Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve metal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

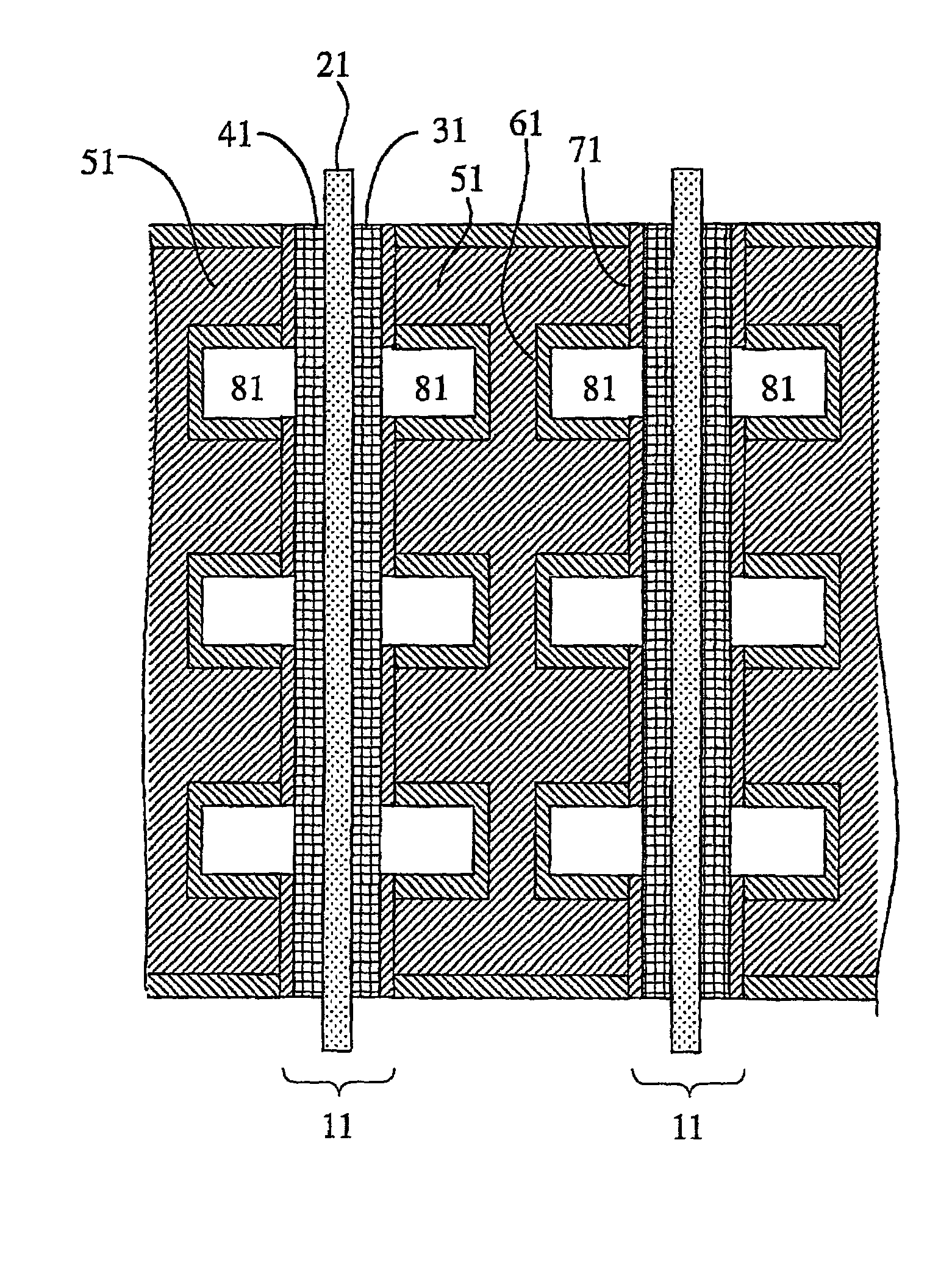

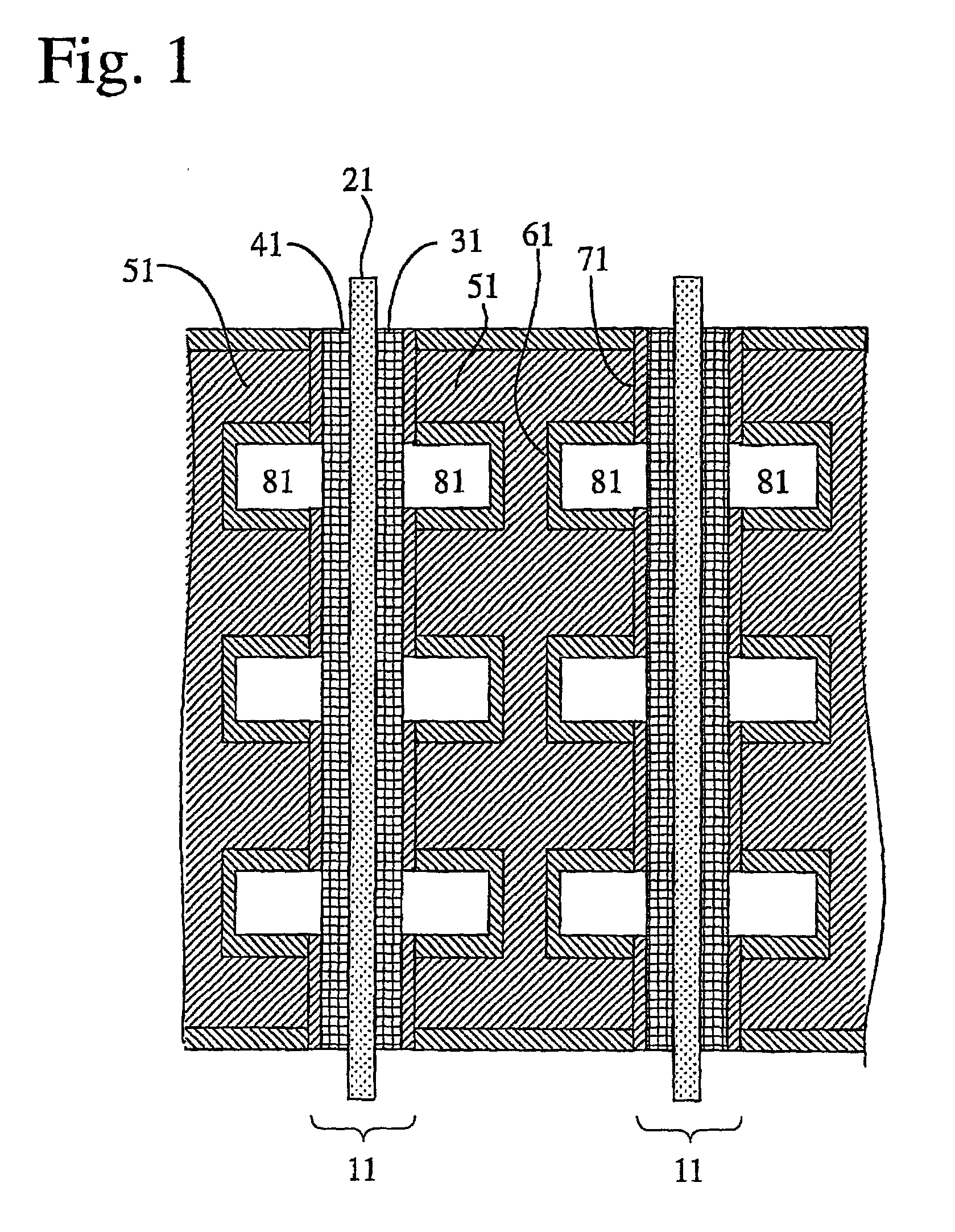

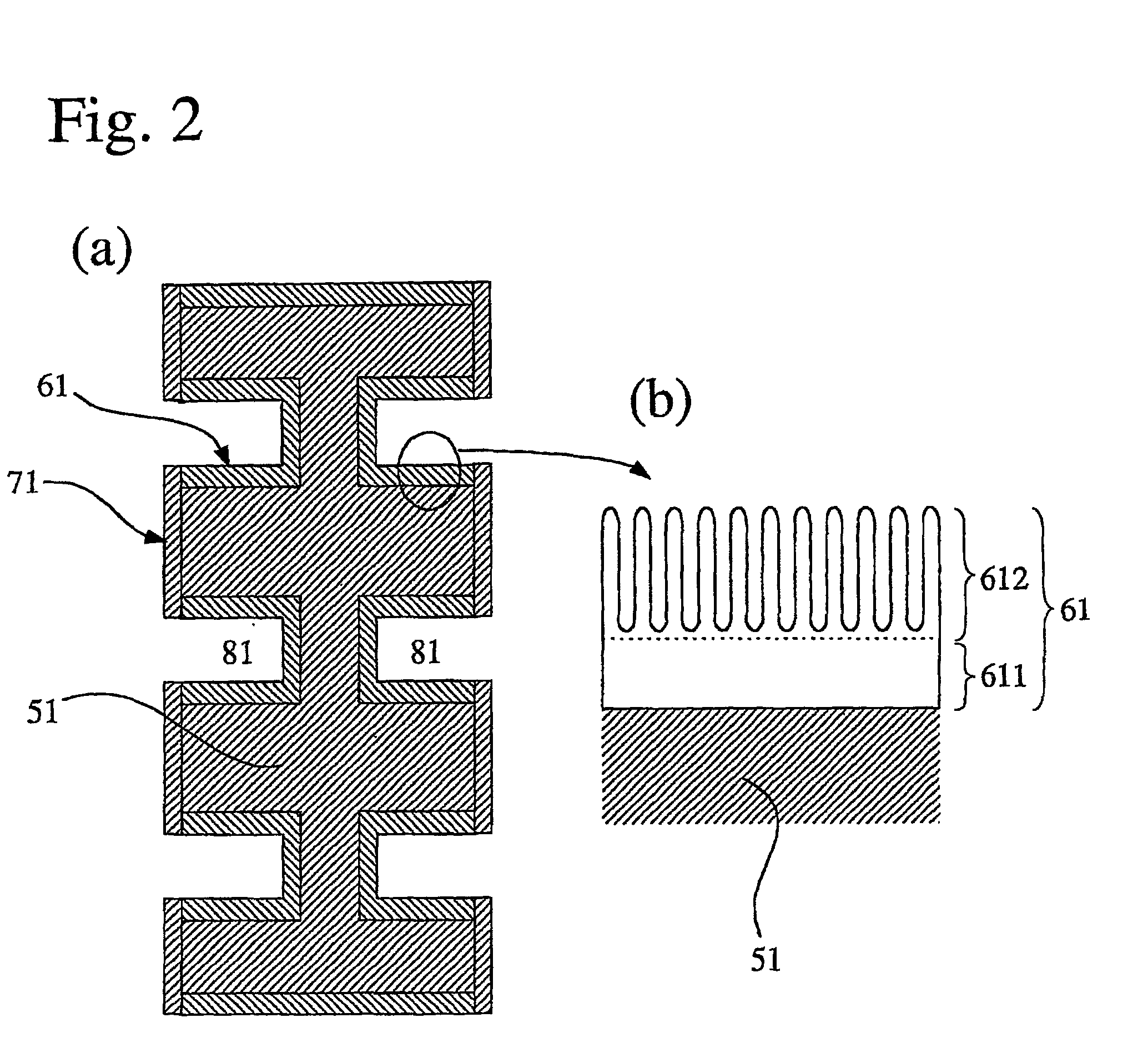

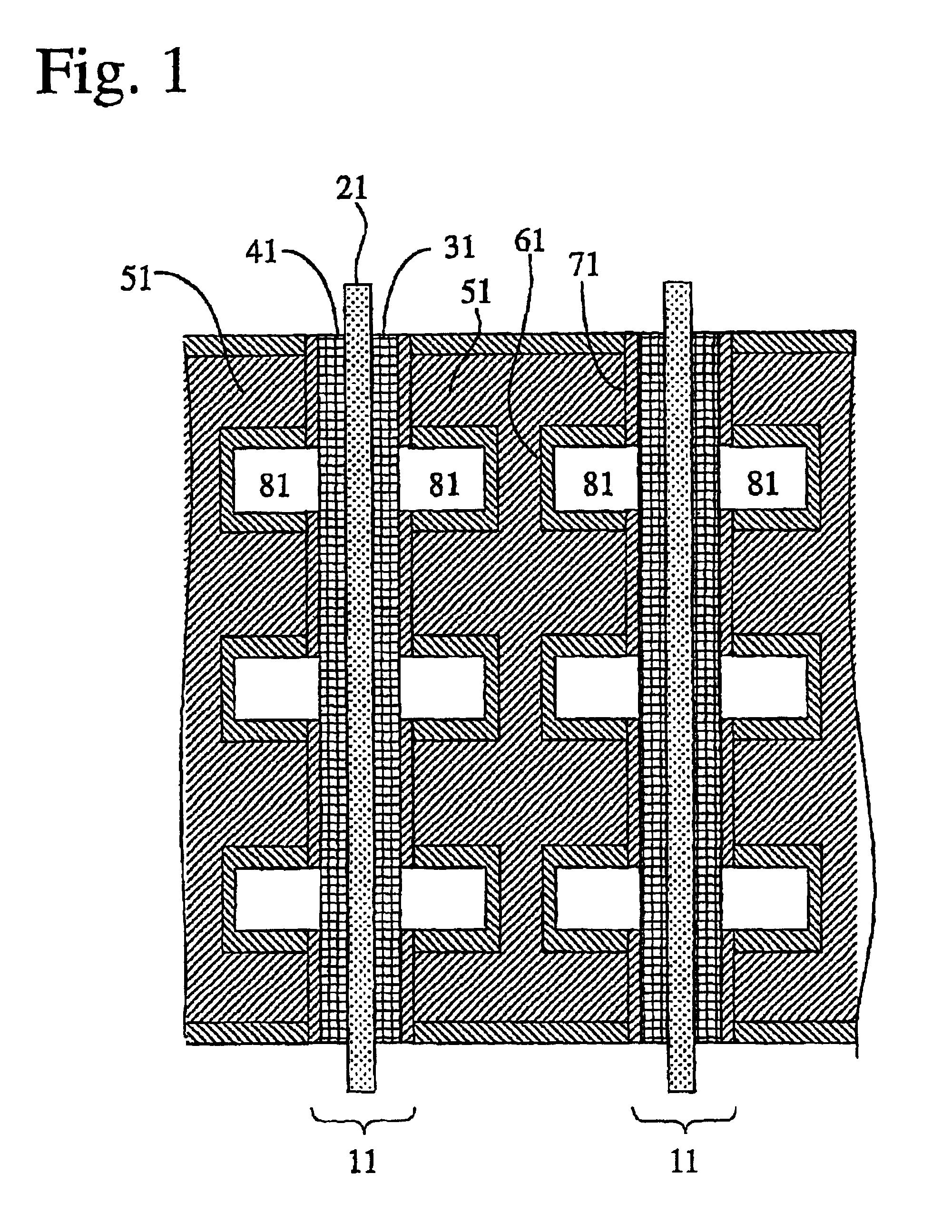

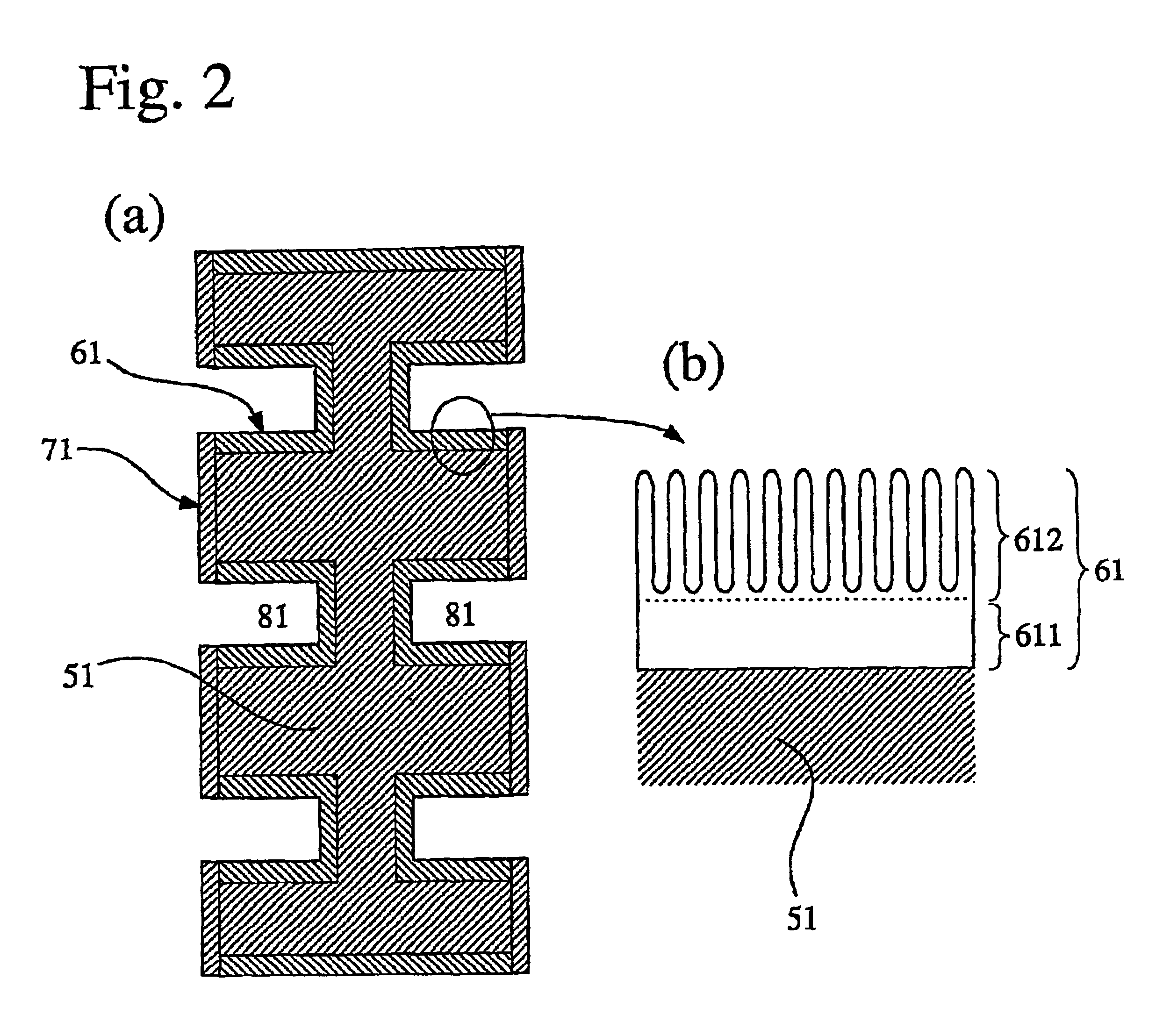

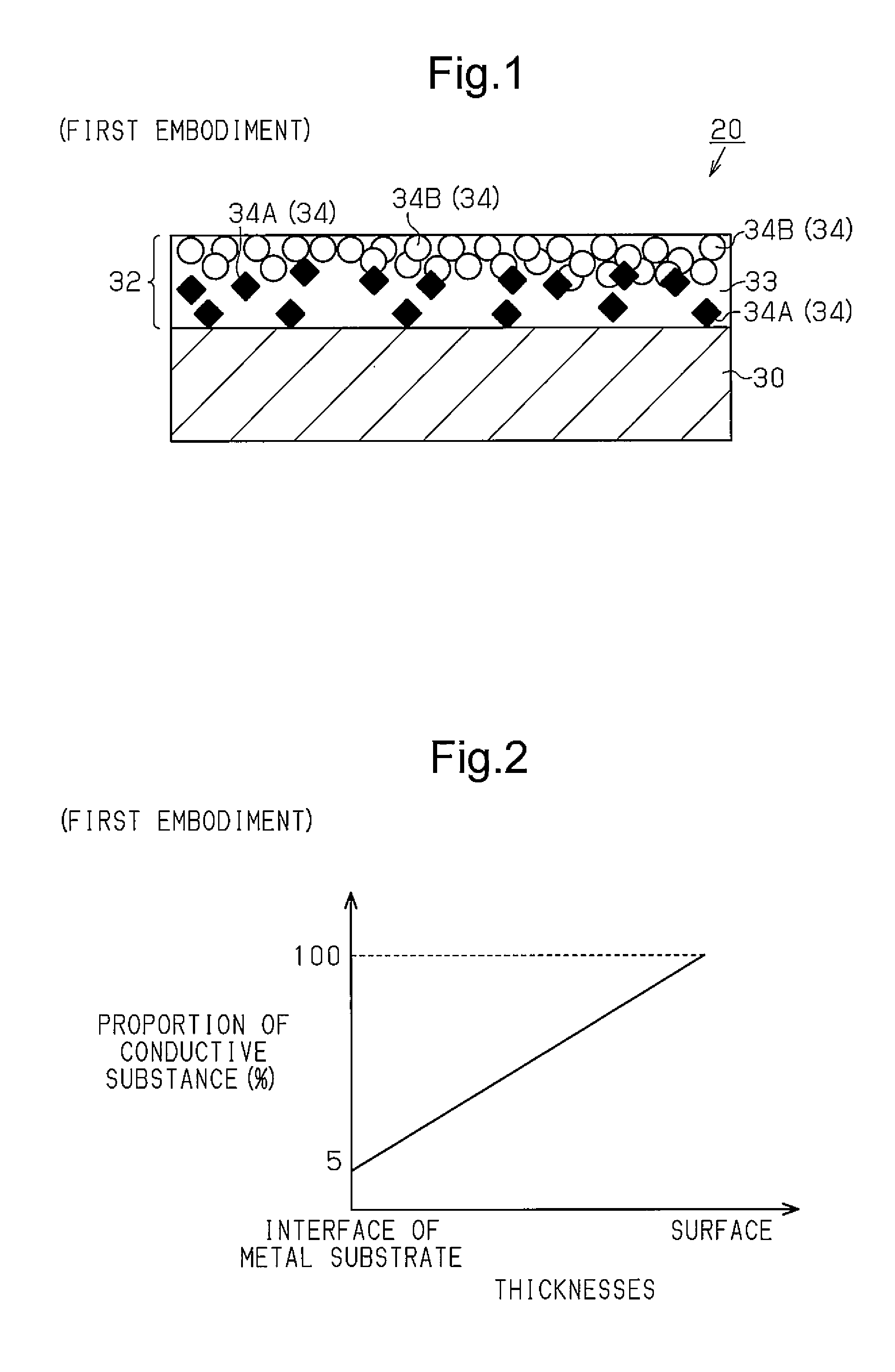

Embossed current collector separator for electrochemical fuel cell

InactiveUS20020009630A1Improve conductivityImprove corrosion resistanceElectrode carriers/collectorsSpecial surfacesFuel cellsEngineering

A bipolar current collector separator for a fuel cell composed of a metal plate having flow channels and contact faces that come into contact with electrodes or collectors, wherein a corrosion-resistant layer such as an anodized aluminum layer and a heat-resistant polymer layer is disposed on each of the flow channels.

Owner:RIKEN CO LTD

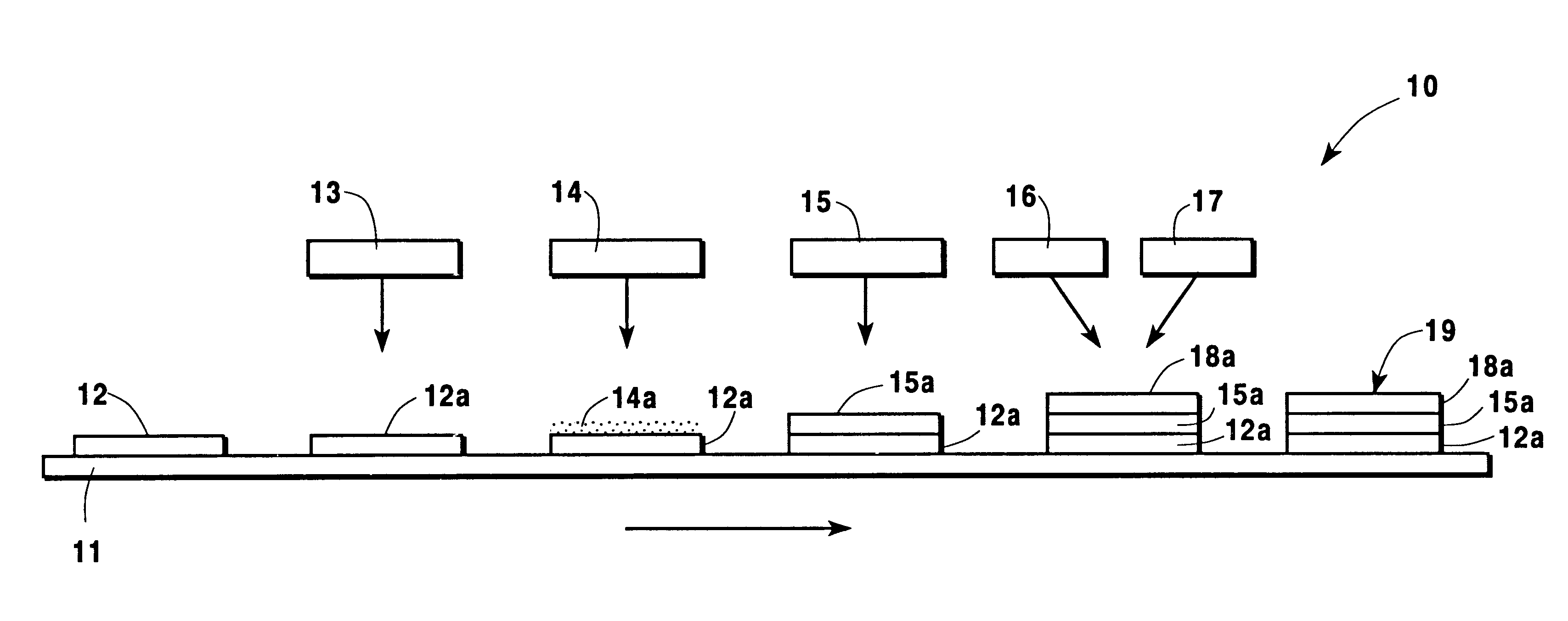

Coating compositions exhibiting corrosion resistance properties, related coated substrates, and methods

InactiveUS20070088111A1Improve metal resistanceSynthetic resin layered productsConductive materialCorrosionMaterials science

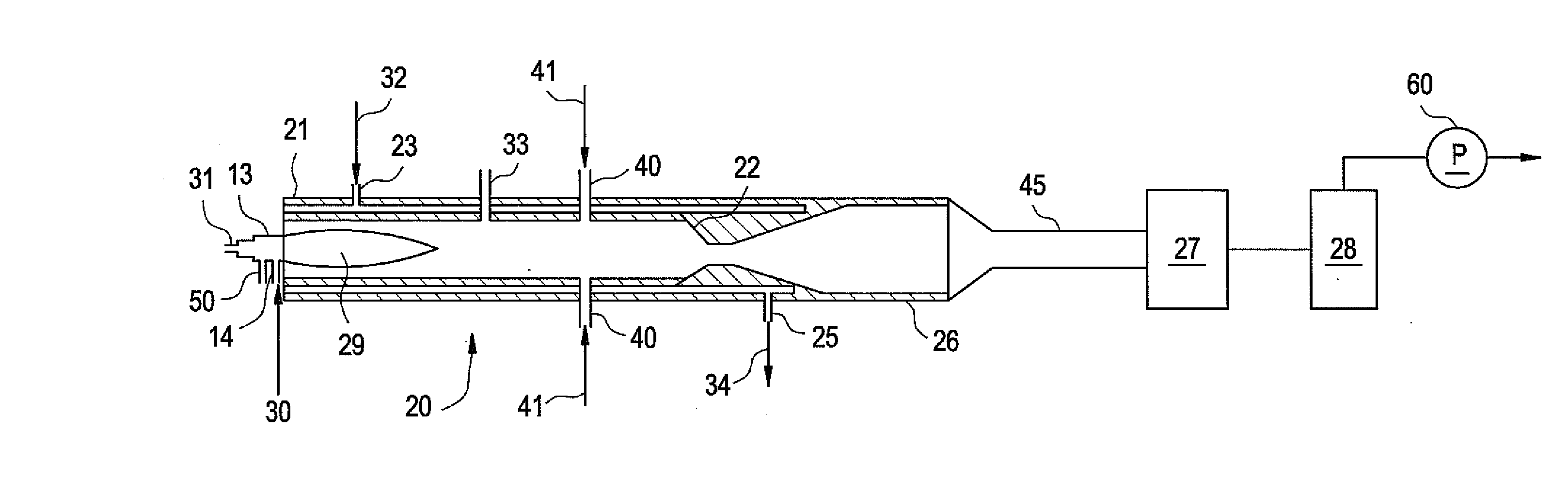

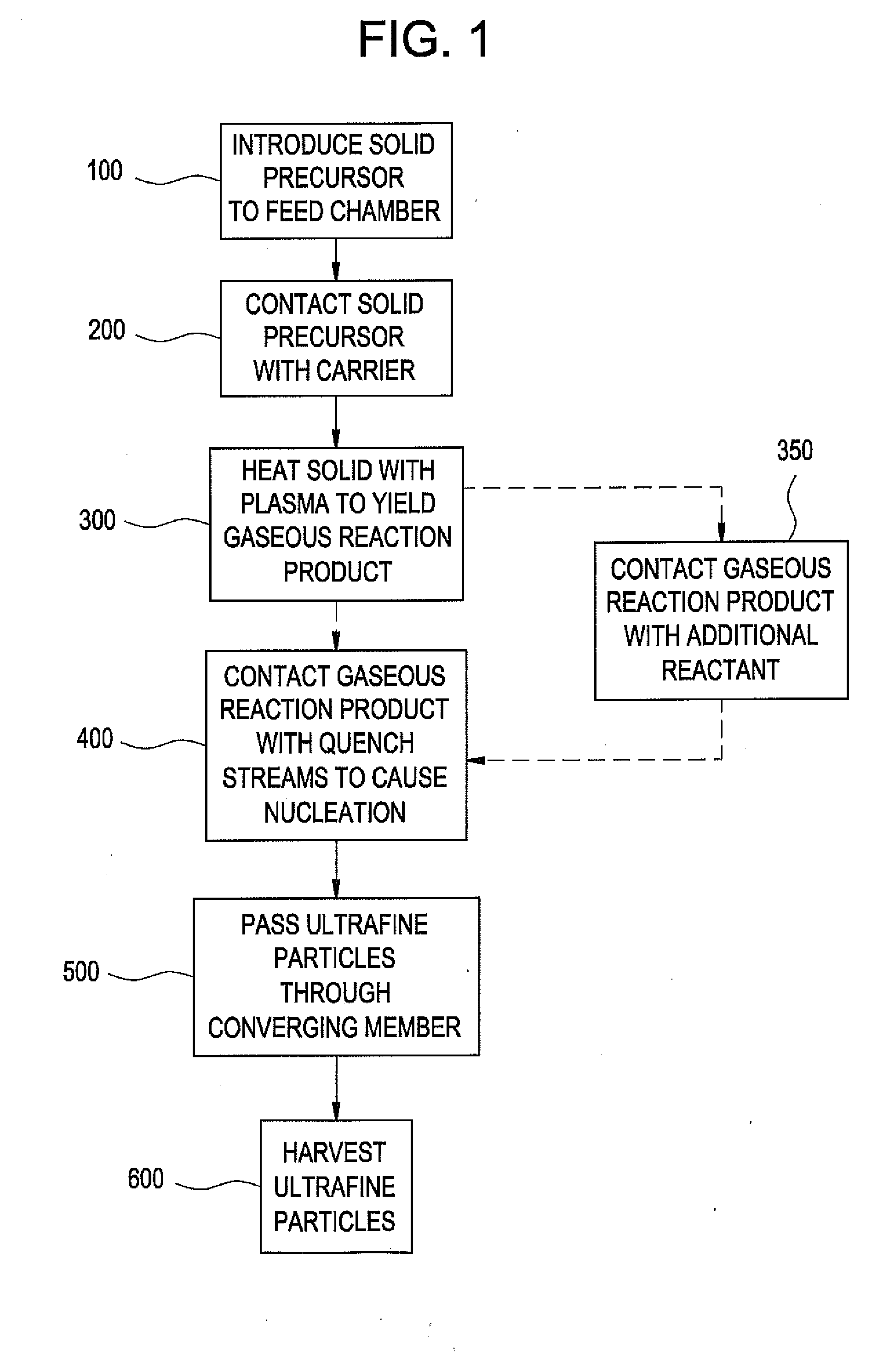

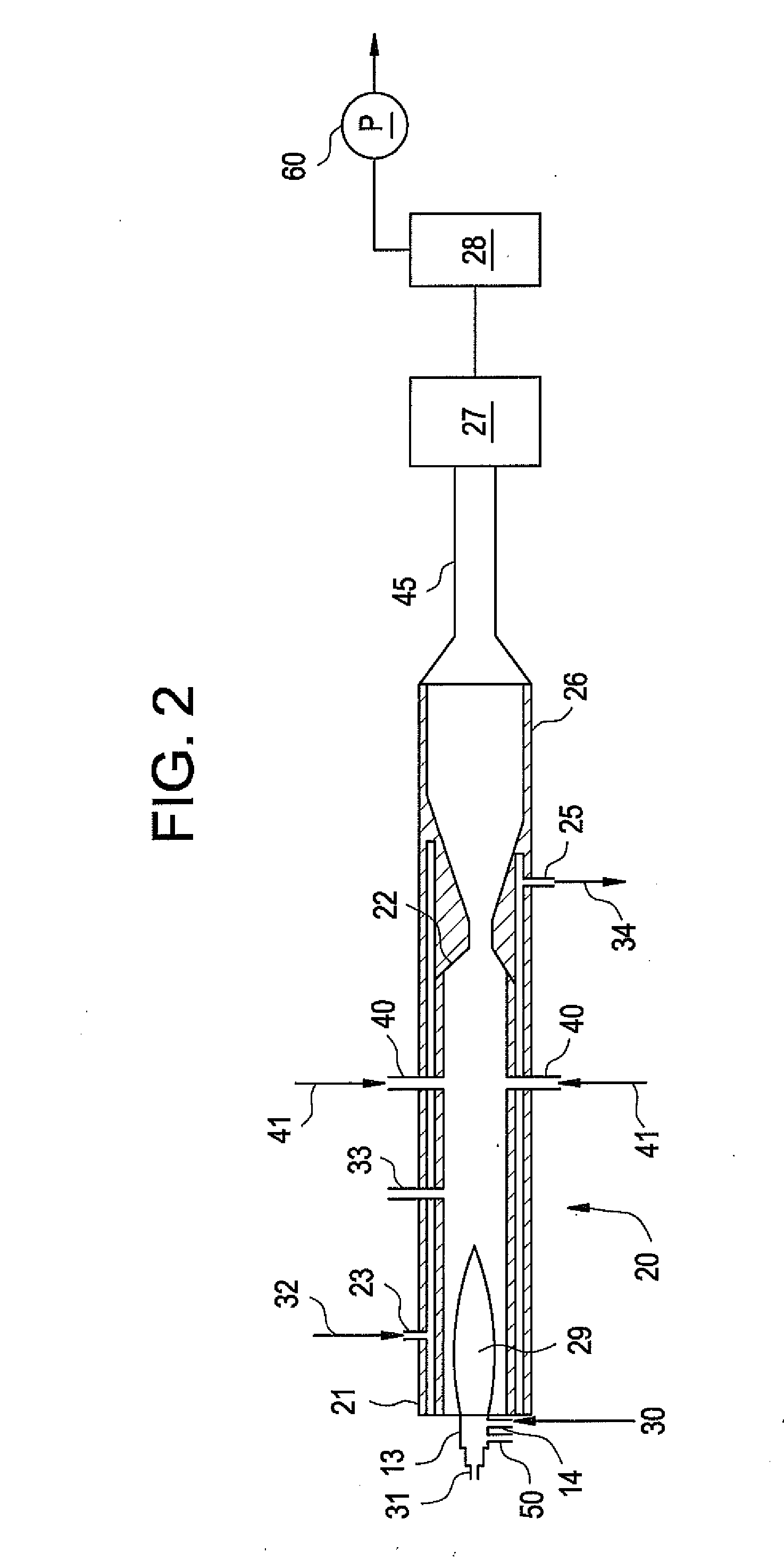

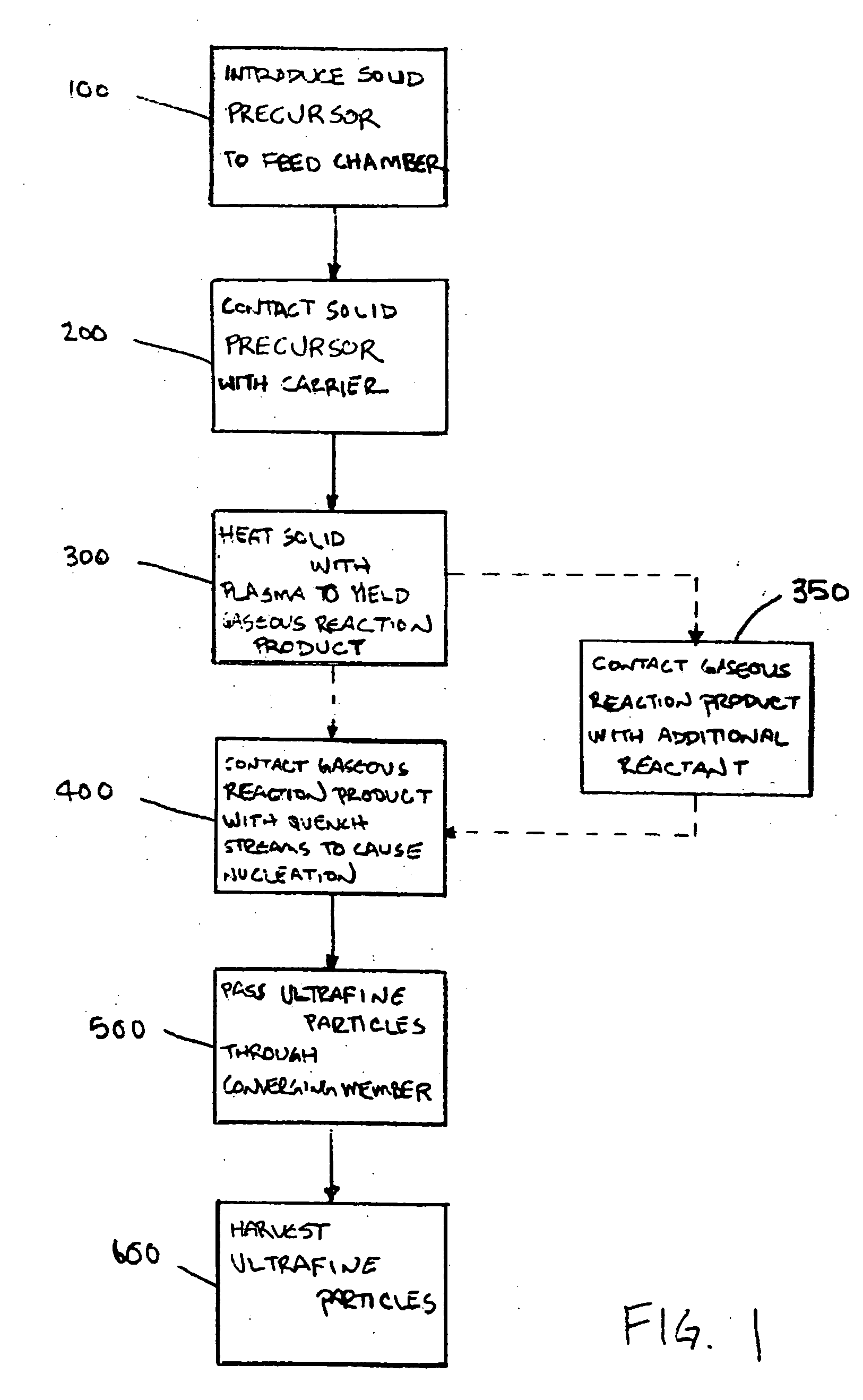

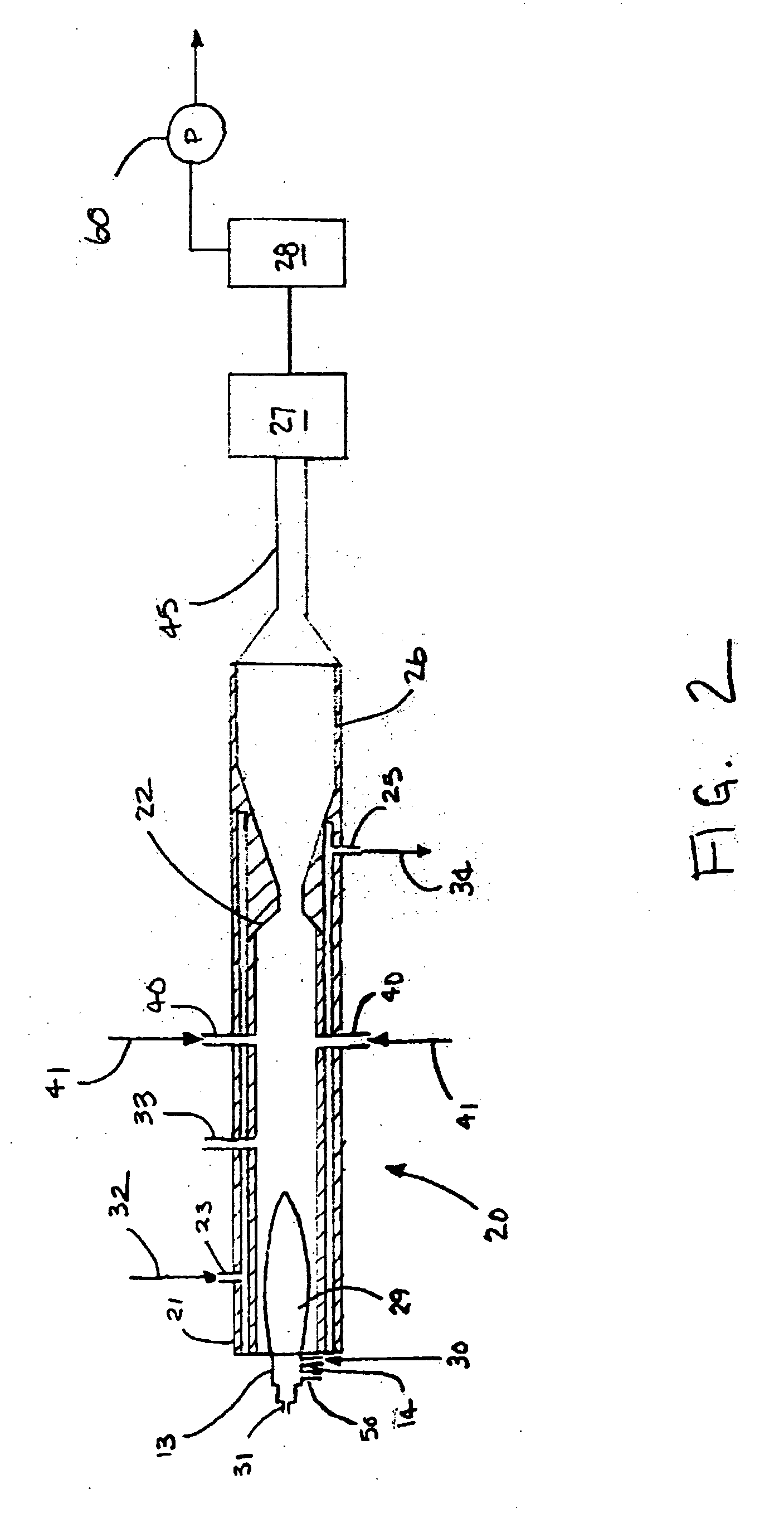

Coating compositions are disclosed that include corrosion resisting particles such that the coating composition can exhibit corrosion resistance properties. Also disclosed are substrates at least partially coated with a coating deposited from such a composition and multi-component composite coatings, wherein at least one coating layer is deposited from such a coating composition. Methods and apparatus for making ultrafine solid particles are also disclosed.

Owner:PPG IND OHIO INC

Method for high temperature mercury capture from gas streams

ActiveUS7033419B1Maintain thermal efficiencyIncrease temperatureGas treatmentOther chemical processesIridiumSorbent

A process to facilitate mercury extraction from high temperature flue / fuel gas via the use of metal sorbents which capture mercury at ambient and high temperatures. The spent sorbents can be regenerated after exposure to mercury. The metal sorbents can be used as pure metals (or combinations of metals) or dispersed on an inert support to increase surface area per gram of metal sorbent. Iridium and ruthenium are effective for mercury removal from flue and smelter gases. Palladium and platinum are effective for mercury removal from fuel gas (syngas). An iridium-platinum alloy is suitable for metal capture in many industrial effluent gas streams including highly corrosive gas streams.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

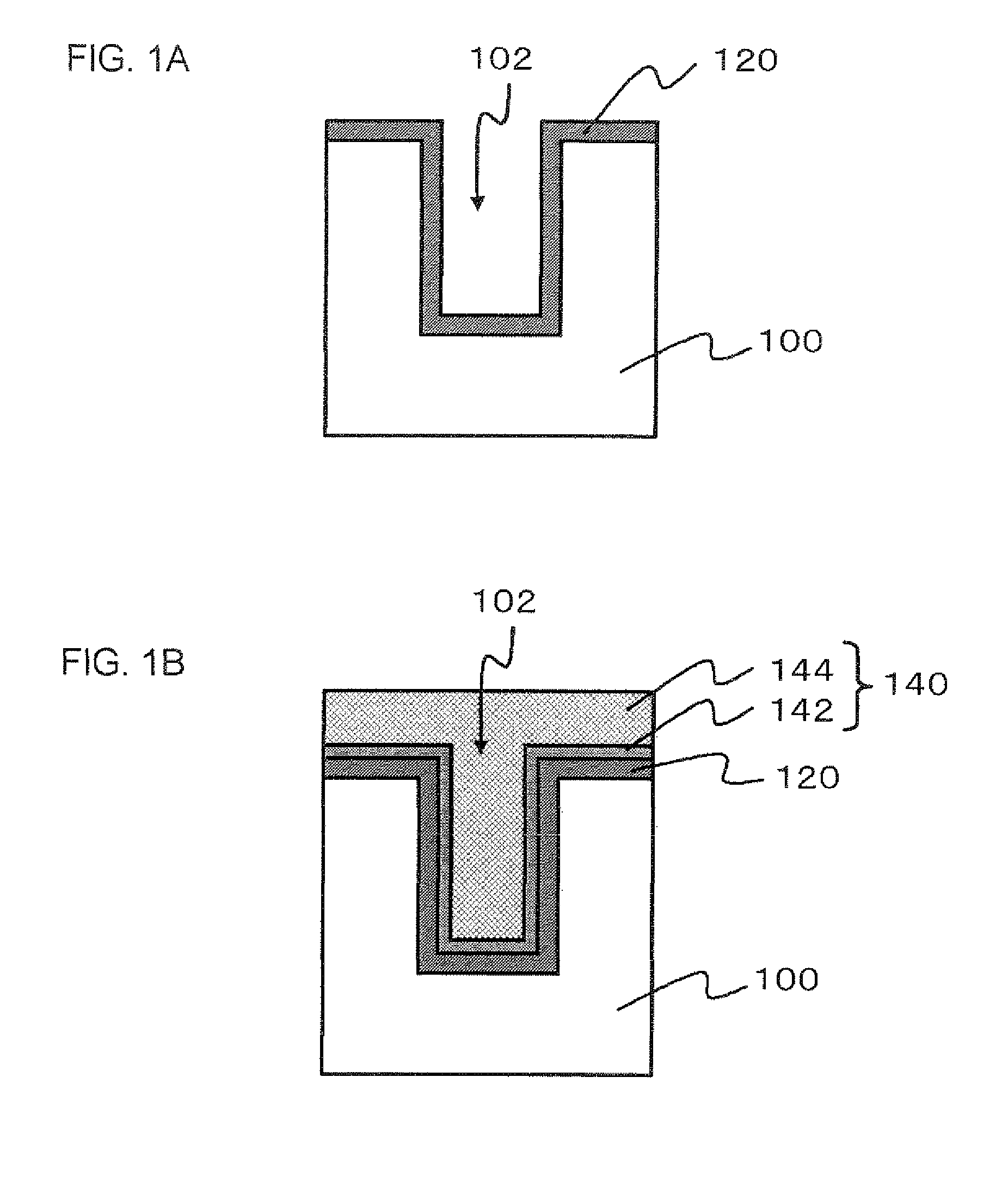

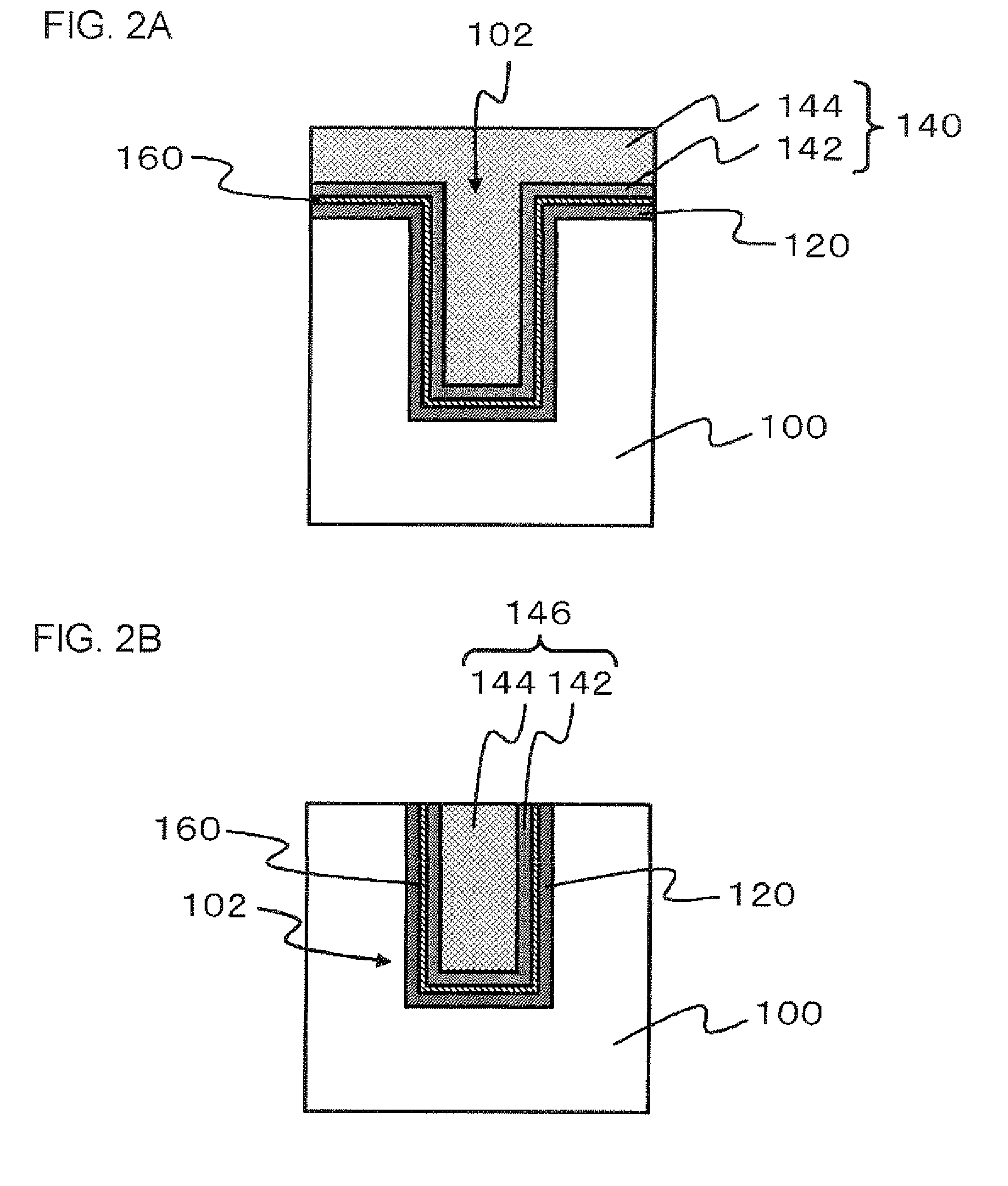

Semiconductor device and method of manufacturing the same

InactiveUS20100078820A1Improve metal resistanceAdhesivenessSemiconductor/solid-state device detailsSolid-state devicesAlloySemiconductor

A metal barrier film which contains an additive element is formed on the side face and on the bottom of a trench formed in an insulating film; a seed film is formed over the metal barrier film; a plated layer (Cu film) is formed using the seed film as a seed so as to fill up the trench with a metal film; the metal barrier film and the metal film are annealed to thereby form therebetween an alloy layer which contains a metal composing the metal barrier film, the additive element, and a metal composing the metal film, and to thereby allow the additive element to diffuse into the metal film.

Owner:RENESAS ELECTRONICS CORP

Coating compositions exhibiting corrosion resistance properties, related coated substrates, and methods

ActiveUS20070275256A1Improve metal resistanceMaterial nanotechnologyOther chemical processesSolid particleMaterials science

Coating compositions are disclosed that include corrosion resisting particles such that the coating composition can exhibit corrosion resistance properties. Also disclosed are substrates at least partially coated with a coating deposited from such a composition and multi-component composite coatings, wherein at least one coating later is deposited from such a coating composition. Methods and apparatus for making ultrafine solid particles are also disclosed.

Owner:PPG IND OHIO INC

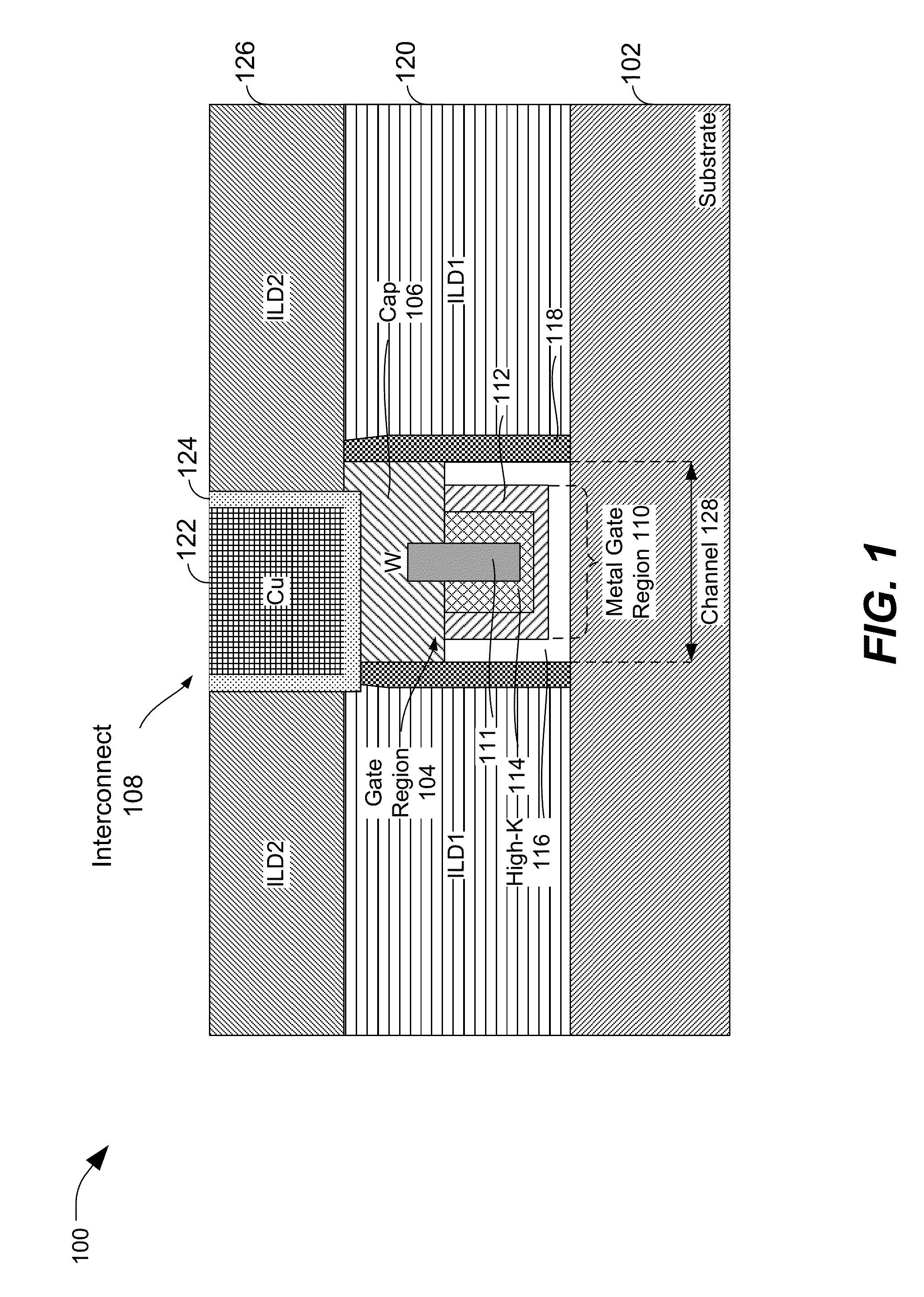

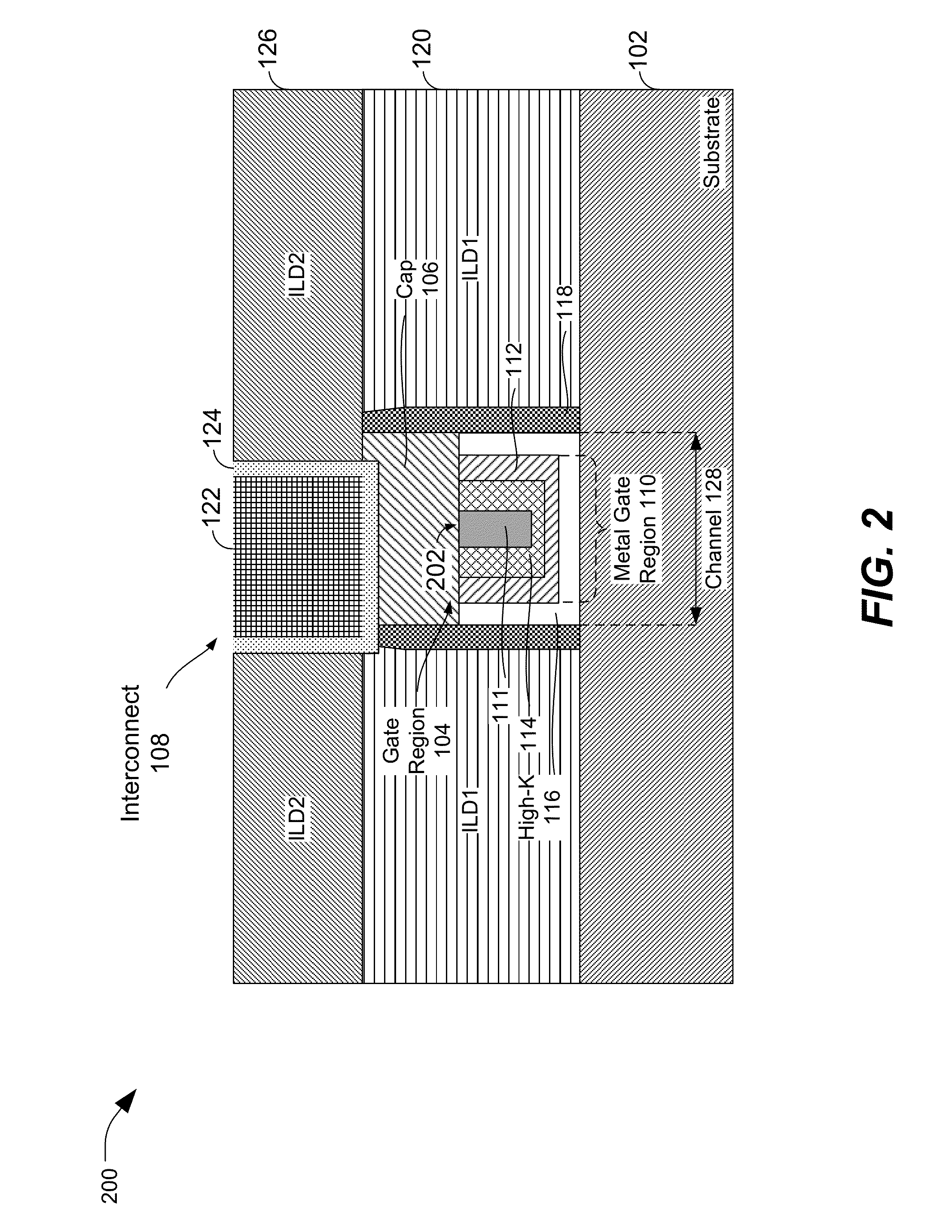

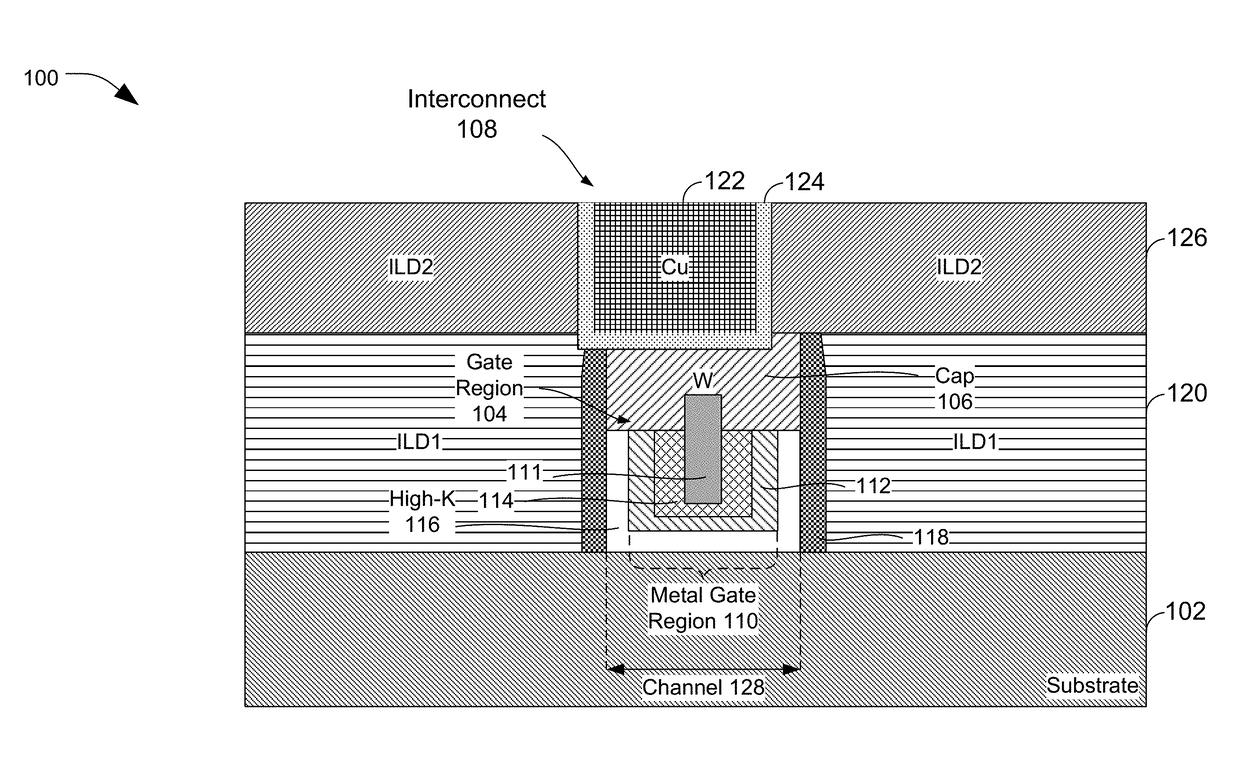

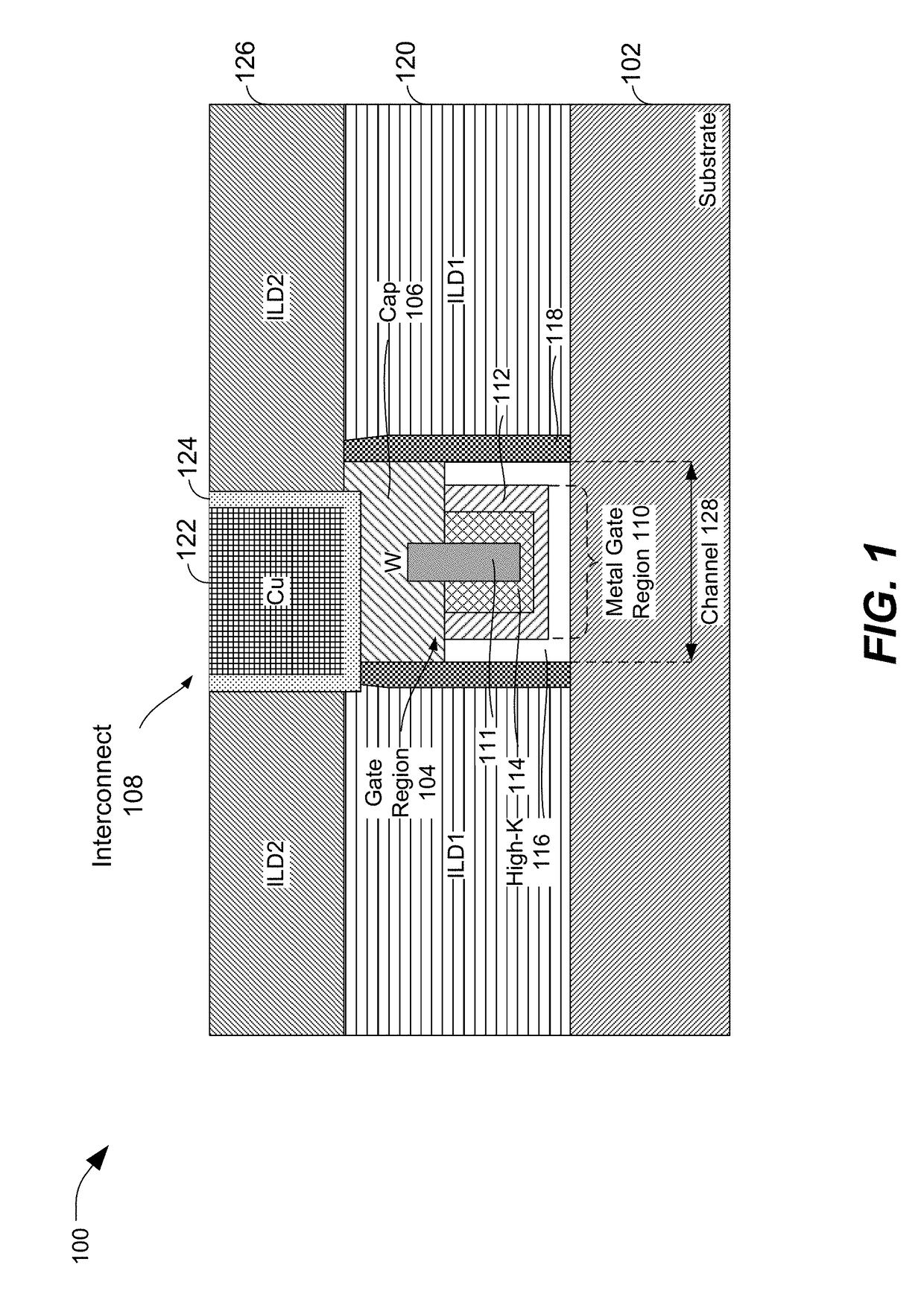

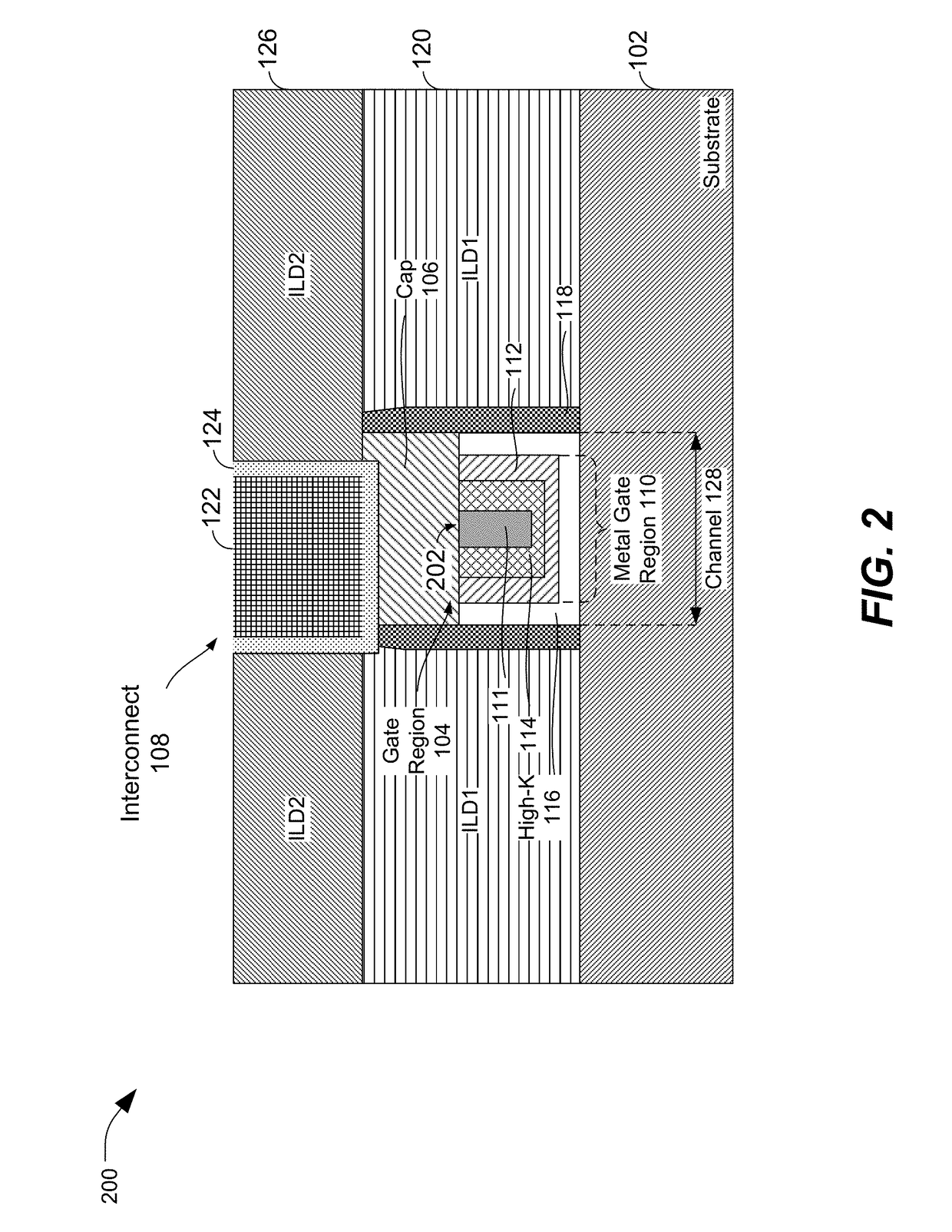

Conductive cap for metal-gate transistor

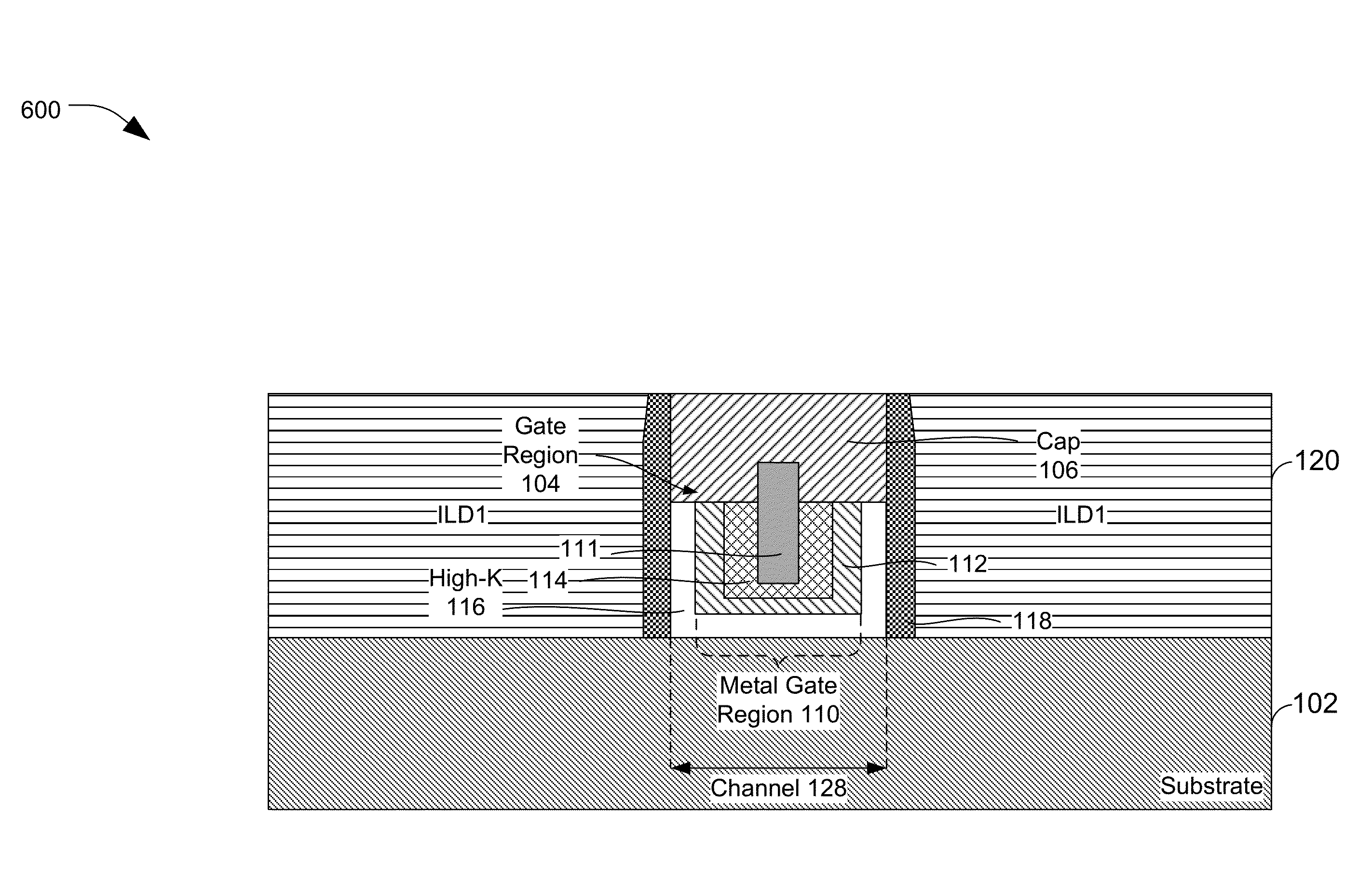

ActiveUS20160276455A1Reduce the possibilityImprove metal resistanceTransistorSemiconductor/solid-state device detailsGate dielectricEngineering

A semiconductor device includes a gate region, a conductive cap, and an interconnect. The gate region (e.g., a metal-gate transistor) includes a metal gate region and a high dielectric constant (high-K) gate dielectric region. The conductive cap is disposed on a surface of the metal gate region and on a surface of the high-K gate dielectric region, and the interconnect is disposed on the conductive cap. The conductive cap includes a conductive material that electrically connects the gate region to the interconnect.

Owner:QUALCOMM INC

Coating compositions exhibiting corrosion resistance properties, related coated substrates, and methods

ActiveUS20070048540A1Improve corrosion resistanceSufficient amountMaterial nanotechnologyLiquid surface applicatorsSolid particleMaterials science

Coating compositions are disclosed that include corrosion resisting particles such that the coating composition can exhibit corrosion resistance properties. Also disclosed are substrates at least partially coated with a coating deposited from such a composition and multi-component composite coatings, wherein at least one coating later is deposited from such a coating composition. Methods and apparatus for making ultrafine solid particles are also disclosed.

Owner:PPG IND OHIO INC

Silver film incorporating protective insoluble metallic salt precipitate

InactiveUS6432200B2Improve corrosion resistanceImprove metal resistanceInorganic chemistryMirrorsProduction lineWater insoluble

An apparatus is provided for making mirrors having enhanced reflective layer resistance to corrosion. The reflective layer of the mirror, typically silver, is contacted, preferably simultaneously, with a first solution containing a specific cation and a second solution containing a specific anion, or alkaline material which forms hydroxyl ions, the specific cation and specific anion or hydroxyl ion reacting to form a water insoluble precipitate on the silver surface. The mirror may then be painted to provide additional corrosion resistance to the mirror. The apparatus device for forming the precipitate eliminates the need for a device to form a copper layer on the silver surface and the device may be incorporated into existing mirror production lines as a replacement for the copper layering device. Also provided are mirrors made using the apparatus of the invention. A preferred cation containing solution contains tin (e.g., SnCl2) and a preferred anion containing solution contains hydroxyl ions (e.g, NaOH).

Owner:SWIMC LLC

Conductive cap for metal-gate transistor

ActiveUS9698232B2Inhibited DiffusionImprove electrical performanceTransistorSemiconductor/solid-state device detailsGate dielectricConductive materials

Owner:QUALCOMM INC

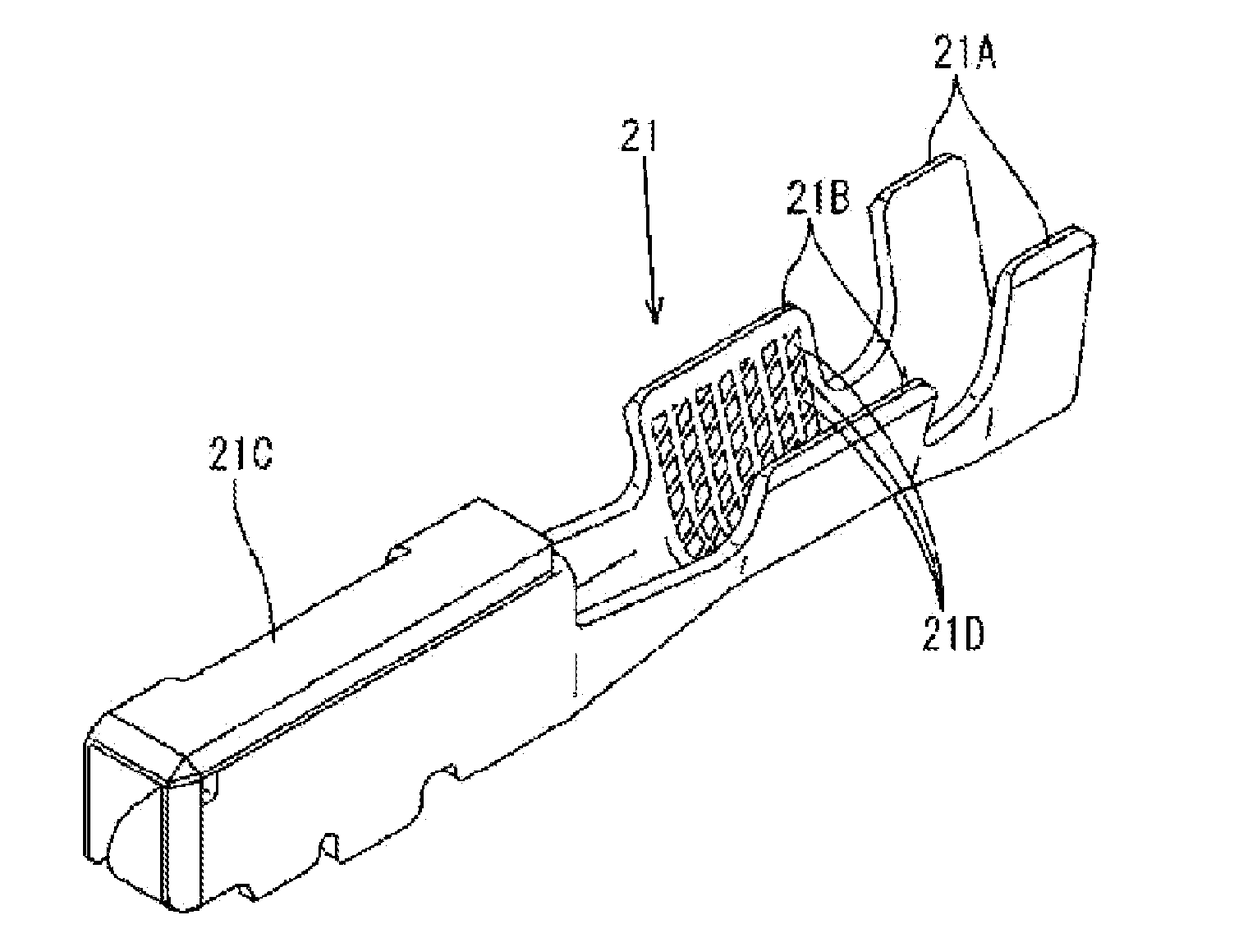

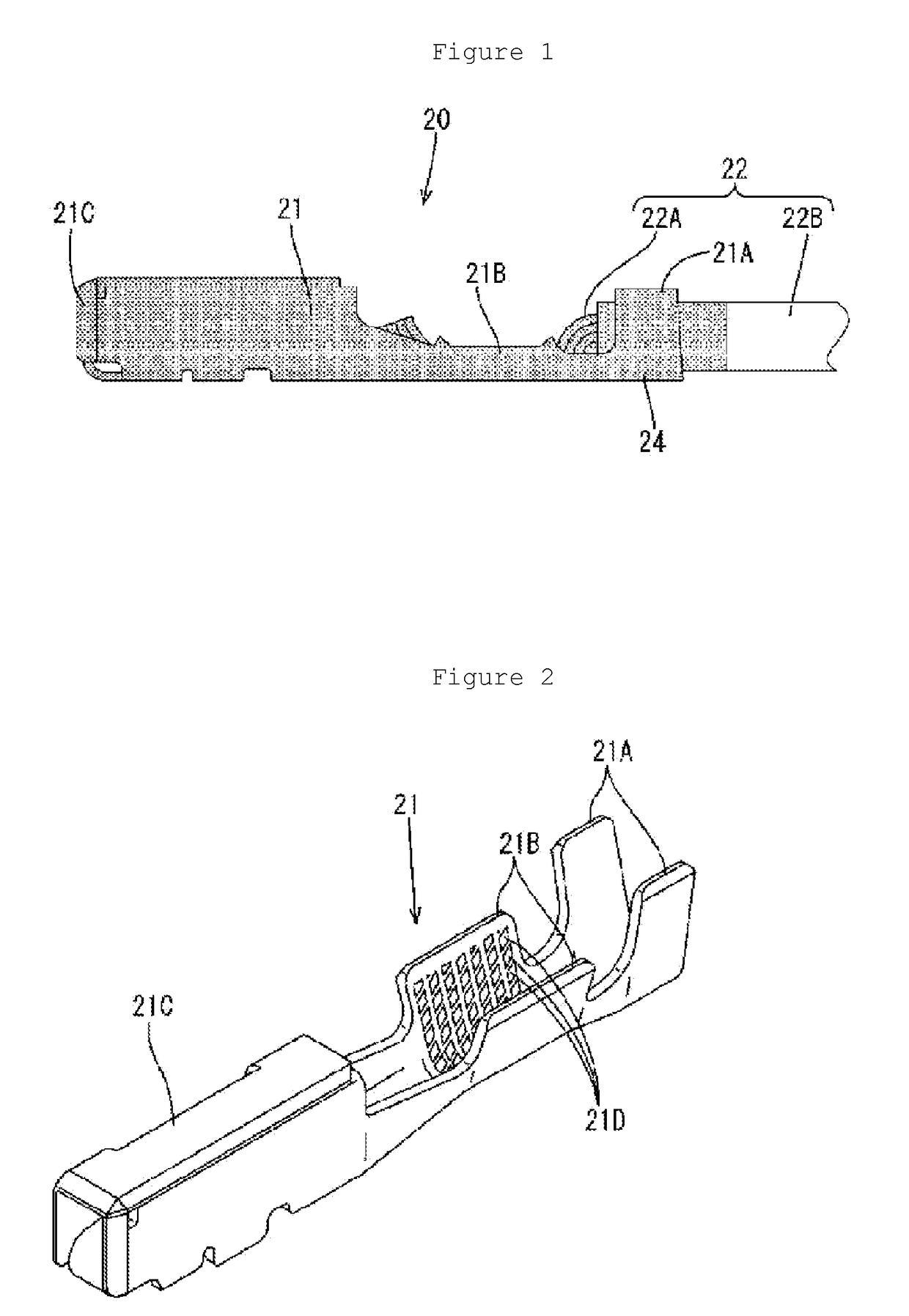

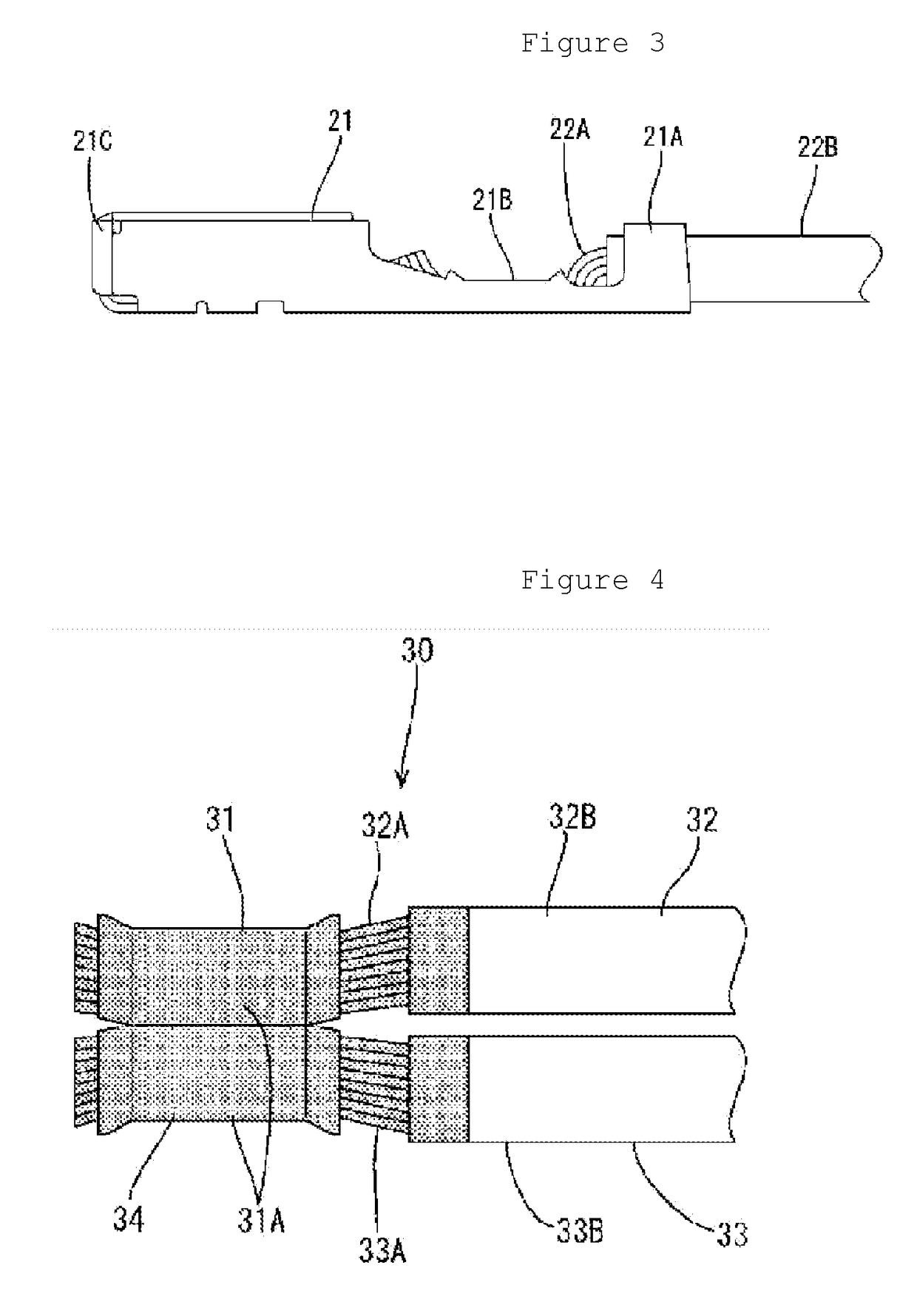

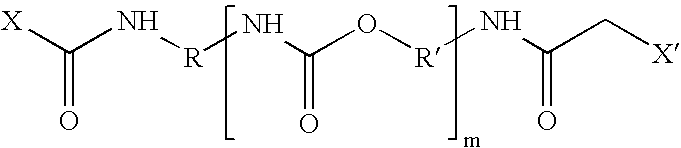

Surface Protective Agent Composition, Electric Connection Structure Using Same, and Method for Manufacturing Electric Connection Structure

InactiveUS20170117650A1Avoid corrosionImprove metal resistanceLine/current collector detailsCoupling contact membersElectricityBase oil

To provide a surface protective agent composition that suppresses corrosion of members of different kinds of metals close to each other due to corrosion current between the metals of the members, and to provide an electric connection structure and a method for producing an electric connection structure using the same. The surface protective agent composition contains (a) a lubricant base oil; (b) a prescribed amount of at least one compound selected from the group consisting of particular phosphorus compounds and a metal salt or an amine salt thereof; and (c) a prescribed amount of an amide compound, and in the case where the component (b) does not contain the metal salt of the phosphorus compound, the surface protective agent composition further contains (d) a prescribed amount of a salicylate of a particular metal and / or a basic (or perbasic) salt thereof, and the electric connection structure containing a surface protective layer consisting of the surface protective agent composition.

Owner:JX NIPPON OIL & ENERGY CORP +4

Articles having improved corrosion resistance

ActiveUS20090220689A1Improve metal resistanceIncrease surface tensionLiquid surface applicatorsMetallic material coating processesSilorane ResinsMetal

The present application relates to a method for enhancing metal corrosion resistance of a metal deposited on a substrate, the method comprises contacting the metal coated substrate with a treating composition comprising a film forming organic component which treating composition forms a hydrophobic film on the metal coated substrate with a thickness of less than 1 μm. Furthermore, the present application relates to a method for making a mirror comprising a substrate having a metal coated thereon, the method comprises contacting the metal coated substrate with a treating composition comprising a film forming organic component which treating composition forms a hydrophobic film on the metal coated substrate with a thickness of less than 1 μm. Preferably, the film forming organic component is selected from the group consisting of an aromatic triazole compound and a silicone resin. In addition the present application relates to the products obtainable by these methods.

Owner:SWIMC LLC

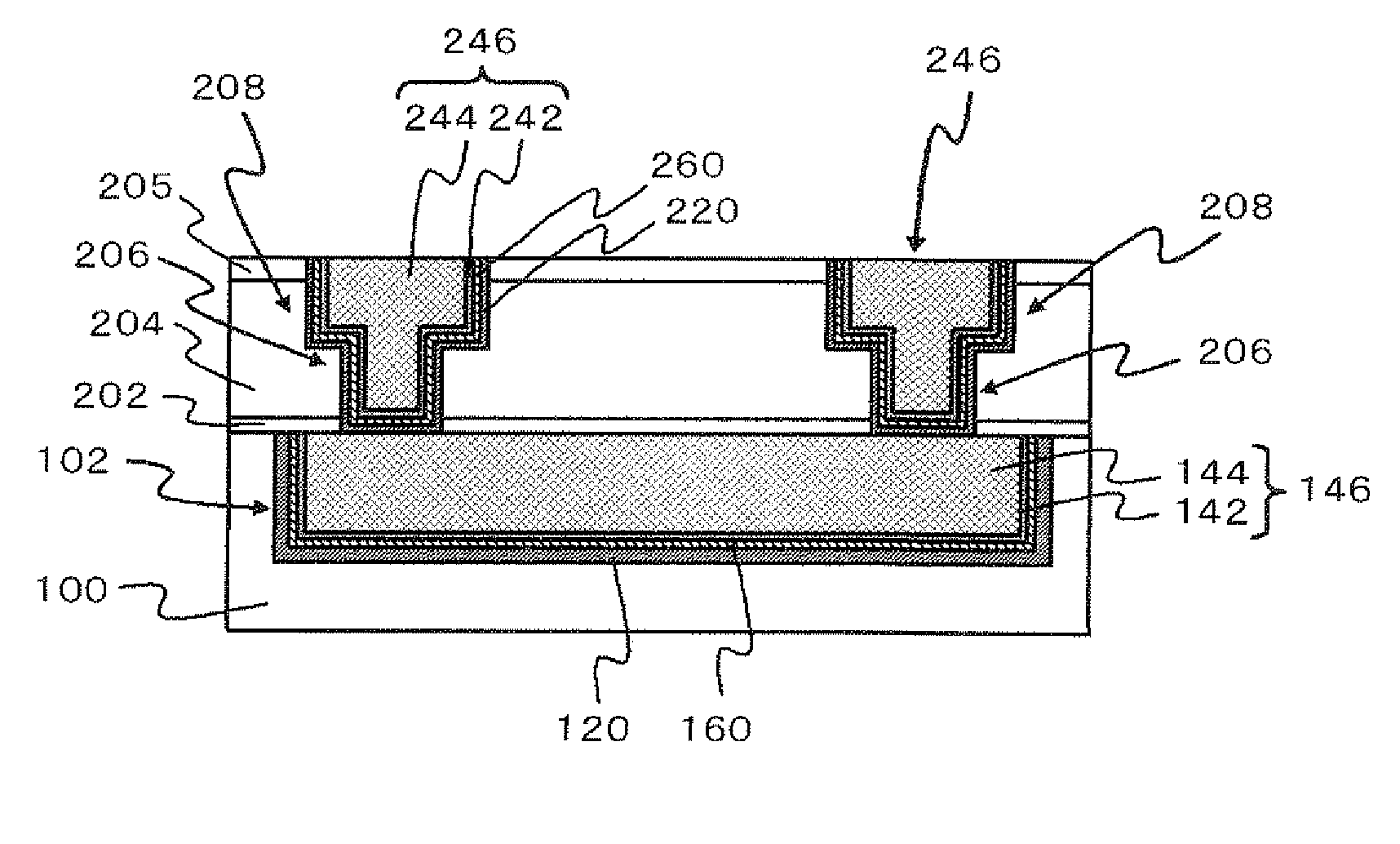

Embossed current collector separator for electrochemical fuel cell

InactiveUS6852438B2Improve corrosion resistanceImprove metal resistanceElectrode carriers/collectorsCell component detailsFuel cellsEngineering

A bipolar current collector separator for a fuel cell composed of a metal plate having flow channels and contact faces that come into contact with electrodes or collectors, wherein a corrosion-resistant layer such as an anodized aluminum layer and a heat-resistant polymer layer is disposed on each of the flow channels.

Owner:RIKEN CO LTD

Trichrome passivates for treating galvanized steel

ActiveUS20090266450A1Good bath stabilityImprove performanceWelding/cutting media/materialsSuperimposed coating processOrganic acidAmmonium compounds

In one embodiment, the invention provides a composition useful for passivating a metal surface, in particular a zinciferous surface, comprising, preferably consisting essentially of, most preferably consisting of water and:(A) dissolved phosphate ions;(B) dissolved trivalent chromium ions;(C) dissolved anions of at least one complex fluoride of an element selected from the group consisting of Ti, Zr, Hf, Si, Sn, Al, Ge and B; preferably Ti, Si and / or Zr;(D) an optional component of dissolved free fluoride ions;(E) organic acid inhibitor, preferably comprising quaternary ammonium compounds; and, optionally(F) a pH adjusting component; andoptionally organic hydroxyl acids.

Owner:HENKEL KGAA

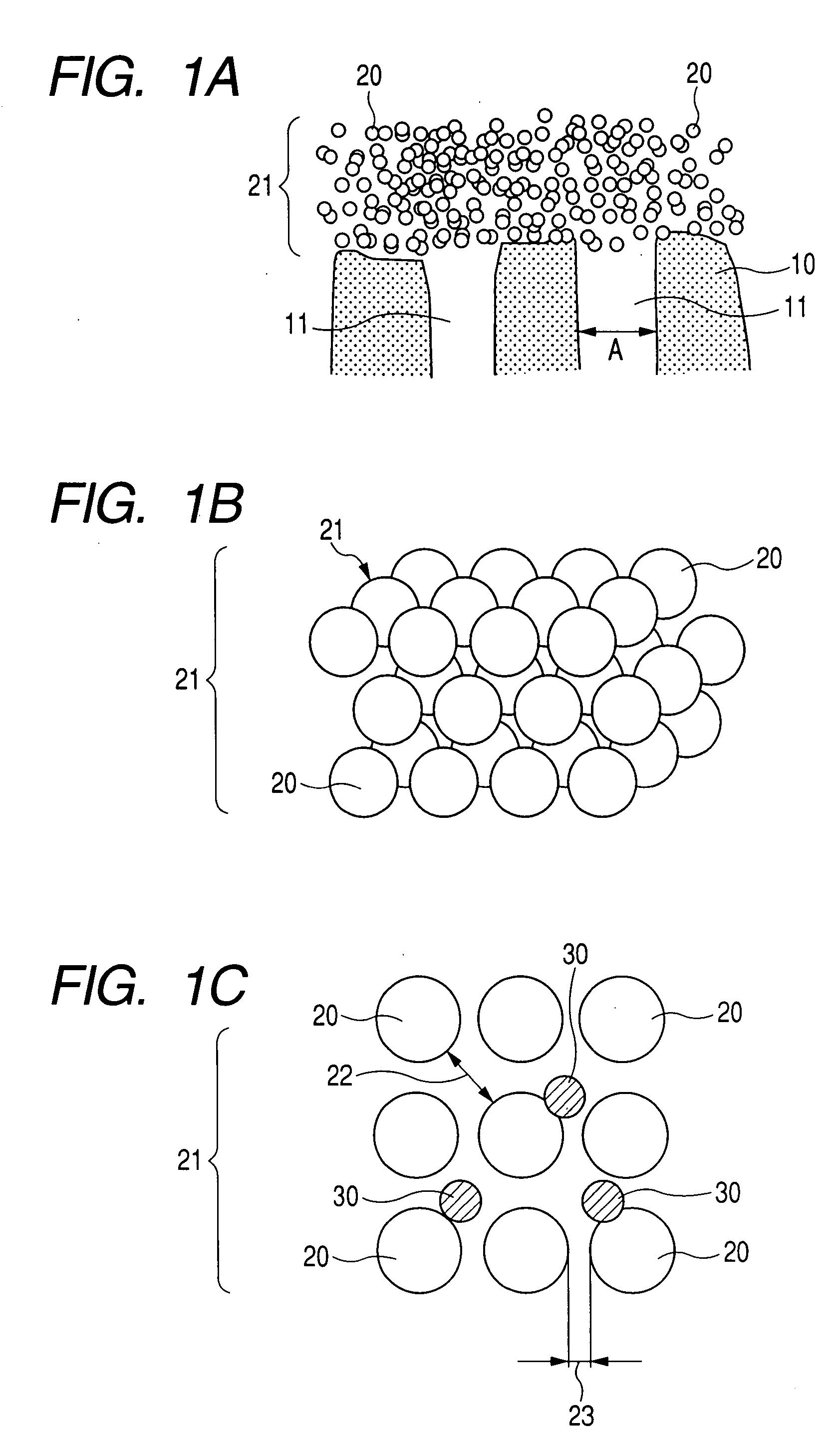

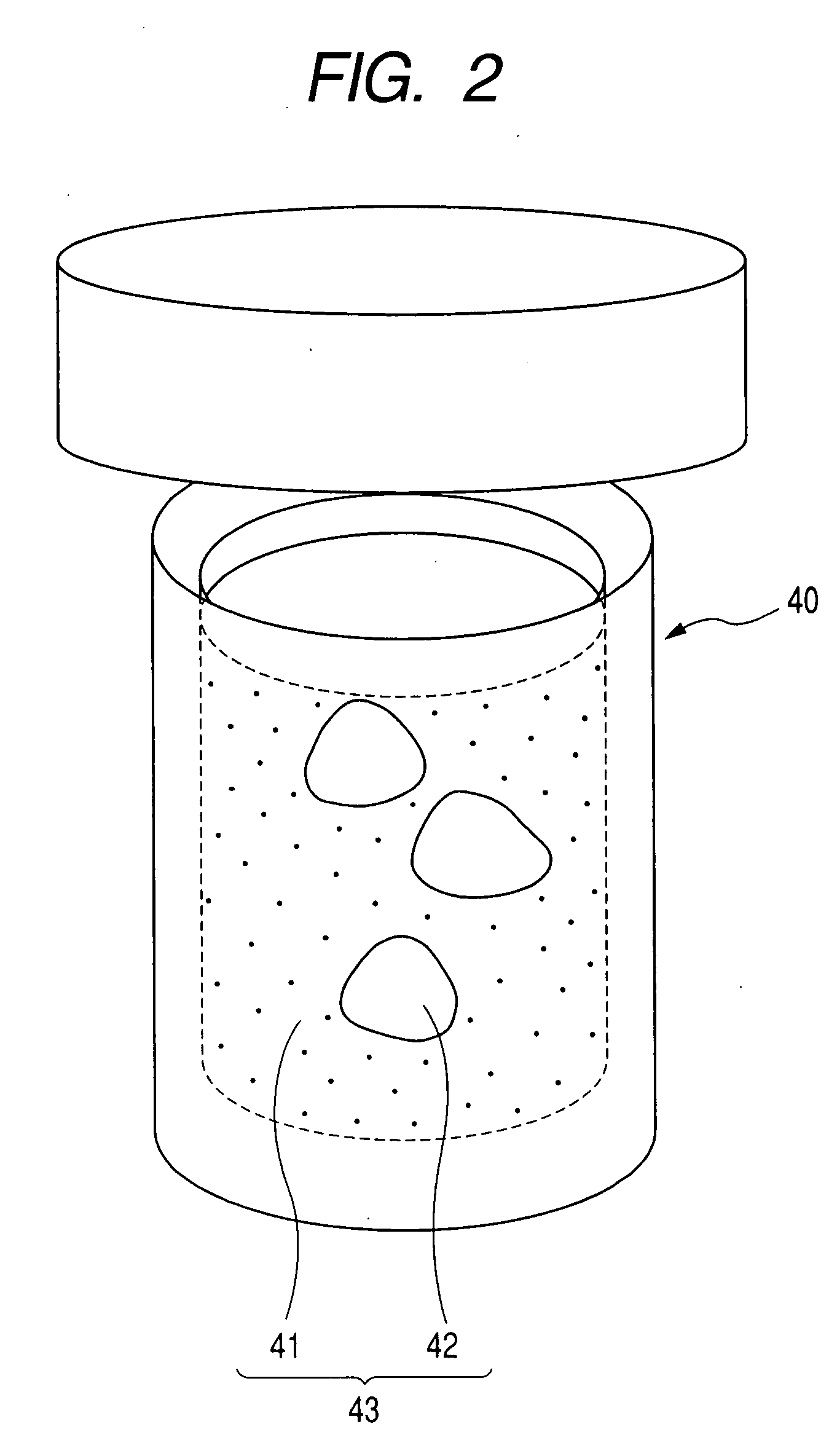

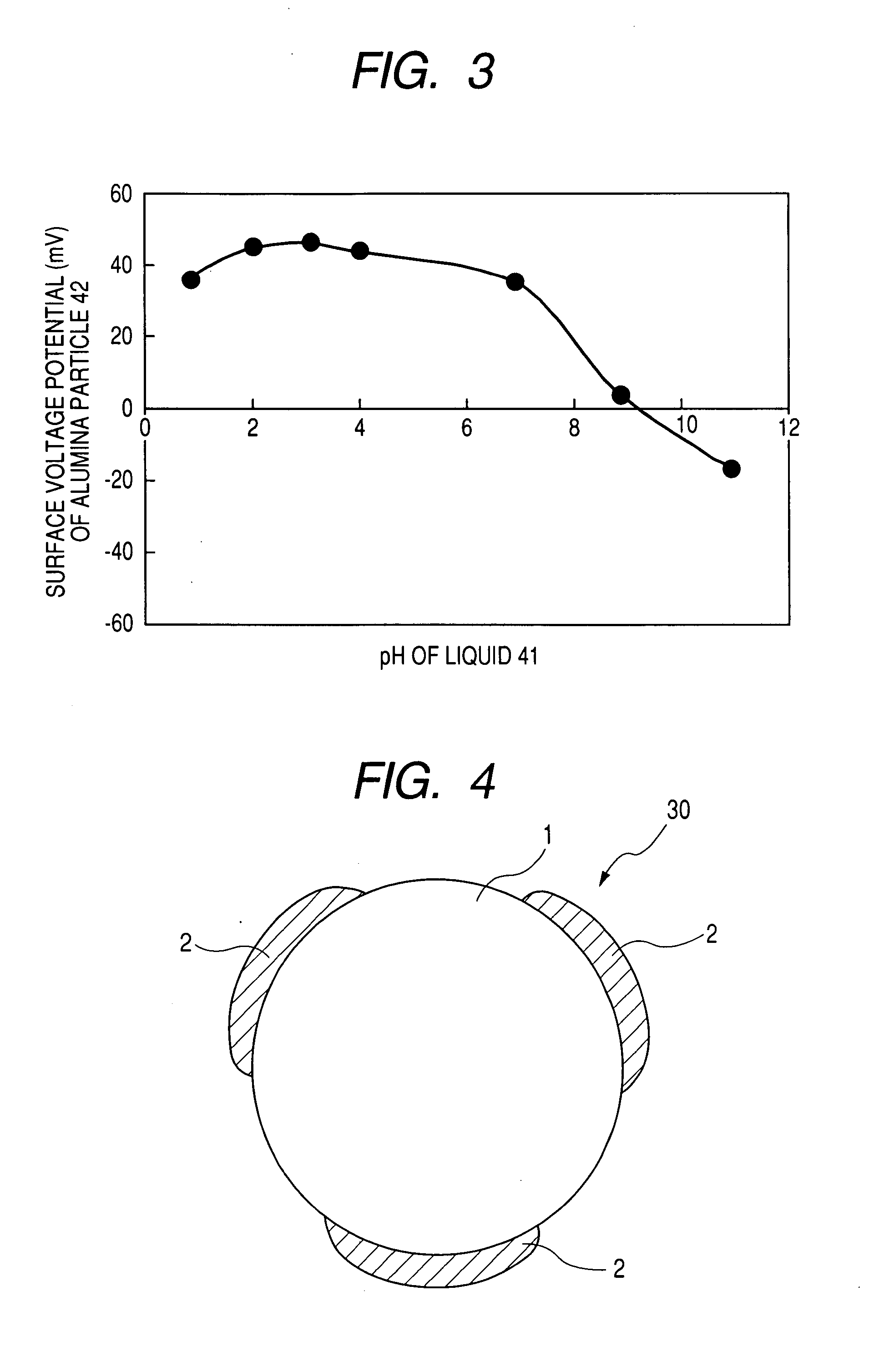

Method of producing catalyst support particles and a catalyzer using the catalyst support particles

InactiveUS20070281856A1Slow changeImprove heat resistanceMaterial nanotechnologyAluminium compoundsHeat resistanceHeat treated

Catalyst support particles and a catalyzer are produced by using γ-alumina particles or alumina precursor particles treated in advance by hydrothermal treatment in an autoclave. Performing the hydrothermal treatment improves the thermal resistance of the alumina particles because of suppressing deformation of the alumina particles when used at a high temperature such as 1000° C.

Owner:DENSO CORP

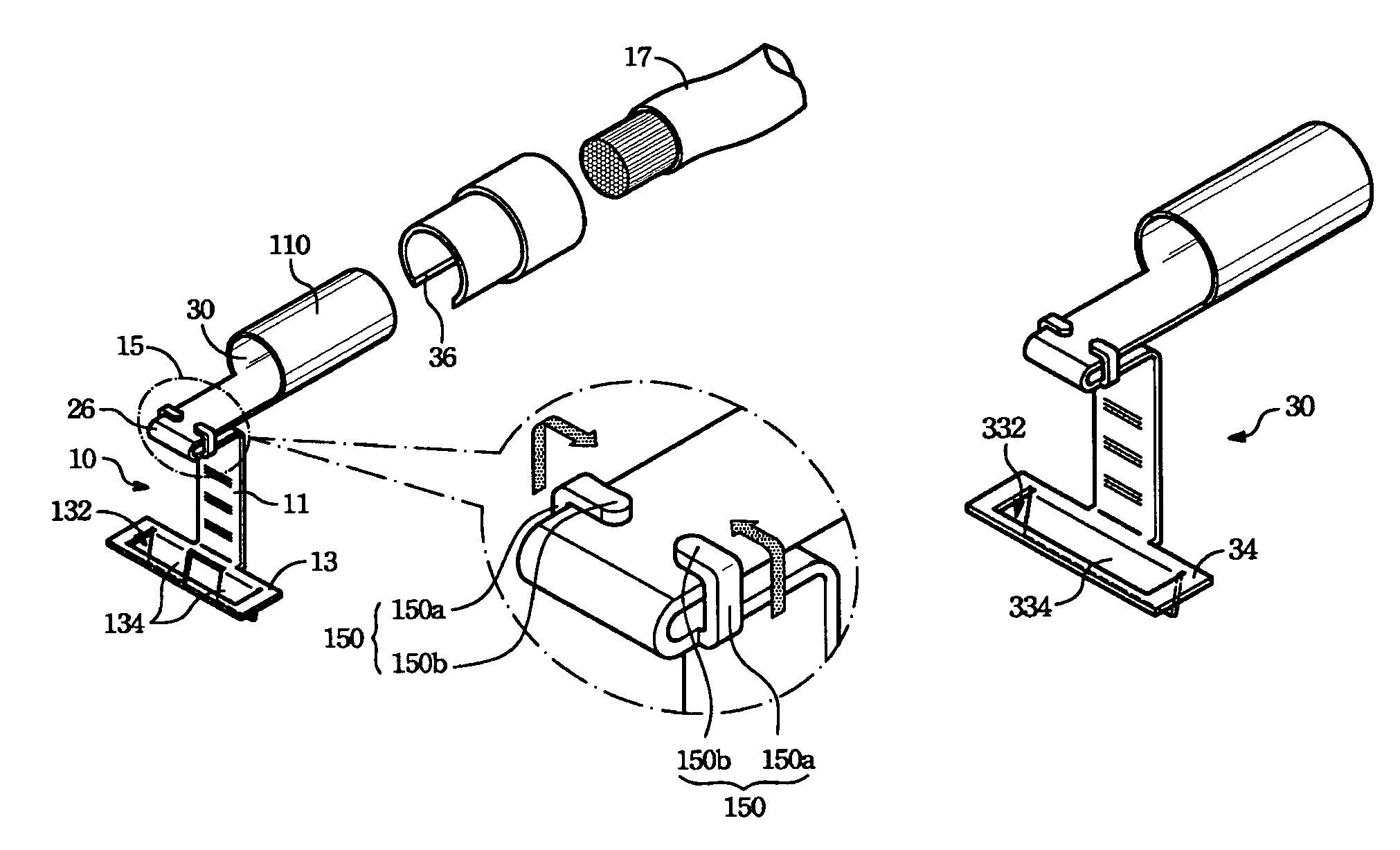

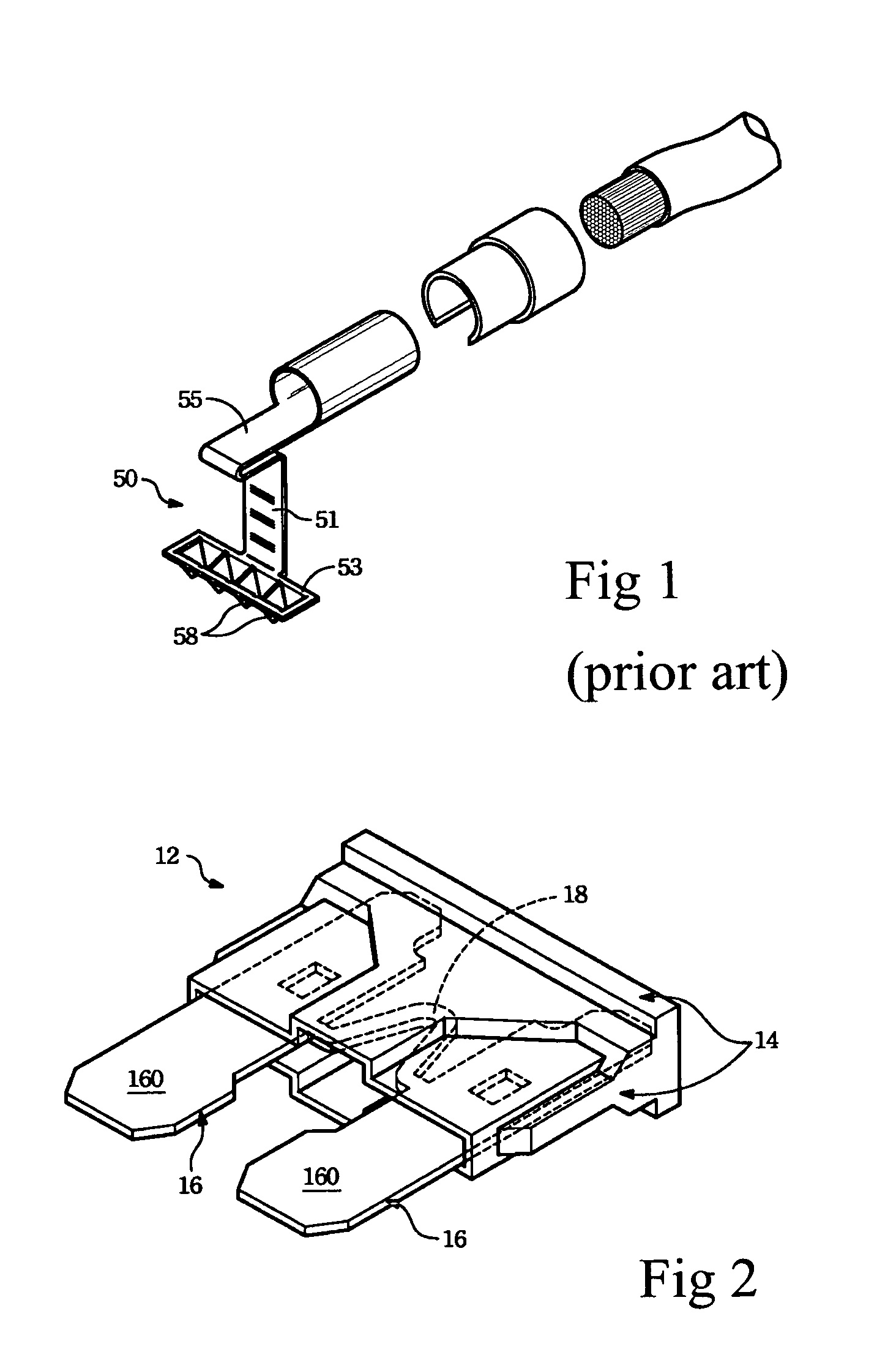

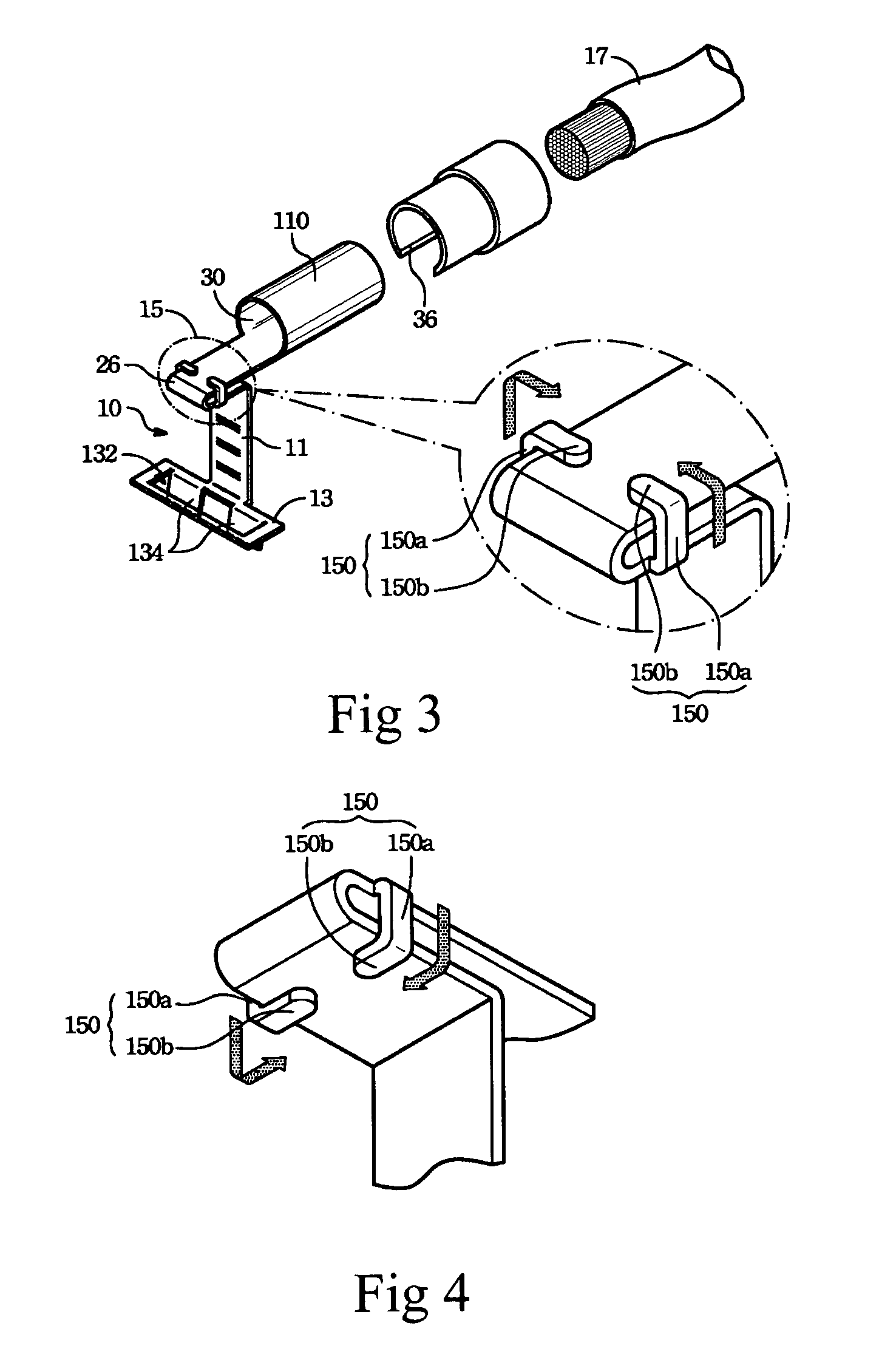

Fuse cap for a blade fuse

InactiveUS7532102B2Extended service lifeImprove protectionCoupling contact membersElectric connection basesEngineeringMechanical engineering

Owner:KS TERMINALS INC

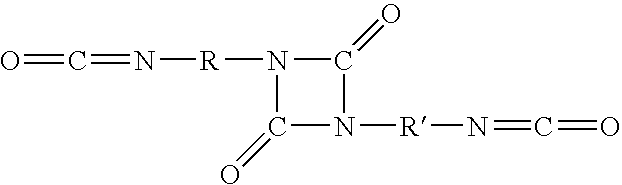

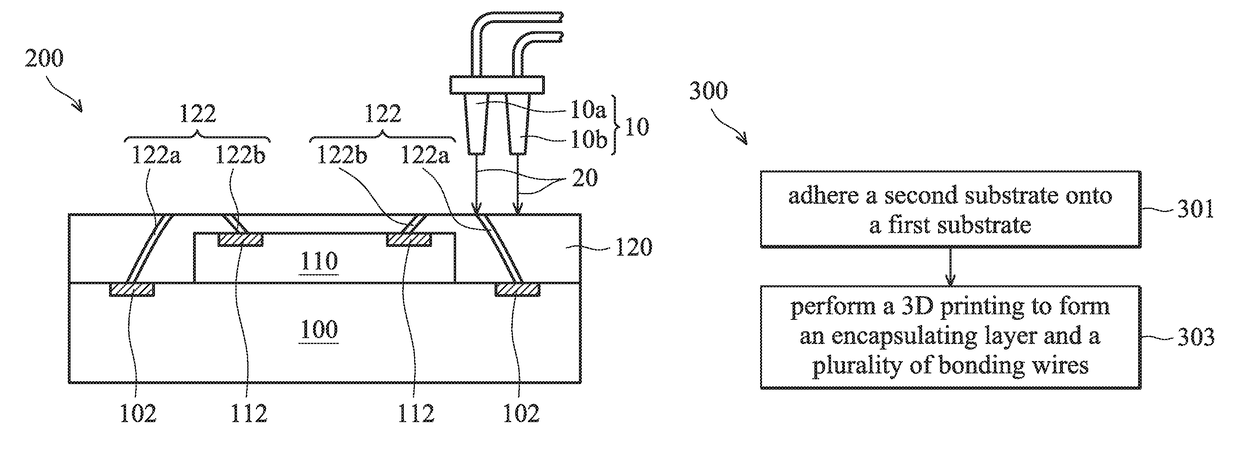

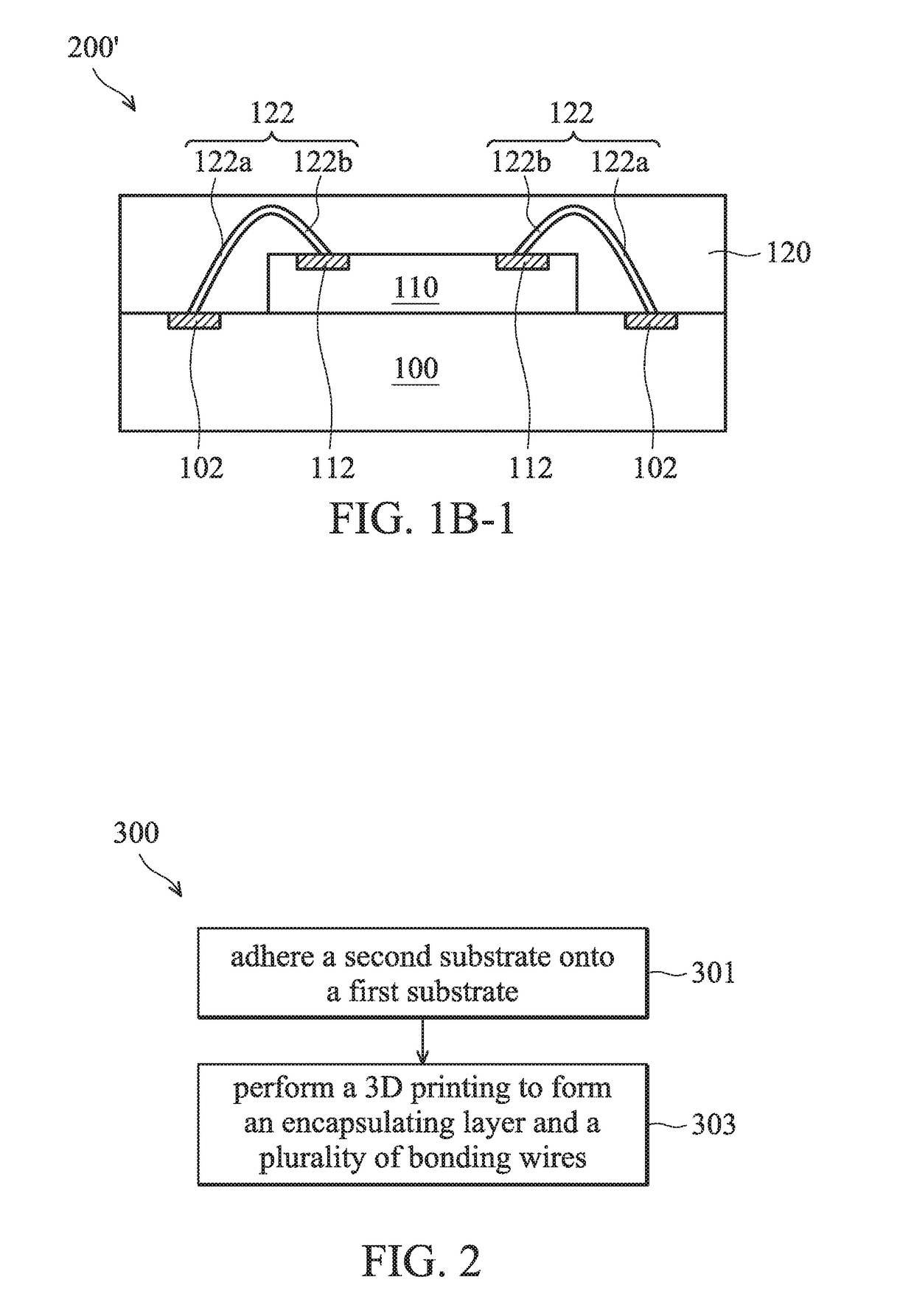

Stacked package device and method for fabricating the same

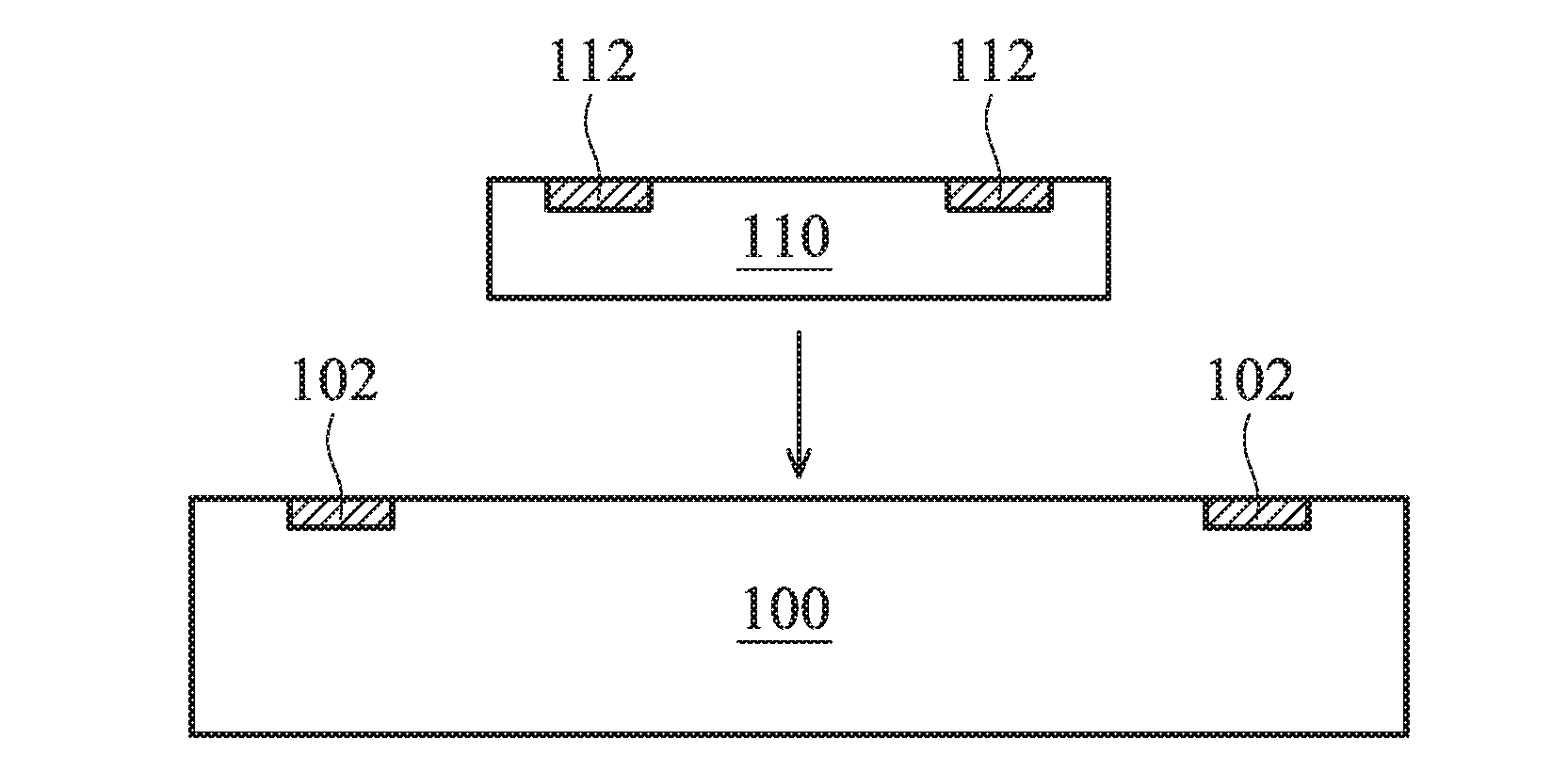

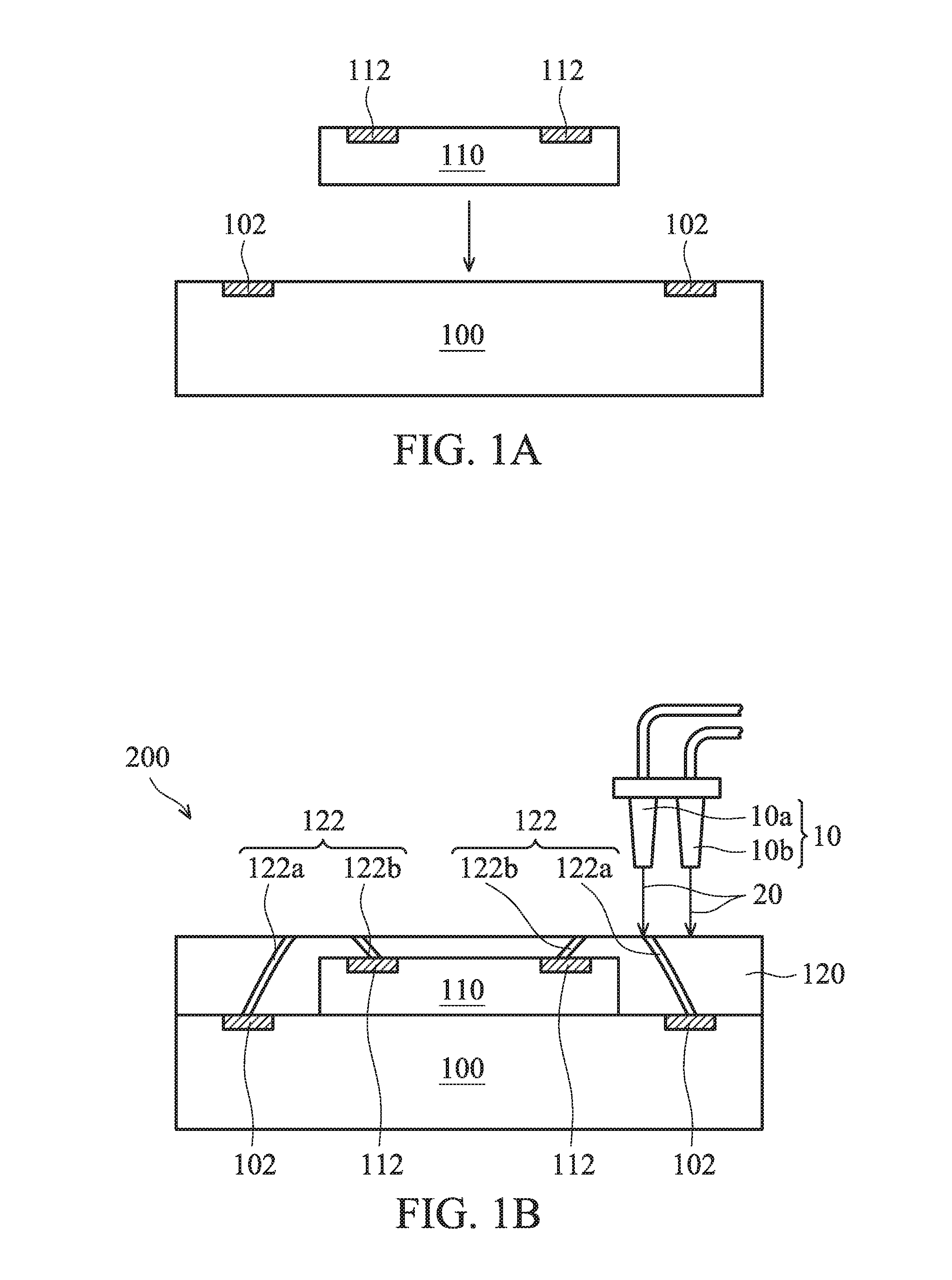

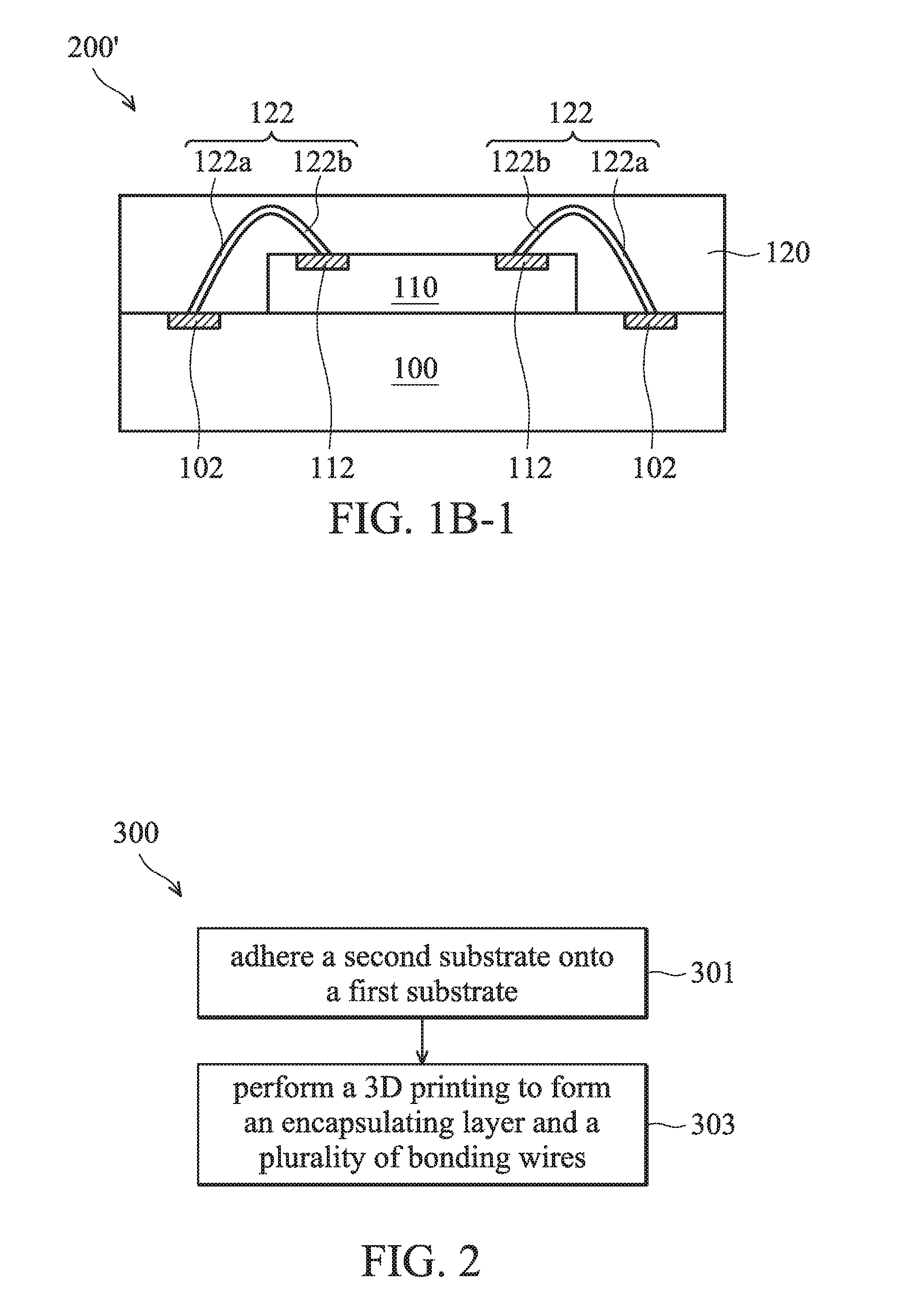

ActiveUS20160329305A1Easy to oxidizeLow reliabilitySolid-state devicesSemiconductor devicesDevice formElectrical and Electronics engineering

A method for fabricating a stacked package device is provided. A second substrate is adhered onto a first substrate. The first substrate includes a plurality of first bonding pads, and the second substrate includes a plurality of second bonding pads. A three-dimensional (3D) printing is performed to form an encapsulating layer covering the first substrate and the second substrate and to form a plurality of bonding wires in the encapsulating layer. Each bonding wire includes a first portion connected to one of the plurality of first bonding pads. The disclosure also provides a stacked package device formed by such a method.

Owner:WINBOND ELECTRONICS CORP

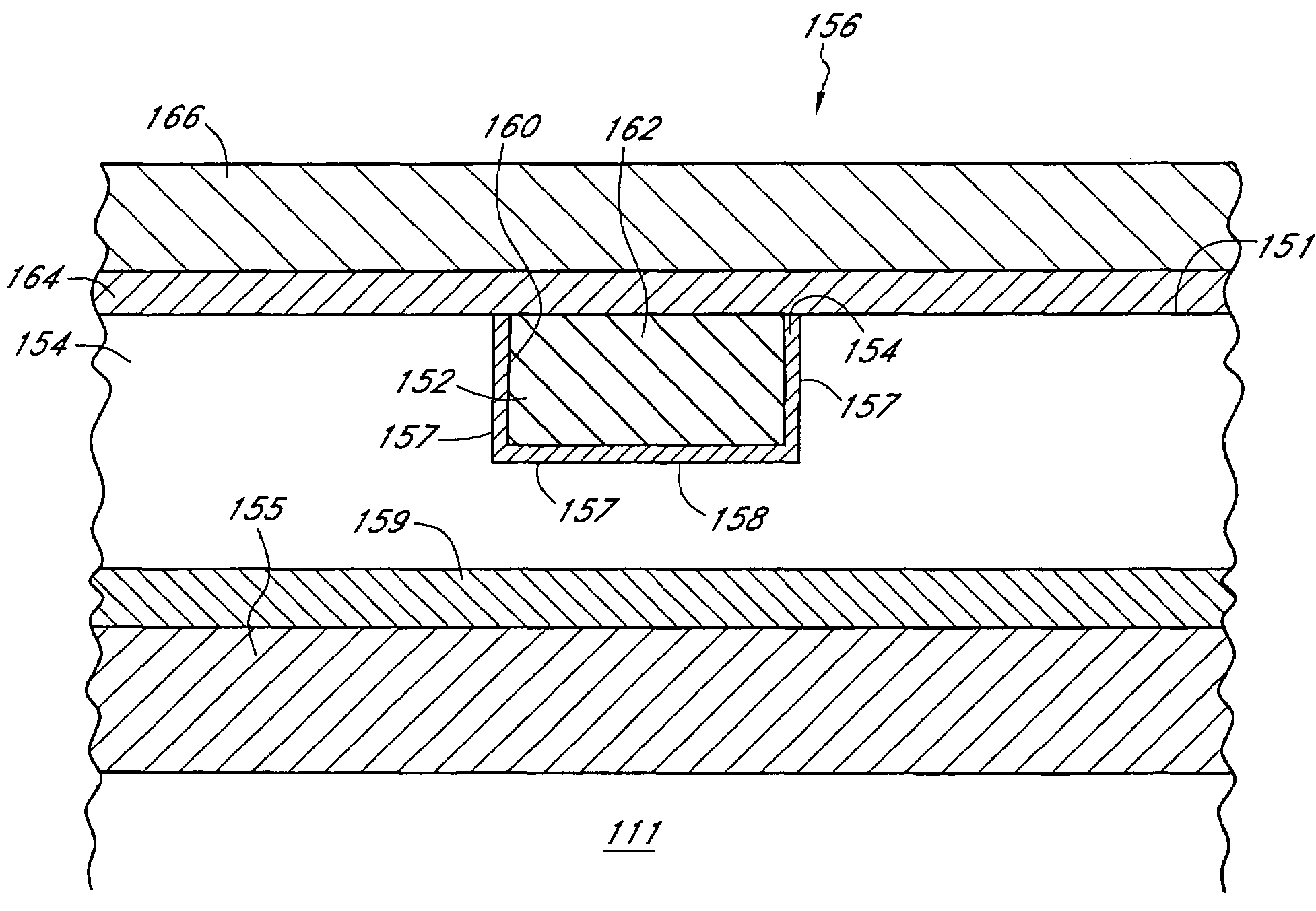

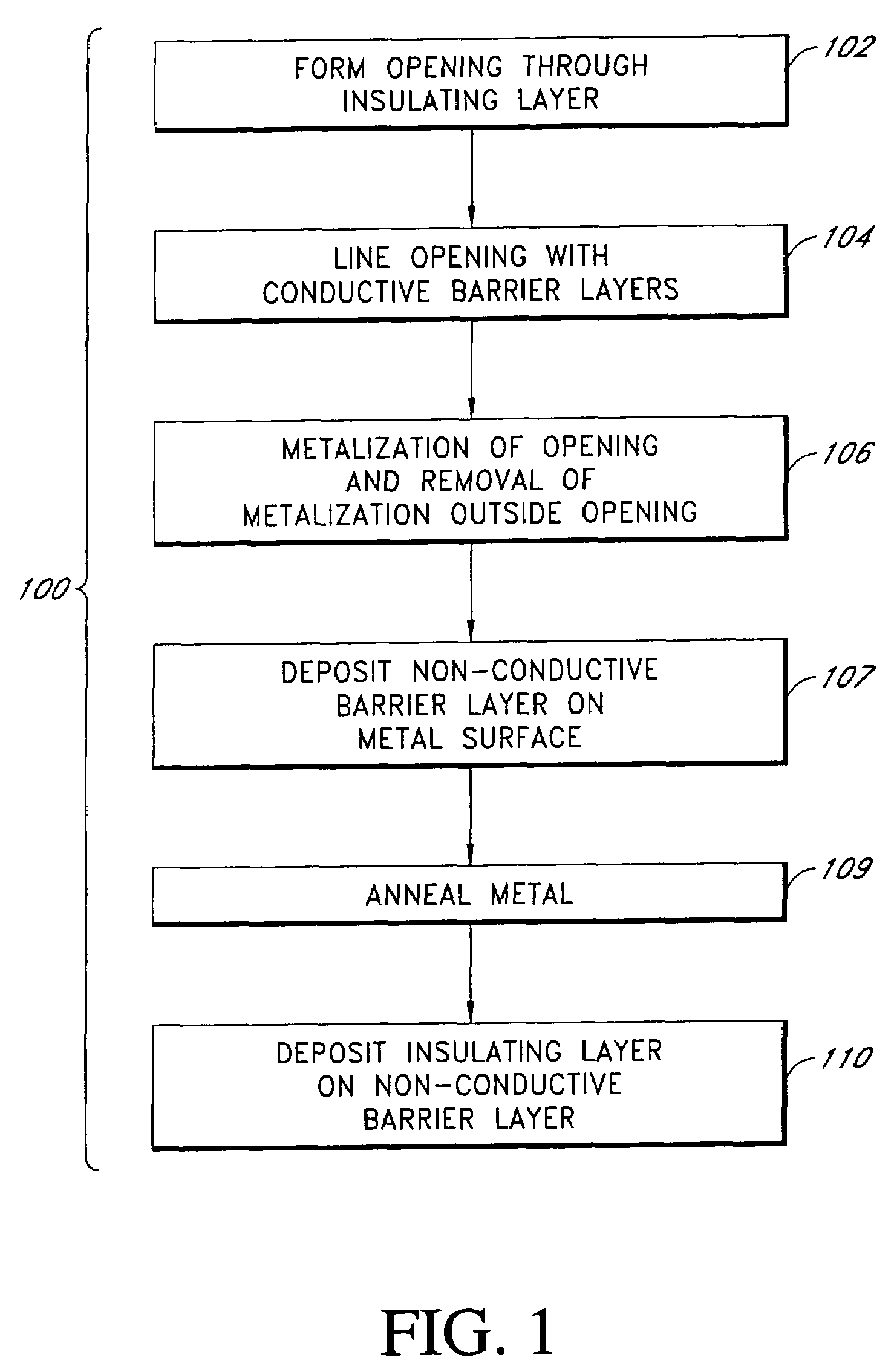

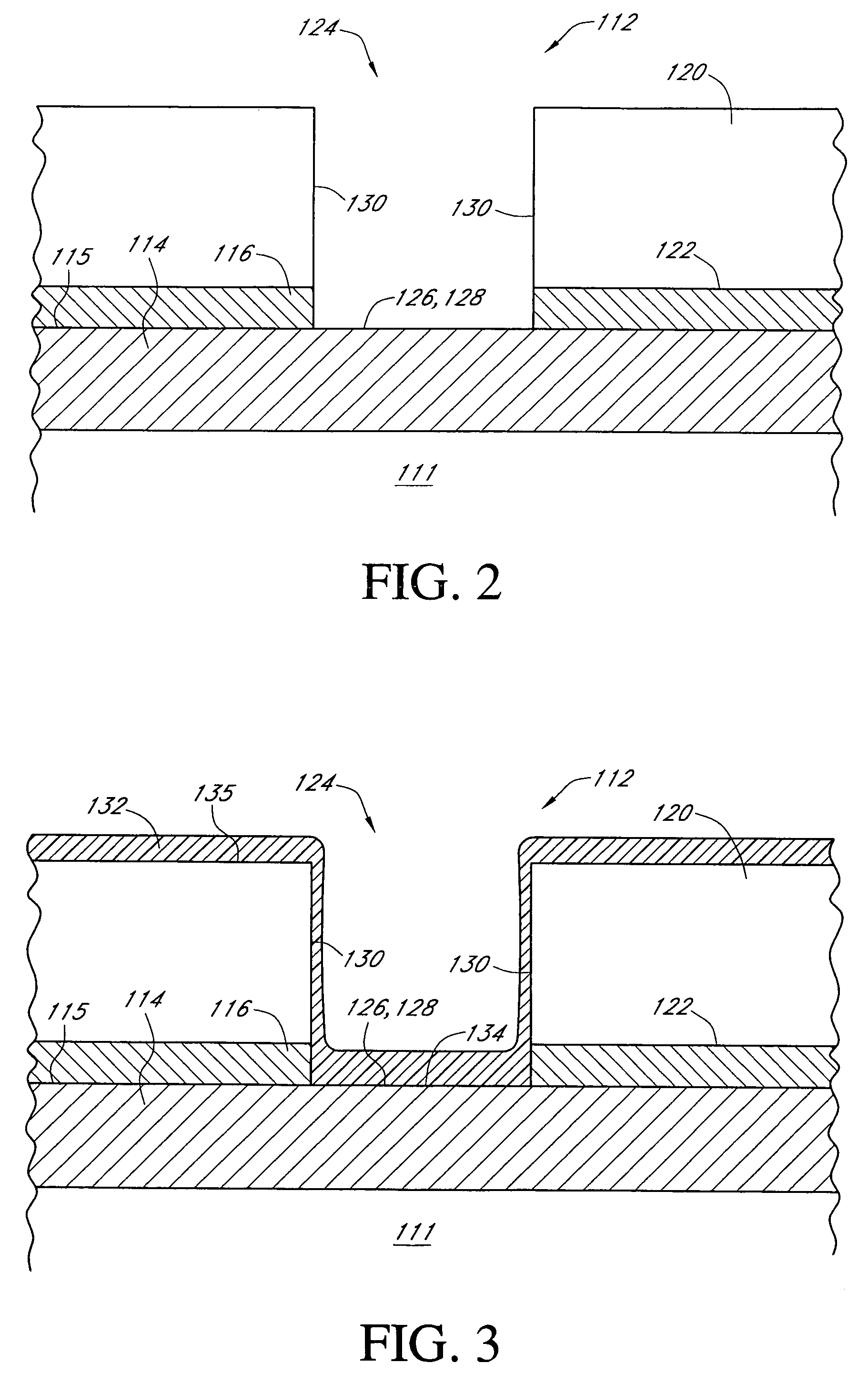

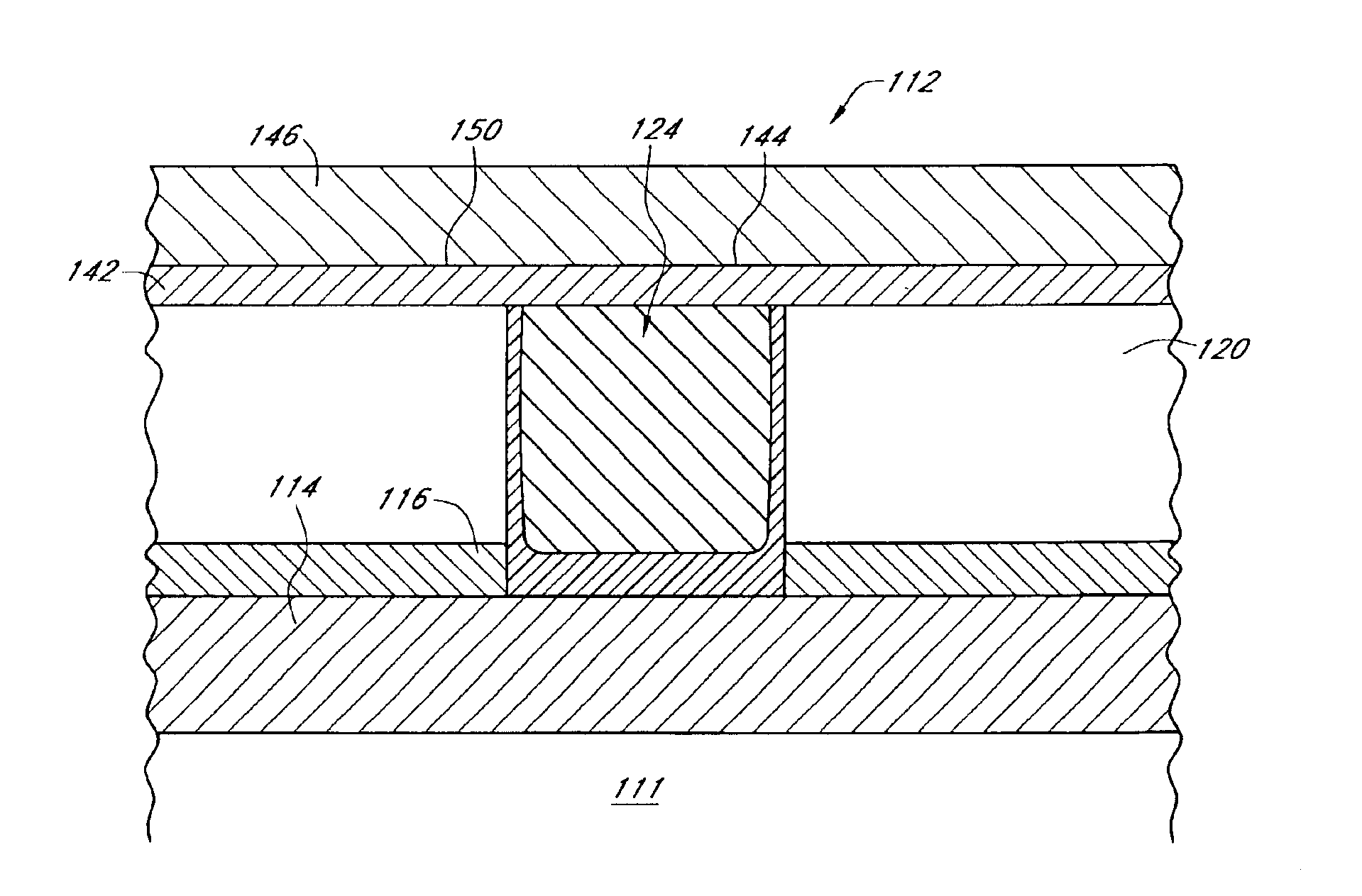

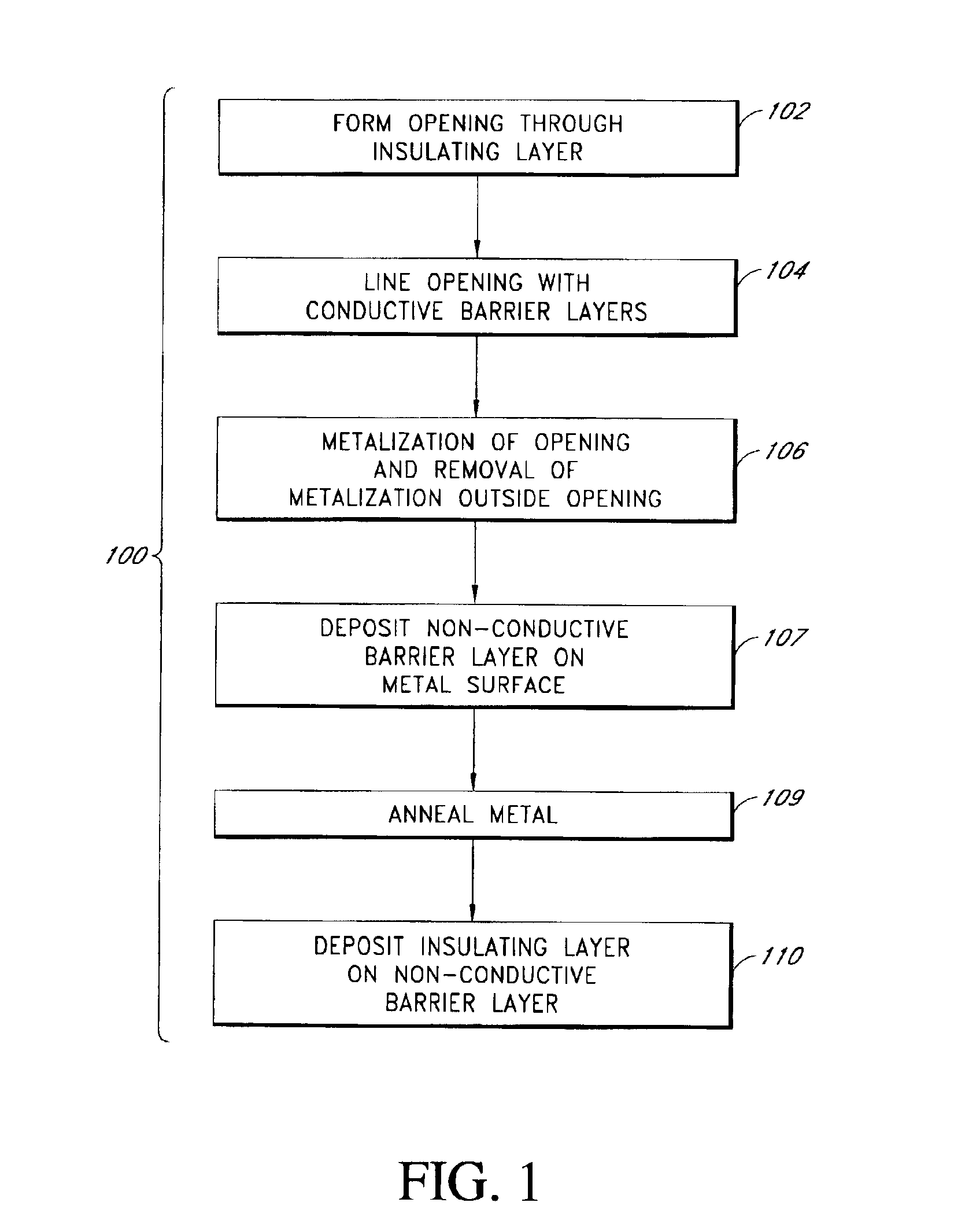

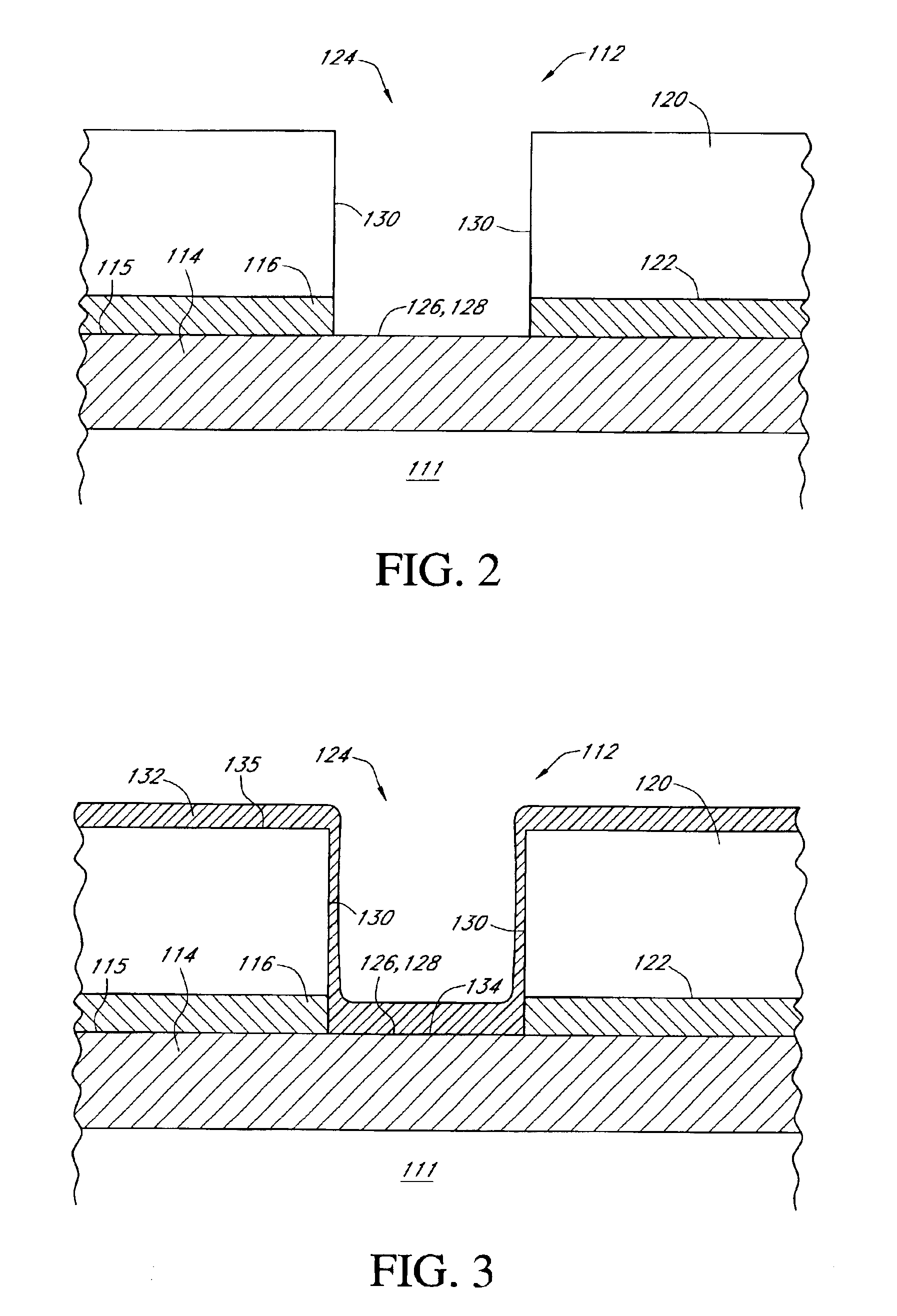

Low temperature nitride used as Cu barrier layer

InactiveUS7186642B2Improve metal resistanceIncrease blockingSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceSalicide

Owner:MICRON TECH INC

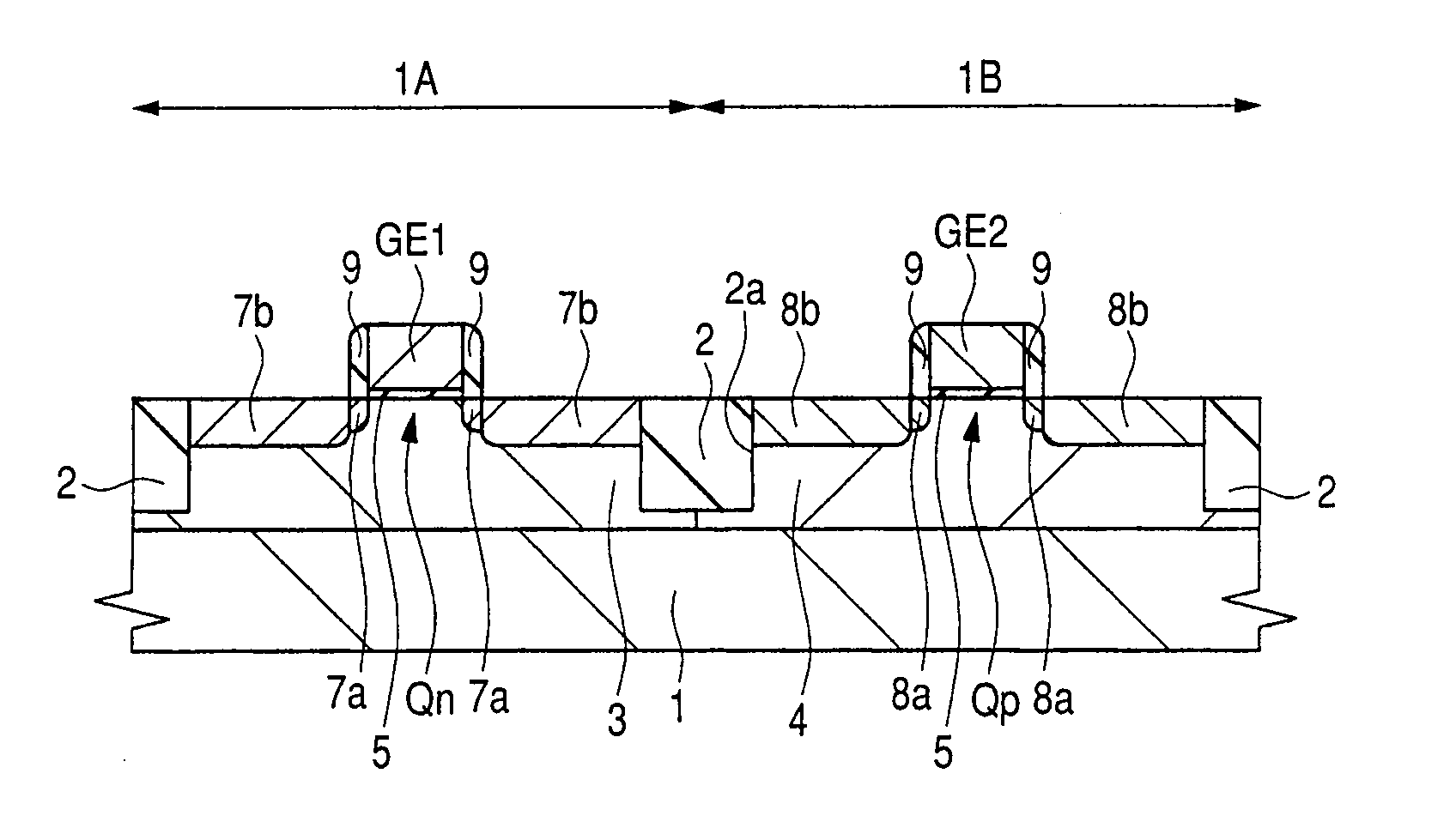

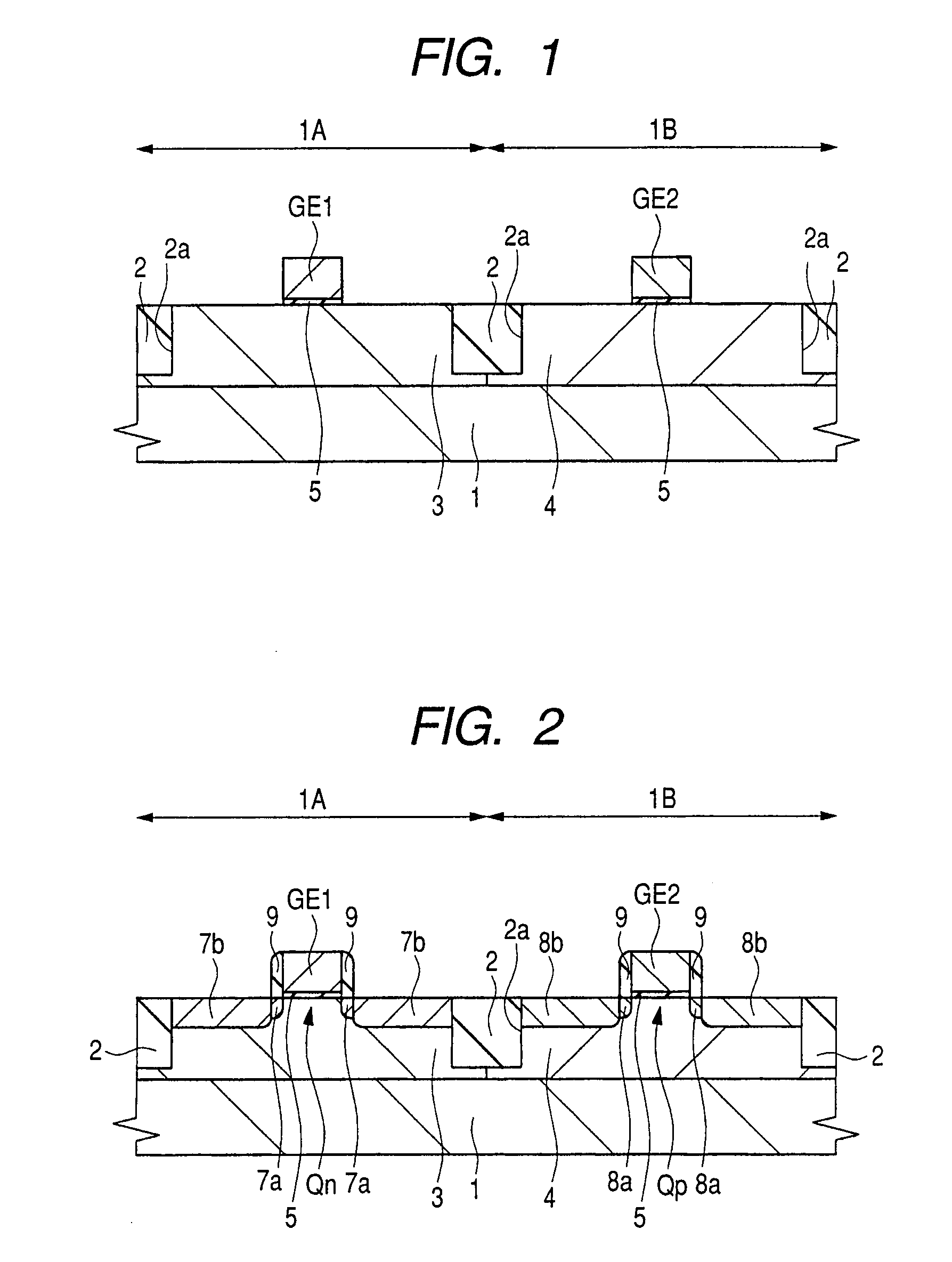

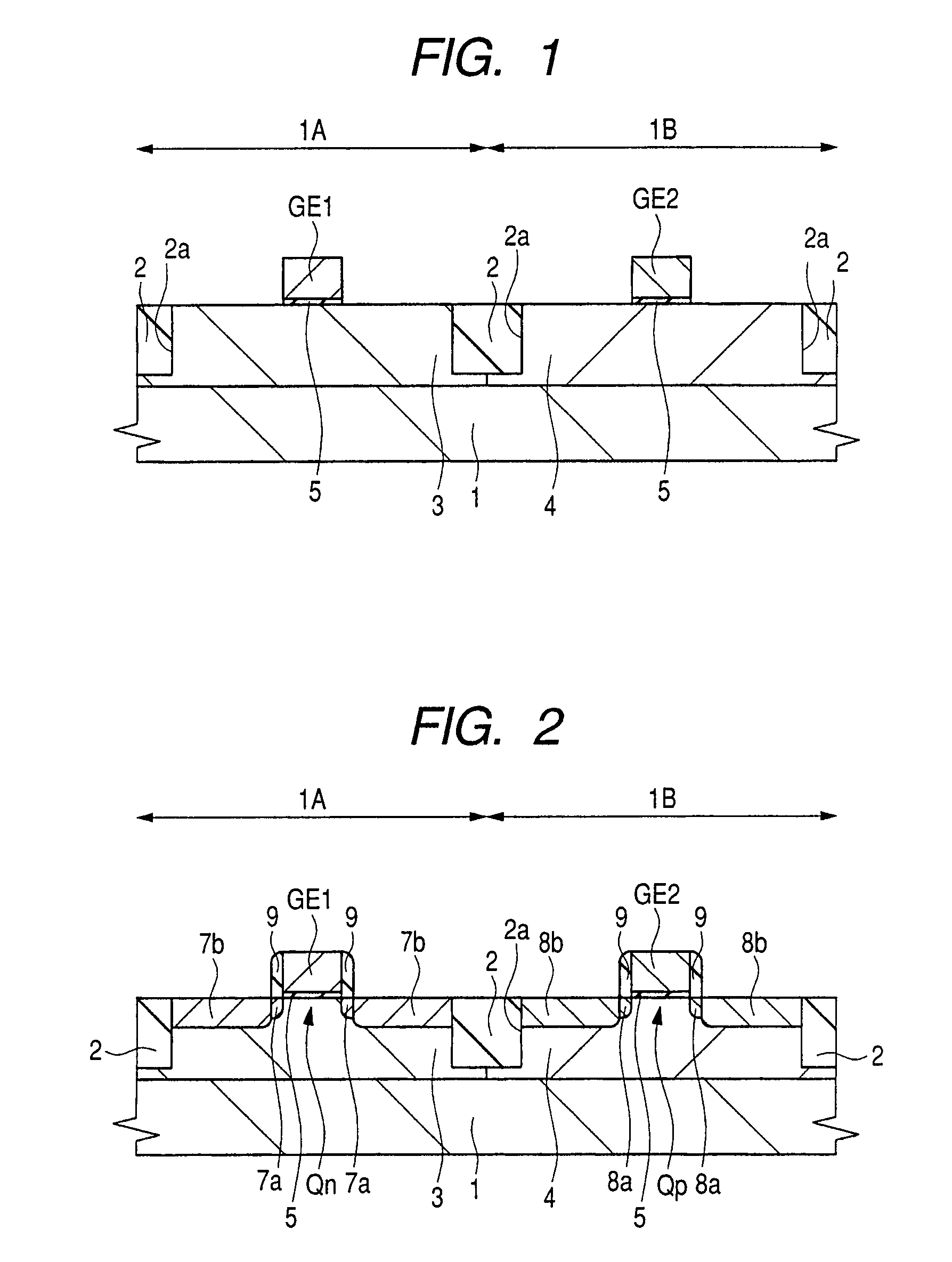

Semiconductor device and method of manufacturing same

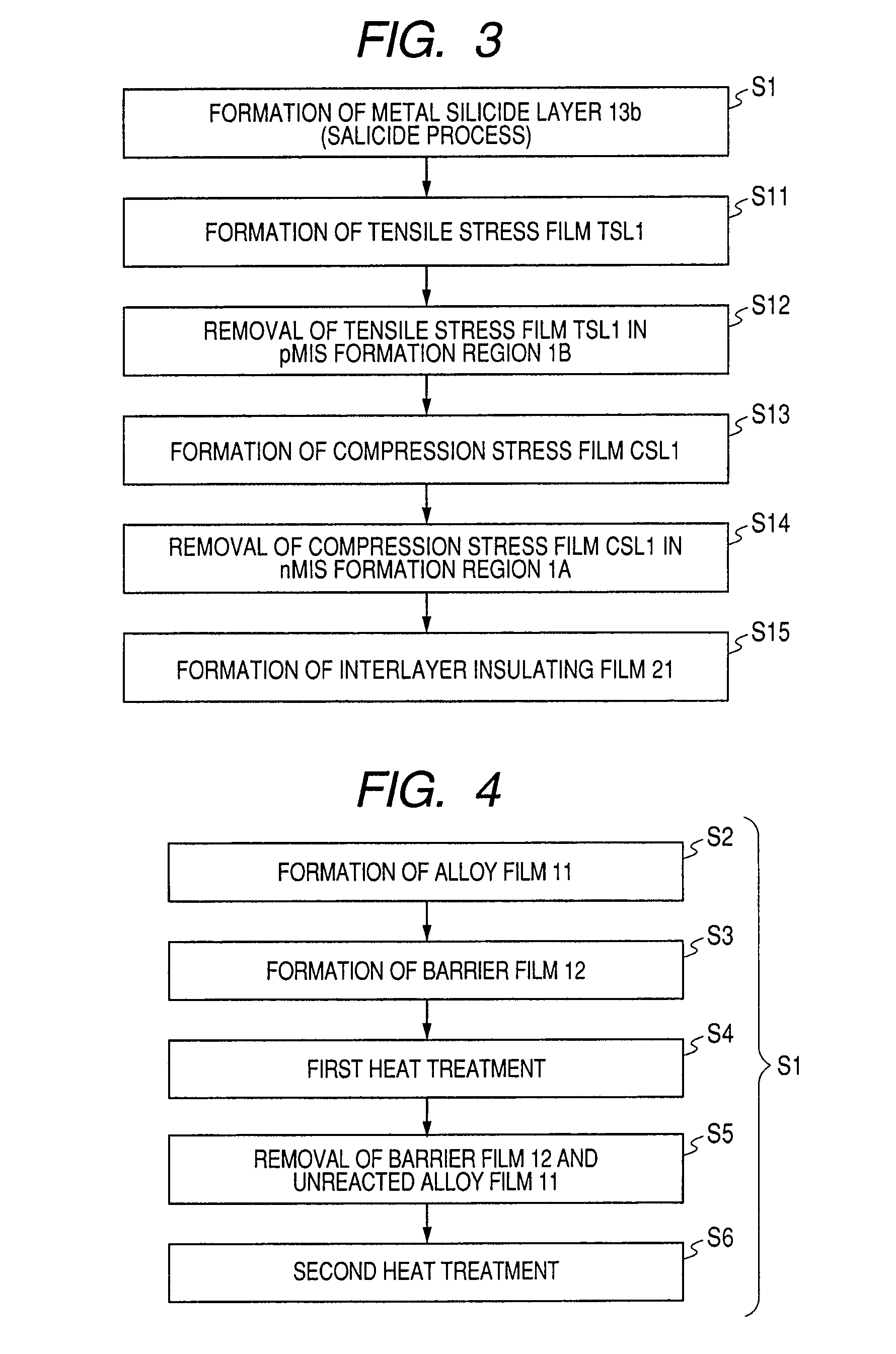

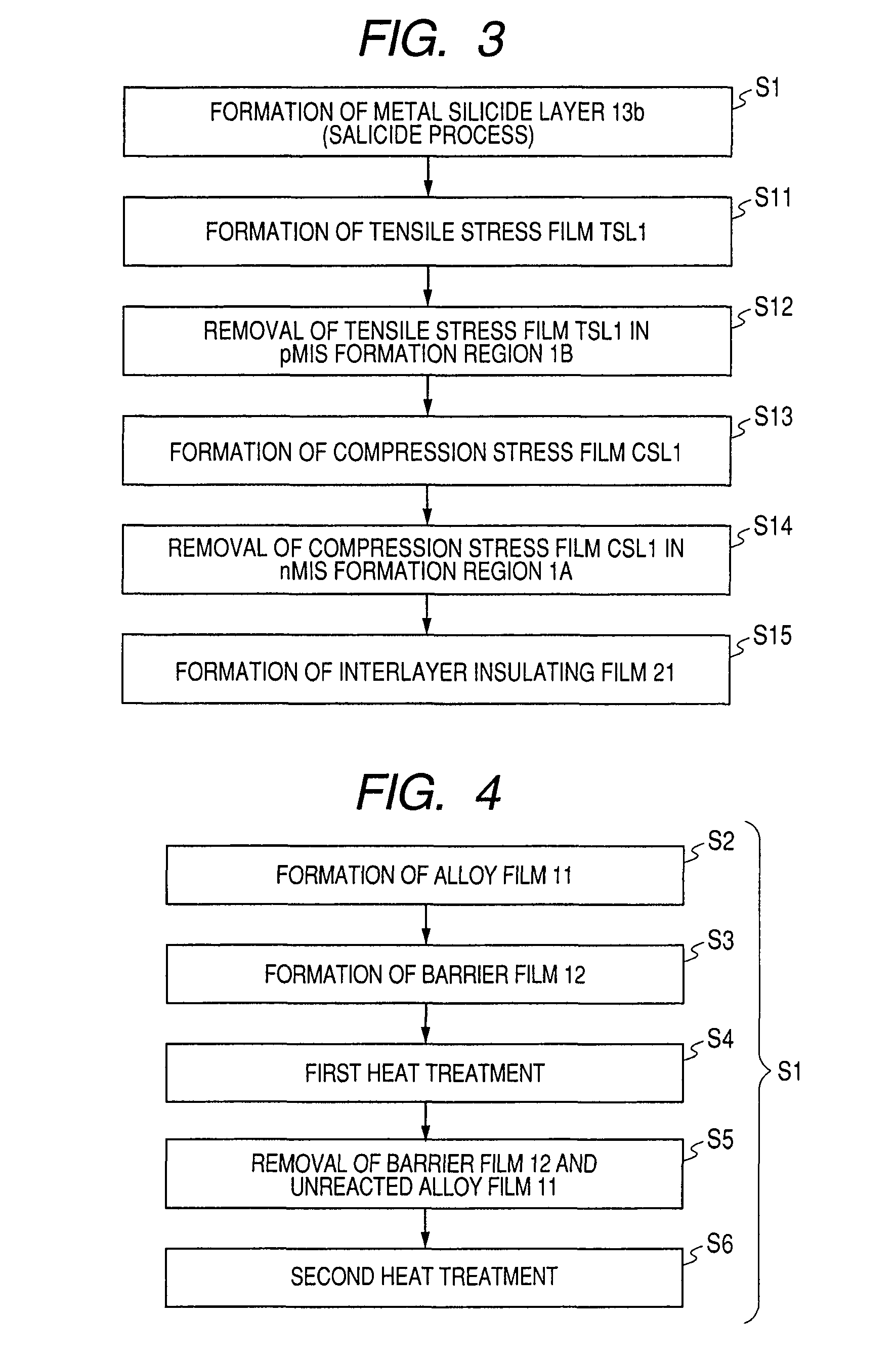

InactiveUS20100230761A1Improve semiconductor device performanceImprove performanceTransistorSemiconductor/solid-state device manufacturingSalicidePlatinum silicide

To improve the performance of semiconductor devices. Over an n+-type semiconductor region for source / drain of an n-channel type MISFET and a first gate electrode, and over a p+-type semiconductor region for source / drain of a p-channel type MISFET and a second gate electrode, which are formed over a semiconductor substrate, a metal silicide layer including nickel platinum silicide is formed by a salicide process. After that, a tensile stress film is formed over the whole face of the semiconductor substrate, and then the tensile stress film over the p-channel type MISFET is removed by dry-etching, and, after a compression stress film is formed over the whole face of the semiconductor substrate, the compression stress film over the n-channel type MISFET is removed by dry-etching. The Pt concentration in the metal silicide layer is highest at the surface, and becomes lower as the depth from the surface increases.

Owner:RENESAS ELECTRONICS CORP

Low temperature nitride used as Cu barrier layer

InactiveUS6984893B2Improve metal resistanceIncrease blockingSemiconductor/solid-state device detailsSolid-state devicesDeposition processSalicide

A method of depositing a non-conductive barrier layer onto a metal surface wherein the resistance of the metal remains substantially unchanged before and after the non-conductive barrier layer deposition. The deposition process provides a low temperature processing environment so as to inhibit the formation of impurities such as silicide in the metal, wherein the silicide can adversely increase the resistance of the underlying metal.

Owner:MICRON TECH INC

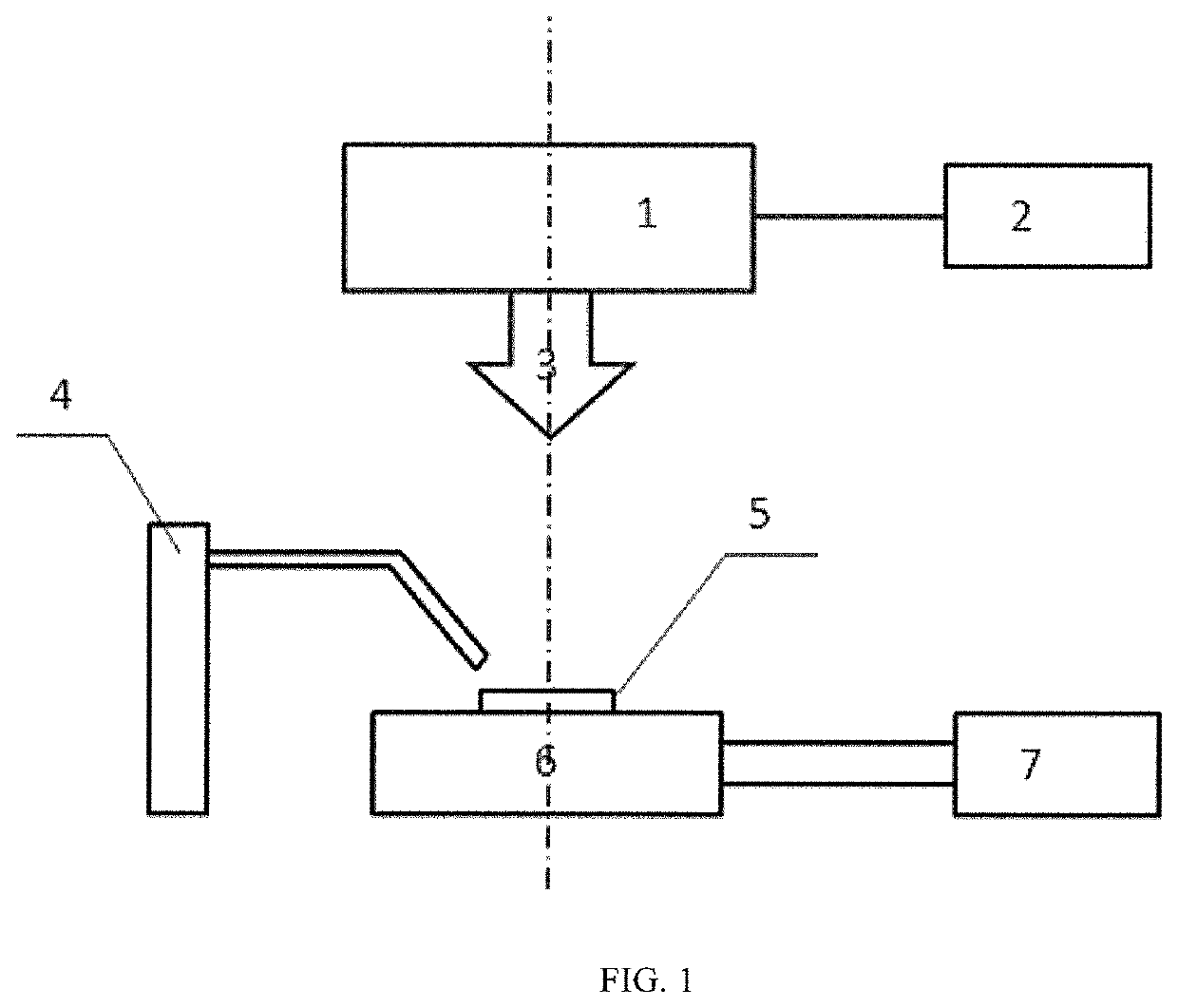

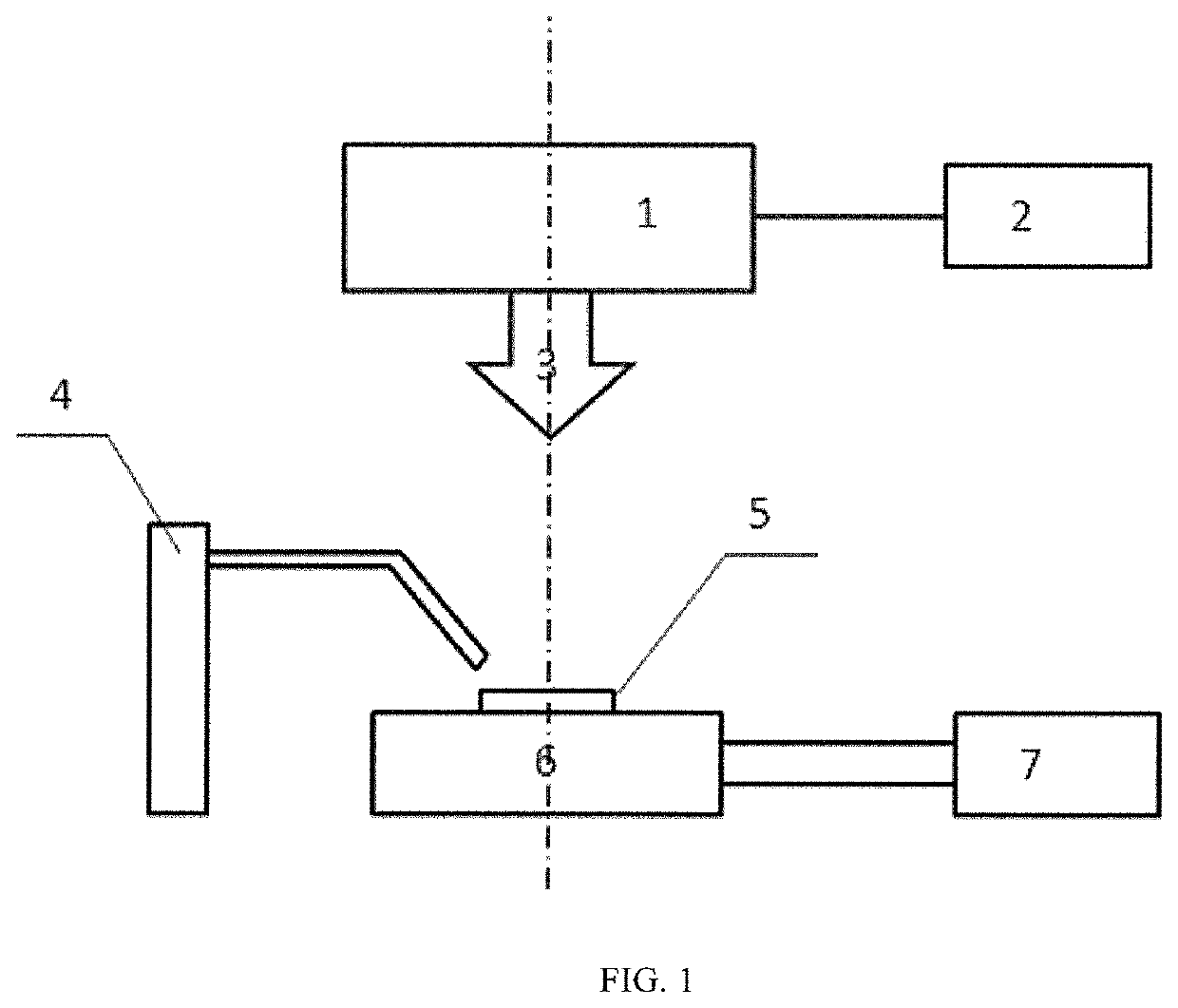

Combined treatment method for improving corrosion resistance of metal component in chlorine-containing solution

ActiveUS20210164106A1Improve corrosion resistanceImprove metal resistanceMetallic material coating processesPeeningMetal

Disclosed is a combined treatment method for improving corrosion resistance of metal component in chlorine-containing solution. First, the metal component is placed in the chlorine-containing solution. Large-area overlapping laser shock peening without an absorbing layer is used, when laser pulses are irradiated on the target metal component, the metal matrix surface absorbs the laser energy, vaporizes and expands to form a high-temperature and high-pressure plasma, a chlorine-containing passivation film is formed, to improve the surface corrosion resistance of the metal component. After that, the surface layer of the metal component is subjected to surface polishing, followed by large-area overlapping laser shock peening with an absorbing layer at room temperature, to further improve the corrosion resistance of the metal component. The combined treatment method of the present invention can be applied to improve the corrosion resistance of metal components in highly corrosive chlorine-containing environments of seawater and the like.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV +1

Semiconductor device and method of manufacturing same

InactiveUS8338247B2Improve mobilityReduce resistanceTransistorSemiconductor/solid-state device manufacturingSalicidePlatinum silicide

To improve the performance of semiconductor devices. Over an n+-type semiconductor region for source / drain of an n-channel type MISFET and a first gate electrode, and over a p+-type semiconductor region for source / drain of a p-channel type MISFET and a second gate electrode, which are formed over a semiconductor substrate, a metal silicide layer including nickel platinum silicide is formed by a salicide process. After that, a tensile stress film is formed over the whole face of the semiconductor substrate, and then the tensile stress film over the p-channel type MISFET is removed by dry-etching, and, after a compression stress film is formed over the whole face of the semiconductor substrate, the compression stress film over the n-channel type MISFET is removed by dry-etching. The Pt concentration in the metal silicide layer is highest at the surface, and becomes lower as the depth from the surface increases.

Owner:RENESAS ELECTRONICS CORP

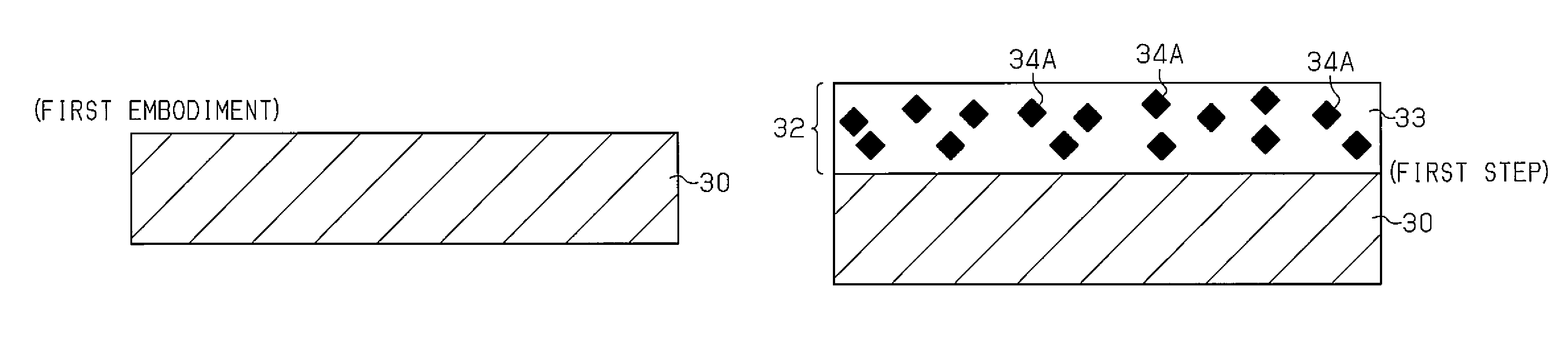

Method for manufacturing fuel cell separator

ActiveUS9515324B2Increase resistanceEfficient dischargeElectrode carriers/collectorsPretreated surfacesFuel cellsMetal substrate

A separator is provided that has a metal substrate and a conductive resin layer on the surface of the metal substrate. The conductive resin layer contains a resin and a conductive substance dispersed in the resin. The separator is configured such that the proportion of the conductive substance to the resin increases continuously from the metal substrate toward the surface of the separator.

Owner:TOYOTA SHATAI KK

Articles having improved corrosion resistance

ActiveUS10767268B2Improve metal resistanceIncrease surface tensionLiquid surface applicatorsAnti-corrosive paintsCorrosion resistantOrganic component

The present application relates to a method for enhancing metal corrosion resistance of a metal deposited on a substrate, the method comprises contacting the metal coated substrate with a treating composition comprising a film forming organic component which treating composition forms a hydrophobic film on the metal coated substrate with a thickness of less than 1 μm. Furthermore, the present application relates to a method for making a mirror comprising a substrate having a metal coated thereon, the method comprises contacting the metal coated substrate with a treating composition comprising a film forming organic component which treating composition forms a hydrophobic film on the metal coated substrate with a thickness of less than 1 μm. Preferably, the film forming organic component is selected from the group consisting of an aromatic triazole compound and a silicone resin. In addition the present application relates to the products obtainable by these methods.

Owner:SWIMC LLC

Corrosion resistant coatings

InactiveUS7473324B2Solve the lack of corrosion resistanceImprove metal resistanceLiquid surface applicatorsSuperimposed coating processEpoxyZinc phosphate

Autodeposition of a coating containing an epoxy resin is accomplished over a metal substrate that has been coated with a zinc phosphate conversion coating without significant removal of the zinc phosphate conversion coating.

Owner:HENKEL KGAA

Stacked package device and method for fabricating the same

ActiveUS9881901B2Easy to oxidizeLow reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDevice formEngineering

A method for fabricating a stacked package device is provided. A second substrate is adhered onto a first substrate. The first substrate includes a plurality of first bonding pads, and the second substrate includes a plurality of second bonding pads. A three-dimensional (3D) printing is performed to form an encapsulating layer covering the first substrate and the second substrate and to form a plurality of bonding wires in the encapsulating layer. Each bonding wire includes a first portion connected to one of the plurality of first bonding pads. The disclosure also provides a stacked package device formed by such a method.

Owner:WINBOND ELECTRONICS CORP

Inorganic non-chrome aqueous treatment composition and process for coating metal surfaces

ActiveUS20180371622A1Improve corrosion resistanceSufficient protectionMetallic material coating processesIonChromium free

A chromium-free aqueous treatment solution for coating metal surfaces which meets corrosion resistance, electrical contact resistance, and paint adhesion requirements set forth in MIL-DTL-81706B, Class 3. The treatment solution contains a compound of a Group IV-B element, and a vanadium ion. The solution may be inorganic and molybdate-free.

Owner:BULK CHEM

Inorganic non-chrome aqueous treatment composition and process for coating metal surfaces

ActiveUS11293104B2Improve corrosion resistanceImprove metal resistanceMetallic material coating processesChromium freeMolybdate

A chromium-free aqueous treatment solution for coating metal surfaces which meets corrosion resistance, electrical contact resistance, and paint adhesion requirements set forth in MIL-DTL-81706B, Class 3. The treatment solution contains a compound of a Group IV-B element, and a vanadium ion. The solution may be inorganic and molybdate-free.

Owner:BULK CHEM

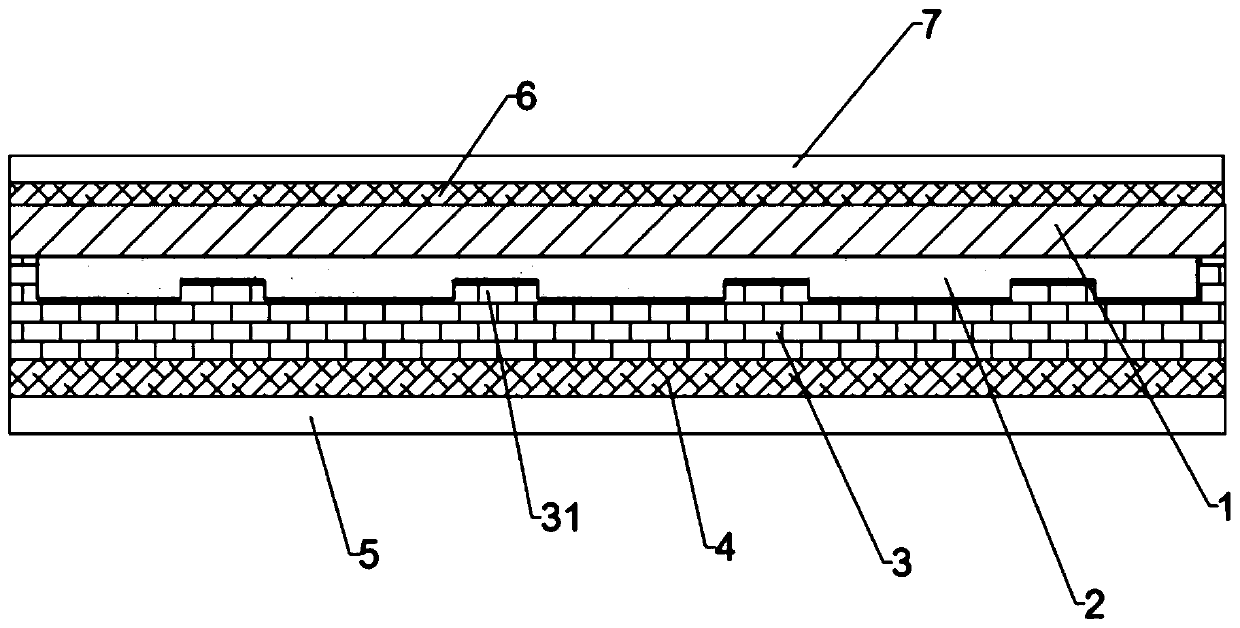

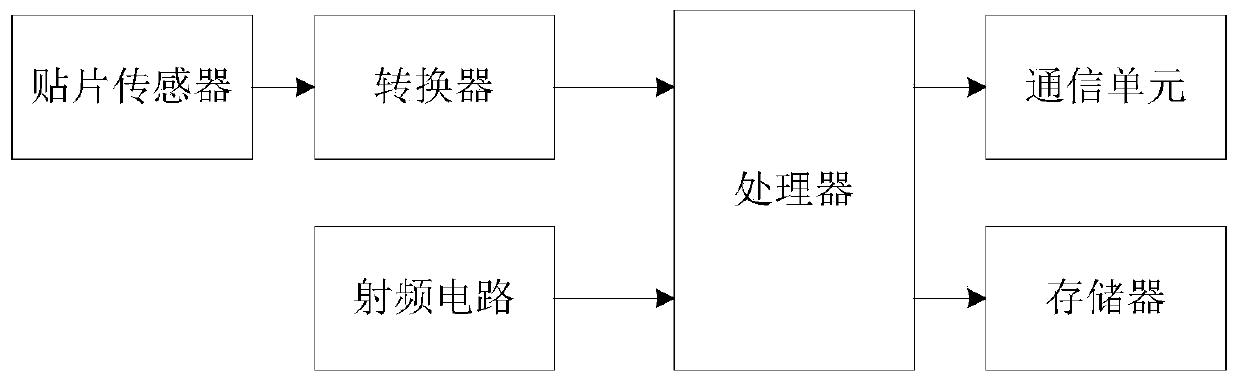

Electronic tag and manufacturing method thereof

PendingCN111105003AImprove metal resistanceAvoid diversionRecord carriers used with machinesRadio frequency circuitsEngineering

The invention provides an electronic tag. The electronic tag comprises a release paper layer, a first adhesive layer, a metal-resistant material layer, a chip layer, a second adhesive layer and a fragile paper layer which are arranged in sequence, wherein a plurality of grooves are formed in one side, opposite to the chip layer, of the metal-resistant material layer, a silicone oil layer is arranged between the groove surfaces and the chip layer, the chip layer adopts a flexible circuit board, and a processor, a patch sensor, a radio frequency circuit and a communication unit are arranged on the flexible circuit board, and the patch sensor, the radio frequency circuit and the communication unit are respectively connected with the processor. The electronic tag has a certain extended function, and is high in metal resistance and not prone to damage.

Owner:江苏孚登物联网技术有限公司

Combined treatment method for improving corrosion resistance of metal component in chlorine-containing solution

ActiveUS11248299B2Improve corrosion resistanceImprove metal resistanceMetallic material coating processesMaterials sciencePlasma formation

Disclosed is a combined treatment method for improving corrosion resistance of metal component in chlorine-containing solution. First, the metal component is placed in the chlorine-containing solution. Large-area overlapping laser shock peening without an absorbing layer is used, when laser pulses are irradiated on the target metal component, the metal matrix surface absorbs the laser energy, vaporizes and expands to form a high-temperature and high-pressure plasma, a chlorine-containing passivation film is formed, to improve the surface corrosion resistance of the metal component. After that, the surface layer of the metal component is subjected to surface polishing, followed by large-area overlapping laser shock peening with an absorbing layer at room temperature, to further improve the corrosion resistance of the metal component. The combined treatment method of the present invention can be applied to improve the corrosion resistance of metal components in highly corrosive chlorine-containing environments of seawater and the like.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV +1

Method for embedding intelligent label of high-voltage power cable

InactiveCN108831637AAchieve ultra-thin designPaste effect is goodConductor/cable markingEpoxyPower cable

The invention relates to the technical field of power facilities, and particularly relates to a method for embedding an intelligent label of a high-voltage power cable. According to the invention, a base material carrier of the intelligent label is set to be a flexible carrier, and the main material of the flexible base material carrier is epoxy resin, so that flexible base material carrier is high in flexibility and tension resistant, thereby realizing an ultrathin design of the intelligent label; and an anti-magnetic wave absorbing material is added into the flexible base material carrier, thereby enhancing the metal resistance of the intelligent label of the high-voltage power cable, and enabling the read-write distance of the intelligent label after being embedded into the cable to befarther than the read-write distance of the intelligent label when being not on the cable. The carrier is externally coated with an acrylic adhesive at both sides, so that the intelligent label can beattached to the external part of a cable armor layer more tightly, the intelligent label is enabled to be integrated with the cable and stably placed inside the cable, and the service life of the cable is prolonged. Meanwhile, the design is more convenient for the embedding operation of the intelligent label of the high-voltage power cable and can greatly improve the embedding efficiency of the intelligent label.

Owner:石家庄杰泰特动力能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com