Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Maintain electrical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

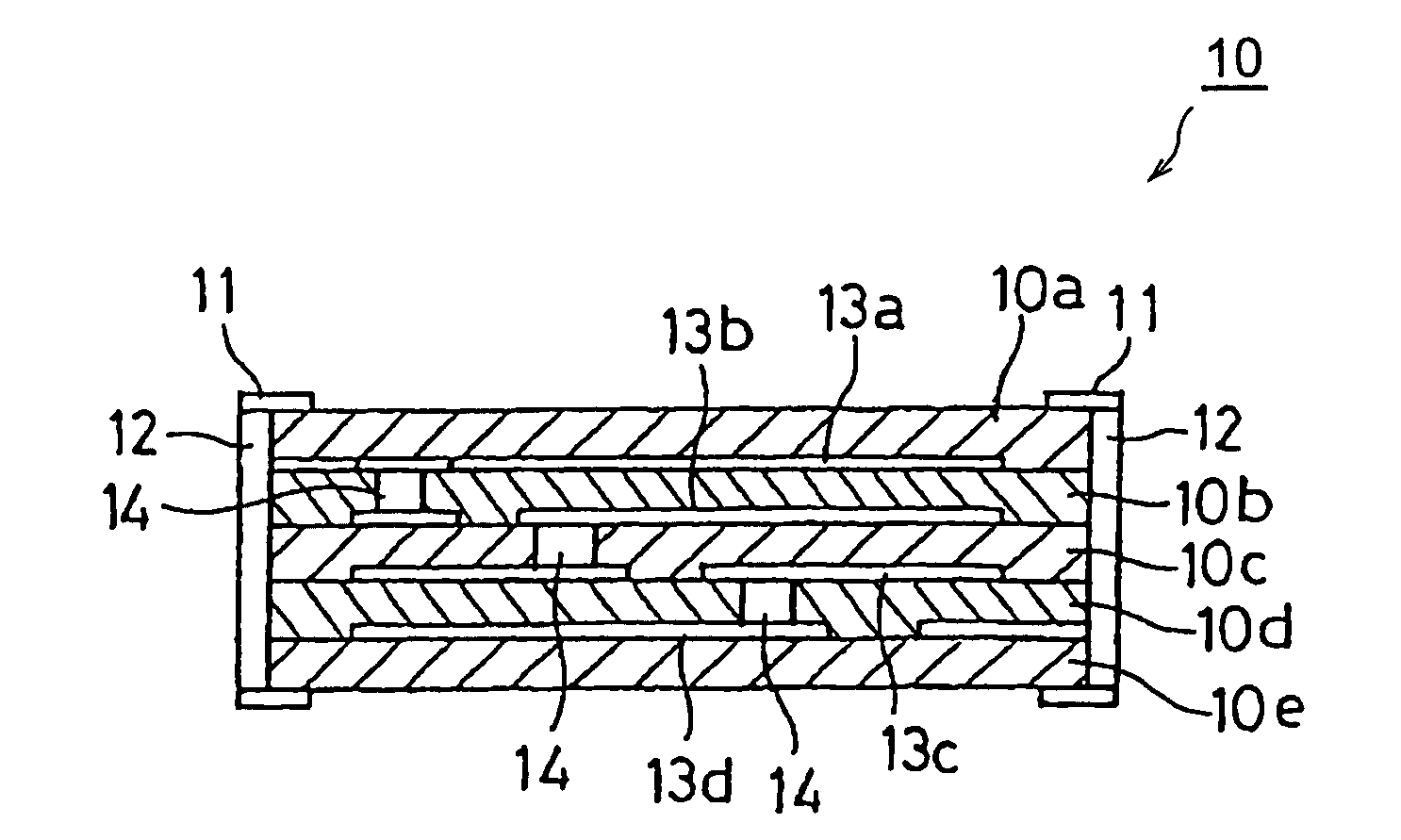

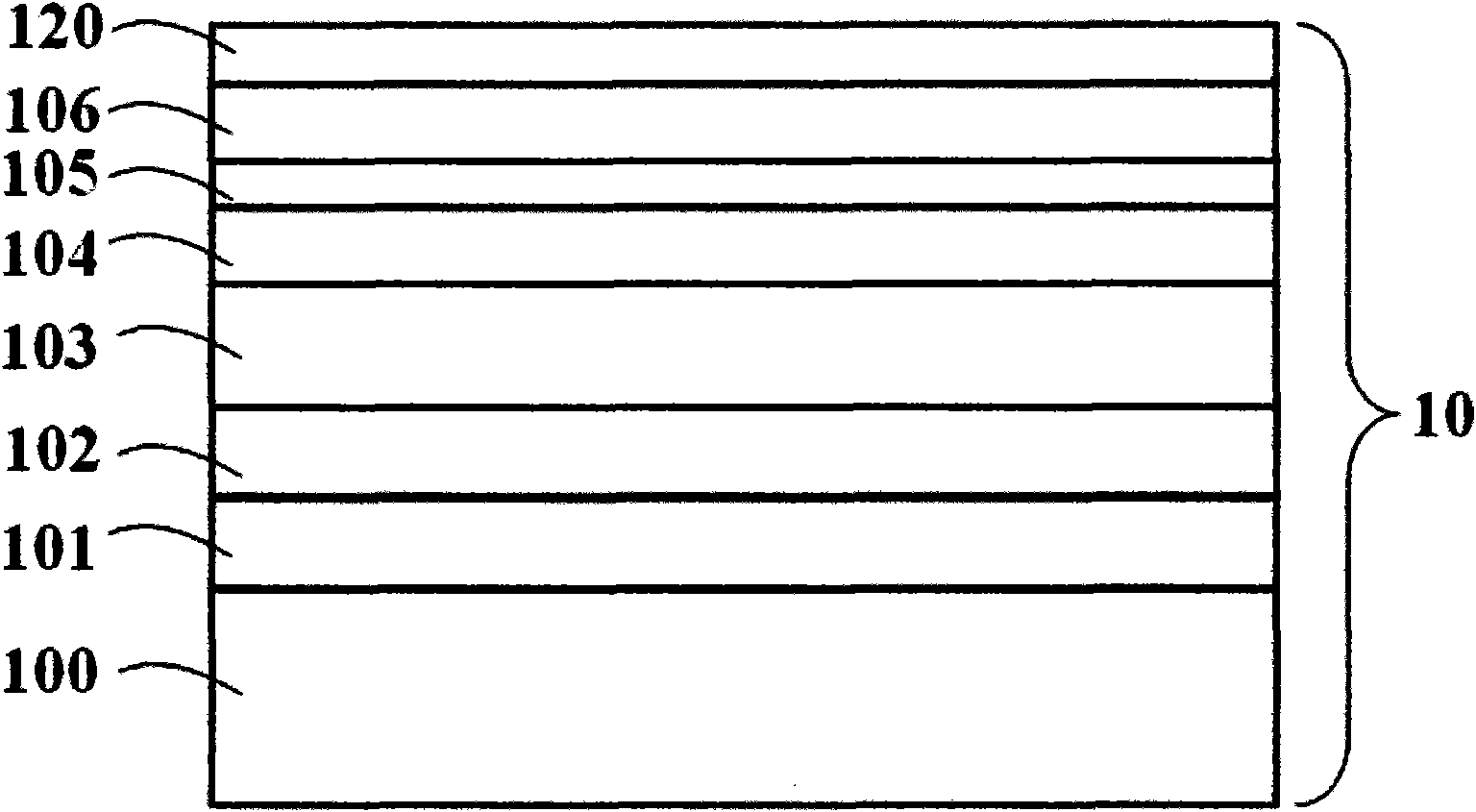

Resin composition, cured resin, sheet-like cured resin, laminated body, prepreg, electronic parts and multilayer boards

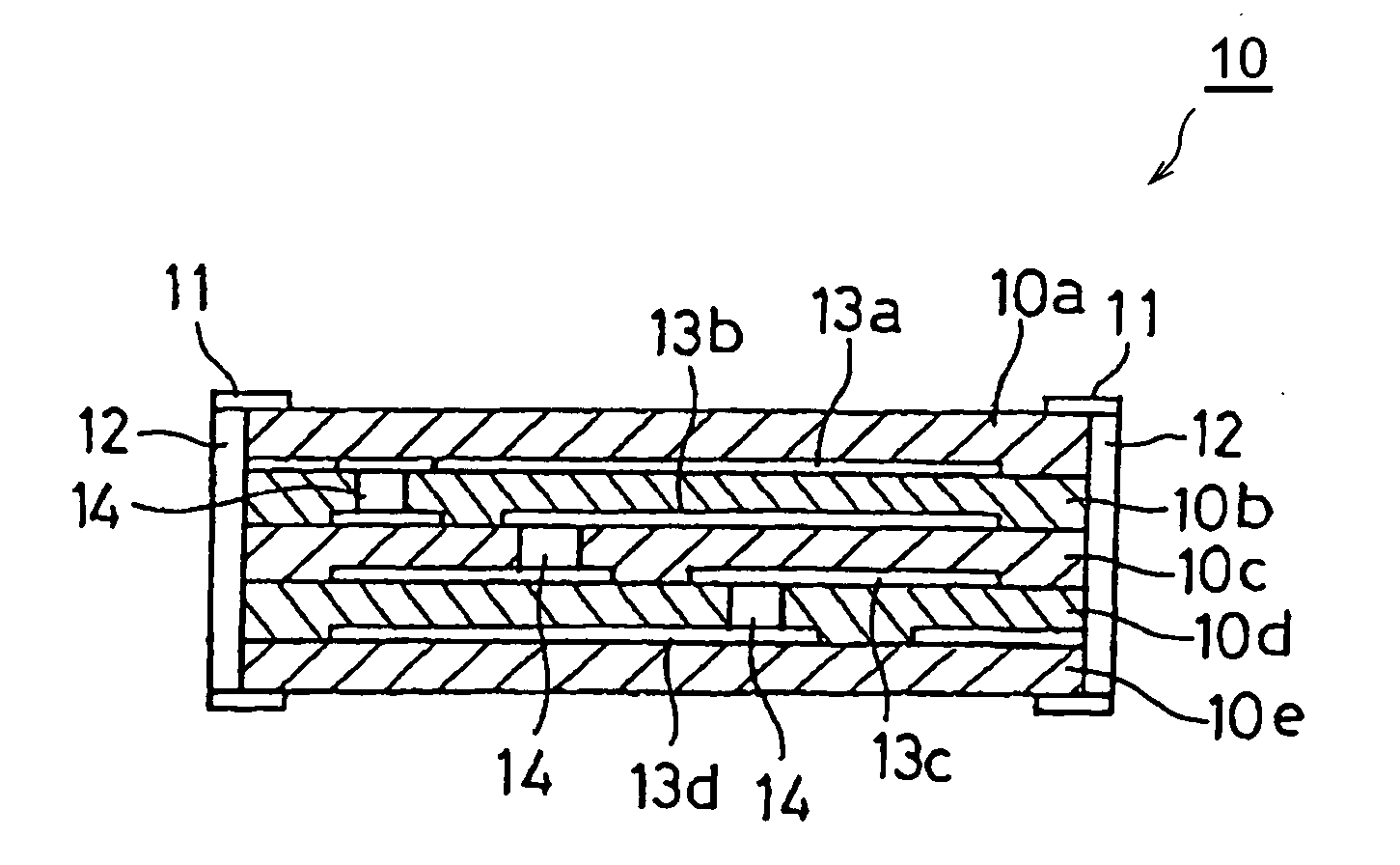

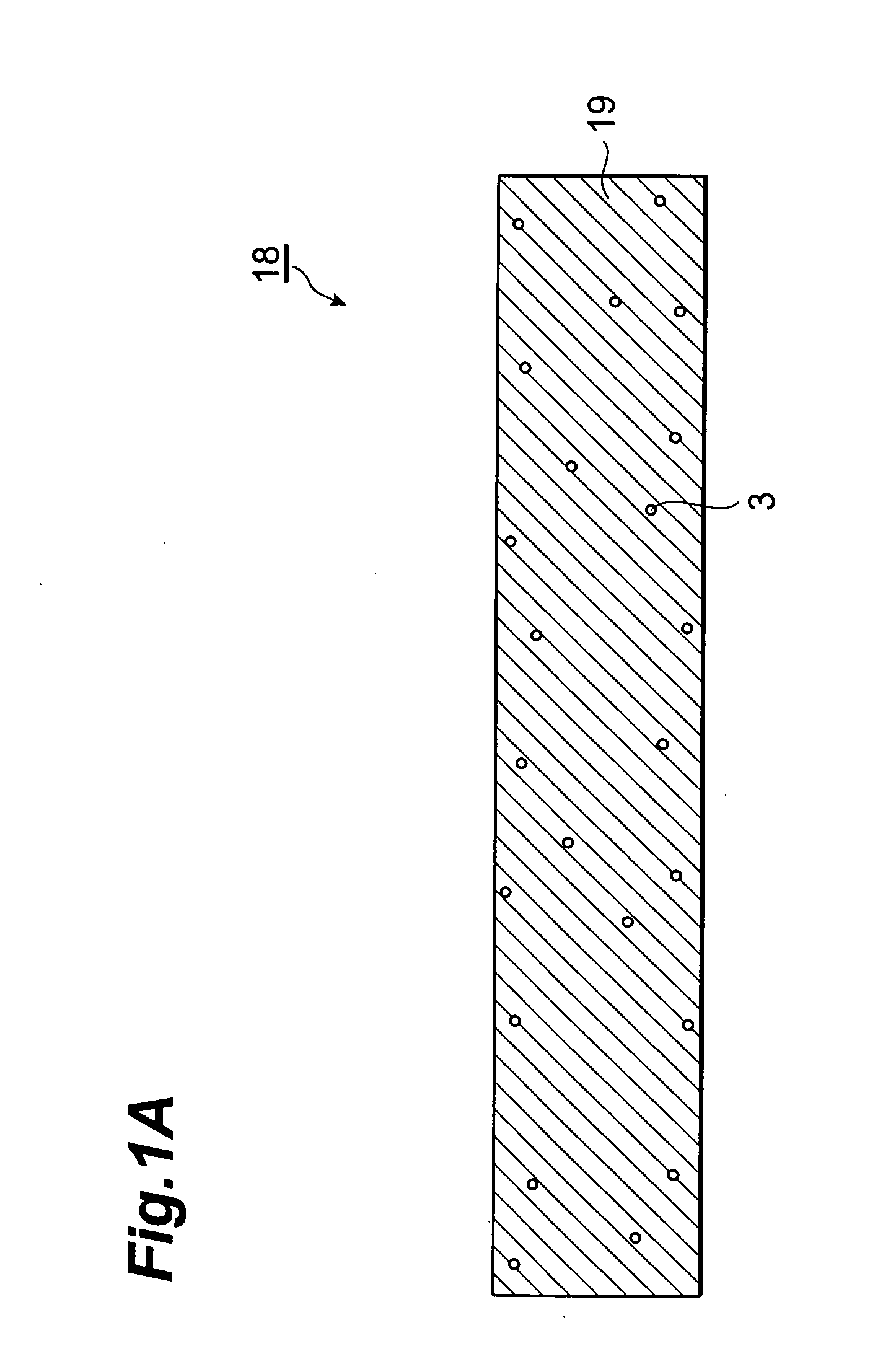

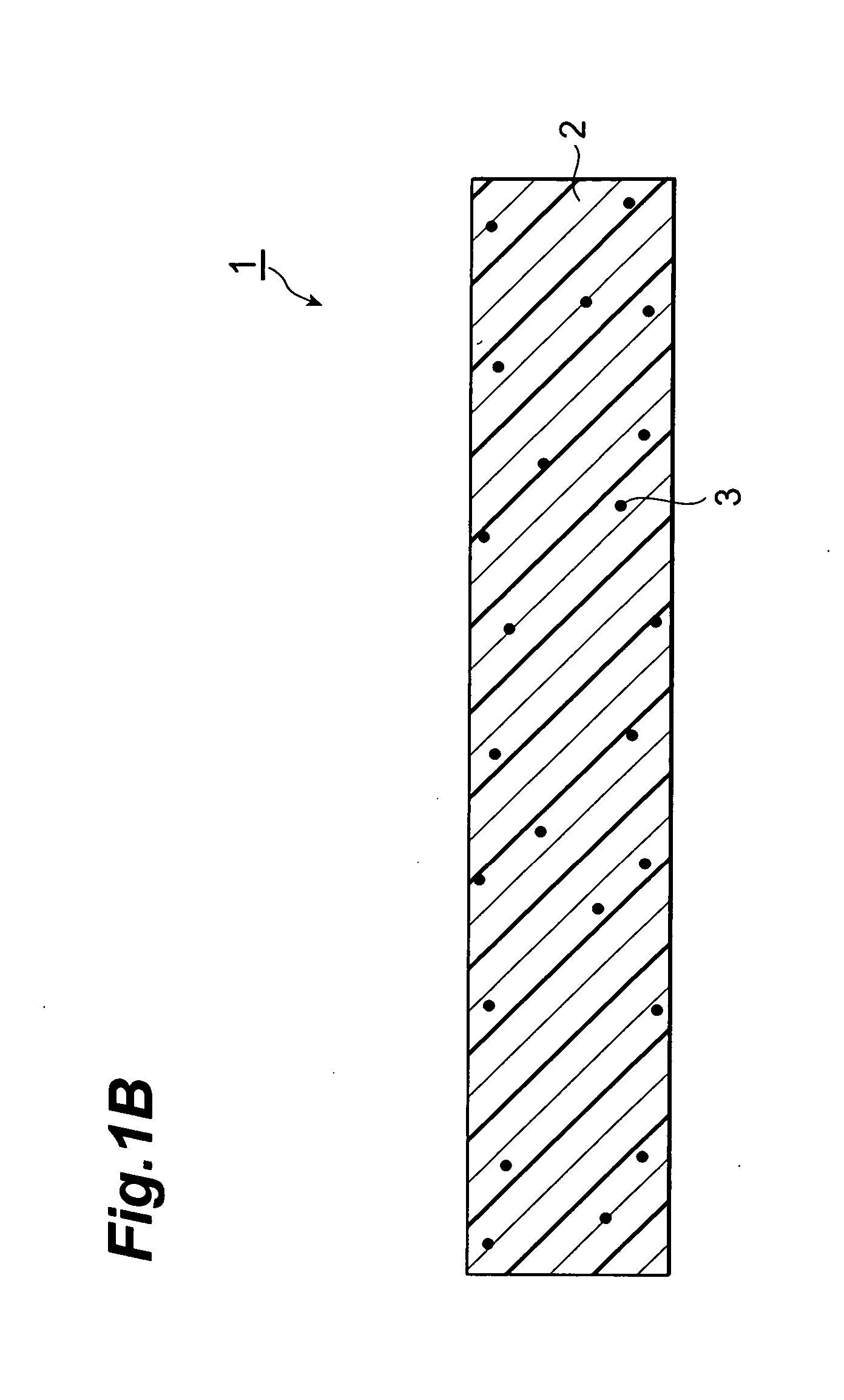

InactiveUS20050003199A1Maintain electrical propertiesHigh dielectric constantSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEpoxyDielectric loss

The invention provides electronic parts which comprise a composite dielectric layer composed of an organic insulating material and a dielectric ceramic powder having a larger relative dielectric constant than the organic insulating material, and which also comprise conductive element sections forming inductor elements, etc., wherein the organic insulating material comprises a cured resin obtained by curing reaction of an epoxy resin with an active ester compound obtained by reaction between a compound with two or more carboxyl groups and a compound with a phenolic hydroxyl group. The dielectric ceramic powders of the described electronic parts have larger relative dielectric constants than the organic insulating materials, and the organic insulating materials have low dielectric loss tangents. It is possible to adequately reduce time-dependent dielectric constant changes in the high-frequency range of 100 MHz and above even with prolonged use at high temperatures of 100° C. and higher, while it is also possible to satisfactorily prevent deformation and other damage to the electronic parts during their handling.

Owner:TDK CORPARATION

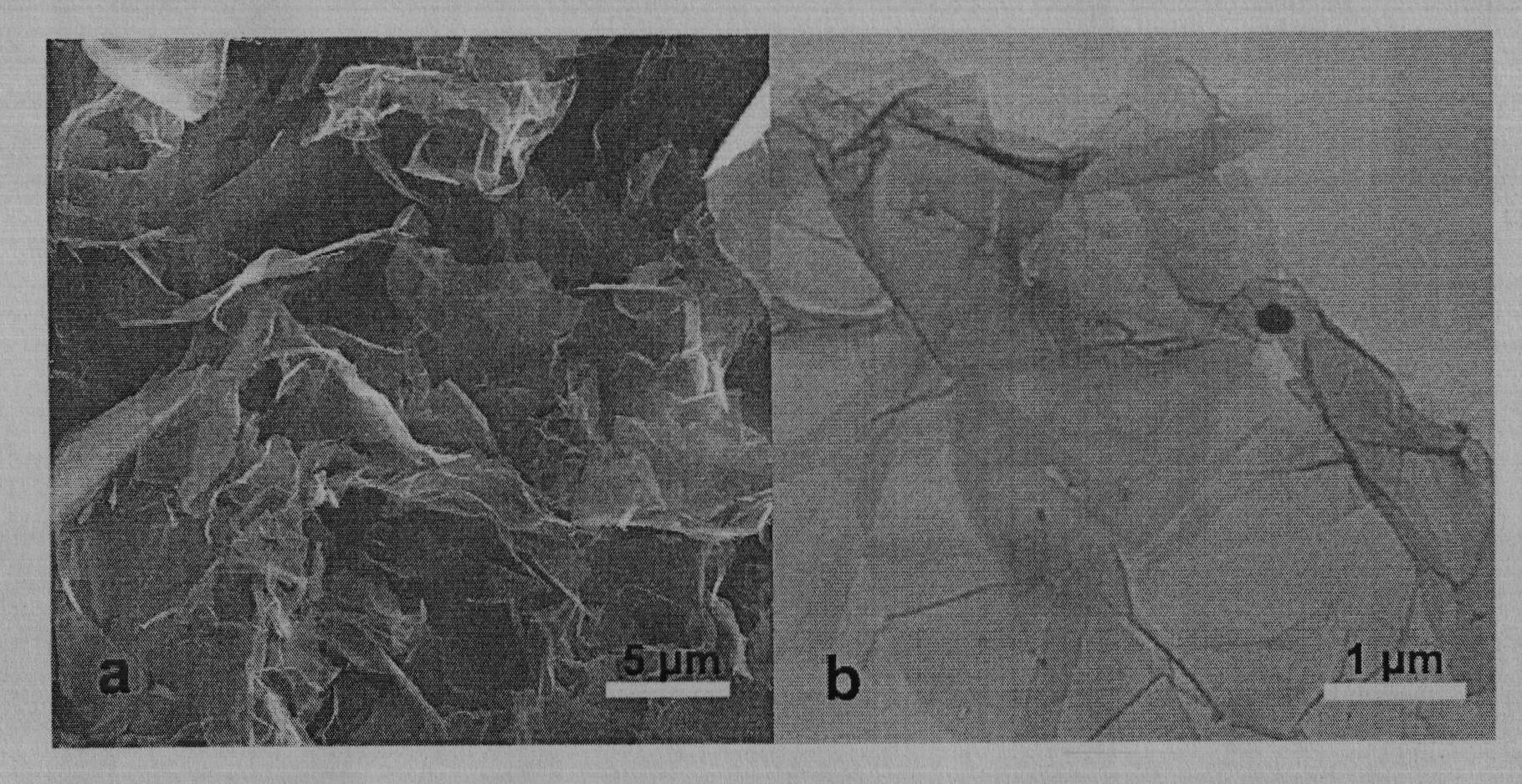

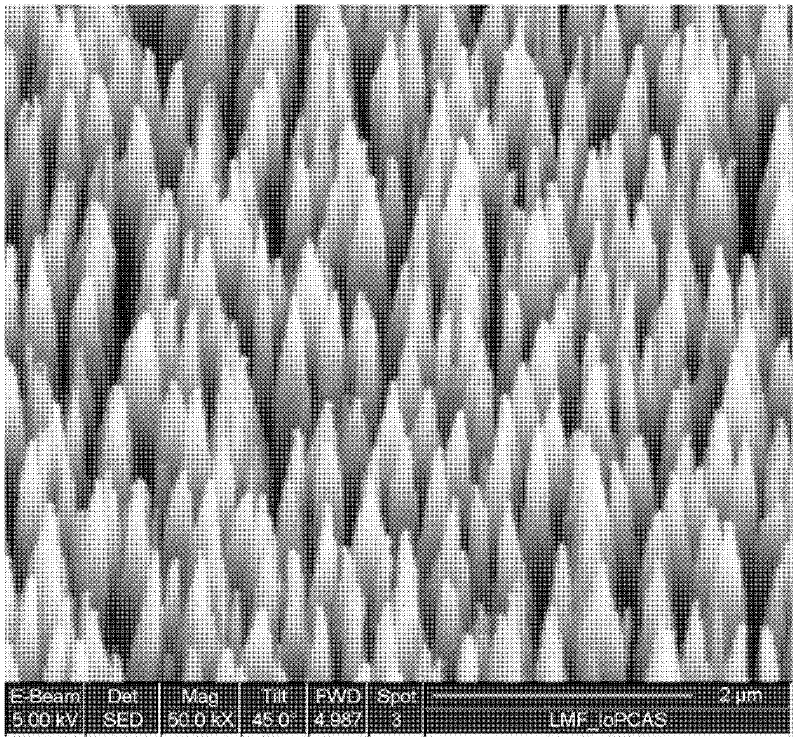

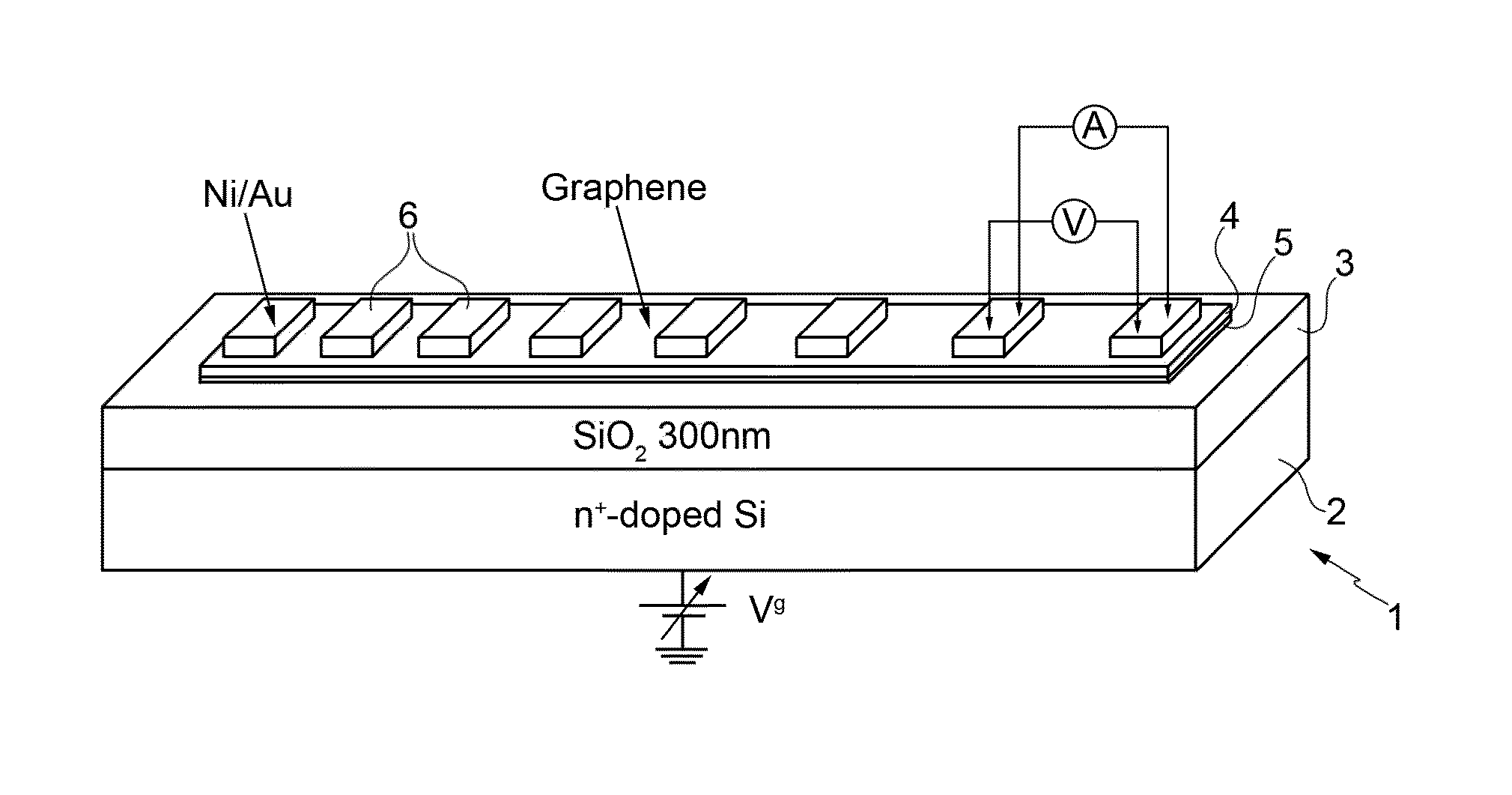

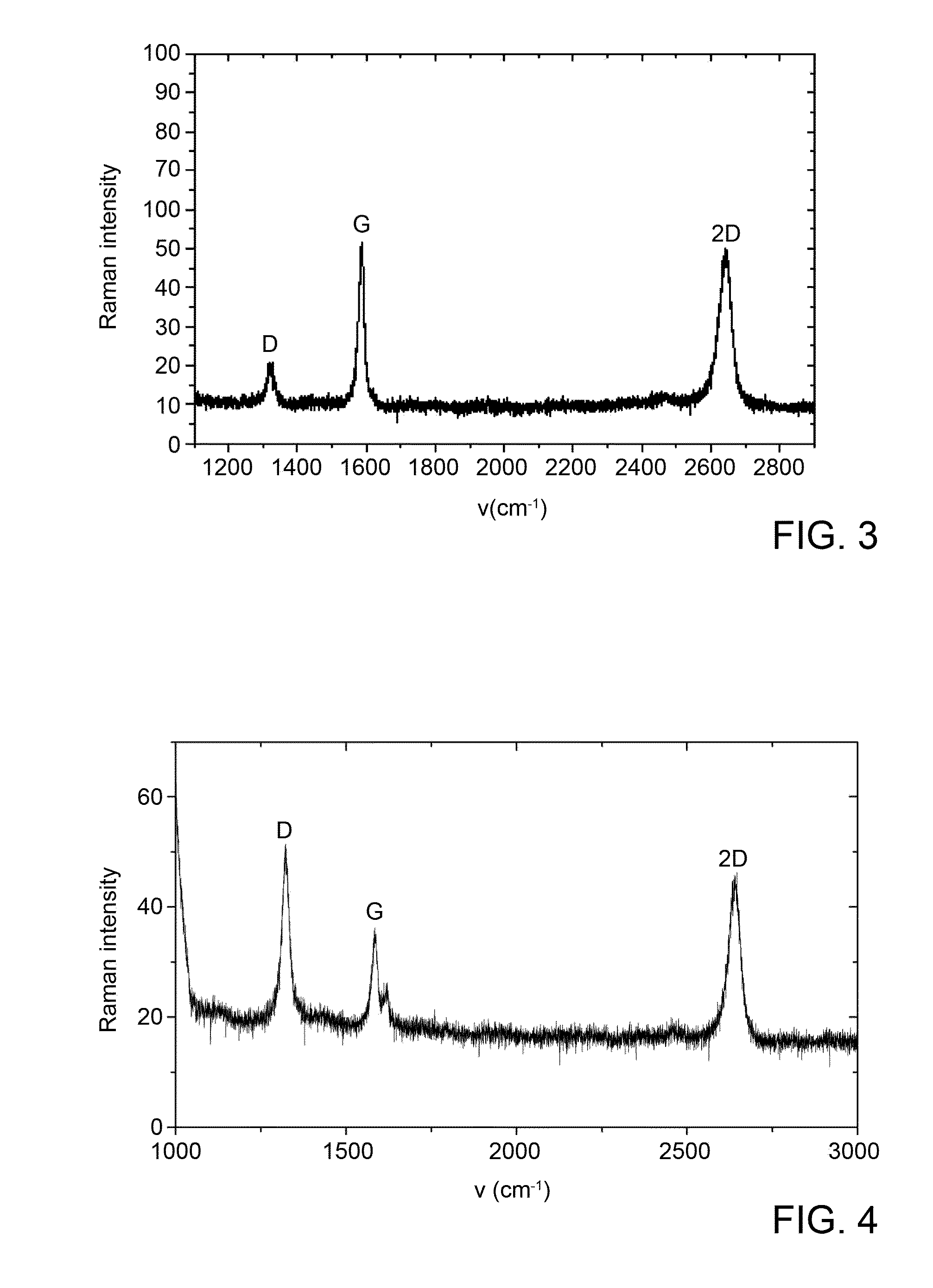

Method for preparing high-quality graphene in large scale by intercalation stripping of graphite by chemical method

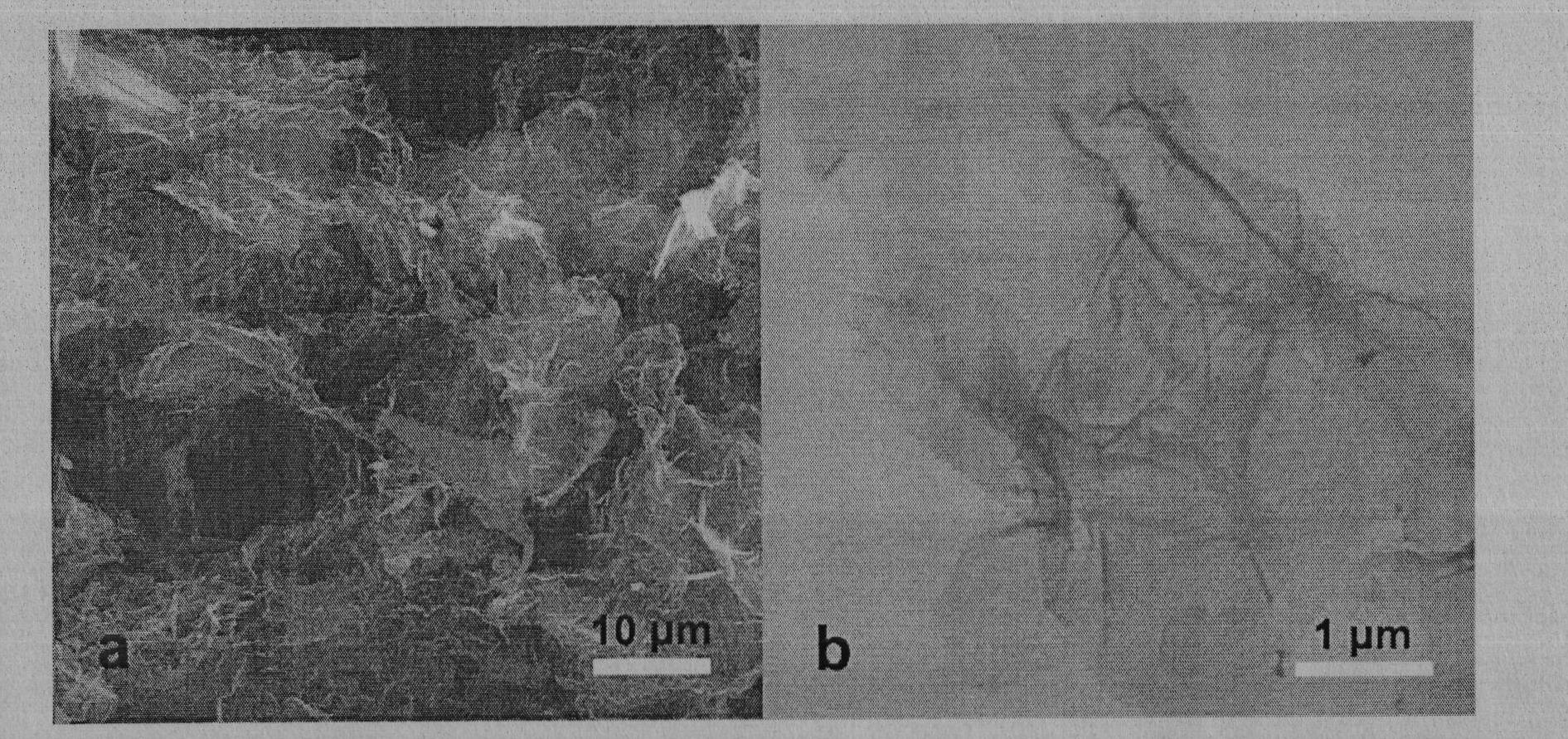

The invention discloses a method for preparing high-quality graphene in large scale by intercalation stripping of graphite by chemical method. The main principle and approach are as follows: inserting some reagent into graphite intercalation by chemical method, then adding energy or some reagent to make intercalation material rapidly and violently react to release air and stripping graphite into graphene. The specific embodiment proposal comprises means of liquid phase stripping, solid phase stripping and two-step liquid phase and solid phase combined stripping. The prepared graphene has high single intercalation quality and few detects since it does not go through oxidation and reduction processes. The oxygen content is only 1.63% and is the lowest in known graphene preparation method by graphite. There is no impurity or molecule absorbed on the graphene surface. The invention has low cost, high yield, simple and feasible preparation method and low energy consumption and is suitable for large scale generation.

Owner:深圳市长宜景鑫投资有限公司

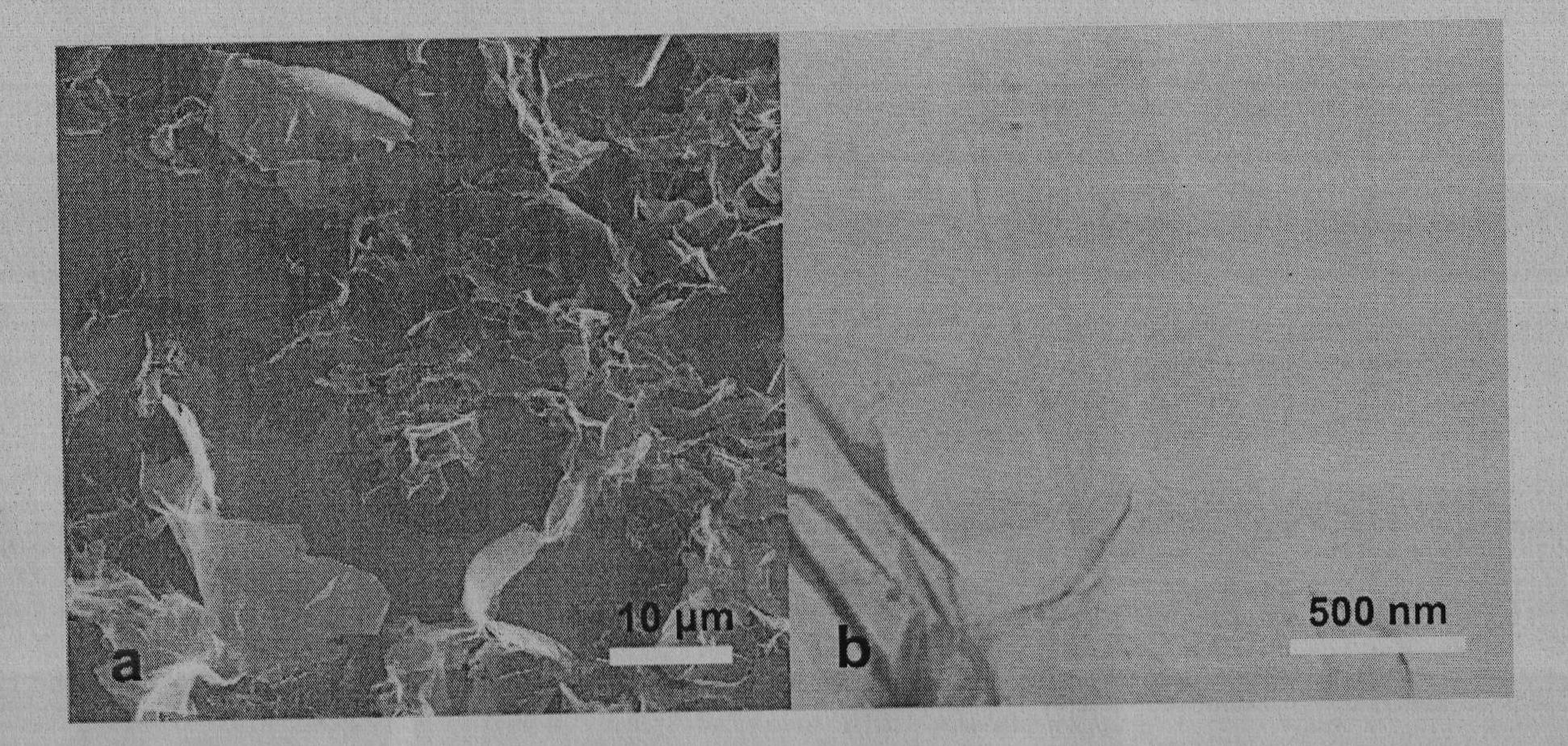

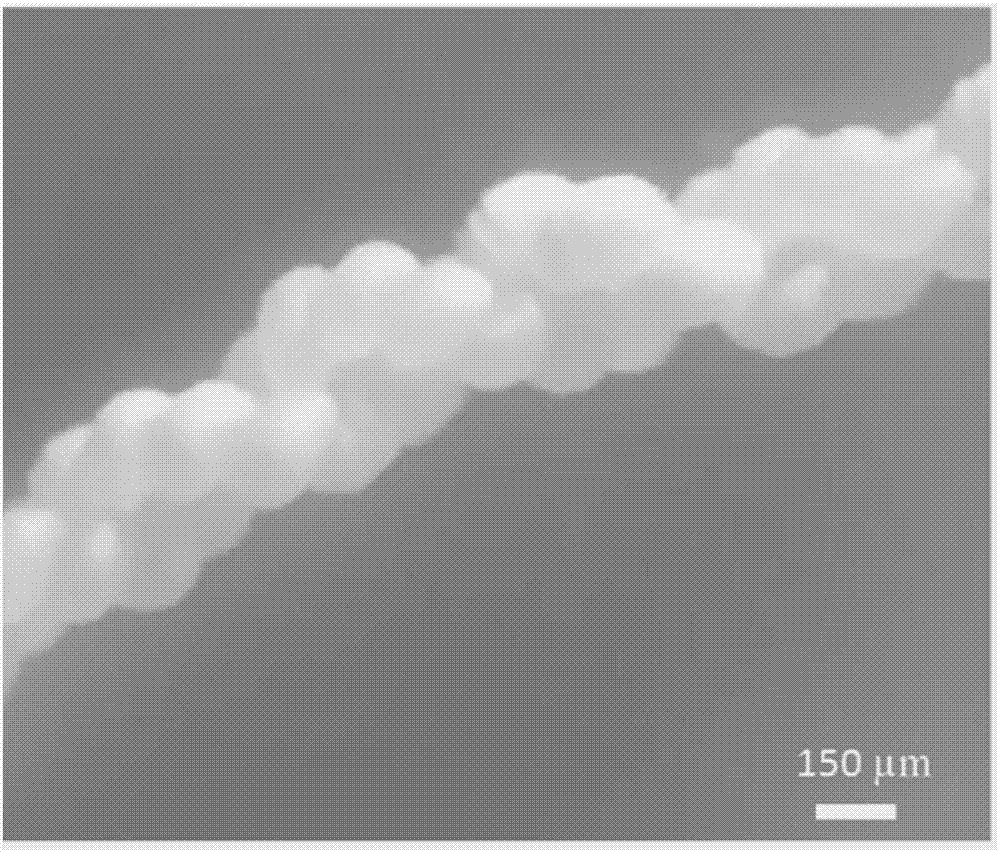

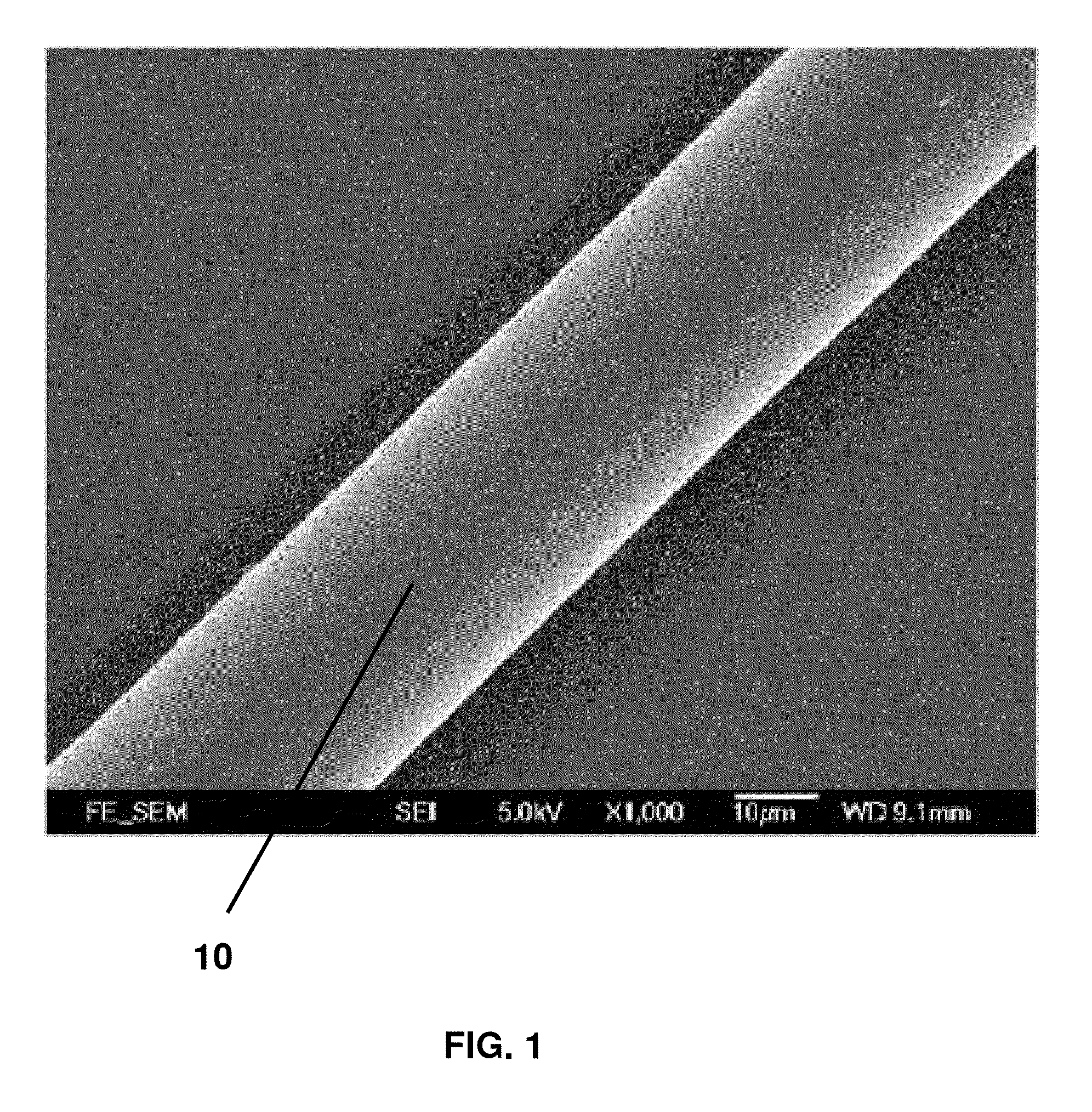

Carbon nano tube fiber-graphene composite material and preparation method of the same

InactiveCN103306132AMaintain mechanical propertiesMaintain electrical propertiesFibre treatmentCvd grapheneCarbon nanotube

The invention discloses a preparation method of carbon nano tube fiber-graphene composite material. The method comprises the following steps of: a, preparing carbon nano tube fiber, meanwhile, wetting and modifying the carbon nano tube fiber by solution; b, providing graphene, adding the graphene into water solution, forming uniformly dispersed graphene dispersion liquid under the action of ultrasonic wave; c, dropping a dispersing agent into the graphene dispersion liquid, and stirring uniformly; d, fully contacting the carbon nano tube fiber with the graphene dispersion liquid so as to coat the surface of the carbon nano tube fiber with the graphene; e, then, drying the carbon nano tube fiber coated with the graphene, thereby obtaining the composite material. The carbon nano tube fiber-graphene composite material provided by the invention keeps the mechanical property and the electrical property of the carbon nano tube fiber, and endows the surface of the carbon nano tube fiber with lots of functional modification groups, such as carboxyl, hydroxyl and epoxy group, so that the surface hydrophilicity of the carbon nano tube fiber can be regulated effectively.

Owner:SUZHOU CREATIVE CARBON NANOTECH

Resin composition, cured resin, sheet-like cured resin, laminated body, prepreg, electronic parts and multilayer boards

InactiveUS20080044660A1Improve propertiesImprove electrical performanceSemiconductor/solid-state device detailsPrinted circuit aspectsEpoxyDielectric loss

The invention provides electronic parts which comprise a composite dielectric layer composed of an organic insulating material and a dielectric ceramic powder having a larger relative dielectric constant than the organic insulating material, and which also comprise conductive element sections forming inductor elements, etc., wherein the organic insulating material comprises a cured resin obtained by curing reaction of an epoxy resin with an active ester compound obtained by reaction between a compound with two or more carboxyl groups and a compound with a phenolic hydroxyl group. The dielectric ceramic powders of the described electronic parts have larger relative dielectric constants than the organic insulating materials, and the organic insulating materials have low dielectric loss tangents. It is possible to adequately reduce time-dependent dielectric constant changes in the high-frequency range of 100 MHz and above even with prolonged use at high temperatures of 100° C. and higher, while it is also possible to satisfactorily prevent deformation and other damage to the electronic parts during their handling.

Owner:TDK CORPARATION

Piezoelectric element and method for manufacturing the same

InactiveCN1879230AMaintain electrical propertiesMaintain piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyForce measurement using piezo-electric devicesMetallurgyAbsorption of water

A piezoelectric element is provided with a piezoelectric composition pressure sensitive body, a first electrode, a second electrode and a coat layer. The piezoelectric composition pressure sensitive body includes a piezoelectric ceramic powder and a flexible organic polymer. The first electrode and the second electrode are connected with the piezoelectric composition pressure sensitive body and are insulated from one another. The coat layer is provided on the outer side of the piezoelectric ceramic powder and suppresses absorption of water into the piezoelectric ceramic powder.

Owner:PANASONIC CORP

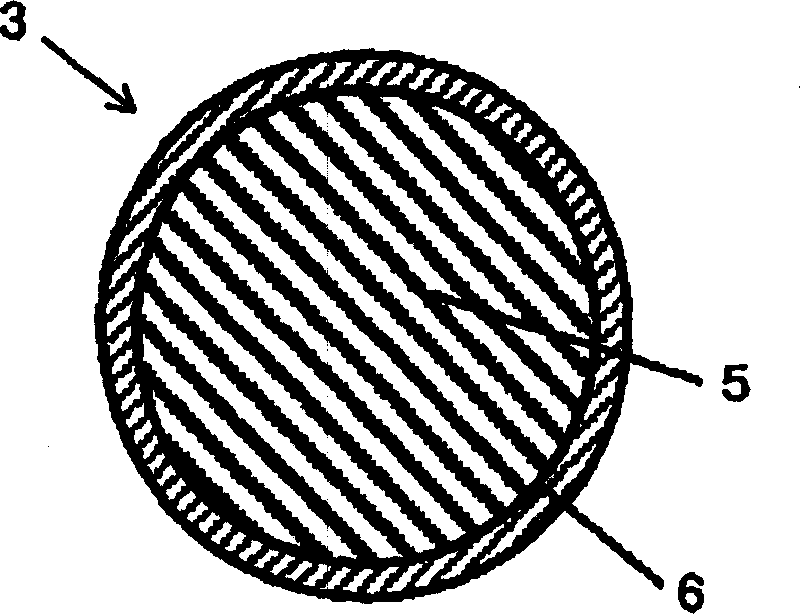

Preparation method for silicon surface anti-reflection nanometer array structure

ActiveCN102351569AOrientation to overcomeReduce light reflectivityInductively coupled plasmaReactive-ion etching

The invention relates to a preparation method for a silicon surface anti-reflection nanometer array structure, which comprises the following steps that: silicon chips are placed into an inductively coupled plasma (ICP) system, and nanometer conical array structures are obtained at the silicon surface under the conditions of the basic vacuum being 1.0*10<-6> Torr, the temperature being -100 DEG C to -140 DEG C, the gas flow rate ratio (SF6 / O2) being 36 / 22 to 44 / 14, the air pressure being 6 to 25mTorr, the reactive ion etching (RIE) power being 3 to 6W and the ICP power being 800 to 1000W. The method adopts a low-temperature etching technology, the masking process is not needed, the large-area silicon surface nanometer conical array structure with the super anti-reflection characteristic is directly prepared through etching, and in addition, the regulation and control on the nanometer conical structure feature is realized through regulating and controlling the corresponding parameters.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Bonding structure of electronic equipment

ActiveUS20150043175A1Mechanical reliabilityMaintain electrical propertiesCircuit bendability/stretchabilityFinal product manufactureEngineeringElectric equipment

Provided is a bonding structure of an electronic equipment including first electrodes extended in a first direction and arranged in a second direction on a stretchable display panel having stretchability, second electrodes extended in a first direction and arranged in a second direction on a substrate and facing the first electrodes, and solder bonding parts interposed between the first electrodes and the second electrodes, facing each other in the second direction, and constituting a plurality of rows in the first direction.

Owner:ELECTRONICS & TELECOMM RES INST

Silicone rubber coating composition

InactiveUS20050009956A1Effective level of flowEffective of workabilityPlastic/resin/waxes insulatorsCoatingsSilazaneSilanes

A silicone rubber coating composition comprising (A) an organopolysiloxane, (B) an organosilicon compound having at least three hydrolyzable groups or a partial hydrolyzate thereof, and (C) aluminum hydroxide surface treated with a silane, siloxane or silazane is coated onto the surface of an insulator body to form a high-voltage electric insulator film which maintains the stabilized electrical properties of silicone rubber over a long term even in the ambient environment.

Owner:SHIN ETSU CHEM IND CO LTD

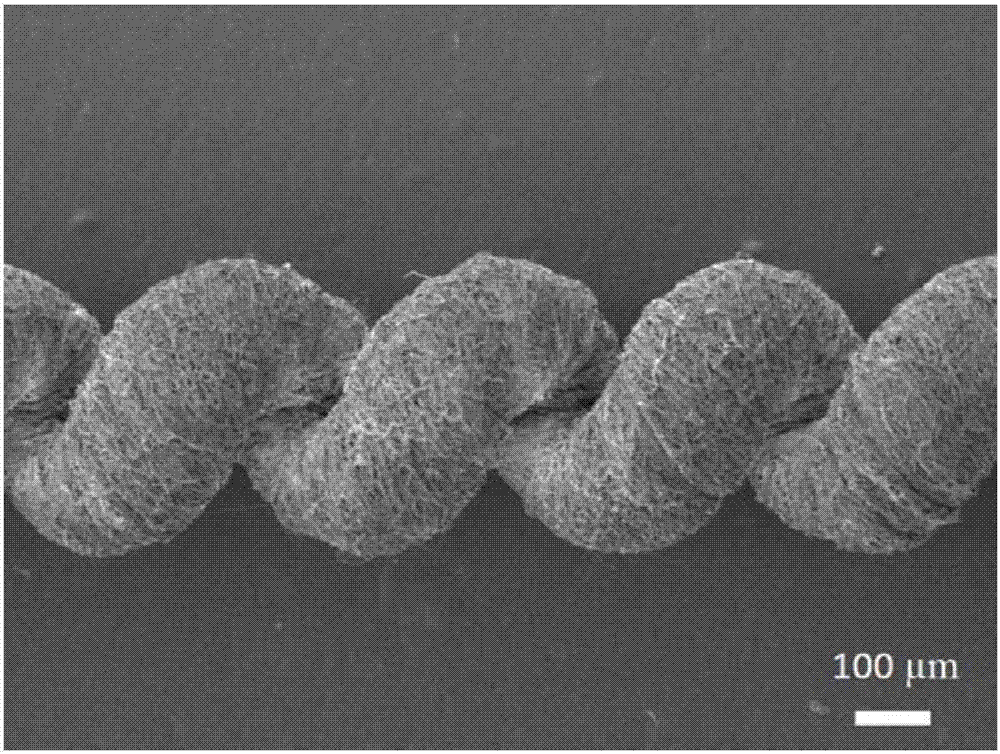

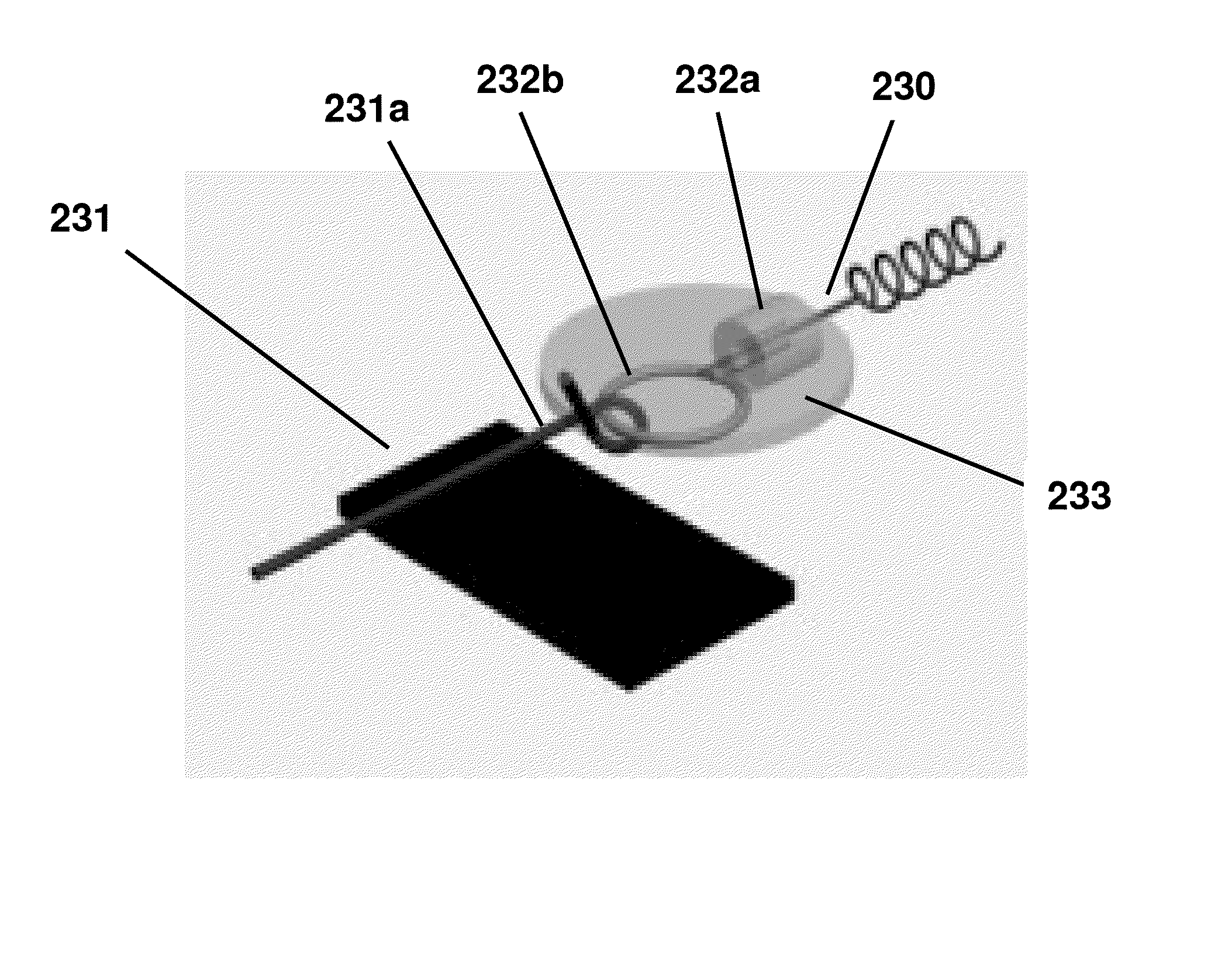

Electrospinning-based flexible tensile strain sensor with spiral wound structure

ActiveCN107574493AEasy to fixUniform movementFibre typesFilament/thread formingTensile strainHelical line

The invention discloses an electrospinning-based flexible tensile strain sensor with a spiral wound structure, and a preparation method of the electrospinning-based flexible tensile strain sensor. A sensitive resistor of the product is made of a bifilar helix prepared through twice twisting of a conductive nanofiber membrane prepared through the combination with an electrospinning method. The sensor has relatively high conductivity, still has a conductive property at relatively large tension and large-size tension, has advantages of relatively good toughness, high tensile recovery property, good tensile stability, wide strain withstanding range, simple preparation method and low production cost, and is suitable for large-scale production.

Owner:QINGDAO AGRI UNIV

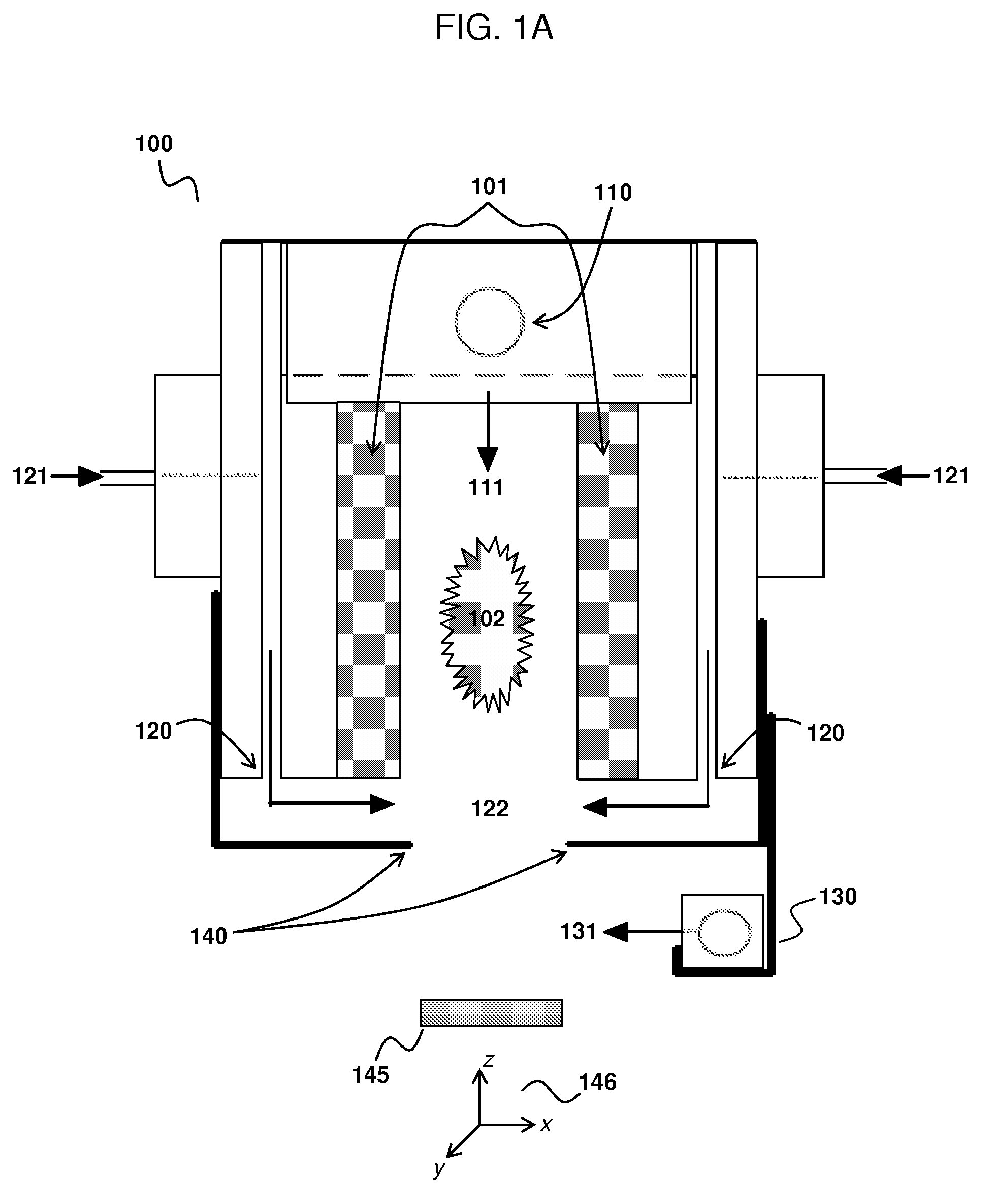

Method for Fabricating a Doped and/or Alloyed Semiconductor

InactiveUS20100320456A1Easily optimize dopant concentrationMaintaining desired structuralCellsVacuum evaporation coatingAlloySemiconductor

The present invention is directed to methods for depositing doped and / or alloyed semiconductor layers, an apparatus suitable for the depositing, and products prepared therefrom.

Owner:NEW MILLENNIUM SOLAR EQUIP CORP

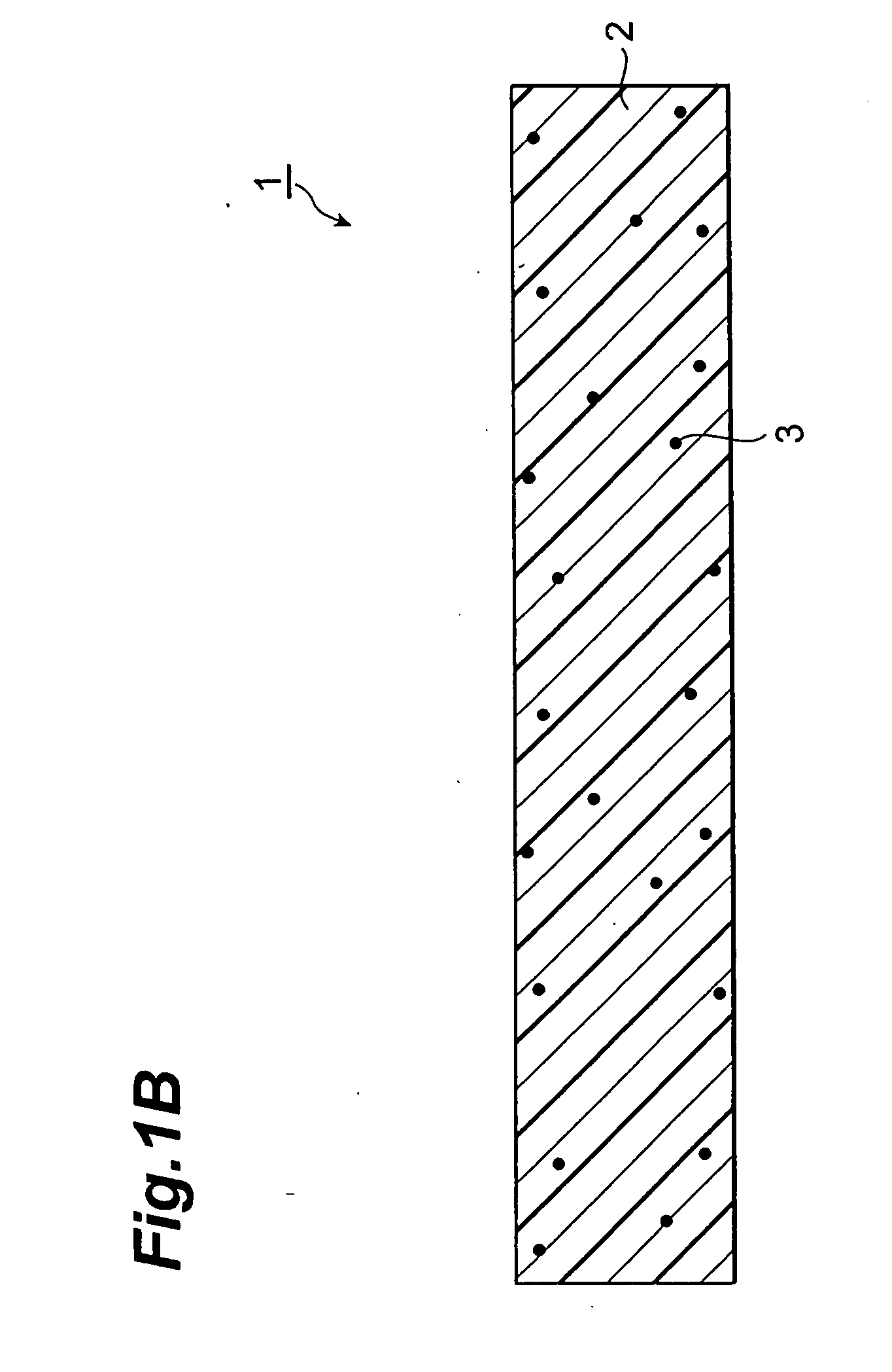

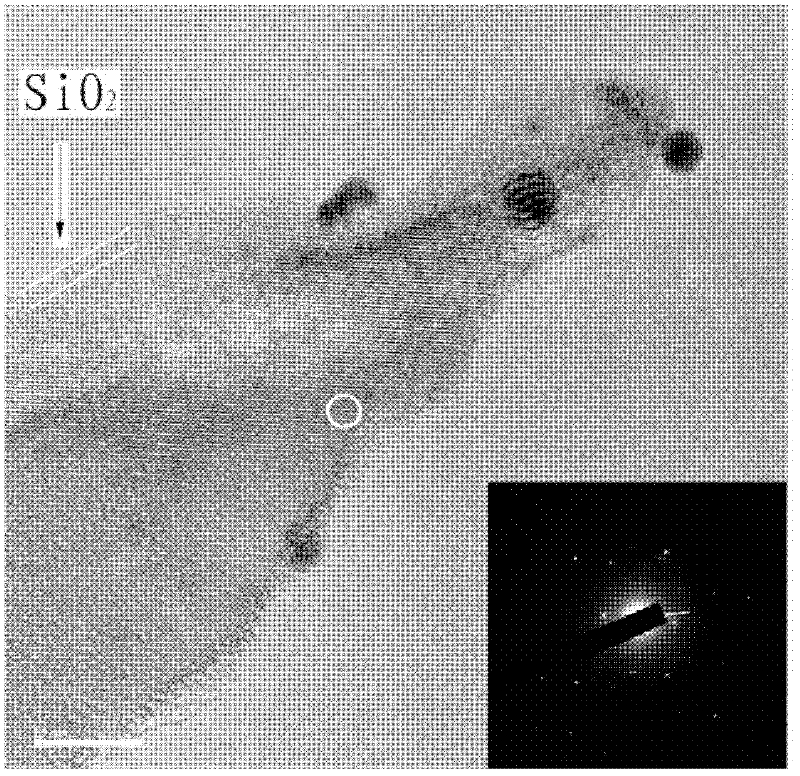

Polymer carbon nano tube compound structure and preparation method thereof

The invention relates to a polymer carbon nano tube compound structure and a preparation method thereof and the structure is similar to shish-kebab crystal formed under polymer shear field. The preparation method includes the following steps: adding carbon nano tube to an organic solution by 0.01 to 0.1wt mass percent and forming a carbon nano tube suspension through ultrasonic dispersion; adding polymer to the organic solution by 0.01 to 10wt mass percent and heating to dissolve the polymer to obtain a polymer solution; dripping the carbon nano tube suspension to the polymer solution to form a mixed solution and maintaining constant temperature for 10 minutes; slowly cooling the mixed solution to room temperature and filtering to obtain the polymer carbon nano tube compound structure. The invention can increase the dispersibility of the carbon nano tube in polymer matrix and solution, therefore, the carbon nano tube is easy to be further processed. The invention can be also applied in modification of other nano tubes and nano lines, such as Ti2 nano pipe and PET fiber, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for increasing yield of graphene prepared by supercritical fluid through pretreatment of natural graphite

ActiveCN104229787AHigh yieldDoes not affect intrinsic propertiesGrapheneBulk chemical productionState of artSlurry

The invention relates to a method for increasing the yield of graphene prepared by a supercritical fluid through pretreatment of natural graphite. The method comprises the steps as follows: natural graphite powder and acid are added into a container and stirred uniformly; an additive is added, and the mixture is cooled to obtain low-temperature graphite slurry; the low-temperature graphite slurry is sprayed to a high-pressure reaction kettle containing supercritical fluid media for supercritical treatment; and then a material after the supercritical treatment is rapidly sprayed into a normal-pressure production material tank and is filtered, separated and dried to obtain the graphene product. Compared with the prior art, the low-temperature natural graphite slurry pretreated by the acid is taken as feedstock; compared with the normal-temperature natural graphite serving as feedstock, the yield of graphene is increased by about 2-5 times through the supercritical fluid stripping process; and not only is the yield of graphene increased, but also the electrical property and the thermal property of graphene are further maintained.

Owner:SHANGHAI JIAO TONG UNIV

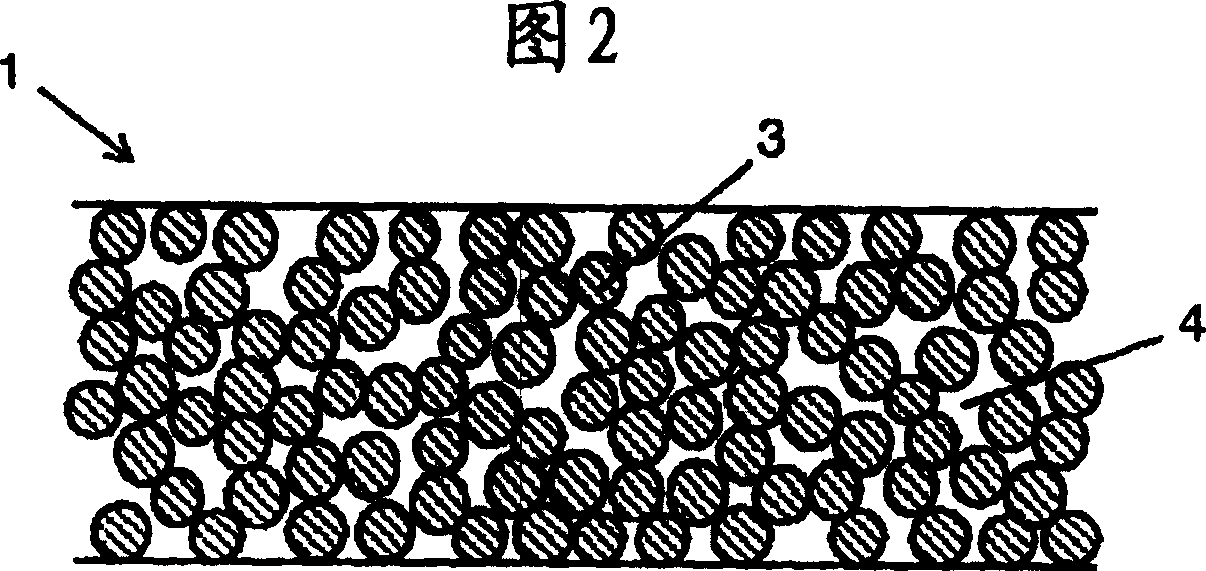

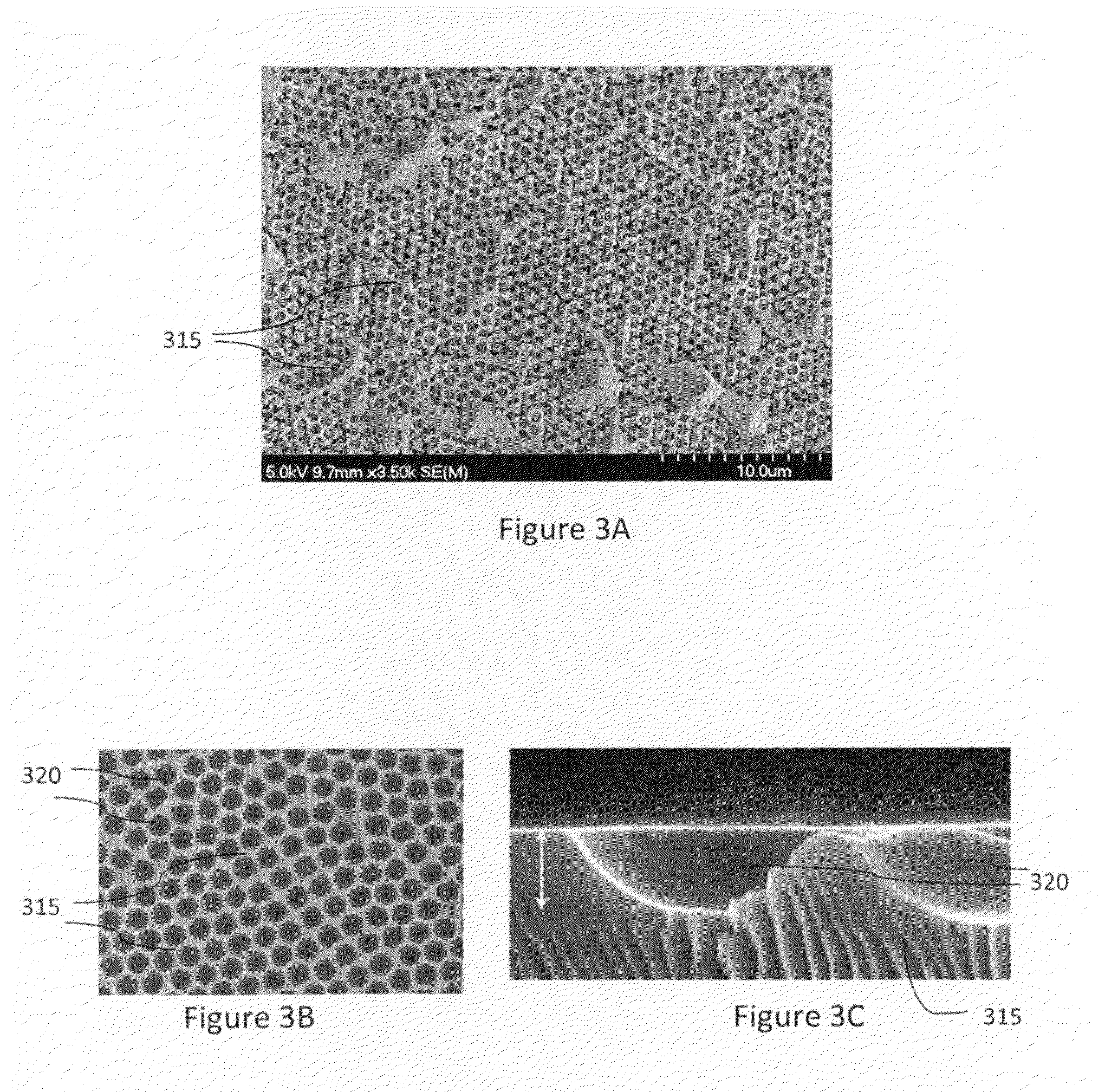

Porous device for optical and electronic applications and method of fabricating the porous device

ActiveUS20100065889A1Maintain electrical propertiesImprove efficiencyPowder deliveryLayered productsSingle crystal substrateSingle crystal

A porous device for optical and electronic applications comprises a single crystal substrate and a porous single crystal structure epitaxially disposed on the substrate, where the porous single crystal structure includes a three-dimensional arrangement of pores. The three-dimensional arrangement may also be a periodic arrangement. A method of fabricating such a device includes forming a scaffold comprising interconnected elements on a single crystal substrate, where the interconnected elements are separated by voids. A first material is grown epitaxially on the substrate and into the voids. The scaffold is then removed to obtain a porous single crystal structure epitaxially disposed on the substrate, where the single crystal structure comprises the first material and includes pores defined by the interconnected elements of the scaffold.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

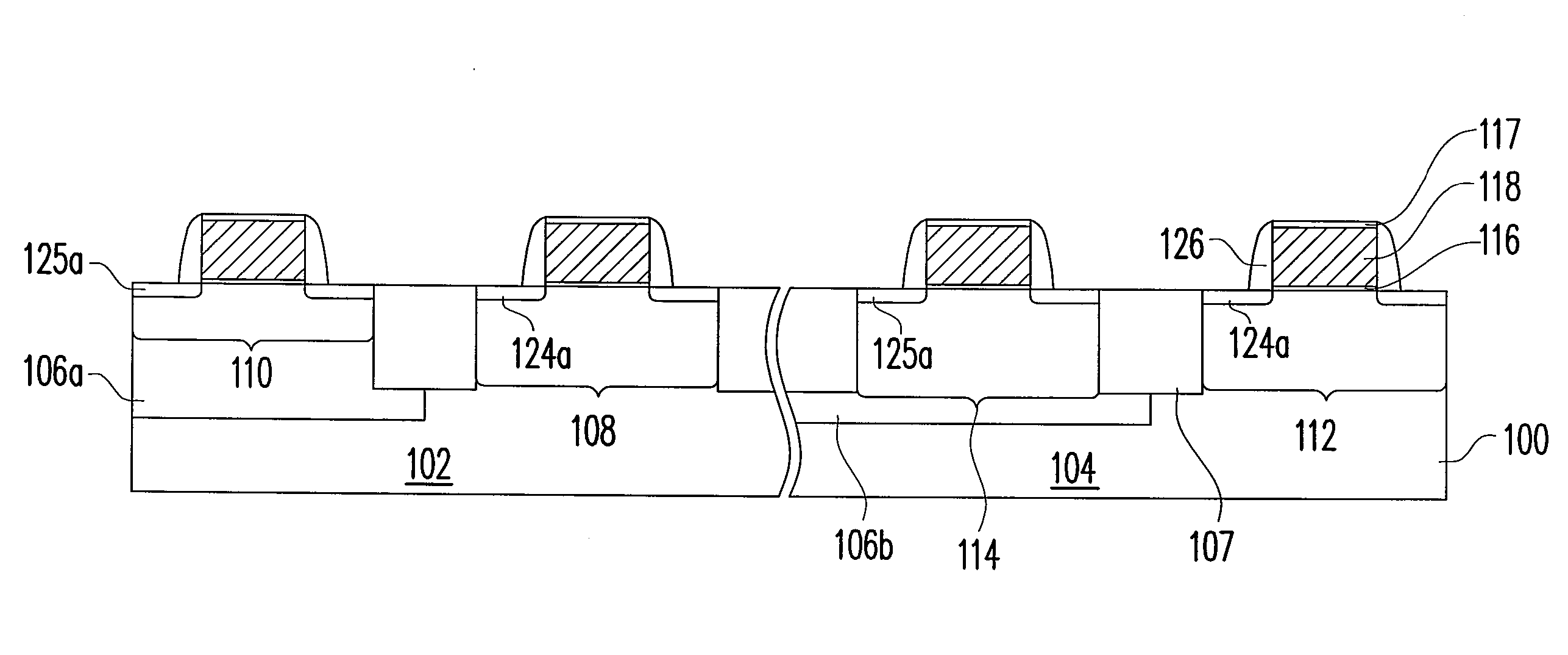

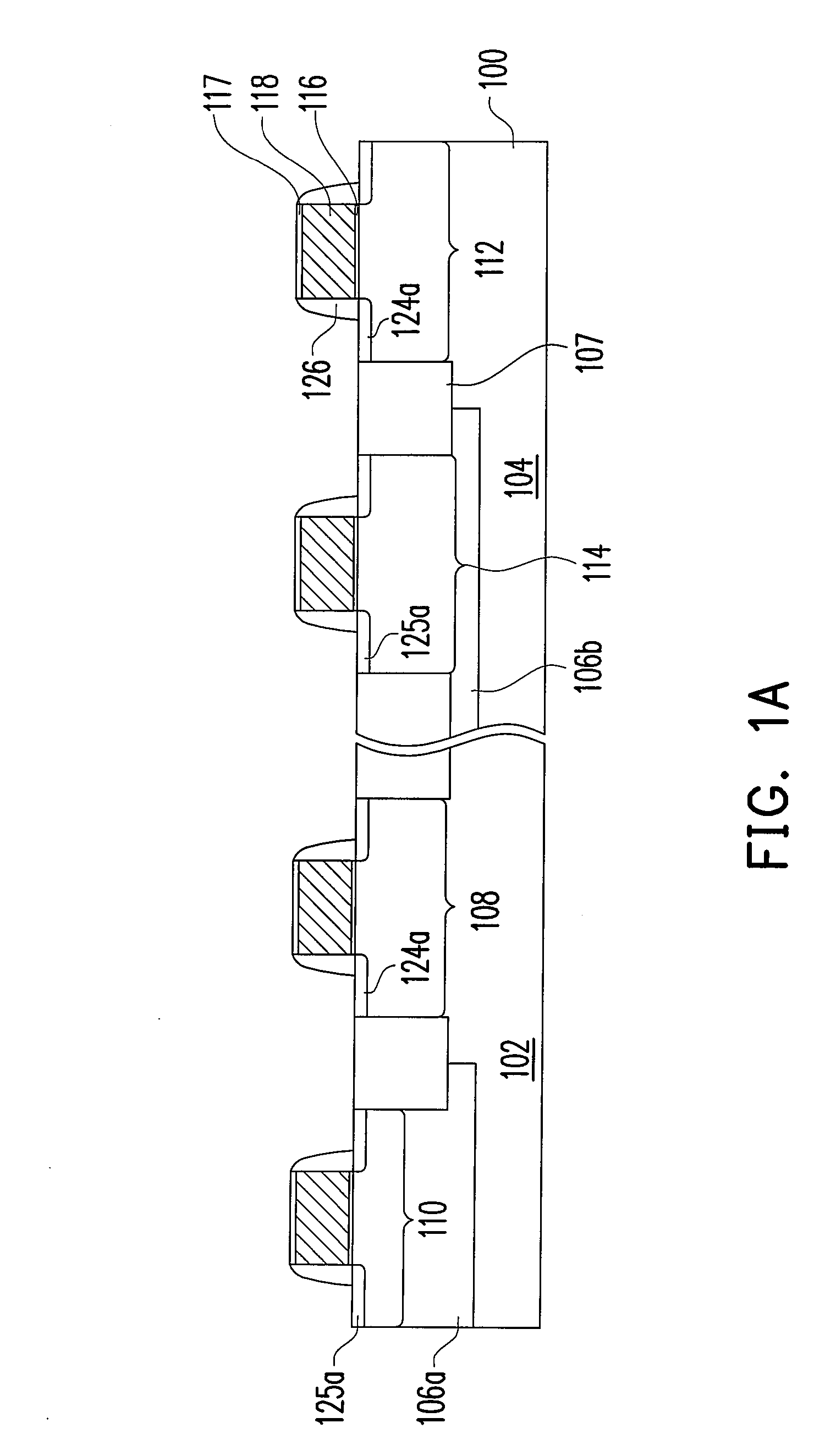

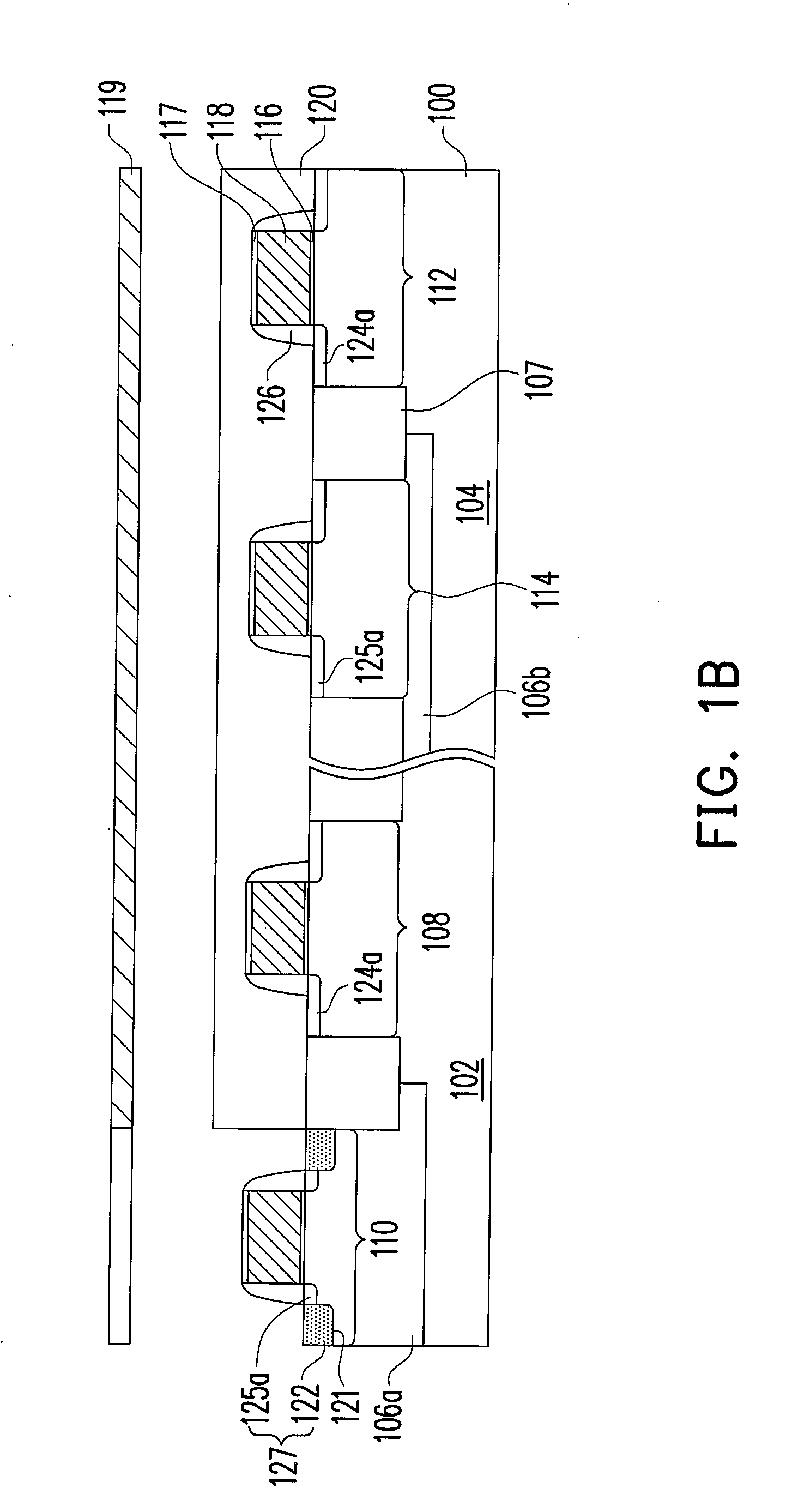

Semiconductor device and method of fabricating the same

InactiveUS20080237659A1Improve equipment efficiencyImprove efficiencyTransistorSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

A method of fabricating a semiconductor device is provided. Devices are formed on a core region and a non-core region in a substrate. A strain process is performed to the device on the core region but is not performed to the device on the non-core region.

Owner:UNITED MICROELECTRONICS CORP

Introduction-type roughening nitrogen polar surface gallium nitride based light-emitting diode and manufacturing method thereof

ActiveCN101807648AMaintain electrical propertiesMaintain Manufacturing YieldSemiconductor devicesNitrogenGallium nitride

The invention discloses an introduction-type roughening nitrogen polar surface gallium nitride based light-emitting diode and a manufacturing method thereof. Based on the chip structure of the conventional allium nitride based light-emitting diode, a nitrogen polar surface gallium nitride epitaxial layer with a roughened surface is introduced through diffusion bonding and substrate removal, thereby solving a series of problems and limitations in the existing epitaxial surface roughening technology by using a chemical wet method, improving the light extraction efficiency of the light-emitting diode, keeping the original electrical properties of a chip unchanged, and obtaining the manufacturing yield almost same as the conventional gallium nitride based light-emitting diode.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Preparation method of epitaxial wafer for FRD

InactiveCN105575772AThickness is easy to controlMaintain electrical parameter characteristics such as reverse voltageSemiconductor/solid-state device manufacturingDopantHydrogen

The invention discloses a preparation method of an epitaxial wafer for FRD, relating to the technical field of a method of depositing a semiconductor material on a substrate. The method comprises the following steps: growing an intrinsic layer on the upper surface of a silicon substrate; fixing the flow of a silicon source, reducing the flow of an injected dopant gradually and increasing the flow of diluted hydrogen gradually at the same time, so as to grow a buffer layer with gradually varying impurity concentration on the upper surface of the intrinsic layer; and growing an epitaxial layer on the buffer layer. According to the method, through controlling the flow, a controllable long-transition-area epitaxial layer with gradually varying epitaxial concentration is formed; therefore, the soft factor of a device can be improved and the original electric property of the device can be maintained.

Owner:HEBEI POSHING ELECTRONICS TECH

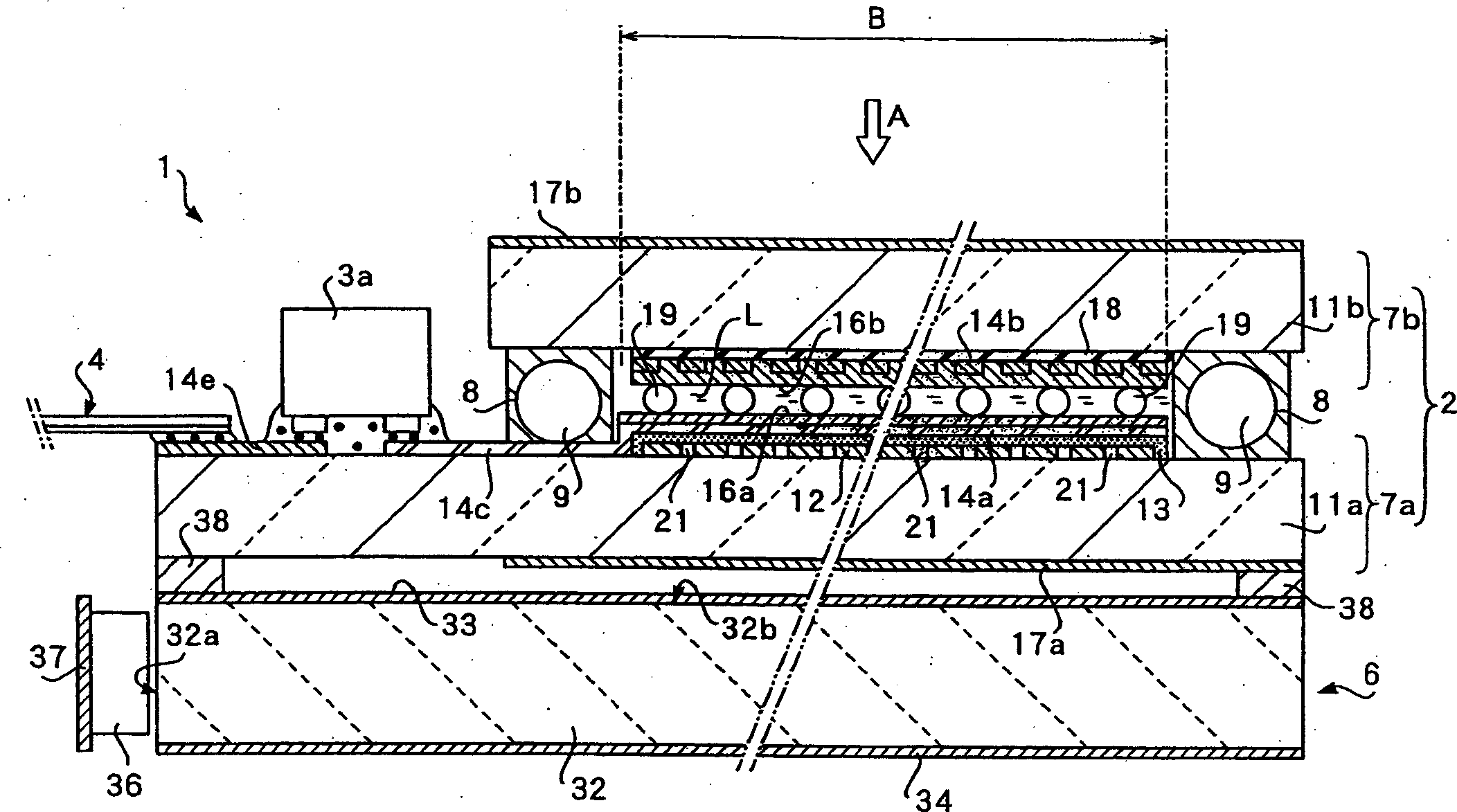

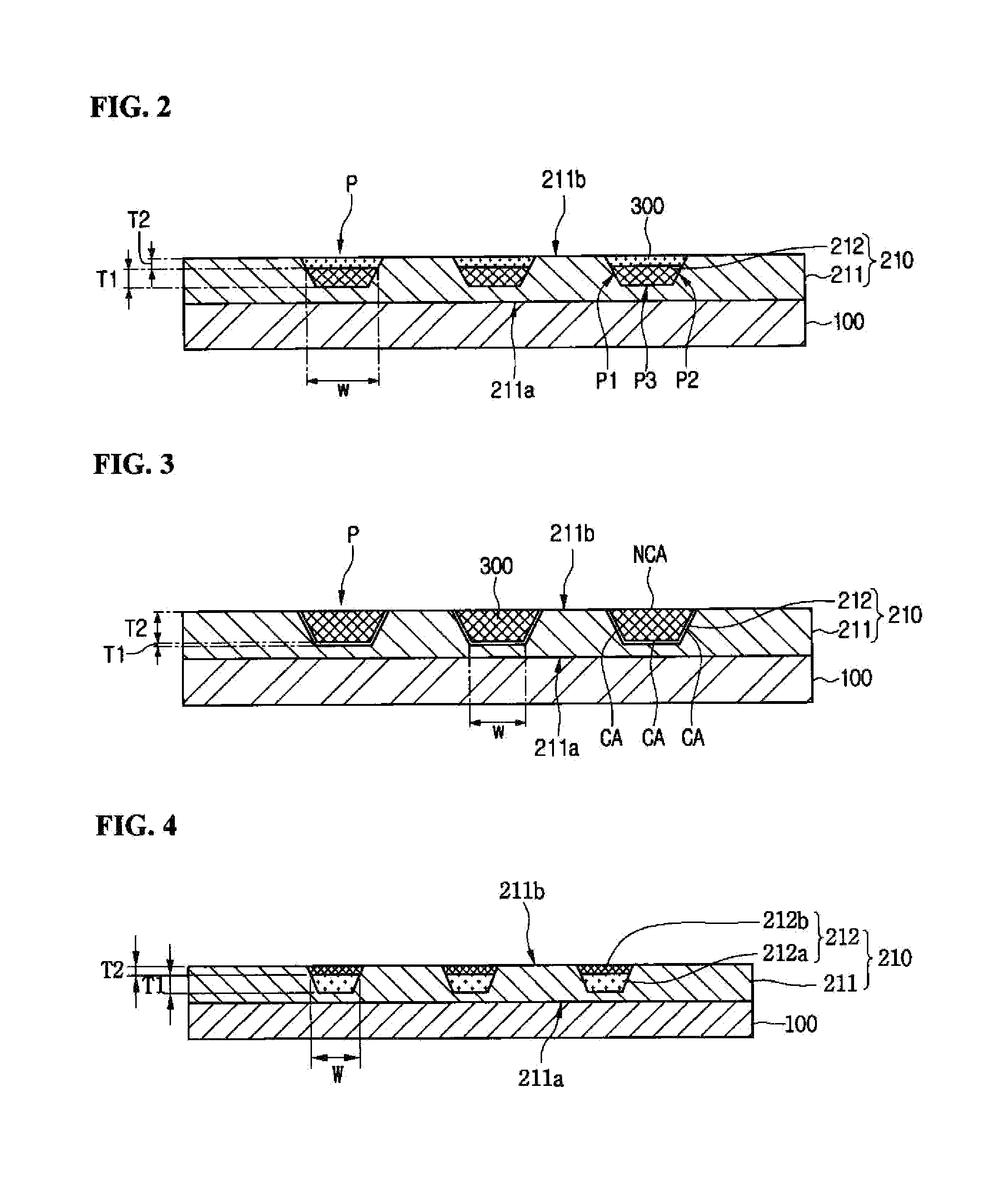

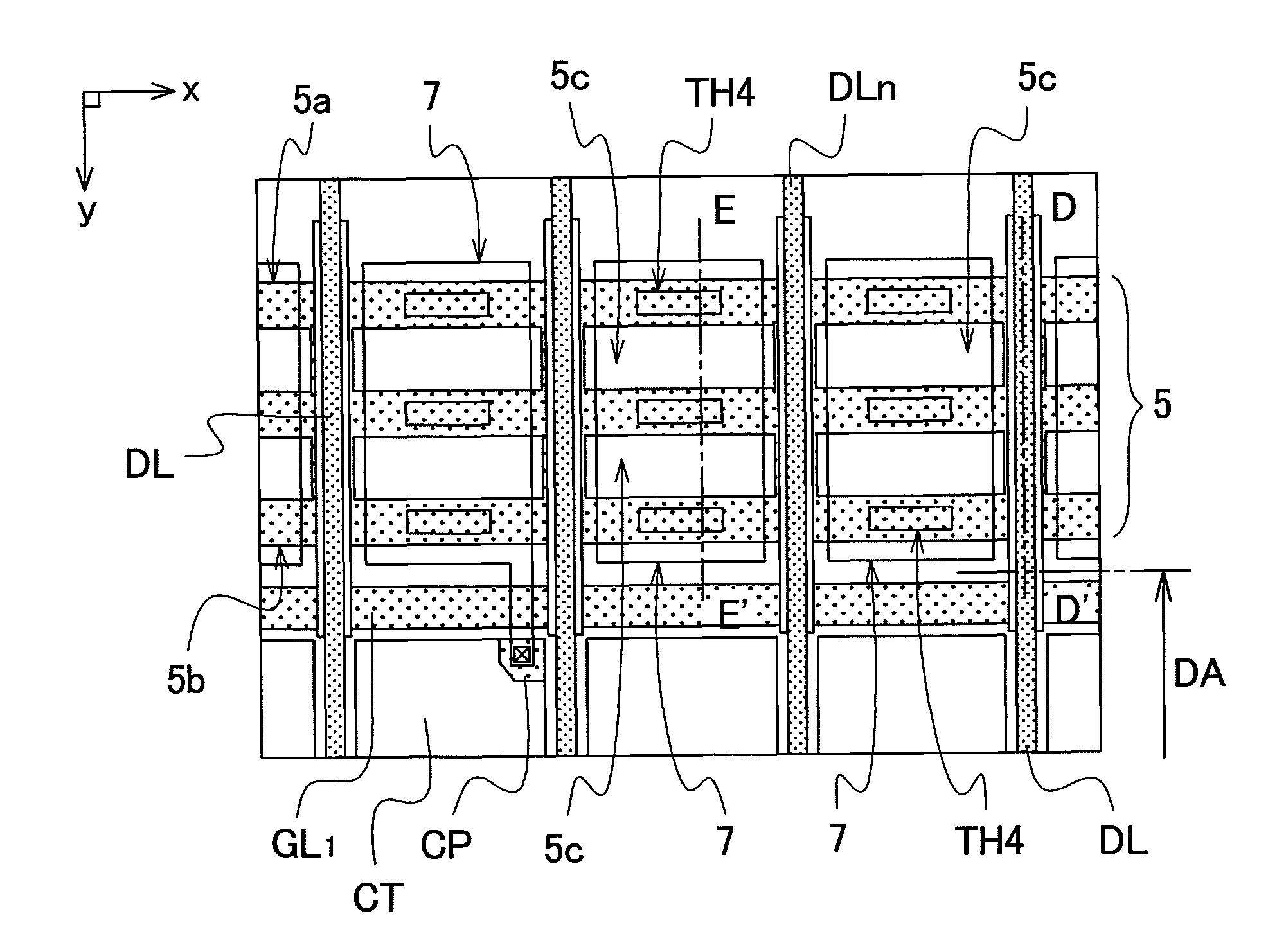

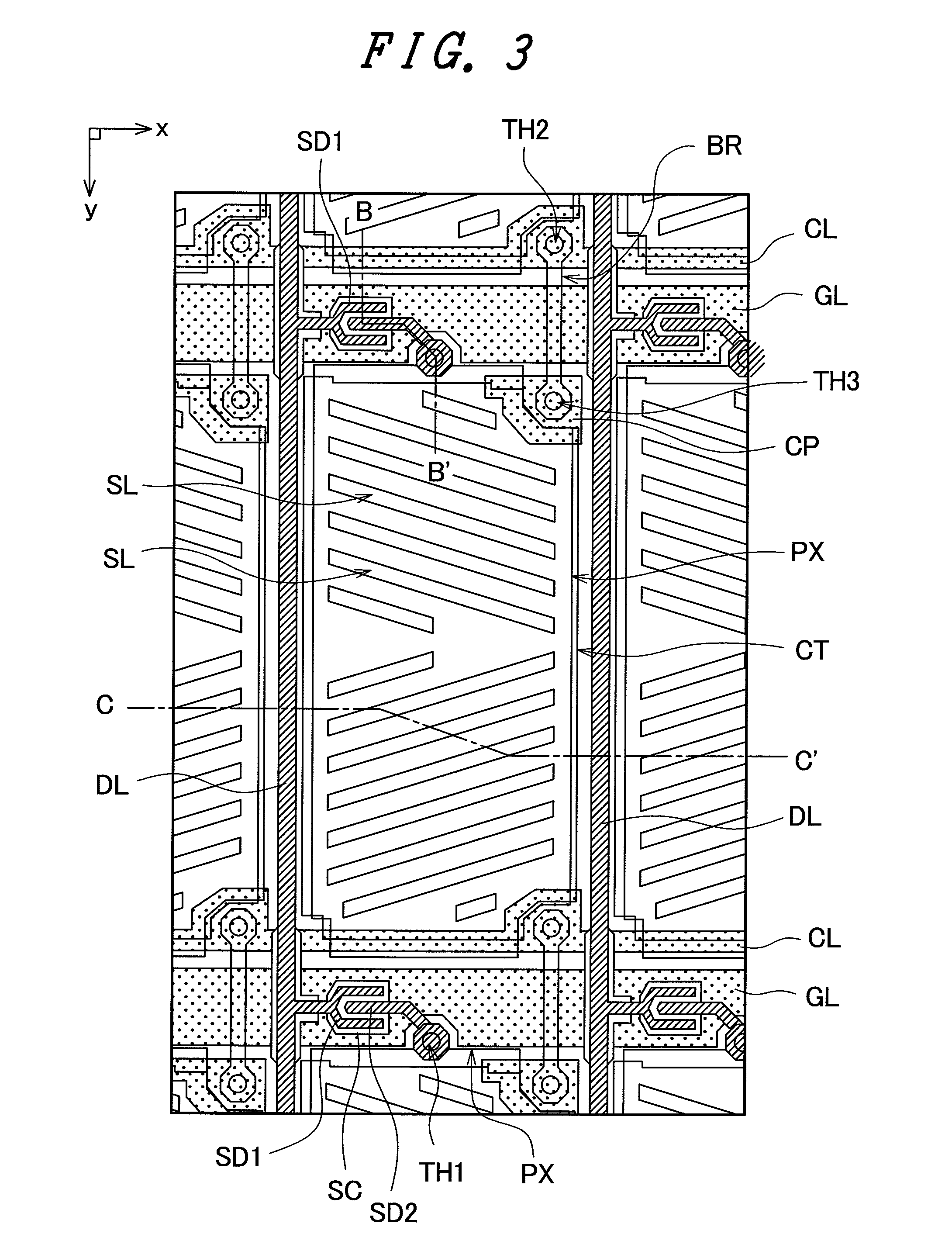

Liquid crystal display device

In a substrate of a liquid crystal display device which forms a bus line which three-dimensionally intersects scanning signal lines, video signal lines and an insulation layer thereon, the present invention facilitates repairs of short-circuiting between the respective signal lines and the bus line. A liquid crystal display device includes a liquid crystal panel which is constituted of a pair of substrates with liquid crystal sandwiched therebetween. Out of the pair of substrates, one substrate includes a bus line which is arranged outside a display region and is electrically connected to a first conductive layer arranged inside the display region, and a plurality of signal lines which three-dimensionally intersect the bus line by way of an insulation layer. The bus line includes opening portions outside intersecting regions where the bus line is overlapped to the signal lines as viewed in a plan view. The opening portions are arranged on both sides of each intersecting region.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

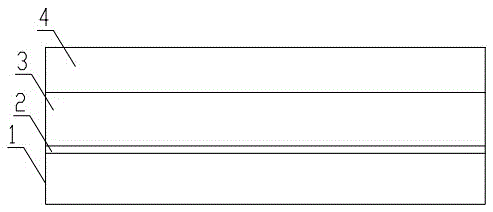

Method for coupling a graphene layer and a substrate and device comprising the graphene/substrate structure obtained

ActiveUS20140319655A1Avoid high temperature processingReduce quality problemsSemiconductor/solid-state device manufacturingSemiconductor characterisationCvd grapheneIsopropyl alcohol

The present disclosure regards a method for coupling a graphene layer to a substrate having at least one hydrophilic surface, the method comprising the steps of providing the substrate having at least one hydrophilic surface, depositing on the hydrophilic surface a layer of a solvent selected in the group constituted by acetone, ethyl lactate, isopropyl alcohol, methylethyl ketone and mixtures thereof and depositing on the solvent layer a graphene layer. It moreover regards an electronic device comprising the graphene / substrate structure obtained.

Owner:STMICROELECTRONICS INT NV

Stretchable electrical interconnect and method of making same

ActiveUS20130263351A1Maintain electrical propertiesLimited stretchabilityContact member manufacturingNon-insulated conductorsElectrically conductiveEngineering

An electrical interconnect including at least one electrically-conductive fibre configured to form a stretchable interlaced configuration.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Manufacturing method of gate pole structure with metal layer lateral surface part removed

ActiveCN1619776AWon't happenAvoid improper short circuitSemiconductor/solid-state device manufacturingSemiconductor devicesBit lineInsulation layer

A method for making gate structure contains providing a silicon substrate, forming conductive layer on silicon substrate, forming metal layer on conductive layer, forming the per-patterned first protective layer on metal layer wherein every gate pattern has exposed top and side surface, removing part of side surface to form first gate assembly, transferring the pattern of first gate assembly to metal layer to form the second gate assembly, on the substrate, the exposed of first and second gate assembly forming the second protective layer, transferring the first gate assembly and pattern of second gate assembly to conductive layer to form third gate assembly. Said invention ca avoid the improper short circuit between bit line metal layer and gate metal layer without generating cavity in insulation layer between gates.

Owner:NAN YA TECH

Wiring base plate, display device, semiconductor chip and electronic machine

InactiveCN1350201AMaintain display functionMaintain electrical propertiesSemiconductor/solid-state device detailsPrinted circuit aspectsMetallic materialsSemiconductor chip

Owner:BOE TECH GRP CO LTD

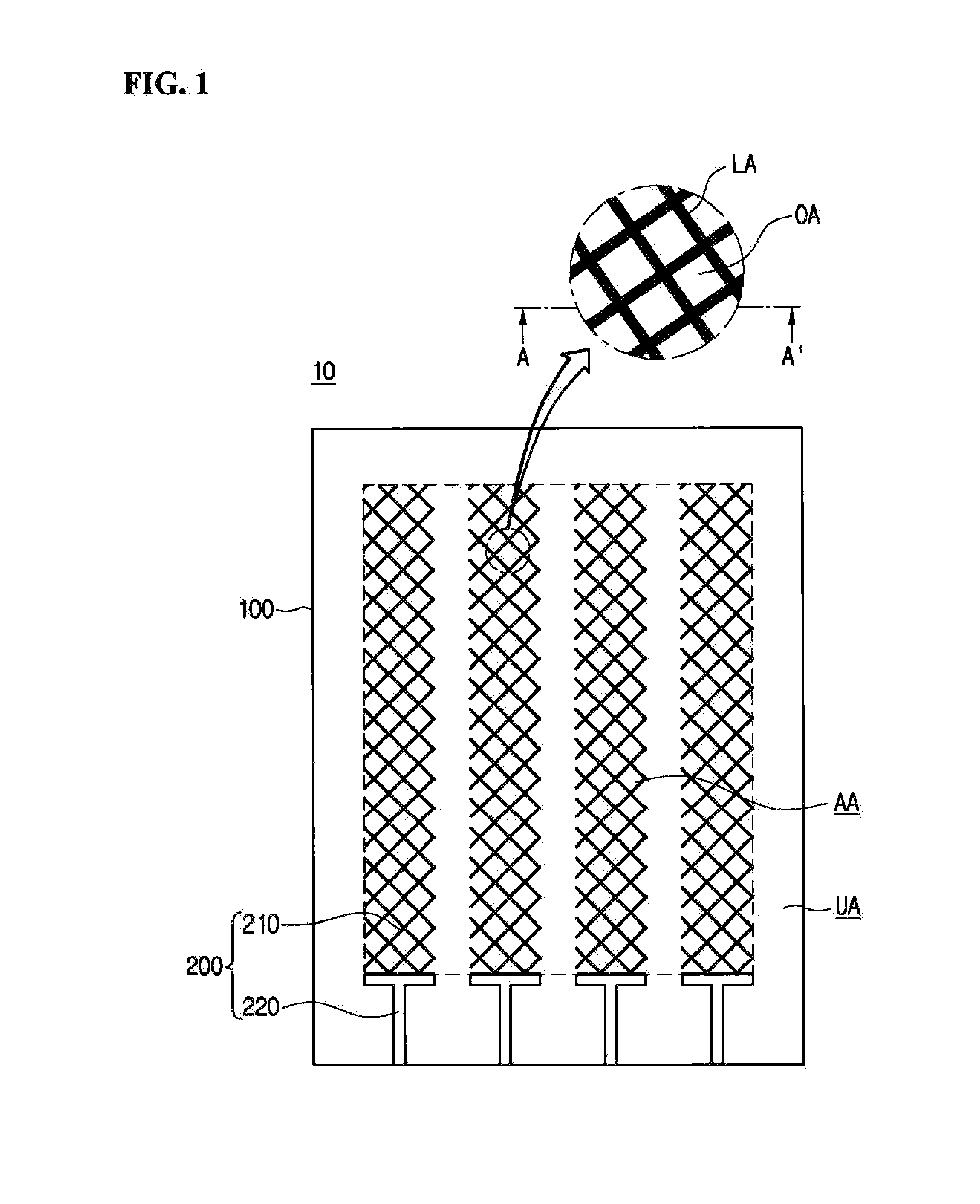

Touch window

ActiveUS20160004340A1Electrode thickness can be decreasedReduce thicknessInput/output processes for data processingOptoelectronicsElectrode

Owner:LG INNOTEK CO LTD

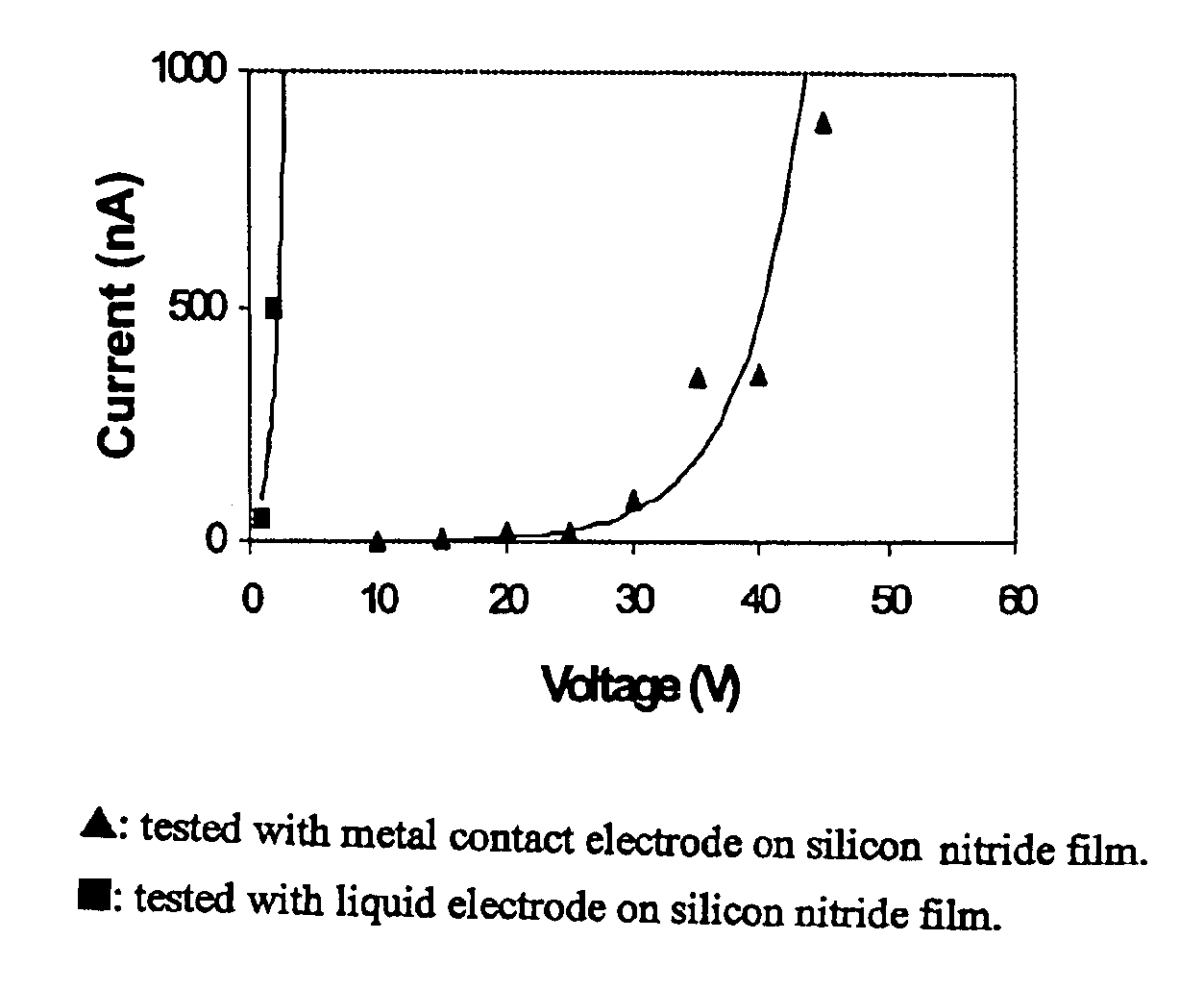

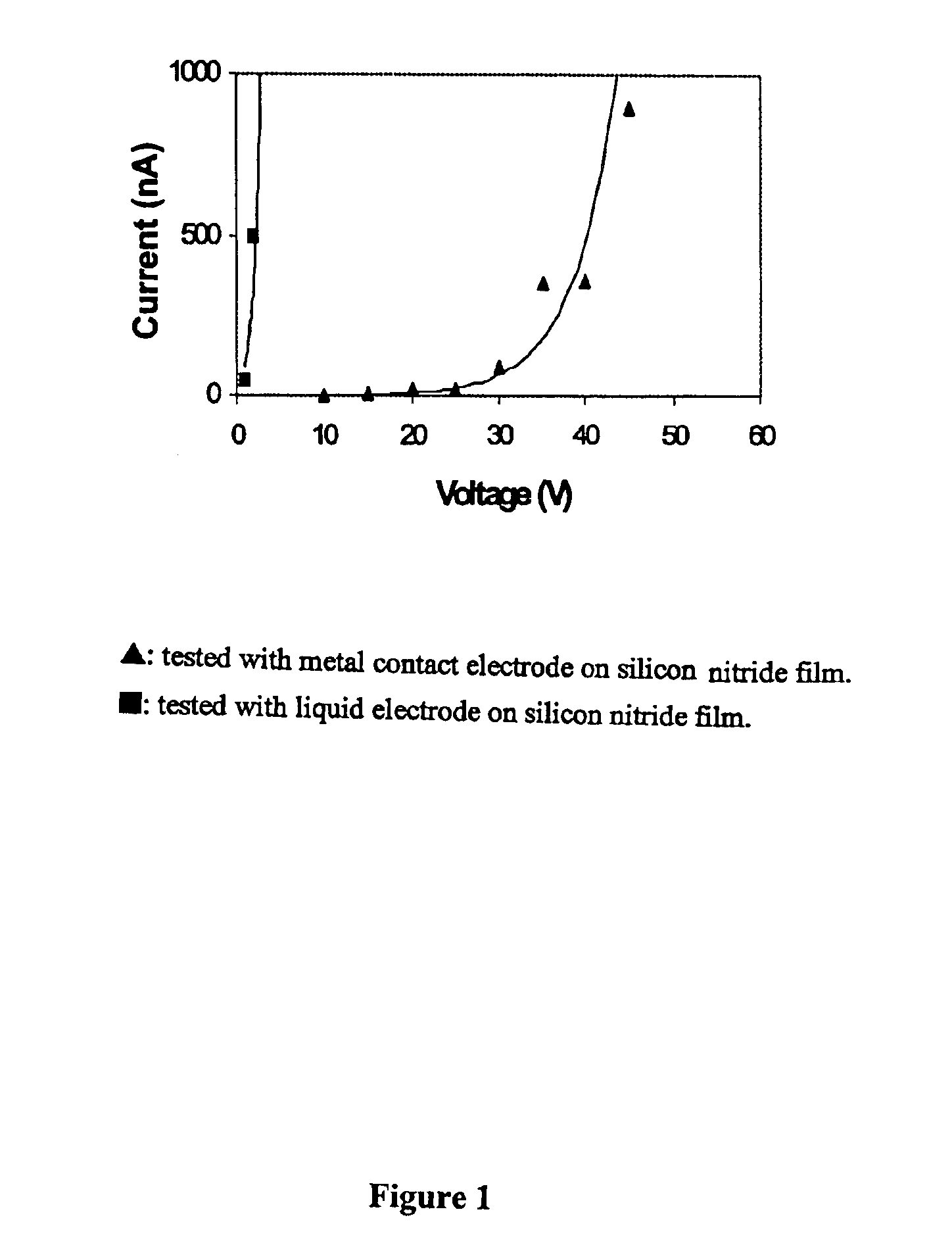

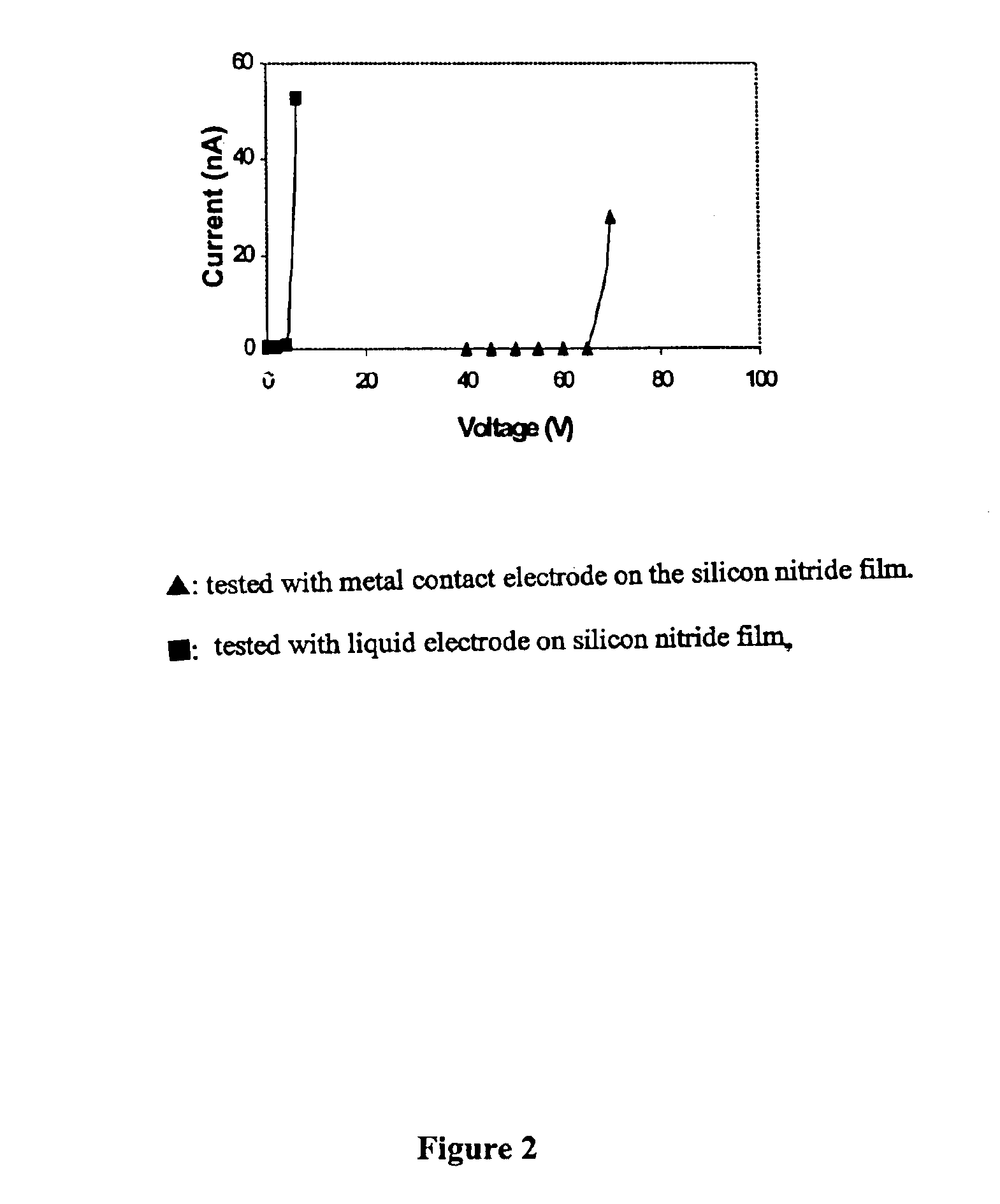

Dielectric film

InactiveUS6891155B2Apparent advantageMaintain electrical propertiesParticle separator tubesFixed microstructural devicesDielectricMoisture

A dielectric film is provided which includes a base layer and a capping layer, preferably silicon oxynitride, wherein the film is an effective moisture and ion barrier when disposed between a conductive substrate and a liquid having an electrical potential different than the electrical potential of the substrate.

Owner:ADVION

Preparation method of modified aluminum hypophosphite

InactiveCN104448948BTightly boundImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment physical treatmentAluminium chloridePhosphate

The invention belongs to the technical field of preparation of a flame retardant, and particularly relates to a preparation method of modified aluminium hypophosphite. The preparation method comprises the following steps: dissolving sodium hypophosphite into water to prepare sodium hypophosphite solution, adding phosphate, and stirring at high speed and dissolving; dissolving aluminum chloride and polyethylene glycol into water to prepare aluminum chloride solution; stirring at 10-30 DEG C, normal pressure and high speed, adding the aluminum chloride solution into the sodium hypophosphite solution, slowly stirring and reacting to obtain turbid solution containing aluminum hypophosphite; pumping the turbid solution into a centrifugal machine for centrifuging, washing with water, and drying to obtain the modified aluminium hypophosphite. The prepared modified aluminium hypophosphite can be excellently dispersed into a high-molecular material, the mechanical performance and flame-retardant property of the high-molecular material can be obviously improved, and the electrical property of resin can be maintained; the preparation is simple in technology, temperature rise and regulation of pH value of the reaction solution are not needed, the yield can achieve up to 98.0%, and the modified aluminium hypophosphite is pollution-free and environmental friendly.

Owner:SHANDONG CHUANJUN CHEM

Liquid crystal display device having bus line with opening portions overlapped by conductive films

ActiveUS7800727B2Prevent short-circuitingLarge bus widthNon-linear opticsElectricityLiquid-crystal display

In a substrate of a liquid crystal display device which forms a bus line which three-dimensionally intersects scanning signal lines, video signal lines and an insulation layer thereon, the present invention facilitates repairs of short-circuiting between the respective signal lines and the bus line. A liquid crystal display device includes a liquid crystal panel which is constituted of a pair of substrates with liquid crystal sandwiched therebetween. Out of the pair of substrates, one substrate includes a bus line which is arranged outside a display region and is electrically connected to a first conductive layer arranged inside the display region, and a plurality of signal lines which three-dimensionally intersect the bus line by way of an insulation layer. The bus line includes opening portions outside intersecting regions where the bus line is overlapped to the signal lines as viewed in a plan view. The opening portions are arranged on both sides of each intersecting region.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

Display panel

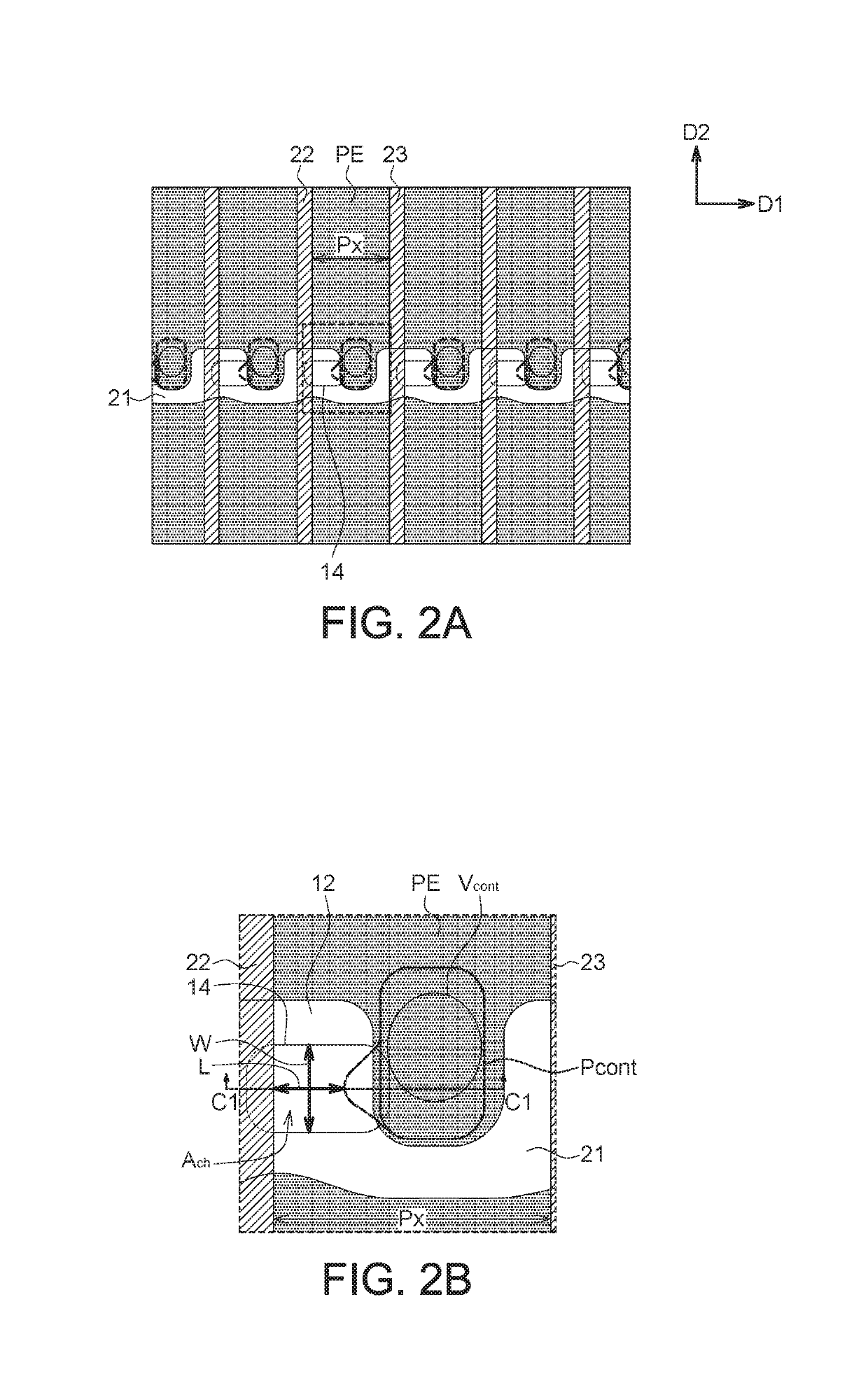

ActiveUS10304965B2Small sizeMaintain electrical propertiesTransistorSolid-state devicesContact padEngineering

Owner:INNOLUX CORP

General halogen-free and flame-retardant low-smoke cable material for sheath and insulation materials and preparation method of cable material

InactiveCN108727676AImprove flame retardant performanceGuaranteed mechanical propertiesPlastic/resin/waxes insulatorsProcedure AgentsHydromagnesite

The invention provides a general halogen-free and flame-retardant low-smoke cable material for sheath and insulation materials. The general halogen-free and flame-retardant low-smoke cable material comprises the following components in parts by weight: 5-10 parts of polyethylene, 10-30 parts of an ethylene-vinyl acetate copolymer, 3-15 parts of an ethylene-octene copolymer, 32-70 parts of a main flame retardant, 0-20 parts of an auxiliary flame retardant, 1-4 parts of a surface activating agent and 2-8 parts of a processing aid. A preparation method comprises the following steps: respectivelyadding the main flame retardant, the auxiliary flame retardant and the surface activating agent into a high-speed mixer; activating at 80-140 DEG C for 5-40 min to obtain a highly active flame-retardant filler; and mixing and granulating the highly active flame-retardant filler with other components in mixing equipment to obtain the halogen-free and flame-retardant low-smoke cable material. The preparation method provided by the invention has the advantages that hydromagnesite is used as the main flame retardant to improve flame retardancy of the cable material and maintain mechanical properties, electrical properties and processing properties of the cable material at the same time on the premise of high filling, i.e., high cost performance.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC

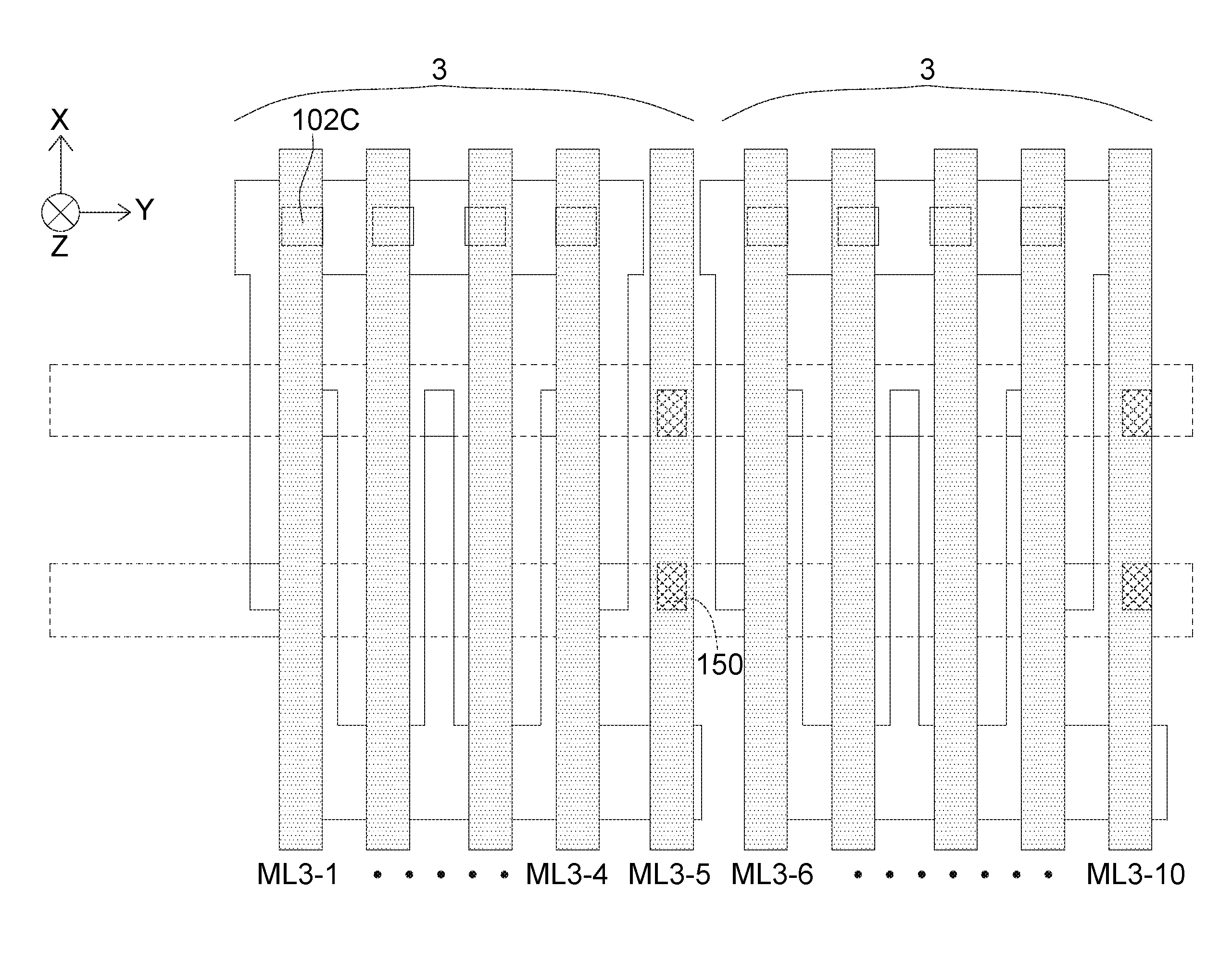

Semiconductor structure

ActiveUS9368507B2Reduce areaMaintain electrical propertiesSolid-state devicesRead-only memoriesBit lineSemiconductor structure

A semiconductor device comprises a plurality of stacking blocks and a plurality of conductive lines. Each stacking blocks comprises two opposite finger VG structures. Each finger VG structure includes a staircase structure and a plurality of bit line stacks. The staircase structure is perpendicular to the bit line stacks, and the bit line stacks of the two opposite finger VG structures are arranged alternately. The conductive lines is disposed over the stacking blocks at interval. The direction of the conductive lines is parallel to a direction of the bit line stacks. The conductive lines include a plurality of bit lines and a plurality of ground lines, and each stacking block includes at least one ground line.

Owner:MACRONIX INT CO LTD

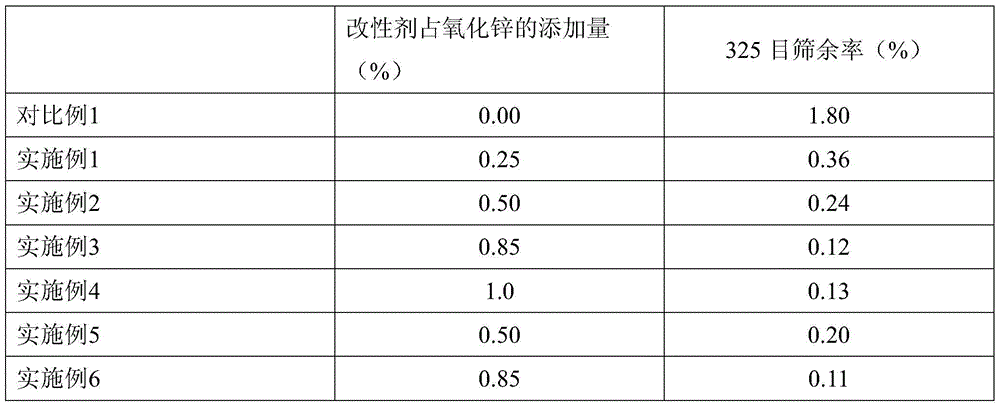

Modified zinc borate and preparation method thereof

InactiveCN103937031BTightly boundImprove mechanical propertiesPigment treatment with organosilicon compoundsDispersityTalc / Zinc Oxide

The invention belongs to the field of flame-retardant materials, and particularly relates to modified zinc borate prepared by taking dimethyl polysiloxane and a silane coupling agent as modifying agents and boric acid and zinc oxide as raw materials. According to the invention, a very good synergic effect can be achieved by simultaneously using the dimethyl polysiloxane and the silane coupling agent as the modifying agents, and the modified zinc borate and a high-molecular compound are more closely combined together, so that various mechanical properties of a material are further enhanced. The modified zinc borate disclosed by the invention is reduced in surface potential and improved in lipophilicity, enhanced in the dispersive capacity in a high-molecular material through surface modification; and the product is enhanced in fineness, high in dispersity and compatibility after the surface is subjected to modification treatment. The invention also provides a preparation method of the modified zinc borate. The preparation method disclosed by the invention is simple in process, achieves the productivity as high as more than 98.0%, easily obtains the raw material and is pollution-free and environment-friendly.

Owner:SHANDONG CHUANJUN CHEM

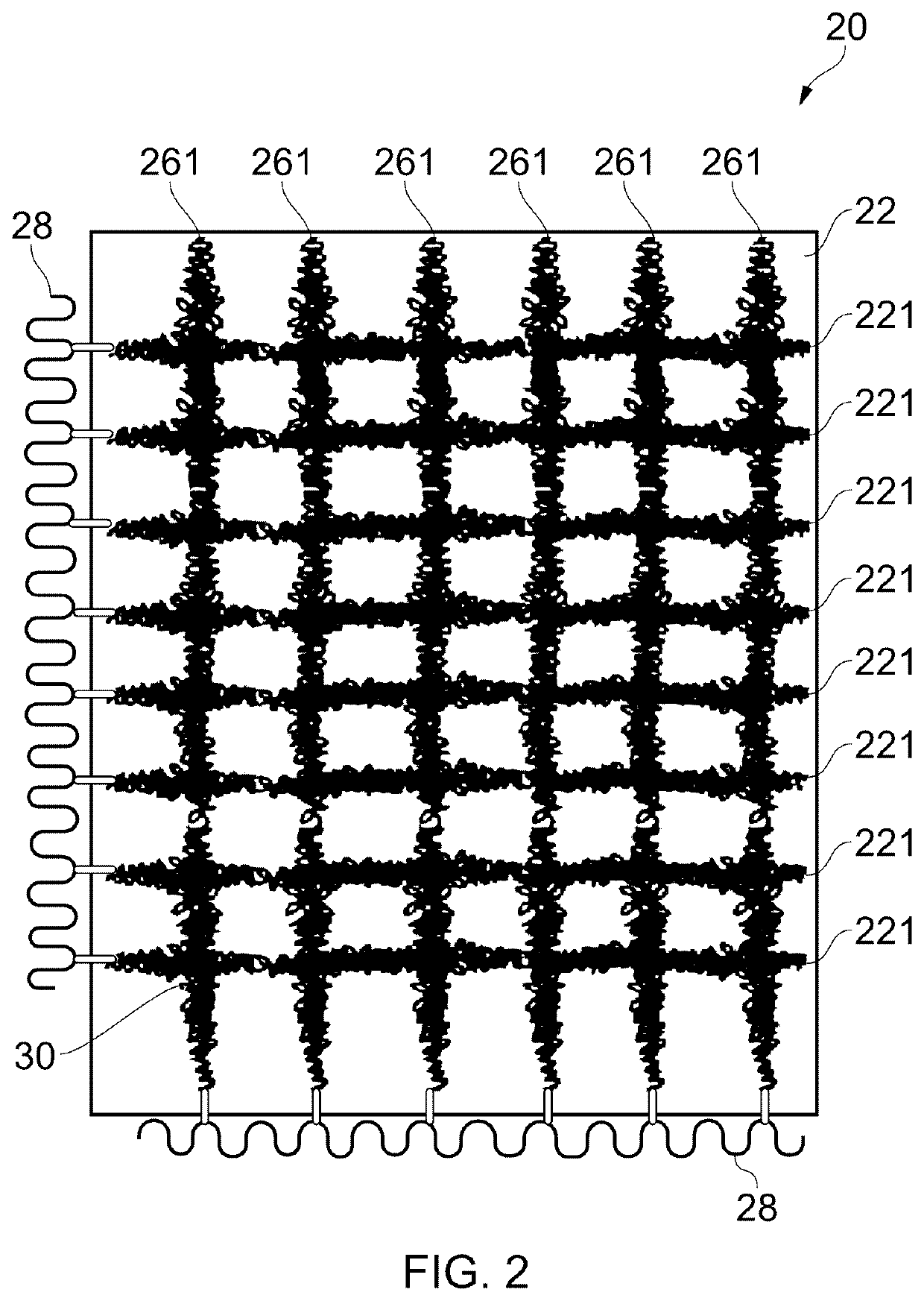

A stretchable bidirectional capacitive pressure sensor and method of use

PendingUS20220090982A1High resolutionMaintain electrical propertiesAerodynamic testingVolume/mass flow measurementCapacitive pressure sensorElastomer

A stretchable bidirectional capacitive pressure sensor (20) comprising: a first elastomeric sheet (22) made from a dielectric material, with a series of conductor lines (221) located on or in the first elastomeric sheet; a second elastomeric sheet (28) made from a dielectric material, with a series of conductor lines (261) located on or in the second elastomeric sheet; wherein the conductor lines of the first elastomeric sheet are substantially orthogonal to the conductor lines of the second elastomeric sheet; a microstructure comprising a plurality of elastomeric pillars (241) made from a dielectric material, disposed between the elastomeric sheets; wherein the microstructure is bonded to both the first and second elastomeric sheets so that the bidirectional sensor can register positive and negative pressure by the movement of the first and second elastomeric sheets. A further aspect of the invention discloses a method of collecting data related to fluid flow over an object by using a two-dimensional capacitive pressure sensor.

Owner:HYVE DYNAMICS HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com