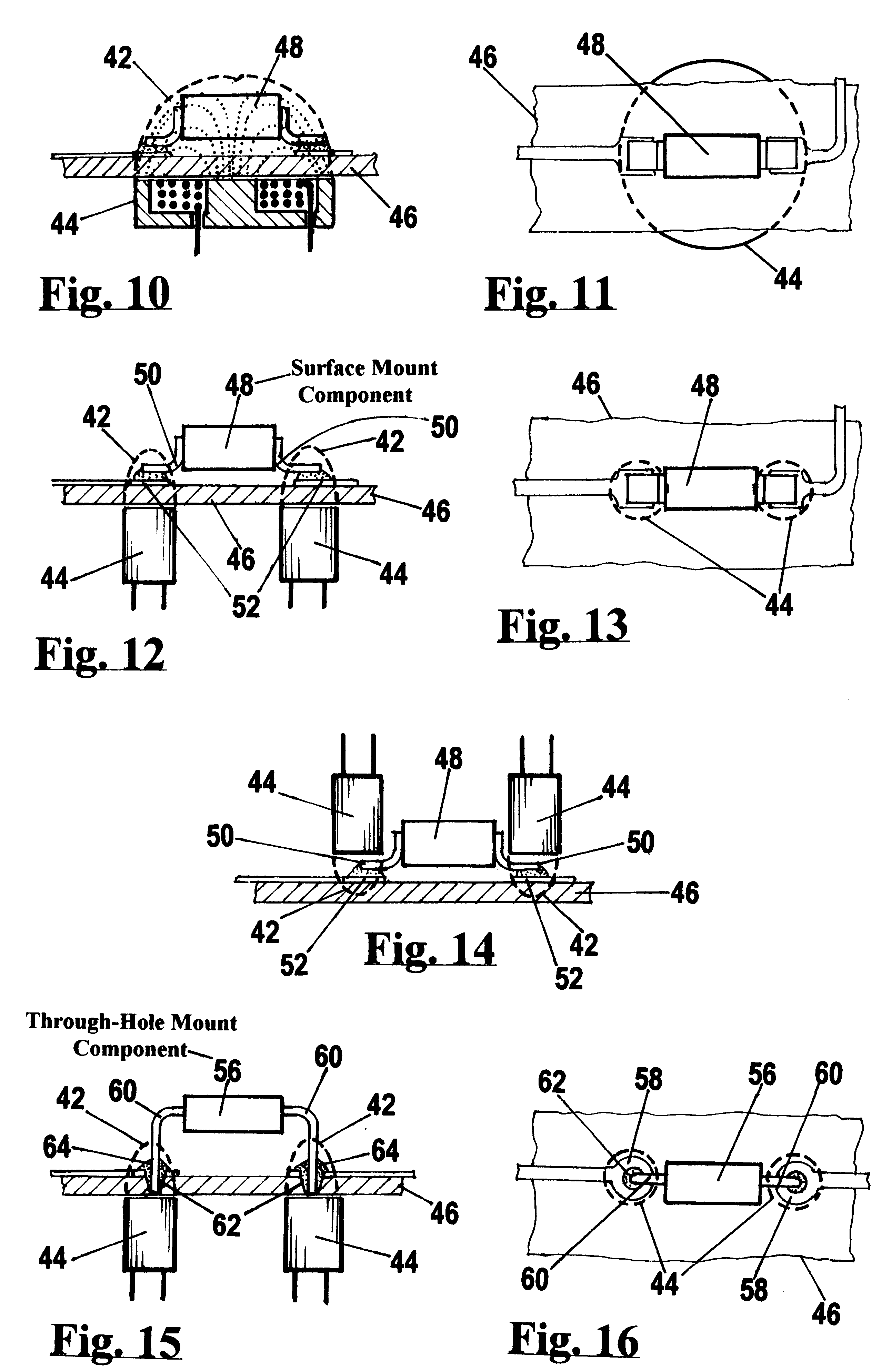

Matrix-inductor soldering apparatus and device

InactiveUS6188052B1Reduce manufactured-product costQuality improvementPrinted circuit assemblingLine/current collector detailsManufacturing technologySurface mounting

A new apparatus and process for soldering surface-mount and through-hole type electronic components into a printed circuit board (PCB) in an automated fashion utilizing localized electromagnetic induction heating. Current manufacture technology for packaging electronic components depends exclusively on the reflow and wave soldering processes. Both processes heat up to relatively high temperature the entire assembly, namely its PCB and all the electronic components been soldered into it. Such high temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention however, during a soldering operation only the leads and pads, or joints, being soldered are heated but neither the body, or casing, of said electronic components nor the dielectric material forming said PCB are heated. Because of this selectively localized heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. This invention consumes about 200 times less energy than the reflow and wave soldering processes. Also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a PCB is completed. This invention also provides for an useful de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

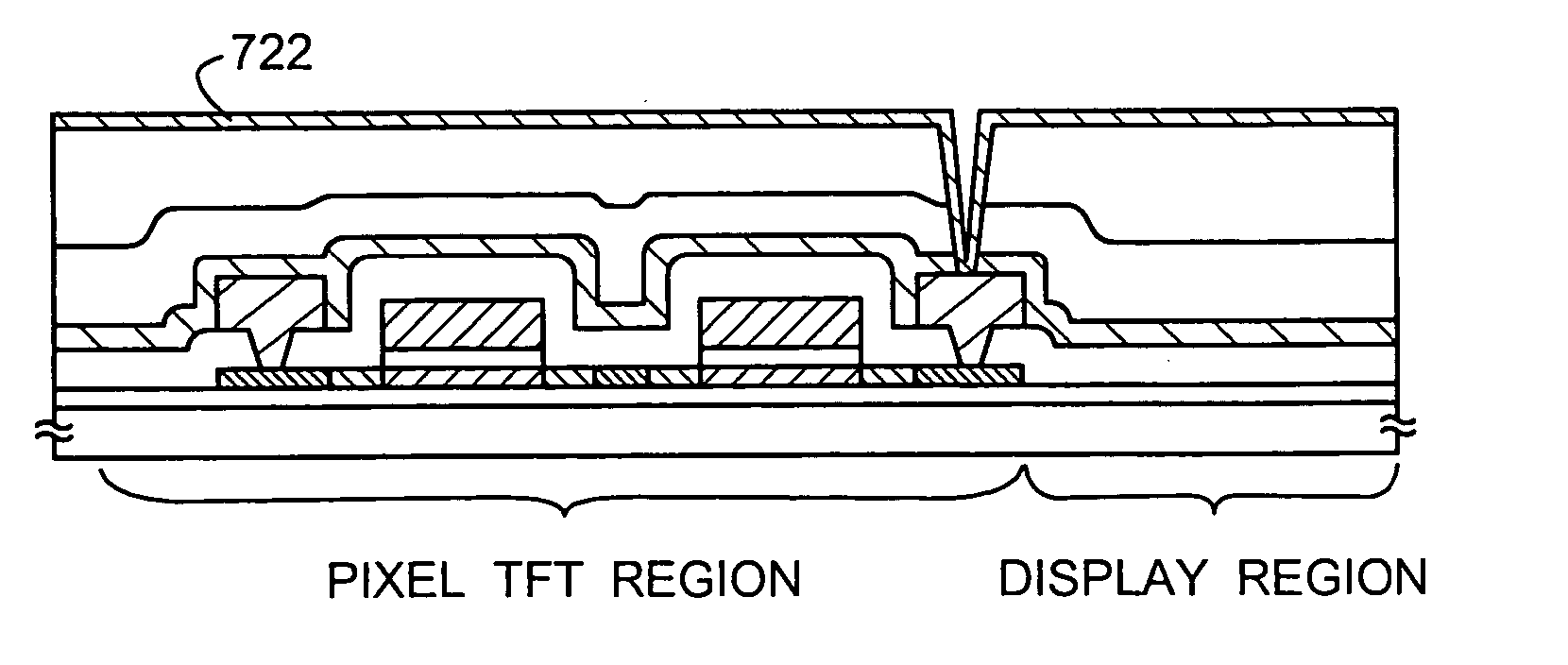

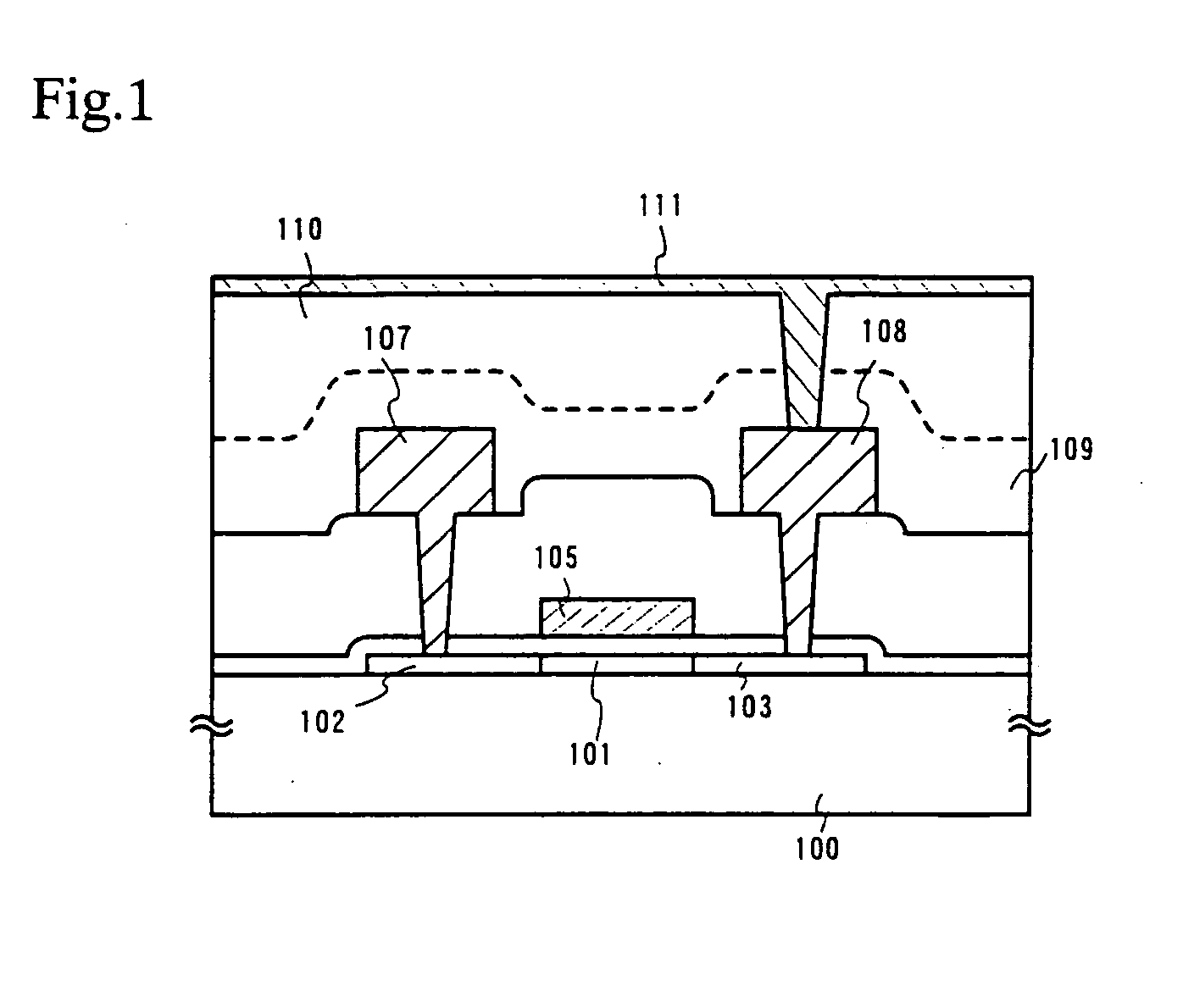

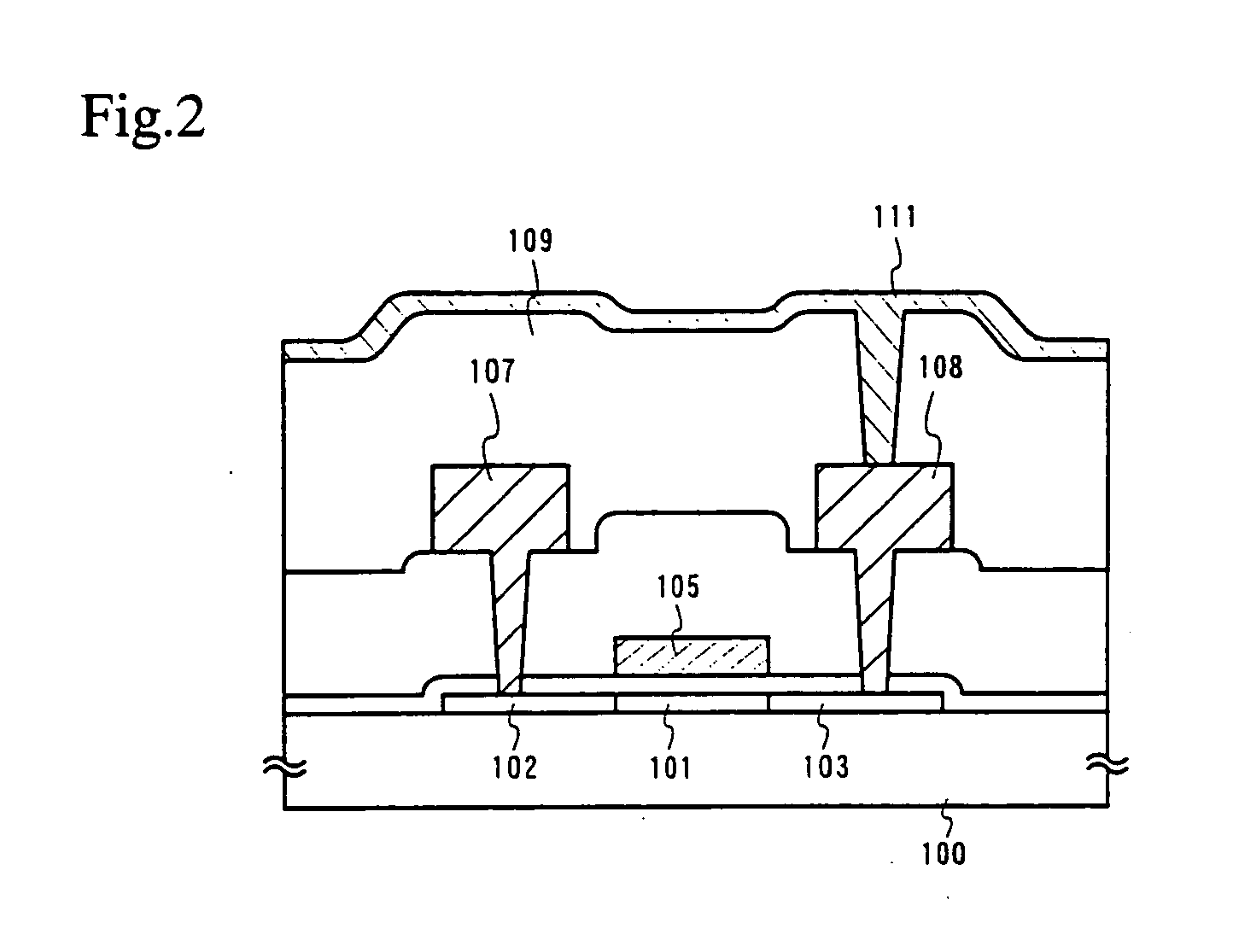

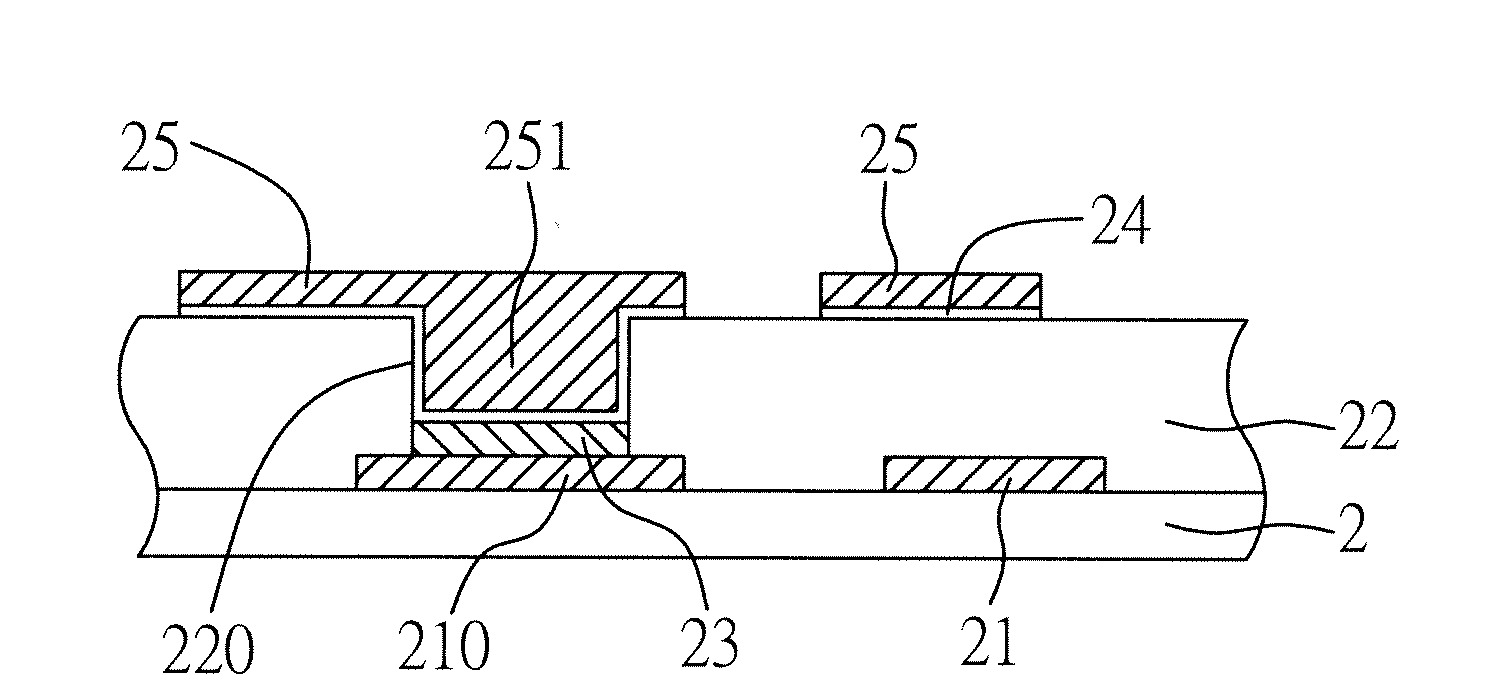

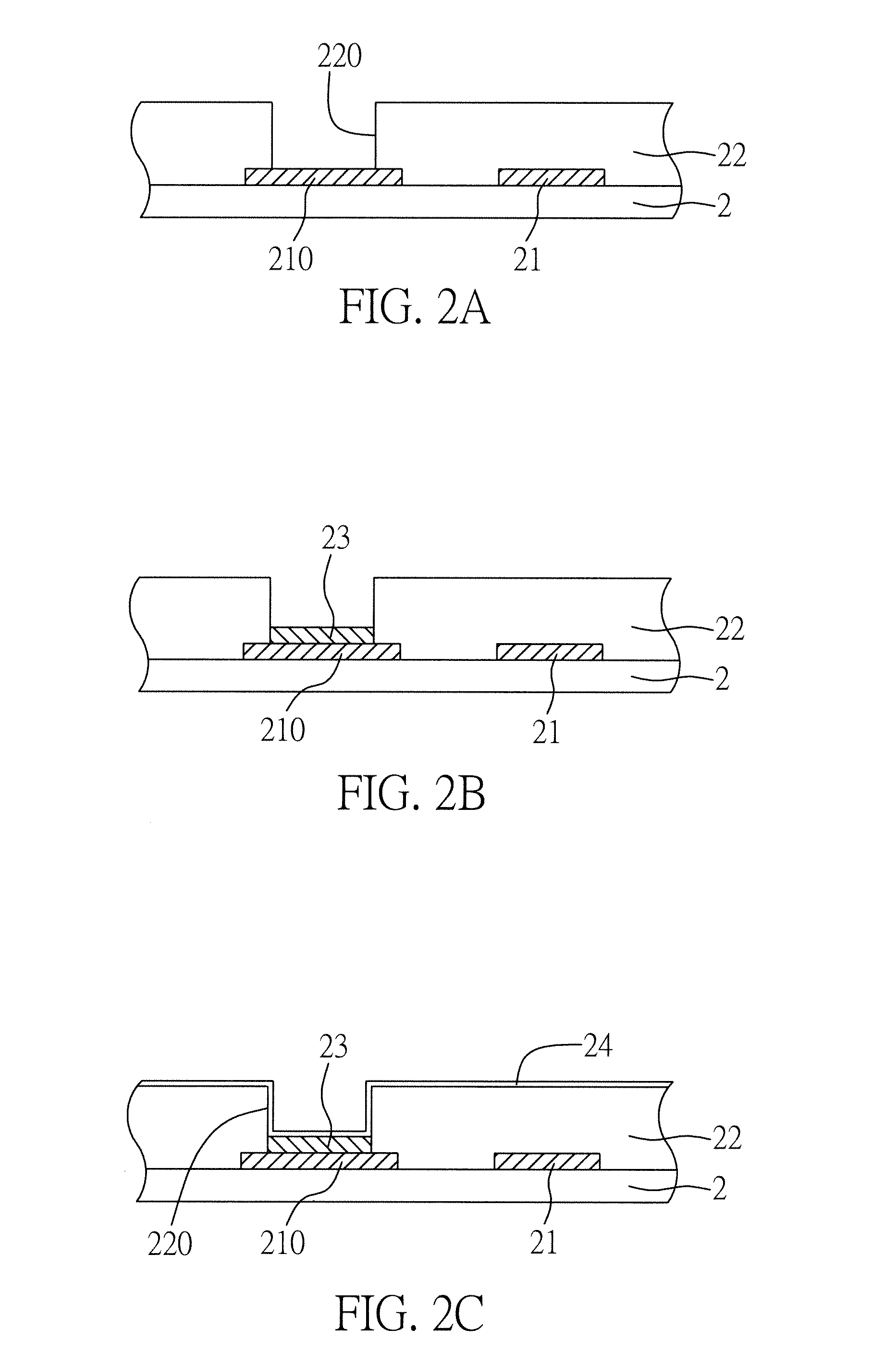

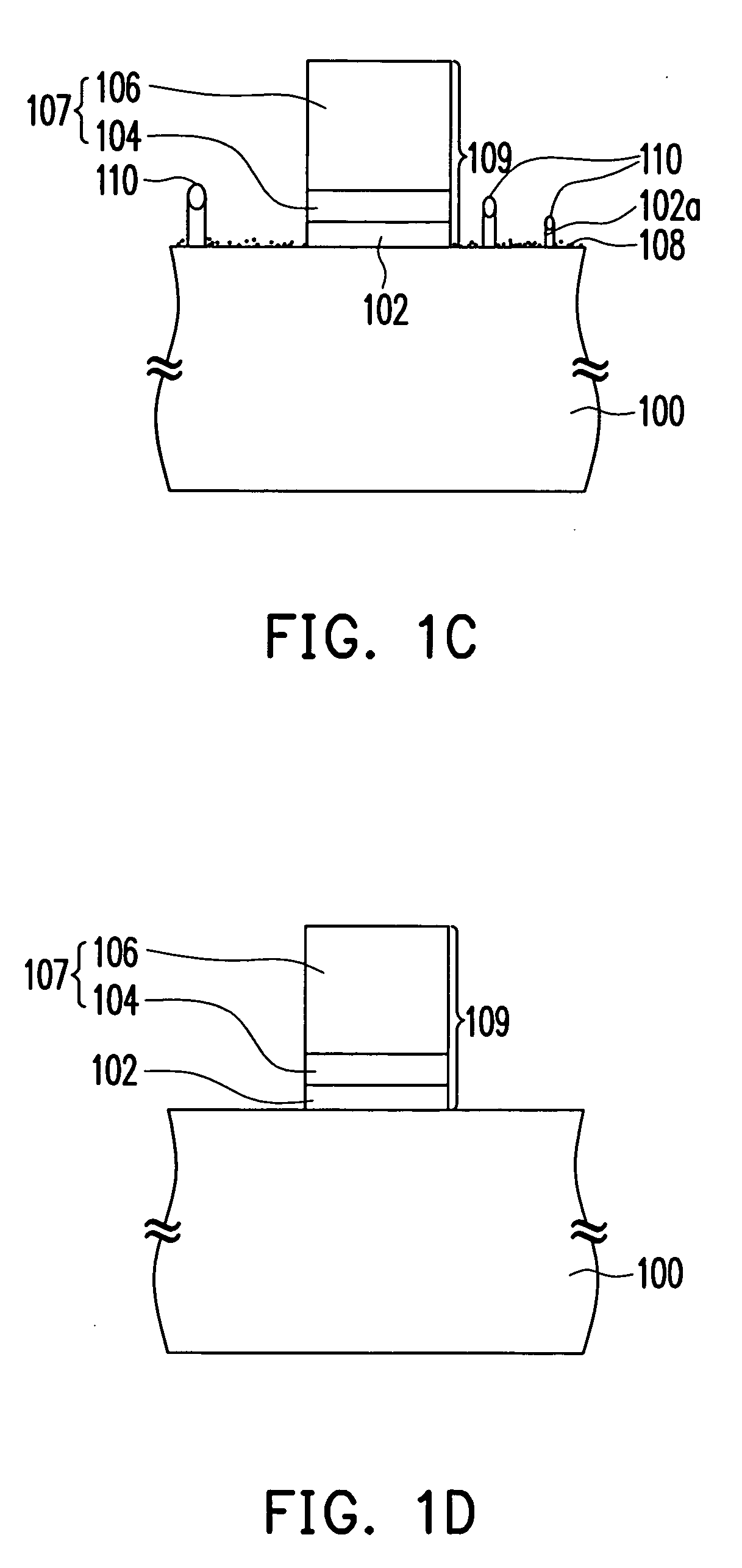

Method of fabricating display device

InactiveUS20050037529A1Highly reliable wiringUniform imagingSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDisplay device

The present invention improves the reliability of wirings, facilitates the orientation control of liquid crystal, or improves a reflectance of a reflective liquid crystal display device. In the case where a plurality of levelling films are laminated, a first levelling film is formed to have a thickness smaller than that of a second levelling film, thereby realizing a higher levelling rate. Therefore, unevenness of the surface due to level differences is reduced and it becomes possible to attain the above objects.

Owner:SEMICON ENERGY LAB CO LTD

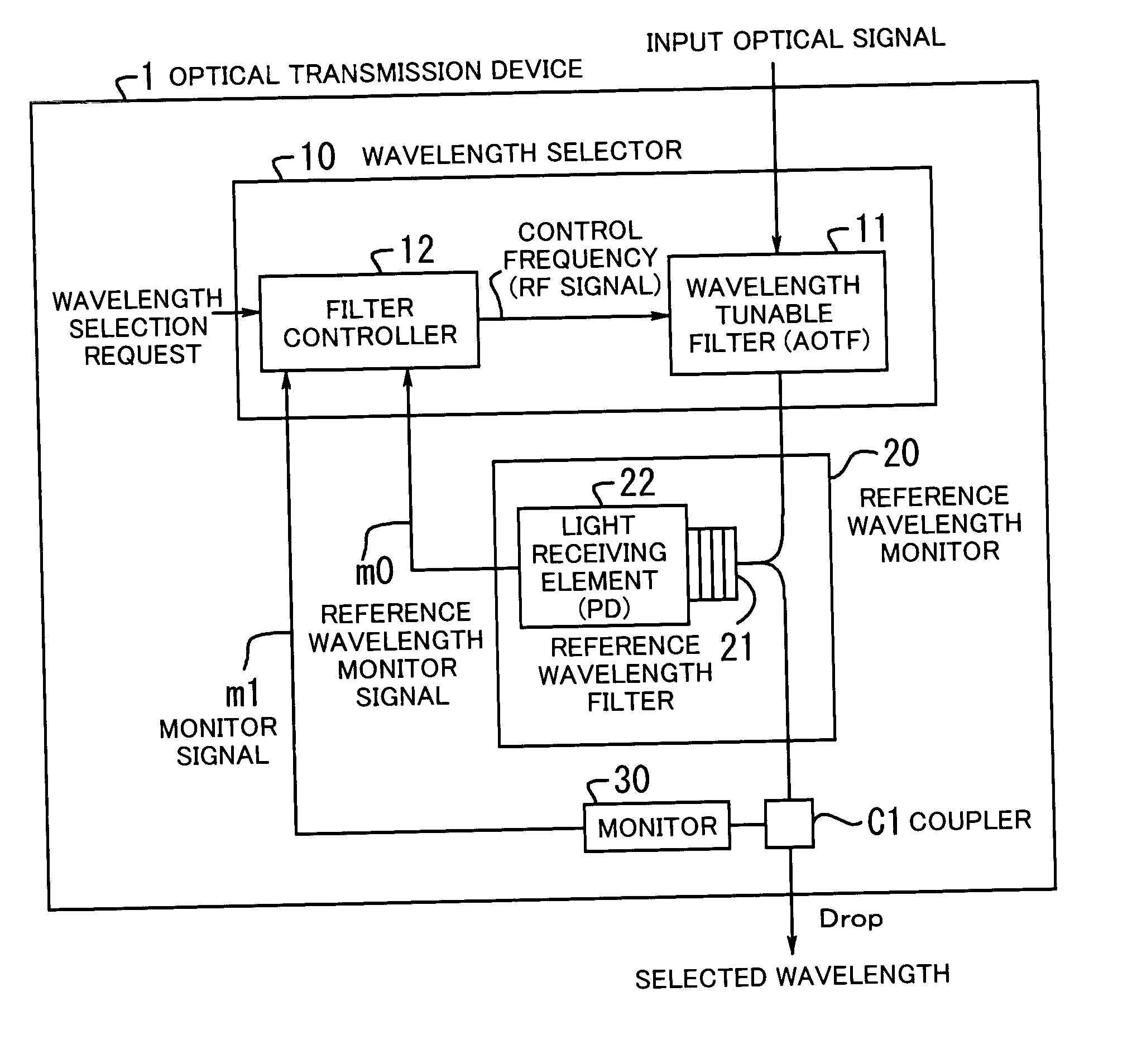

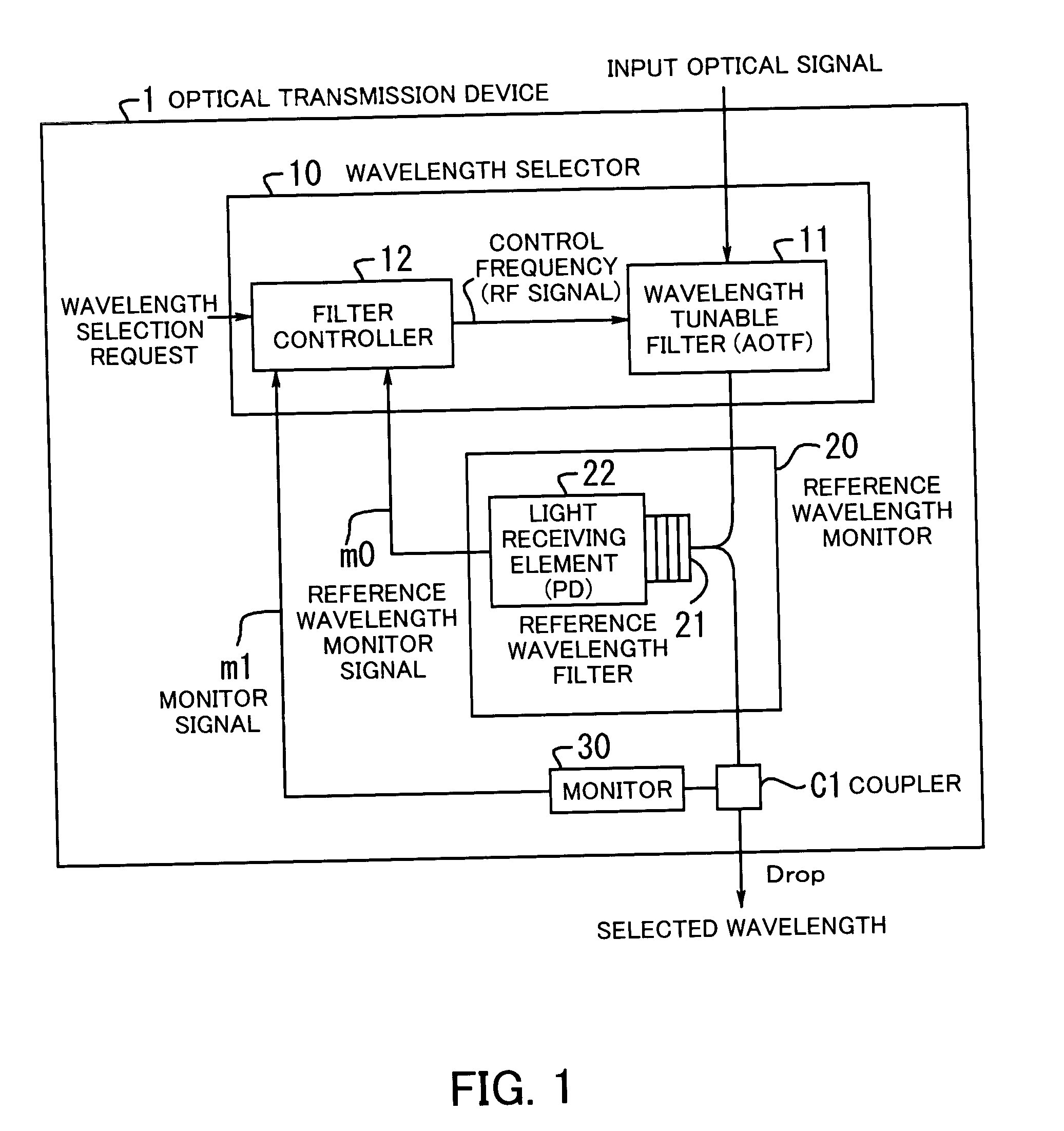

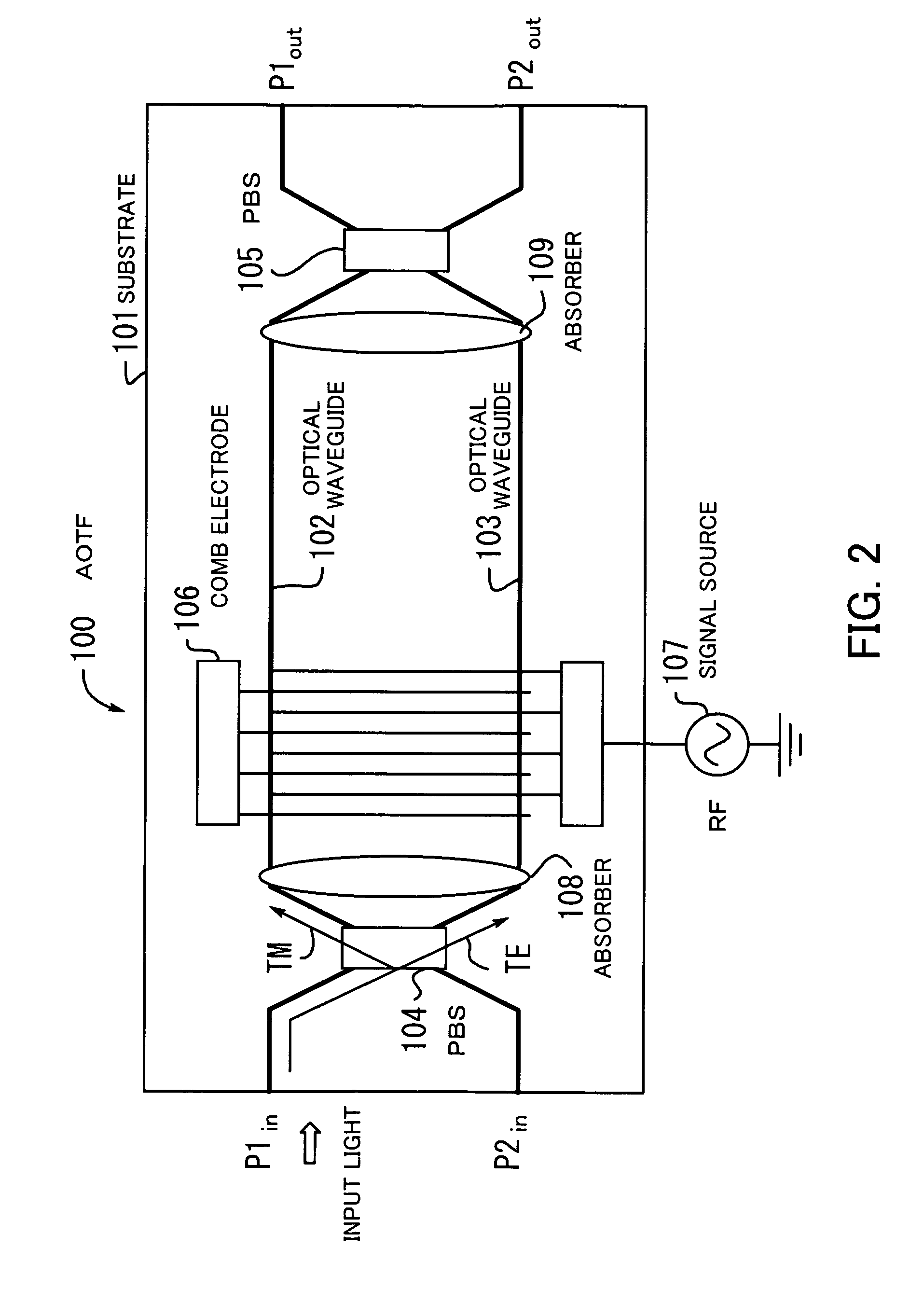

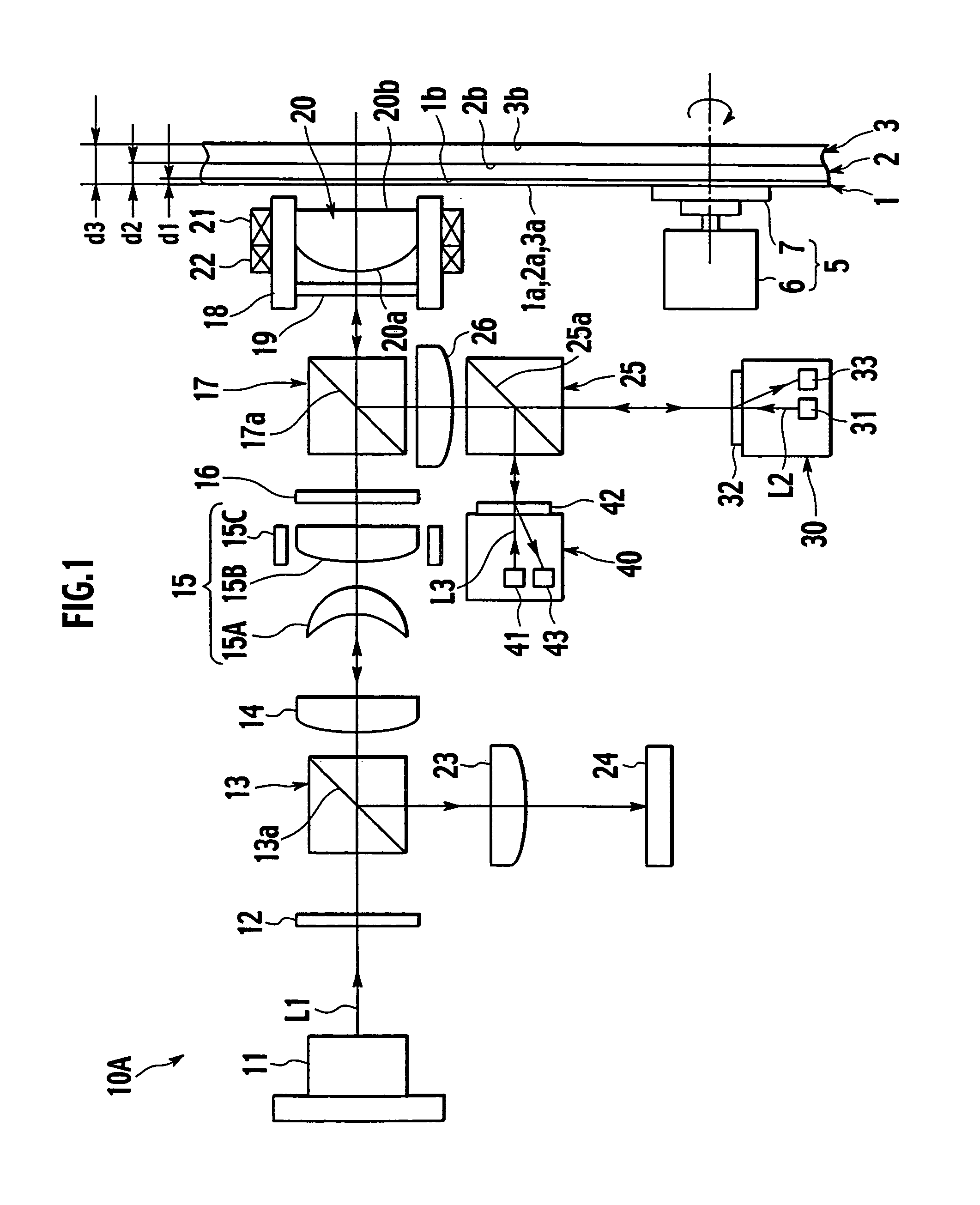

Optical transmission device

InactiveUS20050169633A1Quality improvementImprove reliabilityRing-type electromagnetic networksLaser detailsWavelength filterTarget control

An optical transmission device improved in quality and reliability of OADM function and permitting configuration of highly-flexible, economical OADM networks. A wavelength tunable filter variably selects a wavelength according to a control frequency. A filter controller applies the control frequency to the filter while scanning wavelength over an entire signal bandwidth, to detect, from a reference wavelength monitor signal supplied thereto, a reference control frequency which permits the filter to select a reference wavelength and according to which wavelength is matched. On receiving a wavelength selection request, the controller obtains a target control frequency from the reference control frequency and the position of a target wavelength relative to the reference wavelength, and applies the obtained frequency to the filter. A reference wavelength filter transmits the reference wavelength therethrough. A light-receiving element monitors the transmitted reference wavelength to generate the monitor signal.

Owner:FUJITSU LTD

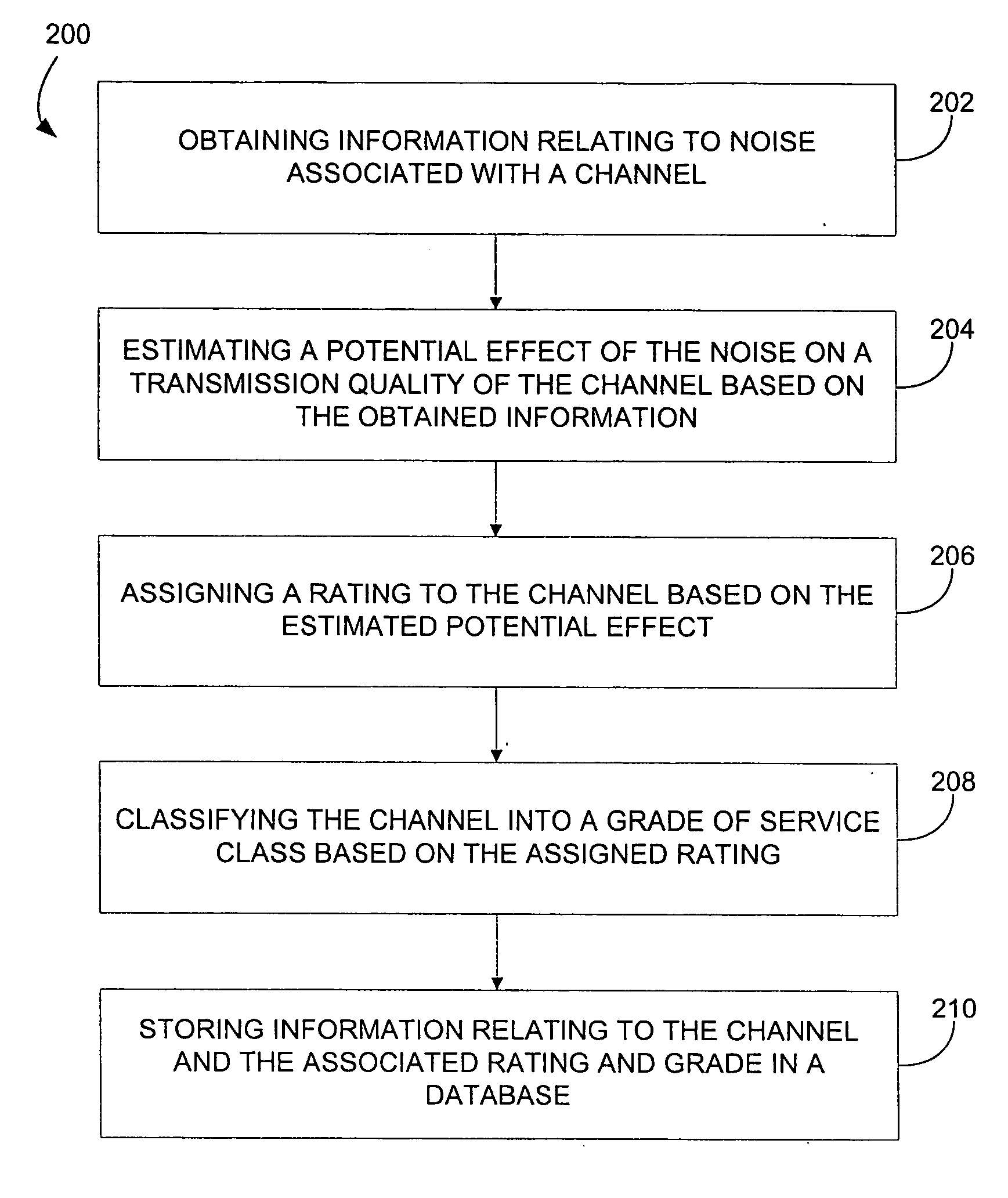

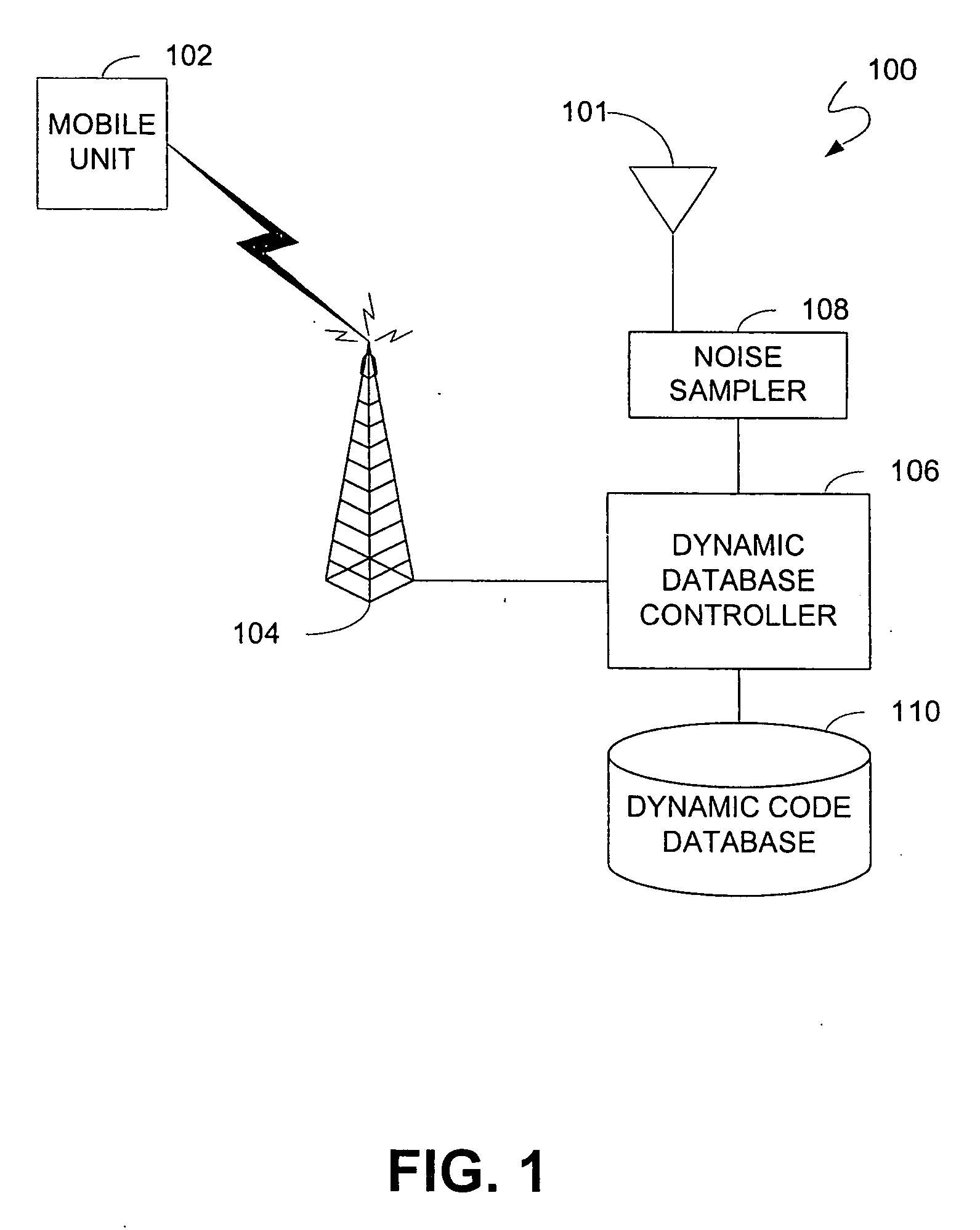

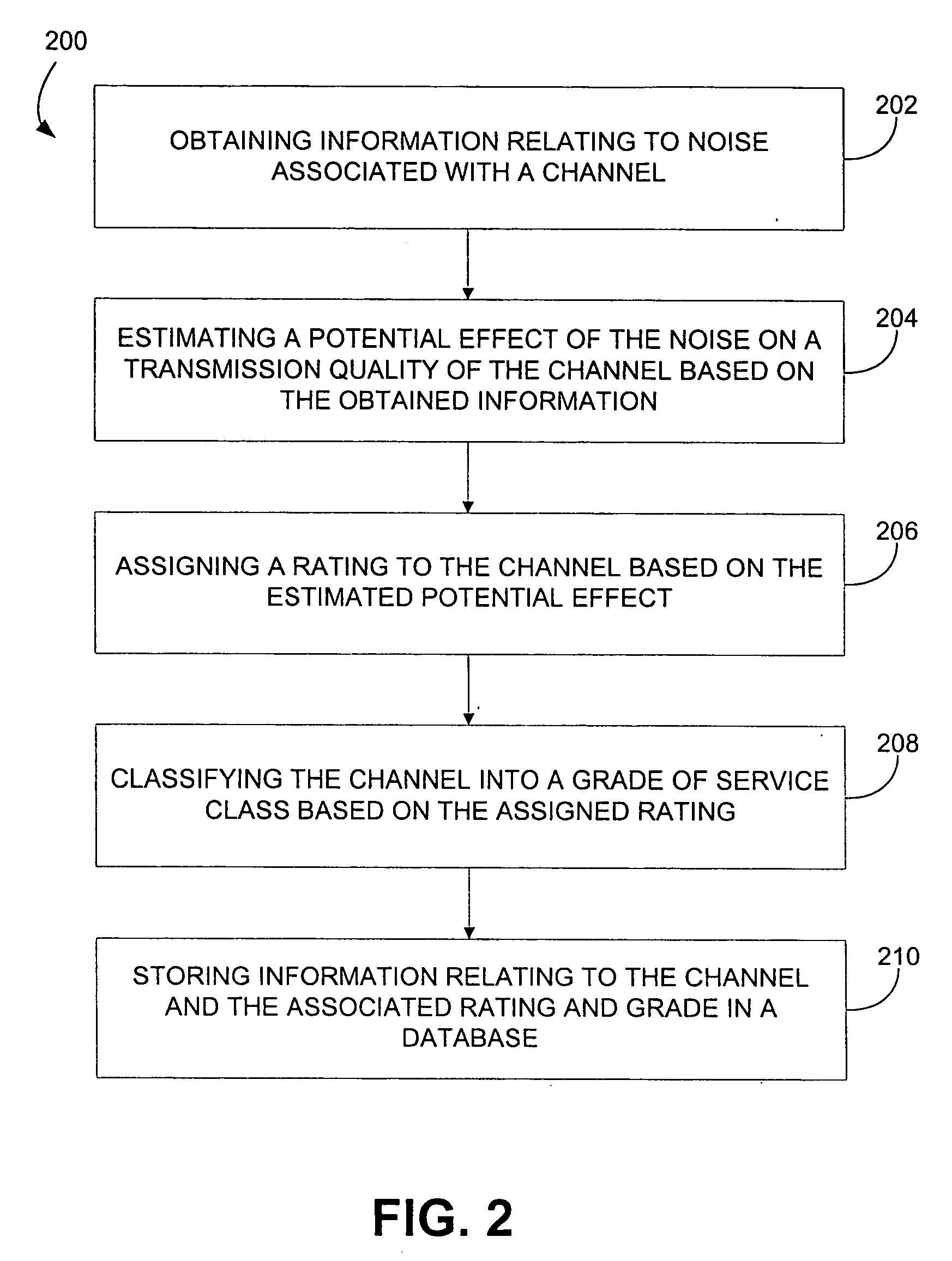

Mapping radio-frequency noise in an ultra-wideband communication system

InactiveUS20060285577A1Improve quality and reliabilityError prevention/detection by using return channelError detection/prevention using signal quality detectorTime segmentEngineering

A system and method for mapping. radio-frequency (RF) noise, and estimating channel quality in a multi-channel ultra-wideband communication system is provided. One method includes placing a plurality of time bins within a plurality of time frames and assigning a plurality of UWB communication channels comprising selected time bins. RF noise amplitude data is then sampled from selected time bins. The sampled RF noise amplitude data from the time bins is then averaged, thereby obtaining an average RF noise amplitude in each of the plurality of channels. The RF noise amplitude indicates the amount of RF noise present in a channel. The channels may then be ranked based on the characteristics of the RF noise.

Owner:INTELLECTUAL VENTURES HOLDING 81 LLC

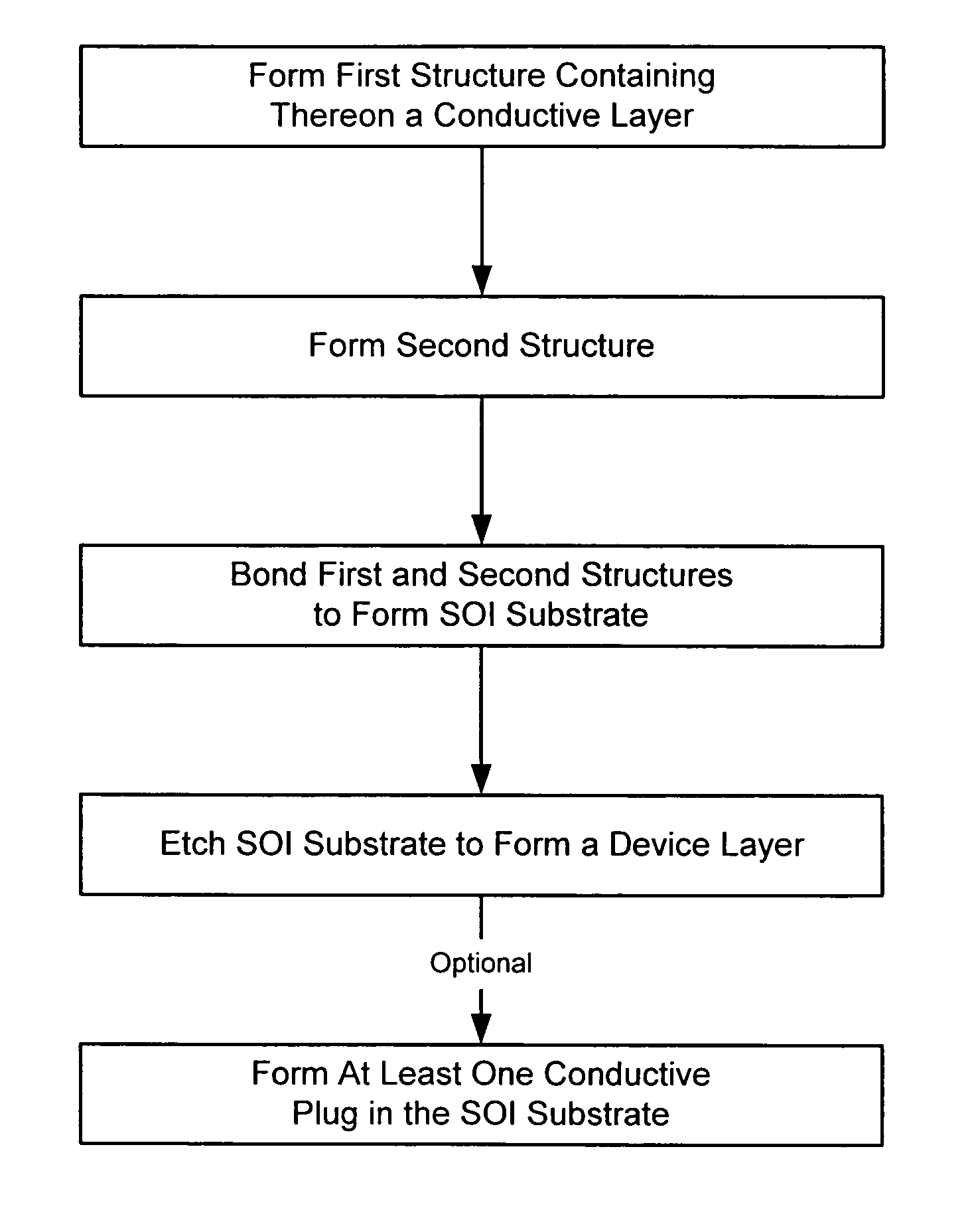

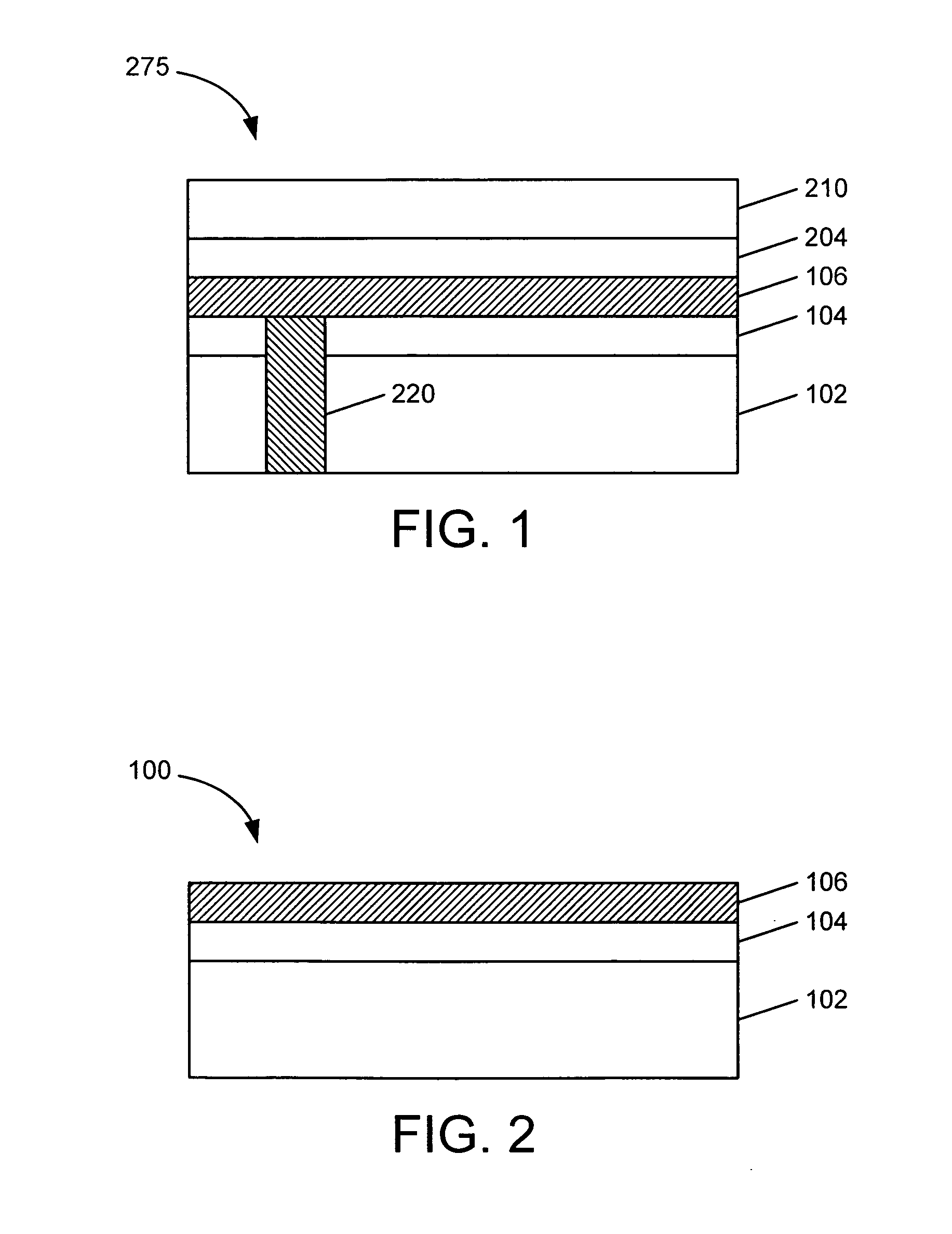

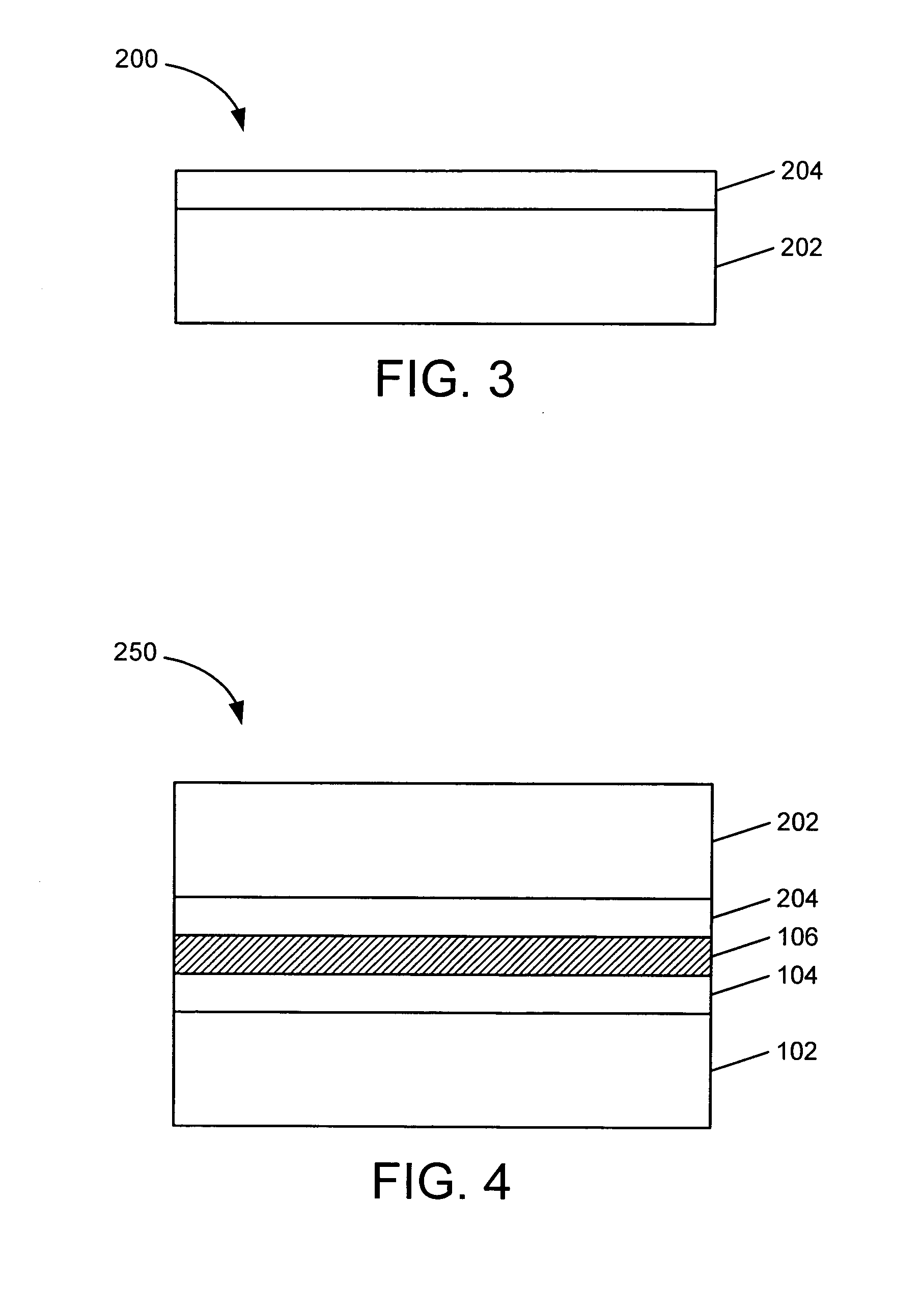

Heat removal in SOI devices using a buried oxide layer/conductive layer combination

InactiveUS7238591B1Improve heat transfer performanceQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerBuried oxide

A method of forming a silicon-on-insulator substrate is disclosed, including providing a silicon substrate; depositing a first insulation layer over the silicon substrate; forming a conductive layer over the first insulation layer to a first structure; providing a second structure comprising a silicon device layer and a second insulation layer; bonding the first structure and the second structure together so that the conductive layer is located between the first and second insulation layers; and removing a portion of the silicon device layer thereby providing the silicon-on-insulator substrate having two discrete insulation layers. In one embodiment, the method further includes forming at least one conductive plug through the silicon substrate and the first insulation layer and / or the second insulation layer so as to contact the conductive layer. Methods of facilitating heat removal from the device layer are disclosed.

Owner:GLOBALFOUNDRIES INC

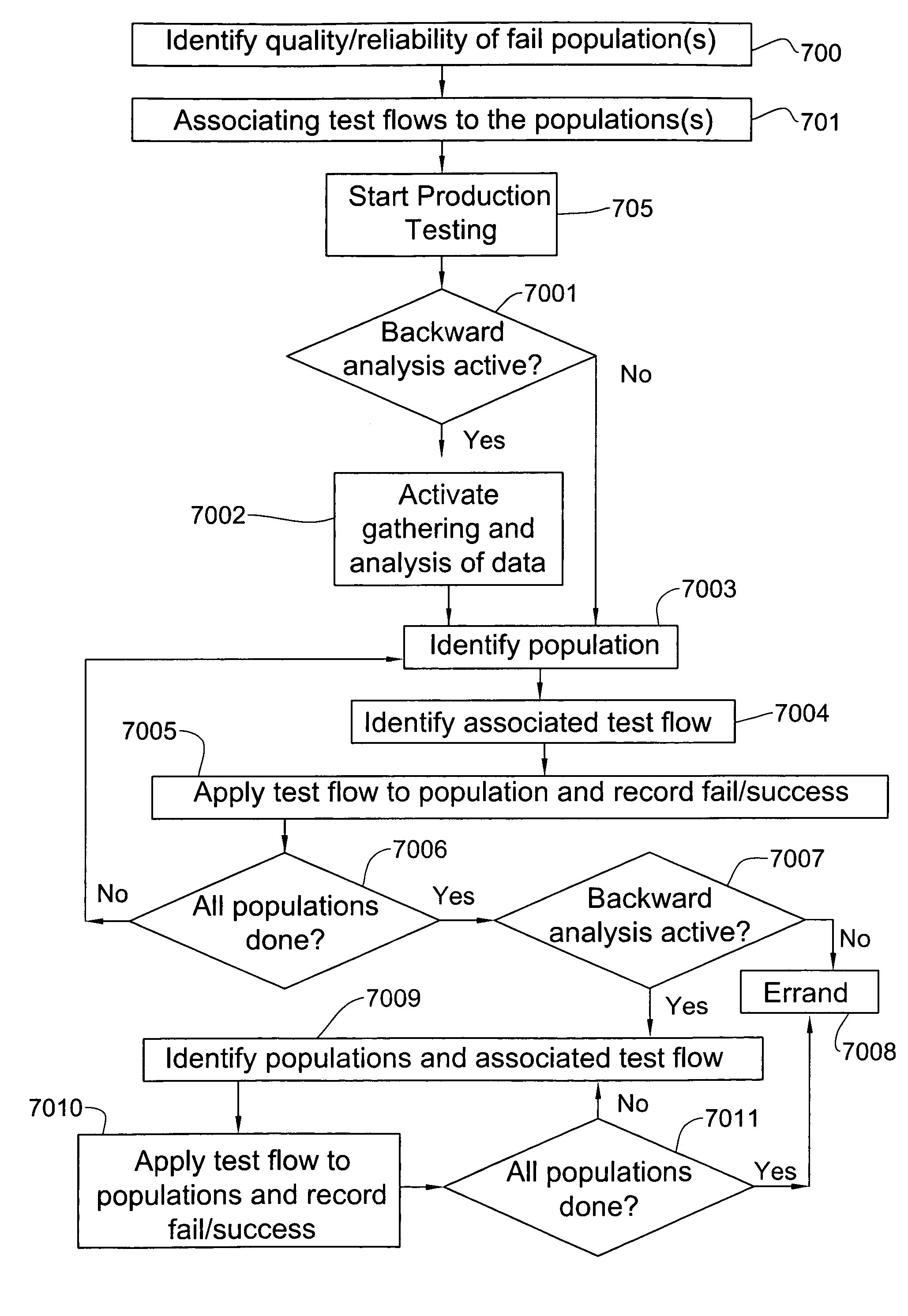

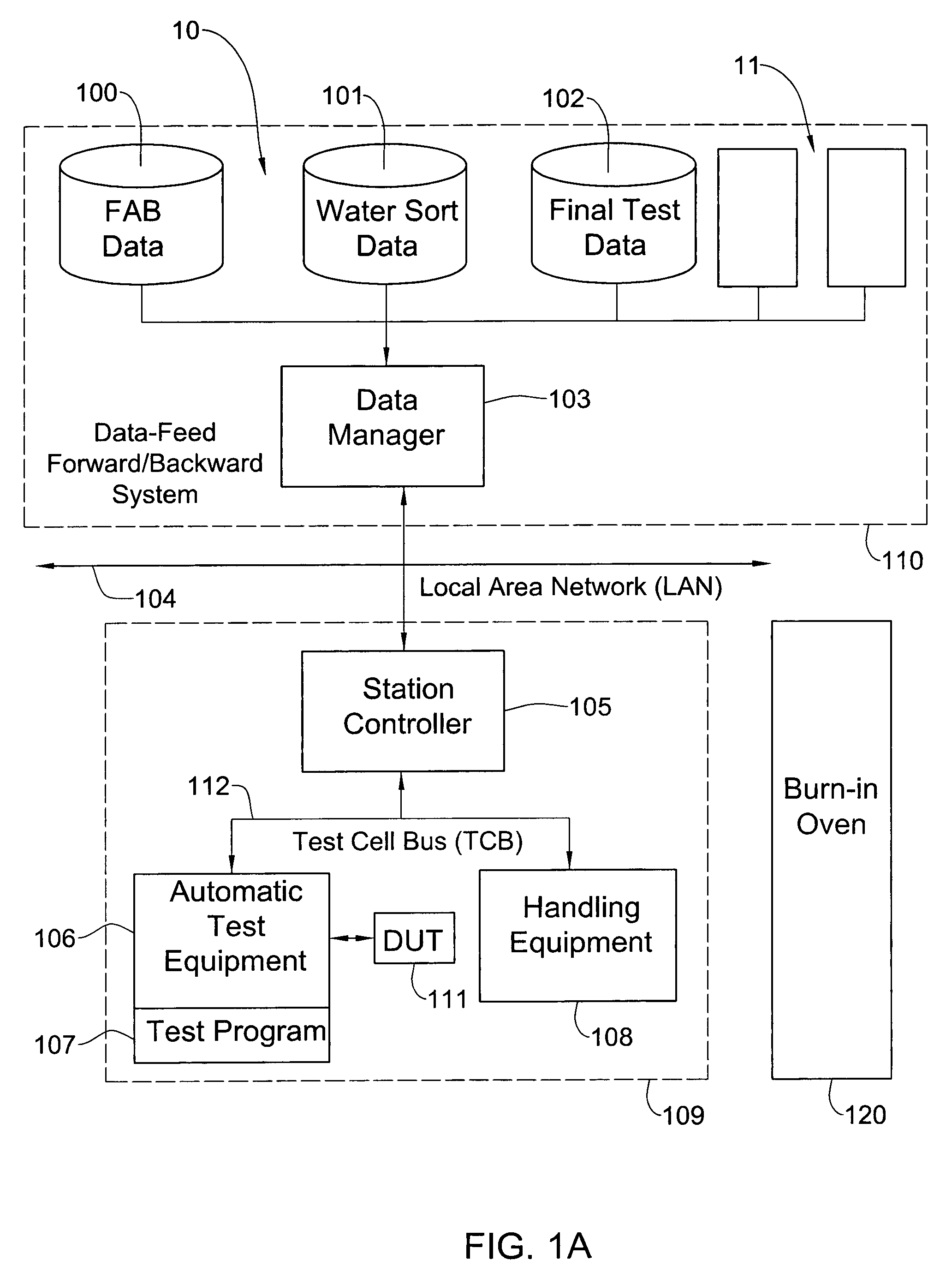

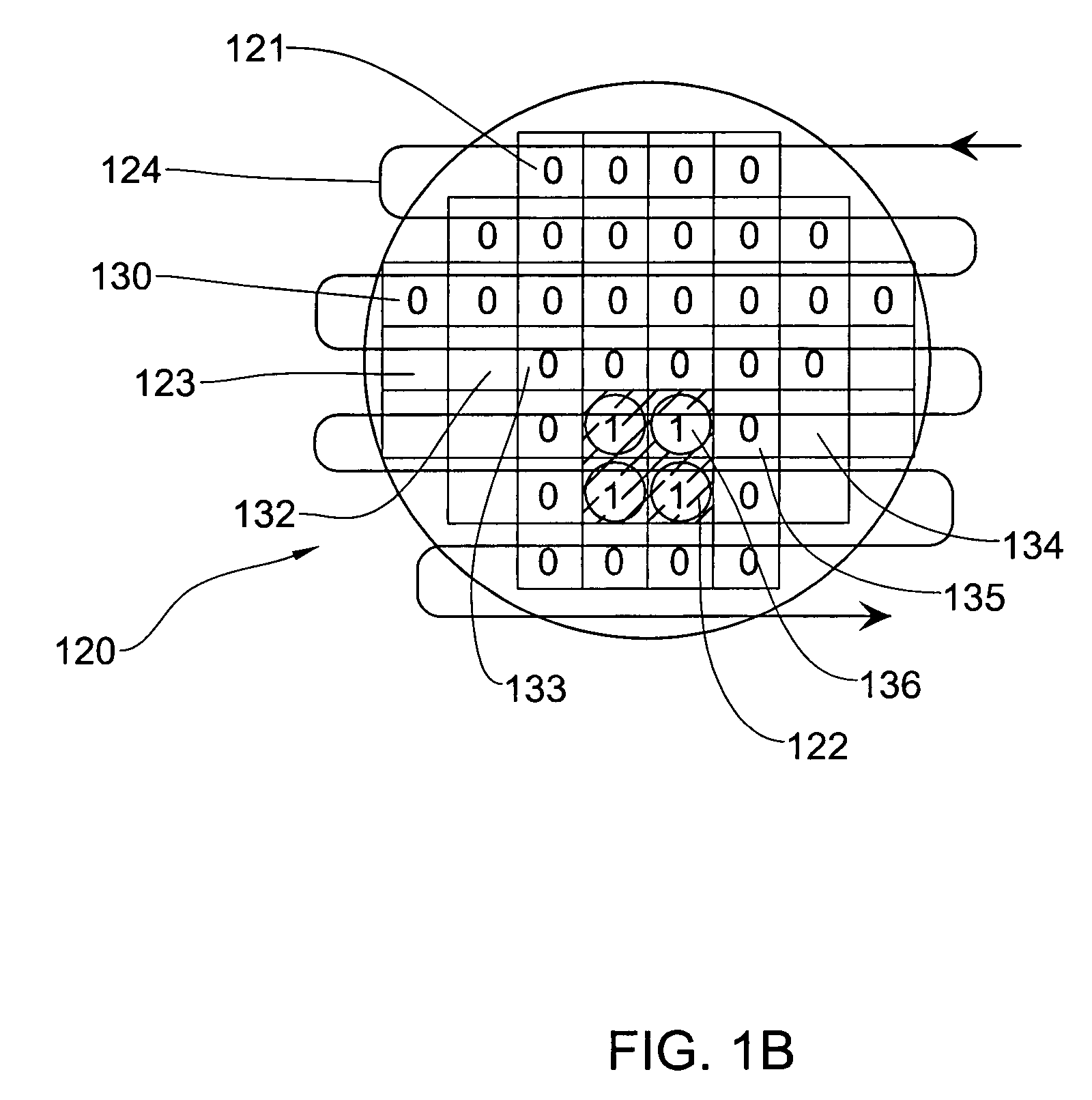

Augmenting semiconductor's devices quality and reliability

ActiveUS7340359B2Improve reliabilityImprove quality and reliabilityResistance/reactance/impedenceStatic storageTest flowCrowds

A method for augmenting quality or reliability of semiconductor units, including providing few populations of semiconductor units that are subject to quality or reliability testing. The populations include few quality or reliability fail candidate populations and other population(s). The method includes the step of associating test flows to the populations. Each test flow includes stress testing sequence. The stress testing sequence for the quality or reliability fail candidate population includes a stress test of increased duration compared to duration of a stress test in the test flow of the other population. The stress test sequence for the other population includes a stress test of increased voltage compared to corresponding operating voltage specification for a semiconductor unit. The method further includes the step of applying, within a sort testing stage, the corresponding test flow to the populations and identifying any unit which failed the stress sequence.

Owner:OPTIMAL PLUS

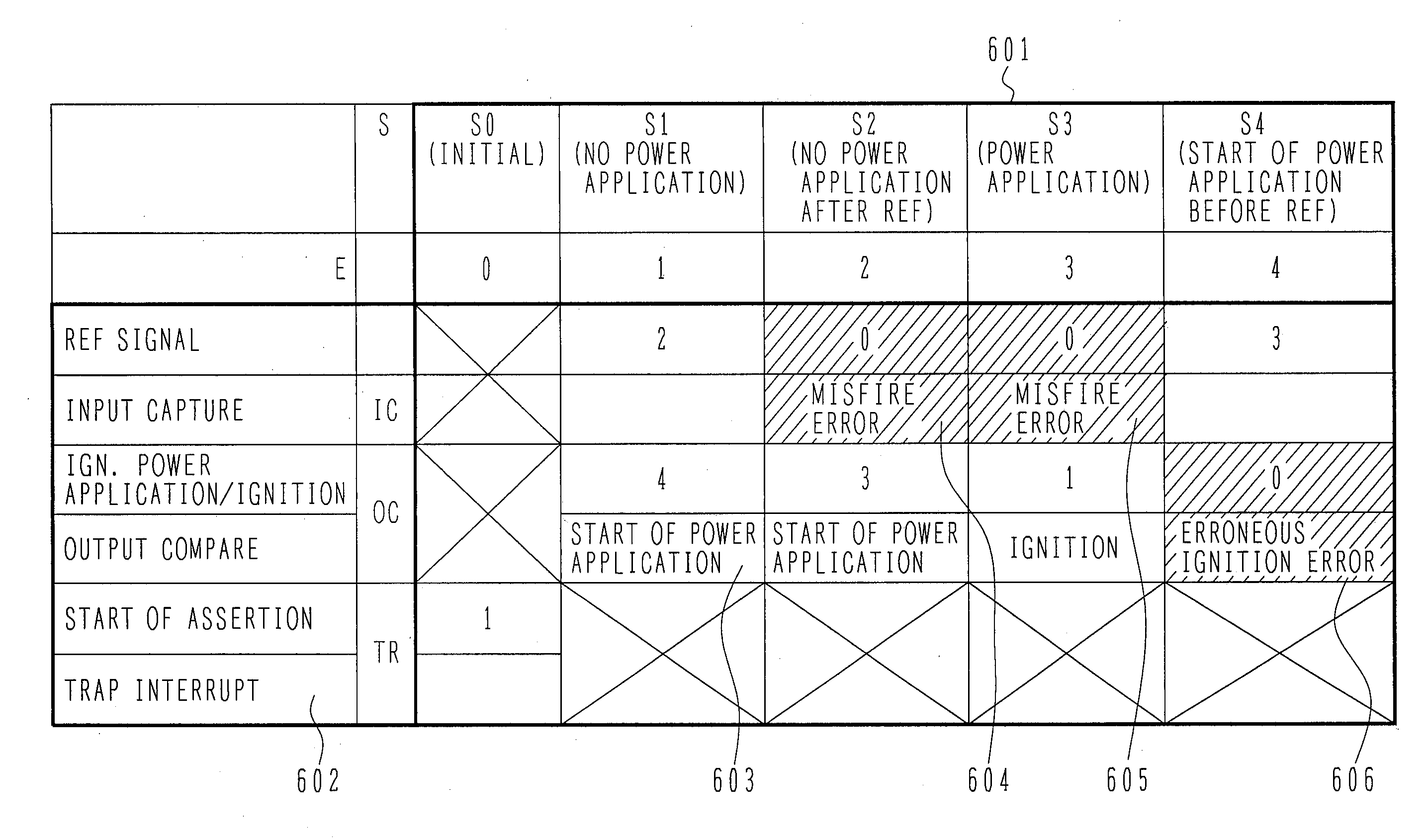

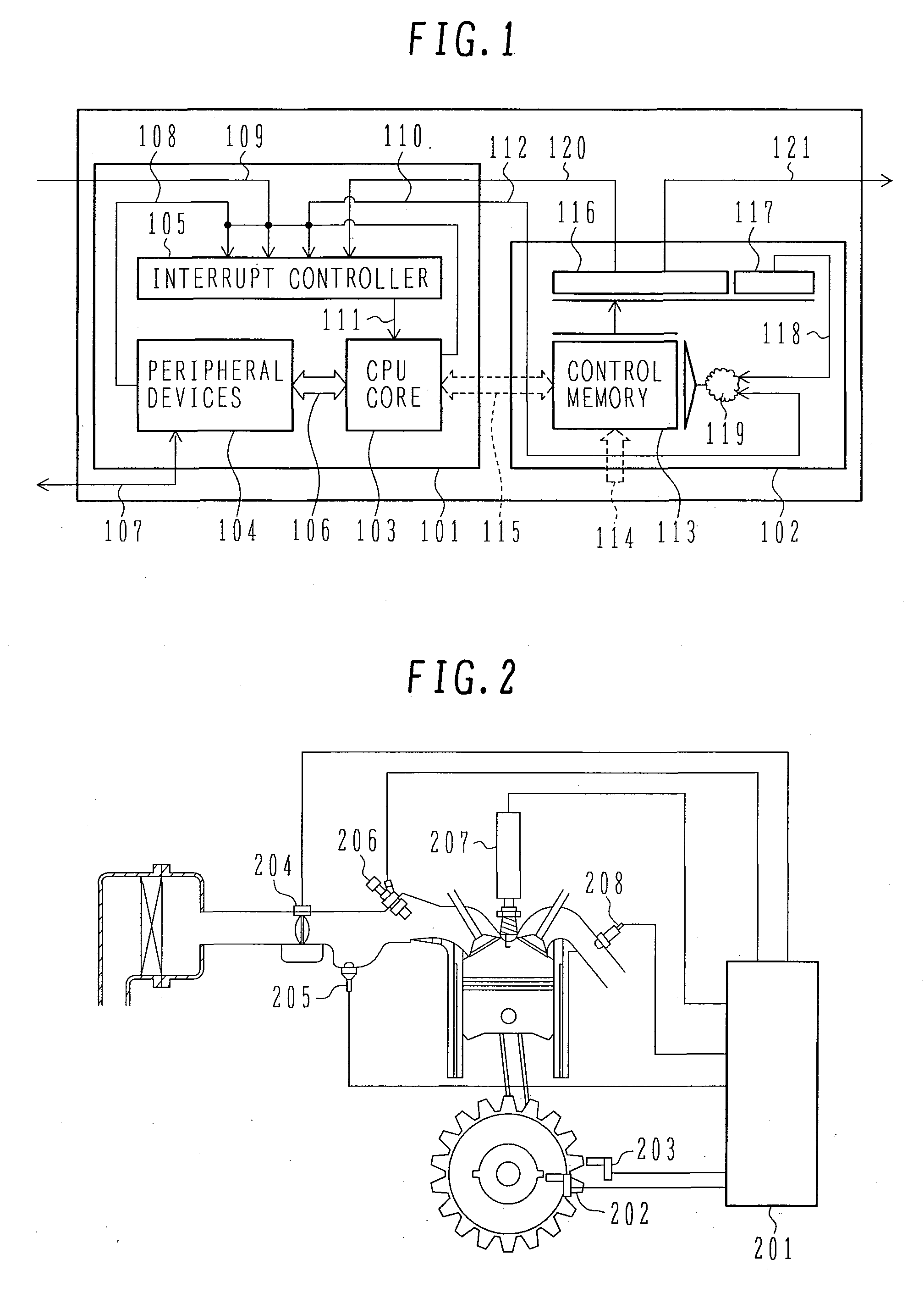

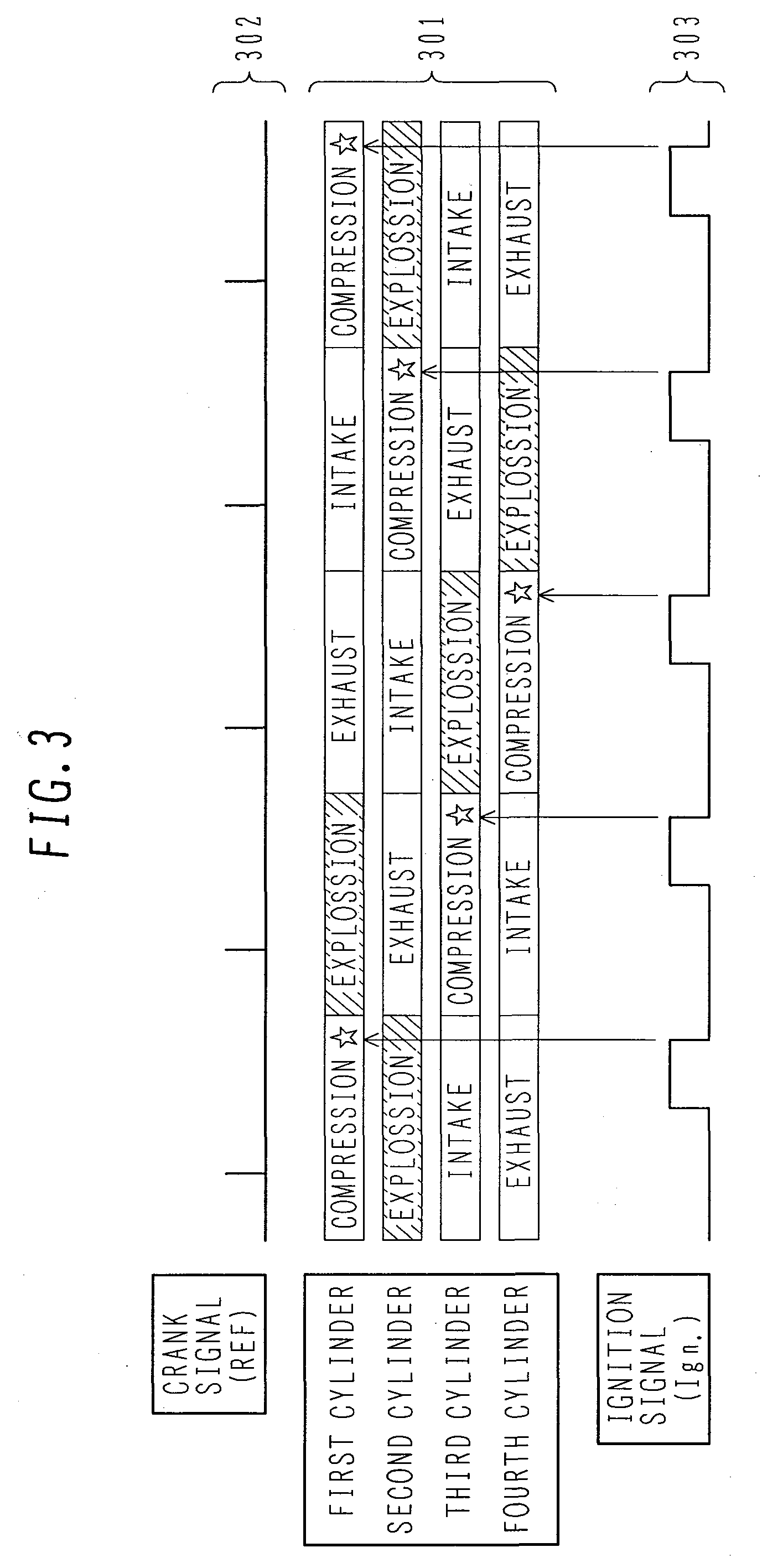

Control microcomputer verification device and vehicle-mounted control device

InactiveUS20080147949A1Improve verification efficiencyImprove quality and reliabilityHardware monitoringRedundant operation error correctionMicrocomputerFinite-state machine

The present invention offers an advanced control software verification technology, particularly, an assertion-based verification technology, by providing a control microcomputer verification device and vehicle-mounted control device that exhibit improved verification efficiency. Assertion-based verification is performed with a verification device that has a hardware configuration in which the verification device is independent of a CPU core of a microcomputer but operates in parallel with the CPU core of the microcomputer, which sequentially executes control software. The hardware to be employed to achieve the above purpose is a finite state machine based on microprogrammed control. An interrupt factor is branched immediately before an interrupt controller for the microcomputer and used as a transition input. When an abnormal transition is detected, a warning is output to the microcomputer as an interrupt or output to the outside in the form of a signal.

Owner:HITACHI LTD

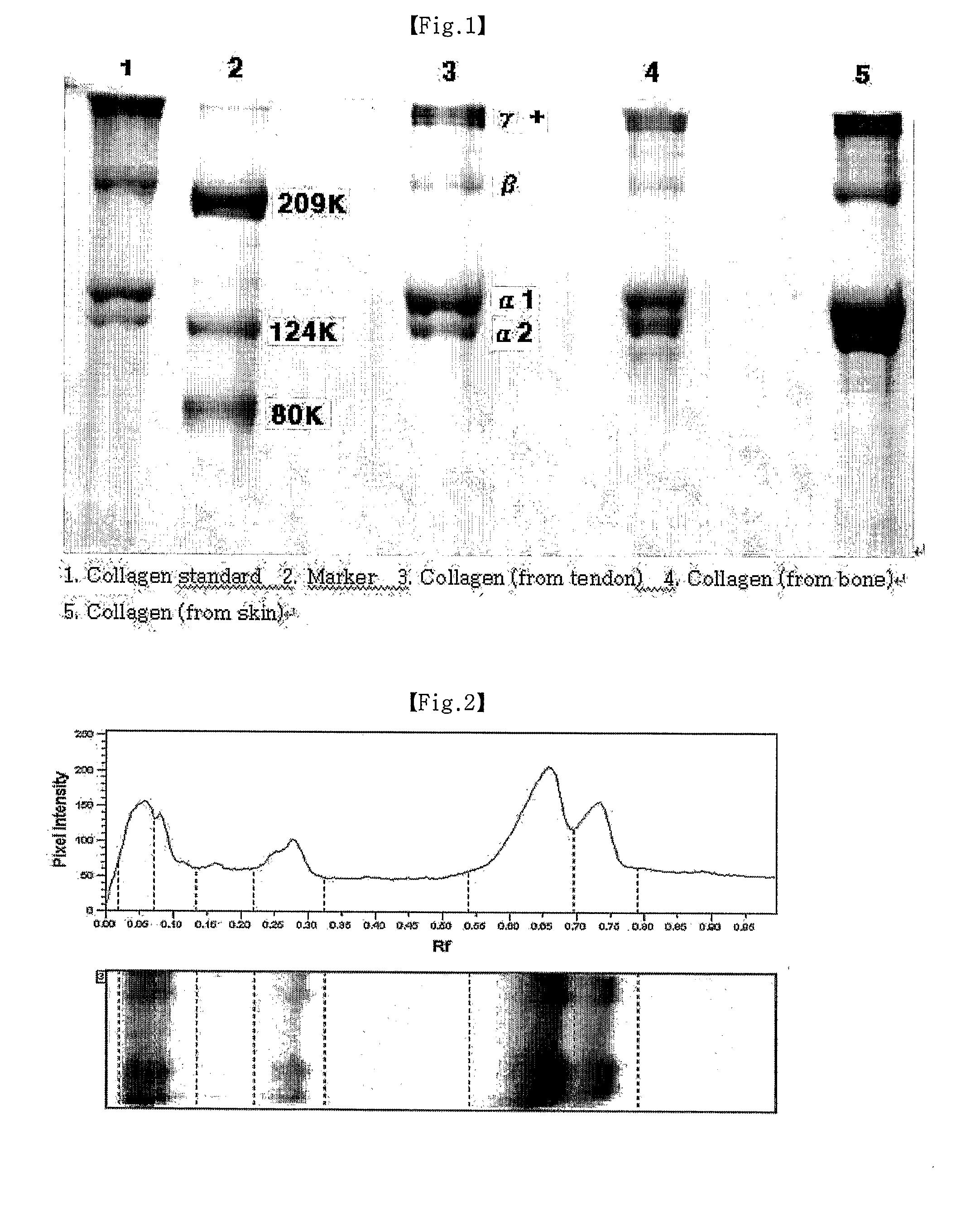

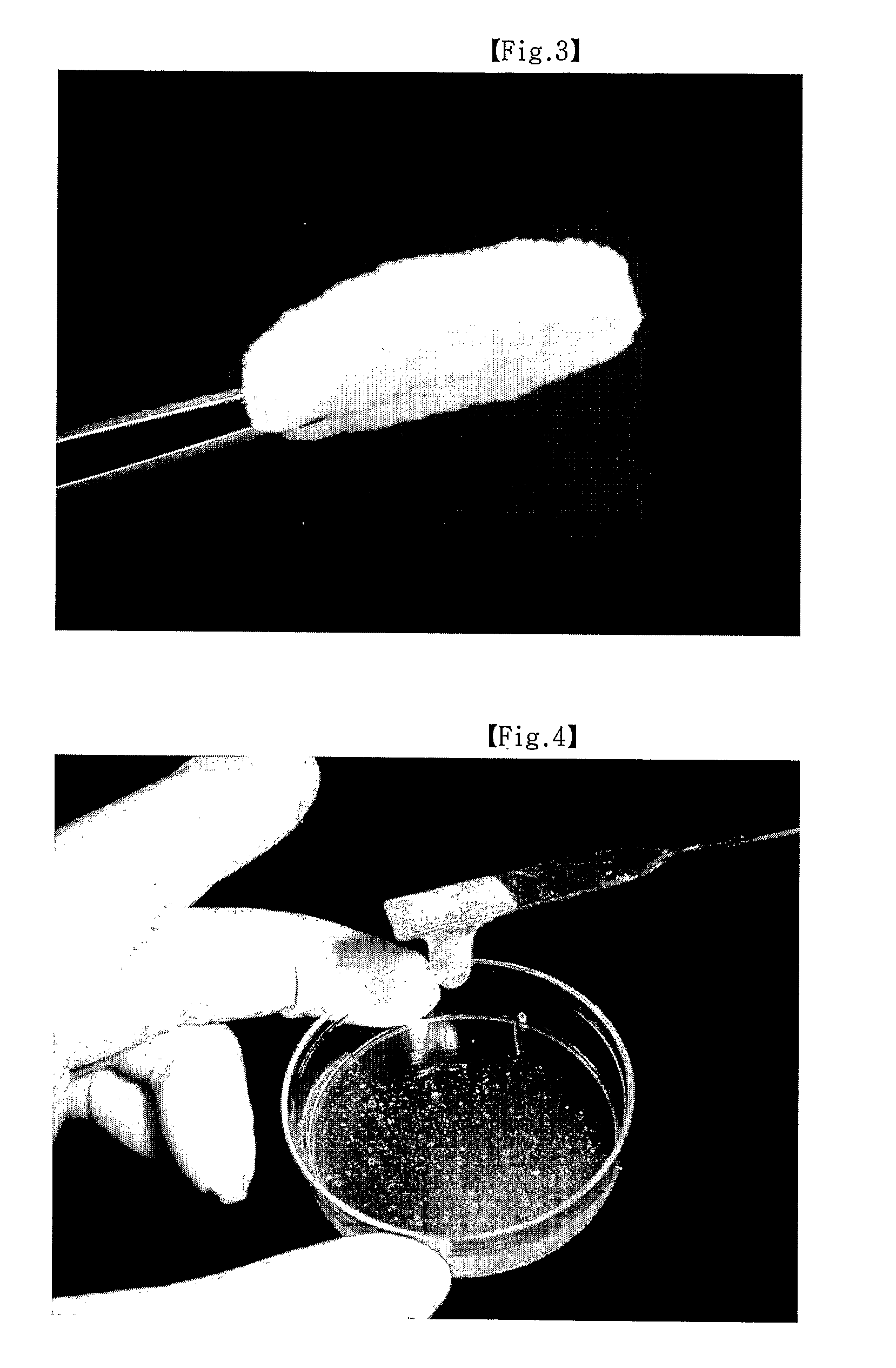

Method of Separating Collagen From the Various Animal Tissues for Producing Collagen Solution and Product Using the Same

ActiveUS20080118947A1Improve customer satisfactionQuality improvementConnective tissue peptidesPeptide/protein ingredientsPhosphateFractionation

A method for separation the collagen from the various animal tissues is disclosed for preparing collagen solution and product using the same. The porcine tissues are processed to have proper form and size for acid-treatment. The acid-treatment is repeated with pepsin to separate type I or II collagens. The separated collagen is salt-treated for fractionation and ethanol-treated for obtaining 5˜10% of collagen from the initial tissue weight. The prepared tissues are processed for separating collagen through the collagen separating process. The separated collagen is processed for preparing product. The method for preparing product is comprised: treating a collagen solution having a predetermined concentration under a neutral condition at a low temperature, followed by overnight treatment at a temperature of 30 to 35° C.; concentrating collagen by centrifugation; and dissolving the thus-concentrated collagen in refrigerated weakly-acidic solvent or phosphate buffered saline (PBS), thereby preparing collagen having a concentration of 1 to 5 mg / mL.

Owner:CELLONTECH

Insulation cap and joined electrical wire using the same

ActiveUS20050191882A1Improve quality and reliabilityEnhance waterproofnessRelieving strain on wire connectionClimate change adaptationFastenerEngineering

Providing an insulation cap, improving waterproofness of a wire joint of a joined electrical wire, the insulation cap includes a cap main body for receiving the wire joint being ‘formed by’ joining cores of a plurality of covered wires and an electro-conductive sleeve, and a flexible fastener provided on an inner wall of the cap main body for fastening the wire joint by contacting a rear end of the electro-conductive sleeve thereon. The flexible fastener is formed as an integral part of the cap main body by fastening a molding die through a hole provided at an opposite end of a joint insertion end of the cap main body. A plurality of flexible fasteners are provided axial symmetrically to extend toward a direction of inserting the wire joint from a base formed as an integral part of the inner wall of the cap main body.

Owner:YAZAKI CORP

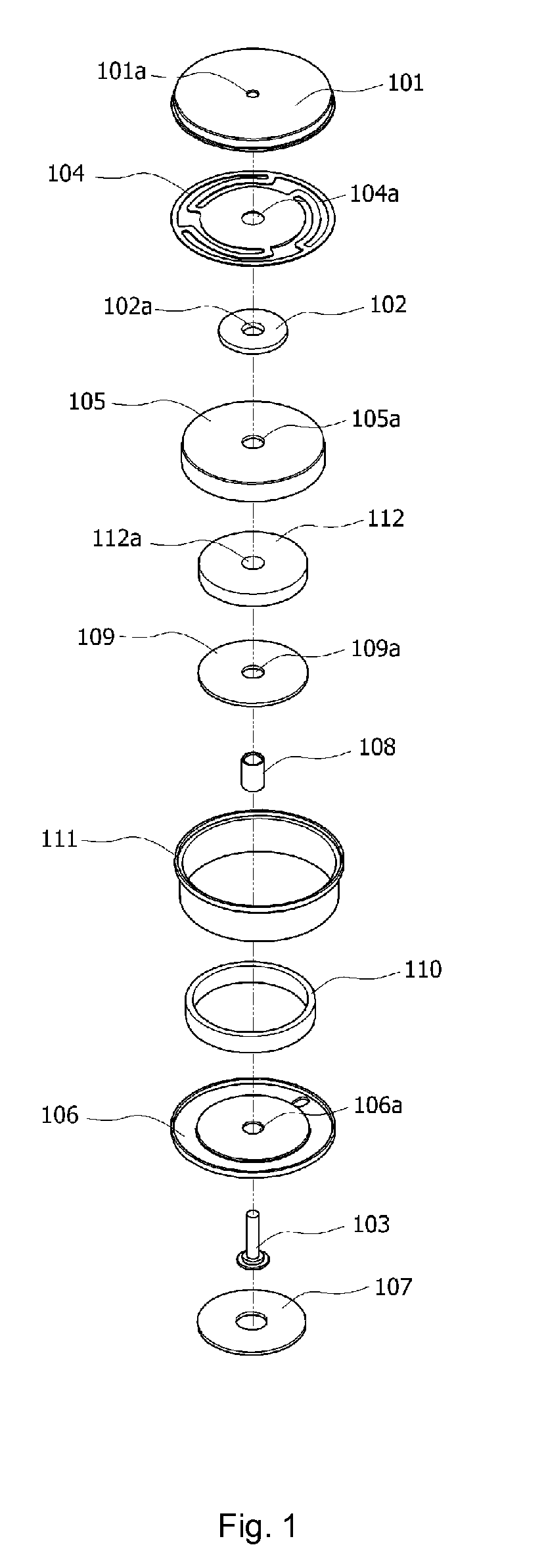

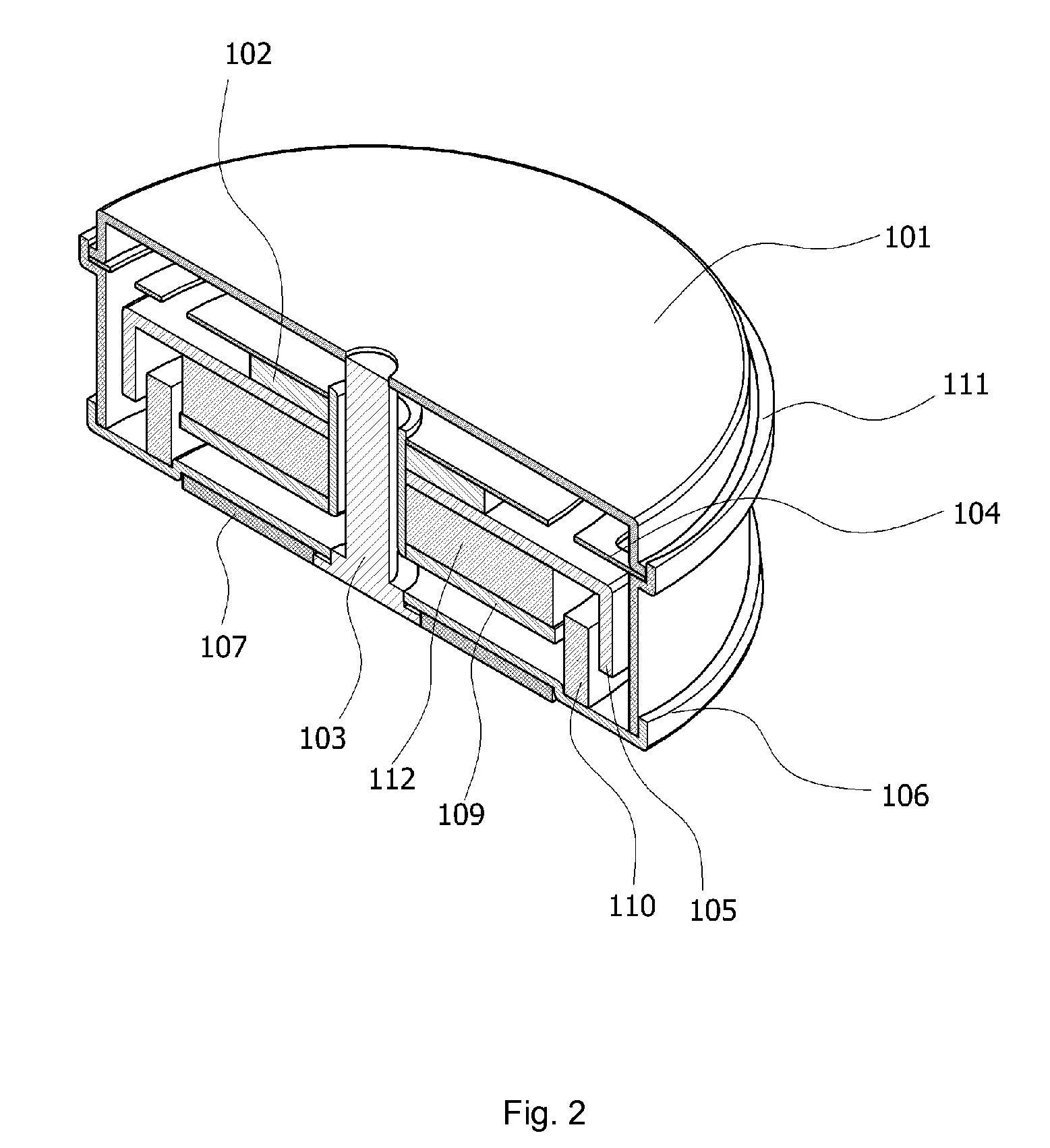

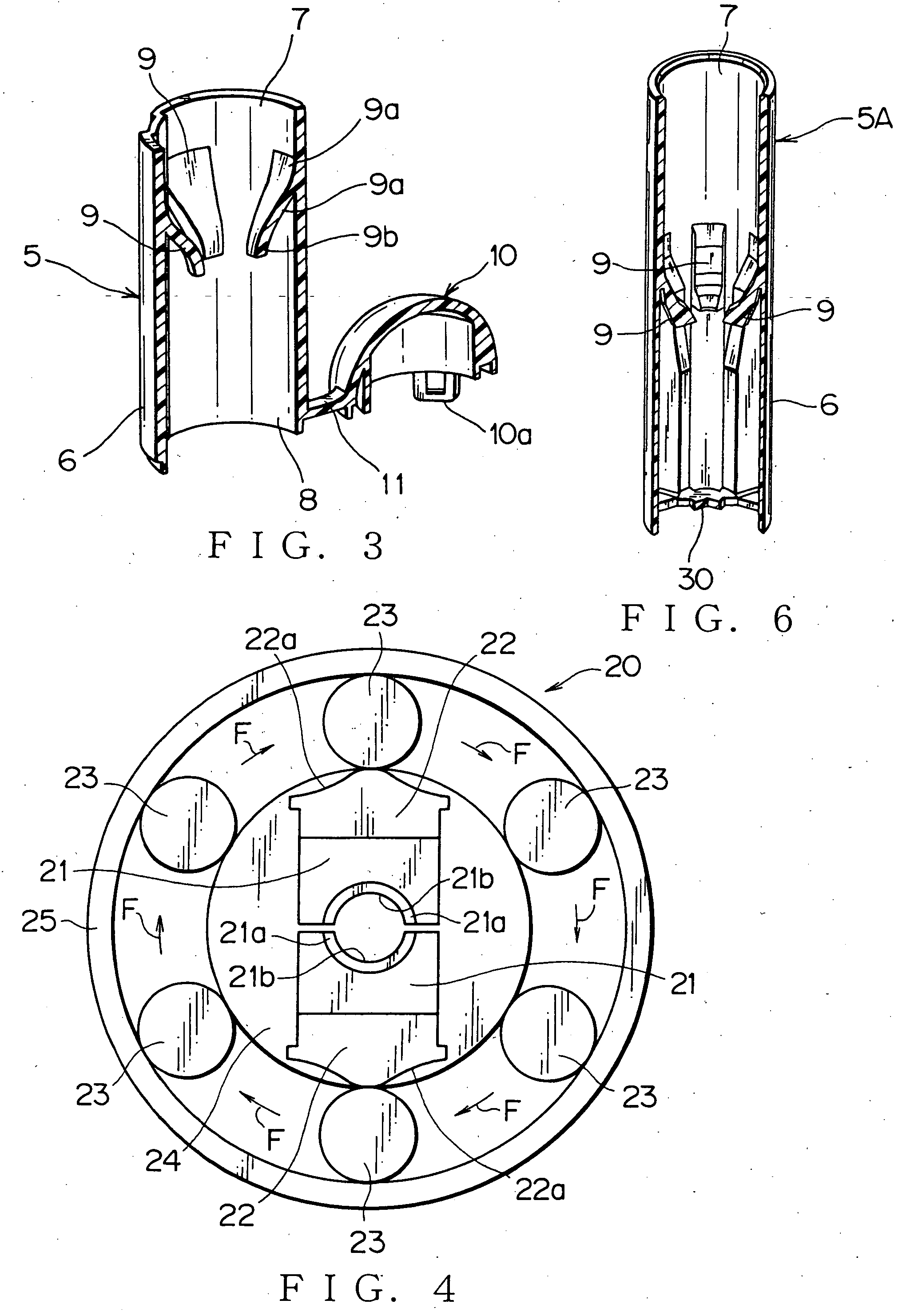

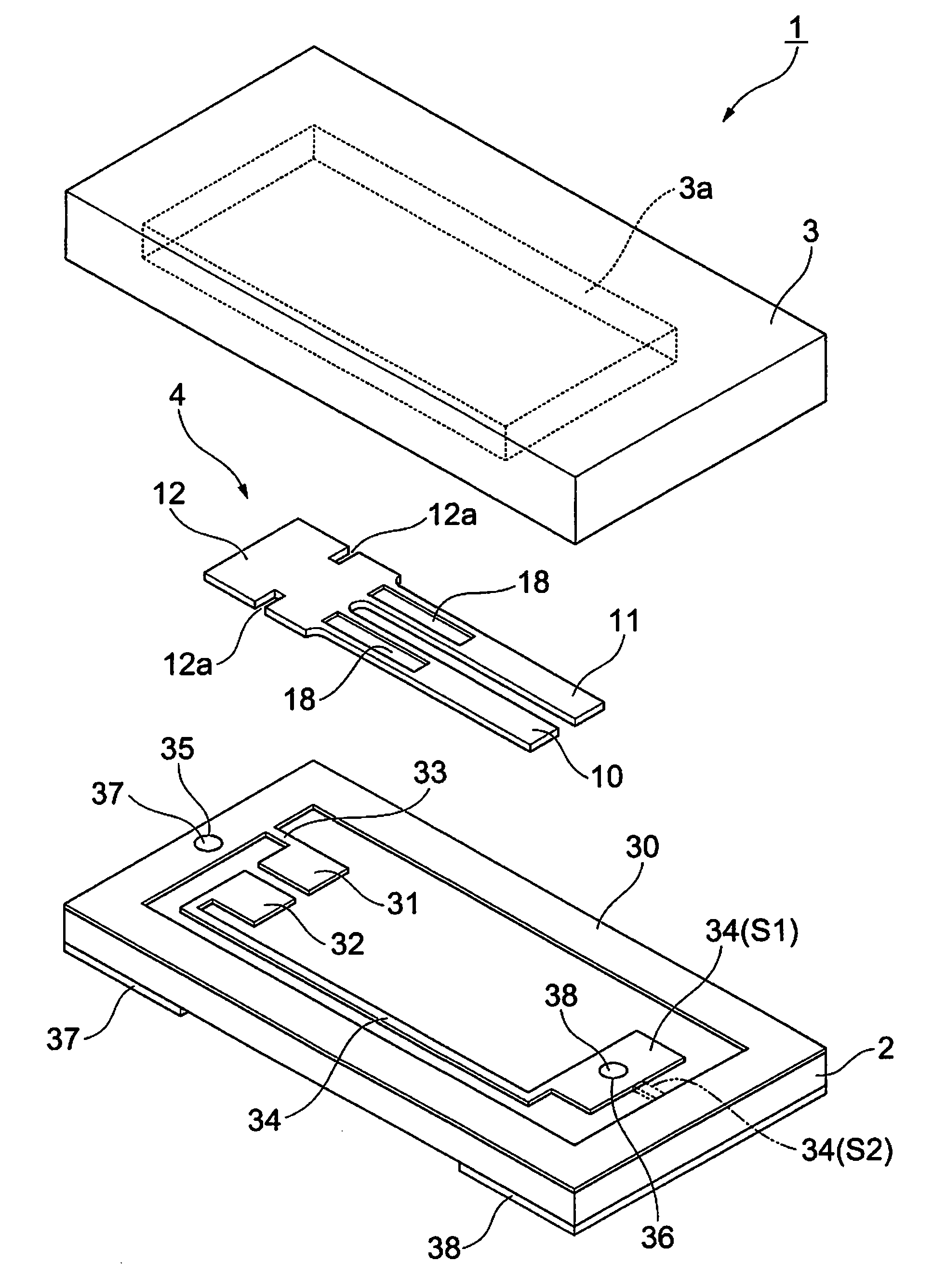

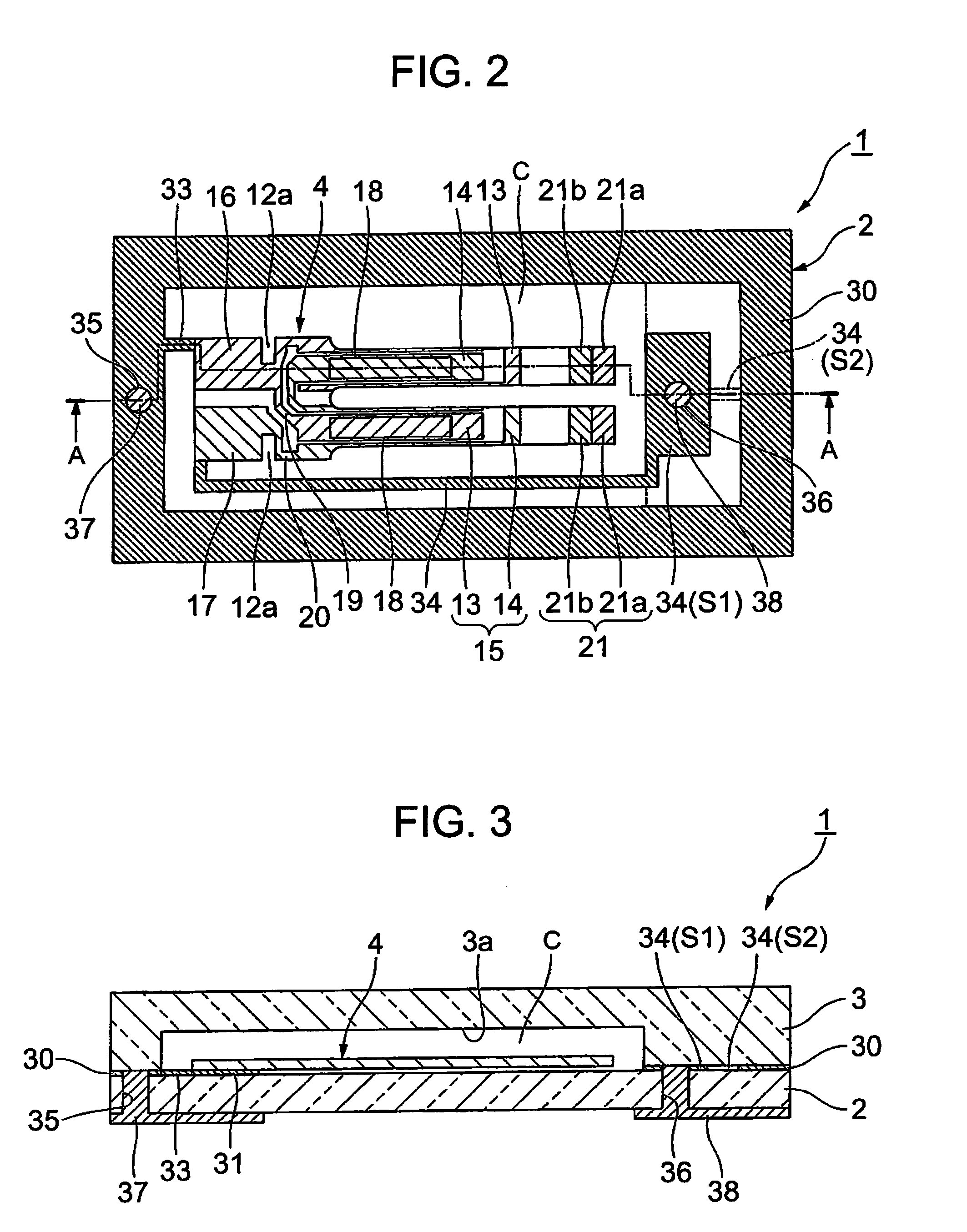

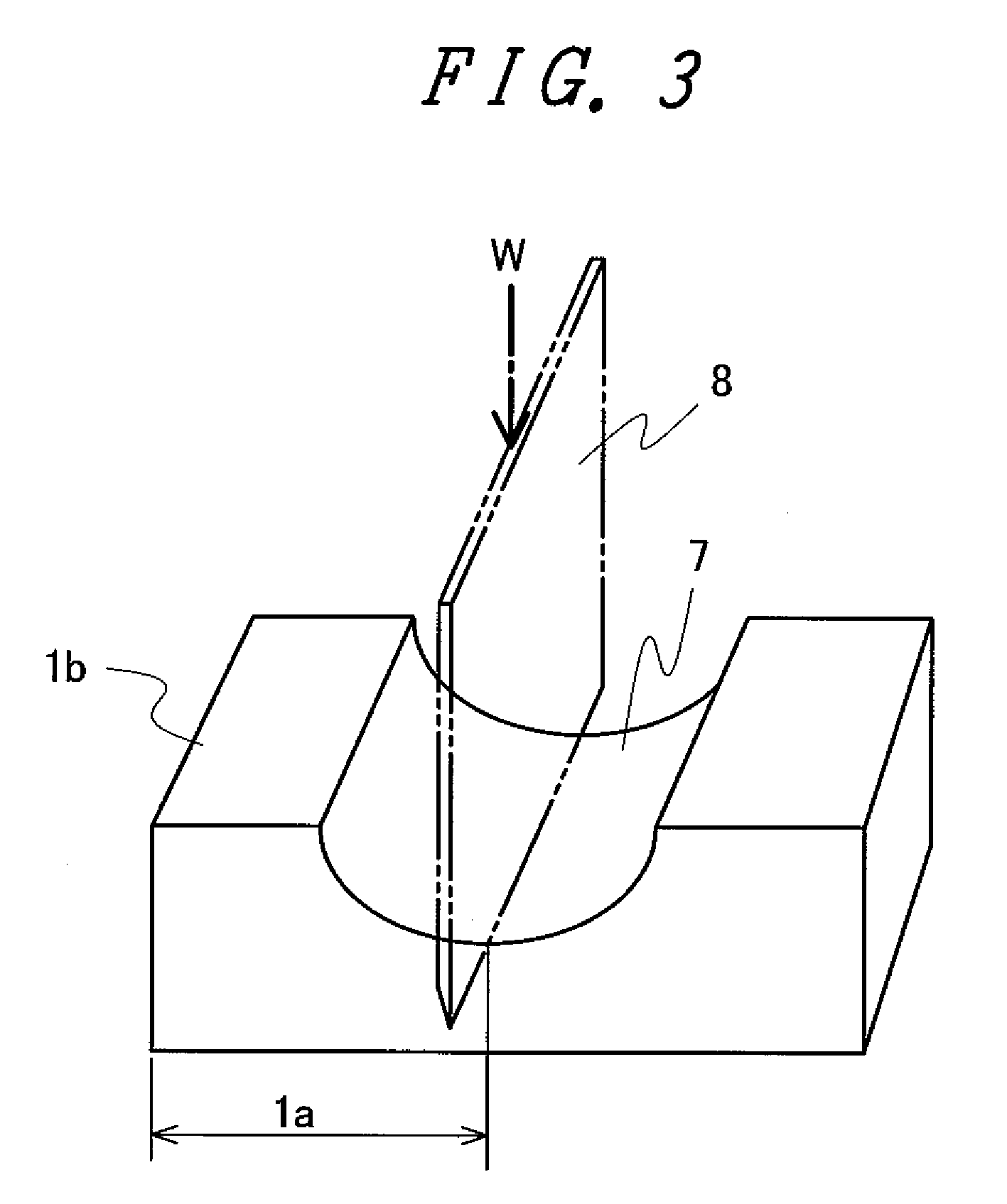

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20100237740A1Improve quality and reliabilityReduce manufacturing costPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyLaser lightRadio clock

There is provided a method of manufacturing piezoelectric vibrators 1. The method includes a process for through holes 35 and 36, which pass through a base substrate wafer, so that openings of the through holes are opened to the outside of the recesses for cavities C; a process for patterning a bonding layer 30, pairs of mounting layers, and pairs of extraction electrode layers 33 and 34 on the upper surface of the base substrate wafer with the same conductive material; and a process for electrically isolating the extraction electrode layers 34 in the middle by irradiating a part (area S2) of the extraction electrode layers 34, which are formed between the bonding layer and openings of through holes 36, with laser light after both the wafers are anodically bonded to each other. The bonding layer 30 surrounds the recesses, the pairs of mounting layers are in the recesses, and the pairs of extraction electrode layers 33 and 34 electrically connect the pairs of mounting layers to the bonding layer.

Owner:SII CRYSTAL TECH

Image stabilizer

InactiveUS8120661B2Improve quality and reliabilityMinimize complexityTelevision system detailsImage analysisDigital videoFrame sequence

A method for digital video image stabilization, the method including: estimating, from at least one portion of a frame, global frame displacement between an initial reference digital video frame and a current frame in a video sequence of frames; verifying, for the entire frame, the validity of the estimated frame displacement; and compensating for the estimated frame displacement by aligning at least one frame in the sequence with respect to the initial reference frame; wherein the step of aligning includes producing a corrected motion vector for the frame to be aligned and displacing the frame within the video frames sequence in accordance with the corrected motion vector.

Owner:HUMAN MONITORING

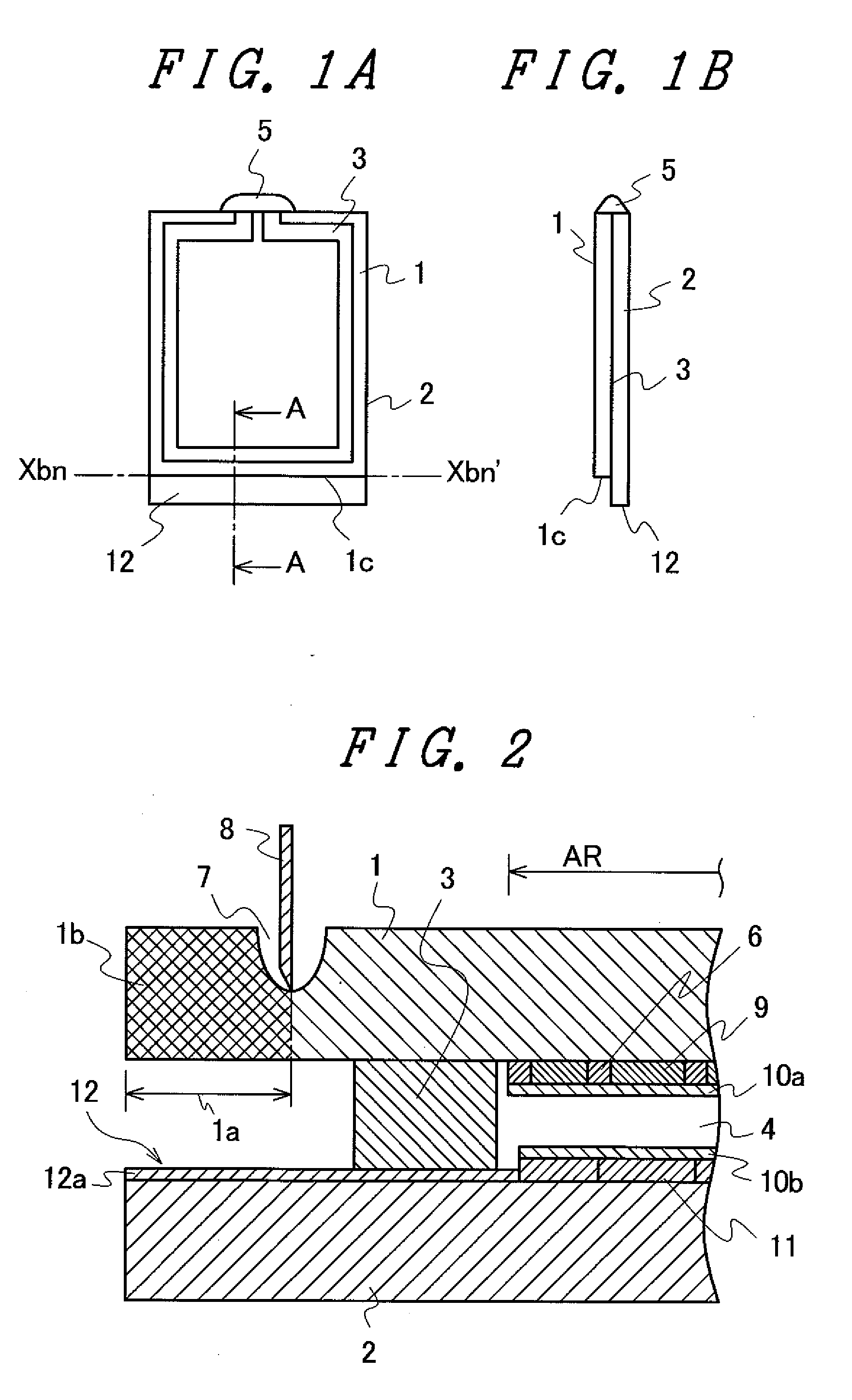

Manufacturing method of display device

ActiveUS20090275158A1Quality improvementImprove reliabilitySemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDisplay device

A liquid crystal display device having high quality and high reliability is manufactured by preventing the occurrence of damages on a terminal portion due to the radiation of laser beams in cutting a substrate of the display device which is formed using a plastic substrate by the radiation of laser beams. A first substrate has a cutting line at a position which faces a terminal portion of a second substrate. In cutting the first substrate along the cutting line, laser beams are radiated to the first substrate along the cutting line so as to form a groove having a predetermined depth in the first substrate. Then, a load is applied to the first substrate along the groove so as to cut the first substrate.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

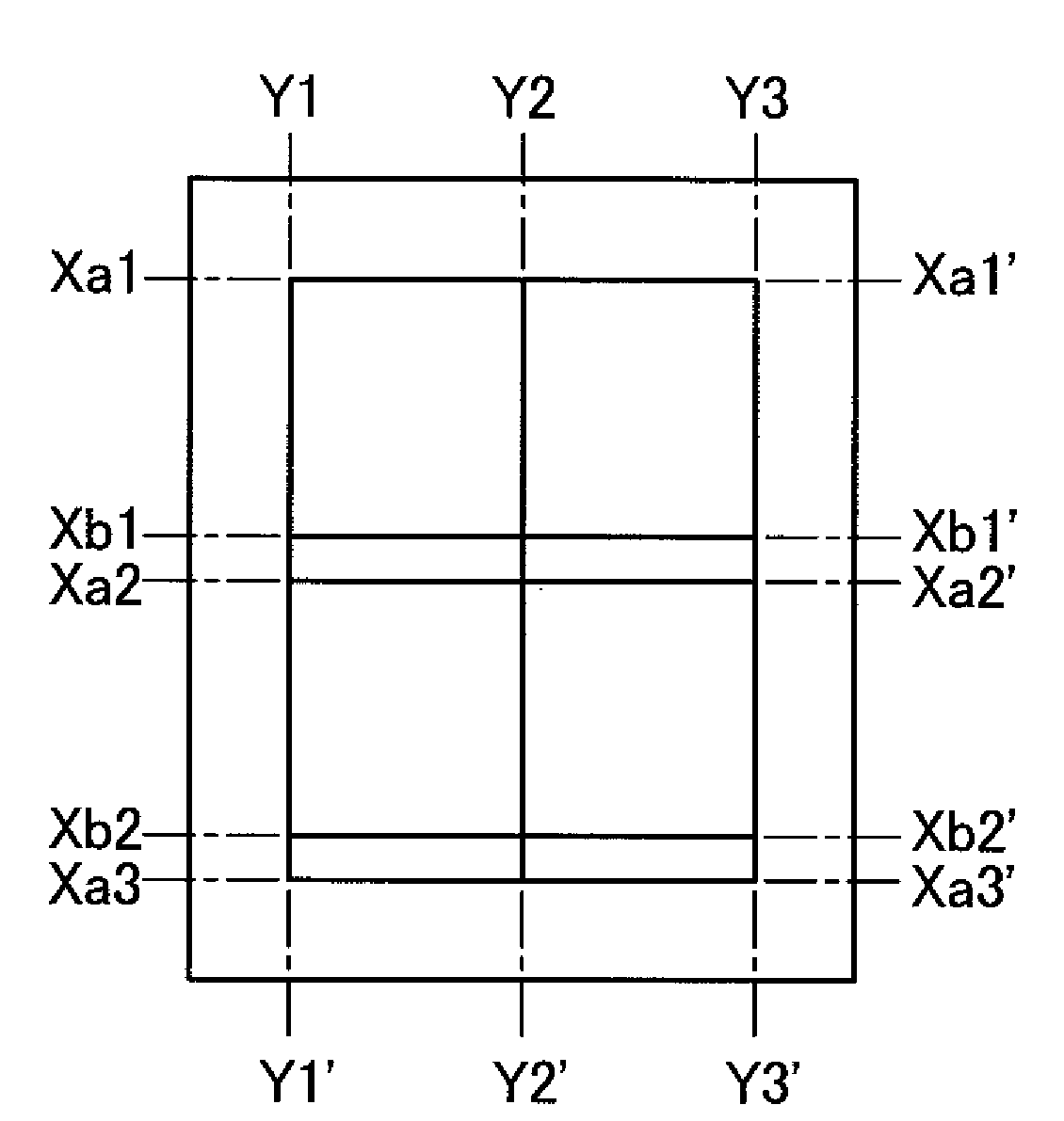

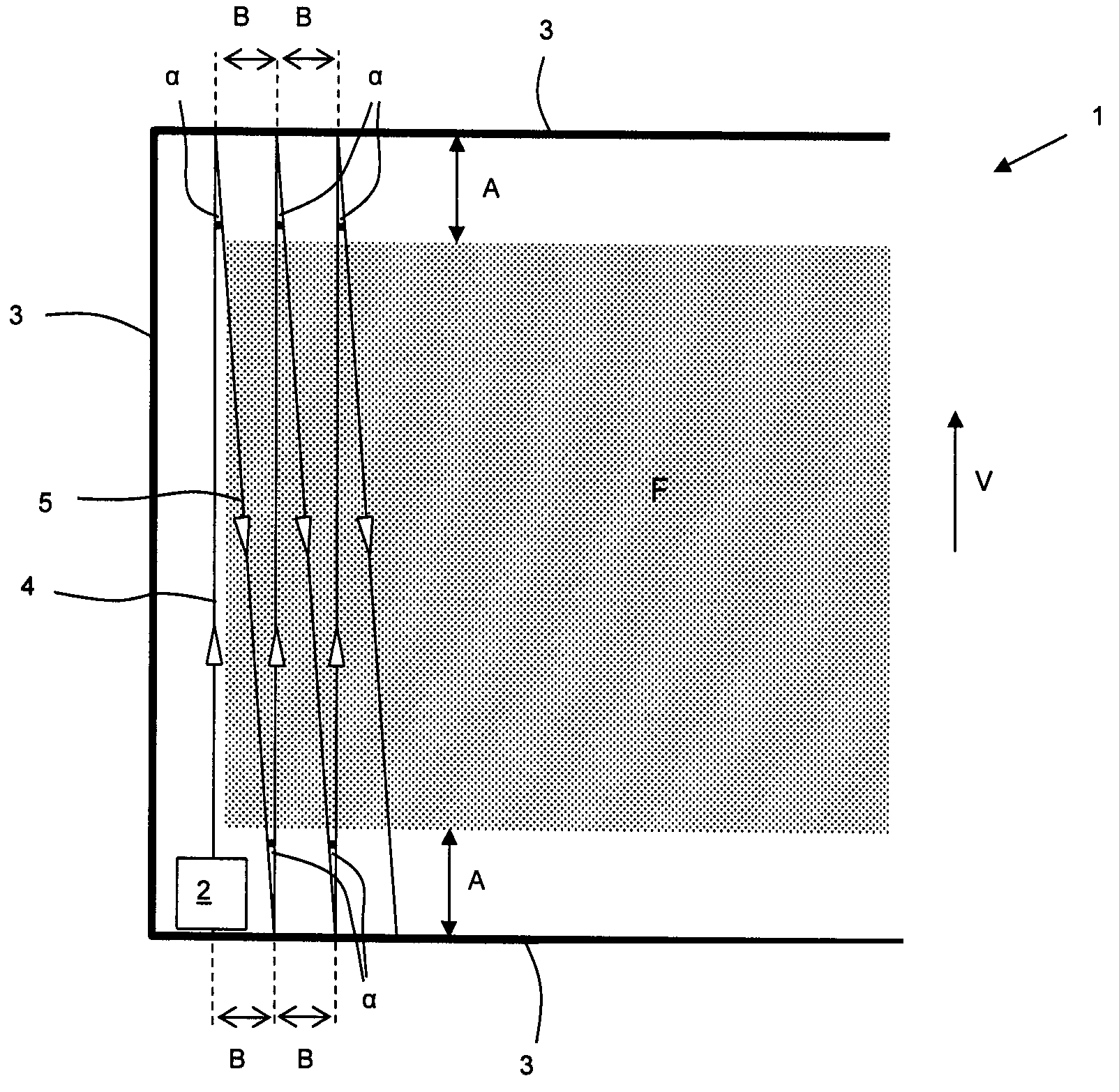

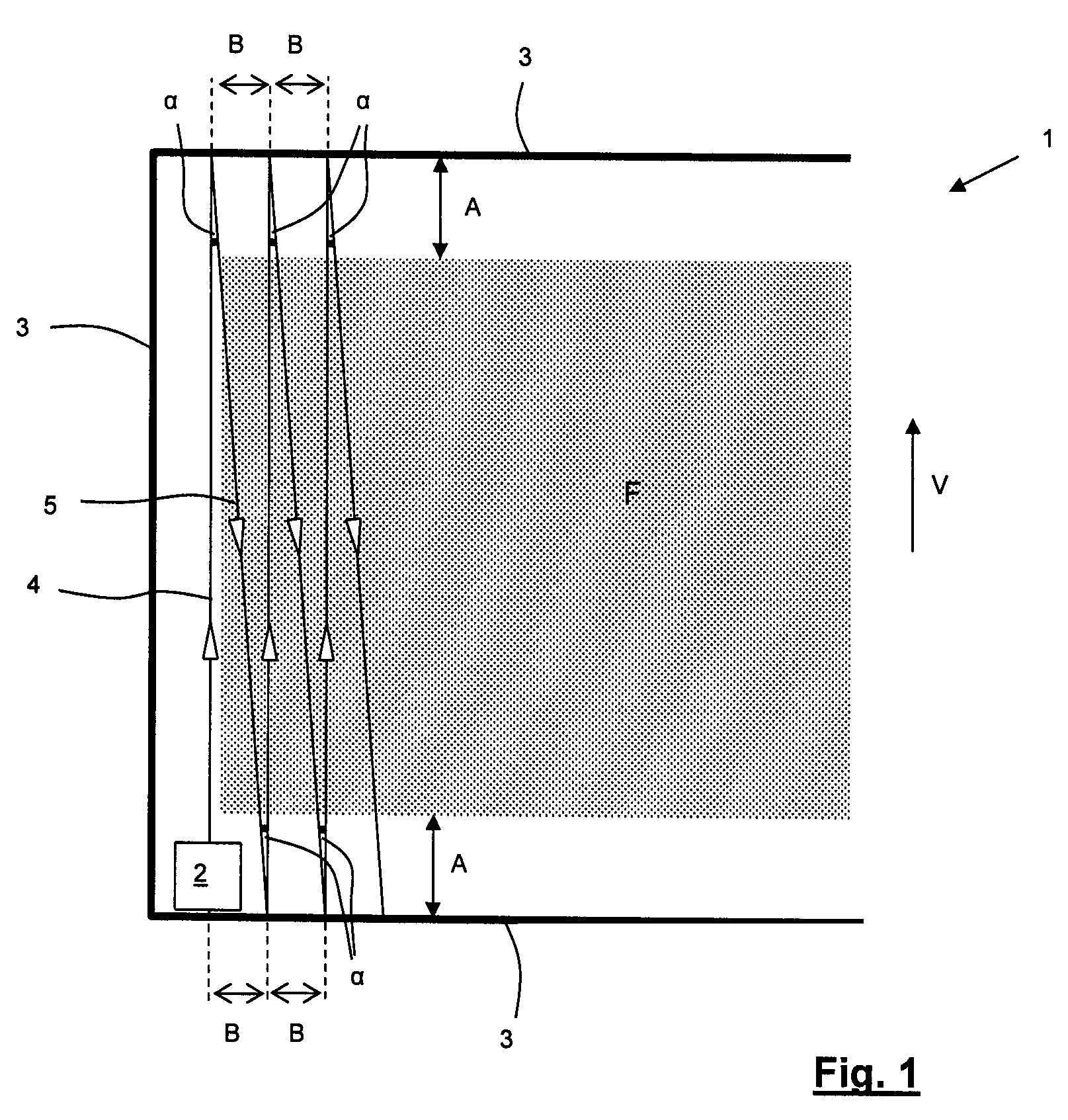

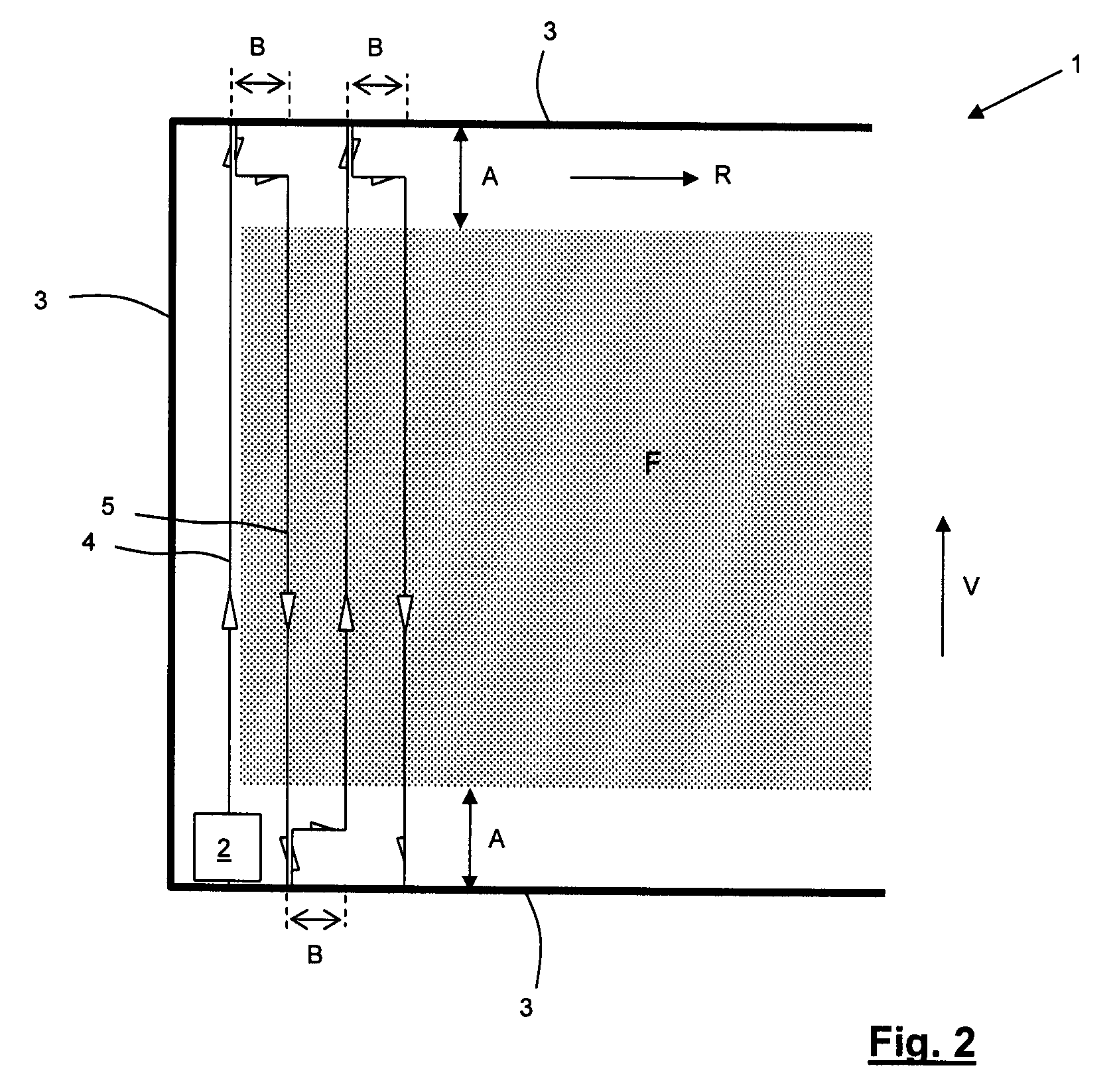

Working method and cleaning device to clean a swimming pool

ActiveUS7682461B2Improve quality and reliabilityHigh precisionCleaning using liquidsSwimming poolsLow speedEngineering

In a working method for a cleaning device (2) that moves back and forth in a swimming pool (1), control thereof is such thatthe cleaning device (2) moves from a starting position at a low speed in a forward direction V in a first pass in a first cleaning path (4) until it runs up to a pool wall (3), wherein the distance D1 traversed along the first cleaning path is measured or determined,the cleaning device (2) is then guided to a second cleaning path (5) deviating from or offset relative to the first cleaning path (4) in a second pass, initially at a low speed, whereupon the cleaning device then moves in a backward direction along the second cleaning path (5) at a high speed until the distance Dz traversed is smaller than the distance D1 traversed in the previous pass by an amount A,upon reaching distance Dz the cleaning device (2) continues to move along the second cleaning path (5) at low speed until it runs up to a swimming pool wall (3), wherein the distance D2 traversed along the second cleaning path is measured or determined, andthe cleaning device (2) is controlled in the same manner in each subsequent pass as in the previous pass.

Owner:3S SYSTTECHN AG

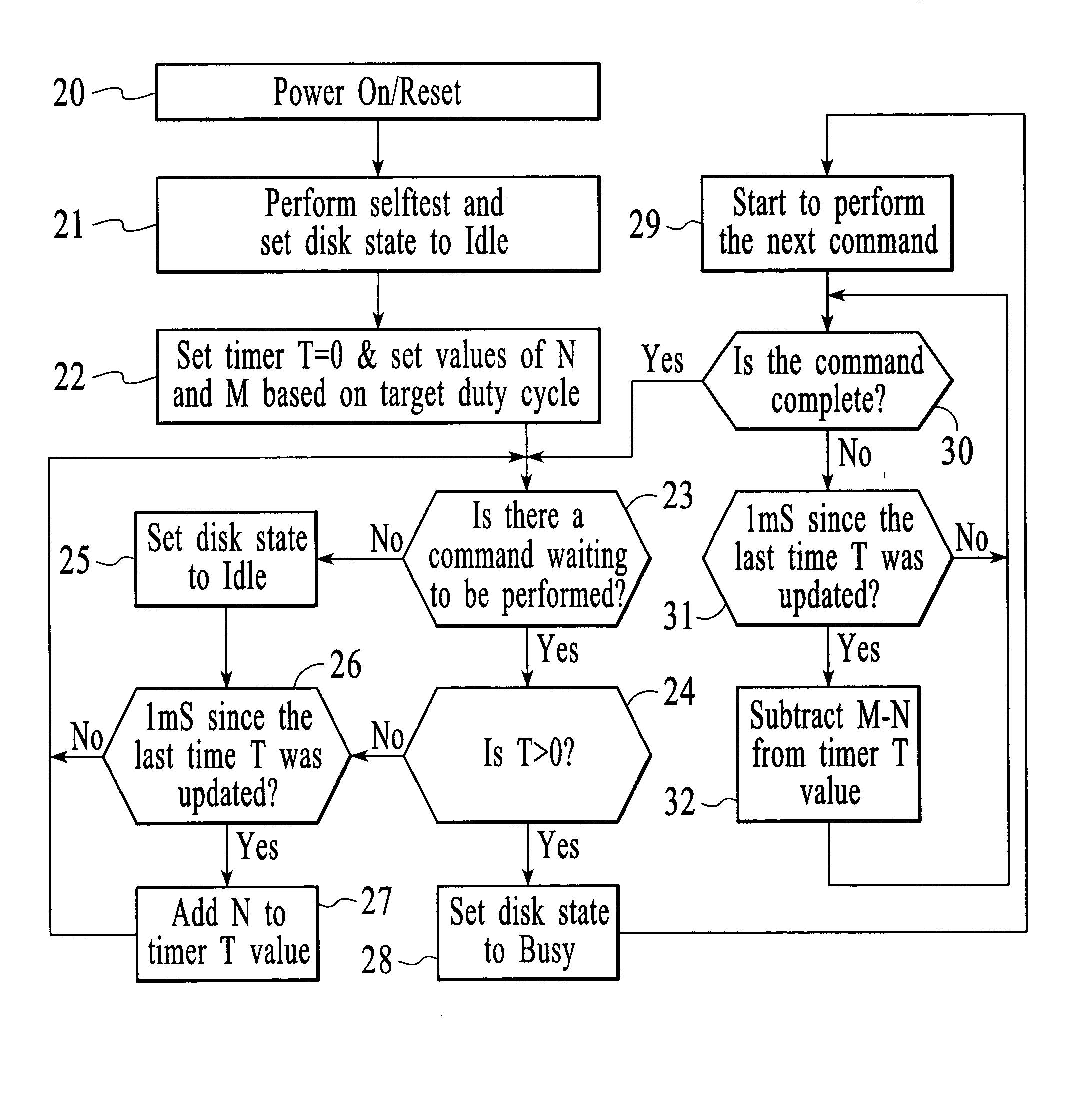

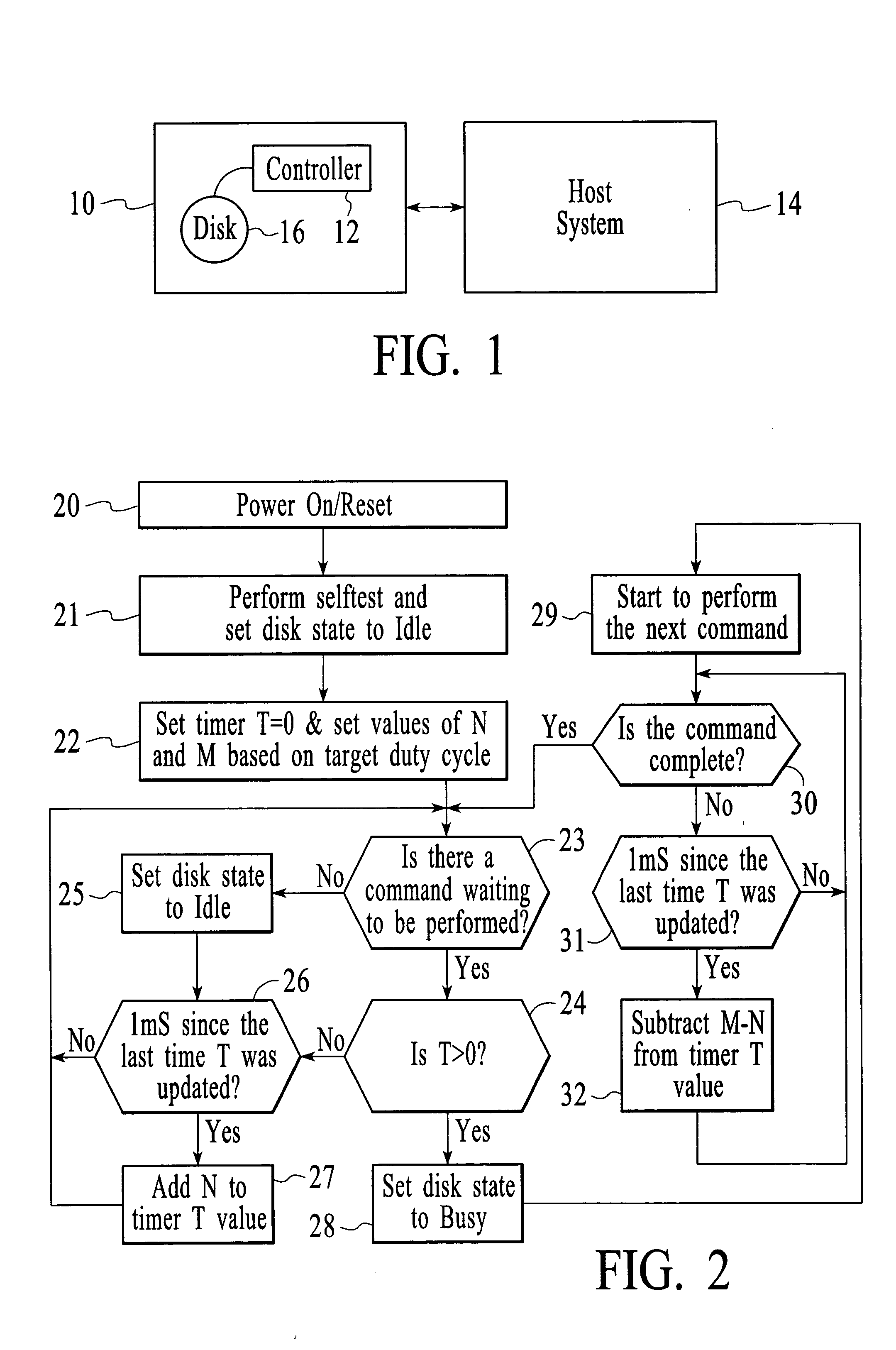

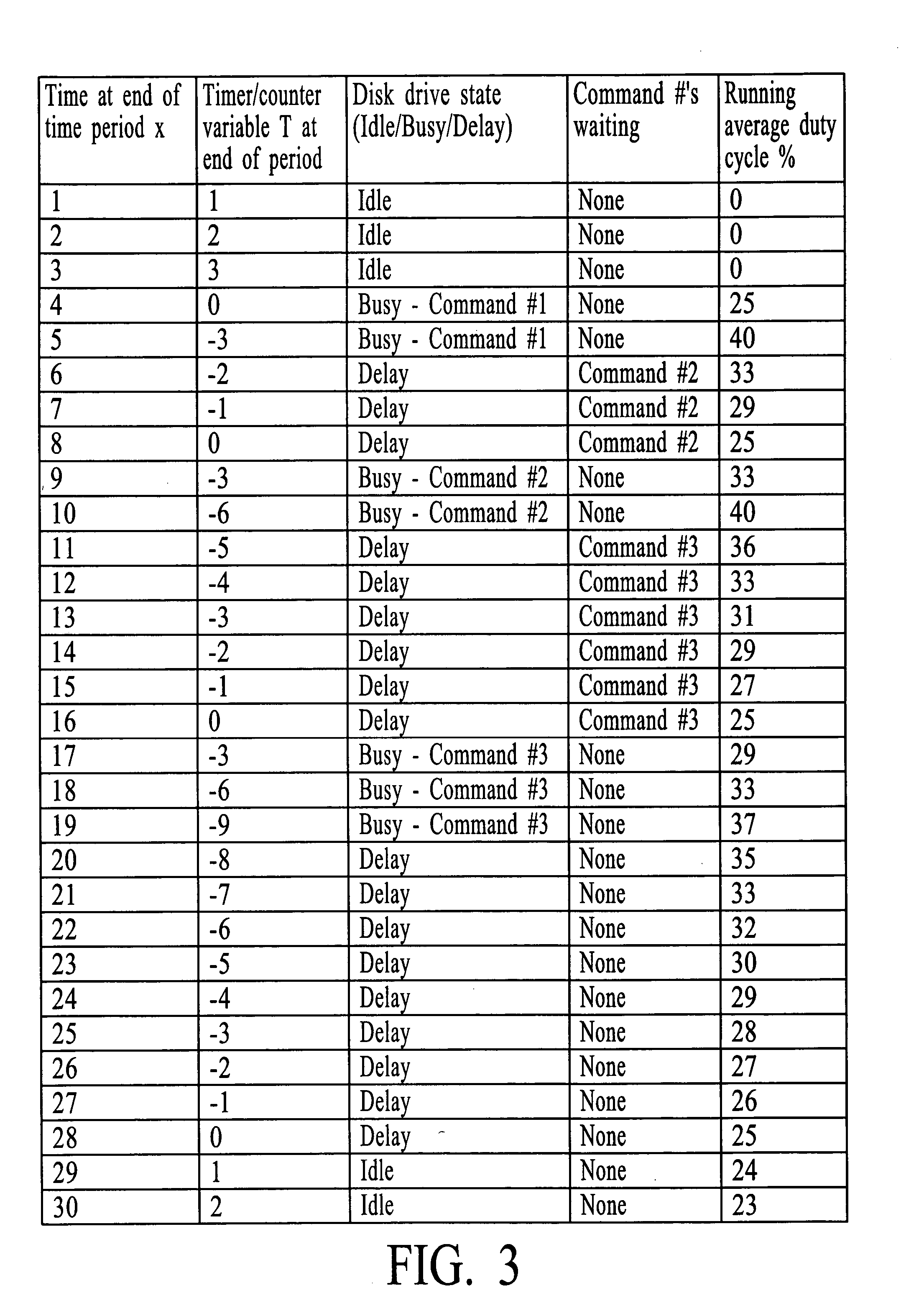

Reliable use of desktop class disk drives in enterprise storage applications

ActiveUS20050160189A1Increase reliability and qualityLimit performanceInput/output to record carriersError detection/correctionEnterprise storageDuty cycle

Aspects of increasing the quality and reliability of desktop class storage disks in enterprise storage applications are described. The aspects include monitoring a number of idle states and busy states in a disk drive, and limiting performance of read / write commands by the disk drive based on whether a sufficient number of idle states has been monitored to avoid exceeding a duty cycle rating of the disk drive.

Owner:LENOVO GLOBAL TECH INT LTD

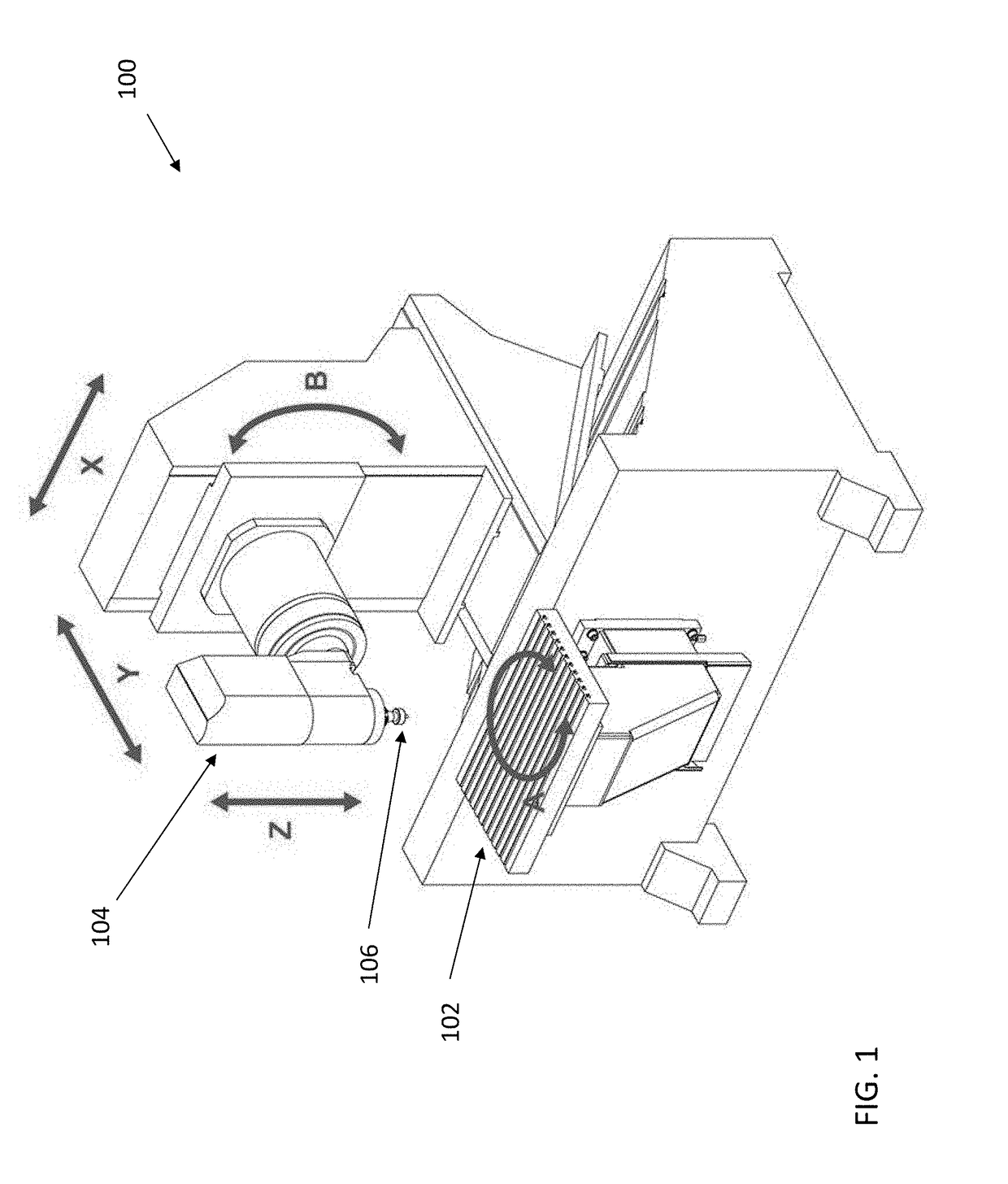

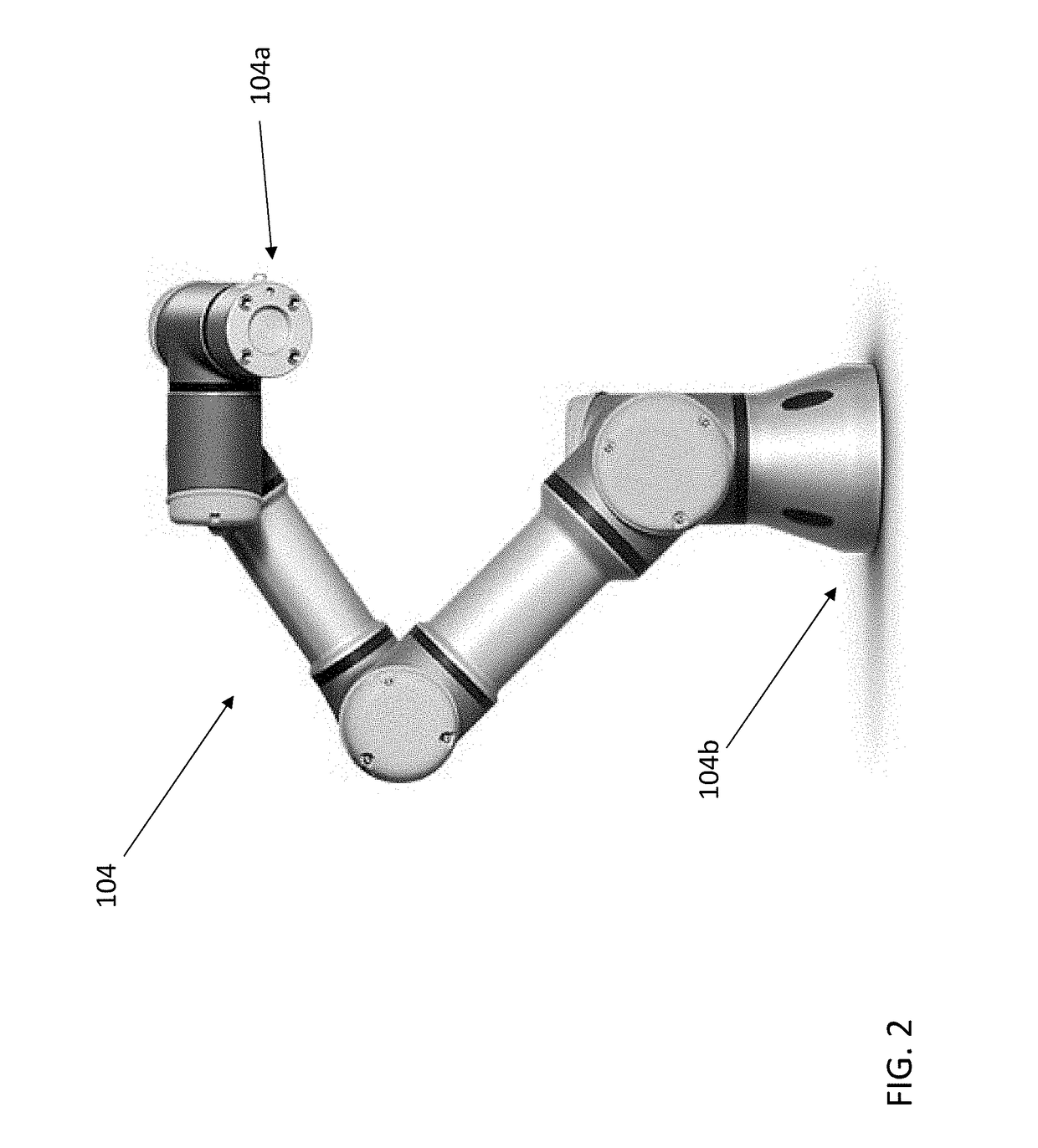

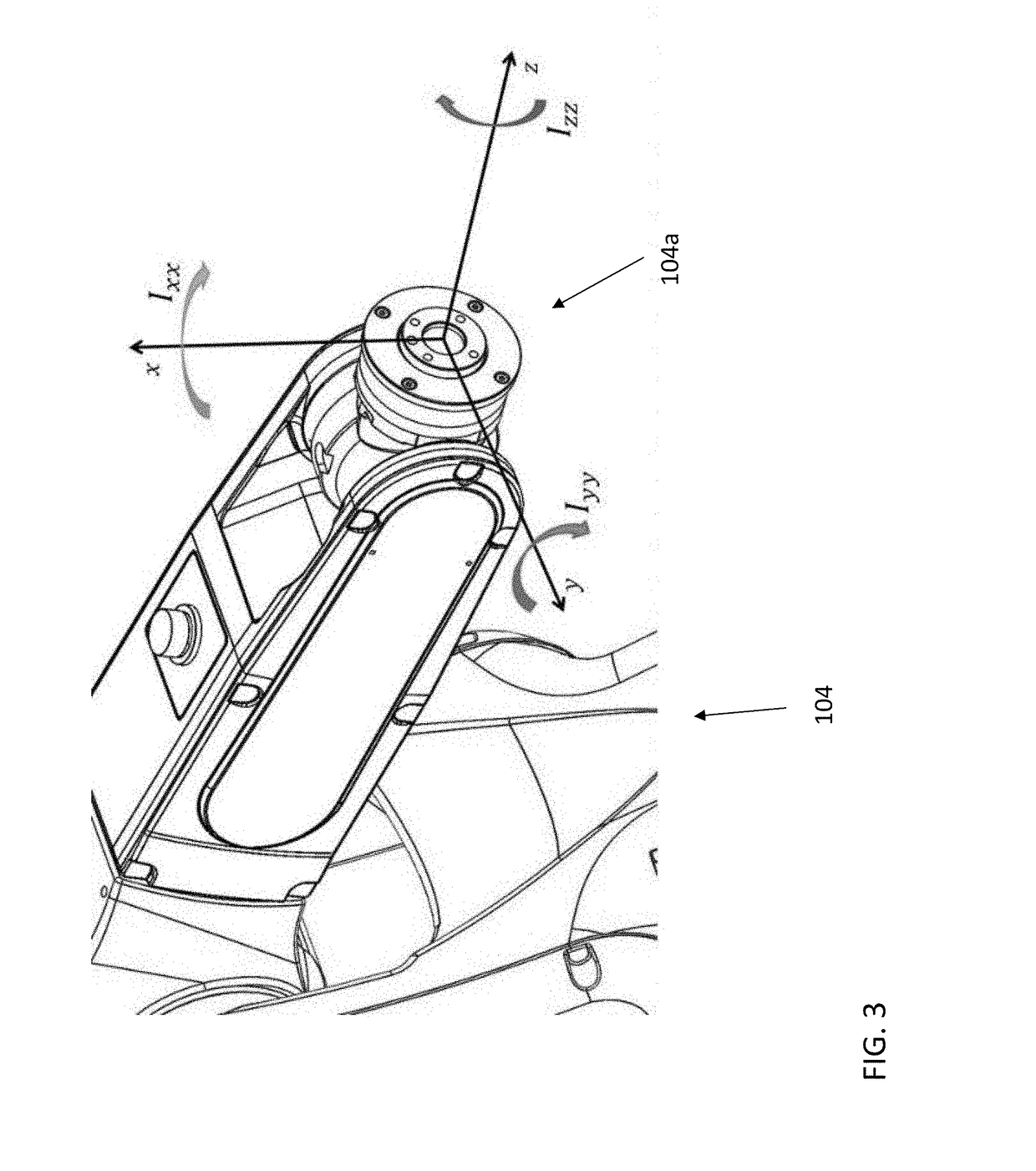

System and method for automated defect detection

InactiveUS20190080446A1Inspection speed is fastQuality improvementProgramme controlGeometric CADForeign objectMetallic materials

The present invention relates in general to systems and methods for automating various aspects of defect detection, such as surface anomaly and foreign object and debris detection in workpieces fabricated from metallic or non-metallic materials.

Owner:ALL AXIS ROBOTICS LLC

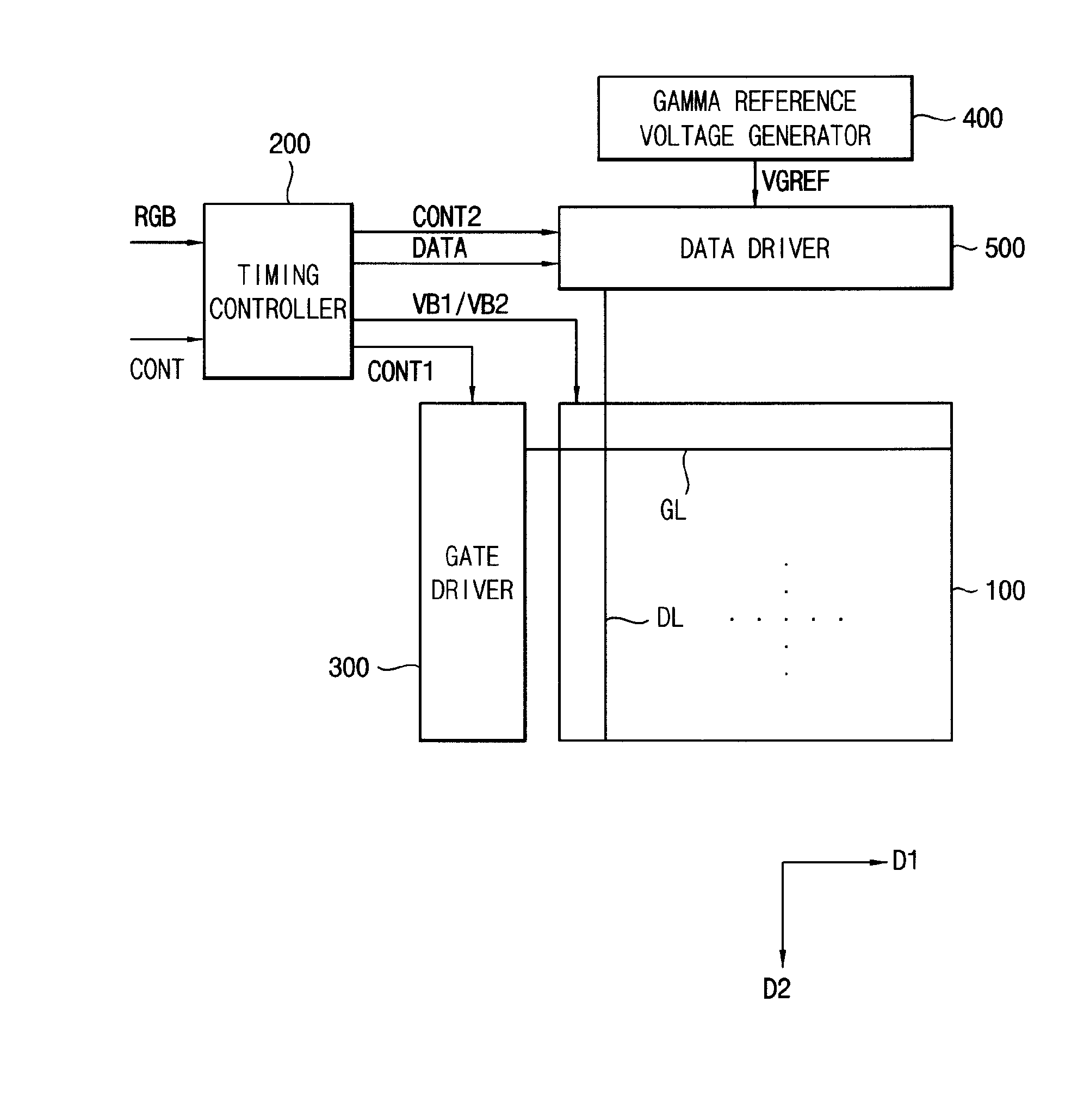

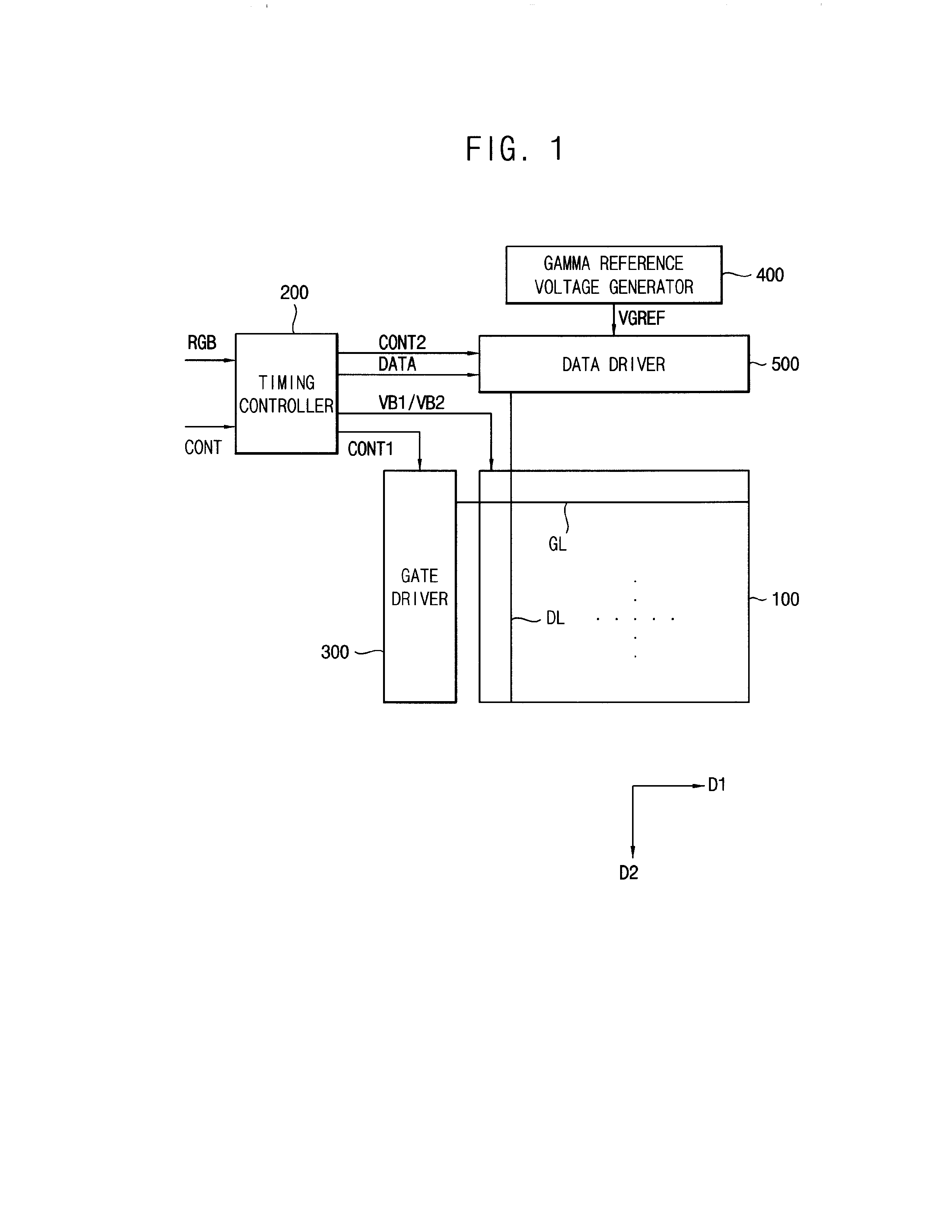

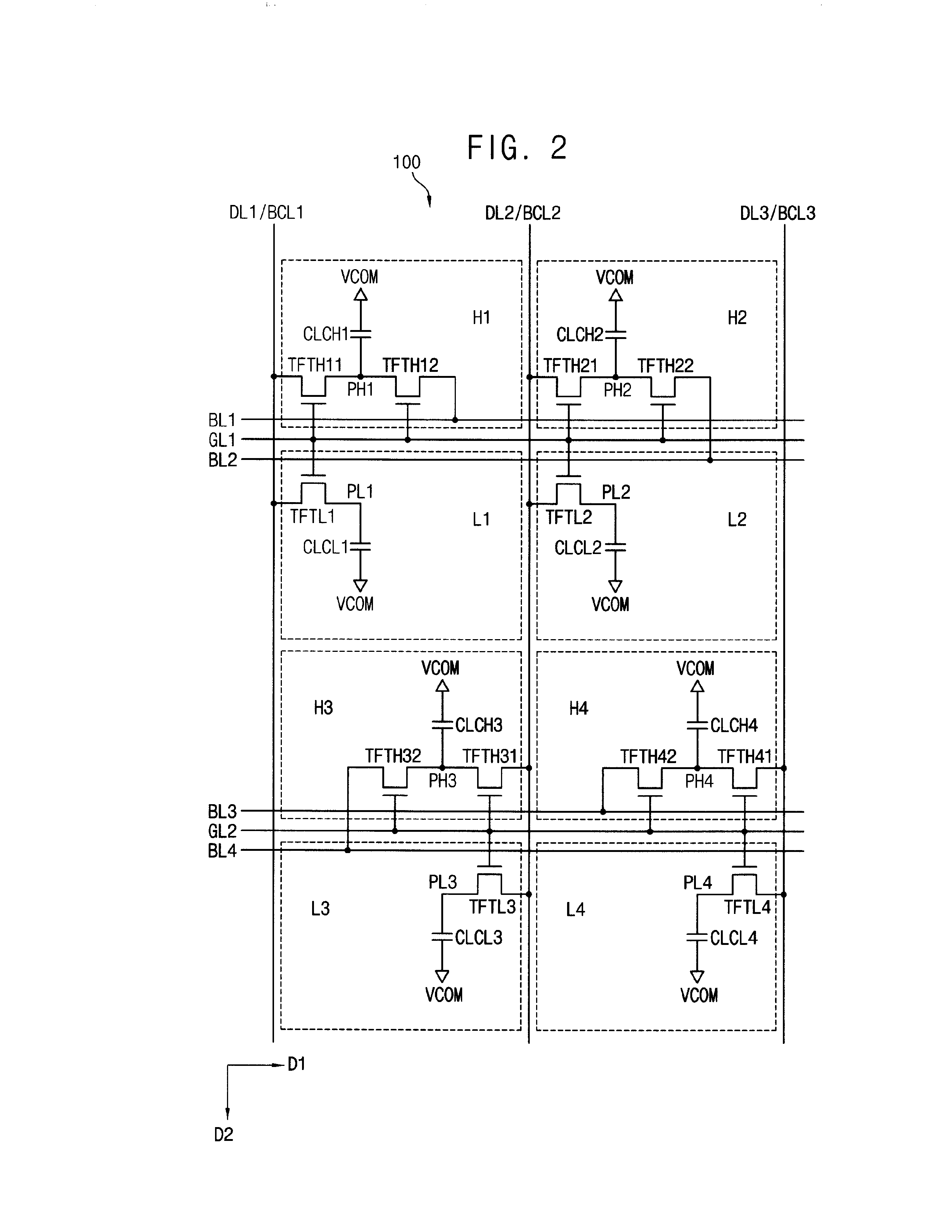

Display panel and method of driving the same

ActiveUS20130182018A1Improve quality and reliabilityQuality improvementMowersCathode-ray tube indicatorsVoltageComputer science

A display panel comprises a plurality of pixels. A first pixel among the plurality of pixels comprises a first subpixel which further comprises a first subpixel electrode, a first switching element configured to apply a data voltage to the first subpixel electrode, and a second switching element applying a boosting voltage to the first subpixel electrode. The first pixel further comprises a second subpixel comprising a second subpixel electrode and a third switching element applying the data voltage to the low pixel electrode. Accordingly, the display quality and the reliability of the display panel may be improved.

Owner:SAMSUNG DISPLAY CO LTD

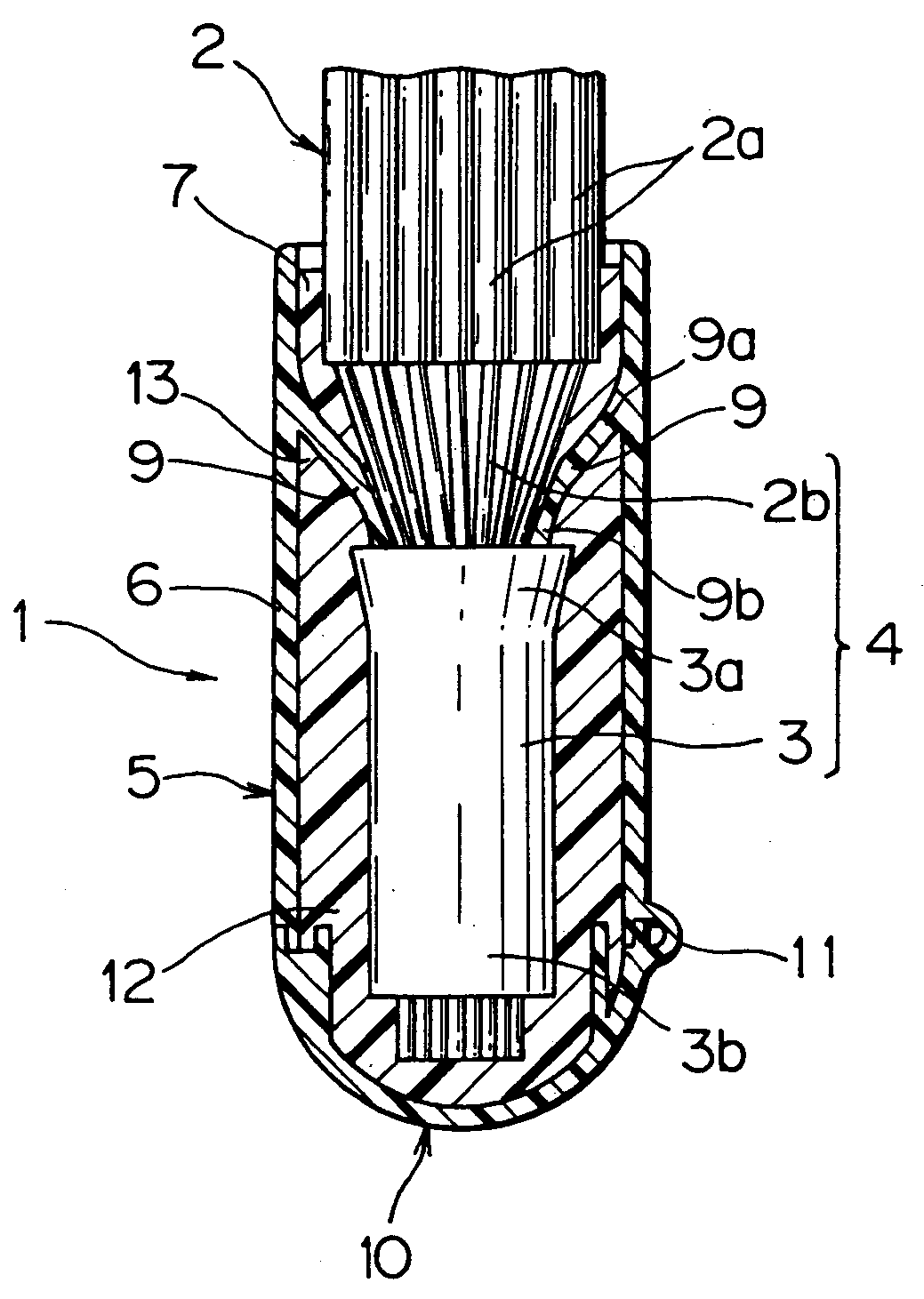

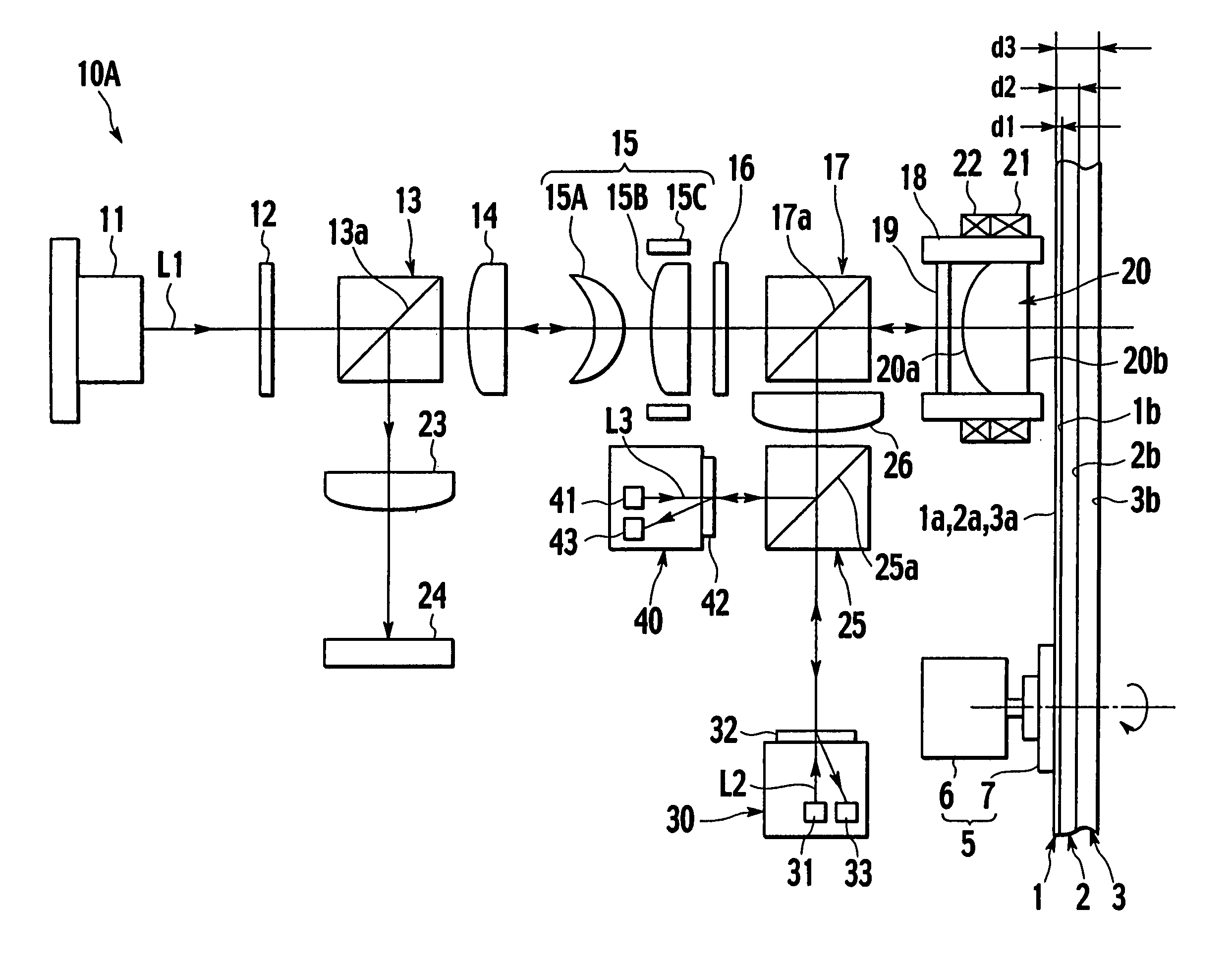

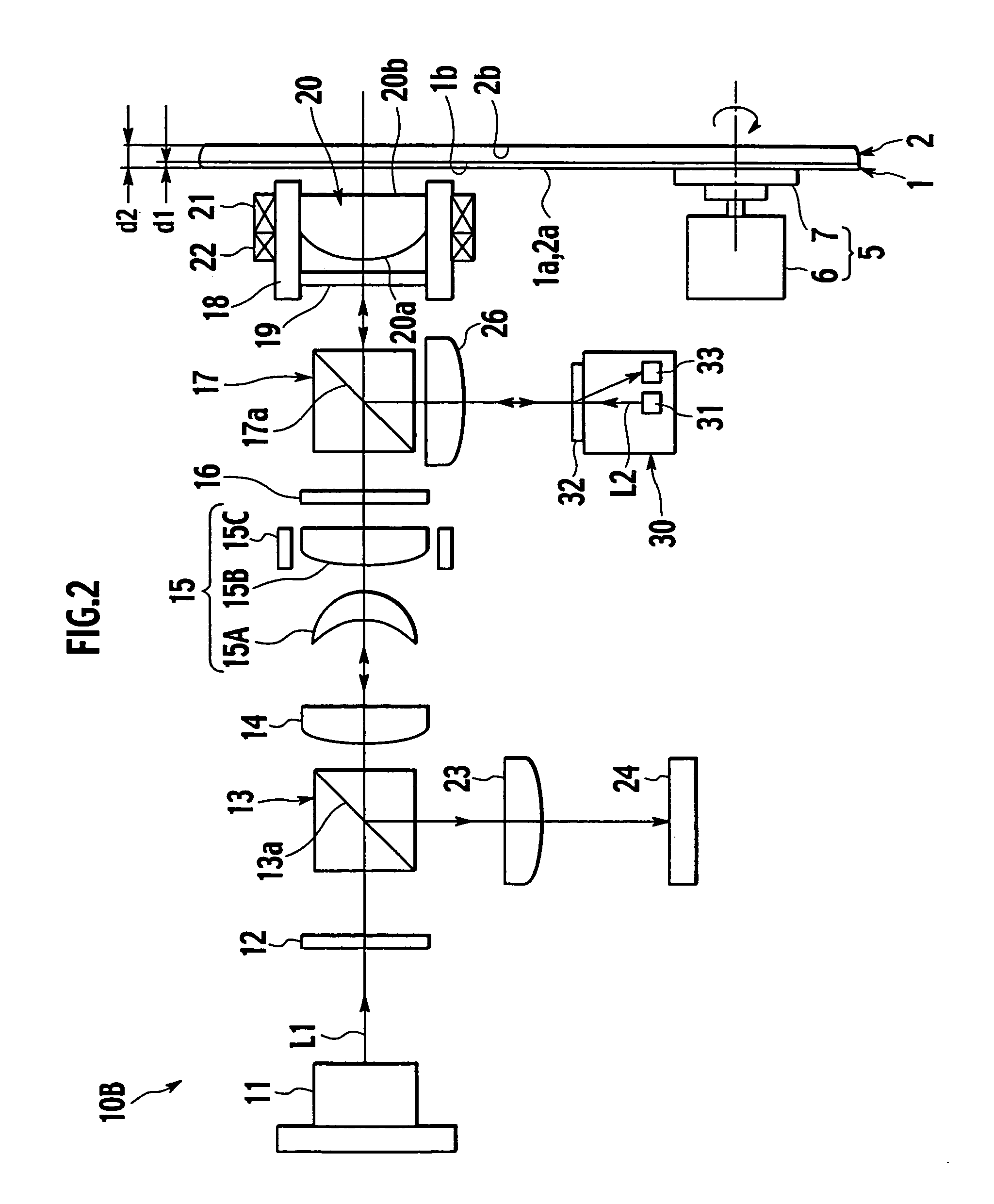

Optical pickup device

ActiveUS7233562B2Large thicknessImprove quality and reliabilityOptical beam sourcesRecord information storageOptical pickupHigh density

When an extra-high density optical disc, a DVD having a recording density lower than that of the extra-high density optical disc, a CD having a recording density lower than that of the DVD, and a combined optical recording medium in which the extra-high density optical disc, DVD, and CD are appropriately combined and integrally stacked are selectively recorded or reproduced by an objective lens whose numerical aperture (NA) is set to 0.75 or more, the objective lens satisfies the following expression:t<a·f+b wherein t: an axial thickness of the objective lens, f: a focal distance of the objective lens, a: a coefficient, and b: a constant, and the coefficient a and the constant b satisfies that a=2.02, b=−1.94; a=2.08, b=−1.84; or a=2.11, b=−1.77.

Owner:JVC KENWOOD CORP

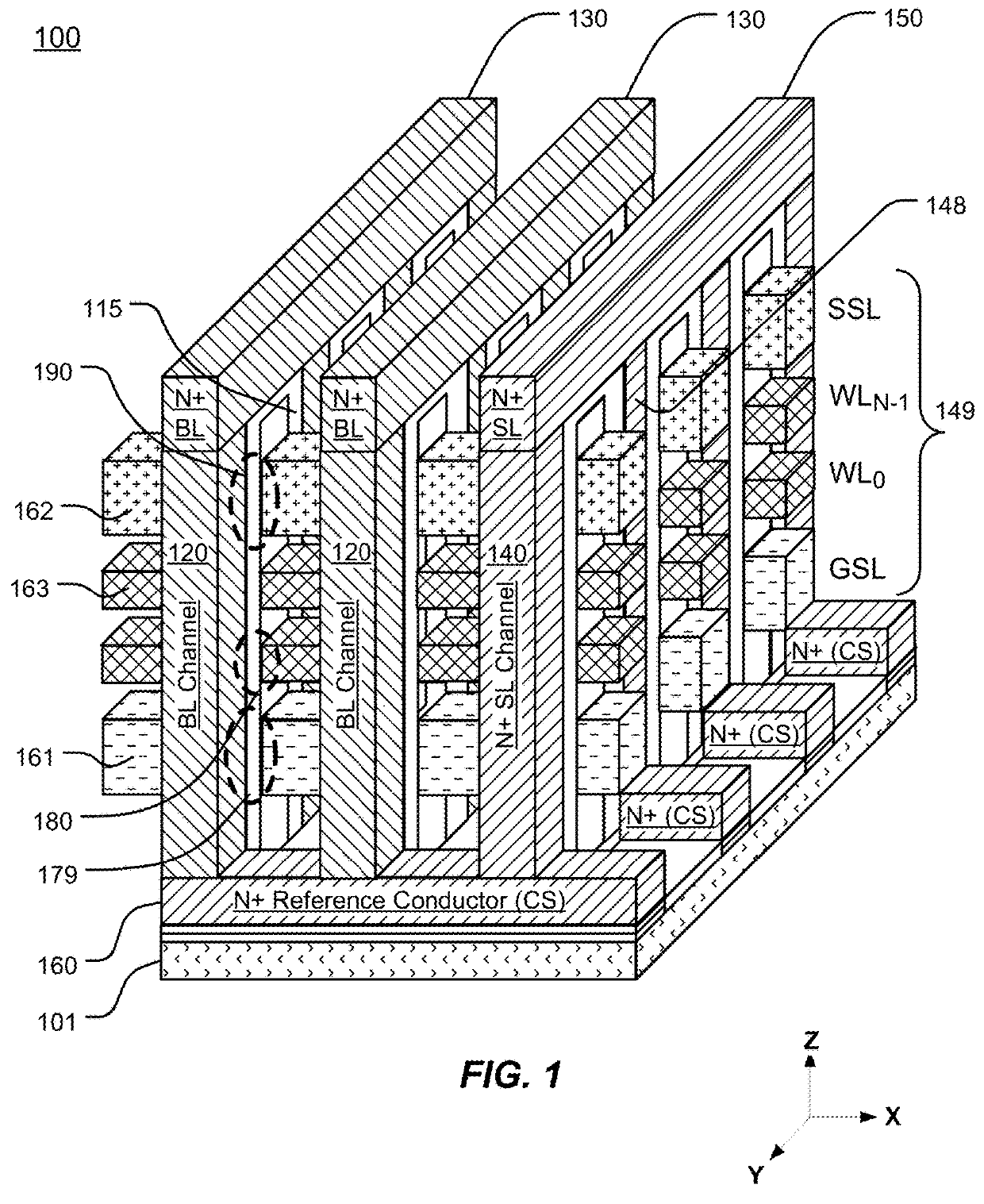

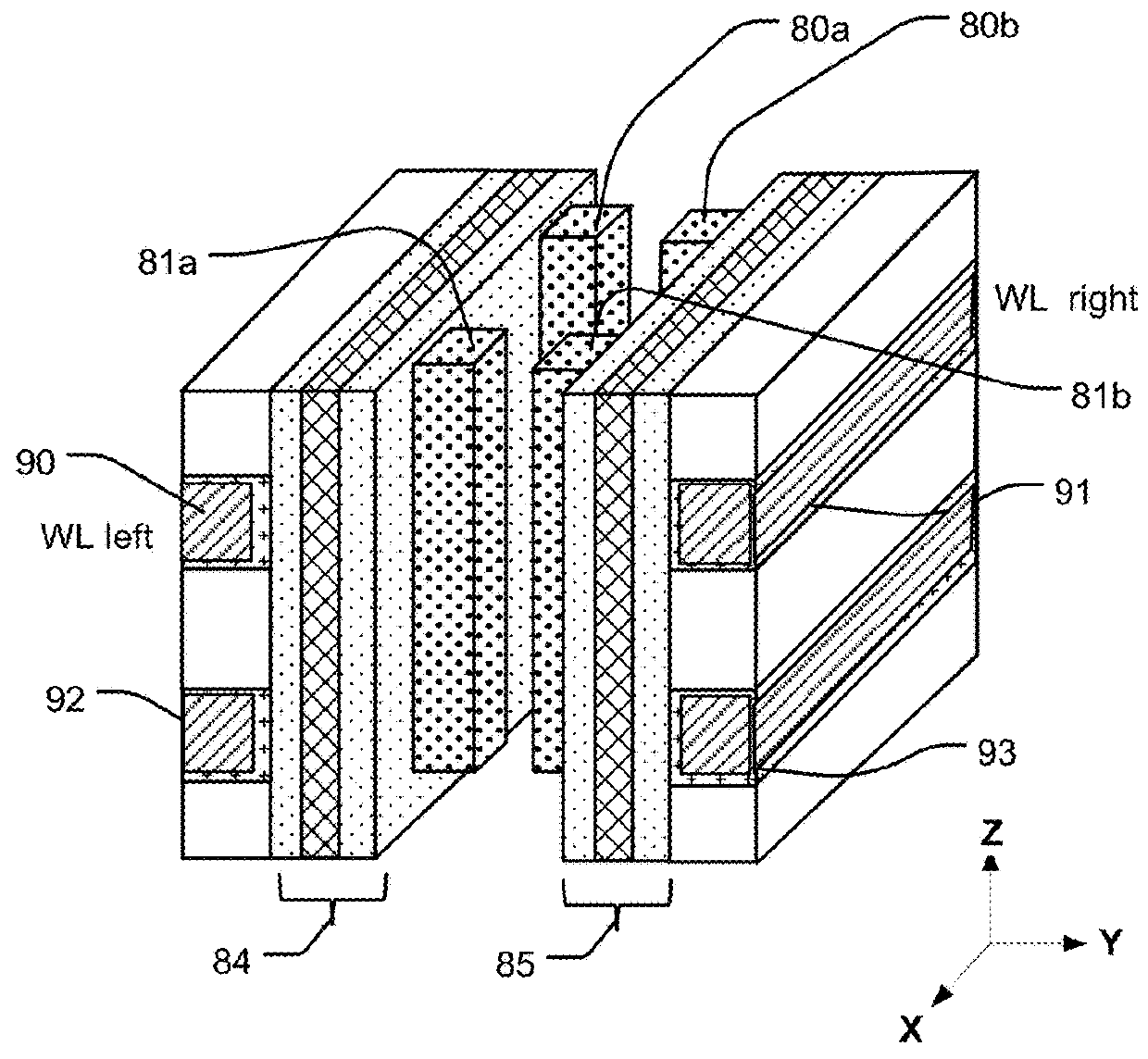

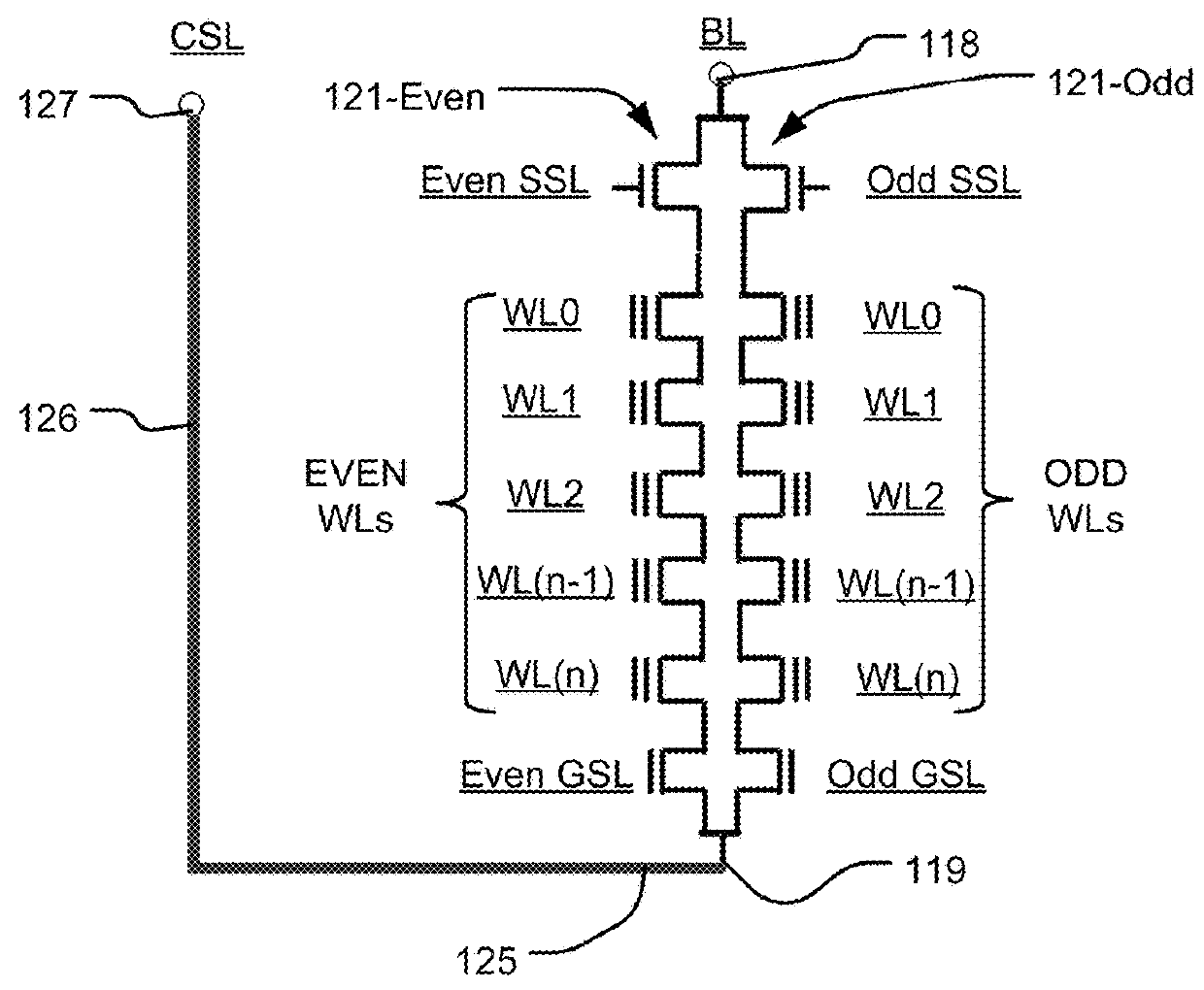

Method for manufacturing 3D NAND memory using gate replacement, and resulting structures

ActiveUS10043819B1Improve operating characteristicsImprove quality and reliabilityTransistorSemiconductor/solid-state device detailsEtchingTrapping

A 3D memory device includes a plurality of vertical pillars composed of a vertical channel and a multilayer data storage structure. The multilayer data storage structure can comprise a dielectric charge trapping structure. A stack of dielectric lined conductive strips separated in the stack by insulating strips have sidewalls disposed adjacent the corresponding vertical pillars. The conductive strips have a dielectric liner having a dielectric constant κ greater than 7 on the sidewalls in contact with the outside layer of the multilayer data storage structure on the corresponding pillar. The conductive strips in embodiments described herein can comprise a relatively low resistance material, such as a metal or a metal nitride. A manufacturing method using Si—Ge selective etching of sacrificial layers can be used in a gate replacement process to form the dielectric conductive strips.

Owner:MACRONIX INT CO LTD

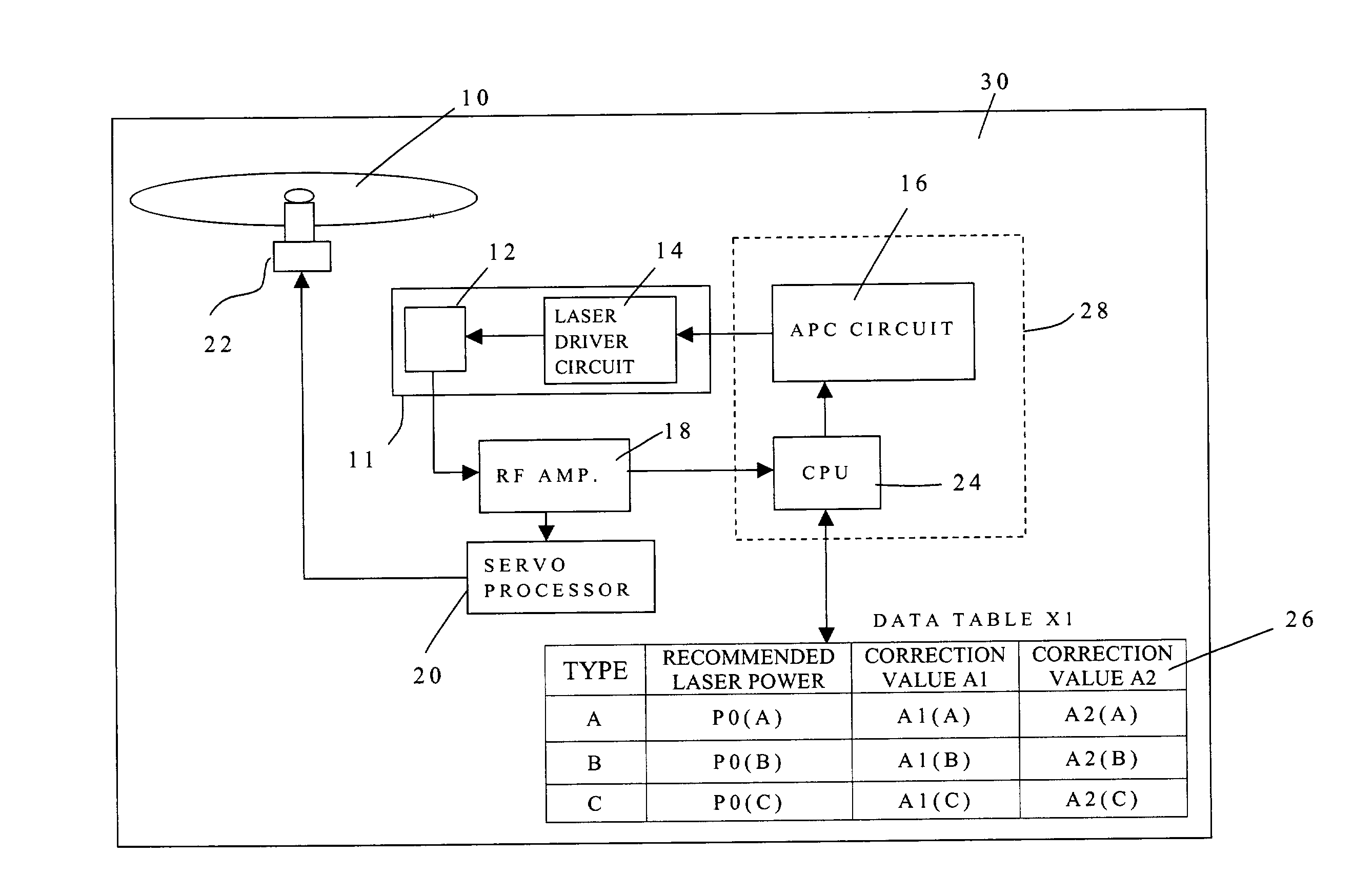

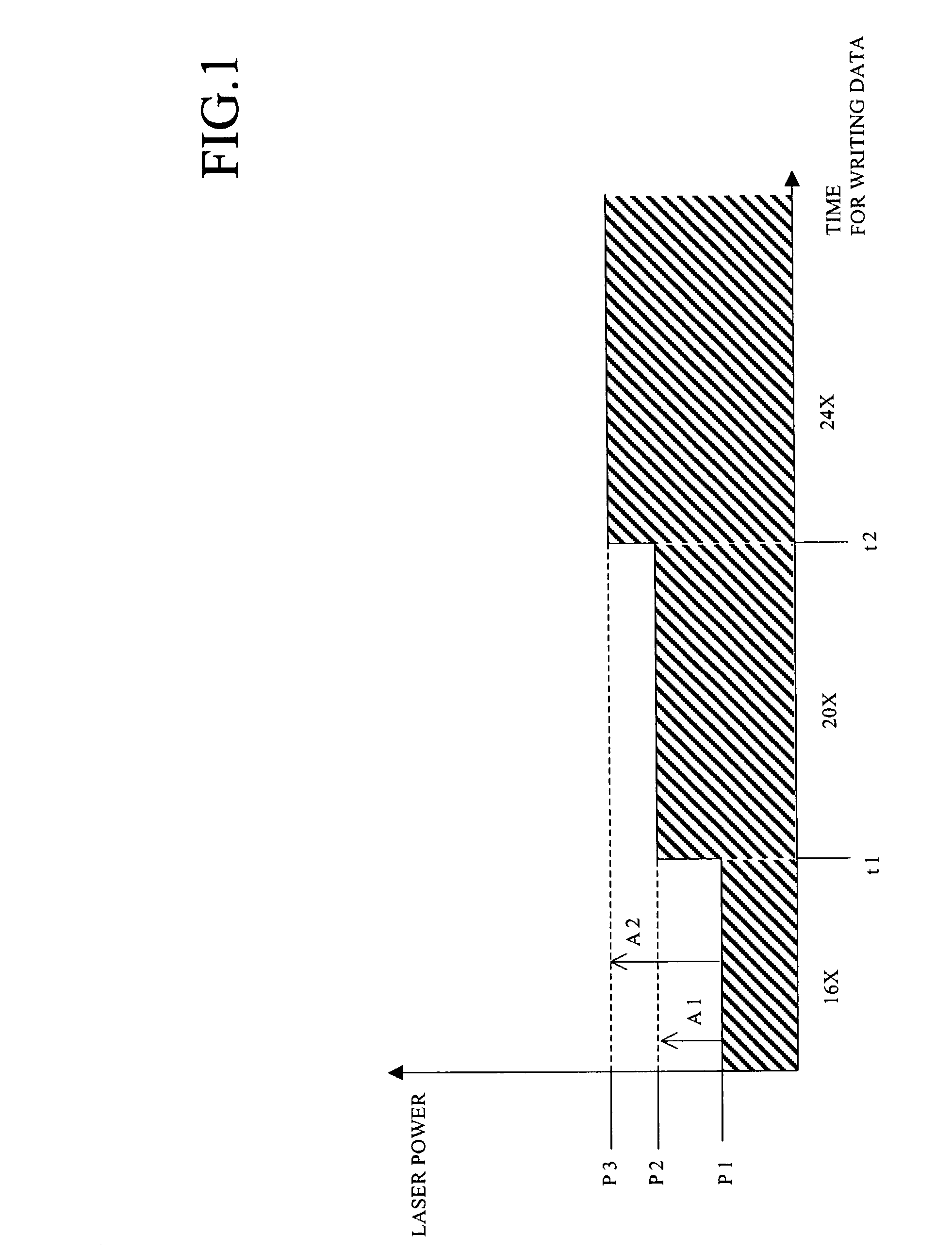

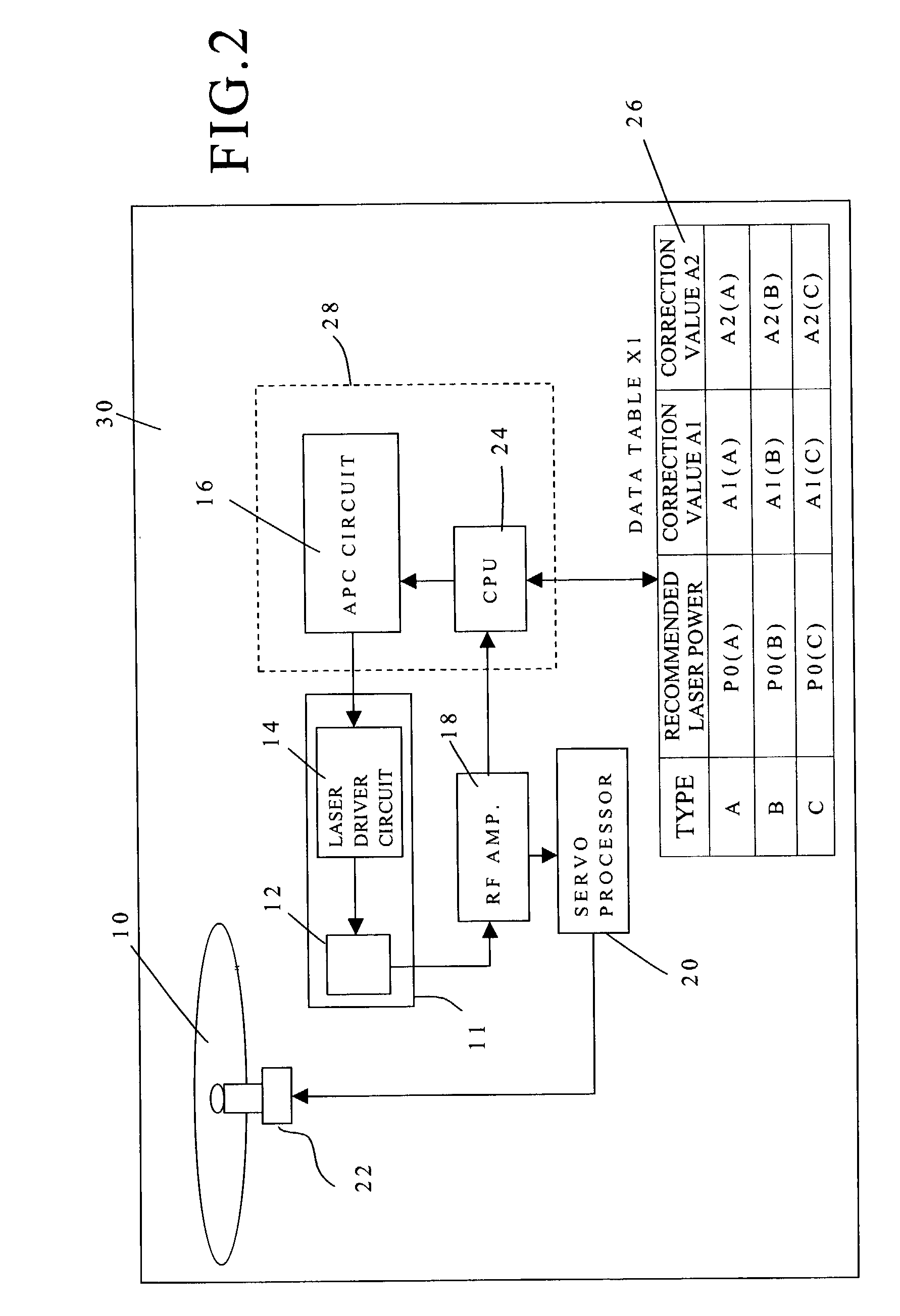

Method of controlling laser power and optical disk player

InactiveUS7099251B2Improve quality and reliabilityCombination recordingOptical beam sourcesConstant linear velocityClassical mechanics

A method of controlling a laser power of a zone Constant Linear Velocity (CLV) type optical disk player, in which a linear velocity of writing data is accelerated, by stages, toward an outer edge of an optical disk. The method includes changing a laser power for writing data onto the optical disk when the linear velocity is changed.

Owner:SHINANO KENSHI

Circuit Board with Conductive Structure and Method for Fabricating the same

InactiveUS20070158852A1Improve quality and reliabilityReinforces combing strengthSemiconductor/solid-state device detailsPrinted circuit aspectsUltimate tensile strengthMetal

A method for fabricating a circuit board with a conductive structure and the same are proposed. A buffer metal layer is formed on an electrically connecting pad of a circuit layer of a circuit board in advance. A conductive structure is then formed on the buffer metal layer to form the conductive structure of the present invention and is connected to the circuits located in the different layers of the circuit board. The combining strength of the conductive structure and the electrically connecting pad is reinforced by the buffer metal layer as the buffer metal layer has high ductility. The long-term electrical quality and stability are also enhanced.

Owner:PHOENIX PRECISION TECH CORP

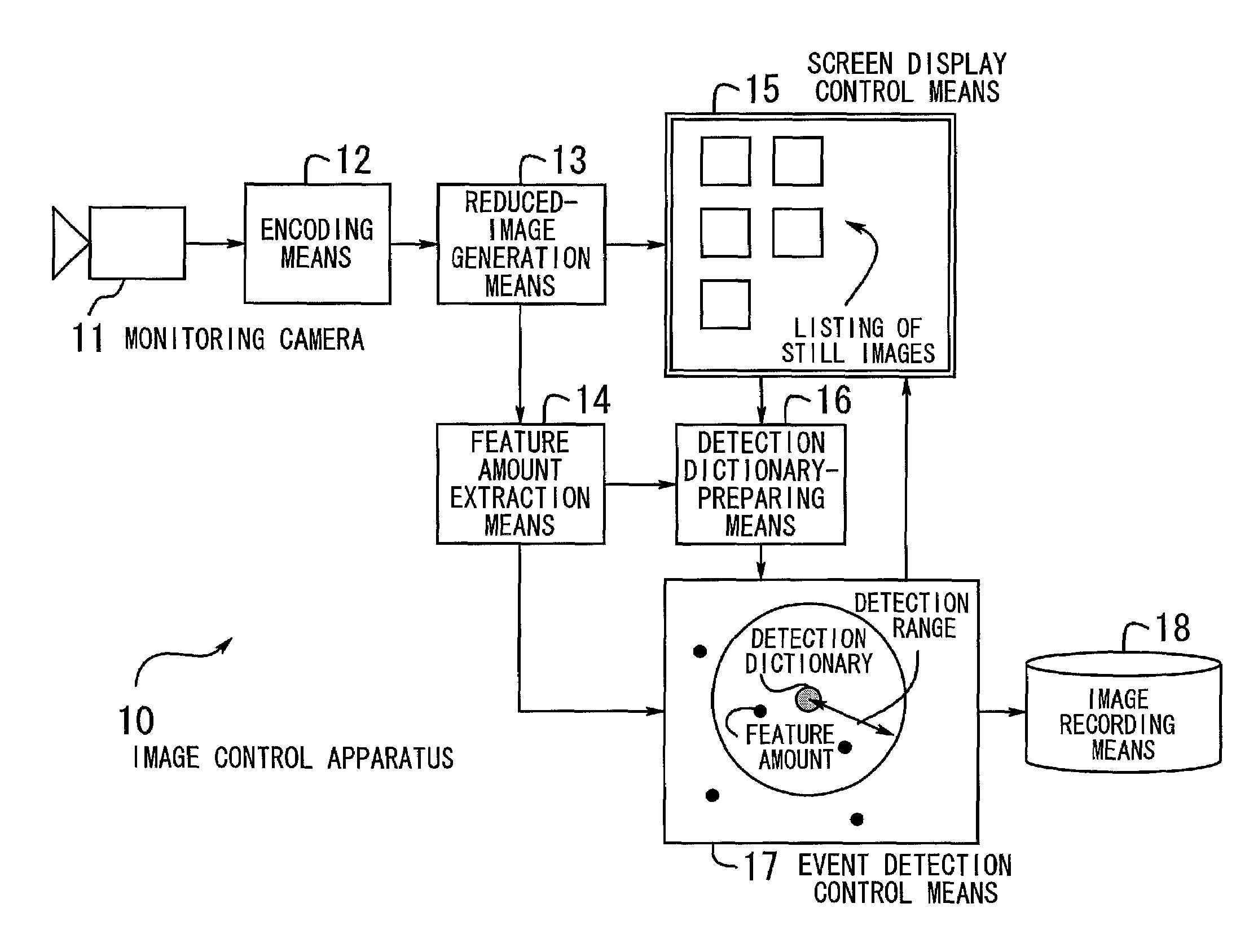

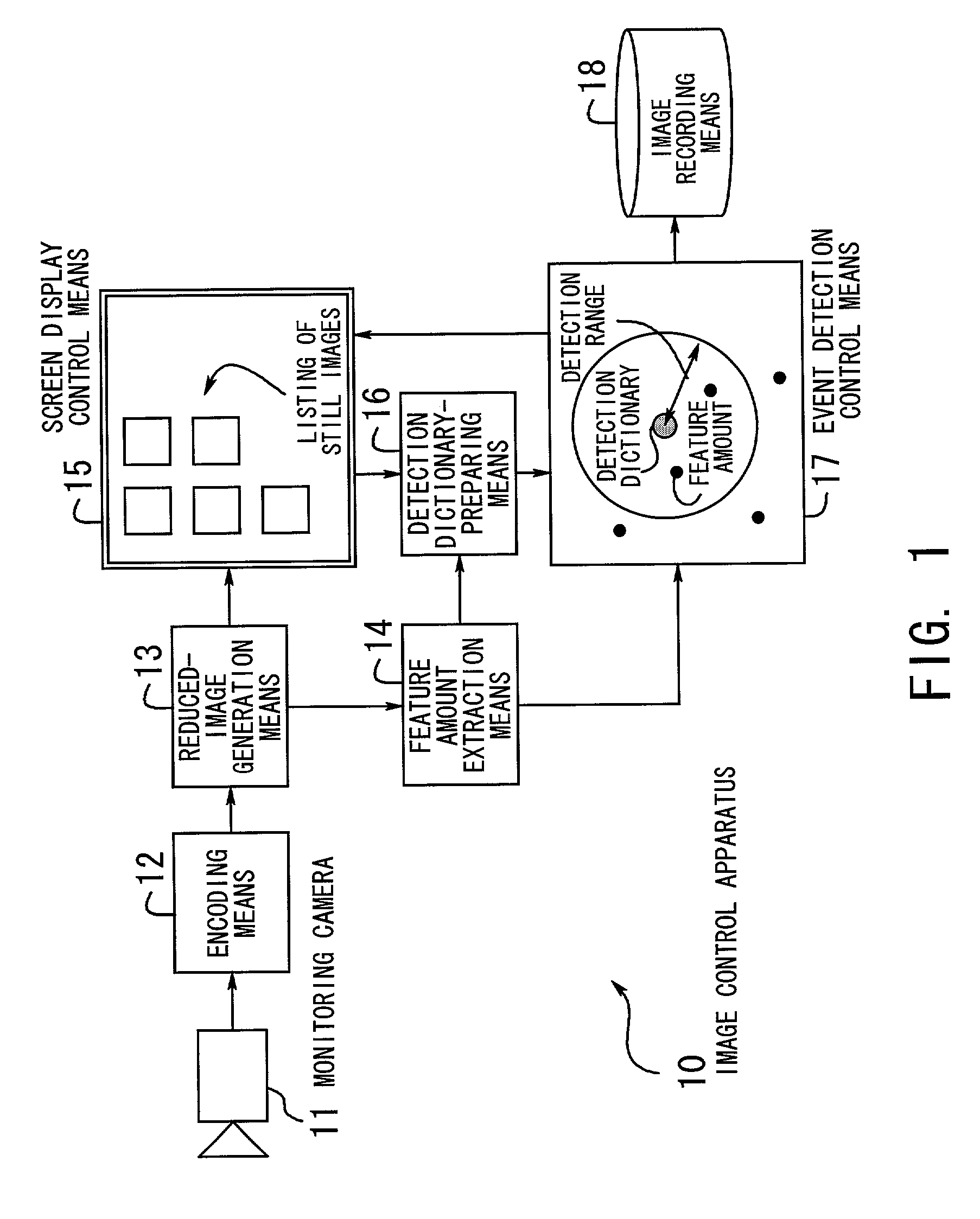

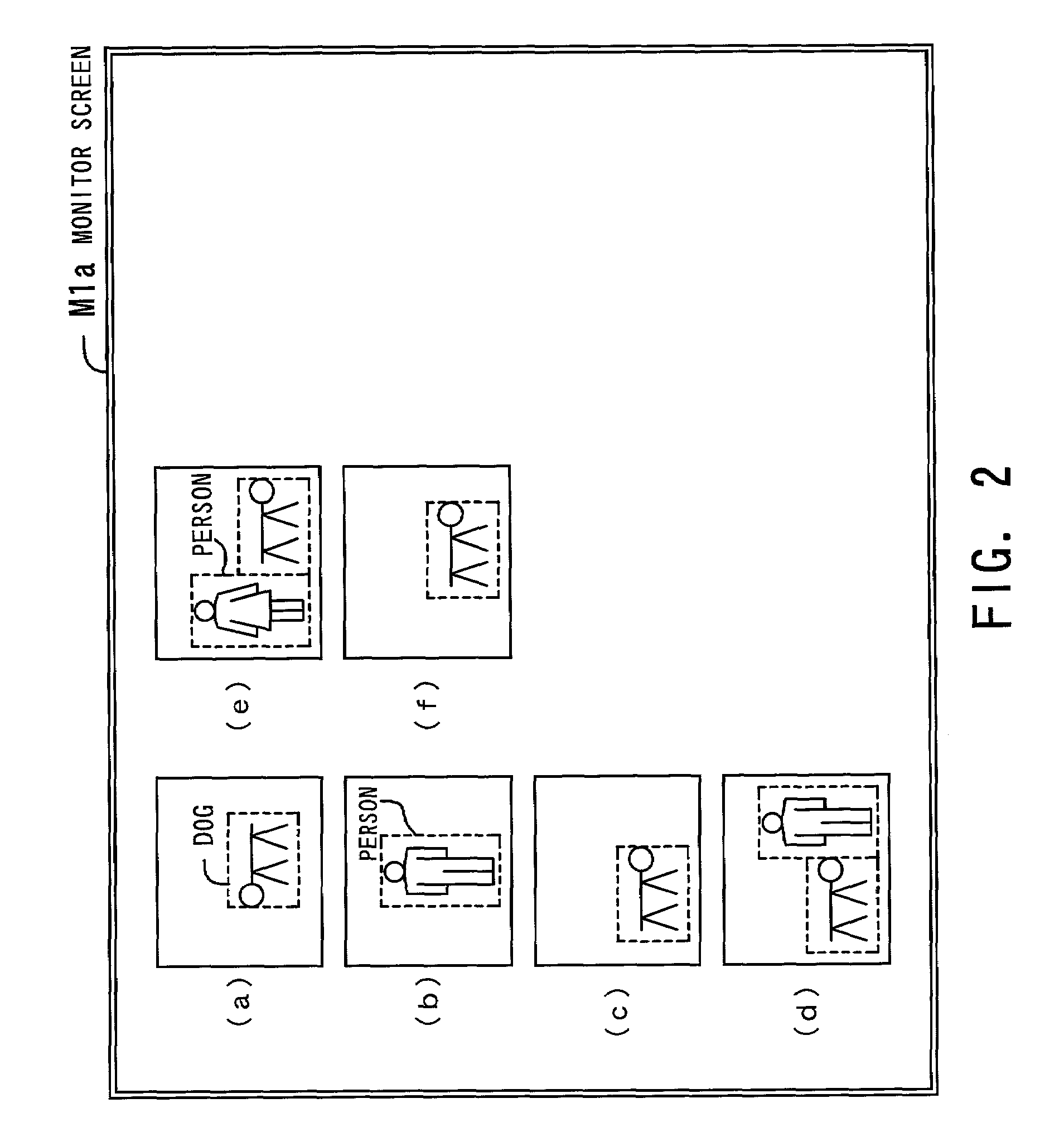

Image control apparatus

InactiveUS6996275B2Efficient event detectionQuality improvementTelevision system detailsImage analysisDisplay deviceImage recording

There is provided an image control apparatus which incorporates an automatic configuration mechanism for setting parameters used in event detection, to thereby perform efficient event detection, and improve quality and reliability of image monitoring control. An encoding section encodes an image from a monitoring camera. A reduced image generation section performs simplified decoding of an encoded image to generate a reduced image. A feature amount extraction section detects an image event from the reduced image and extracts feature amounts therefrom. A screen display control section performs screen display control such that a listing of static images of the reduced image is displayed on a display, and a detection event can be set which is an event to be detected. A detection dictionary-preparing section measures variance values from the feature amounts of the detection event to thereby prepare a detection dictionary containing detection parameters which are feature amounts having small variance values. An event detection control section calculates distances between the detection dictionary and the feature amounts to determine a detection range. An image recording section compares the distances and a threshold value for recording images, and based on a result of the comparison, records monitored images.

Owner:FUJITSU LTD

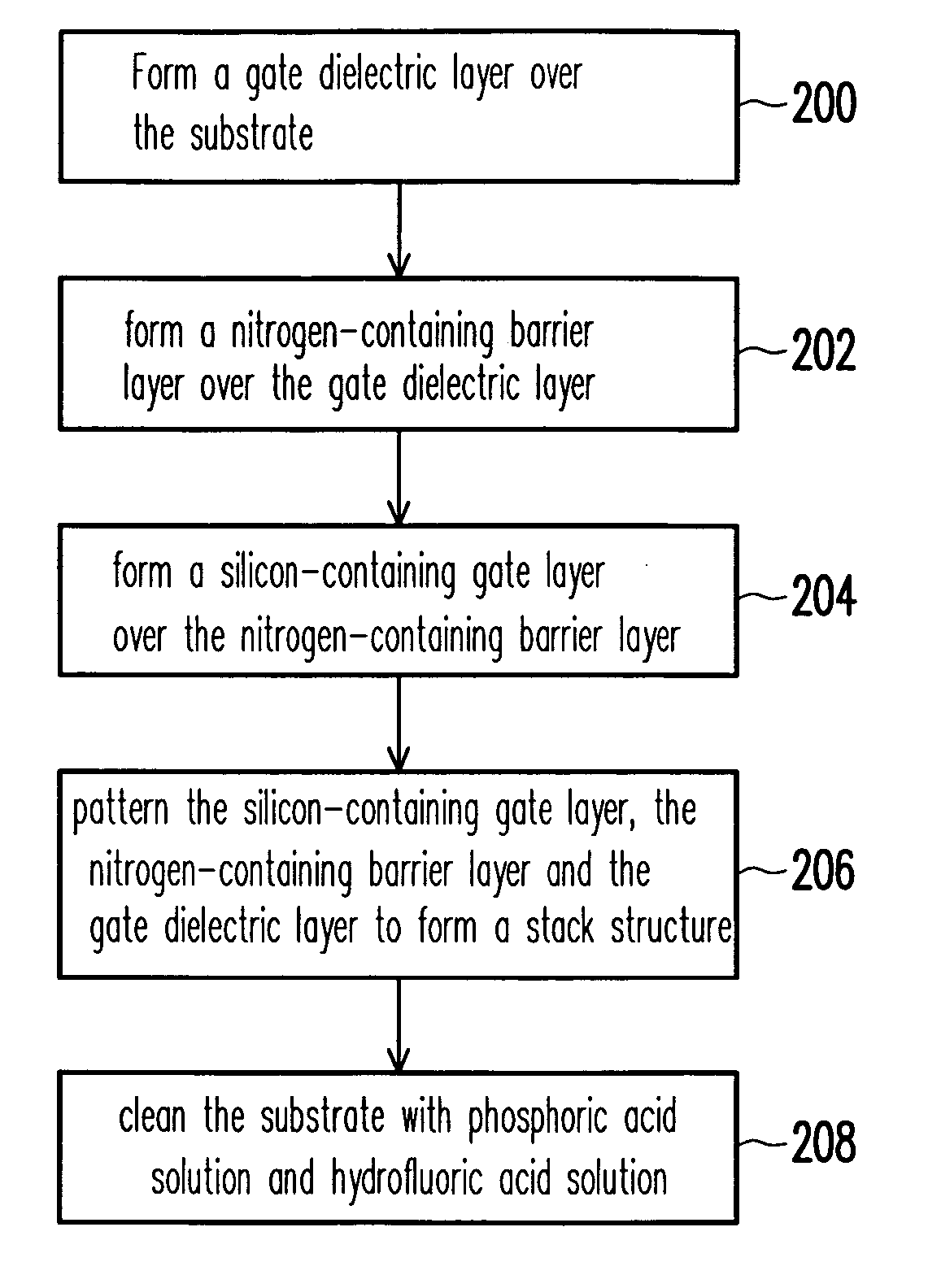

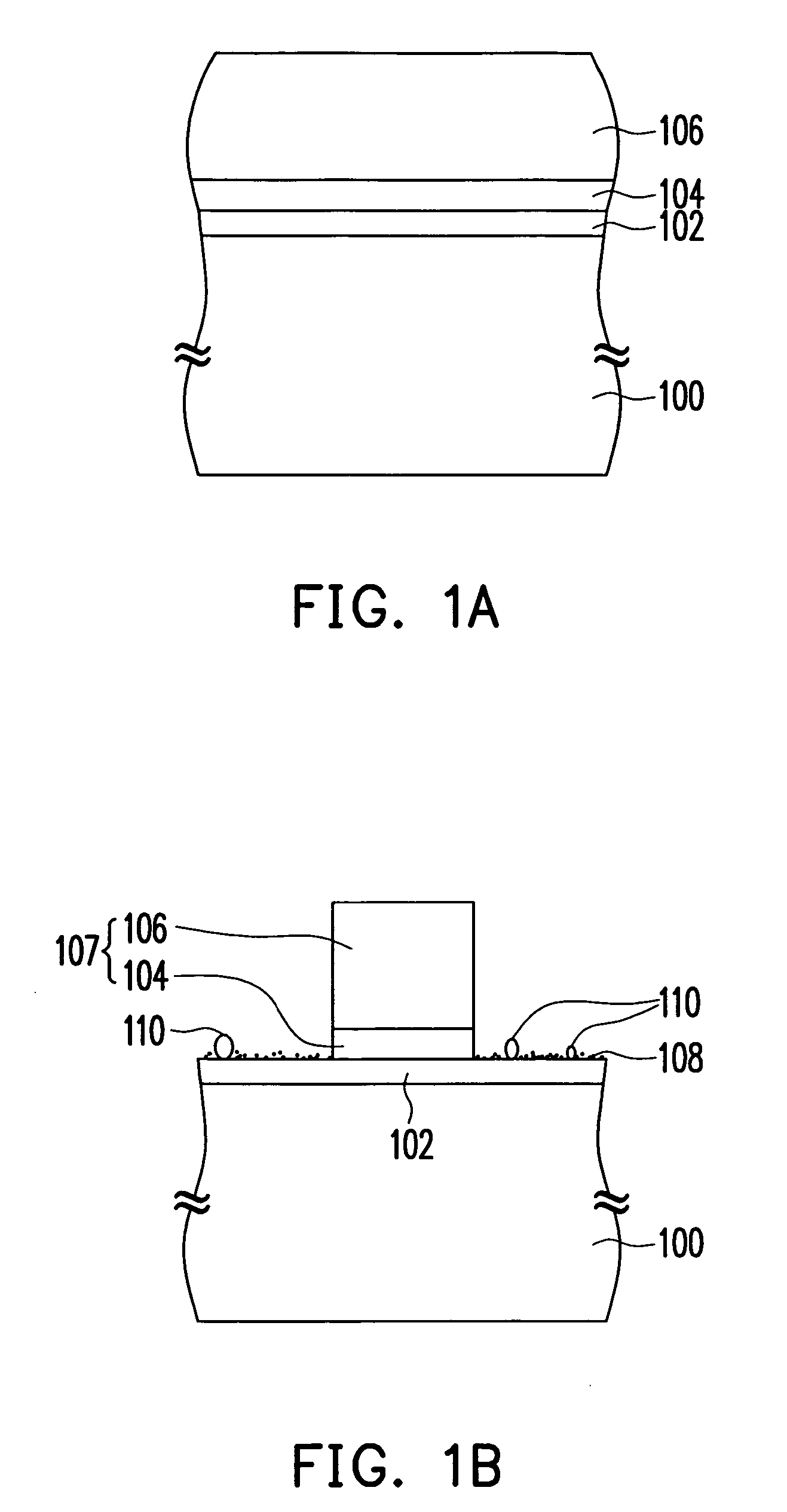

Method of cleaning wafer and method of manufacturing gate structure

ActiveUS20060172548A1High yieldEfficient removalSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricO-Phosphoric Acid

A method of cleaning a wafer, adapted for a patterned gate structure. The gate structures comprise a gate dielectric layer, a nitrogen-containing barrier layer and a silicon-containing gate layer sequentially stacked over the substrate. The method includes cleaning the substrate with phosphoric acid solution and hydrofluoric acid solution so that silicon nitride residues formed in a reaction between the nitrogen-containing barrier layer and the silicon-containing gate layer can be removed and the amount of pollutants and particles can be reduced. Ultimately, the yield of the process as well as the quality and reliability of the device are improved.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com