Water-based high-gloss finish paint as well as preparation method and application thereof

A water-based, topcoat technology, applied in the field of coatings, can solve the problems of low VOC content, insufficient flexibility, and detachment from the primer, so as to reduce environmental protection treatment costs, expand application scenarios, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

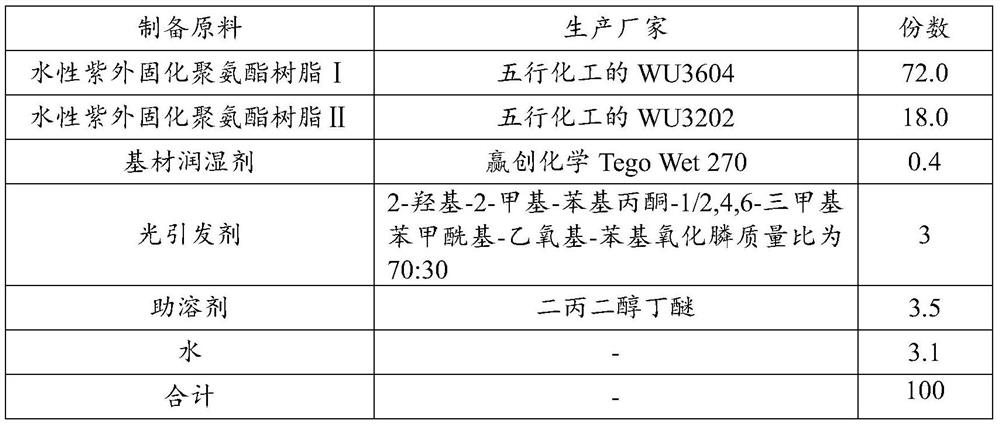

[0096] The water-based high-gloss finish paint of the present embodiment is prepared by the preparation raw materials shown in Table 1:

[0097] The preparation raw material of the water-based high-gloss finish paint of table 1 present embodiment

[0098]

Embodiment 2

[0100] The water-based high-gloss finish paint of the present embodiment is prepared by the preparation raw materials shown in Table 2:

[0101] The preparation raw material of the water-based high-gloss finish paint of table 2 present embodiment

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com