Method for preventing box cover from rebounding in paper box processing

An anti-rebound, carton technology, applied in papermaking, paper/cardboard containers, box making operations, etc., can solve the problems of tearing carton, poor safety of sheet metal parts, construction risks, etc., and achieves a reduction in material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

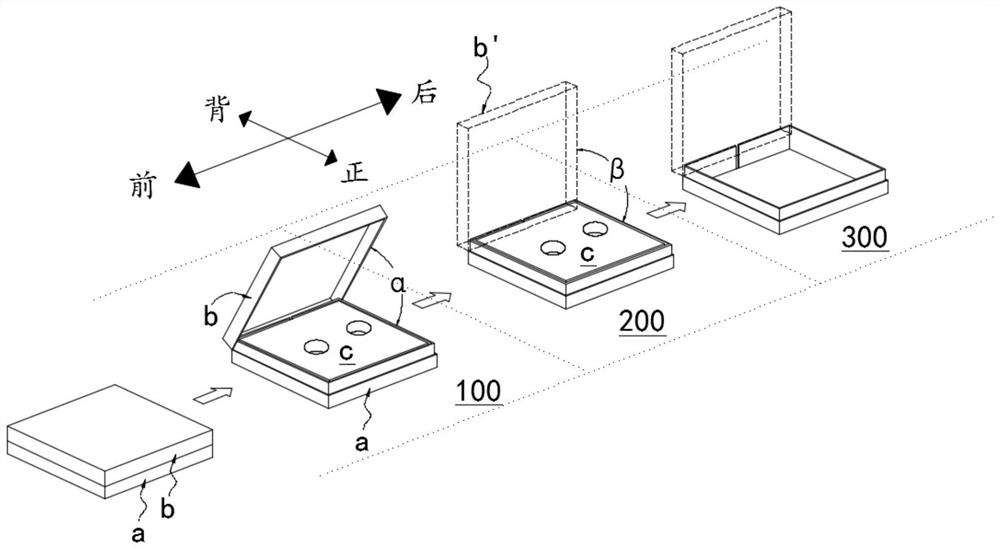

[0033] A schematic diagram of an outer box opening process provided by the present invention. When the outer box is input into the edge trimming and mold taking device, the upper cover b and the lower cover a are wrapped together by the outer paper, and then the There are blades inserted in the center, when the paper box is cut along the edge cutting path, the paper on three sides of the carton will be cut, at this time, the two covers have not been opened by external force and are in a closed state.

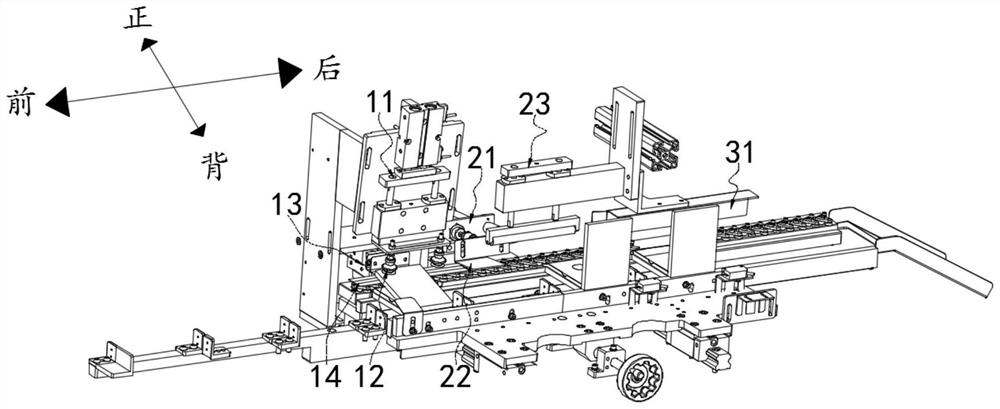

[0034] The present invention intends to continue the conveying path downstream of the trimming path, on which the opening station 100, the non-return station 200 and the mold-taking station 300 are arranged in sequence, and the carton is processed at these three stations.

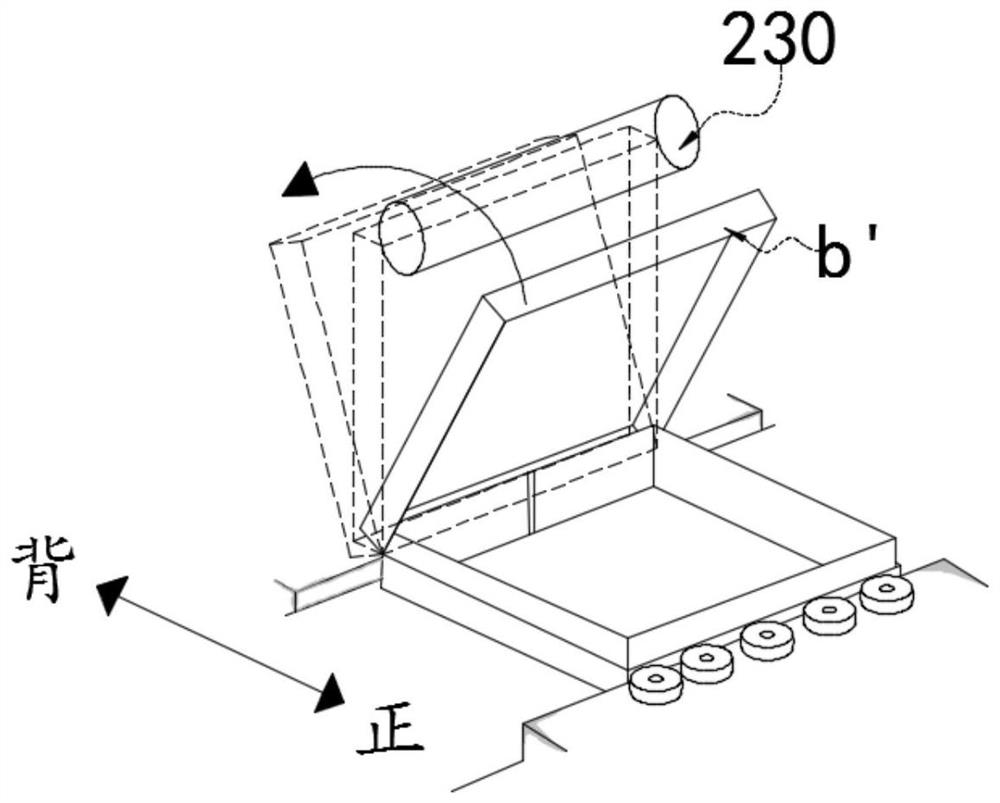

[0035] On the opening station 100, the upper cover is opened at a small angle, and then a blocking piece is inserted from the front of the box mouth to block the upper cover b to prevent the upper cover b from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com