Incineration smoke gas ultralow exhaust purification treatment method and treatment system thereof

A technology for incineration and purification of flue gas, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problem that flue gas treatment technology is difficult to meet environmental protection requirements, and the control of pollutant emission concentration and total amount is strict. and other problems, to achieve the effect of improving efficiency and strong operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

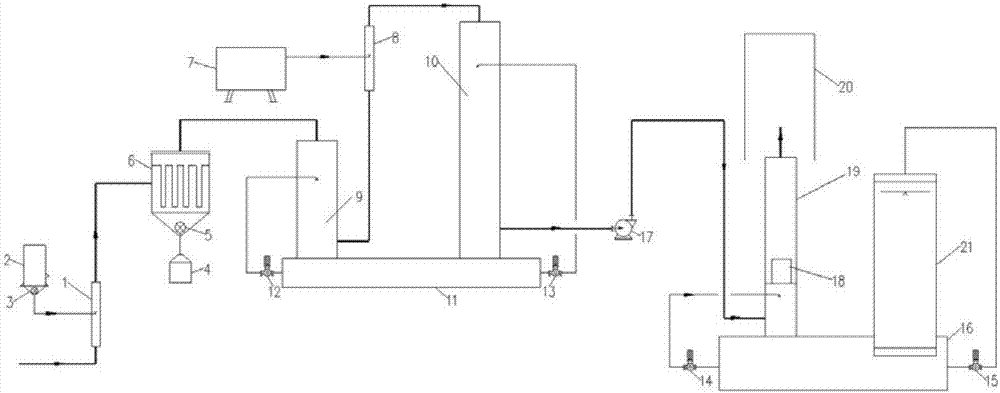

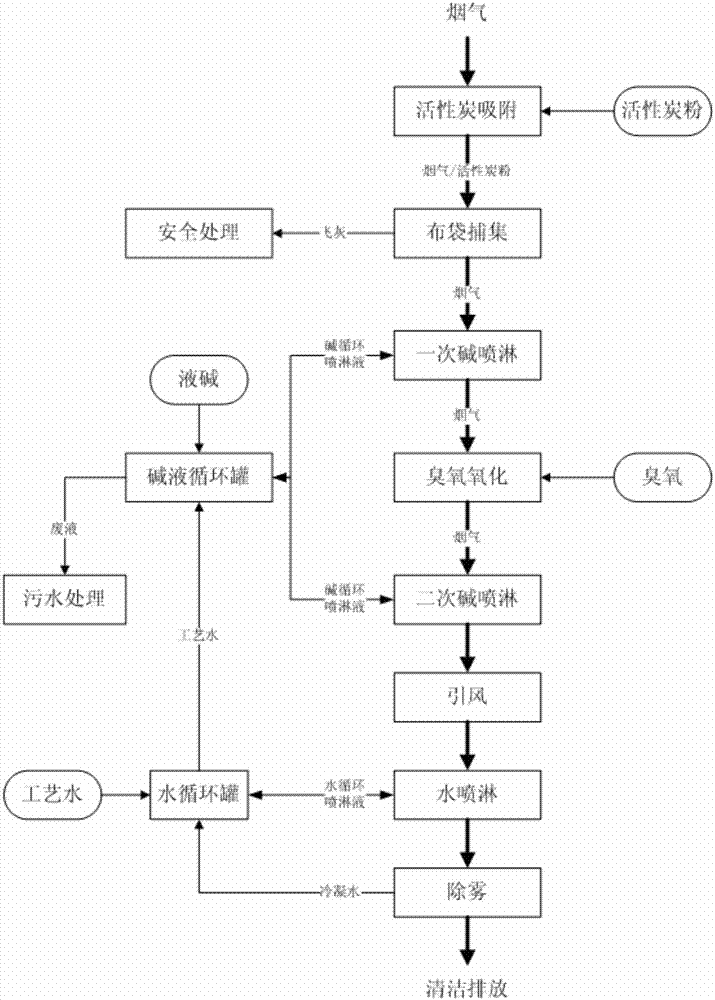

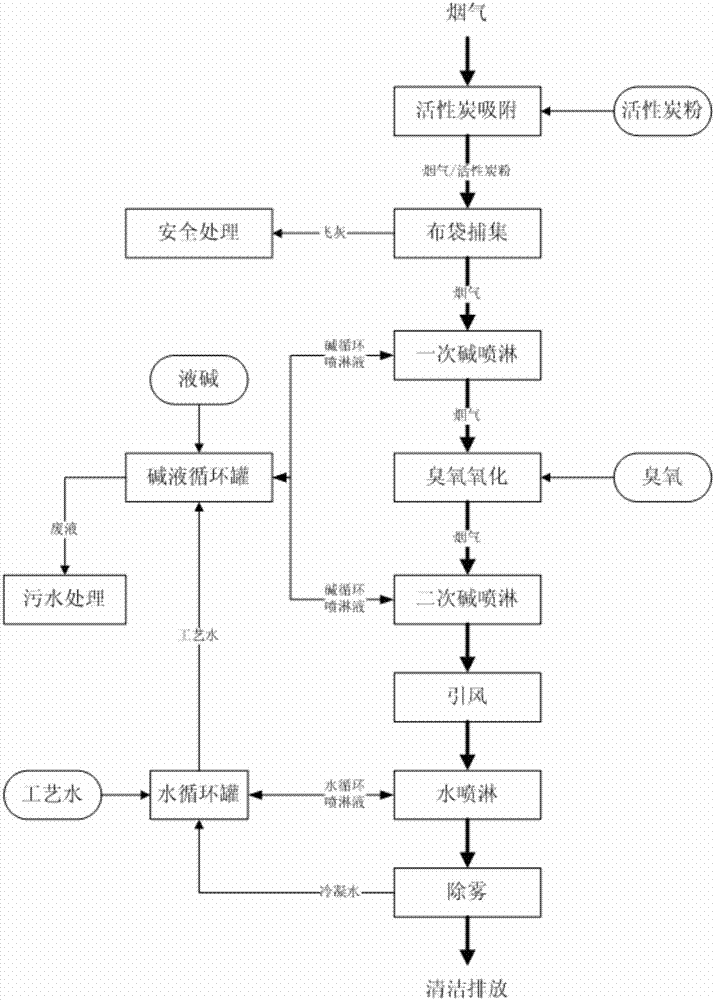

[0031] Such as figure 1 As shown, an incineration flue gas ultra-low emission purification treatment system includes activated carbon powder injection / mixing device 1, bag dust removal device 6, primary alkali spraying device 9, ozone injection / mixing device 8, secondary alkali Spraying device 10 , induced draft fan 17 , water spraying device 19 , demister 18 , cooling tower 21 and chimney 20 . The activated carbon injection device 1 is connected to the activated carbon powder tank 2 through the activated carbon metering and conveying device 3; the ozone injection / mixing device 8 is connected to the ozone generator 7, and the lye circulation tank 11 is connected to the alkali spray device 9, 10 through the lye pump 12, 13 , the water circulation tank 16 is connected to the water spraying device 19 and the cooling tower 21 through the water pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com