Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "High pattern accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

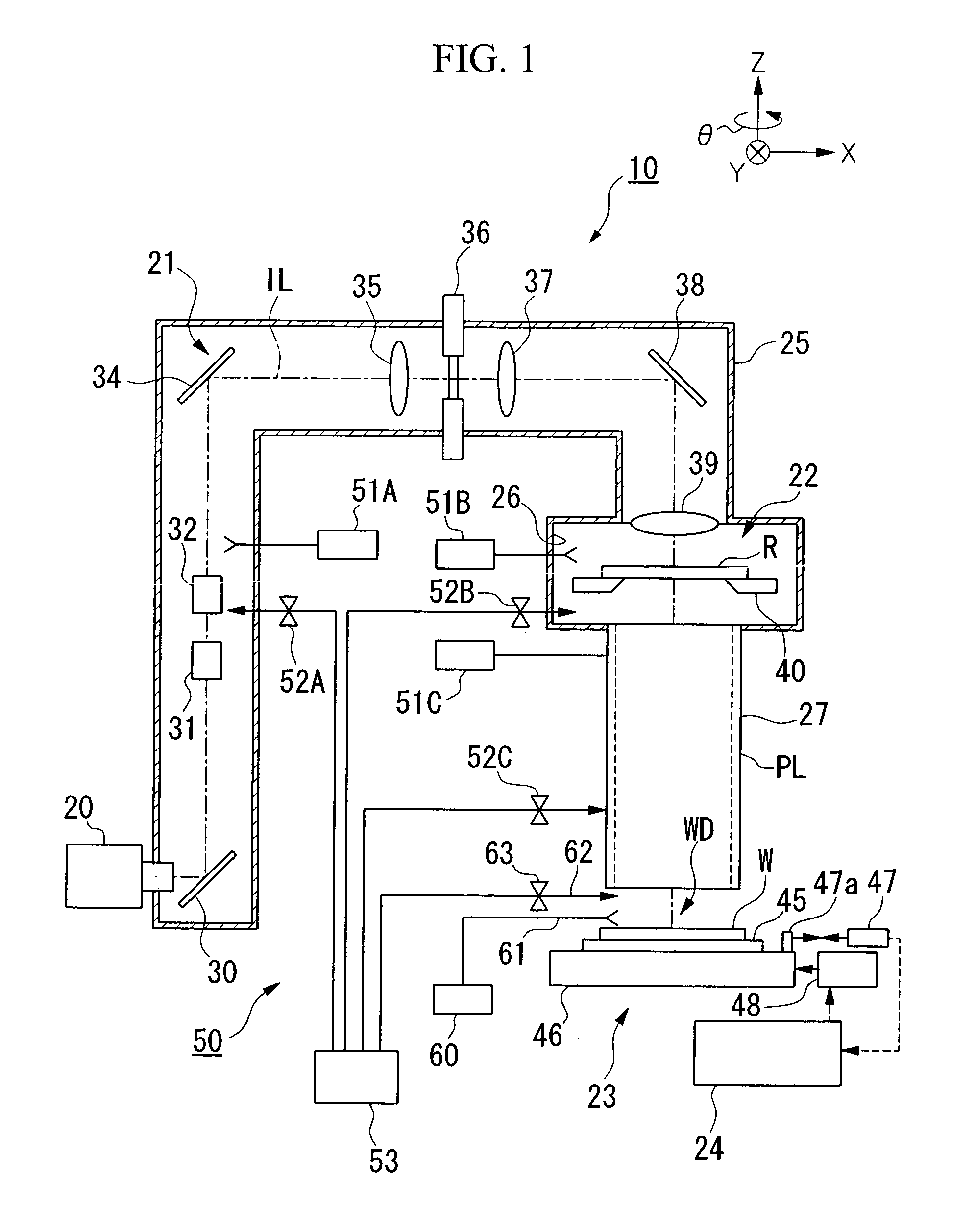

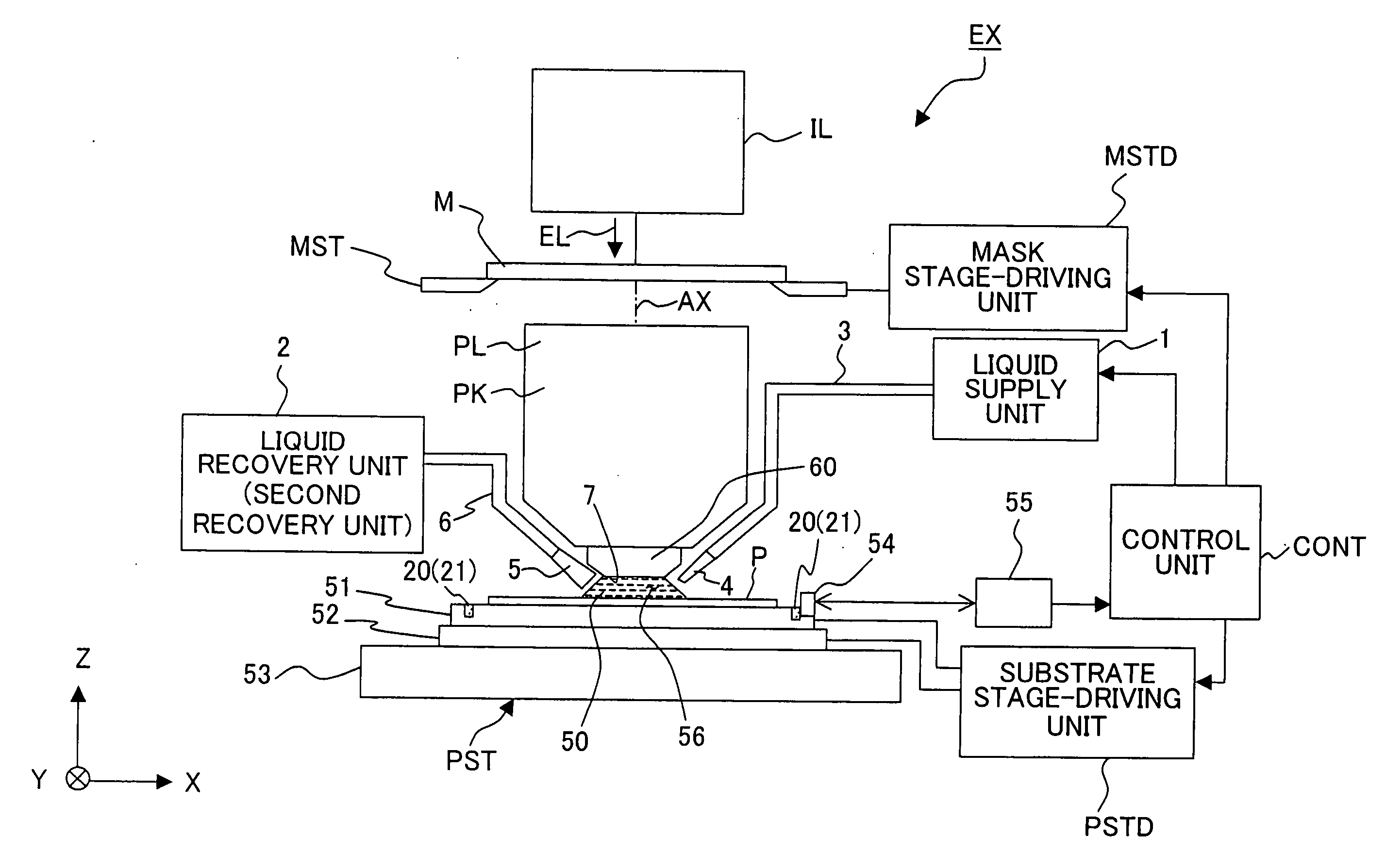

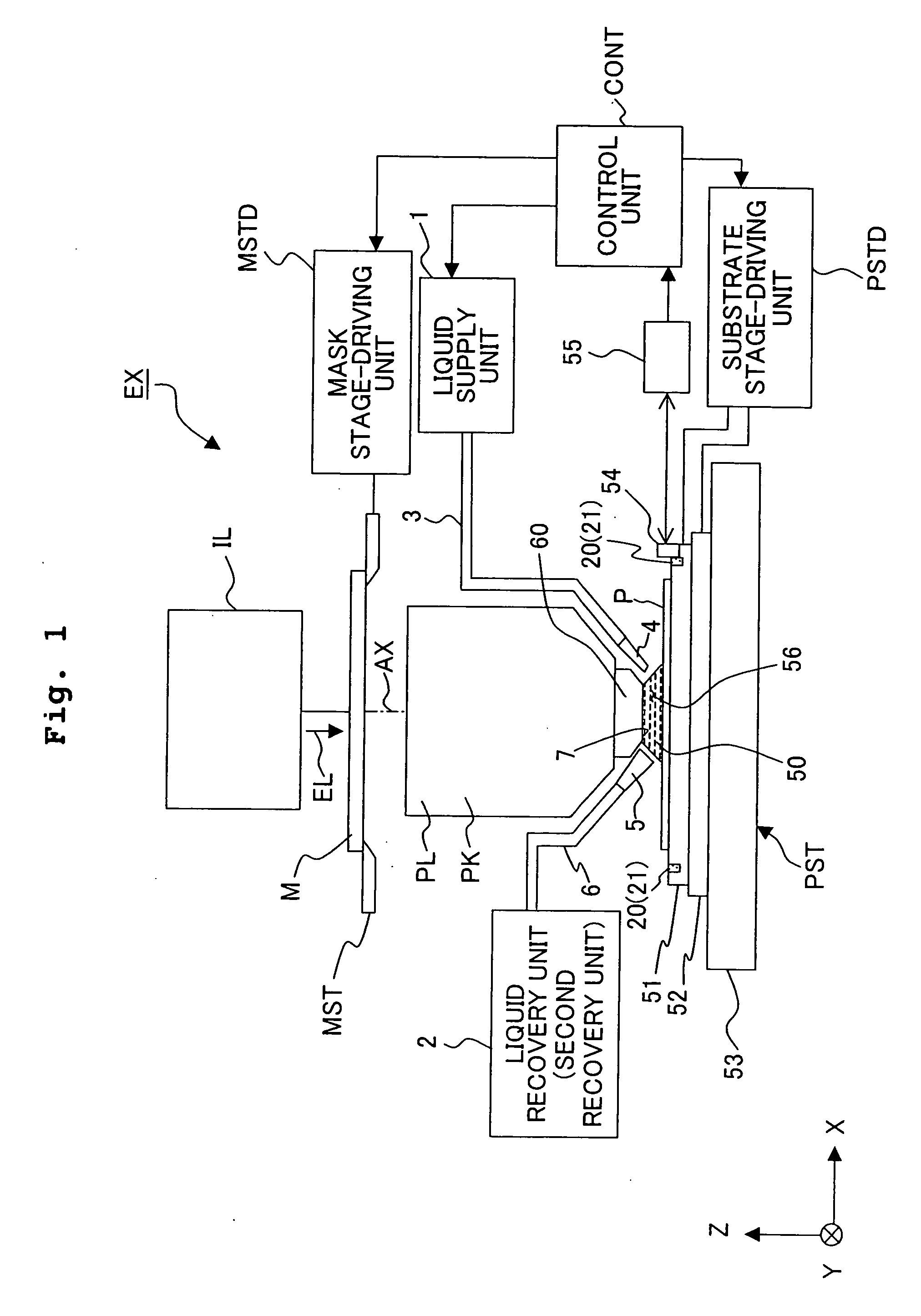

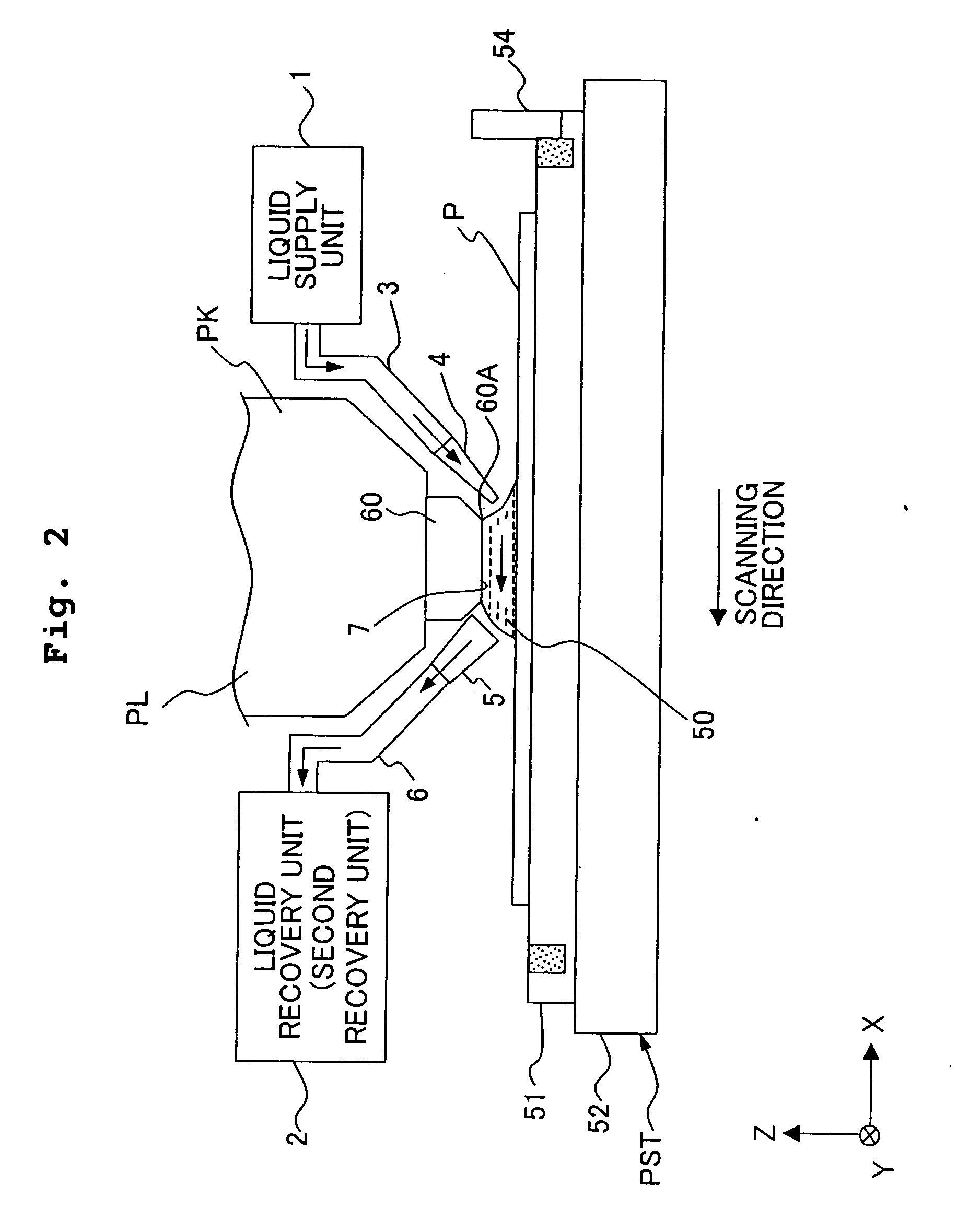

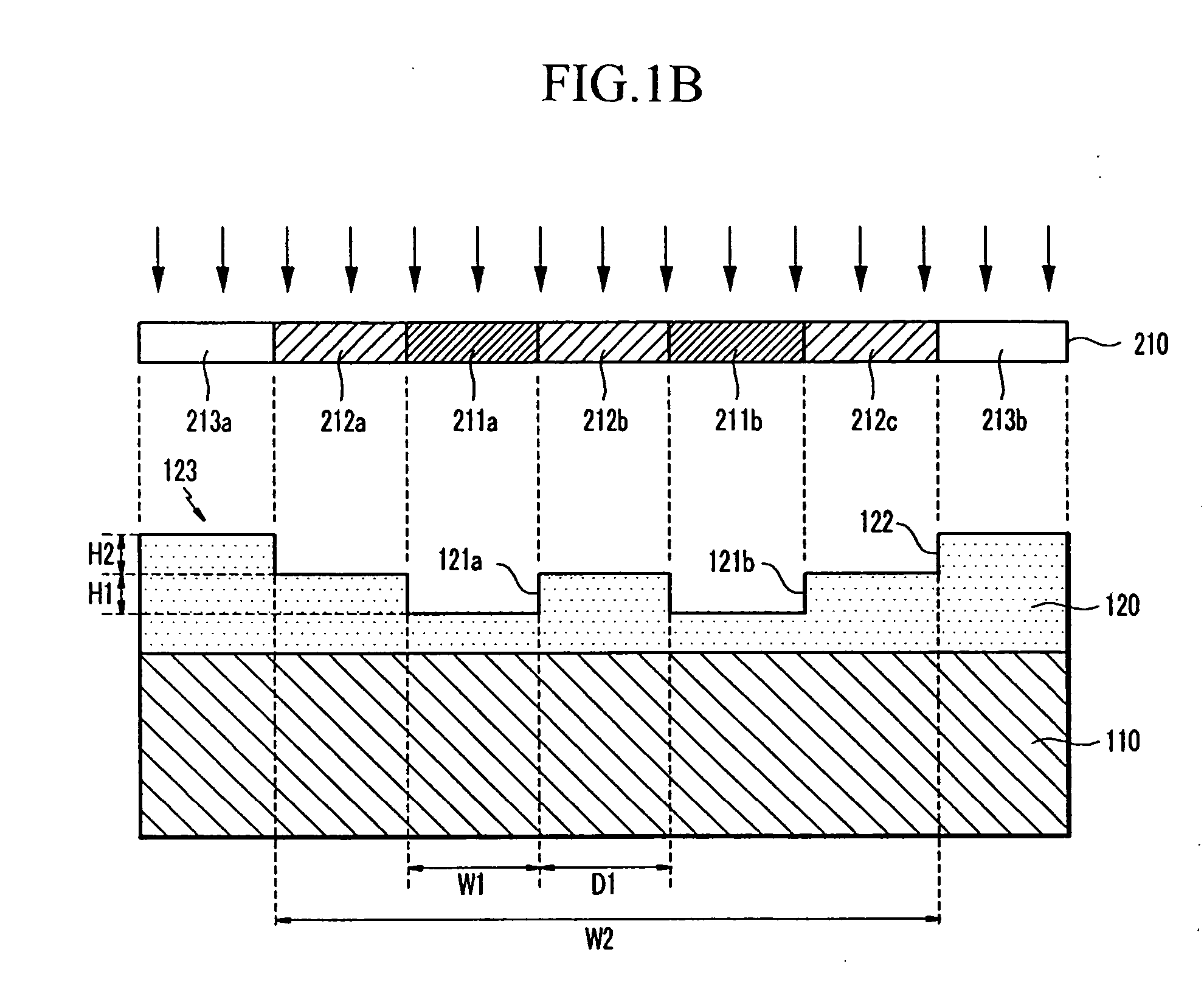

Exposure apparatus and method for producing device

InactiveUS20050219488A1Accurate transferHigh pattern accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

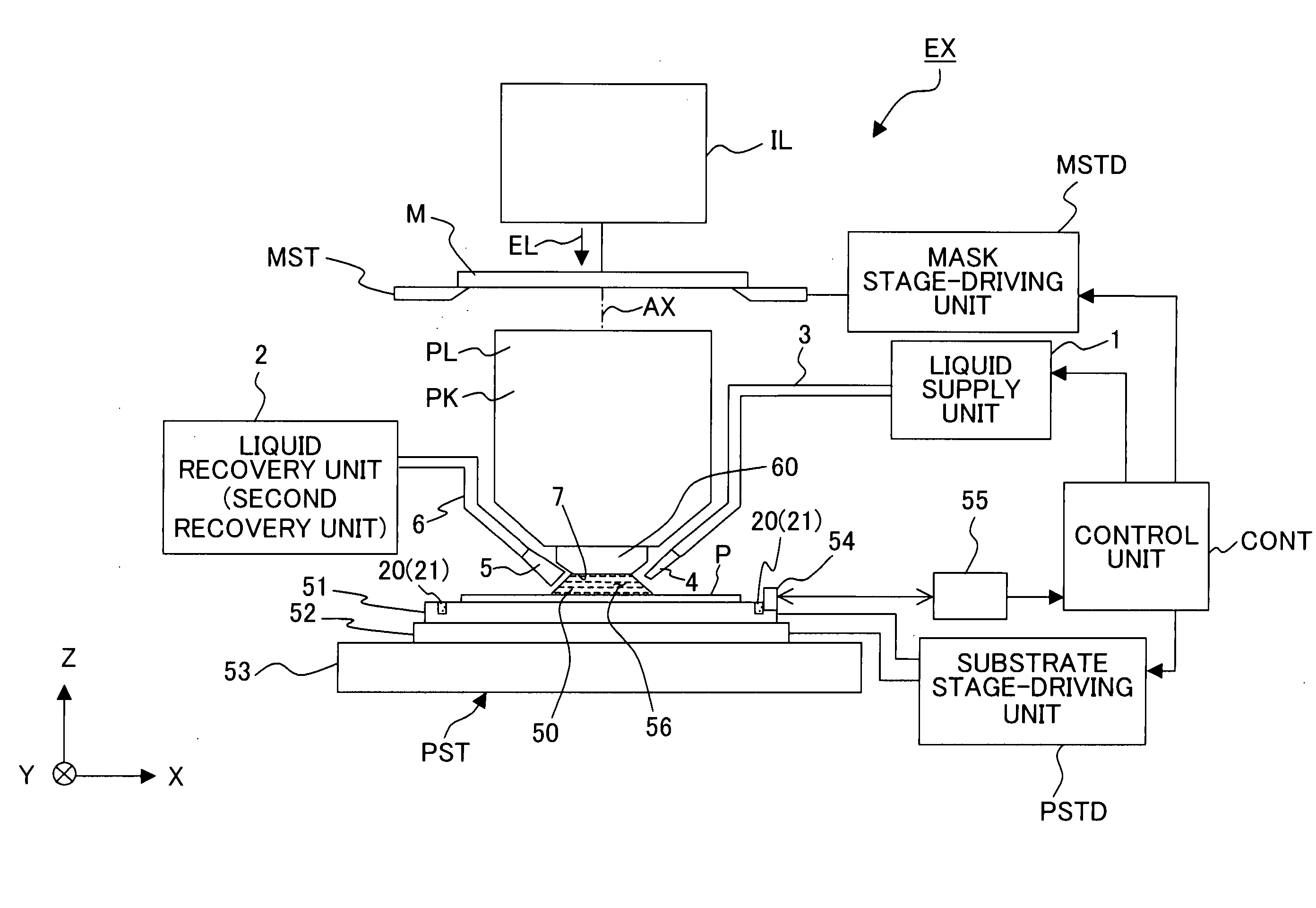

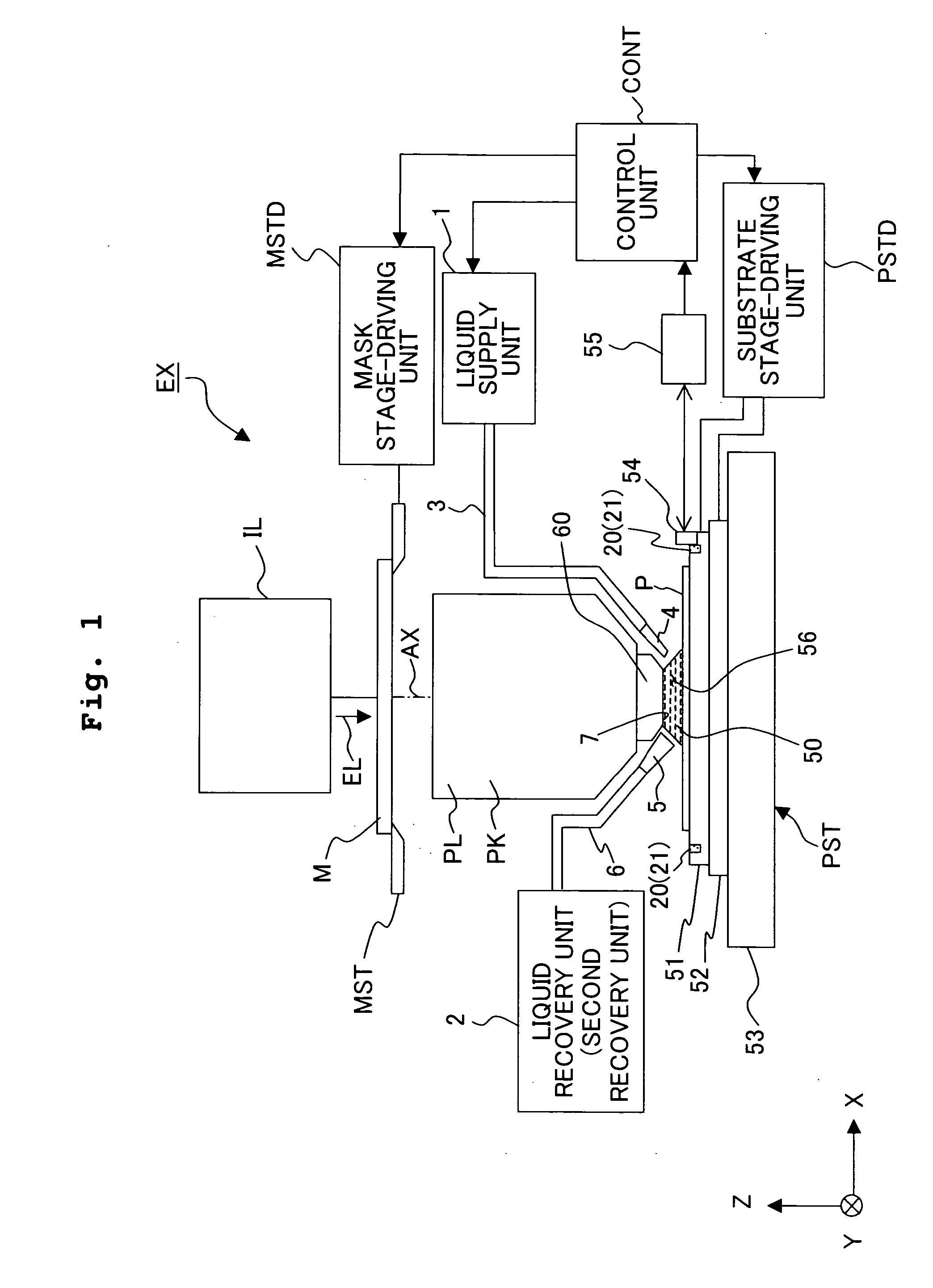

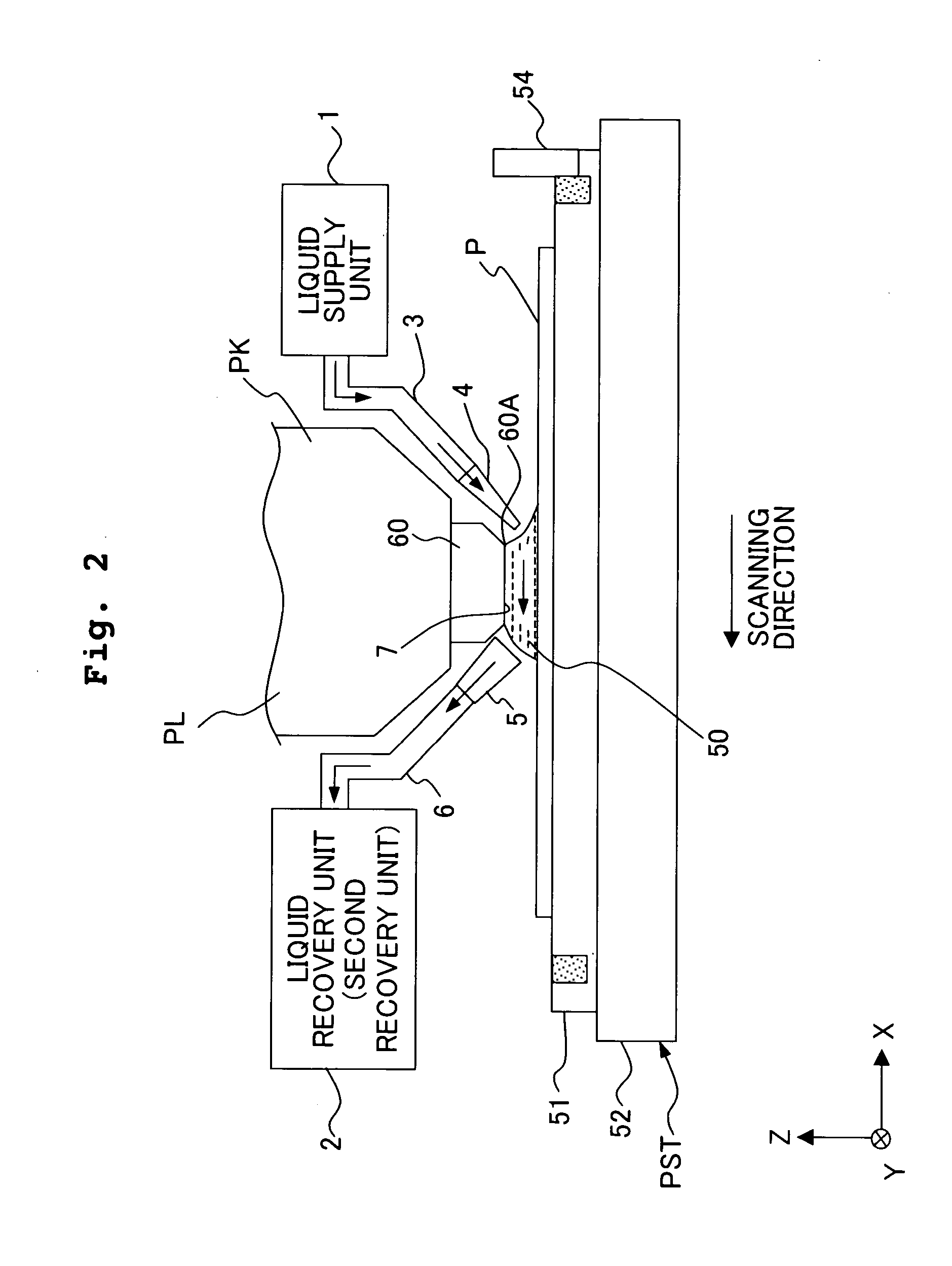

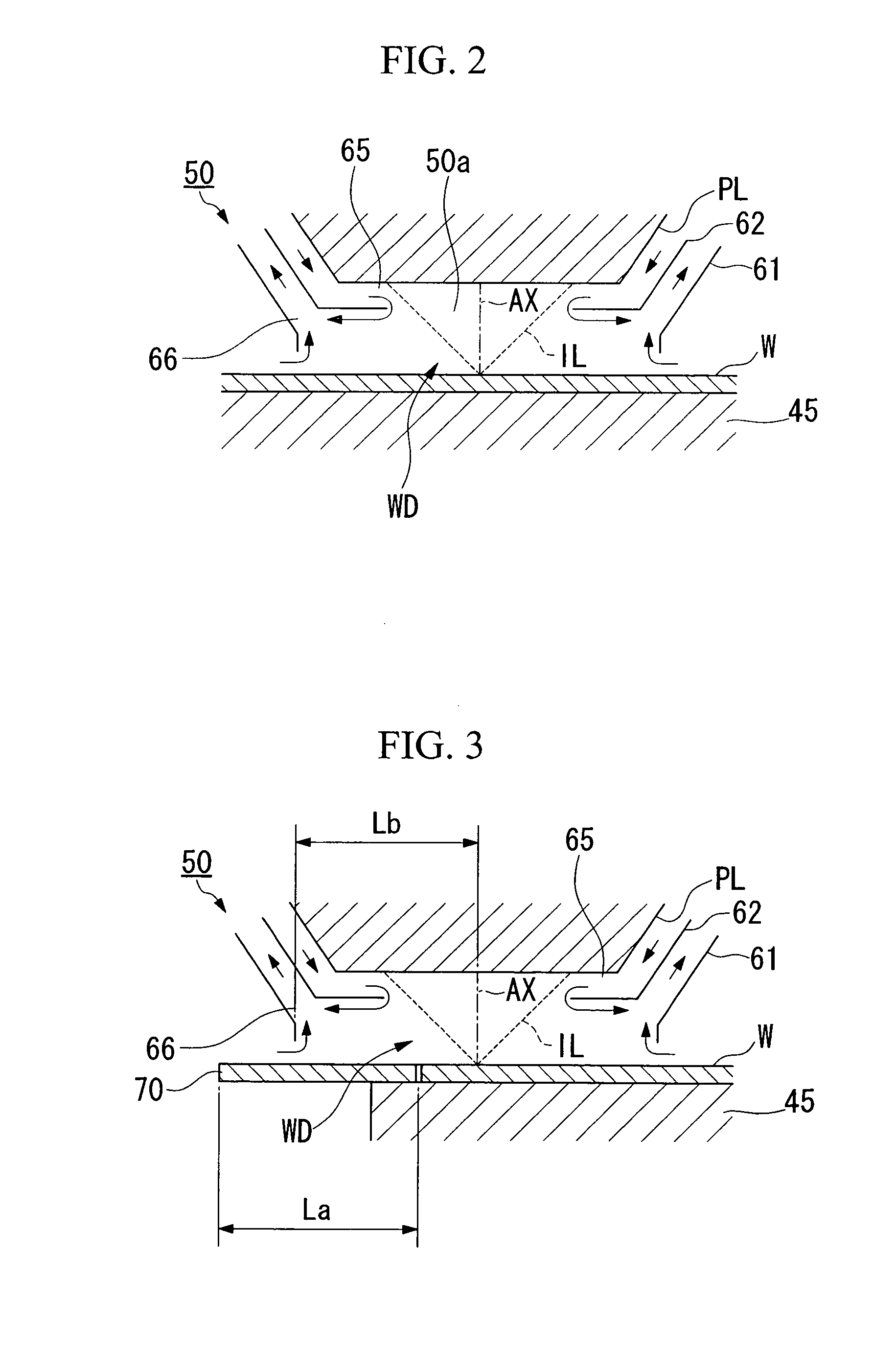

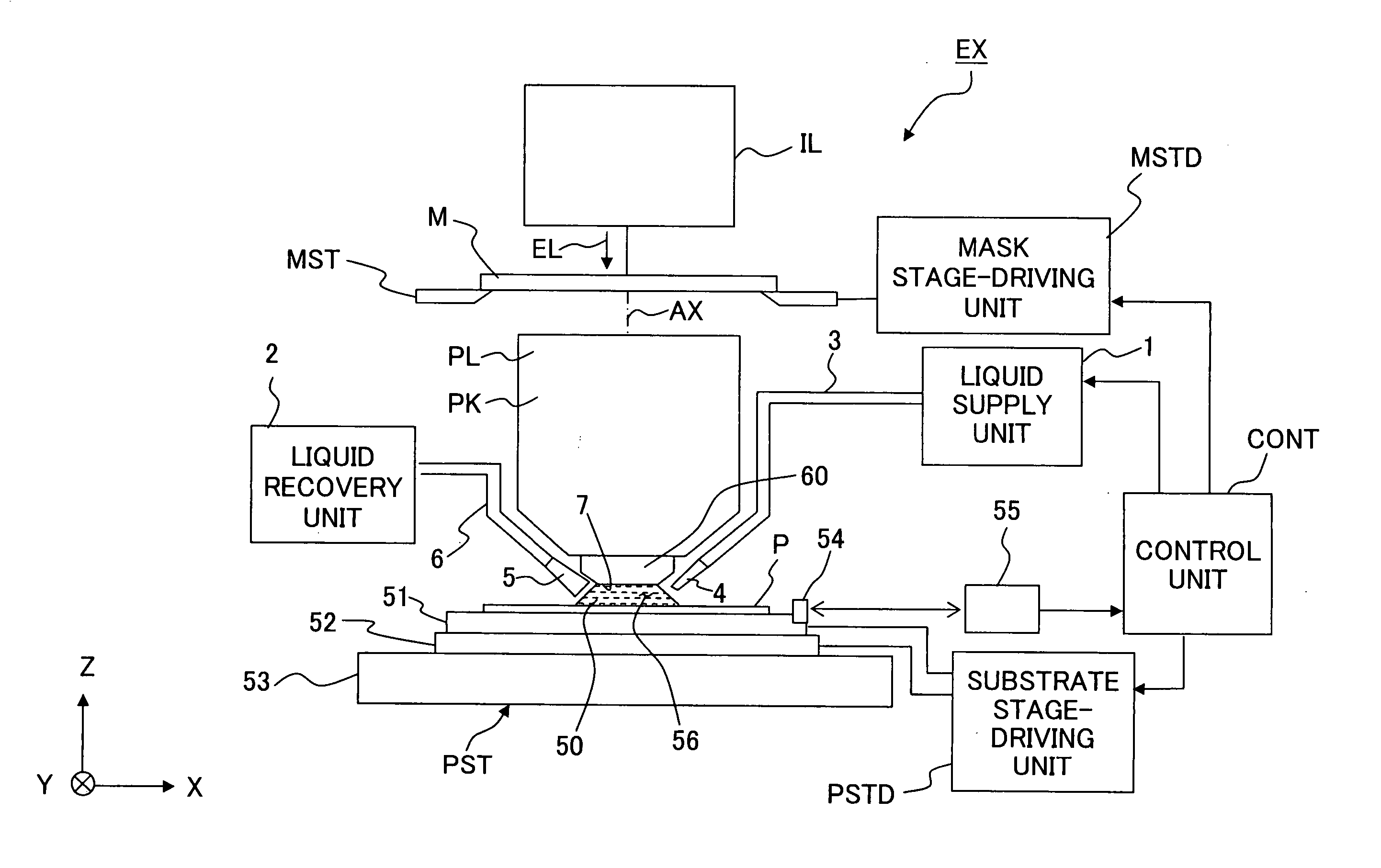

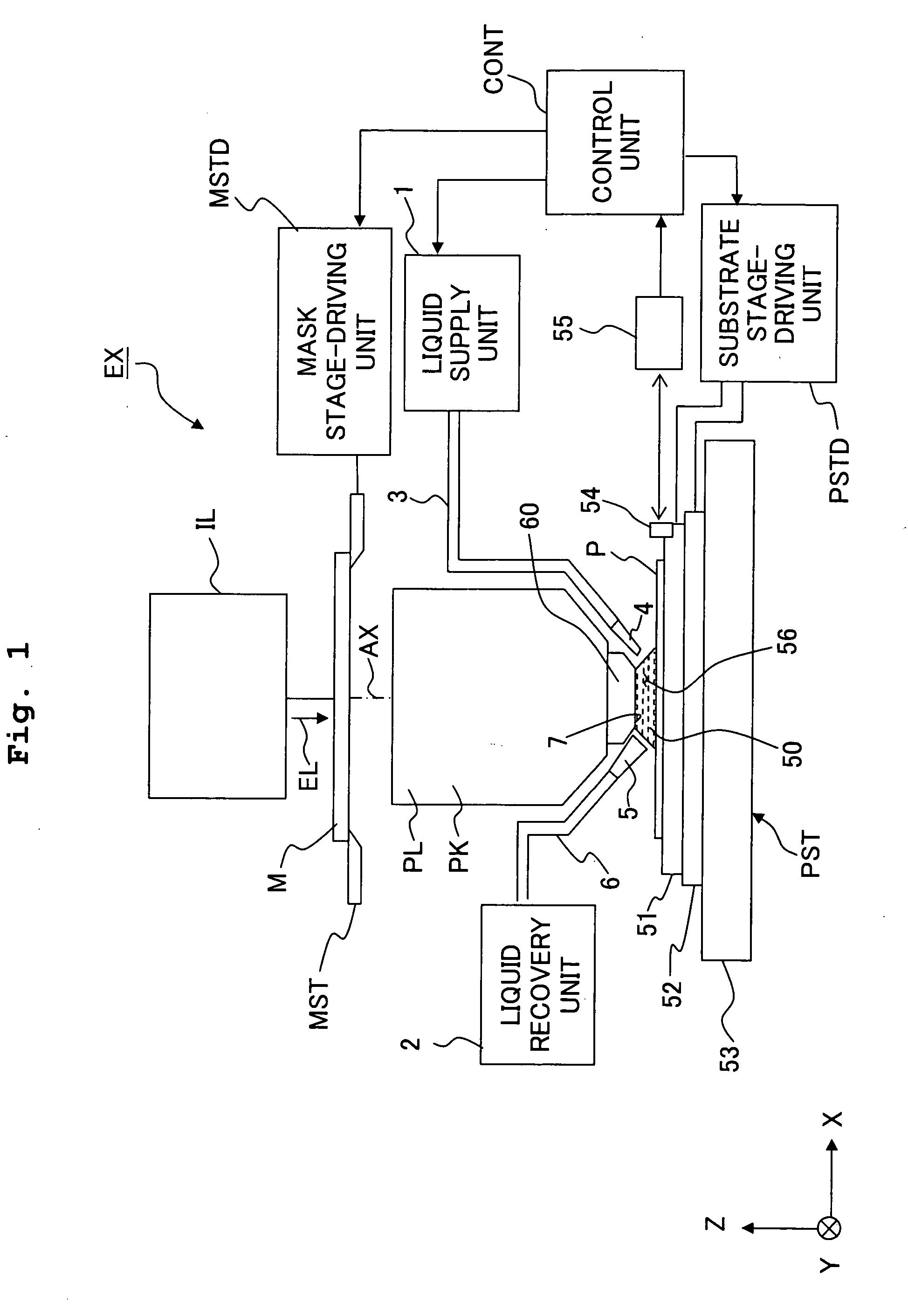

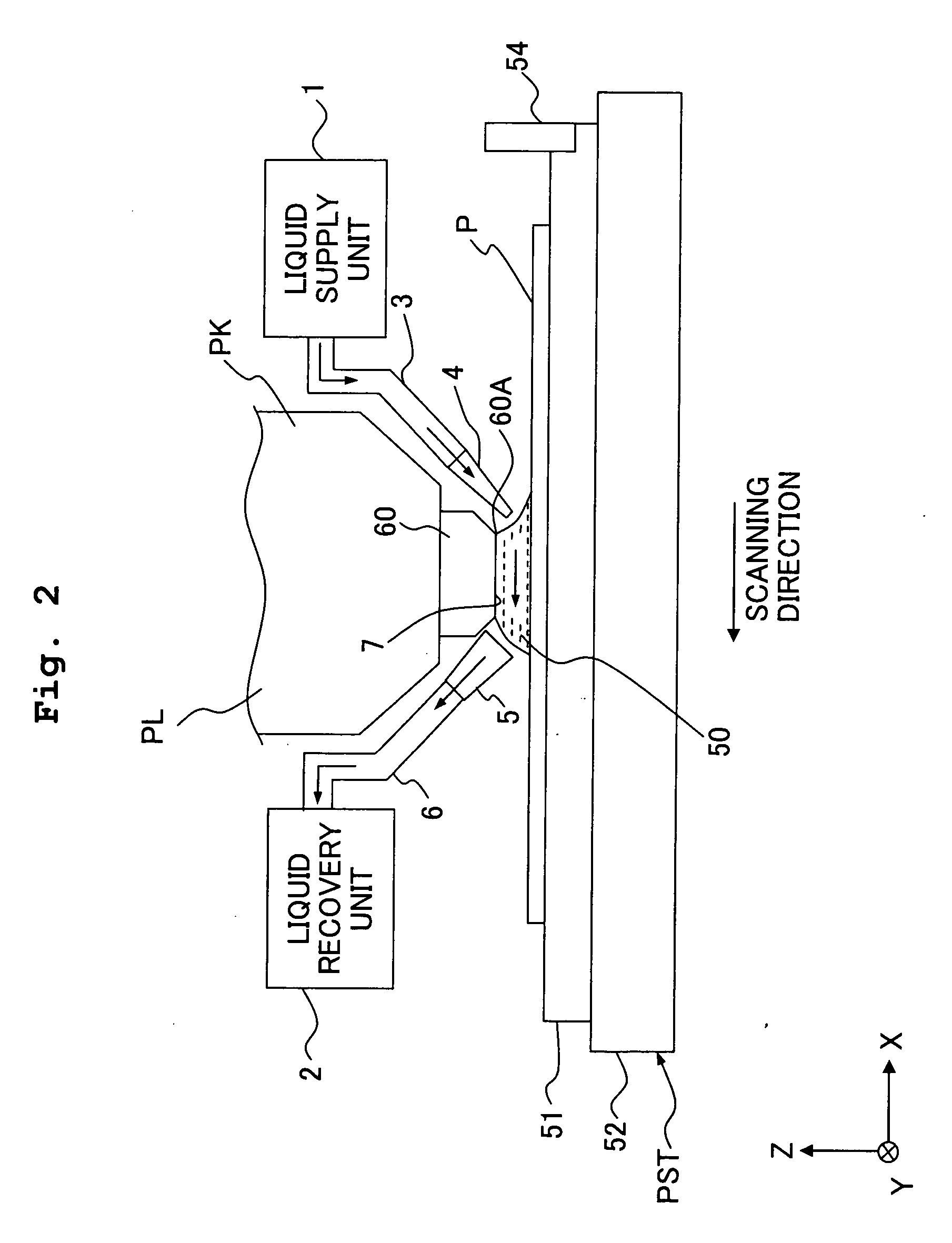

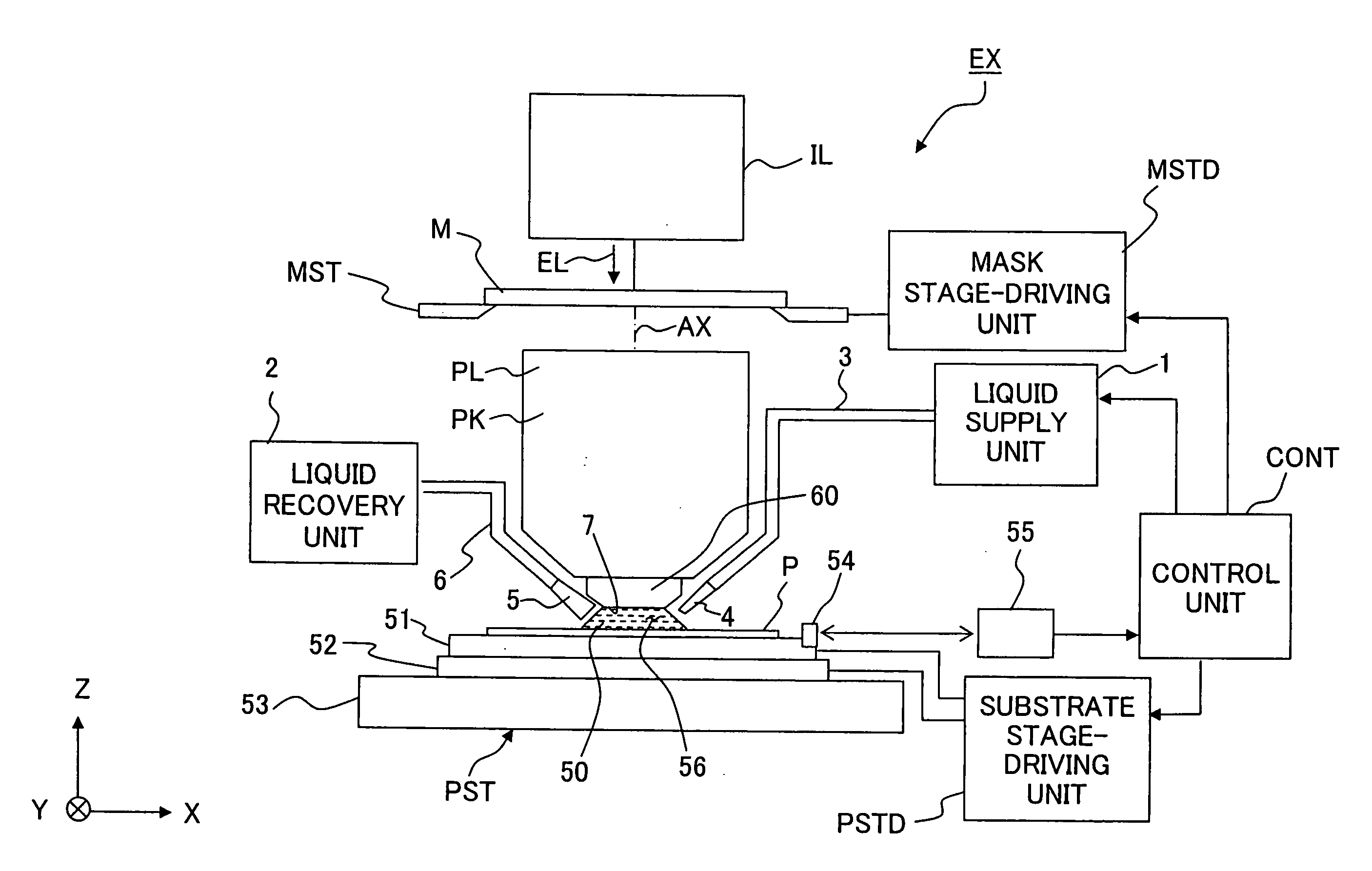

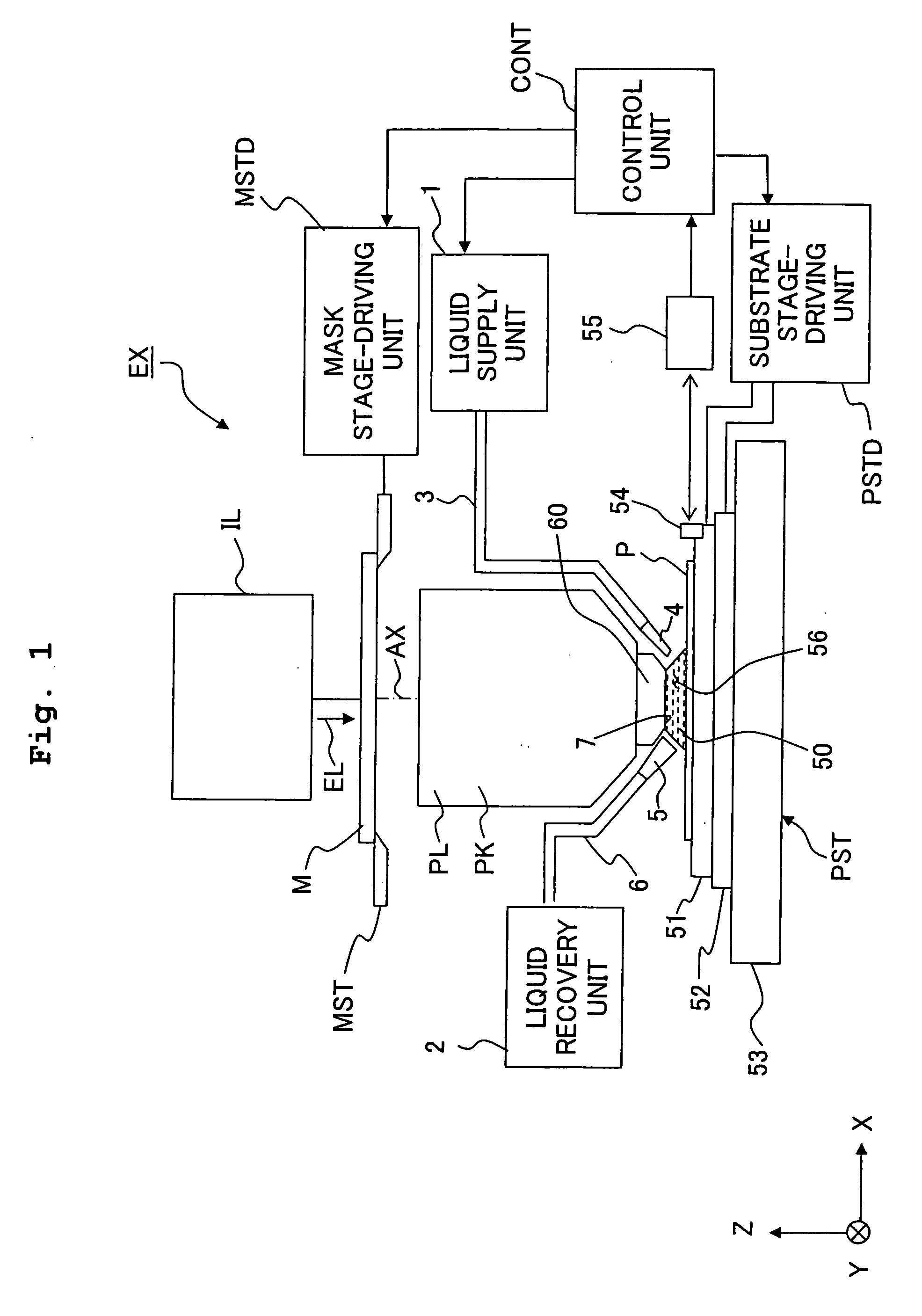

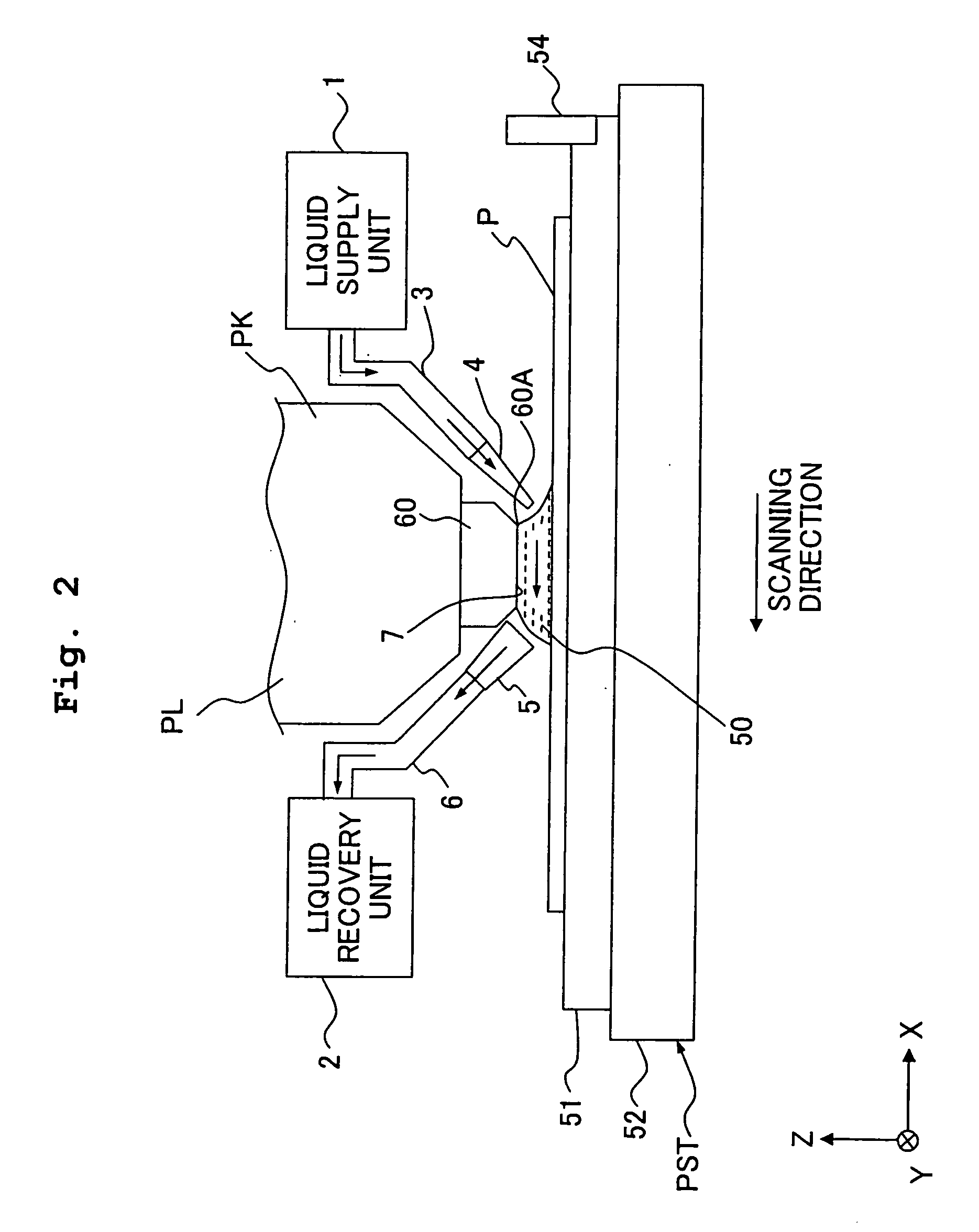

An exposure apparatus exposes a substrate P by locally filling a side of an image plane of a projection optical system PL with a liquid 50 and projecting an image of a pattern onto the substrate P through the liquid 50 and the projection optical system PL. The exposure apparatus includes a recovery unit 20 which recovers the liquid 50 outflowed to the outside of the substrate P. When the exposure process is performed in accordance with the liquid immersion method, the pattern can be transferred accurately while suppressing any environmental change even when the liquid outflows to the outside of the substrate.

Owner:NIKON CORP

Exposure method, exposure apparatus, and method for manufacturing device

InactiveUS7098991B2Containment leakHigh control precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronics

According to one embodiment of the invention, a pattern of a mask is transferred onto a substrate via a projection optical system using an energy beam by placing a substrate on side of an energy beam emitting end portion of projection optical system, when the substrate is exposed, and placing an object on the side of the energy beam emitting end portion of the projection optical system in place of the substrate when the substrate is exchanged. This can adequately remove a light absorptive substance from the region near an output end of the projection optical system and can maintain the gas state even at a time of moving or replacing the substrate.

Owner:NIKON CORP

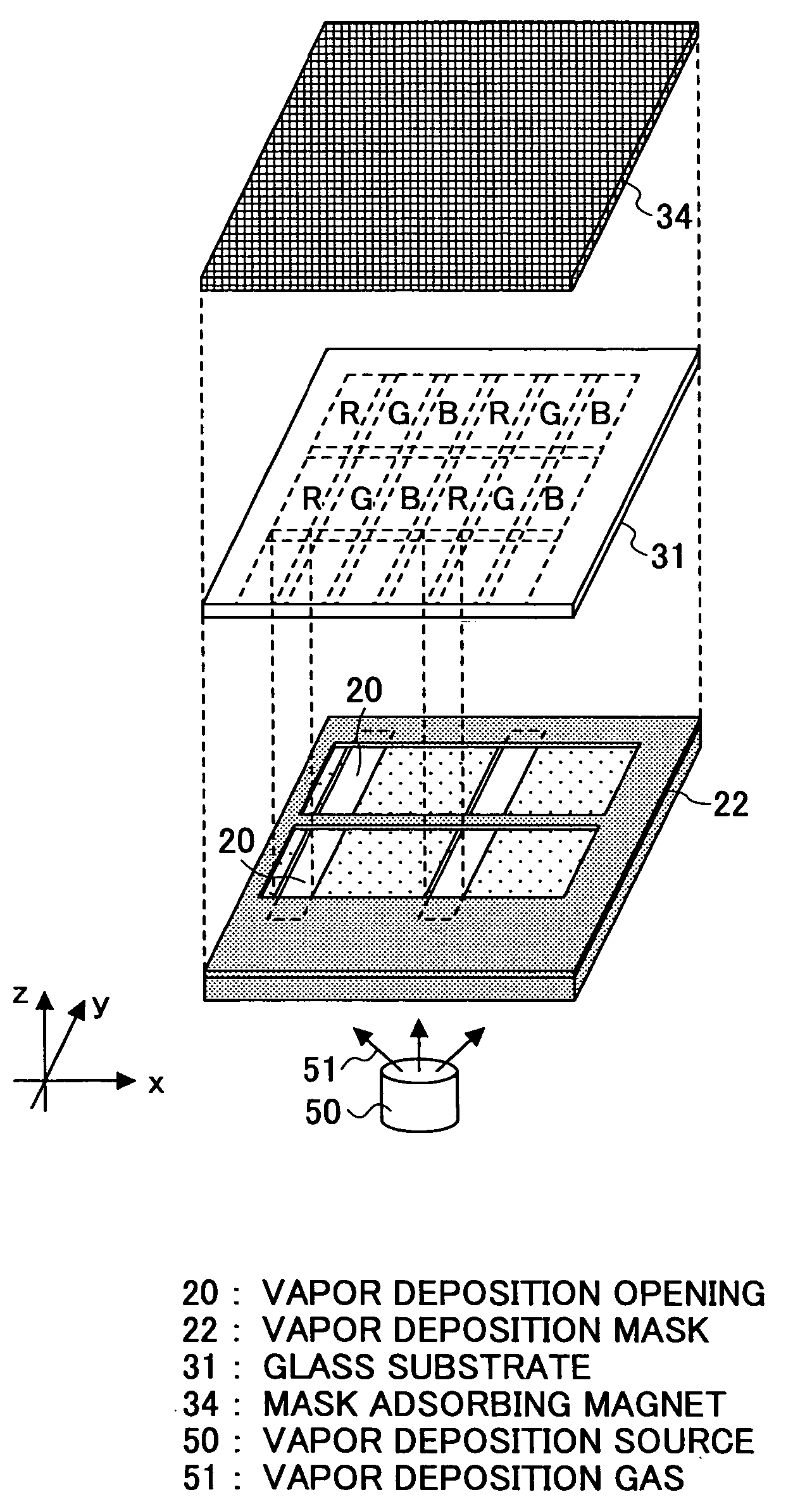

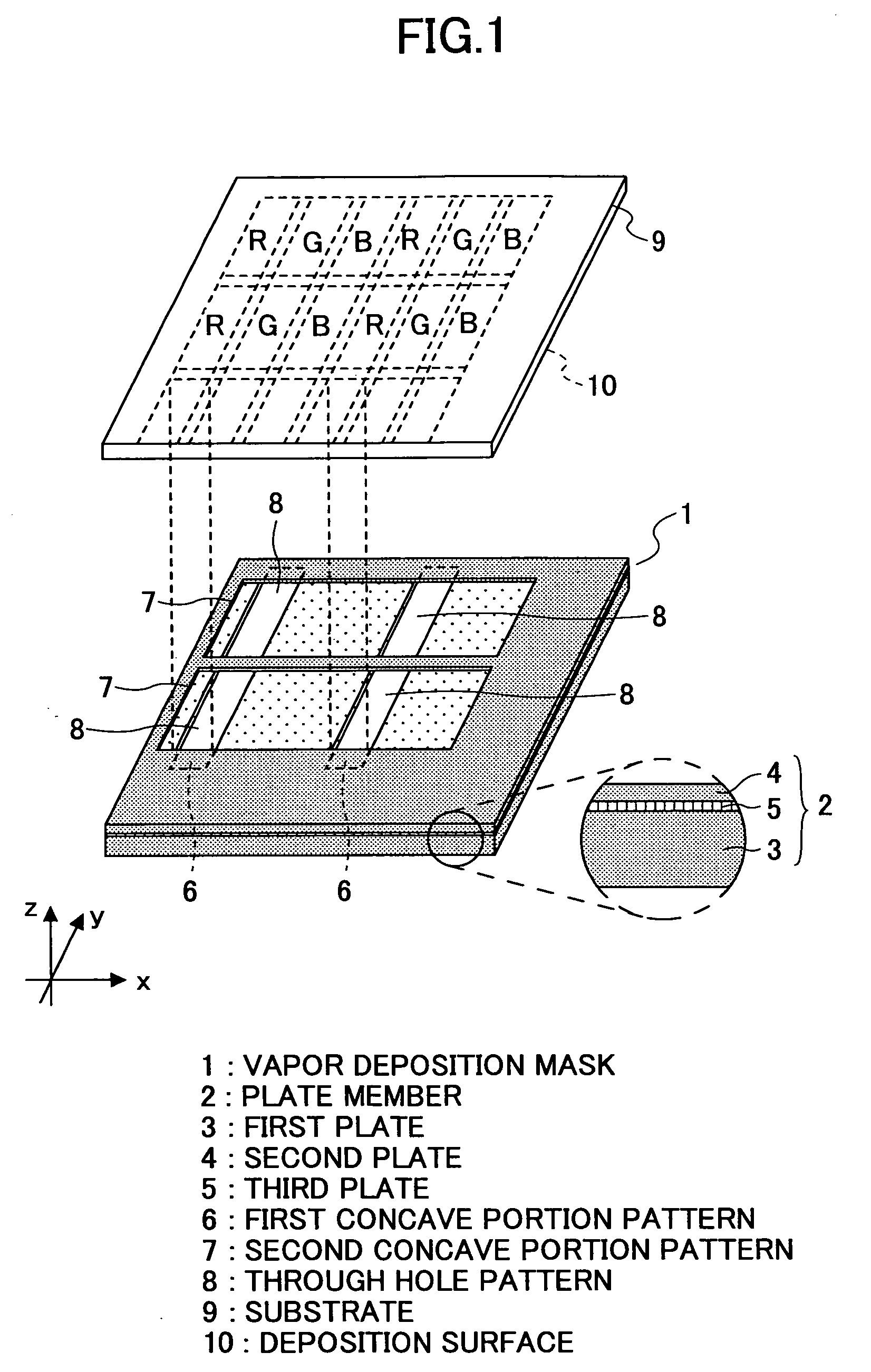

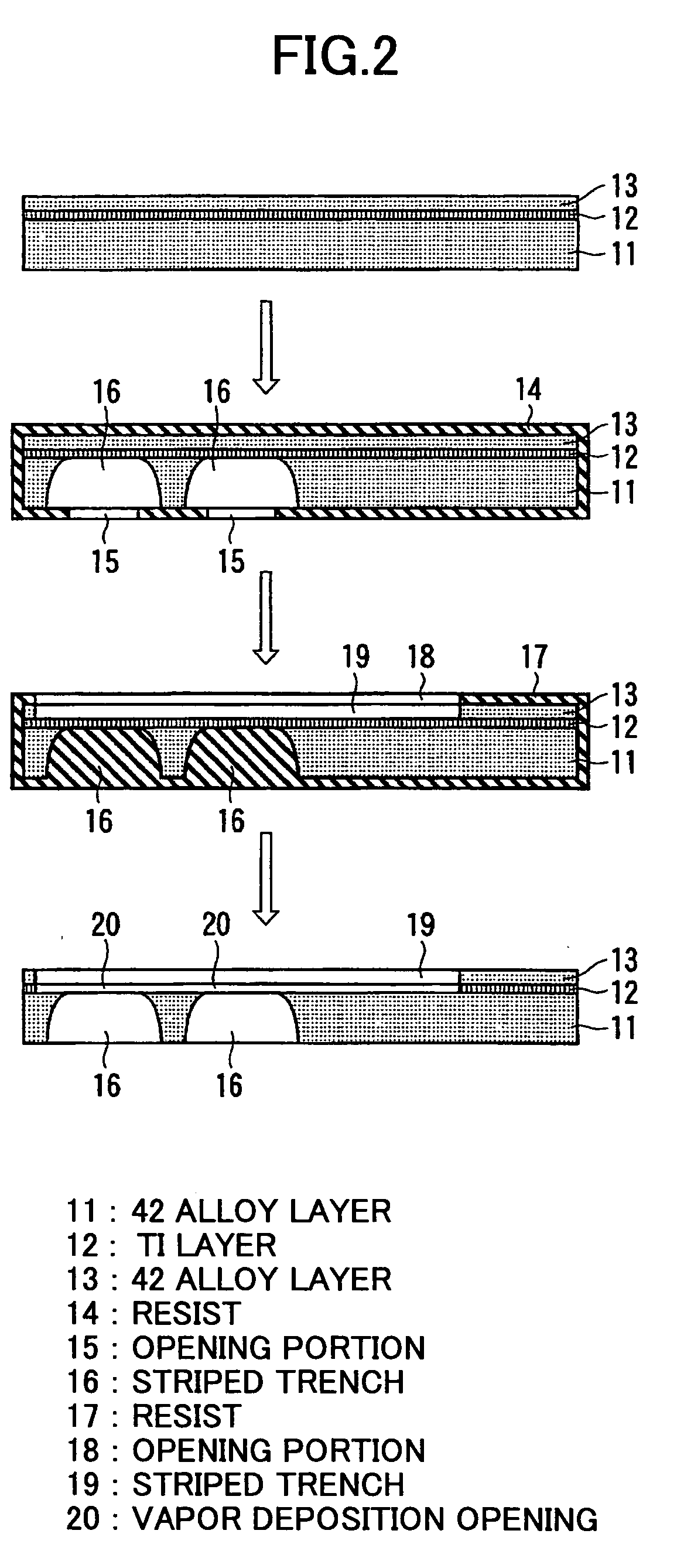

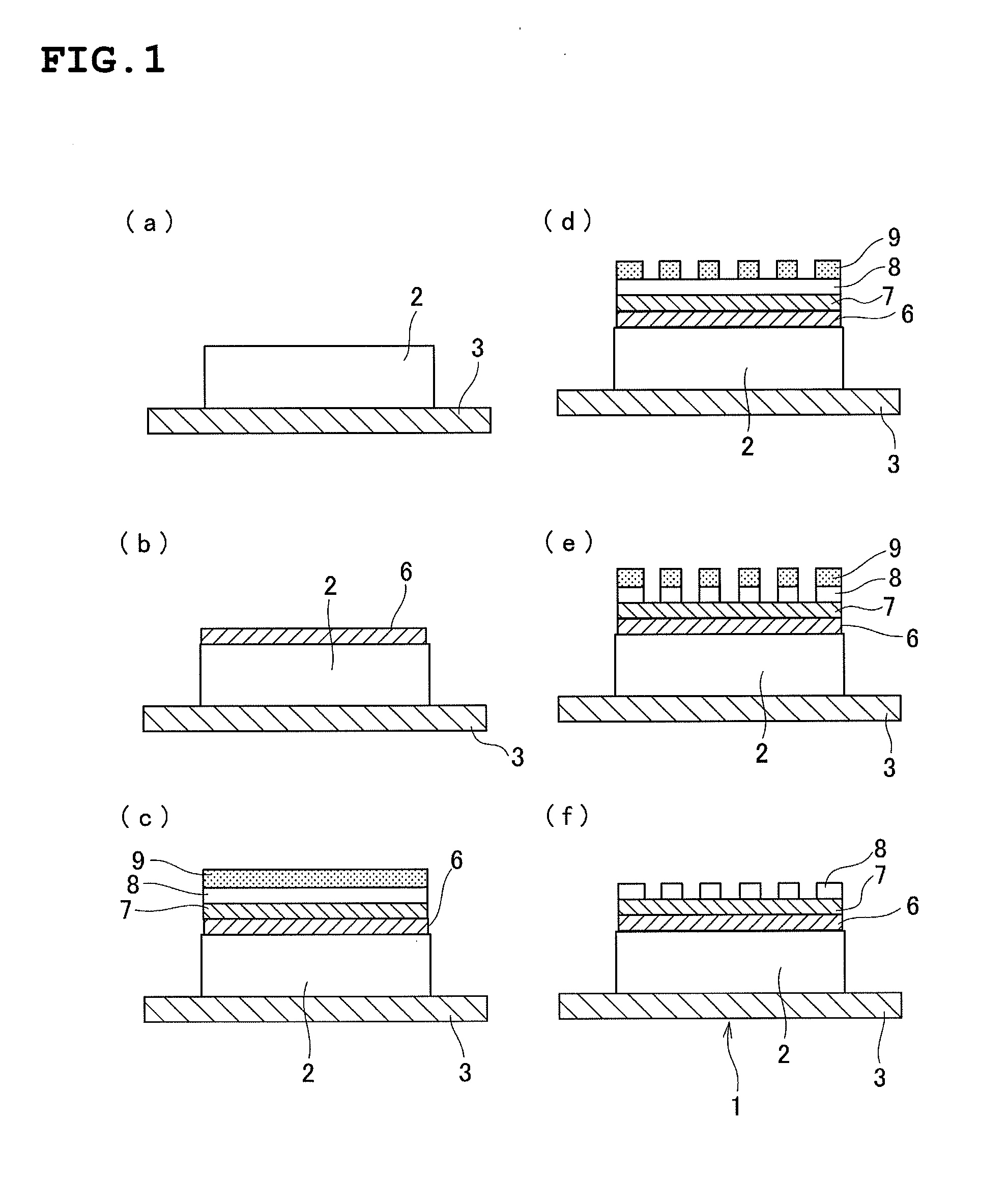

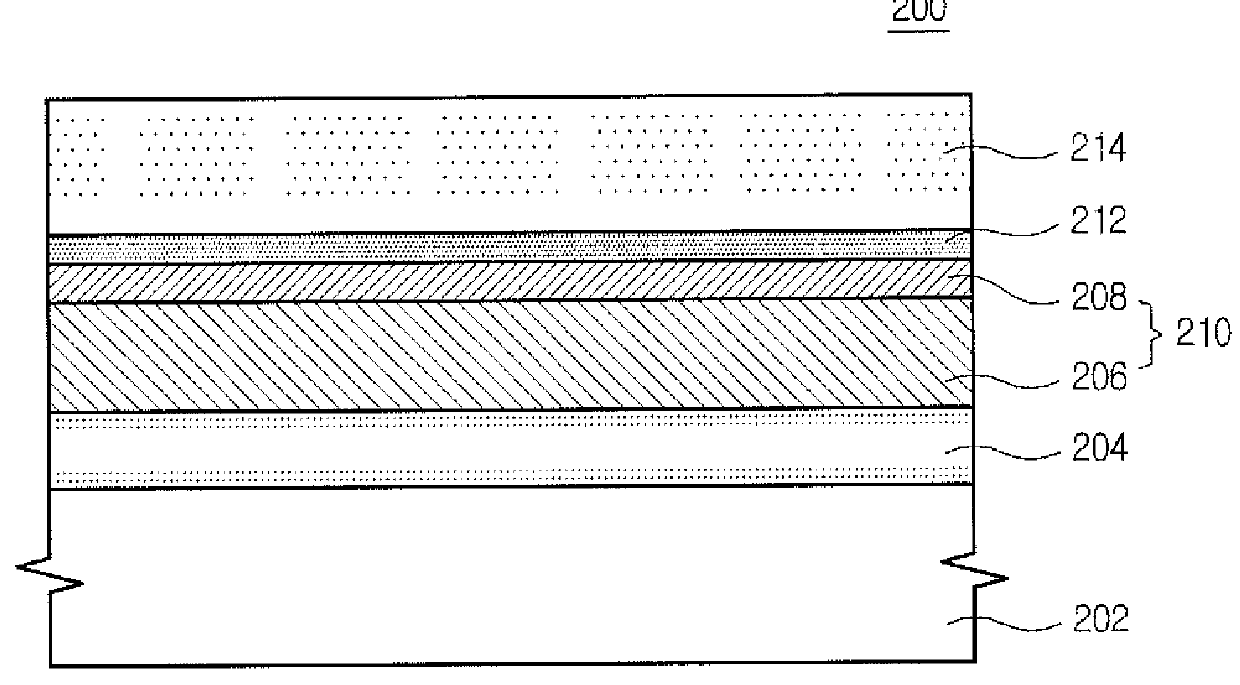

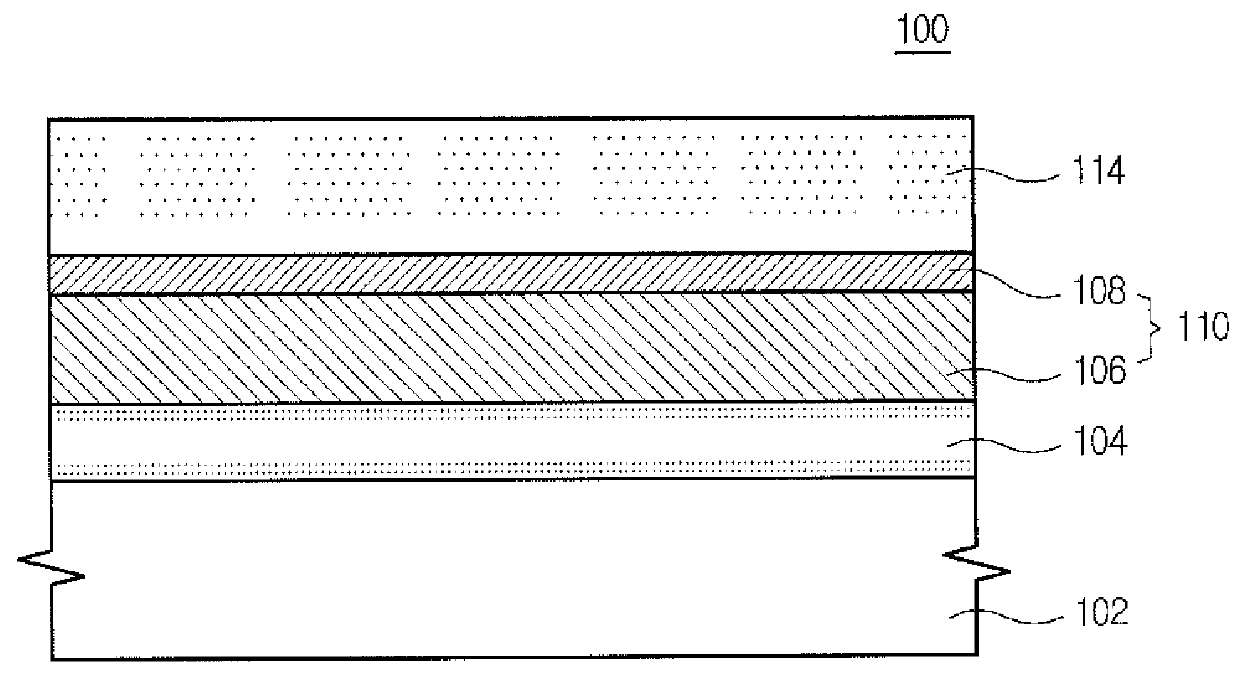

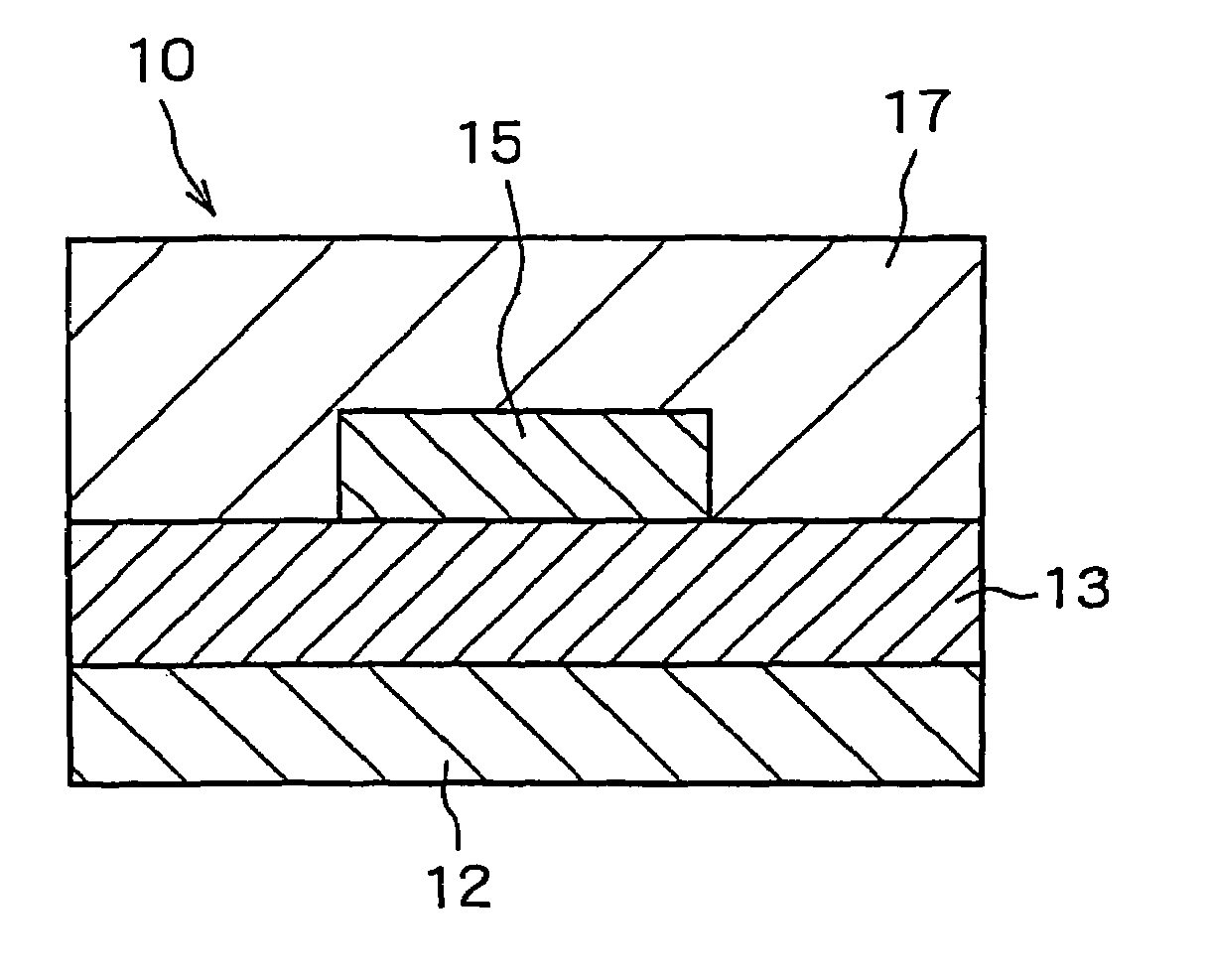

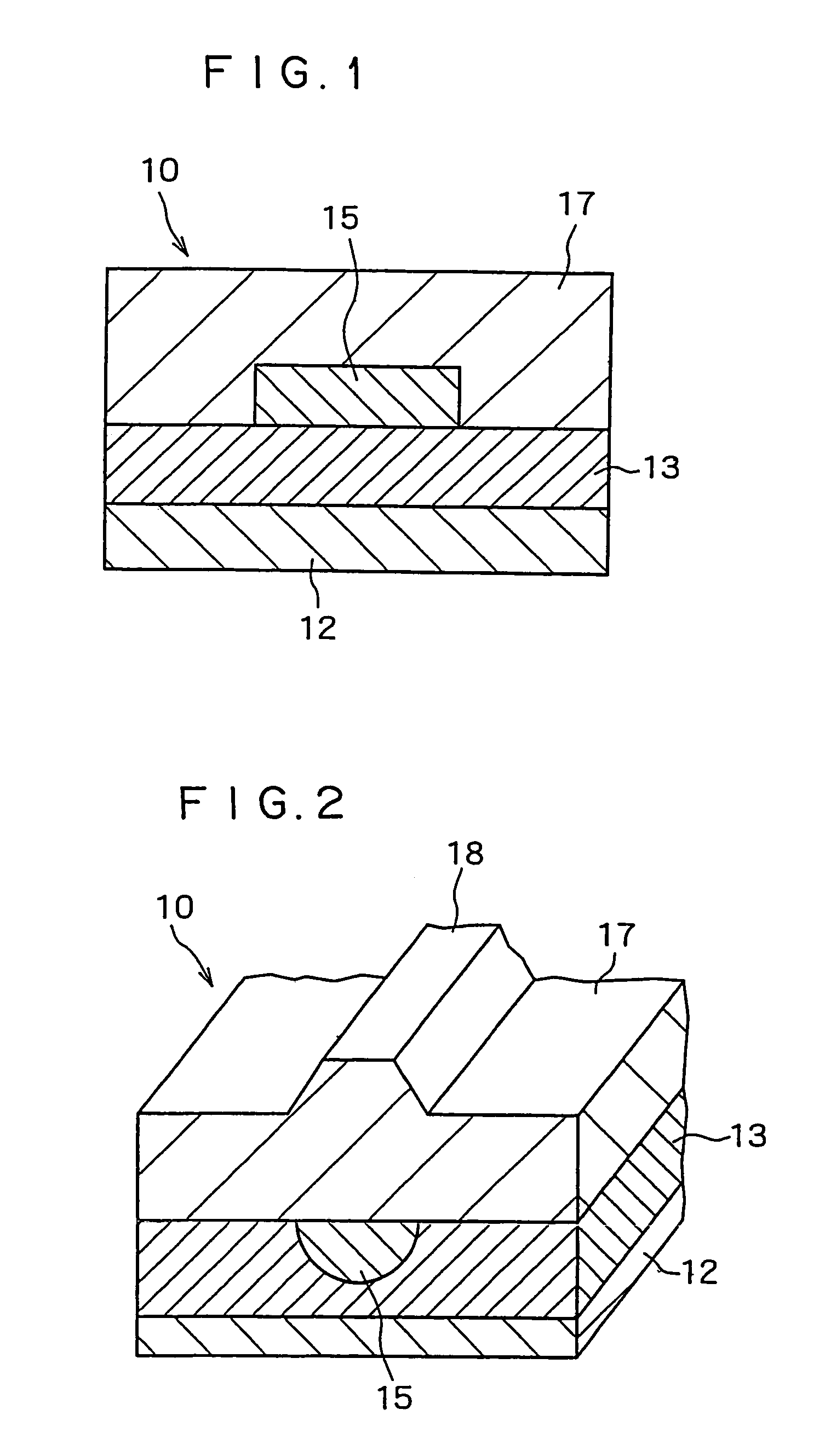

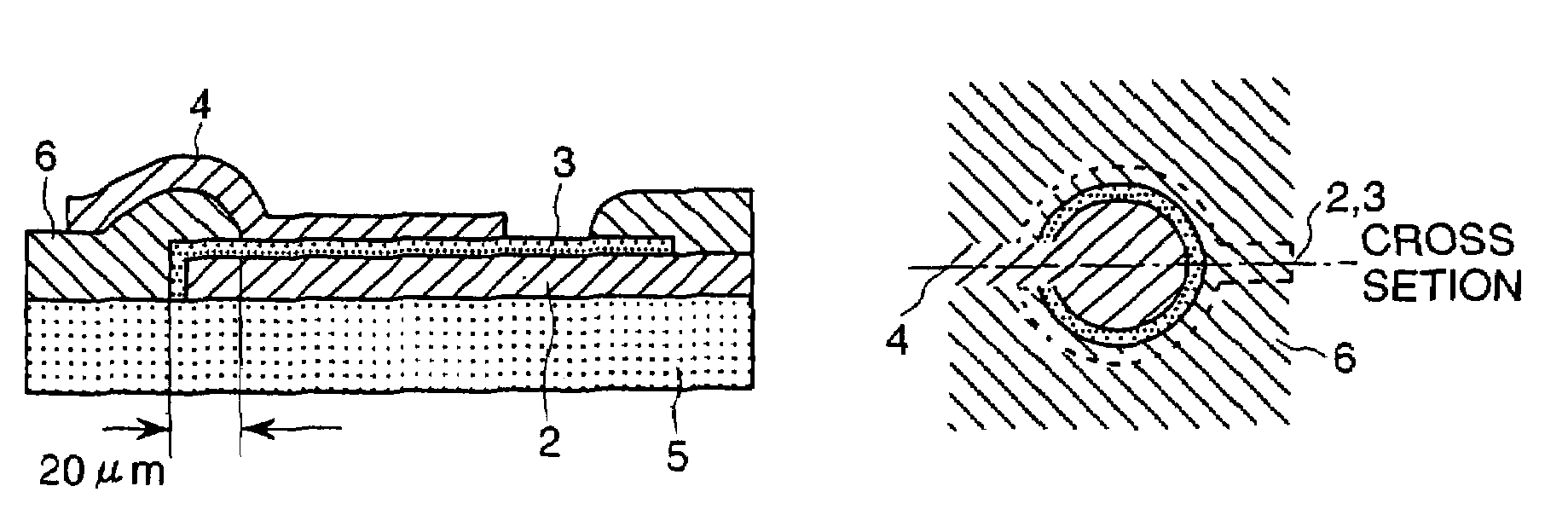

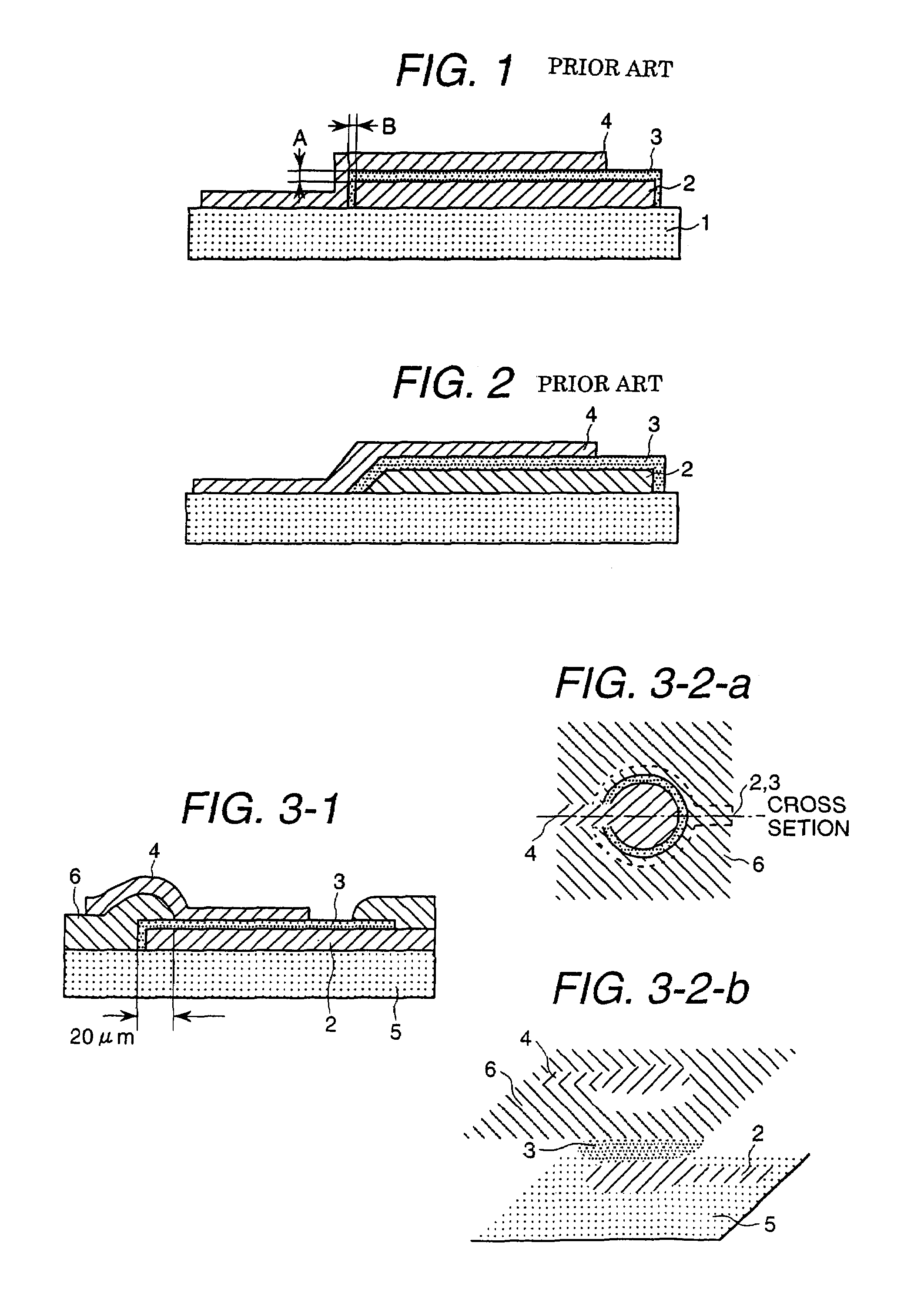

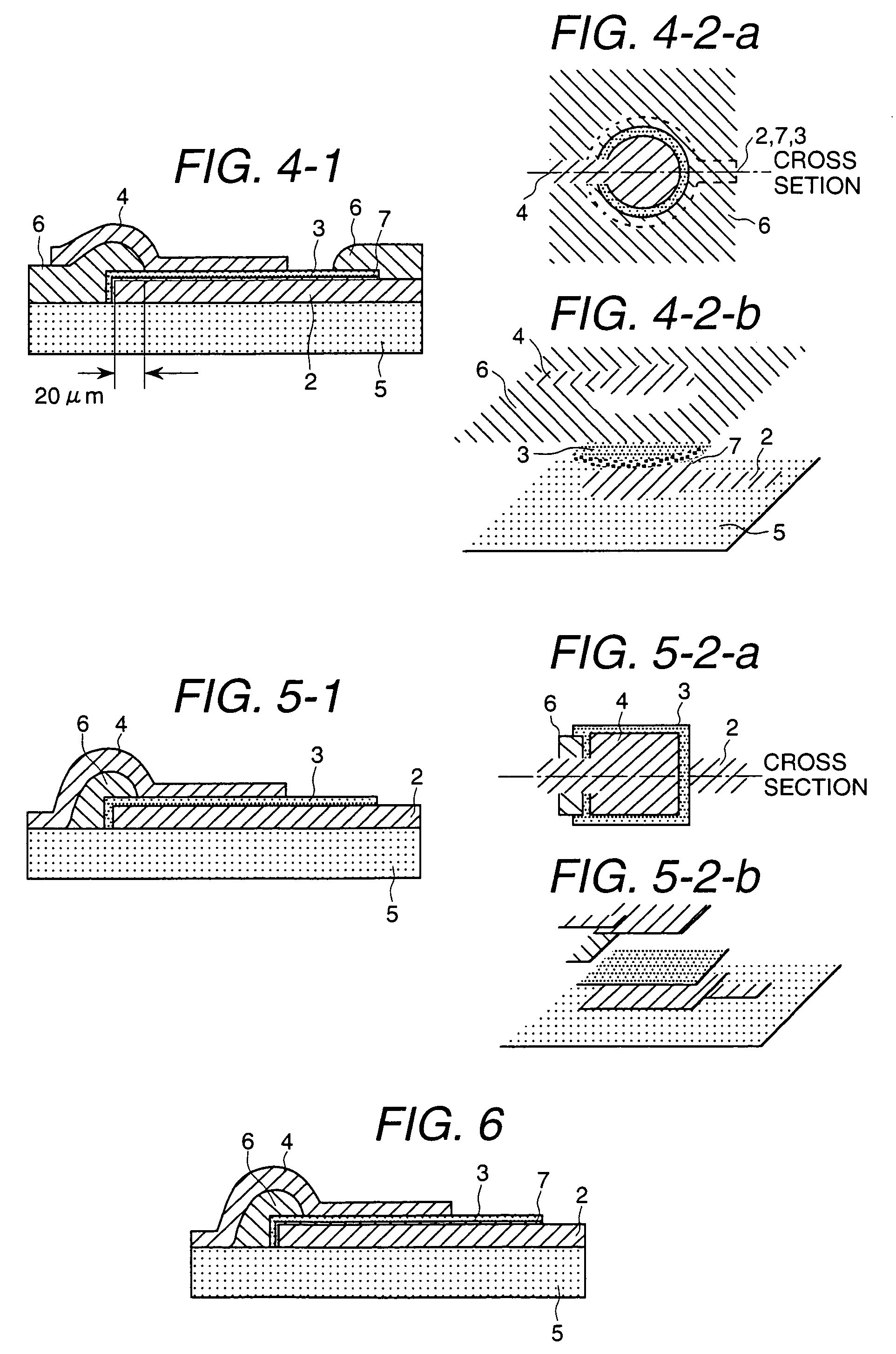

Vapor deposition mask and organic EL display device manufacturing method

InactiveUS20050166842A1High pattern accuracyElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A vapor deposition mask with high pattern accuracy particularly at vapor deposition openings is realized without changing the substrate structure. The vapor deposition mask includes a plate member, a first concave pattern provided at a first surface of the plate member, a second concave pattern provided at a second surface of the plate member on the opposite side of the plate member, and a through hole pattern provided at meeting or intersecting portions of the first concave pattern and the second concave pattern. The shape of the through hole pattern is arranged to be different from both that of the first concave pattern and that of the second concave pattern.

Owner:FUJIFILM HLDG CORP +1

Exposure apparatus and method for producing device

InactiveUS20060238730A1Accurate transferHigh pattern accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

An exposure apparatus exposes a substrate P by locally filling a side of an image plane of a projection optical system PL with a liquid 50 and projecting an image of a pattern onto the substrate P through the liquid 50 and the projection optical system PL. The exposure apparatus includes a recovery unit 20 which recovers the liquid 50 outflowed to the outside of the substrate P. When the exposure process is performed in accordance with the liquid immersion method, the pattern can be transferred accurately while suppressing any environmental change even when the liquid outflows to the outside of the substrate.

Owner:NIKON CORP

Exposure apparatus and method for producing device

InactiveUS20050219490A1Inhibit deteriorationSuppress generationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineering

An exposure apparatus, wherein exposure is carried out while filling a space between a projection optical system and a substrate with a liquid, enables to suppress deterioration of a pattern image caused by any bubble in the liquid. The exposure apparatus includes a liquid supply unite 1 which fills at least a part of the space between the projection optical system and the substrate with a liquid 50, and exposes the substrate by projecting an image of a pattern onto the substrate via the projection optical system. The liquid supply unite 1 includes a degassing unit 21 which suppresses the generation of the bubble in the liquid 50.

Owner:NIKON CORP

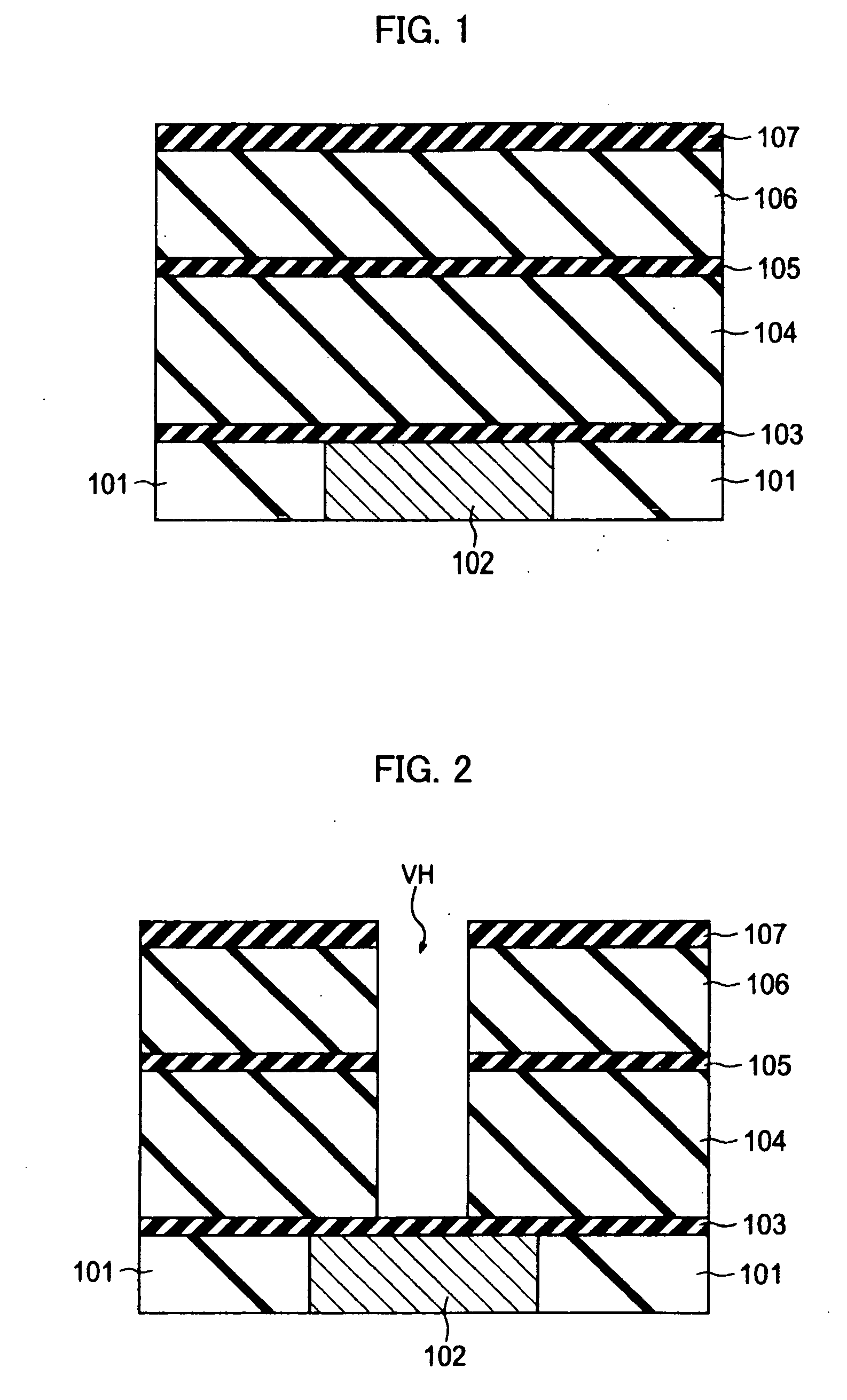

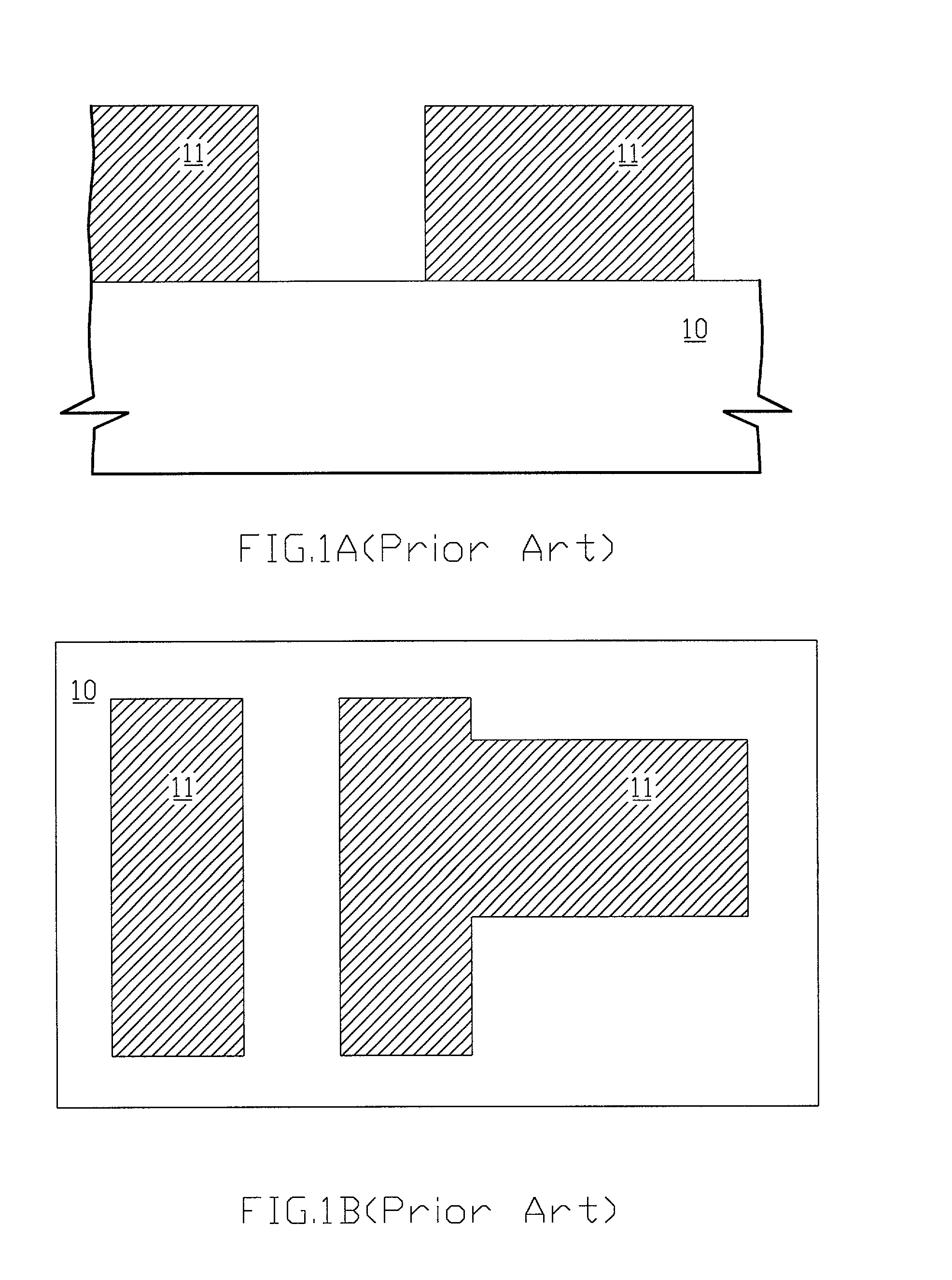

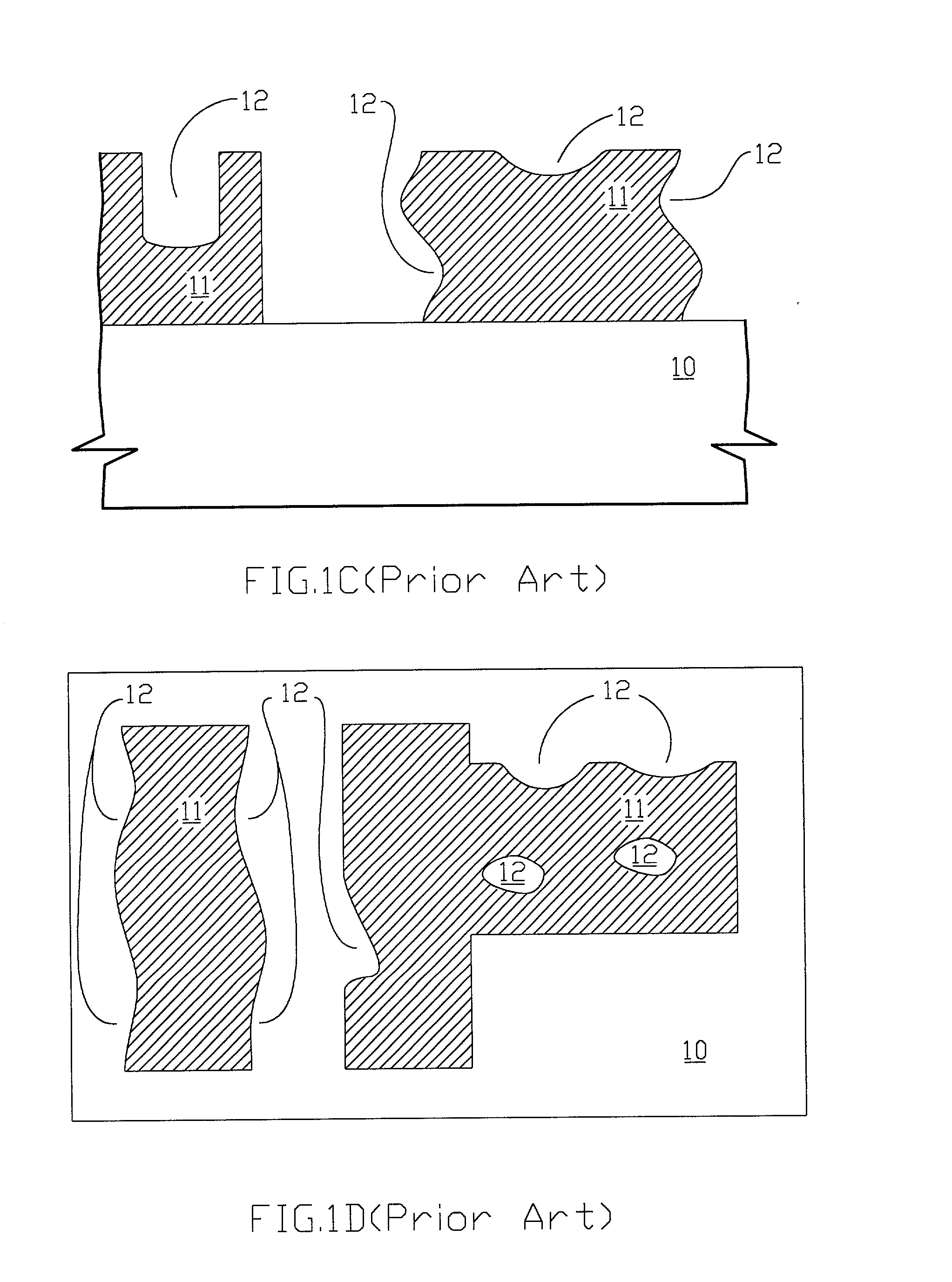

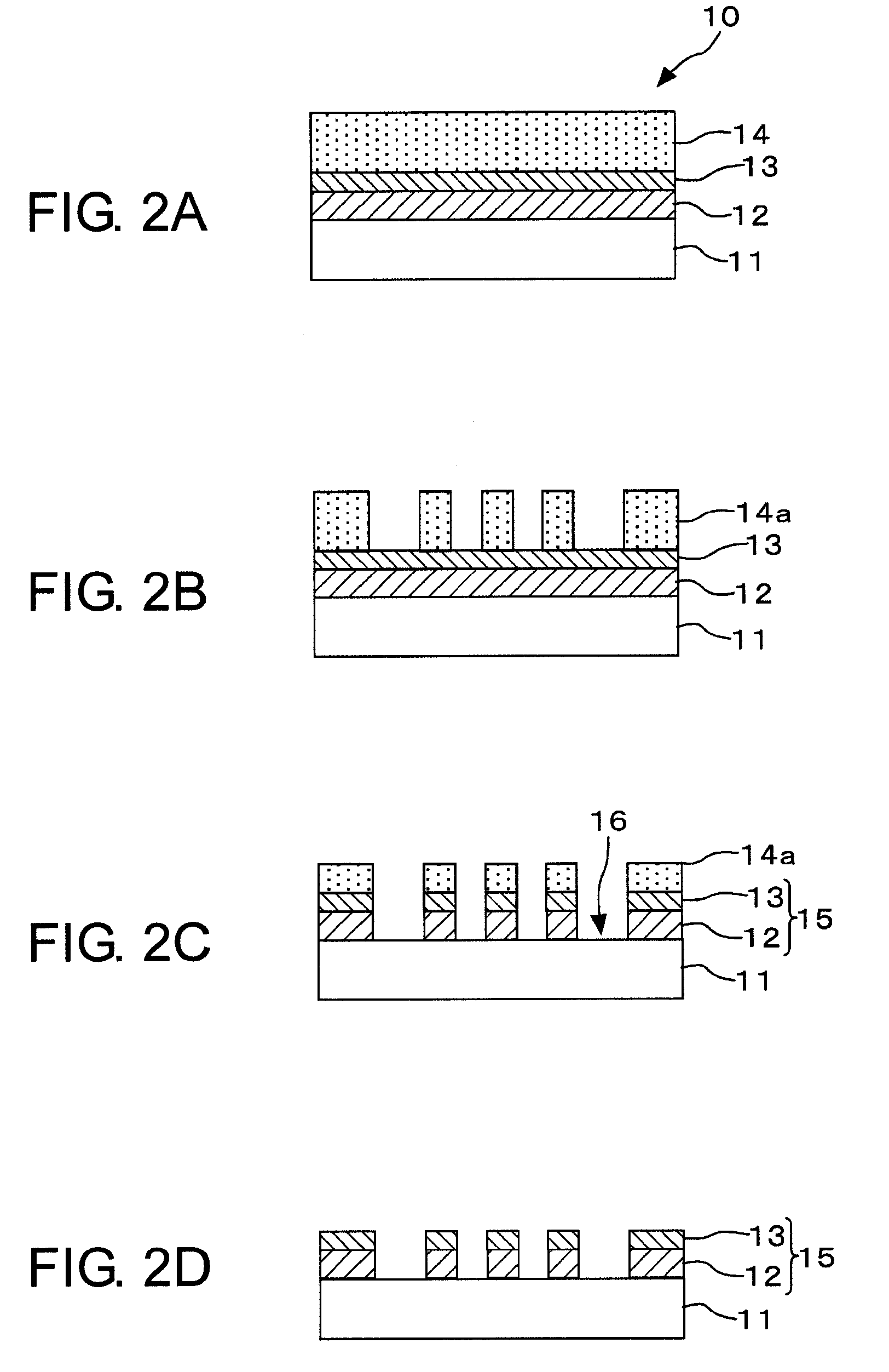

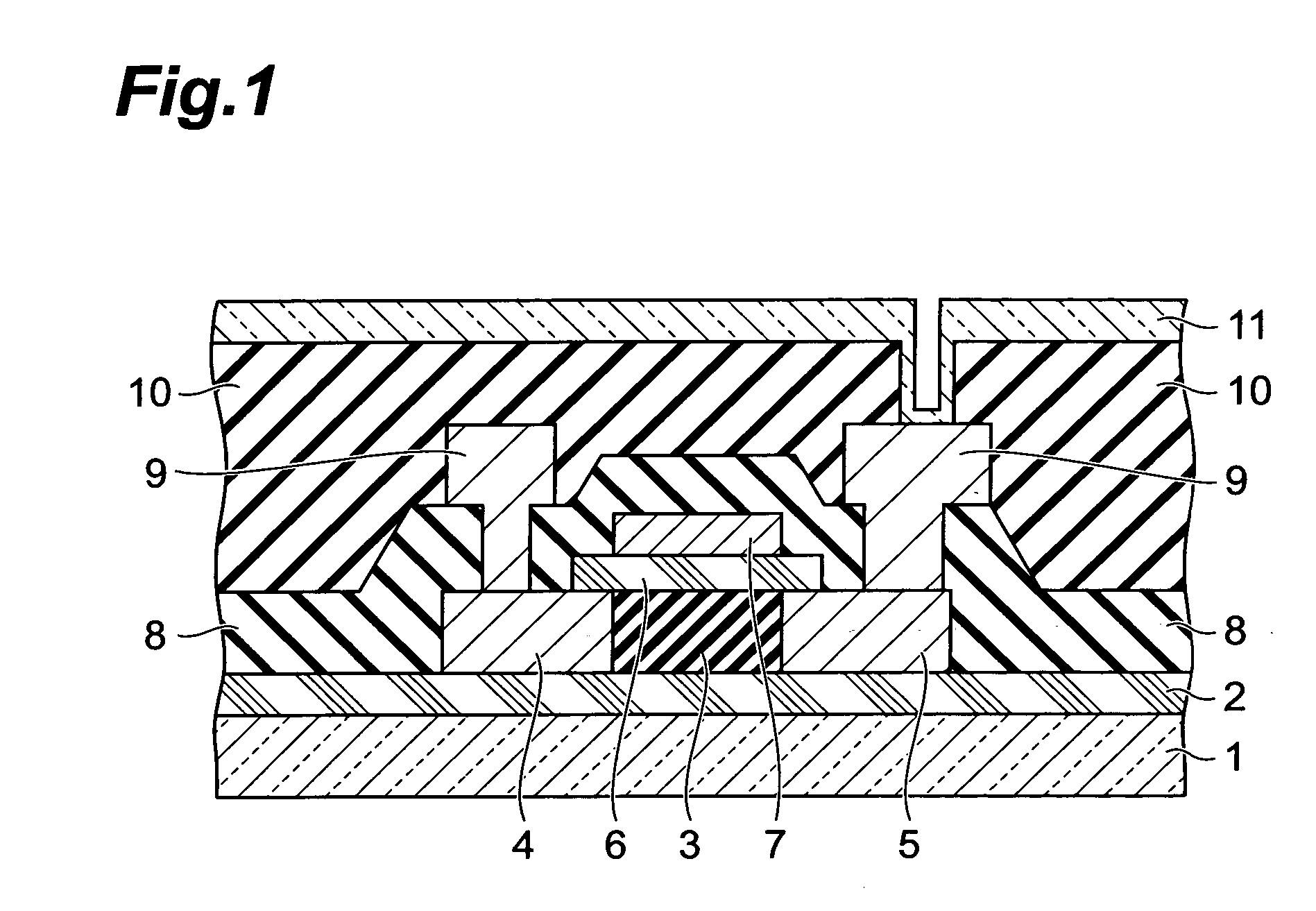

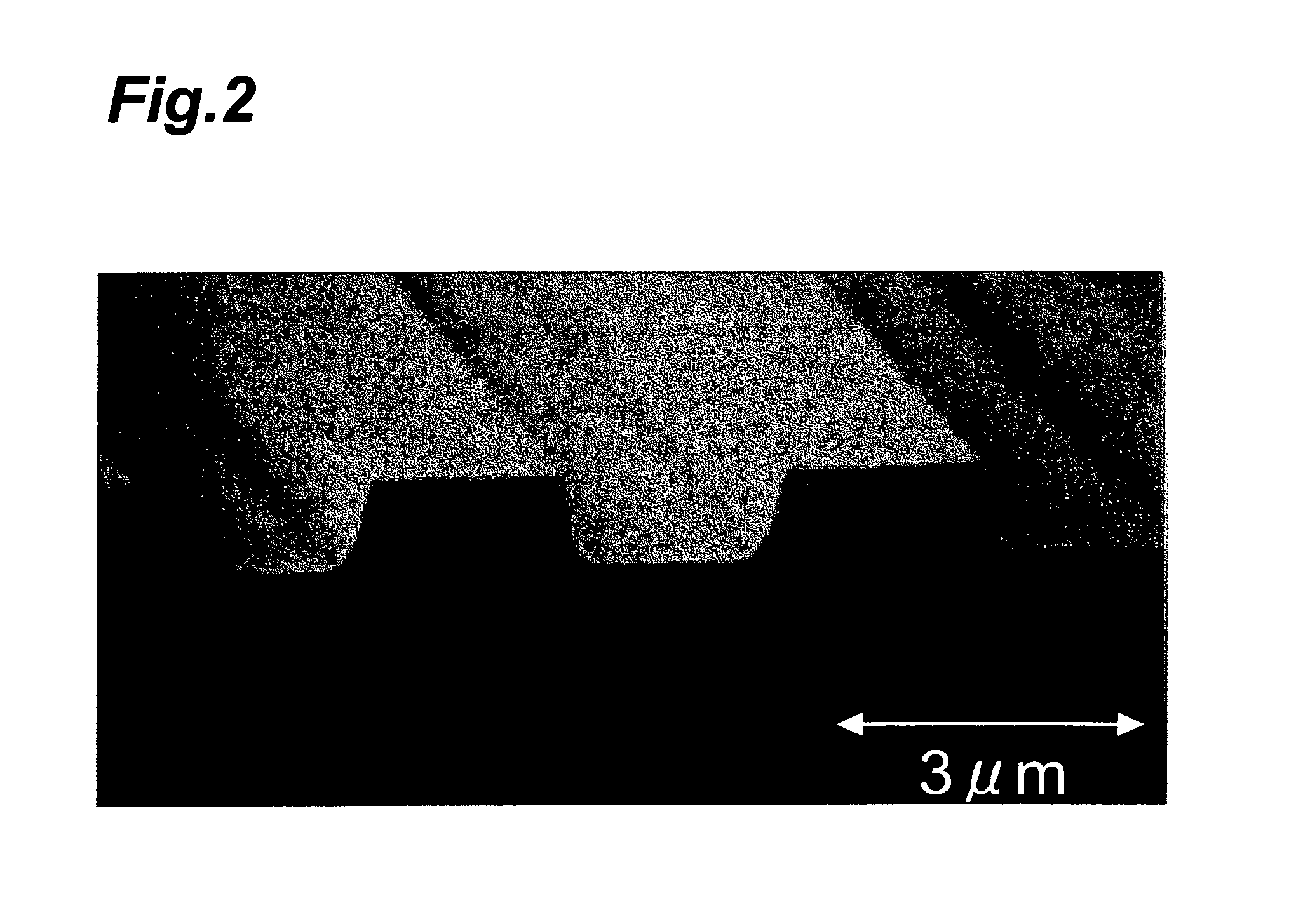

Process for producing semiconductor device and semiconductor device

InactiveUS20050079705A1High maintenanceLower power consumptionSemiconductor/solid-state device manufacturingOrganic baseEngineering

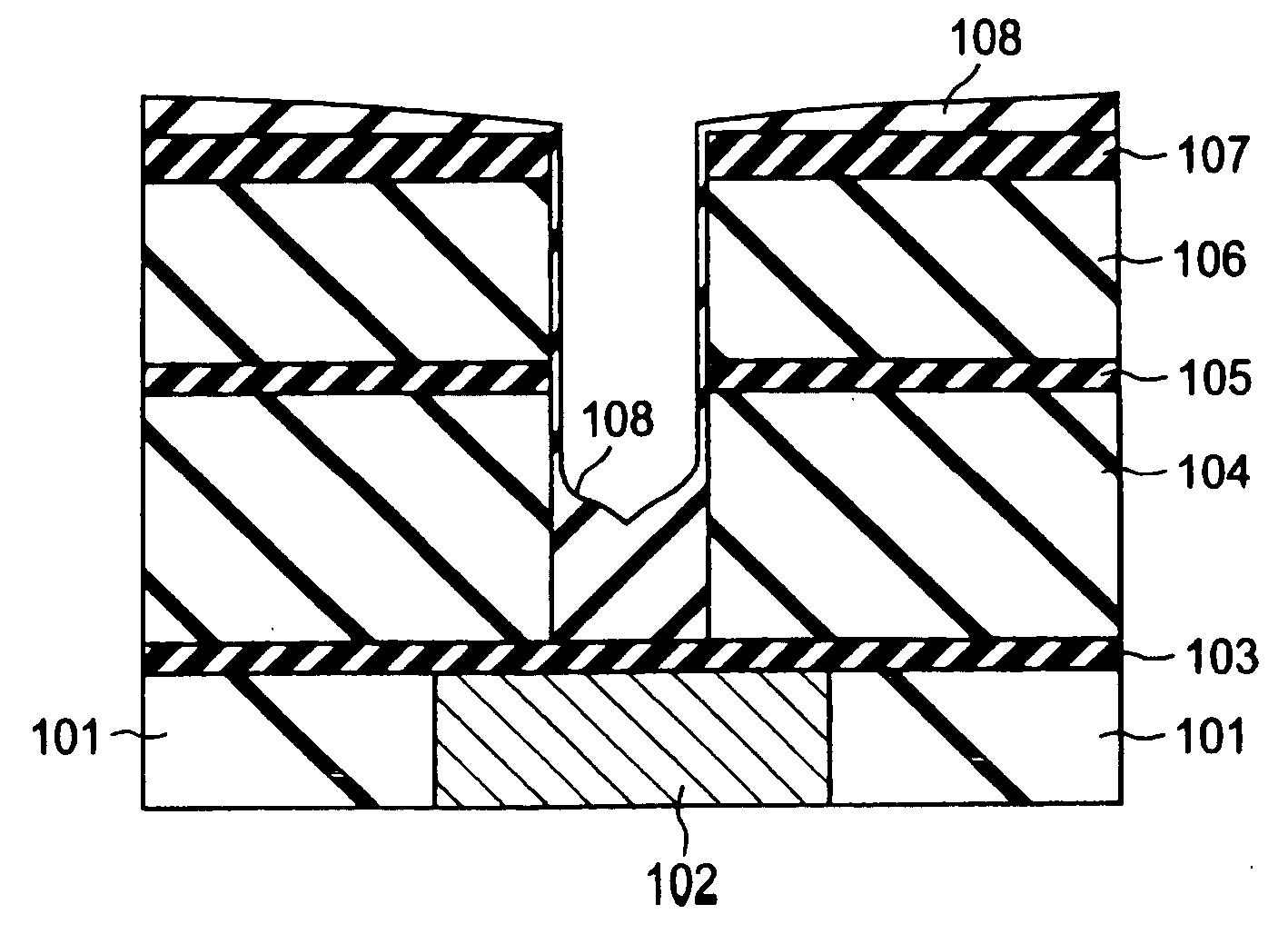

A method of producing a semiconductor device wherein an already formed opening portion inner wall of an organic based interlayer insulation film is prevented from changing in quality or corroding when performing etching on other organic material. The production method includes a step of depositing organic based interlayer insulation films (4, 6), a step of forming an opening on the organic based interlayer insulation films (4, 6), and a step of silylating a wall surface portion of the organic based interlayer insulation films (4, 6) exposed in the opening portion for reforming (forming reformed layers (4a, 6a) by silylation). A more preferable production method further includes a step of forming protective layers (4b, 6b) including an inorganic based insulation material on a surface of the silylated opening portion wall surface.

Owner:SONY CORP

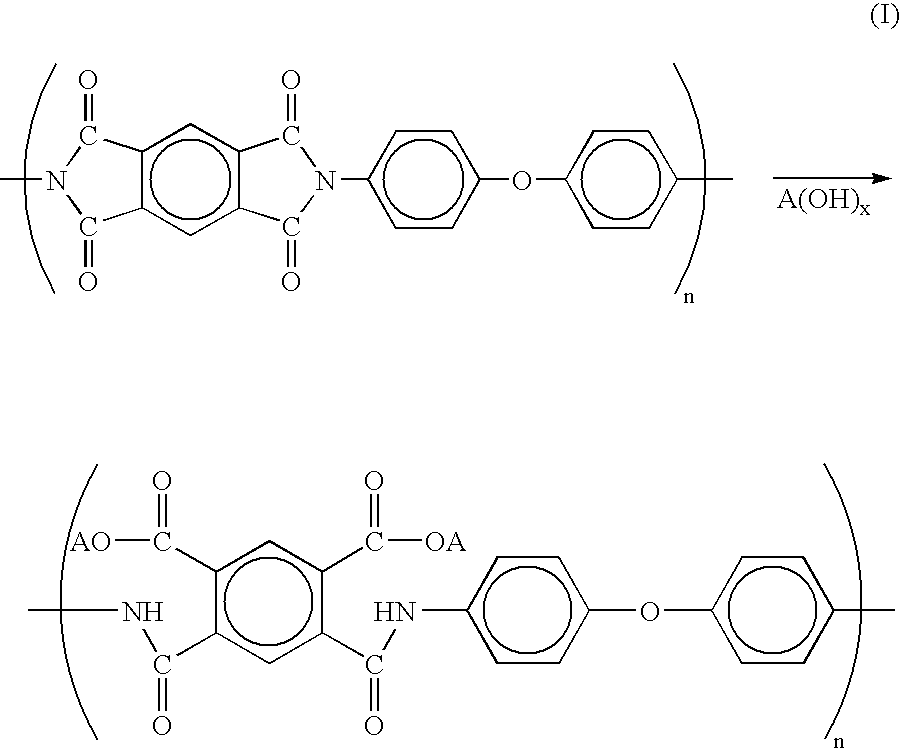

Method for forming inorganic thin film pattern on polyimide resin

InactiveUS20060165877A1Improve reliabilityHigh pattern accuracyPrinted circuit aspectsPretreated surfacesImideAqueous solution

The present invention provides 1. A method for forming an inorganic thin film pattern on a polyimide resin, which has: (1) a step of forming an alkali-resistant protective film having a thickness of 0.01 to 10 μm on a surface of a polyimide resin; (2) a step of removing the alkali-resistant protective film and a superficial portion of the polyimide resin at the site where an inorganic thin film pattern is formed to form a concave part; (3) a step of contacting an alkaline aqueous solution to the polyimide resin in the concave part to cleave an imide ring of the polyimide resin so as to produce a carboxyl group whereby a polyimide resin having the carboxyl group is formed; (4) a step of contacting a solution containing a metal ion to the polyimide resin having the carboxyl group so as to produce a metal salt of the carboxyl group; and (5) a step of separating the metal salt as a metal, a metal oxide or a semiconductor on the surface of the polyimide resin so as to form the inorganic thin film pattern.

Owner:MITSUBOSHI BELTING LTD +1

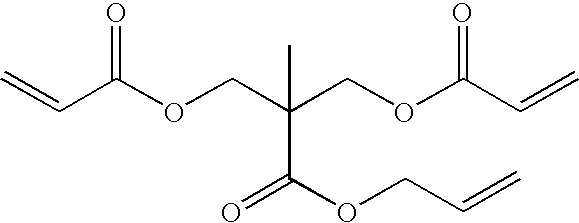

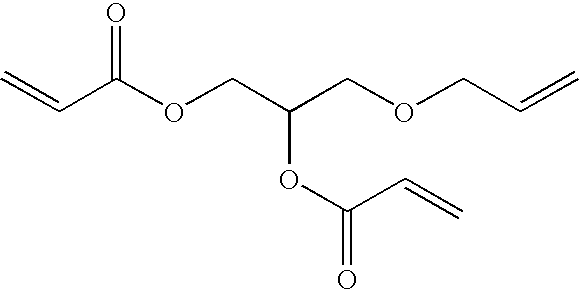

Curable composition for photoimprint, and method for producing cured product using same

InactiveUS20100133728A1High pattern accuracyImprove accuracyNanoinformaticsPhotomechanical apparatusViscosityMonomer

A curable composition for photoimprints containing a photopolymerizable monomer and a photopolymerization initiator, wherein the proportion of the compound having a molecular weight of at most 190 in the composition is at most 20% by mass, and the viscosity of the composition is from 3 to 50 mPa·s at 25° C., is excellent in patterning accuracy.

Owner:FUJIFILM CORP

Mold for imprinting and production method thereof

InactiveUS20120328728A1Exquisite patternHigh pattern accuracyNanoinformaticsConfectioneryComposite material

Owner:HOYA CORP

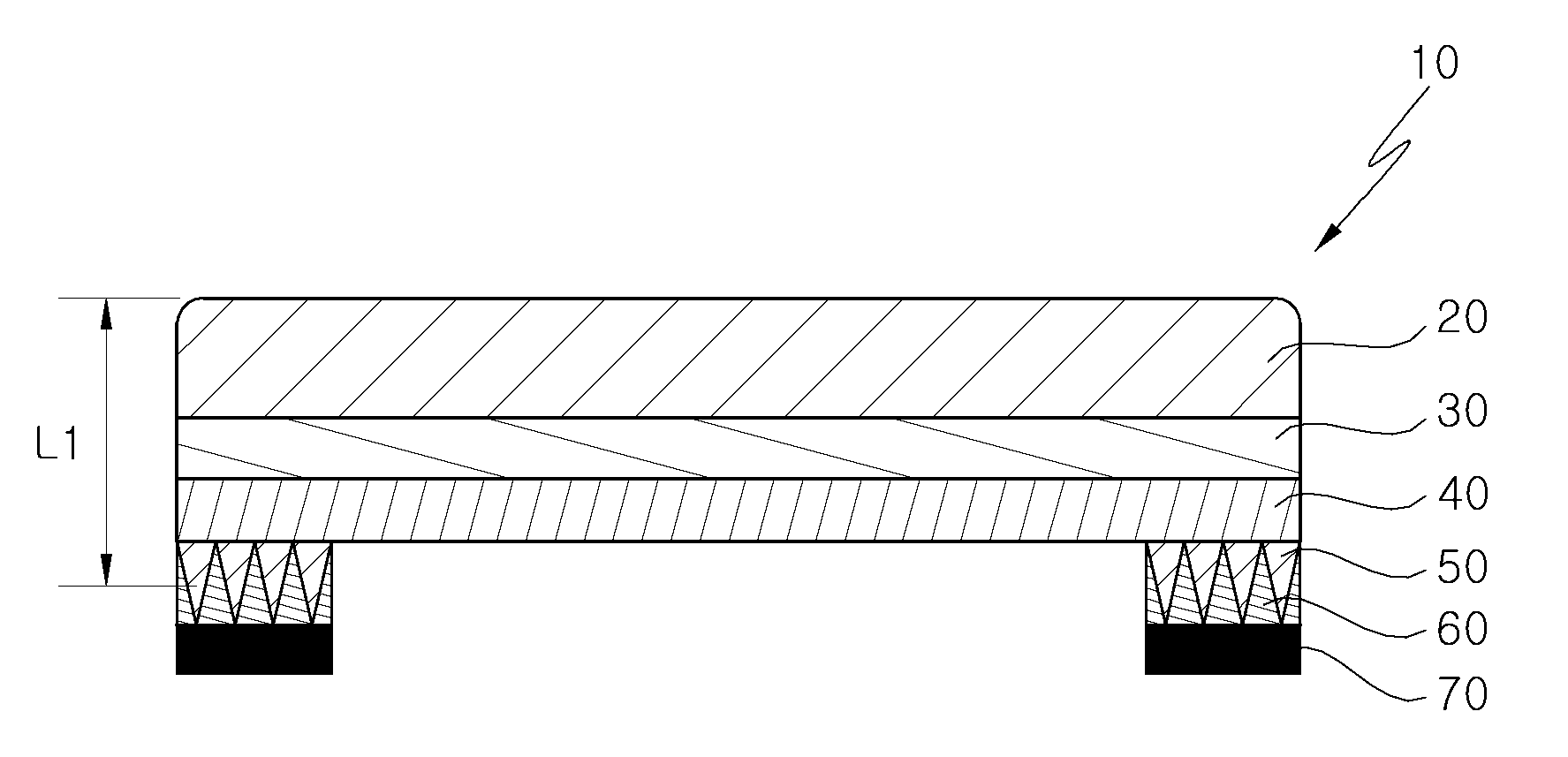

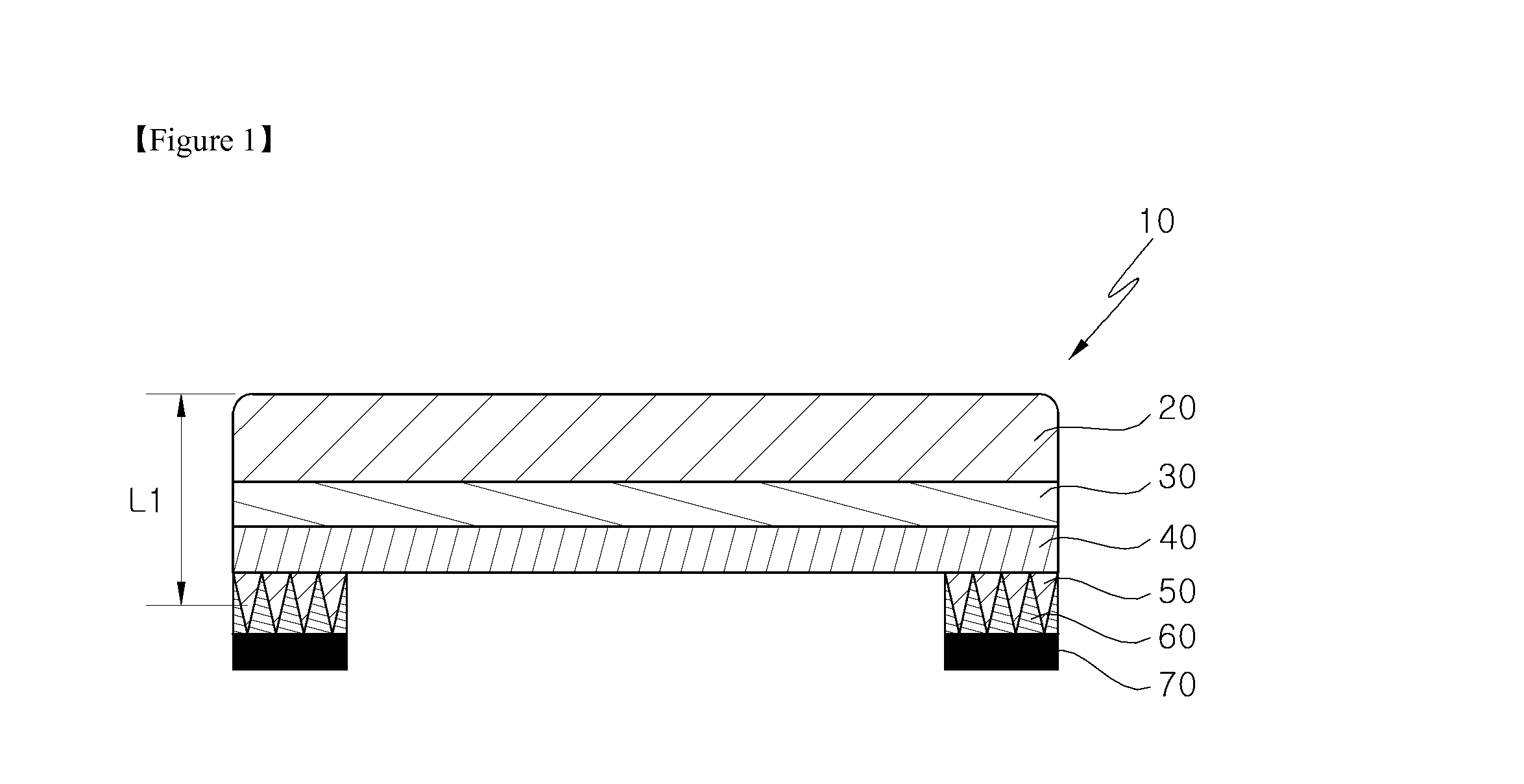

Cover glass and method for manufacturing same

InactiveUS20160016845A1Reduce thicknessImprove transmittanceLayered productsDigital data processing detailsMetallurgyCover glass

An embodiment of the present invention provides a cover glass which is slim and gives a better aesthetic feeling, and a method for manufacturing the same. The cover glass according to an embodiment of the present invention comprises: a glass substrate; a pattern portion formed on the glass substrate by etching; and a multi-layered thin film coated on the surface of the pattern portion.

Owner:CRUCIALTEC

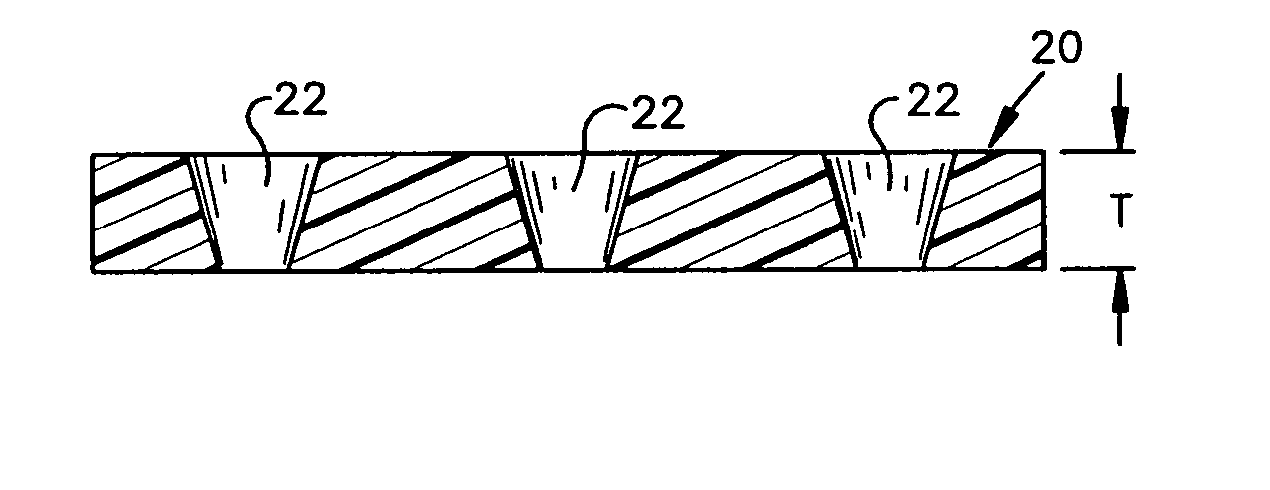

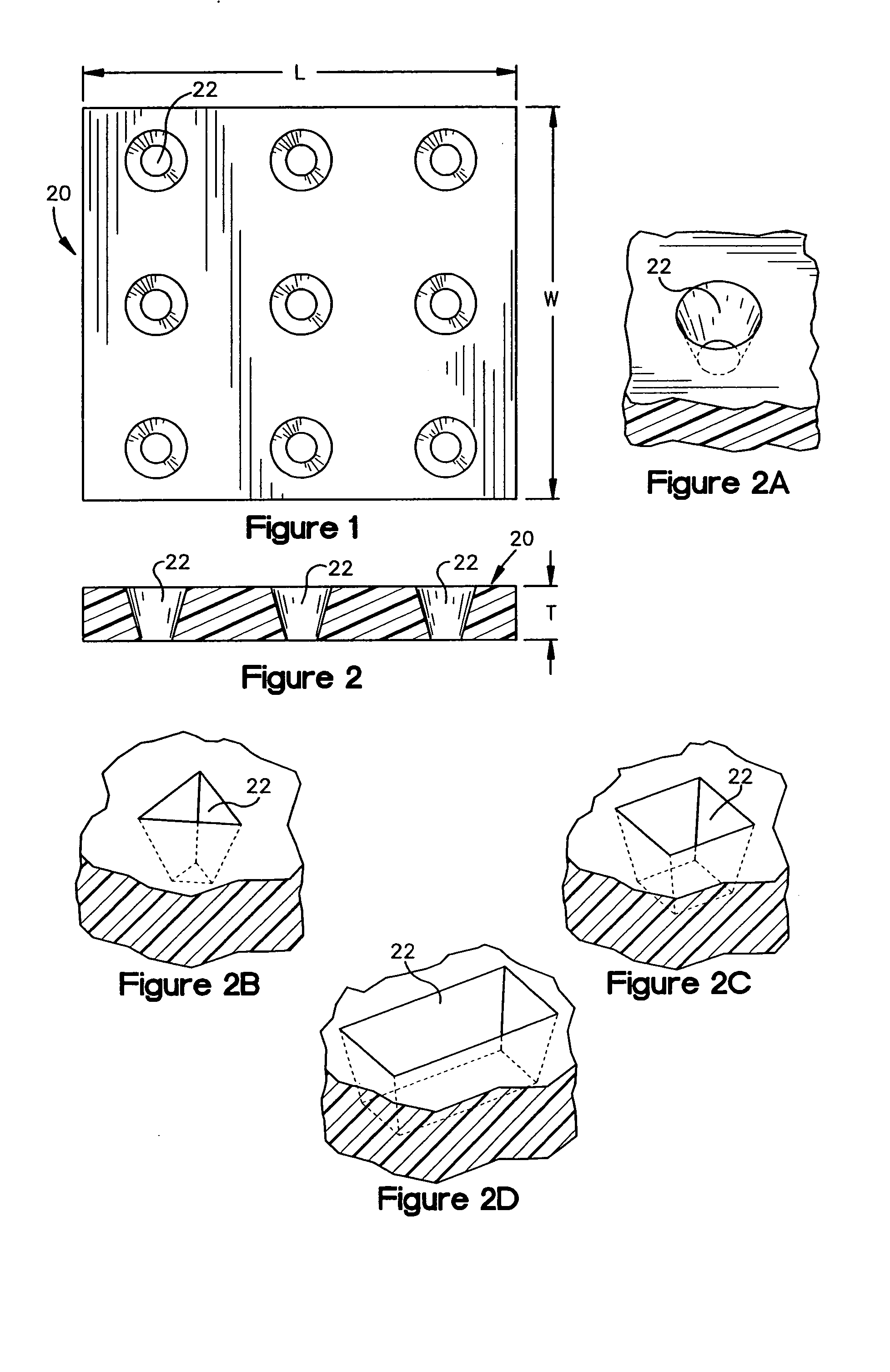

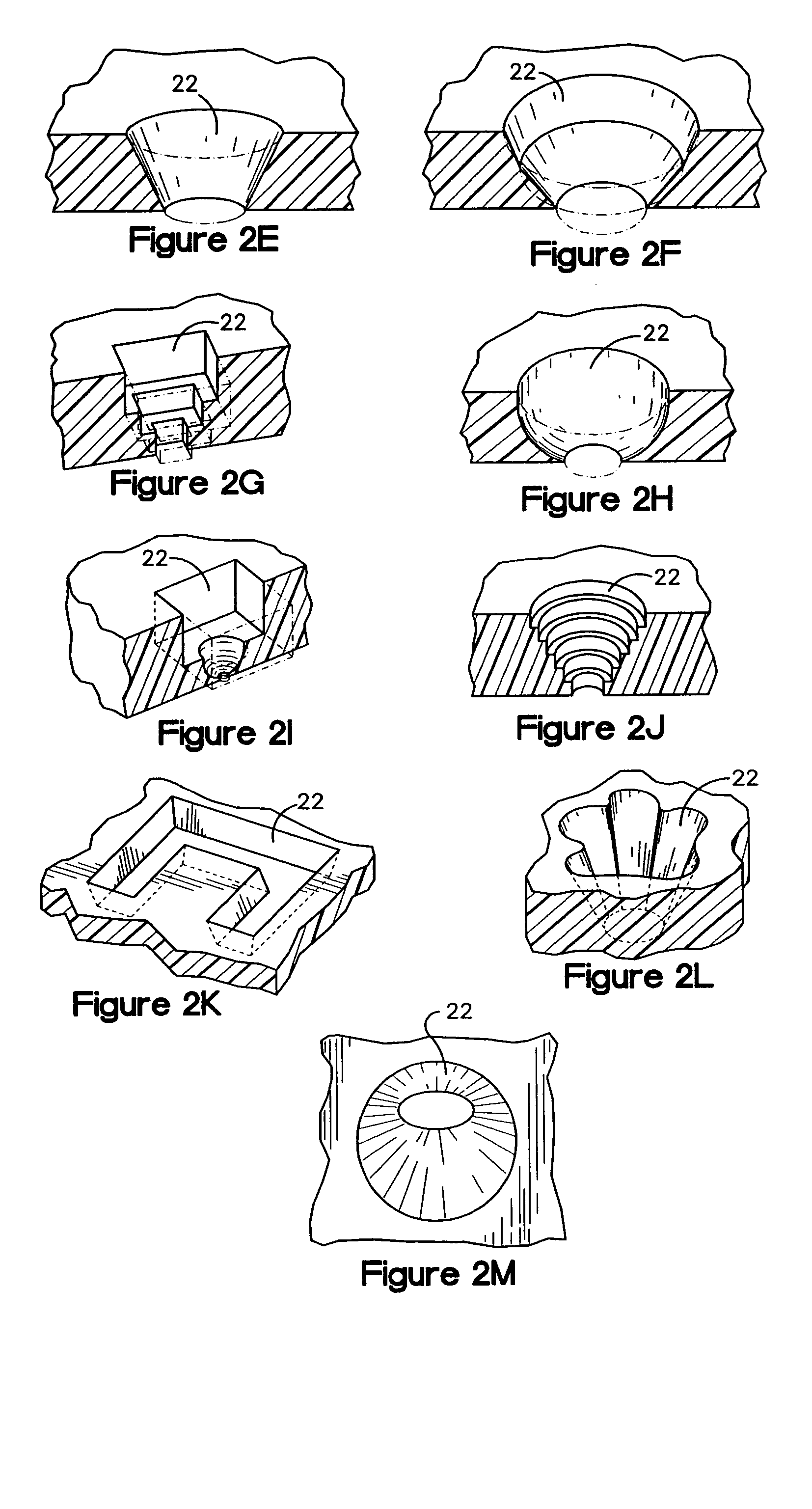

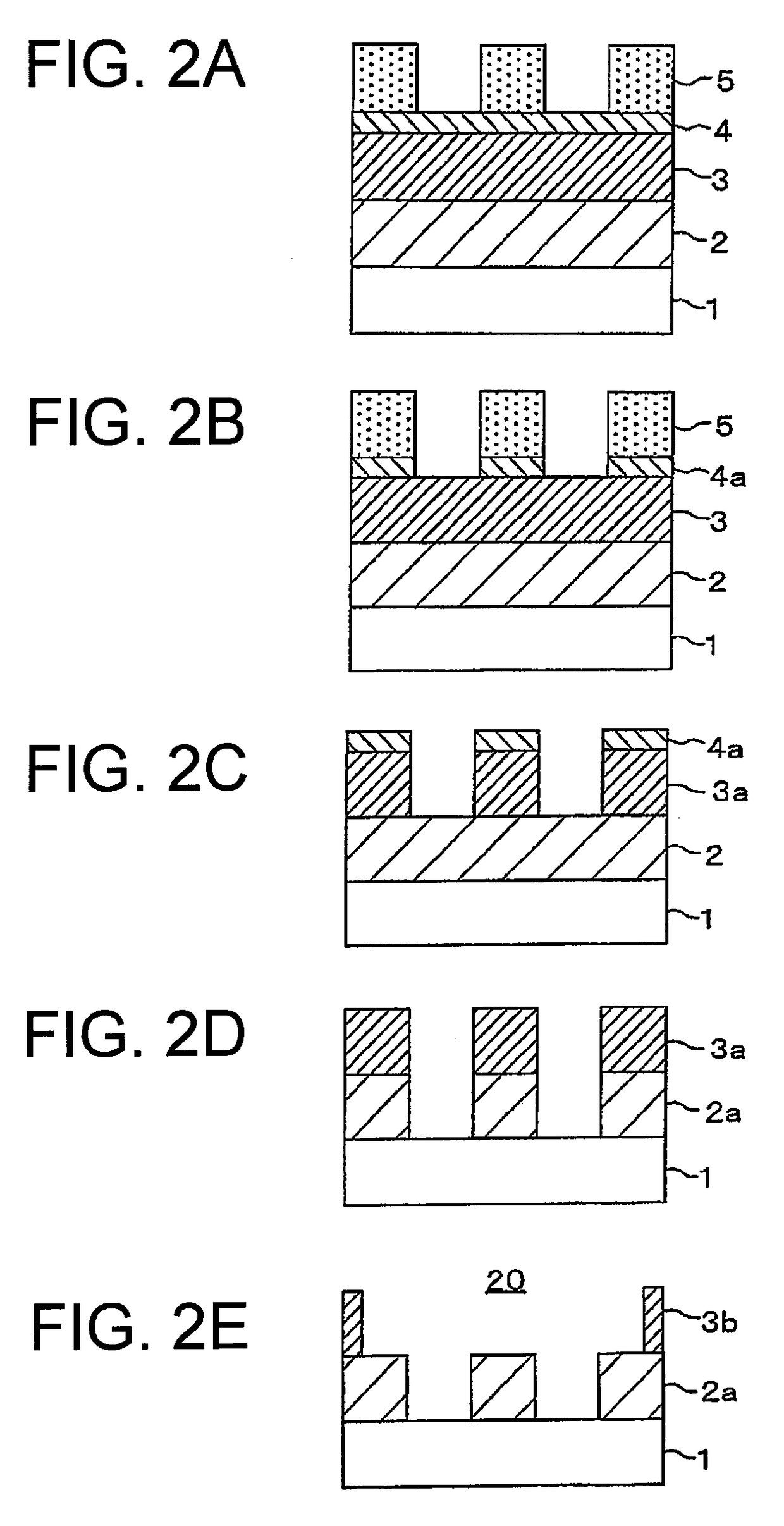

Sheet having microsized architecture

InactiveUS20050118393A1Closer size-exactnessHigh pattern accuracyLayered productsThin material handlingEngineeringThrough transmission

A sheet (20) for use in microfluidic, microelectronic, micromechanical, and / or microoptical applications requiring through-flow, through-conductivity, through-transmission, and / or other through patterns. The sheet (20) includes micro-sized architecture including at least one via (22) extending through the thickness of the layer of thermoplastic material. The via-defining walls in the thermoplastic layer are formed by the thermoplastic material flowing around a projection and then solidifying around the projection.

Owner:CORCORAN CRAIG S +5

Method for reducing line edge roughness of photoresist

InactiveUS20030027080A1Reduced line edge roughnessReduce roughnessRadiation applicationsSemiconductor/solid-state device manufacturingPhotoresistMaterials science

A method for reducing line edge roughness of photoresist, at least include: provide a photoresist which at least has a trench and is located on substrate; fill trenches so let that trenches are totally filled by an additional material; remove part of additional material which is located on photoresist and substrate; and treat additional material so let that adhesion between additional material and photoresist is enhanced after additional material is treated. Moreover, while only trenches are filled by additional material, step of removing part of additional material could be omitted; while adhesion between additional material and photoresist is good, step of treating additional material could be omitted.

Owner:MACRONIX INT CO LTD

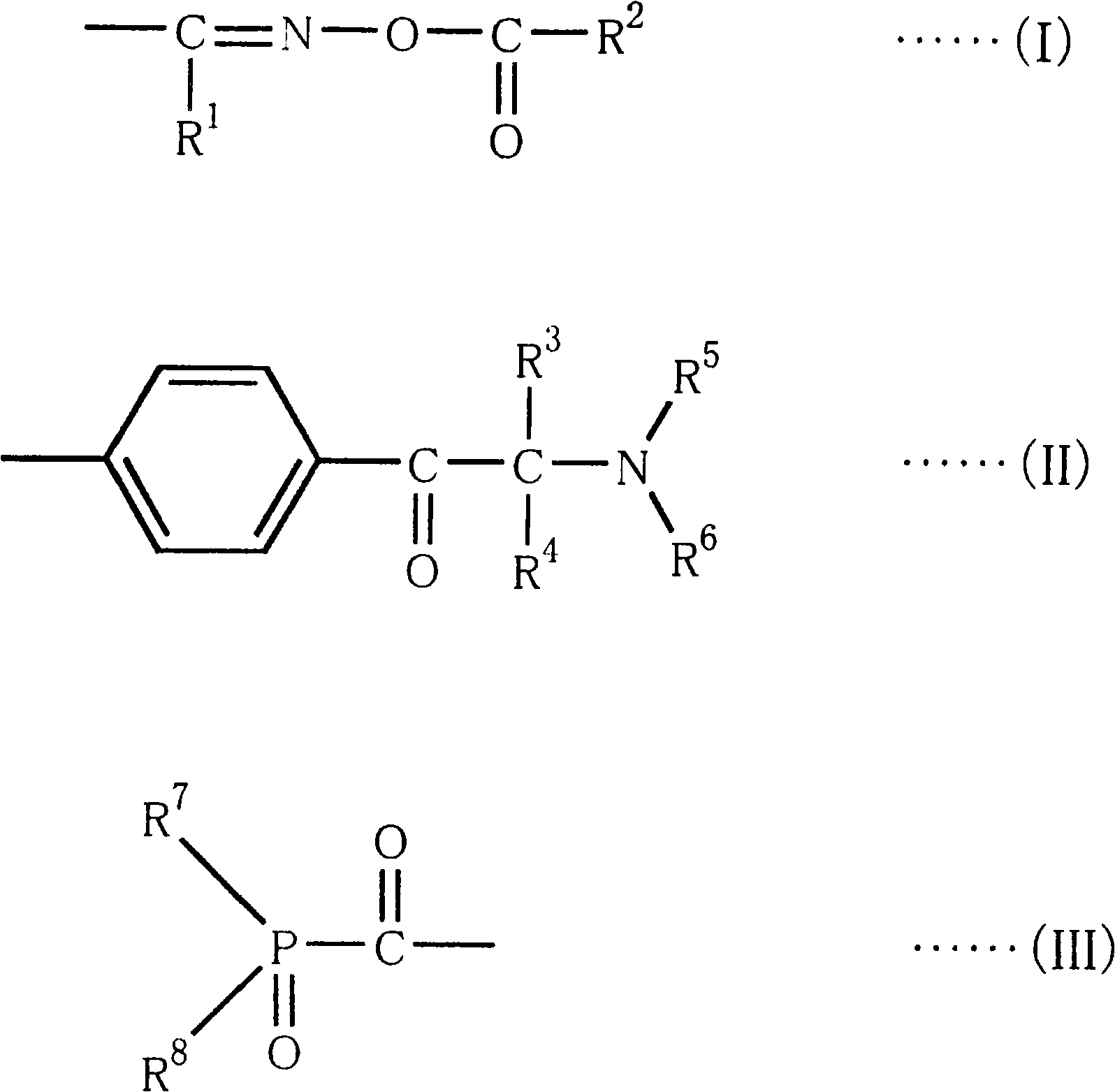

Photo-cured heat-cured resin composition and printed circuit board produced with the same

ActiveCN101320212AExcellent developabilityAvoid inactivationPhotomechanical apparatusPrinted circuit manufactureM-aminoacetophenoneUltraviolet

A light-curing thermo-curing resin composition and a printed circuit board obtained using the same are provided, the composition has high light sensitivity and excellent curing depth in ultraviolet ray and laser exposure, thus further having great developing ability to pass through diluted alkaline aqueous solution while being excellent in storage stability and operability, so the composition is suitable for solder resisting agent. The light-curing thermo-curing resin composition comprises (A) carboxyl-containing resin, (B) mercaptobutyric acid or derivatives thereof, (C) photopolymerization initiator, (D) compounds having 2 or more of olefinic unsaturated groups in the molecules, and (E) thermo-curing components. The suitable (A) carboxyl-containing resin is preferably the carboxyl-containing resin capable of free radical polymerization and having unsaturated double bond. In addition, the (C) photopolymerization initiator is preferably oximes photopolymerization initiator (C1), particularly preferably proxetil photopolymerization initiator, aminoacetophenone photopolymerization initiator and / or acyl phosphine oxide photopolymerization initiator.

Owner:TAIYO HLDG CO LTD

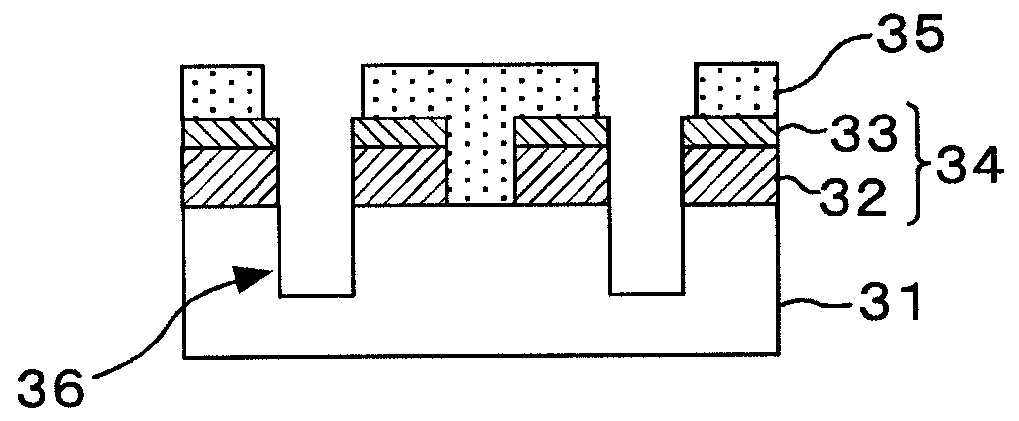

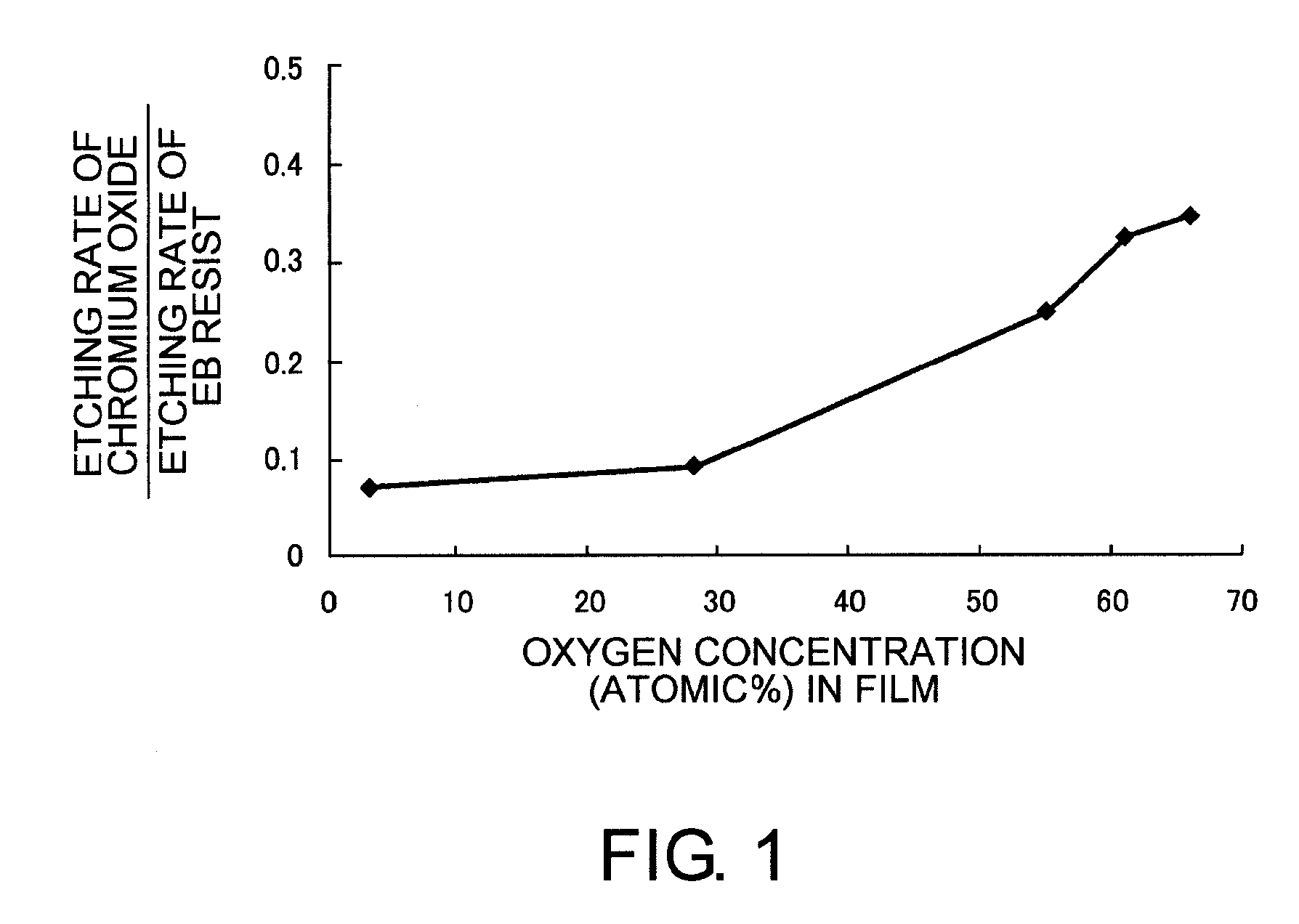

Mask blank, method of manufacturing an exposure mask, and method of manufacturing an imprint template

ActiveUS20080206655A1Reduce resolutionNon-uniform removalNanoinformaticsPhotomechanical apparatusResistOxygen

A mask blank includes a substrate and a thin film formed thereon and used to form a pattern. The mask blank is adapted to be subjected to dry etching corresponding to a method of producing an exposure mask by patterning the thin film by dry etching using an etching gas substantially free from oxygen with a resist pattern formed on the thin film used as a mask. The thin film has a protective layer formed at least at its upper layer and containing 60 atomic % or more oxygen. For example, the dry etching is performed by the use of a chlorine-based gas substantially free from oxygen.

Owner:HOYA CORP

Exposure apparatus and method for producing device

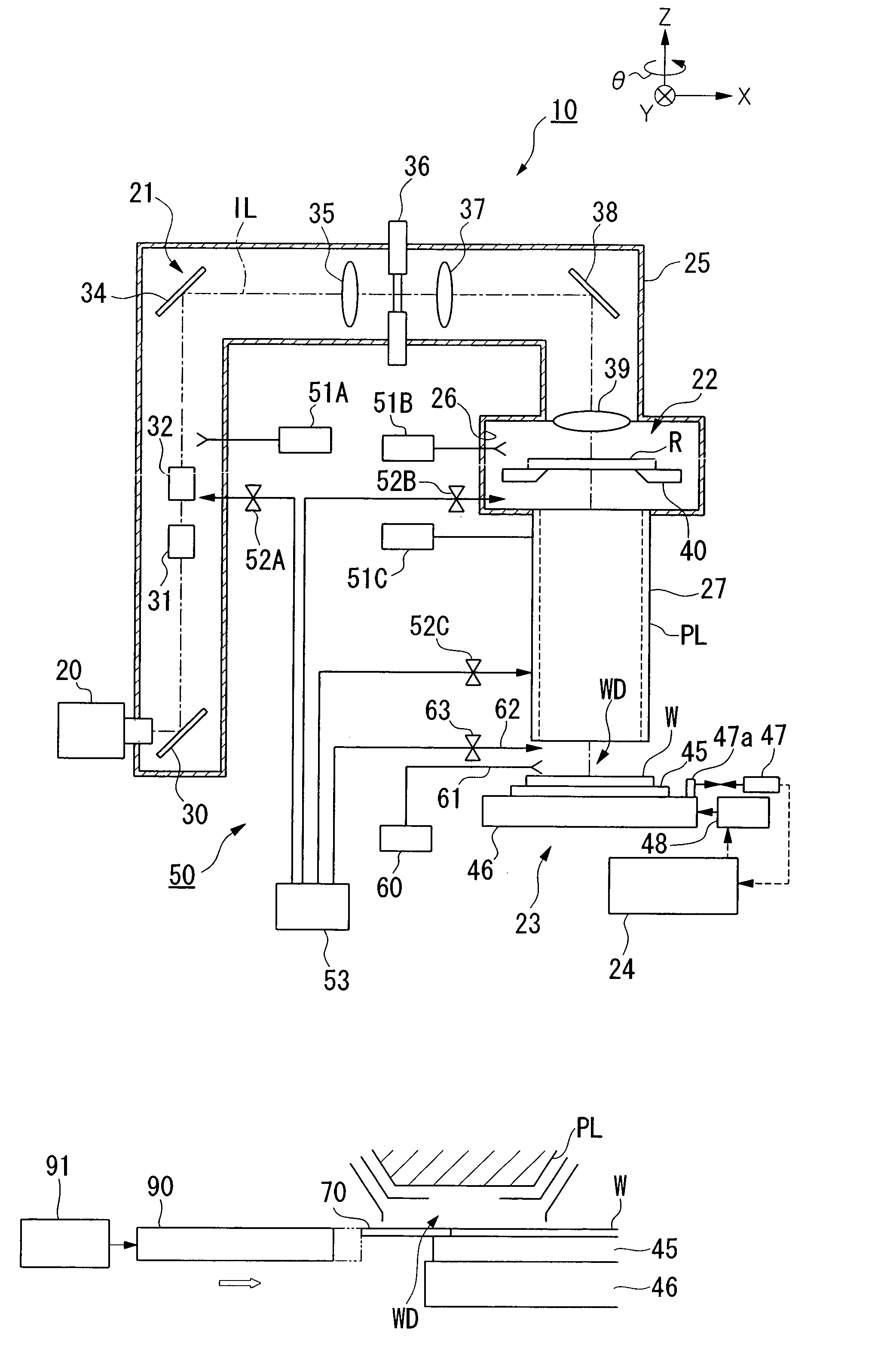

InactiveUS20070024832A1Inhibit deteriorationSuppress generationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineering

An exposure apparatus, wherein exposure is carried out while filling a space between a projection optical system and a substrate with a liquid, enables to suppress deterioration of a pattern image caused by any bubble in the liquid. The exposure apparatus includes a liquid supply unit 1 which fills at least a part of the space between the projection optical system and the substrate with a liquid 50, and exposes the substrate by projecting an image of a pattern onto the substrate via the projection optical system. The liquid supply unit 1 includes a degassing unit 21 which suppresses the generation of the bubble in the liquid 50.

Owner:NIKON CORP

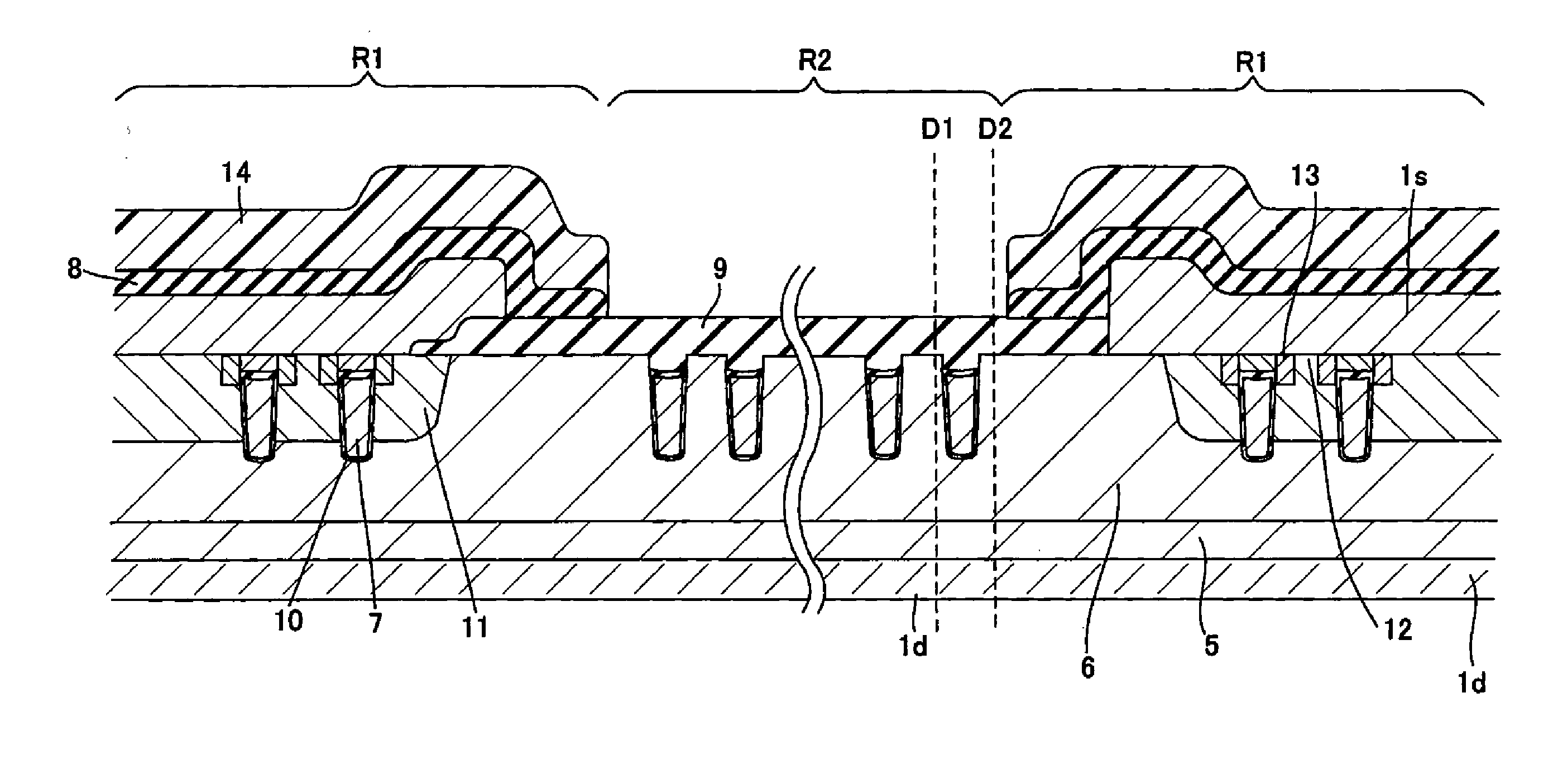

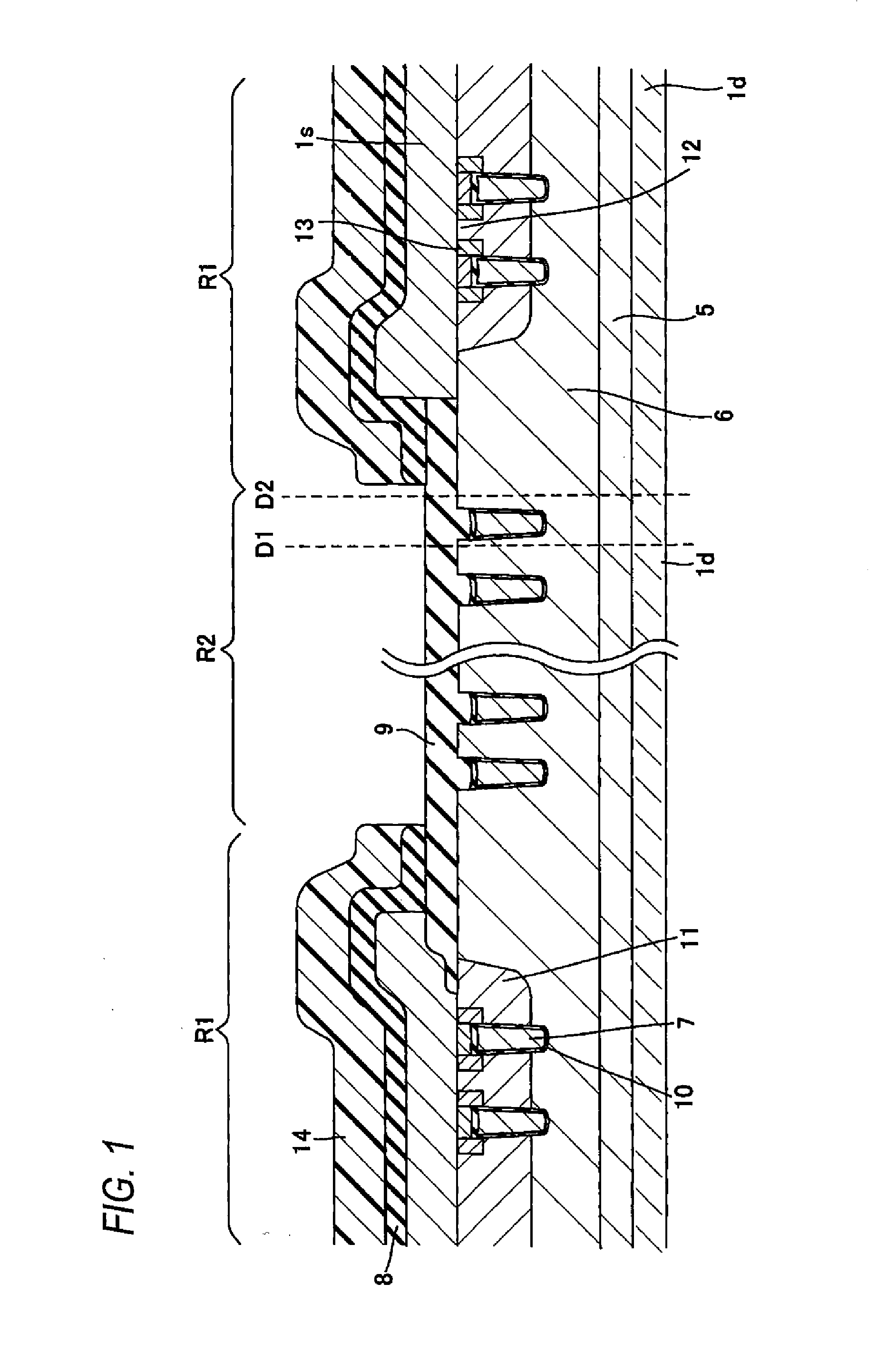

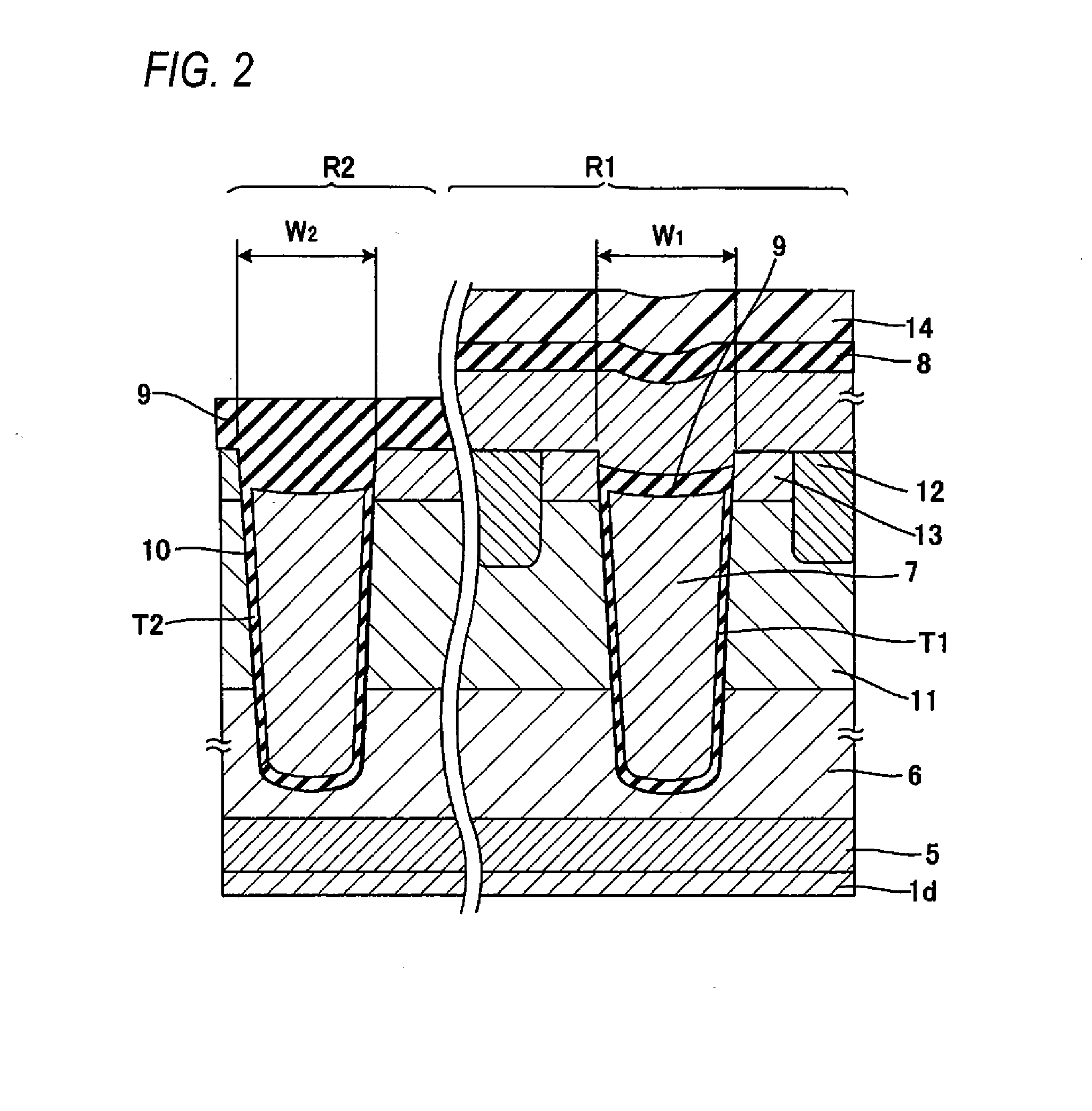

Semiconductor device and manufacturing method thereof

InactiveUS20120007178A1Improve reliabilityAvoid it happening againTransistorSemiconductor/solid-state device detailsEngineeringTrench gate

A semiconductor device having trench gates in element regions R1 formed in a semiconductor substrate. Second trenches T2 having the same depth as that of first trenches T1 making up the trench gates are provided along a marginal area of the semiconductor substrate.

Owner:PANASONIC CORP

Phase-shift blankmask and photomask

ActiveUS20160054650A1Increase speedReduce sheet resistanceOriginals for photomechanical treatmentResistPhase shifted

Disclosed is a phase-shift blankmask, in which a light-shielding film includes a metal compound and having a structure of a multi-layer film or a continuous film, which includes a first light-shielding layer and a second light-shielding layer. The second light-shielding layer has higher optical density at an exposure wavelength per unit thickness (Å) than the first light-shielding layer. The first light-shielding layer occupies 70% to 90% of the whole thickness of the light-shielding film. With this, the blankmask secures a light-shielding effect, has an improved etching speed, and makes a resist film thinner, thereby achieving a fine pattern.

Owner:S & S TECH

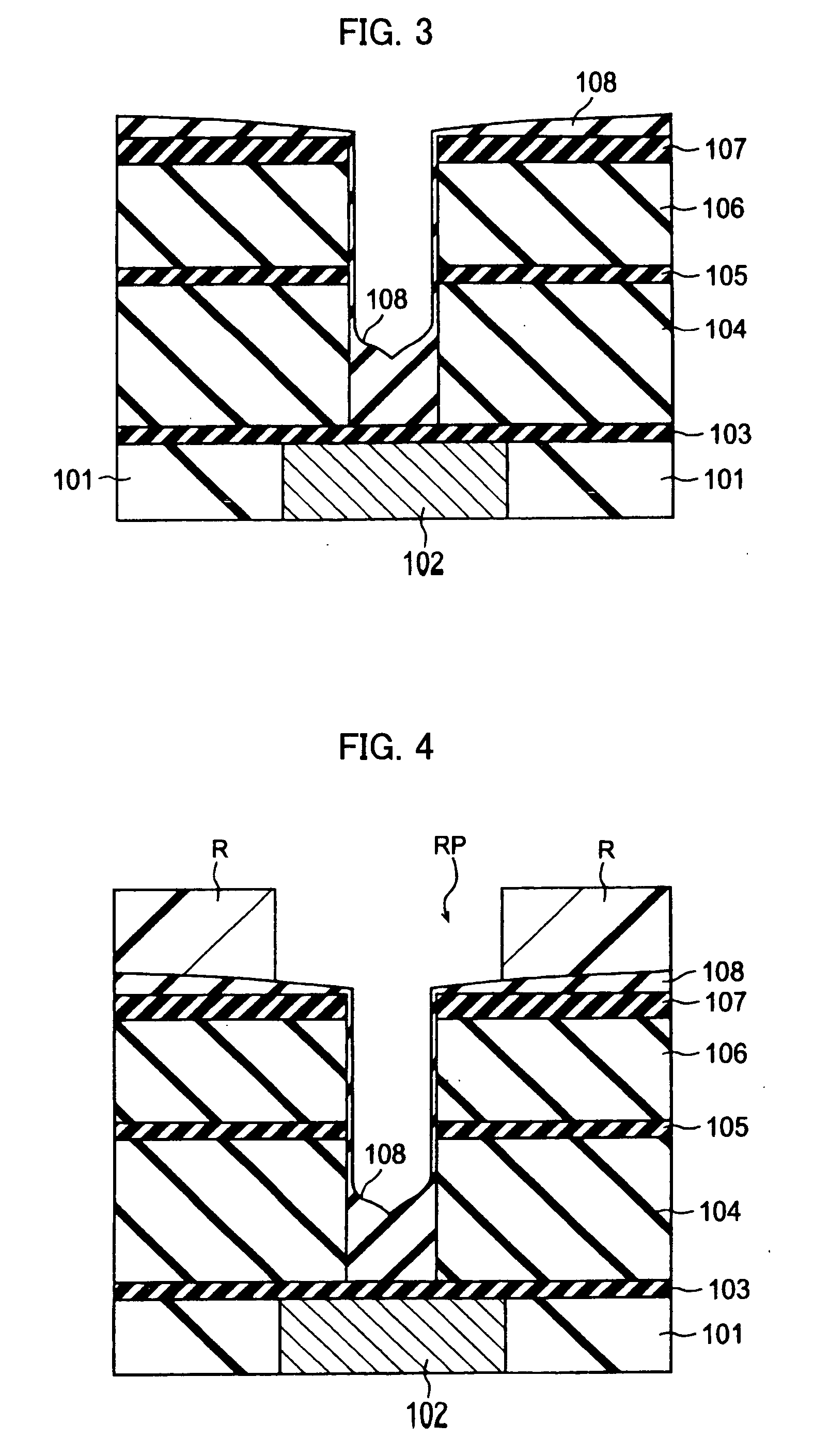

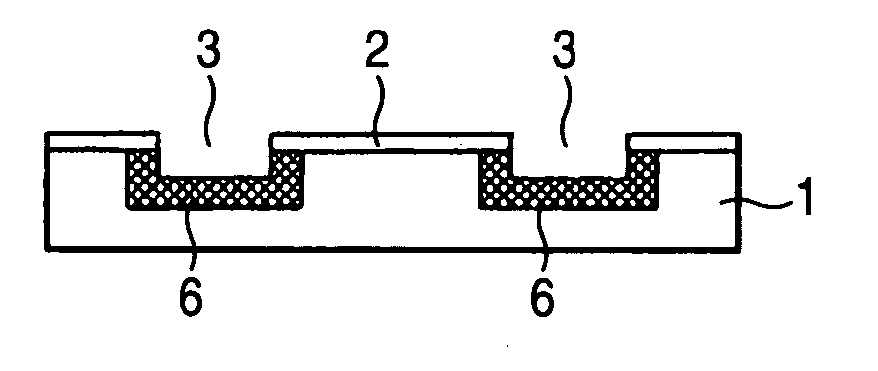

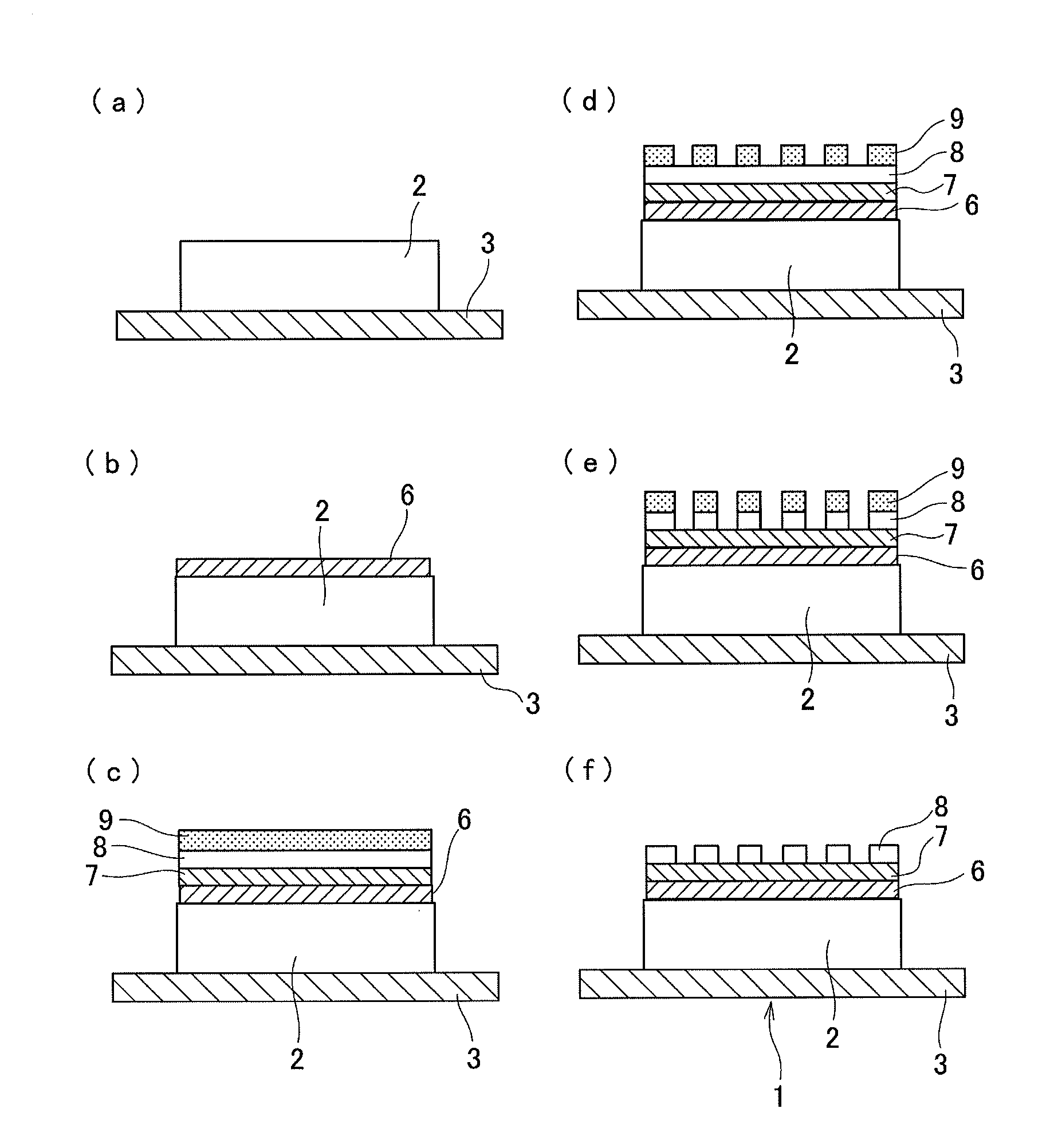

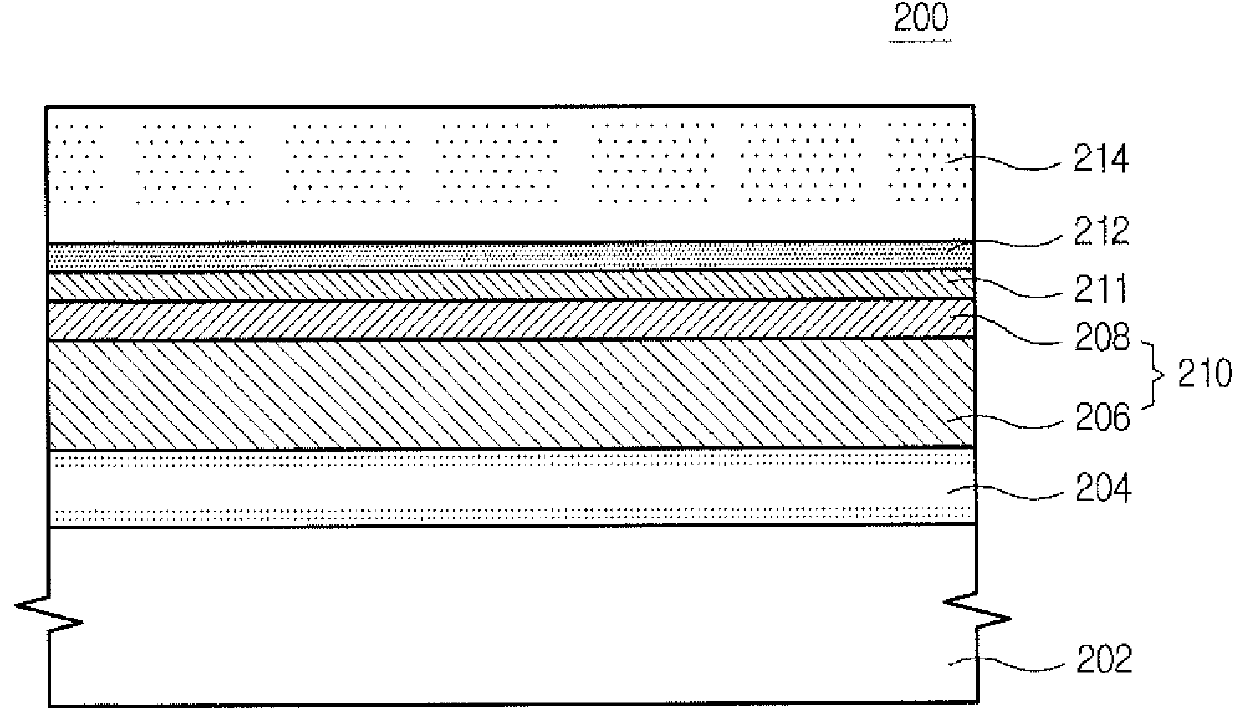

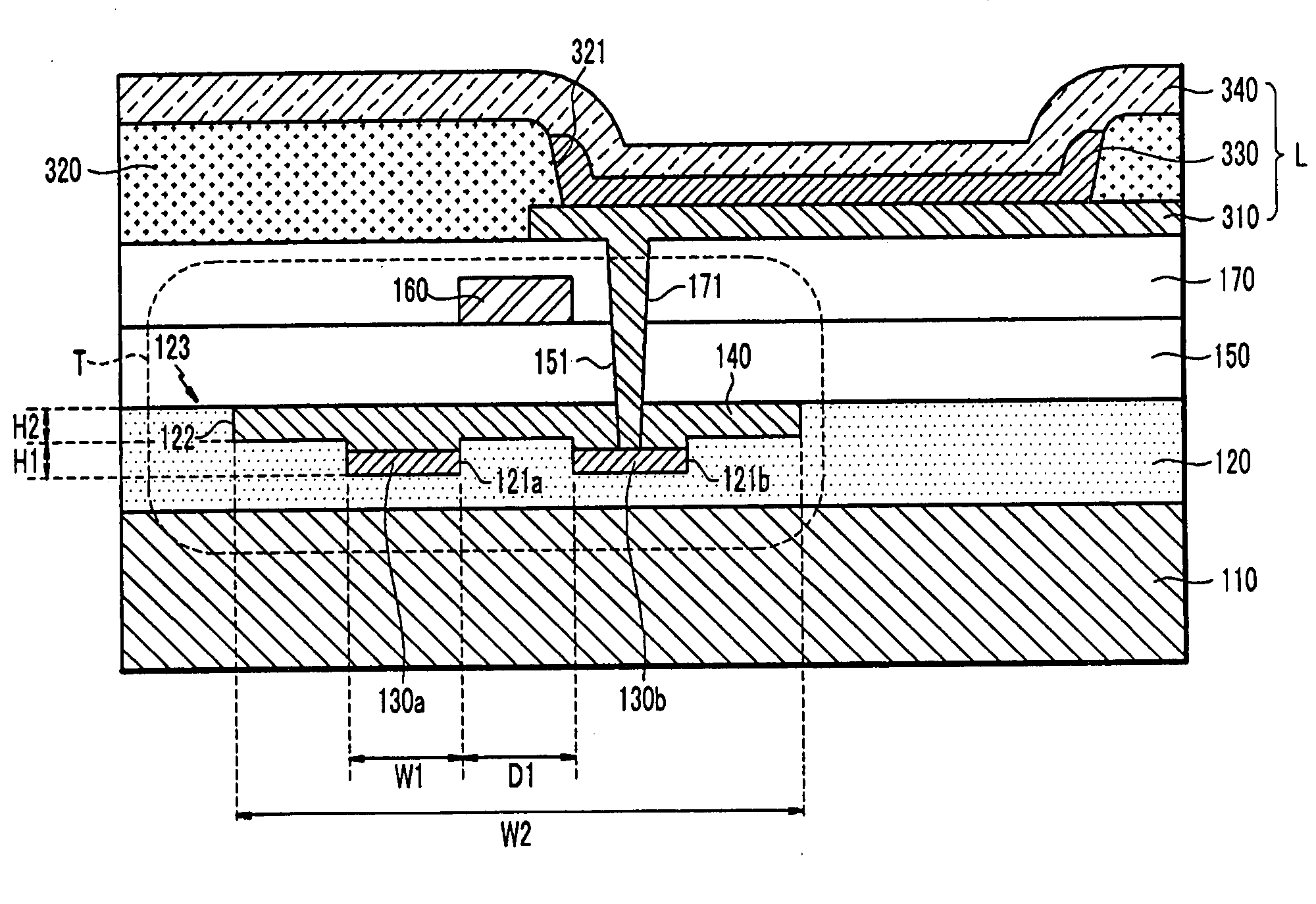

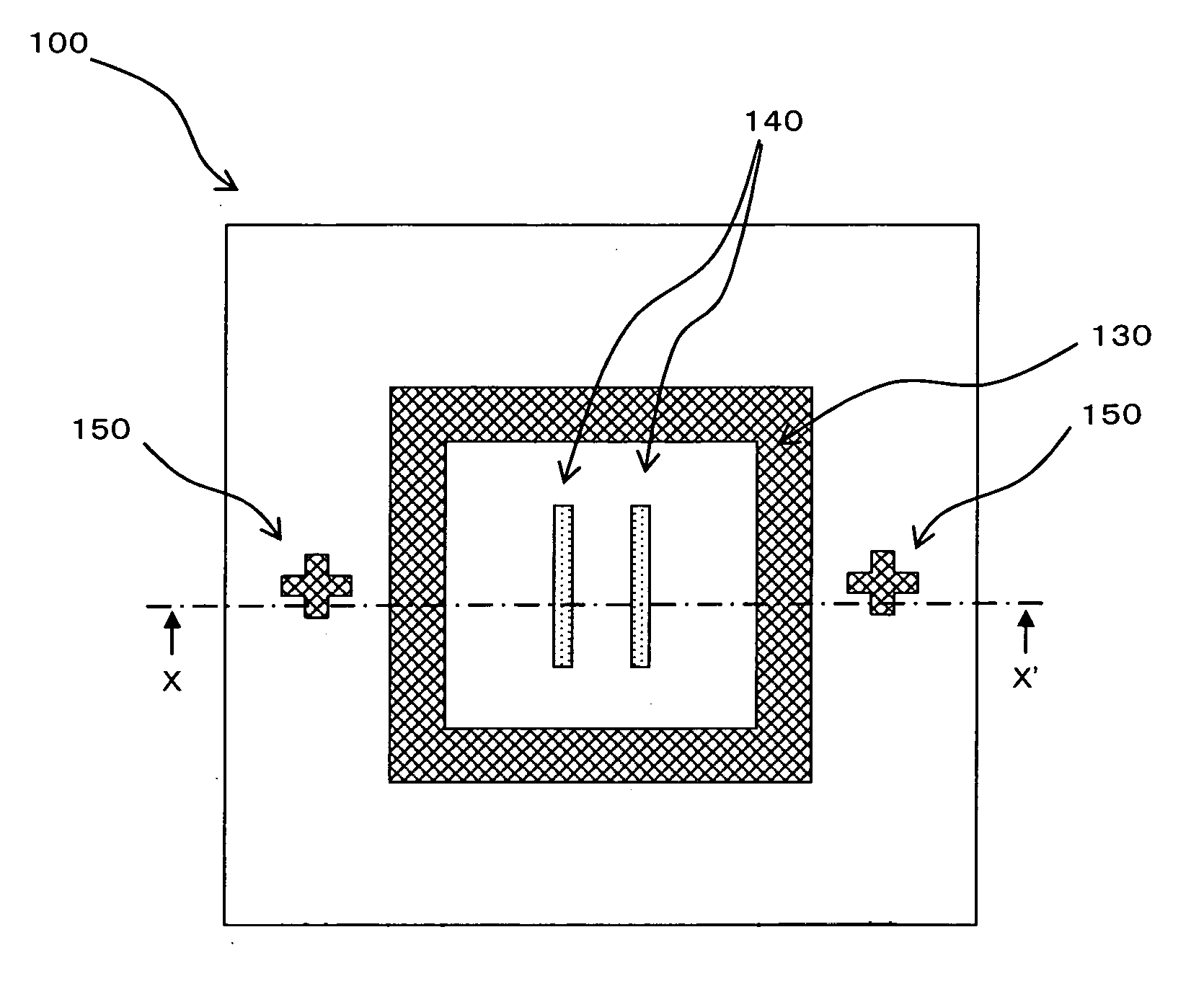

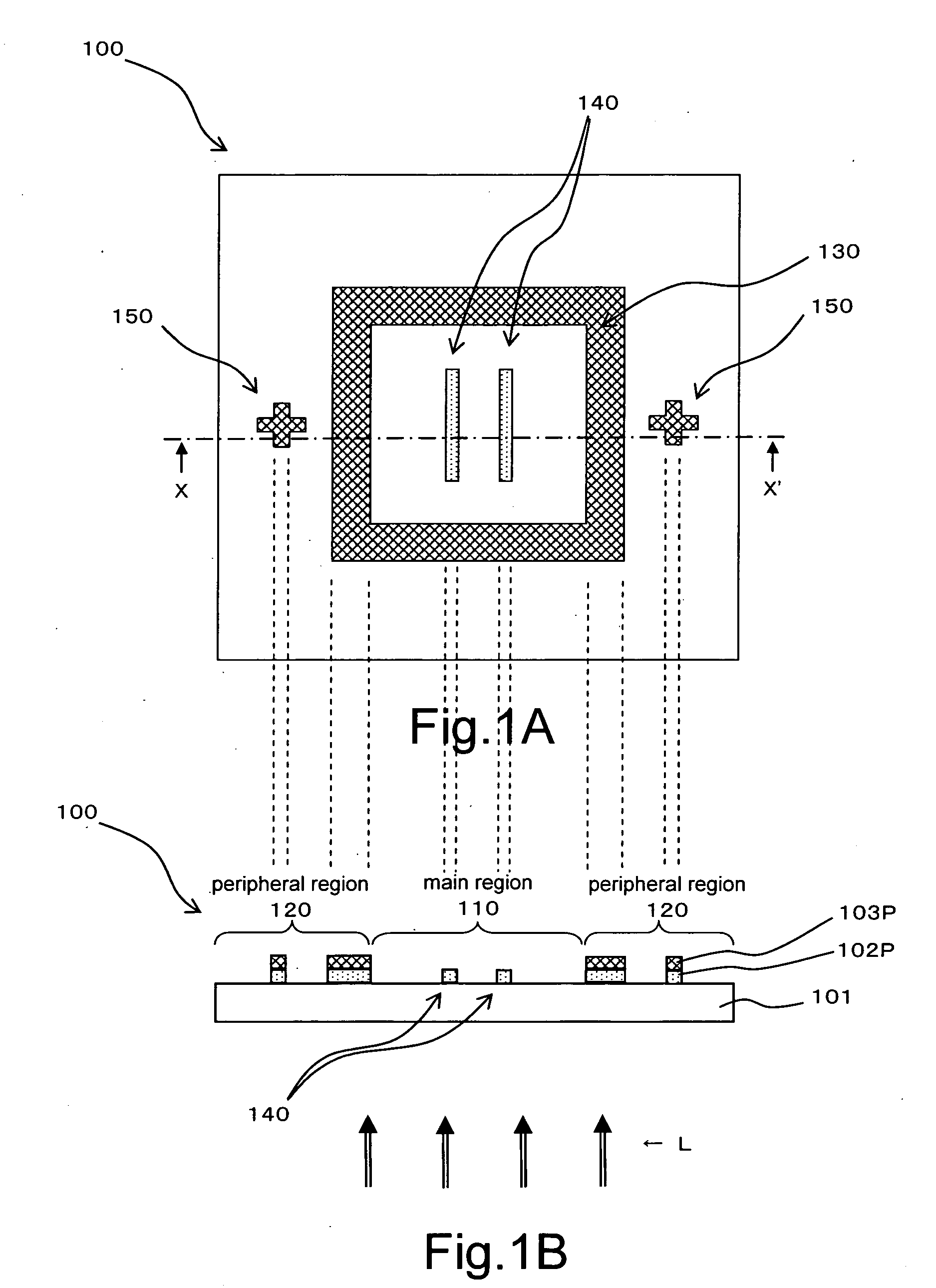

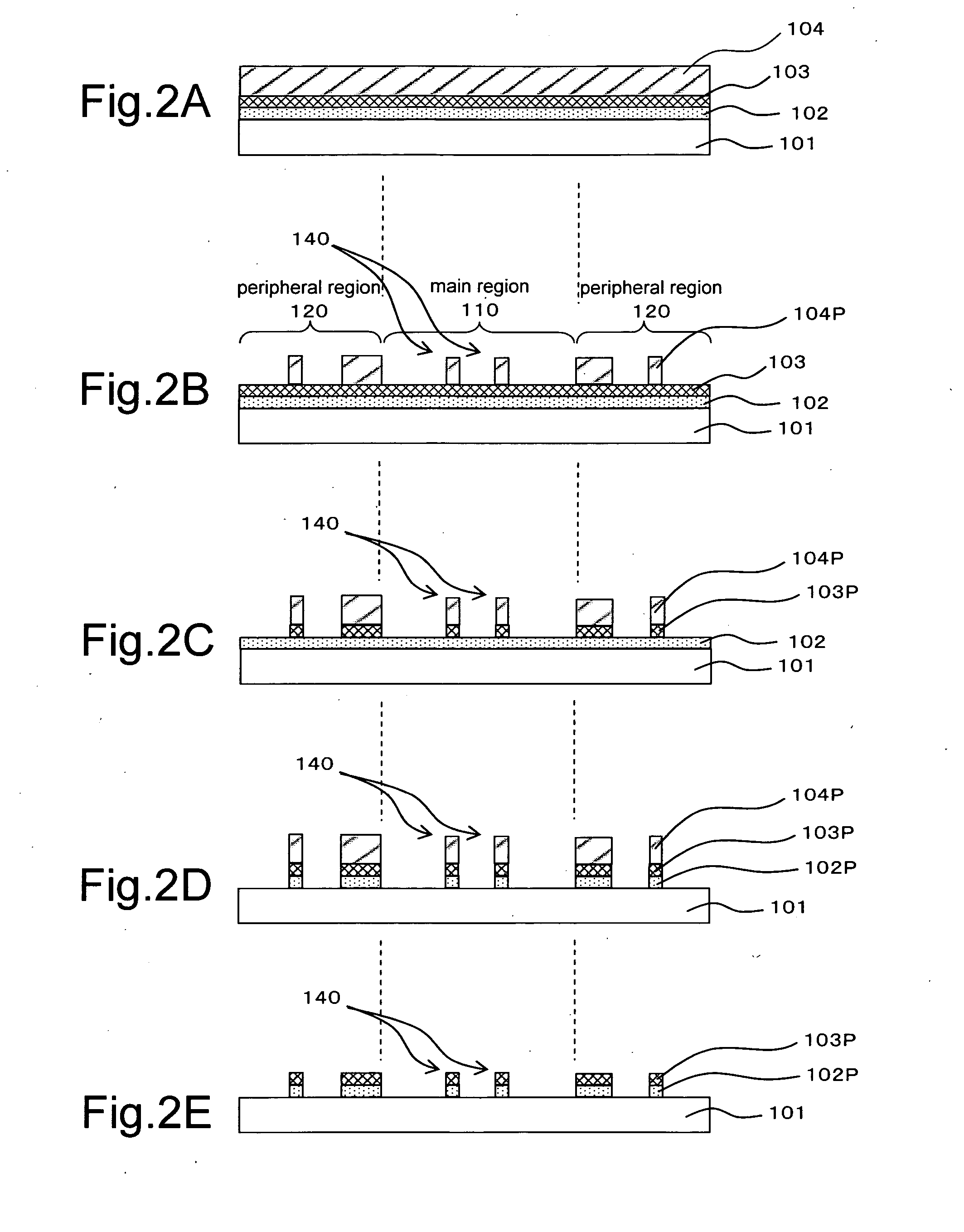

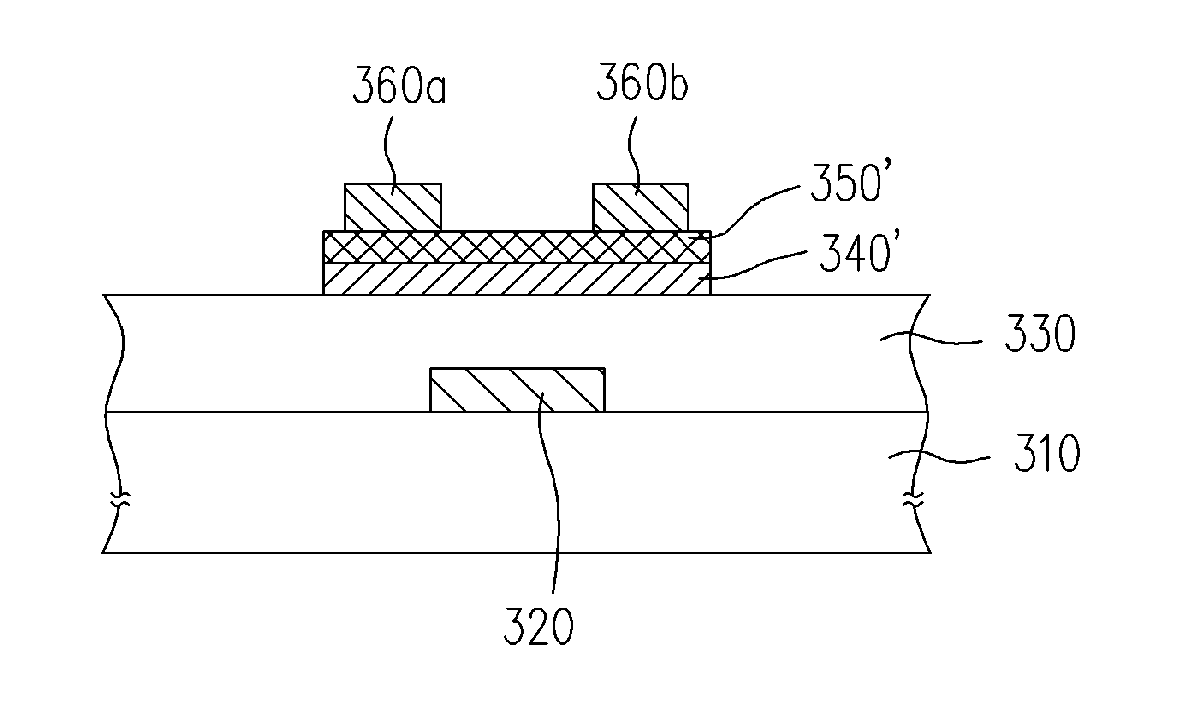

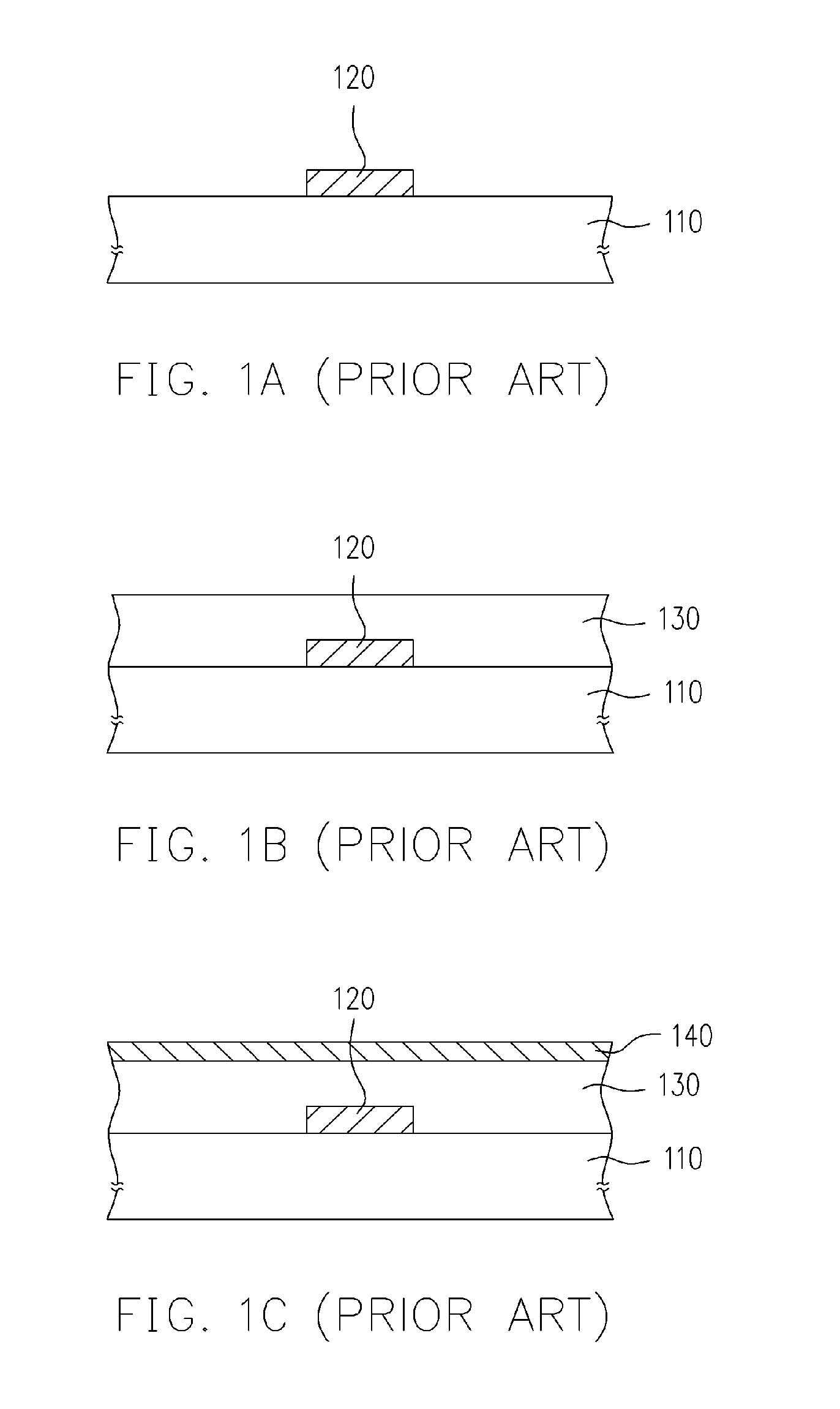

Method of manufacturing thin film transistor, thin film transistor manufactured by the method, and display device employing the same

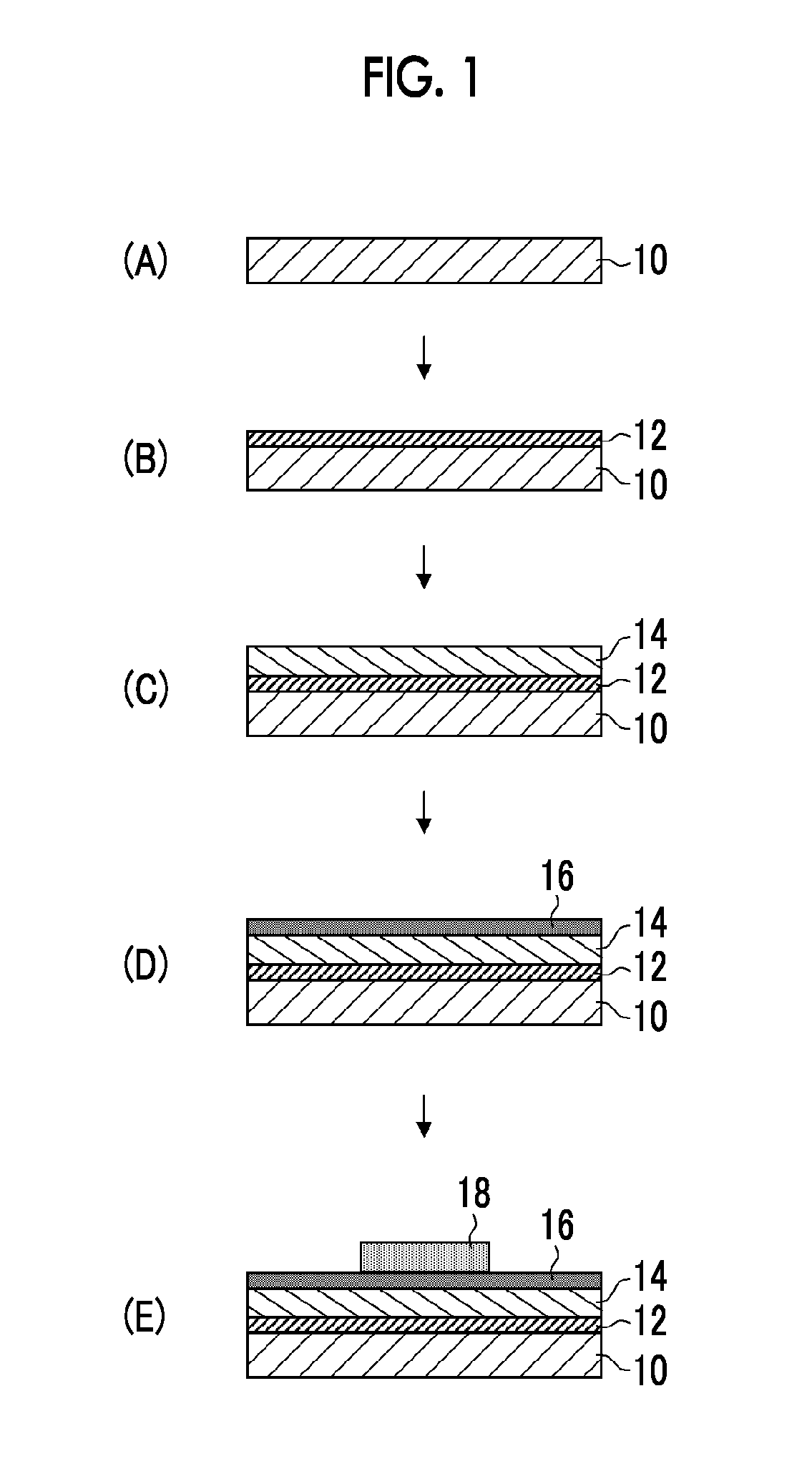

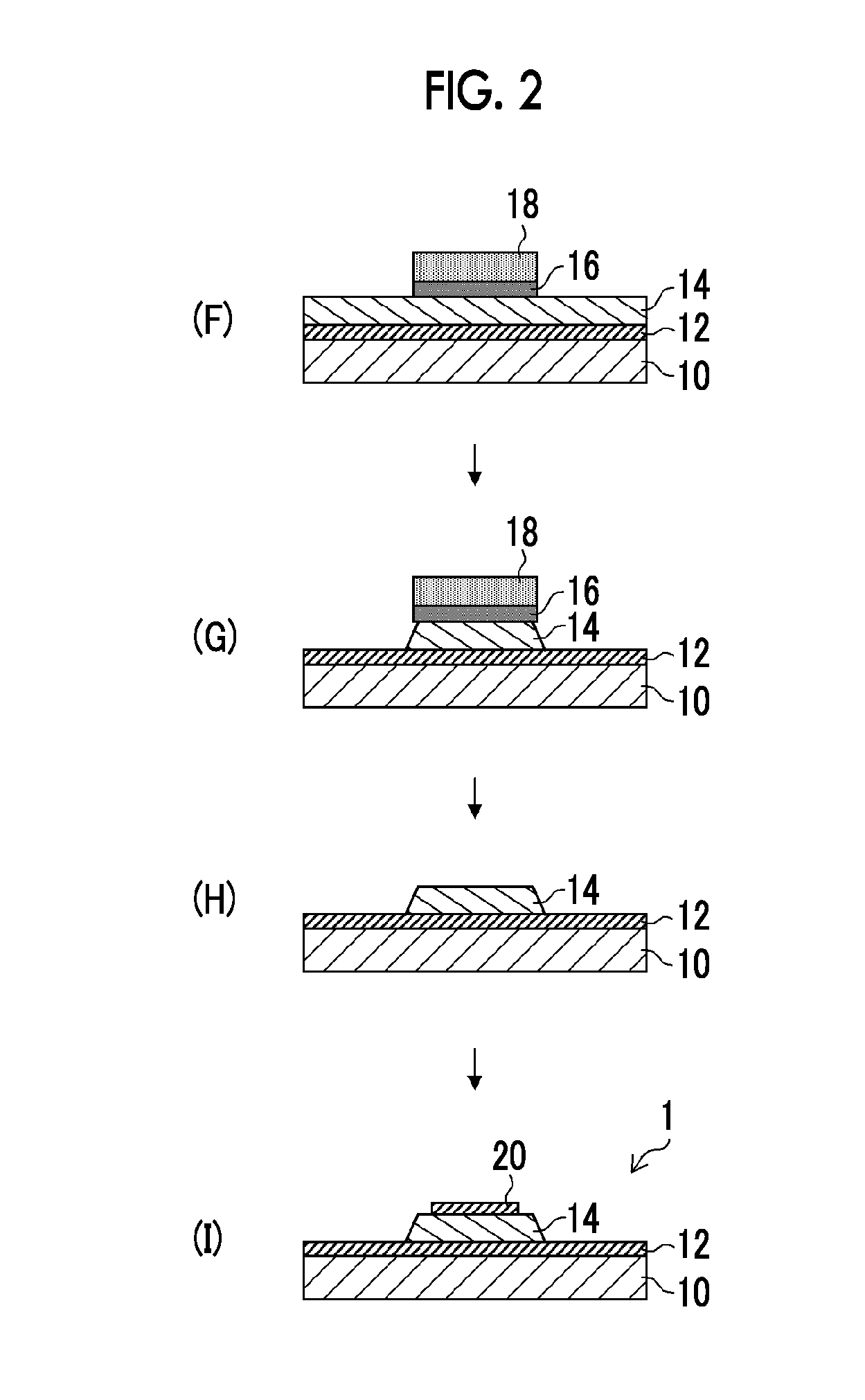

ActiveUS20060197079A1Enhance pattern precisionSimplify patterning processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic semiconductor

A method of manufacturing a thin film transistor is capable of enhancing pattern precision of an organic semiconductor layer and simplifying a patterning process. The method includes forming an organic insulating film on a substrate and forming a bank having the first and second concave portions and a third concave portion in the organic insulating film, the third concave portion being formed on the first and second concave portions. The method further includes forming a source electrode and a drain electrode in the first and second concave portions and forming an active layer in the third concave portion, the active layer contacting the source electrode and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

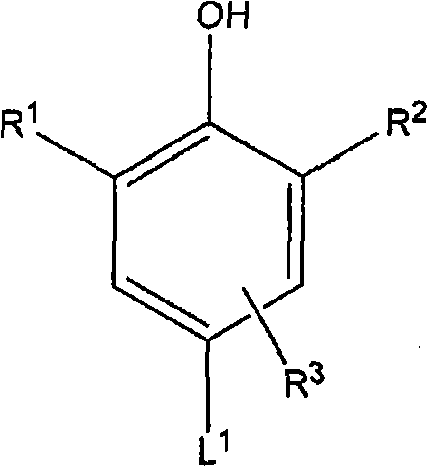

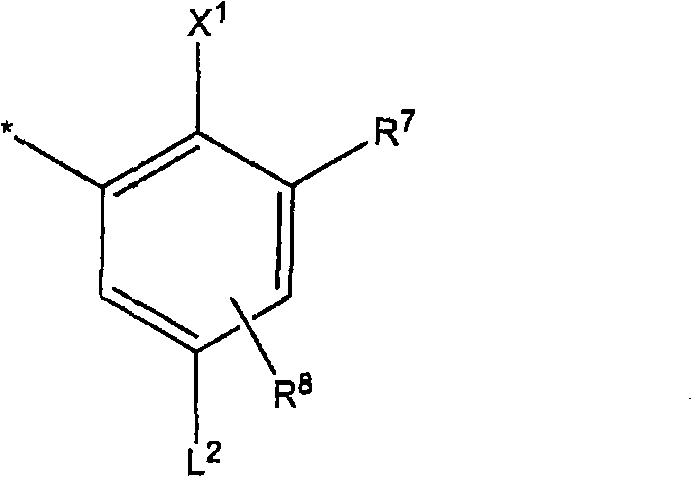

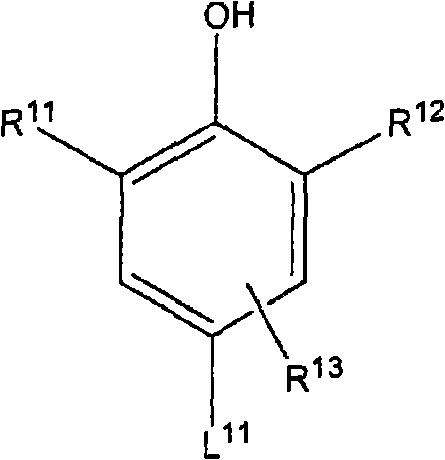

Curing combination for stamping, condensate using the combination and method for producing the same, and members for liquid crystal display device

ActiveCN101620376AHigh pattern accuracyExcellent surface hardnessPhotosensitive materials for photomechanical apparatusNon-linear opticsLiquid-crystal displayHindered amine light stabilizers

The present invention provides curing combination for stamping, having characters of good stamping and photo-curing, mechanical features and various durability, wherein the photo-curing character, heat resisting property and elastic restitution rate are excellent, condensate using the combination and a method for producing the same, and members for a liquid crystal display device. The curing combination contains optical polymeric monomer, optical polymerization initiator and anti-oxidant, characterized in that a content of the optical polymerism monomer is 80-99% by weight, a content of the anti-oxidant is 0.3-7% by weight, and the anti-oxidant is one of only hindered phenol series anti-oxidant, only semi hindered phenol series anti-oxidant, mixture of hindered phenol series anti-oxidant and semi hindered phenol series anti-oxidant, or only hindered amine series anti-oxidant.

Owner:FUJIFILM CORP

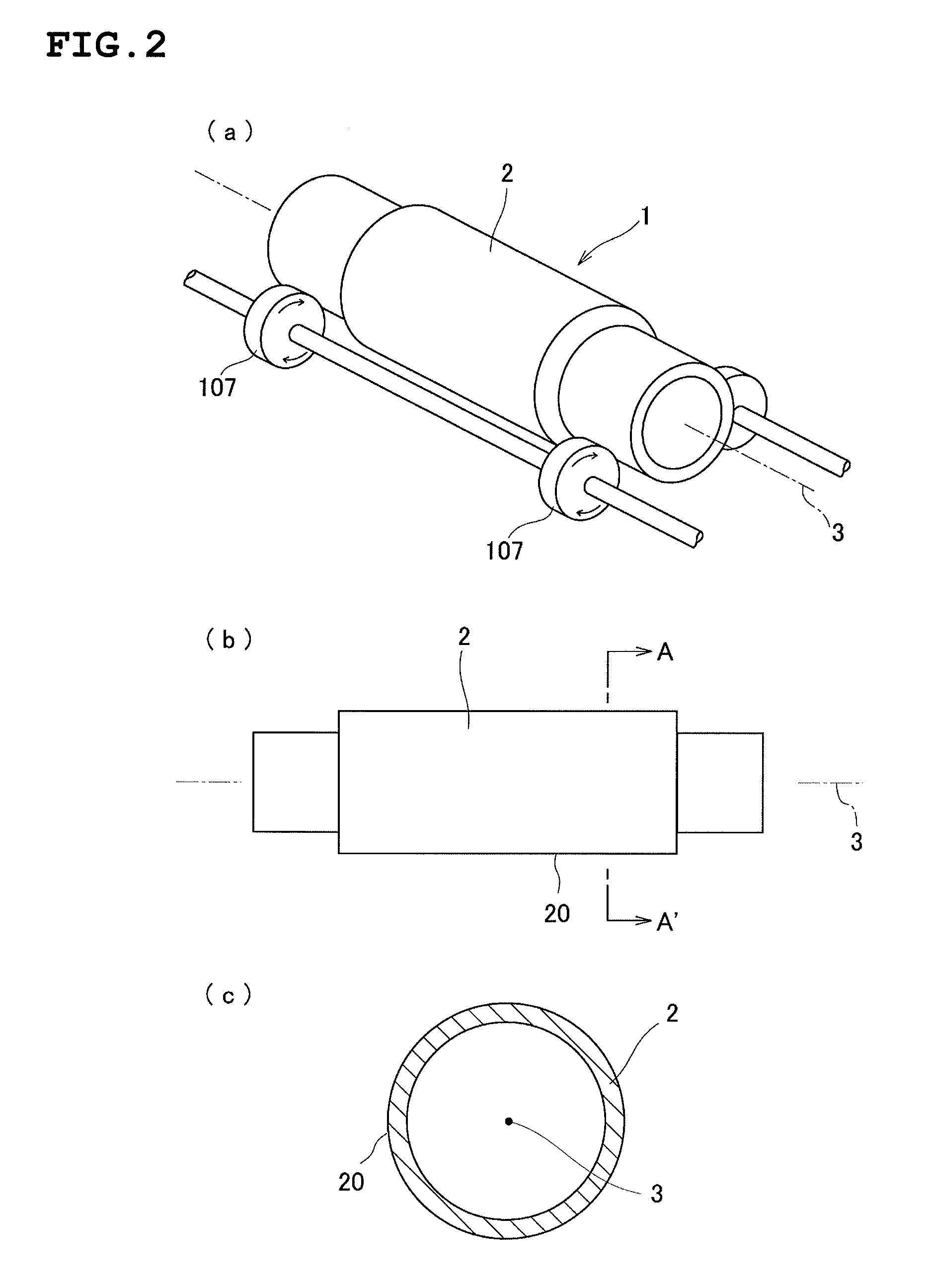

Method for manufacturing roller mold

InactiveUS20090311629A1The process steps are simpleReliable handlingNanoinformaticsPhotomechanical exposure apparatusOptoelectronicsLight exposure

A method for manufacturing a roller mold is described, including the following steps. A body is provided, wherein the body is a cylinder. A photoresist layer is formed to completely cover a cambered surface of the body. A mold including a pattern structure including a convex portion and a concave portion is provided, and the convex portion and the concave portion are covered with a transferred pattern layer. The mold is pressed on the photoresist layer. The body is rolled to transfer the transferred pattern layer on the convex portion onto the photoresist layer. The mold is removed. An UV light exposure step is performed on an exposed portion of the photoresist layer to transfer a pattern of the transferred pattern layer to the photoresist layer. The exposed portion of the photoresist layer is removed to expose a portion of the cambered surface of the body. A structure layer is formed on the portion of the cambered surface and the transferred pattern layer. The photoresist layer, and the structure layer and the transferred pattern layer on the photoresist layer are removed.

Owner:NAT CHENG KUNG UNIV

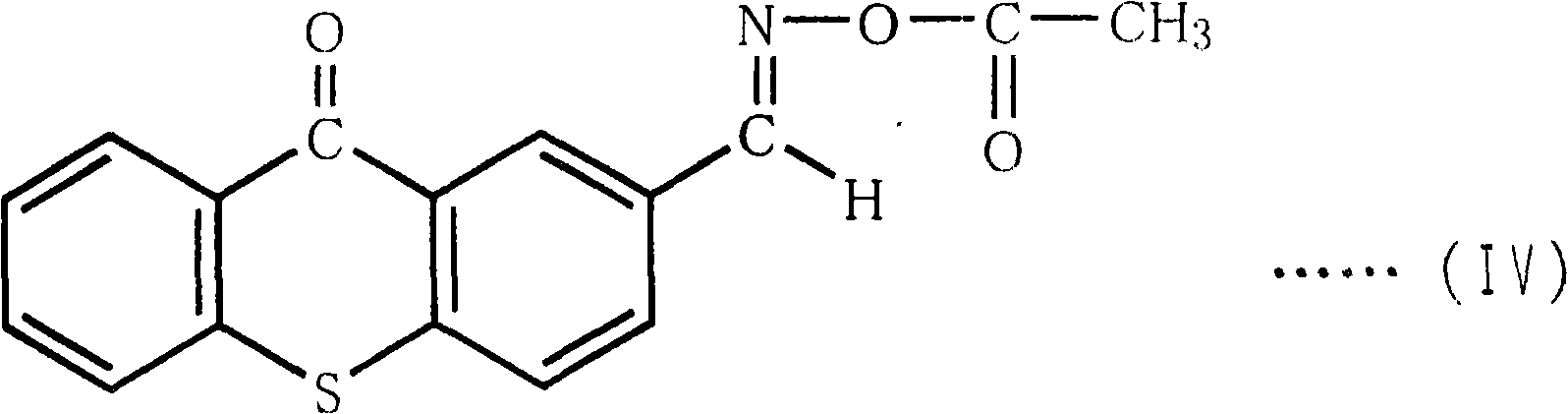

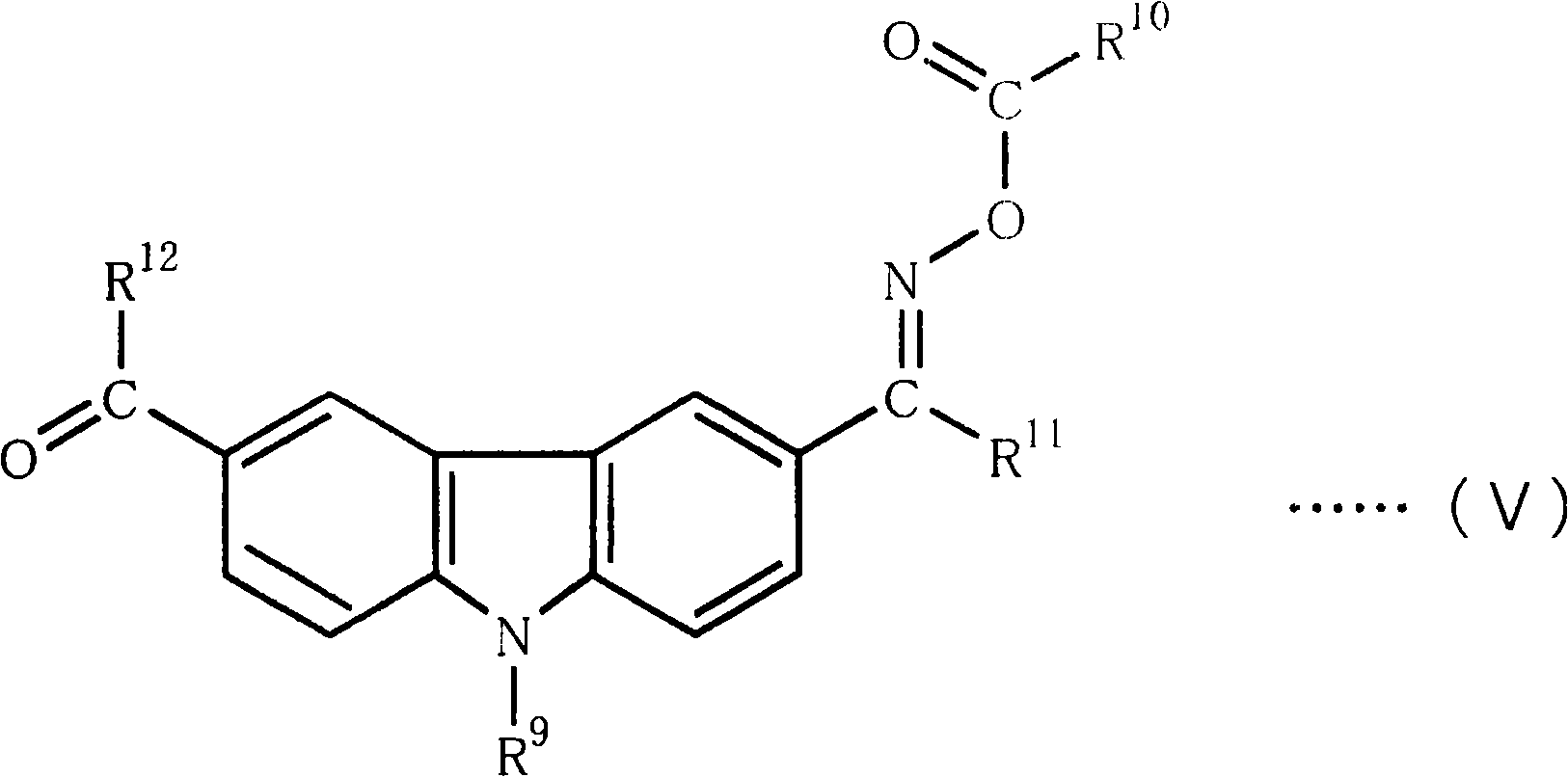

Radiation curable composition, storing method thereof, forming method of cured film, patterning method, use of pattern, electronic components and optical waveguide

InactiveUS7297464B2Reduce exposure doseHigh pattern accuracyRadiation applicationsPhotosensitive material processingPhotoacid generatorSolvent

Owner:HITACHI CHEM CO LTD

Photomask, method for fabricating photomask, and method for fabricating semiconductor device

InactiveUS20070065731A1High pattern accuracyEliminate the effects ofDecorative surface effectsSemiconductor/solid-state device manufacturingResistPhase shifted

A method for fabricating a photomask includes the steps of forming a phase shift layer, a light-shielding layer, and a negative resist layer in that order on a transparent substrate, forming a first resist pattern including a pattern corresponding to a transfer pattern by performing first exposure and development on the negative resist layer, forming a light-shielding pattern by etching the light-shielding layer using the first resist pattern as a mask, removing the first resist pattern, and then forming a positive resist layer thereon, forming a second resist pattern including a pattern corresponding to a light-absorbing pattern by performing second exposure and development on the positive resist layer, and forming a phase shift pattern by etching the phase shift layer using the second resist pattern as a mask.

Owner:FUJITSU SEMICON LTD

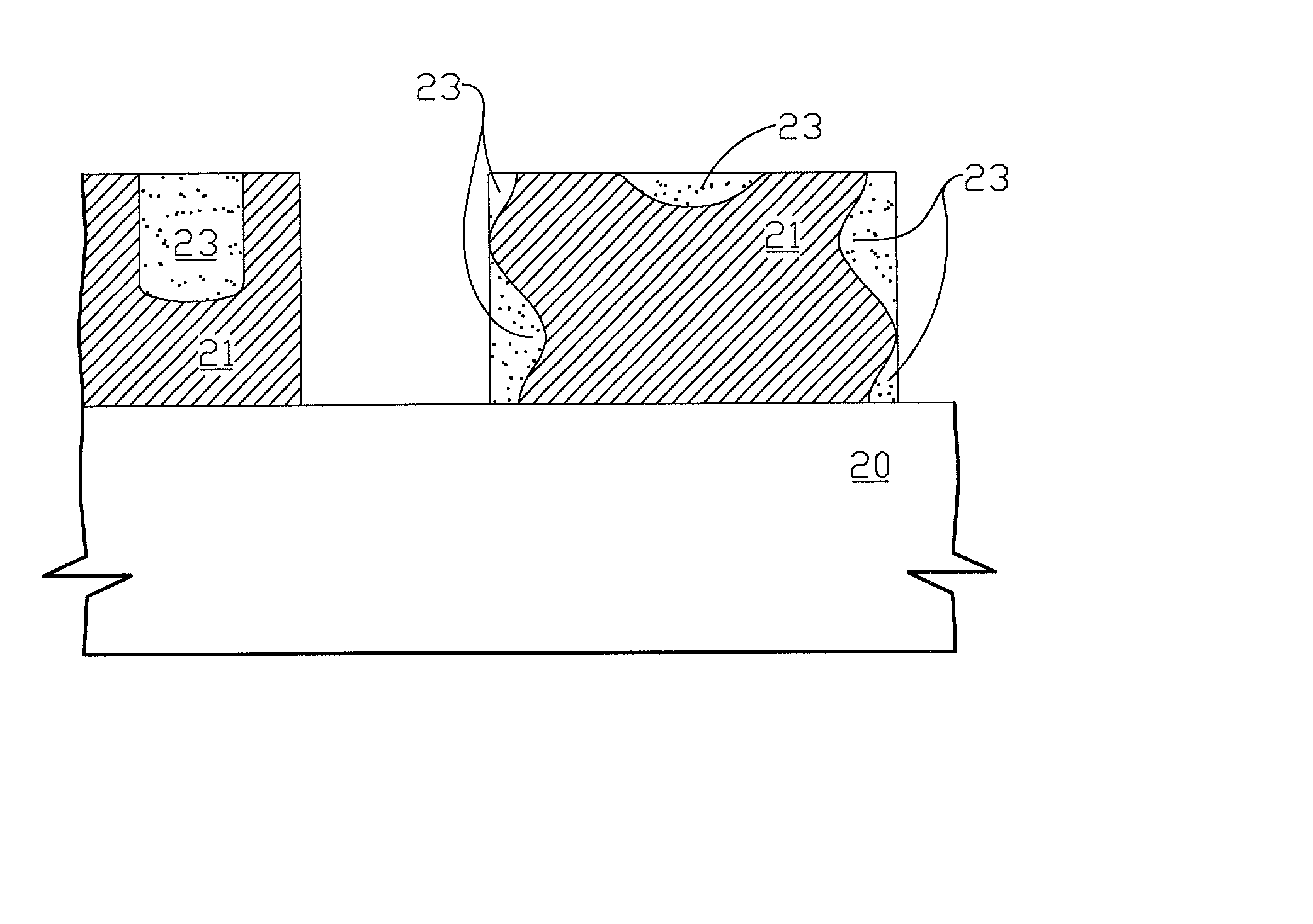

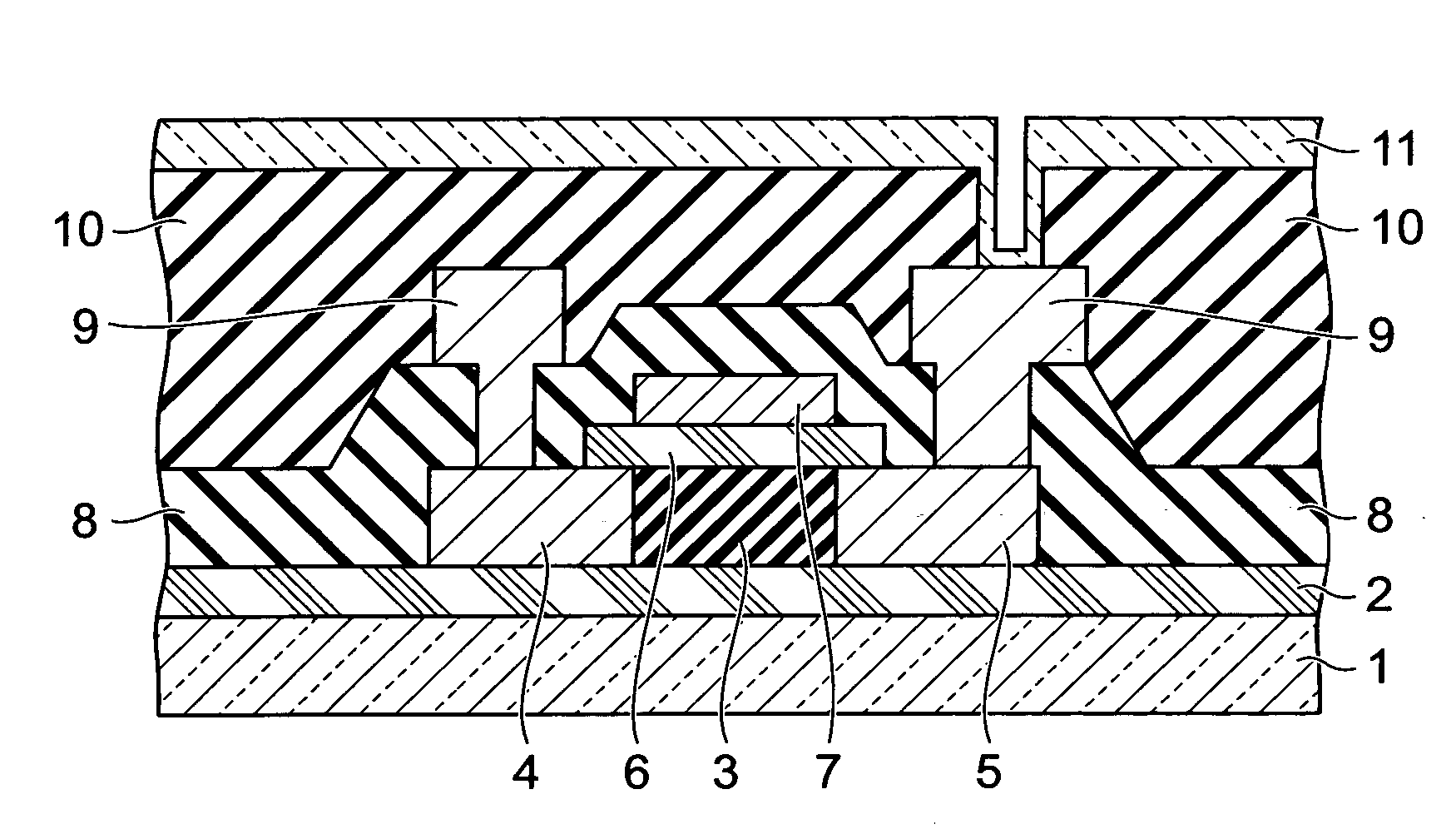

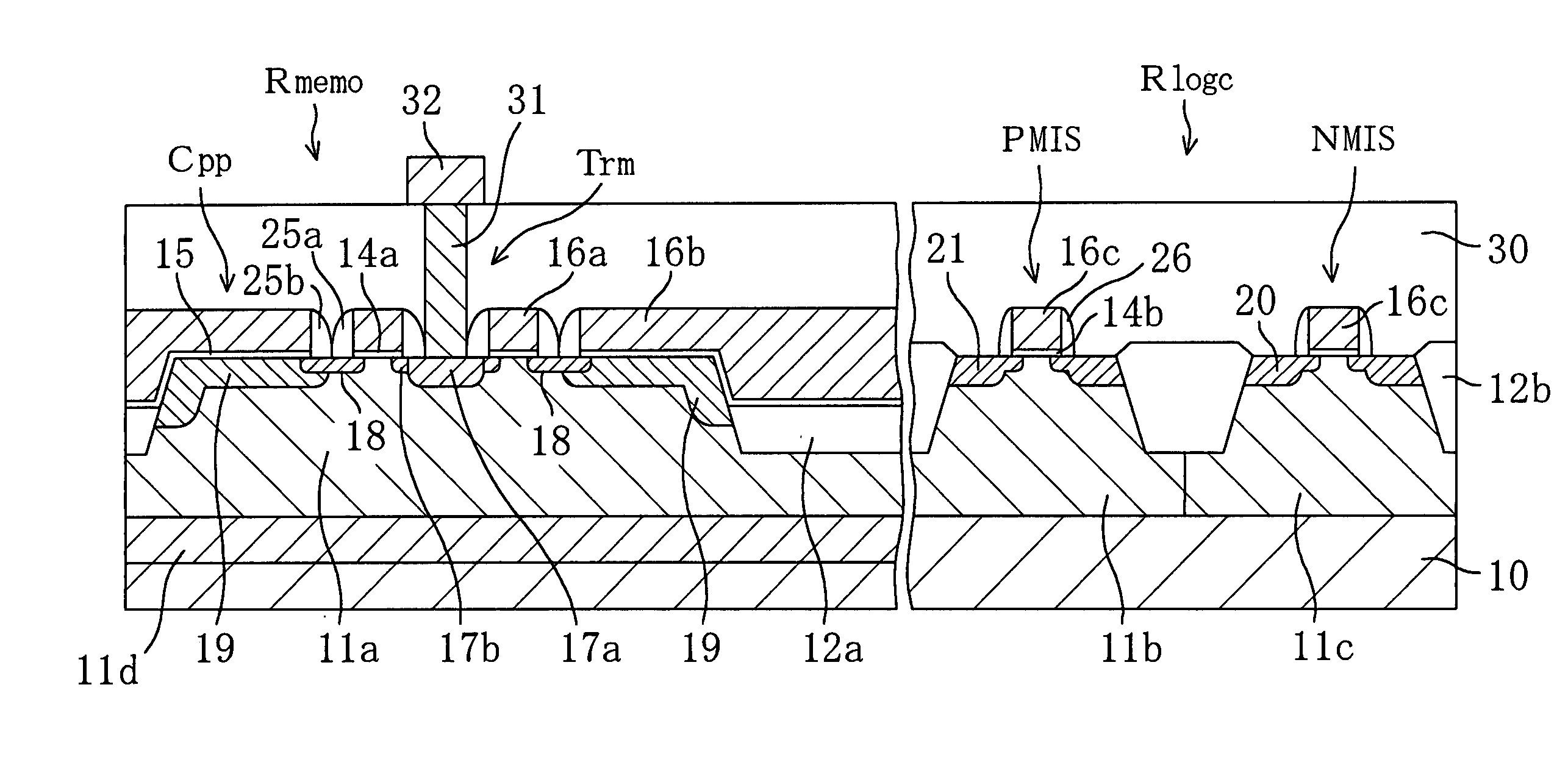

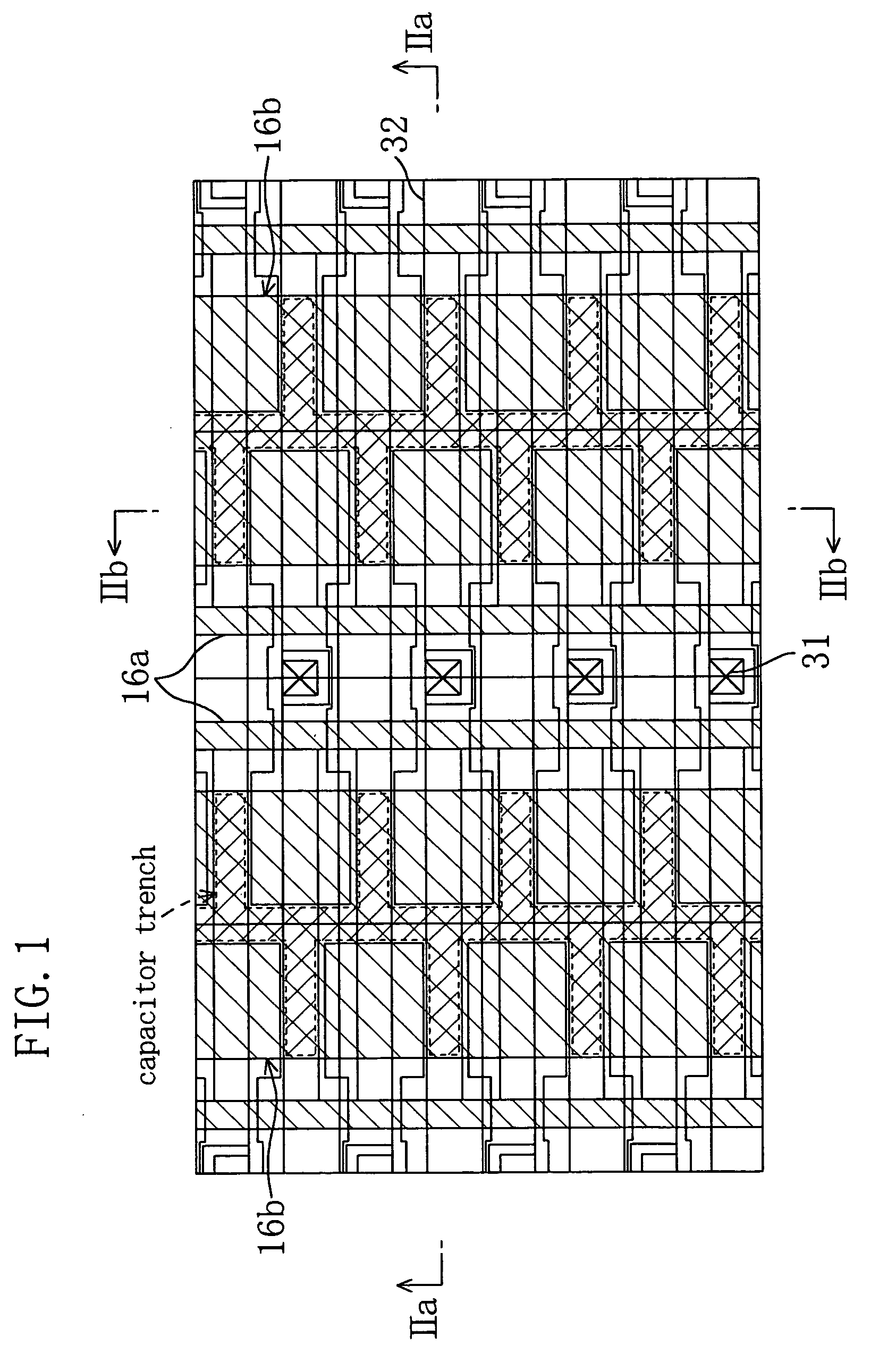

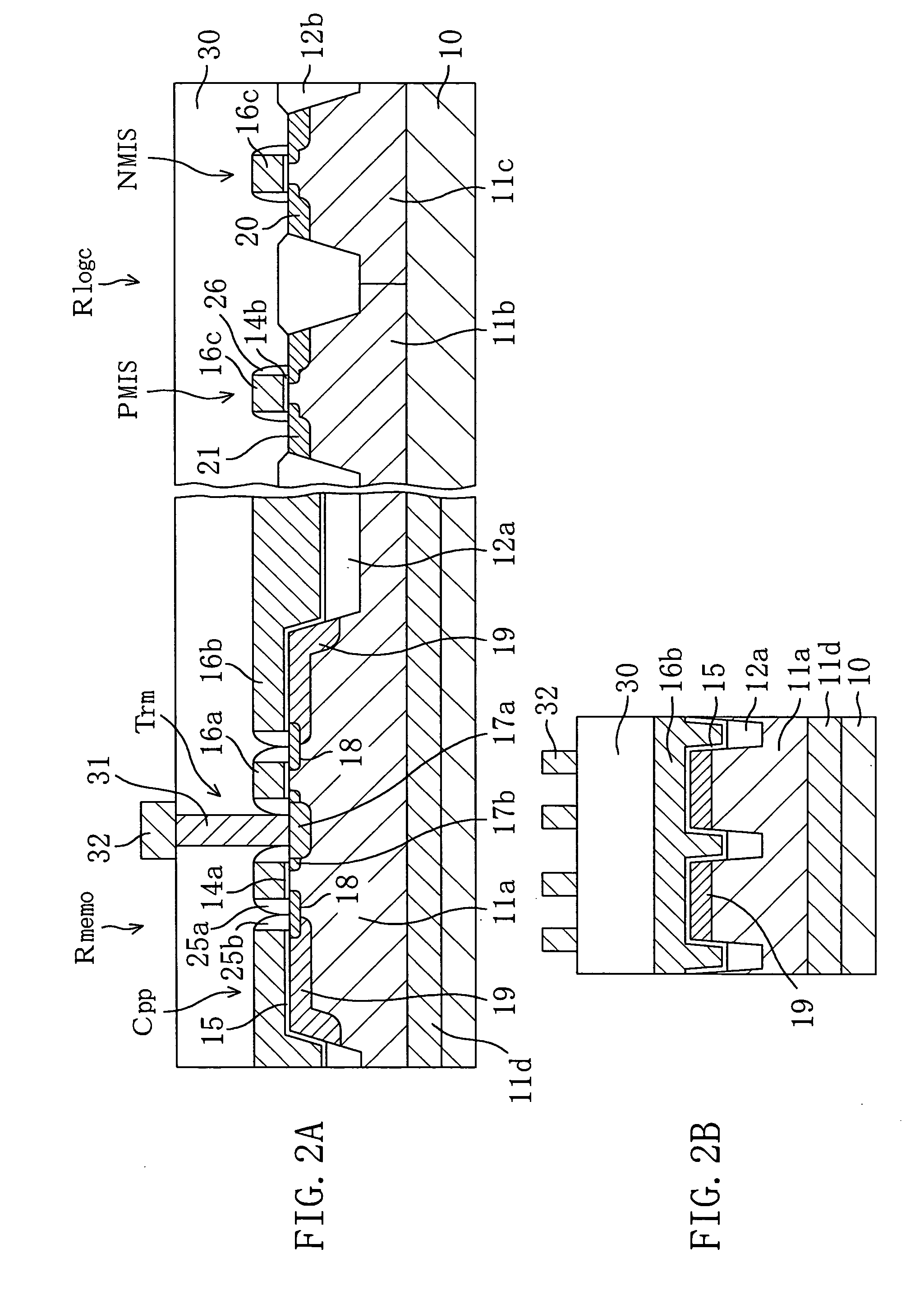

Semiconductor device and its manufacturing method

InactiveUS20040137667A1High pattern accuracyImprove flatnessTransistorSolid-state devicesCapacitanceDielectric

A memory cell transistor and a planar capacitor are provided in a memory region, and both transistors of a CMOS device are provided in a logic circuit region. A capacitance dielectric 15 and a plate electrode 16b of the planar capacitor are provided over a trench shared with a shallow trench isolation 12a, and the upper part of the trench is filled with the capacitance dielectric 15 and the plate electrode 16b. An n-type diffusion layer 19 that is a storage node is formed, with an end region thereof extending along one side of the upper part of the trench, to a region of the substrate overlapping with the shallow trench isolation 12a. The area of a part of the substrate functioning as a capacitor can be increased without increasing the substrate area.

Owner:GK BRIDGE 1

Positive type radiosensitive composition and method for forming pattern

InactiveUS7005231B2High resolutionReduce waveguide lossPhotosensitive materialsPhotomechanical exposure apparatusSilane compoundsPositive type

A positive-tone radiation-sensitive composition including: (A) at least one compound selected from the group consisting of a hydrolyzable silane compound represented by general formula (R1)pSi(X)4−p (wherein R1 is a non-hydrolyzable organic group having 1 to 12 carbon atoms, X is a hydrolyzable group, and p is an integer from 0 to 3), hydrolyzates thereof and condensates thereof; (B) a photoacid generator; and (C) a basic compound. A cured product that is excellent in terms of pattern precision and so on can be obtained by using the composition. The composition can be used as a material for forming optical waveguides.

Owner:JSR CORPORATIOON

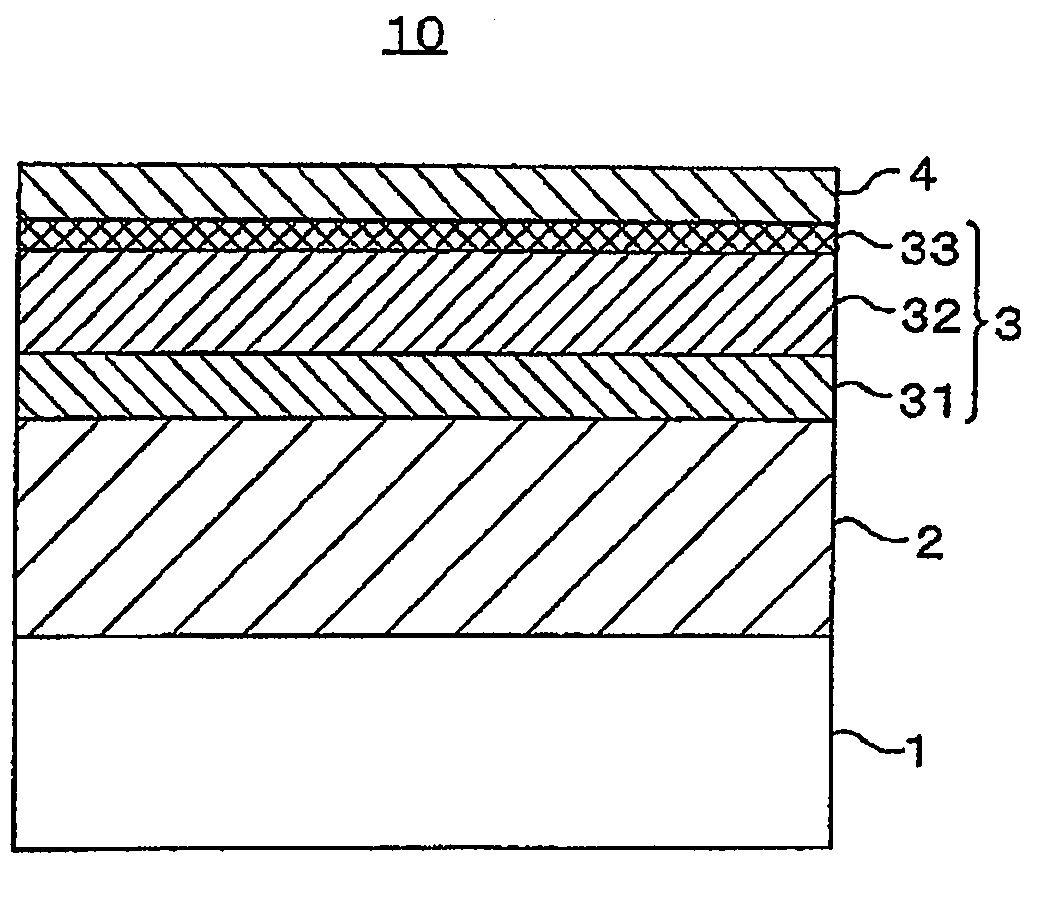

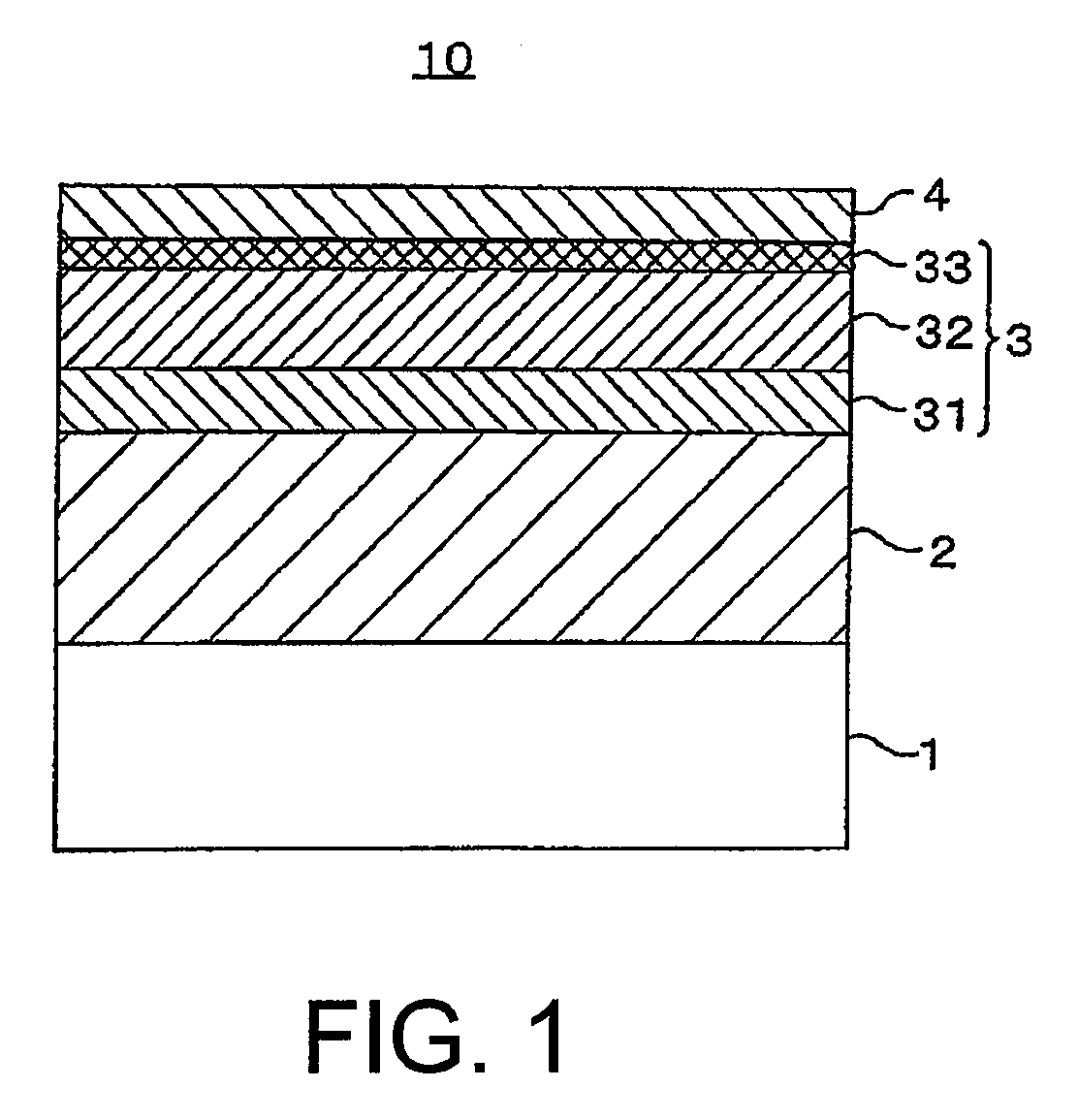

Patterning process and method of manufacturing organic thin film transistor using the same

InactiveUS20070264747A1High pattern accuracySimple interfaceSolid-state devicesSemiconductor/solid-state device manufacturingSelf-assembled monolayerOptoelectronics

A patterning process is provided. The patterning process includes the following steps. First, a substrate is provided. Then, a patterned self-assembled monolayer (SAM) is formed on the substrate. Afterwards, an organic material layer is formed over the substrate to cover the self-assembled monolayer. Thereafter, a portion of the organic material layer is removed, wherein the organic material layer in contact with the patterned SAM is retained such that a patterned organic material layer.

Owner:CHUNGHWA PICTURE TUBES LTD

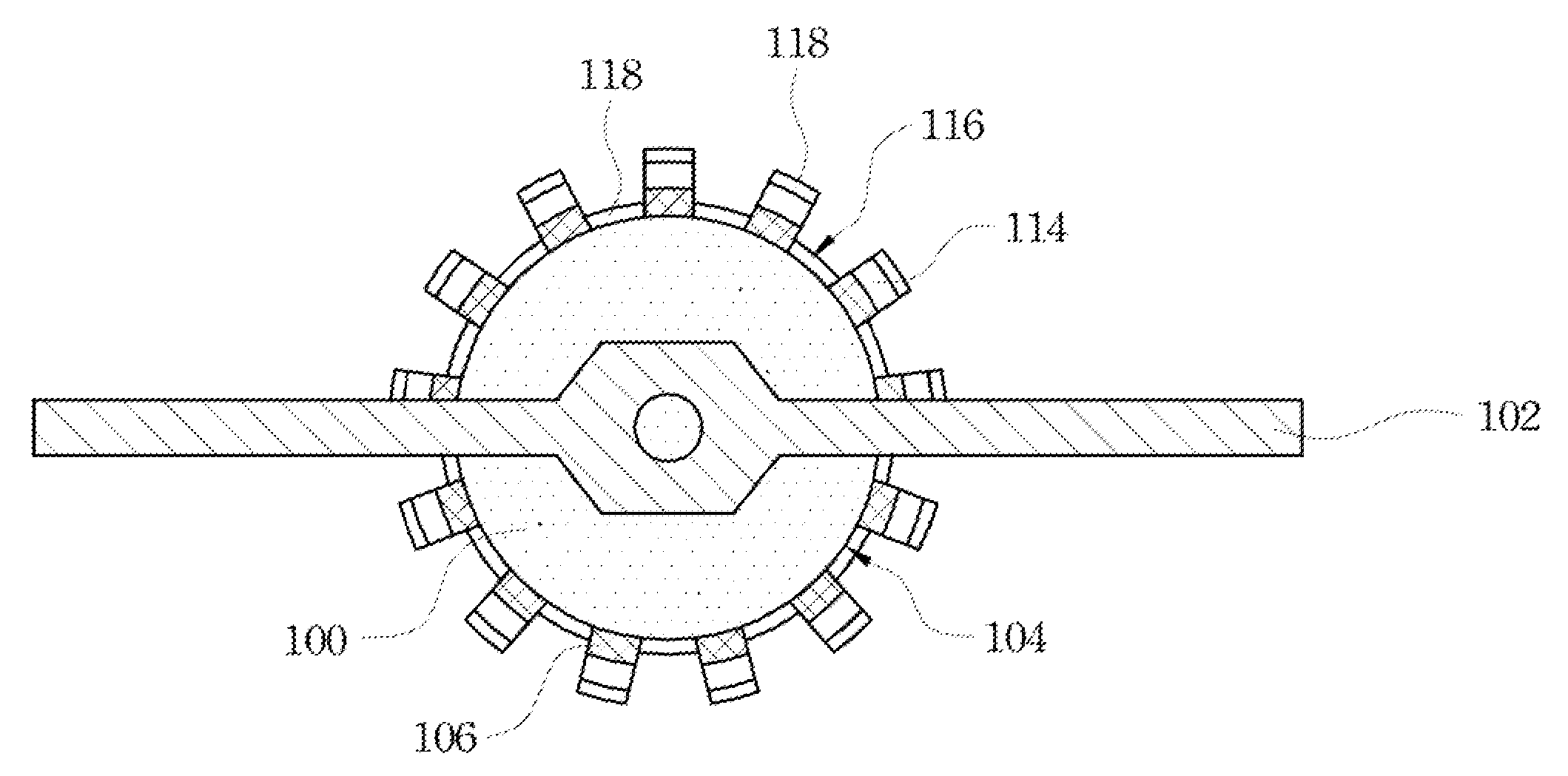

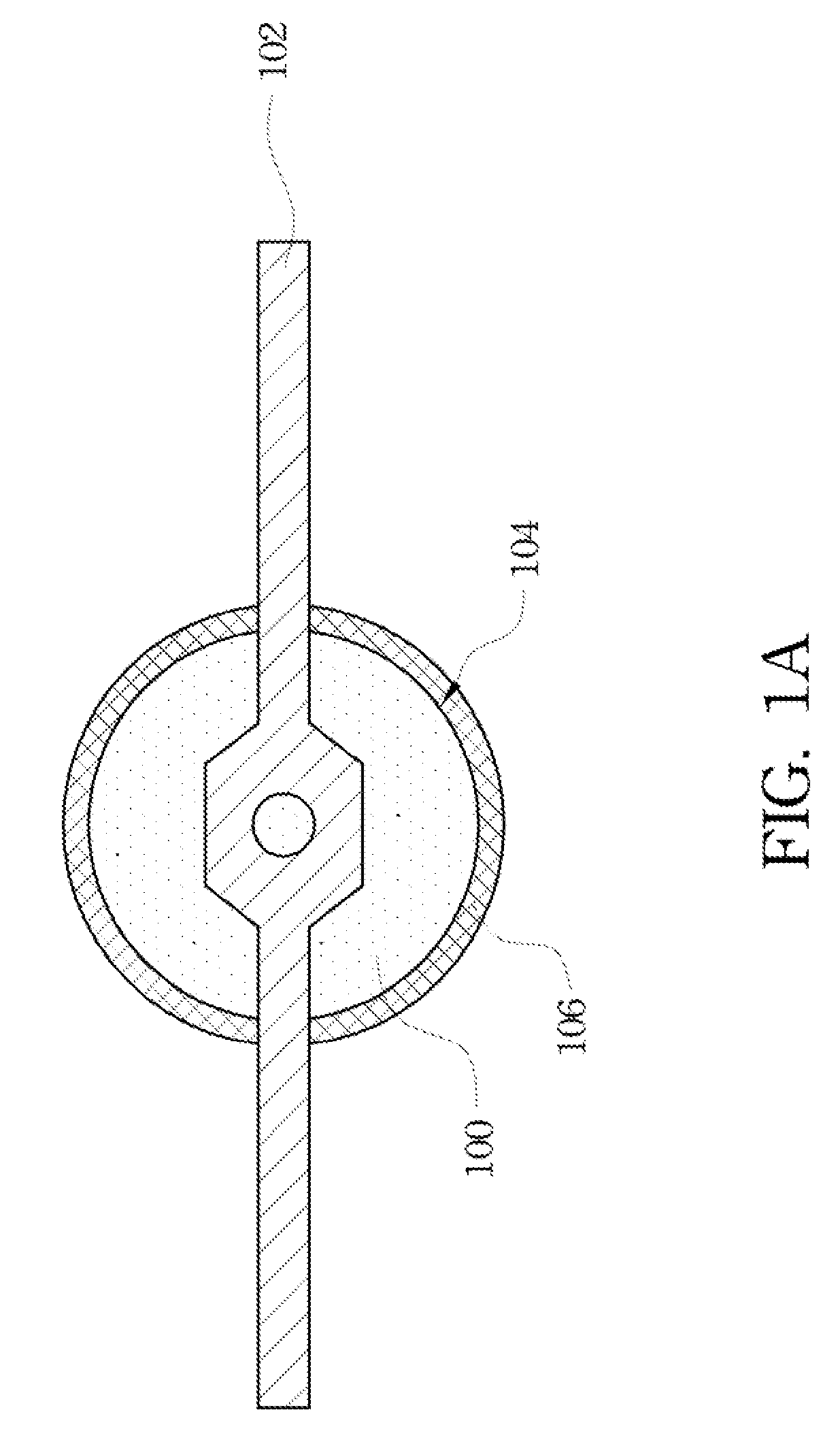

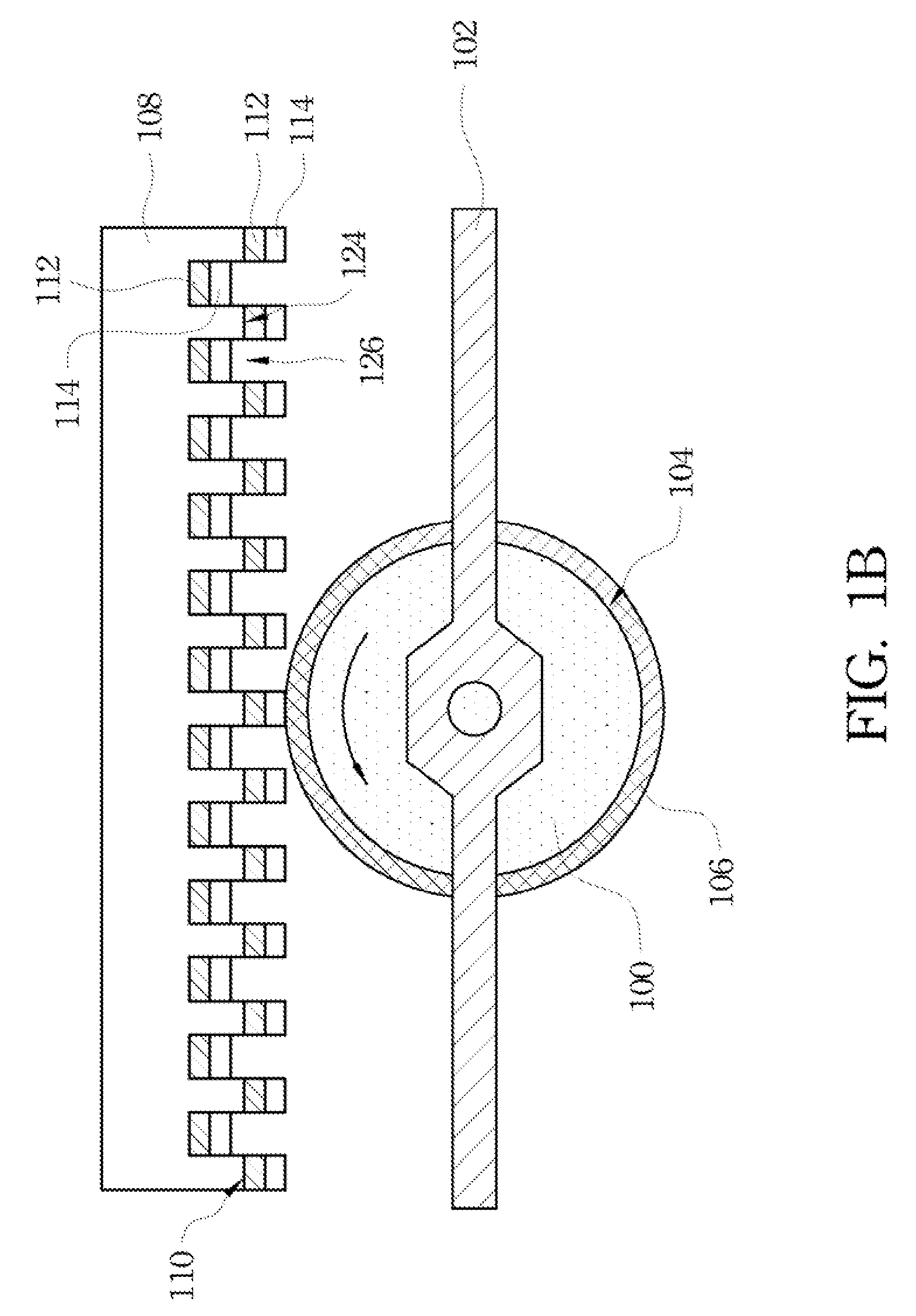

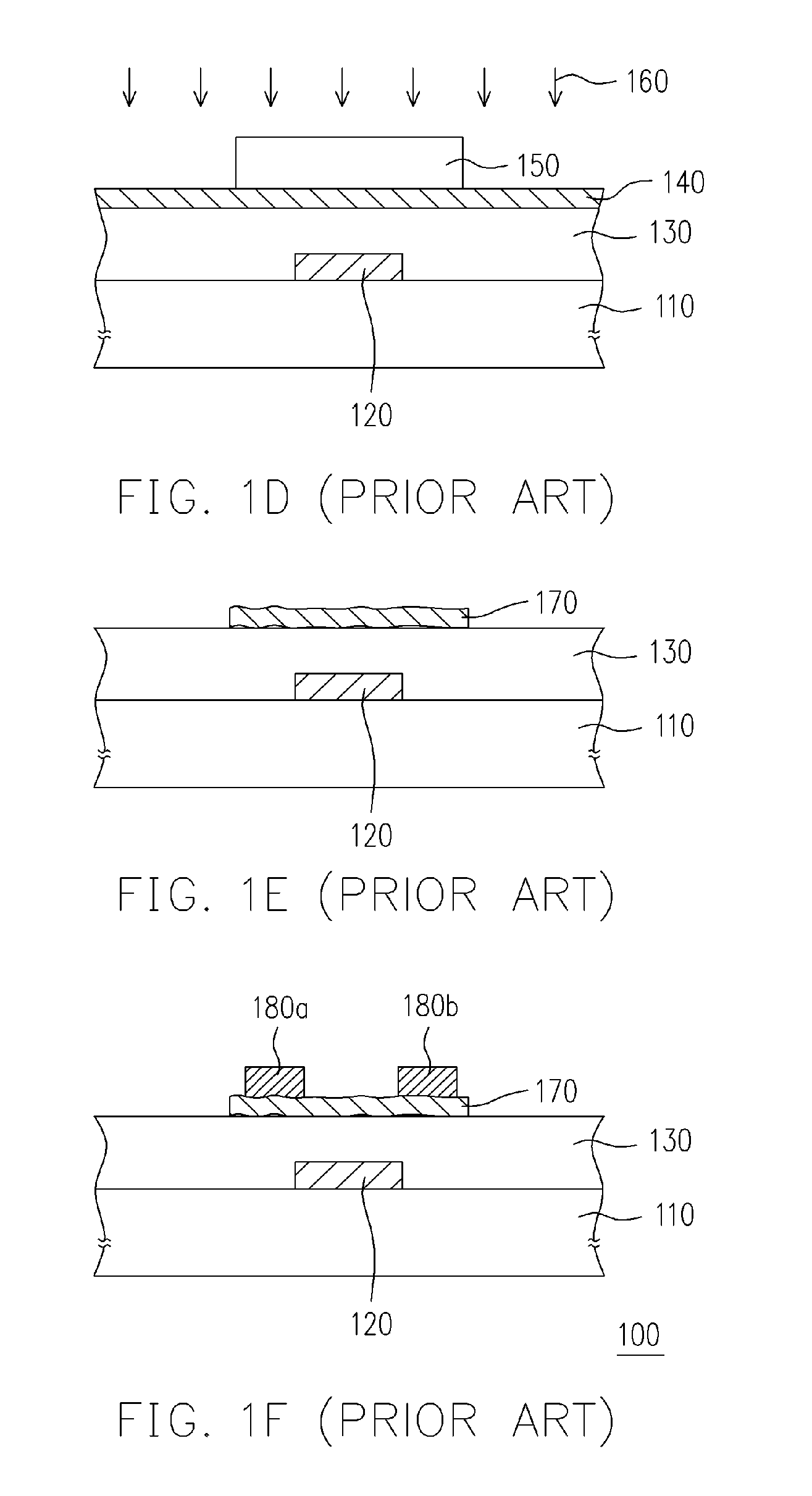

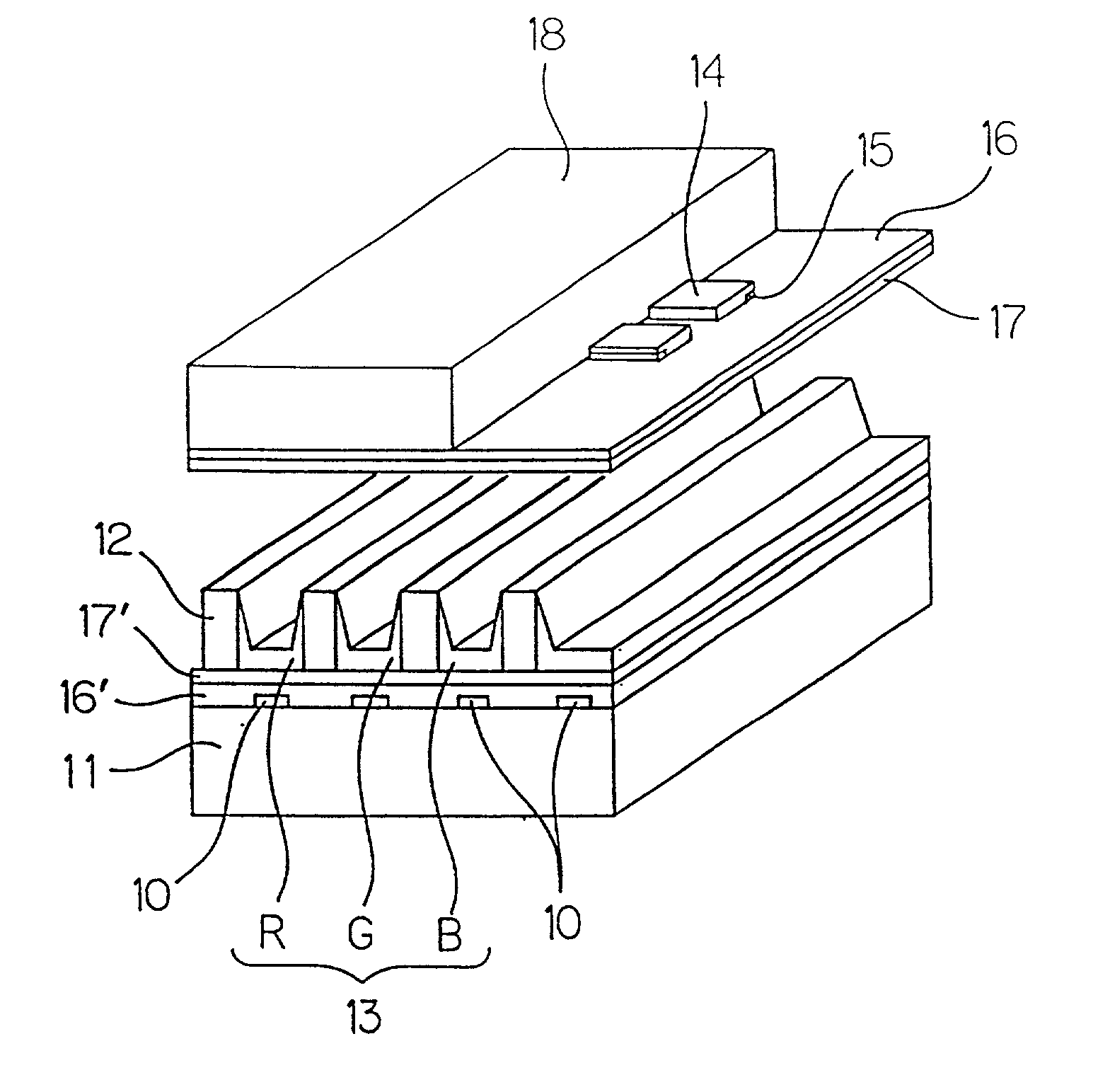

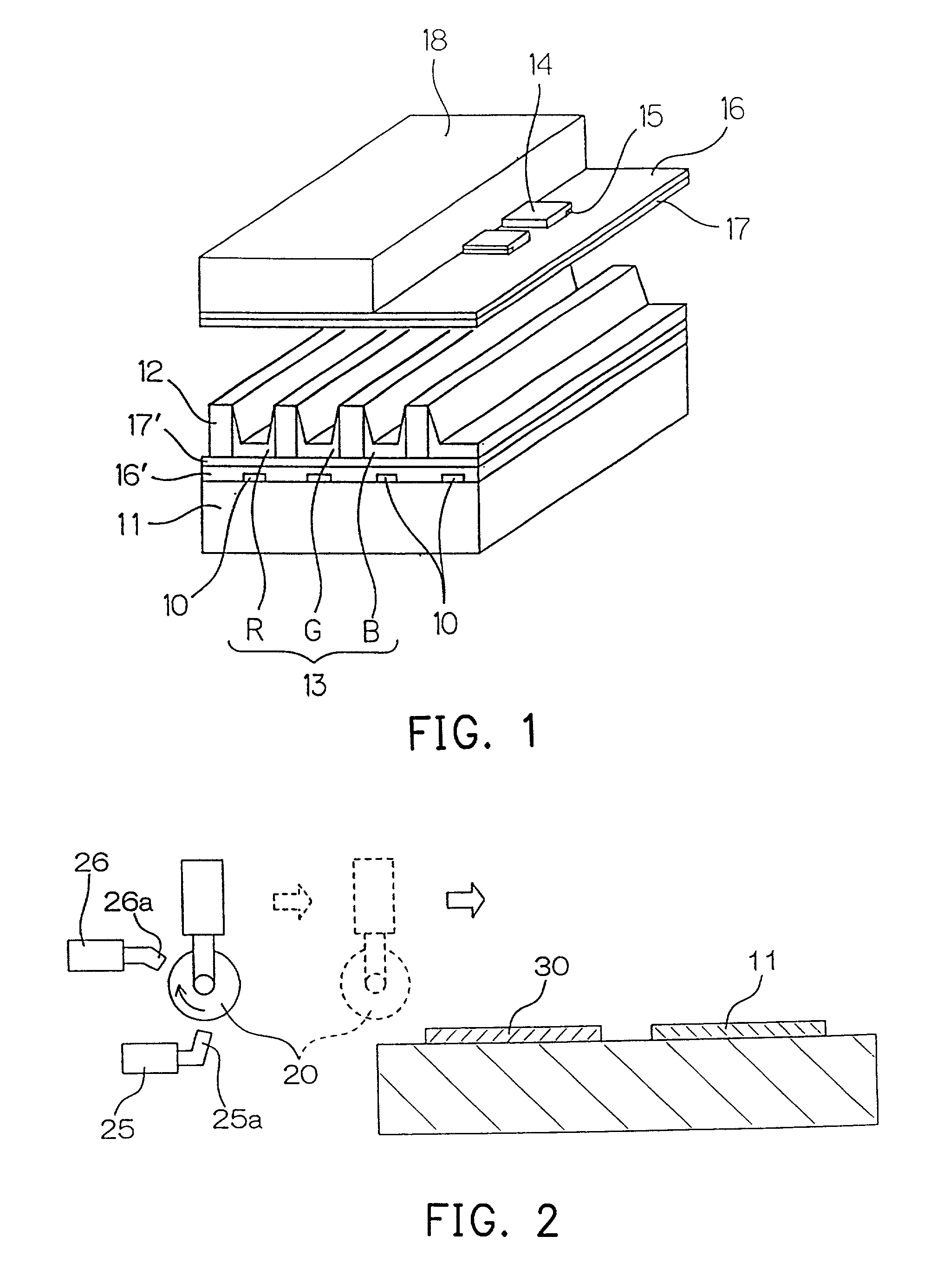

Electrode substrate of plasma display panel and method for making the same

InactiveUS20020125486A1Reduce manufacturing costNot to wasteSolid-state devicesPattern printingEngineeringSolvent

An electrode substrate of a PDP has an electrode pattern on a glass substrate and is made by baking and removing a resin binder in a conductive pattern composed of a conductive ink. The conductive pattern is formed by printing the conductive ink on the glass substrate by an intaglio offset printing method. The conductive ink is formed by dispersing or dissolving a metal powder and a resin binder into a solvent. A printing blanket used for printing the conductive pattern has a rubber layer on the surface of the printing blanket, and the rubber layer poses a volume increasing rate under 20% when the rubber is immersed in the solvent for 24 hours at 23° C. The printing blanket is heated such that a surface temperature TB of the printing blanket is about 40~200° C., and then the printing blanket is cooled in a condition that the surface temperature TB (° C.) of the printing blanket with respect to a surface temperature TP (° C.) of the intaglio satisfies the equation |TP-TB|<=5° C. As a result, the electrode substrate has a tiny and highly precise electrode pattern.

Owner:SUMITOMO RUBBER IND LTD

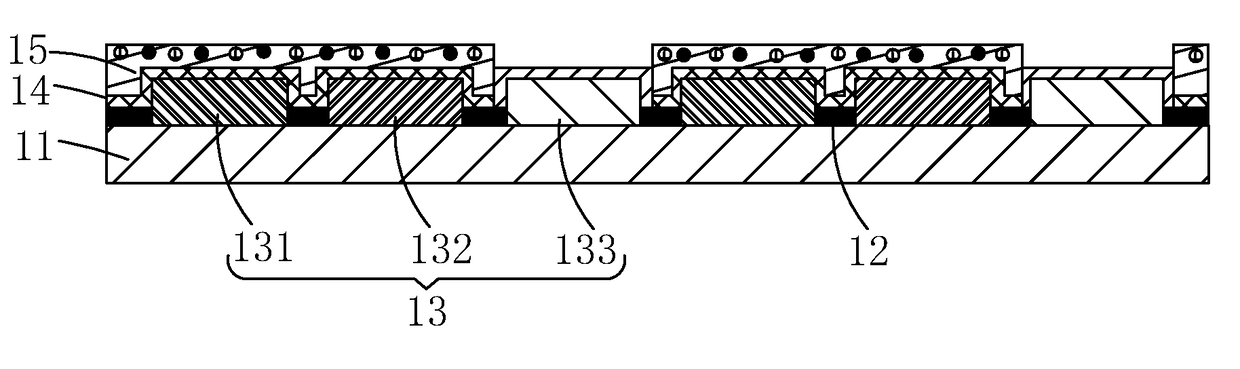

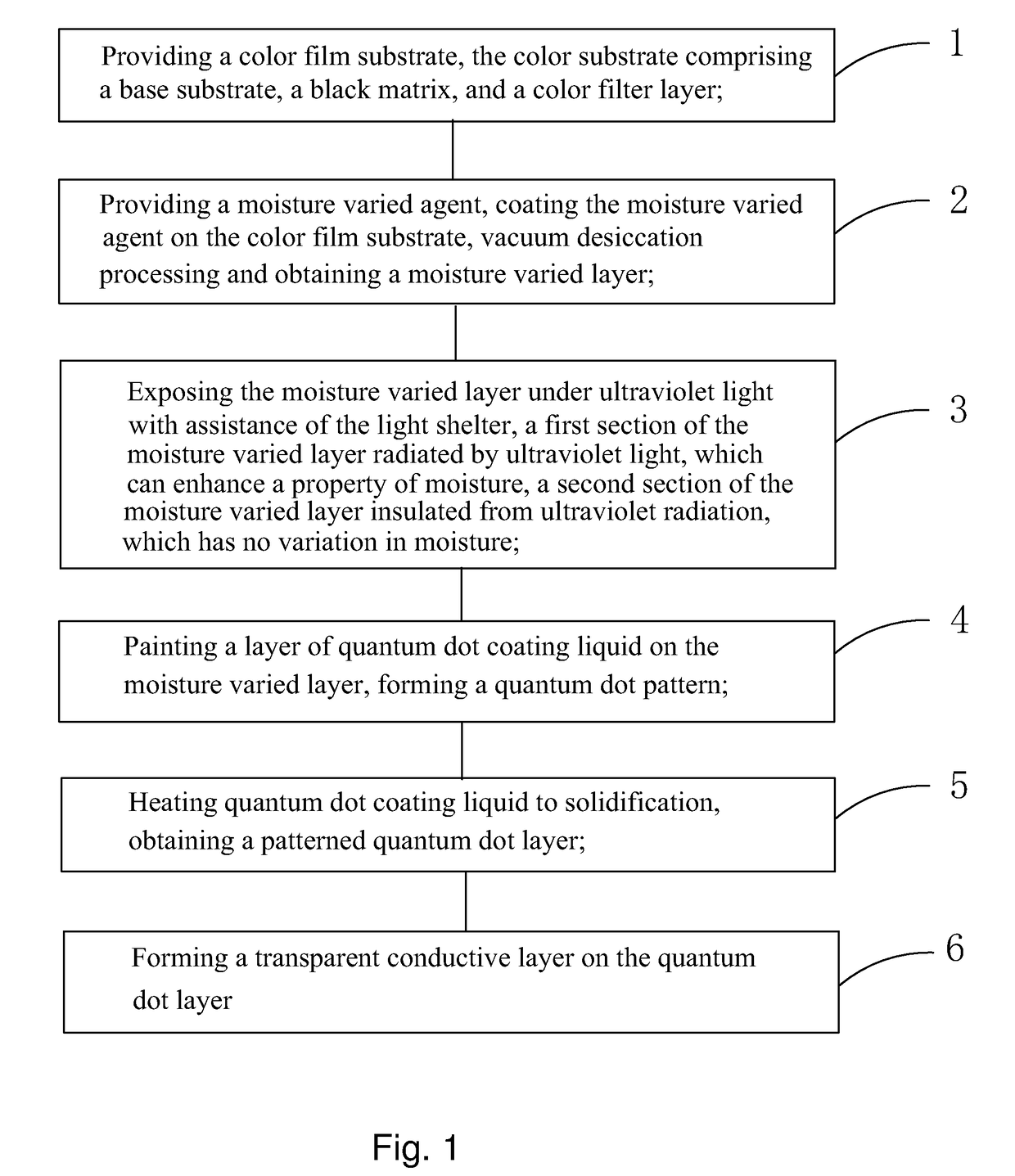

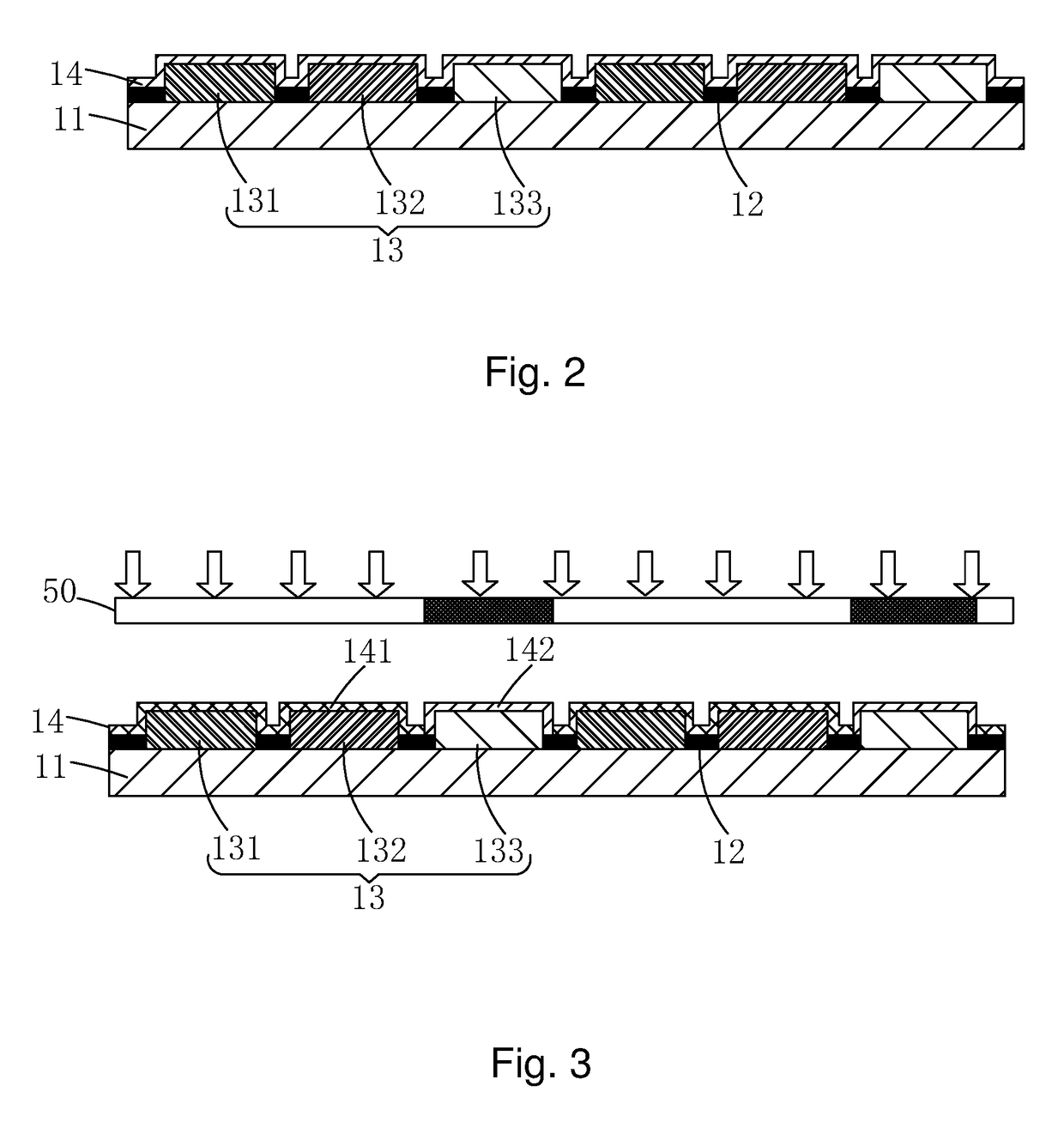

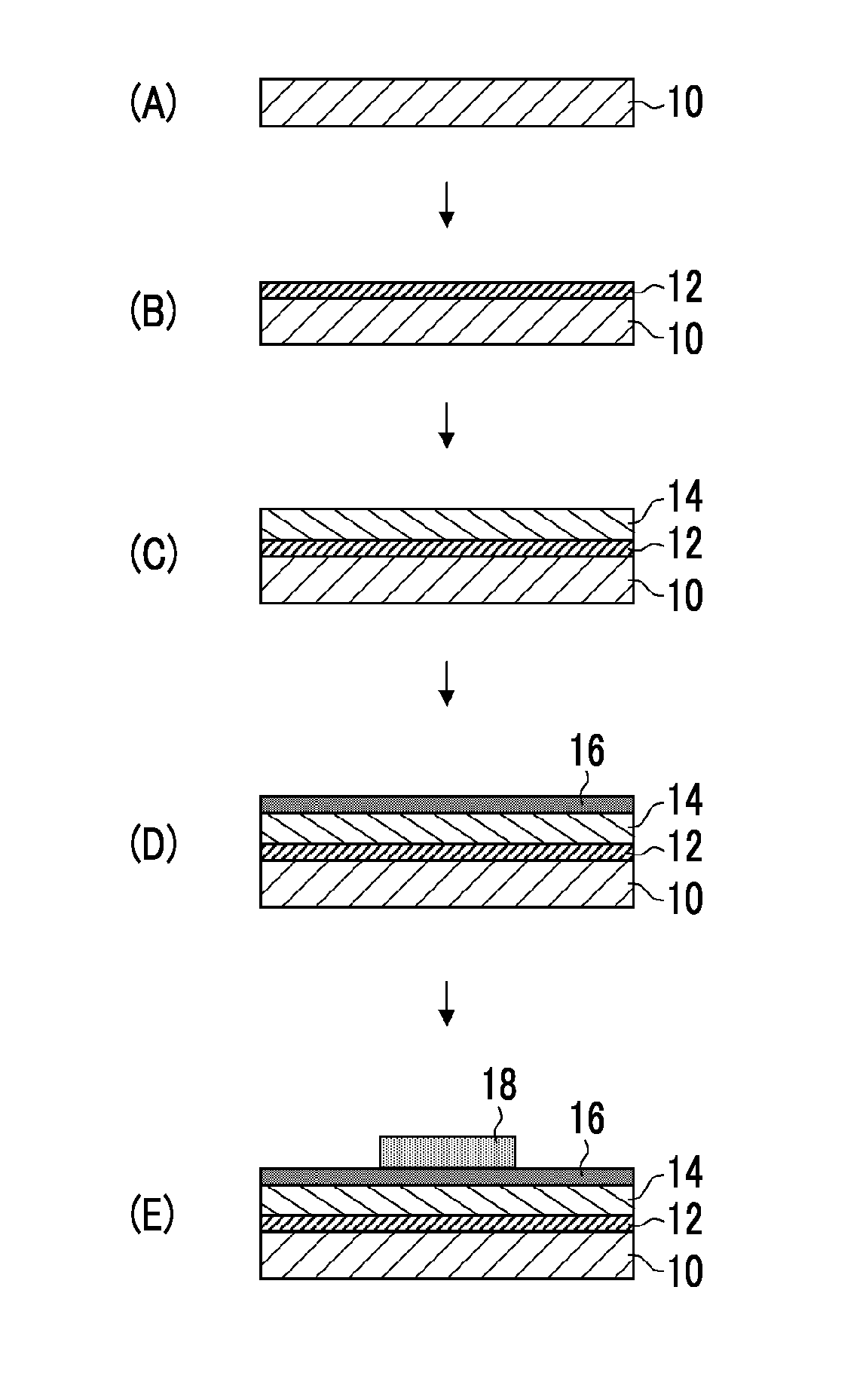

Manufacture method of quantum dot color film substrate

InactiveUS20180031911A1Good moistureSimple manufacturing processMaterial nanotechnologyOptical articlesColor saturationQuantum dot

The disclosure provides a manufacture method of a quantum dot color film substrate, a high precision quantum dot pattern is formed utilizing a property of moisture varied layer of a photocatalyst achieving better moisture after being radiated by ultraviolet light, manufacture process of a quantum dot pattern is simplified as well as enhancing precision of quantum dot layer pattern, and consuming less quantum dot materials and costs, produced quantum dot color film substrate can improve color saturation and gamut of a display device efficiently, reinforcing color display ability of a display panel

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for etching piezoelectric film and method for manufacturing piezoelectric element

ActiveUS20160027996A1Improve accuracySatisfactory patterningPiezoelectric/electrostrictive device manufacture/assemblyCable/conductor manufactureThin membranePiezoelectric membrane

In a method for etching a piezoelectric film and a manufacturing method thereof, a piezoelectric film is formed on a substrate on which a lower electrode is formed, a metal film having a thickness of 20 nm to 300 nm is formed, a patterned resist film is formed, the metal film is etched with a first etchant to which the piezoelectric film has etching resistance, and the piezoelectric film is etched with a second etchant to which the metal film has etching resistance.

Owner:FUJIFILM CORP

Mask blank, method for manufacturing transfer mask, and method for manufacturing semiconductor device

ActiveUS20170168384A1High accuracyAccurately transferSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEtching rateChromium

In order to form a fine mask pattern with high accuracy, in a mask blank in which a light-semitransmissive film, a light shielding film, and a hard mask film are laminated in the stated order on a transparent substrate, the light-semitransmissive film containing silicon and additionally nitrogen, the hard mask film containing silicon or tantalum, and additionally oxygen, the light shielding film having the laminate structure of a lower layer, an intermediate layer, and an upper layer and containing chromium, conditions on the light shielding film are adjusted so that etching rates using a mixture gas of chlorine and oxygen are the lowest for the upper layer and the next lowest for the lower layer.

Owner:HOYA CORP

Thin film capacitor and electronic circuit component

InactiveUS7294905B2Improve accuracyIncrease productionTransistorSemiconductor/solid-state device detailsOptoelectronicsDielectric layer

A thin film capacitor comprising a lower electrode formed on a predetermined surface, a dielectric layer formed on the lower electrode, and an upper electrode formed on the dielectric layer, wherein the end portion of the lower electrode is further covered by an insulator other than the dielectric layer.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com