Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce surface unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

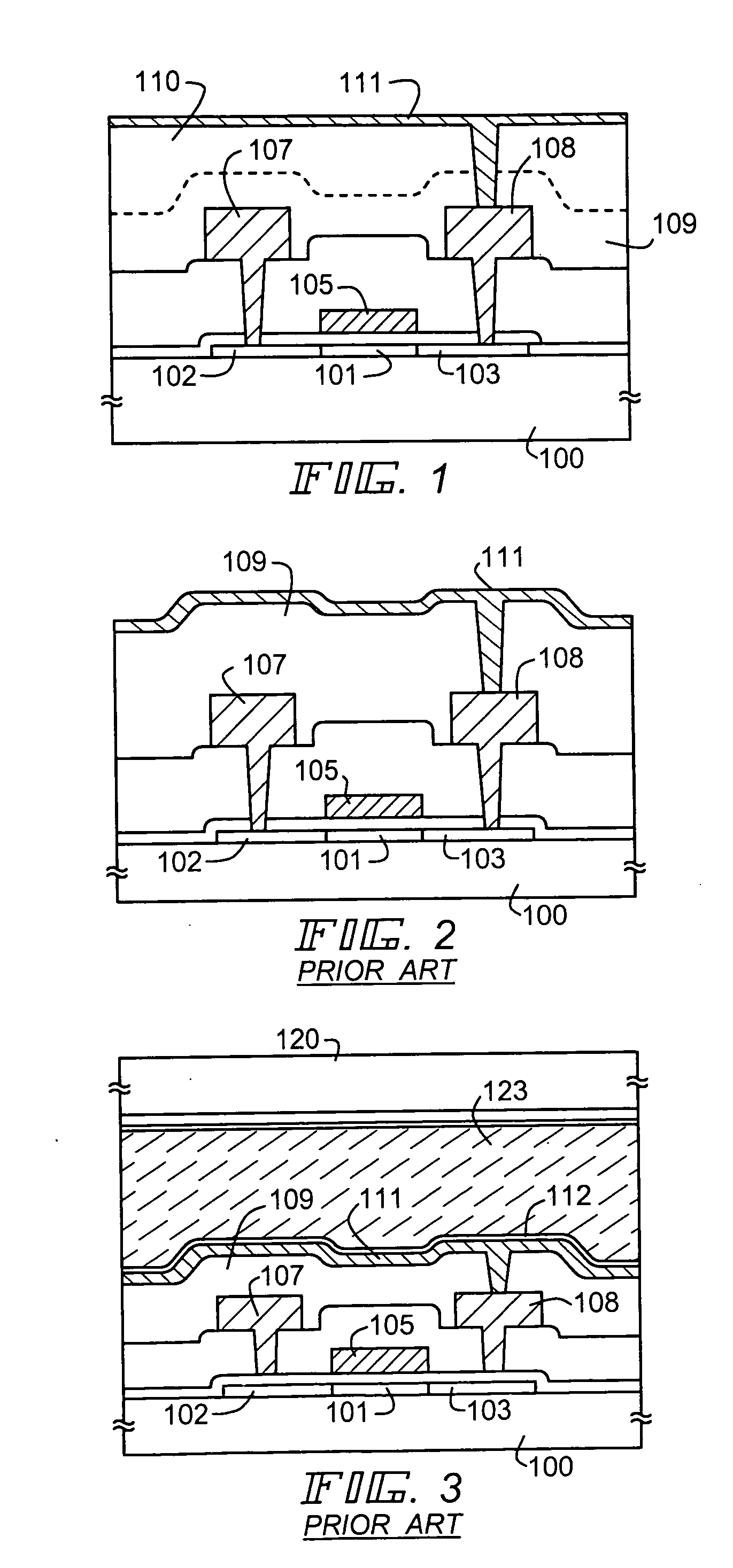

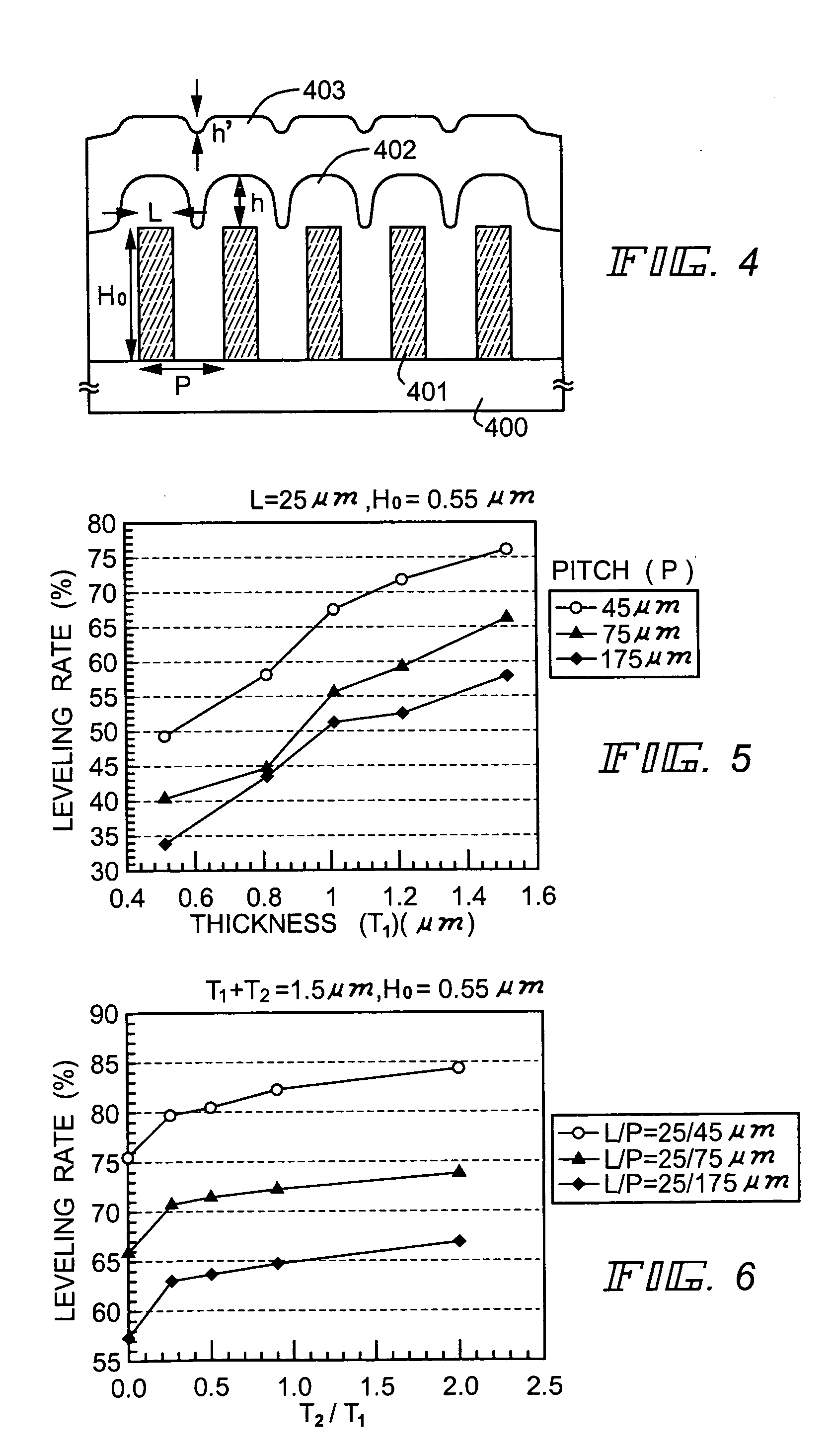

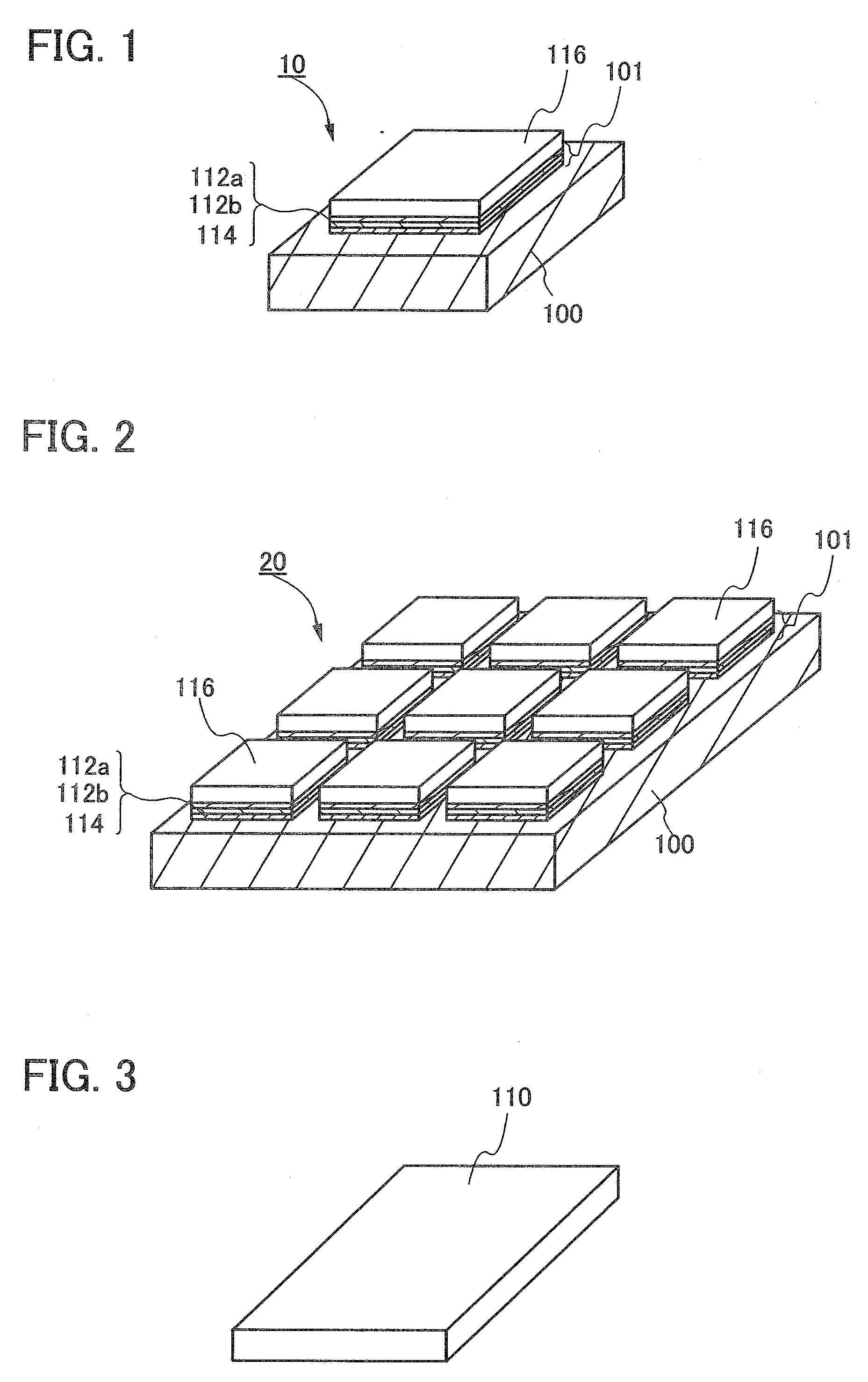

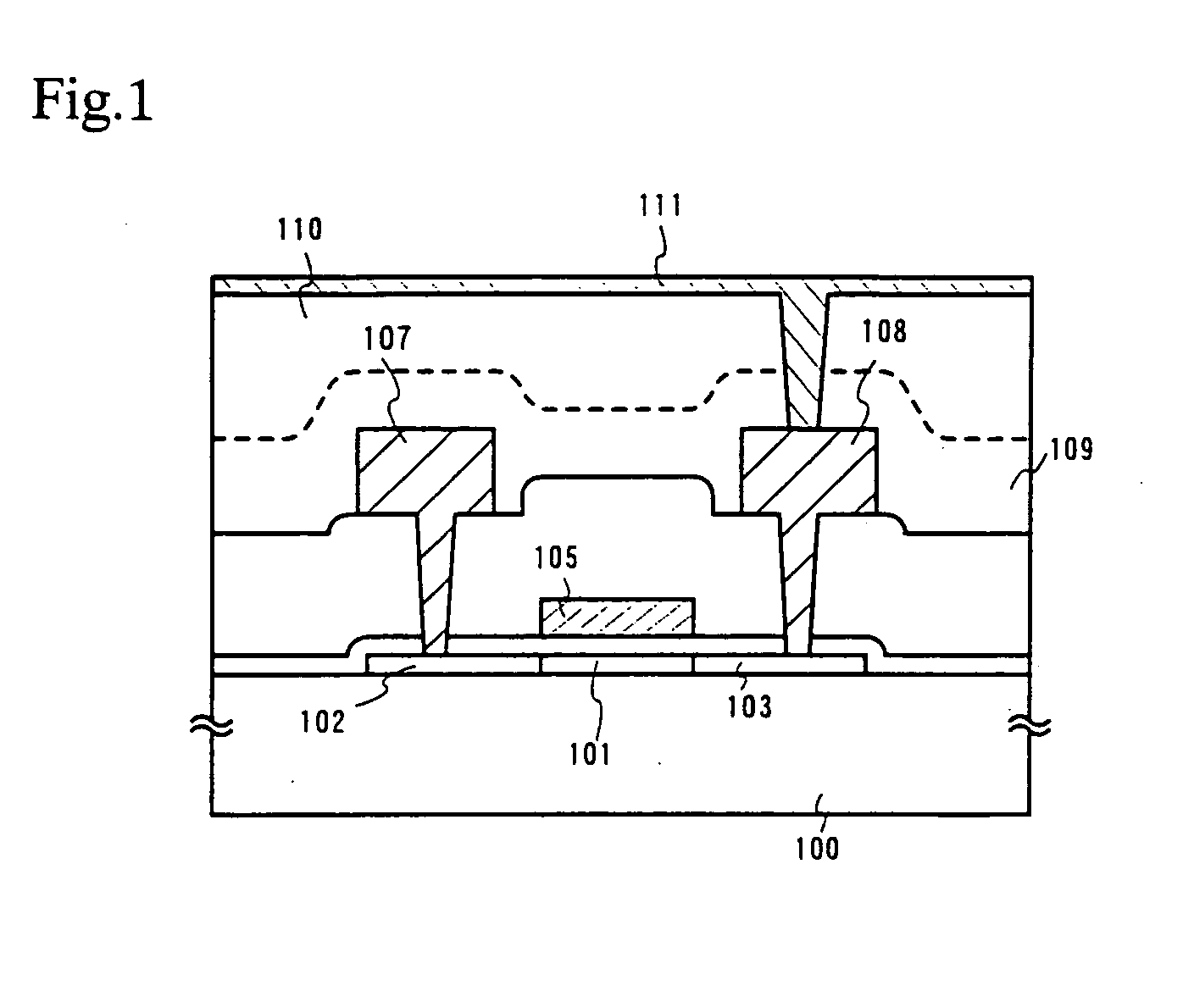

Method of fabricating display device

InactiveUS20050042798A1Highly reliable wiringUniform imagingSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDisplay device

The present invention improves the reliability of wirings, facilitates the orientation control of liquid crystal, or improves a reflectance of a reflective liquid crystal display device. In the case where a plurality of leveling films are laminated, a first leveling film is formed to have a thickness smaller than that of a second leveling film, thereby realizing a higher leveling rate. Therefore, unevenness of the surface due to level differences is reduced, and it becomes possible to attain the above objects.

Owner:SEMICON ENERGY LAB CO LTD

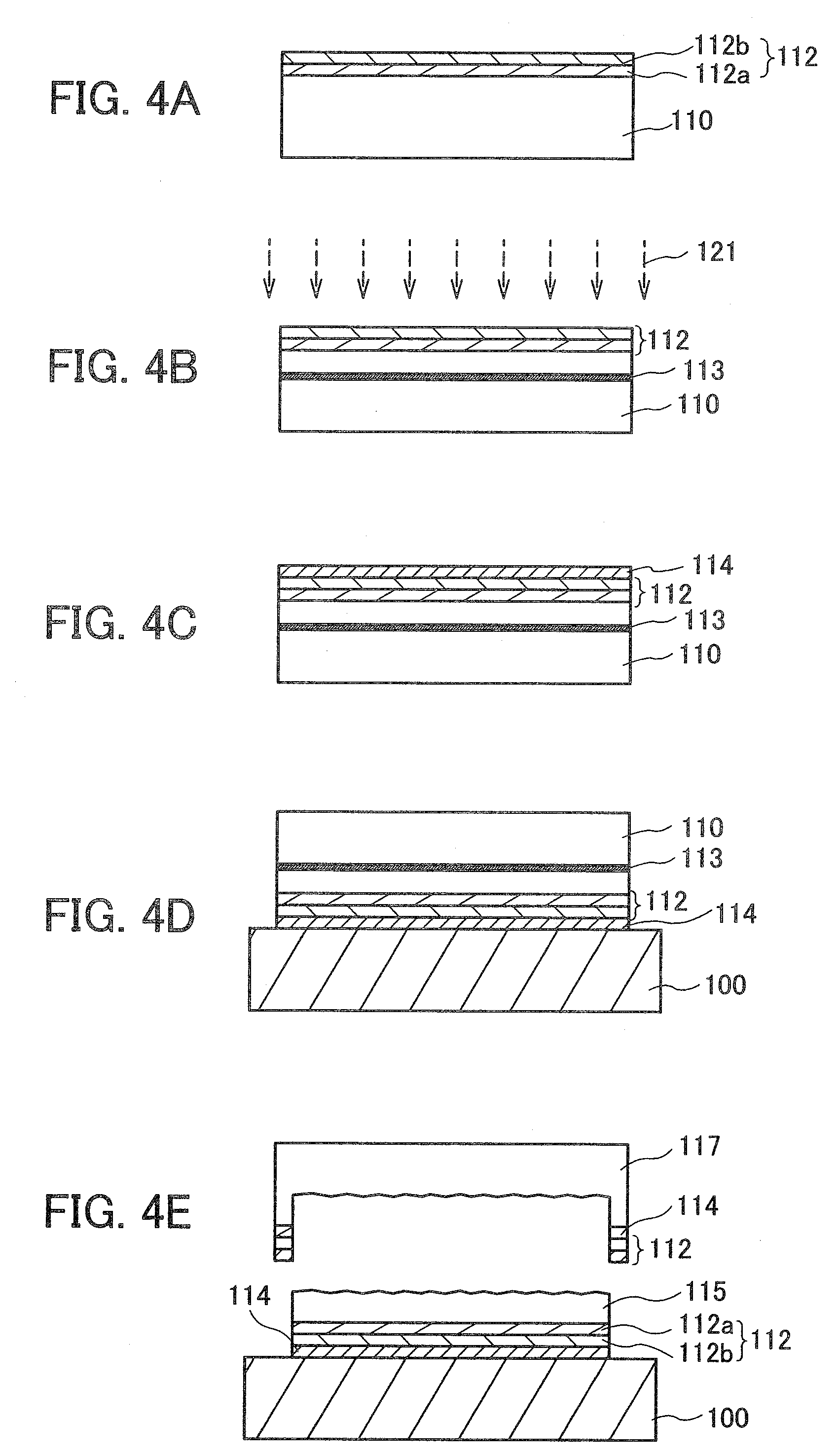

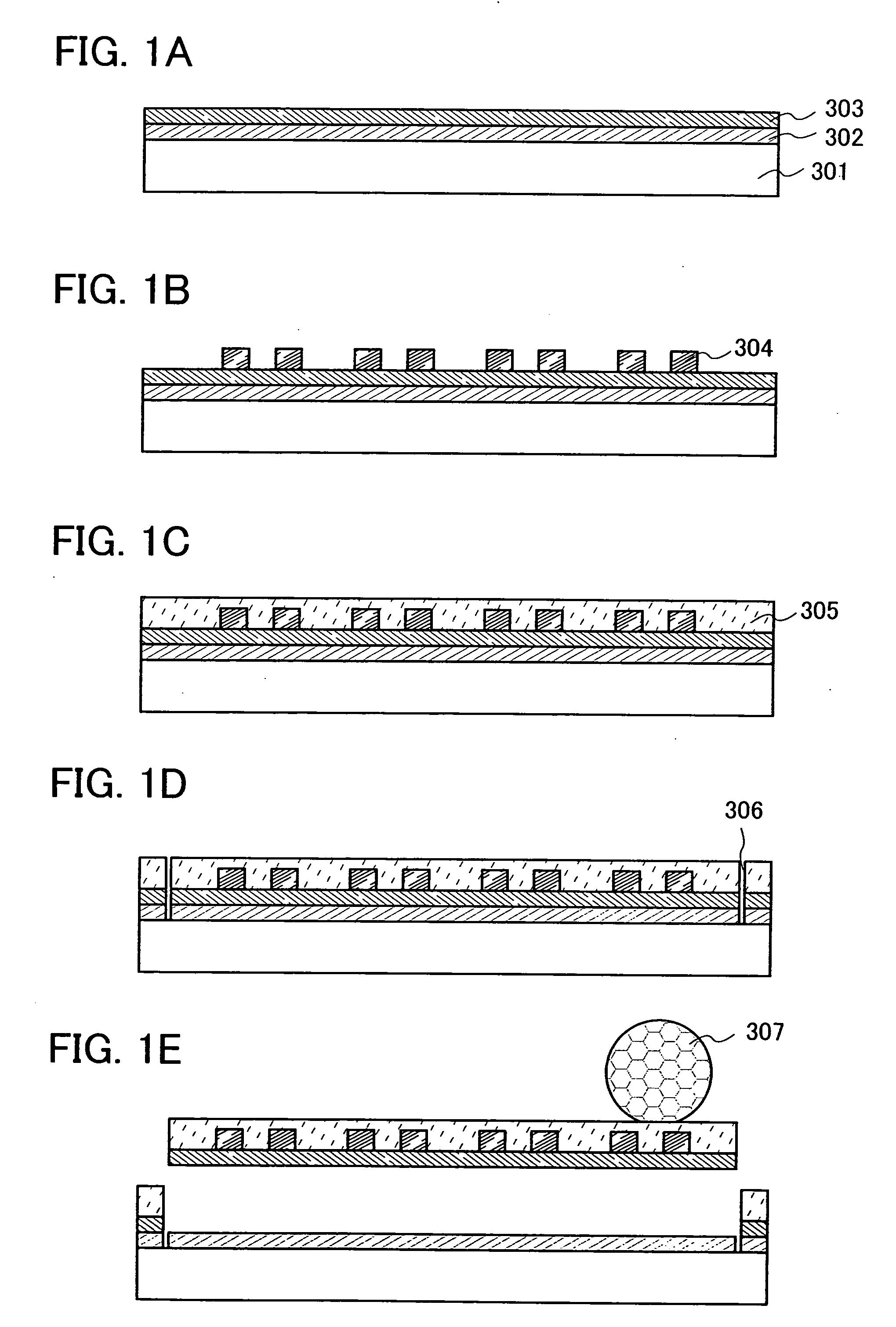

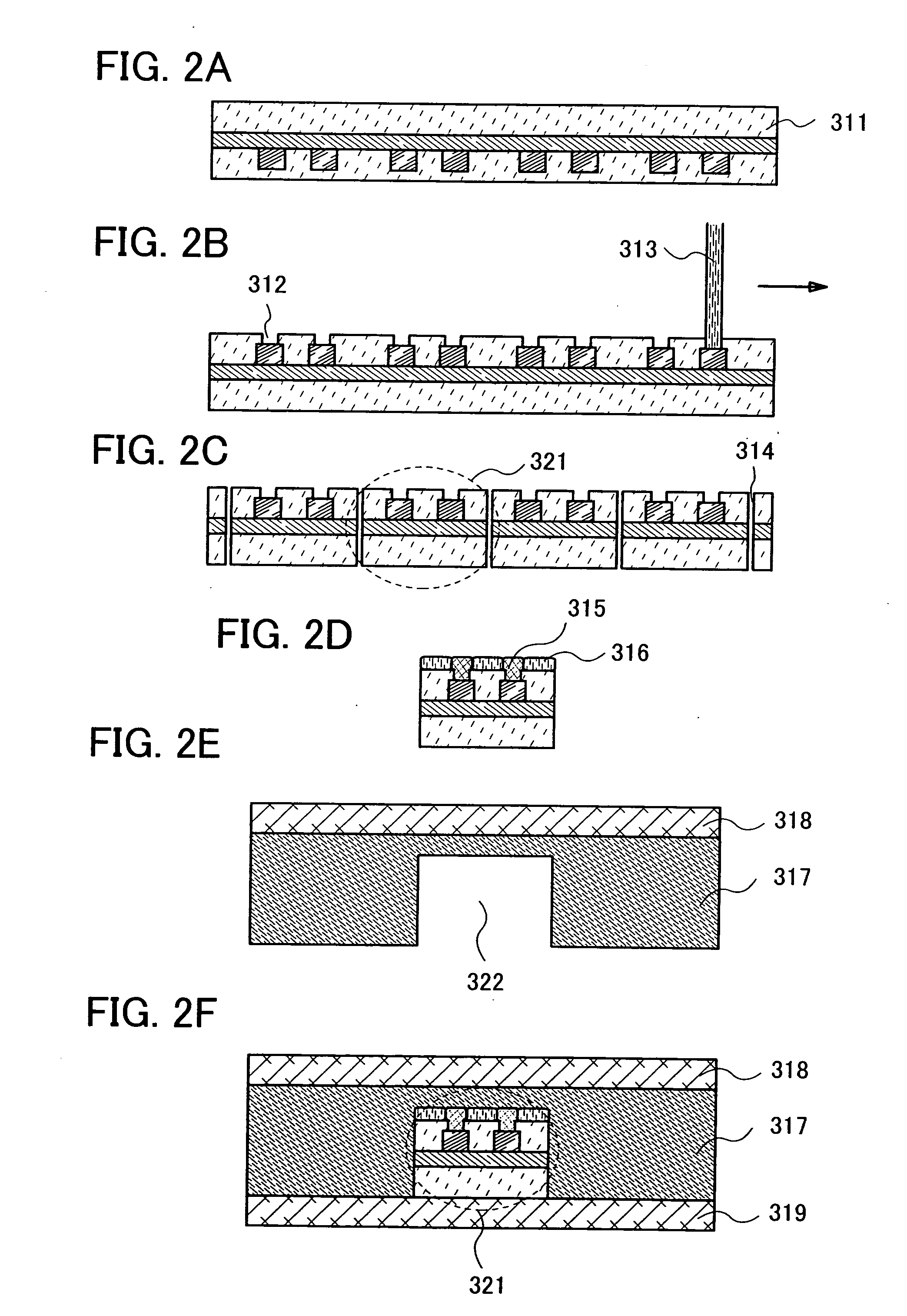

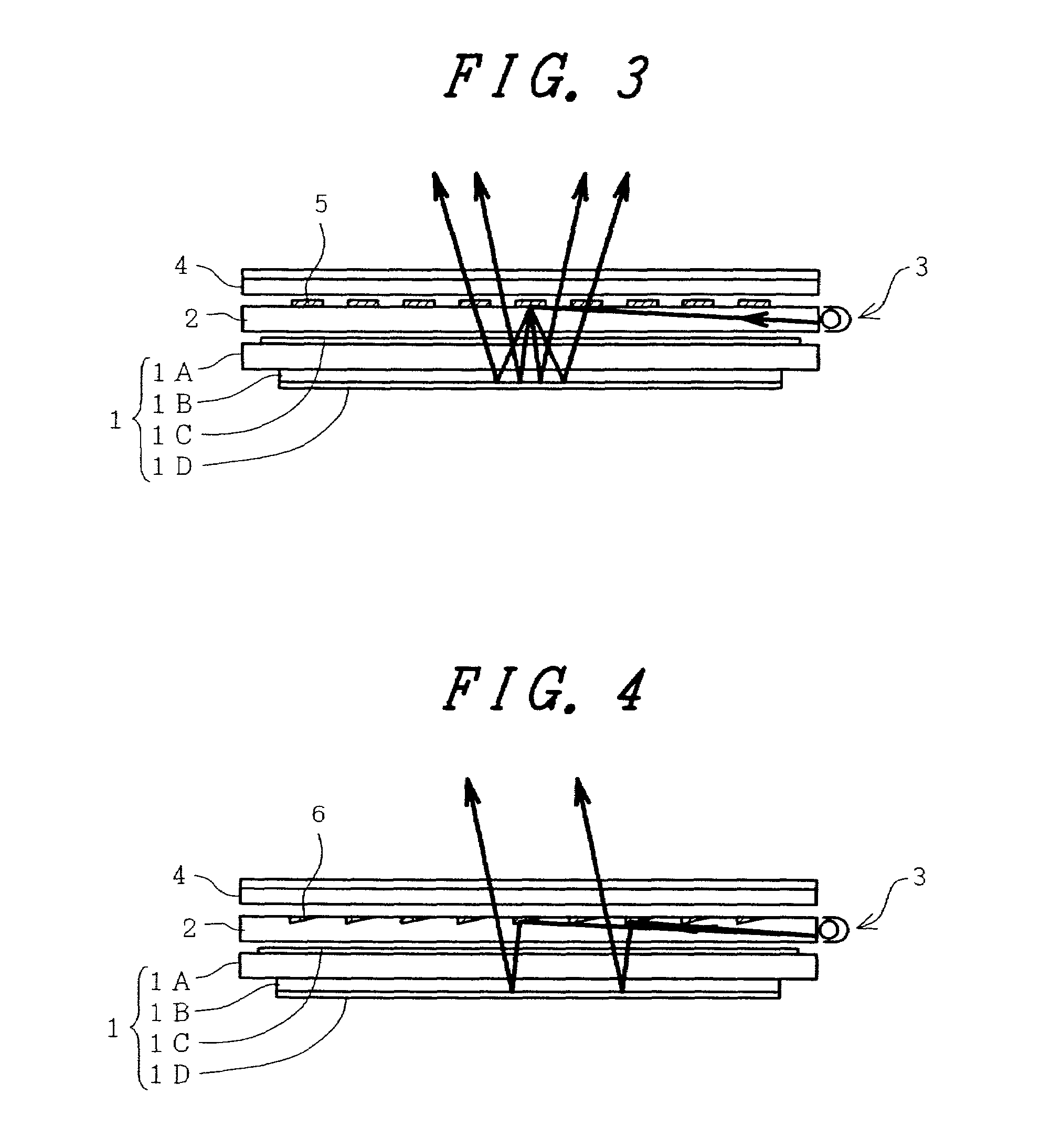

Method for manufacturing semiconductor substrate and method for manufacturing semiconductor device

InactiveUS20090098710A1Low heat resistanceEasy to bendSemiconductor/solid-state device detailsSolid-state devicesHigh surfaceNitrogen gas

An SOI substrate having a single crystal semiconductor layer with high surface planarity is manufactured. A semiconductor substrate is doped with hydrogen, whereby a damaged region which contains large quantity of hydrogen is formed. After a single crystal semiconductor substrate and a supporting substrate are bonded together, the semiconductor substrate is heated, whereby the single crystal semiconductor substrate is separated in the damaged region. While a heated high-purity nitrogen gas is sprayed on a separation plane of the single crystal semiconductor layer separated from the single crystal semiconductor substrate, laser beam irradiation is performed. By irradiation with a laser beam, the single crystal semiconductor layer is melted, whereby planarity of the surface of the single crystal semiconductor layer is improved and re-single-crystallization is performed.

Owner:SEMICON ENERGY LAB CO LTD

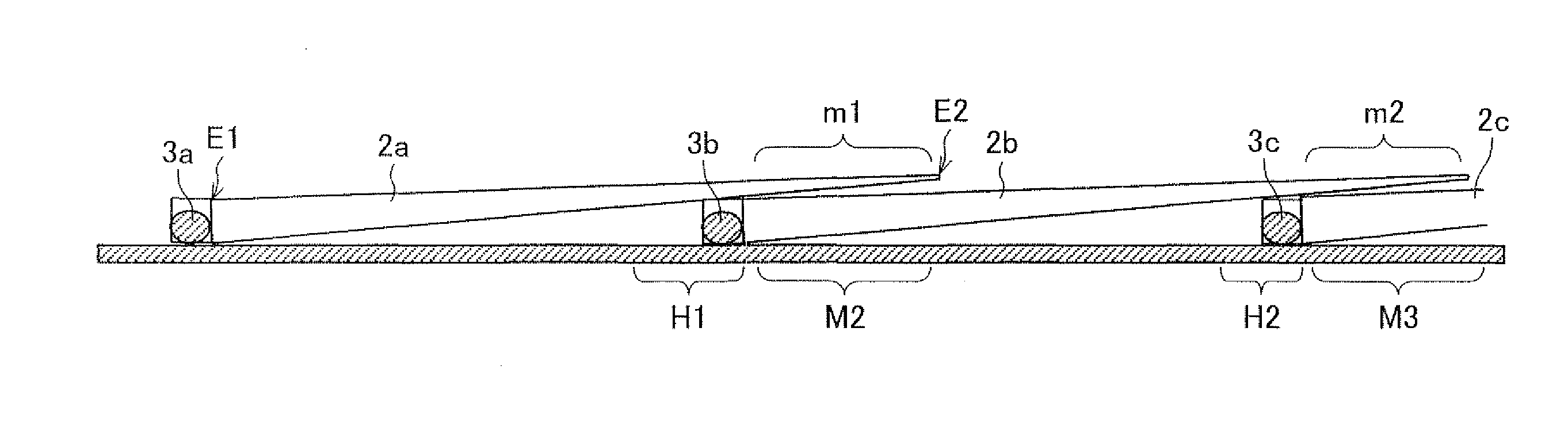

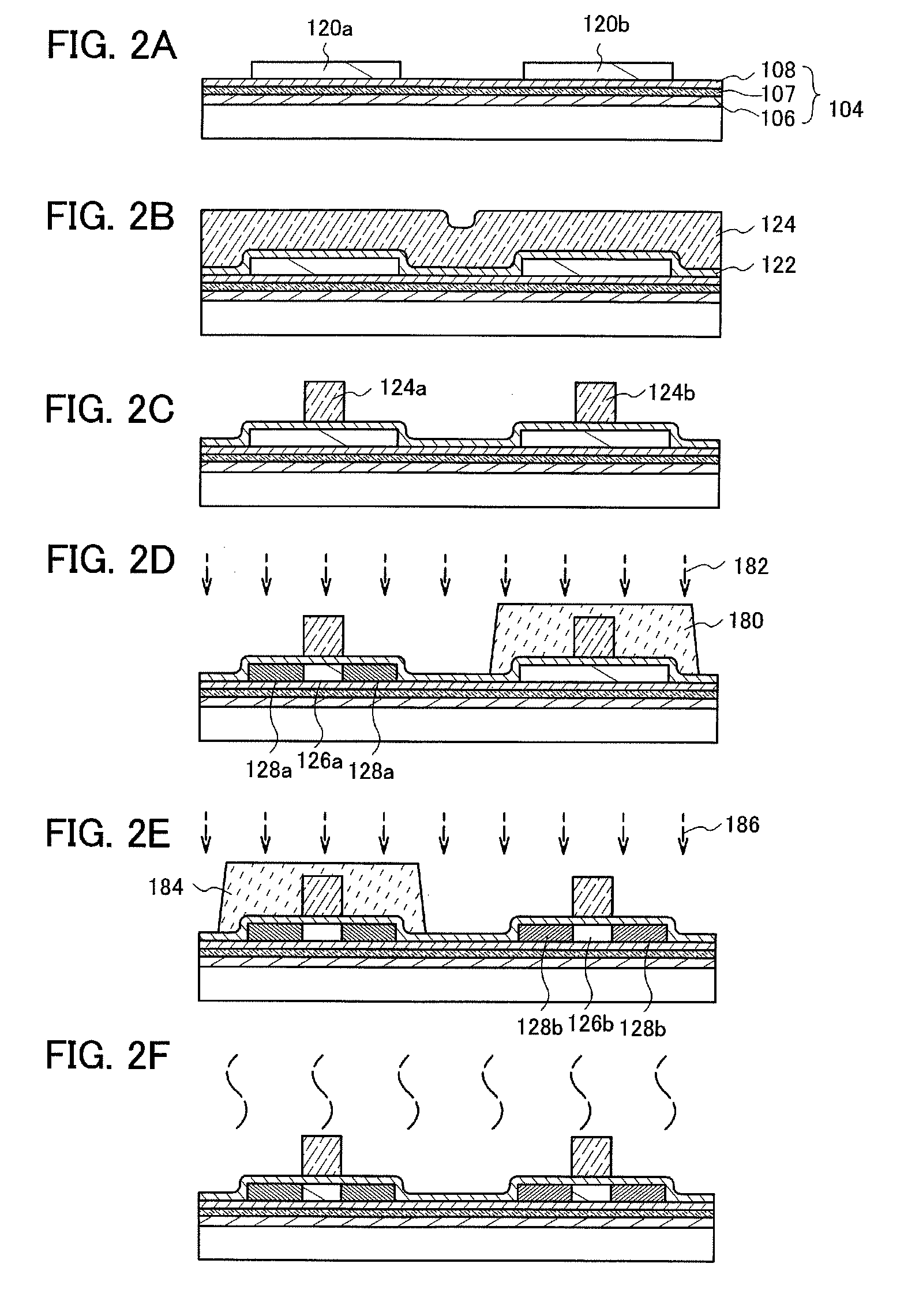

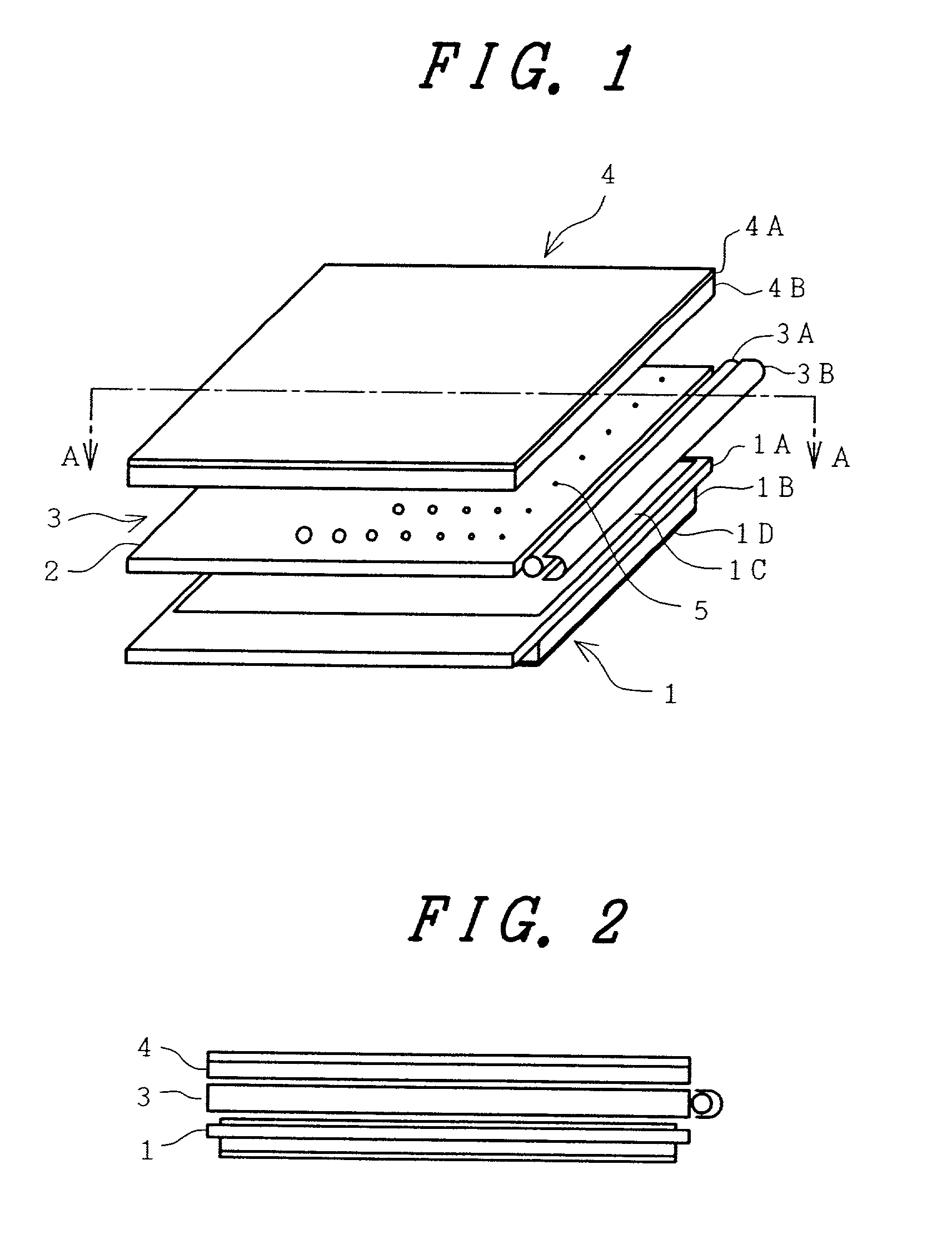

Light source device, backlight device, and liquid crystal display device

InactiveUS20090316074A1Optical unevenness can be reducedAvoid displacementMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayLight guide

A light source device having light guide elements (2a to 2f) and light emitting elements (3a to 3f) for supplying light to each of the light guide elements. The light guide elements each has a wedge-like shape whose thickness is reduced from one end to the other end. The light guide elements are tandem arranged such that the thinner end of a light guide element lies over the thicker end of the other light guide element. Each light guide element has holding sections recessed in the width direction (8a to 8f, 9a to 9f) in its thicker end on which the other light guide element lies. In the light guide device in which the wedge shaped light guide elements are tandem arranged, positional displacement between light guide elements is prevented.

Owner:SHARP KK

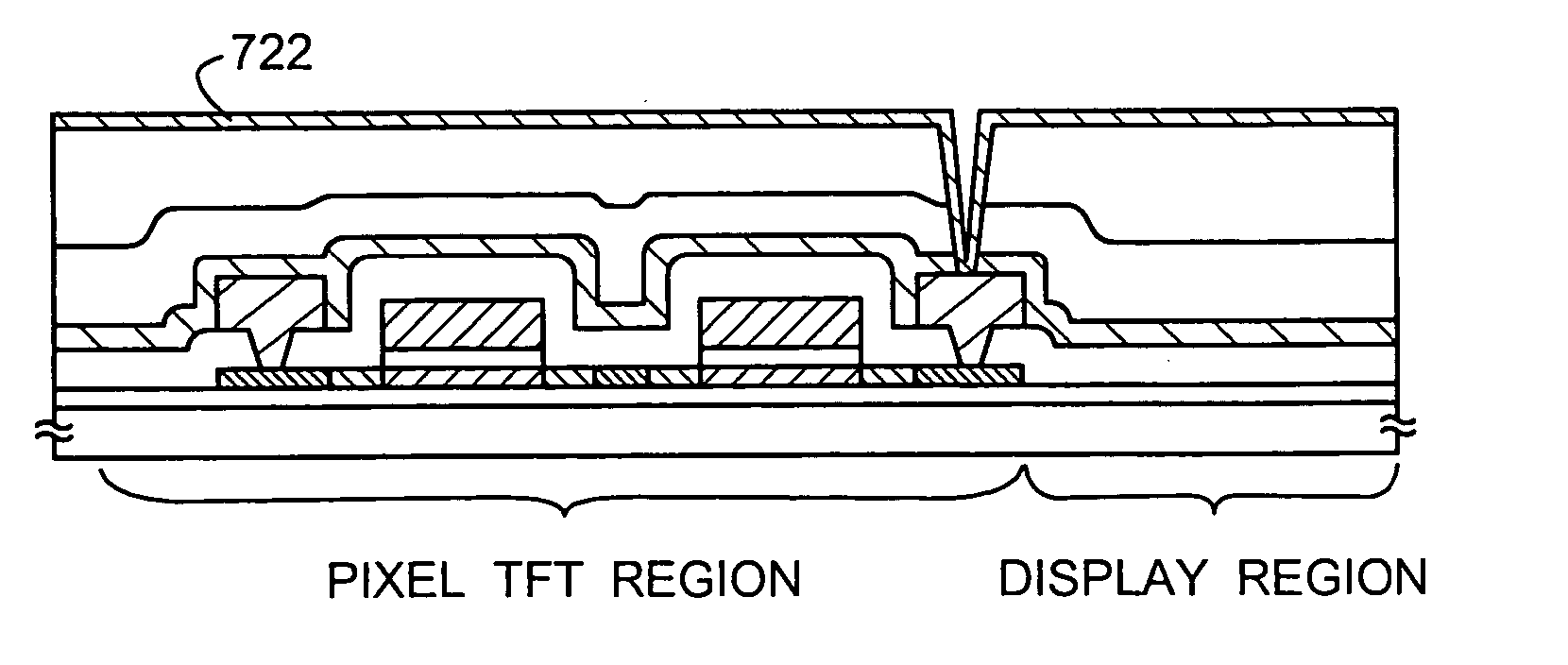

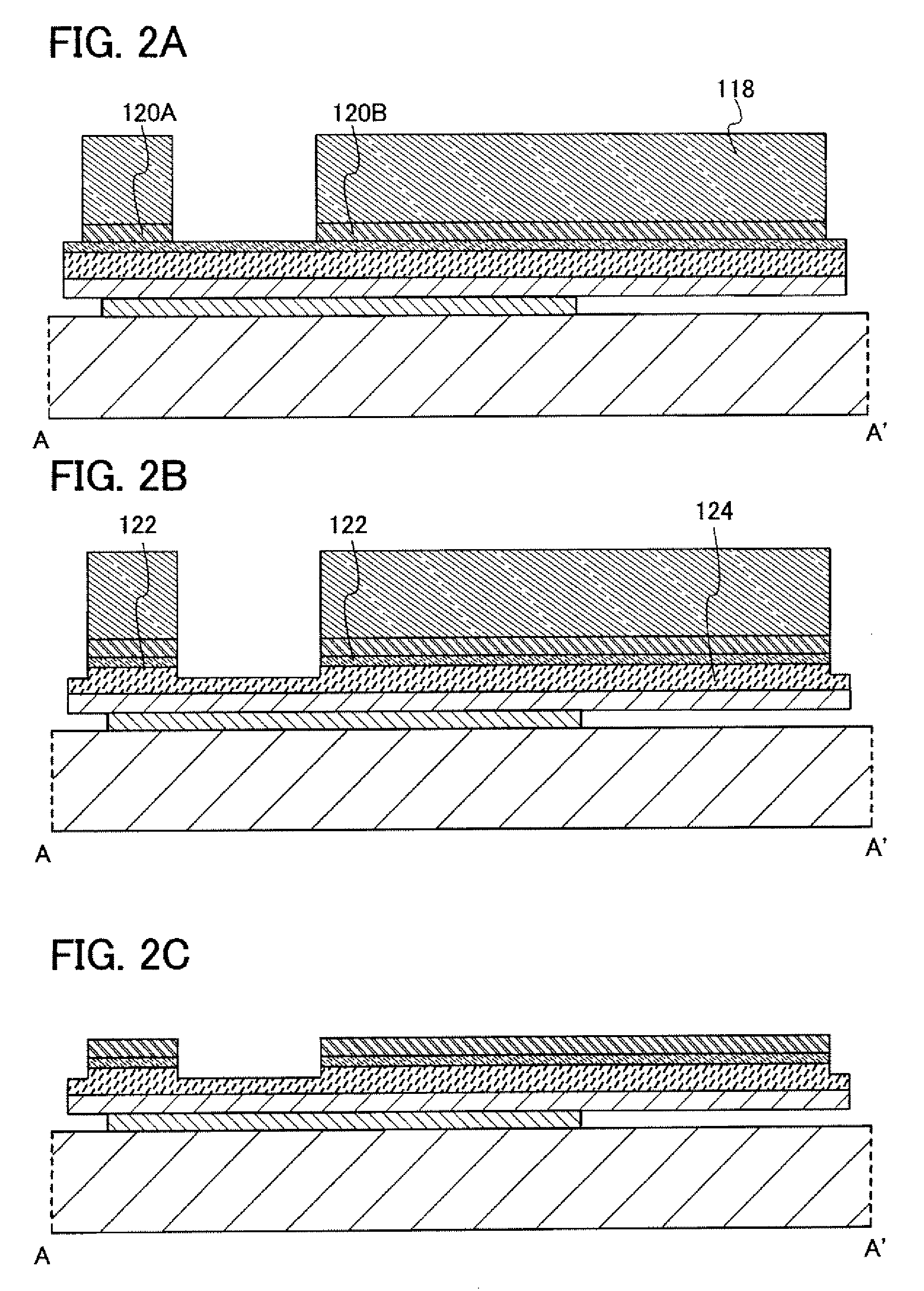

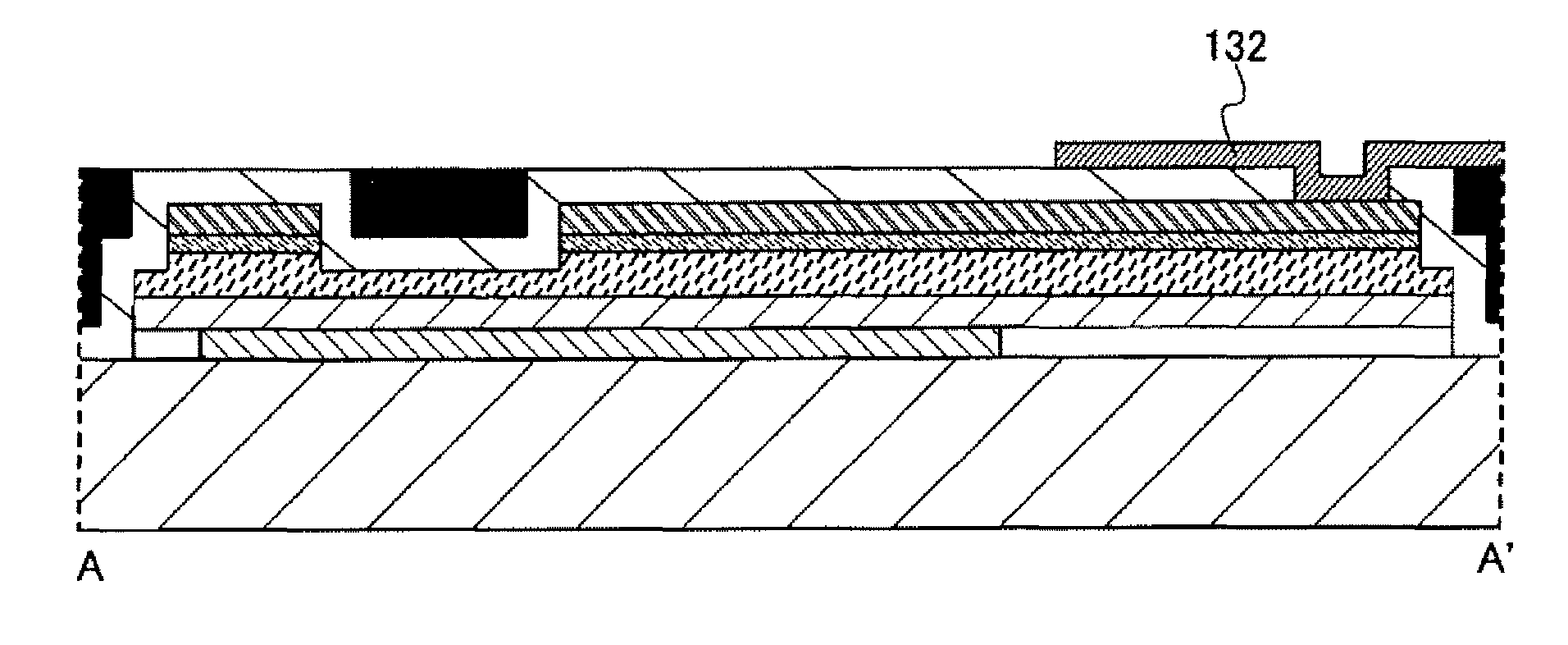

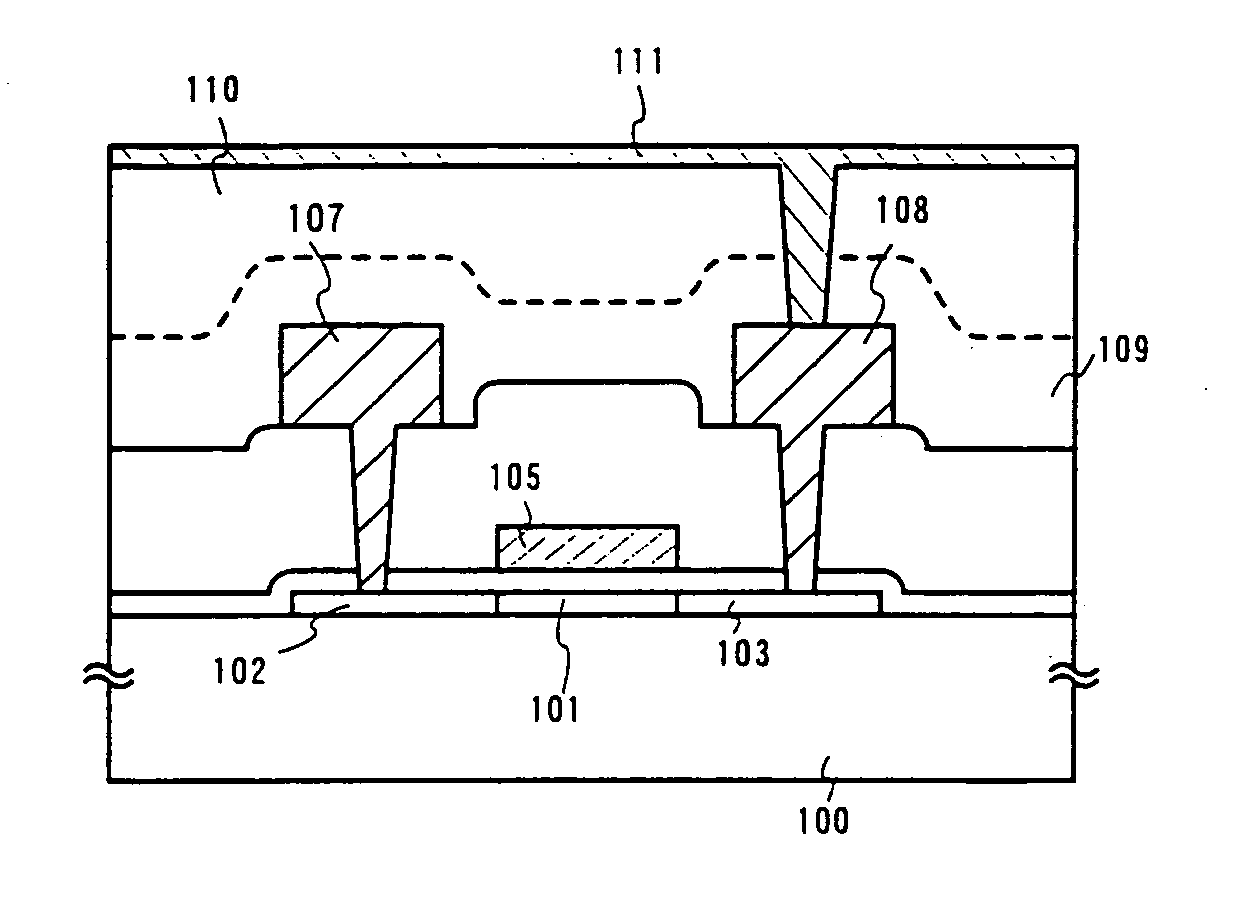

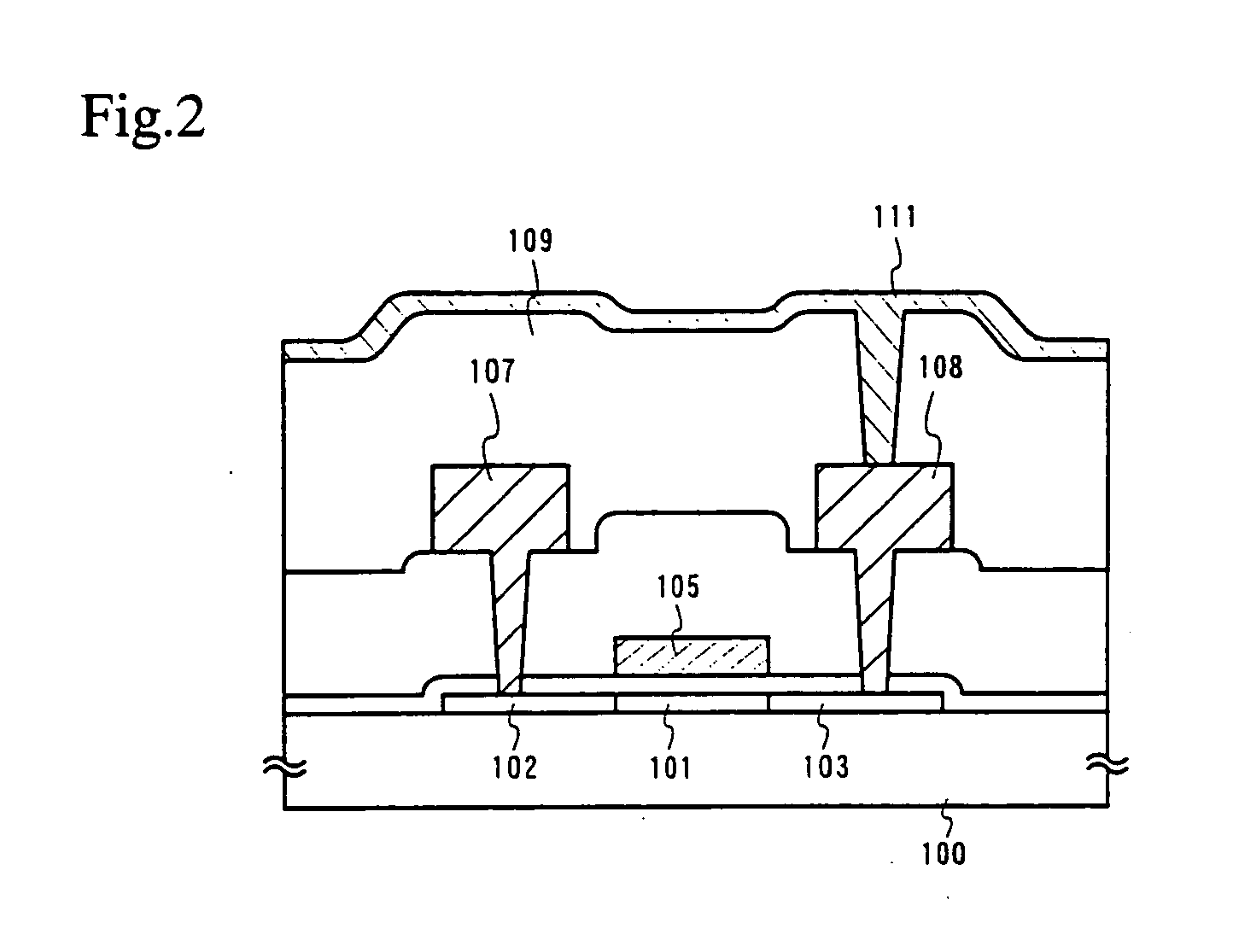

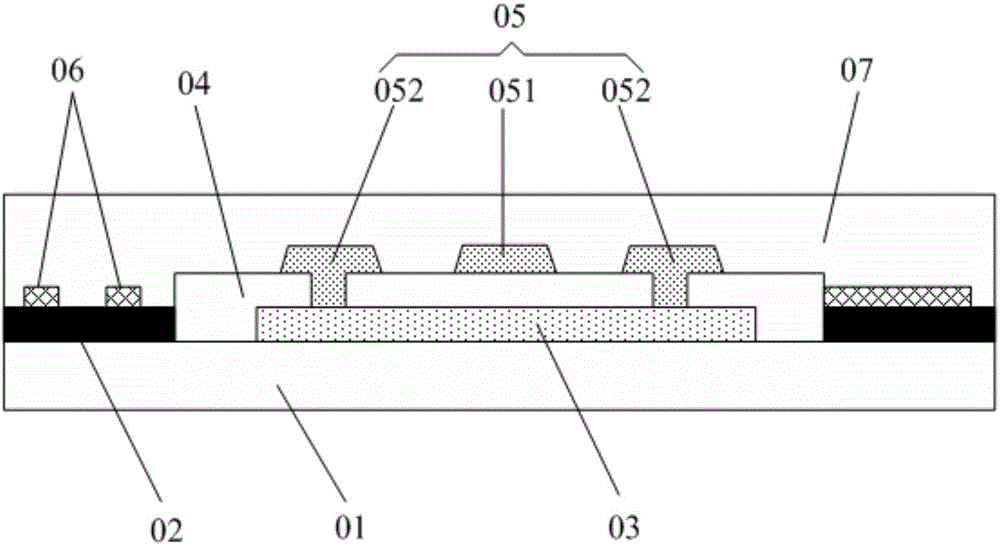

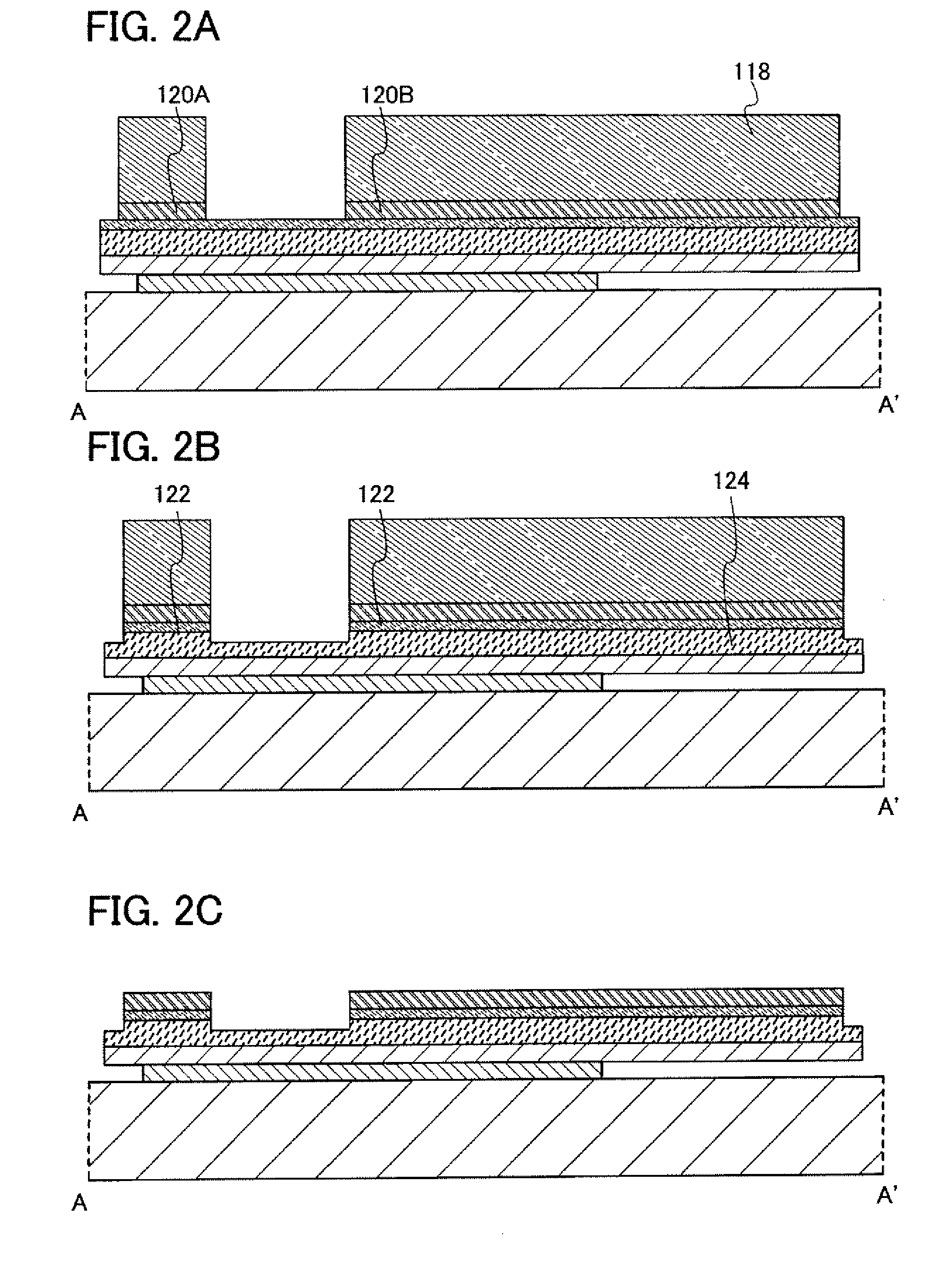

Liquid crystal display device and manufacturing method thereof, and electronic device

InactiveUS20090212300A1Reduce the number of stepsSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEtching

An objective is simplification of a manufacturing method of a liquid crystal display device or the like. In a manufacturing method of a thin film transistor, a stack in which a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film are stacked in this order is formed, and the first conductive film is exposed by first etching and a pattern of the second conductive film is formed by second etching. Further, after thin film transistors are formed, a color filter layer is formed so that unevenness caused by the thin film transistors or the like is relieved; thus, the level difference of the surface where the pixel electrode layer is formed is reduced. Alternatively, a color filter layer is selectively formed utilizing the unevenness caused by thin film transistors or the like.

Owner:SEMICON ENERGY LAB CO LTD

Liquid crystal display device

InactiveUS8049221B2Reduce in quantitySimple processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEtching

An objective is simplification of a manufacturing method of a liquid crystal display device or the like. In a manufacturing method of a thin film transistor, a stack in which a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film are stacked in this order is formed, and the first conductive film is exposed by first etching and a pattern of the second conductive film is formed by second etching. Further, after thin film transistors are formed, a color filter layer is formed so that unevenness caused by the thin film transistors or the like is relieved; thus, the level difference of the surface where the pixel electrode layer is formed is reduced. Alternatively, a color filter layer is selectively formed utilizing the unevenness caused by thin film transistors or the like.

Owner:SEMICON ENERGY LAB CO LTD

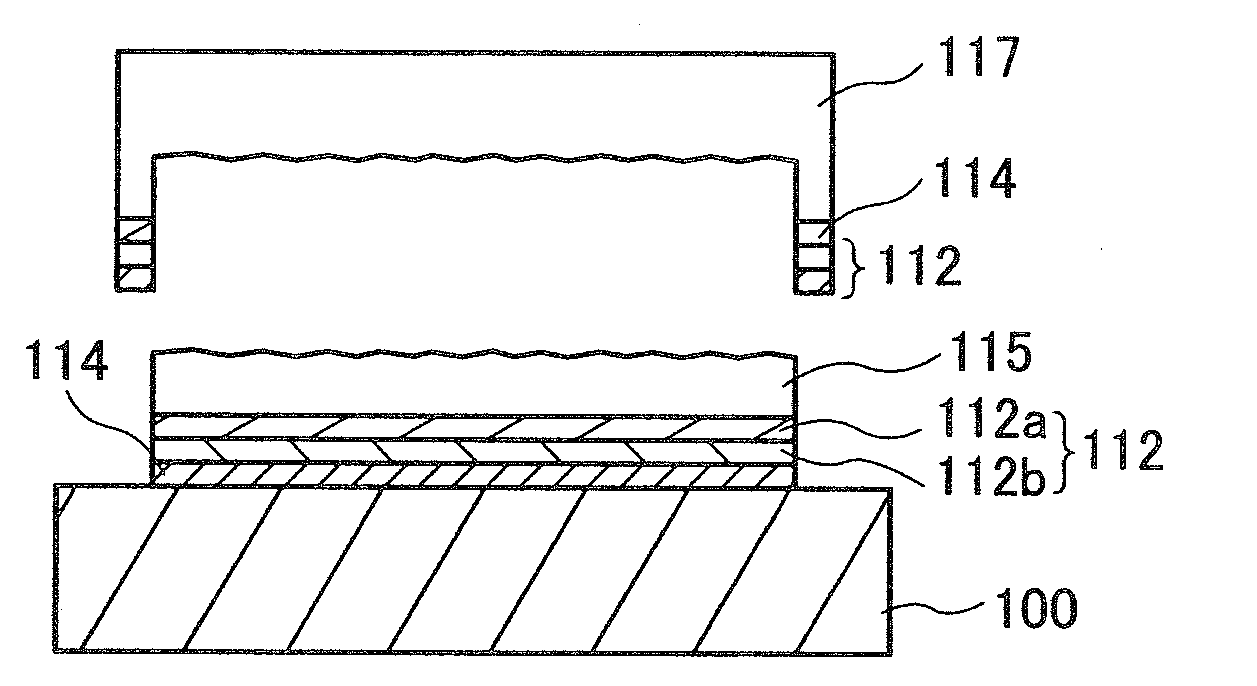

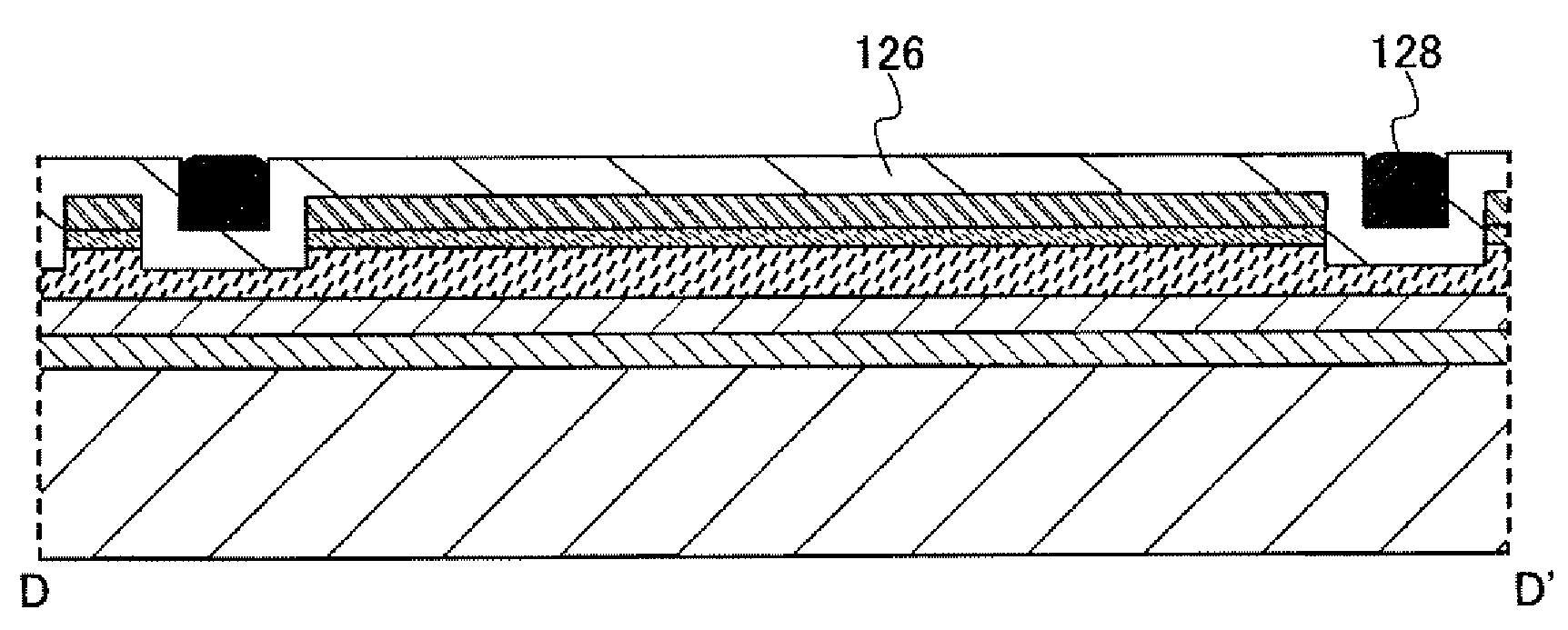

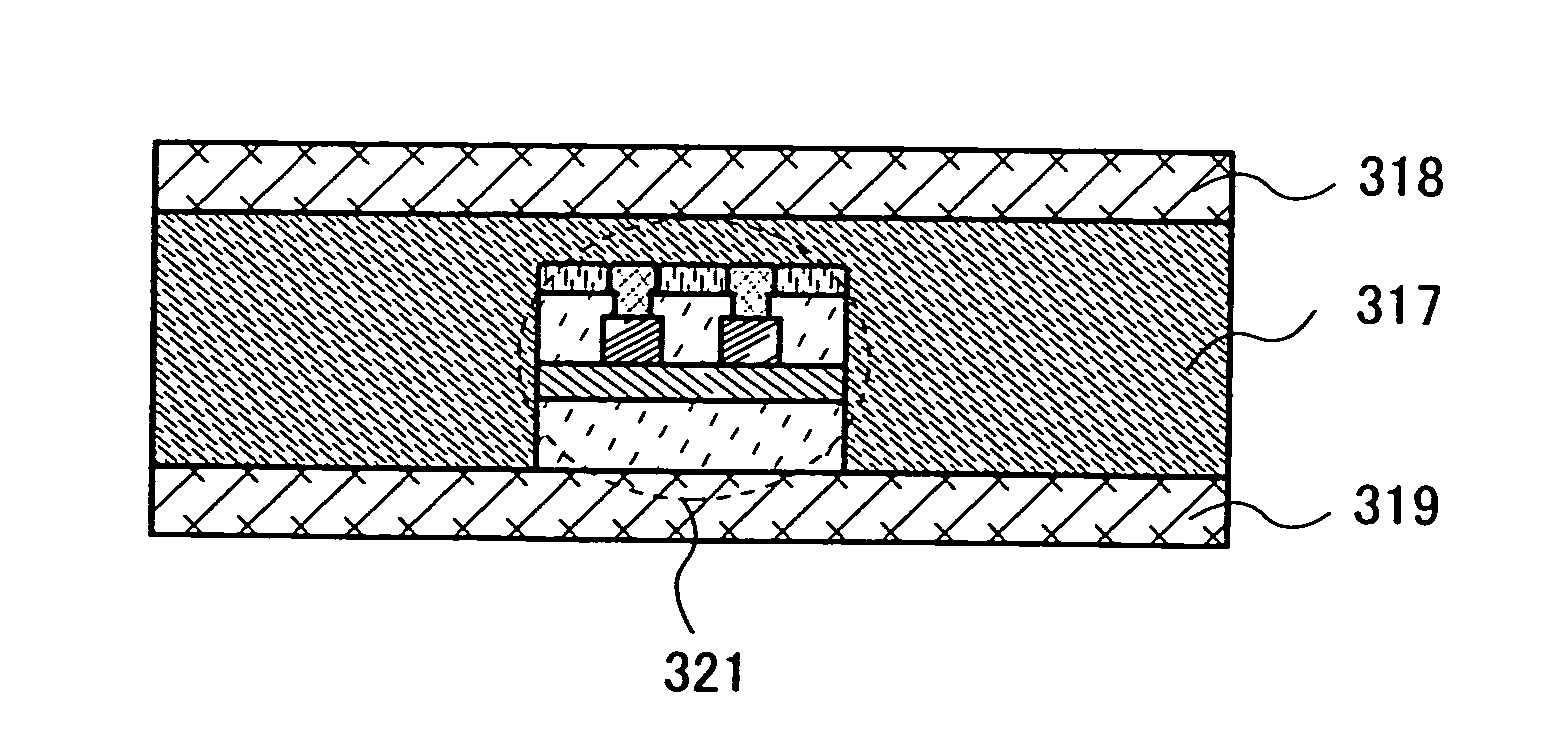

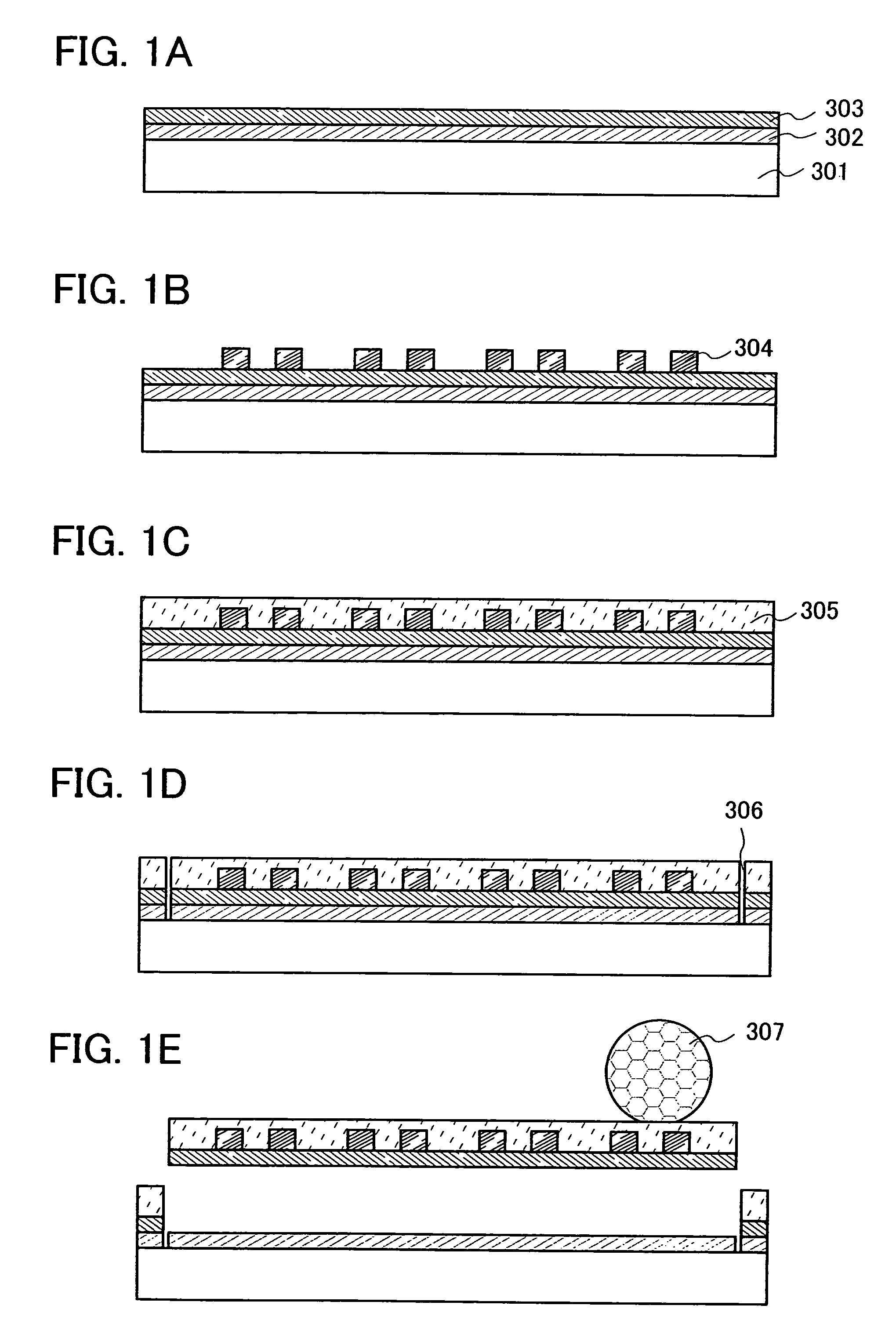

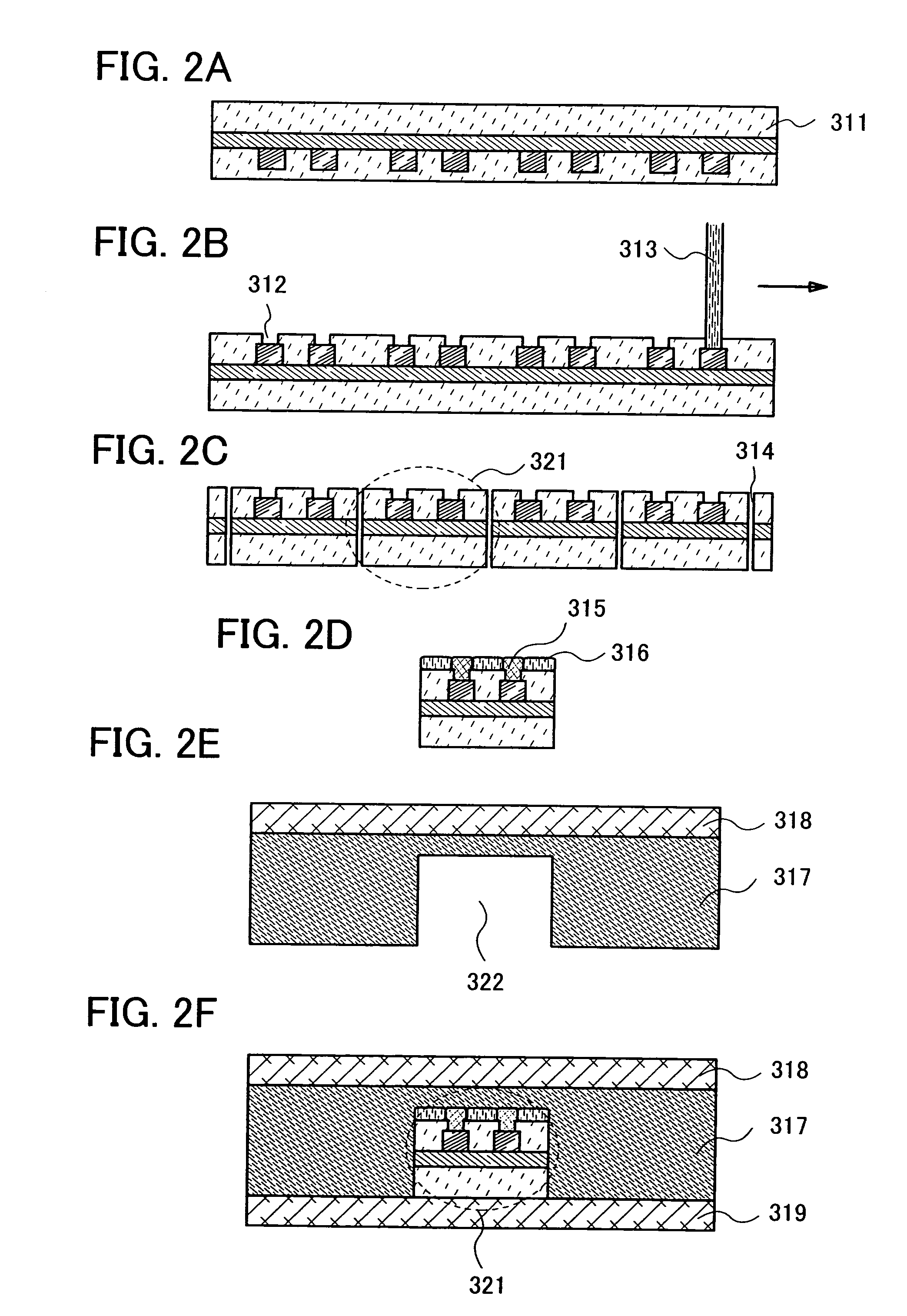

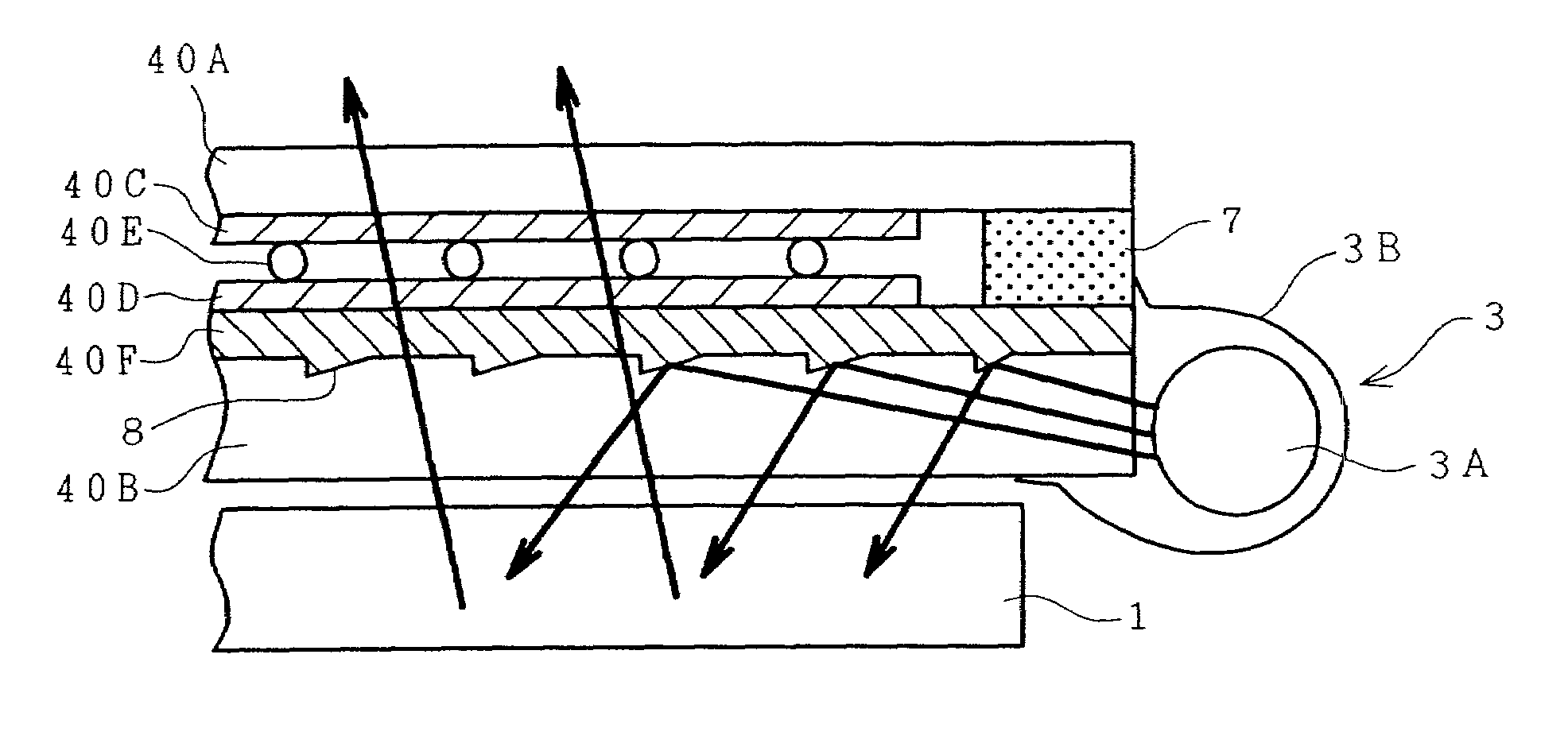

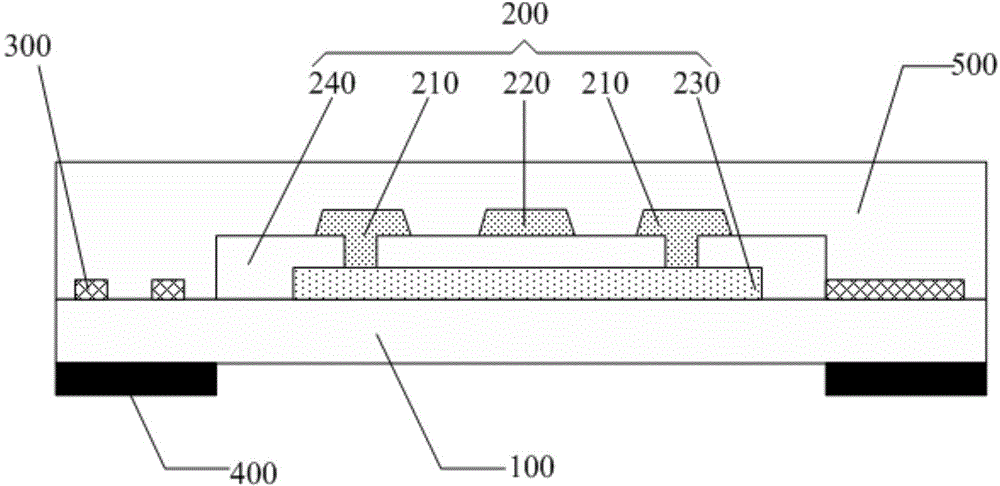

Semiconductor device

InactiveUS20090057875A1Improve reliabilityHigh yieldSemiconductor/solid-state device detailsSolid-state devicesFiberEngineering

A highly reliable semiconductor device which is not damaged by local pressing force from the outside and in which unevenness of a portion where an antenna and an element overlap with each other is reduced. The semiconductor device includes a chip and an antenna. The chip includes a semiconductor element layer including a thin film transistor; a conductive resin electrically connected to the semiconductor element layer; and a sealing layer. The sealing layer in which a fiber body is impregnated with an organic resin covers the semiconductor element layer and the conductive resin, and has a thickness of 10 to 100 μm. The antenna has a depressed portion and is electrically connected to the semiconductor element layer through the conductive resin. The chip is embedded inside the depressed portion. The thickness of the chip is equal to the depth of the depressed portion.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device

InactiveUS7759788B2Improve reliabilityReduce unevennessSemiconductor/solid-state device detailsSolid-state devicesFiberEngineering

A highly reliable semiconductor device which is not damaged by local pressing force from the outside and in which unevenness of a portion where an antenna and an element overlap with each other is reduced. The semiconductor device includes a chip and an antenna. The chip includes a semiconductor element layer including a thin film transistor; a conductive resin electrically connected to the semiconductor element layer; and a sealing layer. The sealing layer in which a fiber body is impregnated with an organic resin covers the semiconductor element layer and the conductive resin, and has a thickness of 10 to 100 μm. The antenna has a depressed portion and is electrically connected to the semiconductor element layer through the conductive resin. The chip is embedded inside the depressed portion. The thickness of the chip is equal to the depth of the depressed portion.

Owner:SEMICON ENERGY LAB CO LTD

Method of fabricating display device

InactiveUS20050037529A1Highly reliable wiringUniform imagingSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayDisplay device

The present invention improves the reliability of wirings, facilitates the orientation control of liquid crystal, or improves a reflectance of a reflective liquid crystal display device. In the case where a plurality of levelling films are laminated, a first levelling film is formed to have a thickness smaller than that of a second levelling film, thereby realizing a higher levelling rate. Therefore, unevenness of the surface due to level differences is reduced and it becomes possible to attain the above objects.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of semiconductor device

InactiveUS20090117692A1Favorable electric characteristicLow costSolid-state devicesSemiconductor/solid-state device manufacturingLaser beamsSingle crystal

A single crystal semiconductor substrate bonded over a supporting substrate with a buffer layer interposed therebetween and having a separation layer is heated to separate the single crystal semiconductor substrate using the separation layer or a region near the separation layer as a separation plane, thereby forming a single crystal semiconductor layer over the supporting substrate. The single crystal semiconductor layer is irradiated with a laser beam to re-single-crystallize the single crystal semiconductor layer through melting. An impurity element is selectively added into the single crystal semiconductor layer to form a pair of impurity regions and a channel formation region between the pair of impurity regions. The single crystal semiconductor layer is heated at temperature which is equal to or higher than 400° C. and equal to or lower than a strain point of the supporting substrate and which does not cause melting of the single crystal semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

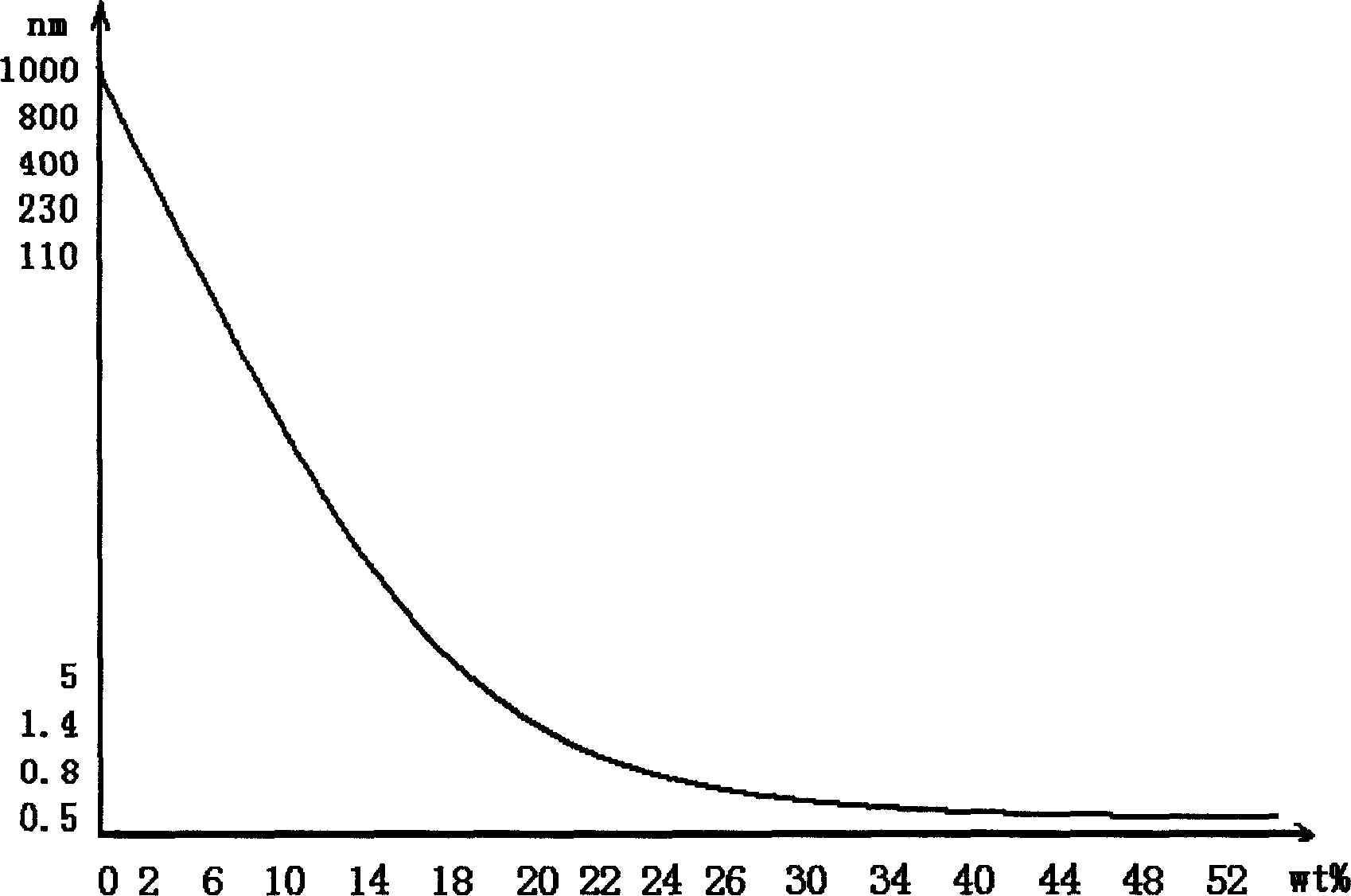

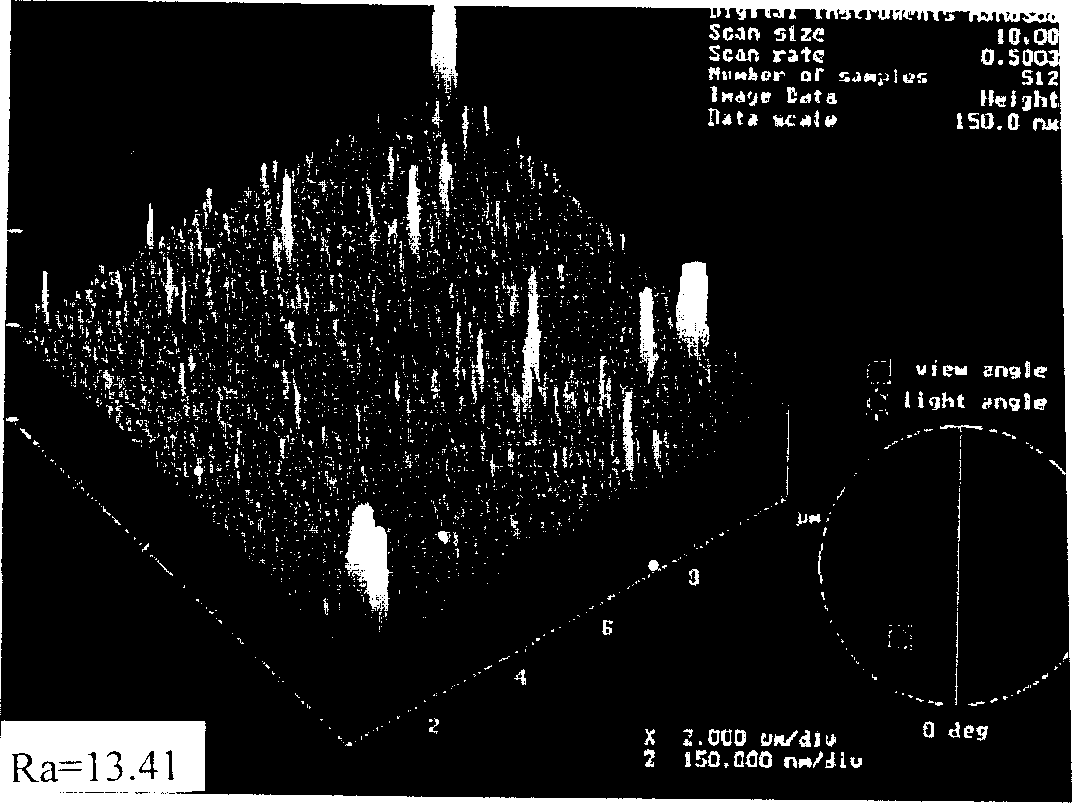

Method for controlling roughness of silicon crystal substrate material surface

InactiveCN1864926ALow roughness controlImprove removal ratePolishing machinesSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

The invention relates to a method for controlling the surface roughness of silicon single-crystal liner material. According to the chemical property of silicon single-crystal liner material, the invention selects alkali medium; uses SiO2 hydrosol as abrasive; uses pH adjuster to adjust the pH value of solution 9-13.5; adds surface activator as FA / O to prepare the polish liquid. The invention uses two polishing steps as roughly polishing and finely polishing at different polishing conditions; roughly polishes for 10-20mins while the flux is 100-200ml / min, the temperature is 30-40Deg. C, the rotation speed is 40-120rpm and the pressure is 0.10-0.20MPa; finely polishing for 4-7mins while the flux is 800-1000ml / min, the temperature is 20-30Deg. C, the rotation speed is 30-60rpm, and the pressure is 0.05-0.10MPa. The invention can realize low roughness of single-crystal liner material.

Owner:HEBEI UNIV OF TECH

Liquid crystal display device with a touch panel

InactiveUS7068261B2High-quality image displayIncrease screen brightnessCathode-ray tube indicatorsElectric switchesLiquid-crystal displayEngineering

A liquid crystal display device including a liquid crystal display panel having a first surface for displaying an image and a second surface different from the first surface, and a position information input device provided on a first-surface side of the liquid crystal display panel. The position information input device is made of a first substrate and a second substrate more easily deformable than the first substrate. A transparent insulation film is formed over a surface of the first substrate opposed to the second substrate, a first transparent electrode is provided on the transparent insulation film, and the transparent insulation film is located between the first substrate and the first transparent electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Chemical and mechanical water-free polishing liquid for lithium-cessium borate crystal and leveling method

InactiveCN1858134AGood suspensionModerate concentrationPolishing machinesAqueous dispersionsLithiumOrganic solvent

The present invention discloses a kind of chemical and mechanical water-free polishing liquid for polishing lithium-cesium borate crystal and its polishing method. The polishing liquid of the present invention consists of nanometer silica abrasive 4-8 wt%, organic solvent 72-95 wt%, organic alkali 0.5-10 wt% and surfactant 0.5-10 wt%. It is used in polishing lithium-cesium borate crystal at polishing pressure of 0.05 MPa to 0.1 MPa, polishing disc speed of 30 rpm to 60 rpm, and polishing time of 5-10 min. The water-free polishing liquid of the present invention has high flowability, no toxicity, no pollutant, no corrosion, moderate concentration and good floatability, and can obtain polished lithium-cesium borate crystal surface with high smoothness and no crack.

Owner:HEBEI UNIV OF TECH

Cover joining structure for outboard engine unit

InactiveUS6846211B2Eliminate sink mark problemGood lookingPropulsion power plantsOutboard propulsion unitsEngineeringFastener

Owner:HONDA MOTOR CO LTD

Method for manufacturing semiconductor substrate and method for manufacturing semiconductor device

InactiveUS7799658B2Low heat resistanceEasy to bendSemiconductor/solid-state device detailsSolid-state devicesHydrogenHigh surface

An SOI substrate having a single crystal semiconductor layer with high surface planarity is manufactured. A semiconductor substrate is doped with hydrogen, whereby a damaged region which contains large quantity of hydrogen is formed. After a single crystal semiconductor substrate and a supporting substrate are bonded together, the semiconductor substrate is heated, whereby the single crystal semiconductor substrate is separated in the damaged region. While a heated high-purity nitrogen gas is sprayed on a separation plane of the single crystal semiconductor layer separated from the single crystal semiconductor substrate, laser beam irradiation is performed. By irradiation with a laser beam, the single crystal semiconductor layer is melted, whereby planarity of the surface of the single crystal semiconductor layer is improved and re-single-crystallization is performed.

Owner:SEMICON ENERGY LAB CO LTD

Ink composition for printing, paper container material using the ink composition, and heat insulating foamed paper container

ActiveUS20110101083A1Flat surfaceGood lookingPattern printingPreformed elementsRoom temperaturePrinting ink

There is provided a printing ink to be used in the production of a heat insulating foamed paper container obtained by heating a paper container which has a container body unit laminated with a high-melting point thermoplastic synthetic resin film on the inner surface and with a low-melting point thermoplastic synthetic resin film (low-Mp resin film) on the outer surface, and thereby foaming the low-Mp resin film, the printing ink being printed on the laminated low-Mp resin film upon the production of the paper container but inhibiting the occurrence of differences in level at the foamed surface of the low-Mp resin film. In an ink composition for printing on foamed paper containers, which contains a colorant, a binder resin and a solvent, a resin having an elongation ratio (elongation ratio as measured with a small-size tensile tester manufactured by Intesco Co., Ltd., under the conditions of a tensile speed of 100 mm / min and room temperature (25° C.)) of 400% to 3,000% is used as the binder resin. The binder resin is preferably a mixture of a urethane resin:vinyl chloride / vinyl acetate copolymer (=50:50 to 99:1), and the urethane resin is more preferably a polyurethane-urea resin. A non-aromatic solvent is used as the solvent.

Owner:NISSIN YORK +1

Method for controlling planeness during chemically mechanical polishing for ULSI multiple-layered copper wiring

InactiveCN1861321ASolve the problem of selectivitySolve many disadvantages such as copper wire collapse after polishingPolishing machinesAqueous dispersionsCopper-wiringMultiple layer

A method for controlling the level degree on the ULSI multi-layer wiring in chamico-mechanical polishing includes such steps as diluting SiO2 hydrosol by deionized water, adding metal ion chelating agent to regulate pH=10-13, adding alcohol-ether kind of surfactant and oxidant while stirring to obtain polishing liquid, and polishing at 20-40 deg.C and 60-120 rpm under 100-250 g / sq.cm.

Owner:天津河北工业大学资产经营有限责任公司

Three-dimensional stacked phase change memory and preparation method thereof

ActiveCN110707209AIncrease processing costReduce demandSolid-state devicesSemiconductor devicesPhase-change memoryPhysical chemistry

The invention belongs to the technical field of microelectronic devices and memories, and discloses a three-dimensional stacked phase change memory and a preparation method thereof. The preparation method specifically comprises the following steps of preparing a multi-layer structure on which a horizontal electrode layer and an insulating layer are crossly stacked, on a substrate; then etching toform a groove and a discrete three-dimensional strip-shaped electrode; filling an insulating medium in the groove, forming small holes in the boundary area of the three-dimensional strip-shaped electrode and the insulating medium, sequentially depositing a phase change material on the walls of the small holes, and filling an electrode material in the small holes to prepare a vertical electrode, thereby obtaining the multi-layer stacked three-dimensional stacked phase change memory. According to the present invention, by improving the whole flow process of the preparation method, a three-dimensional phase change memory array can be established by utilizing the vertical electrode structure, and compared with the prior art, the problems of complex multi-layer stacking steps, high process implementation difficulty, unit size miniaturization and the like of an existing three-dimensional stacked phase change memory in process preparation, can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Image forming apparatus and image forming method

InactiveUS20110103814A1Image density is accuratelyDensity is accurateElectrographic process apparatusLatent imageImage formation

The image forming apparatus includes a first latent image carrier; a first developing member develops the latent image by a first liquid developer; a second latent image carrier; a second developing member develops the latent image by a second liquid developer; a transfer medium that forms first and second nip portion; a detecting unit; and a control unit, that, when the first image is a first image density, detect the first image passed through the second nip portion formed by the transfer medium and the second latent image carrier while the second developing member contacts with the second latent image carrier, and when the first image is a second image density higher than the first image density, detect the first image passed through the second nip portion formed by the transfer medium and the second latent image carrier while the second developing member separates form the second latent image carrier.

Owner:SEIKO EPSON CORP

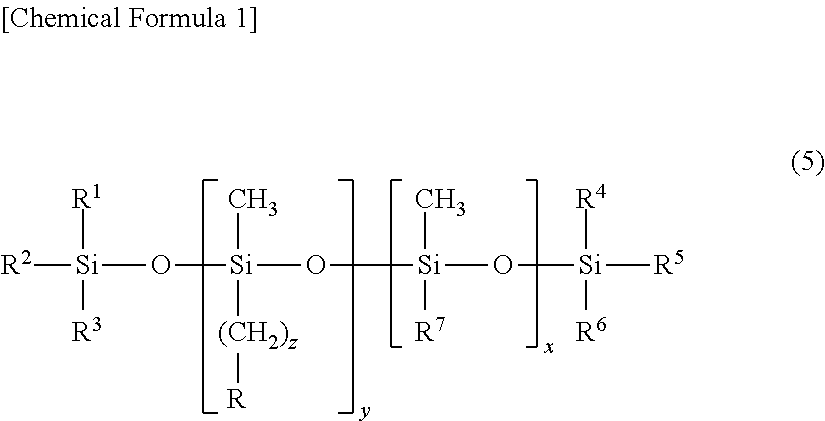

Adhesion method using gray-scale photolithography

InactiveUS20070160936A1Improve adhesionProlong lifeSemiconductor/solid-state device detailsSolid-state devicesSolventBonds hydrogen

A method for adhering substrates using gray-scale photolithography includes: (a) applying a photopatternable corn-position to a surface of a substrate to form a film; (b) exposing a portion of the film to radiation having a wavelength of from 150 to 800 nm through a gray-scale photomask to produce an exposed film having non-exposed regions covering at least a portion of the surface; (c) heating the exposed film for an amount of time such that the exposed regions are substantially insoluble in a developing solvent and the nonexposed regions are soluble in the developing solvent; (d) removing the non-exposed regions of the heated film with the developing solvent to form a patterned film; (e) heating the patterned film for an amount of time sufficient to form a cured patterned film having a surface; (f) activating the surface of the cured patterned film and a surface of an adherend; (g) contacting the activated surface of the cured patterned film with the activated surface of the adherend. The photopatternable composition includes: (A) an organopolysiloxane containing an average of at least two silicon-bonded unsaturated organic groups per molecule, (B) an organosilicon compound containing an average of at least two silicon-bonded hydrogen atoms per molecule in a concentration sufficient to cure the composition, and (C) a catalytic amount of a photoactivated hydrosilylation catalyst.

Owner:GARDNER GEOFFREY BRUCE +1

Method for controlling roughness in ULSI multi-layer copper metallization chemico-mechanical polishing

InactiveCN1864925AMeet the requirements of wiring CMP precision machiningAvoid secondary contaminationPolishing machinesAqueous dispersionsCopper wireSurface roughness

The invention relates to a method for controlling mechanically polished surface roughness of ULSI multilayer copper wire. It is characterized in that: it uses SiO2 hydrosol at small diameter as abrasive; uses organic alkali as the pH adjuster and complex builder; adds non-ionic surface activator to prepare the polish liquid; the preparation comprises following steps that first, preparing the polish liquid that a, diluting the SiO2 abrasive whose diameter is 15-20nm with the 1-5 times of deionized water; b, using pH adjuster organic alkali to adjust said solution, to make the pH value between 10-12; c, mixing and adding 0.5-10% (volume percentage) aether mellow activator to prepare the polish liquid; then, polishing form 3-5mins, while the flux is 3-5L / min, the temperature is 15-25Deg. C, the rotation speed is 30-120rpm, and the external pressure is zero that there is only the weight of carrier; the invention can effectively reduce the roughness of copper, baffle material and tantalum surface, via the strong complex function and accelerating the surface quantity transmission at alkali condition, with simple process and significant effect.

Owner:HEBEI UNIV OF TECH

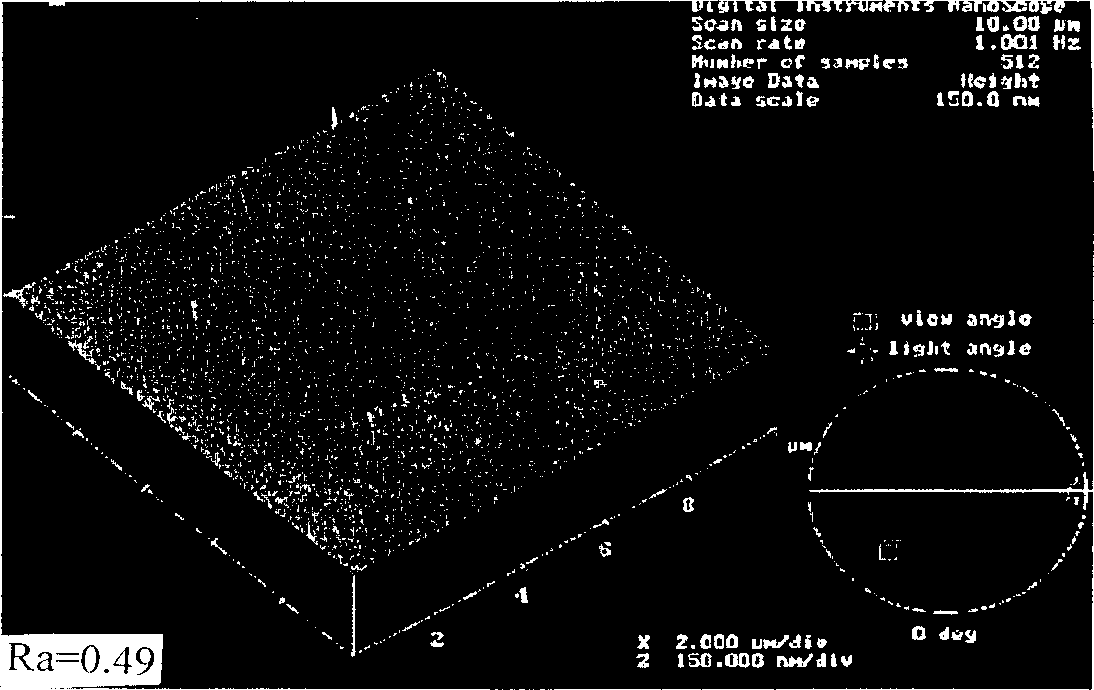

Manufacturing method of semiconductor memory element and the element

PendingCN110491876AImprove flatnessImprove manufacturing yieldTransistorSemiconductor/solid-state device manufacturingBit lineEtching

The invention discloses a manufacturing method of a semiconductor memory element and the element, and belongs to the technical field of semiconductors. The method comprises the following steps of: forming a bit line structure and a groove at the peripheral side of the bit line structure on a substrate; depositing a first isolation layer on the surfaces of the substrate and the bit line structure,with the first isolation layer comprising silicon nitride and silicon carbonitride; thinning the first isolation layer through a wet etching process; forming a second isolation layer on the surfaces of the substrate and the bit line structure; filling a third isolation layer in the trench; and forming a fourth isolation layer on the second isolation layer on the surface of the bit line structure.According to the method and the element, the silicon carbonitride is added into the material of the first isolation layer; and therefore, the problem that the surface of the first isolation layer is uneven due to different reaction rates of phosphoric acid and silicon nitride at different positions is solved, the flatness of the thinned first isolation layer is improved to a certain extent, and the flatness of the bit line structure is improved to a certain extent.

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

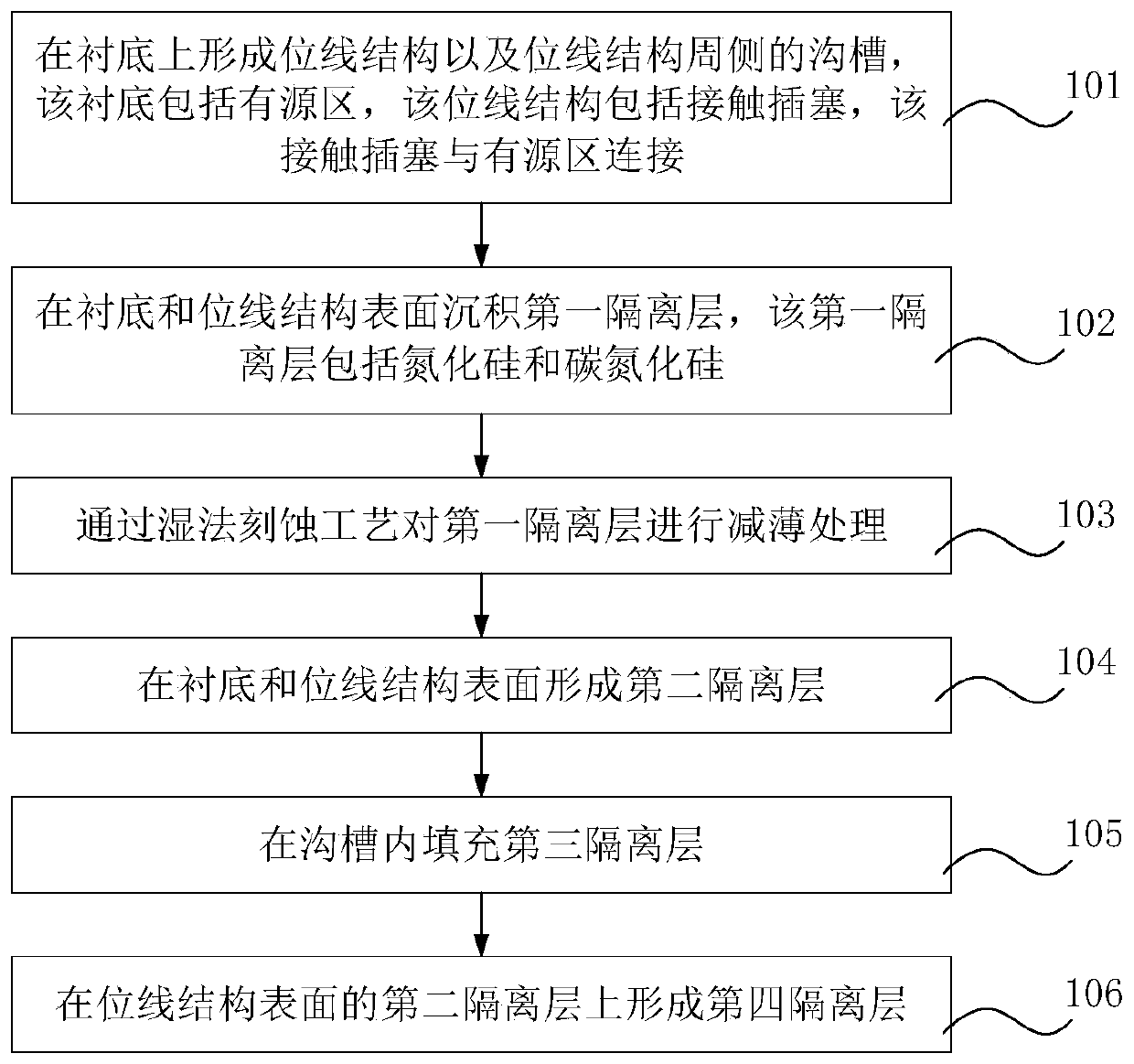

Semiconductor laser device having thickened impurity-doped aluminum-free optical waveguide layers

InactiveUS6625190B1Reduce deterioration rateOptical waveguide layer is further thickenedOptical wave guidanceLaser detailsQuantum wellWaveguide

In a semiconductor laser device including an active region which is made of an aluminum-free material and a plurality of cladding layers made of at least one AlGaAs or AlGaInP material, the active region includes a quantum well layer and at least one optical waveguide layer; a portion of the at least one optical waveguide layer located on one side of the quantum well layer has a thickness of 0.25 mum or more; and the at least one optical waveguide layer, other than a portion of the at least one optical waveguide layer being located near the quantum well layer and having a thickness of at least 10 nm, is doped with impurity of 10<17 >cm<-3 >or more.

Owner:FUJIFILM HLDG CORP +1

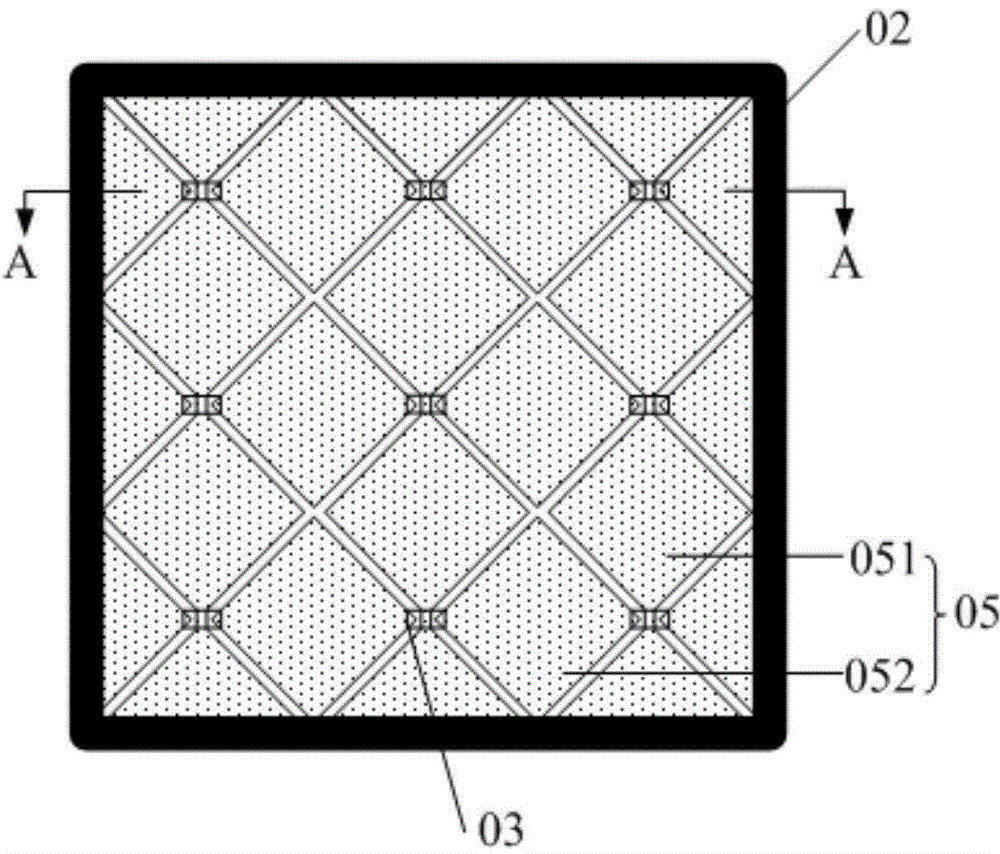

Touch screen, touch screen manufacturing method and display device

InactiveCN103914183AQuality assuranceAvoid pollutionInput/output processes for data processingDisplay deviceTouchscreen

The invention discloses a touch screen, a touch screen manufacturing method and a display device. Since a touch structure and peripheral lines are positioned on one side of a substrate while a shielding layer is positioned on the other side of the substrate, namely the shielding layer and the touch structure are positioned on two sides of the substrate respectively, when the touch structure and the peripheral lines are made on the substrate of the touch screen by means of sputtering, and the shielding layer on the other side of the substrate can be protected from strafing of plasmas in a sputtering cavity so as to be prevented from contaminating the cavity. In addition, due to the fact that the shielding layer is positioned on the other side of the substrate, compared with the prior art in which the touch structure and the peripheral lines are formed on a film layer of the shielding layer, the touch screen, the touch screen manufacturing method and the display device have the advantages that the problem of unevenness of the touch structure resulted from unevenness of the shielding layer is avoided, and quality of the touch screen is guaranteed.

Owner:BOE TECH GRP CO LTD

Full-color image-forming method

InactiveUS20110151373A1Good colorGood chromaDevelopersElectrographic processes using charge patternHueEngineering

Provided are a toner containing at least a binder resin and a colorant, the toner having a specific hue angle and an absorbance at a specific wavelength in reflectance spectrophotometry, and a full-color image-forming method involving the use of the toner, the method including the steps of: forming an electrostatic image on a charged electrostatic image bearing member; developing the formed electrostatic image with the toner to form a toner image; transferring the formed toner image onto a transfer material; and fixing the transferred toner image to the transfer material to form a fixed image.

Owner:CANON KK

Liquid crystal polyester-containing liquid composition

ActiveUS20120183697A1Reduce surface defectsExcellent surface appearanceLiquid crystal compositionsPrinted circuit aspectsPolyesterPolymer science

An object of the present invention is to provide a liquid crystal polyester-containing liquid composition which is capable of producing a prepreg and a resin film in which surface defects are remarkably reduced even in case of drying at high temperature to remove the solvent in the production process. Disclosed are a liquid crystal polyester-containing liquid composition comprising a liquid crystal polyester, an organic solvent, and one or more kinds of selected leveling agents, wherein the content of the leveling agent is from 0.001 to 2.0 parts by mass based on 100 parts by mass of the total amount of the liquid crystal polyester and the organic solvent; and a method for producing a resin film, which comprises applying the above-described liquid crystal polyester-containing liquid composition on a support, and then removing the solvent from the liquid crystal polyester-containing liquid composition on the support at 50° C. or higher.

Owner:SUMITOMO CHEM CO LTD

Rod lens array and method of manufacturing the same

In a rod lens array having a structure in which a plurality of rod lens elements are arranged between two side panels and a resin is filled and cured in spaces between the rod lens elements to be integrally formed, the side panels are made of a glass fiber reinforced epoxy resin and a phenol-based curing agent is used as a curing agent of the epoxy resin. In detail, the curing agent is exemplified by a phenol-based curing agent including a tris-hydroxyphenyl-methane skeleton.

Owner:NIPPON SHEET GLASS CO LTD

Method for controlling roughness of computer hard disk substrate

InactiveCN1864924AReduce surface tensionDamage reduction layerPolishing machinesAqueous dispersionsWater contentOxidizing agent

Owner:TIANJIN JINGLING MICROELECTRONIC MATERIALS CO LTD

Ink composition for printing, paper container material using the ink composition, and heat insulating foamed paper container

ActiveUS8431195B2Reduce surface unevennessLarge suppressive powerPattern printingPreformed elementsCarbamateSolvent

An ink composition having a colorant; a binder resin; and a solvent; wherein the elongation ratio of the binder resin is 400% to 3,000%; wherein the binder resin comprises a urethane resin and a vinyl chloride / vinyl acetate copolymer, and the mixing ratio of the urethane resin:vinyl chloride / vinyl acetate copolymer relative to the total weight of the urethane resin and the vinyl chloride / vinyl acetate copolymer is 50:50 to 99:1; and wherein the urethane resin comprises a urethane-urea resin that is obtained by a process comprising reacting dibutylamine and a urethane prepolymer obtained by a process comprising reacting a polymeric polyol component having a number average molecular weight of 500 to 10,000 and an organic diisocyanate component having terminal isocyanate groups. A heat insulating foamed paper container material having at least one print pattern formed from said ink composition.

Owner:NISSIN YORK +1

Method for quickly discriminating ice blast type for cigarette

PendingCN109358022AEliminate noise and distractionsFast analysisColor/spectral properties measurementsTechnical supportStandard samples

The invention discloses a method for quickly discriminating the type of ice blast for cigarettes, comprising the following steps of: collecting the original spectra for different types of cigarettes,and establishing standard samples of different types of ice blast for cigarette; performing pre-treatment on the original spectrum of the different types of ice blast for cigarette collected to eliminate various noises and interferences, and reducing the influence of unevenness of the sample surface; further establishing a classification model for spectra for different types of cigarettes after pre-treatment; identifying the ice blast to be tested using the classification model. The near-infrared spectroscopy is not only suitable for quality control and quantitative analysis of product components, but also possible to use the composition and structural information reflected by the spectrum for qualitative discrimination. It can quickly and accurately determine the type of ice blast for cigarette. The sample does not require complex pre-treatment, the analysis speed of the sample is fast, non-destructive, the operation is simple and convenient, and the model prediction accuracy is high.A preliminary exploration of the rapid analysis of the category of ice blast for cigarettes is provided, and further technical support can be provided for the quality analysis of the ice blast for cigarettes.

Owner:CHINA TOBACCO SHAANXI IND

Liquid crystal display device and manufacturing method thereof, and electronic device

ActiveUS20120045860A1Reduce in quantitySimple processSolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

An objective is simplification of a manufacturing method of a liquid crystal display device or the like. In a manufacturing method of a thin film transistor, a stack in which a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film are stacked in this order is formed, and the first conductive film is exposed by first etching and a pattern of the second conductive film is formed by second etching. Further, after thin film transistors are formed, a color filter layer is formed so that unevenness caused by the thin film transistors or the like is relieved; thus, the level difference of the surface where the pixel electrode layer is formed is reduced. Alternatively, a color filter layer is selectively formed utilizing the unevenness caused by thin film transistors or the like.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com