Engine local oil anti-emulsification system and using method thereof

An engine and anti-emulsification technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of inability to solve the problem of oil emulsification, insufficient ventilation, etc., to solve the problem of oil emulsification, improve the effect, gas utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

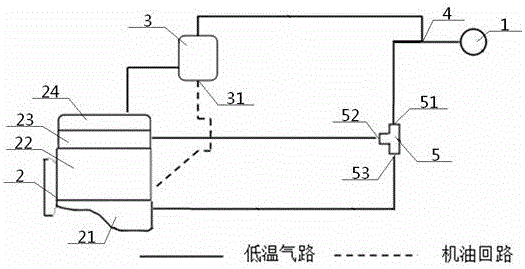

[0048] see Figure 1 to Figure 3 , a local engine oil anti-emulsification system, including an engine 2, a fresh air inlet 1 and an oil-gas separator 3, the engine 2 sequentially includes an oil pan 21, a cylinder block 22, a cylinder head 23, and a cylinder Cover 24, the cylinder head cover 24 communicates with the exhaust gas outlet 4 after the oil-gas separator 3, and the exhaust gas outlet 4 and the fresh air inlet 1 communicate with the cylinder head 23;

[0049] The anti-emulsification system also includes a three-way valve 5, the upper air inlet 51 of the three-way valve 5 communicates with the waste gas outlet 4 and the fresh air inlet 1, and the flat air outlet 52 of the three-way valve 5 communicates with the cylinder head 23 , The vertical air outlet 53 of the three-way valve 5 communicates with the oil pan 21 .

[0050] A method of using the local engine oil anti-emulsification system of the above-mentioned engine, the method of using includes replacing the exhaus...

Embodiment 2

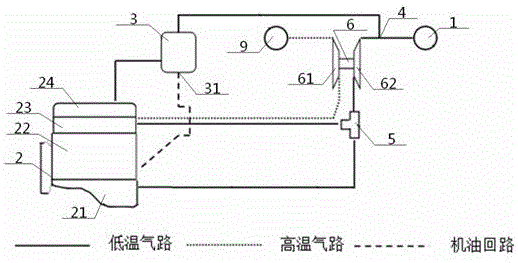

[0053] Basic content is the same as embodiment 1, the difference is:

[0054] The anti-emulsification system also includes a supercharger 6, which includes a turbine 61 and a compressor 62 connected to each other, the air inlet of the compressor 62 communicates with the exhaust gas outlet 4 and the fresh air inlet 1, The gas outlet of the compressor 62 communicates with the upper air inlet 51 .

[0055] In use, the fresh air or the separated waste gas flows through the compressor 62 to increase the pressure before it flows into the upper air inlet 51 .

Embodiment 3

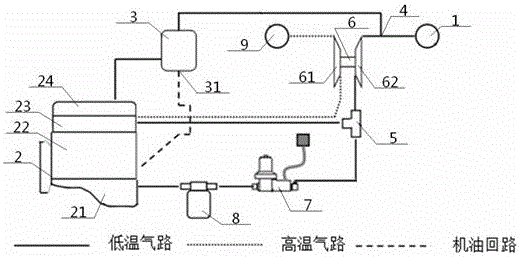

[0057] Basic content is the same as embodiment 2, the difference is:

[0058] The anti-emulsification system also includes a solenoid valve 7 and an air filter 8 .

[0059] When in use, the gas flowing out of the vertical air outlet 53 enters the oil pan 21 through the solenoid valve 7 and the air filter 8 in sequence; the opening condition of the solenoid valve 7 is that the speed of the engine 2 is less than or equal to 1000 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com