PCB and FPC welding method and surface mounting jig

A welding method and fixture technology, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components, can solve the problems of surface mount dislocation and other problems, and achieve high production efficiency, high reliability, and good consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

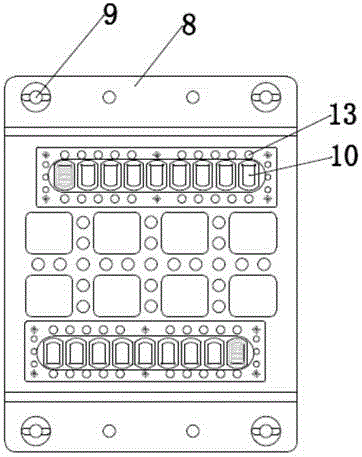

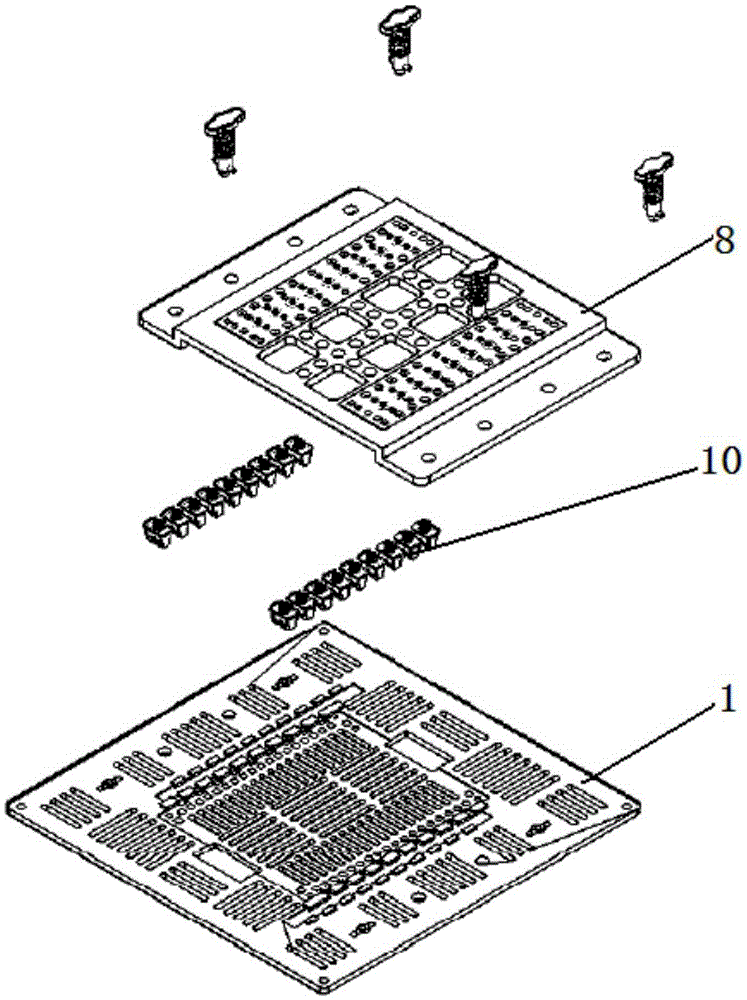

[0029] Cooperate see Figure 1 to Figure 6 , a kind of PCB and FPC welding method of the present invention, comprises the following steps:

[0030] A. Install the PCB imposition on the patch fixture;

[0031] B. Solder paste printing or patching on the PCB imposition pad;

[0032] C. Take out the patch fixture with PCB imposition and place it flat on the mounting base;

[0033] D. Place the FPC that needs to be welded on the PCB layout through the patch fixture, so that there is printed solder paste between the PCB and the FPC welding area in each PCB layout;

[0034] E. Assemble the press-fit cover on the mounting base, press the press-fit cover on the patch fixture and fix it;

[0035] F. Put the assembled board base, press-fit cover and patch fixture into the automatic reflow soldering furnace, so that the solder paste at the position where the PCB and FPC are attached is solidified after reflow soldering, and the soldering is completed.

[0036] Wherein, the patch fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com