Fluorgypsum-based plastering material as well as preparation method and application thereof

A gypsum-based, fluorine gypsum technology, applied in the field of building materials, can solve the problems of increasing the difficulty of the preparation process, long setting time, high fineness requirement of fluorine gypsum, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

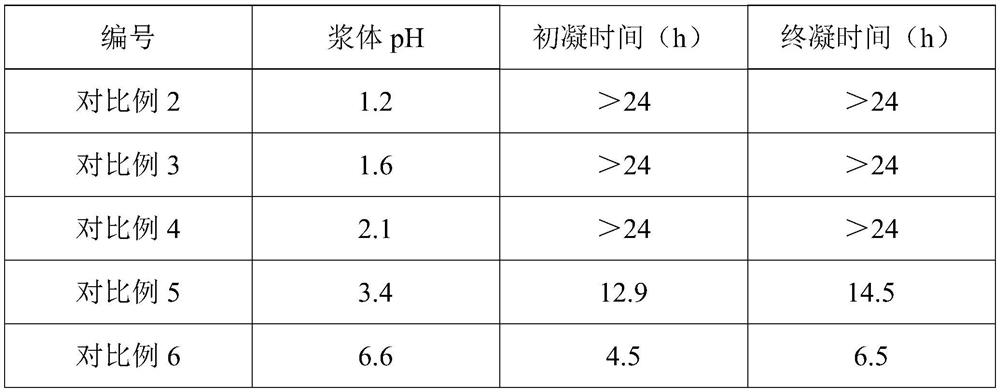

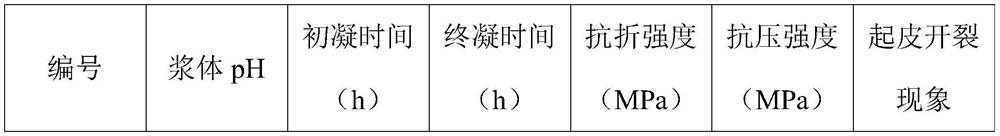

Examples

Embodiment 1

[0054] This embodiment provides a fluorogypsum-based plastering material. The fluorogypsum-based plastering material includes 5600 parts by weight of fluorogypsum, 2500 parts of β-type hemihydrate gypsum, 900 parts of hollow vitrified microspheres (100 μm), 300 parts of fly ash, 150 parts of potassium sulfate, 25 parts of starch ether and 200 parts of calcium oxide.

[0055] The preparation method comprises the following steps:

[0056] (1) transporting fluorinated gypsum to a roller ball mill for grinding to obtain fluorinated gypsum particles with a fineness of 150 mesh;

[0057] (2) Add fluorogypsum particles, β-type hemihydrate gypsum, hollow vitrified microspheres, fly ash, potassium sulfate, starch ether and calcium oxide into the V-type mixer in proportion, and mix for 10 minutes to obtain fluorogypsum-based plastering material;

[0058] Wherein, the pH of the fluorogypsum raw material is 1.5, and after the raw materials are mixed in proportion, the pH of the fluorogy...

Embodiment 2

[0060] This embodiment provides a fluorogypsum-based plastering material. The fluorogypsum-based plastering material includes 6300 parts by weight of fluorogypsum, 2000 parts of β-type hemihydrate gypsum, 700 parts of hollow vitrified microspheres (100 μm), 350 parts of silica fume, 150 parts of activator (mixed potassium sulfoaluminate, sulfoaluminate cement and calcium sulfate dihydrate at a mass ratio of 5:5:1), 25 parts of starch ether and 125 parts of calcium oxide.

[0061] The preparation method comprises the following steps:

[0062] (1) transporting fluorinated gypsum to a roller ball mill for grinding to obtain fluorinated gypsum particles with a fineness of 150 mesh;

[0063] (2) Fluorogypsum particles, β-type hemihydrate gypsum, hollow vitrified microspheres, silica fume, activator (potassium sulfoaluminate, sulfoaluminate cement and calcium sulfate dihydrate in a mass ratio of 5:5) :1 mixed), starch ether and calcium oxide were added into a V-type mixer, and mixe...

Embodiment 3

[0066] This embodiment provides a fluorogypsum-based plastering material. The fluorogypsum-based plastering material includes 6100 parts by weight of fluorogypsum, 2200 parts of β-type hemihydrate gypsum, 700 parts of hollow vitrified microspheres (300 μm), 350 parts of Portland cement, 150 parts of activator (mixing potassium sulfoaluminate, sulfoaluminate cement, calcium sulfate dihydrate and potassium sulfate at a mass ratio of 25:25:5:3), water-retaining thickener (made by mixing starch ether and magnesium aluminum silicate at a mass ratio of 1:1) 25 parts and 150 parts of calcium oxide.

[0067] The preparation method comprises the following steps:

[0068] (1) Grinding the fluorinated gypsum to a roller ball mill to obtain fluorinated gypsum particles with a fineness of 400 meshes;

[0069] (2) Fluorogypsum particles, β-type hemihydrate gypsum, hollow vitrified microspheres, Portland cement, activator (potassium sulfoaluminate, sulfoaluminate cement, calcium sulfate dih...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com