Cement-based grouting material used for strengthening repairing as well as preparation method and application thereof

A grouting material, cement-based technology, applied in the field of building materials, can solve the problems of organic grouting materials that are not environmentally friendly, difficult to disperse, poor in volume stability and durability, to ensure volume stability and durability, and increase viscosity. Effect of knot strength, workability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

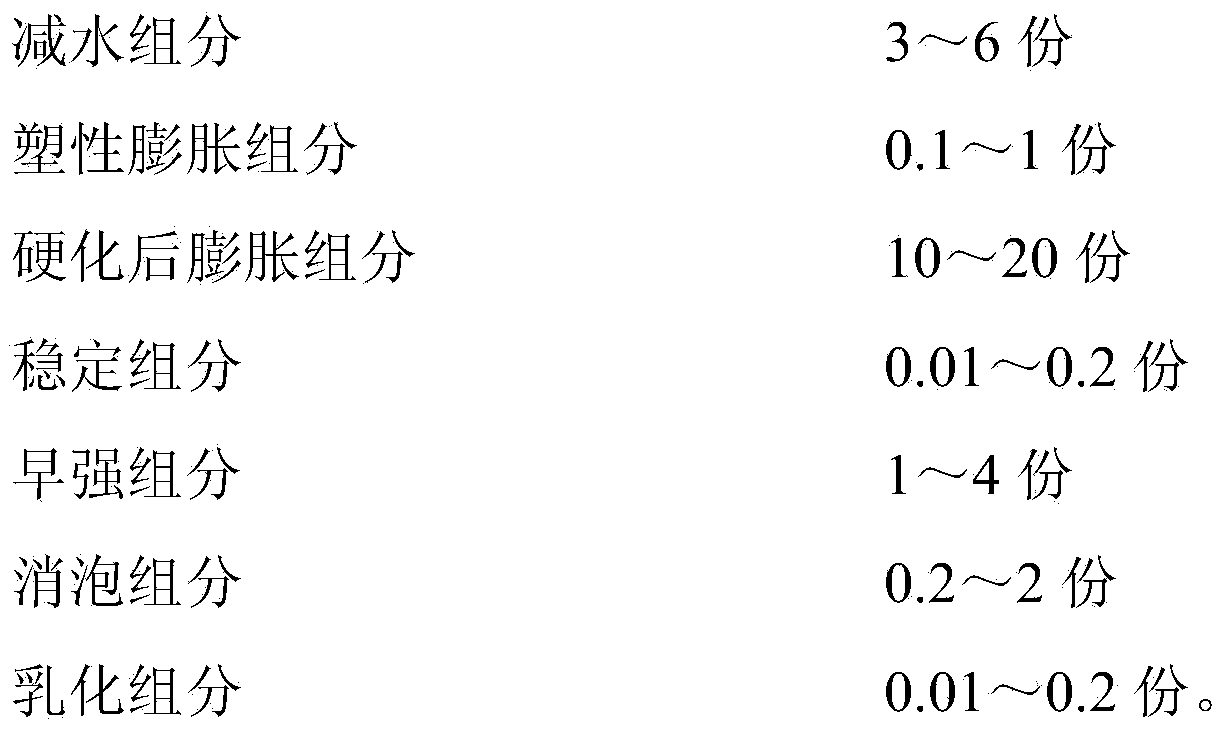

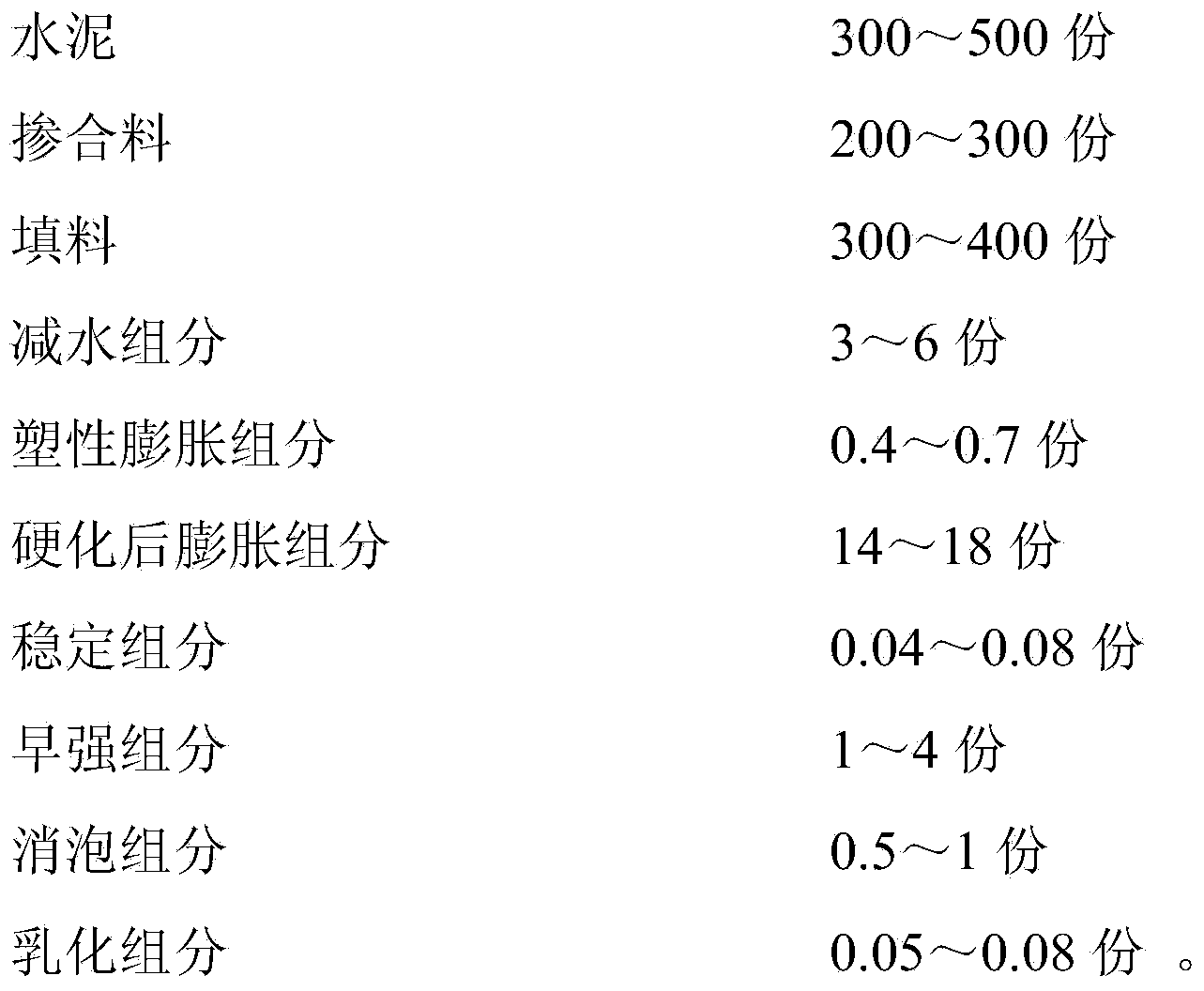

[0040] The distribution of each group is as follows:

[0041] Portland cement (Qinhuangdao Asano Cement Plant P·I, strength 42.5MPa, specific surface area 450cm 2 / g)

[0042] 300 copies,

[0043] The fineness is 200 parts of superfine fly ash of 1250 mesh,

[0044] heavy calcium 400 parts,

[0045] Polycarboxylate superplasticizer 5 parts,

[0046] Activated carbon 0.1 part,

[0047] 15 parts of calcium oxide expansion agent (model ZS of Zhengzhou Zhengsen New Materials Co., Ltd.),

[0048] Cellulose ether (Dow Chemical MKW4000PF, viscosity 400cps at 20°C) 0.1 parts,

[0049]Calcium formate (Shanghai Qiyi Chemical) 2 parts,

[0050] Organosiloxane defoamer (German munzing-chemie company P803) 1 part,

[0051] Dodecylphenol polyoxyethylene ether (Jiangsu Haian Chemical OP-15) 0.02 parts,

[0052] The above-mentioned components are put into a JS-500 mixer according to their mass parts, and continuously stirred and mixed fo...

Embodiment 2

[0057] The distribution of each group is as follows:

[0058] Ordinary Portland cement (Taihang Brand P·O42.5R of Handan Cement Factory) 200 parts,

[0059] Sulphoaluminate cement (Polar Bear brand 42.5 grade of Tangshan Polar Bear Cement Factory) 300 parts

[0060] 200 parts of superfine fly ash with a fineness of 1500 mesh,

[0061] Steel slag powder 300 parts

[0062] Polycarboxylate superplasticizer 6 parts,

[0063] Activated carbon 0.2 part,

[0064] Magnesium oxide expansion agent (Tianjin Baoming Co., Ltd.) 20 parts,

[0065] Starch ether (German munzing-chemie company 235) 0.2 parts,

[0066] Sodium silicate (Yongqing Juli Chemical Industry) 1 part,

[0067] Organosiloxane defoamer (Germany munzing-chemie company P801) 0.8 parts,

[0068] Nonylphenol polyoxyethylene ether (Jiangsu Haian Chemical SOP-20) 0.03 parts,

[0069] The above-mentioned components are put into a JS-500 mixer according to their mass parts, and continuously stirred and mixed for 5 to 10 m...

Embodiment 3

[0074] The distribution of each group is as follows:

[0075] Sulphoaluminate cement (Polar Bear brand 42.5 grade of Tangshan Polar Bear Cement Factory) 300 parts,

[0076] The fineness is 100 parts of superfine fly ash of 1500 mesh,

[0077] Fineness is 150 parts of superfine wollastonite powder of 1500 mesh,

[0078] Kaolin 400 parts,

[0079] 4 parts of melamine superplasticizer,

[0080] 0.5 parts of aluminum powder,

[0081] 7 parts of ettringite expansion agent (UEA of Tianjin Baoming Co., Ltd.),

[0082] Zeolite (Qingdao Jiade Filter Material Co., Ltd.) 8 parts

[0083] Xanthan gum (viscosity 800cps at 20°C) 0.1 parts,

[0084] Lithium carbonate 2 parts,

[0085] Organosiloxane defoamer (German munzing-chemie company P801) 1.2 parts,

[0086] Nonylphenol polyoxyethylene ether (Jiangsu Haian Chemical SOP-20) 0.05 parts,

[0087] Put the above-mentioned components into JS-500 type mixer according to their mass parts, and continuously stir and mix for 5-10 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com