Electromagnetic wave absorber

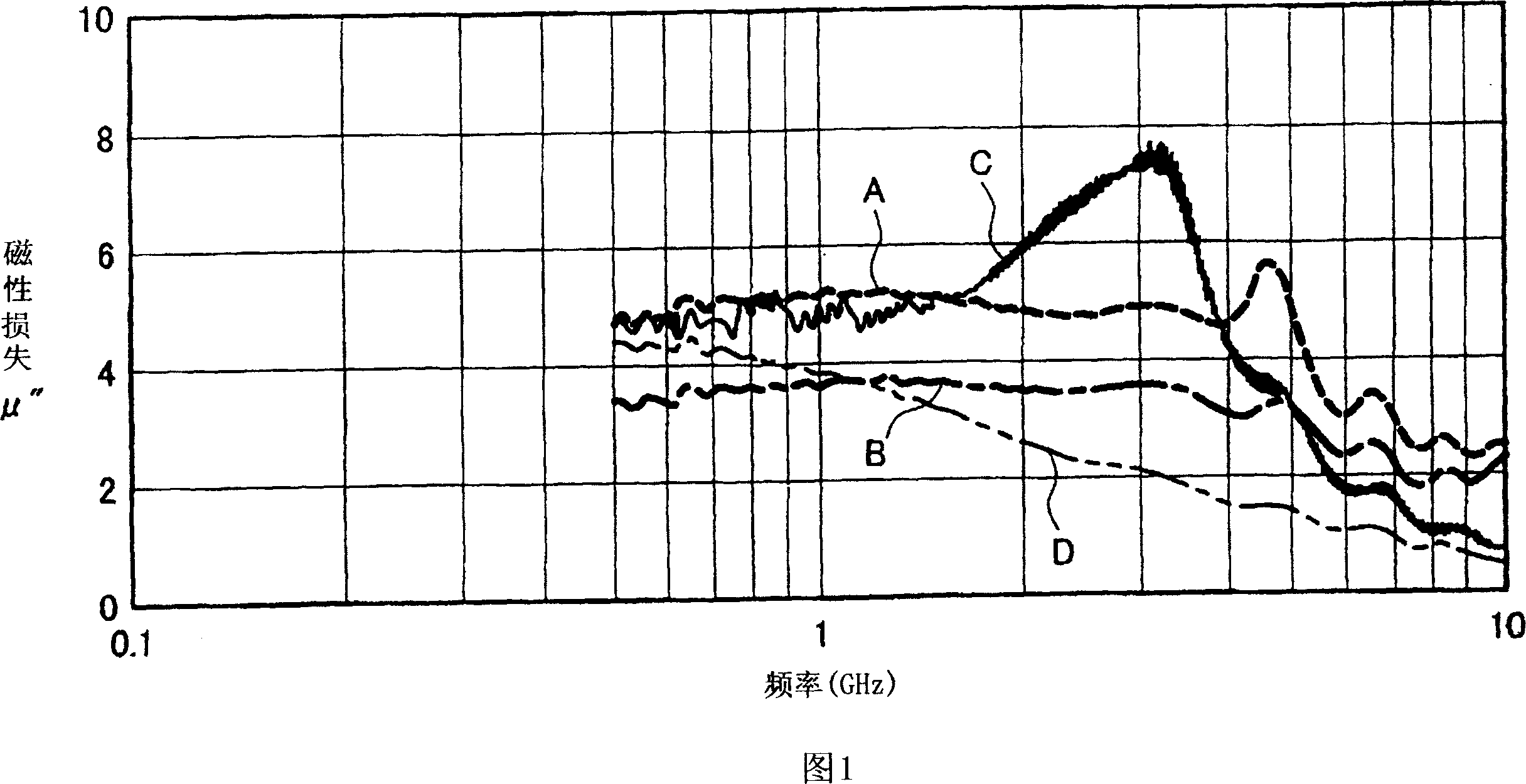

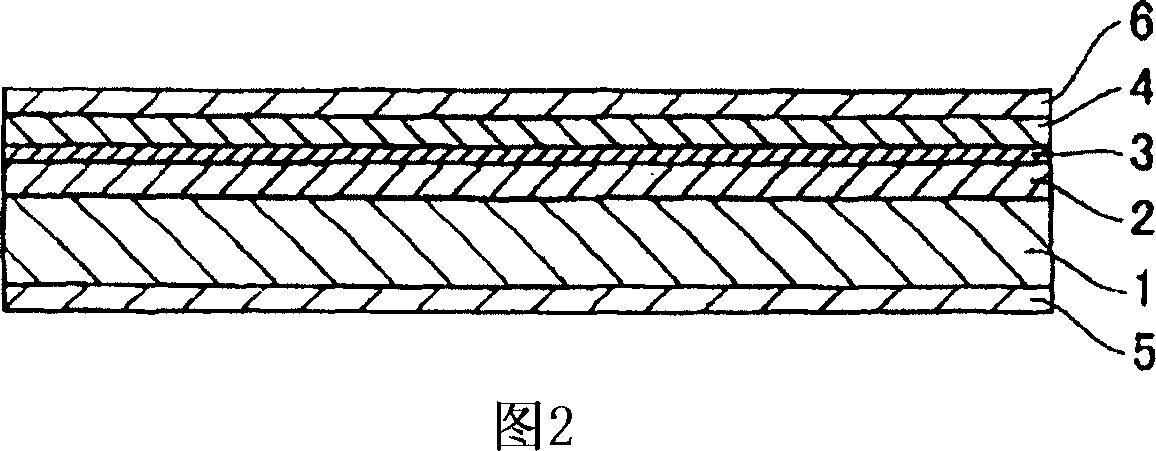

An electromagnetic wave and absorber technology, applied in the field of laminated electromagnetic wave absorbers, can solve the problems of limited filling degree of flat soft magnetic body powder, inability to install well, and limited installation locations, and achieves excellent electromagnetic wave shielding properties and adhesion strength. Excellent effect with little temperature dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] Methyltrimethoxysilane will be used for particle size distribution D 50 83% by weight of Ni-Zn soft ferrite (BSN-828 (trade name): manufactured by Toda Industry Co., Ltd.) with a surface treatment of 10 to 30 μm, particle size distribution D 50 Octahedral magnetite particles (KN-320 (trade name): manufactured by Toda Industries Co., Ltd.) of 0.1 to 0.4 μm in 5% by weight, and JIS K2207-1980 (50 g load) with a penetration of 150 Silicone gel (CF-5106 (trade name): manufactured by Toray Dow Corning Silicone Co., Ltd.) 12% by weight was mixed, vacuum degassed, and then flowed between the glass plates so as not to mix air, and Press molding was carried out by heating at 70°C for 60 minutes to obtain a molded body with a thickness of 1 mm and a smooth surface. Table 1 shows the evaluation results of the molded body.

Embodiment 2

[0150] Except for changing the compounding amount of magnetite and silicone gel to the amounts shown in Table 1, the same operation as in Example 1 was carried out to obtain a molded body, and the evaluation results of the molded body are shown in Table 1. .

Embodiment 3

[0168] Methyltrimethoxysilane will be used for particle size distribution D 50 50% by weight of Ni-Zn-based soft ferrite (BSN-714 (trade name): manufactured by Toda Kogyo Co., Ltd.) with a surface treatment of 1 to 10 μm, particle size distribution D 50 25% by weight of flat soft magnetic metal powder (JEM-M (trade name) manufactured by Jemco Co., Ltd.) with a self-oxidizing property of 0.26% by weight and a particle size distribution of 8 to 42 μm. 50 Octahedral magnetite particles (KN-320 (trade name): Toda Kogyo Co., Ltd.) 5% by weight of 0.1-0.4 μm and silicon with a penetrability of 150 according to JIS K2207-1980 (50 g load) Ketone gel (CF-5106 (trade name): manufactured by Toray Dow Corning Silicone Co., Ltd.) was mixed at 20% by weight, and after vacuum defoaming, it was poured between the glass plates so as not to mix air, and the Press molding was carried out by heating at 70°C for 60 minutes to obtain a smooth-surfaced molded body with a thickness of 1 mm. Table 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com