Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Good adhesion between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

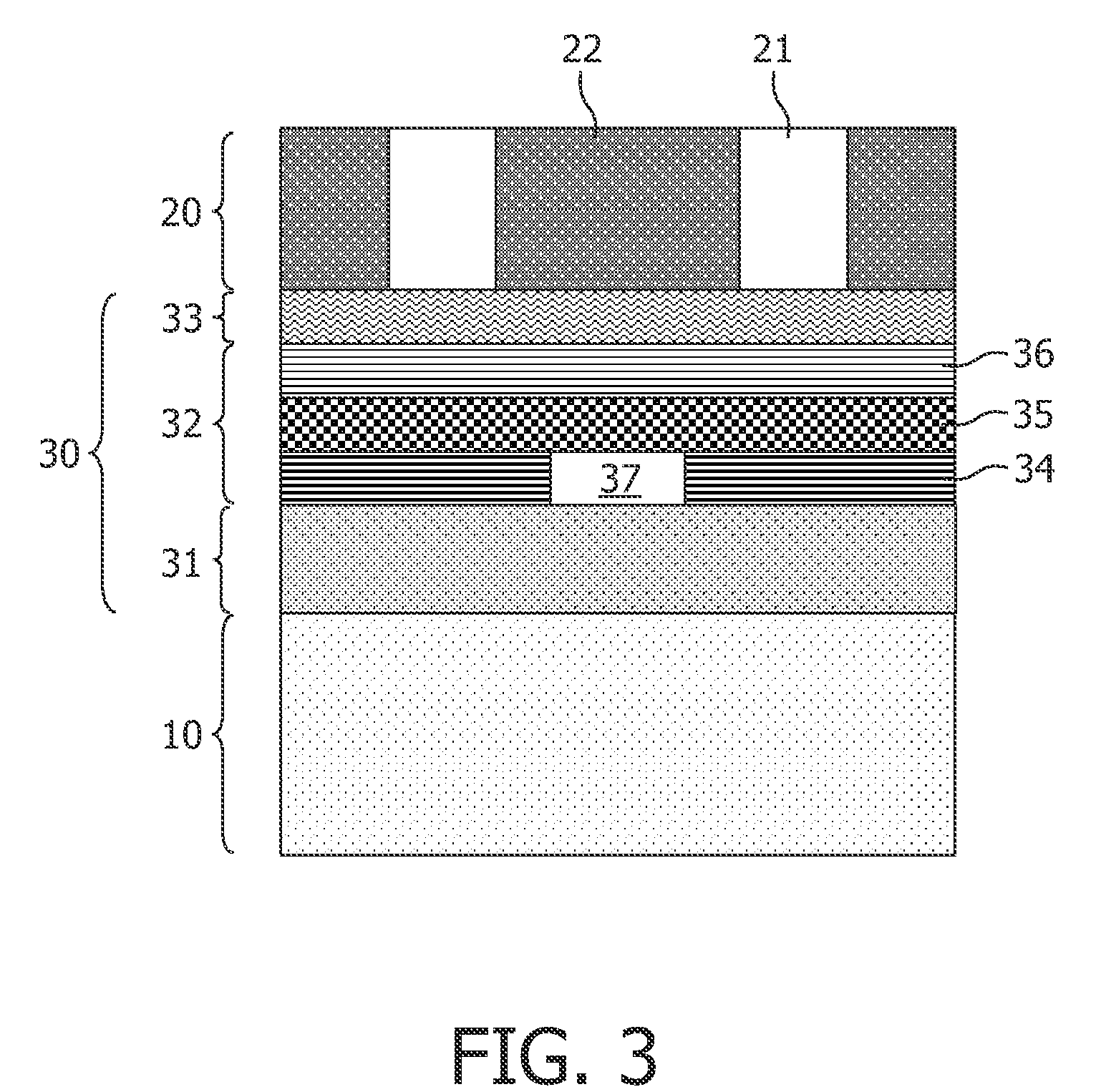

Interconnects containing bilayer porous low-k dielectrics using different porogen to structure former ratio

InactiveUS20080171431A1High strengthHigh hardnessRadiation applicationsSemiconductor/solid-state device detailsAtomic compositionDielectric permittivity

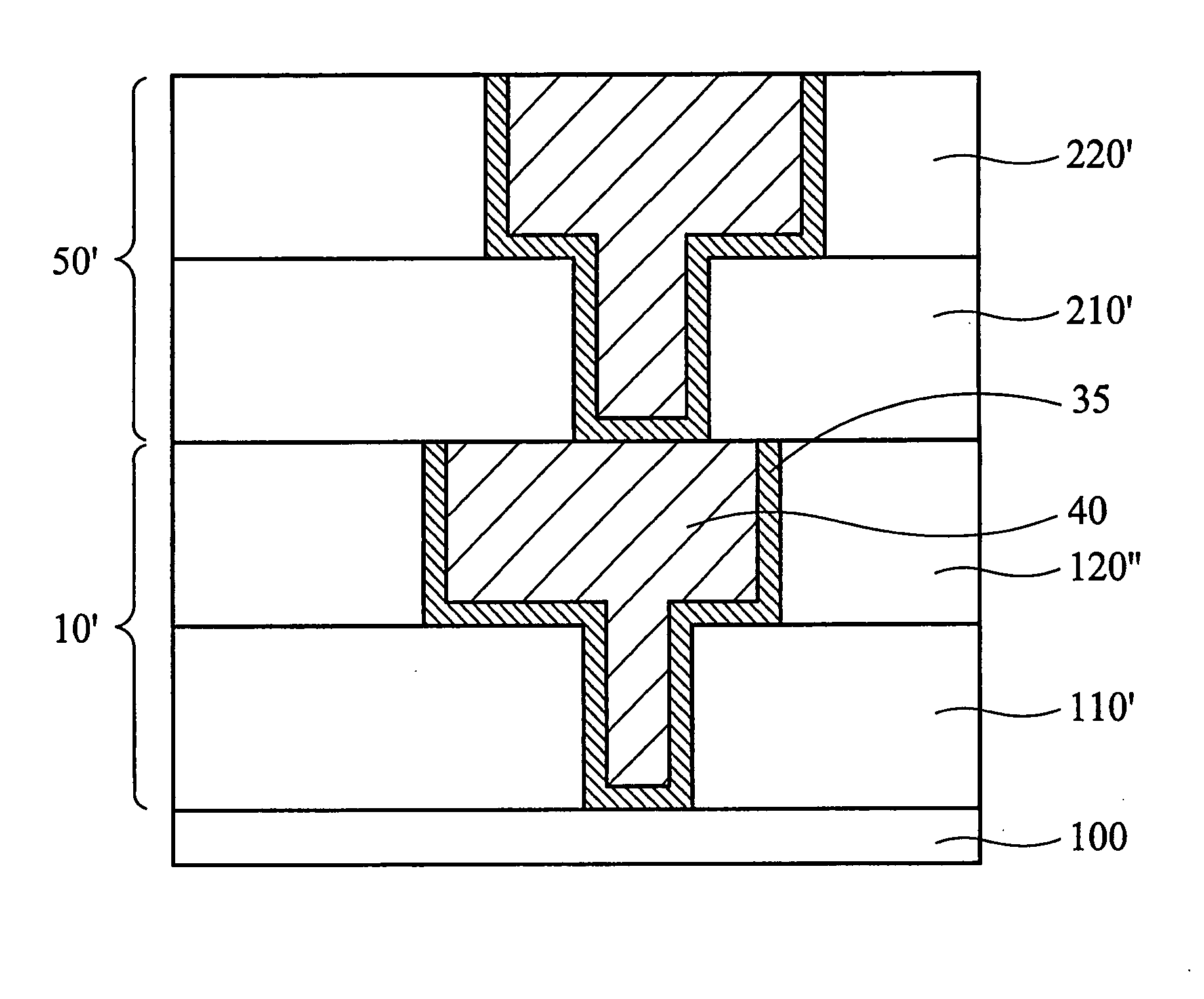

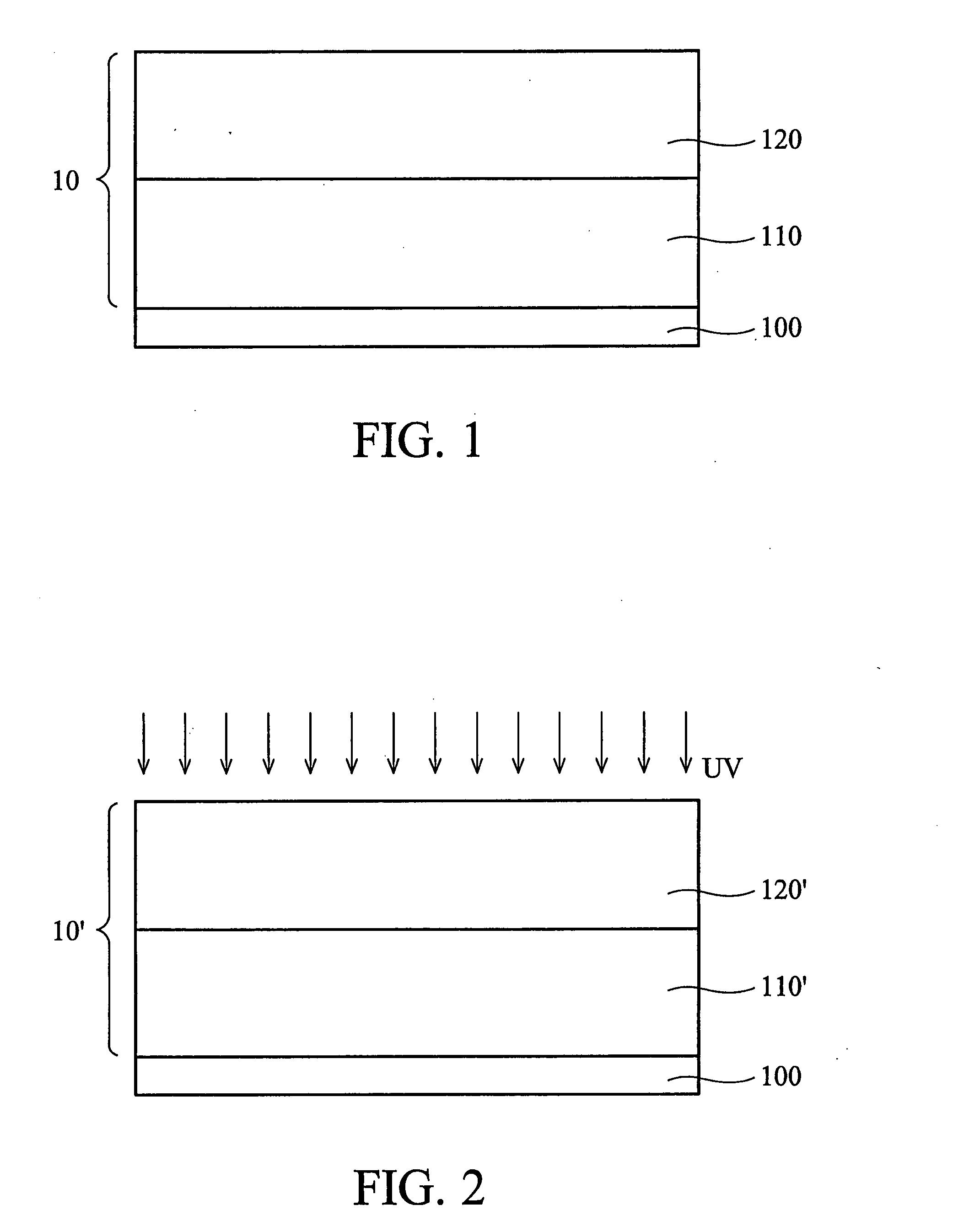

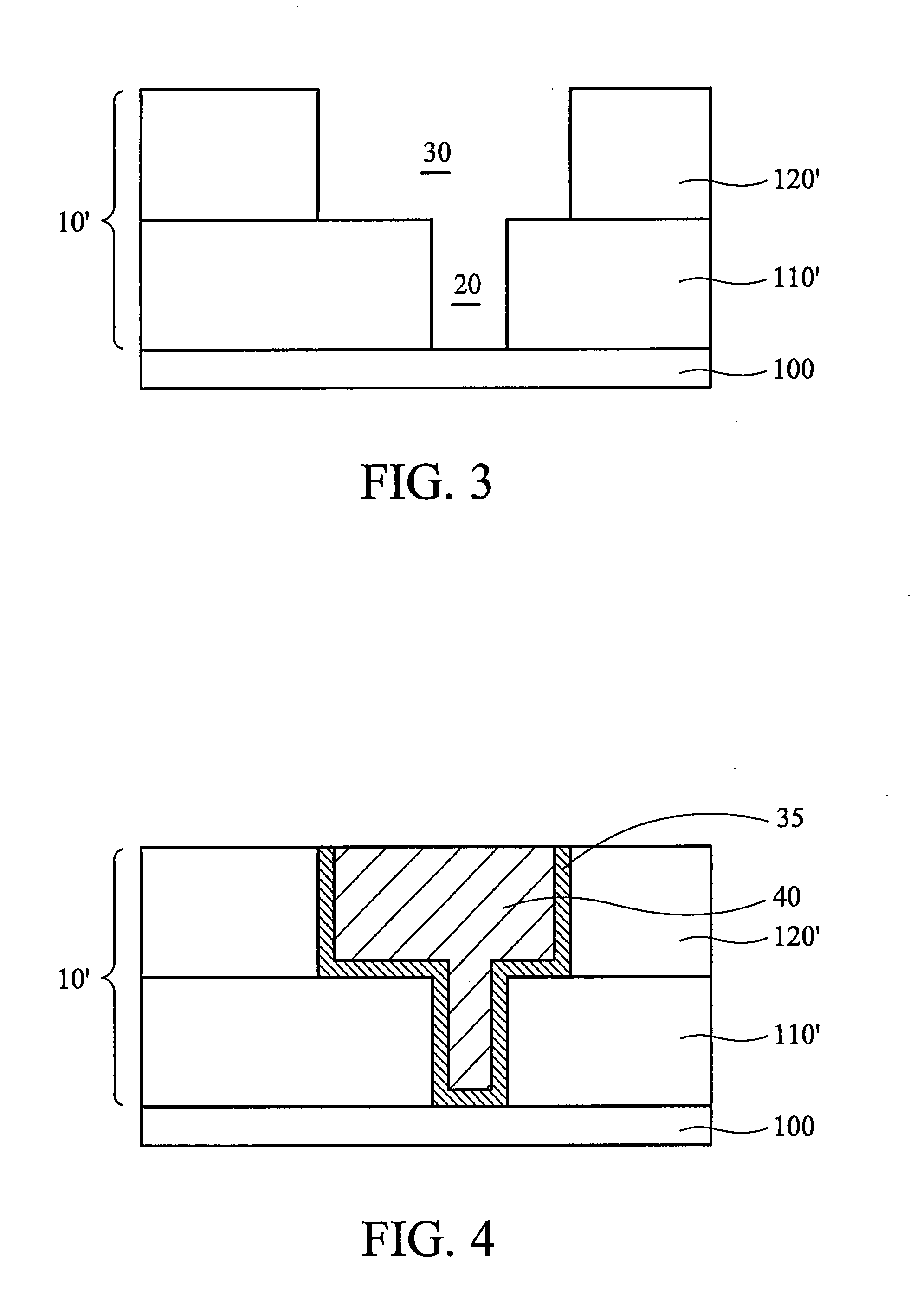

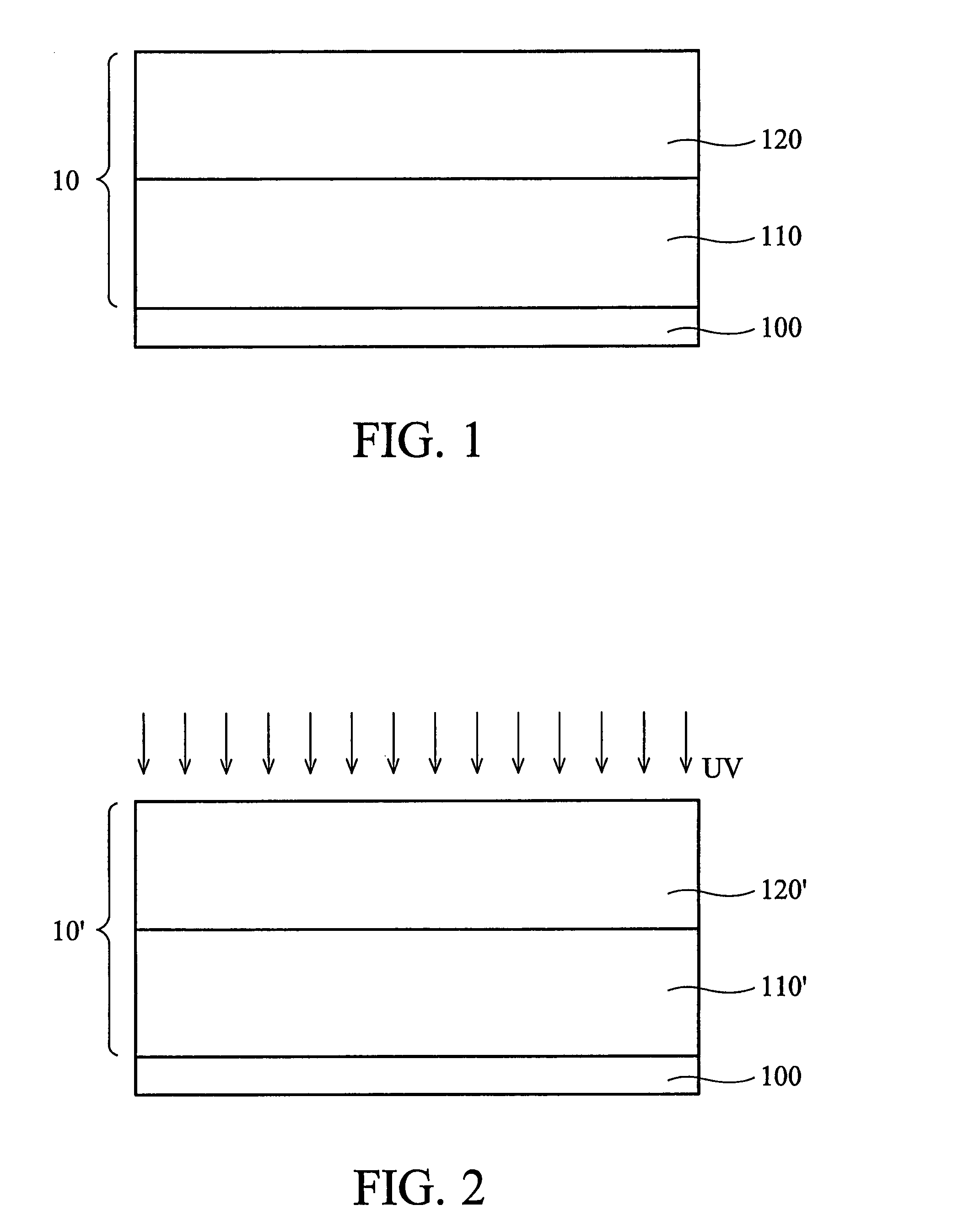

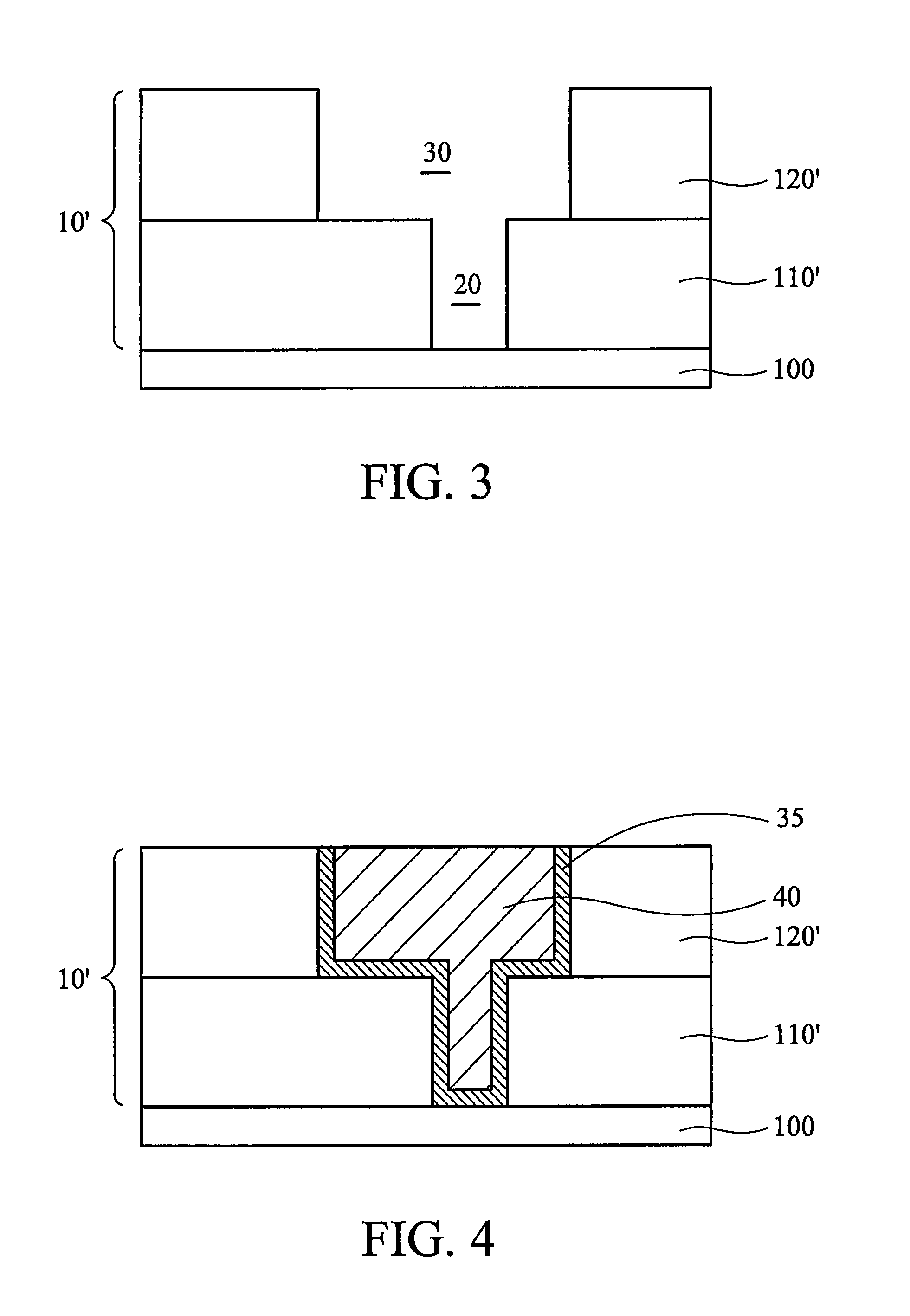

A bilayer porous low dielectric constant (low-k) interconnect structure and methods of fabricating the same are presented. A preferred embodiment having an effective dielectric constant of about 2.2 comprises a bottom deposited dielectric layer and a top deposited dielectric layer in direct contact with the former. The bottom layer and the top layer have same atomic compositions, but a higher dielectric constant value k. The bottom dielectric layer serves as an etch stop layer for the top dielectric layer, and the top dielectric layer can act as CMP stop layer. One embodiment of making the structure includes forming a bottom dielectric layer having a first porogen content and a top dielectric layer having a higher porogen content. A curing process leaves lower pore density in the bottom dielectric layer than that left in the top dielectric layer, which leads to higher dielectric value k in the bottom dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

Firmly adhering silicon nitride-containing release layer

InactiveUS20090119882A1Relieve pressureSinter activity is reducedMaterial nanotechnologyBy pulling from meltNonferrous metalSolid particle

The invention relates to a slip for producing a durable, firmly adhering release layer on a substrate, comprising a suspension of solid particles, wherein the solid particles comprise 67-95% by weight of silicon nitride and 5-33% by weight of an SiO2-based high-temperature binder and the SiO2-based high-temperature binder is derived from SiO2 precursors and has been pretreated by heat treatment in a temperature range of 300-1300° C.The invention further provides shaped bodies comprising a substrate having a durable, firmly adhering release layer and also processes for producing them. The shaped bodies of the invention are suitable for use in the field of corrosive nonferrous metal melts.

Owner:3M INNOVATIVE PROPERTIES CO

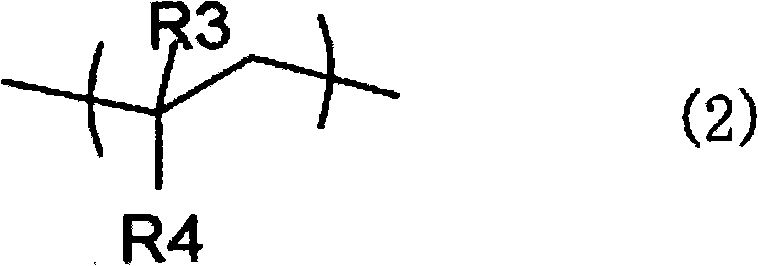

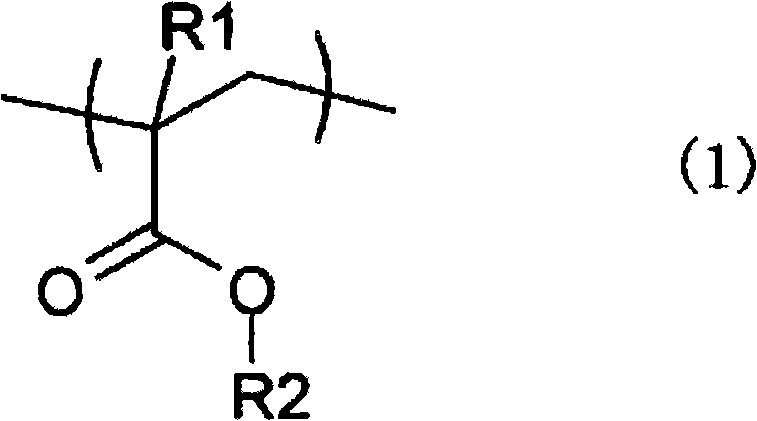

Fluorocopolymer and its applications

ActiveCN1765982AGood heat resistanceGood adhesion between layersSynthetic resin layered productsVehicle componentsWeather resistanceRepeat unit

A fluorine-containing copolymer comprising a repeating unit (a) based on tetrafluoroethylene and / or chlorotrifluoroethylene, a repeating unit based on a cyclic hydrocarbon monomer comprising a dicarboxylic anhydride group and a bridging ring polymerizable unsaturated group (b) and recurring units (c) based on other monomers (excluding tetrafluoroethylene, chlorotrifluoroethylene and said cyclic hydrocarbon monomers), with said recurring units (a), (b) and (c) Based on the total molar weight, the content of repeating unit (a) is 50-99.89 mol%, the content of repeating unit (b) is 0.01-5 mol%, and the content of repeating unit (c) is 0.1-49.99 mol%. , the volume flow rate of the fluorine-containing copolymer is 0.1-1000 cubic millimeters per second, and the present invention also relates to a laminate and a coated product. The fluorocopolymer has excellent adhesion, heat resistance, weather resistance, stress crack resistance and fuel barrier properties. The laminates have excellent interlayer adhesion and fuel barrier properties. The coated product has excellent heat resistance, chemical resistance, oil resistance, weather resistance, abrasion resistance and lubricity.

Owner:ASAHI GLASS CO LTD

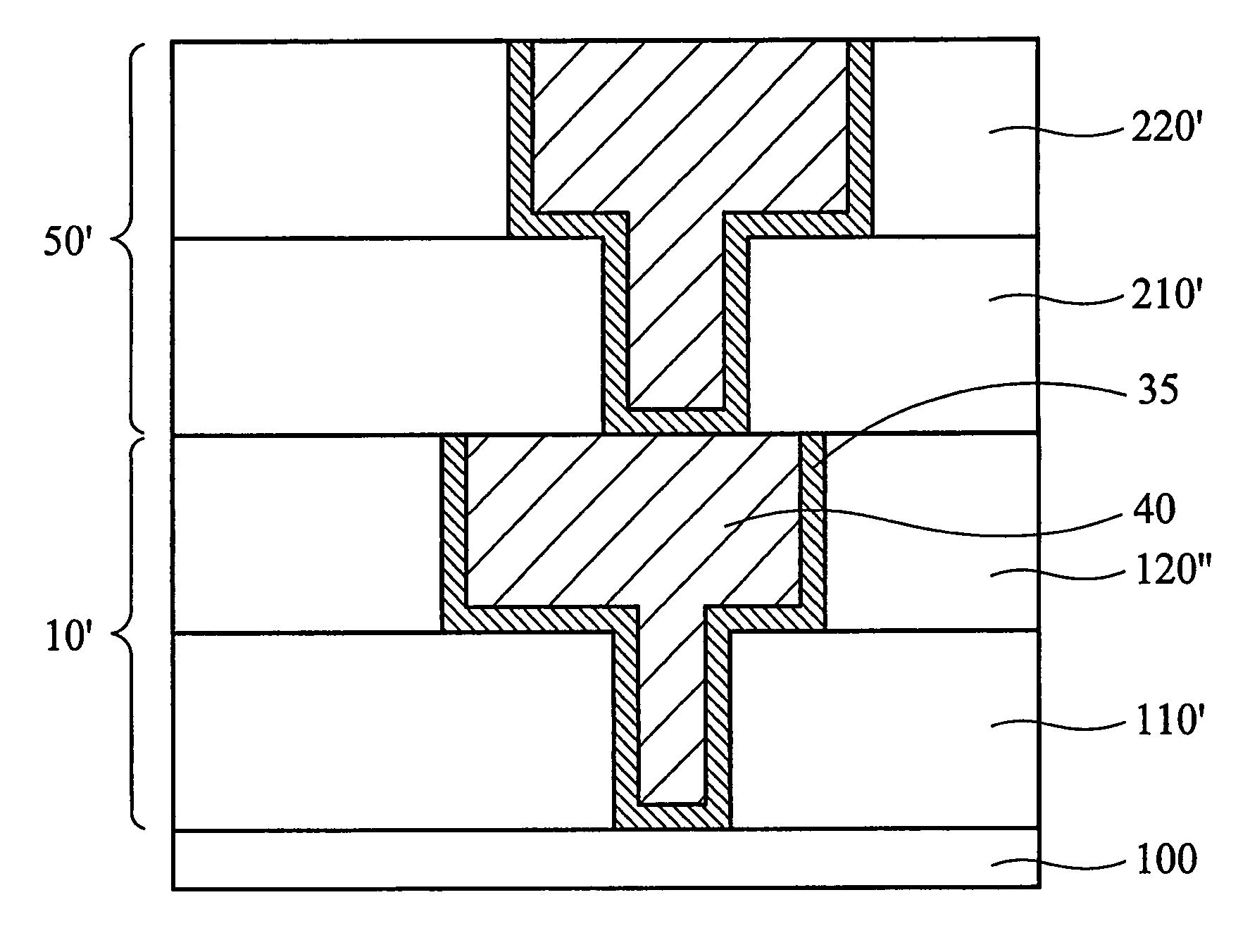

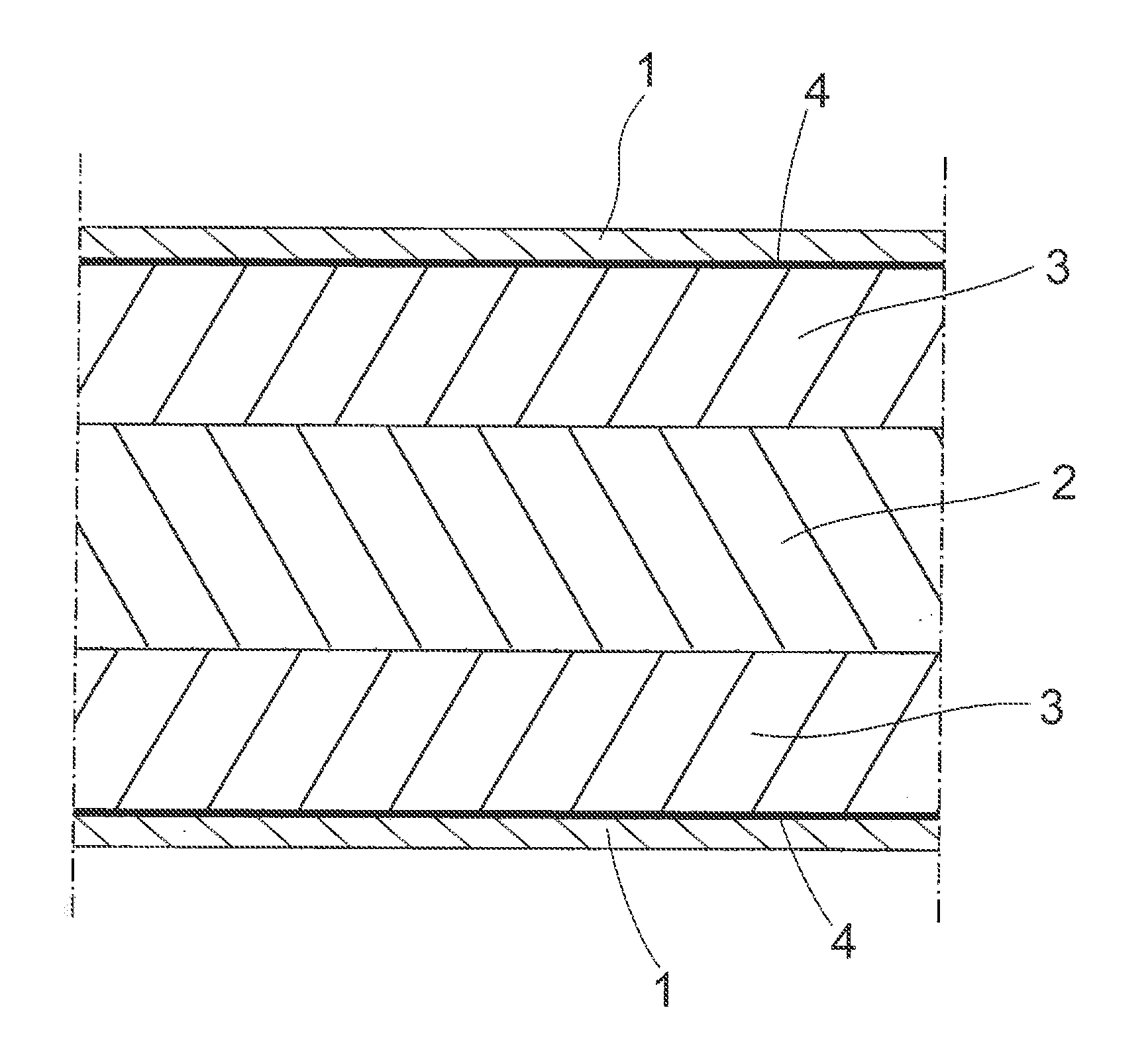

Interconnects containing bilayer porous low-k dielectrics using different porogen to structure former ratio

InactiveUS7723226B2High strengthHigh hardnessRadiation applicationsSemiconductor/solid-state device detailsAtomic compositionDielectric permittivity

A bilayer porous low dielectric constant (low-k) interconnect structure and methods of fabricating the same are presented. A preferred embodiment having an effective dielectric constant of about 2.2 comprises a bottom deposited dielectric layer and a top deposited dielectric layer in direct contact with the former. The bottom layer and the top layer have same atomic compositions, but a higher dielectric constant value k. The bottom dielectric layer serves as an etch stop layer for the top dielectric layer, and the top dielectric layer can act as CMP stop layer. One embodiment of making the structure includes forming a bottom dielectric layer having a first porogen content and a top dielectric layer having a higher porogen content. A curing process leaves lower pore density in the bottom dielectric layer than that left in the top dielectric layer, which leads to higher dielectric value k in the bottom dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

Thermoplastic resin laminate

InactiveCN102137756AGood weather resistanceImprove scratch resistanceSynthetic resin layered productsThin material handlingWeather resistanceMeth-

The present invention provides a thermoplastic resin laminate including: a thermoplastic transparent resin (A) layer; a thermoplastic resin (B) layer formed of a methyl methacrylate-styrene copolymer and / or an acrylonitrile-styrene copolymer; and a thermoplastic resin (C) layer formed of a polycarbonate-based resin, the (B) layer being laminated on one surface, or each of both surfaces, of the (C) layer, and the (A) layer being laminated on the surface of the (B) layer, in which the thermoplastic transparent resin (A) includes a vinyl copolymer resin containing a (meth)acrylate constituent unit (a) and an aliphatic vinyl constituent unit (b) each having a specific structure at a molar ratio between the (meth)acrylate constituent unit (a) and the aliphatic vinyl constituent unit (b) of 15:85 to 85:15. The thermoplastic resin laminate has such characteristics as to be excellent in, for example, weather resistance against high-temperature, high-humidity environments, abrasion resistance, and interlayer adhesion, and is used, as a transparent substrate material or a transparent protective material, for an optical product, and in particular, portable display devices such as portable phone terminals, portable electronic game devices, and PDA's.

Owner:MITSUBISHI GAS CHEM CO INC

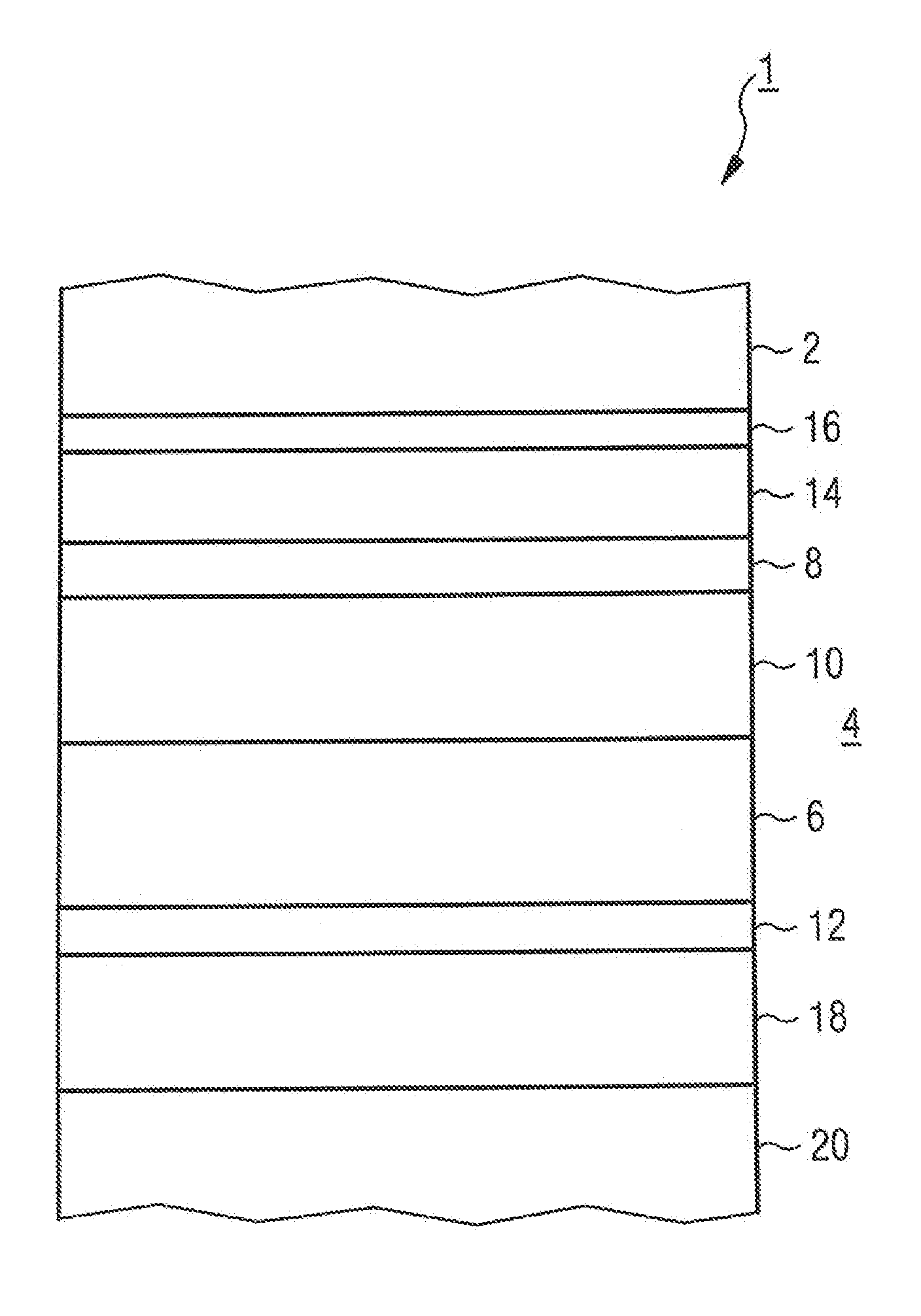

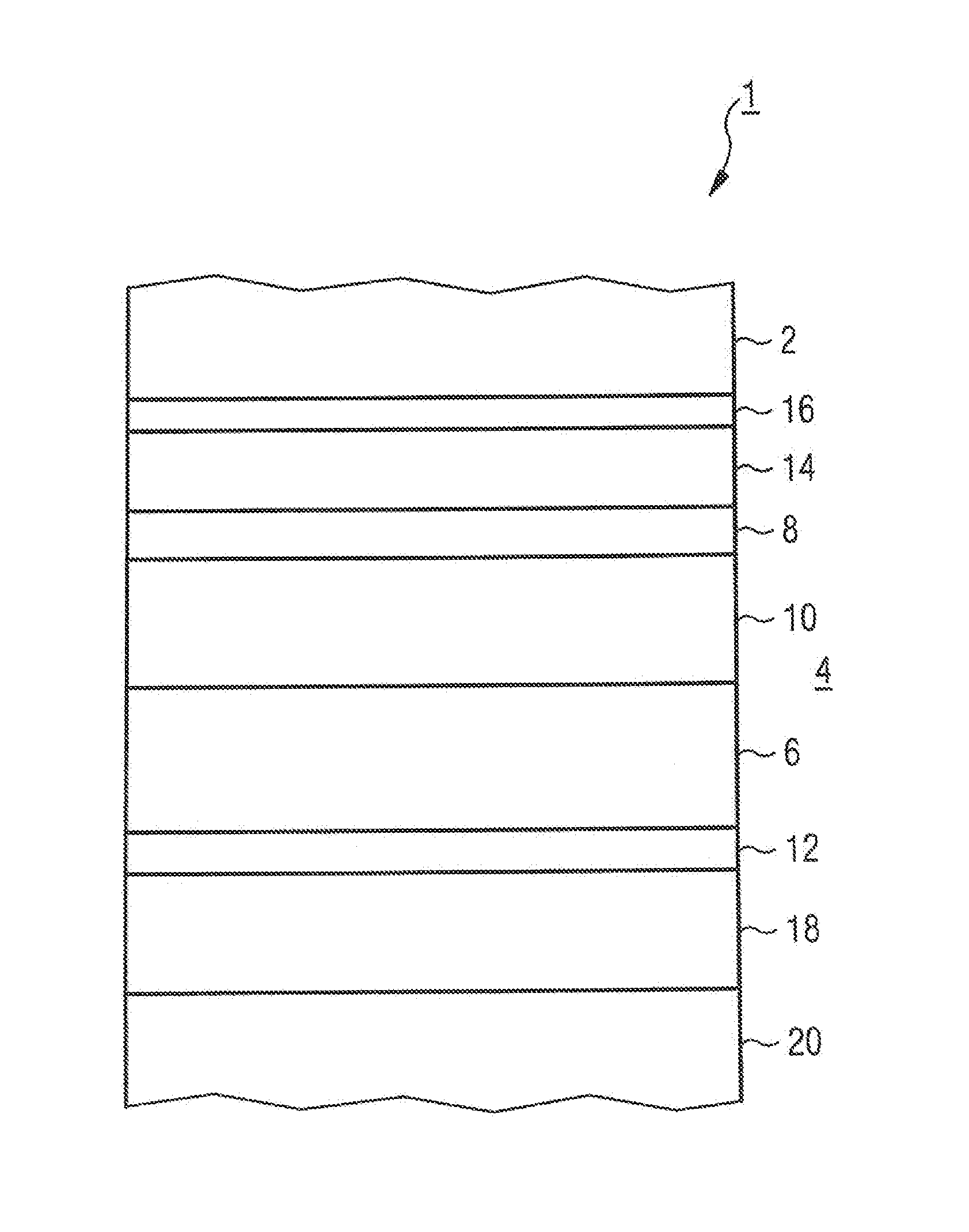

Method for producing a multilayer system on a carrier, in particular in an electrochromic element

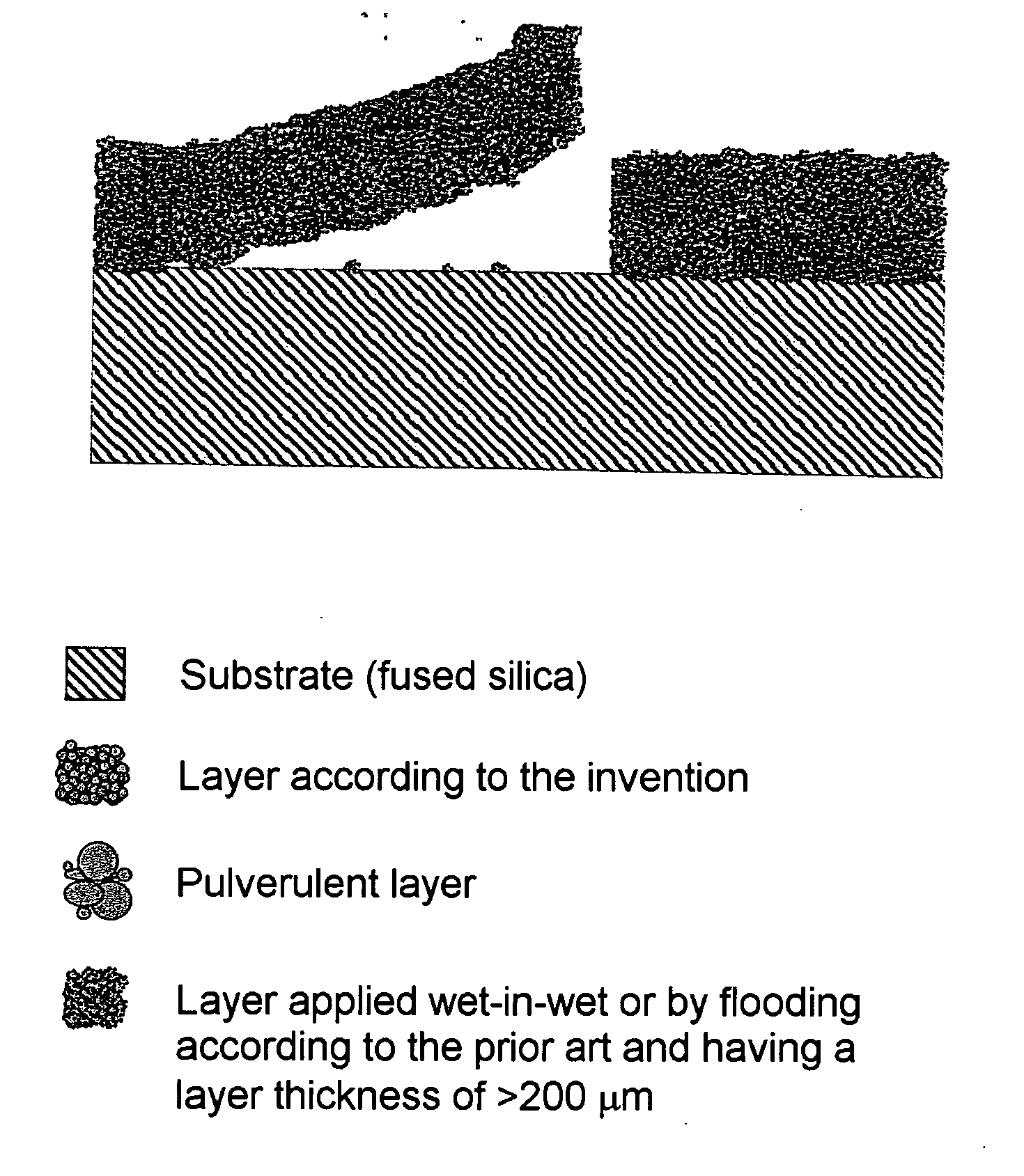

InactiveUS20070237898A1High porosityEasy to usePretreated surfacesSemiconductor/solid-state device manufacturingEngineeringVacuum coating

A method for producing a multilayer system on a substrate, wherein a first and a second layer are applied on the substrate, in each case by means of a vacuum coating process, provides adherence of the layers on each other, even if at least one of the layers of the multilayer system is porous. The layer applied first is, after its application and prior to the application of the other layer, partly removed again through an ion etching operation.

Owner:FLABEG GMBH & CO KG

Foamed polyurethane intramode paint color modifier and preparation method thereof

The invention discloses a foamed polyurethane intramode paint color modifier and a preparation method of the foamed polyurethane intramode paint color modifier. The foamed polyurethane intramode paint color modifier comprises the following ingredients in parts by mass: 10 to 20 parts of acrylic resin, 20 to 30 parts of solvents, 1 to 2 parts of anti-settling agents, 50 to 60 parts of fillings and 1 to 8 parts of pigments, wherein the acrylic resin is thermoplastic weatherability type acrylic resin of 50 percent dimethylbenzene solution, the solvents are arene S-100 solvents with the boiling point being 157 to 174 DEG C, the anti-settling agents are bentonite or gas-phase silicon dioxide, the fillings are quartz sand, calcium carbonate or barium sulfate, and the pigments are iron oxide red, iron oxide yellow or carbon black. The color modifier disclosed by the invention is suitable for color modification on the foamed polyurethane intramode paint surface, the material impurity effect of a stone plate after the color modifying is extremely similar to that of a natural stone plate, and the color and the luster are very distinct, natural and attractive. In addition, the color modifier disclosed by the invention has good performance of adhesive force, weather resistance, water resistance, durability and the like.

Owner:展辰涂料集团股份有限公司

Multilayer hollow body having high leaching resistance

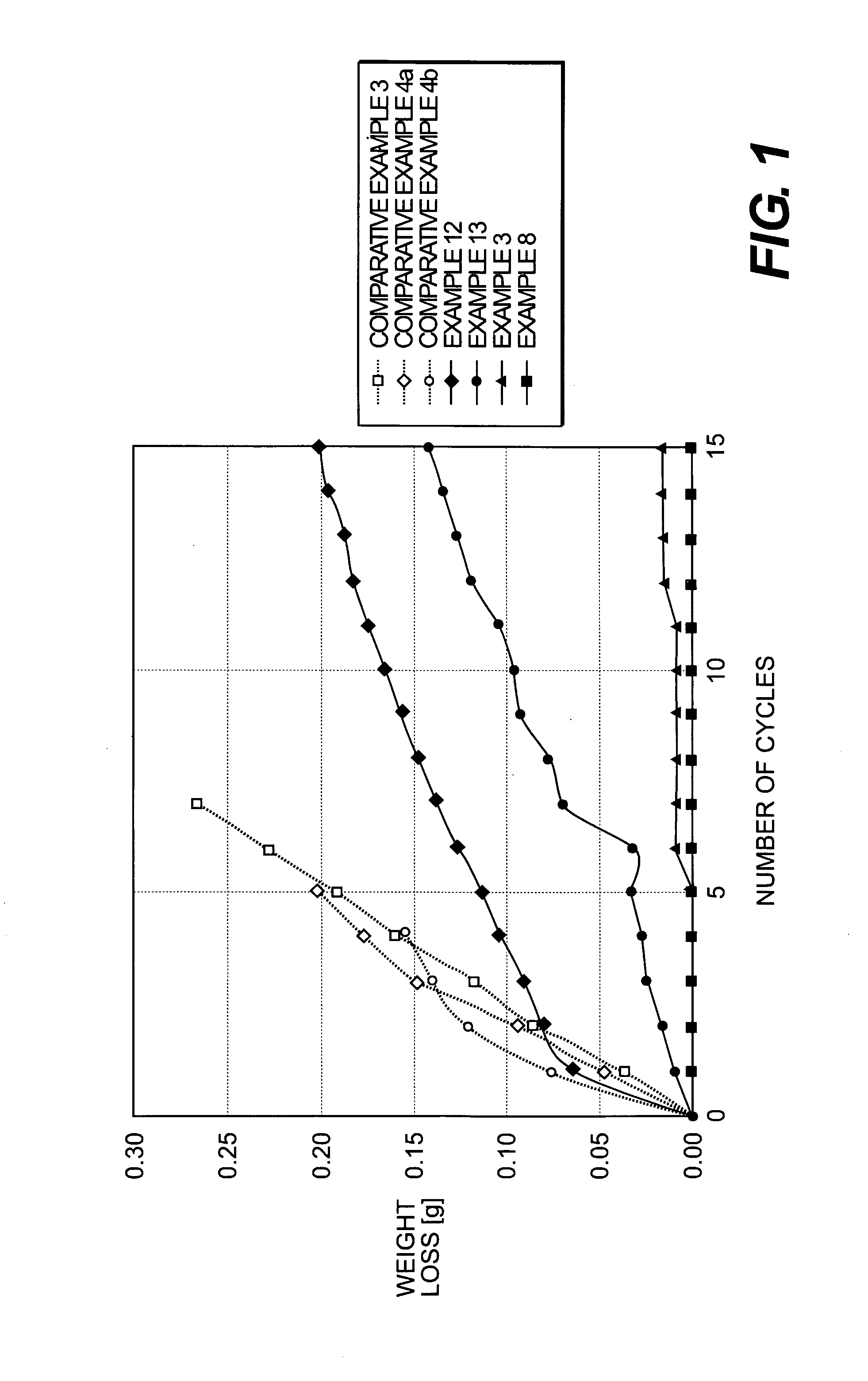

InactiveUS20180080586A1Improve impact resistanceGood adhesion between layersSynthetic resin layered productsMachines/enginesChemistryPolyamide

A multilayer hollow body has the following layers: I. an inner layer (layer I) containing a moulding composition based on PA612, PA610, PA1010, PA1012 and / or PA1212 and copolymers thereof and mixtures thereof; II. optionally an adhesion promoter layer (layer II) containing a moulding composition based on the following components: a) 0 to 80 parts by weight of a polyamide selected from PA6, PA66, PA6 / 66 and mixtures thereof, b) 0 to 100 parts by weight of a polyamine-polyamide copolymer and c) 0 to 80 parts by weight of a polyamide selected from PA11, PA12, PA612, PA1010, PA1012, PA1212 and mixtures thereof, where the sum total of the parts by weight of components a), b) and c) is 100; III. a layer (layer III) containing an ethylene-vinyl alcohol copolymer moulding composition is executed in such a way that not more than 0.2 g / m2 of insoluble extract and not more than 7.0 g / m2 of soluble extract are washed out of the multilayer hollow body as an overall system on first exposure to fuel, determined on a multilayer pipe having the same layer structure, a wall thickness of 1 mm and an internal diameter of 6 mm.

Owner:EVONIK OPERATIONS GMBH

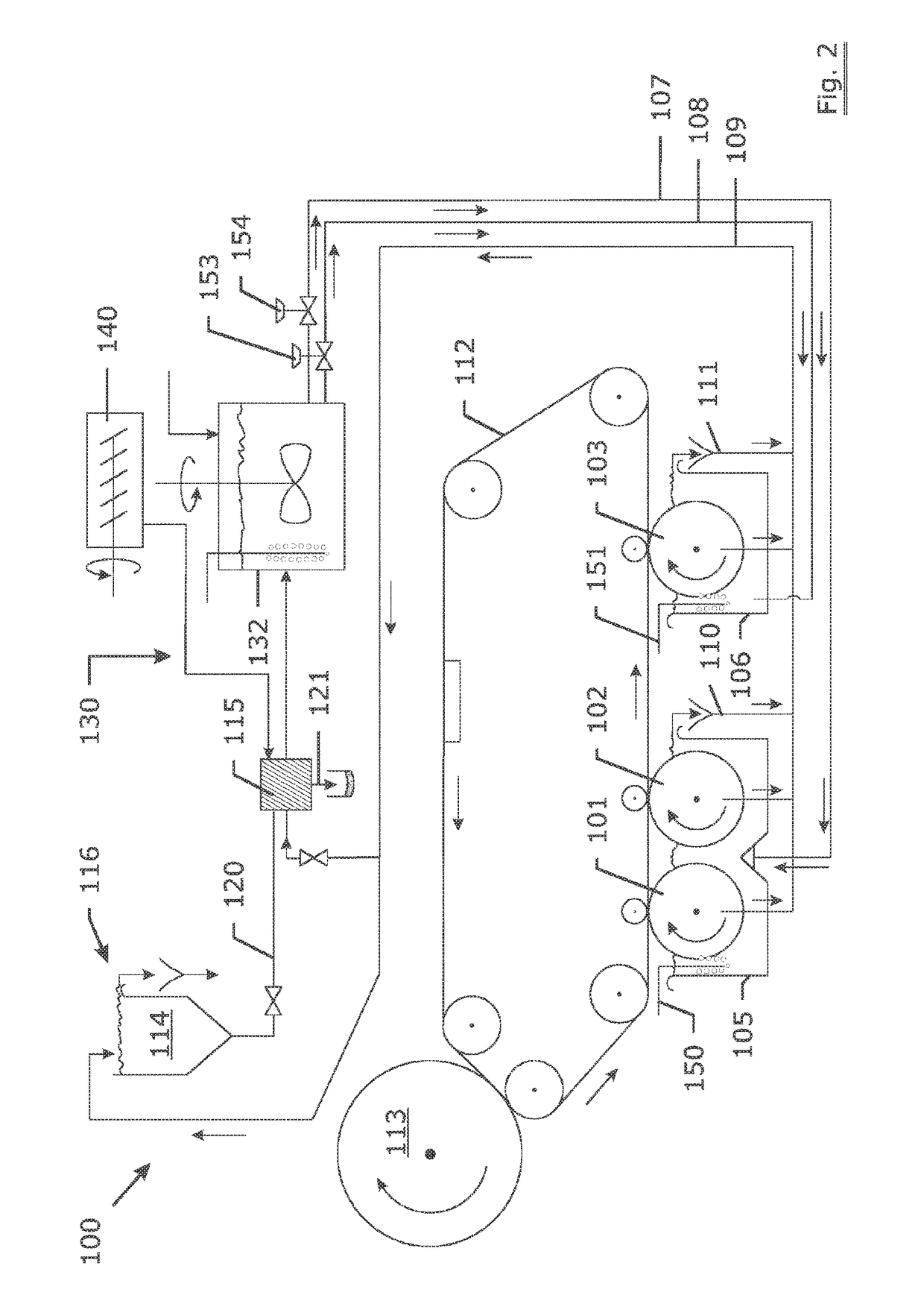

Hatschek process

InactiveUS20180169895A1Good adhesion between layersImprove adhesionFeeding arrangmentsLine tubingThin layer

A Hatschek machine for the manufacture of fibre cement sheets is provided, comprising at least three rotatable sieve cylinders which are suitable for rotating in a bath, filled with fibre cement slurry, wherein liquid flows from the slurry through the sieve, and wherein a thin layer of fibre cement remains on the sieve, characterized by the presence of at least two baths, at least two sieve cylinders are rotatably mounted in one and the same bath, and each bath has a separate feed line to supply fibre cement slurry into the bath.

Owner:ETERNIT AG +1

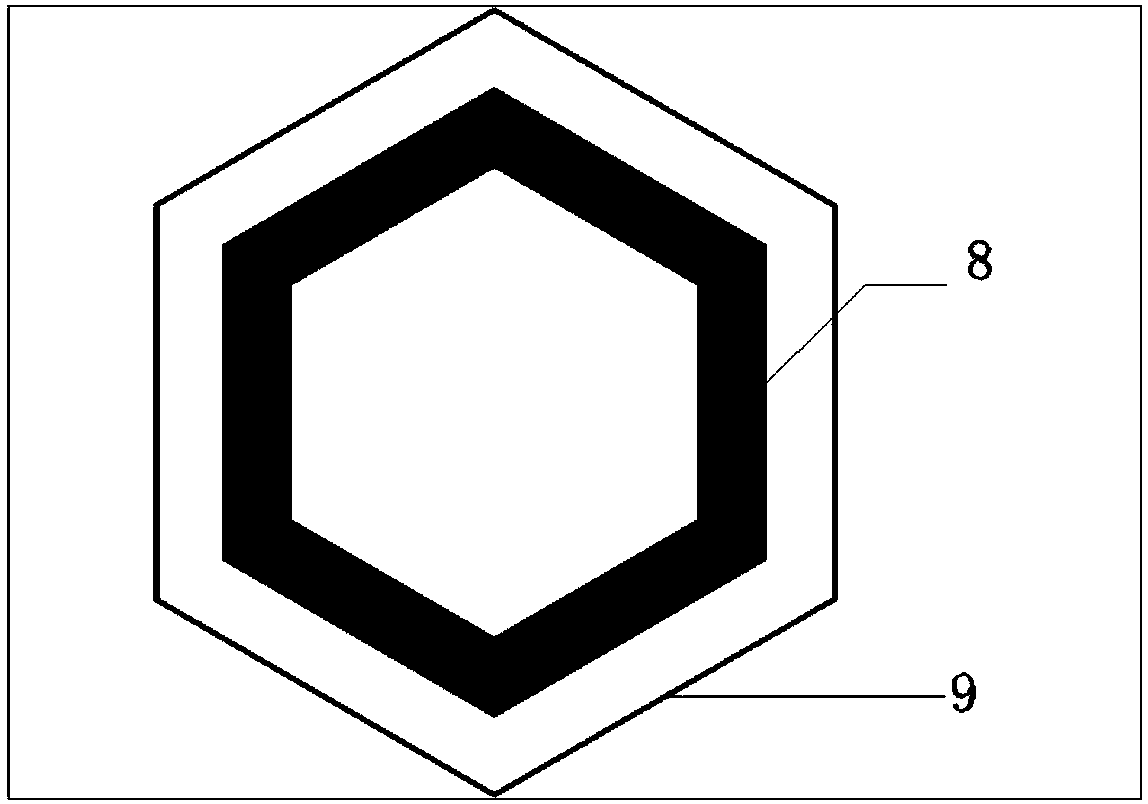

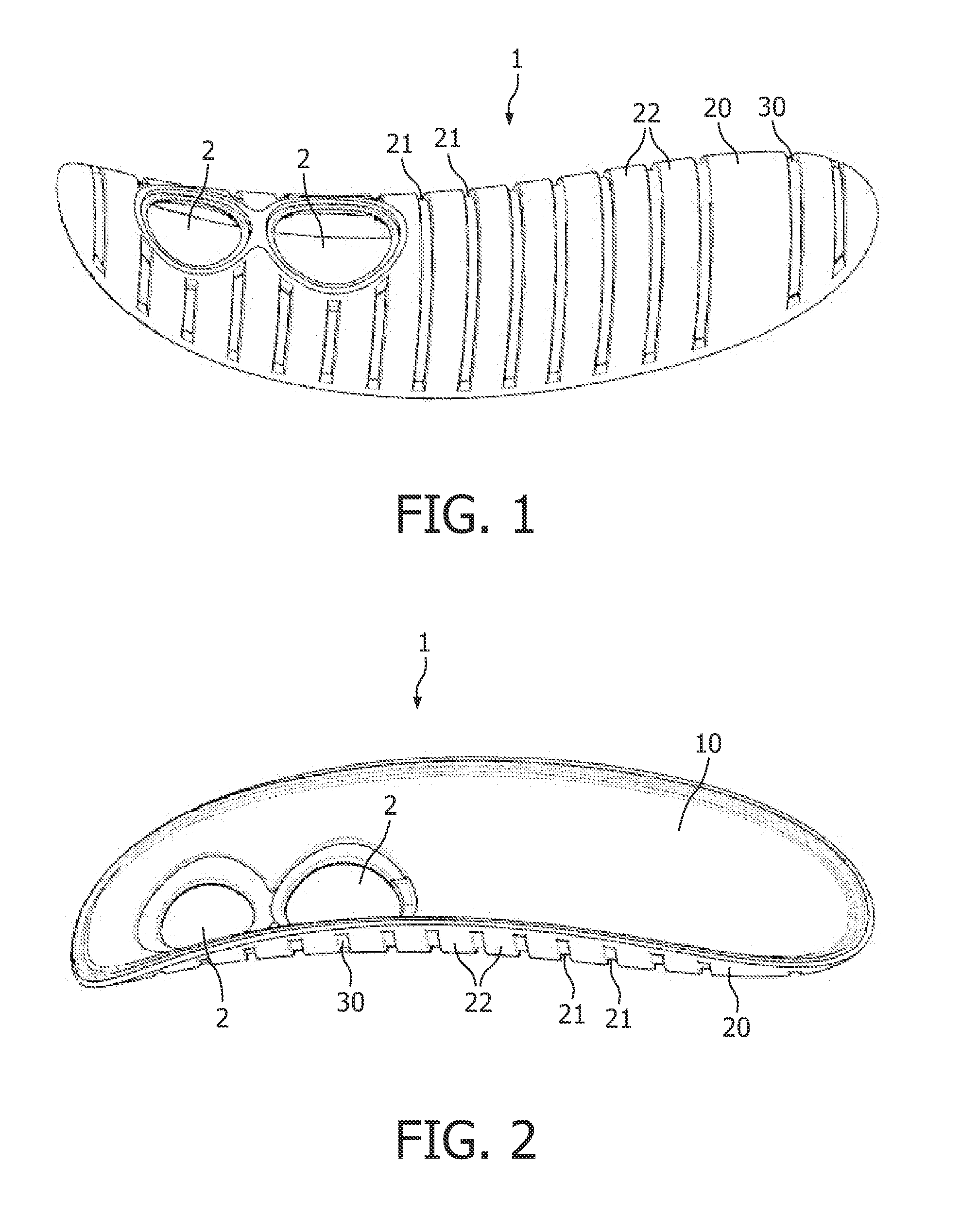

Frequency selecting radome for wideband wide-angle operation

InactiveCN108110418ALow costComposite process is matureRadiating element housingsEngineeringRadar cross-section

The invention relates to a frequency selecting metalized radome which can be widely used for various fields such as radar, communication and electronic countermeasures for realizing specific electromagnetic compatibility, reducing a radar scattering section area of the equipment, reducing interception probability and improving stealth performance. The radome is substantially a spatial domain filter which has advantages of low in-band insertion loss, high out-band suppression degree, wide passband, wide stopband and large incidence angle operation. The radome is composed of two frequency selecting surface layers and a plurality of dielectric layers. The cross section of the cover wall is provided with a fluorine carbon paint layer, an outer sheath, a periodical metal paster layer and a medium substrate thereof, a rubber film, a core layer, a periodical metal paster layer and a substrate thereof, and an inner sheath layer. The radome has advantages of excellent telecommunication performance, excellent structure and environment adaptability, and relatively high engineering practicability.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

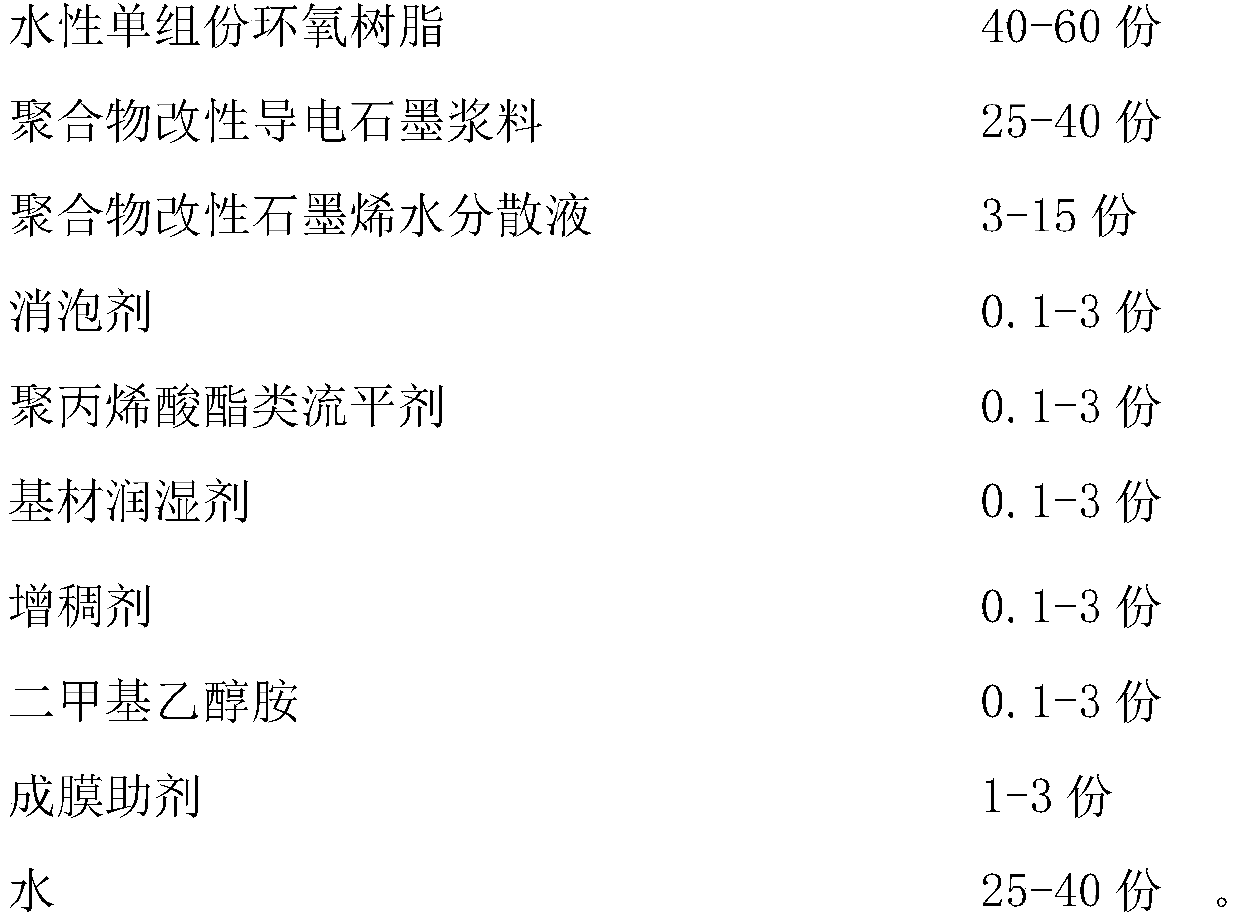

Aqueous single component conductive coating for insulator and preparation method thereof

ActiveCN111454641AImprove conductivityImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer modified

The invention discloses an aqueous single component static conductive coating for an insulator and a preparation method thereof, and belongs to the field of coatings. The coating is a single-componentsystem and is mainly prepared from single component aqueous epoxy resin, polymer modified graphite water dispersion, polymer modified conductive graphite slurry, auxiliaries and water. The coating has the characteristics of high static conductive stability, corrosion resistance, low VOC emission during coating, high storage stability, excellent long-acting sealing property and the like, has an excellent adhesive force with metal and concrete, and has an excellent interlayer binding force with a zinc sleeve.

Owner:NANJING CHANGJIANG PAINT

Multilayer blown film for producing labels

ActiveUS20150259487A1Increase stiffnessGood die-cuttingStampsSynthetic resin layered productsPolypropyleneMelt flow index

Owner:MONDI GRONAU

Atmospheric pressure plasma method for producing plasma polymer coatings

InactiveUS20200020953A1Good ageing protectionGood adhesion between layersHybrid capacitor electrodesElectrode carriers/collectorsNitrogen gasMetallic substrate

A method for depositing a plasma polymer layer in an atmospheric-pressure plasma on a metallic substrate, wherein the plasma is obtained by a discharge between two electrodes. At least one organic coating precursor compound is fed into the region of the relaxing plasma and is deposited on the metallic substrate as a plasma polymer layer. Nitrogen or a forming gas is used as a treatment gas and the at least one organic coating precursor compound is selected from various compounds. Also disclosed is an article, an electrode and a capacitor which utilize the method and include a metallic substrate having a surface and a plasma polymer layer on the surface. Also disclosed is a method for producing the electrode or for producing the capacitor, a battery cell or a lithium-ion accumulator which comprises the electrode.

Owner:PLASMATREAT GMBH

Organic silicon composite polyurethane synthetic leather and preparation method thereof

ActiveCN111231473AGood adhesion between layersSoft and plumpLamination ancillary operationsSynthetic resin layered productsPolymer sciencePtru catalyst

The invention discloses organic silicon composite polyurethane synthetic leather. The synthetic leather is composed of an organic silicon surface layer and a polyurethane base layer in sequence from top to bottom, the organic silicon surface layer is prepared from the following raw materials in parts by weight: 100 parts of vinyl polysiloxane, 1 to 40 parts of phenyl silicone resin, 1 to 15 partsof hydrogen-containing polysiloxane, 1 to 50 parts of a filler and 0.1 to 10 parts of a platinum catalyst. The synthetic leather compounded by the organic silicon and the polyurethane is good in interlayer adhesion, soft and plump in hand feeling, outstanding in hydrolysis resistance, salt mist resistance and flame retardance, low in VOCs emission and extremely small in pinhole and the like. Meanwhile, the invention further discloses a preparation method of the organic silicon composite polyurethane synthetic leather.

Owner:江西赛欧特科新材料有限公司

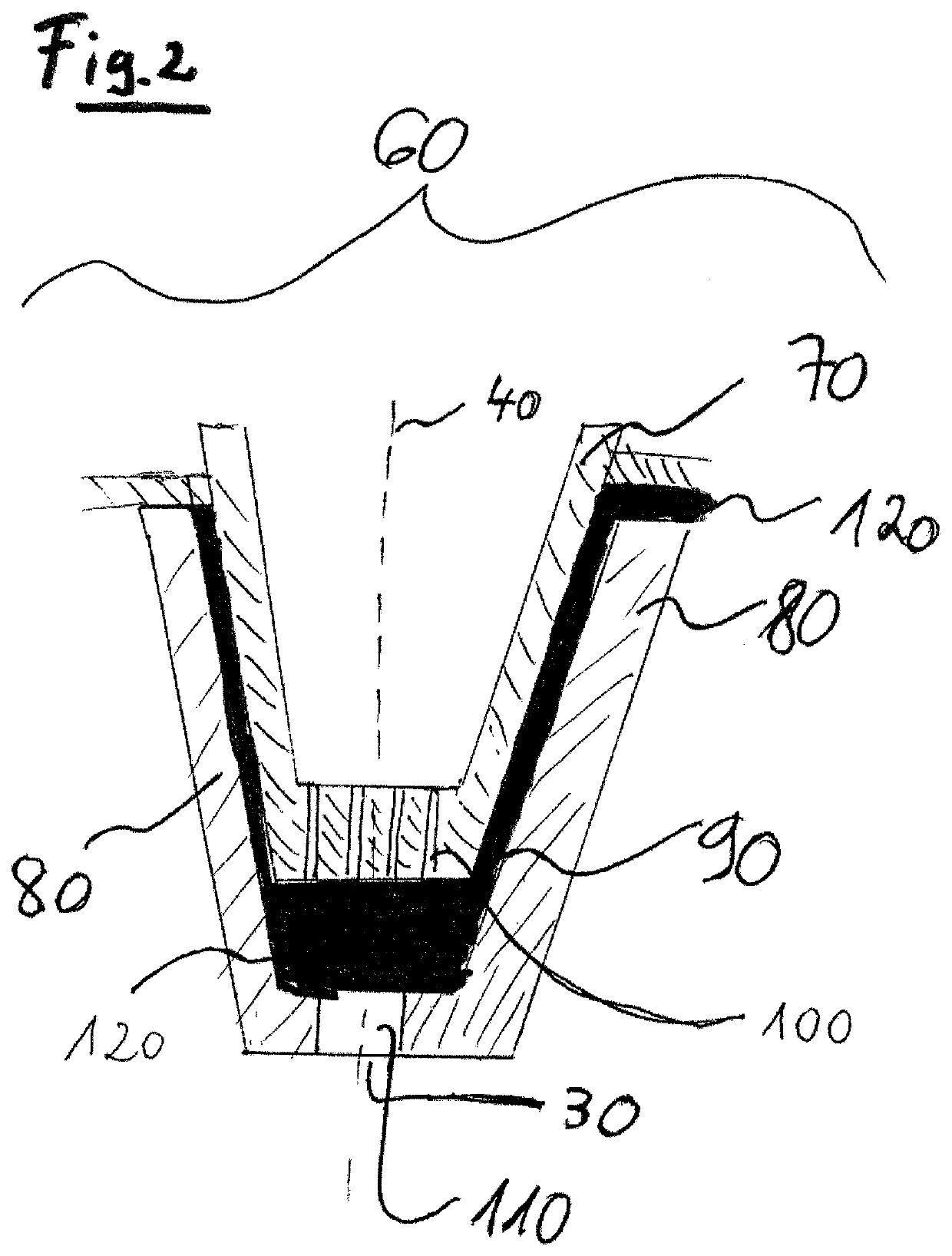

Inner decorative trim panel for a support

The present disclosure relates to an assembly for a flexible decorative inner panel and a support such as the inner wall of a vehicle door for example. The panel comprises at least one support layer obtained in a foam or similar material and a layer of adhesive on said lower face of the support layer in order to allow bonding of the panel on the support. The support has a groove to receive the peripheral edge of the panel. The panel, at its periphery on its lower face, includes a non-adhesive strip having a width substantially equal to the overhang of the panel relative to the outer wall of the groove. During placement of said panel, the latter is not bonded on the support outside the groove, and after the peripheral edge of the panel becomes embedded in the groove, the adhesive layer bonds to the inner wall of the groove.

Owner:ADHEX TECH

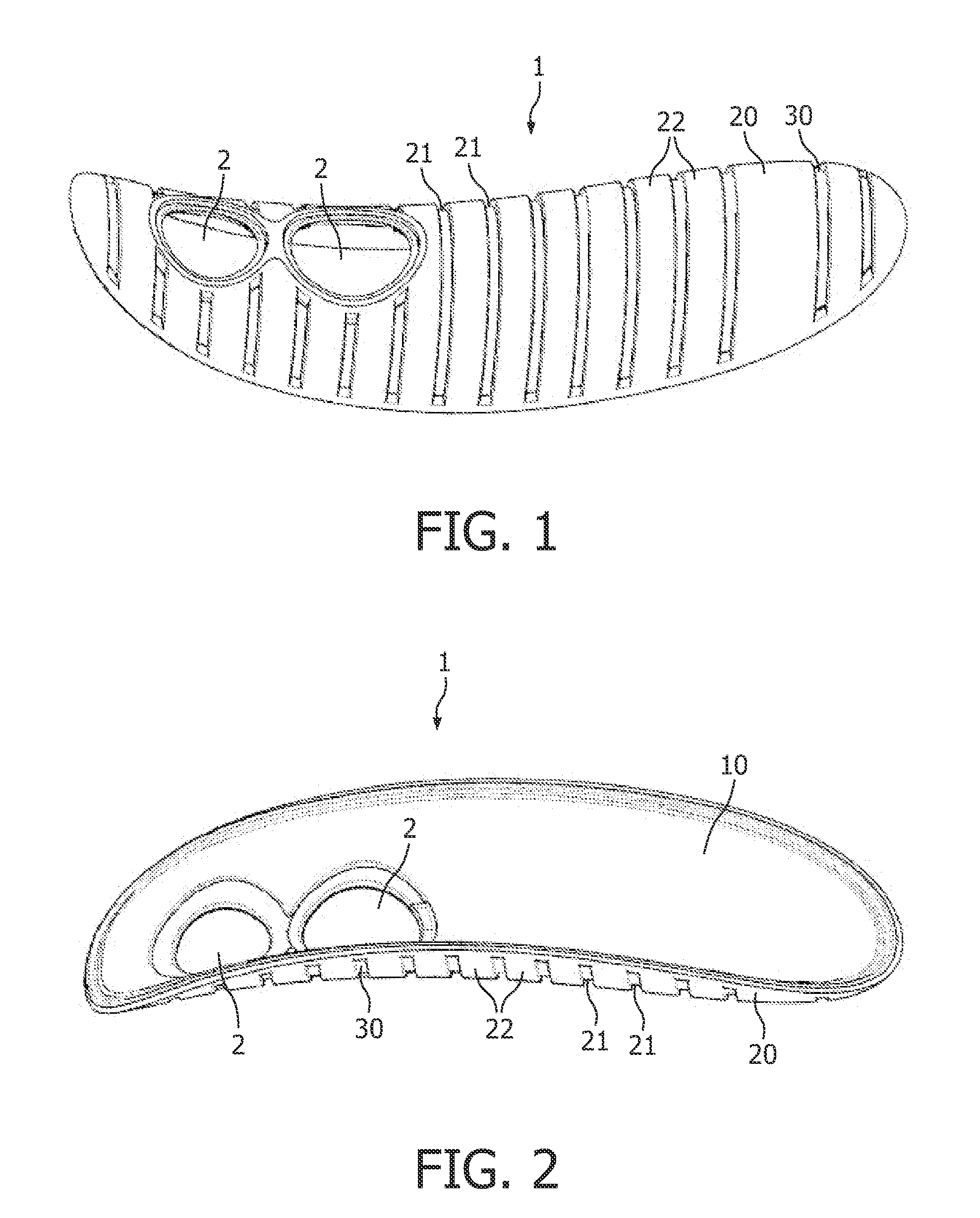

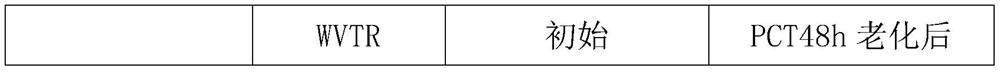

Method for manufacturing a housing element having a decorative covering and a grip layer

ActiveUS20100055403A1Sufficient adhesionSufficient grip effectManual label dispensersFilm/foil adhesivesEngineeringPrinting ink

A housing element (1) of a product comprises a foil (30) having a decorated side, wherein this side of the foil (30) is covered by a grip layer (20) for realizing a grip effect, and wherein another side of the foil (30) is covered by a supportive layer. Preferably, the grip layer (20) has a rib structure. In a preferred way of manufacturing the housing 5 element (1), each of the supportive layer and the grip layer (20) is applied to the foil (30) in an injection molding process. A processing temperature of the material of the grip layer (20) is significantly lower than an activation temperature of printing ink of a decorative covering of the foil (30), so that washout of the printing ink is prevented, whereas material of an adhesive layer of the foil (30) is adapted to establish adhesion to the material of the grip layer 10 (20) at this relatively low temperature.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Multilayer composite comprising a fluoropolymer layer

ActiveUS20160271918A1High heat distortion temperatureImprove impact resistanceSynthetic resin layered productsFlexible pipesPolymer scienceMeth-

A multilayer composite containing the following layers: I. a first layer (layer I) of a moulding compound containing at least 40 wt. % of the following components: 1) 60 to 99 parts by wt. of a copolyamide based on hexamethylenediamine, terephthalic acid and an aliphatic dicarboxylic acid having 8 to 19 carbon atoms and 2) 40 to 1 parts by wt. of an olefinic copolymer as impact modifier, wherein the parts by wt. of 1) and 2) sum to 100; and II. a second layer (layer II) of a moulding compound containing at least 60 wt. % of fluoropolymer, has a high heat distortion temperature, a very good impact resistance, a high elongation at break and good layer adhesion.

Owner:EVONIK OPERATIONS GMBH

Multilayer composite comprising layers of partly aromatic polyamides

ActiveUS10464296B2Easy to processProduced economicallySynthetic resin layered productsFlexible pipesHexamethylenediamineCarboxylic acid

A multilayer composite containing the following layers: 1. a first layer (layer I) of a moulding compound containing at least 40 wt. % of the following components: 1) 60 to 99 parts by wt. of a copolyamide based on hexamethylenediamine, terephthalic acid and an aliphatic dicarboxylic acid having 8 to 19 carbon atoms and 2) 40 to 1 parts by wt. of an olefinic copolymer as impact modifier, wherein the parts by wt. of 1) and 2) sum to 100; and II. a second layer (layer II) of a moulding compound containing at least 60 wt. % of a mixture of the following components: 1) 75 to 100 parts by wt. of a partly aromatic copolyamide and 2) 25 to 0 parts by wt. of an olefinic copolymer as impact modifier with the proviso that in the moulding compound of layer II the mixture of components 1) and 2) comprises at least 5 fewer parts by wt, of olefinic copolymer than in the moulding compound of layer I, has a high heat distortion temperature, a very good impact resistance, a high elongation at break and good layer adhesion.

Owner:EVONIK OPERATIONS GMBH

Multilayer composite comprising an evoh layer

ActiveUS20160271913A1High heat distortion temperatureGood adhesion between layersSynthetic resin layered productsVehicle componentsPolymer scienceMeth-

A multilayer composite containing the following layers: I. a first layer (layer I) of a moulding compound containing at least 40 wt. % of the following components: 1) 60 to 99 parts by wt. of a copolyamide based on hexamethylenediamine, terephthalic acid and an aliphatic dicarboxylic acid having 8 to 19 carbon atoms and 2) 40 to 1 parts by wt. of an olefinic copolymer as impact modifier, wherein the parts by wt. of 1) and 2) sum to 100; II. a second layer (layer II) of a moulding compound containing at least 60 wt. % of EVOH; III. a third layer of a polyamide moulding compound, has a high heat distortion temperature, a very good impact resistance, a high elongation at break and good layer adhesion.

Owner:EVONIK OPERATIONS GMBH

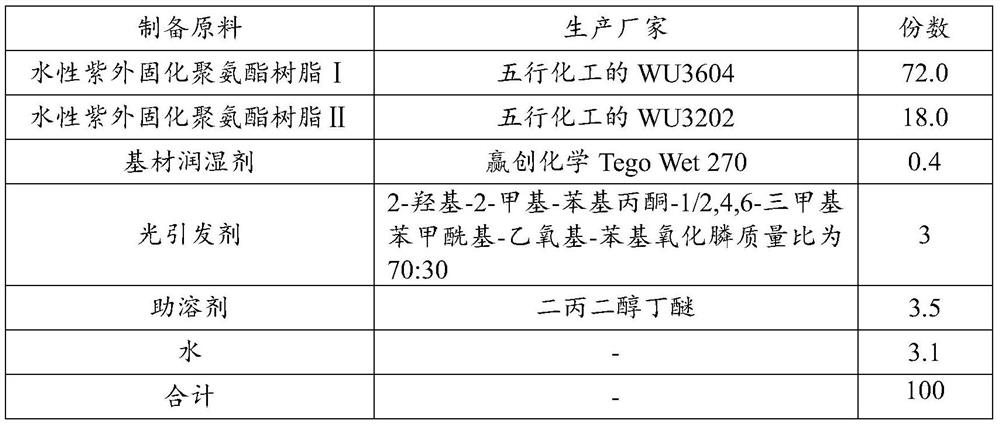

Water-based high-gloss finish paint as well as preparation method and application thereof

ActiveCN113817394AGood adhesion between layersWide adaptabilityPolyurea/polyurethane coatingsUltraviolet lightsPhotoinitiator

The invention discloses water-based high-gloss finish paint as well as a preparation method and application thereof. The water-based high-gloss finish paint is prepared from the following raw materials: water-based ultraviolet curing polyurethane resin, a base material wetting agent, a cosolvent and a photoinitiator, and the water-based ultraviolet light curing polyurethane resin is prepared from water-based ultraviolet light curing polyurethane I and water-based ultraviolet light curing polyurethane II. A coating formed by curing the water-based high-gloss finish paint has excellent flexibility when being applied to a base coat, and has certain bending resistance while keeping high hardness, so that the application scene of the coating is expanded. The coating disclosed by the invention has excellent interlayer adhesion to a base coat, is wide in adaptability to the base coat, and can keep a relatively good mirror surface leveling effect on various base coats.

Owner:HUNAN SOKAN NEW MATERIAL

Multilayer composite comprising a polyester layer

ActiveUS10427390B2High heat distortion temperatureImprove impact resistanceFlexible coversWrappersHeat deflection temperatureHexamethyldiamine

A multilayer composite containing the following layers: I. a first layer (layer I) of a molding compound containing at least 40 wt. % of the following components: 1) 60 to 99 parts by wt. of a copolyamide based on hexamethylenediamine, terephthalic acid and an aliphatic dicarboxylic acid having 8 to 19 carbon atoms and 2) 40 to 1 parts by wt. of an olefinic copolymer as impact modifier, wherein the parts by wt. of 1) and 2) sum to 100; and II. a second layer (layer II) of a molding compound containing at least 60 wt. % of thermoplastic polyester, has a high heat distortion temperature, a very good impact resistance, a high elongation at break and good layer adhesion.

Owner:EVONIK OPERATIONS GMBH

Multilayer composite comprising an EVOH layer

ActiveUS10252498B2High heat distortion temperatureImprove impact resistanceSynthetic resin layered productsVehicle componentsHeat deflection temperatureHexamethyldiamine

Owner:EVONIK OPERATIONS GMBH

Method for producing a multilayer system on a carrier, in particular in an electrochromic element

InactiveUS7772037B2High porosityEasy to useSemiconductor/solid-state device manufacturingPretreated surfacesEngineeringVacuum coating

A method for producing a multilayer system on a substrate, wherein a first and a second layer are applied on the substrate, in each case by means of a vacuum coating process, provides adherence of the layers on each other, even if at least one of the layers of the multilayer system is porous. The layer applied first is, after its application and prior to the application of the other layer, partly removed again through an ion etching operation.

Owner:FLABEG GMBH & CO KG

Synthetic leather of organosilicon composite polyurethane and preparation method thereof

ActiveCN111231473BGood adhesion between layersSoft and plumpLamination ancillary operationsSynthetic resin layered productsPolymer sciencePhenyl group

Owner:江西赛欧特科新材料有限公司

Carbon fiber reinforced resin matrix composite material current heating LOM manufacturing method and device

The invention relates to a method and device for manufacturing a carbon fiber reinforced resin matrix composite material current heating LOM, wherein a prepreg tape of the carbon fiber reinforced resin-based composite material is conveyed to the upper part of a working platform, the working platform is moved upward to fit the prepreg tape, a pressing plate mechanism moves downwards to press the prepreg tape on the working platform, at the same time, the electrodes at both ends of the pressing plate are powered on the prepreg tape of a pressing area, the pressing plate mechanism is moved upwardaway from the prepreg tape after the prepreg tape is heated and solidified, a laser emitter cuts the prepreg tape along the cross-section of the three-dimensional model, the outer part of the cross-section is cut into fine pieces, and after the cutting is finished, the working platform descends off the prepreg tape, and then the whole prepreg tape is conveyed to the upper part of the working platform, the residual prepreg tape is retracted by a winding drum after being cut, that is, the single-layer forming and solidifying is completed, a process is recycled until the forming and solidifyingof the whole three-dimensional solid component is completed, that is, the required three-dimensional solid component is obtained; the forming mode is rapid and unsupported; the solidifying technologyis low in consumption and energy-saving.

Owner:XI AN JIAOTONG UNIV

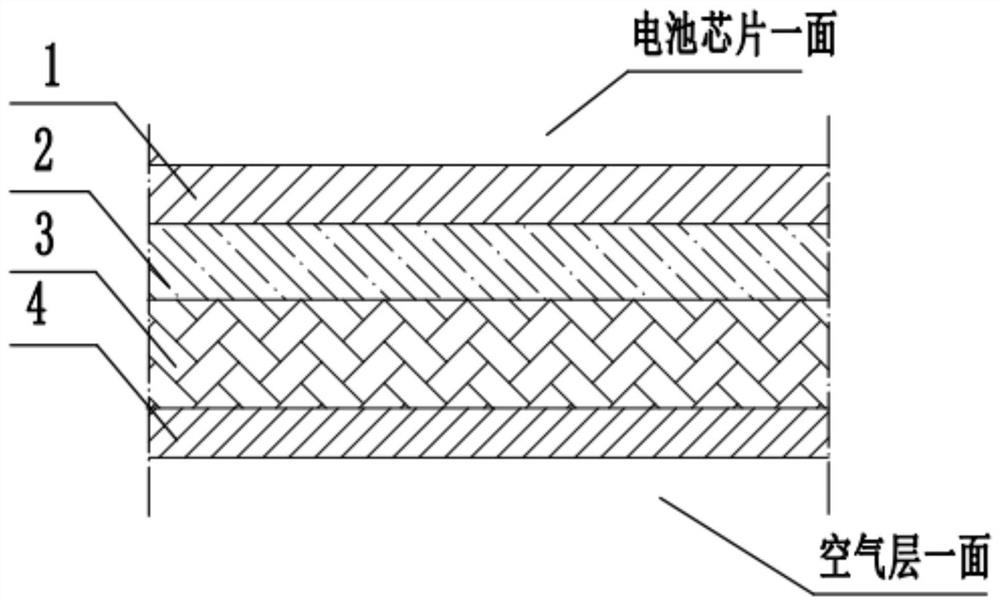

A kind of pvdc emulsion and its solar cell backboard

ActiveCN110437363BImprove heat resistanceGood adhesionCoatingsPhotovoltaic energy generationCarbon coatingPolymer science

A PVDC emulsion, made of the following components by weight: 23-50 parts of vinylidene chloride monomer, 7-23 parts of modified monomer, 0.2-0.5 part of initiator, 1-2 parts of emulsifier, Dispersant 33.8-67.5, PH regulator 0.001-0.02 parts. The present invention improves the heat resistance and adhesiveness of PVDC by selecting comonomers with specific functional groups, so that PVDC can be used as the barrier layer of the coating-type back sheet, which can not only improve the water vapor barrier property of the back sheet, but also add fluorine to the barrier layer. The carbon coating guarantees the weather resistance of the solar cell backsheet.

Owner:乐凯胶片股份有限公司

Method for manufacturing a housing element having a decorative covering and a grip layer

ActiveUS9205583B2Sufficient adhesionSufficient grip effectManual label dispensersAdhesive processes with adhesive heatingPrinting inkEngineering

A housing element of a product includes a foil having a decorated side, where this decorated side of the foil is covered by a grip layer for realizing a grip effect. The other side of the foil is covered by a supportive layer. The grip layer may have a rib structure. Each of the supportive layer and the grip layer is applied to the foil in an injection molding process. A processing temperature of the material of the grip layer is significantly lower than an activation temperature of printing ink of a decorative covering of the foil, so that washout of the printing ink is prevented. Further, material of an adhesive layer of the foil is configured to establish adhesion to the material of the grip layer at this relatively low temperature.

Owner:KONINK PHILIPS ELECTRONICS NV

A kind of preparation method of high-performance nickel-based alloy composite strip

ActiveCN111101007BGood adhesion between layersUniform surface tissueTemperature control deviceFurnace typesMetallurgyAlloy composite

Owner:ZHOUKOU NORMAL UNIV

Sulphuration method of ferrous alloy parts in an aqueous solution

InactiveUS8562812B2Antijamming effectHighly reproducibleElectrolysis componentsFrom normal temperature solutionsElectrolysisChloride salt

The invention relates to a superficial treatment method by electrolysis of ferrous surfaces to enhance friction or tread and seizing resistance features, wherein the surfaces provide the electrolysis anode, the electrolysis bath includes a sulphur species, primarily contains water and also contains a chloride salt and a nitrogen species in quantities which facilitates the sulphuration reaction of the surfaces.

Owner:H E F

Anti-fouling and rubbing-resisting fluorocarbon nano-varnish as well as preparation method and application thereof

InactiveCN108753162AGood adhesion between layersExcellent hardness and glossAntifouling/underwater paintsPaints with biocidesSolventWeather resistance

The invention provides anti-fouling and rubbing-resisting fluorocarbon nano-varnish. The anti-fouling and rubbing-resisting fluorocarbon nano-varnish is prepared from 30-60 parts by weight of fluorocarbon resin, 30-60 parts by weight of fluorosilicon resin, 10-20 parts by weight of amino resin, 0-5 parts by weight of an auxiliary and 2-10 parts by weight of a solvent. The anti-fouling and rubbing-resisting fluorocarbon nano-varnish has excellent gloss and hardness, has superb effect in fouling resistance and graffiti prevention, especially has excellent rubbing resistance, can meet requirements of areas having higher demands for rubbing resistance, also has better compatibility, can be applied to a conventional PVDF fluorocarbon coating and has excellent interlayer adhesion force with theconventional PVDF fluorocarbon coating, use range of the fluorocarbon varnish is expanded, after baking and curing, not only are weather resistance and other conventional properties of the original fluorocarbon coating not sacrificed, but also the original coating is further endowed with excellent gloss and hardness. The invention further provides a preparation method and an application of the anti-fouling and rubbing-resisting fluorocarbon nano-varnish.

Owner:江西亚龙美氟科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com