A two-stroke stratified scavenging engine

An engine and two-stroke technology, applied in the field of two-stroke stratified scavenging engines, can solve the problems of poor economy and emission performance, environmental pollution, and development restrictions of two-stroke gasoline engines, so as to achieve sufficient scavenging, reduce environmental pollution, and replace full blown effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

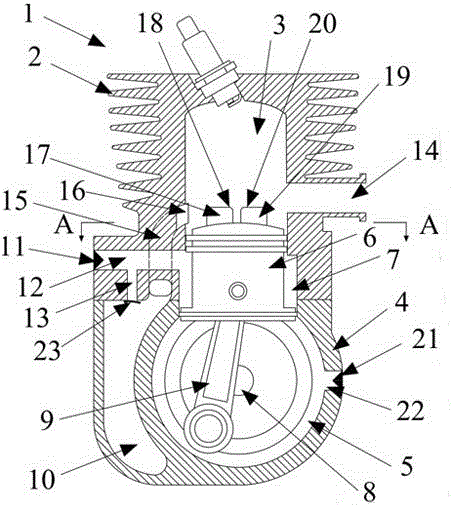

[0025] The present invention as figure 1 , figure 2 As shown, a two-stroke stratified scavenging engine, the main technical solution

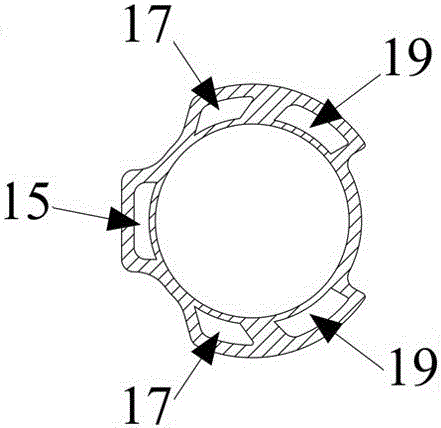

[0026] Yes, it mainly includes: cylinder block 2, body 4, crankcase 5, stepped piston 6, crankshaft 8, air scavenging parts and mixed gas scavenging parts, and the air scavenging parts are mainly arranged on the inner wall of the body 4 The air storage cavity 10 and the air scavenging channel 15 are composed of two ends of the air scavenging channel 15 respectively communicated with the air scavenging port 16 arranged on the inner wall of the cylinder body 2 and the air storage cavity 10 . The mixed gas scavenging component mainly includes mixed gas scavenging channels 17, 19, the mixed gas scavenging channels 17, 19 are arranged on the inner wall of the cylinder body 2, and are closed cavity structures, and the mixed gas scavenging channels The two ends of 17,19 communicate with the mixed gas scavenging port 18,20 and the crankcase 5 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com