Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Guaranteed volume stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based grouting material used for strengthening repairing as well as preparation method and application thereof

InactiveCN103880372AHigh injectabilityImprove anti-seepage performanceSwelling ratioCompressive strength

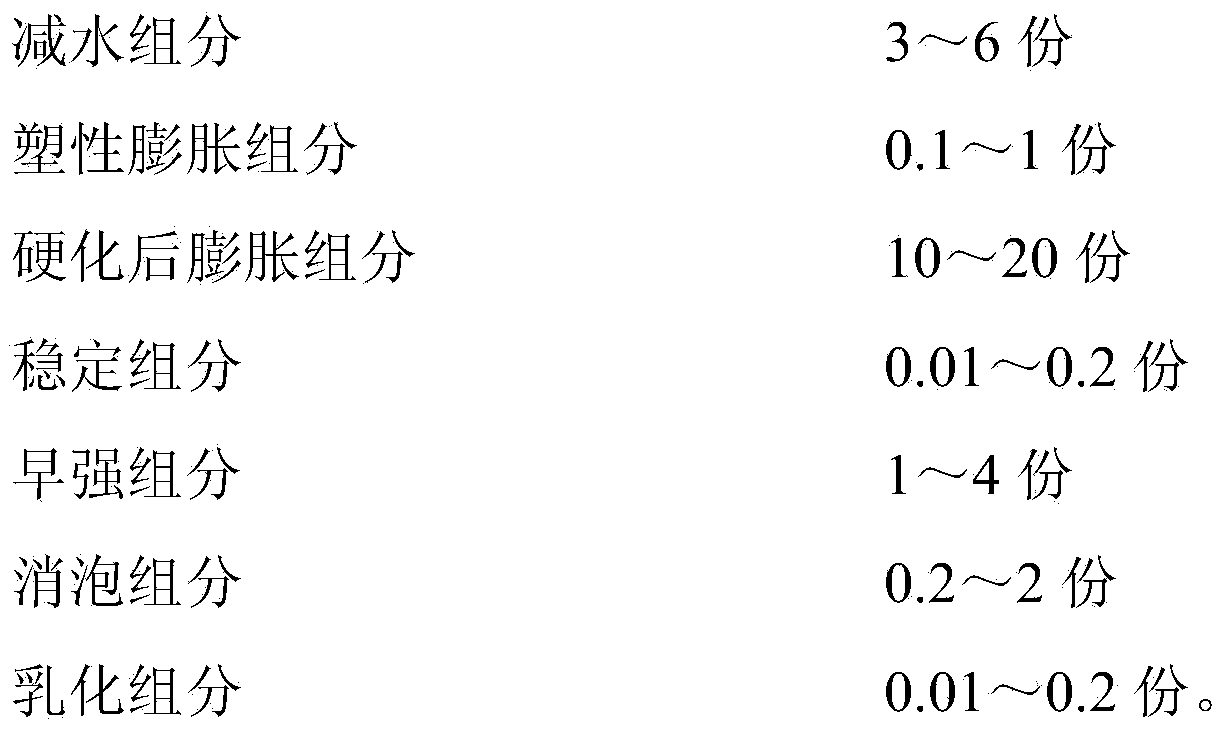

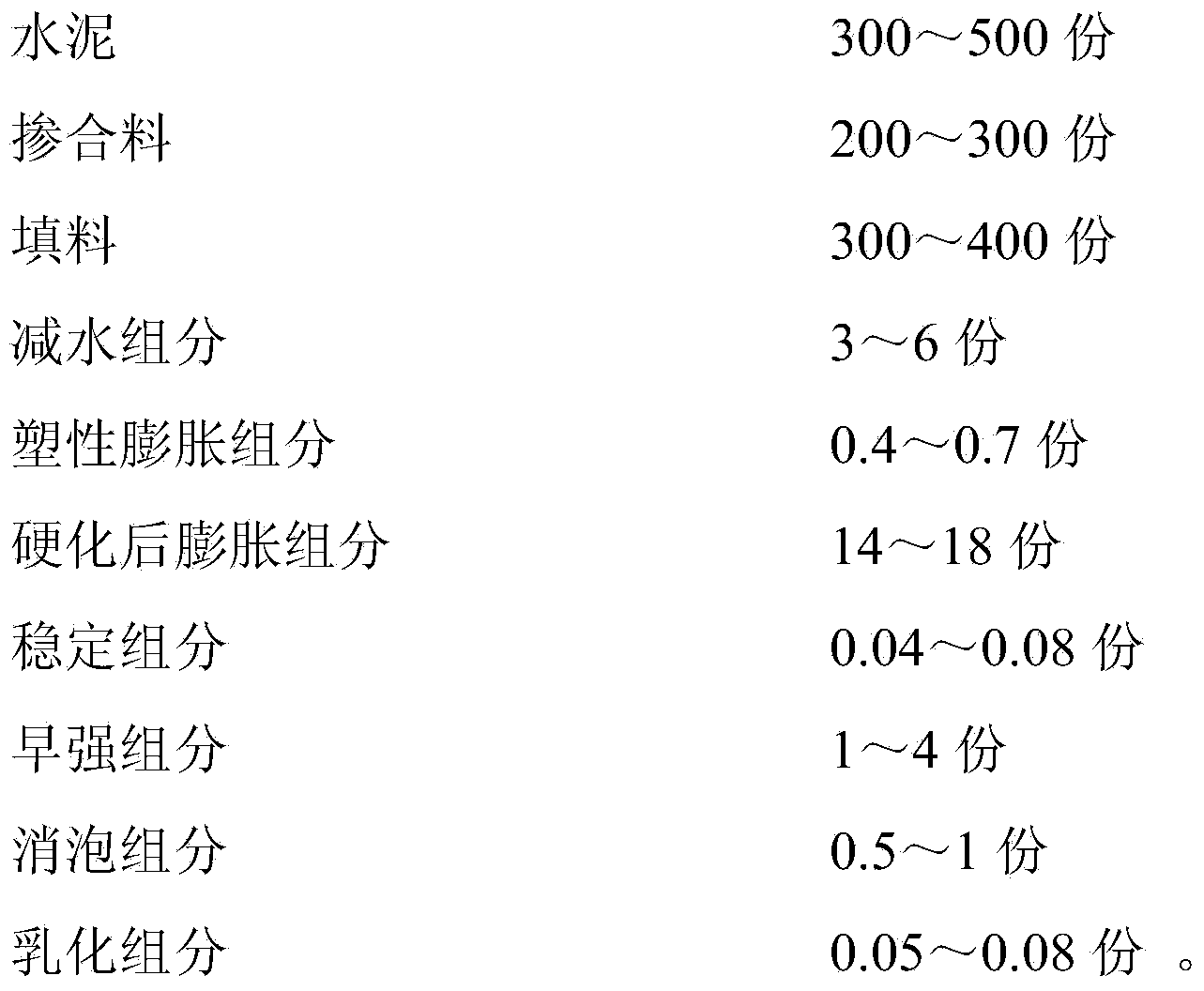

The invention relates to a cement-based grouting material used for strengthening repairing as well as a preparation method and application thereof. The cement-based grouting material comprises the following components in parts by weight: 300-500 parts of cement, 200-300 parts of admixtures, 300-400 parts of fillers, 3-6 parts of water-reducing components, 0.1-1 part of plastic swelling component, 10-20 parts of hardened swelling components, 0.01-0.2 part of stable component, 1-4 parts of early strength components, 0.2-2 parts of defoaming components and 0.01-0.2 parts of emulsifying component. The cement-based grouting material disclosed by the invention has performance advantages such as higher injection-molding performance, initial fluidity not greater than 17s, impermeability not exceeding 1mm, wear resistance not exceeding 10cm<3> / cm<2>, compressive strength within 2 hours not lower than 5MPa, compressive strength within 1 day not lower than 30 MPa, and the like. The cement-based grouting material has composite swelling, the free swelling ratio within 3 hours is 0.02%-2% and grouting is full and dense; the viscosity is low, the volume stability is good and durability is good; the cement-based grouting material does not contain VOC (volatile organic compounds), and is environment-friendly.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

Special high strength grouting material for connecting reinforcement sleeve

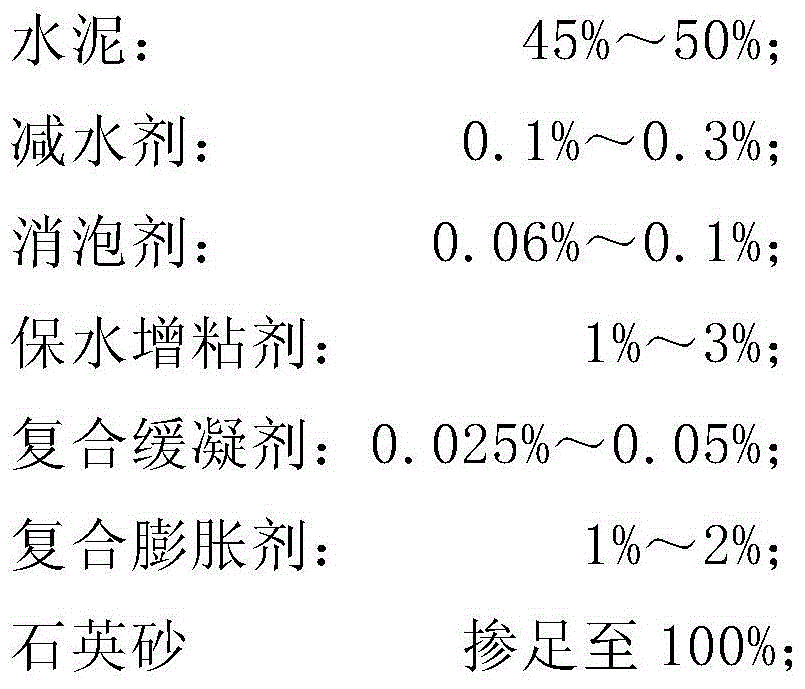

The present invention discloses a special high strength grouting material for connecting a reinforcement sleeve. The special high strength grouting material for connecting the reinforcement sleeve comprises grouting material powder and water, wherein the grouting material powder is prepared from the following raw materials in percentage by weight: 45% to 50% of cement, 0.1% to 0.3% of a water reducing agent, 0.06% to 0.1% of a defoamer, 1% to 3% of a water retention tackifier, 0.025% to 0.05% of a composite retarder, 1% to 2% of a composite expansion agent; and and the balance of quartz sand, totalling 100, wherein the mass ratio of the grouting material powder to the water is 1 to (0.23-0.28). The special high strength grouting material for the connecting reinforcement sleeve provided by the present invention has the characteristics of high strength, high adhesion and slight expansion with no shrinkage; the high strength grouting material can be poured into the reinforcement sleeve to enable fixed connection formed between reinforcements and between the reinforcements and the sleeve, and has excellent durability.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

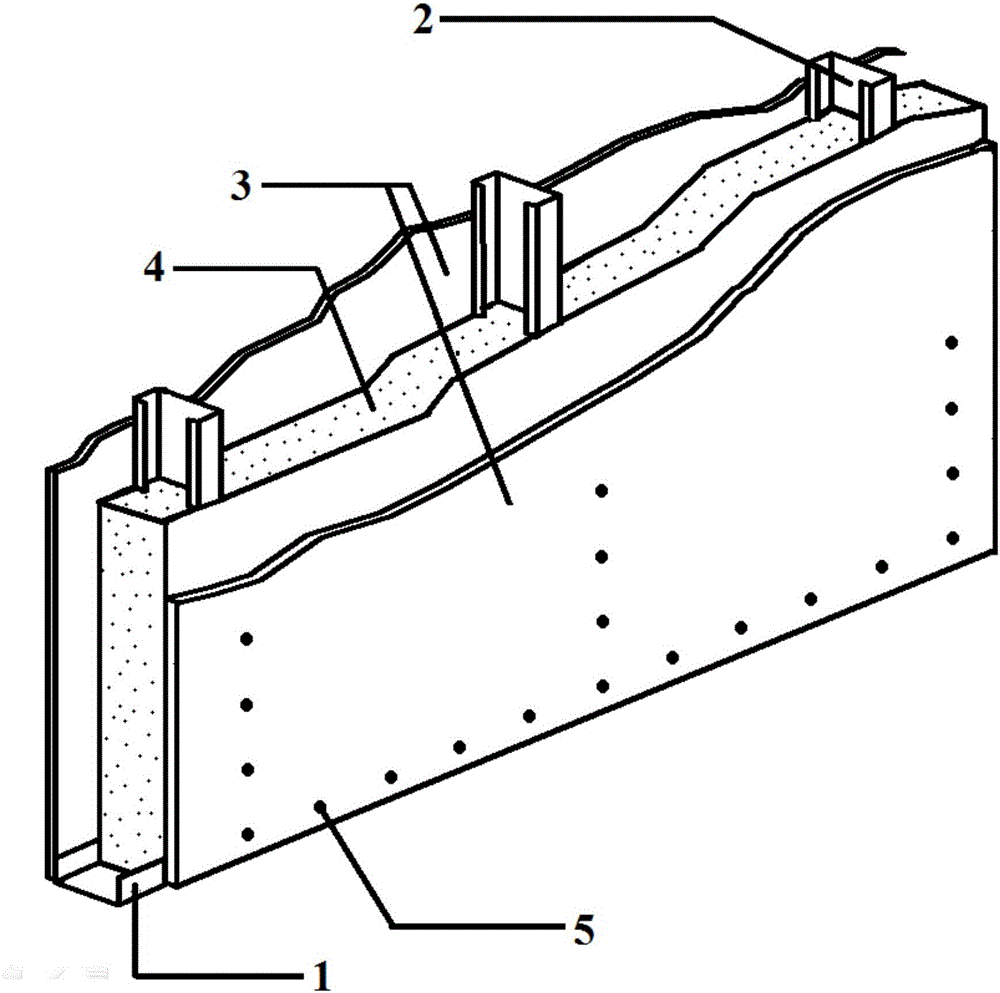

Flue gas desulfurization gypsum-based thermal insulation mortar and lightweight cold-bending thin-wall type steel composite wall

The invention provides flue gas desulfurization gypsum-based thermal insulation mortar and a lightweight cold-bending thin-wall type steel composite wall. The flue gas desulfurization gypsum-based lightweight cold-bending thin-wall type steel composite wall comprises channel steel arranged at the bottom, multiple uniformly distributed cold-bending thin-wall type steel columns are vertically solidified on the channel steel, wall panels are installed on the two sides of the columns, the flue gas desulfurization gypsum-based thermal insulation mortar is poured into a cavity between the wall panels, and the flue gas desulfurization gypsum-based lightweight cold-bending thin-wall type steel composite wall is formed after solidification is achieved. The flue gas desulfurization gypsum-based thermal insulation mortar is prepared from flue gas desulfurization gypsum, cement, fly ash, lightweight aggregates, a water reducing agent, a retarder, a thickening agent and water, wherein the lightweight aggregates are polyphenyl particles or expanded and vitrified small balls. By means of addition of the lightweight aggregates, the weight of the material itself can be decreased to a certain extent, and the strength can be improved; due to the fact that the lightweight aggregates exit, it can be guaranteed that the size of the thermal insulation mortar is stable, the phenomenon that the material is separated from the wall panels due to the fact that the material is dried and then shrinks is avoided, it is guaranteed that the wall is tightly attached to the wall panels, and the comprehensive load capacity of the wall is improved.

Owner:CHANGAN UNIV

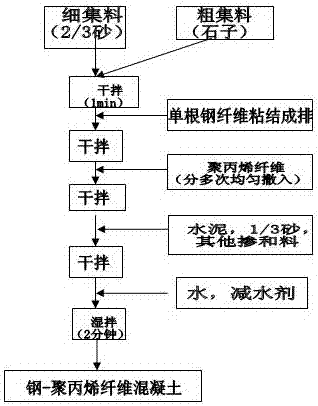

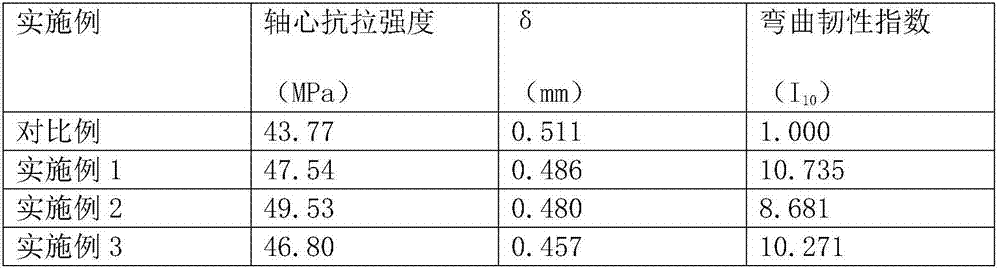

High-performance expanded hybrid fiber concrete material for wet joints, and preparation method thereof

The invention provides a high-performance expanded hybrid fiber concrete material for wet joints, and a preparation method thereof. According to the present invention, based on the practical problems of the wet joint in the whole simply supported-continuous structure system, high-strength hybrid fiber reinforced concrete is used as a joint material to provide the hybrid effect at different levels and different load applying stages so as to well inhibit and restrict the development of cracks, wherein the development of the concrete micro-crack is limited by releasing the concentrated force of the micro-crack in the concrete with Durafibers, the development of the macro-crack is limited by steel fibers, and by mixing the Durafibers and the steel fibers, a variety of mechanical properties of the whole concrete can be improved in the case of the low doping volume, such that the concrete can have characteristics of high bending resistance, high toughness, high impermeability, high fatigue resistance and the like so as to prevent the occurrence of diseases.

Owner:WUHAN UNIV OF TECH

Modified polycarboxylic high performance water reducer and its production method and application method

The invention relates to the technical field of water reducers and provides a modified polycarboxylic high performance water reducer and its production method and application method. The water reducer is prepared from the following raw materials: methallyl alcohol polyoxyethylene ether, isoamylene alcohol polyoxyethylene ether, acrylic acid, methacrylic acid, maleic anhydride, hydrogen peroxide, ammonium persulfate and water. The water reducer provided in the invention has the advantages of non-toxicity, environmental friendliness, cheap and easily available raw materials, easily controllablereaction conditions, simple operation and easy storage and transportation, so popularization and application of the water reducer are facilitated; moreover, the water reducer has a high water-reducing rate, low production cost and high cost performance; the water reducer is favorable for ensuring volume stability and durability of concrete and especially applicable to preparation of high performance concrete with durability as a core characteristic of the concrete and can particularly meet requirements for preparation of concrete which is used for construction of a nuclear power station.

Owner:新疆西建新材料科技有限公司

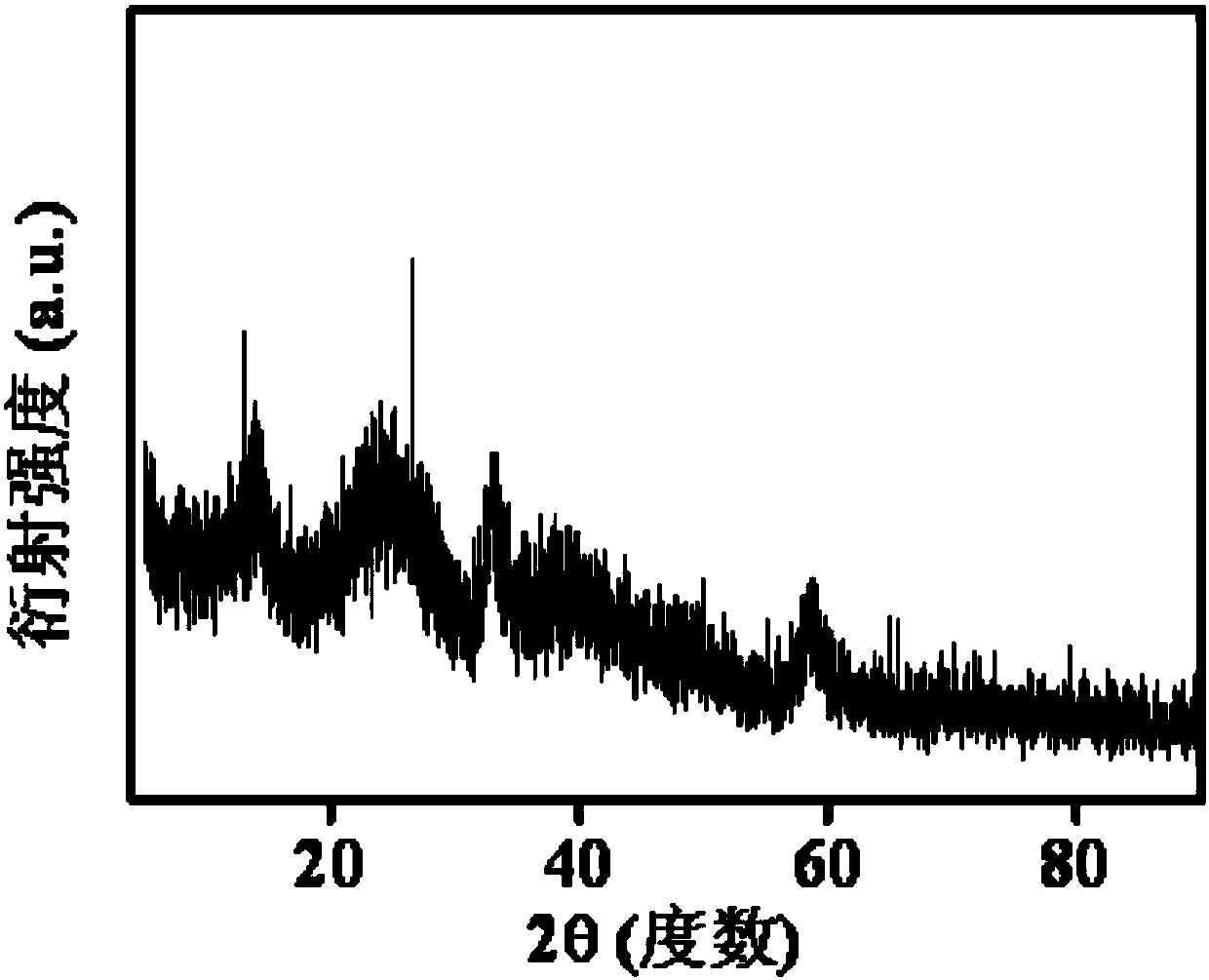

Nitrogen doped carbon nanofiber/molybdenum disulfide composite and preparation method and application thereof

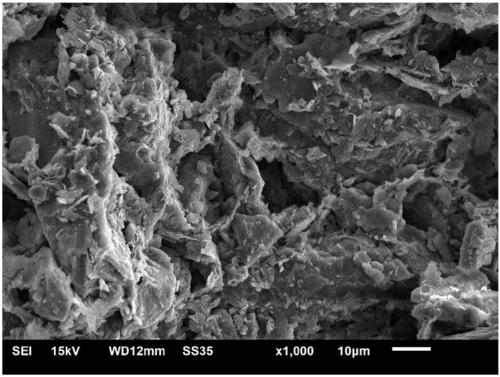

ActiveCN107768622AUniform diameter distributionLarge specific surface areaCell electrodesSecondary cellsFiberHigh rate

The invention relates to a nitrogen doped carbon nanofiber / molybdenum disulfide composite. The nitrogen doped carbon nanofiber / molybdenum disulfide composite takes a polymethyl methacrylate nanofiberas a template, polypyrrole is polymerized on the surface of the nanofiber in situ, the molybdenum disulfide is then grown in situ, the composite has a hollow tubular structure, a molybdenum disulfidesheet is evenly distributed on the surface of the nitrogen doped carbon nanofiber, the size of the nitrogen doped carbon nanofiber is uniform, a preparation method comprises synthesis of a polymethylmethacrylate spinning solution, synthesis of a polymethyl methacrylate nanofiber membrane, synthesis of the polypyrrole / polymethyl methacrylate nanofiber membrane, synthesis of the nitrogen doped carbon nanofiber / molybdenum disulfide nanofiber membrane, and synthesis of the nitrogen doped carbon nanofiber / molybdenum disulfide composite. The method is simple, is easy to operate and is environmentally friendly; the prepared nitrogen doped carbon nanofiber / molybdenum disulfide composite has the advantages of high specific surface area, high cycle stability, high electric conductivity, high rate capability and high specific capacity, and is used as a negative electrode material for a lithium ion battery.

Owner:DONGHUA UNIV

High-doping-amount fly ash concrete road surface material and preparation method thereof

The invention discloses a high-doping-amount fly ash concrete road surface material, which is prepared from the following raw materials in parts by weight: 192 parts of cement, 192 parts of fly ash, 139 parts of water, 587 parts of medium sand, 1,307 parts of macadam and 6.53 parts of a compound additive, wherein the cement is ordinary silicate 42.5-grade cement; the fly ash is graded powder fly ash; the macadam is limestone macadam; and the compound additive consists of an efficient water reducing agent and a fly ash active exciting agent. A preparation method of the road surface material comprises the following steps of: weighing cement, fly ash, water, medium san, macadam and the compound additive according to the burdening proportions for later use; uniformly mixing the cement, fly ash, medium sand and macadam under the normal temperature condition; and adding water and the compound additive, and fully stirring to obtain the high-doping-amount fly ash concrete road surface material. Due to the adoption of the road surface material, the cement using amount is saved, the water-gel ratio is reduced, the problem of cracking of a road surface is effectively solved, the early and later strength increase of the concrete are greatly increased, and the size stability and high durability are ensured.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Compact high-purity zirconium oxide refractory product

The invention belongs to the technical field of refractory materials, and provides a compact high-purity zirconium oxide refractory product. The compact high-purity zirconium oxide refractory productcomprises the following raw materials: particles, fine powder and granulation powder, wherein the particles account for 20%-40% of the total mass of the whole refractory product, the fine powder accounts for 5%-15% of the total mass of the whole refractory product, and the granulation powder accounts for 55%-75% of the total mass of the whole refractory product; and the granulation powder also contains a part of an external binding agent, and the content of the binding agent accounts for 3-5% of the total mass of the granulation powder. The compact high-purity zirconium oxide refractory product has the characteristics of low firing temperature, low porosity, high density, high mechanical strength and excellent slag resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Manufacturing process of light-weight and high-strength self-flow castable

The invention provides a manufacturing process of a light-weight and high-strength self-flow castable. The light-weight and high-strength self-flow castable comprises the following raw materials in parts by weight: 60 parts of mullite lightweight aggregate, 10 parts of alumina clinker powder, 6 parts of mullite powder, 9 parts of silica powder, 5 parts of alumina micro-powder, 10 parts of calcium aluminate cement and 0.5 part of additives, wherein the particle size of the alumina clinker powder is 200 meshes; the particle size of the alumina micro-powder is 3-5 microns. The manufacturing process of the light-weight and high-strength self-flow castable provided by the invention has many excellent performances such as light weight, high strength and heat isolation, is suitable for the working linings and composite linings of industrial furnaces, and especially suitable for places with complex shapes and quite small construction thicknesses.

Owner:LIUZHOU GONGHE REFRACTORY MATERIAL

Micro-expansive coral sand concrete and preparation method thereof

The invention discloses a micro-expansive coral sand concrete and a preparation method thereof. The micro-expansive coral sand concrete is composed of the following components in parts by weight: 300-450 parts of cement, 15-45 parts of admixture, 600-725 parts of coral sand, 975-1150 parts of macadam, 165-205 parts of seawater, 3-7 parts of water reducing agent and 1.5-2.5 parts of liquid expanding agent. The main component of the liquid expanding agent is an emulsion generated by saponifying higher fatty acids. The novel concrete admixture liquid expanding agent is utilized to obviously enhance and improve the dry shrinkage and volume stability of the concrete. The double expansion effects sufficiently enhance the compactness of the concrete, and effectively repair and improve the porosity of the concrete, thereby ensuring the volume stability of the coral sand concrete.

Owner:WUHAN UNIV OF TECH

Full-scale fiber toughened ultra-high performance concrete and preparation method thereof

The invention discloses a full-scale fiber toughened ultra-high performance concrete and a preparation method thereof. Fibers, which are used in the ultra-high performance concrete and are used for toughening the ultra-high performance concrete, are divided into millimeter-scale fibers, micron-scale fibers and nano-scale fibers in a full-scale range. Fibers with three scales are matched based on the stress characteristics of the ultra-high performance concrete so as to meet different requirements on mechanical properties. The concrete comprises the following components in parts by weight: 90 to 250 parts of full-scale fibers, 600 to 900 parts of cement, 100 to 300 parts of mineral powder, 100 to 200 parts of silica fume, 900 to 1200 parts of fine aggregate, 8 to 15 parts of additive and 160 to 190 parts of water. The ultra-high performance concrete is toughened by full-scale fibers in the millimeter, micrometer, and nanometer scales, and thus the cracks in different scales can be constrained and controlled, when a force is applied on the ultra-high performance concrete.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Shrinkage-compensating rapid repairing material for bridge expansion joints

The invention discloses a shrinkage-compensating rapid repairing material for bridge expansion joints. The shrinkage-compensating rapid repairing material is prepared from 25-40 parts of cement, 0-4 parts of gypsum powder, 2-4 parts of silica powder, 1-4 parts of an expanding agent, 25-33 parts of quartz sand and 32-40 parts of gravel, 0.05-0.1 part of a water reducing agent, 0.05-0.15 part of a retarder, 0.01-0.1 part of super absorbent resin, 0.005-0.01 part of a lithium salt and 0-0.01 part of a defoaming agent. The raw materials used in the invention are reasonably proportioned; early strength is high, the fastest 1h can reach 30MPa or above; the later strength is stably increased, the 28-day strength can reach 60 MPa or above, when the shrinkage-compensating rapid repairing material is used as a bridge expansion joint or concrete pavement repairing material, the self internal curing effect of the concrete can be enhanced, the volume shrinkage of the hardened concrete is reduced, the volume stability of the hardened concrete is enhanced, and the requirement for rapid traffic opening is met.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

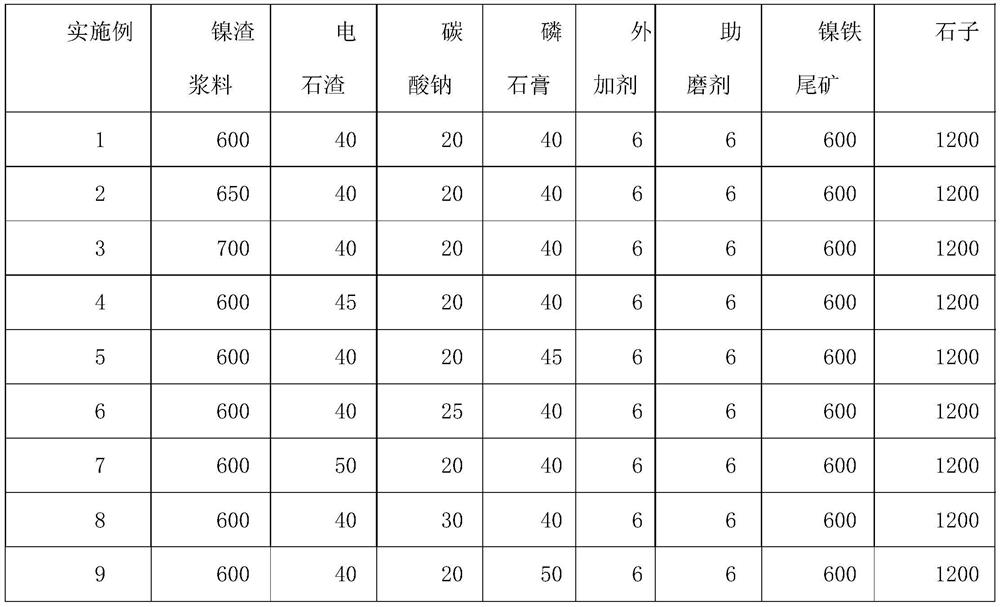

Preparation method of weakly-alkaline-activated nickel slag high-strength concrete

The invention relates to a preparation method of weak-base excited nickel slag high-strength concrete. The weak-base excited nickel slag high-strength concrete is prepared from the following raw materials in parts by mass: 350-450 parts of nickel slag, 40-50 parts of carbide slag, 20-30 parts of sodium carbonate, 40-50 parts of phosphogypsum, 550-650 parts of ferronickel tailings, 1100-1300 parts of stones, 200-300 parts of water, 5-10 parts of a grinding aid and 5-10 parts of an additive. Nickel slag is subjected to wet grinding treatment, nickel slag particles larger in specific surface area and more concentrated in particle size distribution are obtained to replace a cementing material, a weakly alkaline compound (sodium carbonate) and industrial by-products (carbide slag and ardealite) serve as excitants, and ferronickel tailings serve as fine aggregate. The nickel slag is treated in a wet grinding ultra-refining mode, energy consumption is low, and the grinding efficiency is high. Meanwhile, the sodium carbonate is added, so that metal nickel ions can be effectively cured. The prepared concrete is high in strength and good in volume stability, can effectively solve the problem of carbonization of concrete, and can be widely applied to industrial and civil buildings.

Owner:HUBEI UNIV OF TECH

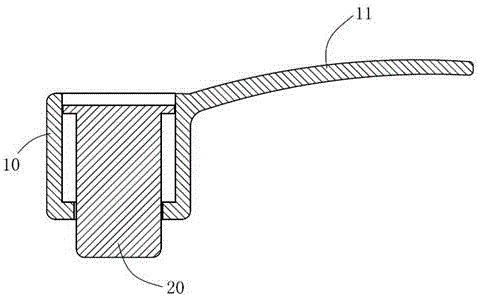

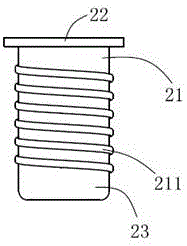

Salt spoon capable of accurately regulating dosage

ActiveCN105982486AIntuitive and accurate measurementReduce or expand volumeKitchen equipmentTablewaresInterference fitEngineering

The invention relates to a salt spoon capable of accurately regulating dosage. The salt spoon comprises a container cavity and a piston, wherein the container cavity is used for containing salt; the piston can be connected with the container cavity through interference fit and can move up and down along the inner wall of the container cavity to change the internal capacity of the container cavity. The salt spoon capable of accurately regulating dosage has the beneficial effects that by arranging the piston capable of moving up and down inside the container cavity and rotating the piston to move up and down along the container cavity to reduce or enlarge the capacity of the cavity, users can conveniently, intuitively and accurately measure the salt in required mass, thus the defect that existing spoons can not regulate the capacity is effectively overcome; the technical effect of being removable can be achieved between the container cavity and the piston, so the aim of facilitating washing can be achieved; the salt spoon capable of accurately regulating dosage has a simple structure, is ingenious in design, is convenient to use, enables the usage amount of the salt to be more accurate and is beneficial to human health.

Owner:HUIZHOU UNIV

Nonbearing concrete hollow brick manufactured by utilizing industrial solid wastes and processing method thereof

InactiveCN103113074AFix instabilitySolve the problem of high f-CaO content in itSolid waste managementBrickSlag

The invention provides a nonbearing concrete hollow brick manufactured by utilizing industrial solid wastes and a processing method thereof. The problems that a lot of the conventional steel slag is stacked, lots of lands are occupied and the environment is polluted are solved. The nonbearing concrete hollow brick manufactured by utilizing industrial solid wastes comprises the following components in parts by weight: 40-60 parts of converter slag, 20-30 parts of mill tailings powder, 5-10 parts of coal ash and 10-20 parts of inorganic gelatinization material. The method is used for manufacturing the nonbearing concrete hollow brick by utilizing industrial solid wastes.

Owner:南京梅山海强新型建材有限公司

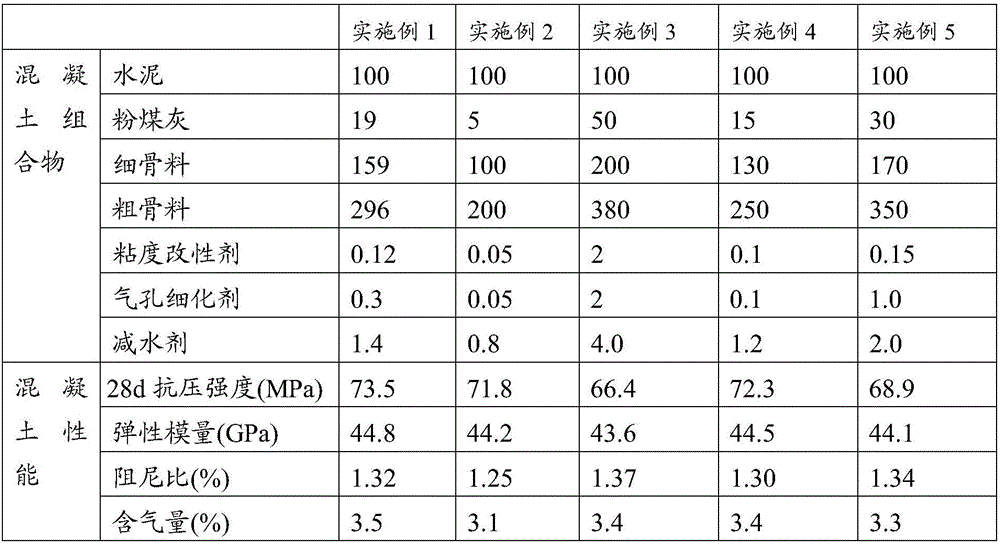

Vibration damping function concrete used for sleepers

ActiveCN106336136AGuaranteed mechanical propertiesGuaranteed volume stabilityCeramicwarePore distributionDamping function

The present invention relates to use of a porous broken stone in preparation of vibration damping function concrete; and the porous broken stone is selected from any one or a variety of porous broken stones in any weight ratio of porous basalt broken stone, porous limestone broken stone and porous granite broken stone. The invention also provides a concrete composition using the porous broken stone as a coarse aggregate and application thereof in preparation of prestressed concrete sleepers. The concrete composition comprises 100 parts by weight of cement, 5-50 parts by weight of fly ash, 100-200 parts by weight of a fine aggregate, 200-380 parts by weight of the coarse aggregate, 0.05-2 parts by weight of a viscosity modifier, 0.05-2 parts by weight of a pore refiner and 0.8-4.0 parts by weight of a water reducing agent. After hardening of fresh mixed concrete prepared from the concrete composition, internal pore distribution is reasonable, strength requirements are met, and at the same time, the fresh mixed concrete has a high damping ratio so as to solve the poor vibration effect problems of conventional prestressed concrete sleepers.

Owner:CHINA ROAD & BRIDGE +2

Light composite baking-free brick for nitrogen kiln and its preparing method

The invention discloses a nitrogen kiln using light compounding unburned brick and the manufacture method. It includes working layer, and identity layer. Working layer, which is made up of 40-50% light aggregate, 2-10% silicon fine powder, 44-54% sintering alumina powder, and 0.3-1% paper pulp powder, occupies 1 / 4-1 / 2, and identity layer, which is made up of 40-50% light aggregate, 50-60% sintering alumina powder, 0.3-1% paper pulp power, occupies 1 / 2-3 / 4. When adding material, using clapboard to separate off, adding material into working layer and identity layer, removing the clapboard, taking shaking pressing or machine pressing molding, baking at 150-250 degree centigrade, the product would be gained. The invention would enhance the thermal shock resistance, and high or low temperature combination intensity of light brick.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Tough oil well cement

InactiveCN106278003AStrong ability to change laterallyLow elastic modulusSolid waste managementFiberPlastic yielding

The invention discloses tough oil well cement. The cement is characterized by being prepared from components in parts by weight as follows: 100 parts of cement, 1-15 parts of active filler, 1-5 parts of a toughening material, 0.01-0.05 parts of staple fibers, 1-5 parts of an additive, 0.1-0.2 parts of a water educing agent, 1-5 parts of a fluid loss agent, 1-2 parts of an antifoaming agent and 1-5 parts of a retarder. An oil well cement sheath is high in lateral deformation capacity, low in elasticity modulus, high in plastic yielding point and good in elasticity; the oil well cement ring has very high ultimate strain value, can absorb larger impact energy and greatly improves the deformation performance of set cement compared with raw slurry, so that the requirement for cement performance in the oil and gas well development process is met, and cementing quality and follow-up development are guaranteed.

Owner:JIAHUA SPECIAL CEMENT

Preparation method of low-zirconium mullite cast steel brick

The invention relates to a preparation method of a low-zirconium mullite cast steel brick, and belongs to the field of preparation of refractory materials. The raw material formula of the low-zirconium mullite cast steel brick provided by the invention comprises electrically smelted mullite, zirconium oxide, Guangxi white clay, andalusite, kyanite and lignin. According to the method provided by the invention, type and grain size of the raw materials are selected to be matched with the sintering temperature and time provided by the invention, so that the prepared low-zirconium mullite cast steel brick has the characteristics of excellent scouring resistance, high temperature resistance, small creep deformation, high compression strength, good thermal stability and the like, and is suitable for being used in large steel ingot casting in nuclear power products.

Owner:四川锦圆耐材有限公司

Ultrafine inorganic grouting material for tunnel inverted arches, and preparation method thereof

ActiveCN109020419AGuaranteed mechanical propertiesImprove early strengthWater reducerMaterials science

The invention discloses an ultrafine inorganic grouting material for tunnel inverted arches. The grouting material comprises, by mass, 75-90% of an ultrafine cementing material, 5-20% of a mineral filler, 2.5-7.5% of a composite expansion agent, 0.04-0.08% of a fluid volume stabilizer, 0.5-1.5% of a film forming modifier, 0.4-0.8% of a water reducer, 0.02-0.05% of a defoamer, 0.1-0.4% of a dispersant, 0.05-0.1% of an anti-seepage water repellent and 1-5% of a nano-reinforcing component. Above components are uniformly mixed, water is added according to a water-cement ratio of 0.25-0.30, and stirring is performed to obtain the grouting material which can be used for grouting reinforcement portions and defect parts of the tunnel inverted arches. The inorganic grouting material obtained in theinvention is suitable for repairing and stabilizing defects and dangerous rock bodies of tunnel inverted arches at 5-35 DEG C, has the advantages of high fluidity, high bonding strength, no shrinkage, good impermeability and good durability, and is suitable for being promoted and applied.

Owner:HUBEI UNIV

Anti-cinder high-temperature coating

The invention discloses an anti-cinder high-temperature coating prepared by the following raw materials in parts by weight: 60-75 parts of chromium oxide green, 20-40 parts of quartz sand powder, 0.2-10 parts of silicon oxide powder and 10-20 parts of inorganic binder. The anti-cinder high-temperature coating prepared by the raw materials has better volume and stability and can form a close-packedstructure after being sintered at high temperature, thereby ensuring that an anti-cinder high-temperature coating and a refractory material layer cannot bond because cinder permeates and enters in the coating layer; in addition, when heating furnaces are centrically treated, the anti-cinder high-temperature coating layer is very easy to strip, and the integrity of the refractory material layer can be also well ensured while stripping.

Owner:PUYANG REFRACTORIES GRP CO LTD +1

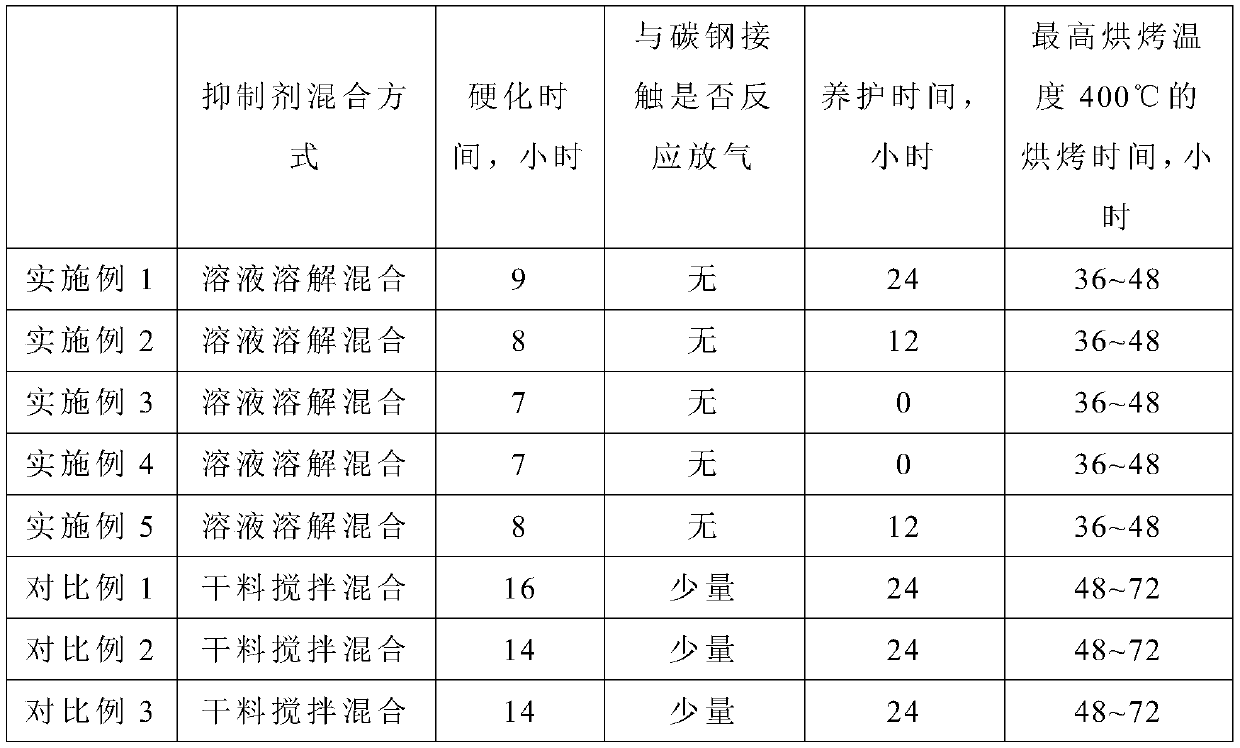

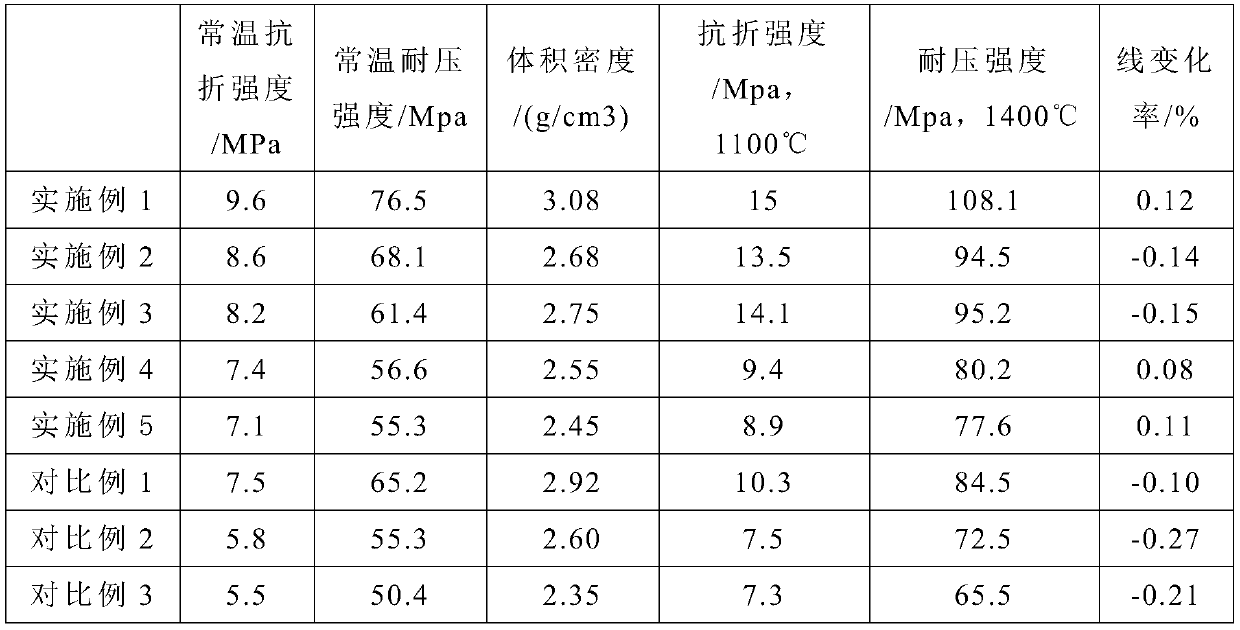

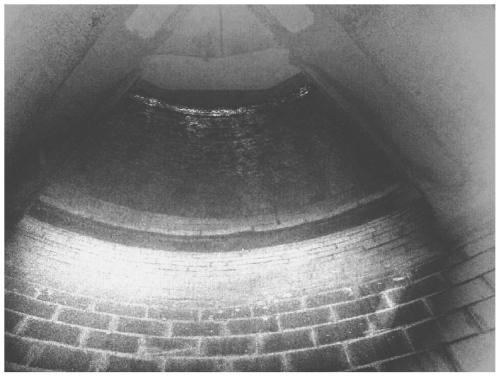

Aluminum dihydrogen phosphate and steel fiber reinforced refractory castable and preparation method

The invention discloses an aluminum dihydrogen phosphate and steel fiber reinforced refractory castable and a preparation method. The aluminum dihydrogen phosphate and steel fiber reinforced refractory castable comprises a main refractory material, an additive and a binding agent; the raw material of the binding agent comprises an aluminum dihydrogen phosphate aqueous solution in mass concentration of 45-50%; thiourea and potassium iodide are dissolved in the aluminum dihydrogen phosphate aqueous solution in mass concentration of 45-50%; the weight of the aluminum dihydrogen phosphate aqueoussolution in mass concentration of 45-50% is 8-12% of total weight of the main refractory material. The aluminum dihydrogen phosphate and steel fiber reinforced refractory castable is adopted for preparing the products, such as a molten iron slagging plate with a carbon steel metal core wrapped with a refractory material; the generation of reaction gas of aluminum dihydrogen phosphate is avoided during the processes of castable preparation and casting molding; water resistance and strength under normal temperature of the casting body are promoted; excellent effects of greatly reducing the timeof casting molding and baking preparation, reducing baking energy consumption and prolonging service life are achieved.

Owner:武汉钢铁有限公司

Columnar mullite brick with high wear resistance, and production method thereof

The invention relates to a columnar mullite brick with high wear resistance. The columnar mullite brick with high wear resistance comprises 57-72 wt% of granulated bauxite, 8-16 wt% of third-level rawbauxite powder, 6-14 wt% of fine pyrophyllite powder, 3-6 wt% of fine SiO2 powder, 1-3 wt% of alpha-Al2O3 micro-powder, 0.2-1 wt% of CeO2 micro-powder, 0.5-2 wt% of Al-Zn alloy powder and 0.5-2 wt% of potassium carbonate powder. The invention also discloses a production method of the columnar mullite brick with high wear resistance. The granulated bauxite material is obtained by batching second-level bauxite clinker particles, second-stage raw bauxite powder, chromite powder, yttrium oxide micro-powder and silica sol according to a mass ratio 65:35:(4-6):(2-8):(10-20), compacting the obtainedmixture, drying the compacted mixture, and crushing the dried mixture. All the raw materials are weighed in proportion, and then are mixed, aged, shaped, dried and fired to produce the columnar mullite brick with high wear resistance. The columnar mullite brick with high wear resistance has the characteristics of high columnar mullite content, excellent wear resistance, good volume stability andhigh cost performance, and can completely meet the needs of no major repairing of the cooling section of a large dry quenching coke oven for 8 years.

Owner:宜兴市丁山耐火器材有限公司

A kind of lightweight ultra-high-strength concrete and its preparation method

The invention relates to a lightweight super-high-strength concrete and a preparation method thereof. The lightweight super-high-strength concrete comprises the following components in parts by weight: 630-650 parts of cement, 280-300 parts of ultrafine fly ash, 180-300 parts of 200 parts of silica fume, 100-120 parts of emery powder, 100-200 parts of floating beads, 150-200 parts of Peek plastic particles, 18-23 parts of organic polymer water-absorbing resin, 20-30 parts of polycarboxylate superplasticizer, 0.13- The water-to-binder ratio is 0.15, and the floating beads are divided into two particle size grades: 40‑100 mesh and 20‑40 mesh. The obtained lightweight ultra-high-strength concrete fully optimizes and improves the internal structure by the powder and aggregates mixed therein, greatly reduces the bulk density, improves the overall strength, has excellent performance, is simple to prepare, and is suitable for popularization.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

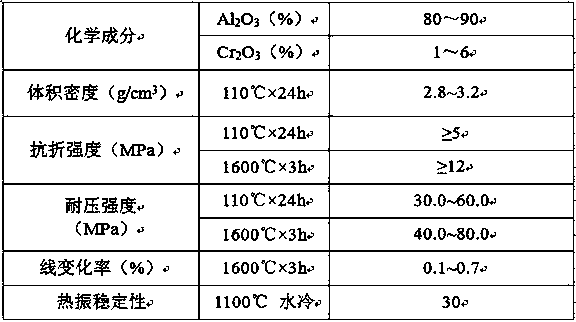

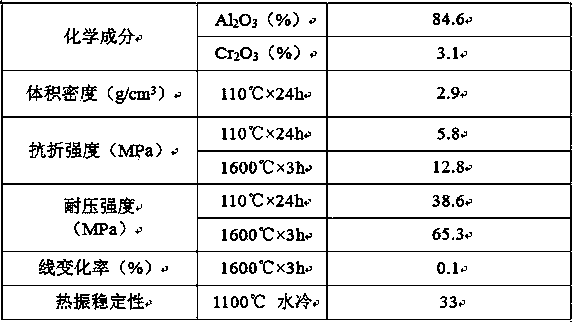

Low-zirconium mullite draft tube brick and preparation method thereof

The invention relates to a low-zirconium mullite draft tube brick and a preparation method thereof, belonging to the field of refractory materials. The low-zirconium mullite draft tube brick comprises the following raw materials by weight: 45 to 55 parts of fused mullite, 15 to 25 parts of zirconia, 3 to 8 parts of Guangxi white mud, 15 to 25 parts of andalusite, 2 to 5 parts of kyanite and 1 to 5 parts of lignin. According to the invention, through selection of types and particle sizes of the raw materials and cooperative usage of sintering temperature and time provided by the invention, the prepared draft tube brick has the characteristics of excellent anti-scouring performance and high temperature resistance, small creep deformation, good thermal stability, etc. and is applicable to vacuum casting of large steel ingots in a nuclear power product.

Owner:四川锦圆耐材有限公司

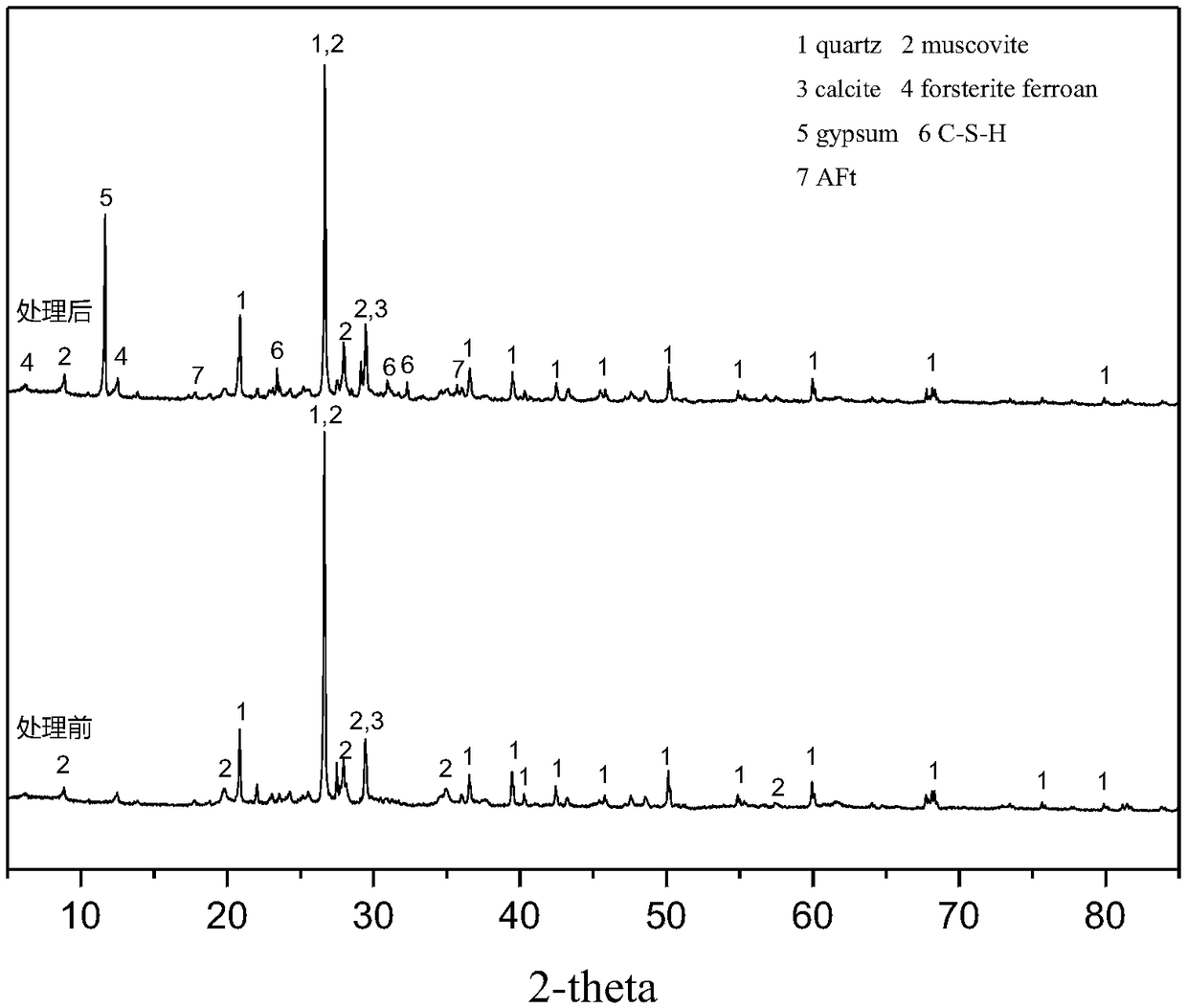

Composite cementing material with double efficacies for curing and improving salted silt soil

The invention discloses a composite cementing material with double efficacies for curing and improving salted silt soil. The composite cementing material not only sufficiently utilizes industrial waste, solves the emission and stacking problems of the industrial waste, but also cures and improves the salted silt. The silt curing cost is reduced, the performance is improved, and the application range is enlarged. The composite cementing material is prepared from the following components in percentage by weight: 6 to 10 percent of phosphogypsum, 7.5 to 12.5 percent of high-magnesium metallurgicwaste residues, 1.5 to 2.5 percent of exciting agent A, 0.4 to 0.7 percent of exciting agent B, and 0.6 to 0.8 or 0.9 to 1.2 percent of improver; the use amount of each component is the weight percentage of each component to the salted silt; and the exciting agent A is prepared from NaOH and water glass, the weight percentage of NaOH is 20 to 40 percent, and the weight percentage of water glass is60 to 80 percent; and the exciting agent B is Na2SO4.

Owner:NANJING UNIV OF TECH +2

Special casting materials for triangular area prefabricated components of electric arc furnace roof

InactiveCN109160808AGood high temperature strength and thermal shock stabilityGuaranteed compactness and volume stabilityIndustrial wasteScrap

The invention discloses special casting materials for triangular area prefabricated components of an electric arc furnace roof. The special casting materials are prepared from the following raw materials: 20-35 parts of highly pure aluminum bauxite, 10-25 parts of tabular corundum, 15-32 parts of chromium corundum, 3-5 parts of spinel fine powder, 1.5-2.5 parts of kyanite, 5-9 parts of active aluminum oxide micro powder, 1-3 parts of chromium oxide green fine powder, 2-4 parts of silicon micro powder, 3.11-5.25 parts of a bonding agent, 0.03-0.06 part of organic fibers and 0.5-1 part of stainless steel fibers. According to the special casting materials disclosed by the invention, scientific grain size distribution is adopted for main body granules, so that the triangular area prefabricatedcomponents are guaranteed to have good high temperature strength and good hot vibration stability; materials of the spinel micro powder, pure calcium aluminate cement, active aluminum oxide and chromium oxide green and the like, which are added, are compounded, and after casting moulding and baking, a high-strength low-temperature solidified combination liner is formed, so that the compactabilityand the volume stability of the prefabricated components are guaranteed; the chromium corundum (Al2O3+Cr2O3 greater than or equal to 95%) in the raw materials is slag for smelting electrofusion chromium metal; through the use of the raw materials, the cost of products can be reduced, discharge of industrial waste can be reduced, and cyclic utilization of the industrial waste can be effectively realized.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Volume-stable high-temperature bedplate and manufacturing method thereof

The invention discloses a volume-stable high-temperature bedplate, belonging to the field of refractory kiln furniture preparation. According to the invention, sintered corundum and fused mullite particles are used as aggregates, and an aluminum titanate composite phase material is introduced into a matrix, and sintering at a high temperature is carried out to obtain the bedplate; and the preparedbedplate can meet the requirements for high-temperature strength and good thermal shock resistance on the bedplate in use and is obviously improved in volume stability, and the size change of the bedplate in an advancing direction is less than or equal to 0.5% after long-time circulation in a use environment.

Owner:江苏三恒高技术窑具有限公司

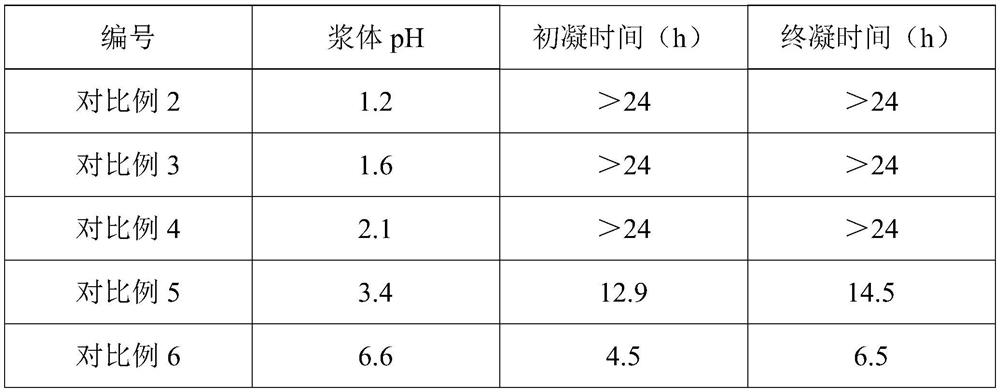

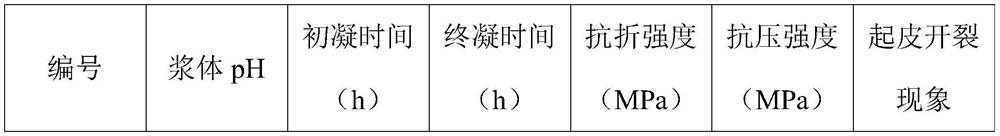

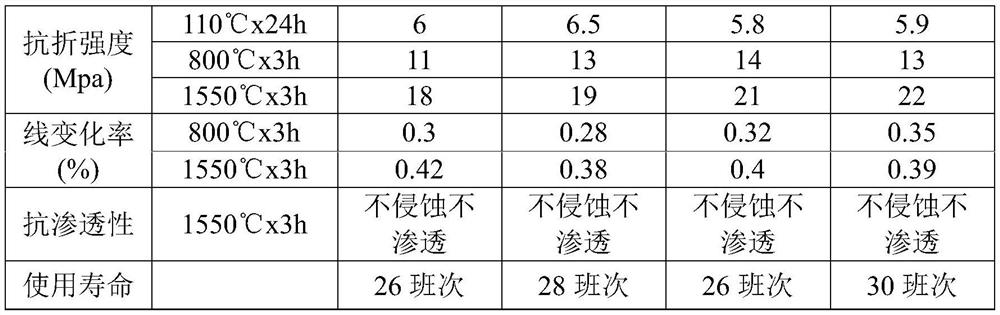

Fluorgypsum-based plastering material as well as preparation method and application thereof

The invention provides a fluorgypsum-based plastering material as well as a preparation method and application thereof. The fluorgypsum-based plastering material is prepared from fluorgypsum, an admixture, aggregate, an expansion inhibitor, an excitant, a water retention thickener and an acid-base regulator. The preparation method comprises the following steps: crushing fluorgypsum to obtain fluorgypsum particles; and mixing the fluorgypsum particles with the admixture, the aggregate, the expansion inhibitor, the excitant, the water retention thickener and the acid-base regulator to obtain thefluorgypsum-based plastering material. The fluorgypsum-based plastering material has the characteristics of short setting time, high strength, small stacking density, good volume stability, high bonding strength, excellent water-retaining property and the like; the preparation method is simple, and the fluorgypsum-based plastering material has a wide application prospect in the field of preparation of building materials.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

Medium-frequency induction furnace bottom impervious castable

The invention discloses a medium-frequency induction furnace bottom impervious castable, and belongs to the field of furnace lining materials. The refractory material comprises the following components in parts by weight: 30-50 weight parts a of dense corundum particles; 8-10 weight parts c of of spinel micro powder; 3-5 weight parts d of active alpha-Al2O3 micro powder; 2-3 weight parts e of zirconium oxide; 0.5-0.8 weight parts f of dispersed Al2O3 micro powder; 3-5 weight parts h of pure aluminate cement; and 0.02-0.1 weight parts i of a water reducing agent. The impervious castable for the furnace bottom of the medium-frequency induction furnace aims at solving the problems that in the prior art, bonded slag permeation is prone to occurring in a furnace bottom refractory material, has the advantages of being easy to construct, high in strength, resistant to slag permeation, capable of saving energy and environmentally friendly, and is an effective measure for solving the bonded slag permeation problem of the current furnace bottom refractory material.

Owner:铜陵旭时新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com