Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Less material loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

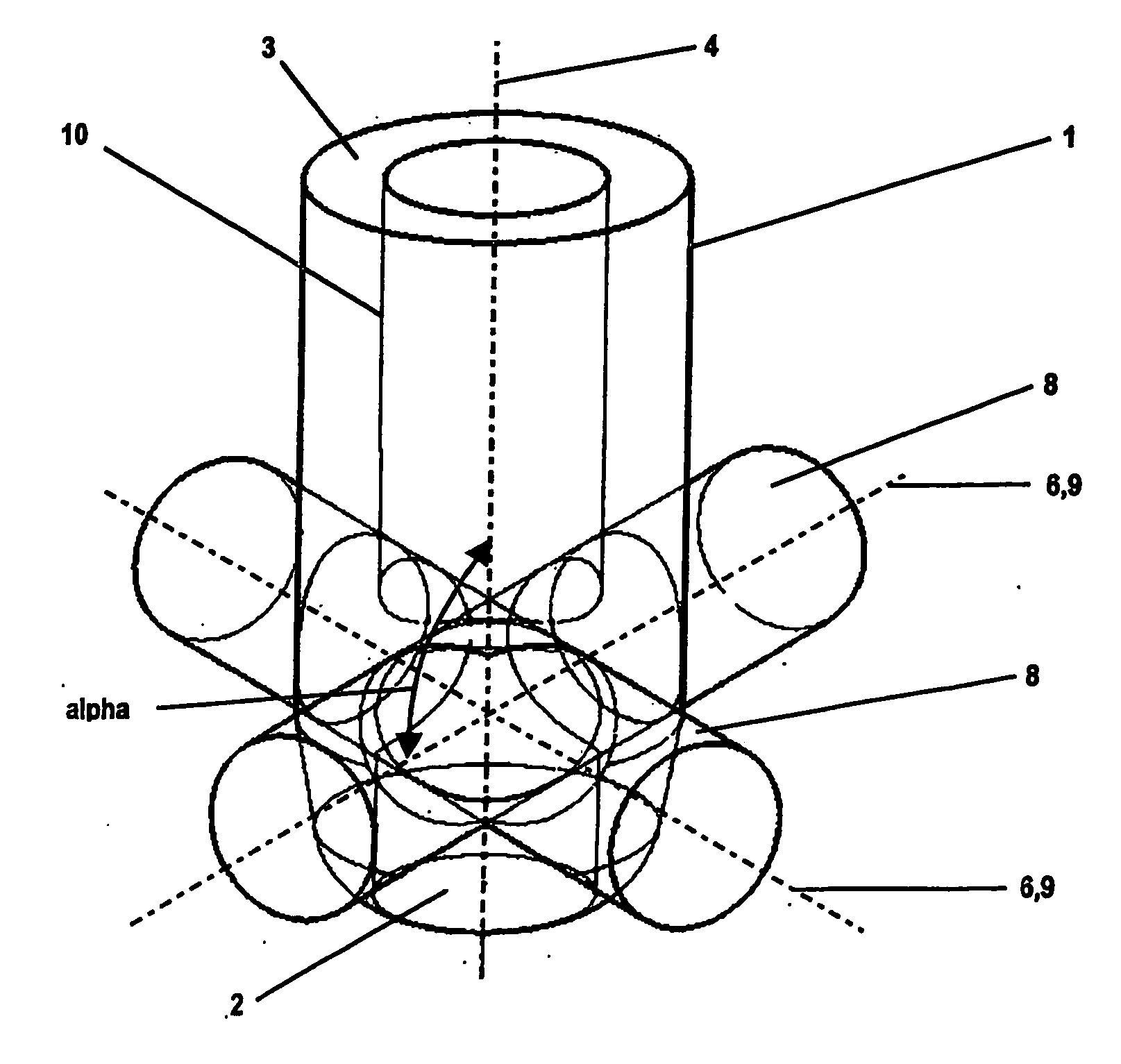

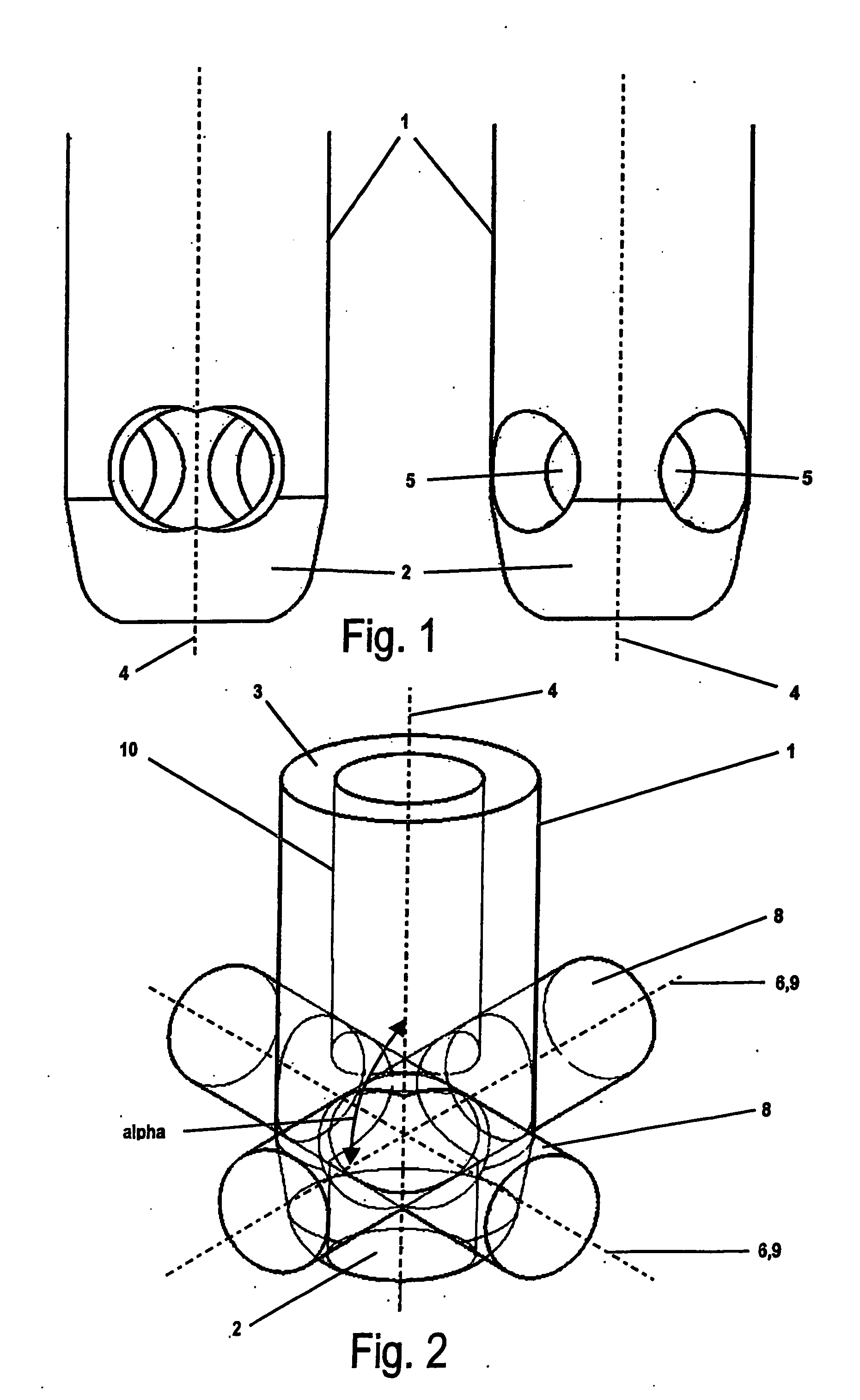

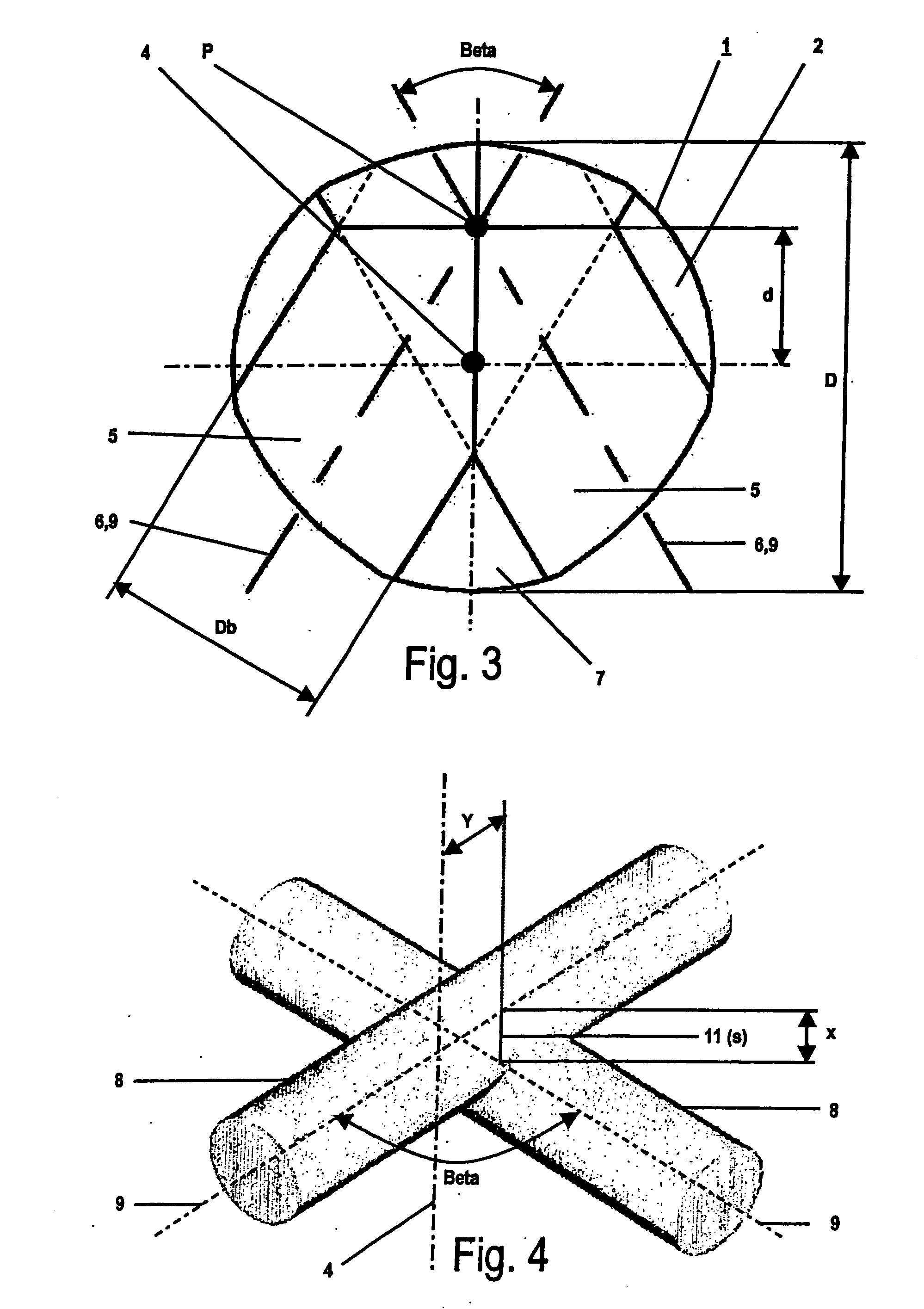

Intramedullary nail

InactiveUS20060111716A1Improve stabilityConvenient treatmentInternal osteosythesisBone implantBiomedical engineeringMedullary cavity

The intramedullary nail has a distal end suitable for insertion in the medullary space, wherein the segment of the intramedullary nail facing the distal end has a diameter D, a proximal end, a central longitudinal axis; and several cross holes with a hole axis, each of which defines a virtual borehole cylinder with a cylinder axis corresponding to the hole axis of the defining cross hole, wherein the borehole cylinders of at least two cross holes penetrate each other. The cylinder axes of the two mutually penetrating borehole cylinders do not have any common intersection point P on the longitudinal axis. This results in improved mechanical strength compared to the state of the art, without any need for the size of the cross section of the intramedullary nail to be increased.

Owner:DEPUY SYNTHES PROD INC

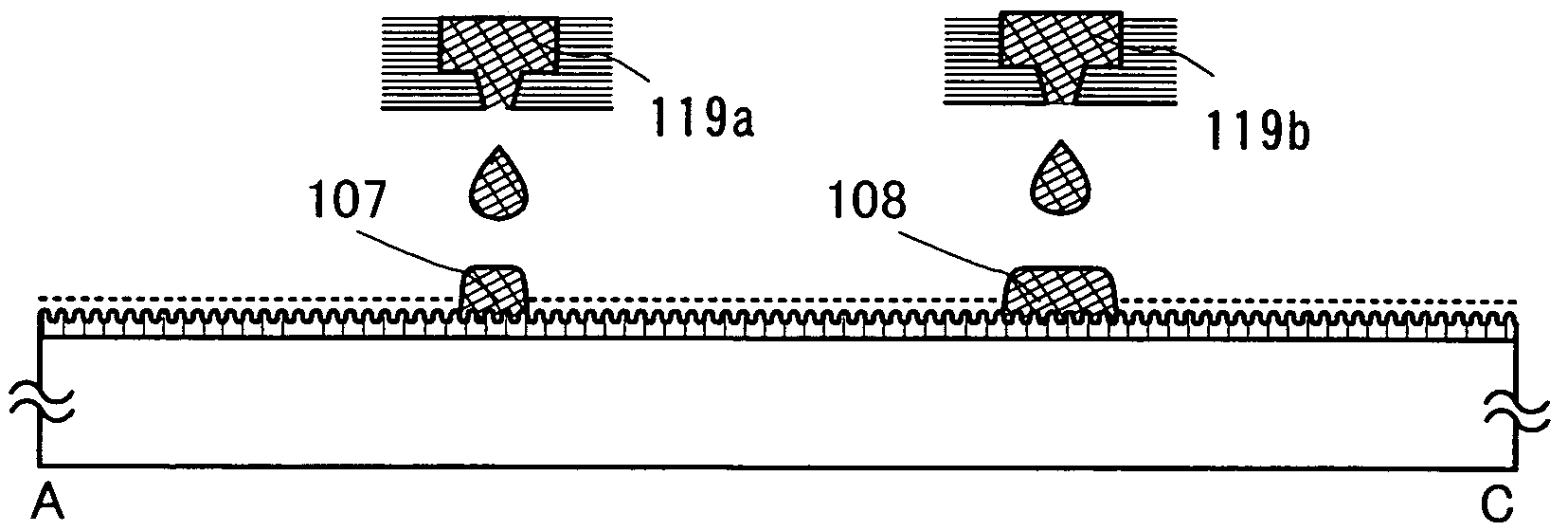

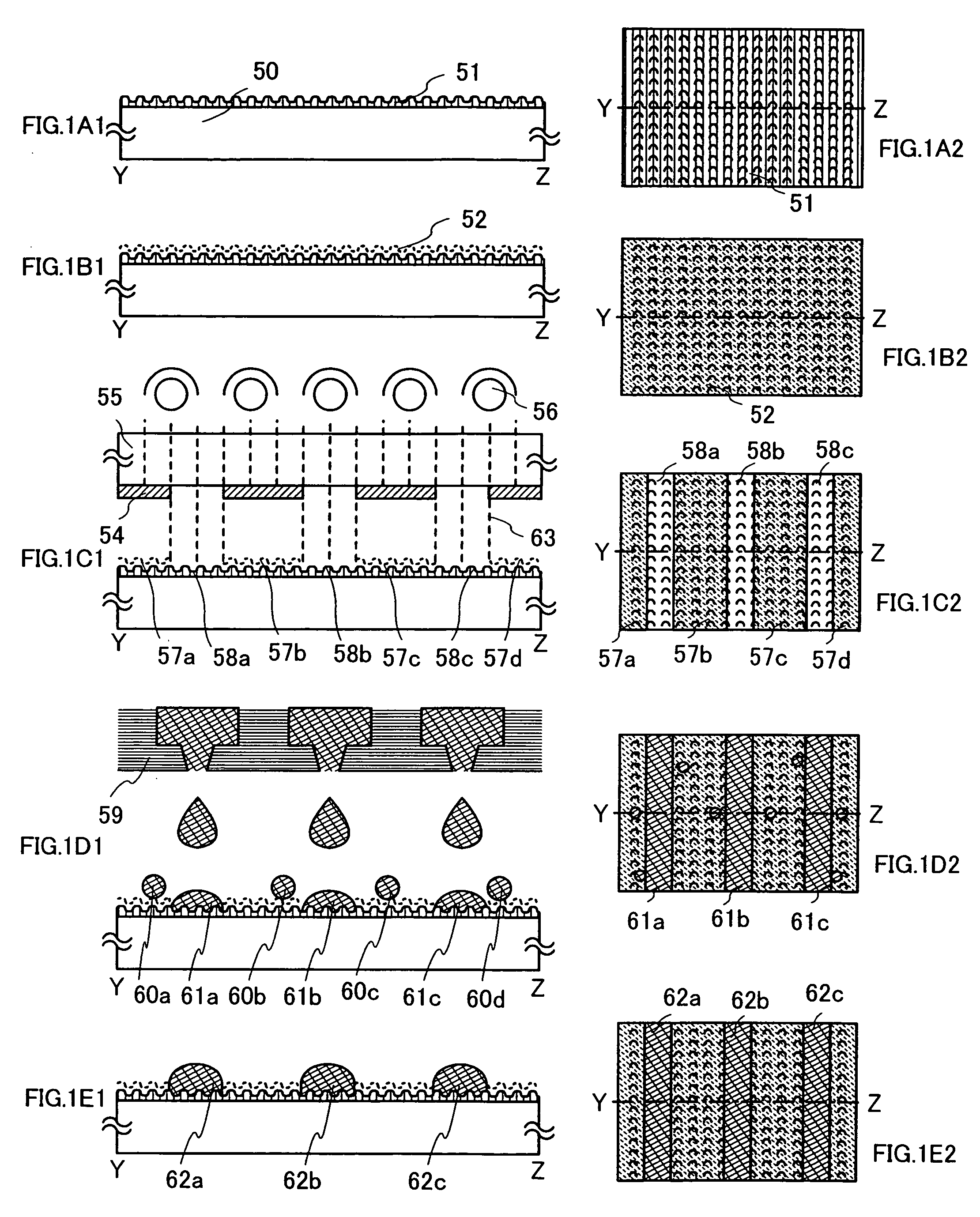

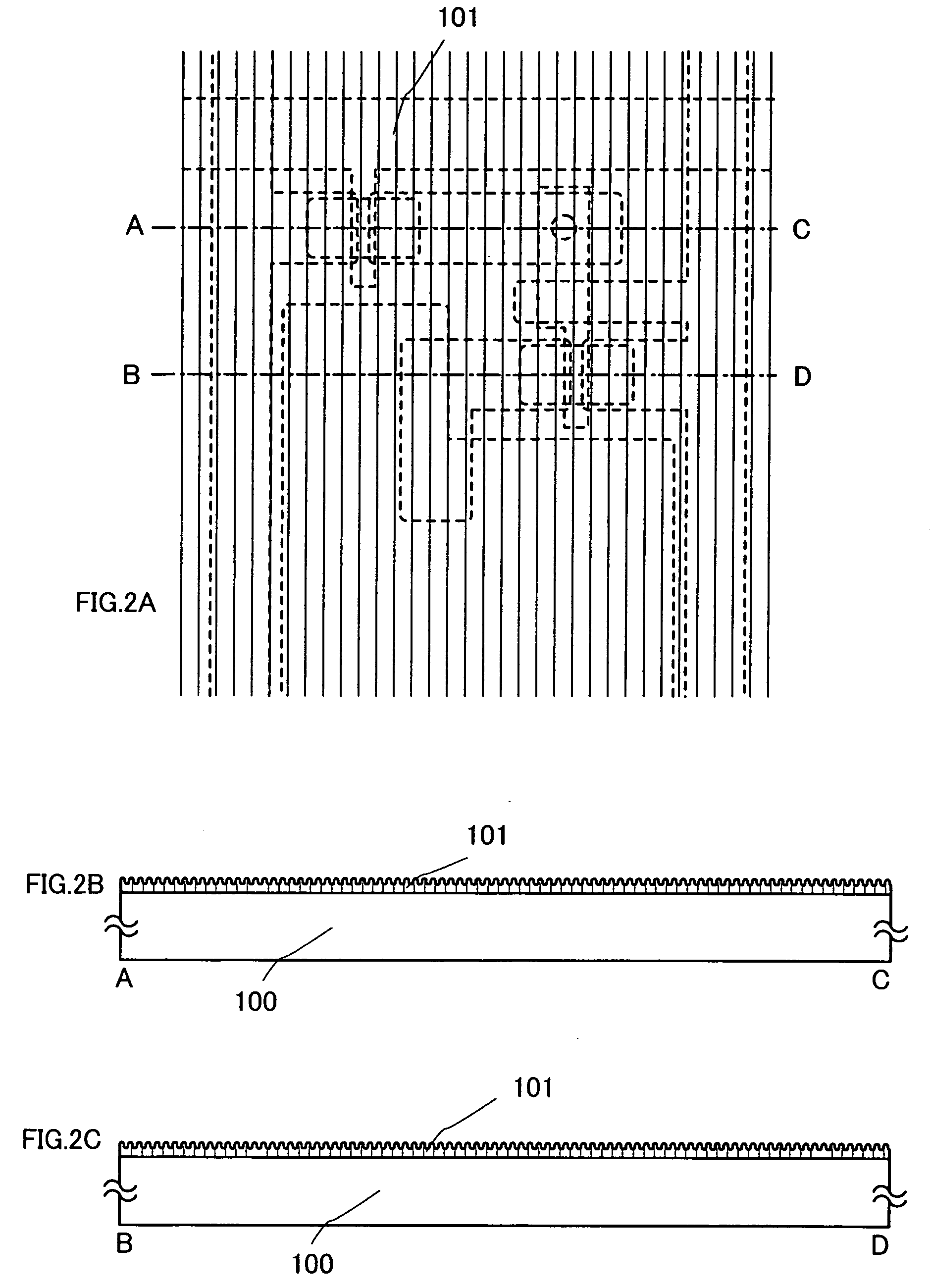

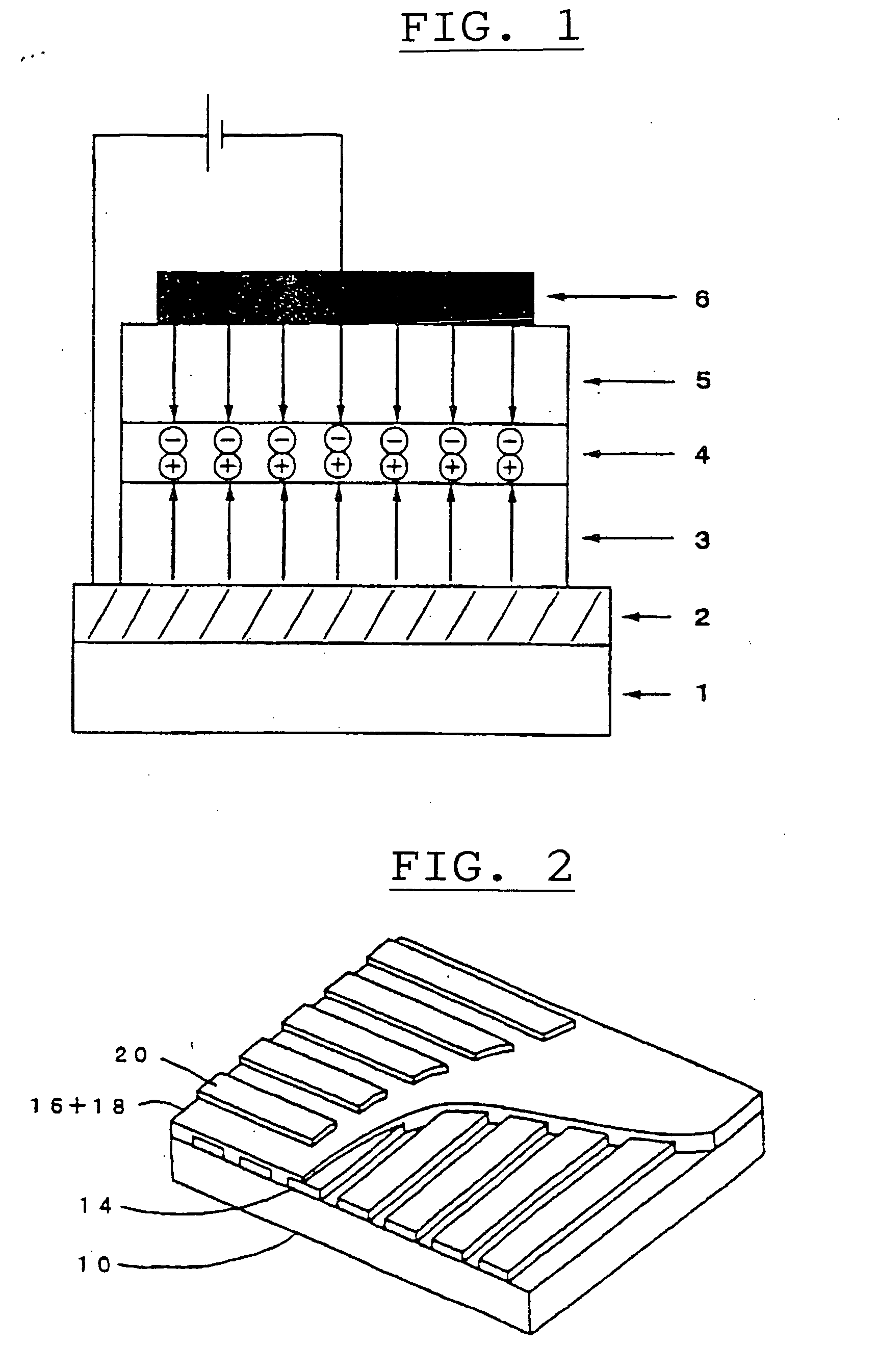

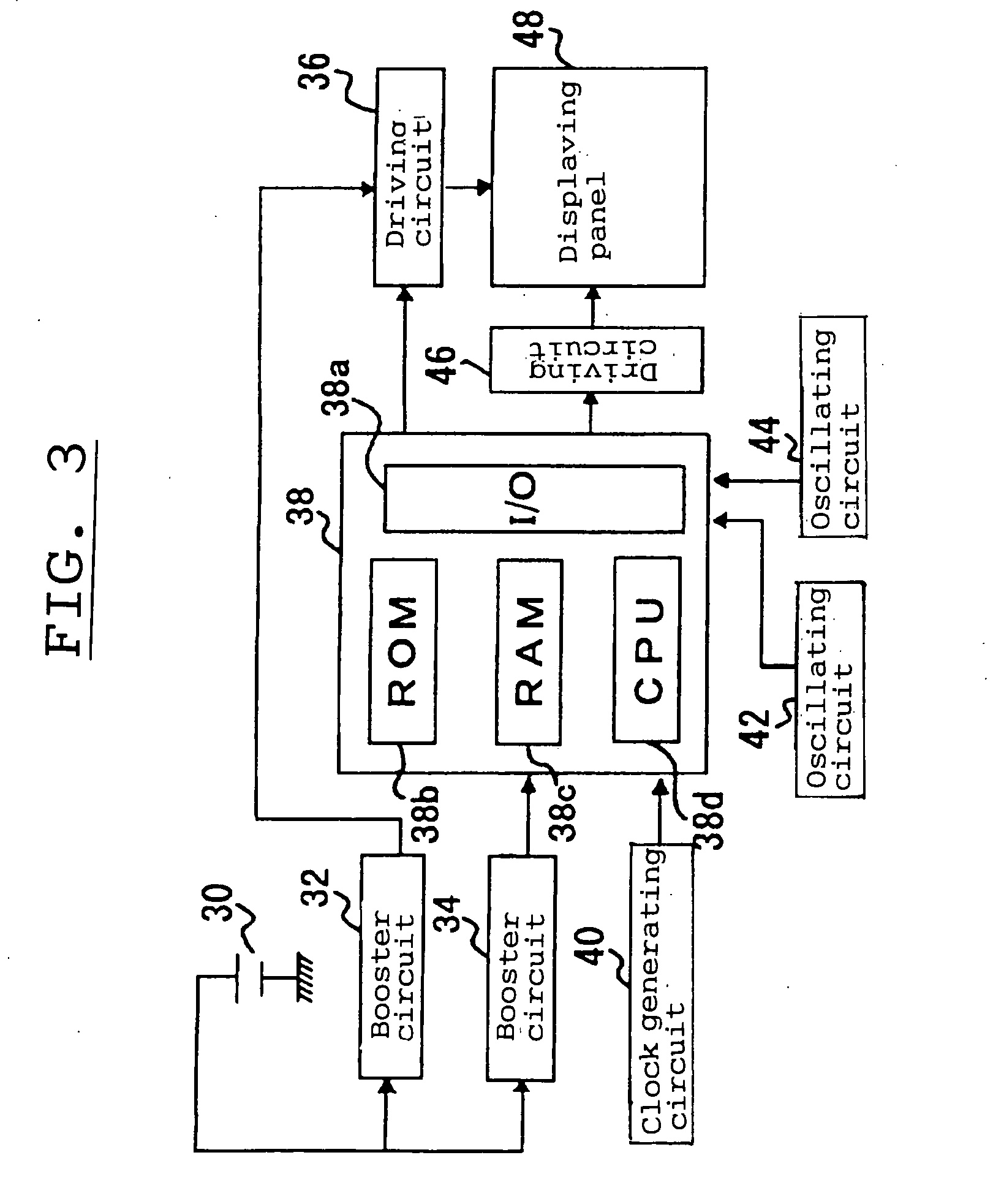

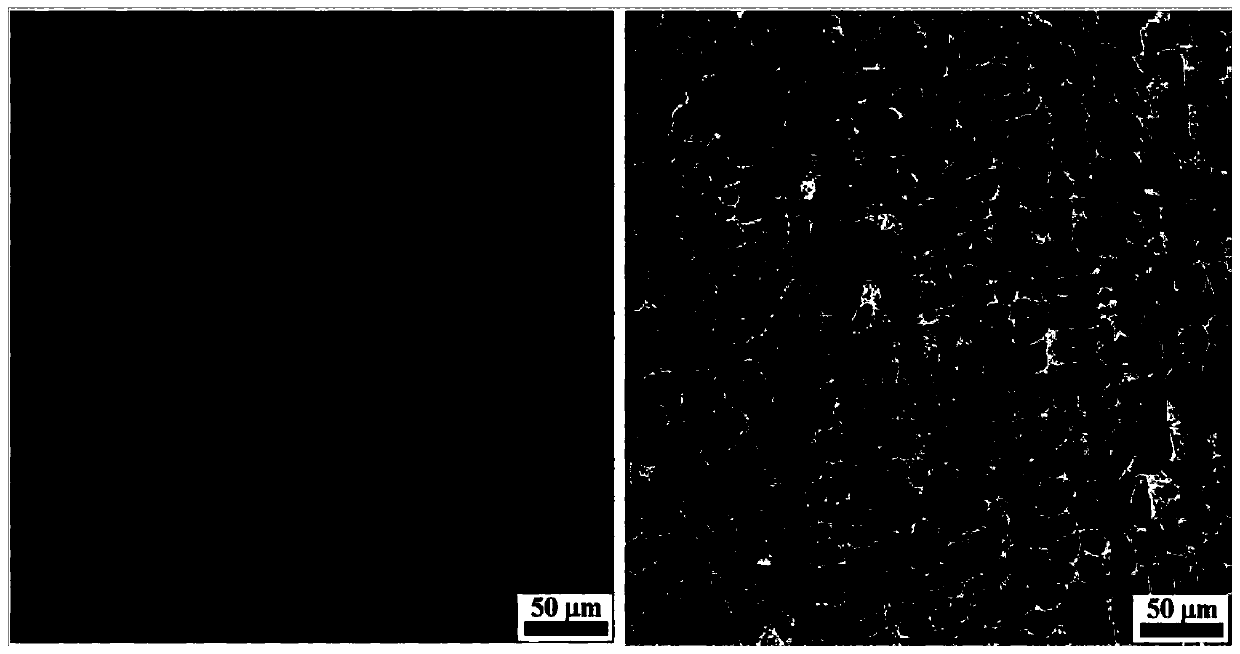

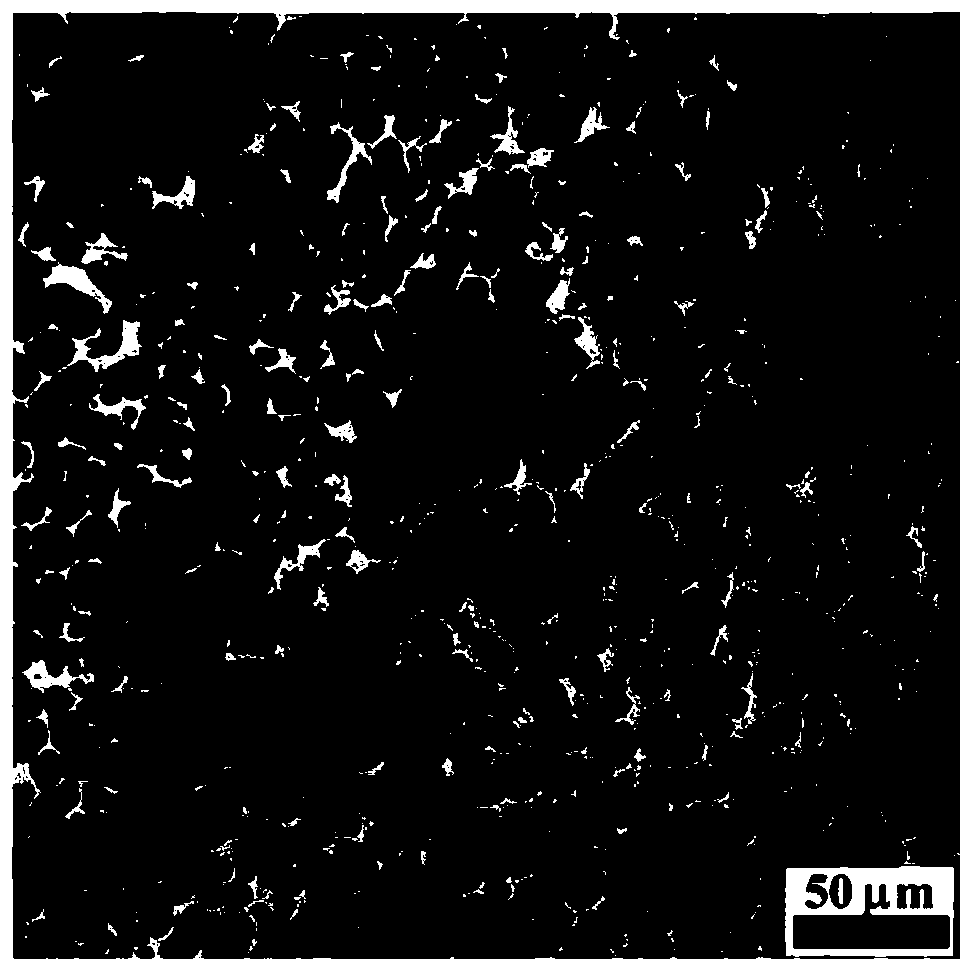

Semiconductor device and manufacturing method thereof

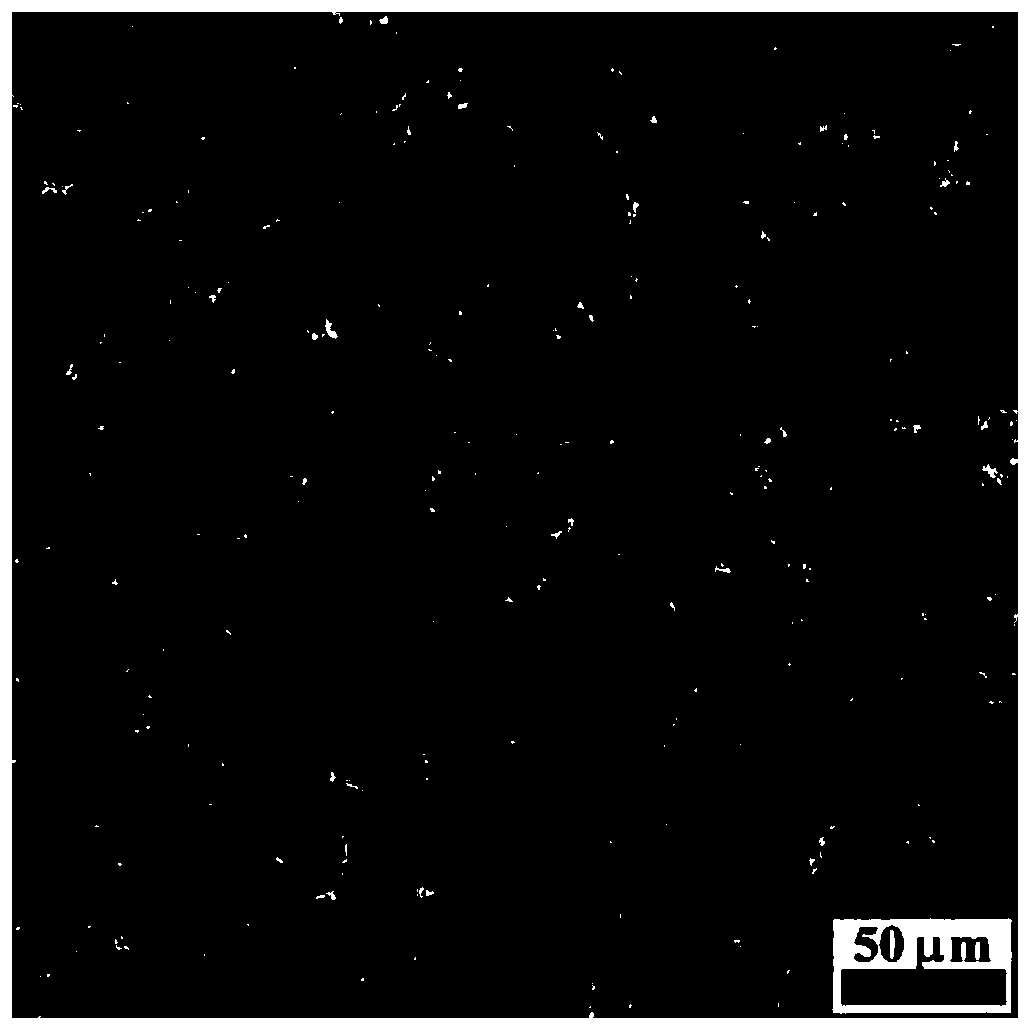

InactiveUS20060166411A1Improve adhesionLess material lossSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceManufacturing technology

An object of the invention is to provide a semiconductor device and a display device which can be manufactured with improved material efficiency through a simplified manufacturing process, and a manufacturing method thereof. Another object is to provide a technique capable of forming a pattern such as a wiring included in the semiconductor device or display device in a desired shape with good controllability. One feature of a method for manufacturing a semiconductor device is to comprise the steps of forming a layer having a rough surface, forming a region having low wettability by a composition containing a conductive material and a region having high wettability by the composition over the rough surface, and forming a conductive material using the composition in the region having high wettability. Since regions having largely different wettability (regions having a large difference in wettability) can be formed, a liquid conductive or insulating material is attached only to a formation region with precision. Accordingly, a conductive or insulating layer can be precisely formed in a desired pattern.

Owner:SEMICON ENERGY LAB CO LTD

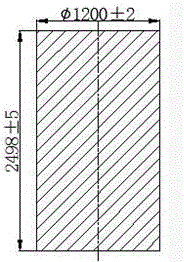

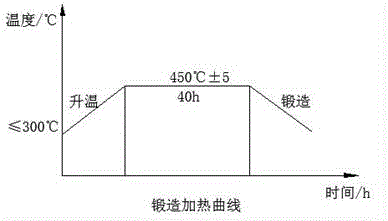

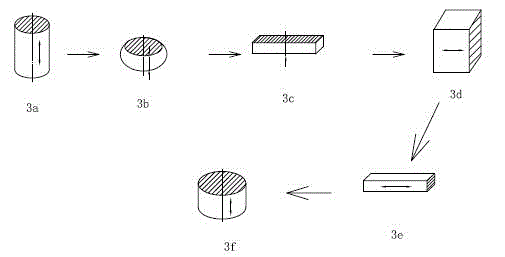

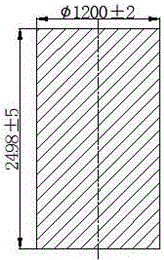

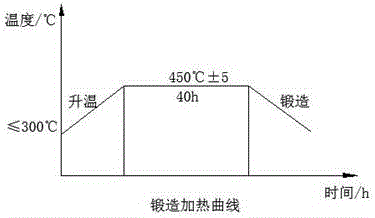

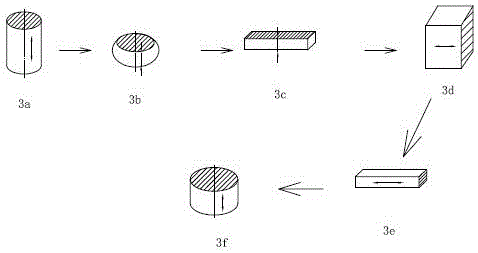

Forging forming technology of aluminum alloy straight-flanked ring with extra-large specification

The invention relates to a forging forming process of an aluminum alloy straight-flanked ring with an extra-large specification. The forging forming process comprises the fist step of blanking; the second step of a first heating before forging, wherein two heating stages are included; the third step of billet fabricating, wherein four stages are included; the fourth step of machining and damage removing; the fifth step of a second heating before forging; the sixth step of forging and ring rolling; the seventh step of heat treatment, wherein two heat treatment stages are included; the eighth step of machining to appropriate dimensions. By means of the forging forming process of the aluminum alloy straight-flanked ring with the extra-large specification, forging formability and mechanical performance of the aluminum alloy straight-flanked ring with the extra-large specification are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

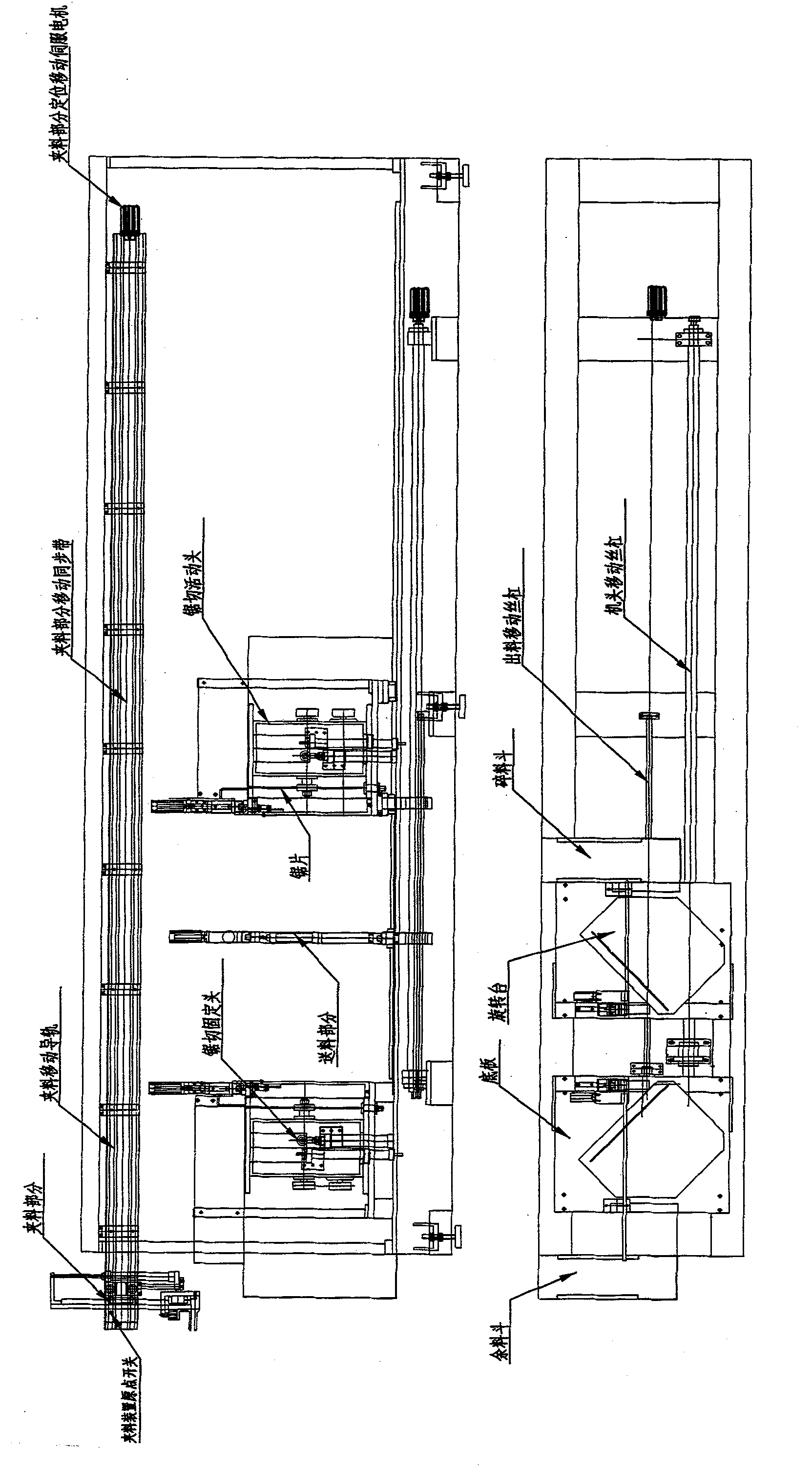

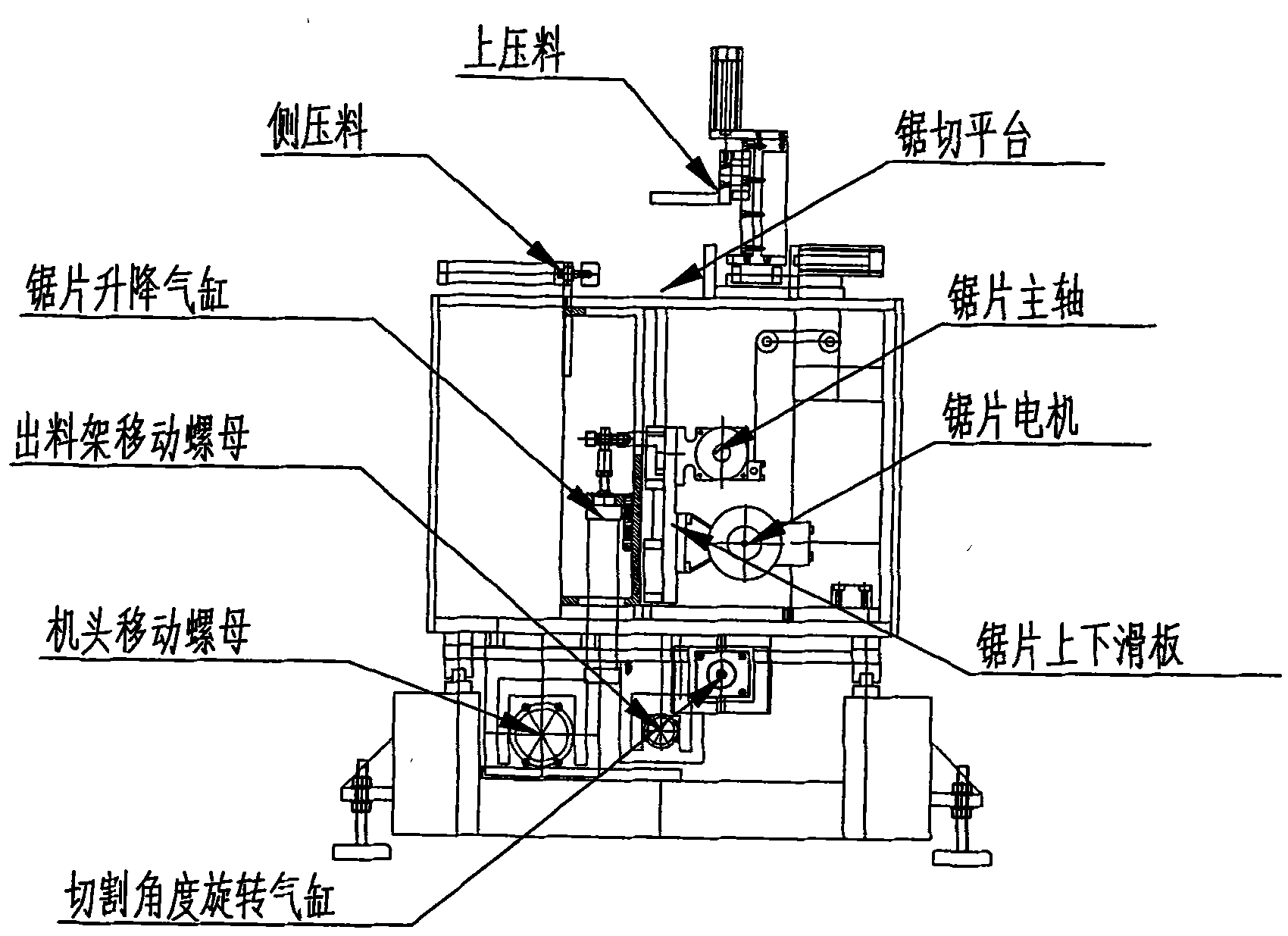

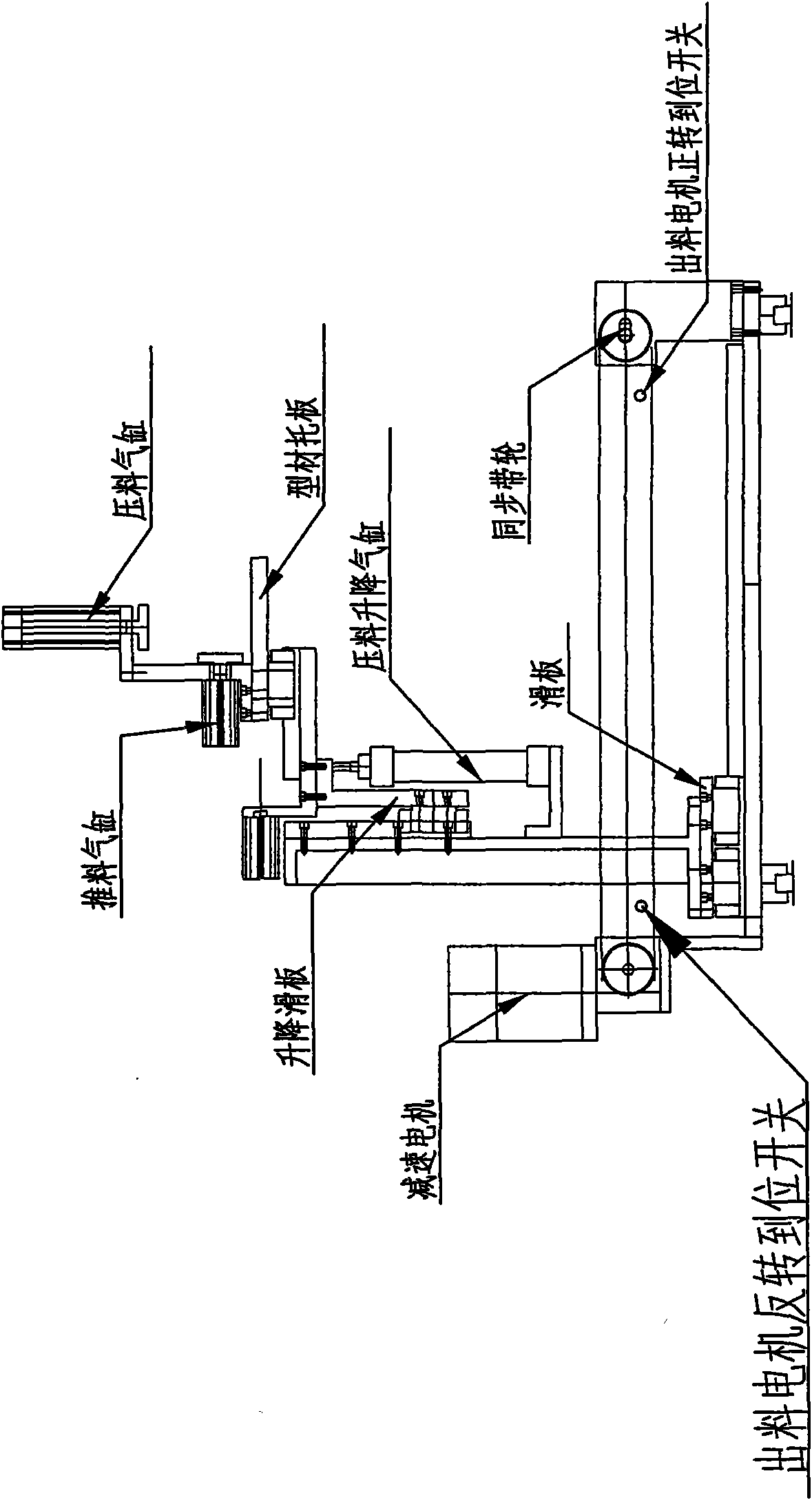

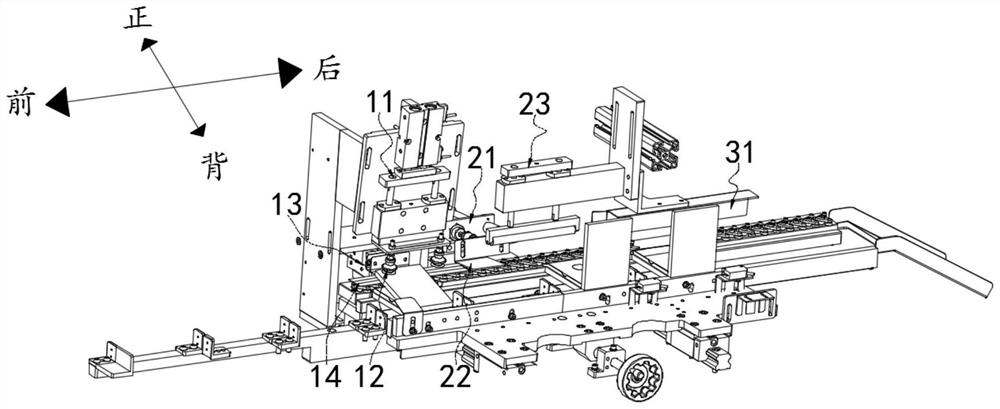

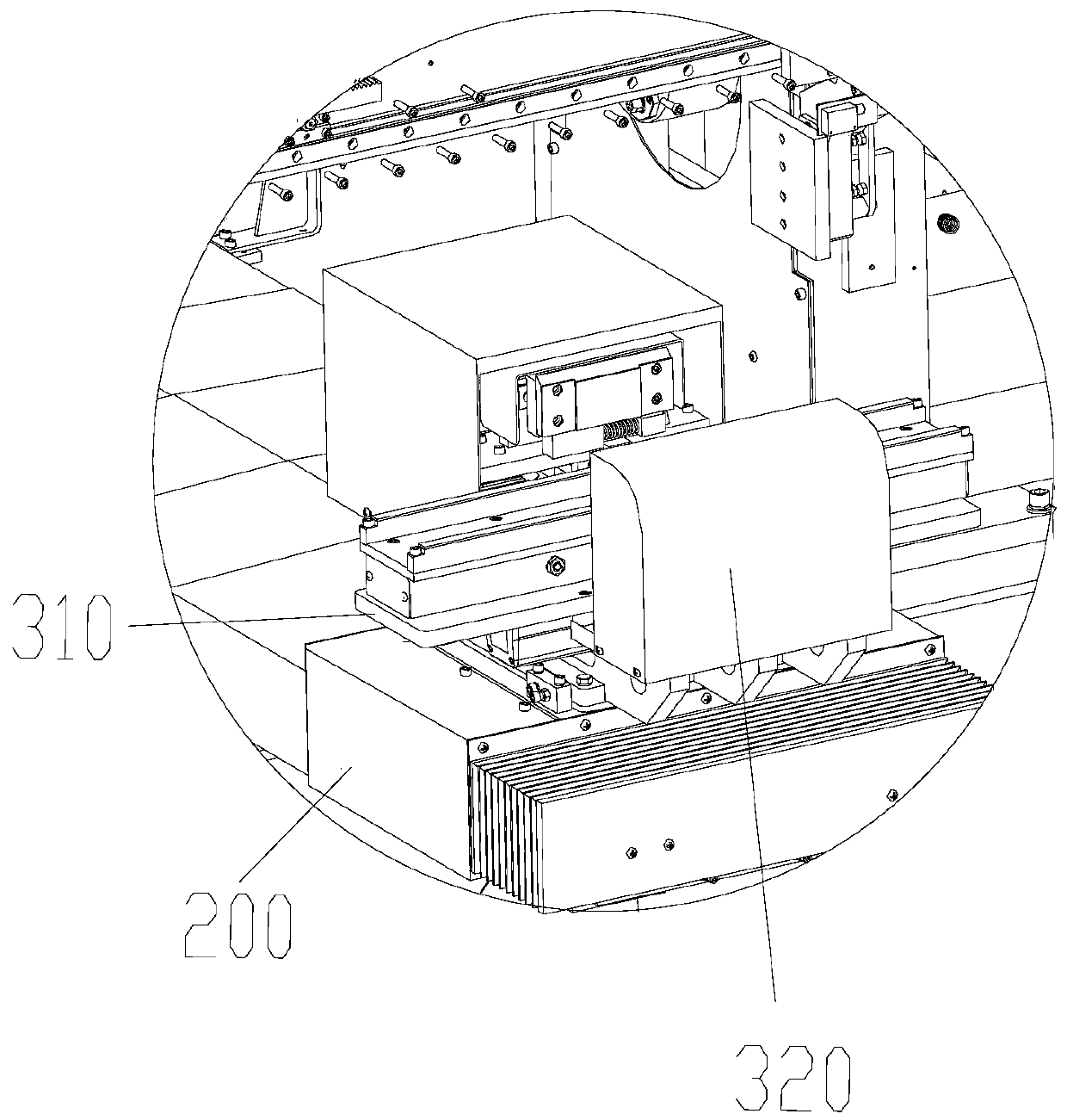

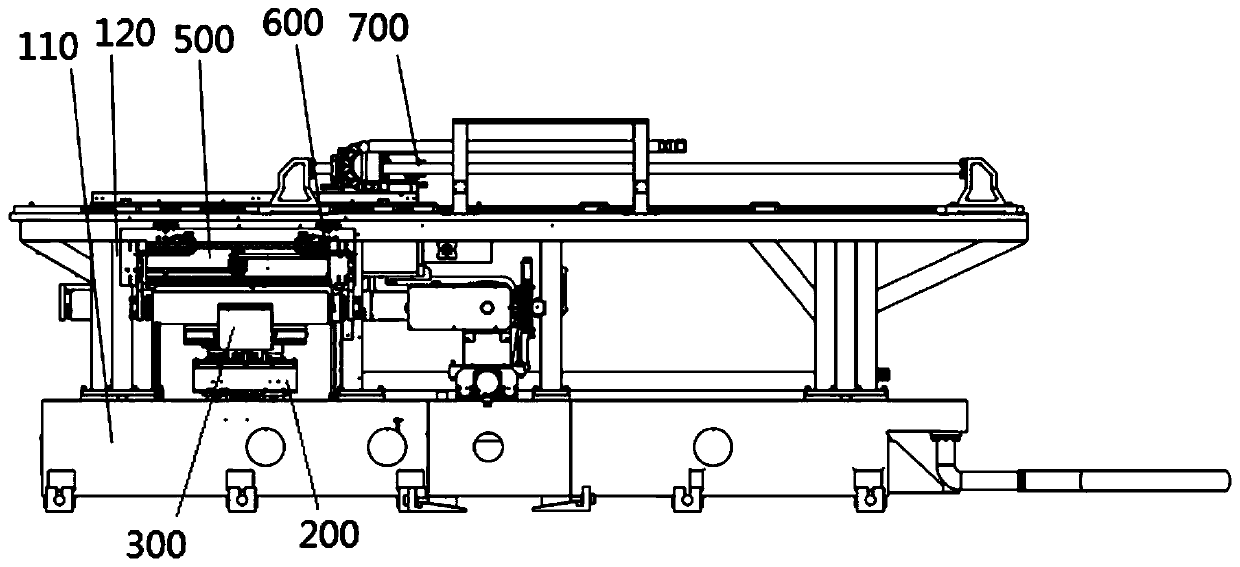

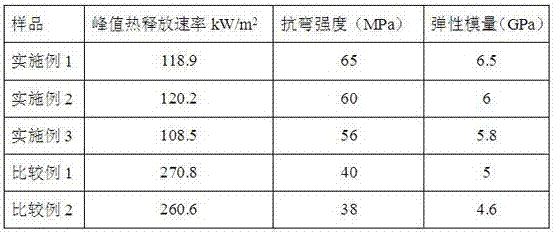

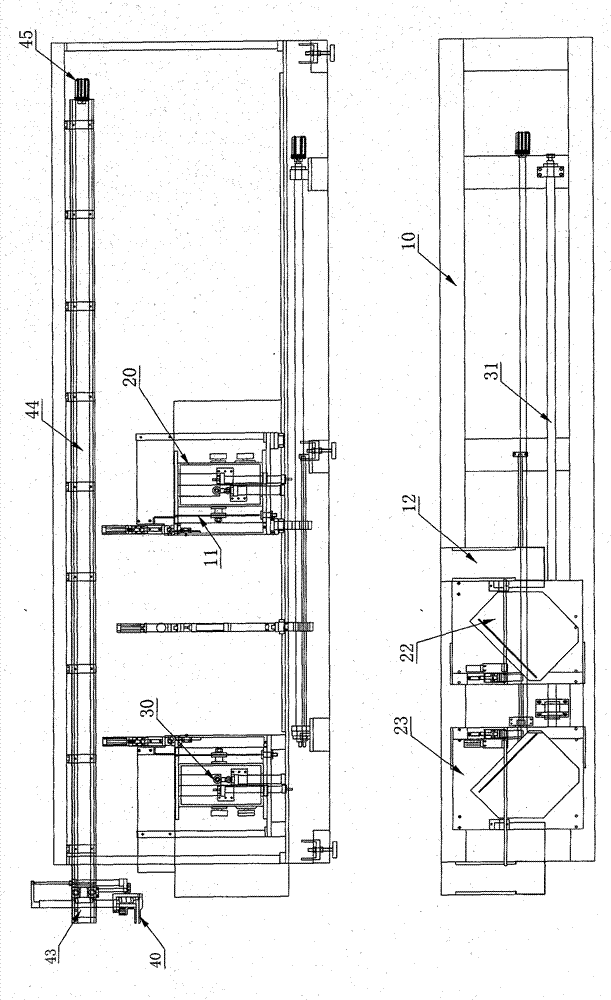

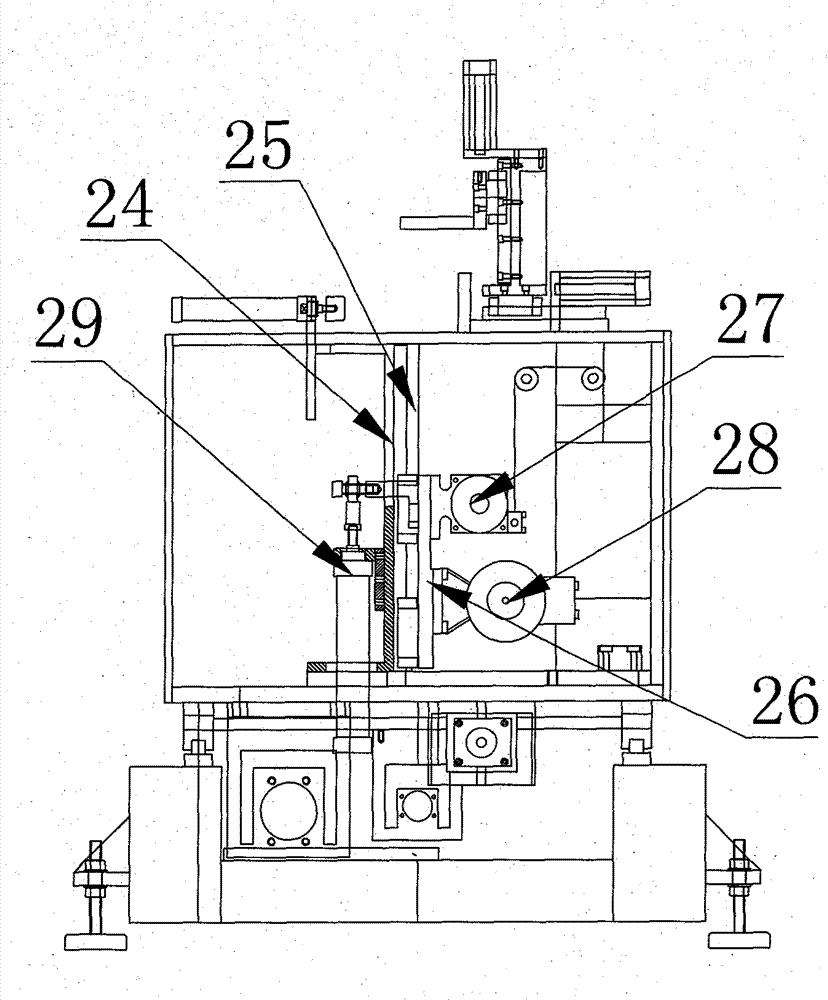

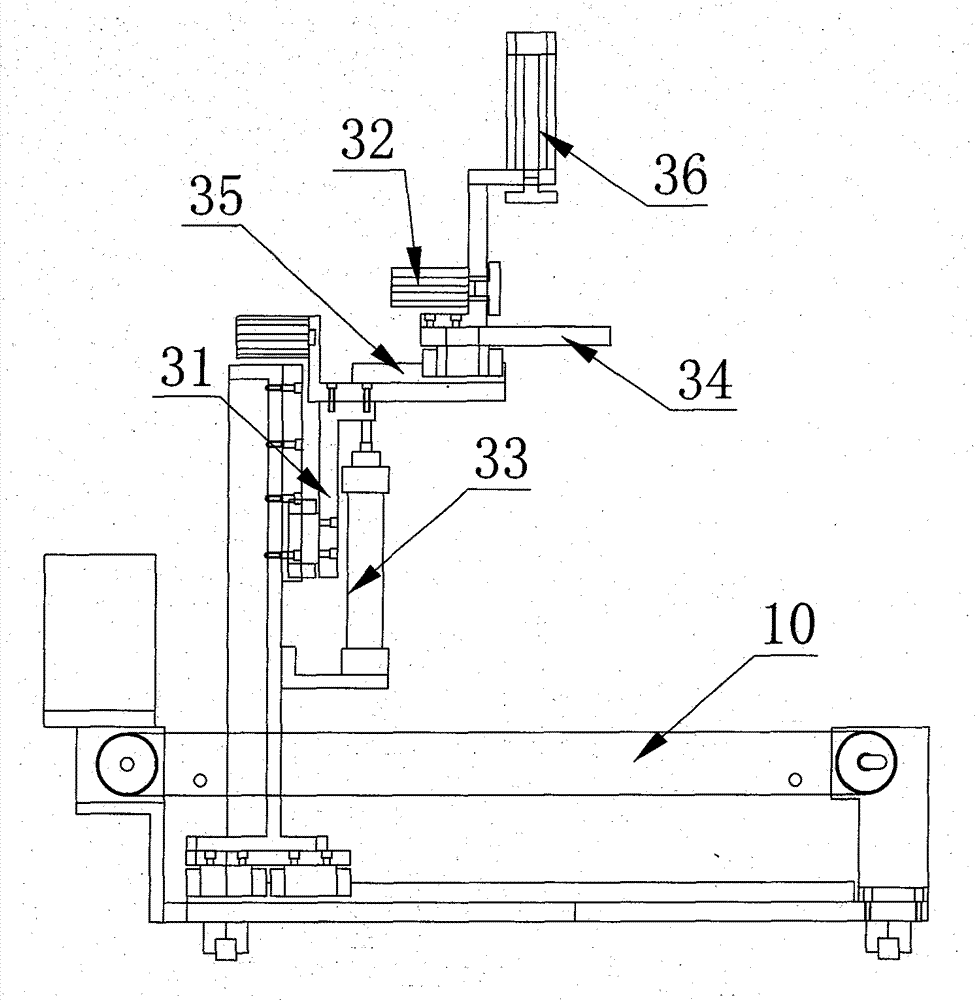

Numerical control double-headed sawing center for aluminum profiles

InactiveCN102101200AWon't scatterRealize humanized designMetal sawing devicesMetal sawing accessoriesNumerical controlSlide plate

The invention discloses a numerical control double-headed sawing center for aluminum profiles, which comprises a machine head up and down sawing part and an automatic loading part, wherein the machine had up and down sawing part mainly comprises a moving sawing machine head and a fixed sawing machine head, which are arranged on a frame, and a sawing platform arranged on top plates of the sawing machine heads, and the moving sawing machine head does horizontal motion under the action of a machine head screw rod through a machine head slide rail; a saw blade pillar is arranged on a baseplate of the sawing machine heads through a rotating baseplate, and the saw blade pillar can rotate around a centering shaft connected on the rotating baseplate; the saw blade pillar is connected with a sliding plate through a saw blade slide rail, a saw blade motor and a saw blade main shaft, which are connected through a belt, are fixedly arranged on the sliding plate, and a saw blade is arranged on the saw blade motor; and the sliding plate is connected with a telescopic rod of a lifting cylinder of the saw blade. Manual intervention is not required during the cutting process, the cutting process is automatically completed, a fundamental plane of the cut profile is large, the discharge is steady, the sawing is smooth, the fundamental plane does not need to be turned over when entering into the next corner combination process step, the processing errors are reduced, and the working efficiency is improved.

Owner:ANYANG JIAMING MACHINERY

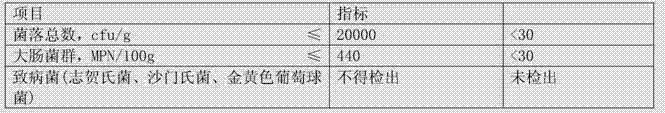

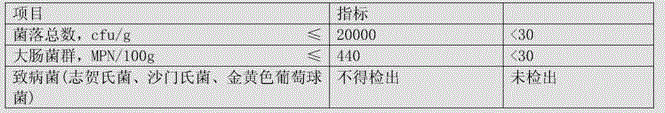

Culture of cordyceps militaris and preparation method of oral cordyceps militaris tablet

ActiveCN102515920AMaintain propertiesGuaranteed breaking effectHorticultureFertilizer mixturesBiotechnologyNutrition

The invention discloses a culture medium for cultivating cordyceps militaris, a preparation method of the culture medium, a culture method of cordyceps militaris and a preparation method of an oral cordyceps militaris tablet. The culture medium for cultivating cordyceps militaris is an aqueous solution and comprises 130 to 140g / L of dry silkworm chrysalis meal, 60 to 65g / L of rice flour, 1.2 to 1.5g / L of potassium dihydrogen phosphate and 0.8 to 1.2g / L of sodium dihydrogen phosphate. The culture method of cordyceps militaris comprises the following steps of inoculation, culture and harvest re-culture. The preparation method of the oral cordyceps militaris tablet comprises the following steps of drying, multiple cold sterilization treatment, crushing, wet granulation and tabletting. Cordyceps militaris cultured by the culture medium provided by the invention has nutrient content far higher than nutrient content of cordyceps militaris cultured by other culture methods, has a golden color, a luster and a heavy fragrance. In the preparation of the dried oral cordyceps militaris tablet, multiple cold sterilization treatment is carried out after drying. Through low-temperature superfine crushing, a cordyceps militaris spore wall breaking effect is guaranteed and a nutrition constituent loss is reduced.

Owner:贵州贵安精准医学股份有限公司

Preparation of industrial asphalt

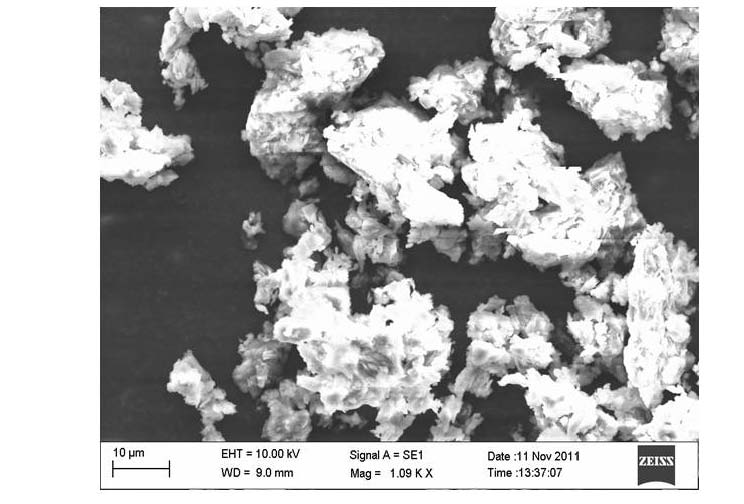

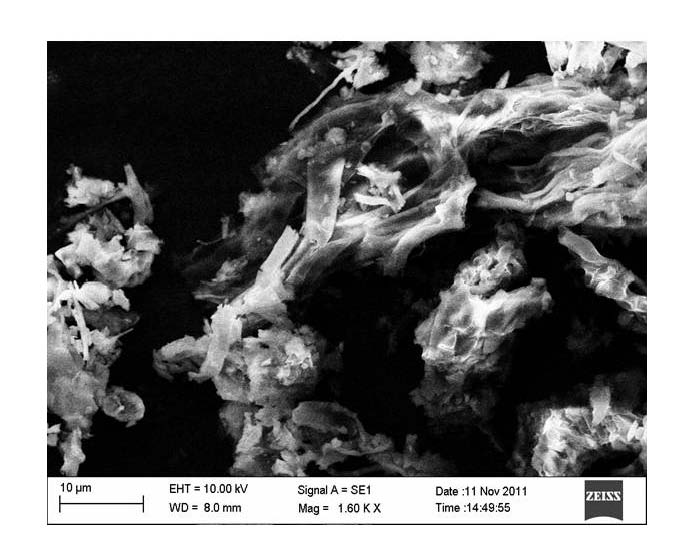

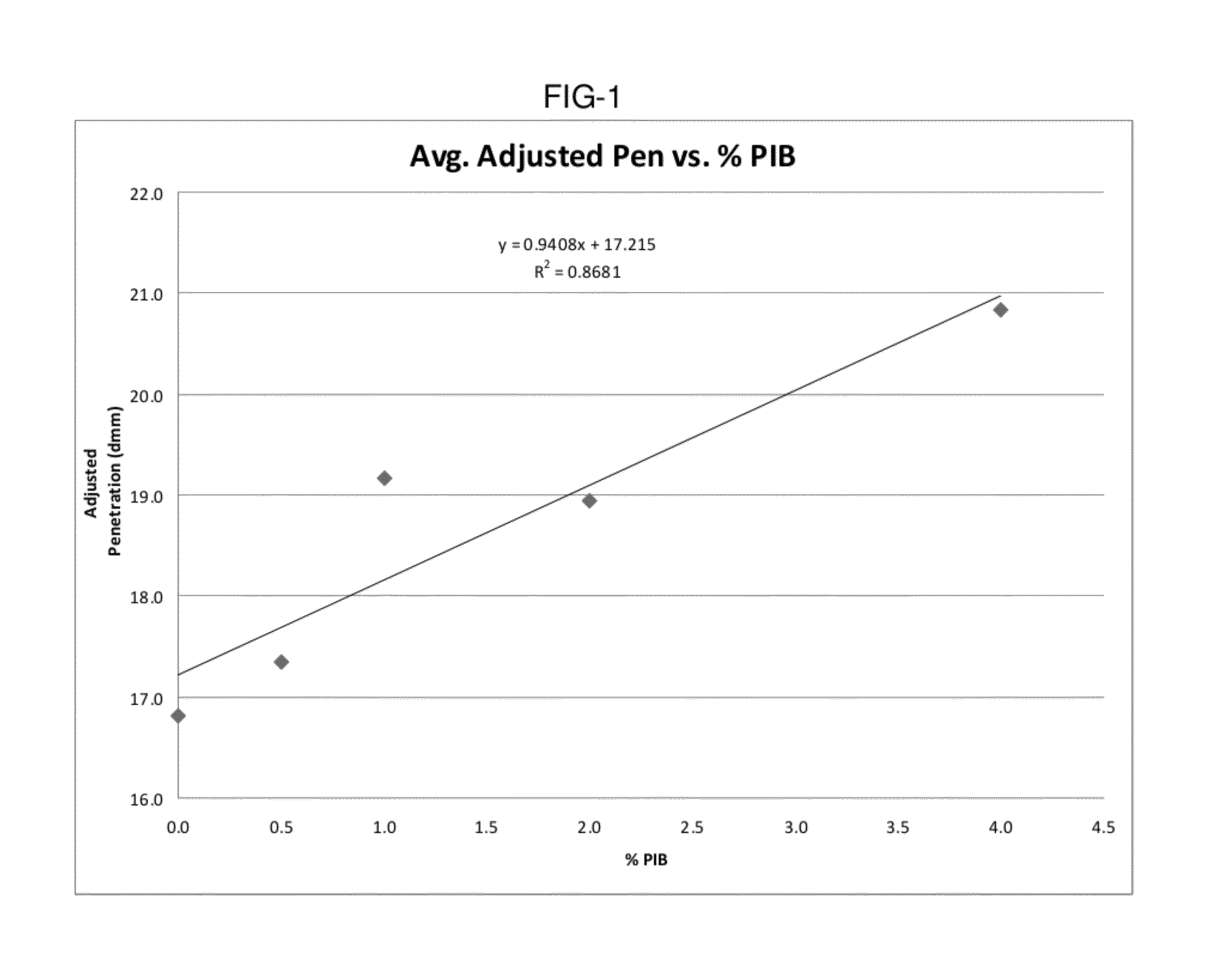

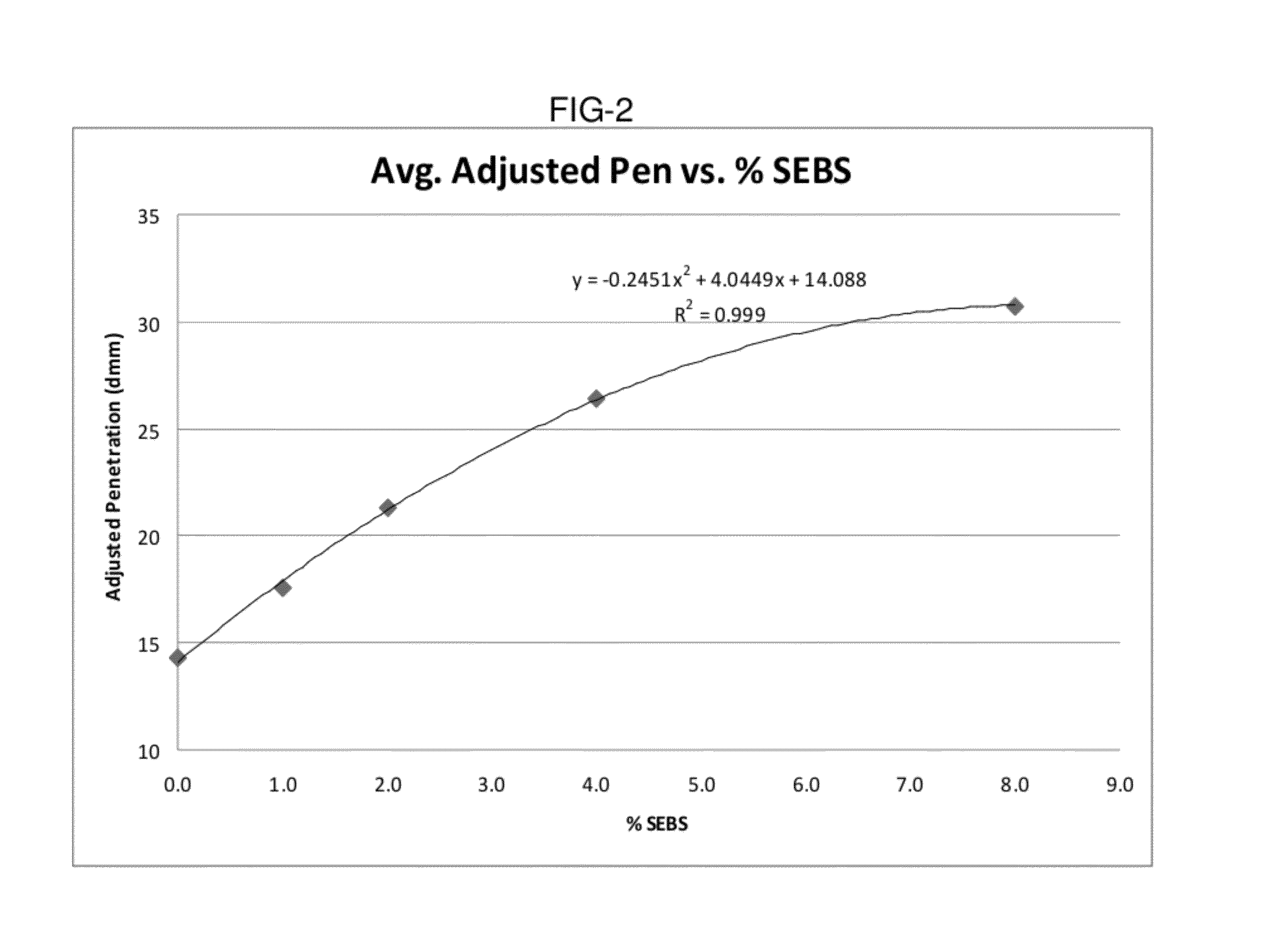

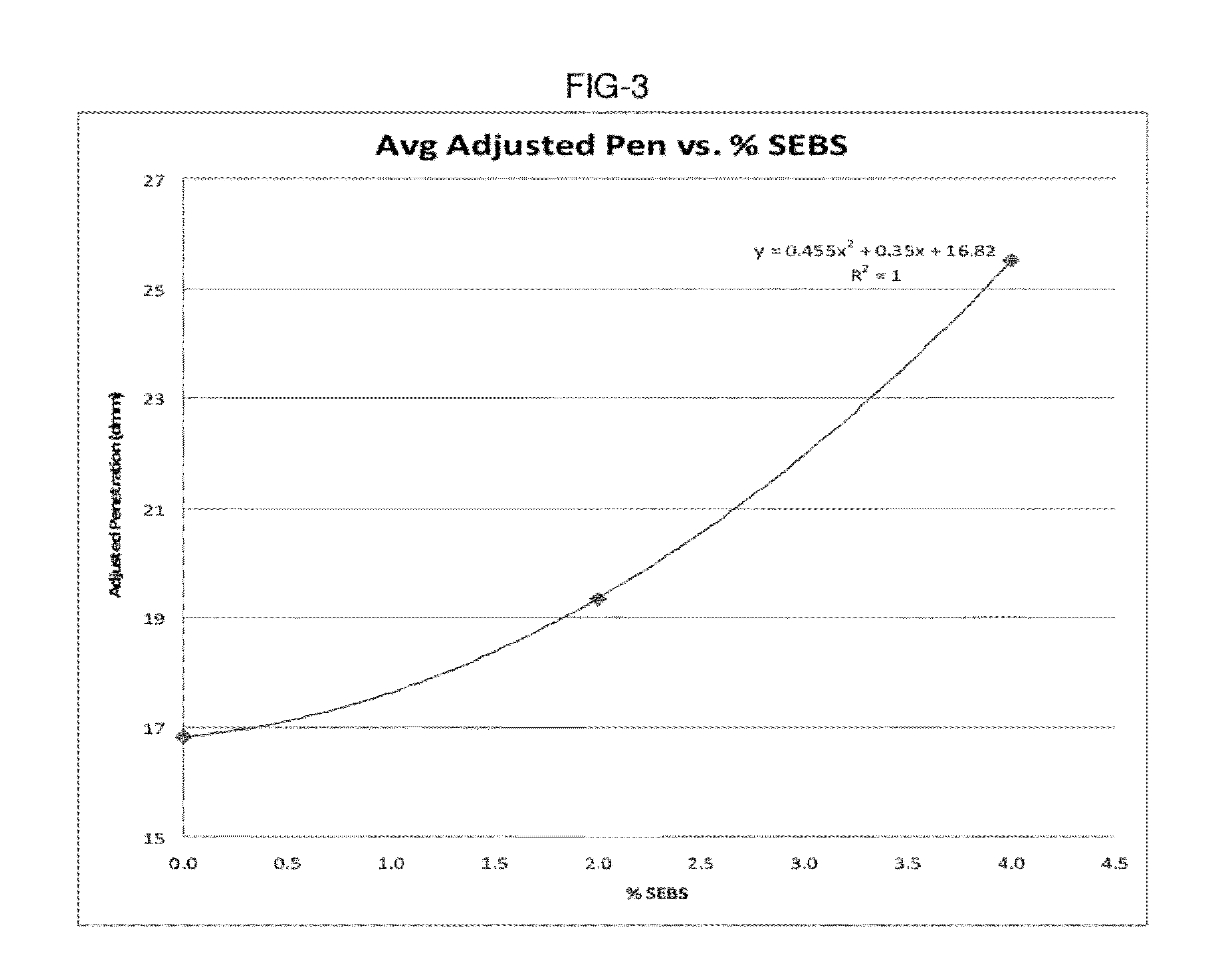

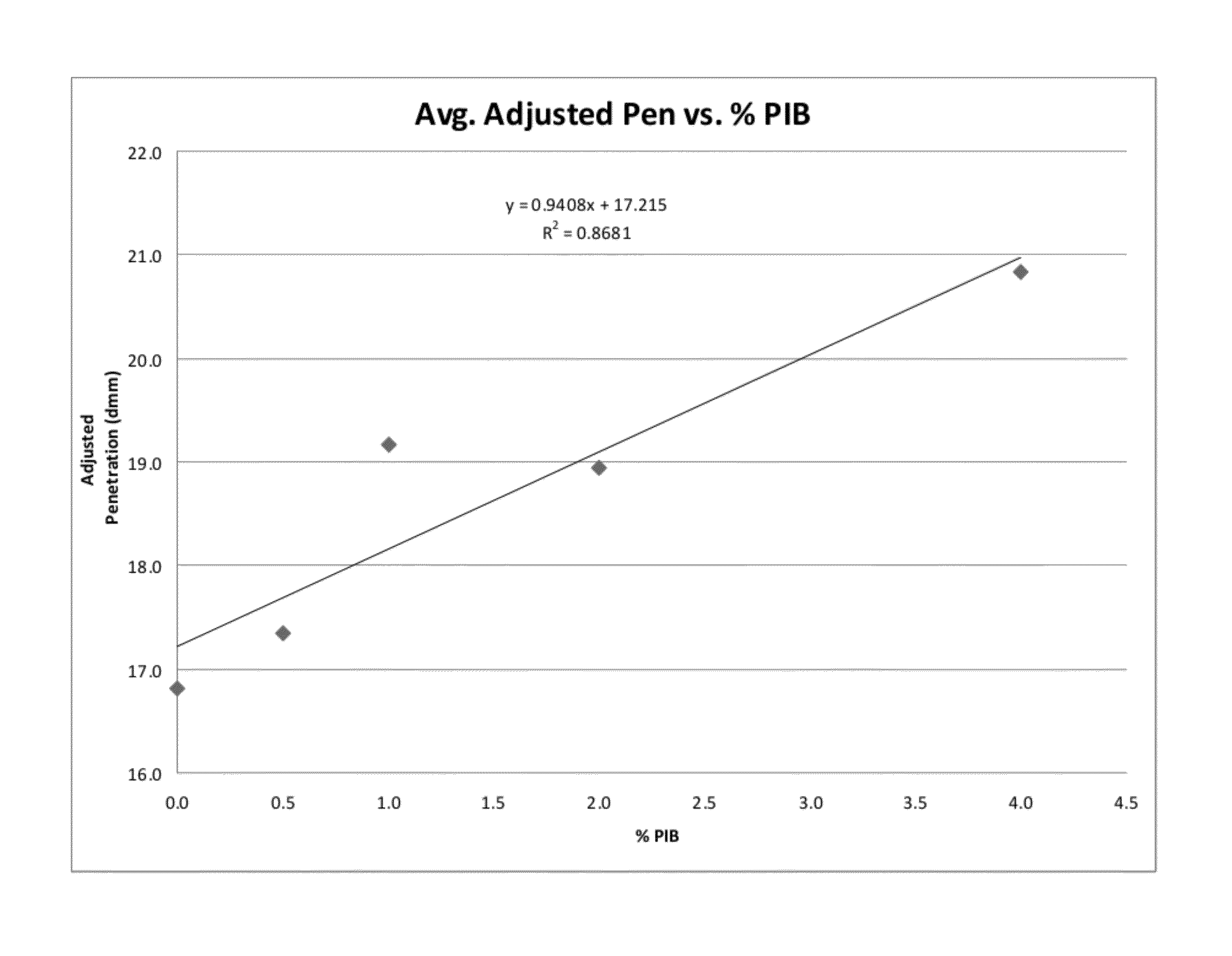

ActiveUS20120302673A1Increase capacityReduce environmental impactRoof covering using tiles/slatesBuilding insulationsPolymer scienceAsphalt

The present invention relates to a method for preparing an industrial asphalt comprising sparging an oxygen containing gas through an asphalt flux in the presence of 0.25 weight percent to about 12 weight percent of a highly saturated rubbery polymer at a temperature within the range of about 400° F. to about 550° F. for a period of time which is sufficient to increase the softening point of the asphalt flux to a value which is within the range of 185° F. to 250° F. and a penetration value of at least 15 dmm to produce the industrial asphalt. The highly saturated rubbery polymer can be a styrene-ethylene / butylene-styrene block copolymer rubber or a highly saturated styrene-ethylene / propylene-styrene block copolymer rubber.

Owner:BMIC LLC

Method for molding hyperbolic streamlined bridge abutment moulding plate space surface

ActiveCN101347897AAccurate locationSmooth transitionSpecial data processing applicationsNumerical controlThree-dimensional space

The invention relates to a shaping method of a space curved surface of a hyperbolic streamline shape bridge pier template; the shaping method includes the following steps: in AutoCAD, the radian of the space curved surface along the height direction is replaced by a segmented chord, and the maximum gap between a segmented arc and a corresponding chord is not larger than 1.5mm; a three-dimensional space model is established in Pro / E, and refining and flattening are carried out to obtain a precise expanded view of the space curved surface; the expanded view in Pro / E is transformed into a CAXA formatted file, proper kneading is carried out on the border splines of the expanded view to obtain an optimized expanded view of the curved surface, the optimized expanded view of the curved surface is transformed into program codes which are sent to a numerical control under water plasma cutting machine to finish cutting; a three-axis roller is adopted for arc rolling according to the radius of the arc corresponding to each segmented curved surface to shape the space curved surface; each shaped segmented space curved surface is treated with welding shaping on a clamping fixture from two sides to the middle to finish the manufacturing of the space curved surface. The shaping method of the invention can improve the shaping quality of the space curved surface, enhance work efficiency and reduce material waste in cutting.

Owner:CRRC TANGSHAN CO LTD

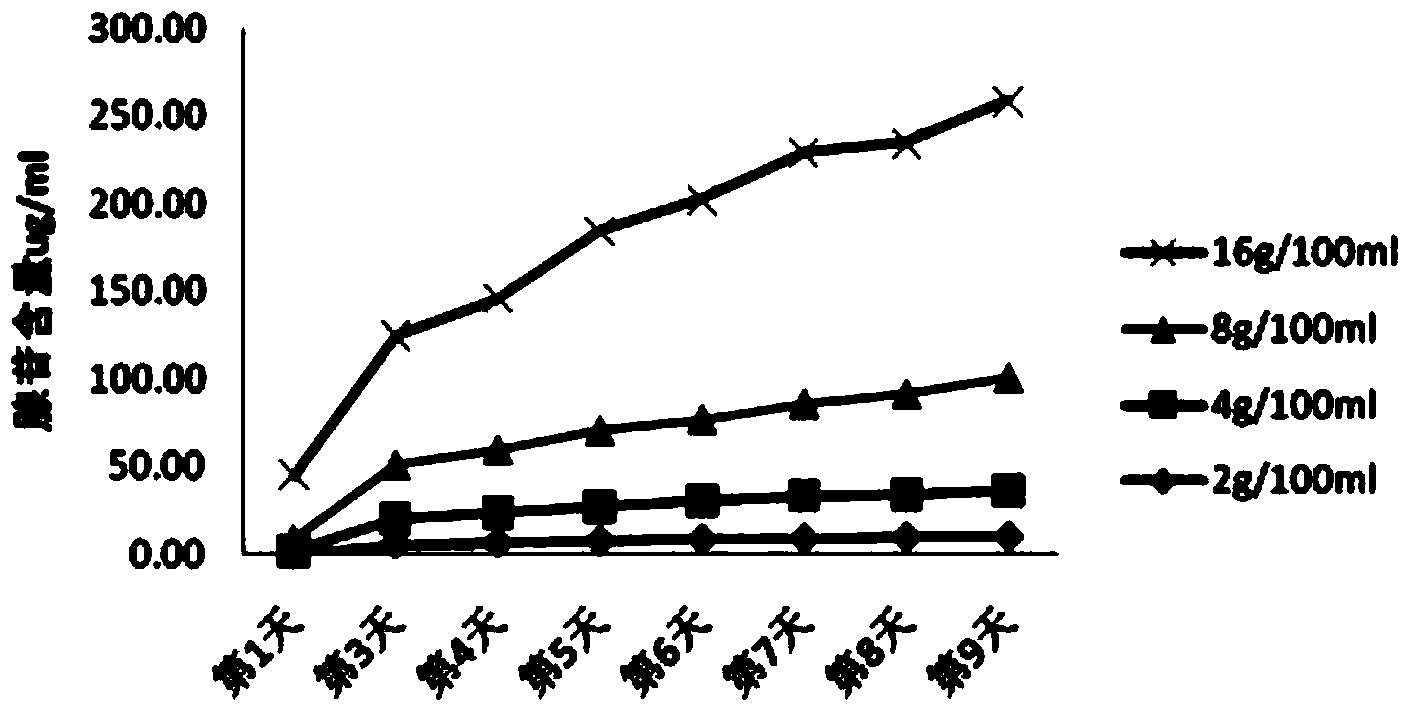

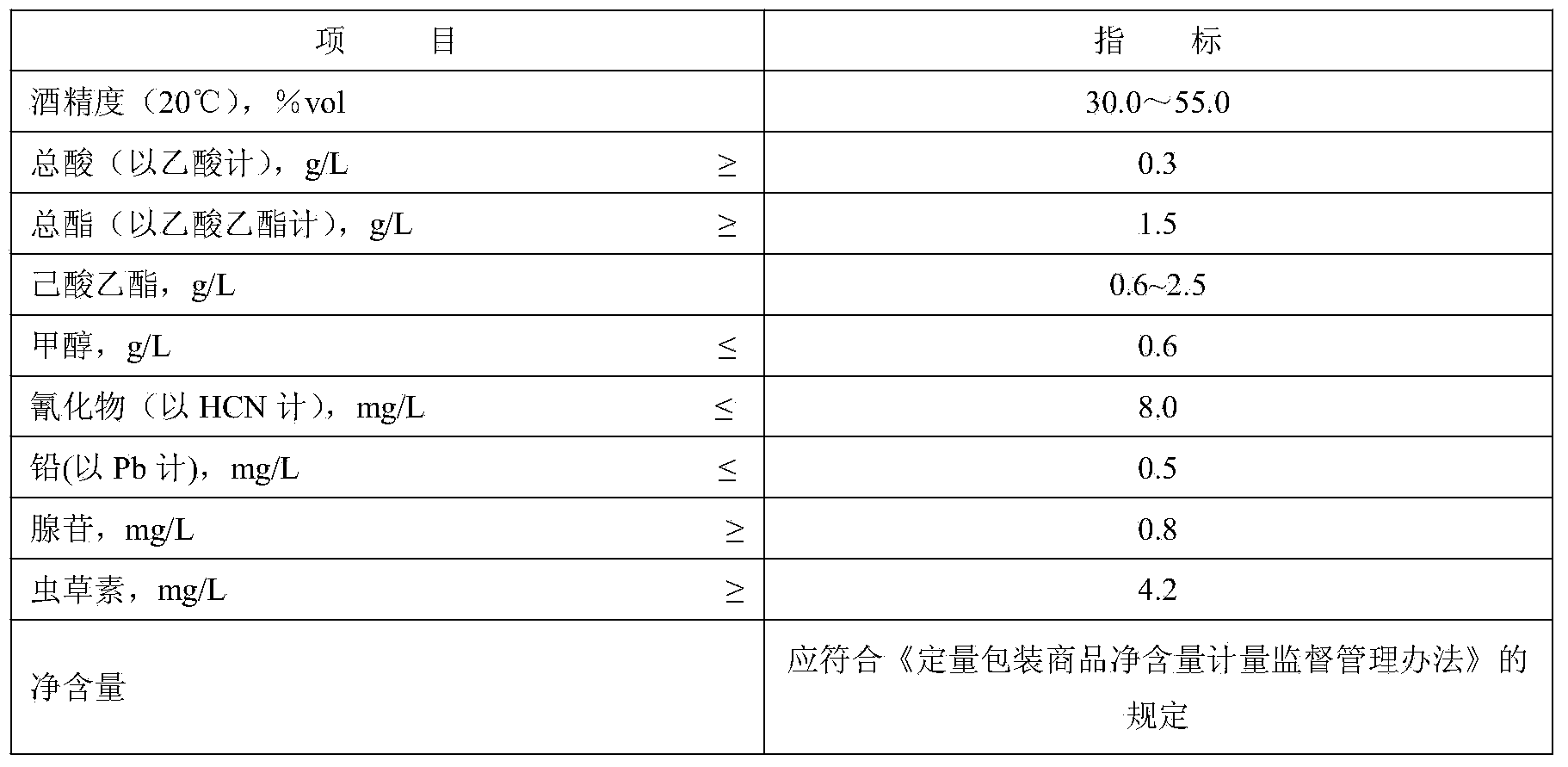

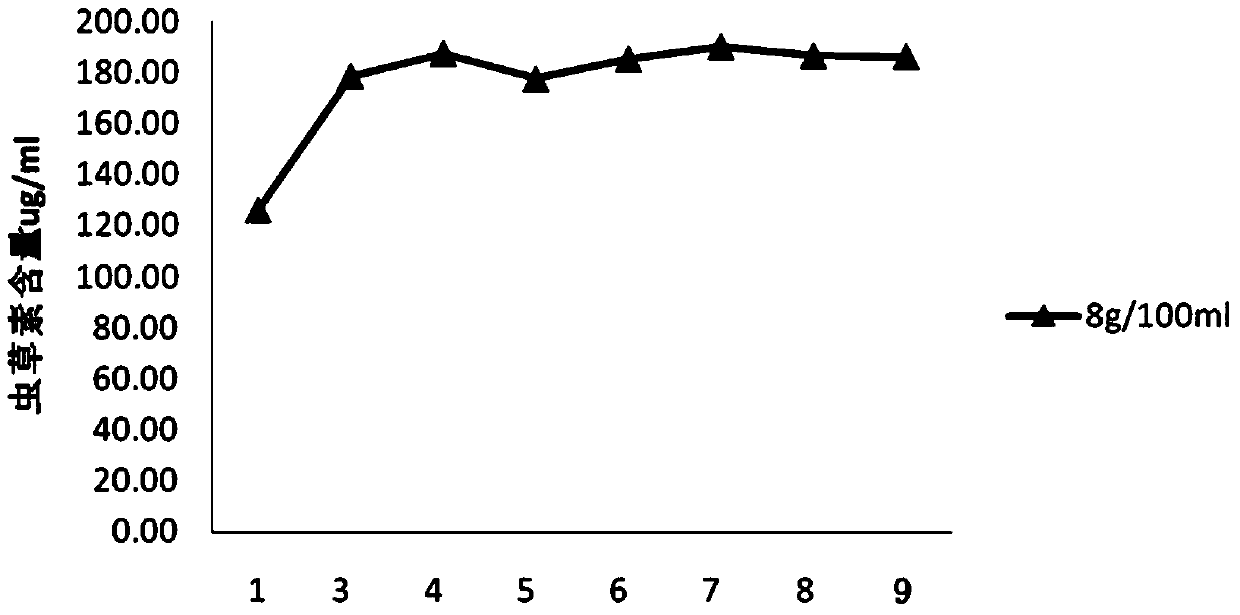

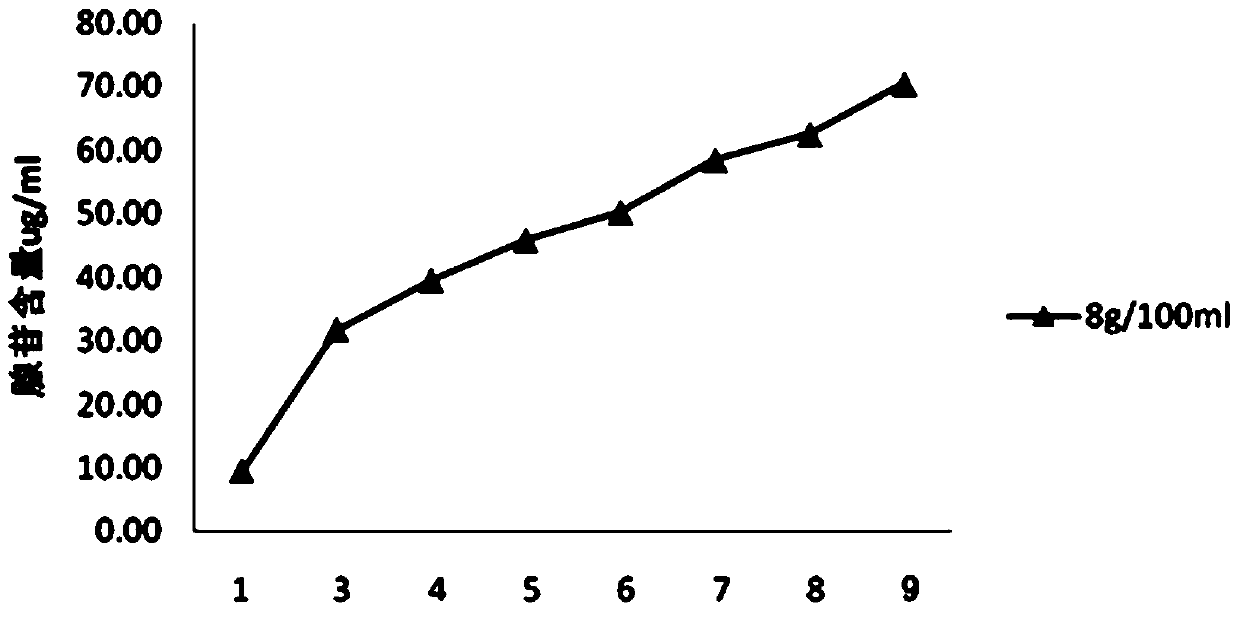

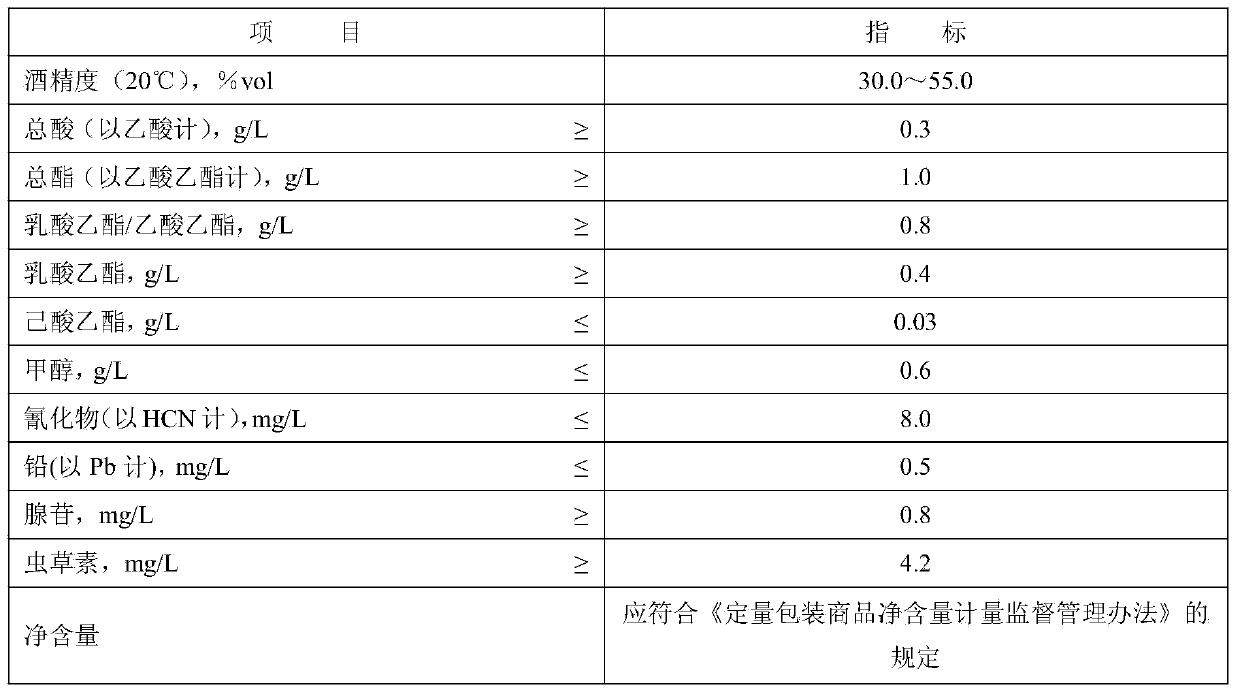

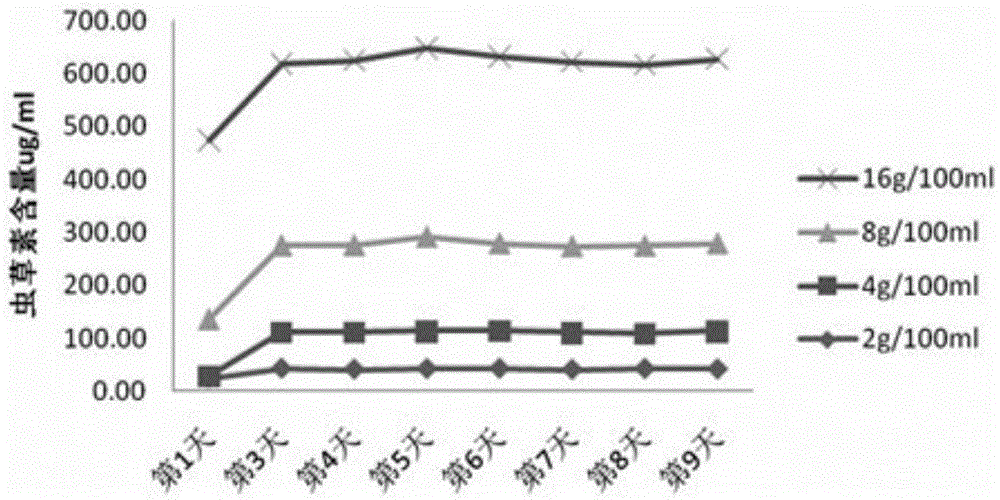

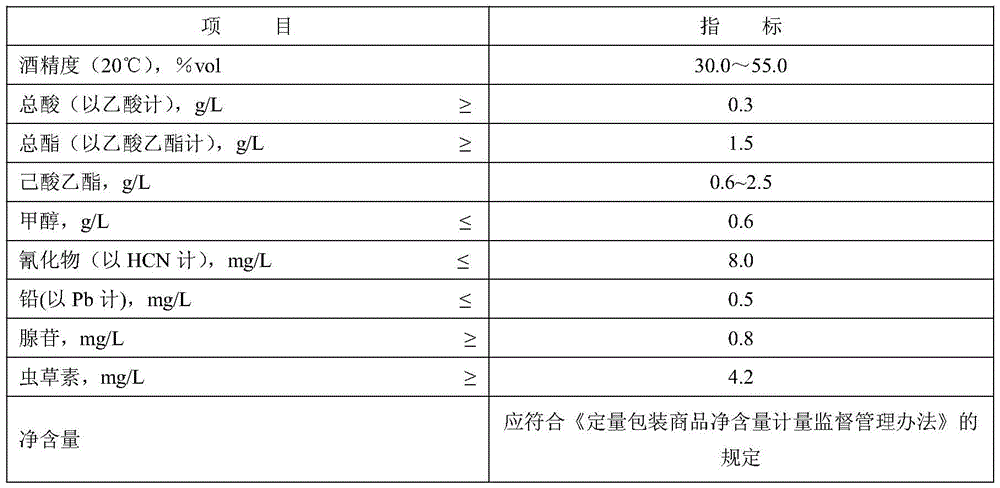

Preparation method of cordyceps militaris compound wine

ActiveCN103710241AHigh content of bioactive substancesImprove product qualityAlcoholic beverage preparationAlcohol contentCordyceps

The invention provides a preparation method of cordyceps militaris compound wine. The preparation method comprises the following steps: selecting and drying high-quality cordyceps militaris fruit bodies and obtaining cordyceps militaris superfine powder by adopting the low temperature superfine grinding technology; fully and uniformly mixing the cordyceps militaris superfine powder with high-quality spirit with high alcohol content, then putting the mixture in a ceramic wine jar to be soaked, controlling the room temperature of the ceramic wine jar to be 15-20 DEG C, stirring the mixture periodically, filtering the solution and taking the supernatant, thus obtaining the cordyceps militaris wine base; blending the cordyceps militaris wine base with a blending liquid to prepare the drink wine with an appropriate alcohol content. The preparation method is simple in steps, has low equipment requirements and is controllable in quality and low in cost and the active ingredients in the body of the cordyceps militaris compound wine prepared by the method are abundant and measurable.

Owner:贵州贵安精准医学股份有限公司

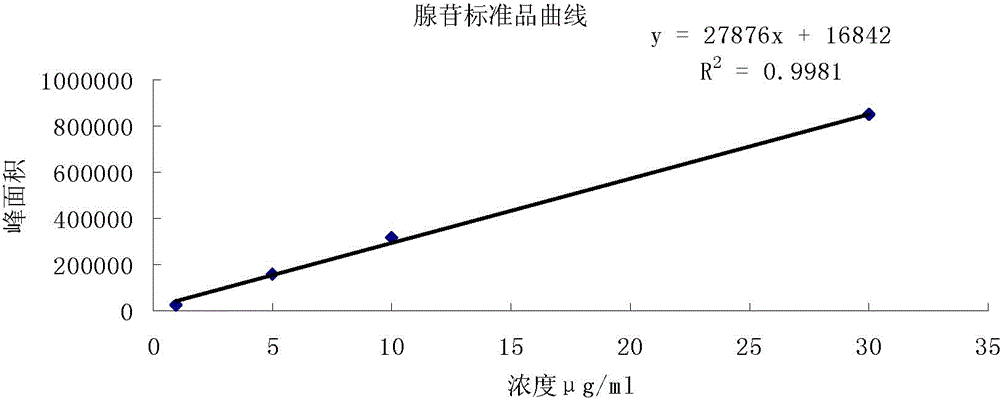

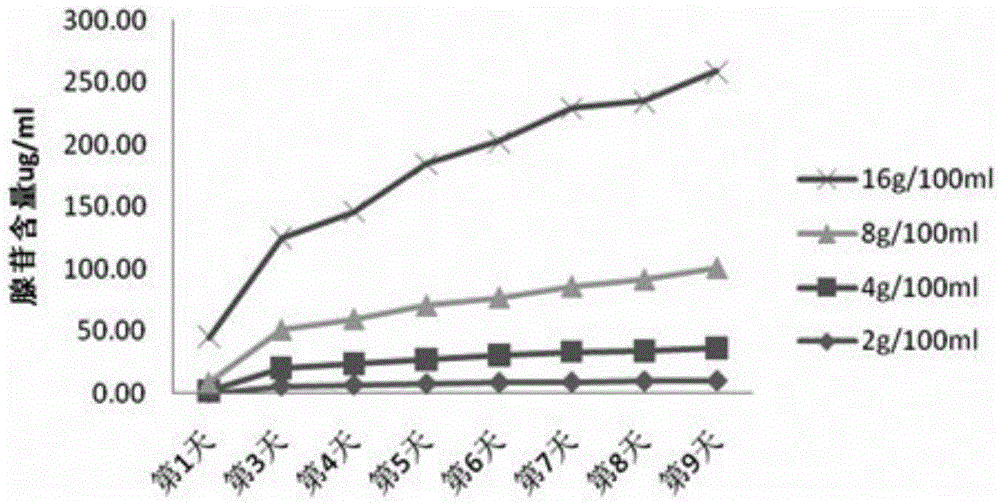

Production method for high-adenosine-content fruiting body of Cordyceps militaris

InactiveCN107311733AHigh extraction rateSimple preparation processAnimal corpse fertilisersCultivating equipmentsBiotechnologyYeast

The invention discloses a production method for a high-adenosine-content fruiting body of Cordyceps militaris. The fruiting body of Cordyceps militaris is cultured in a medium. 2000 g of the medium comprises, by weight, 80 to 120 g of shelled peanuts, 80 to 120 g raw soybeans, 450 to 550 g of rice, 40 to 60 g of tomatoes, 40 to 60 g of dry silkworm chrysalis powder, 40 to 60 g of fish meal, 40 to 60 g of fresh beef, 40 to 60 g of potatoes, 10 to 20 g of glucose, 5 to 10 g of yeast powder, 10 to 20 g of sucrose , 20 to 30 g of agar, 20 to 60 mg of vitamin B1, 450 to 550 ml of straw leachate and 450 to 550 ml of soil leachate. The production method provided by the invention is simple in process; and the prepared fruiting body of Cordyceps militaris is high in extraction rate of adenosine.

Owner:李鹄鸣

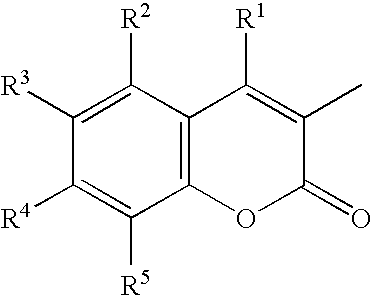

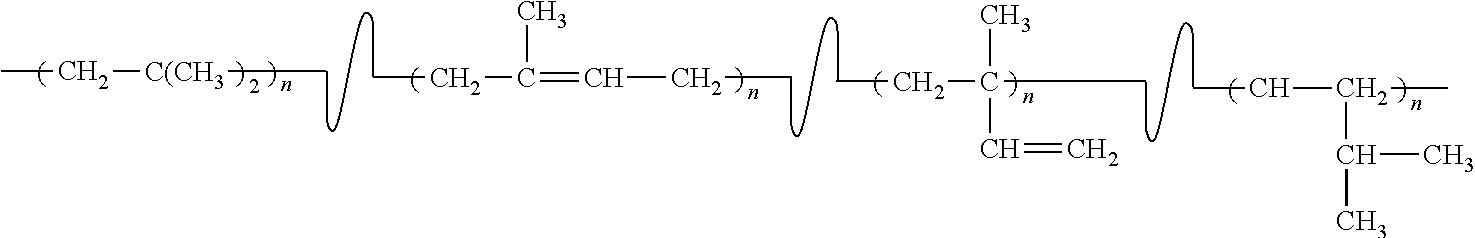

Coumarin compound

InactiveUS20050275341A1Satisfactory yieldReduce reaction efficiencyOrganic chemistryDischarge tube luminescnet screensCombinatorial chemistryMethyl group

A method for producing a coumarin compound represented by Formula 1, which comprises a step of reacting a coumarin compound represented by Formula 1 with a compound having an aldehyde group and an activated methylene group; luminous agents for organic EL elements and organic EL elements which all comprise the coumarin compound; and displaying panels and information displaying apparatuses using the organic EL elements: ø(Z)m Formula 1 wherein in Formula 1, ø is an aromatic ring, heterocycle, or a combination thereof, each Z is the same or a different coumarin group represented by Formula 2; and m is an integer of two or more; Formula 2:

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

Preparation of industrial asphalt

ActiveUS8901211B2Increase capacityReduce environmental impactRoof covering using tiles/slatesBuilding insulationsOxygenAsphalt

The present invention relates to a method for preparing an industrial asphalt comprising sparging an oxygen containing gas through an asphalt flux in the presence of 0.25 weight percent to about 12 weight percent of a highly saturated rubbery polymer at a temperature within the range of about 400° F. to about 550° F. for a period of time which is sufficient to increase the softening point of the asphalt flux to a value which is within the range of 185° F. to 250° F. and a penetration value of at least 15 dmm to produce the industrial asphalt. The highly saturated rubbery polymer can be a styrene-ethylene / butylene-styrene block copolymer rubber or a highly saturated styrene-ethylene / propylene-styrene block copolymer rubber.

Owner:BMIC LLC

Preparation method of dry cordyceps militaris compound wine

InactiveCN103740556AHigh content of bioactive substancesThe content is stable and controllableAlcoholic beverage preparationRoom temperatureCordyceps militaris

The invention provides a preparation method of a dry cordyceps militaris compound wine. The preparation method comprises the following steps: drying high-quality cordyceps militaris fruit bodies, and obtaining cordyceps militaris ultrafine powder by using a low-temperature ultrafine grinding technology; sufficiently mixing the cordyceps militaris ultrafine powder and high-quality and high-alcoholicity dry wine, then, placing the mixture into a ceramic wine jar for soaking, controlling the room temperature of the ceramic wine jar at 15-20 DEG C, stirring regularly, filtering to obtain a supernatant, i.e., a raw cordyceps militaris wine; and blending the raw cordyceps militaris wine by using a blending liquor to prepare an alcoholic drink with a proper alcoholicity. The preparation method is simple in step, low in equipment requirement, controllable in quality and low in cost; and active ingredients in the dry cordyceps militaris compound wine prepared by using the method are abundant and measurable.

Owner:正源堂(天津)生物科技有限公司

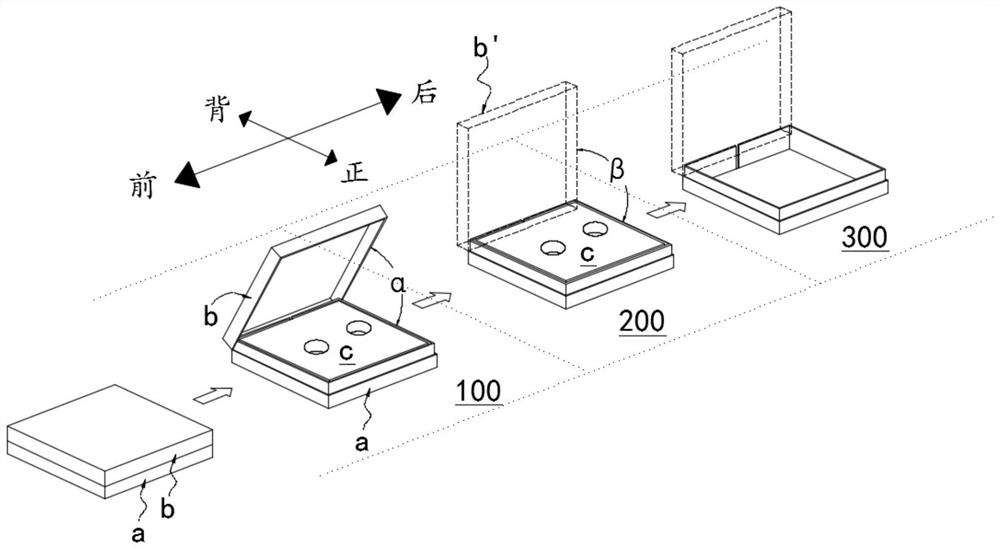

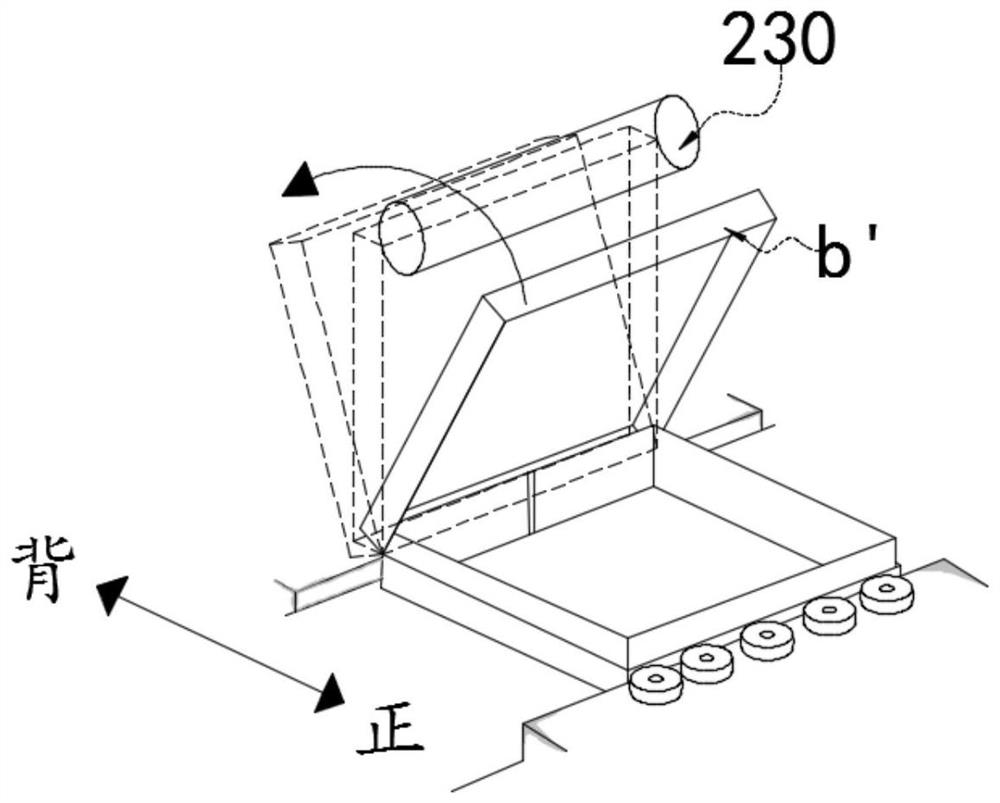

Method for preventing box cover from rebounding in paper box processing

PendingCN113211859ASignificant progressEasy to processBox making operationsPaper-makingStructural engineeringIndustrial engineering

The invention belongs to the technical field of packaging box processing, and discloses a method for preventing a box cover from rebounding in paper box processing. A paper box comprises an upper cover and a lower cover, two cover bodies are input when being in a closed state, a paper box conveying path is provided, and an opening station, a non-return station and a mold taking station are sequentially arranged along the conveying path, wherein the upper cover is opened to a first angle on the opening station, a first blocking piece extends into a box opening, and the tail end of the blocking piece extends to the non-return station; in the non-return station, a pushing piece is arranged on the front face of the box opening to bear the upper cover, then the pushing piece is pushed towards the upper cover to enable the upper cover to be turned to a second angle, and then a non-return assembly extends downwards from the upper portion of the box opening; and the upper cover is kept to be greater than or equal to 90 degrees at the mold taking station. A sliding linear cover turning scheme of the box cover in the prior art is omitted and improved into a sectional cover turning scheme, so that the rebounding prevention effect is more stable, and the material damage rate is lower.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

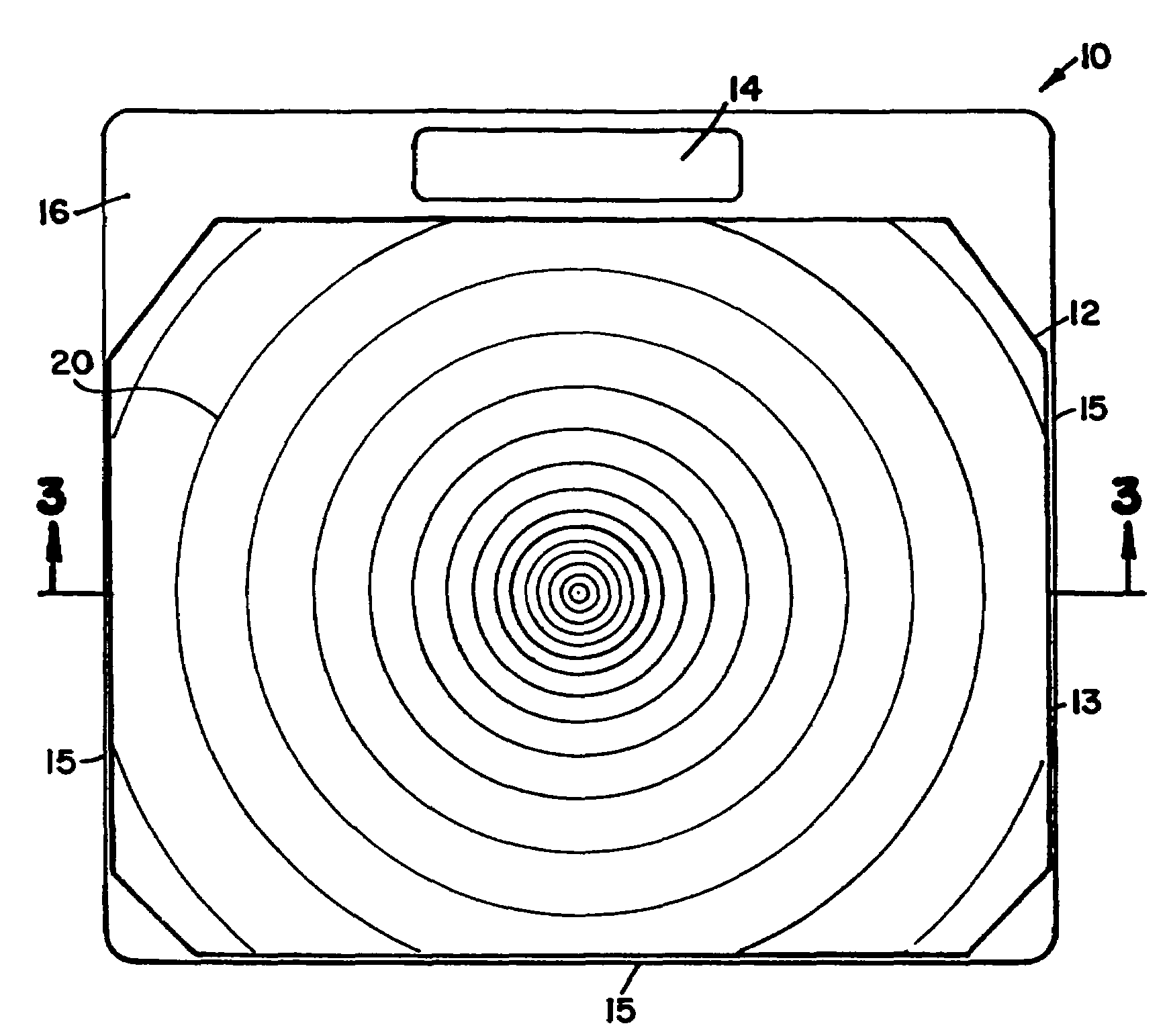

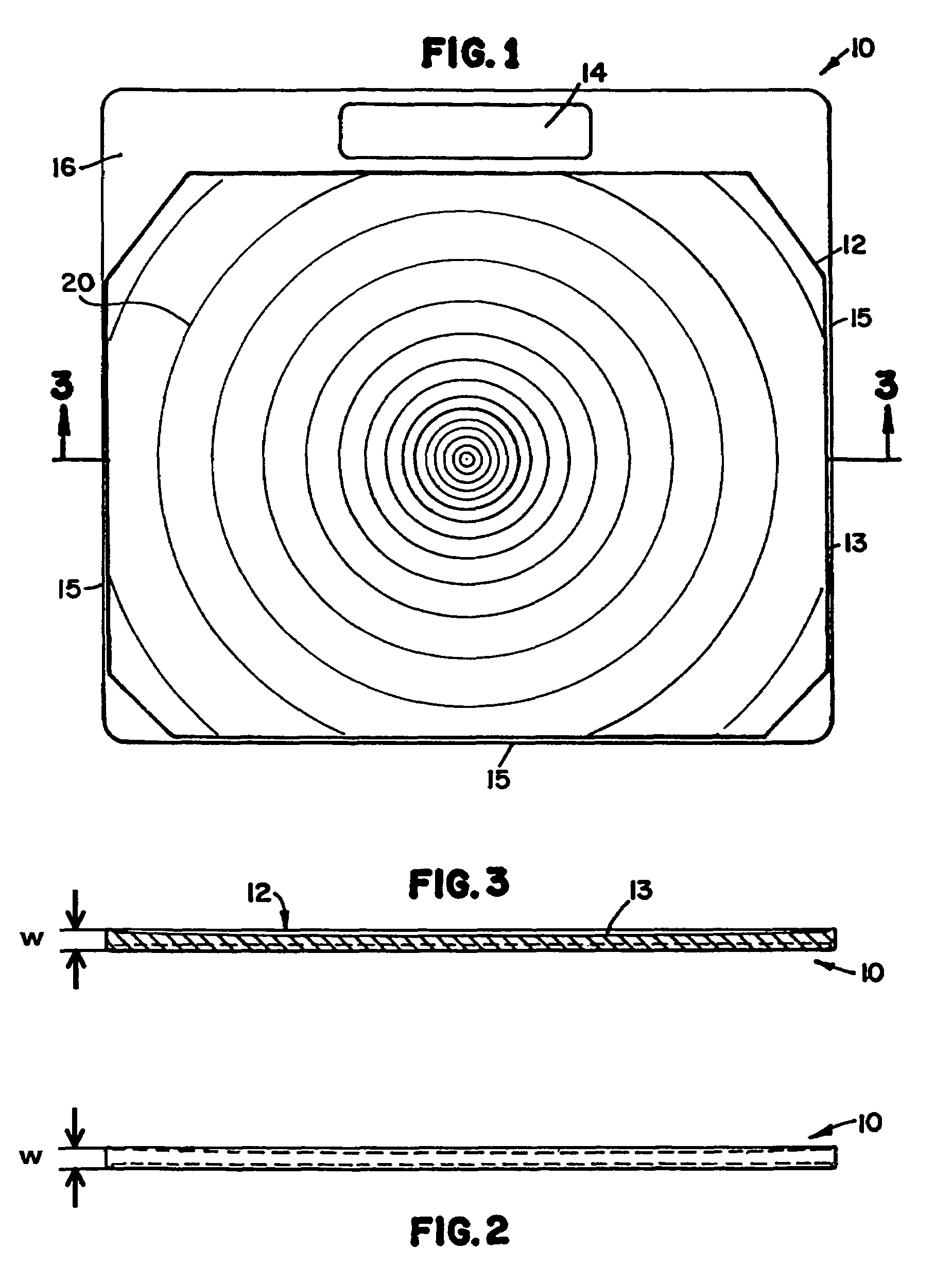

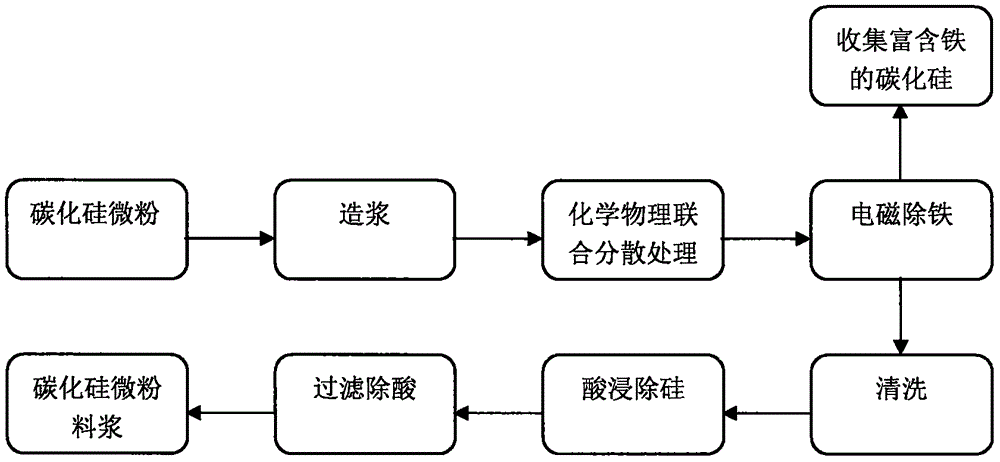

Mortarboard

ActiveUS7425027B2Reduce bondingHigh retention rateBuilding material handlingEngineeringMechanical engineering

The present invention provides an improved mortarboard configuration that is lightweight and durable. In a preferred configuration of the invention, the upper surface of the mortarboard is continuously contoured or dished to enhance retention of the material carried thereby and any water or other liquid used for retempering the material, and to provide for improved material workability. The mortarboard may have a handle to improve portability and handling.

Owner:CARNEY BRIAN P

Dehydrated rohdea japonica lozenges and preparation method thereof

ActiveCN103609990AFull of nutritionComprehensive NutrientsFood shapingFood ingredient functionsCobalt-60Alcohol

The invention provides dehydrated rohdea japonica lozenges which are solid tablets and comprise 100% of rohdea japonica. A preparation method of the dehydrated rohdea japonica lozenges comprises the following steps: performing hot air circulation drying on the dehydrated rohdea japonica at 30-37 DEG C until the water content is less than 8%; performing superfine grinding in a superfine grinding machine; uniformly spraying edible alcohol in a mist spraying manner, continuously stirring to form granules with the same sizes, and granulating in a wet granulating machine; uniformly spreading in a one-layer manner, continuously drying in a drying oven at 30-37 DEG C, and removing the alcohol from rohdea japonica granules until alcohol residues disappear; tabletting in a tabletting machine; irradiating by using cobalt 60 for sterilizing, and packaging to obtain the finished dehydrated rohdea japonica lozenges. The dehydrated rohdea japonica lozenges are high in nutritional value, good in health-care function, convenient to carry and eat, easy to digest and absorb and long in storage time.

Owner:贵州贵安精准医学股份有限公司

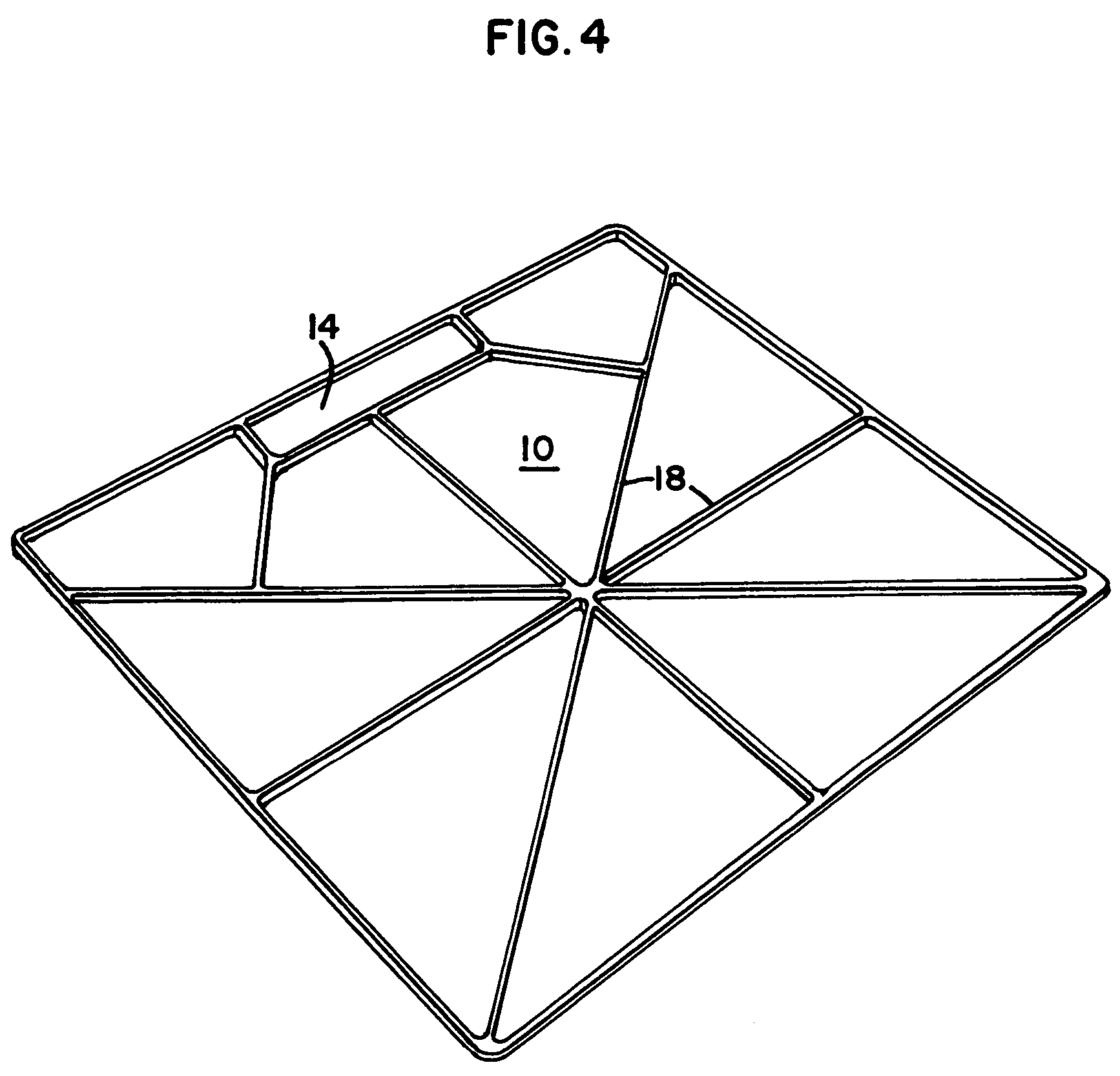

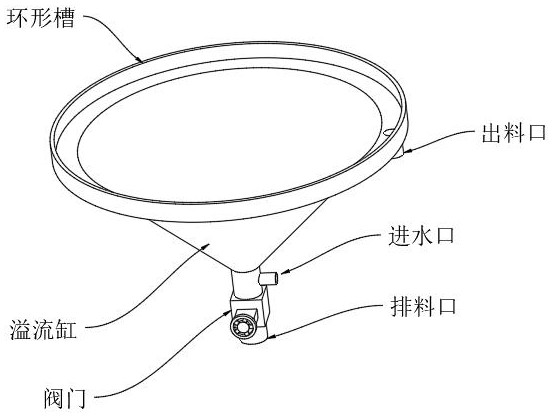

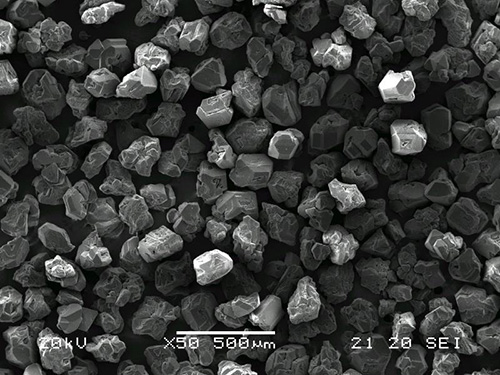

Method for removing iron and silicon impurities in silicon carbide micropowder for crystalline silicon wire cutting

The invention relates to a method for removing iron and silicon impurities in silicon carbide micropowder for crystalline silicon wire cutting. The iron and silicon impurities in the silicon carbide powder are removed through combination of physical iron removal and chemical silicon removal. The method comprises the specific process as follows: the silicon carbide micropowder ground by a Raymond mill is mixed with deionized water for slurry making; a dispersant is added to obtained silicon carbonate micropowder slurry for stirring dispersion treatment; the dispersed silicon carbonate micropowder slurry is pumped into an electromagnetic separator for iron removal by magnetic separation; then the iron-removed and purified silicon carbonate micropower slurry is washed with water; acid is added to the silicon carbonate micropower slurry for acid leaching; finally, the purified silicon carbonate micropowder slurry is obtained through filtration. The method is simple to operate, high in production efficiency, low in cost and good in environmental benefit, and the use chemicals are reduced. The treated silicon carbonate powder product is stable in quality and suitable for industrial production, and the technical indexes meet the process requirement.

Owner:JIANGXI ENK NEW MATERIAL CO LTD

Threshing redrying flavoring and perfuming technology

InactiveCN103704870AShort processLess material lossTobacco preparationTobacco treatmentEngineeringMechanical engineering

The invention relates to a threshing redrying flavoring and perfuming technology. The threshing redrying flavoring and perfuming technology comprises the steps that 1, threshed strips are fed into a roller feeding machine, the roller feeding machine is started, flavored feed liquid is evenly sprayed to the rolling strips in the roller feeding machine, and the strips coated with the flavored feed liquid are stored in a storage cabinet; 2, after the strips absorb the flavored feed liquid completely, the strips are redried; 3, the redried strips are fed into the roller feeding machine, the roller feeding machine is started, perfumed feed liquid is evenly sprayed to the rolling strips in the roller feeding machine, and then the strips coated with the feed liquid are pre-pressed and packaged. According to the threshing redrying flavoring and perfuming technology, as for tobacco leaves, after stems and the leaves are separated, even flavoring is conducted before redrying, even perfuming is conducted after redrying and before pre-pressing and packaging, the technology requirement for flavoring and perfuming of the tobacco leaves is met under the condition that fewest devices are arranged, the technological process is the shortest, and feed liquid consumption is the lowest, and an efficient path is provided for reducing production cost of enterprises, improving production efficiency of the enterprises and improving internal quality of the tobacco leaves.

Owner:FUJIAN WUYI TOBACCO

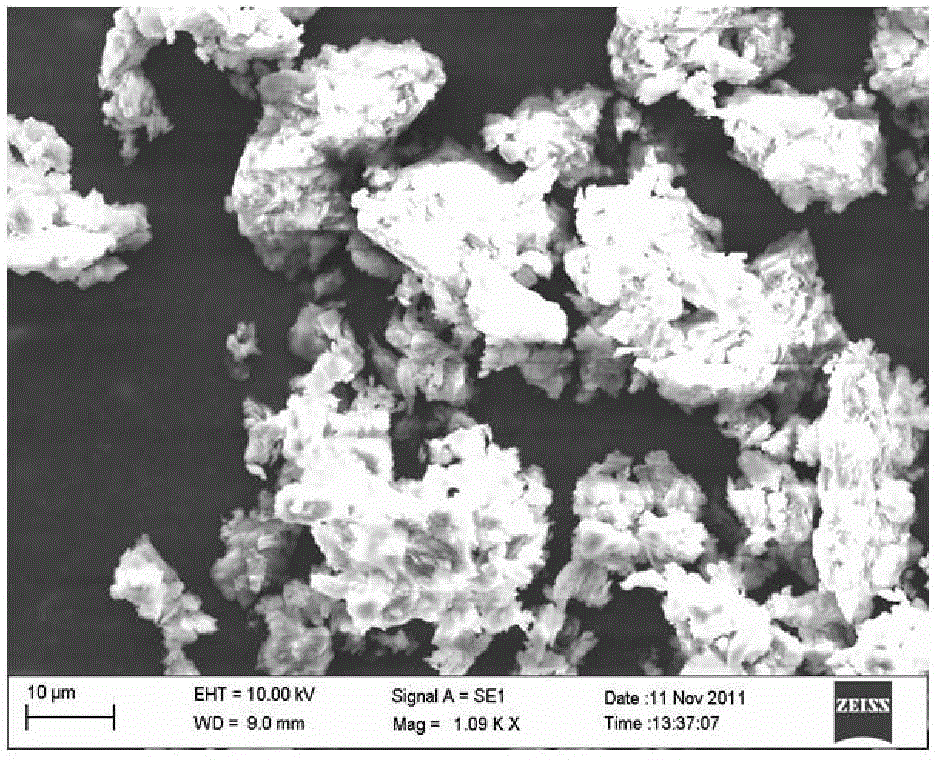

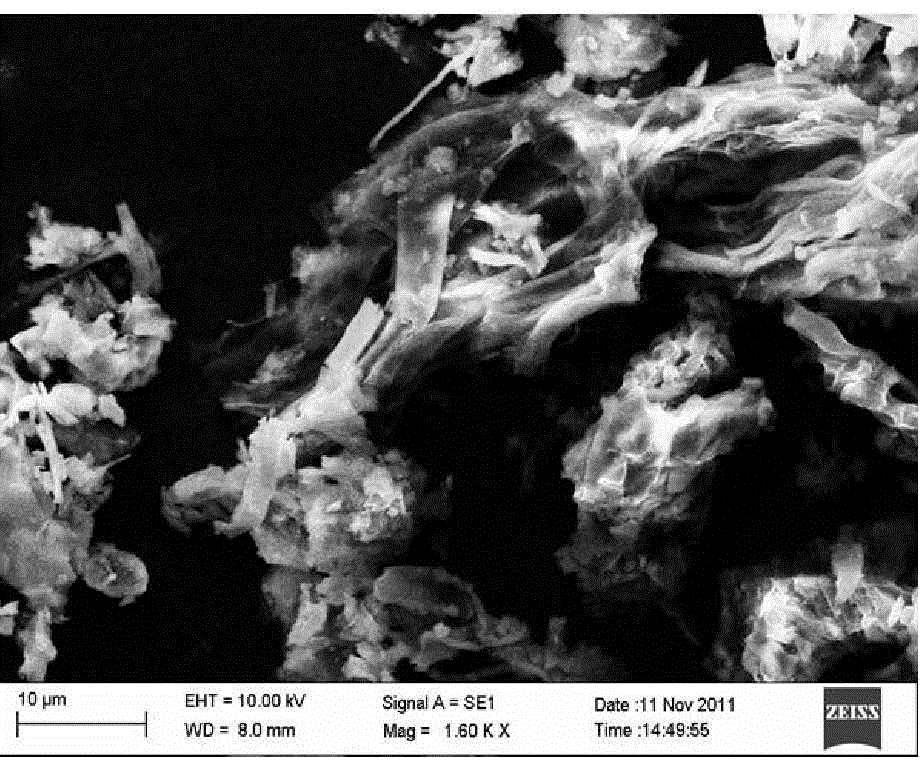

Extract method of cordyceps militaris adenosine

ActiveCN102558265BEasy to processEnsure immediate absorptionSugar derivativesSugar derivatives preparationCordycepsAdenosine

Owner:贵州贵安精准医学股份有限公司

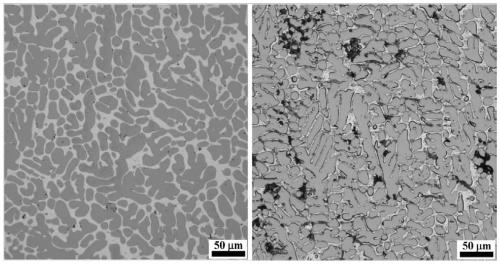

Special composite slag removing agent for beryllium aluminum alloy refining, preparation method and slag removing method

The invention discloses a special composite slag removing agent for beryllium aluminum alloy refining, a preparation method and a slag removing method. The slag removing agent comprises the followingcomponents in parts by weight: 30-50 parts of sodium tetraborate, 2-8 parts of AlB12 intermediate alloy, 2-5 parts of hexachloroethane, 7-10 parts of sodium hexafluorisilicate, 2-6 parts of sodium fluoroaluminate, 1-5 parts of sodium fluoride, 5-12 parts of potassium chloride, 6-13 parts of beryllium chloride, 2-5 parts of lithium chloride, 2-5 parts of sodium carbonate, and 1-3 parts of clay. Theslag removing agent achieves excellent high-temperature stability and reliability under the vacuum condition, and is excellent in adhesiveness after melting, high in spreadability, quick in slag collection, easy incrustation of slag skin and excellent in slag removing and refining effect. Through the synergistic effect of all the components, oxides in melts, magnesium-contained impurities and hydrogen achieve excellent slag removing and absorbing effects; and meanwhile, the slag skin can effectively cover the surfaces of the melts, so that the temperature loss can be effectively reduced, thesplashing of the melts is inhibited, and new melting slag and secondary oxidation are prevented.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

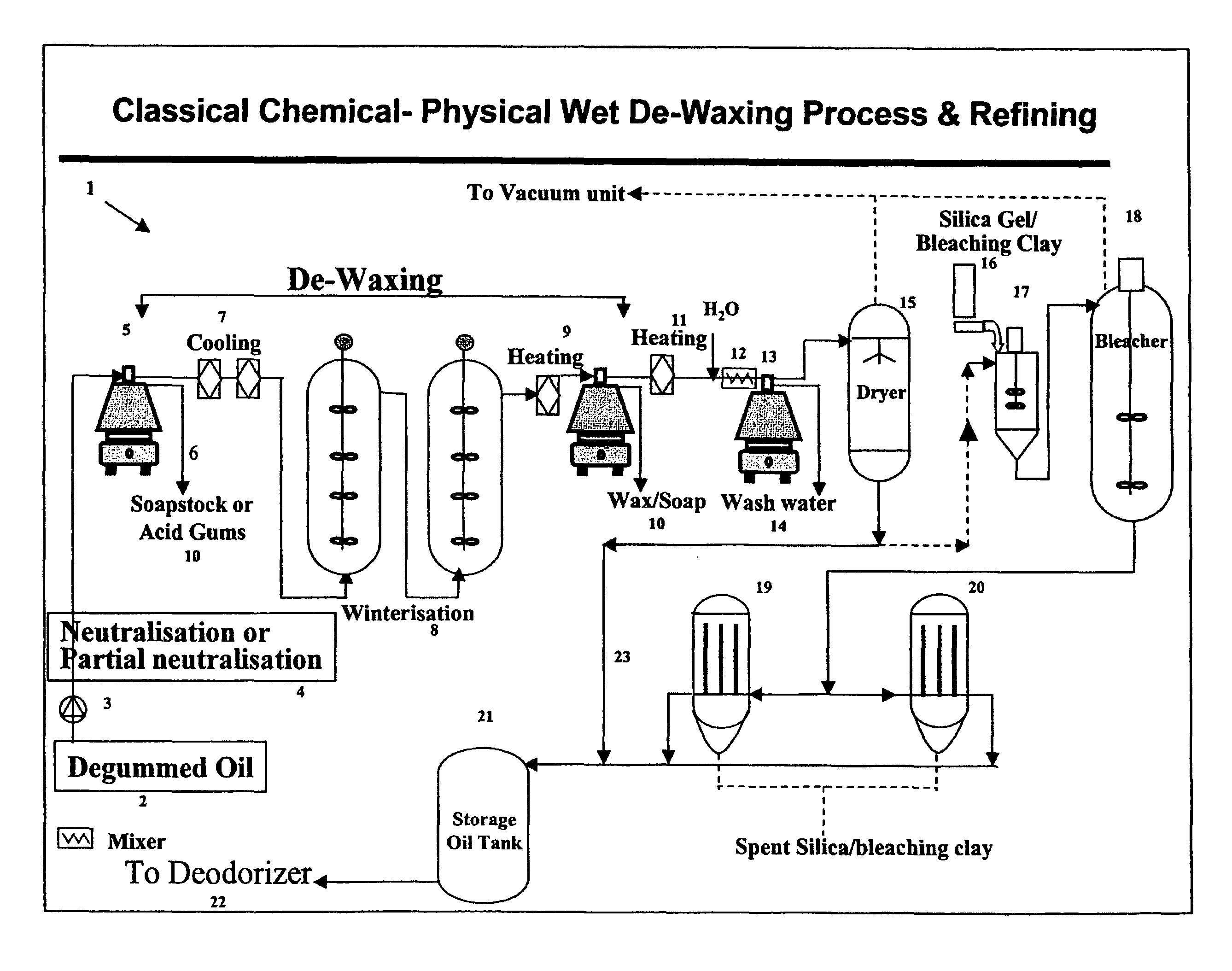

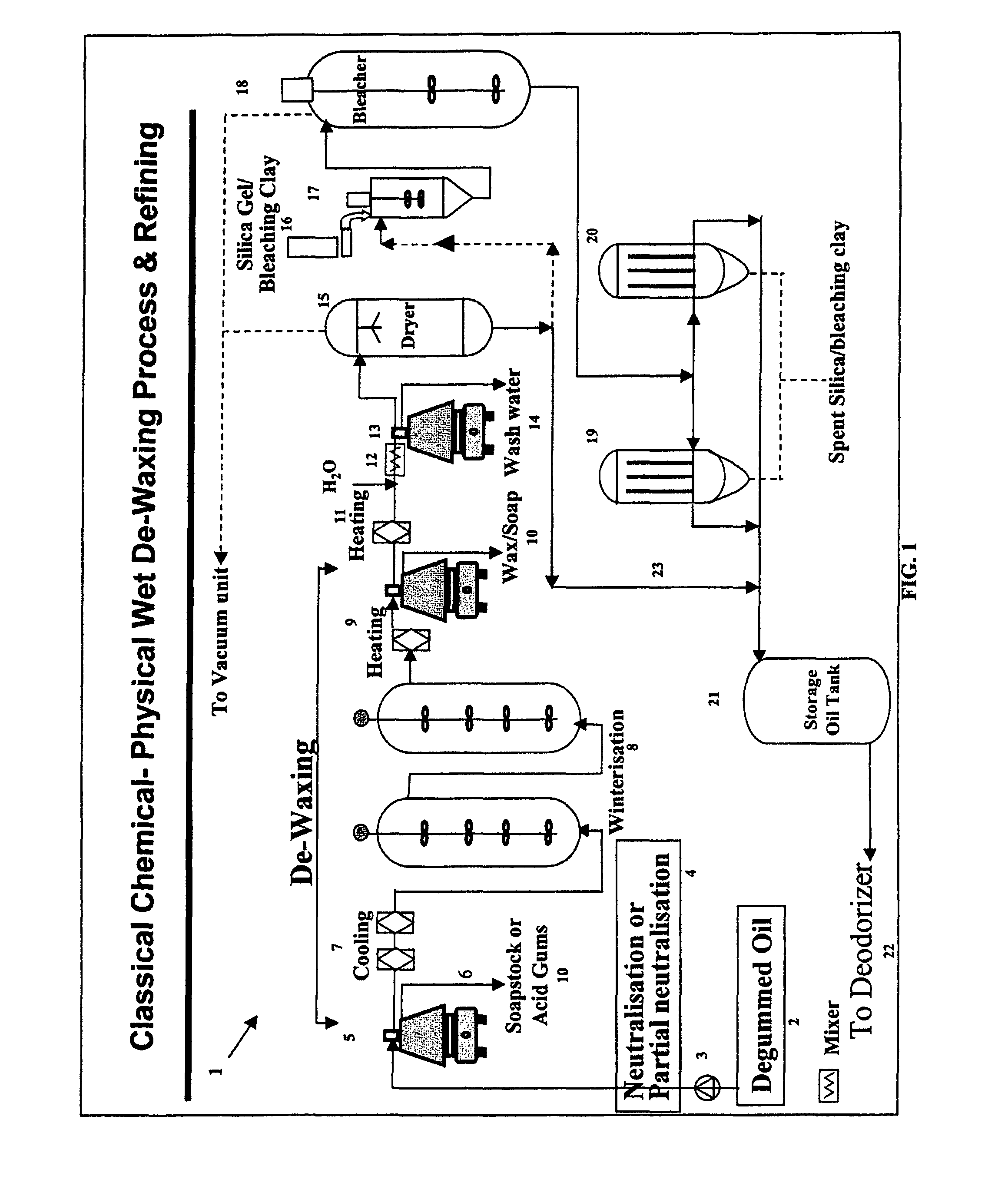

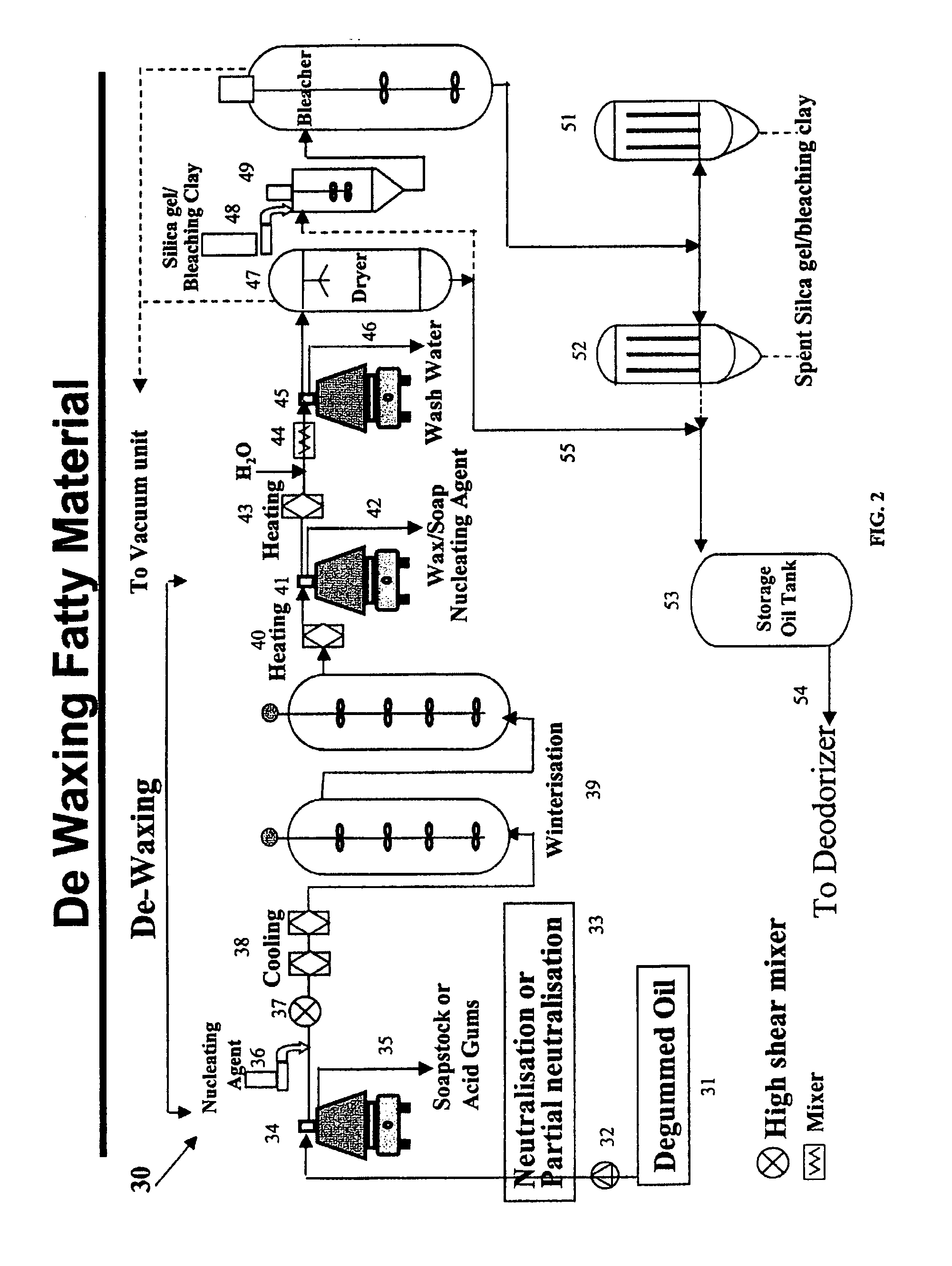

Purification of fatty materials such as oils

InactiveUS8507703B2Eliminate needLightweight productionFatty oils/acids recovery from wasteOrganic compound preparationMaterials processingEdible oil

A purification system suitable for use in fatty material processing is disclosed. A method of using a purification system to process fatty materials, such as oils, edible oils, fats, and similar materials, is also disclosed.

Owner:GRACE GMBH & CO KG

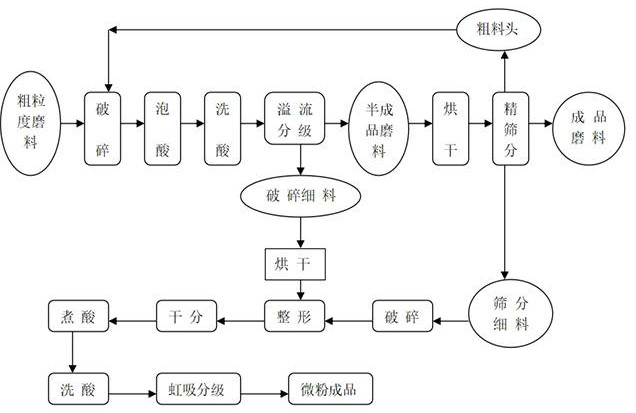

Dry-wet combined production process for superhard material abrasive material

InactiveCN113773805AMeet production supplyHigh quality raw materialOther chemical processesGrain treatmentsSuperhard materialAcid washing

The invention discloses a dry-wet combined production process for a superhard material abrasive material, and relates to the technical field of superhard material production processes. The dry-wet combined production process mainly comprises the following steps: taking a coarse-grained abrasive material as a raw material, and carrying out crushing treatment to obtain a mixture; washing in an acid solution, taking filter residues, and washing with water to obtain an acid-washed material; separating the acid-washed material by using an overflow device to obtain asemi-finished abrasive material and a crushed fine material; controlling water in the semi-finished abrasive material, then drying and screening to obtain a coarse material head, a finished abrasive material and a screened fine material, and mixing the coarse material head into the coarse-grained abrasive material to be used as a raw material; controlling the water in the crushed fine material, drying, crushing the screened fine material, mixing the crushed fine material and the screened fine material, and processing into balls to obtain a shaped material; pre-grading, boiling acid, and washing to obtain an impurity-removed material; and finally, re-grading and drying to obtain the finished micro powder with different particle size ranges. According to the invention, the process is mainly used for producing superhard material abrasive materials, production of the superhard material abrasive material and the micro powder can be carried out at the same time, and the utilization rate of the raw materials is increased.

Owner:开封贝斯科超硬材料有限公司

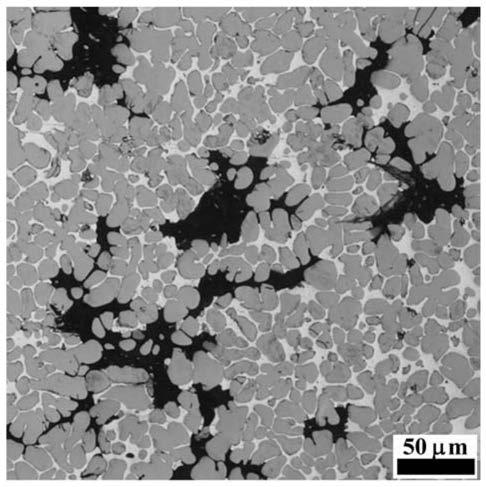

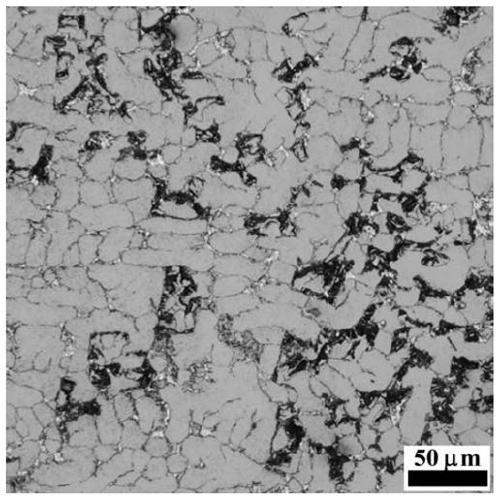

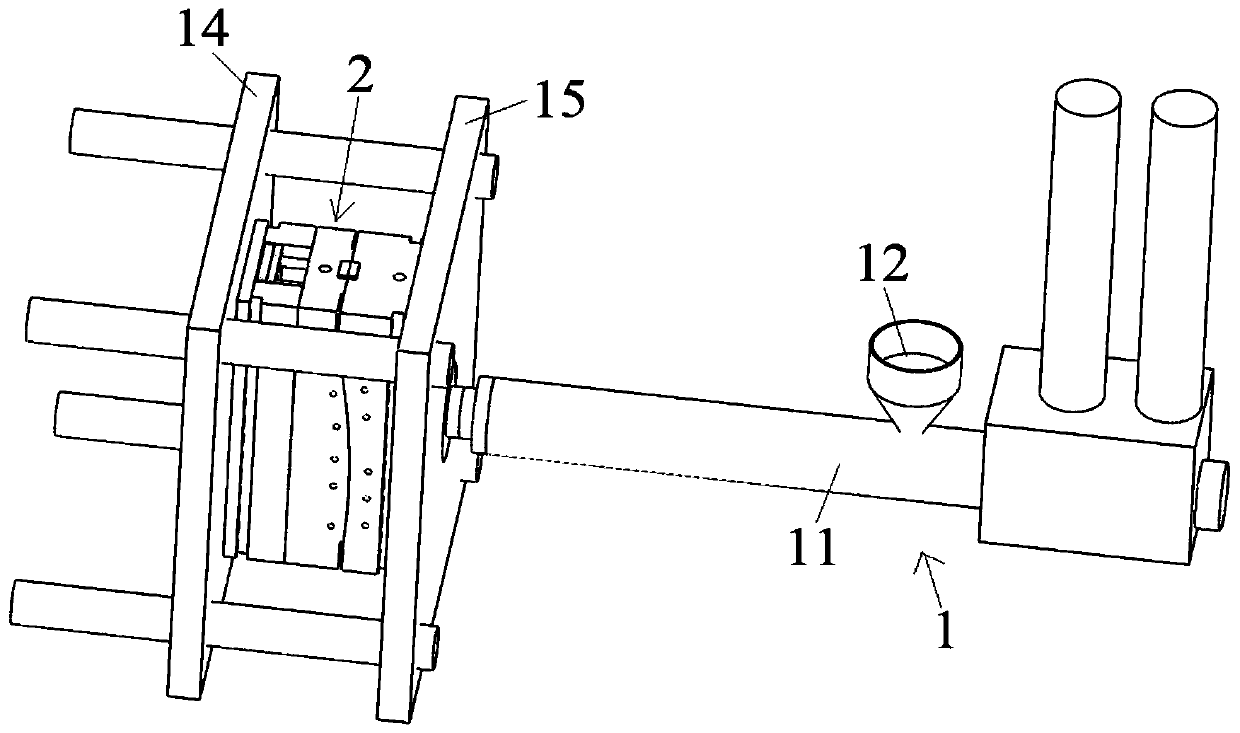

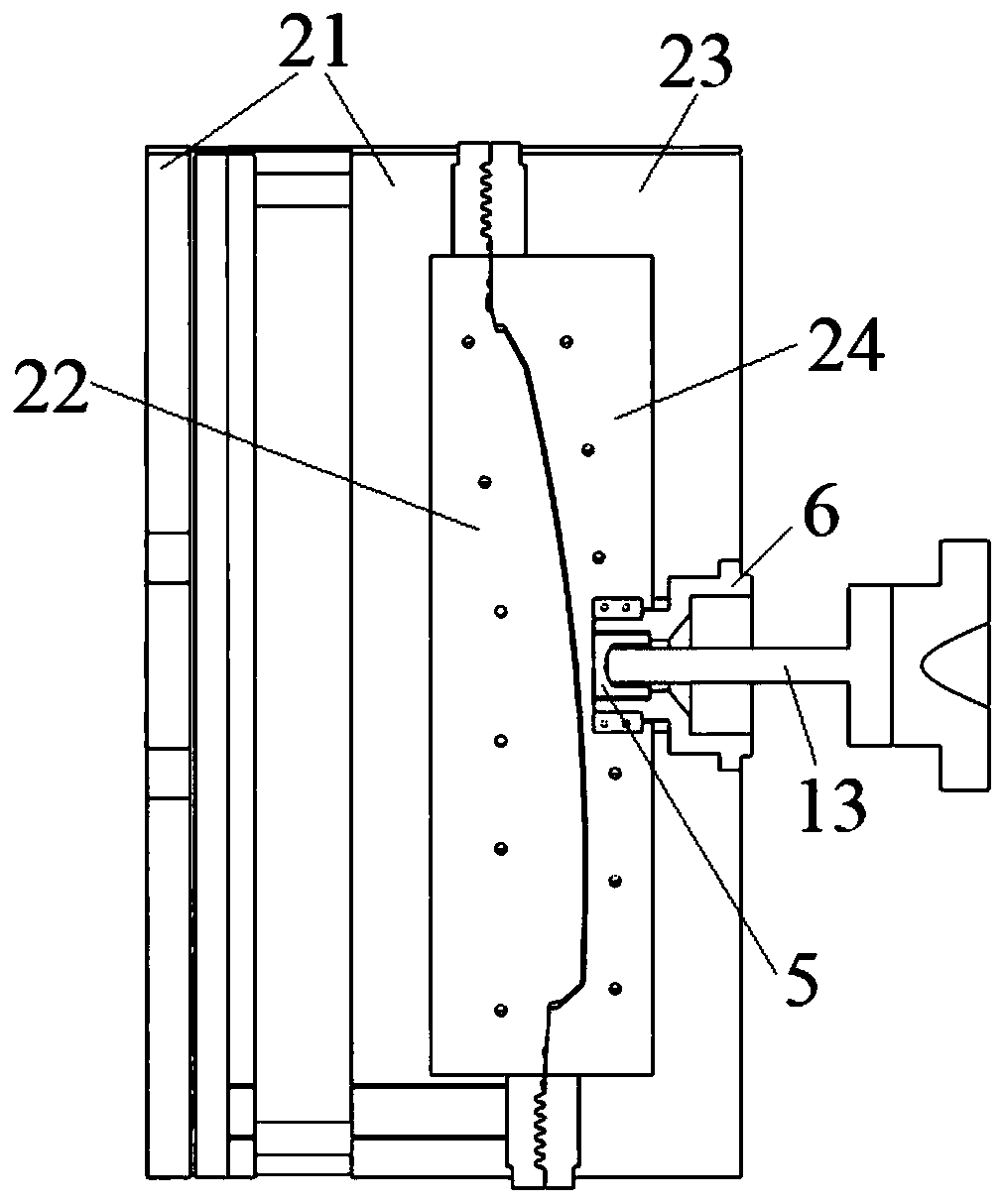

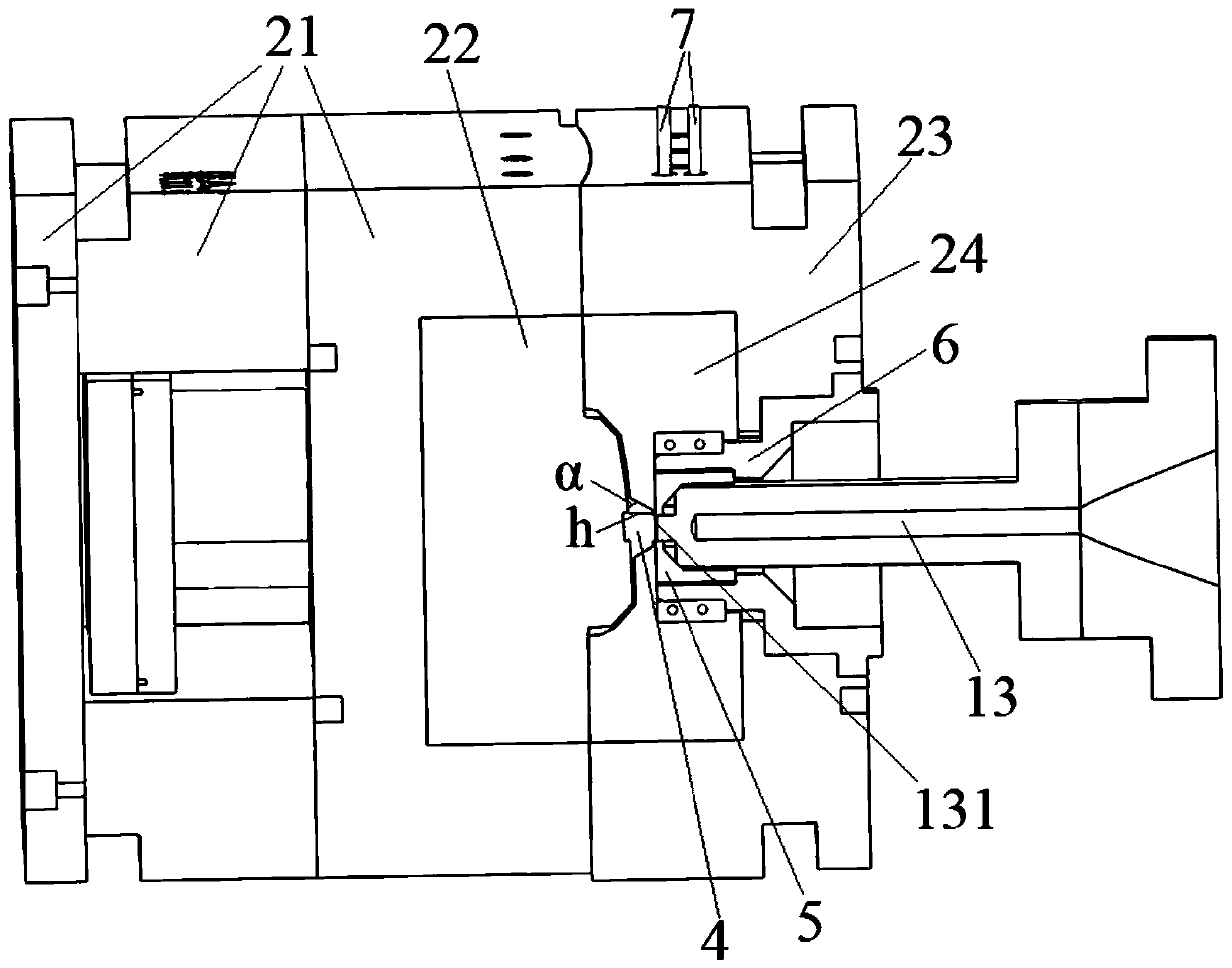

Device and method for realizing magnesium alloy injection molding

The invention discloses a device and a method for realizing magnesium alloy injection molding. The device comprises an injection molding machine and a molding mold, wherein the injection molding machine comprises a screw rod injection mechanism, a hopper, a long nozzle, a movable mold fixing plate and a fixed mold fixing plate; and the molding mold comprises a movable mold frame, a movable mold core, a fixed mold frame and a fixed mold core. The device is characterized in that a feed port is formed in the center of the fixed mold core; two opening ends of the feed port are respectively communicated with a cavity and an injection end of the long nozzle; and a cooling sleeve is sleeved at the injection end of the long nozzle. Semi-solid magnesium alloy materials are creatively and directly fed into the feed port in the center of the fixed mold core by the long nozzle to enter the cavity without adopting a runner mode for feeding, so that the device has such advantages as simple structure, few wastes, low material loss, good product quality and short molding period, is safe and environment-friendly in production, and is prominent in promotion of wide application of a magnesium alloy injection molding technology in the industrial field.

Owner:SHANGHAI WUTENG METAL PROD CO LTD

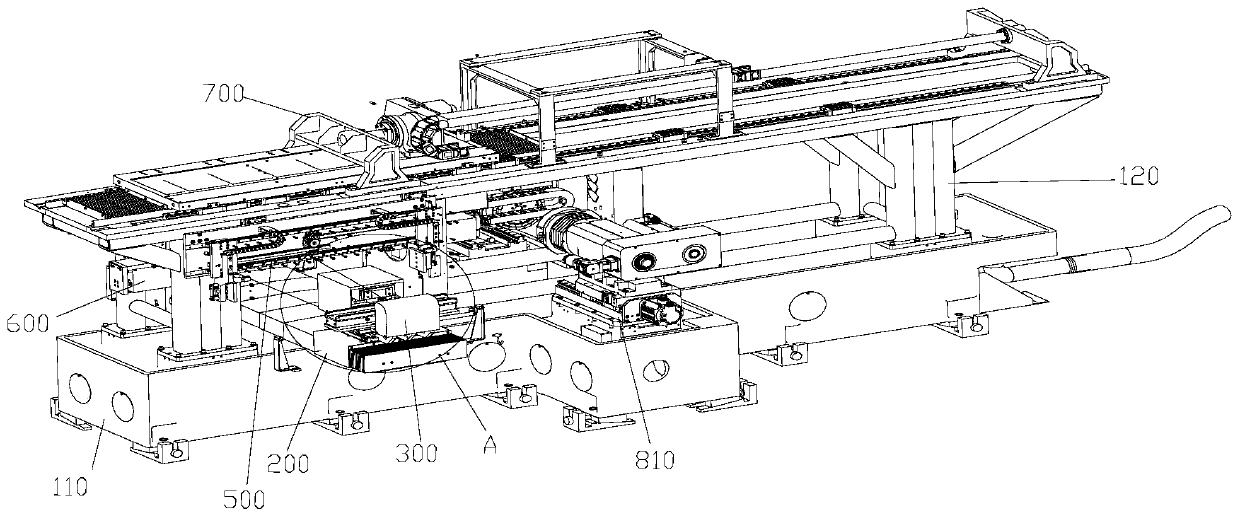

Full-automatic crystal bar coarse grinding and accurate grinding combined surface grinding and chamfering integrated machine and crystal bar grinding unit

PendingCN110788716ALess material lossReduce the number of axesEdge grinding machinesGrinding carriagesDrive motorSurface grinding

The invention discloses a full-automatic crystal bar coarse grinding and accurate grinding combined surface grinding and chamfering integrated machine and a crystal bar grinding unit. The crystal bargrinding unit comprises a coarse grinding and accurate grinding head for grinding and chamfering four planes and four arcs and a grinding driving mechanism connected to the coarse grinding and accurate grinding head. The coarse grinding and accurate grinding head comprises a coarse grinding abrasion wheel head, an accurate grinding abrasion wheel head and a first driving motor. The coarse grindingabrasion wheel head and the accurate grinding abrasion wheel head are in power connection to a first driving motor through transmission shafts, separately. The accurate grinding abrasion wheel head driven by the transmission shaft thereof moves front and back relative to the coarse grinding abrasion wheel head. The full-automatic crystal bar coarse grinding and accurate grinding combined surfacegrinding and chamfering integrated machine integrates functions of four plane chamfering and coarse grinding and four chamfering and accurate grinding, dimension detection, crystal orientation detection and the like, is centralized in processing step, integrates a coarse grinding station and an accurate grinding station in a same station for grinding and chamfering four planes and four arcs, reduces the quantity of coarse and accurate grinding shafts of the equipment, is low in equipment cost, reduces the working allowance left by coarse grinding for accurate grinding, and reduces the quantityof accurate grinding processing cutters while reducing the loss of the crystal bars, so that the processing efficiency is improved and the equipment cost is lowered.

Owner:QINGDAO GAOCE TECH CO LTD

Dehydrated vegetable evergreen buccal tablet and preparation method thereof

ActiveCN103609990BFull of nutritionComprehensive NutrientsFood shapingFood ingredient functionsAlcoholWater content

The invention provides dehydrated rohdea japonica lozenges which are solid tablets and comprise 100% of rohdea japonica. A preparation method of the dehydrated rohdea japonica lozenges comprises the following steps: performing hot air circulation drying on the dehydrated rohdea japonica at 30-37 DEG C until the water content is less than 8%; performing superfine grinding in a superfine grinding machine; uniformly spraying edible alcohol in a mist spraying manner, continuously stirring to form granules with the same sizes, and granulating in a wet granulating machine; uniformly spreading in a one-layer manner, continuously drying in a drying oven at 30-37 DEG C, and removing the alcohol from rohdea japonica granules until alcohol residues disappear; tabletting in a tabletting machine; irradiating by using cobalt 60 for sterilizing, and packaging to obtain the finished dehydrated rohdea japonica lozenges. The dehydrated rohdea japonica lozenges are high in nutritional value, good in health-care function, convenient to carry and eat, easy to digest and absorb and long in storage time.

Owner:贵州贵安精准医学股份有限公司

A kind of preparation method of cordyceps militaris wine

ActiveCN103710241BHigh content of bioactive substancesImprove product qualityAlcoholic beverage preparationAlcohol contentCordyceps

Owner:贵州贵安精准医学股份有限公司

A kind of composite slag remover specially used for beryllium aluminum alloy refining and its preparation method and method of slag removal

ActiveCN109735733BImprove adsorption capacitySuppress splashLithium chlorideSodium hexafluoroaluminate

The invention discloses a special composite slag removing agent for beryllium aluminum alloy refining, a preparation method and a slag removing method. The slag removing agent comprises the followingcomponents in parts by weight: 30-50 parts of sodium tetraborate, 2-8 parts of AlB12 intermediate alloy, 2-5 parts of hexachloroethane, 7-10 parts of sodium hexafluorisilicate, 2-6 parts of sodium fluoroaluminate, 1-5 parts of sodium fluoride, 5-12 parts of potassium chloride, 6-13 parts of beryllium chloride, 2-5 parts of lithium chloride, 2-5 parts of sodium carbonate, and 1-3 parts of clay. Theslag removing agent achieves excellent high-temperature stability and reliability under the vacuum condition, and is excellent in adhesiveness after melting, high in spreadability, quick in slag collection, easy incrustation of slag skin and excellent in slag removing and refining effect. Through the synergistic effect of all the components, oxides in melts, magnesium-contained impurities and hydrogen achieve excellent slag removing and absorbing effects; and meanwhile, the slag skin can effectively cover the surfaces of the melts, so that the temperature loss can be effectively reduced, thesplashing of the melts is inhibited, and new melting slag and secondary oxidation are prevented.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Fast-growing wood flame-retardant laminated board and production method thereof

ActiveCN105014753BShorten the soaking timeBrittleWood treatment detailsWood veneer joiningGlass fiberSurface layer

The present invention discloses a fast-growing wood flame-retardant laminated plate and a production method thereof. The fast-growing wood flame-retardant laminated plate comprises a fast-growing wood flame-retardant core layer and upper and low flame-retardant strengthening surface layers. Material layers are glued through hot pressing. The fast-growing wood flame-retardant core layer is a fast-growing wood single-plate laminated plate which is subjected to flame retardant impact immersion treatment. The flame-retardant strengthening surface layers are fiberglass cloths or hemp fiber cloths which are subjected to flame-retardant adhesive immersion treatment. The fast-growing wood flame-retardant laminated plate and the production method have the advantages that the core-layer plate is subjected to normal pressure shallow processing by using a dynamic impact mode, a soaking time is shortened, a wood property reduction risk is reduced, glass fibers or hemp fibers with excellent tension performance is placed on a composite structure surface layer, the overall mechanical performance of a composite material is improved, a flame-retardant adhesive is used to process a surface layer fiber material, thus the surface layer has effective flame-retardant performance, a flame-retardant high strength laminated plate is obtained, and wood losses are reduced.

Owner:王伟宏

Numerical control double-headed sawing center for aluminum profiles

InactiveCN102101200BWon't scatterRealize humanized designMetal sawing devicesMetal sawing accessoriesNumerical controlEngineering

The invention discloses a numerical control double-headed sawing center for aluminum profiles, which comprises a machine head up and down sawing part and an automatic loading part, wherein the machine had up and down sawing part mainly comprises a moving sawing machine head and a fixed sawing machine head, which are arranged on a frame, and a sawing platform arranged on top plates of the sawing machine heads, and the moving sawing machine head does horizontal motion under the action of a machine head screw rod through a machine head slide rail; a saw blade pillar is arranged on a baseplate of the sawing machine heads through a rotating baseplate, and the saw blade pillar can rotate around a centering shaft connected on the rotating baseplate; the saw blade pillar is connected with a sliding plate through a saw blade slide rail, a saw blade motor and a saw blade main shaft, which are connected through a belt, are fixedly arranged on the sliding plate, and a saw blade is arranged on the saw blade motor; and the sliding plate is connected with a telescopic rod of a lifting cylinder of the saw blade. Manual intervention is not required during the cutting process, the cutting process is automatically completed, a fundamental plane of the cut profile is large, the discharge is steady, the sawing is smooth, the fundamental plane does not need to be turned over when entering into the next corner combination process step, the processing errors are reduced, and the working efficiency is improved.

Owner:ANYANG JIAMING MACHINERY

Method for molding double hyperbolic streamlined bridge pier coping circular arc section space surface

ActiveCN100577347CAccurate locationSmooth transitionSpecial data processing applicationsNumerical controlThree-dimensional space

The invention relates to a shaping method of a space curved surface of a hyperbolic streamline shape bridge pier template; the shaping method includes the following steps: in AutoCAD, the radian of the space curved surface along the height direction is replaced by a segmented chord, and the maximum gap between a segmented arc and a corresponding chord is not larger than 1.5mm; a three-dimensional space model is established in Pro / E, and refining and flattening are carried out to obtain a precise expanded view of the space curved surface; the expanded view in Pro / E is transformed into a CAXA formatted file, proper kneading is carried out on the border splines of the expanded view to obtain an optimized expanded view of the curved surface, the optimized expanded view of the curved surface is transformed into program codes which are sent to a numerical control under water plasma cutting machine to finish cutting; a three-axis roller is adopted for arc rolling according to the radius of the arc corresponding to each segmented curved surface to shape the space curved surface; each shaped segmented space curved surface is treated with welding shaping on a clamping fixture from two sides to the middle to finish the manufacturing of the space curved surface. The shaping method of the invention can improve the shaping quality of the space curved surface, enhance work efficiency and reduce material waste in cutting.

Owner:CRRC TANGSHAN CO LTD

A Forging Forming Process of Super-large Aluminum Alloy Rectangular Ring

The invention relates to a forging forming process of an aluminum alloy straight-flanked ring with an extra-large specification. The forging forming process comprises the fist step of blanking; the second step of a first heating before forging, wherein two heating stages are included; the third step of billet fabricating, wherein four stages are included; the fourth step of machining and damage removing; the fifth step of a second heating before forging; the sixth step of forging and ring rolling; the seventh step of heat treatment, wherein two heat treatment stages are included; the eighth step of machining to appropriate dimensions. By means of the forging forming process of the aluminum alloy straight-flanked ring with the extra-large specification, forging formability and mechanical performance of the aluminum alloy straight-flanked ring with the extra-large specification are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com