Continuous-casting sealed pouring device and technological method for protecting pouring using same

A sealed and continuous casting technology, which is applied in the field of molten steel casting molds, can solve the problems of high inclusion content and unsatisfactory protection pouring effect, so as to ensure the quality of molten steel, reduce the content of oxygen and non-metallic inclusions, and reduce the The effect of tapping temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

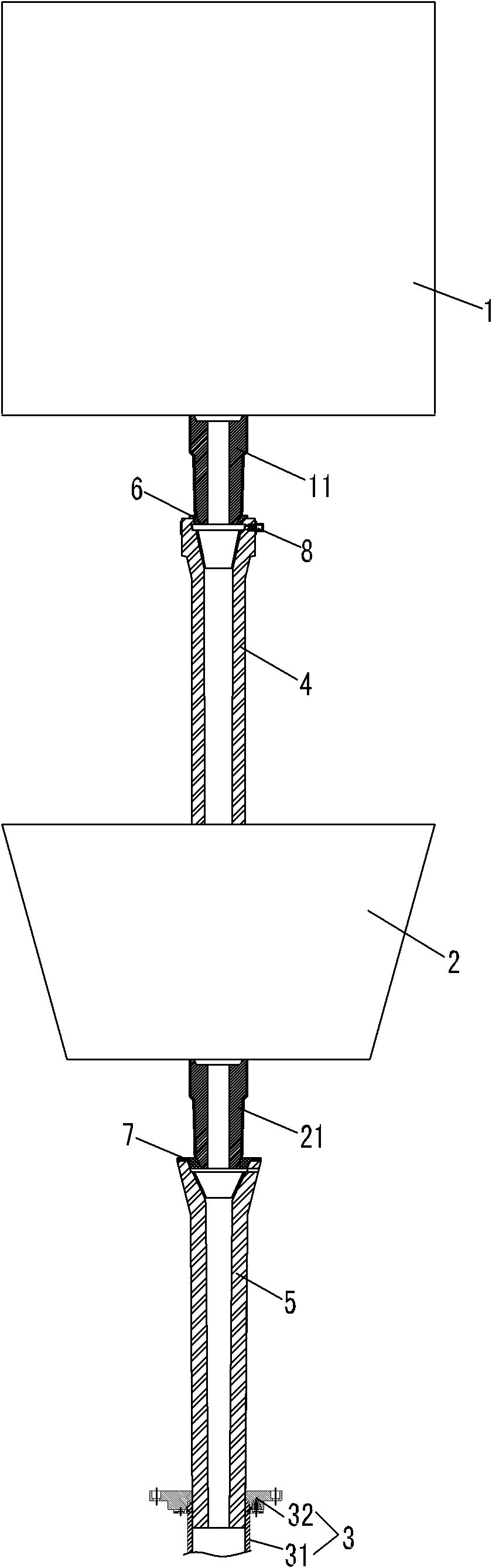

[0027] see figure 1 As shown, the continuous casting sealed pouring device of the present invention includes a ladle 1, a tundish 2, a crystallizer 3, a large ladle argon envelope tube 4, a tundish submerged argon envelope tube 5, a first sealing gasket 6 and a second sealing gasket 7. Ladle 1 and crystallizer 3 are located above and below tundish 2 respectively;

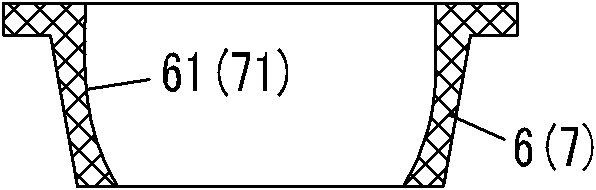

[0028] The following of the ladle 1 is provided with a ladle water outlet 11, combined with figure 2 As shown, the outer surface 111 of the lower part of the ladle water outlet 11 is a spherical surface, the spherical surface at the lower part of the ladle water outlet 11 is socketed with the upper end of the ladle argon sealing sleeve 4, and the ladle argon sealing sleeve 4 and the ladle water outlet 11 are arranged There is a first ferrule 6, such as image 3 As shown, the side wall section of the first sealing gasket 6 is inverted L-shaped, the inner cavity surface of the first sealing gasket 6 is a spherical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com