Converter later-stage low-temperature tapping efficient dephosphorization method

A converter and low-temperature technology is applied in the field of low-temperature tapping and high-efficiency dephosphorization in the later stage of the converter. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The nominal capacity of the converter is 150t, and the loading capacity is 135t of molten iron + 35t of scrap steel. The consumption of molten iron per ton is 890kg / t, and the phosphorus content of the molten iron is 0.120%.

[0032] In the early stage of blowing, a 180cm high gun position is used - 540Nm 3 The large oxygen flow rate per hour oxidizes Si, Mn and part of iron in the slag. With the gradual increase of temperature, the lime (4800kg, 34kg / t per ton of steel) gradually dissolves, and the w(CaO) in the slag continues to rise. At this time, the slag has good thermodynamic conditions for dephosphorization, but more cold materials (scrap steel, lime, light-burned dolomite, etc.) are added in the early stage, the slag temperature is low, the slag fluidity is poor, and the dephosphorization efficiency is low.

[0033] As the oxygen blowing continues, the CO gas generated by the chemical reaction of carbon and oxygen makes the early slag easy to come out. At this t...

Embodiment 2

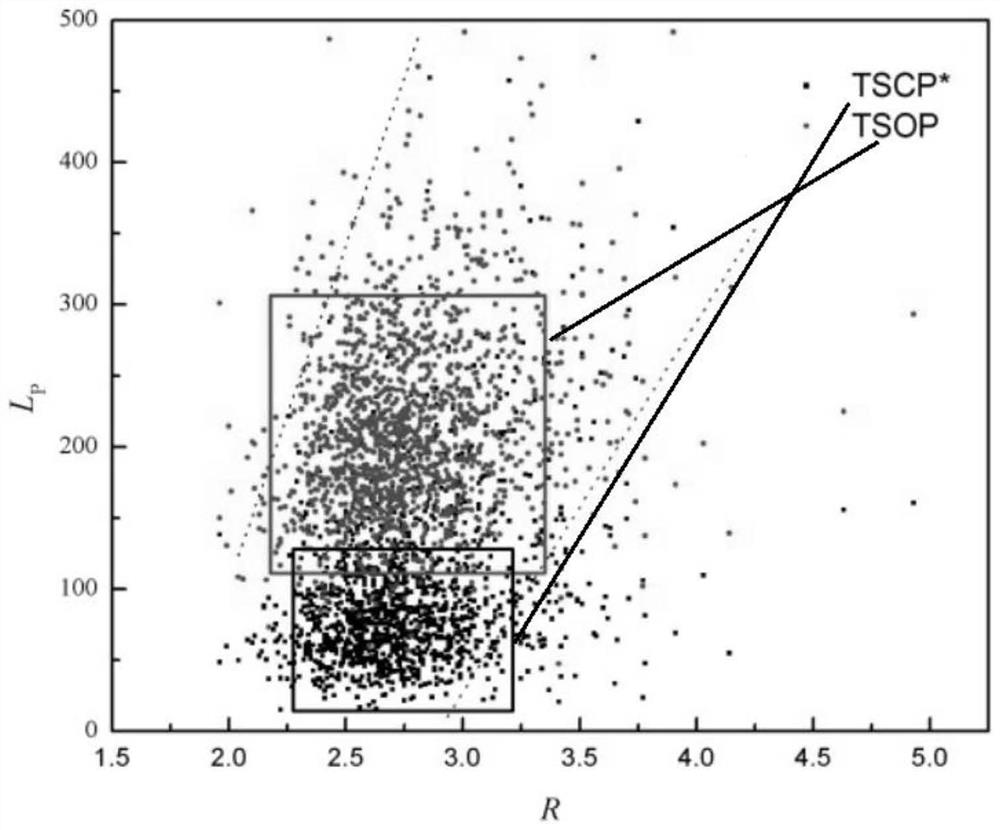

[0045] The low-temperature and high-efficiency dephosphorization process in the later stage of the converter is applied under different ratios of iron and steel materials into the converter (the amount of molten iron / scrap steel). The process gun position and oxygen flow are controlled so that no slag is emitted in the early stage and the carbon-oxygen reaction is stable in the middle stage (CO gas value is stable. rise) and the principle of no slag and no return to dryness in the later stage.

[0046] The amount of sinter added is added according to the requirements of furnace heat balance and end point temperature control, and the gun position and oxygen flow rate are adjusted in real time to improve the slag. The key process parameters of the specific dephosphorization example are as follows:

[0047] Table 2 Process parameters of high-efficiency dephosphorization in converter low-temperature smelting

[0048]

[0049]

[0050] Table 3 Composition of slag sample at co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com