Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

431results about How to "Good insulation properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

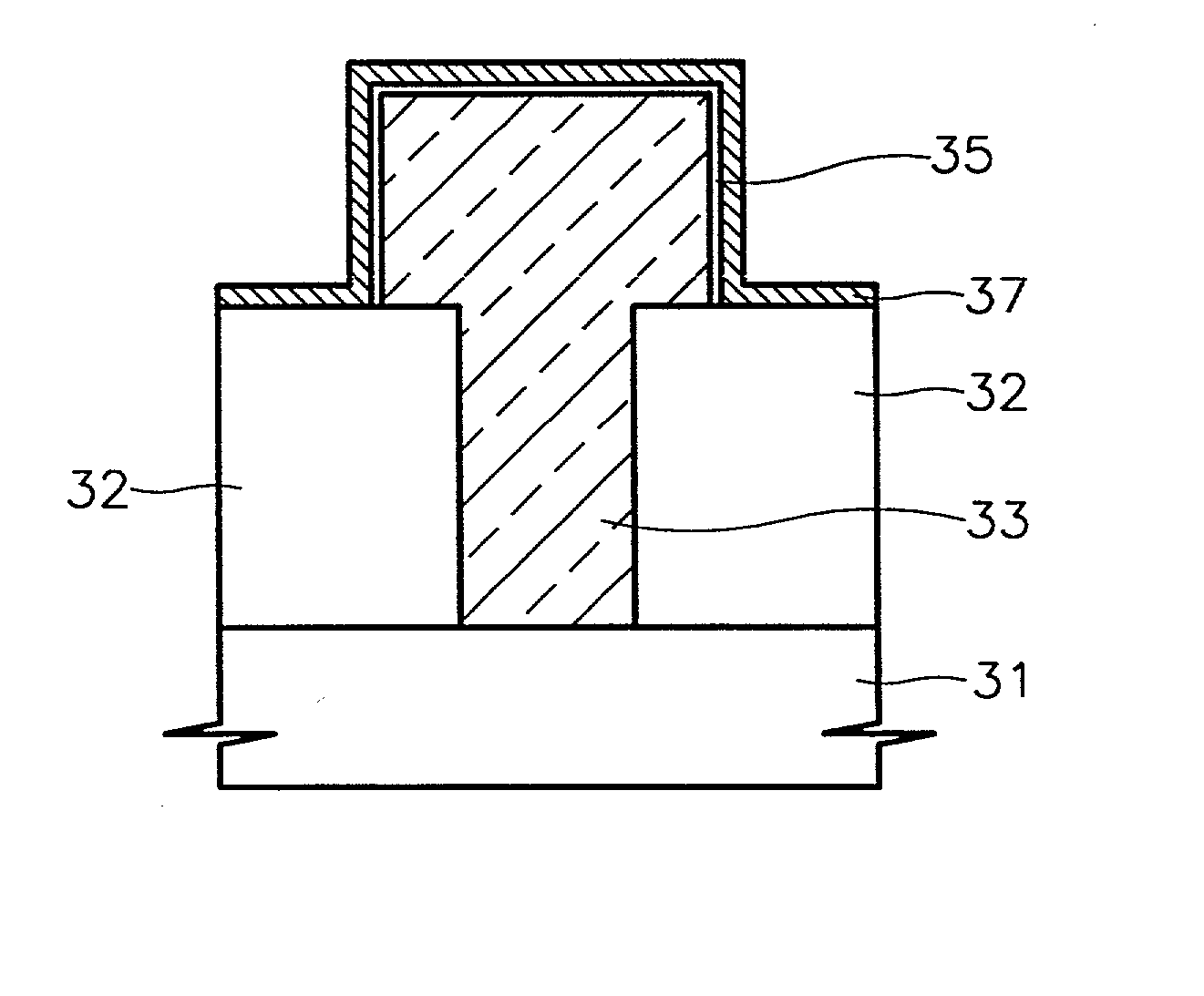

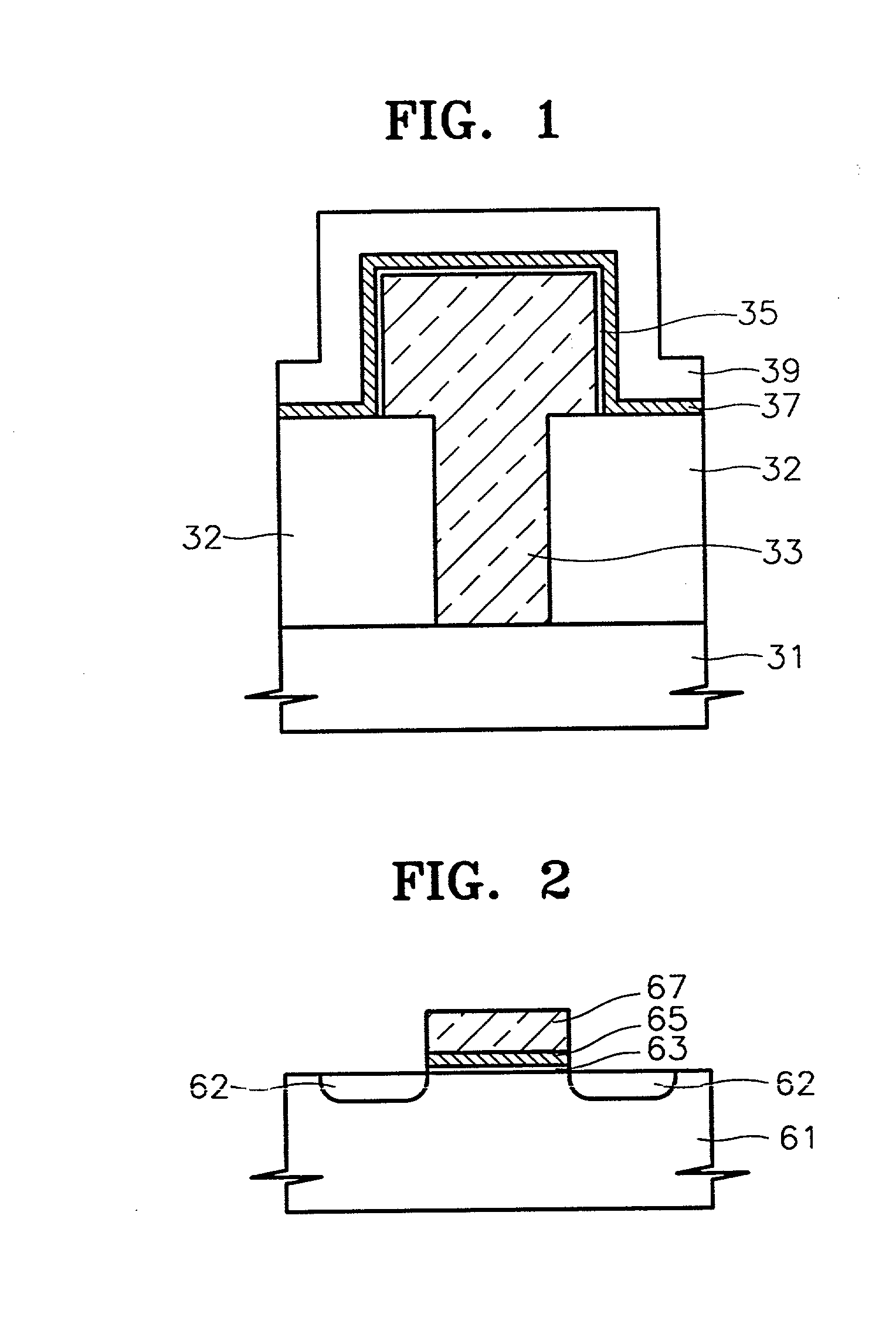

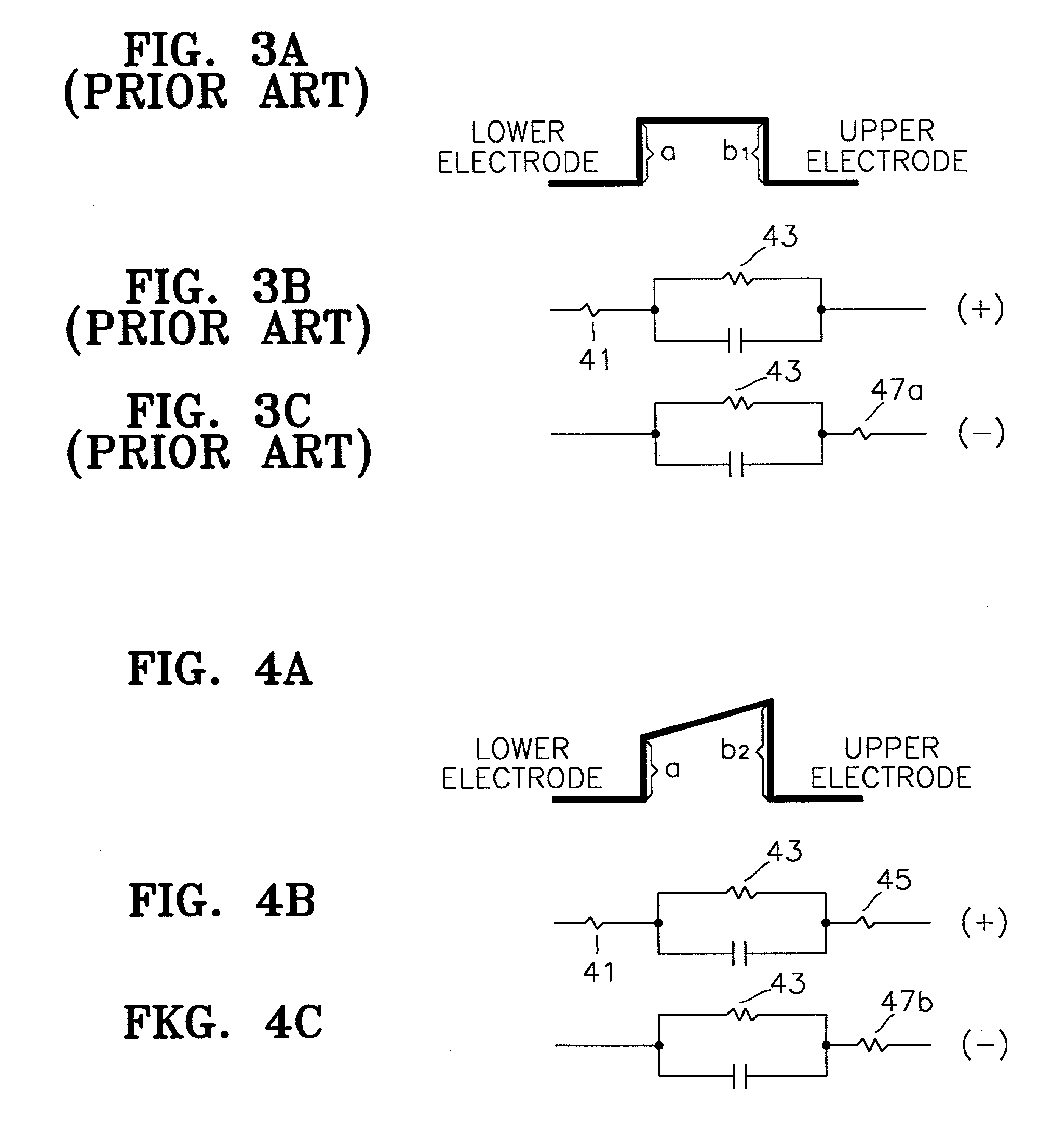

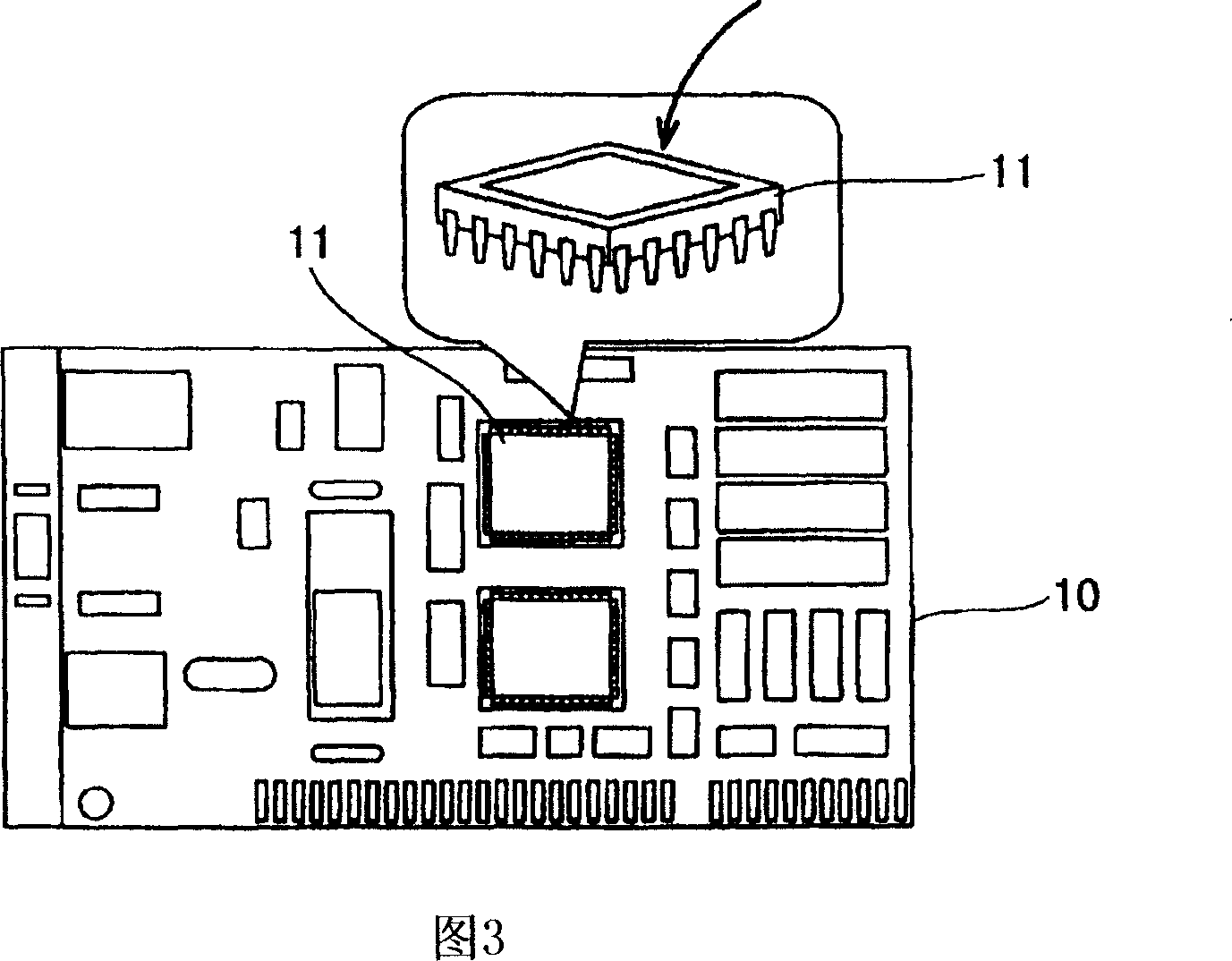

Semiconductor device and method for manufacturing the same

InactiveUS20020195683A1Promote formationGood insulation propertiesTransistorSolid-state devicesCapacitanceDevice material

A semiconductor device includes a first electrode formed of a silicon-family material, a dielectric layer formed by sequentially supplying reactants on the first electrode, and a second electrode having a work function larger than that of the first electrode, with the second electrode being formed on the dielectric layer. The first electrode and the second electrode can be a lower electrode and an upper electrode, respectively, in a capacitor structure. Also, the first electrode and the second electrode can be a silicon substrate and a gate electrode, respectively, in a transistor structure. A stabilizing layer, which is, for example, a silicon oxide layer, a silicon nitride layer, or a composite layer of the silicon oxide layer and the silicon nitride layer, for facilitating the formation of the dielectric layer by hydrophilizing the surface of the first electrode, may be formed on the first electrode. The dielectric layer can be formed by an atomic layer deposition method. Accordingly, in the semiconductor device, it is possible to improve the insulating characteristic of the dielectric layer and to increase a capacitance value in the capacitor structure.

Owner:SAMSUNG ELECTRONICS CO LTD

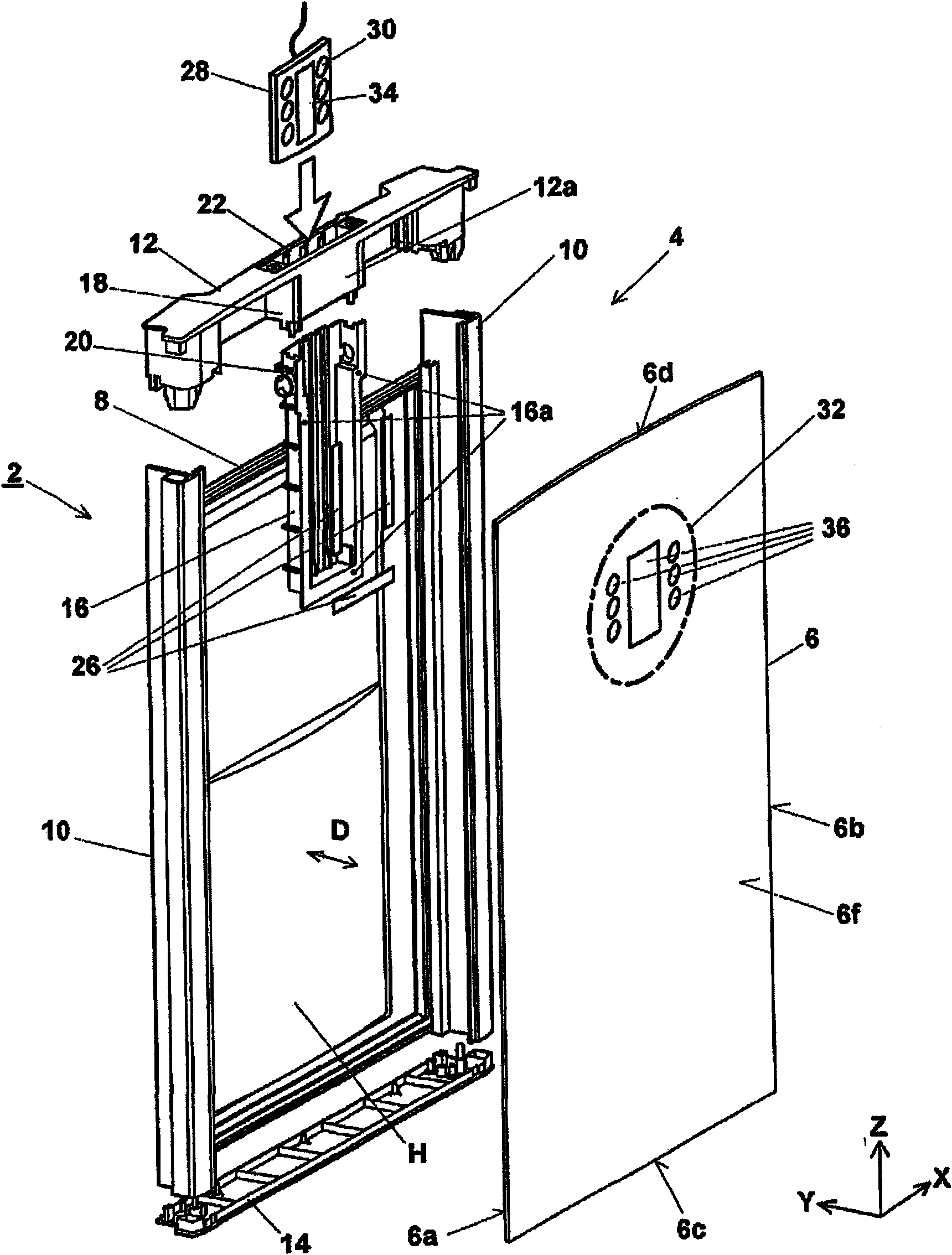

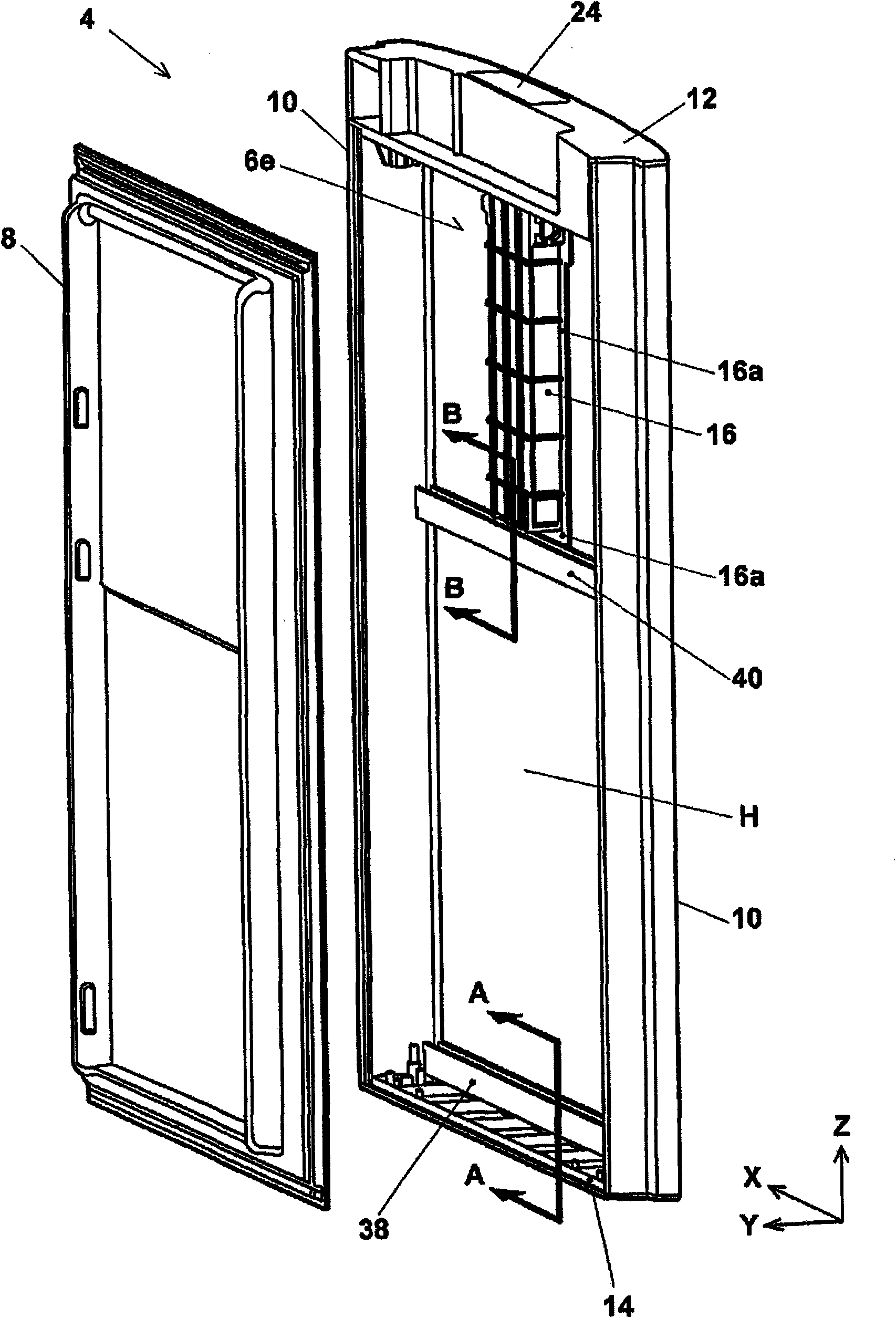

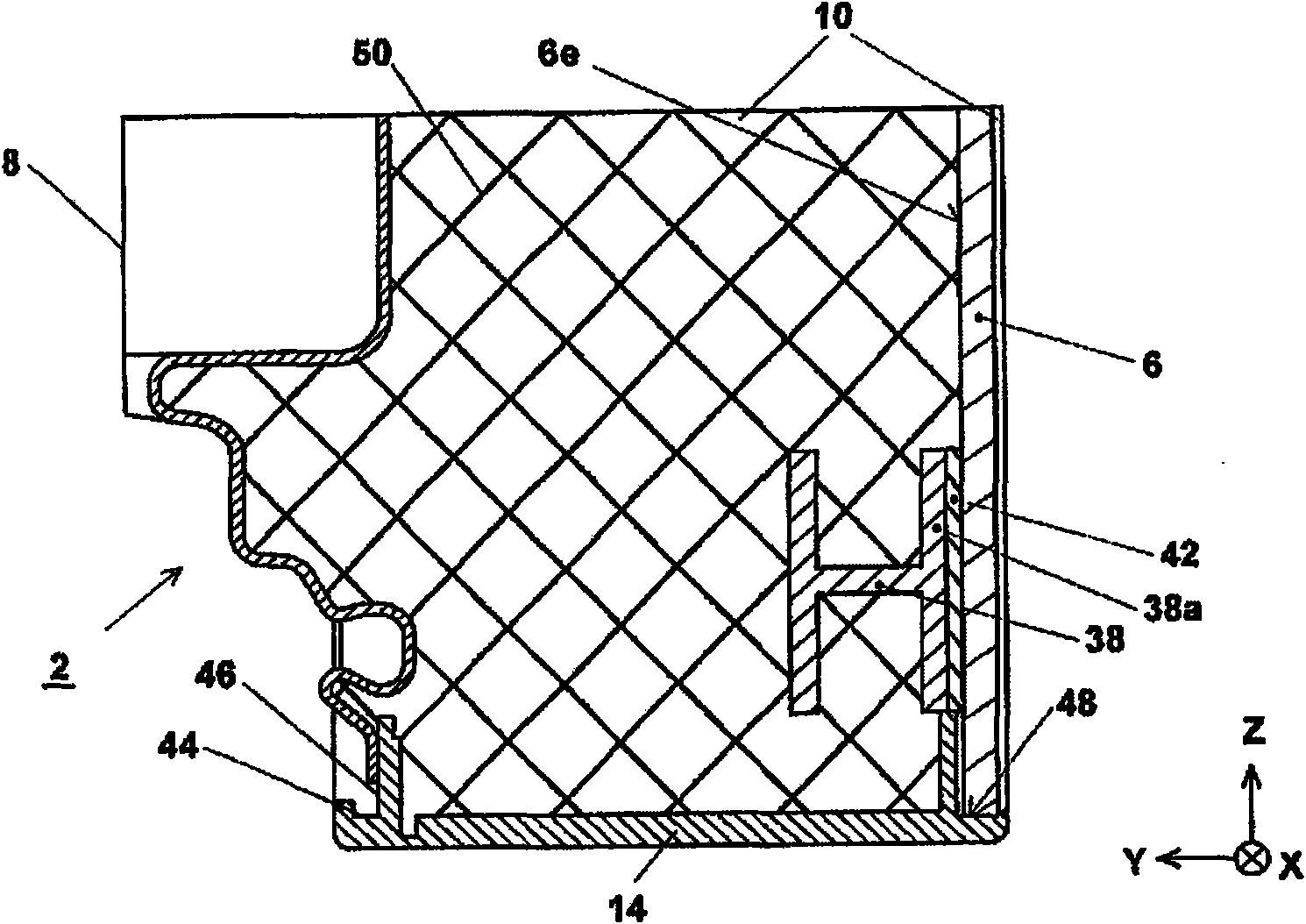

Appliance door and household appliance having such a door

InactiveCN101918778AHigh strengthImprove stabilityLighting and heating apparatusCooling fluid circulationGlass sheetIntermediate space

Appliance door (2), in particular door of a (household) refrigerating appliance, having a door structure (4) with a front-side glass plate (6) and a back plate (8) of another material arranged at a distance (D) from the latter by an intermediate space (H), wherein the front-side glass plate (6) forms a structural component of the door structure (4).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

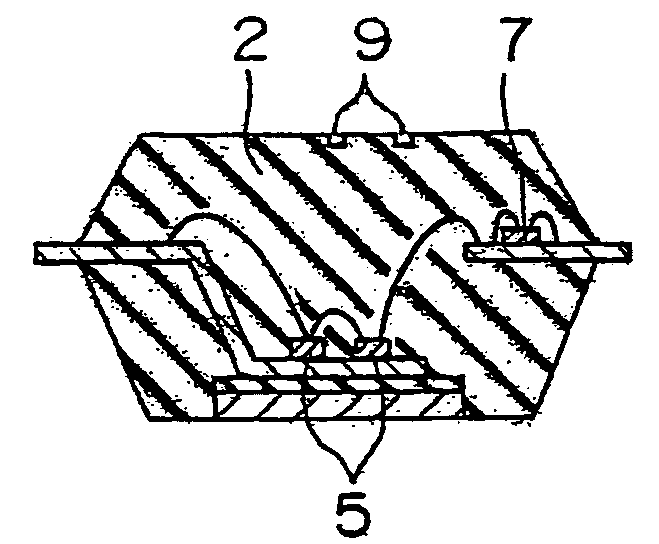

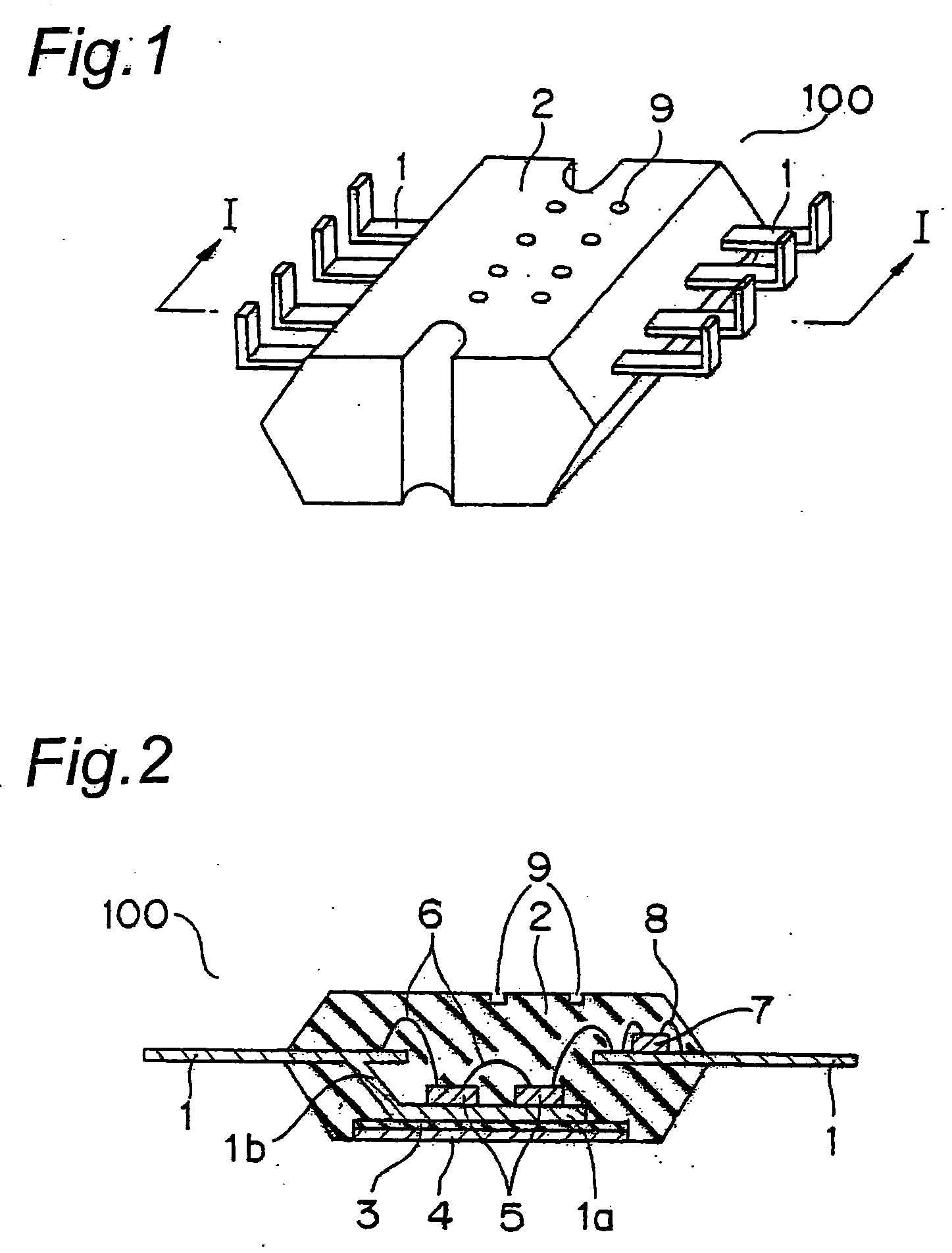

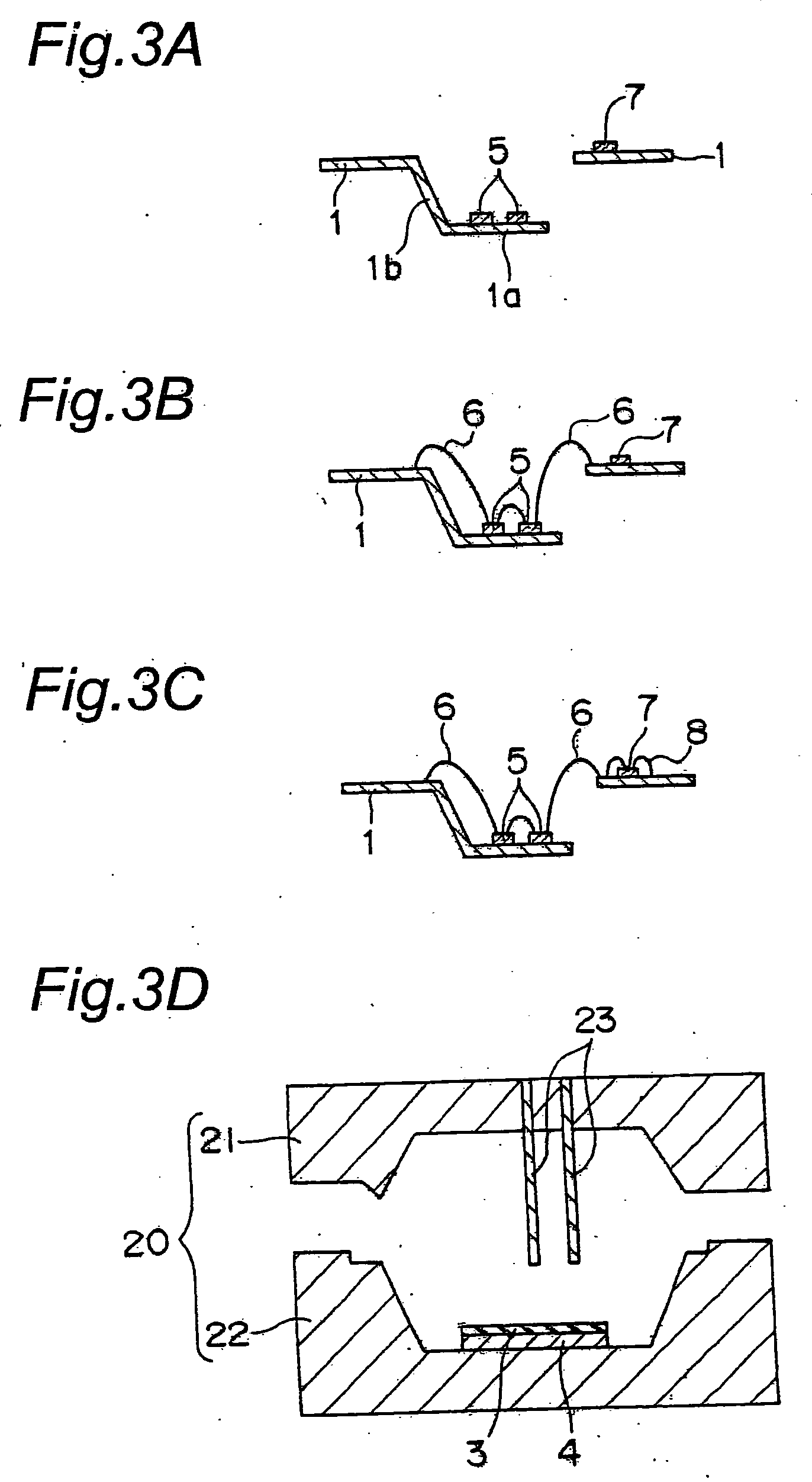

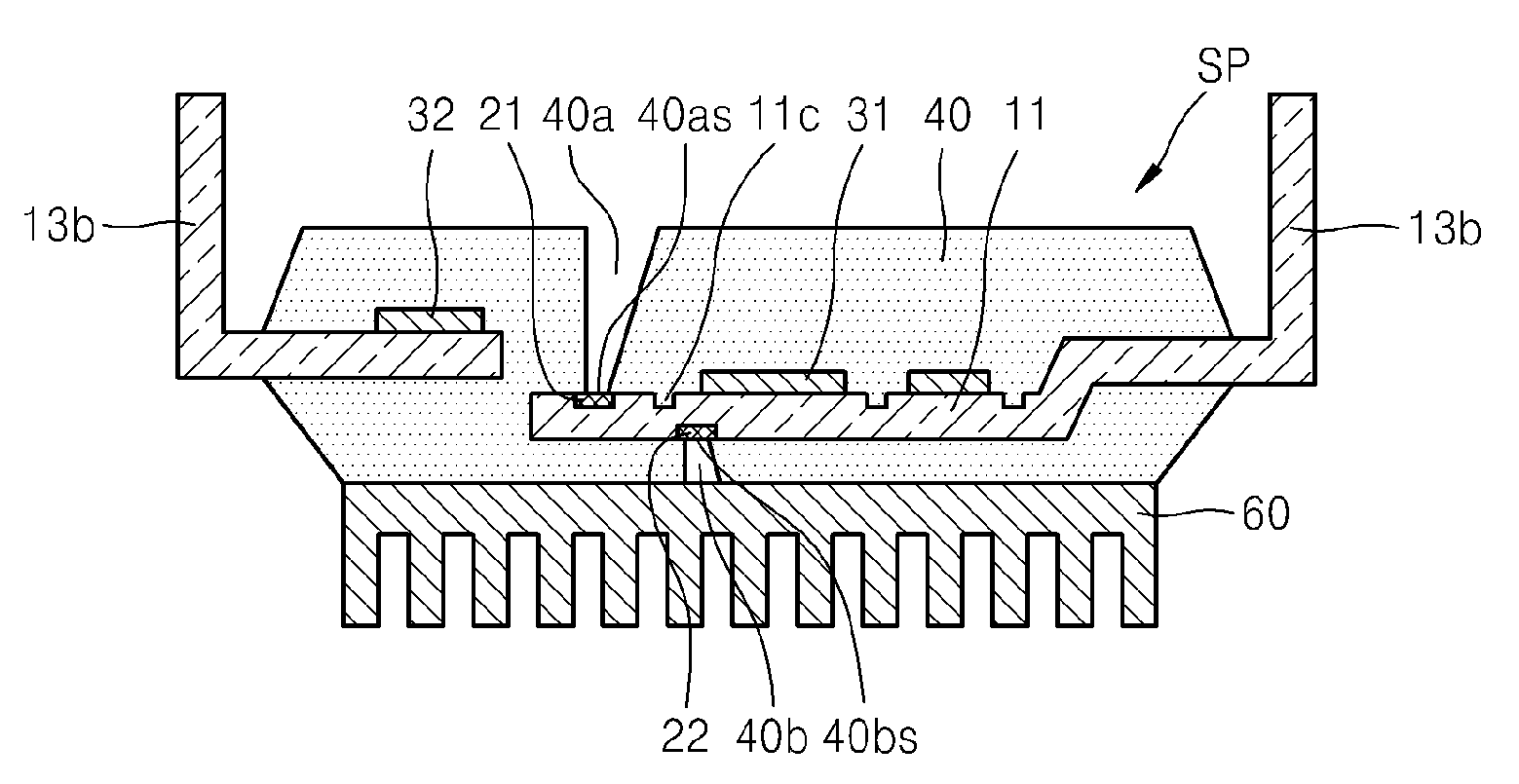

Method for producing semiconductor device and semiconductor device

ActiveUS20050082690A1Improve cooling effectImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialMetal foil

The method of producing a semiconductor device in which chips are resin-molded, including steps of: preparing frames having front and back surfaces and die pads; preparing an insulation resin sheet having a first and a second surfaces; preparing a resin-sealing metal mold having cap pins; mounting the resin sheet inside the resin-sealing metal mold in such a manner that the second surface of the resin sheet contacts an inner bottom surface of the resin-sealing metal mold; mounting power chips on the surfaces of the die pads; positioning the frames on the first surface of the resin sheet in such a manner that the back surfaces of the die pads contact the first surface of the resin sheet; pressing the die pads toward the resin sheet using the cap pins and fixing the die pads; injecting a sealing resin in the resin-sealing metal mold and hardening the sealing resin; and removing the semiconductor device in which the power chips are molded with the sealing resin out from the resin-sealing metal mold. The resin sheet may include a metal foil which is disposed to the second surface.

Owner:MITSUBISHI ELECTRIC CORP

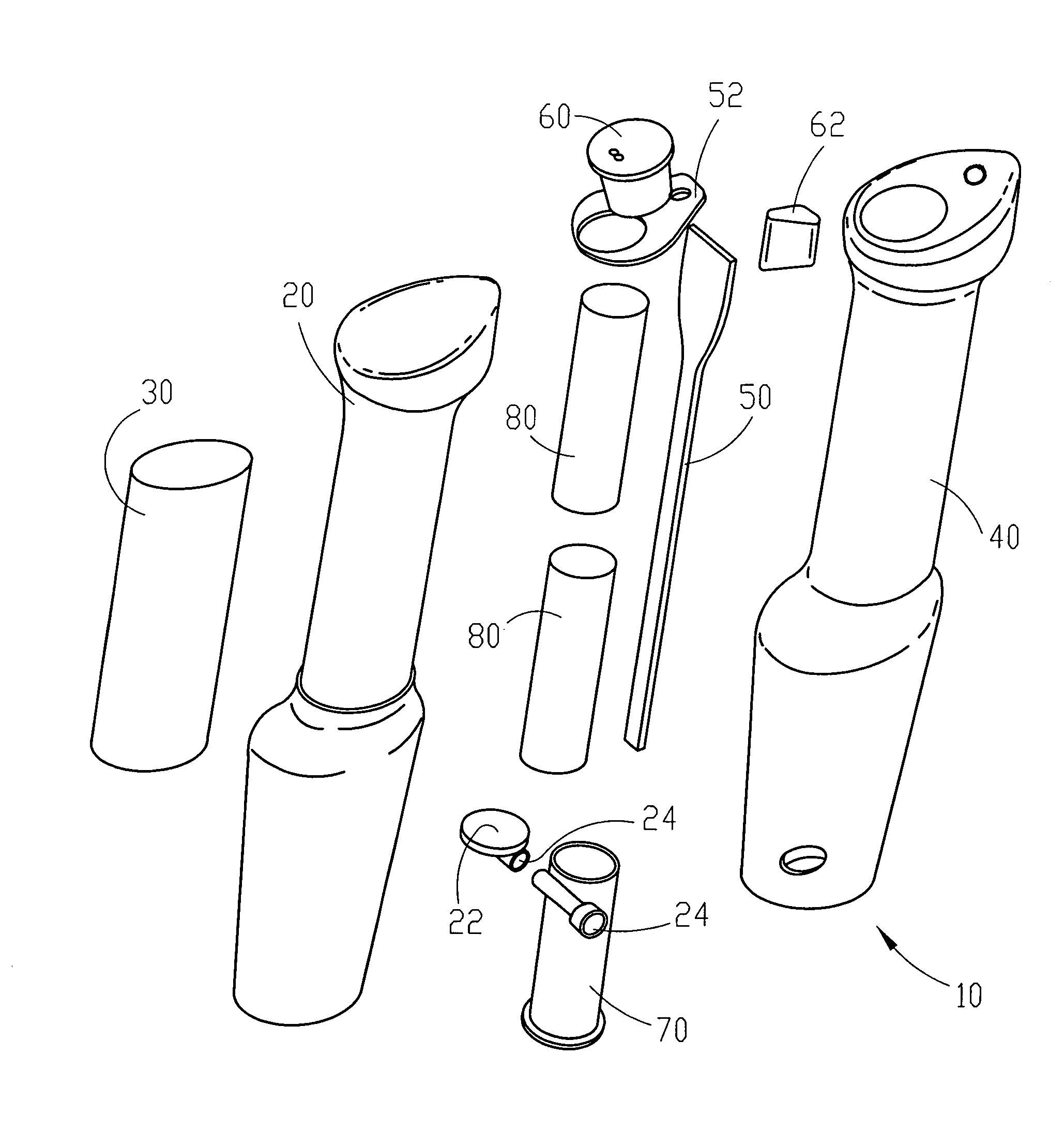

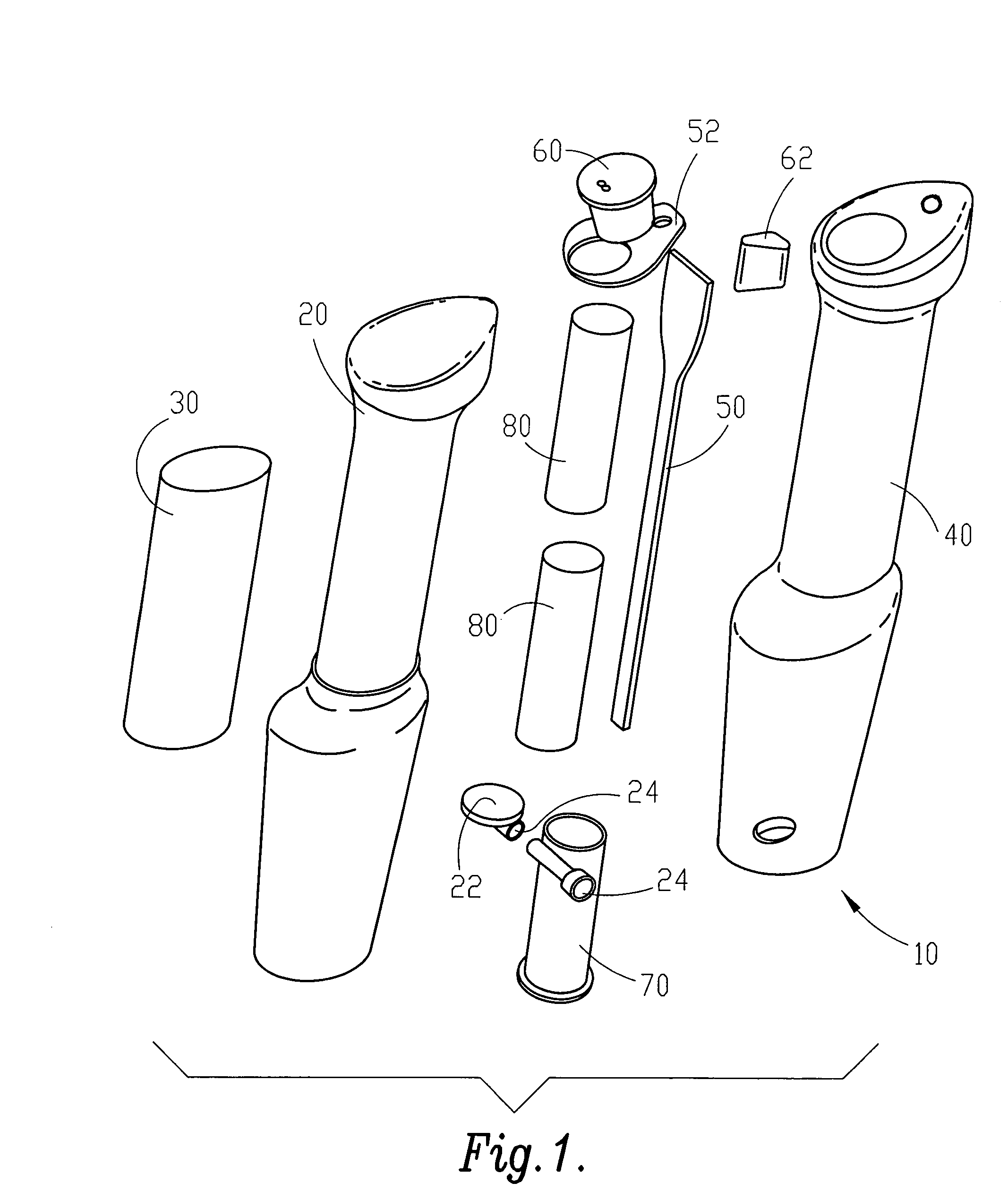

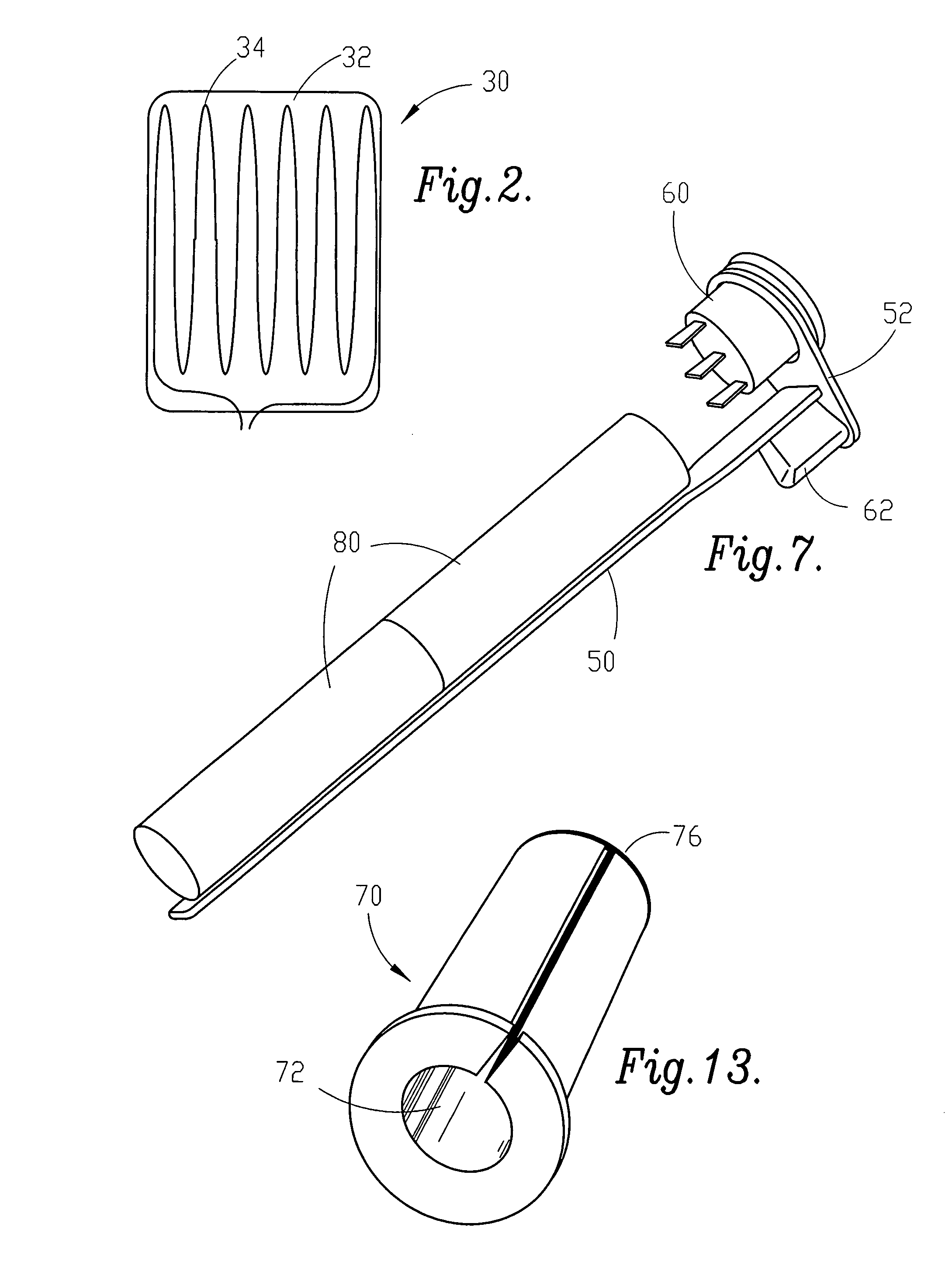

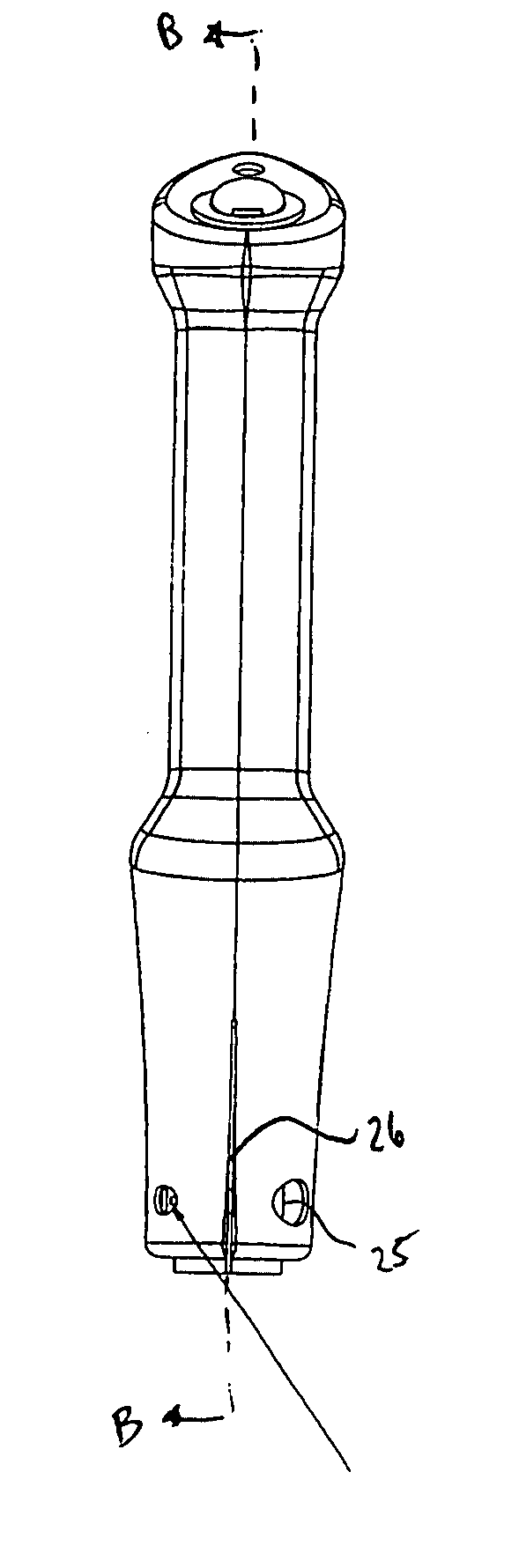

Heated hand grip

InactiveUS7119304B2Easy to installEasy to manufactureSnowboard bindingsBows/crossbowsHand heldCold weather

A rechargeable, reusable heated hand grip for use on a ski pole, shovel or other cold weather hand-held tool or object is provided. The hand grip includes a bushing for receiving the end of a tubular object and retaining the object within a bore in the central core of the hand grip, which compresses around the bushing for tight engagement. A wire-wound heating element is wrapped around the exterior surface of the central core and an outer housing surrounds the heating element and the central core. The bore houses a pair of lithium-ion batteries connected in series, a switch with the switch control protruding from the top of the grip, and a printed circuit board connected to the switch.

Owner:MEYERS MARCY

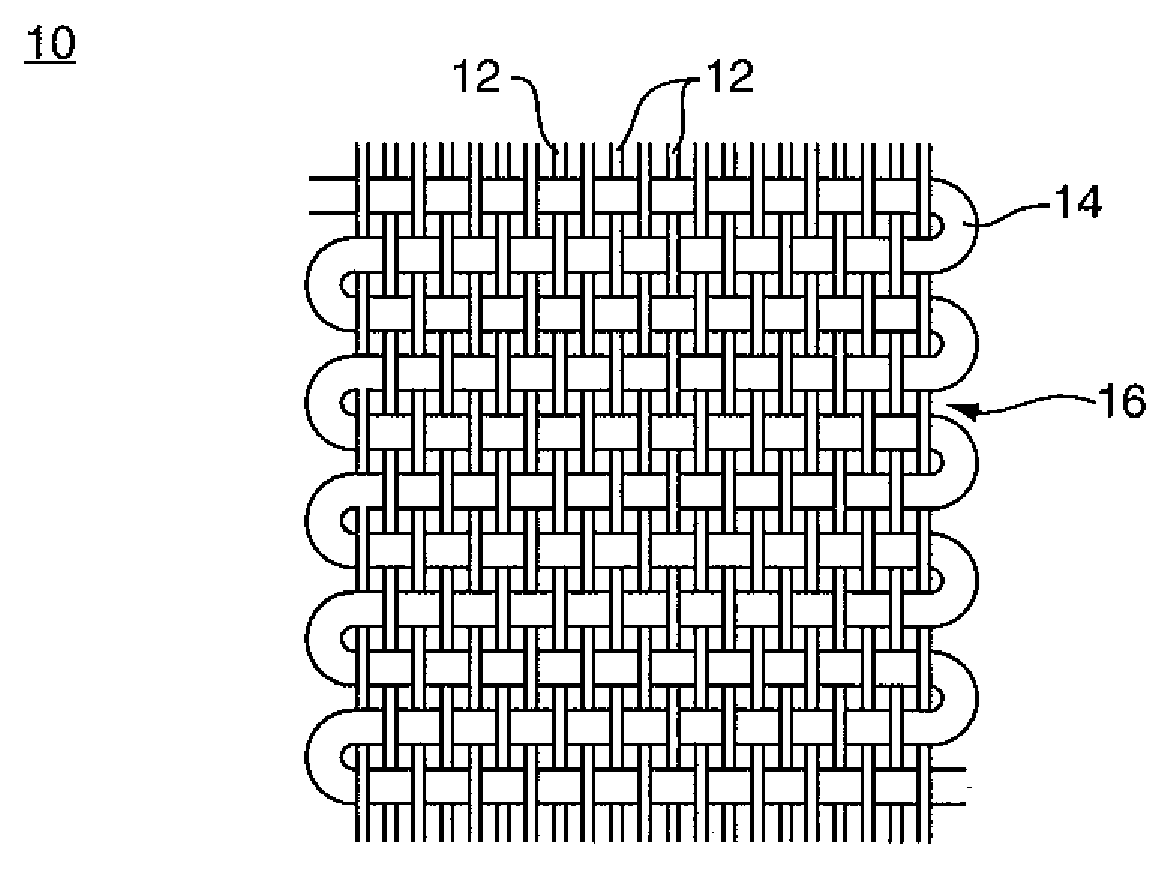

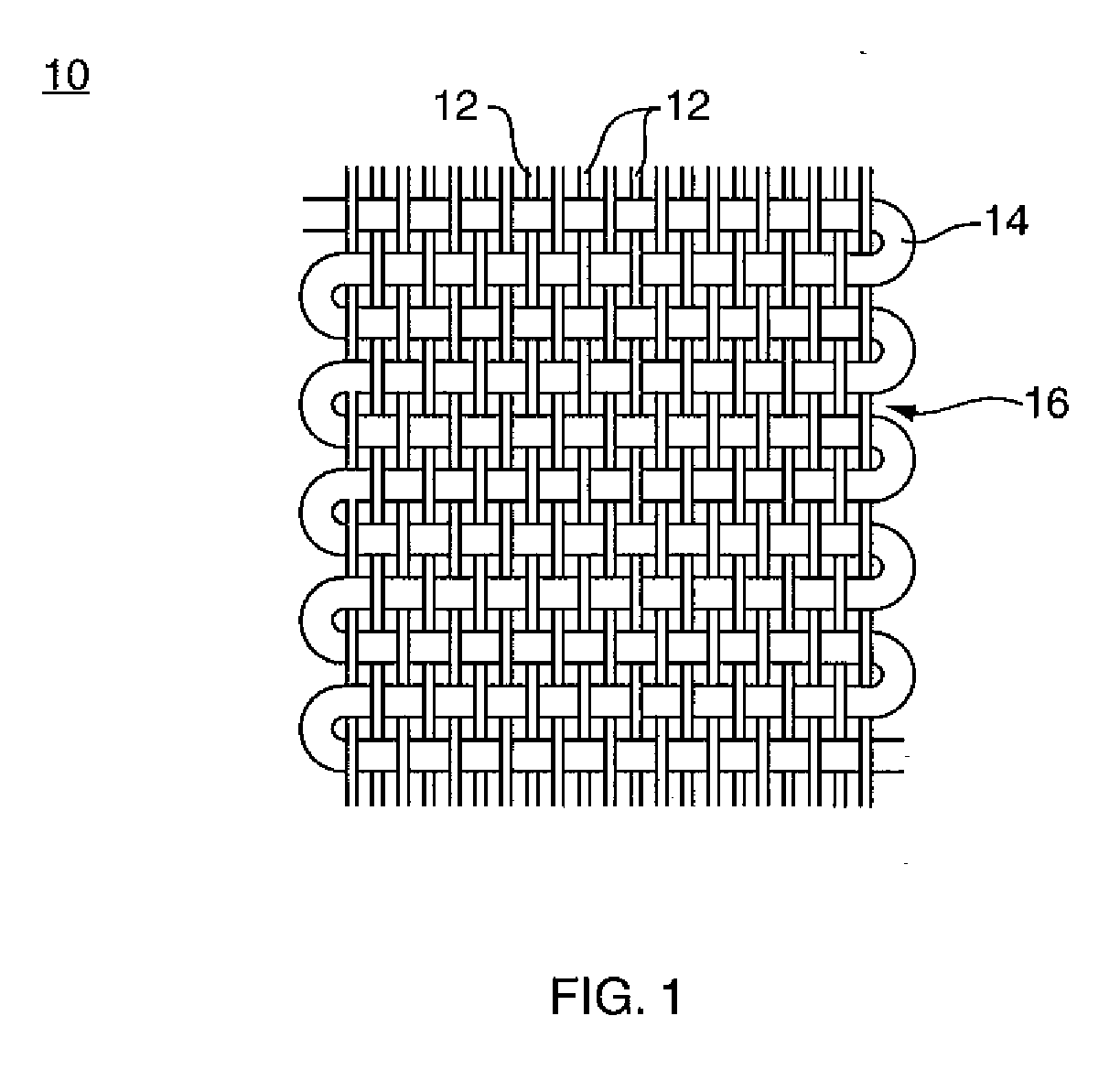

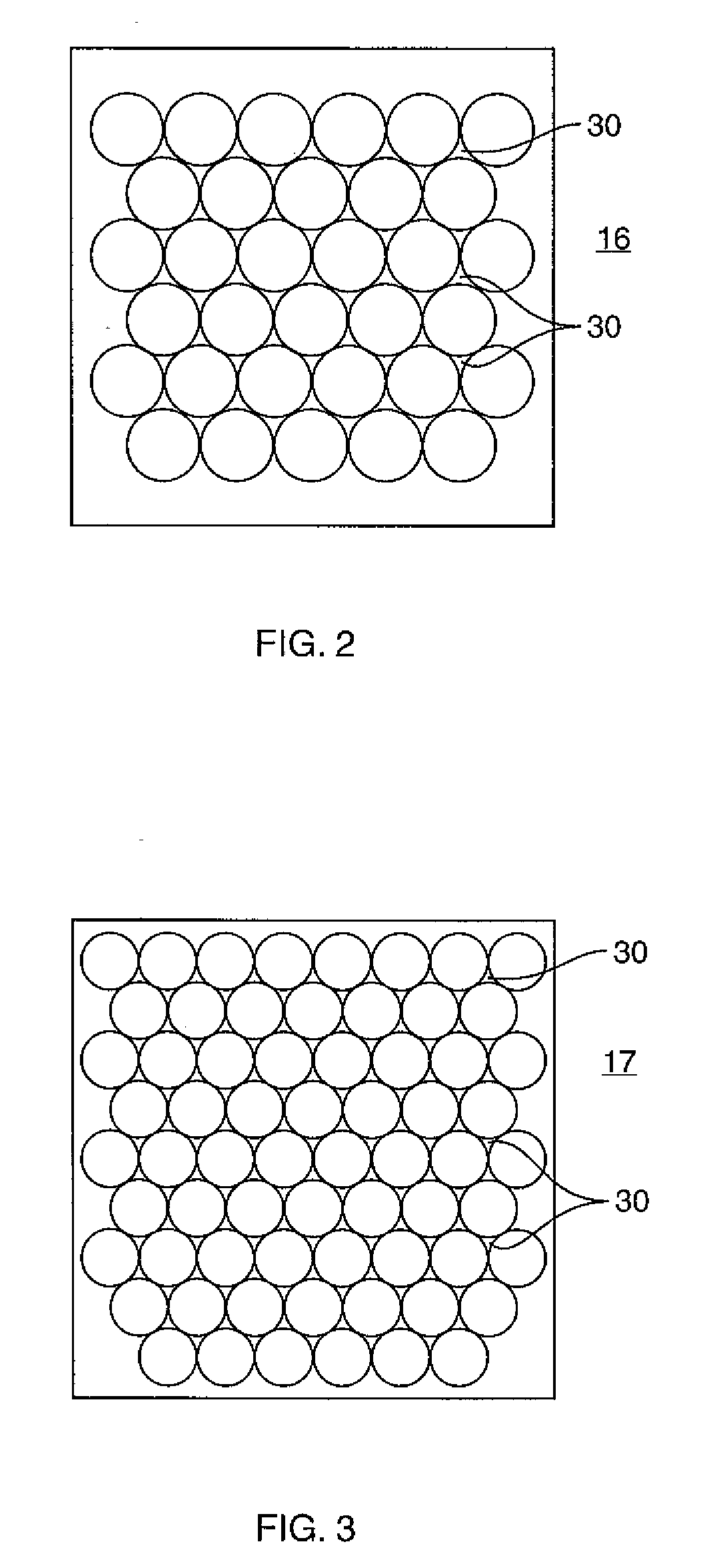

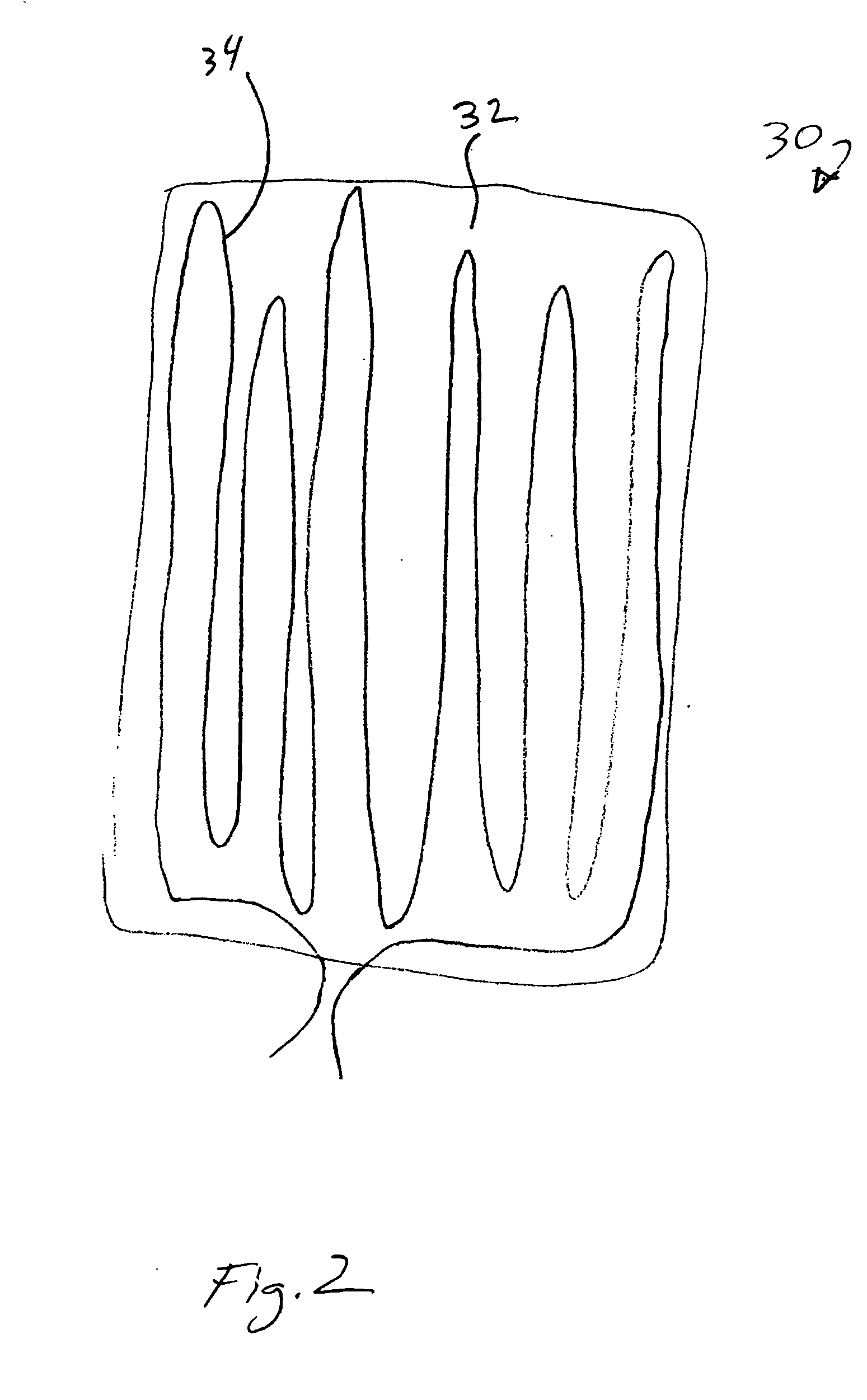

Fabric and method of making the same

ActiveUS20090163099A1Minimal effortMaintaining a sustained thermal condition of an objectOrnamental textile articlesMonocomponent cellulose artificial filamentMulti materialCivil engineering

A fabric for thermal management including the cooling of an object, such as a person's skin. The fabric is formed of a plurality of materials including at least one liquid transport enhancing material and at least one evaporative transport impeding material. When the fabric is in use, the transport enhancing material is located near an object to be cooled, while the evaporation impeding material is spaced away from the object. The fabric is peached so that there is an entanglement of the two materials. Peaching is performed on both sides of the fabric, but initially on the side with the transport enhancing material such that a portion of the evaporation impeding material is pulled into the fabric core. A method of making the fabric is also described.

Owner:CCT LENDING LLC +1

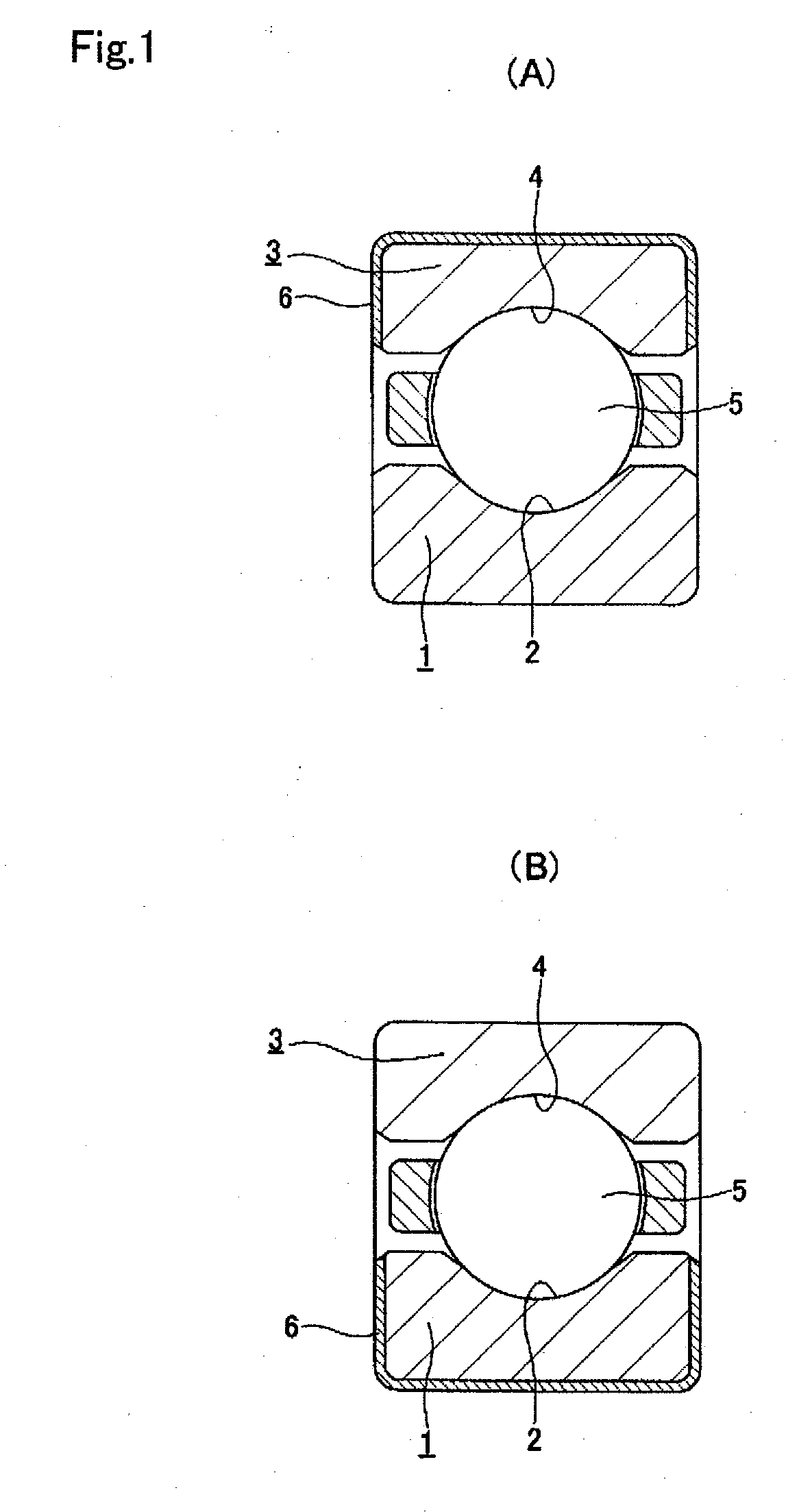

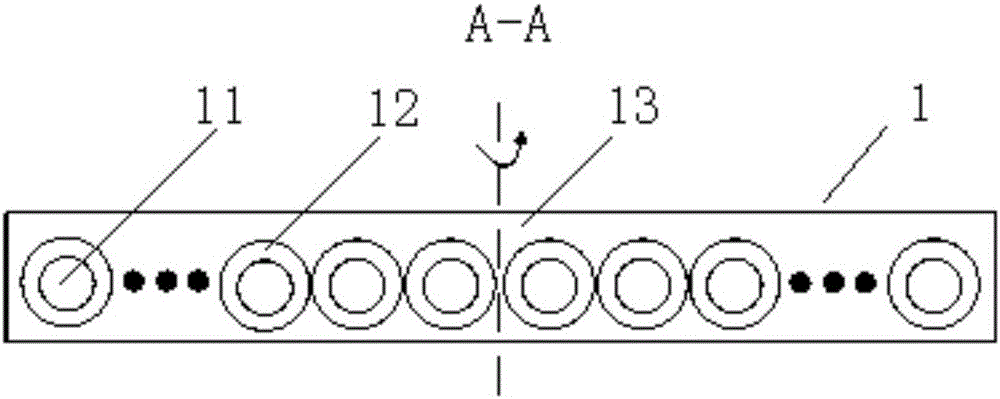

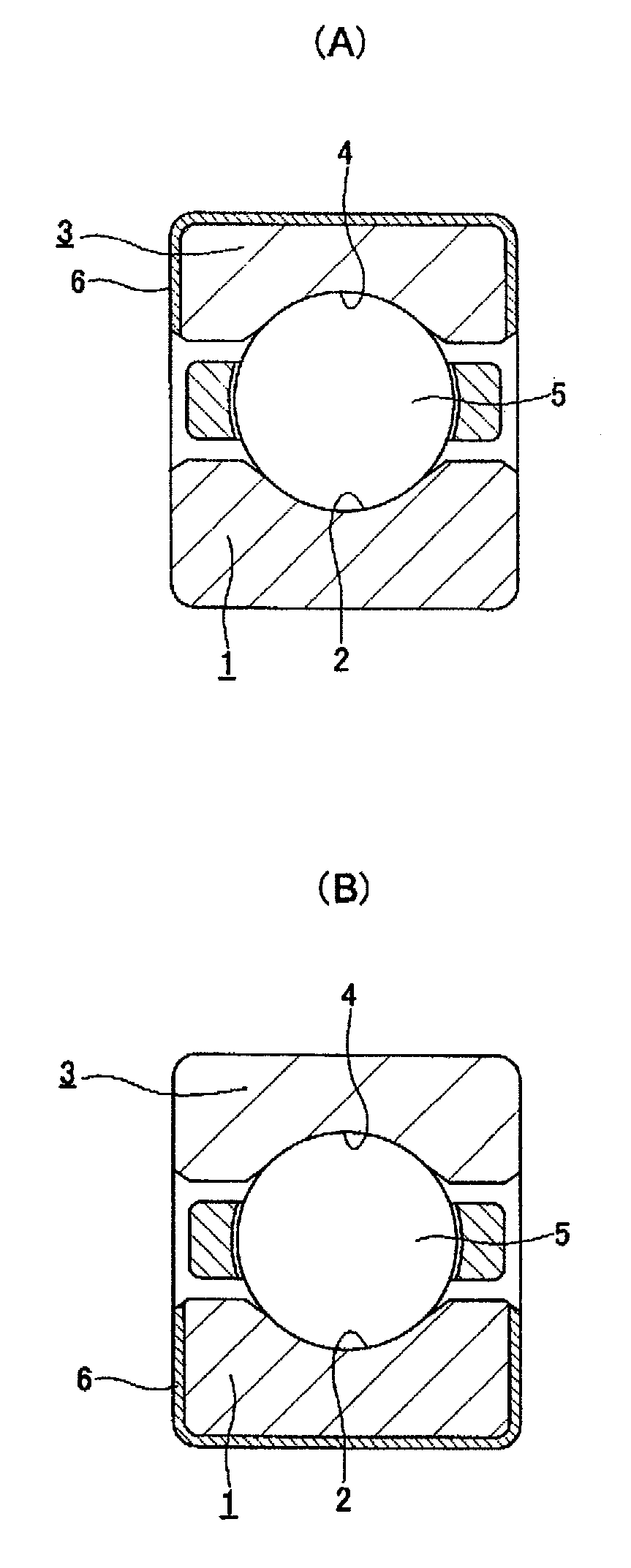

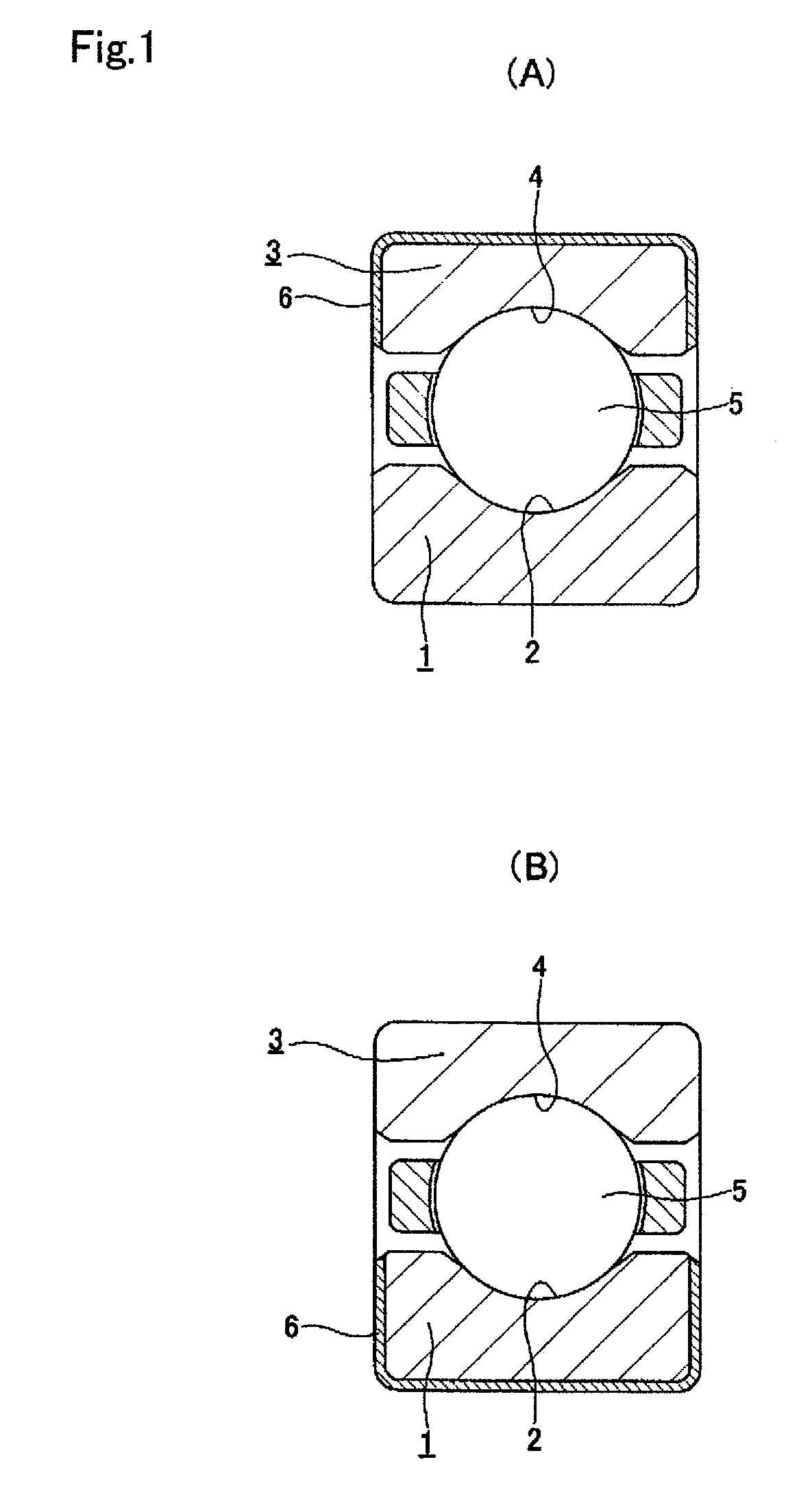

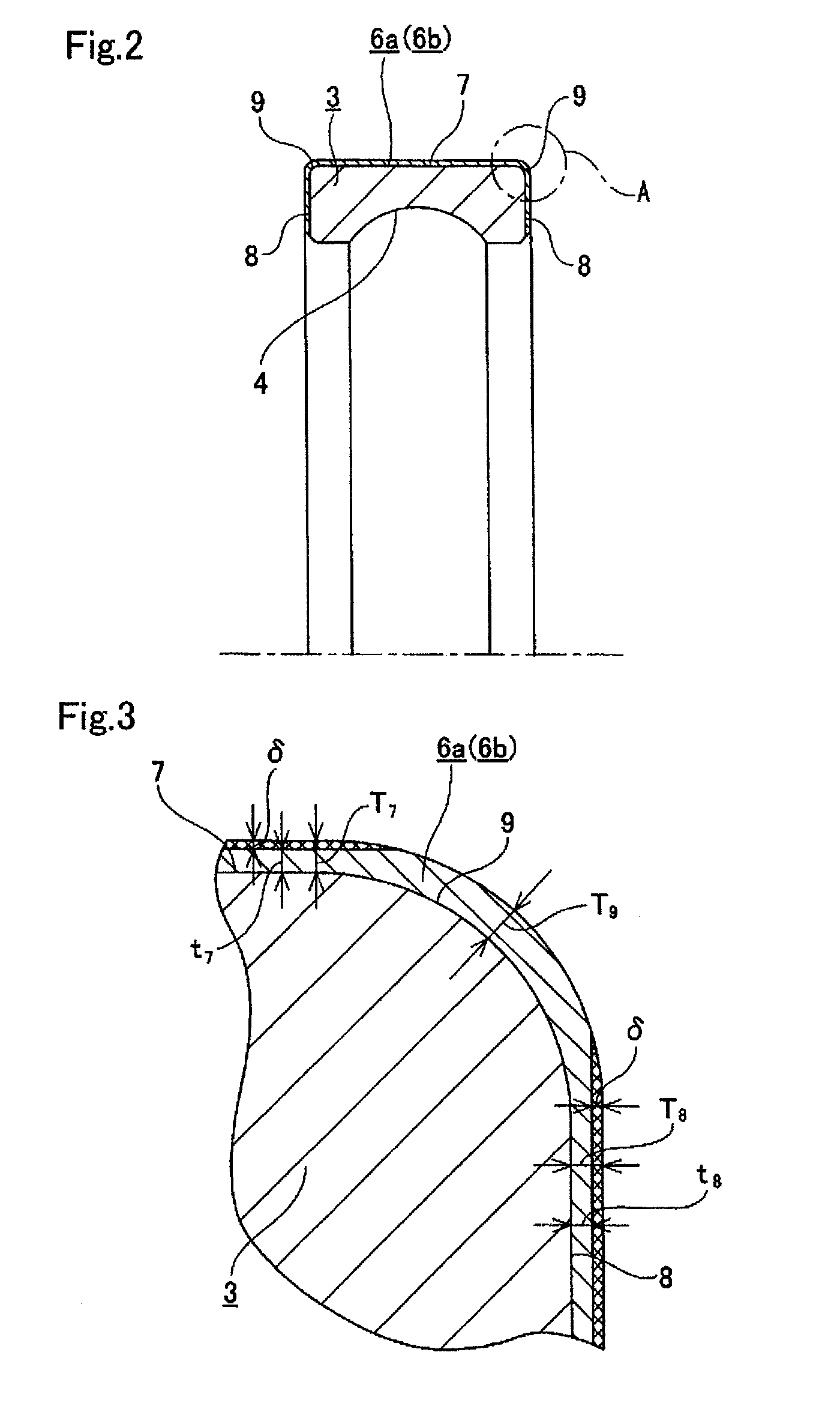

Electrolytic Erosion Preventing Insulated Rolling Bearing, Manufacturing Method Thereof, and Bearing Device

ActiveUS20090304318A1Increased durabilityHigh of insulation performanceBearing assemblyShaftsElectrolysisCeramic coating

In order to ensure high levels of insulation performance, and low cost, and have an excellent external appearance, as a ceramic constituting an insulating coating 6 being a ceramic coating layer, one with alumina as its main component, and in which the content of titanium oxide is limited to 0.01 to 0.2 percent by weight is used. Moreover, a particle size of ceramic forming the coating layer is 10 to 50 μm, and average particle size is 15 to 25 μm. By limiting the content of titanium oxide, the insulating coating 6 can be made thin, and by limiting the particle size the film thickness accuracy can be improved, thus simplifying finishing. Moreover, by mixing of titanium oxide, deterioration of the external appearance after sealing can be prevented. As a result, the above problem is solved.

Owner:NSK LTD

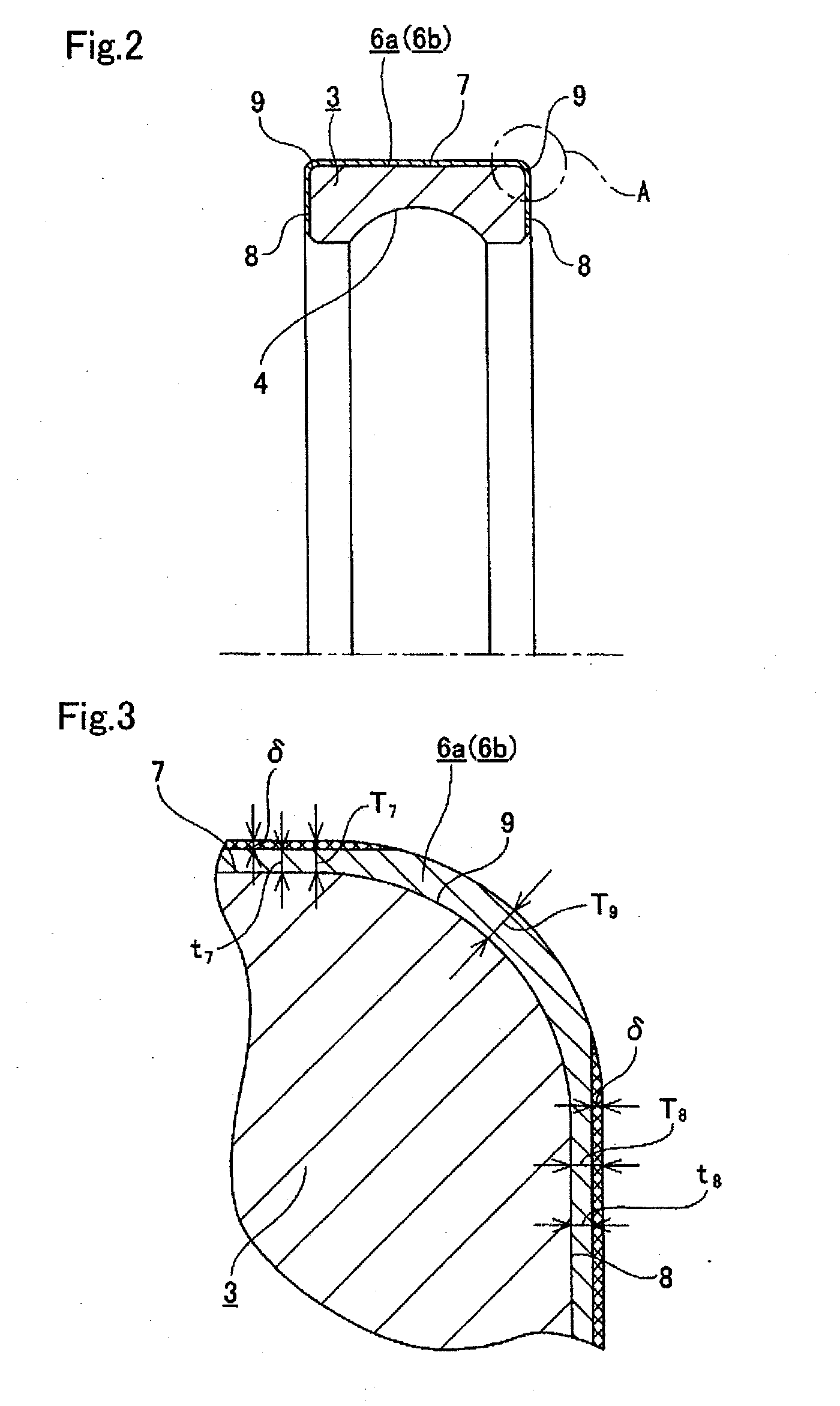

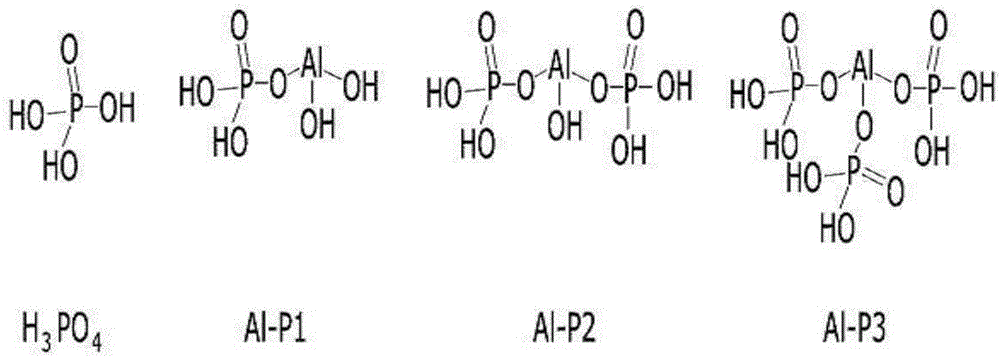

Insulation coating composition for non-aromatic electrical sheet, method for manufacturing same, and non-aromatic electrical sheet to which insulation coating composition is applied

ActiveCN104025207AExcellent insulating filmReduce sizePlastic/resin/waxes insulatorsInorganic insulatorsEpoxyNanoparticle

Disclosed is an insulation coating composition for a non-aromatic electrical sheet. The insulation coating composition for the non-aromatic electrical sheet, according to the present invention, comprises: a mixed metal phosphate comprising aluminum phosphate (Al(H3PO4)x=1~3) and cobalt phosphate (Co(H3PO4)3); an epoxy resin; and an organic-inorganic composite comprising silica (SiO2) nanoparticles which substitutes a functional group of the epoxy resin.

Owner:POSCO CO LTD

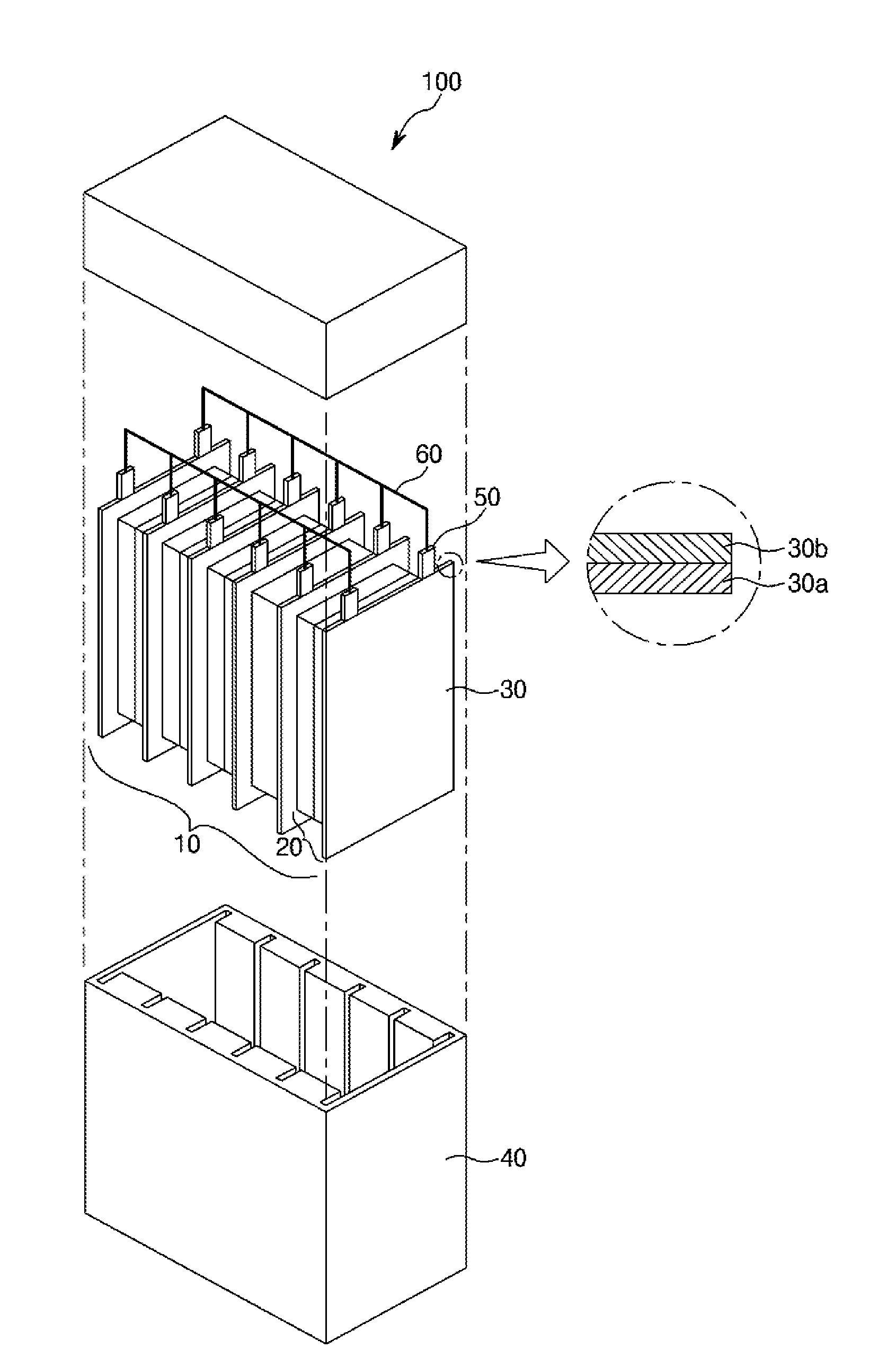

Pouch type lithium secondary battery

ActiveUS20120015226A1Good insulation propertiesImprove formabilityCell electrodesFinal product manufactureElectrical and Electronics engineeringMoisture

A pouch type lithium secondary battery including a medium- or large-sized battery module includes: a jelly-roll type electrode assembly; a resin-type first packing material that is formed of a two-layer structure having an inner resin layer and an outer resin layer, and for packing the jelly-roll type electrode assembly in the form of a unit cell; and a metal-type second packing material that integrally packs and contains two or more unit cells packed in the first packing material in the form of a module, and prevents moisture and gas penetration by a sealed structure. The pouch type lithium secondary battery is applicable particularly to medium- and large-sized batteries for EVs, p-HEVs, HEVs, and so on.

Owner:LG ENERGY SOLUTION LTD

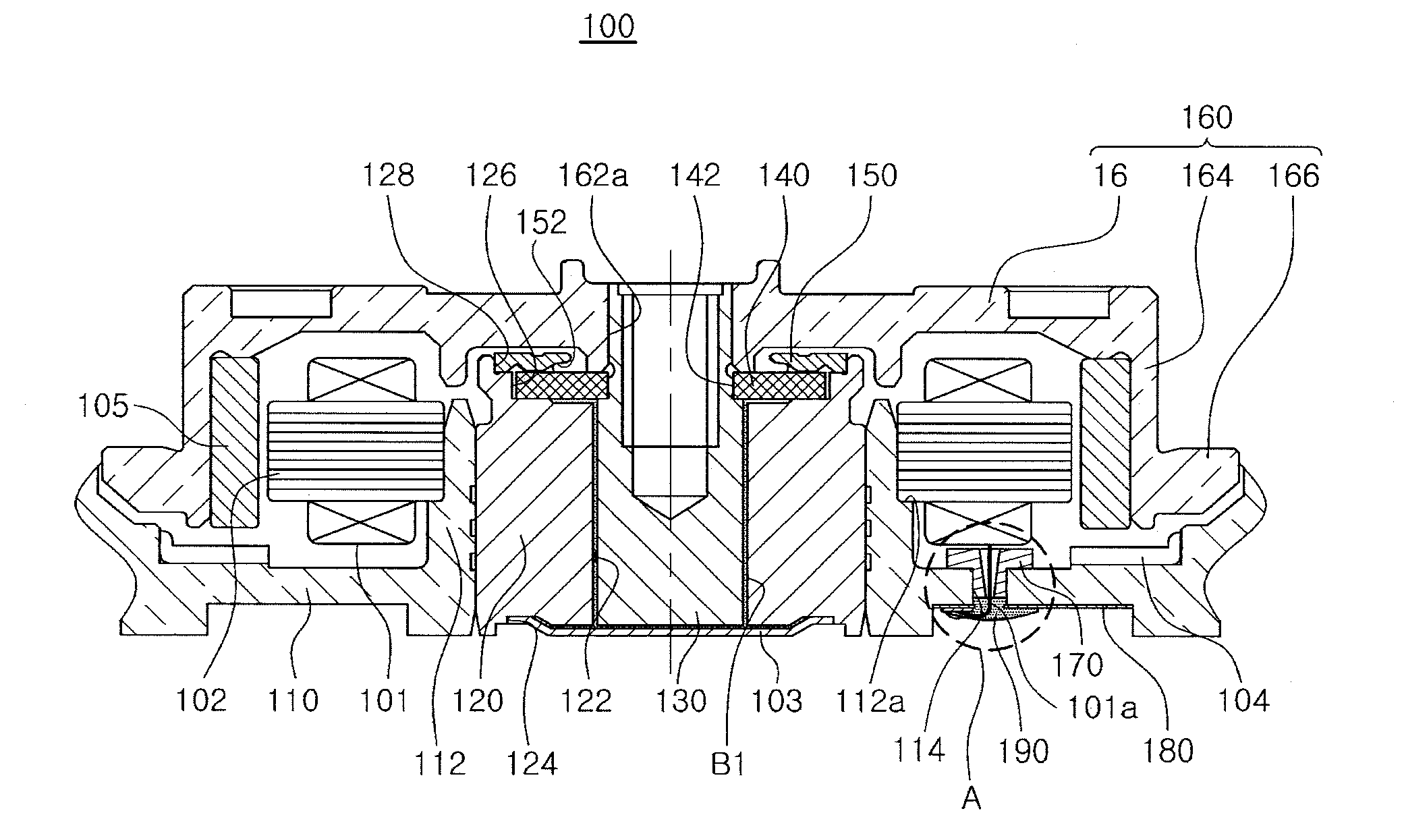

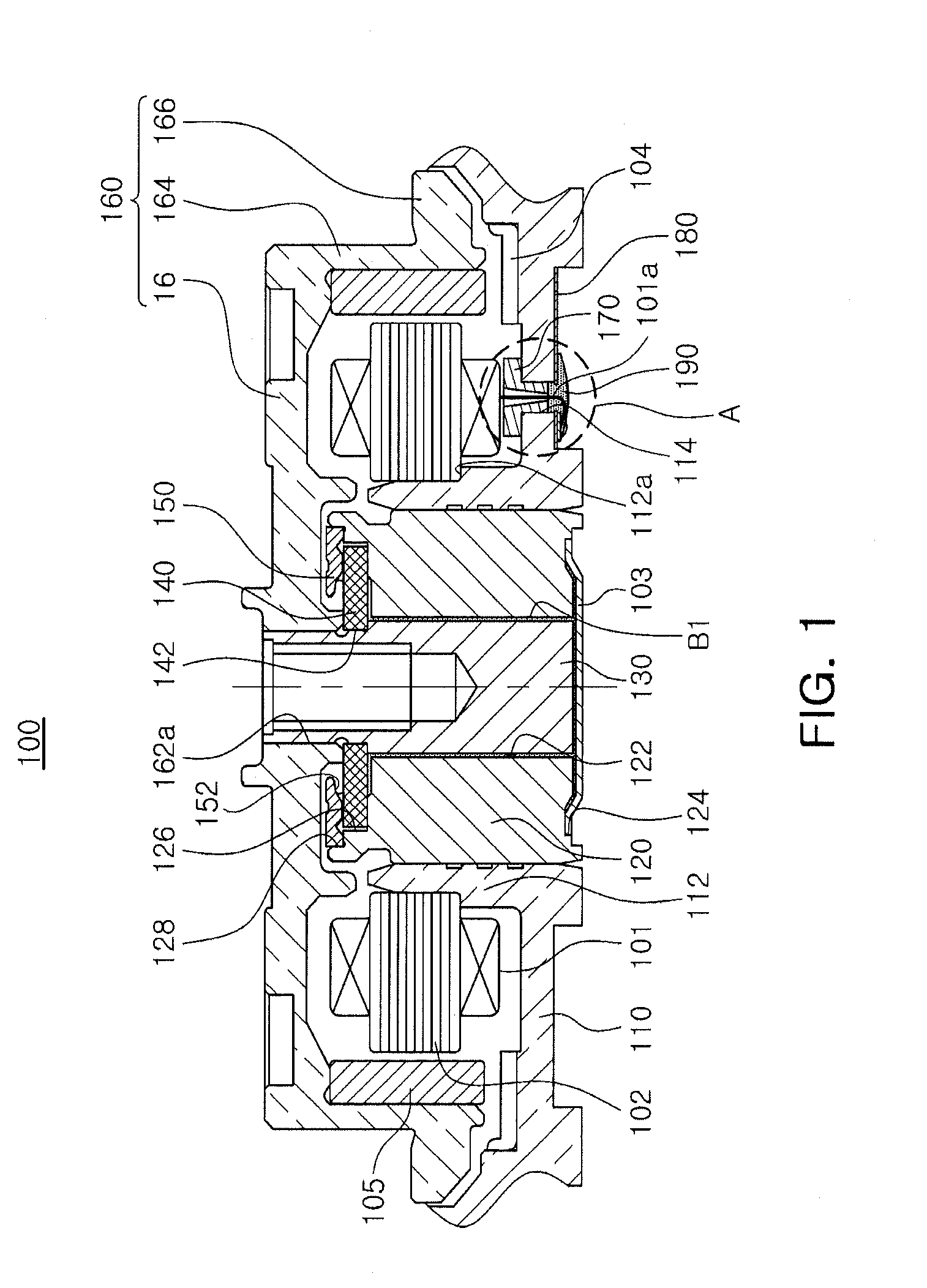

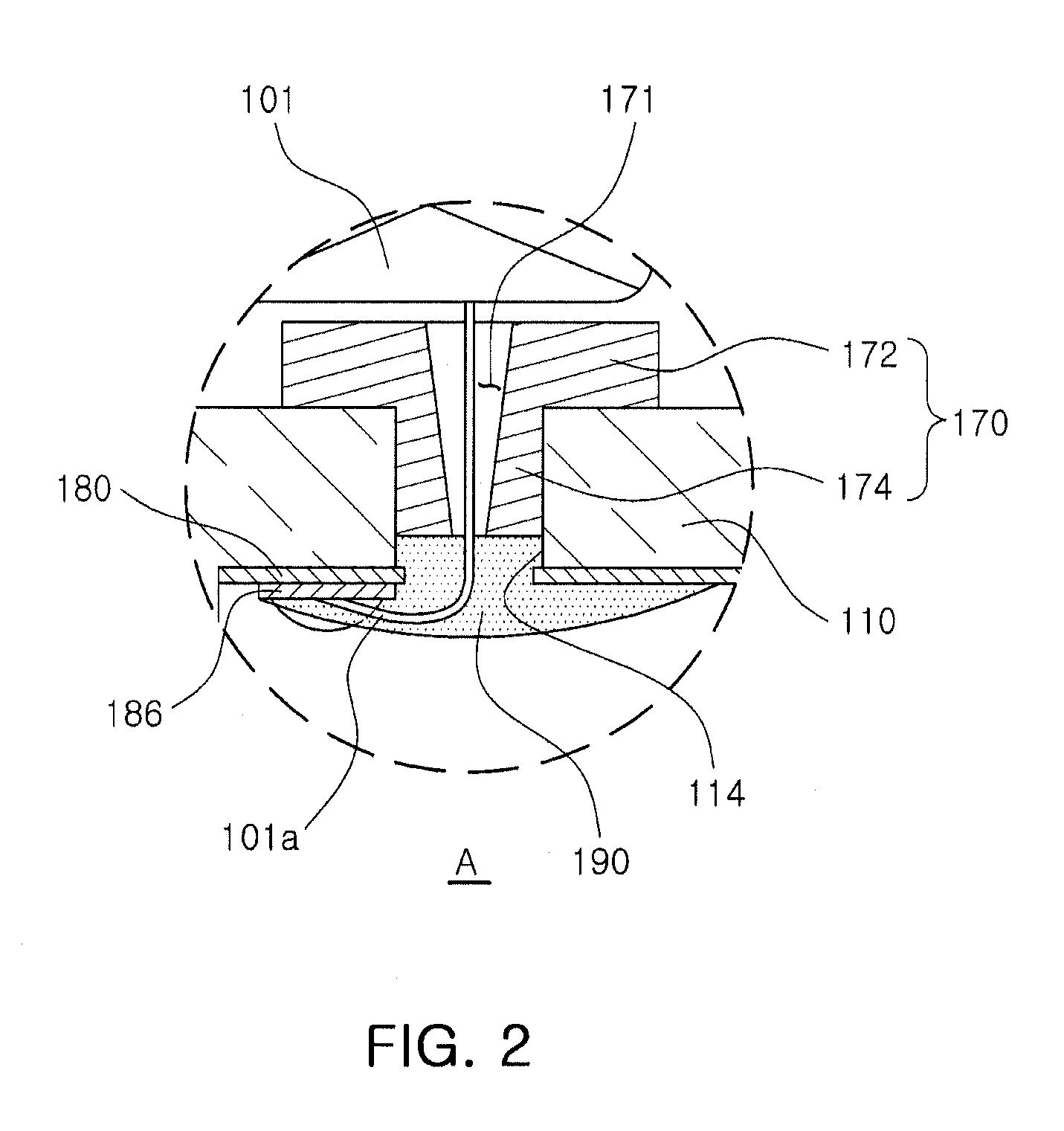

Spindle motor and method of manufacturing the same

InactiveUS20130113314A1Good insulation propertiesLow costWindingsRecord information storageEngineeringElectric motor

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

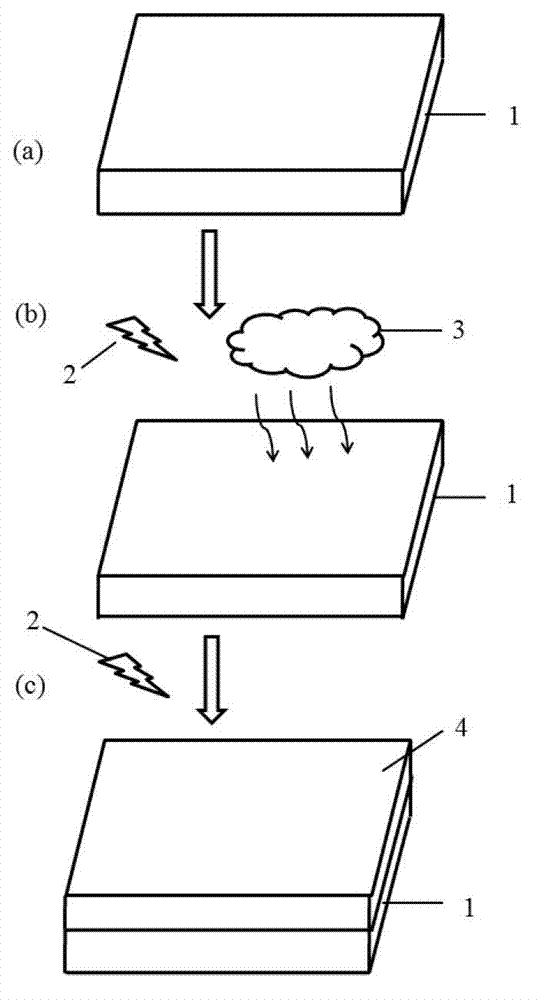

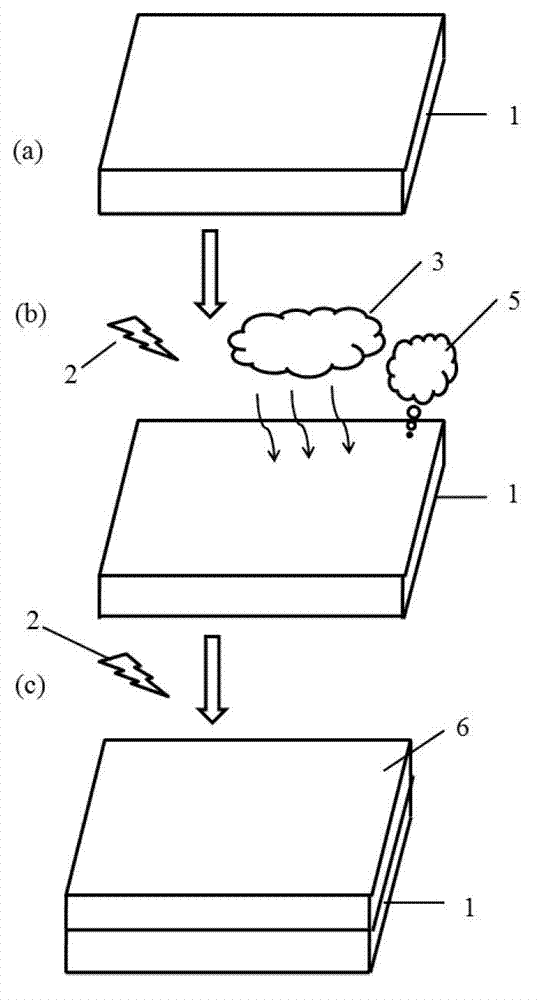

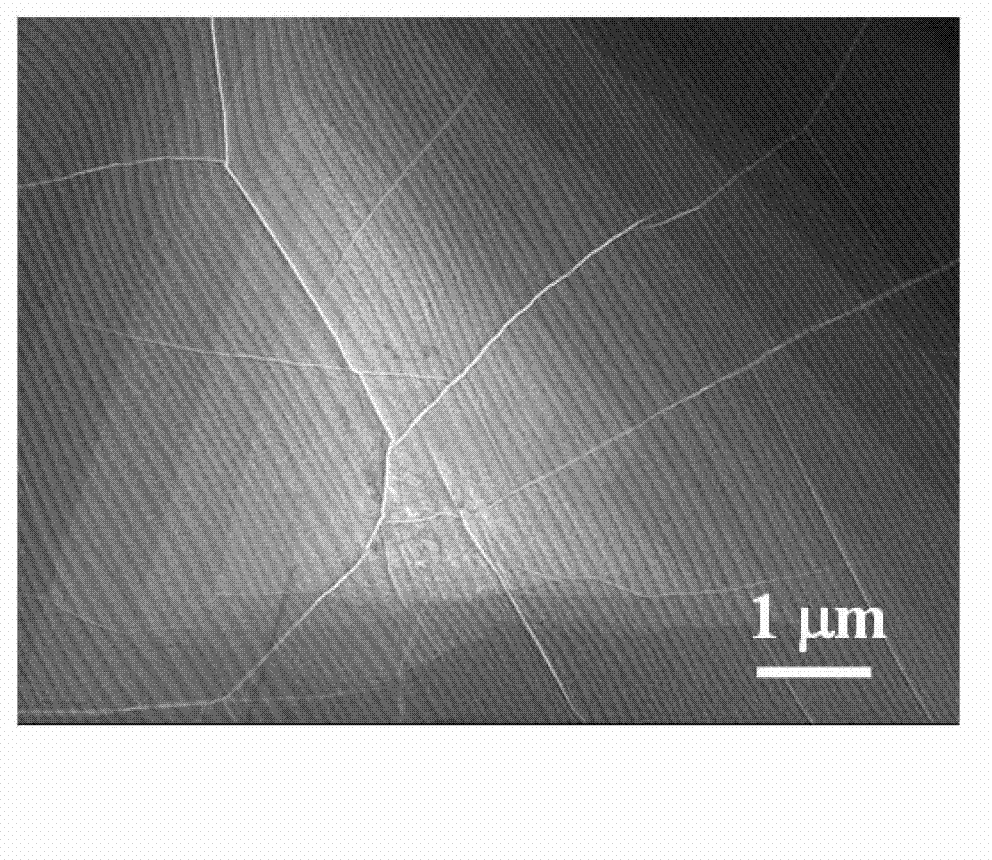

Preparation method of hexagonal phase boron nitride film

ActiveCN103031516AEasy to implementGood insulation propertiesVacuum evaporation coatingSputtering coatingGas phaseRoom temperature

The invention discloses a preparation method of a hexagonal phase boron nitride film. The preparation method comprises the following steps: by a physical vapor deposition method, providing boron atoms by a solid boron source, and forming the hexagonal phase boron nitride film on a substrate, wherein the deposition speed of physical vapor deposition is 0.01 nm / min-20 nm / min, and in the film forming process, the substrate temperature is controlled at 20-1600 DEG C; and the temperature is reduced to room temperature at a speed of 10-400 DEG C / min. when the hexagonal phase boron nitride film is prepared by the preparation method, the solid boron source is used, so that the safety is high, and the preparation method is simple, and easy to implement; the prepared hexagonal phase boron nitride film consists of 1-200 hexagonal phase boron nitride unit layers; and the two-dimensional hexagonal phase boron nitride film prepared by the preparation method has excellent insulating property and flatness and can be used for improving performance of a graphene optoelectronic device.

Owner:ZHEJIANG UNIV

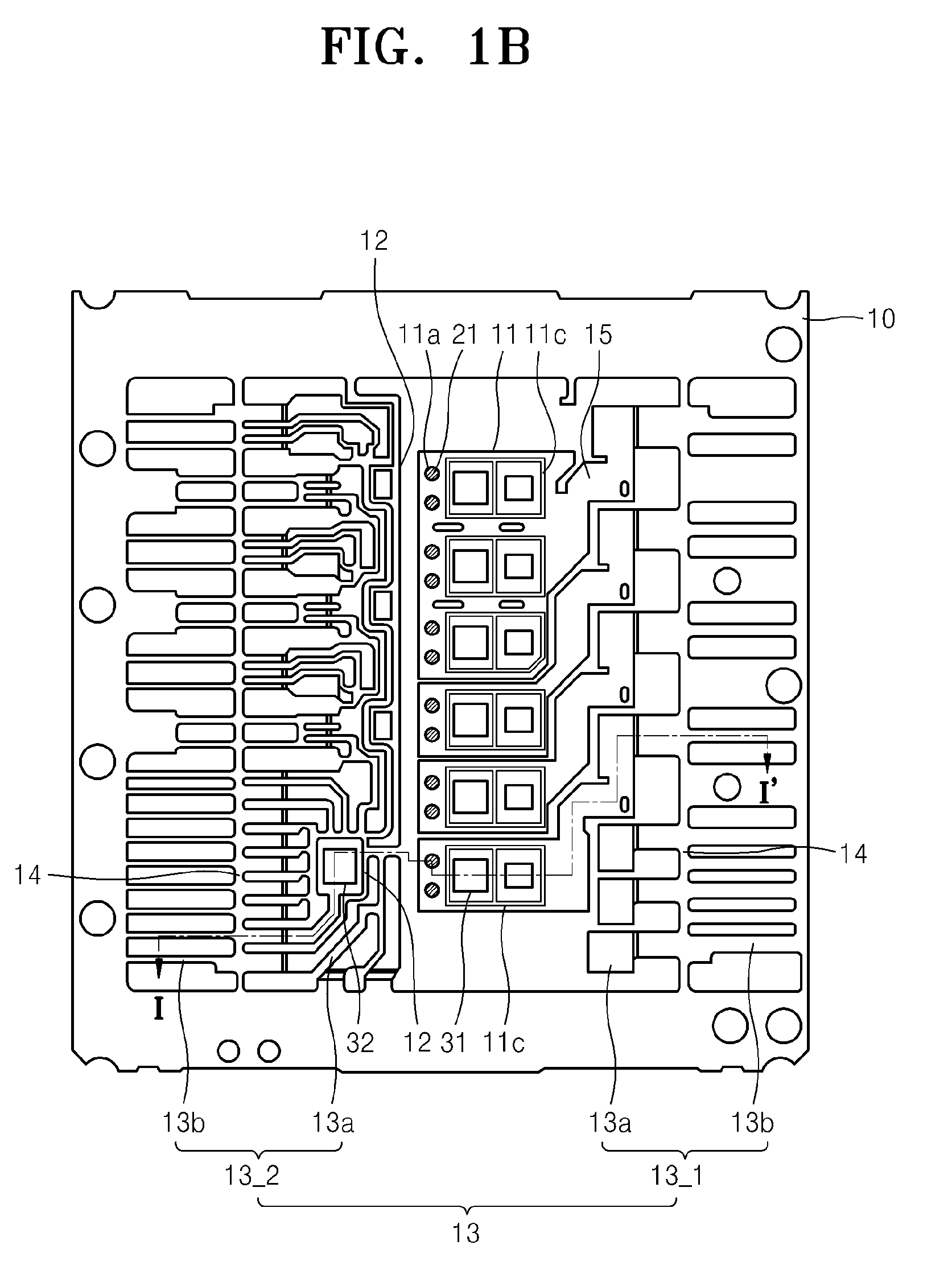

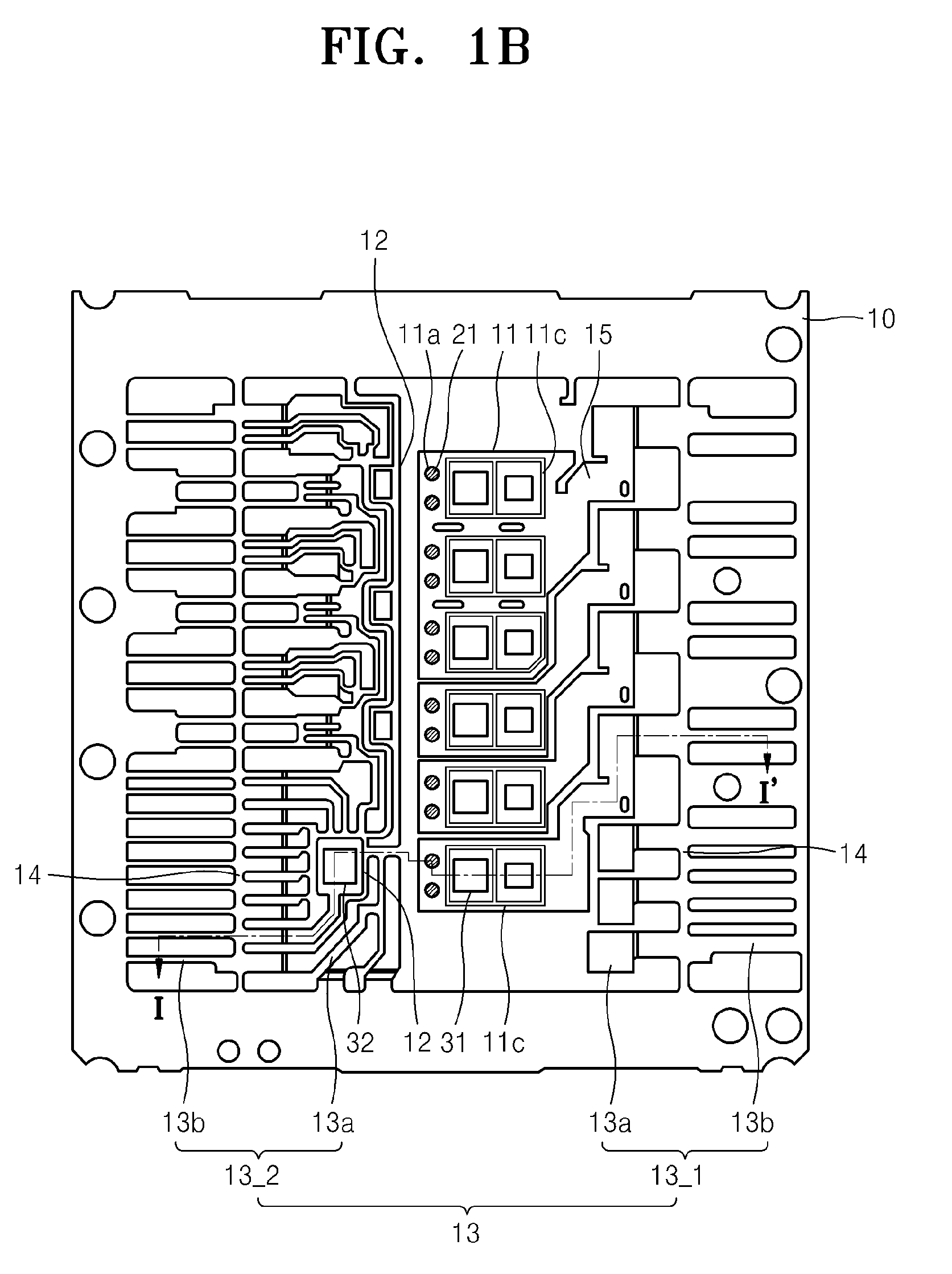

Semiconductor Packages and Methods of Fabricating the Same

ActiveUS20090115038A1Good insulation propertiesSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

Provided are semiconductor packages and methods of fabricating the same. An exemplary semiconductor package includes a die pad including a dimple filled with an insulating material in an upper surface or a lower surface thereof. A semiconductor chip is mounted on the upper surface of the first die pad. A package body encapsulates the first die pad and the first semiconductor chip and includes a pinhole. A bottom surface of the pinhole terminates at the insulating material.

Owner:SEMICON COMPONENTS IND LLC

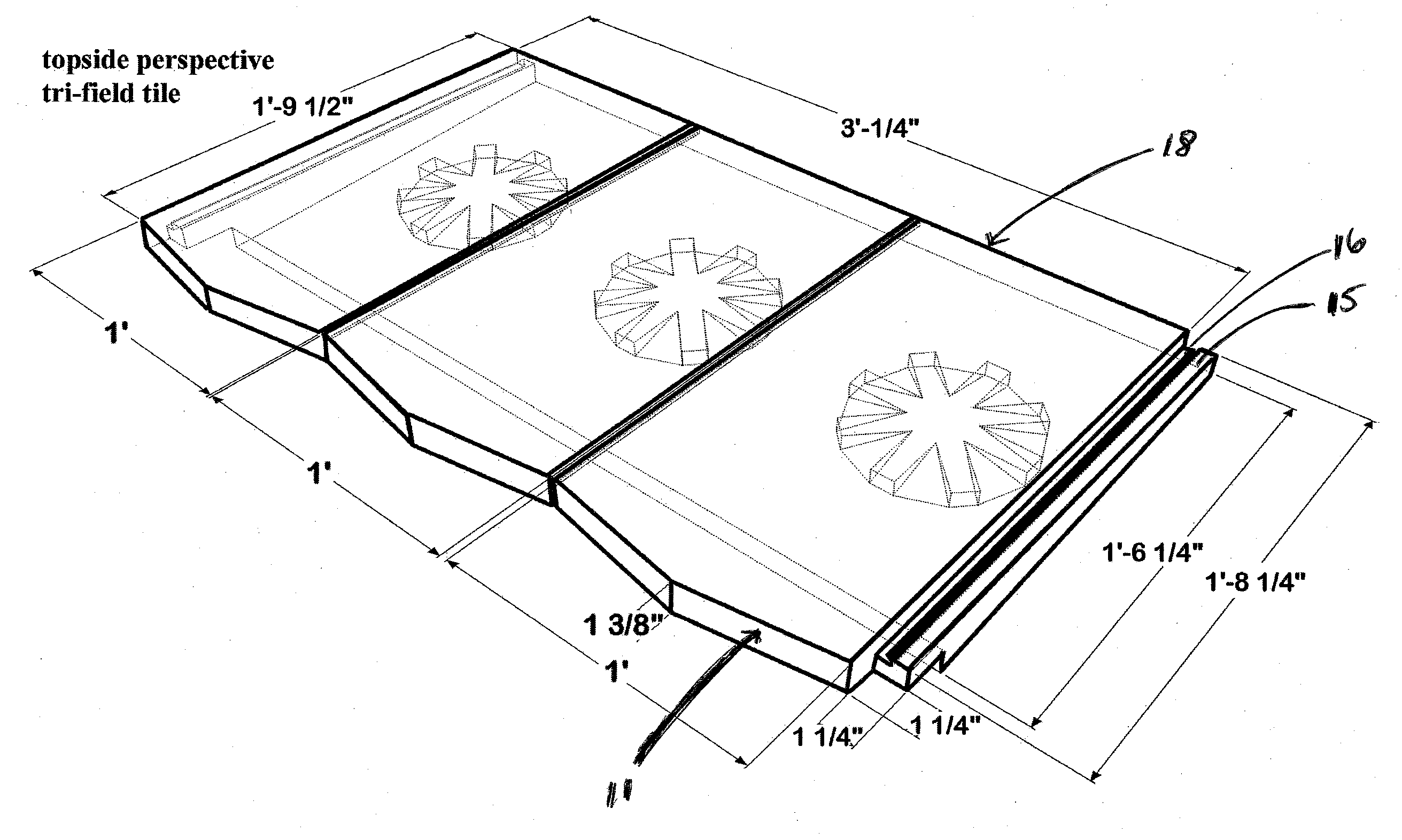

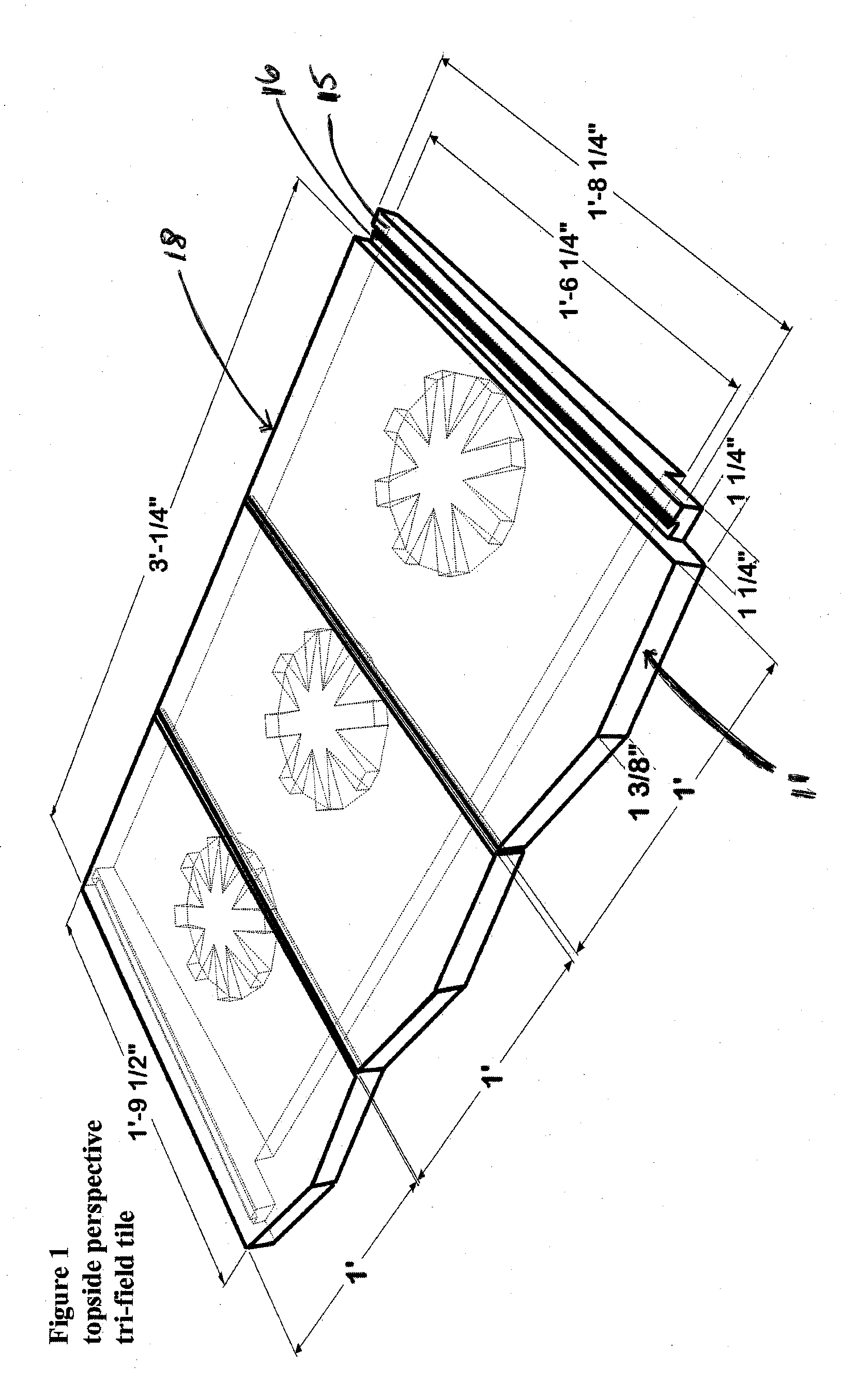

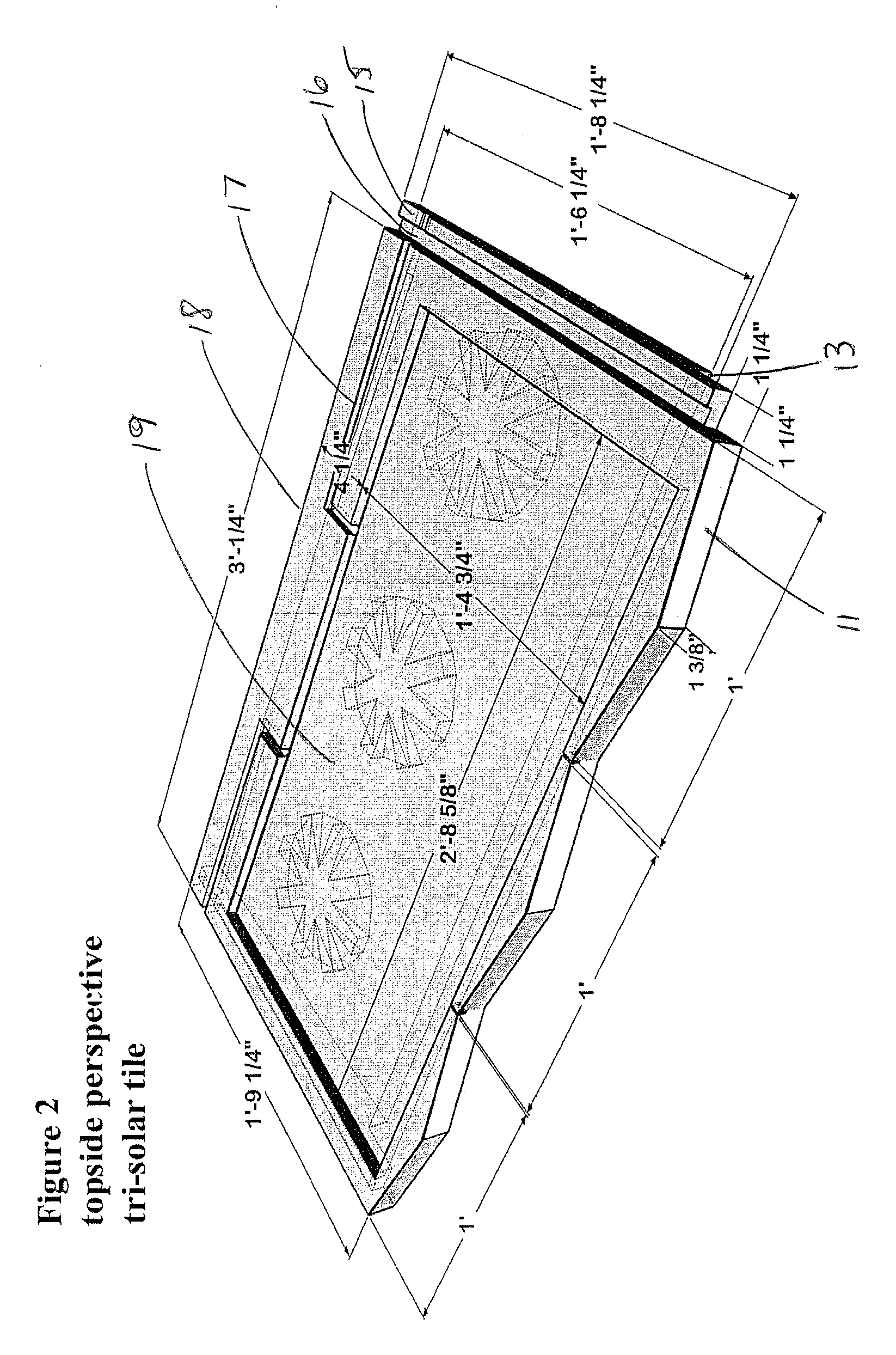

Light weight molded roof tile with integrated solar capabilities

InactiveUS20120272592A1Easy to transportEasy to installPhotovoltaic supportsRoof covering using slabs/sheetsWater basedFlat panel

An improved building roof tile that is featherweight, category 5 hurricane proof, yields a high R-value, offer low thermal transference into attic space, will retrofit any sloped roof without structural build-up, can be molded into single or triple units, cannot break under foot or when extreme pressures are applied, can produce solar energy, is easy to transport and install and can molded to look like slate, wood, flat or roll tile. The tile is made of polymeric isocyanate component and water based HCFC-2455fa blown.

Owner:BELLAVIA CARMEN

Preparation method of high thermal conductive insulating soft magnetic metal powder and soft magnetic metal powder

InactiveCN109326405AGood insulation propertiesImprove thermal conductivityInorganic material magnetismInductances/transformers/magnets manufactureNano siliconAdhesive

The invention discloses a preparation method of high thermal conductive insulating soft magnetic metal powder. The method comprises the following steps that (1) an insulating coating solution is prepared, wherein a coating agent is weighed according to a proportion, the coating agent comprises nano boron nitride, nano aluminum nitride, nano silicon nitride, sodium silicate and nano zirconia, the coating agent is added into distilled water, stirred and dissolved to obtain the insulating coating solution, and the mass concentration of the insulating coating solution is 30-50 g / L; (2) the insulating coating solution obtained in step (1) is adopted to coat metal powder to prepare insulating powder; (3) an adhesive is prepared; (4) the soft magnetic metal powder is prepared. The invention alsoprovides the high thermal conductive insulating soft magnetic metal powder prepared by the method. The preparation method of the high thermal conductive insulating soft magnetic metal powder and the high thermal conductive insulating soft magnetic metal powder have the advantages that through the preparation of composite coating film, not only is the soft magnetic powder uniformly coated, but alsothe insulation property and thermal conductivity of the powder are greatly improved, the method is simple and feasible easily, and the method is very suitable for industrial production.

Owner:HEFEI ECRIEE TAMURA ELECTRIC

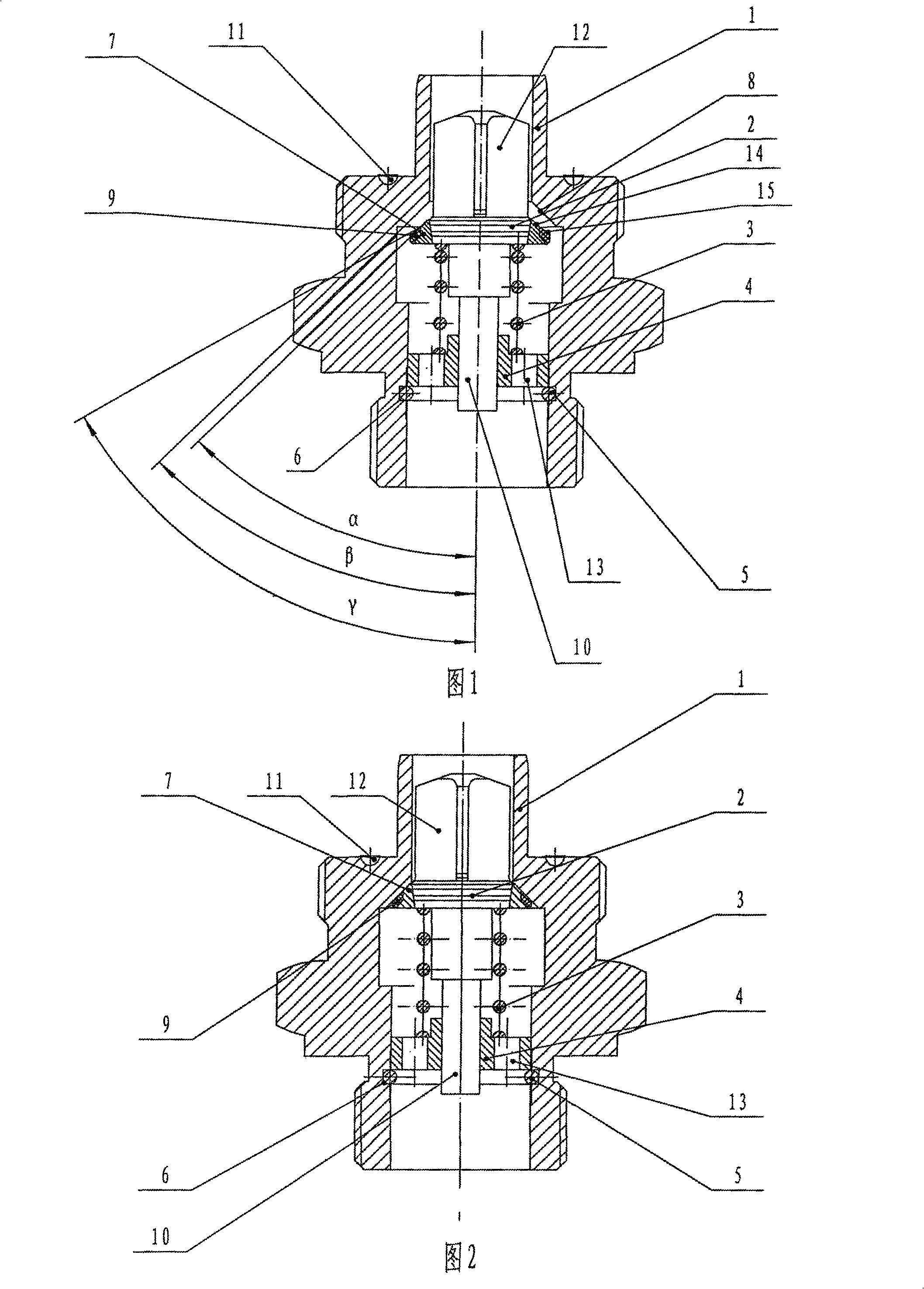

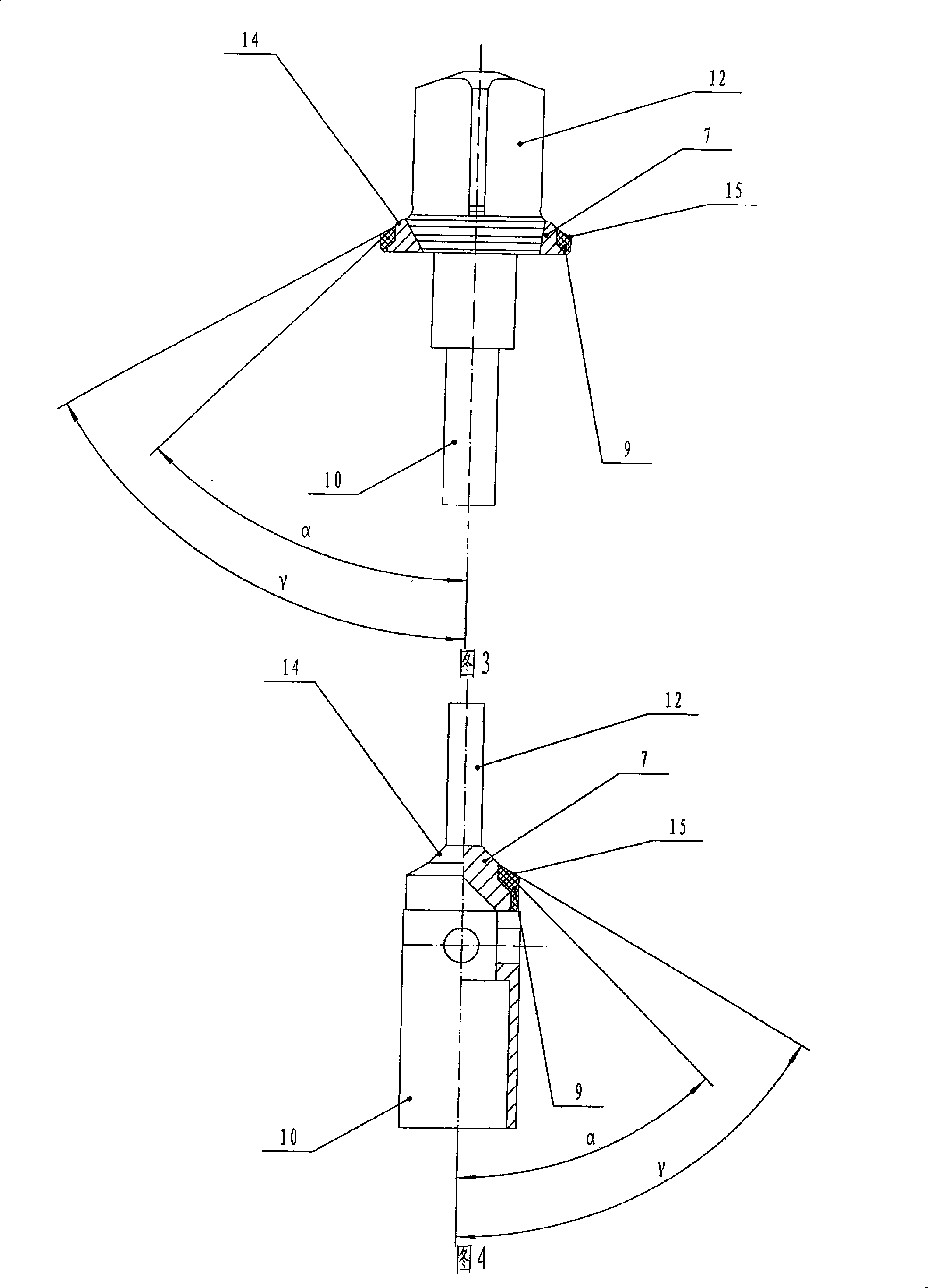

Self-sealing joint

InactiveCN101270842AAvoid wear and tearAvoid sealing gapsCouplingsNatural stateMechanical engineering

The invention discloses a self-sealing joint. The invention comprises a joint body (1) which is provided with a sealing surface (8) of the joint body; a sealing valve core (2), a limiting shield ring (5), a spring seat (4) and a reset spring (3) of a metal limiting scapular (7) which are applied in combination with the sealing surface (8) of the joint body are mounted at the middle part along the axial direction; a ring shaped inclined plane (14) is mounted at the top part of the metal limiting scapular (7); both the angle (Alpha) between the ring shaped inclined plane (14) and the axis of the sealing valve core (2) and the angle (Beta) between the sealing surface (8) of the joint body and the axis of the joint body (1) can be 44 degrees to 46 degrees; the top part of a sealing ring (9) is an inclined plane (15); the sealing ring (9) is embedded at the lower part of a metal limiting scapular (2); the angle (Gamma) between the inclined plane (15) and the axis of the sealing valve core (2) can be 59 degrees to 61 degrees when the sealing ring (9) is in a natural state. The invention has no sealing space and the sealing valve core is protected from abrasion.

Owner:宁波中迪机械有限公司

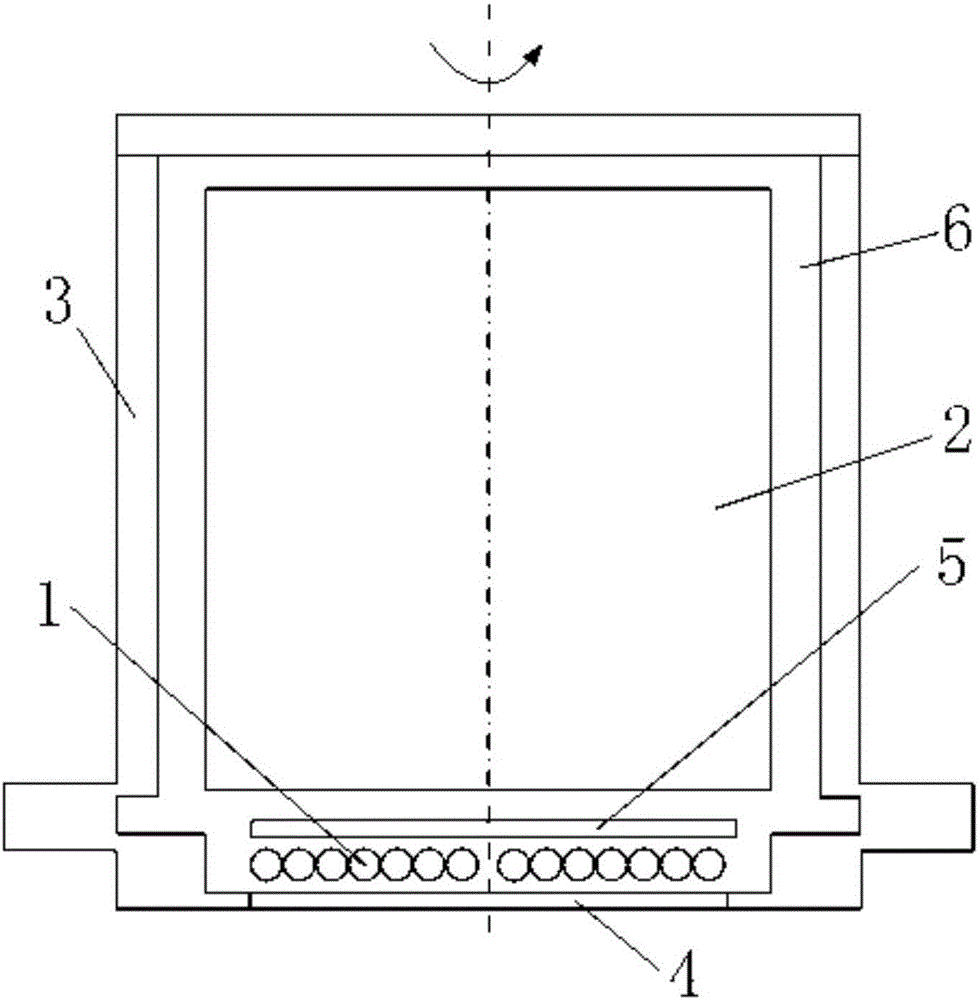

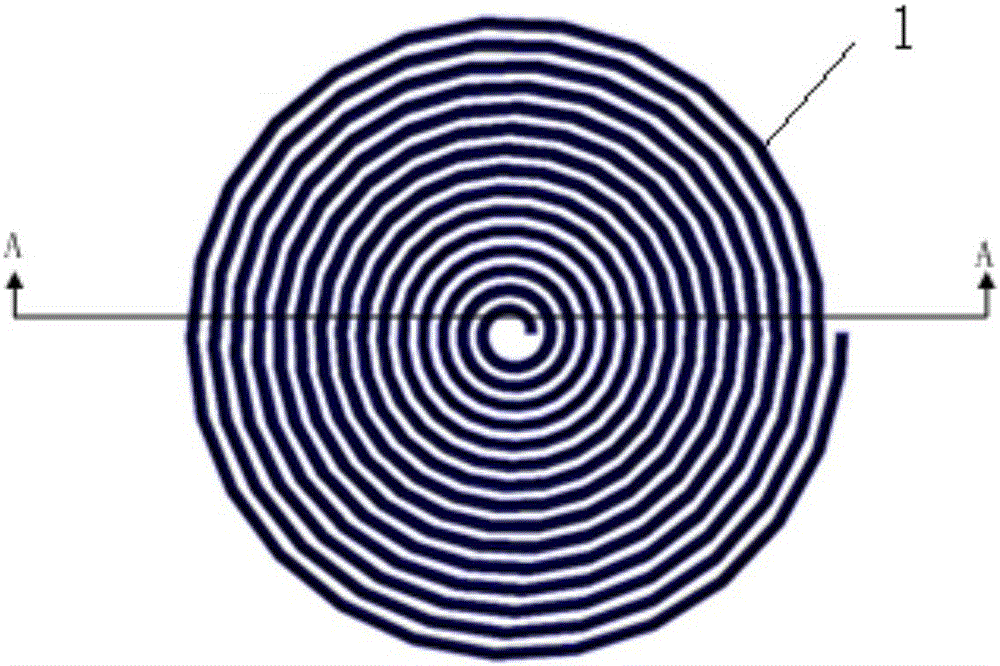

550-DEG C high-temperature metal material electromagnetic ultrasonic flaw detection method and device

ActiveCN105758938AImprove detection accuracyHigh real-time detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesHigh energyHot Temperature

The invention discloses a 550-DEG C high-temperature metal material electromagnetic ultrasonic flaw detection method and device. The structure of a high-temperature electromagnetic ultrasonic probe is that a ceramic coil (1), a copper plate (5) and a high-temperature-resisting permanent magnet (2) are poured into a brass shell (3) through a first ceramic binding agent (6); the copper plate (5) is located between the ceramic coil (1) and the high-temperature-resisting permanent magnet (2); a corundum sheet (4) located on the outer side of the ceramic coil (1) is arranged at a working end of the brass shell (3). Based on a ceramic layer silver wire and a high-temperature-resisting N-AH SmCo permanent magnet, the 550-DEG C high-temperature metal material electromagnetic ultrasonic flaw detection method and device are suitable for preforming long-time and reliable defect nondestructive detection in a 550-DEG C high-temperature environment, and relatively high energy conversion efficiency still can be kept in the high-temperature environment.

Owner:CENT SOUTH UNIV

High heat conducting insulating silicon grease and its manufacturing method

InactiveCN1534690AHigh thermal conductivityGood insulation propertiesPlastic/resin/waxes insulatorsInorganic insulatorsThermal transmittanceSmall particle

An insulating silicon cream with high heat conductivity is prepared from the mixed aluminium nitride particles which high heat conductivity (3.0 W / m.k) and high insulating property and methyl silica oil through proportionally mixing, ball grinding, vacuum stirring and removing air. Said mixed aluminium nitride particles is composed of big particles (12 microns) and small particles (1.5 microns).

Owner:珠海粤科京华电子陶瓷有限公司

Heated hand grip

InactiveUS20060043085A1Easy to installEasy to manufactureSnowboard bindingsBows/crossbowsGlass fiberHand held

A heated hand grip for use on a ski pole, shovel or other cold weather hand-held tool or object is provided. The hand grip includes a bushing for receiving the end of a tubular object, such as a ski pole, and retaining the object within a cavity / bore of a central core of the hand grip. The hand grip is compressed around the bushing for tight engagement. A heating element is wrapped around the exterior surface of the central core and an outer housing surrounds the heating element and the central core. In a preferred embodiment, the outer housing is a pour-over fluid state material that is solidified. In another preferred embodiment, the heating element is a wire-wound heating element laid out in a pattern on a fiberglass backing material. In still another preferred embodiment, the bore houses a pair of lithium-ion batteries connected in series (referred to as the “battery”). A switch is also housed in the bore, with the switch control (such as a push button) protruding from the top of the grip. A printed circuit board (PCB) is connected to the switch and located within the bore. A cavity is located within the central core for positioning a recharge jack.

Owner:MEYERS MARCY

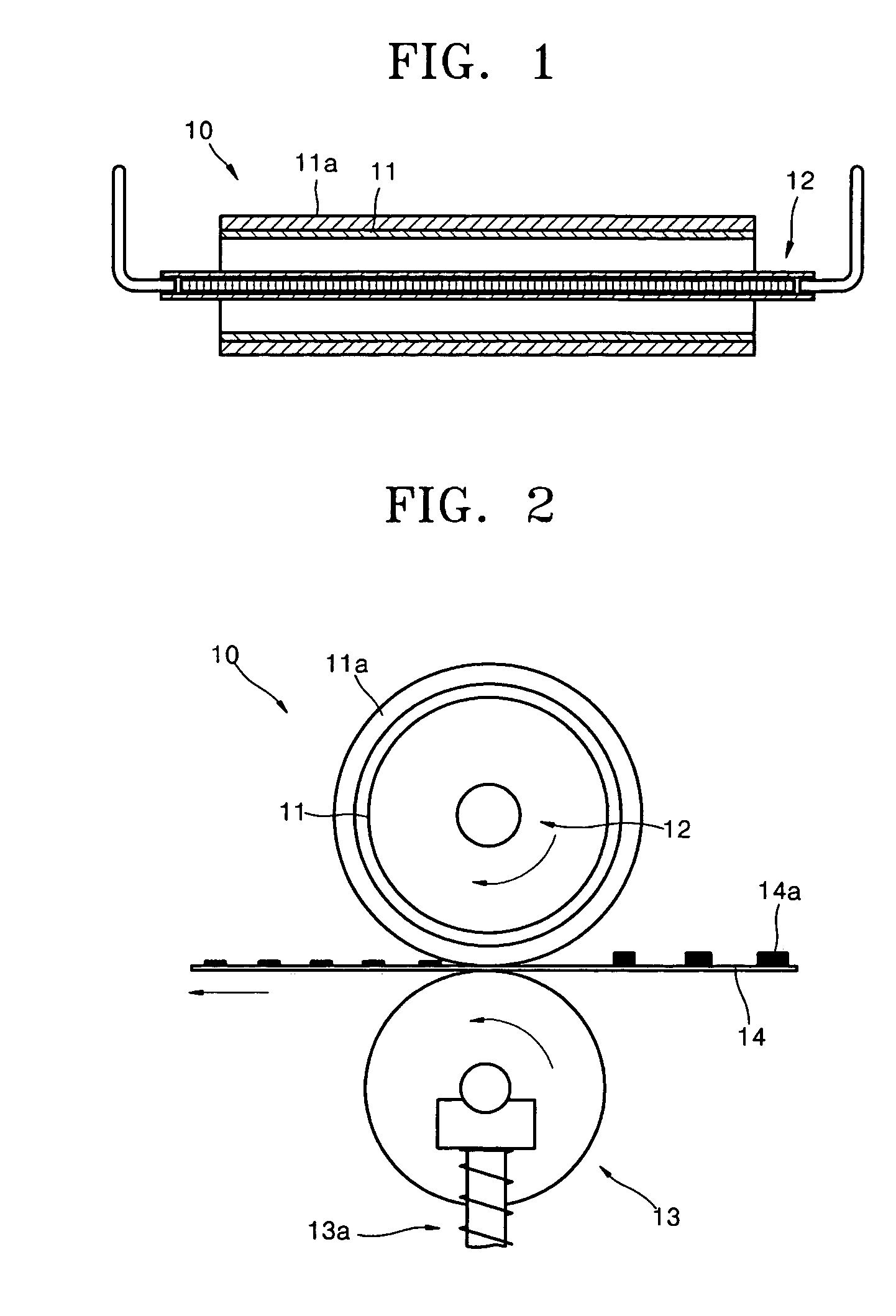

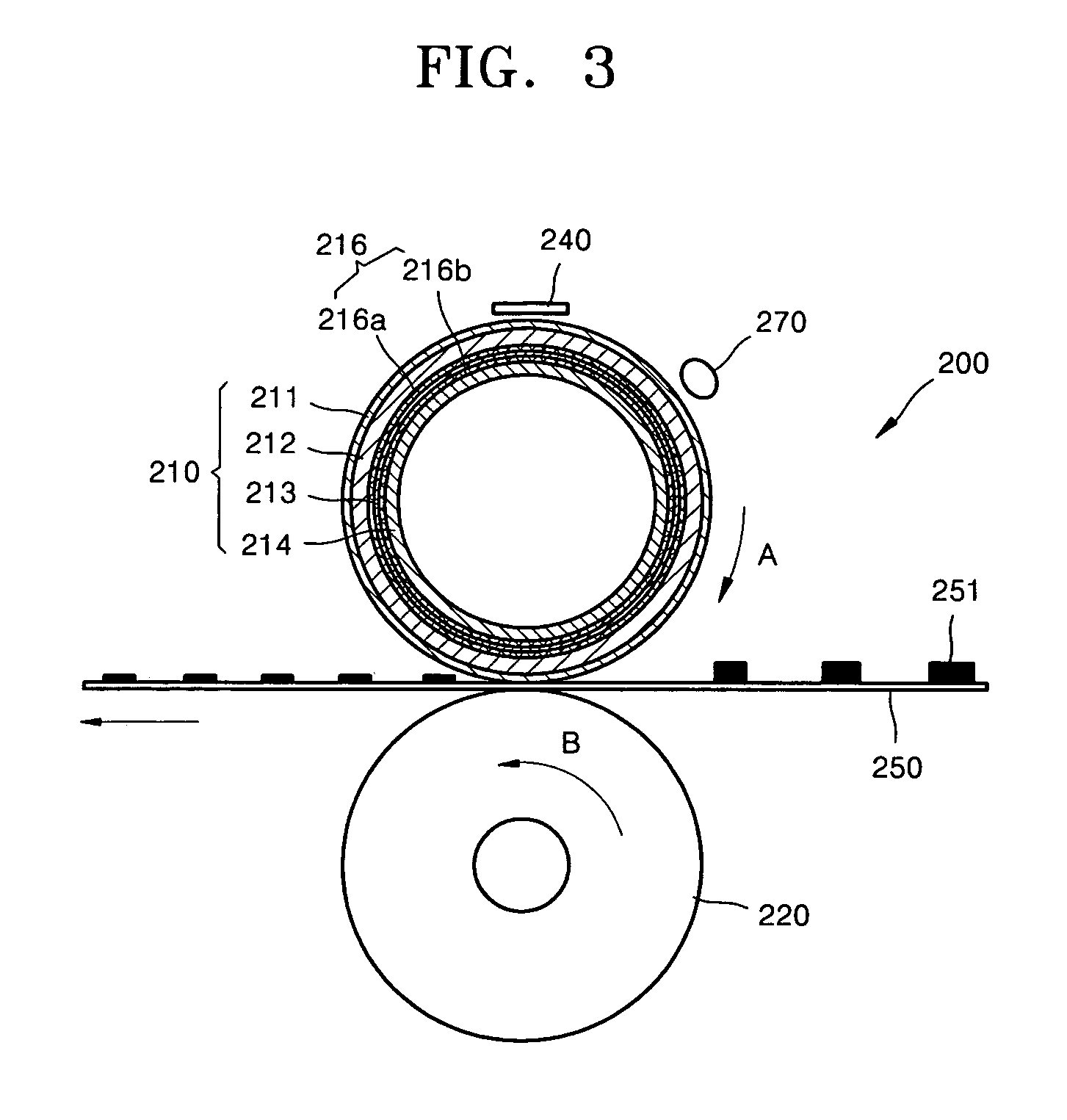

Fusing roller apparatus of electro-photographic image forming apparatus, and a process of manufactuing a fusing roller apparatus

InactiveUS20050129434A1Average power consumptionConsumes small amountElectrographic process apparatusEngineeringImaging equipment

A fusing roller apparatus, and a process of manufacturing thereof, of an electro-photographic image forming apparatus including a cylindrical internal pipe, a fusing unit which is installed to enclose the internal pipe, a heat generator which is installed between the fusing unit and the internal pipe to generate heat, and an insulating layer which includes a first insulating layer that is formed between the heat generator and the fusing unit and a second insulating layer that is formed between the heat generator and the internal pipe to be thicker than the first insulating layer.

Owner:SAMSUNG ELECTRONICS CO LTD

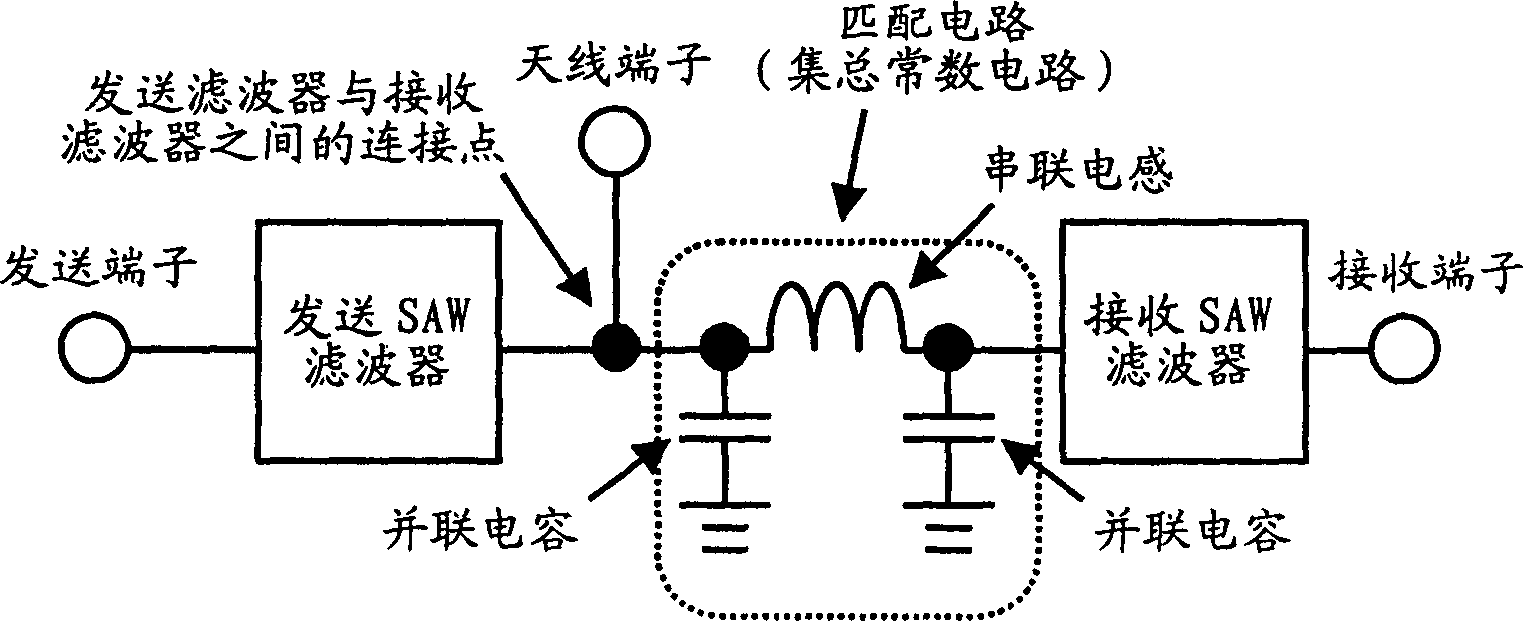

Duplexer

InactiveCN1770628AImprove filter characteristicsIn-band insertion loss is smallImpedence networksCapacitanceInductor

A duplexer includes: a transmission filter and a reception filter connected to a common terminal; and a reactance circuit connected to at least one of the transmission filter and the reception filter. The reactance circuit includes an insulating substrate, a lumped constant inductance and at least one capacitor, the lumped constant inductance and the at least one capacitor being directly formed on the surface of the insulating substrate.

Owner:TAIYO YUDEN KK

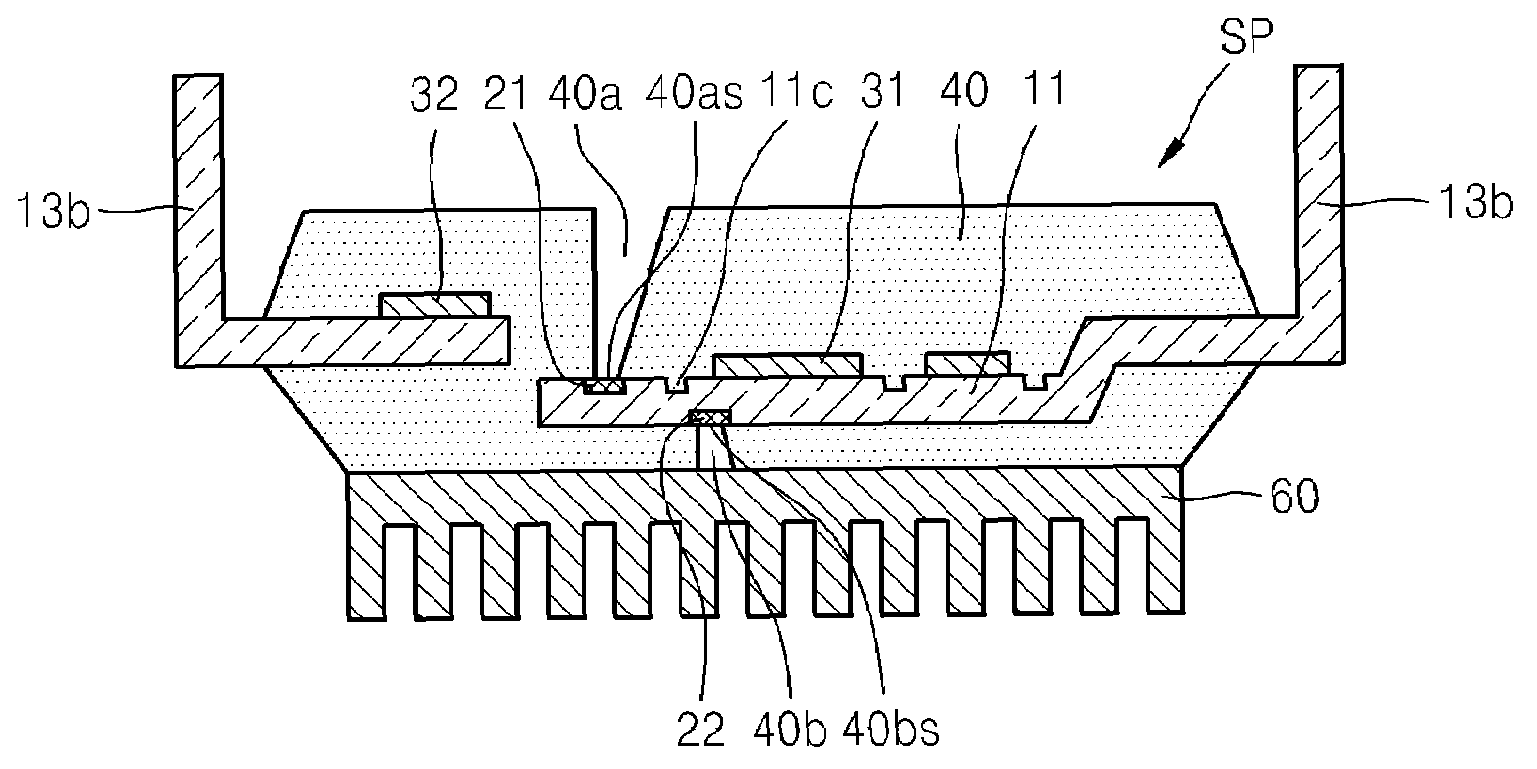

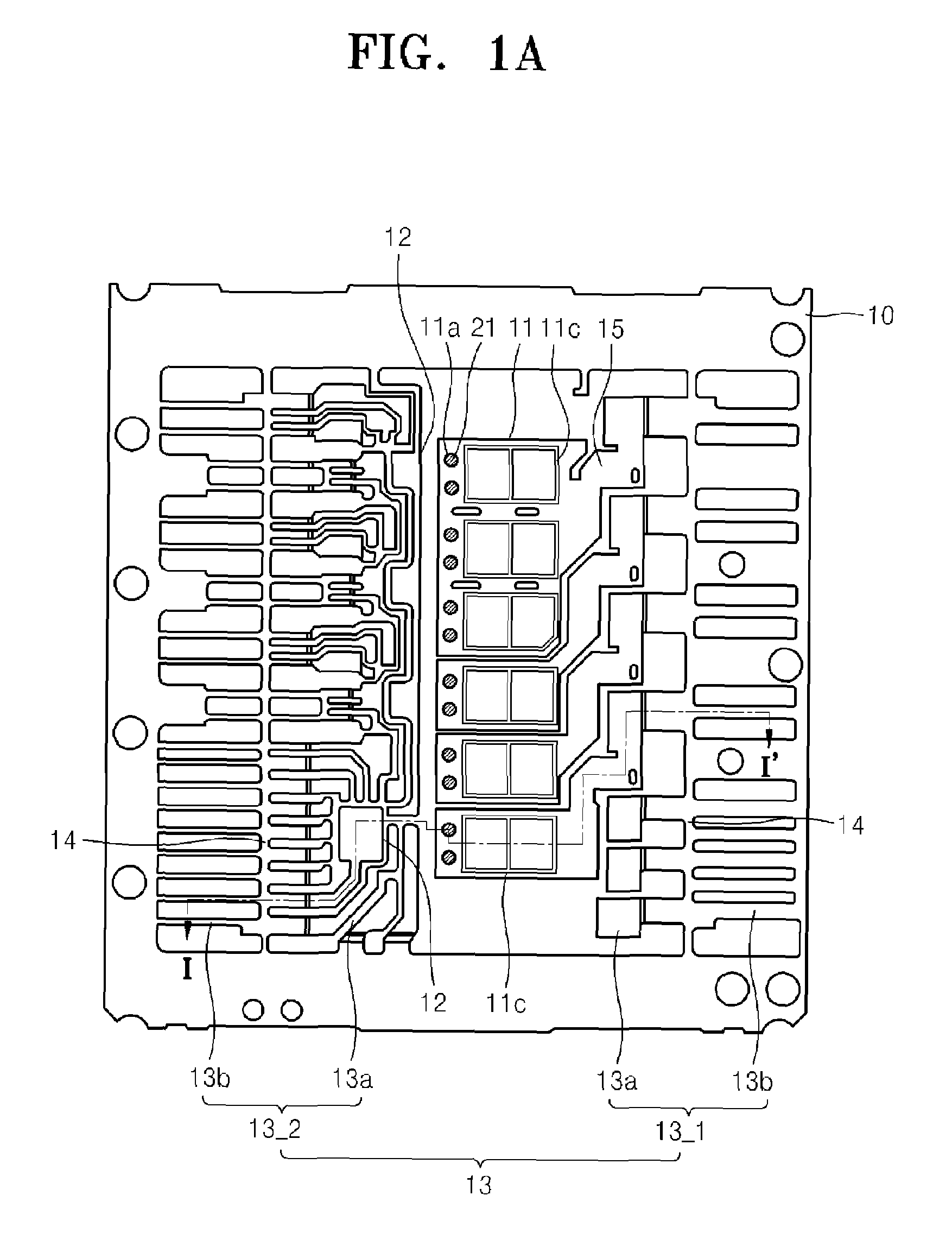

Semiconductor packages and methods of fabricating the same

ActiveUS7714455B2Good insulation propertiesSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

Provided are semiconductor packages and methods of fabricating the same. An exemplary semiconductor package includes a die pad including a dimple filled with an insulating material in an upper surface or a lower surface thereof. A semiconductor chip is mounted on the upper surface of the first die pad. A package body encapsulates the first die pad and the first semiconductor chip and includes a pinhole. A bottom surface of the pinhole terminates at the insulating material.

Owner:SEMICON COMPONENTS IND LLC

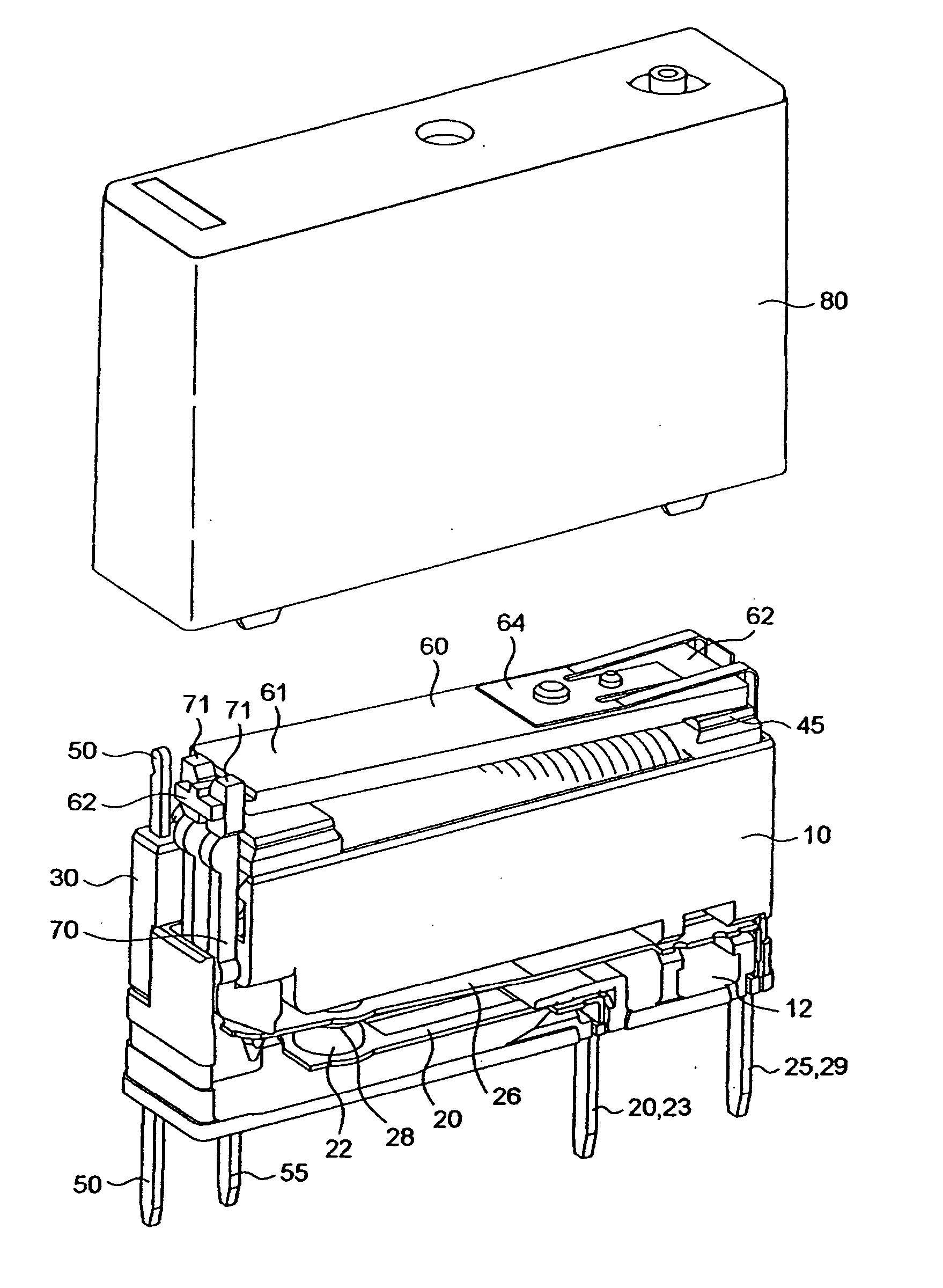

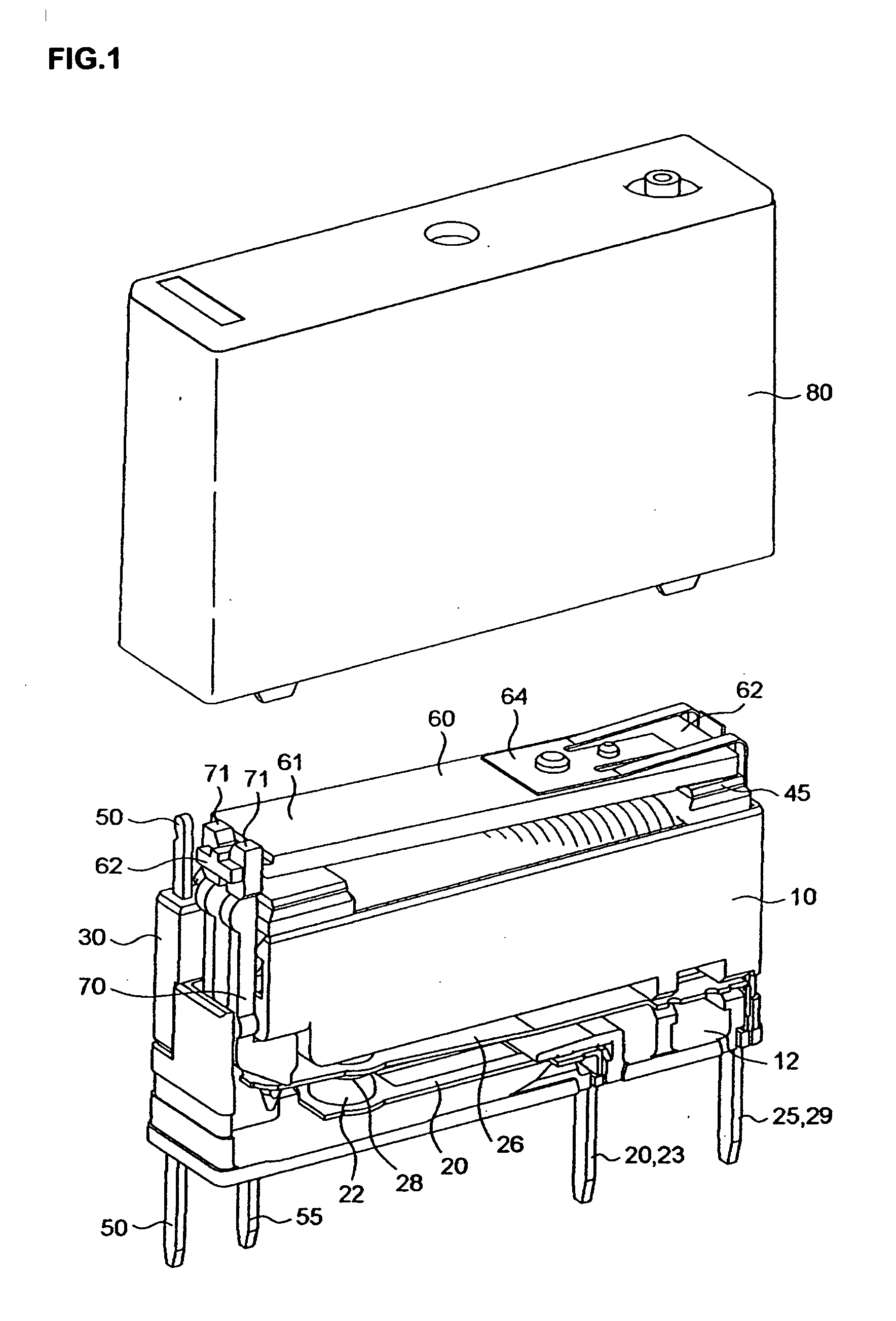

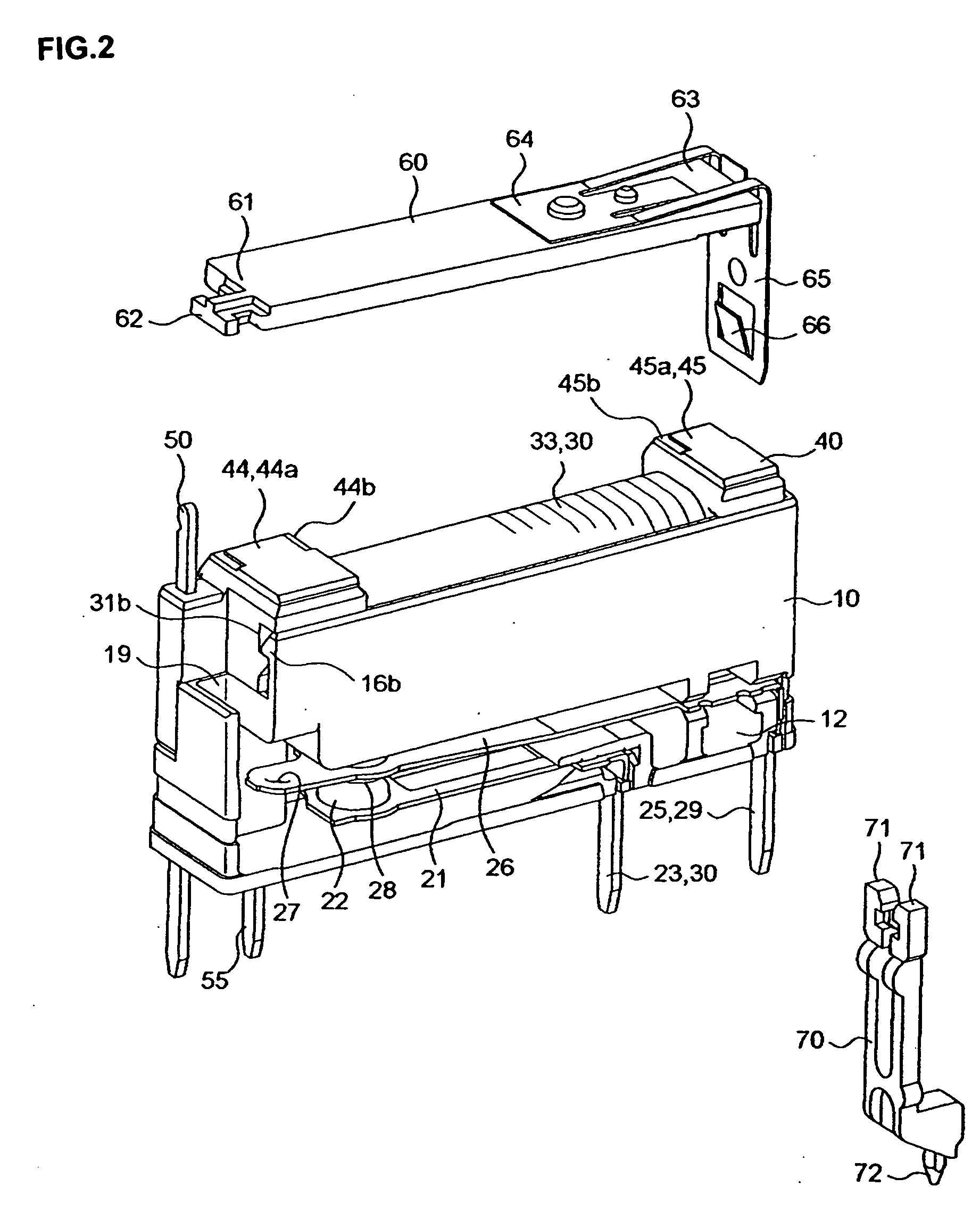

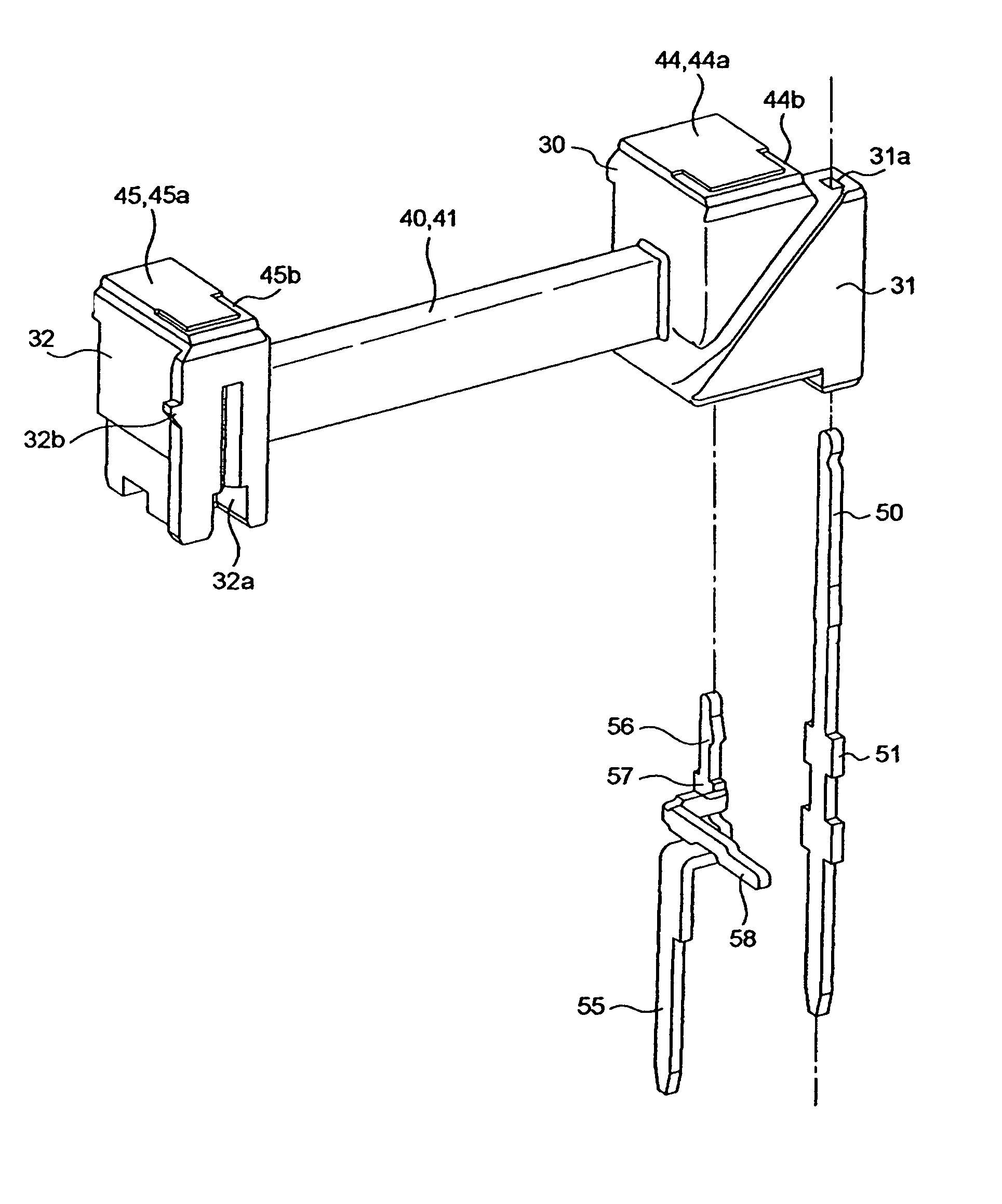

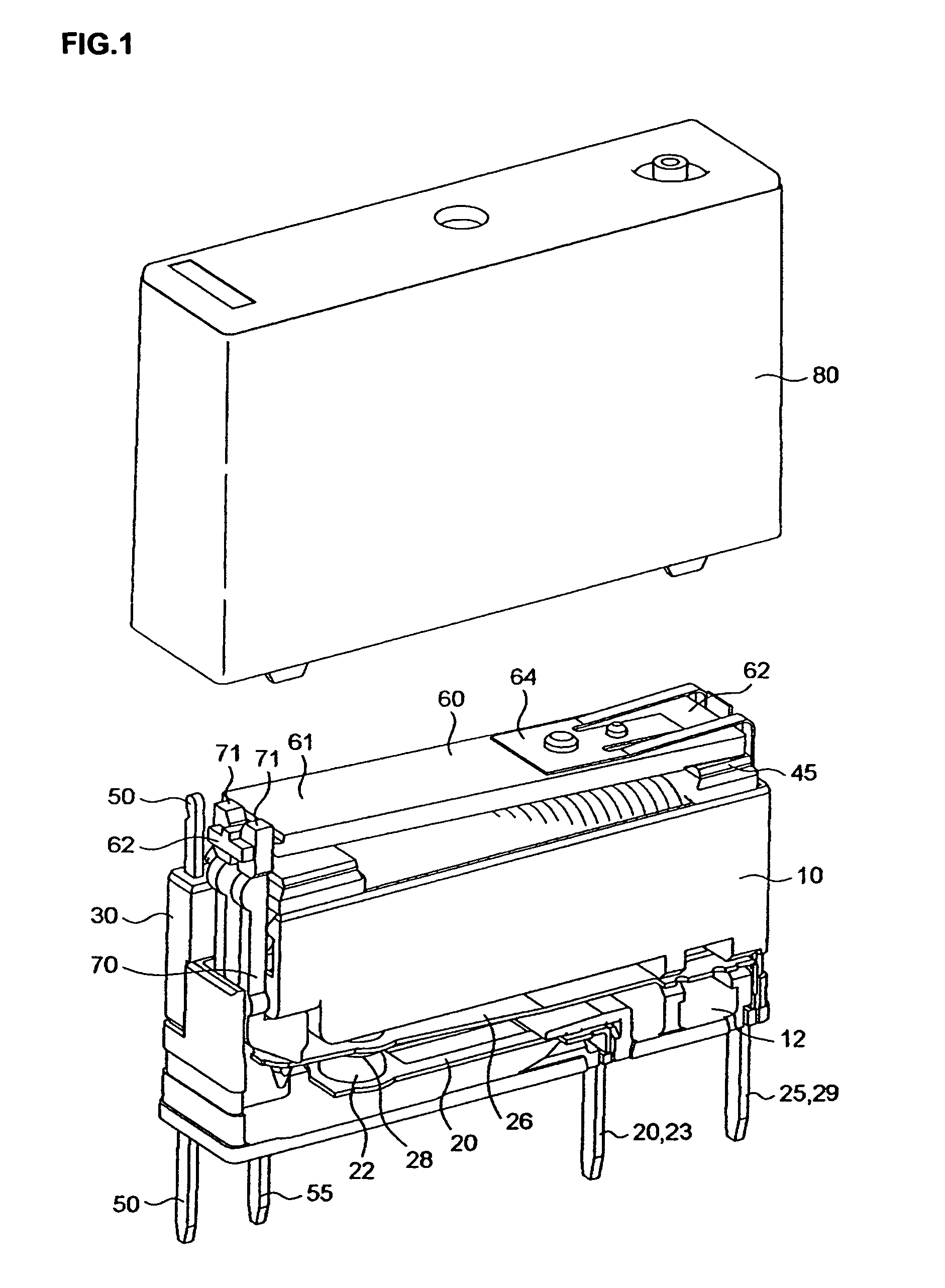

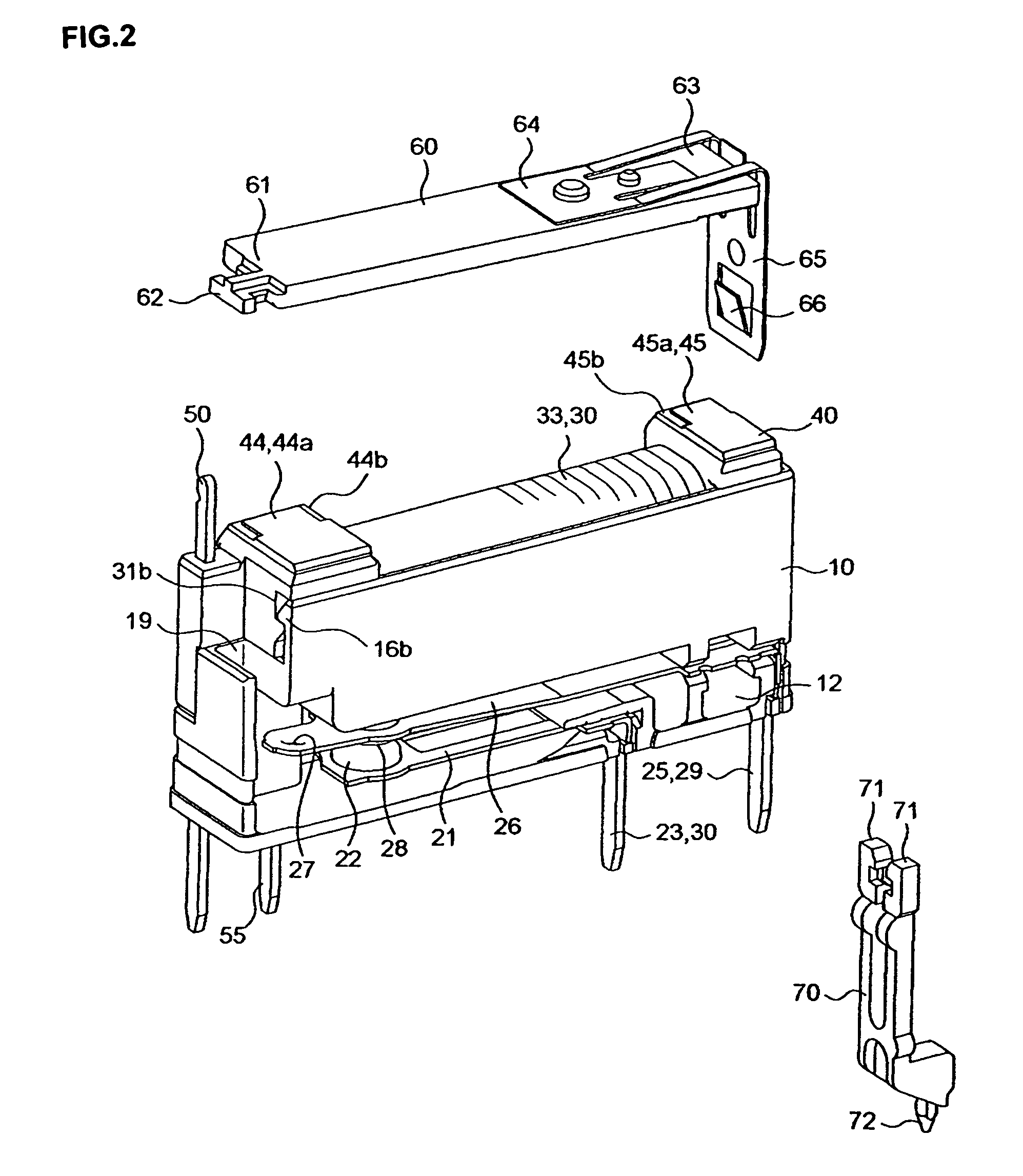

Electromagnetic relay

ActiveUS20050242907A1Shorten the lengthGood insulation propertiesElectromagnetic relay detailsSelector switchesCoil bindEngineering

An electromagnetic relay which is short in length and capable of maintaining a required insulation distance is disclosed. A first coil terminal connecting with one of extension lines of a coil is disposed in the vicinity of one end of a movable iron fragment and a card. A second coil terminal having a binding member which extends from an intermediate portion of the second coil terminal in a horizontal direction and is allowed to be bended toward the electromagnet block with the other of the extension lines of the coil bound to the binding member is further disposed below the electromagnet block.

Owner:ORMON CORP

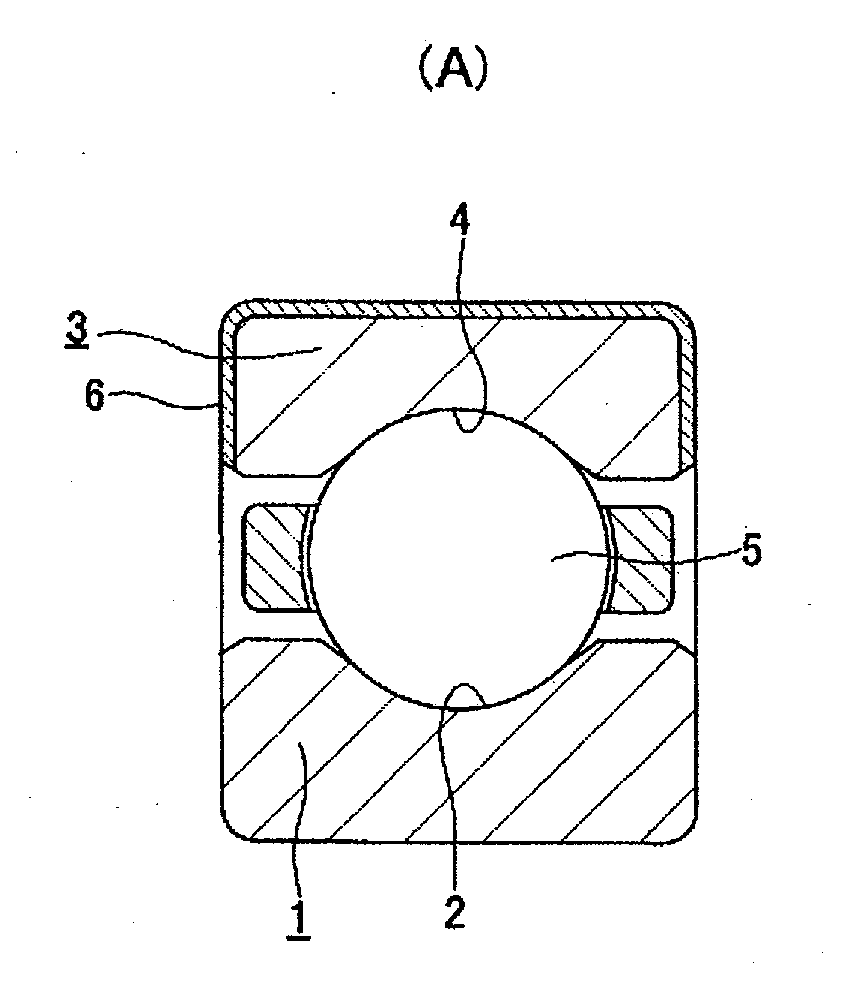

Electrolytic erosion preventing insulated rolling bearing, manufacturing method thereof, and bearing device

ActiveUS8425120B2Increased durabilityImprove performanceBearing assemblyShaftsElectrolysisCeramic coating

Disclosed herein is an electrolytic erosion preventing insulated rolling bearing and a manufacturing method thereof. In one embodiment, the electrolytic erosion preventing insulated rolling bearing includes an insulating coating being a ceramic coating layer including alumina as the main component and 0.01 to 0.2 percent by weight titanium oxide with the alumina having a particle size ranging from 10 to 50 μm and average particle size ranging from 15 to 25 μm.

Owner:NSK LTD

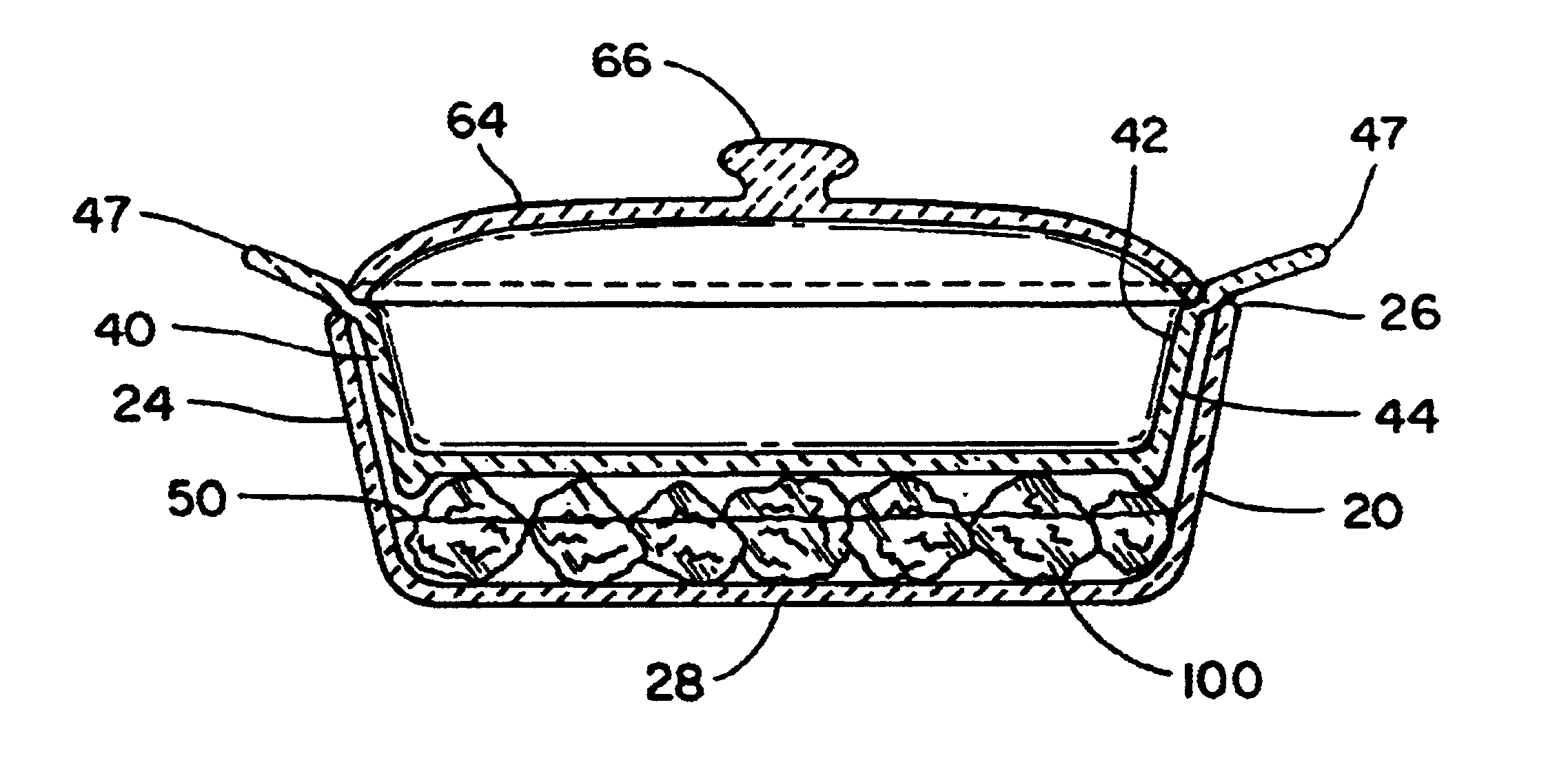

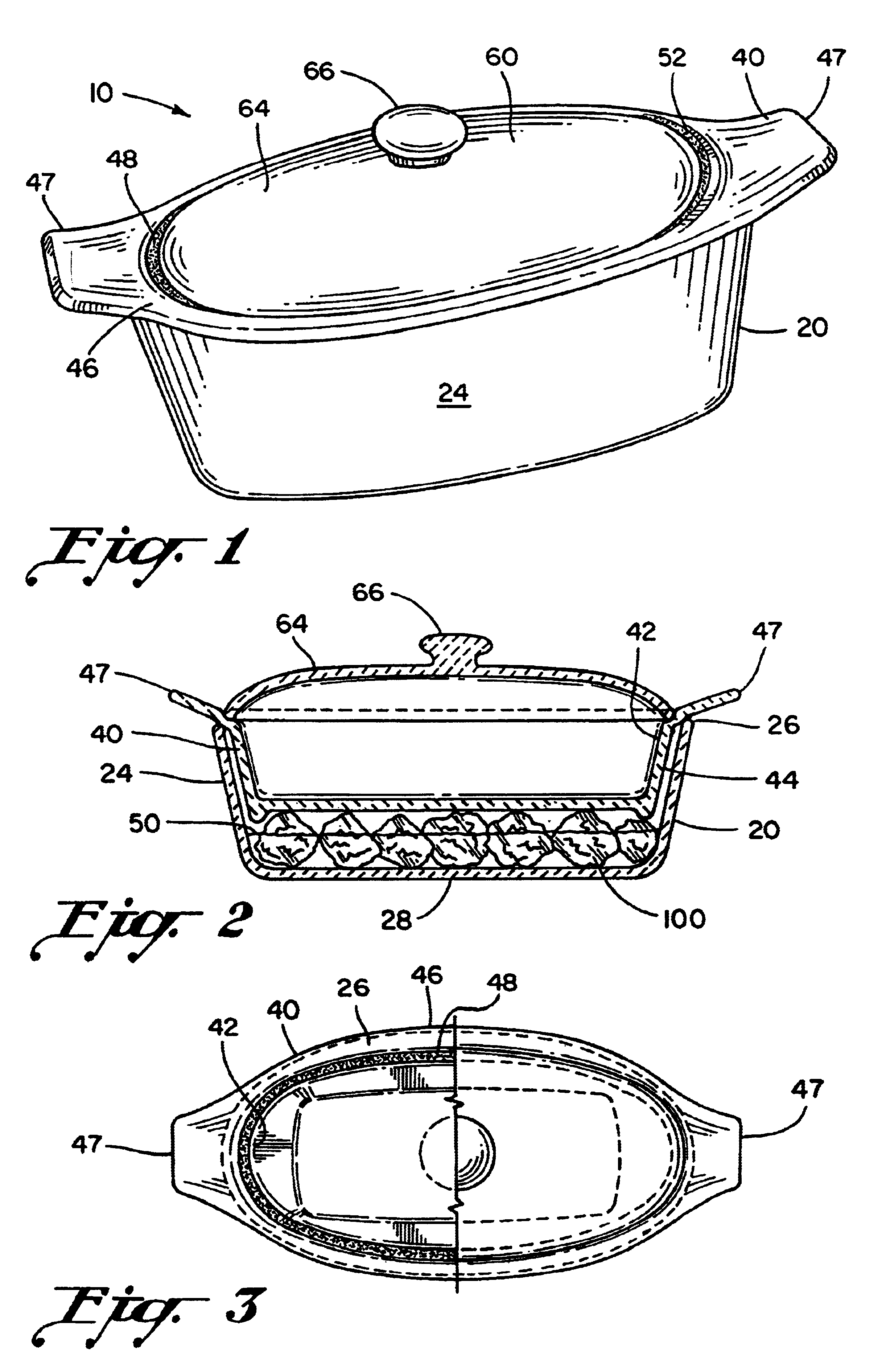

Container assembly for maintaining container contents in a desired ambient temperature

InactiveUS6840396B2Good insulation propertiesMinimizing unnecessary spillageLighting and heating apparatusCooking vesselsLiquid mediumEngineering

The present invention provides a container assembly and method for maintaining container contents in a desired ambient temperature. The device comprises an outer bowl member, an inner vessel member and a lid member, all of which are constructed with porous materials. Critically-select portions of the outer bowl member, the inner vessel member and the lid member are glazed with a vapor-impervious coating while the remaining portions of the container assembly are left unglazed. The glazed portions thus provide an avenue for vapor or liquid media, emanating from temperature-maintaining matter, to permeate through the interstitial pores of the material by entering and exiting through the unglazed portions of the container assemblage. Container contents, housed in the lidded inner vessel member, are thus more efficiently maintained in a desired ambient temperature.

Owner:WUESTMAN PENNY M

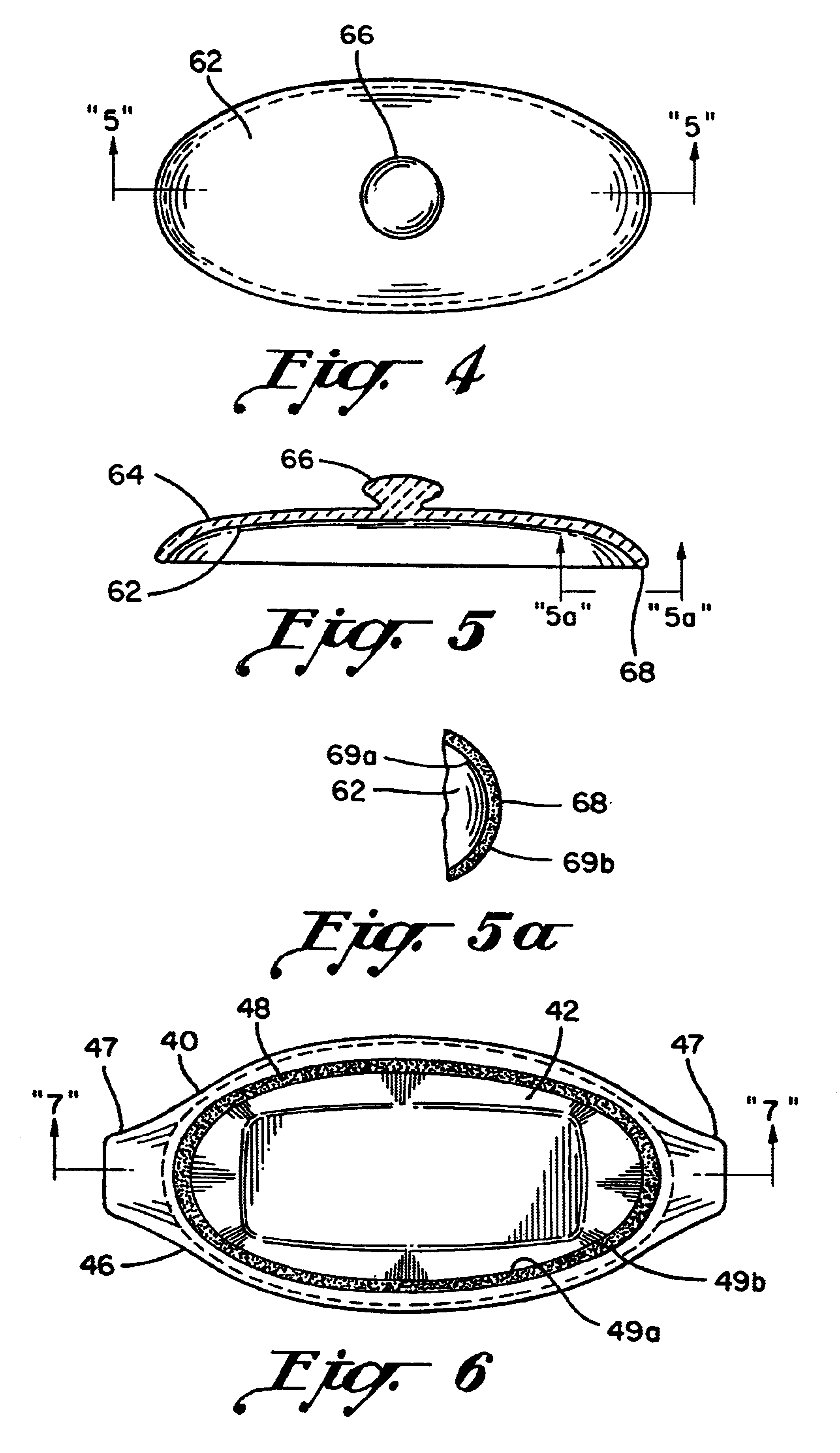

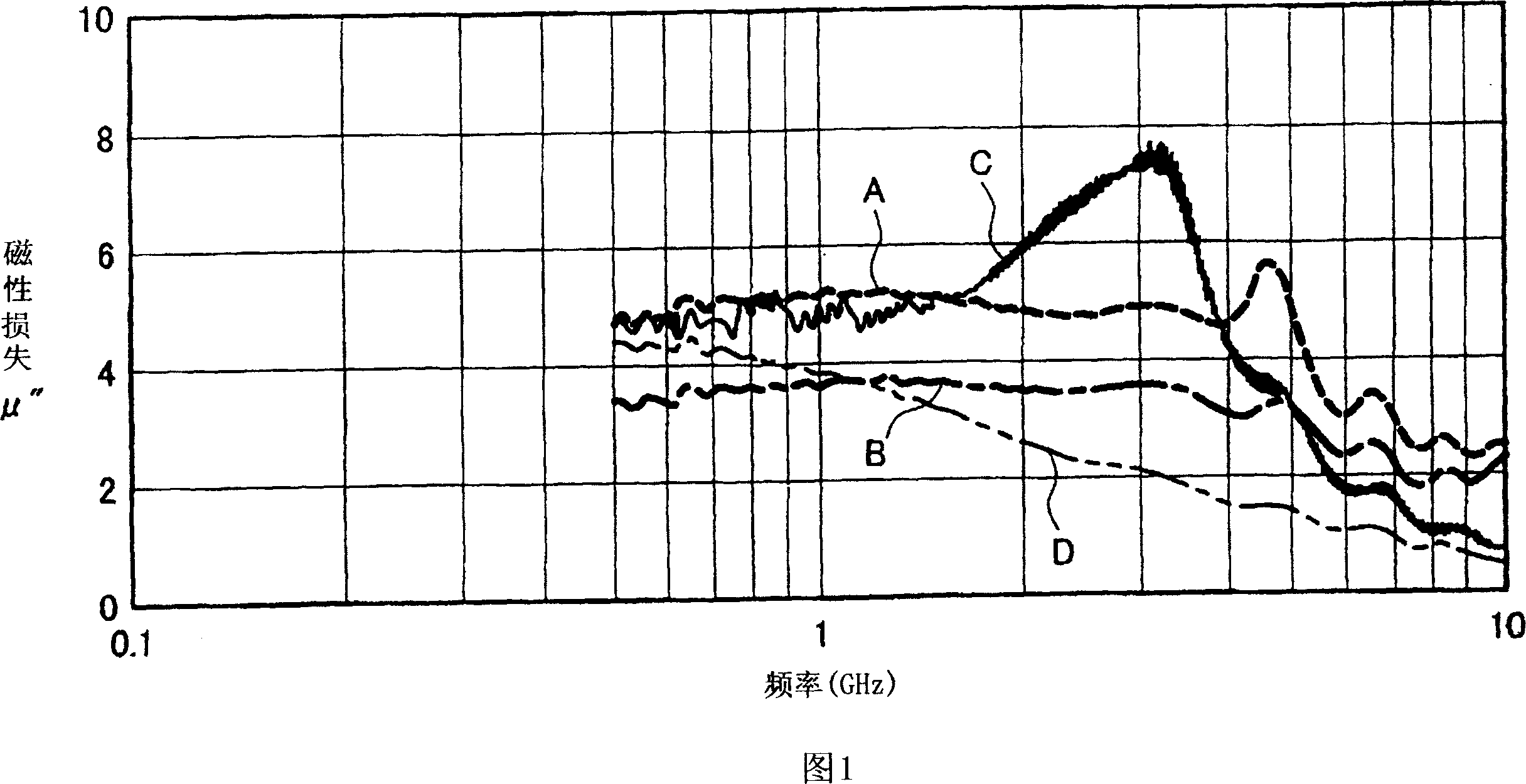

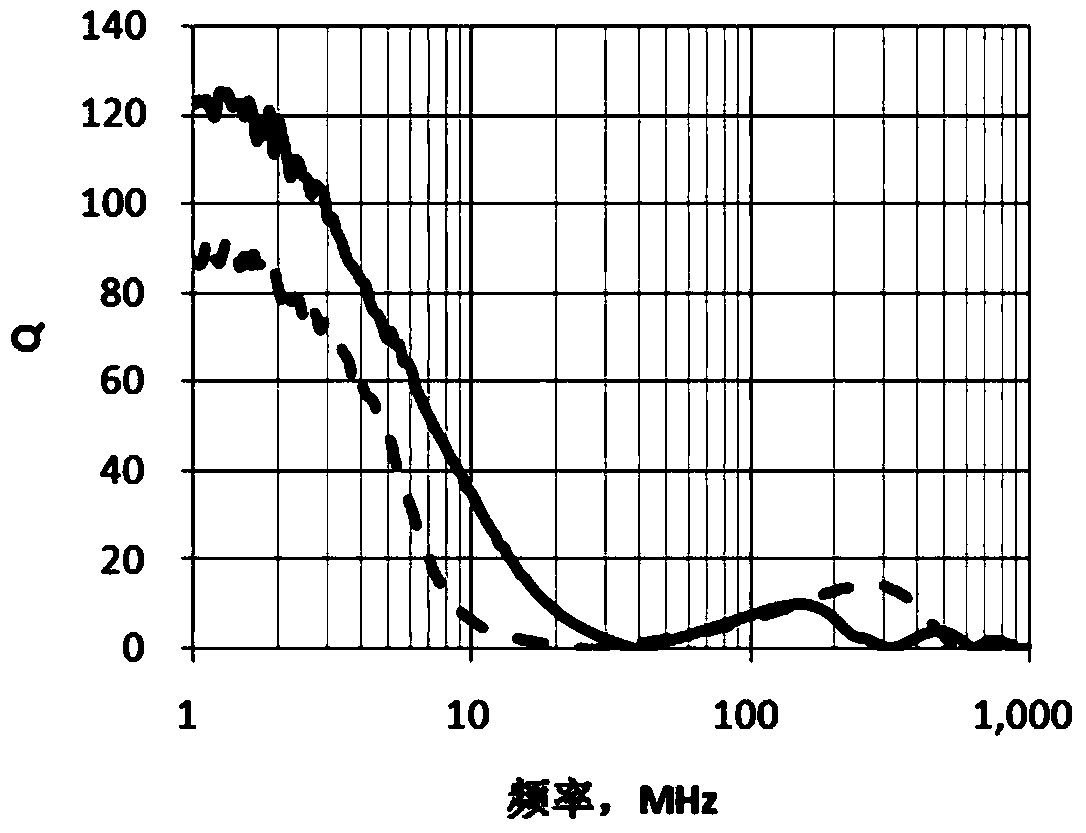

Electromagnetic wave absorber

InactiveCN1926936AExcellent electromagnetic wave absorption performanceImprove thermal conductivityMagnetic/electric field screeningInorganic material magnetismHigh resistanceElectromagnetic wave absorber

An electromagnetic wave absorber comprising (a) soft ferrite having its surface treated with a silane compound having no functional group, (c) magnetite and (d) silicone, or comprising (a) soft ferrite having its surface treated with a silane compound having no functional group, (b) flat soft magnetic metal powder, (c) magnetite and (d) silicone, which electromagnetic wave absorber excels in electromagnetic wave absorption, heat conduction and flame resistance, exhibiting less temperature dependence, and which electromagnetic wave absorber is soft, excelling in adhesion strength and further excelling in high resistance high insulation properties and in energy conversion efficiency being stable in MHz to 10GHz broadband frequency. There is further provided a laminated electromagnetic wave absorber comprising the above electromagnetic wave absorber overlaid with a reflection layer of conductor, which laminated electromagnetic wave absorber can be closely stuck onto an unwanted electromagnetic wave emission source such as a high-speed operating device, having such an adhesive strength that even when stuck to a horizontal glassy-surface ceiling face of resin-made cage, would not fall.

Owner:GELTEC

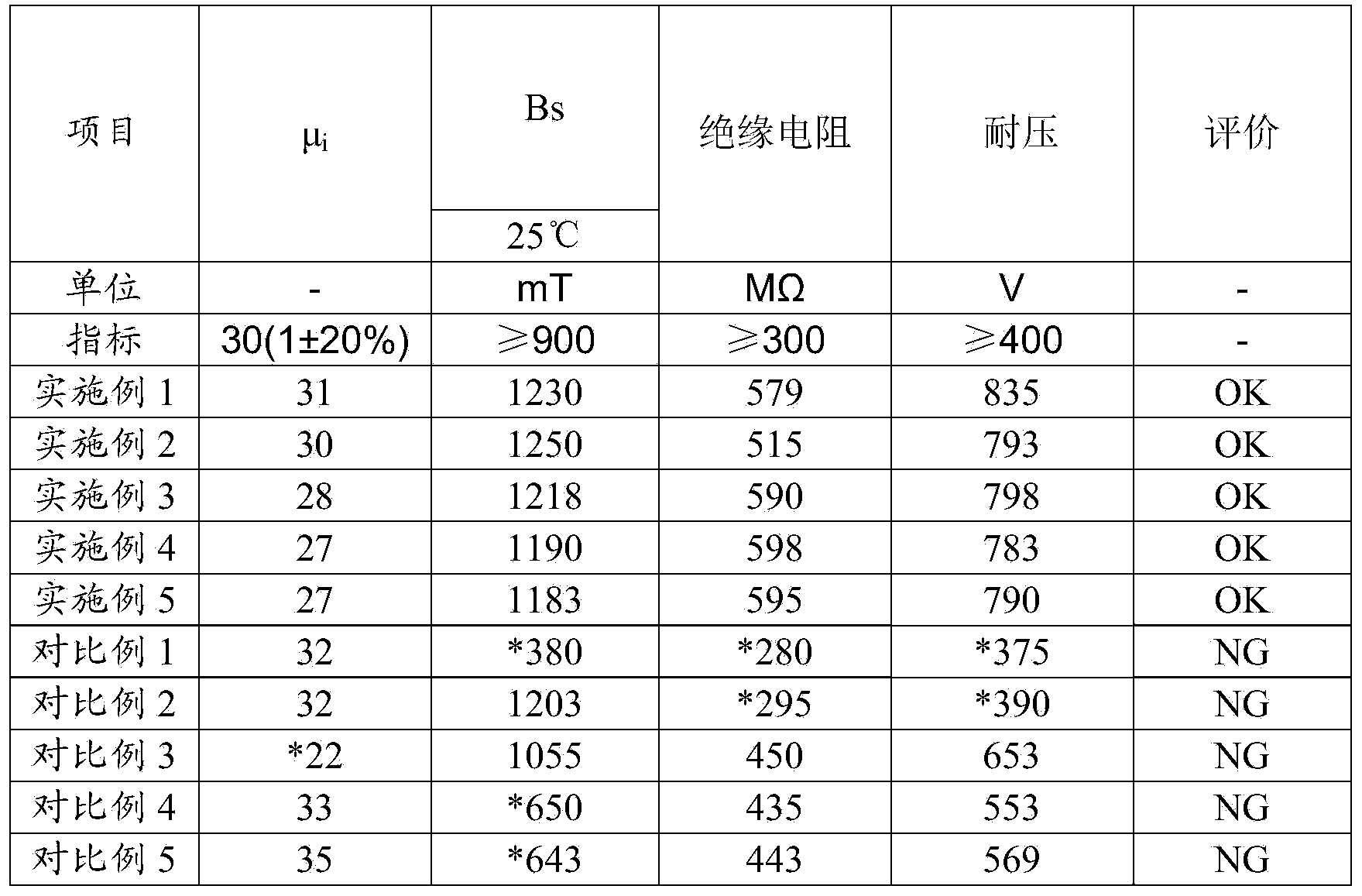

Composite soft magnetic material and preparation method thereof

ActiveCN104392819AImprove insulation performanceImprove pressure resistanceInorganic material magnetismMetallurgyMaterials science

The invention discloses a composite soft magnetic material and a preparation method thereof. The composite soft magnetic material comprises the following components in percentage by mass: 82.56 to 98.45 percent of FeSiCr, 0.3 to 8.9 percent of Fe2O3, 0.1 to 1.93 percent of NiO, 0.1 to 2.13 percent of ZnO and 0.1 to 0.53 percent of CuO. The preparation method of the composite soft magnetic material comprises mixing, pre-burning, smashing, pressing and sintering. The saturation flux density of the composite soft magnetic material is adjusted by adjusting the content of FeSiCr, and the content of generated NiCuZn ferrite is adjusted by adjusting the content of Fe2O3, NiO, ZnO and CuO, so that the insulation and pressure-resistant property of the composite soft magnetic material are enhanced.

Owner:SHENZHEN SUNLORD ELECTRONICS

Electromagnetic relay

ActiveUS6995639B2Shorten the lengthGood insulation propertiesElectromagnetic relay detailsSelector switchesCoil bindEngineering

An electromagnetic relay which is short in length and capable of maintaining a required insulation distance is disclosed. A first coil terminal connecting with one of extension lines of a coil is disposed in the vicinity of one end of a movable iron fragment and a card. A second coil terminal having a binding member which extends from an intermediate portion of the second coil terminal in a horizontal direction and is allowed to be bended toward the electromagnet block with the other of the extension lines of the coil bound to the binding member is further disposed below the electromagnet block.

Owner:ORMON CORP

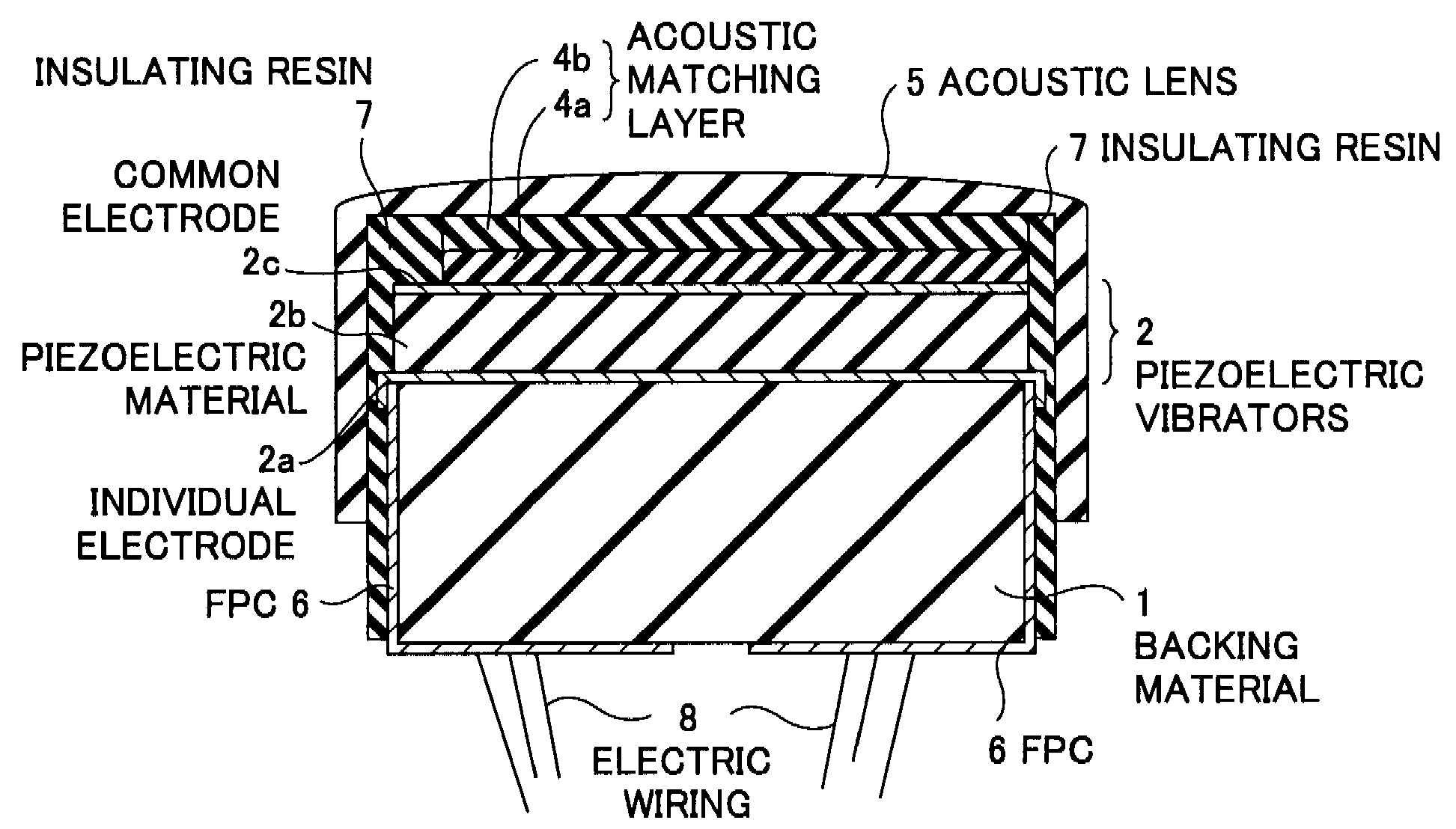

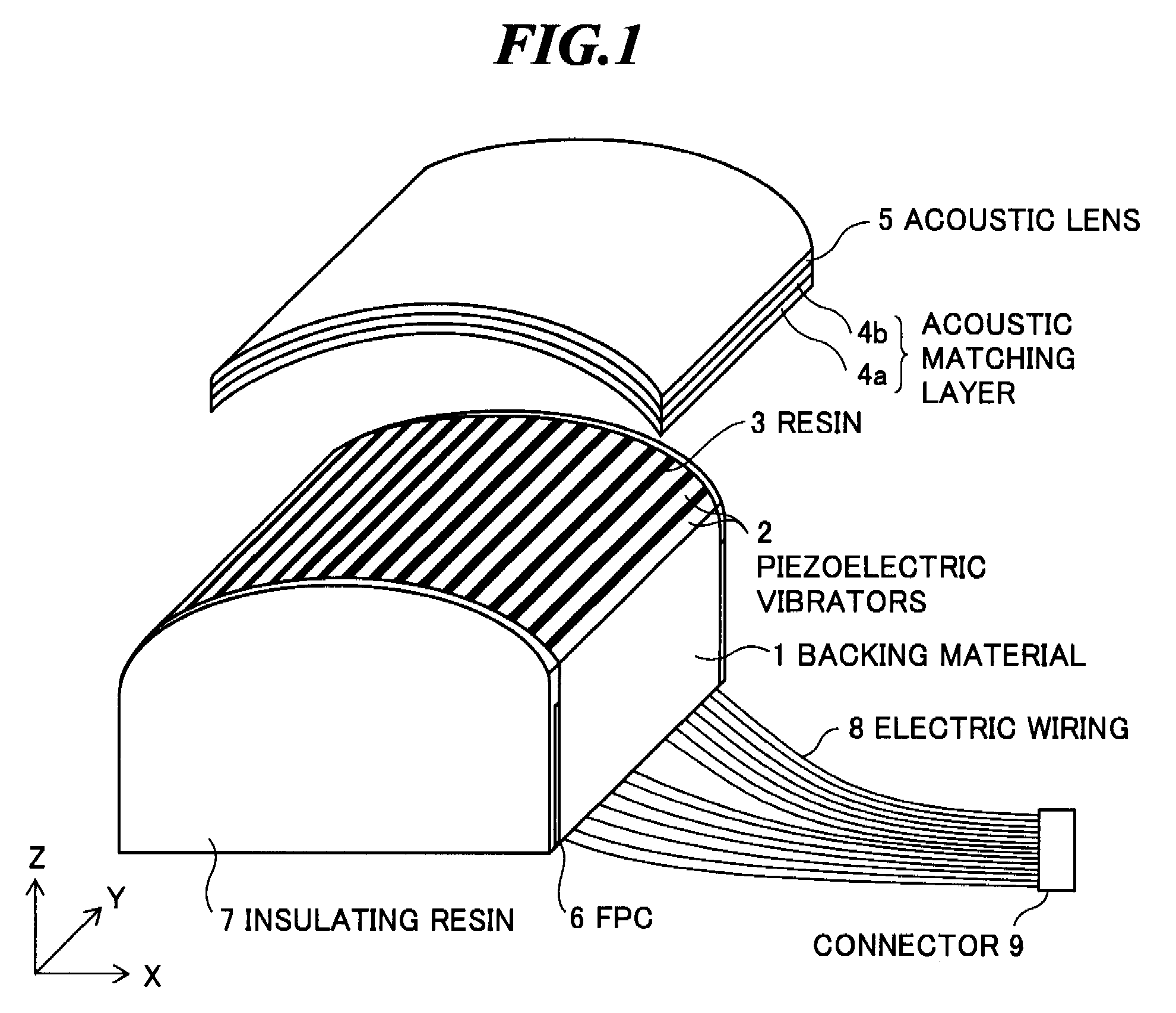

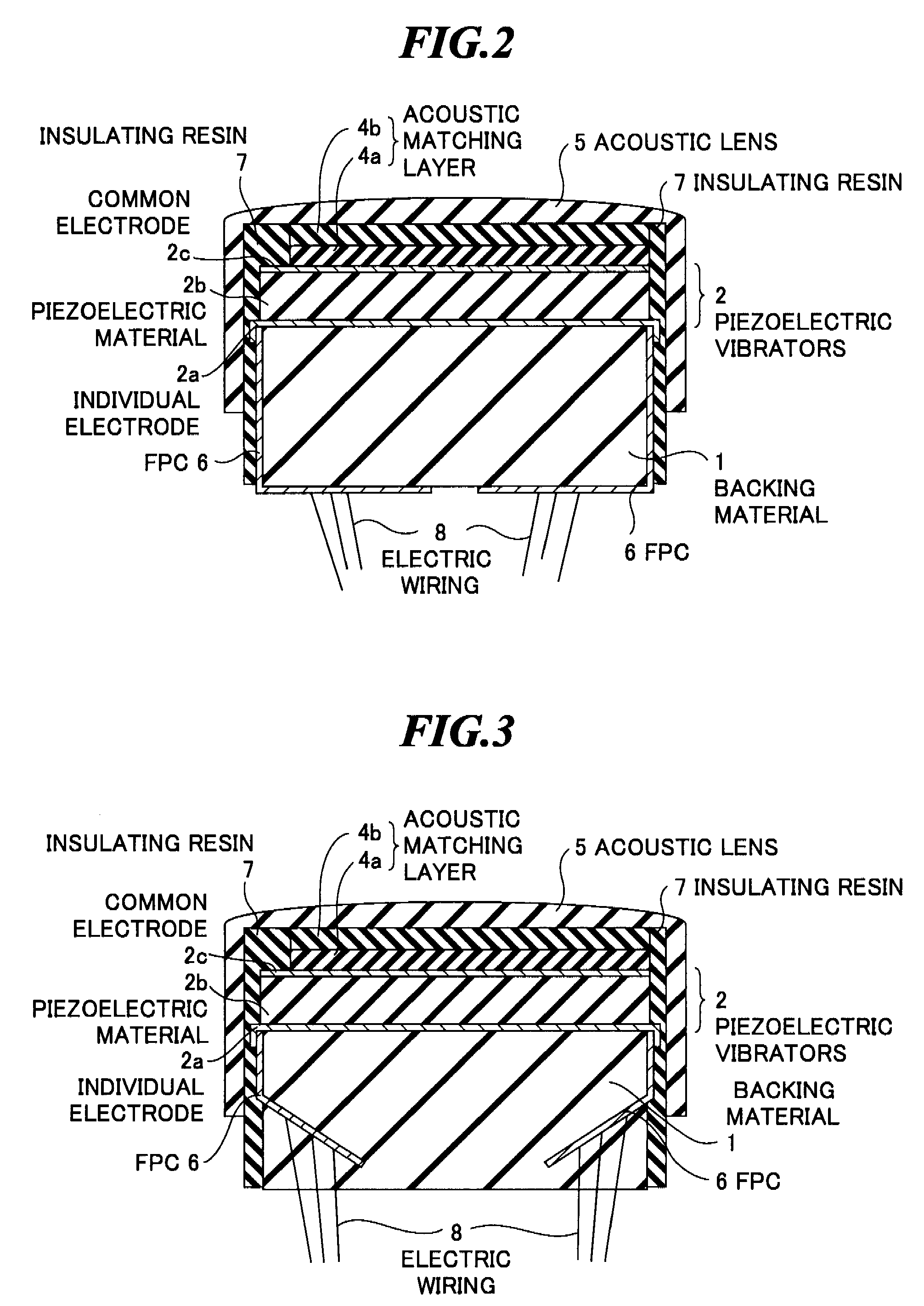

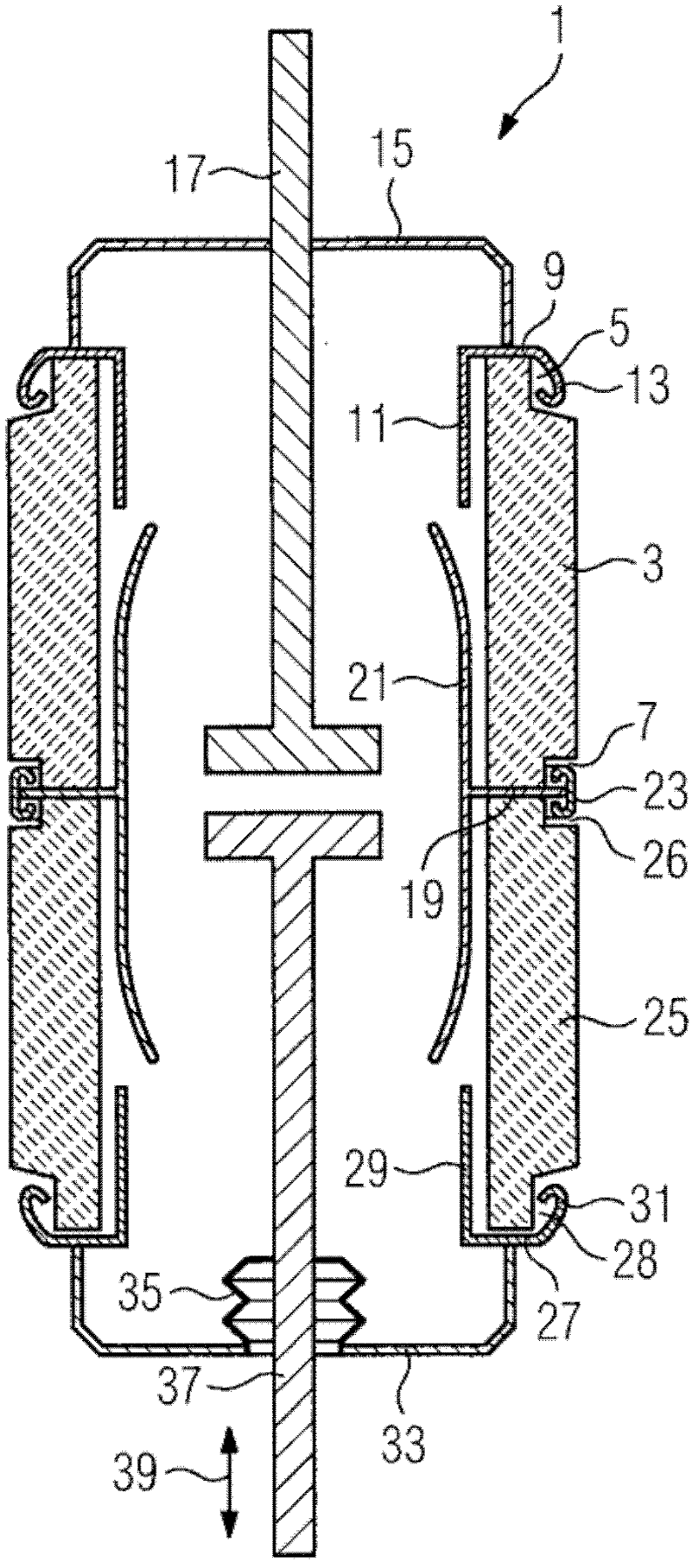

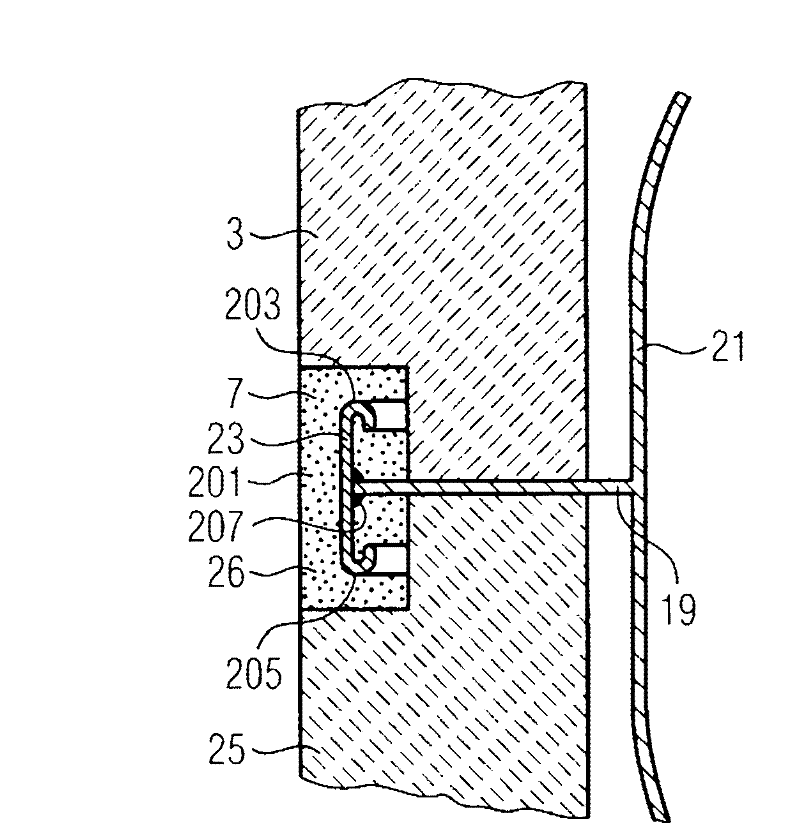

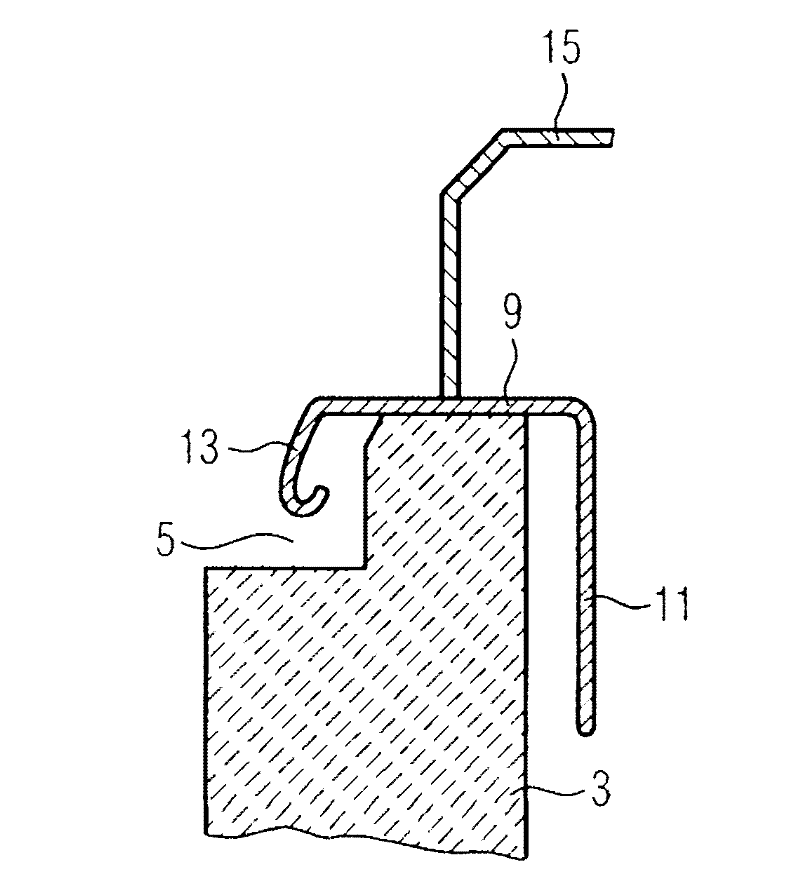

Ultrasonic probe, backing material for ultrasonic probe, and method of manufacturing the same

InactiveUS20080303381A1Good insulation propertiesImprove insulation performanceUltrasonic/sonic/infrasonic diagnosticsLiquid surface applicatorsParent materialOxide

A backing material that is advantageous in insulation property and can realize a desired acoustic impedance without making the cross-linking and curing reaction of elastomer or resin as a parent material unstable. The backing material is provided on a backside of vibrators for transmitting and / or receiving ultrasonic waves in an ultrasonic probe, and the backing material includes: a parent material containing elastomer or resin and having an insulation property; and composite powder dispersed to fill the parent material, and the composite powder includes powder of a material having a larger acoustic impedance than that of the parent material and an insulation coating for covering a surface of the powder, and the insulation coating contains an oxide of an element of group XIII to group XV except for carbon (C), nitrogen (N), phosphorus (P).

Owner:FUJIFILM CORP

Vacuum switch tube

InactiveCN102292788AHigh compressive strengthImprove lateral insulationHigh-tension/heavy-dress switchesAir-break switchesVacuum interrupterVacuum switch

The invention relates to a vacuum switching tube (1) having at least one essentially cylindrical, electrically insulating housing part (3) which is connected in a vacuum-tight manner to a metal part (9). Here, the metal component is provided with a field control element (13). The field control element (13) is arranged in a groove (5) of the housing part (3) in such a way that the field control element (13) sinks relative to the outer surface of the housing part (3). set flush with the outside surface.

Owner:SIEMENS AG

Polyester film for capacitors

InactiveCN1397077AGood insulation propertiesNo reduction in processing characteristicsFixed capacitor dielectricDomestic articlesDielectricPolyester

A film which is a biaxially oriented film comprising polyethylene-2,6-naphthalenedicaboxylate as a principal component, having a thermal strain ratio RMD (150) in the machine direction of the film at a temperature of 150 DEG C is -1.5%< / =RMD (150)< / =0.0% when the thermal strain ratio RMD (T) in the machine direction of the film at a temperature T DEG C based on the length LMD (t) in the machine direction (MD) of the film at a temperature t DEG C is defined by <DF>RMD (T) = äÄLMD(T) - LMD (35)Ü / LMD (35)ü x 100 (%), < / DF> excellent in insulation characteristics without lowering processing characteristics, especially the characteristics during hot-pressing and suitable as a dielectric for capacitors.

Owner:TEIJIN LTD

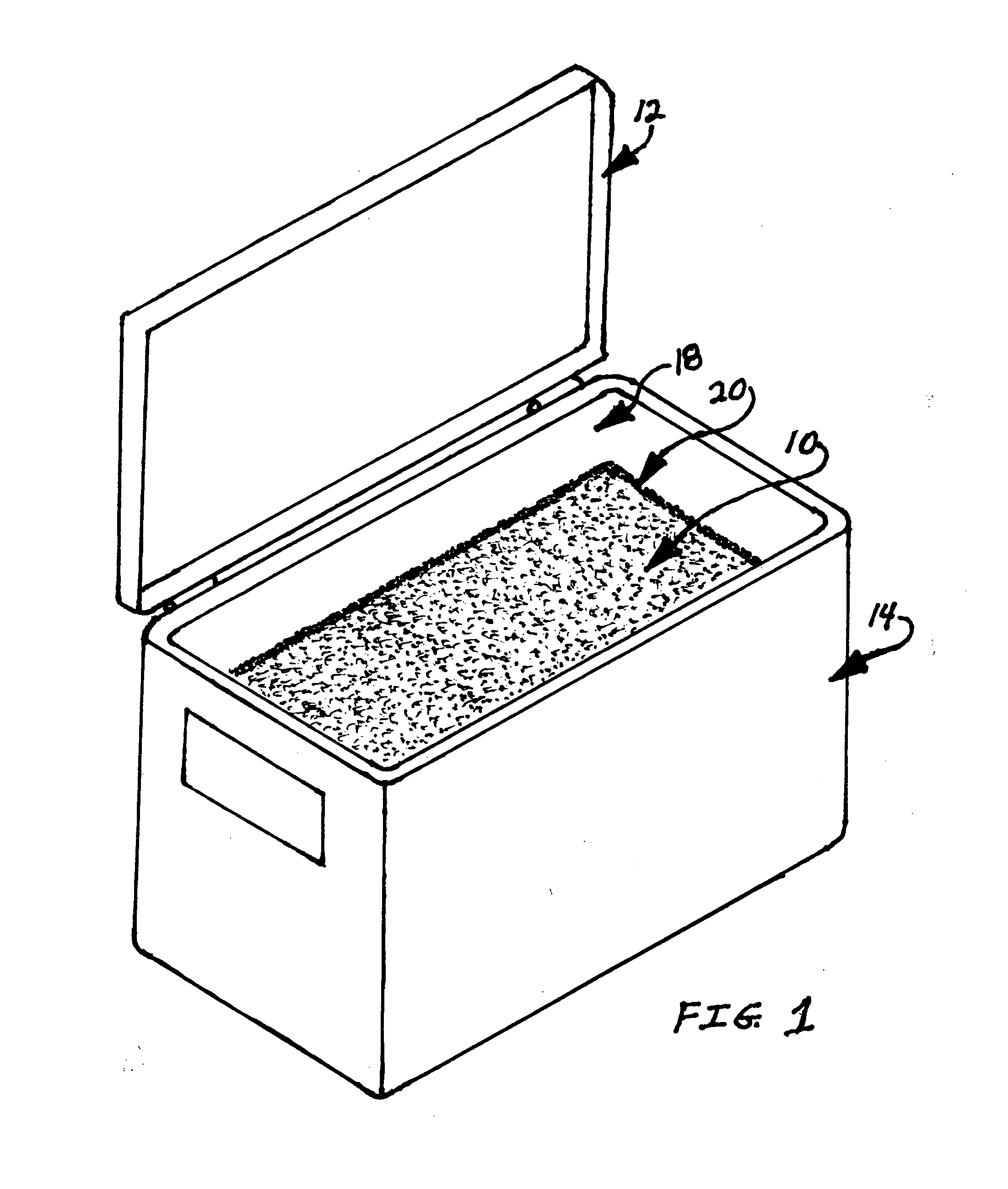

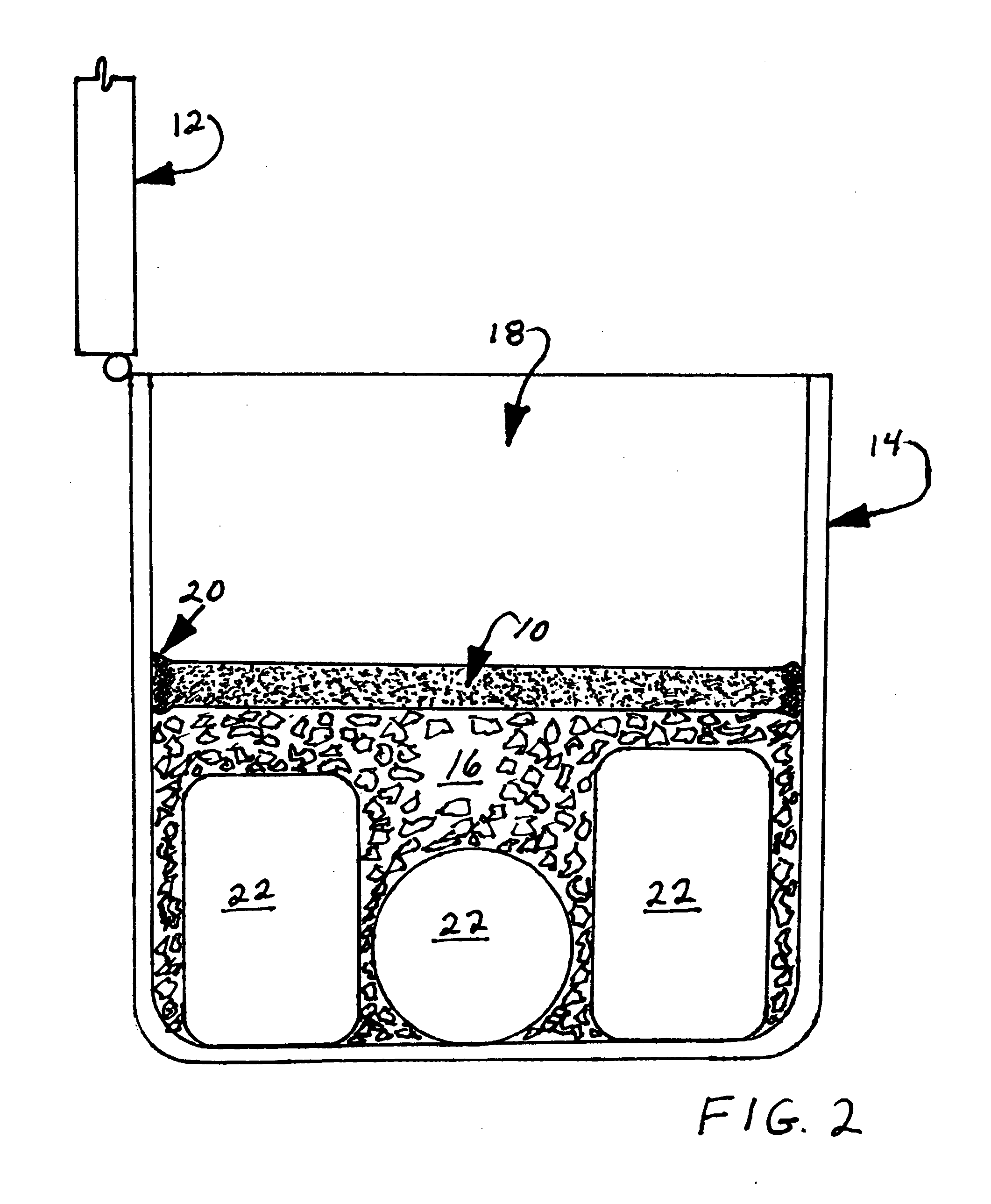

Cooler Chest Interior Insulation Device

InactiveUS20160187045A1Readily apparentGood insulation propertiesMetal-working apparatusOther accessoriesPolyvinyl chlorideEngineering

An insulated cooler chest for carrying perishables and cooling medium such as ice is improved to provide an extended period during which low temperatures are maintained. A sheet of flexible, synthetic, closed cell foam insulation material is placed over the perishables and the cooling medium. The sheet is trimmed or cut oversized, compared to the size of the cavity of the cooler chest. The sheet is pressed downward in the cavity and against the perishables and cooling medium, substantially conforming to the upper surface thereof. As the insulating sheet is oversized, the edges of the insulating sheet compress and seal against the interior walls of the cooler cavity, thus sealing perishables and cooling medium from outside convection currents and conductive heat. Preferably, the insulating material is of closed cell polyvinyl chloride nitrile butadiene rubber foam (PVC / NBR), which possesses elastic, compressive and rebound properties. It is lightweight, washable, sufficiently flexible and can be easily trimmed or cut to size. The insulation material is preferably of sufficient thickness to seal against the interior cooler walls and not bow significantly.

Owner:MCGARRY VERN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com