Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Lower tapping temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting method capable of increasing scrap ratio of steel per ton

The invention discloses a smelting method capable of increasing scrap ratio of steel per ton. Adding position and mode of steel scrap are optimized, and a LF furnace refining station light treatment process is used to perform temperature supplementing, alloying, desulfurization and impurity removal on molten steel. The method specifically includes steps: a, blast furnace ironmaking process: addingsteel scrap into an iron tap channel of a blast furnace; b, mixer furnace process: in the process when a mixer furnace discharges iron, adding steel scrap into a molten iron flow impact area of a molten iron ladle; c, converter steelmaking process: adding steel scrap into a converter; d, furnace rear argon blowing process: adding steel scrap into a furnace rear argon blowing ladle; e, LF refiningprocess: controlling treatment period of a LF finery to be shorter than or equal to molten steel pouring period, bottom-blowing argon while weakly stirring in the process of refining, and controllingalkalinity of refining slag to be within a range of 1.5-1.7, wherein adding amount of a diffusion deoxidizing agent is 0.5-1.0kg / ton of steel. By the smelting method, product quality is improved, carbon emission of steel per ton is reduced, and the objectives of improving enterprise operation benefit and social benefit are achieved.

Owner:TANGSHAN DELONG STEEL CO LTD

Method for producing thick-wall large-caliber acid-corrosion-resistant pipeline steel with high-phosphorus molten iron

ActiveCN107557683AReduce heart segregationReduce acid corrosion channelsManufacturing convertersSmelting processSulfur

The invention discloses a method for producing thick-walled and large-diameter acid-resistant and corrosion-resistant pipeline steel by using high-phosphorus molten iron. For Grade B-X70M acid-resistant and corrosion-resistant pipeline steels with a thickness of 35mm-40mm and a width of 3500mm-5000mm, the smelting process of the present invention is BOF→RH→LF→CCM→billet heating→rolling, using ultra-low carbon, ultra-low phosphorus and sulfur, The design of low manganese content reduces the segregation of the slab center, reduces the formation of MnS inclusions, eliminates the accumulation of carbides in the core, reduces the grain size of the rolled plate through TMCP rolling, eliminates or reduces the band structure, and ensures the acid resistance of the product. Corrosion performance, so as to achieve acid and corrosion resistant pipeline steel matrix to meet the acid and corrosion resistance.

Owner:NANJING IRON & STEEL CO LTD

High-silicon-molybdenum ductile iron material and preparation method thereof

The invention discloses a high-silicon-molybdenum ductile iron material and a preparation method thereof. The high-silicon-molybdenum ductile iron material comprises the following components in percentage by weight: 2.90 to 3.35 percent of C, 4.40 to 4.80 percent of Si, 0.50 to 0.75 percent of Mo, 0.30 to 0.50 percentage of Cr, 0.20 to 0.45 percent of V, 0.10 to 0.30 percent of Mn, 0.04 to 0.07 percent of Mg, less than or equal to 0.07 percent of P, less than or equal to 0.02 percent of S, and the balance of Fe. For the high-silicon-molybdenum ductile iron material, the tensile strength is more than or equal to 710 MPa, the yield strength is more than or equal to 500 MPa, the extensibility is more than or equal to 10 percent, and the hardness is 230 to 265 HBW5 / 750. The high-silicon-molybdenum ductile iron material also contains a trace amount of Sn and Sb. The high-silicon-molybdenum ductile iron material eliminates fragmental graphite and graphite deterioration layers, ensures the spheroidization grades of the parts with different wall thicknesses, and the defects of microscopic shrinkage and the like are overcome.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

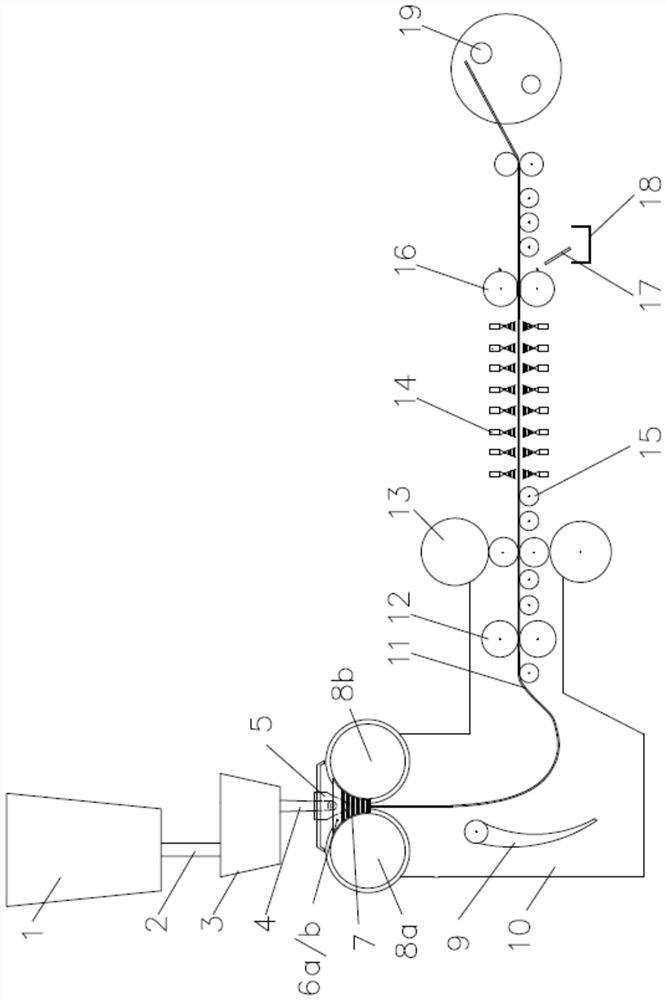

Efficient continuous water atomizing process for producing steel powder

ActiveCN104249157ARealize continuous and uninterrupted operationUniform physical and chemical propertiesProduction lineThermal insulation

The invention relates to an efficient continuous water atomizing process for producing steel powder. The process includes: continuously injecting molten steel into an intermediate thermal insulation heating device, continuously adjusting components and temperatures, continuously providing temperature signals to a control system by a temperature measuring device during atomizing, and controlling tundish temperature to be at 1550-1580 DEG C; by a weighing system located on the tank support base of the large tank of the intermediate thermal insulation heating device. continuously displaying the weight of the residual molten steel in the large tank to guarantee that the weight of the residual molten steel in the large tank is not less than 5 tons. Compared with the prior art, the efficient continuous water atomizing process has the advantages that two magnetic separation drying production lines are used, two working high-pressure pump and a backup high-pressure pump are equipped, and continuous steel powder water atomizing is achieved; atomizing temperature is fed back and controlled through real-time temperature measuring, and the physical and chemical performance of base powder is allowed to be even and consistent; reasonable nozzle size, draining hole diameter and atomizing pressure are used, tapping temperature is lowered, atomizing efficiency is increased, and base powder quality is increased.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

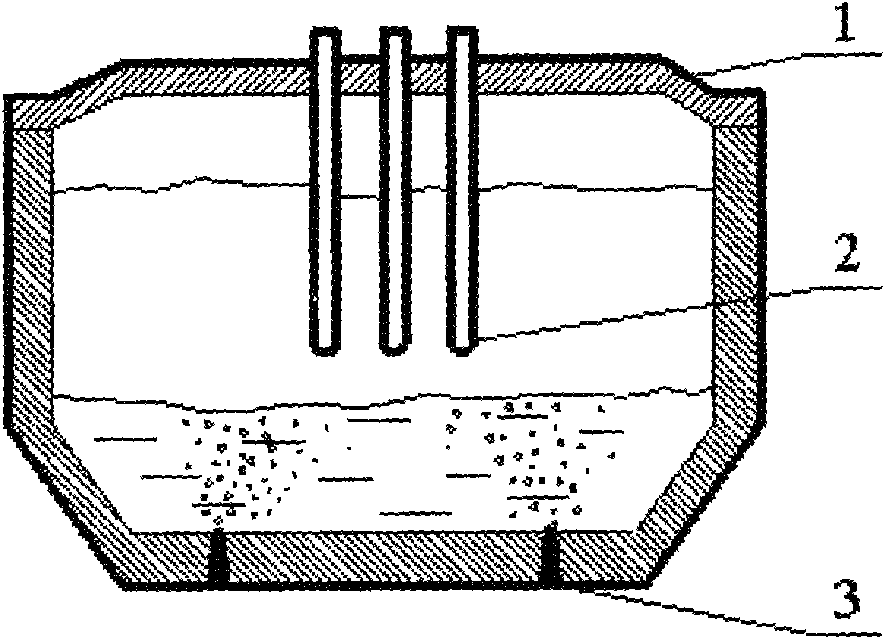

Bottom dusting electrical furnace steelmaking process

InactiveCN101787412ASmall particle sizeQuick responseProcess efficiency improvementElectric furnaceMelting tankSteelmaking

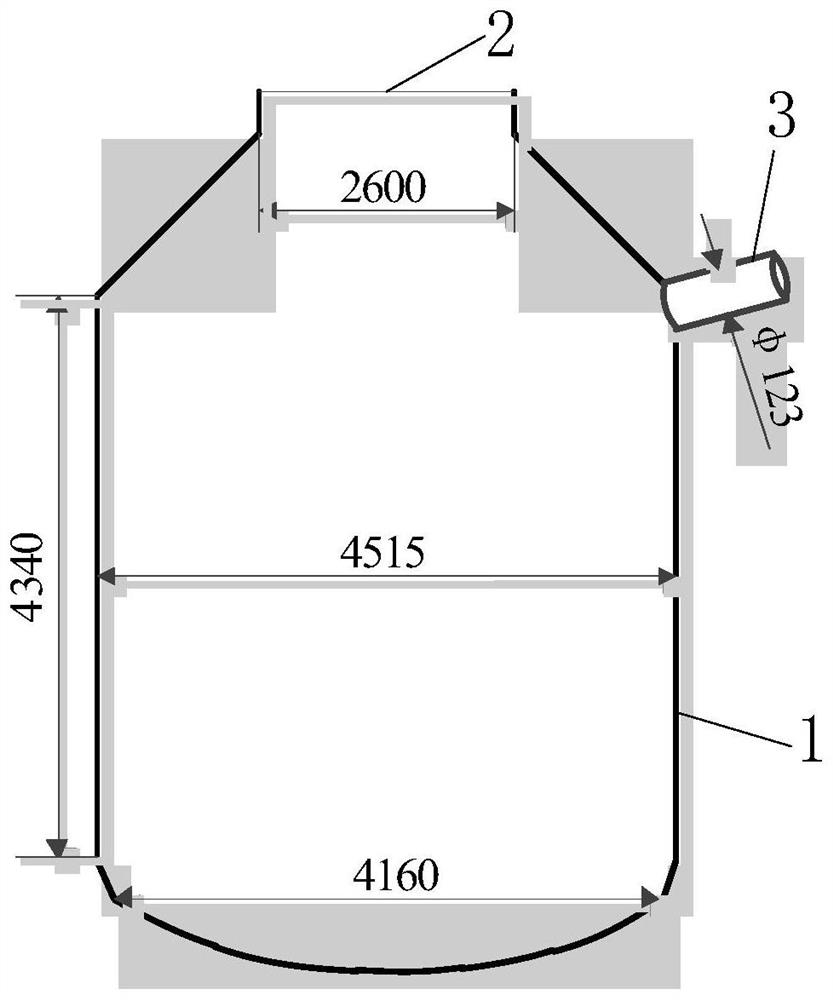

The invention relates to a bottom dusting electrical furnace steelmaking process. The technical scheme includes that the bottom of an electrical furnace 1 is provided with 1-6 bottom guns 3 based on electrical furnace steelmaking method with precharing system, current-carrying gas is adopted to blow powder into a metal pool by 1-6 bottom guns 3, and blowing amount of powder is 20-100wt% of addition when the powder is added into the furnace; wherein, the bottom guns 3 are arranged symmetrically or asymmetrically 0-0.7 time of furnace bottom radius away from the furnace bottom center; the bottom gun 3 is in contact or non-contact structure; the current-carrying gas is one of Ar, N2, natural gas, O2 and CO2; the powder is one or more than one of ground quick lime, limestone powder, ferric oxide powder, concentrate fines, carbon dust, dolomite powder, flousper powder, calcium carbide powder and alloy powder; powder granularity is 0.01-0.10mm; blowing technological parameters include that pressure is 0.3-1.2MPa, gas supply flow is 0.1-1.0Nm3 / t steel and powder gas ratio is 4-10. The invention has the characteristics that stirring effect is enhanced, metal material yield is improved and residue material utilization ratio is improved, duration of heating is shortened and steel quality is improved.

Owner:WUHAN UNIV OF SCI & TECH

Converter less-slag smelting method

ActiveCN112646944ALow oxygenCutting costsManufacturing convertersProcess efficiency improvementSmelting processHeat balance

The invention relates to a converter less-slag smelting method. The converter less-slag smelting method uniformly adopts a less-slag single-slag mode under the conditions of high iron consumption or low iron consumption and complex molten iron silicon change. The converter less-slag smelting method comprises the following process flows of: finishing tapping, remaining slags, adjusting the slags, splashing the slags, adding scrap steel, mixing molten iron, conducting calculation, conducting blowing, controlling an end point and tapping. In the smelting process, the lance position and the oxygen supply intensity are controlled by referring to the CO value; the end oxidizability is effectively controlled through heat balance accurate calculation; the molten steel oxidizability is reduced through process low lance position control; the alloying cost is effectively reduced; and meanwhile, the final slag oxidizability is reduced; the slag splashing furnace protection effect is promoted; and the furnace condition maintenance cost is effectively reduced.

Owner:扬州圣莱特冶金科技有限公司

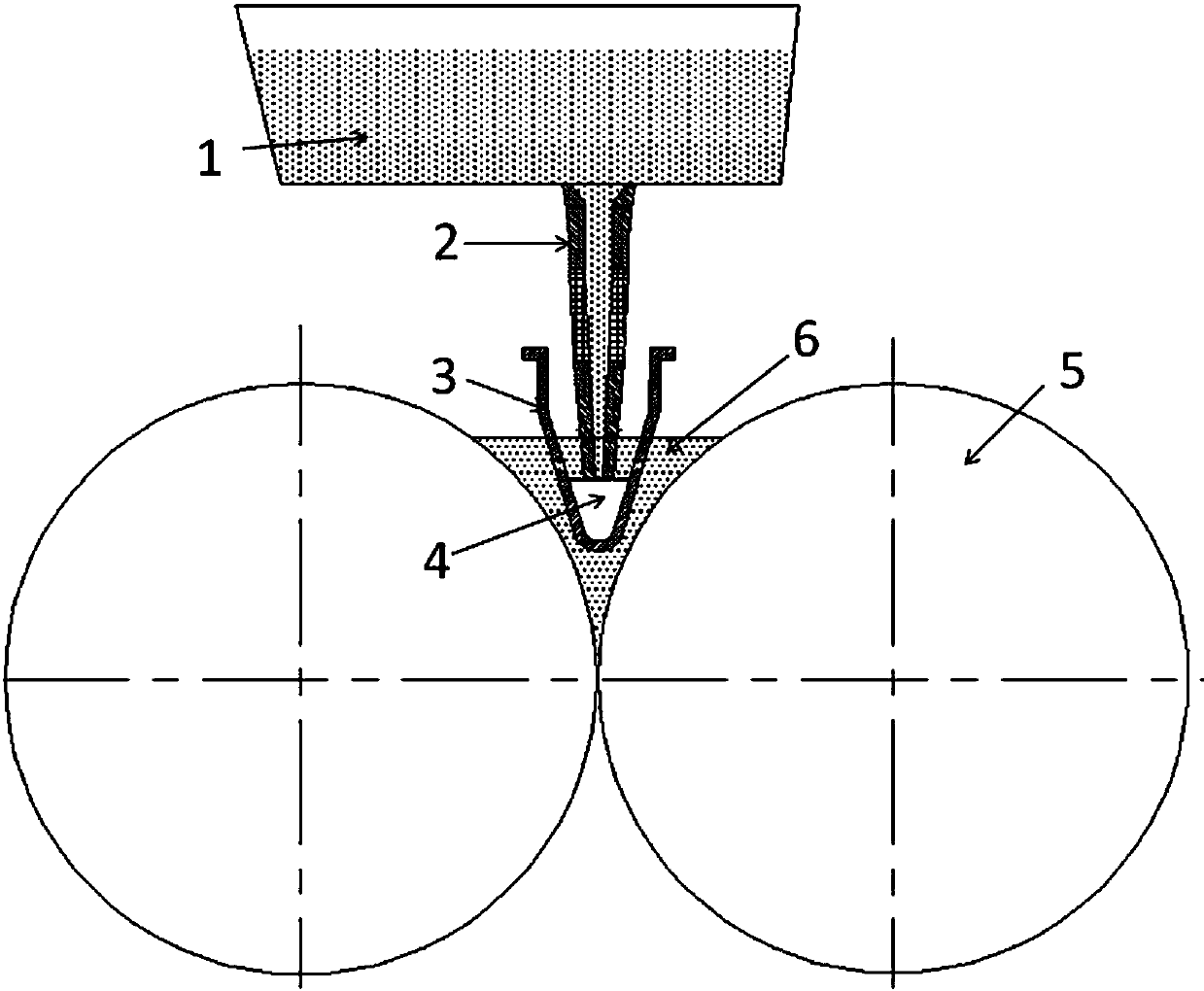

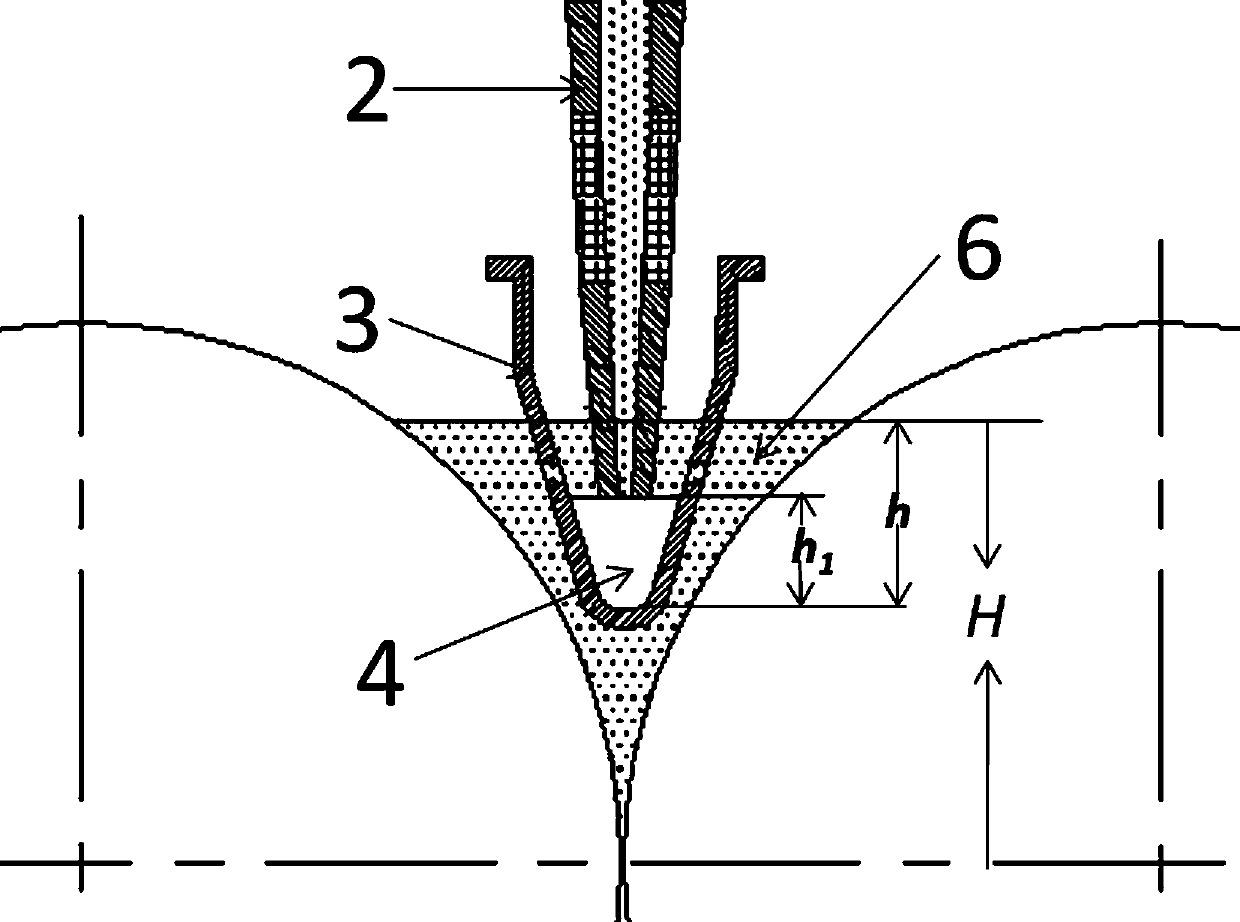

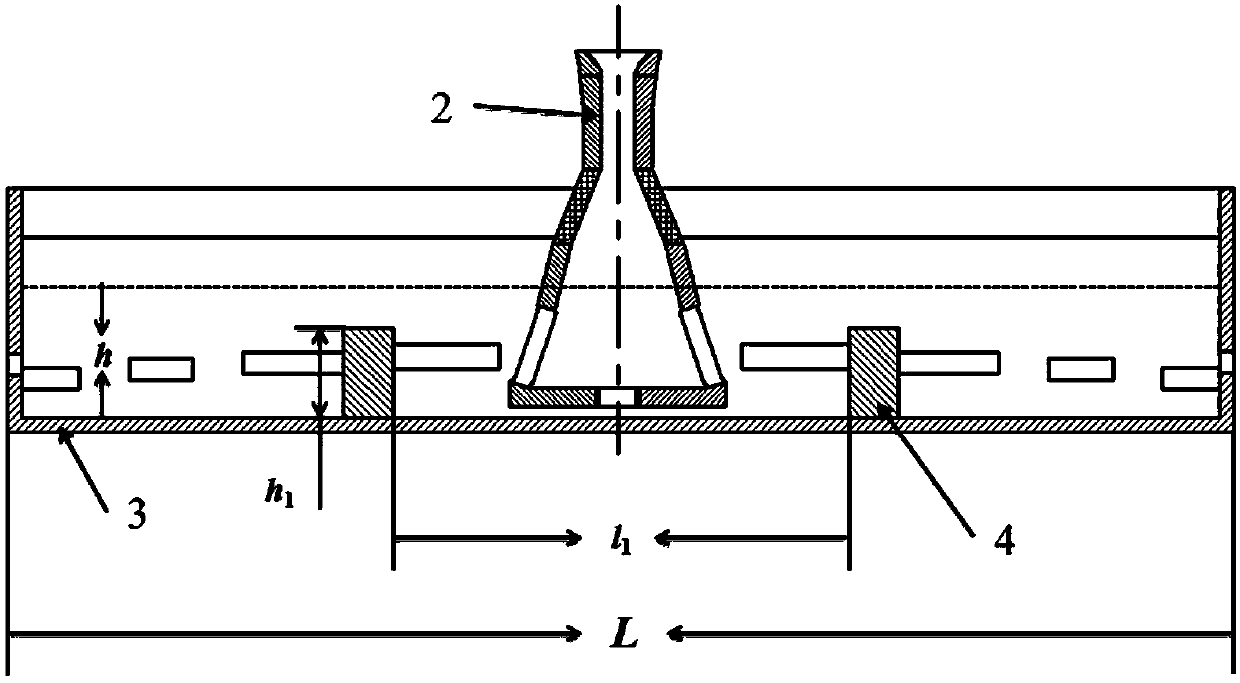

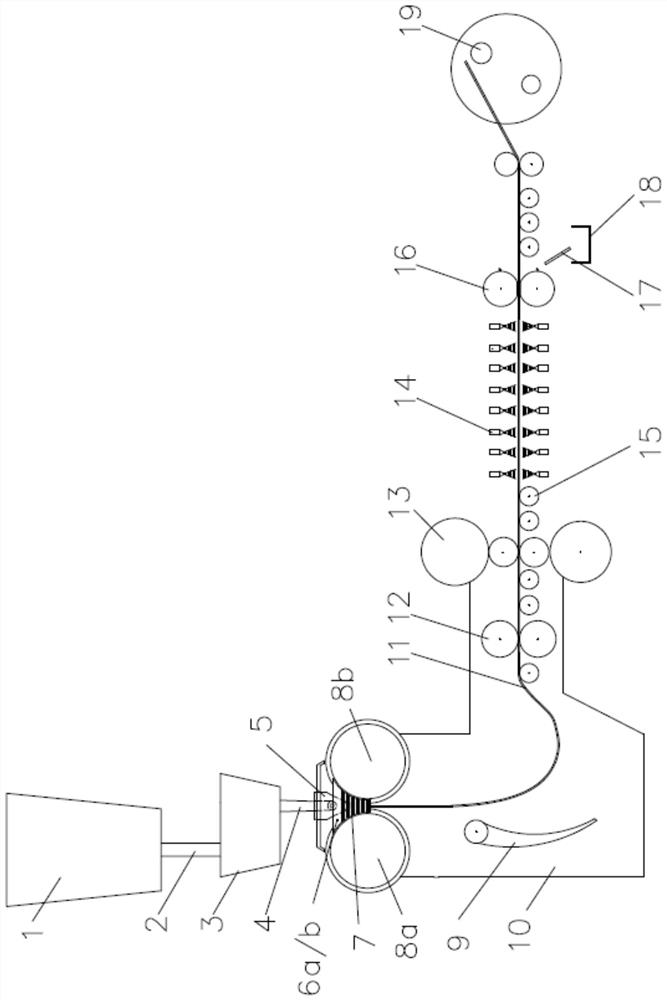

Casting system used for twin-roll thin strip continuous casting and use method thereof

The invention relates to a casting system used for twin-roll thin strip continuous casting and a use method thereof, and belongs to the technical field of thin strip continuous casting. The system comprises a submerged flow distribution water gap and a flow distributor, wherein the submerged flow distribution water gap consists of an inflow section, a transition section and an outflow section; the outflow section is divided into a contraction section and an expansion section from top to bottom; and the expansion section is in a fan-shaped and wedge-shaped flat shape and is provided with steel outlets. A use method comprises the steps that the submerged flow distribution water gap and the flow distributor are arranged under a tundish; liquid steel flows into the submerged flow distribution water gap, enters the flow distributor, and enters the gap between two casting rolls from flow distribution holes in the flow distributor; and the two casting rolls are started to move in opposite directions, the liquid level of a molten bath is kept to be higher than the upper edge of each steel outlet and each flow distribution hole, and the liquid steel is formed into thin strip steel after being cast-rolled by the casting rolls. Two times of flow distribution are realized for the liquid steel by the fan-shaped and wedge-shaped flat expansion section, the multi-hole flow distributor and flow guide dams of the multi-hole flow distributor, the fluctuation of the liquid steel level is reduced, and the smooth going of a cast rolling process and the quality of thin strips are guaranteed.

Owner:NORTHEASTERN UNIV

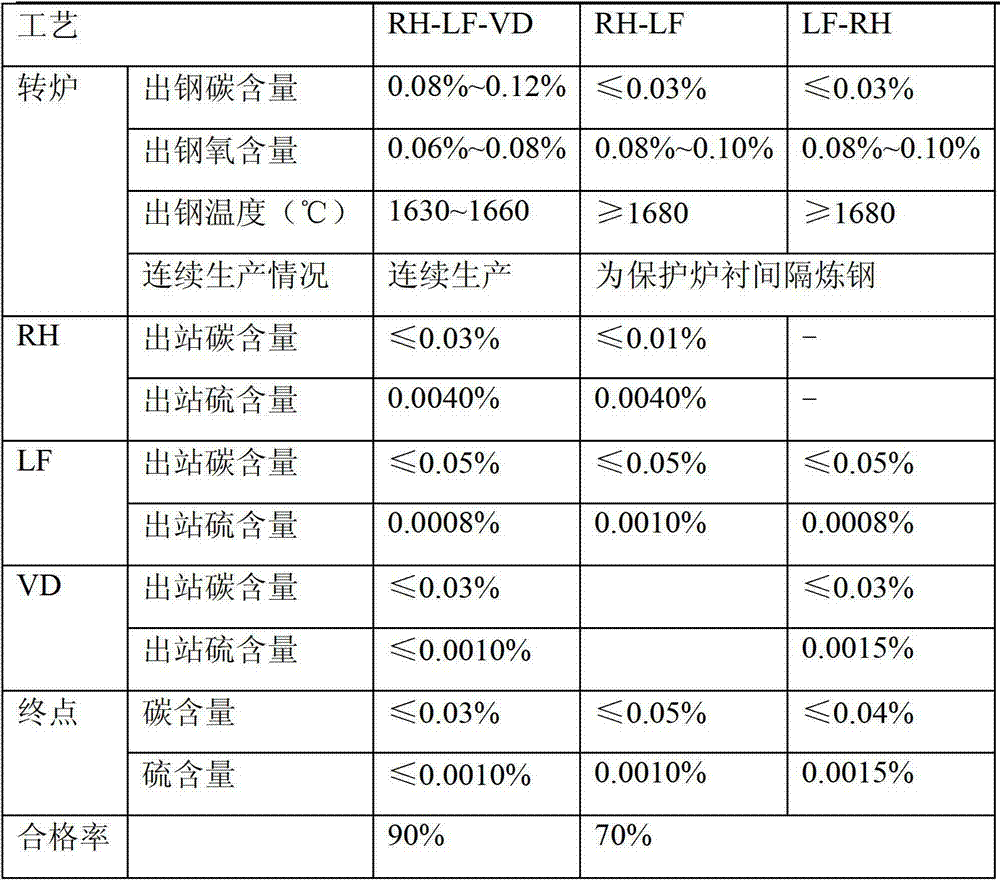

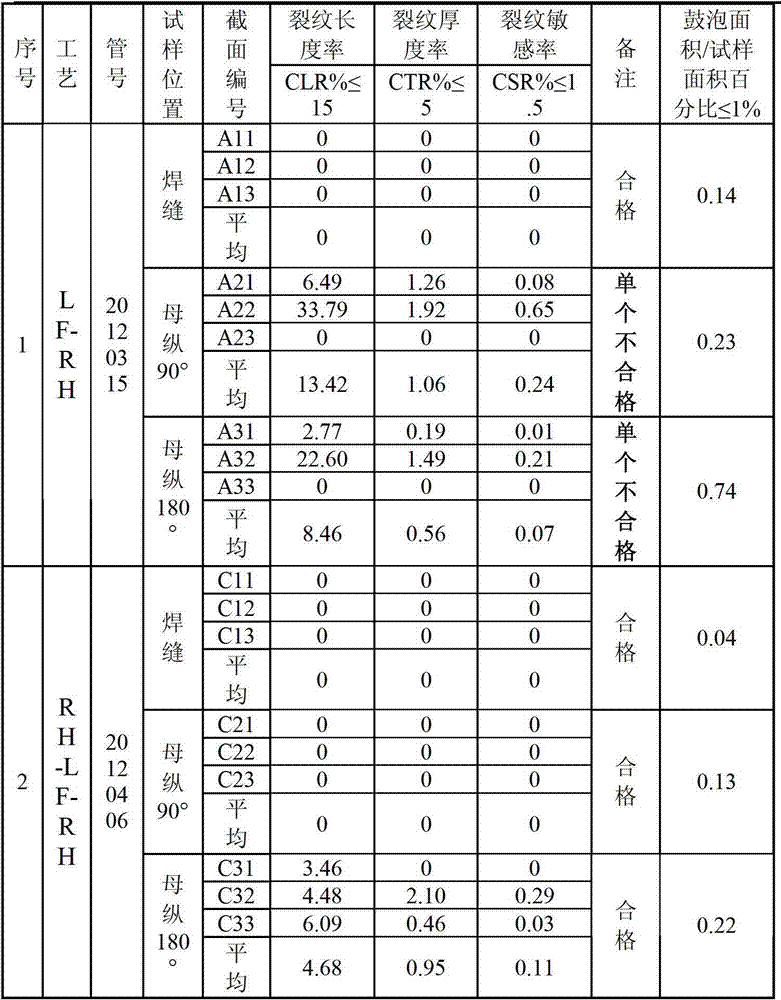

Process for producing anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining

InactiveCN102719614AReduce production burdenReduce non-metallic inclusion contentManufacturing convertersHydrogenStress corrosion cracking

The invention discloses a process for producing an anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining. In the process, the composition of molten steel is controlled by converter smelting and RH-LF-RH refining process, so as to produce a low-carbon low-sulfur anti-acid (hydrogen-induced cracking HIC and stress corrosion cracking SCC resistant) pipeline steel. The specific flow is as follows: pre-desulphuzation of molten steel - converter smelting-primary RH vacuum refining - LF refining desulphuzation - secondary RH vacuum refining - continuous casting. By the secondary RH vacuum refining process, the decarburization burden of the converter and the oxidability of the molten steel can be reduced, and the adverse effect caused by recarburization in the LF refining process can be eliminated; furthermore, the use of a strong deoxidizer is reduced, the production is stabilized, and the composition of the molten steel is ensured to be controlled within a production target stably to meet the control requirements of the anti-acid pipeline steel on the low-carbon low-sulfur and high-purity composition. The carbon content of the finished steel produced by the process of the invention can be stably controlled to be 0.03% to 0.04%, and the sulfur content is stably controlled to be less than or equal to 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

Technique for producing anti-acid pipeline steel by RH-LF-VD refining

InactiveCN102719728AReduce production burdenReduce oxidationManufacturing convertersProcess efficiency improvementMolten steelDecarburization

The invention relates to a technique for producing anti-acid pipeline steel by RH-LF-VD refining. According to the technique, convertor steel making and RH-LF-VD refining techniques are utilized to control the components of molten steel, thereby producing the low-carbon low-sulfur anti-acid (anti-HIC and anti-SCC) pipeline steel. The technique comprises the following steps: predesulfurizing molten iron, smelting in a convertor, carrying out RH vacuum decarburization, carrying out LF heating for desulfurization, carrying out VD vacuum decarburization, carrying out calcium treatment, carrying out soft blowing, continuously casting, and carrying out hot rolling. By using the secondary vacuum refining processes (RH vacuum refining and VD vacuum refining), the invention can reduce the decarburization load of the convertor, lower the oxidizability of the molten steel, eliminate the adverse effect of carburization in the LF furnace refining process, reduce the consumption of a strong deoxidizer, stabilize the production, ensure that the molten steel components are stably controlled within the production target, and satisfy the component control requirements of low carbon, low sulfur and high purity for anti-acid pipeline steel. The carbon content of the finished steel produced by the technical process provided by the invention can be controlled to 0.03%, and the sulfur content can be stably controlled to at most 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

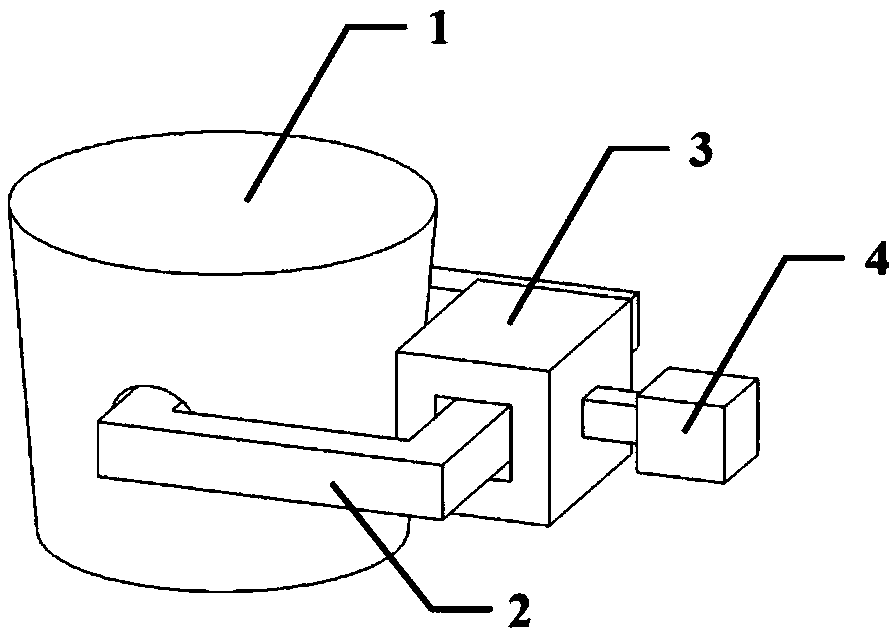

Refining ladle flow diverter and preparation method thereof

ActiveCN106881458ASimple and efficient operationStable qualityMelt-holding vesselsFlow diversionFlow diverter

The invention relates to a refining ladle flow diverter and a preparation method thereof. The flow diverter comprises a flow diverter main body. The flow diverter main body is a hollow cylindrical steel pipe with one end being sealed. Flow guiding holes and a flow guiding window are formed in the flow diverter main body. The refining ladle flow diverter is characterized in that the inner wall of the flow diverter main body is coated with a carbon layer; the flow guiding holes and the flow guiding window are sealed through flow diverter fusible slices; the opening end of the flow diverter main body is sealed through an opening end fusible slice; the positions, located at an water discharging opening and a seating brick part, in the flow diverter main body are filled with lower filling sand; the positions, located above the bottom of a seating brick bowl opening, in the flow diverter main body are filled with upper filling sand; and the upper filling sand and the lower filling sand are separated through an intermediate fusible slice. According to the flow diverter, operation of a using customer is simplified, the pouring rate is increased to 98% or above, and the using quality of a product is stable. Compared with traditional flow diversion sand, the problem of the quality fluctuation of the product is avoided, and market use is met.

Owner:张国令

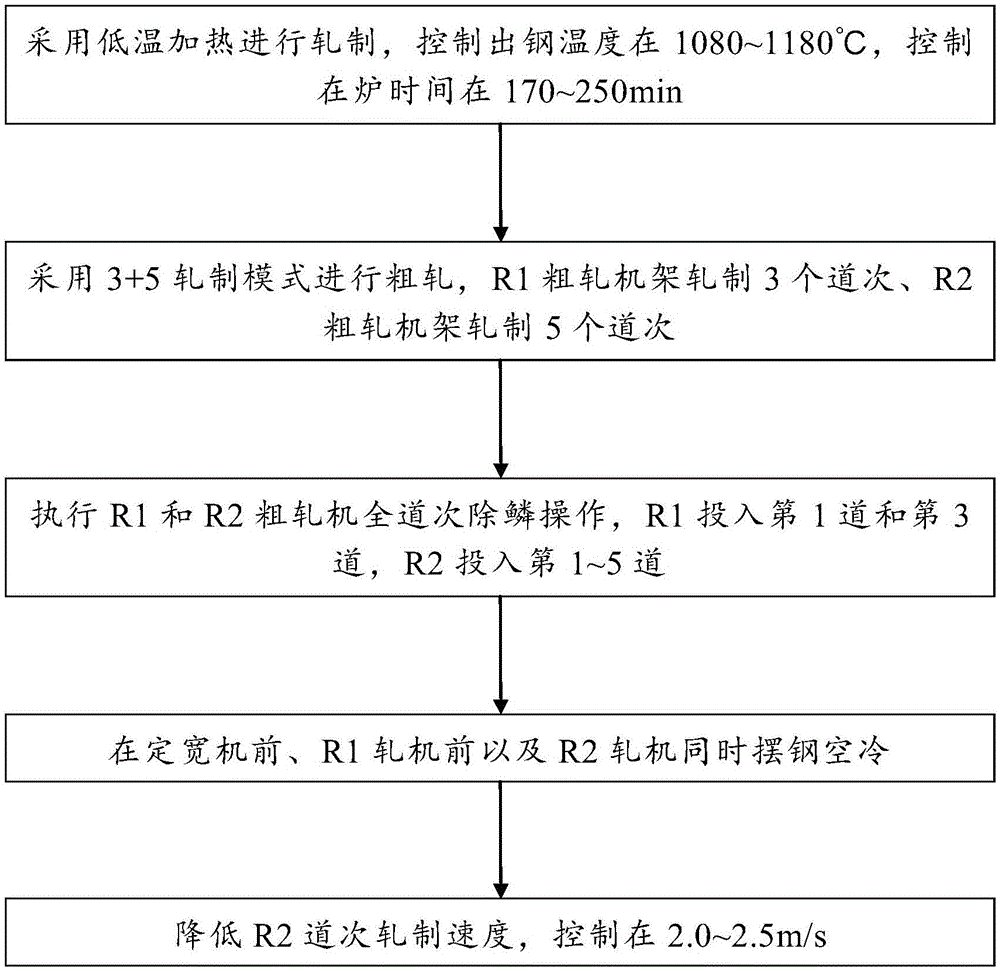

Method and device for increasing hot rolling speed of ferrite

ActiveCN106583465ALower tapping temperatureWeakening rangeTemperature control deviceWork cooling devicesRolling millRolling speed

The invention belongs to the technical field of hot rolling processes, and discloses a method for increasing the hot rolling speed of a ferrite. The method comprises the following steps of rolling by adopting a low-tempreature heating method, controlling the tapping temperature to be 1,080-1,180 DEG C, and controlling the time in the furnace to be 170-250 min; conducting rough rolling by adopting a 3+5 rolling mode, forming 3 passes through rolling of a rough mill frame R1, and forming 5 passes through rolling of a rough mill frame R2; executing all-pass scale removal operations by a rough mill R1 and a rough mill R2, putting the rough mill R1 in the first pass and the third pass, and putting the rough mill R2 in the first pass, the second pass, the third pass, the fourth pass and the fifth pass; synchronously conducting steel placing and air cooling in front of a width gauge and the rough mill R1 and on the rough mill R2; and reducing the pass rolling speed of the rough mill R2, and controlling the pass rolling speed of the rough mill R2to be 2.0-2.5 m / s.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

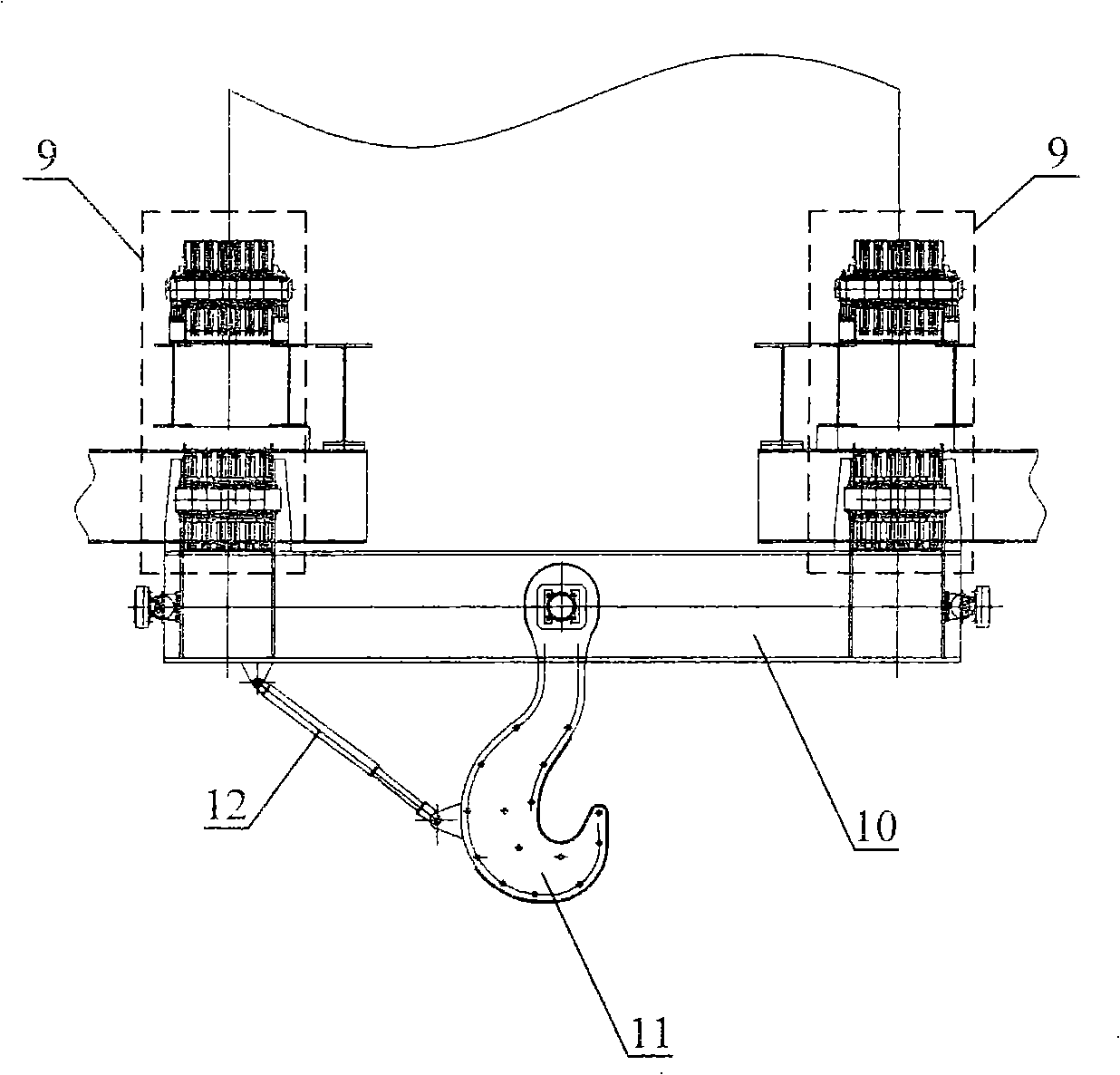

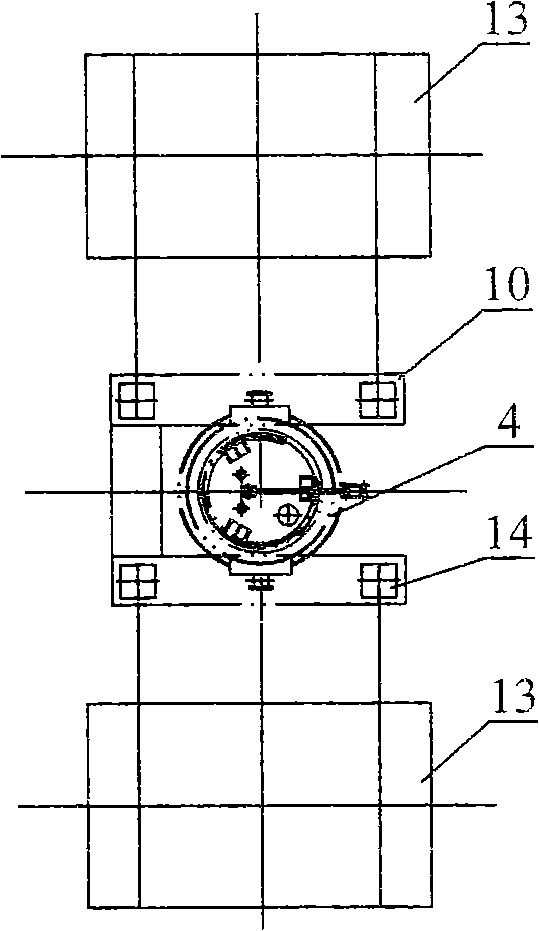

Ladle capping device

The invention relates to a ladle capping device and belongs to the technical field of molten iron transportation of iron works. The ladle capping device comprises a rack, a lifting device, a ladle cap, a walking trolley, a ladle vehicle and a ladle cap clamping device, wherein one end of the lifting device is connected with the ladle cap through the ladle cap clamping device, the other end of the lifting device is connected with the rack, and the lifting device can horizontally move relative to the rack; the ladle cap moves up and down and moves leftwards and rightwards relative to the rack through the lifting device and is added or removed; the walking trolley and the ladle vehicle drive in opposite directions and run in the front-back direction of the rack. The ladle capping device is reasonable in structure, simple to operate and capable of reducing heat loss in the transportation process of the molten iron.

Owner:唐山瑞丰钢铁(集团)有限公司

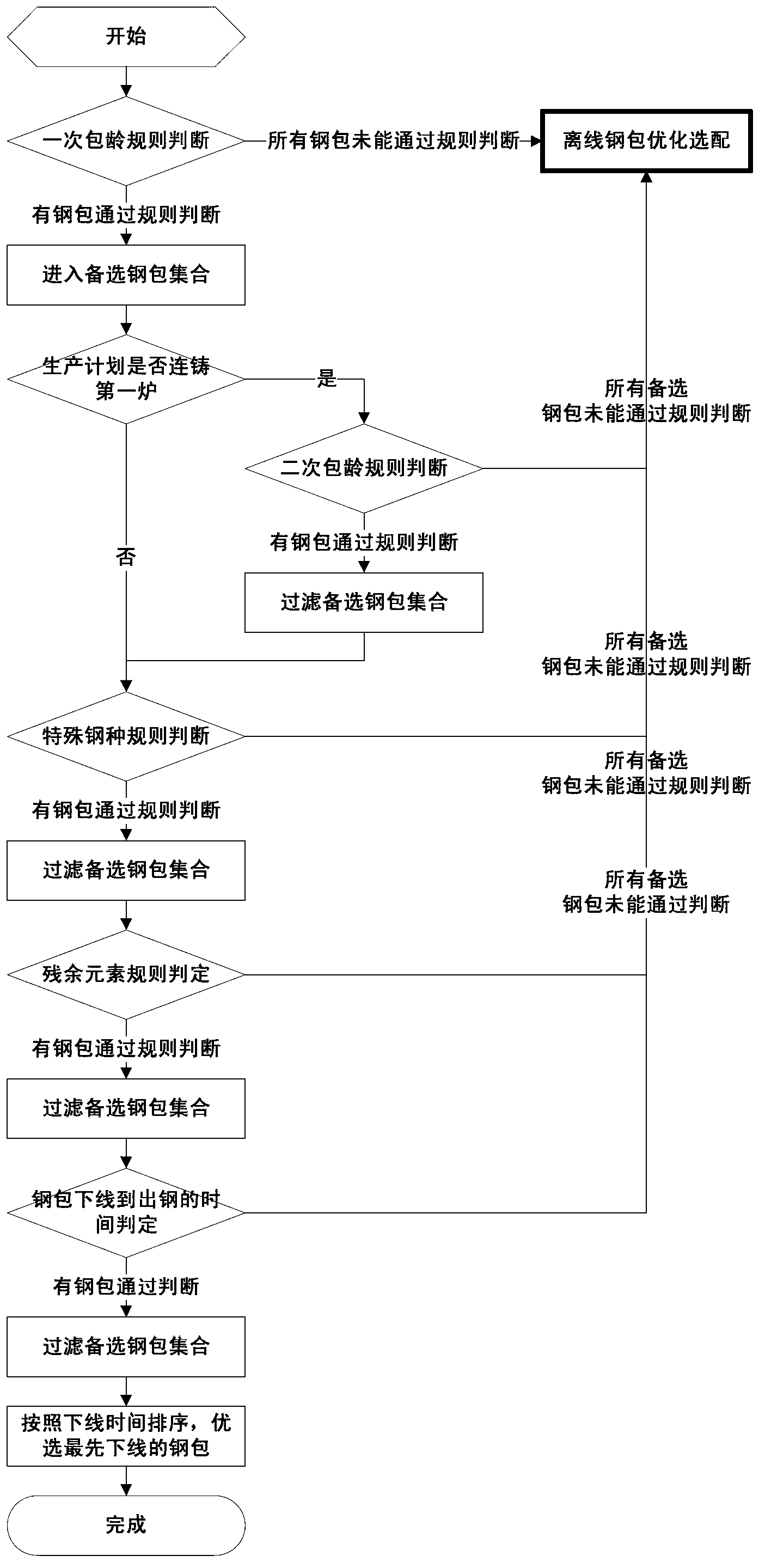

Selection matching method for steel ladles of steel plant

ActiveCN103212700AAvoid optional interferenceImprove turnover rateMelt-holding vesselsManufacturing convertersSteel mill

The invention discloses a selection matching method for steel ladles of a steel plant, and relates to the technical field of selection matching of the steel ladles of the steel plant. The method comprises the following steps that information of all steel ladles is obtained, and the steel ladles comprise on-line turnover steel ladles or off-line baking steel ladles; and according to the information of the steel ladles, the selection matching method also comprises the steps that the selection matching ladles do not comprise steel ladles reaching the repair period, and the repair period refers to the number of use times of the steel ladles when the steel ladles require to be repaired after being used for several times. The selection matching method for the steel ladles of the steel plant provided by the invention has the advantage that the energy-saving and consumption reduction control in the steel ladle turnover process can be effectively realized.

Owner:BEIJING SHOUGANG CO LTD

Method for producing high-corrosion-resistance steel through twin-roll thin-strip continuous casting

The invention discloses a method for producing high-corrosion-resistance steel through twin-roll thin-strip continuous casting. The method comprises the following steps of (a) smelting: carrying out smelting according to the following chemical components in percentage by weight, 0.02-0.06% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, smaller than or equal to 0.02% of P, 4.0-6.0% of Cr, 1.0-3.0% of Ni, smaller than or equal to 0.007% of S, 0.004-0.010% of N, smaller than 0.001% of Als, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]T and the balance of Fe and inevitable impurities; (b) continuous casting: adopting a twin-roll thin-strip continuous casting process; c) protecting in a lower closed chamber; d) online hot rolling; e) cooling after rolling: cooling the rolled strip steel ina gas atomization cooling manner; and f) strip steel coiling: directly coiling the cooled hot-rolled strip steel into a coil after the end with poor quality of the cooled hot-rolled strip steel is cutoff by an end shear, and controlling the coiling temperature of the hot-rolled strip to be 600-700 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

Converter later-stage low-temperature tapping efficient dephosphorization method

PendingCN112609034AReduce steel consumptionImprove dephosphorization efficiencyManufacturing convertersElectric furnaceSlagManufacturing engineering

The invention discloses a converter later-stage low-temperature tapping efficient dephosphorization method. The method comprises the following steps that Si, Mn and part of iron in slag are oxidized by adopting high lance position and large oxygen flow in the early stage of blowing; with the continuation of oxygen blowing, CO gas generated by chemical reaction of carbon and oxygen enables the early-stage slag to be prone to emerge, the lance position is raised, and the oxygen flow is reduced; the lance position is lowered in the middle stage of blowing; in the middle and later stages of smelting, the lance position is increased for slag adjustment, a part of sinter is added in multiple batches, the dephosphorization effect of the slag is good, and meanwhile good thermodynamic and dynamic conditions are achieved; and then a sublance is put down for TSC, and in the later stage of smelting, the final TSO temperature is controlled to be 1590-1620 DEG C . According to the method, an in-furnace efficient dephosphorization production process under a converter end-point low-temperature tapping condition is provided, and by reducing tapping end-point temperature, the distribution ratio of phosphorus in slag and steel in the later stage of smelting of a converter is increased, and therefore the dephosphorization efficiency in the later stage of smelting is improved.

Owner:LIUZHOU IRON & STEEL

Method for calculating tapping time of steelmaking converter

PendingCN112347530ATheoretically reliableAccurate calculationGeometric CADManufacturing convertersSteelmakingProcess engineering

The invention provides a method for calculating tapping time of a steelmaking converter, which belongs to the field of ferrous metallurgy and comprises the following steps: determining a converter profile, a structural size, a converter tapping tilting mechanism type, working characteristics and a rotating speed range; calculating each inclination angle of the converter from tapping to ending, thevolume of molten steel and slag in the converter corresponding to each subdivided liquid level height, and the mass of the molten steel; calculating the corresponding tapping molten steel mass flow and outflow time further, and building a basic database; and in combination with a tilting operation system in the converter tapping process, calculating the tapping time. According to the invention, the influences of the irregular structural shape of the converter, the size of the tapping hole, the weight of molten steel and slag loaded in the converter, the tapping tilting angle, the tilting speed and other operation systems are fully considered. The method is reliable in theory, practical and accurate in calculation, and lays an important foundation for influence factor analysis of the tapping time of the converter, optimization of a tapping operation system, reduction of tapping temperature and other process optimization.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for supplying heat in converter by using carbon-based heating agent

InactiveCN110904299AReduce power consumptionExtremely fewManufacturing convertersProcess efficiency improvementSteelmakingThermodynamics

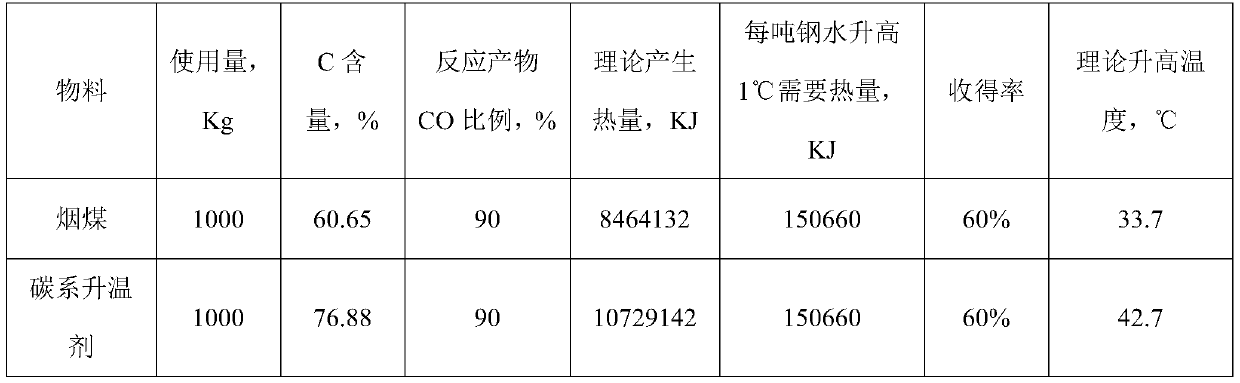

The invention discloses a method for supplying heat in a converter by using a carbon-based heating agent. Specifically, the method comprises: after scrap steel is added to the converter, firstly adding the carbon-based heating agent and then adding iron. In this way, the temperature rising rate is increased after the heating agent is added and the heat utilization rate is higher. In the steelmaking process of the converter, if the amount of scrap steel is increased, it is obvious that the heat is insufficient; if a heat source is not added, the converter tapping temperature is inevitably lowered, and then temperature is increased in a finery. The method supplies the heat in the converter by using the heating agent so as to reduce electrodes and power consumption in the finery, and therebyreduce costs relatively.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

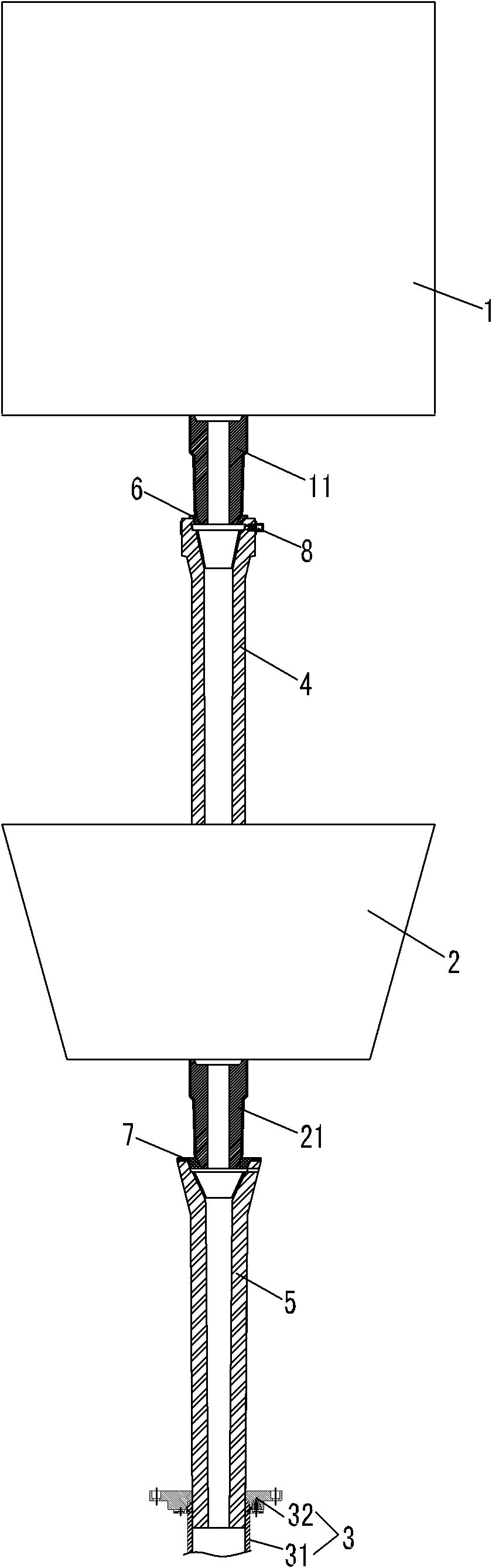

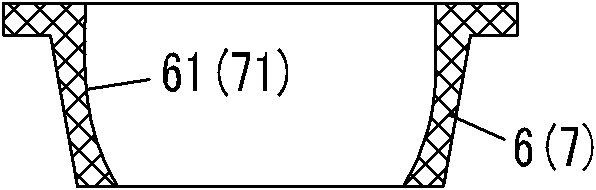

Continuous-casting sealed pouring device and technological method for protecting pouring using same

The invention discloses a continuous-casting sealed pouring device and a technological method for protecting the pouring by using same. The device comprises a ladle and the like. The ladle and a crystallizer are respectively arranged above and below a tundish. The lower outer surface of the ladle down nozzle is spherical, and the ladle down nozzle and the tundish down nozzle are respectively muff-coupled with a ladle immersion argon-sealing sleeve and a tundish immersion argon-sealing sleeve. Seal washers are installed between the ladle immersion argon-sealing sleeve and the ladle down nozzle and between the tundish immersion argon-sealing sleeve and the tundish down nozzle. A circle of inner grooves, a first argon through-hole and a second argon through-hole are arranged at the upper parts of the ladle immersion argon-sealing sleeve and the tundish immersion argon-sealing sleeve, wherein the first argon through-hole and the second argon through-hole are vertically communicated with the grooves. The device and technological method provided by the invention are characterized in that the sealing performance of molten steel is improved in the pouring process; the secondary oxidation is avoided; the content of impurity in the steel is reduced; the tapping temperature in a converter is reduced; and the molten steel quality is effectively ensured.

Owner:储鸿文 +2

On-line vacuum arrangement apparatus

Disclosed is a vacuum on-line layout device, belonging to the field of vacuum refining processing molten steel in steelmaking plants of steel enterprises. Aiming at the problem that the off-line layout structures of the present RH vacuum processing equipment and the smelting furnace do not meet with the production needs of higher RH vacuum processing ratio of the molten steel, the invention provides a vacuum on-line layout device, which is characterized in that a buggy ladle from the smelting furnace is directly driven to an RH processing site; ladles are hoisted by a frame structure driven by a hoisting; the action that the ladles are hoisted makes an insert pipe be immersed into the molten steel to start refining processing the molten steel; and at the same time, the buggy ladle from the smelting furnace can return to the smelting furnace to proceed with tapping from the seat tank of the next furnace. The molten steel processed by RH is dropped down by the hoisting to the RH buggy ladle which carries the ladles to the receiving straddle, and the ladles are hung by a driving to a caster to be continuously cast. The vacuum on-line layout device has the advantages of saving process time, safe and stable running and simple production structure. Thus, the vacuum on-line layout device is a successful example of process design in newly-built steelmaking plants, and is favorable for popularization and application.

Owner:武汉钢铁有限公司

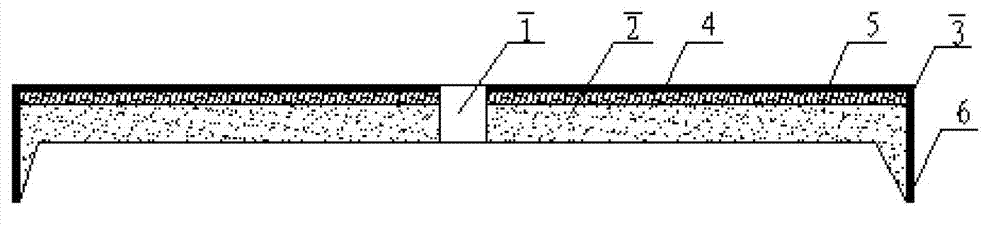

Steel ladle capping heat-preservation method

InactiveCN103394679AReduce cooling rateReduce baking timeMelt-holding vesselsThermal insulationMetallurgy

The invention discloses a steel ladle capping heat-preservation method, and belongs to the technical field of steel-making steel ladle transferring. According to the steel ladle capping heat-preservation method, a heat-preservation baking ladle cover is manufactured, a layer of thermal-insulation heat-preservation materials are additionally arranged between fireproof knotting materials and a steel case, the diameter of the ladle cover is prolonged, and a ladle cover skirt hem is increased. The steel ladles exiting transferring are all caped to preserve heat, and the steel ladles are put into a transferring sequence. The steel ladle capping heat-preservation method has the advantages that steel ladle heat loss during the transferring process is reduced, consumption of natural gas is greatly reduced, transferred steel ladle lining temperature is improved, and tapping temperature is reduced.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

Method for improving furnace age of converter

InactiveCN108251590AReduce TFe contentReduce erosion rateManufacturing convertersAlkalinityMolten steel

The invention discloses a method for improving the furnace age of a converter and belongs to the technical field of metallurgy. In order to improve the furnace age of the converter, the invention provides the method for improving the furnace age of the converter; the method comprises the following steps: adding dolomite into the converter; after blending semi-steel into the converter; blowing andadding active lime, dolomitic lime, an acidic composite slag forming agent and converter waste residues into the converter; controlling a lance position and oxygen blowing strength of an oxygen lanceand controlling the alkalinity of terminal-point furnace slag to 3 to 4, so as to obtain terminal-point molten steel and terminal-point slag. According to the method disclosed by the invention, the dolomite is used for producing the slag and the converter waste residues are added to replace part of metallurgy auxiliary materials, so that the content of TFe in the terminal-point slag is reduced, the tapping temperature is reduced and the terminal-point carbon content is improved; the furnace age of the converter is remarkably improved and the smelting effect is not influenced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ultra-low carbon steel and production method thereof

ActiveCN106834906AImprove performanceGuaranteed temperature uniformityChemical compositionStrip steel

The invention discloses ultra-low carbon steel. The ultra-low carbon steel comprises, by mass, 0.001-0.01% of C, 0-0.03% of Si, 0-0.005% of N, 0.02-0.05% of Al, 0.02-0.05% of Ti and the balance Fe and unavoidable impurities. The invention further discloses a method for ultra-low carbon steel production. A plate blank obtained through smelting and with chemical components shown as the specification is heated and then subjected to semi-continuous type rough rolling and finish rolling to obtain a hot rolled plate; during finish rolling, the speed difference of the finish rolling outlet full-length rolling head and tail is controlled to be less than or equal to 1.5 m / s, the accelerated speed of a finish rolling end rack is controlled to be less than or equal to 0.02 m / s<2>, and it is guaranteed that the speed of band steel rolling is uniform; and after the hot rolled plate is subjected to laminar flow cooling and then reeled up, a finished product is obtained. According to the ultra-low carbon steel and the production method thereof, the technical problem that in the prior art, the properties of ultra-low carbon steel are not uniform is solved, and uniformity and stability of product performance are improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Slag-iron separation promoter as well as preparation method and use method thereof

InactiveCN111593168AIncrease surface tensionOptimizationRecycling and recovery technologiesProcess efficiency improvementIron powderSmelting process

The invention belongs to the technical field of titanium slag smelting, and particularly relates to a slag-iron separation promoter as well as a preparation method and a use method of the slag-iron separation promoter. The slag-iron separation promoter is prepared from the following components in percentage by mass: 70-90 % of iron powder, 5-15 % of coke powder, 2-8 % of magnesium oxide powder, 1-5 % of a binder, and 1-5 % of water. The slag-iron separation promoter is used for slag-iron separation in the titanium slag smelting process, the slag-iron separation time can be effectively shortened, the iron inclusion proportion in slag can be reduced, and the tapping temperature can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

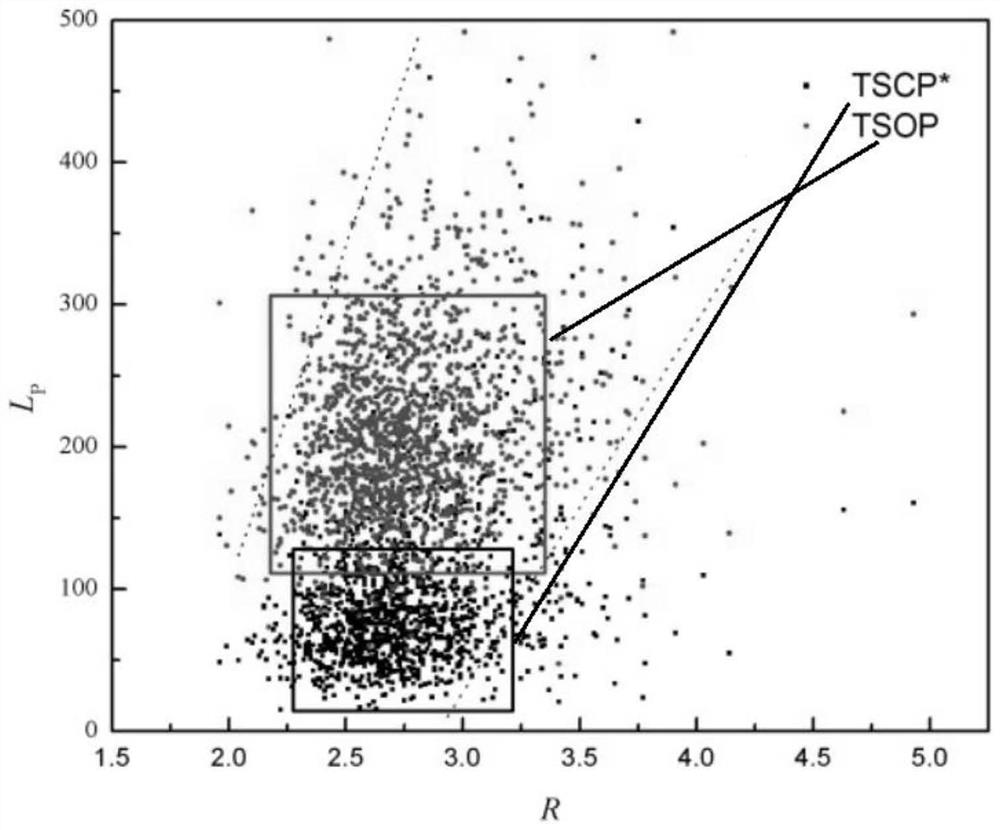

High-strength fire-resistant and weather-resistant steel plate/strip and production method thereof

The invention relates to a high-strength fire-resistant and weather-resistant steel plate / strip and a production method thereof. The steel plate / strip comprises the following chemical components in percent by weight: 0.02-0.06% of C, 0.1-0.55% of Si, 0.4-1.7% of Mn, less than or equal to 0.03% of P, less than or equal to 0.007% of S, 0.30-0.80% of Cr, 0.10-0.60% of Cu, 0.20-0.60% of Mo, 0.01-0.08%of Nb, 0.004-0.010% of N, less than or equal to 0.001% of Als, 0.007-0.020% of total oxygen [O]T and the balance Fe and inevitable impurities, wherein Mn / S is greater than 250; and Pcm is smaller than or equal to 0.27%. The production method comprises the following steps of: selectively adding micro-alloy elements such as Mo / Nb / Cr into steel, and controlling the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als; then casting a cast strip through double-roller thin strip continuouscasting, and then feeding the cast strip into an on-line rolling mill for hot rolling; and after rolling, cooling the strip steel in a gas atomization cooling mode, and finally coiling the strip steeldirectly into a steel coil.

Owner:BAOSHAN IRON & STEEL CO LTD

Channel-type induction-heating ladle device and heating method

InactiveCN109128122AReduce temperature lossLower tapping temperatureMelt-holding vesselsMolten steelWater cooling

The invention belongs to the technical field of steel and iron metallurgy, and discloses a channel-type induction-heating ladle device and heating method. The channel-type induction-heating ladle device and heating method are used for heating molten steel in a ladle and reducing the cooling of the molten steel during steel and iron production. The channel-type induction-heating ladle device comprise the ladle, a ladle cover, an iron core, a coil and a water cooling or air cooling device, wherein a channel is arranged in the ladle, and capable of horizontally penetrating through the side wall of the ladle and perpendicularly penetrating the center of the ladle; the iron core penetrates through the channel and surrounds one side of the ladle; the coil is wound around the iron core on the outer side of the ladle; the axis of the coil and the that of the iron core are kept perpendicular; and the coil is connected with the water cooling or air cooling device. The channel-type induction-heating ladle heating method comprises the following steps: (1) conveying the ladle to a refining or pouring station; (2) starting the water cooling or air cooling device to cool the coil, so as to prevent the coil from overheating during the subsequent power-on operation; (3) introducing an alternating current into the coil, so as to generate variable magnetic flux in the iron core, wherein the current magnitude reaches 1-10000 A and the frequency reaches 1-10000 Hz; and (4) after the refining or pouring operation is completed, stopping the power-on operation, shutting down the water cooling or air cooling device, and proceeding with the next working procedure.

Owner:NORTHEASTERN UNIV

Steel-making alloy on-line baking method

InactiveCN109282656AImprove heating uniformityImprove heating efficiencyPreheating chargesControl devices for furnacesAirflowHeating efficiency

The invention discloses a steel-making alloy on-line baking method. A combustor along the tangential direction of the circumferential direction of a furnace body is arranged on a furnace body of an alloy baking furnace; a high-temperature airflow produced by the combustor bakes and heats an alloy along the tangential direction of the circumferential direction of the furnace body; and the baked alloy is discharged from a discharge hole of the furnace body so as to be directly added into a steel ladle. According to the steel-making alloy on-line baking method provided by the invention, the heating uniformity is effectively improved, the temperature of the whole alloy in the furnace body is ensured to be increased by heating, the baking and heating efficiency is improved, and the alloy can bequickly heated so as to meet the demand, so that the molten steel quality can be improved, the tapping temperature is reduced, the production energy consumption is effectively reduced, the service life of a converter is prolonged, the production efficiency is improved, the production cost is reduced, and the product economic benefit is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Control method of steel inclusions for railway bogie

InactiveCN111455257AReduce inclusion contentImprove quality stabilityManufacturing convertersBogieSmelting process

The invention discloses a control method of steel inclusions for a railway bogie. According to the method, through pretreatment of molten iron, the content of slag in the molten iron and the low sulfur content are effectively reduced, the heat source of a converter is guaranteed, and the smelting pressure of the converter is relieved; through smelting of the converter, the original oxygen contentof the molten iron is effectively reduced, oxide inclusions generated after the molten iron reaches a steel ladle are greatly reduced, and the number of the inclusions generated in the molten iron ina smelting process is reduced; through a refining treatment mode, the inclusions are denatured, and solid inclusions mainly containing CaO-CaS are generated; and a high overheating degree and weak cooling mode is adopted for continuous casting, it is guaranteed that the molten iron effectively floats and is adsorbed at a ladle, a tundish, a cleaner and a solidification tail end in a casting process, a quite small amount of inclusions are gathered in the center of a casting blank, the purity of the molten iron is effectively improved, and the anti-fatigue characteristic of a product is improved.

Owner:NANJING IRON & STEEL CO LTD

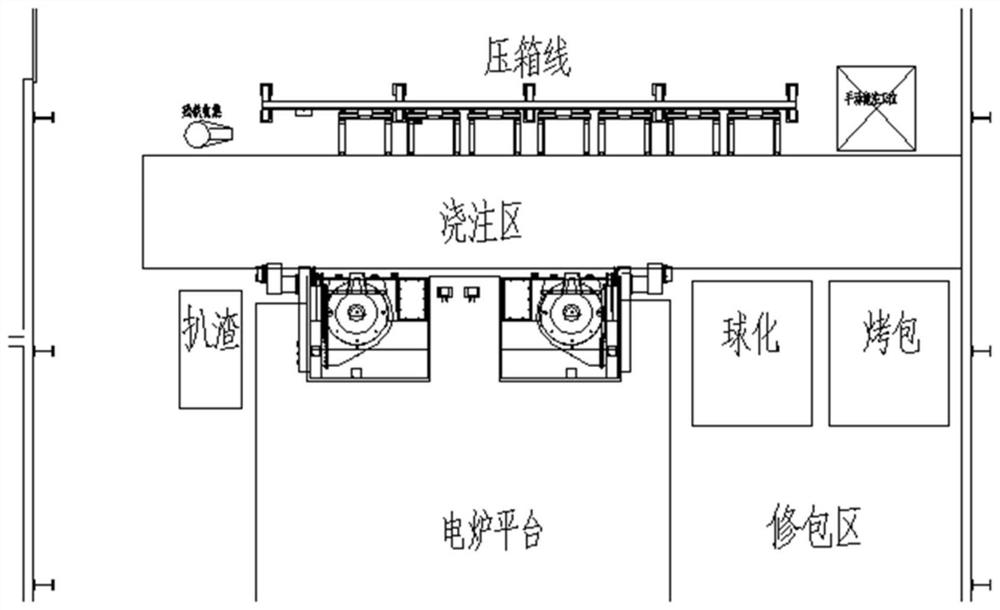

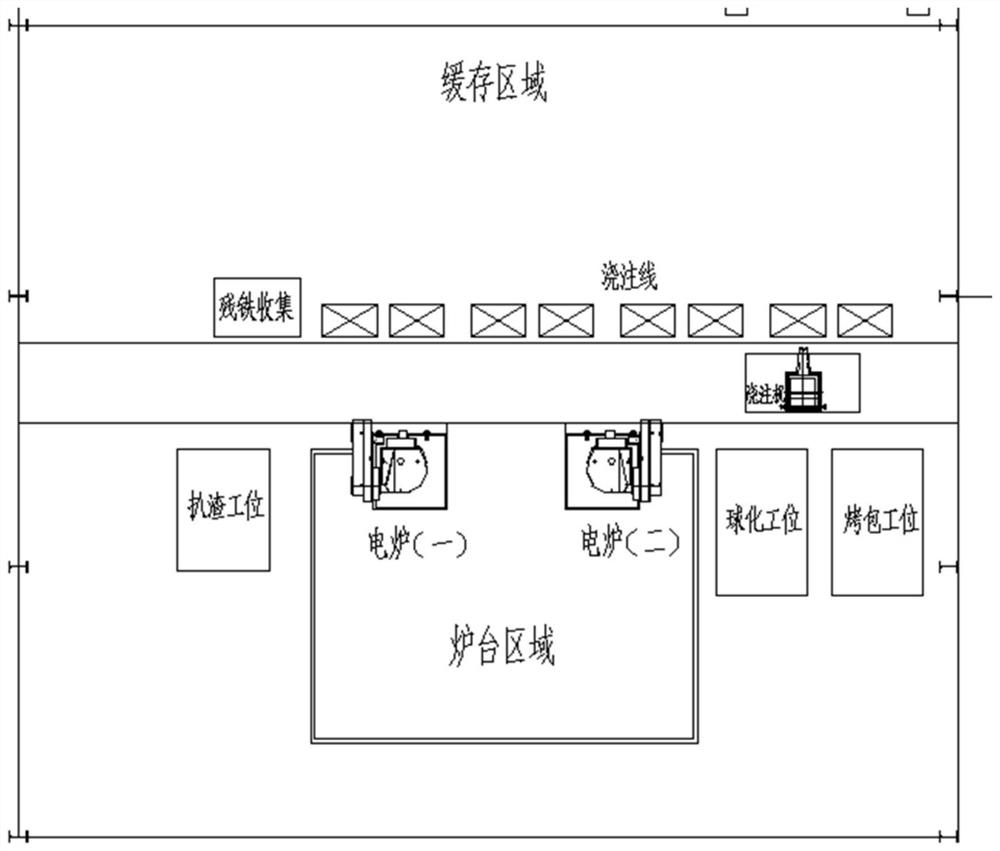

Intelligent smelting system and operation method thereof

PendingCN113523265AReduce in quantityShort process routeCasting plantsProcess engineeringElectric cables

The invention discloses an intelligent smelting system and an operation method thereof, and relates to the technical field of casting. The system comprises AGV transfer equipment, automatic pouring equipment, automatic box pressing equipment, a spheroidizing baking ladle, automatic box turning equipment, casting head removing equipment, shakeout equipment, shot blasting equipment and power and free equipment. The interior of the automatic pouring equipment comprises a barrel-shaped pouring ladle, a tilting mechanism, a transverse moving mechanism, a lifting mechanism, a pouring vehicle body, a rail system, a control and operation system, a safety system and a cable device, and the interior of the automatic box pressing equipment comprises a stand column, a cross beam, a lifting mechanism, a box pressing mechanism, a transverse moving mechanism and a lifting and transverse moving driving mechanism. The production area is compactly arranged, so that equipment is reasonably arranged, the number of production equipment can be reduced, the process route can be shortened, and the requirements of efficiency improvement, cost reduction and environment-friendly production are met.

Owner:烟台冰轮智能机械科技有限公司 +1

Method for reducing iron consumption

ActiveCN109136451AGuarantee the phenomenon of impenetrable blowing when the amount added is largeGuaranteed impenetrable phenomenonManufacturing convertersProcess efficiency improvementSlagHeat balance

The invention discloses a method for reducing iron consumption. The method specifically includes the following steps that 35-45 wt% of slag is poured into a furnace; qualified molten iron is introduced into the heating furnace for heating; the molten iron after heating in the above step is put into an oxygen top-blowing converter, and qualified steel scrap is added into the oxygen top-blowing converter at the same time; a slag-forming material is added for gun drop blowing, and the gun position in the blowing process needs to be specifically adjusted according to different silicon amounts in the molten iron. According to the method for reducing the iron consumption, by ensuring that the temperature of the molten iron is 1290 DEG C to 1320 DEG C, physical heat of the molten iron is stabilized, the heat balance of the converter is ensured, and correspondingly the consumption of the molten iron in a steel making process of the converter is reduced. By adding a carbonaceous heat-generatingagent into the converter, an important way of increasing the heat of the converter and increasing a cold-to-material ratio is achieved, the surplus heat is increased, the adding proportion of the steel scrap is increased, and thus the consumption of the molten iron is reduced; during gun drop blowing, the phenomena that the adding amount of the steel scrap is large and the steel scrap cannot be blown thoroughly are ensured, the operation is stable, and a better use prospect is brought.

Owner:LINZHOU FENGBAO PIPE

Process for producing anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining

InactiveCN102719614BReduce production burdenReduce non-metallic inclusion contentManufacturing convertersHydrogenStress corrosion cracking

The invention discloses a process for producing an anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining. In the process, the composition of molten steel is controlled by converter smelting and RH-LF-RH refining process, so as to produce a low-carbon low-sulfur anti-acid (hydrogen-induced cracking HIC and stress corrosion cracking SCC resistant) pipeline steel. The specific flow is as follows: pre-desulphuzation of molten steel - converter smelting-primary RH vacuum refining - LF refining desulphuzation - secondary RH vacuum refining - continuous casting. By the secondary RH vacuum refining process, the decarburization burden of the converter and the oxidability of the molten steel can be reduced, and the adverse effect caused by recarburization in the LF refining process can be eliminated; furthermore, the use of a strong deoxidizer is reduced, the production is stabilized, and the composition of the molten steel is ensured to be controlled within a production target stably to meet the control requirements of the anti-acid pipeline steel on the low-carbon low-sulfur and high-purity composition. The carbon content of the finished steel produced by the process of the invention can be stably controlled to be 0.03% to 0.04%, and the sulfur content is stably controlled to be less than or equal to 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com