Special casting materials for triangular area prefabricated components of electric arc furnace roof

A technology of prefabricated parts and triangular areas, which is applied in the field of refractory materials for electric arc furnaces, can solve the problems that cannot meet the requirements of electric arc furnace steelmaking, reduce the life of electric arc furnace cover, high temperature radiation and slag erosion, etc., to ensure compactness and volume stability, remarkable energy-saving effect, and the effect of realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

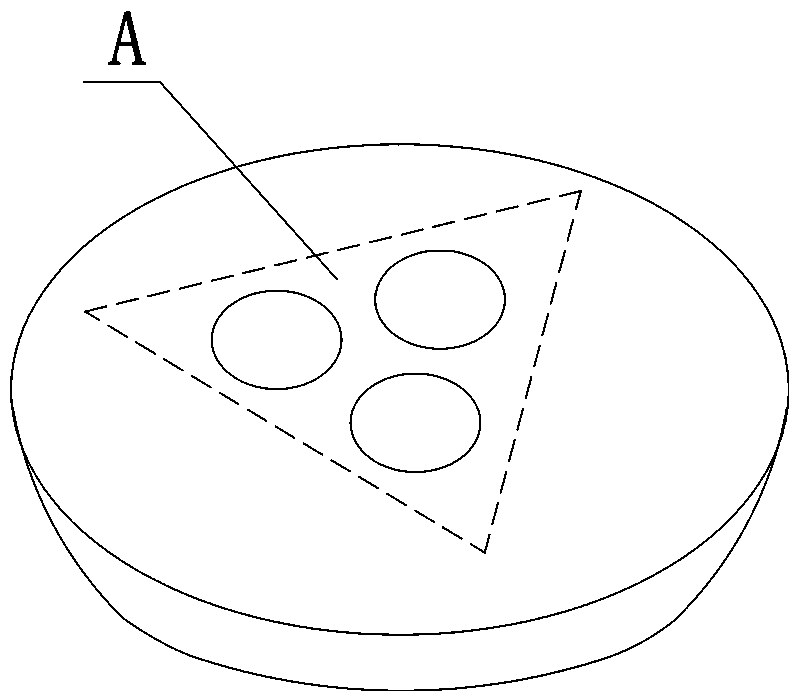

[0024] Example 1 Burning 30 tons of electric arc furnace cover triangular area prefabricated parts ( figure 1 Middle A)

[0025] Its raw material proportioning by weight is:

[0026] 35 parts of high-purity bauxite pellets with a particle size of 3-15 mm, 15 parts of plate-shaped corundum pellets with a particle size of 0.1-5 mm, 20 parts of chrome corundum pellets with a particle size of 0.1-3 mm, and 11 parts of 180-220 mesh chrome corundum powder , 3 parts of spinel fine powder, 1 part of chromium oxide green fine powder, 1.5 parts of 80 mesh kyanite powder, 5 parts of 2μm activated alumina powder, 3.5 parts of 0.7μm silica powder, 5 parts of pure calcium aluminate cement, three 0.15 part of sodium polyphosphate, 0.05 part of sodium hexametaphosphate, 1 part of 304# stainless steel fiber, 0.06 part of JT-80 organic fiber.

[0027] Firing: Accurately weigh the above-mentioned raw materials according to their parts by weight. First, chrome corundum powder, spinel fine powde...

Embodiment 2

[0030] Example 2 Firing a 60-ton electric arc furnace cover triangular area prefabricated parts

[0031] Its raw material proportioning by weight is:

[0032] 30 parts of high-purity bauxite pellets with a particle size of 3~15mm, 20 parts of plate-shaped corundum pellets with a particle size of 0.1~5mm, 20 parts of chrome corundum pellets with a particle size of 0.1~3mm, and 8 parts of 180~220 mesh chrome corundum powder , 4 parts of spinel fine powder, 2 parts of chromium oxide green fine powder, 2 parts of 80 mesh kyanite powder, 7 parts of 2μm activated alumina powder, 3 parts of 0.7μm silica powder, 4 parts of pure calcium aluminate cement, three 0.15 part of sodium polyphosphate, 0.05 part of sodium hexametaphosphate, 1 part of 304# stainless steel fiber, 0.06 part of JT-80 organic fiber.

[0033] Firing: Accurately weigh the above-mentioned raw materials according to their parts by weight. First, chrome corundum powder, spinel fine powder, chromium oxide green fine pow...

Embodiment 3

[0036] Example 3 Firing a 100-ton electric arc furnace cover triangular area prefabricated parts

[0037] Its raw material proportioning by weight is:

[0038] 20 parts of high-purity bauxite pellets with a particle size of 3~15mm, 25 parts of plate-shaped corundum pellets with a particle size of 0.1~5mm, 25 parts of chrome corundum pellets with a particle size of 0.1~3mm, and 5.5 parts of 180~220 mesh chrome corundum powder , 5 parts of spinel fine powder, 3 parts of chromium oxide green fine powder, 2.5 parts of 80 mesh kyanite powder, 9 parts of 2μm activated alumina powder, 2 parts of 0.7μm microsilica powder, 3 parts of pure calcium aluminate cement, three 0.15 part of sodium polyphosphate, 0.05 part of sodium hexametaphosphate, 1 part of 304# stainless steel fiber, 0.06 part of JT-80 organic fiber.

[0039] Firing: Accurately weigh the above-mentioned raw materials according to their parts by weight. First, chrome corundum powder, spinel fine powder, chromium oxide green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com