Partition-sealed deashing device of electric dust collector

A technology of cleaning device and electrostatic precipitator, which is applied in electrostatic separation, electrode cleaning, etc., can solve the problems of particularly serious fugitive dust, secondary dust generation, and inconvenient maintenance, so as to suppress secondary dust phenomenon and reduce outlet emissions. , the effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

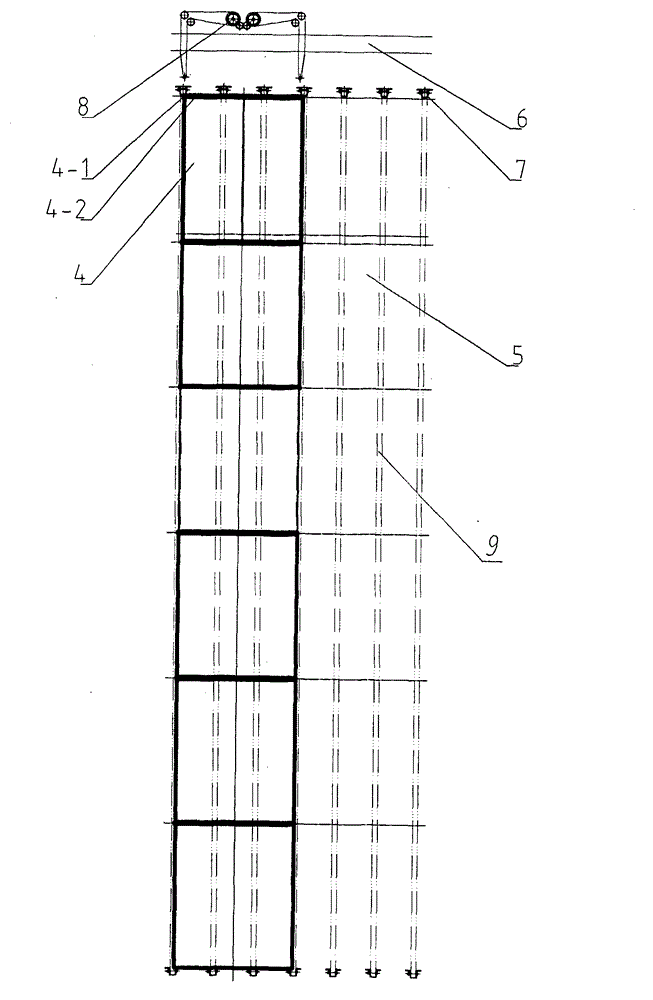

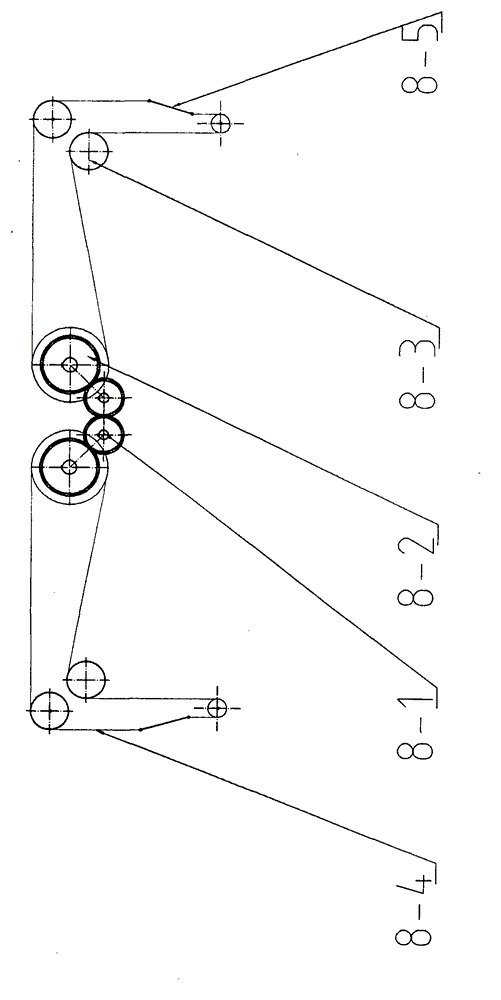

[0020] see figure 1 , there are several electric fields arranged in sequence from the inlet to the outlet in the electrostatic precipitator casing, each electric field is composed of a number of anode plates 9 arranged in parallel, and the electric field channel is between two adjacent anode plates 9 5. In the electric field at the end of the dust collector, install a partition sealing dust removal device consisting of a baffle drive mechanism, a sealing baffle and a dust cleaning mechanism. At least one or more electric field channels 5 form a sealed partition. According to the dust collector The number of electric field channels 5 in the sealed partition is set according to the size, usually 1 to 4 electric field channels form a sealed partition, and the side of each sealed partition is evenly equipped with louver-type sealing baffles 4, and the sealing baffles 4 The size corresponds to the size of the sealing partition; the self-weight sealing louver-type sealing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com