Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Full overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

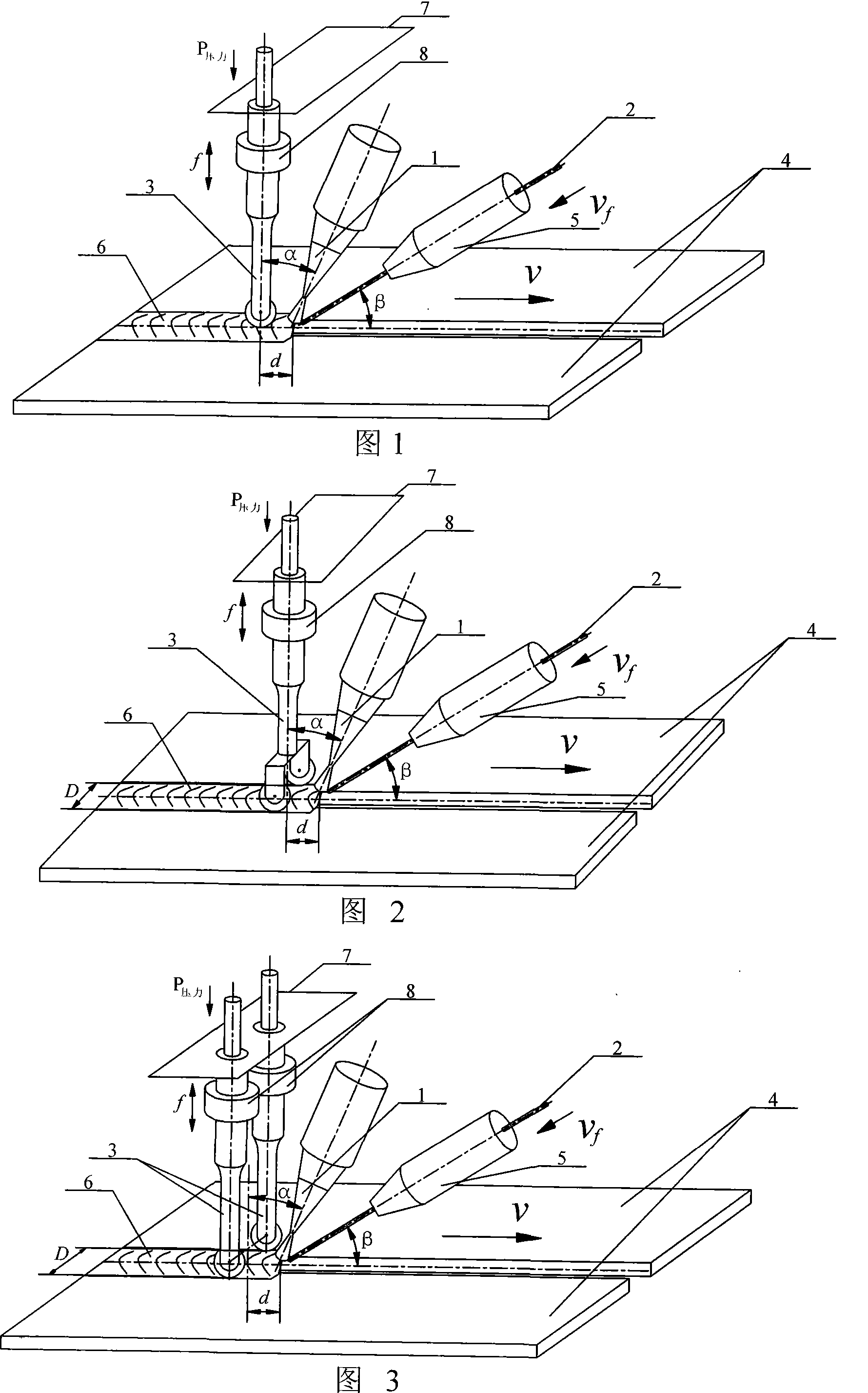

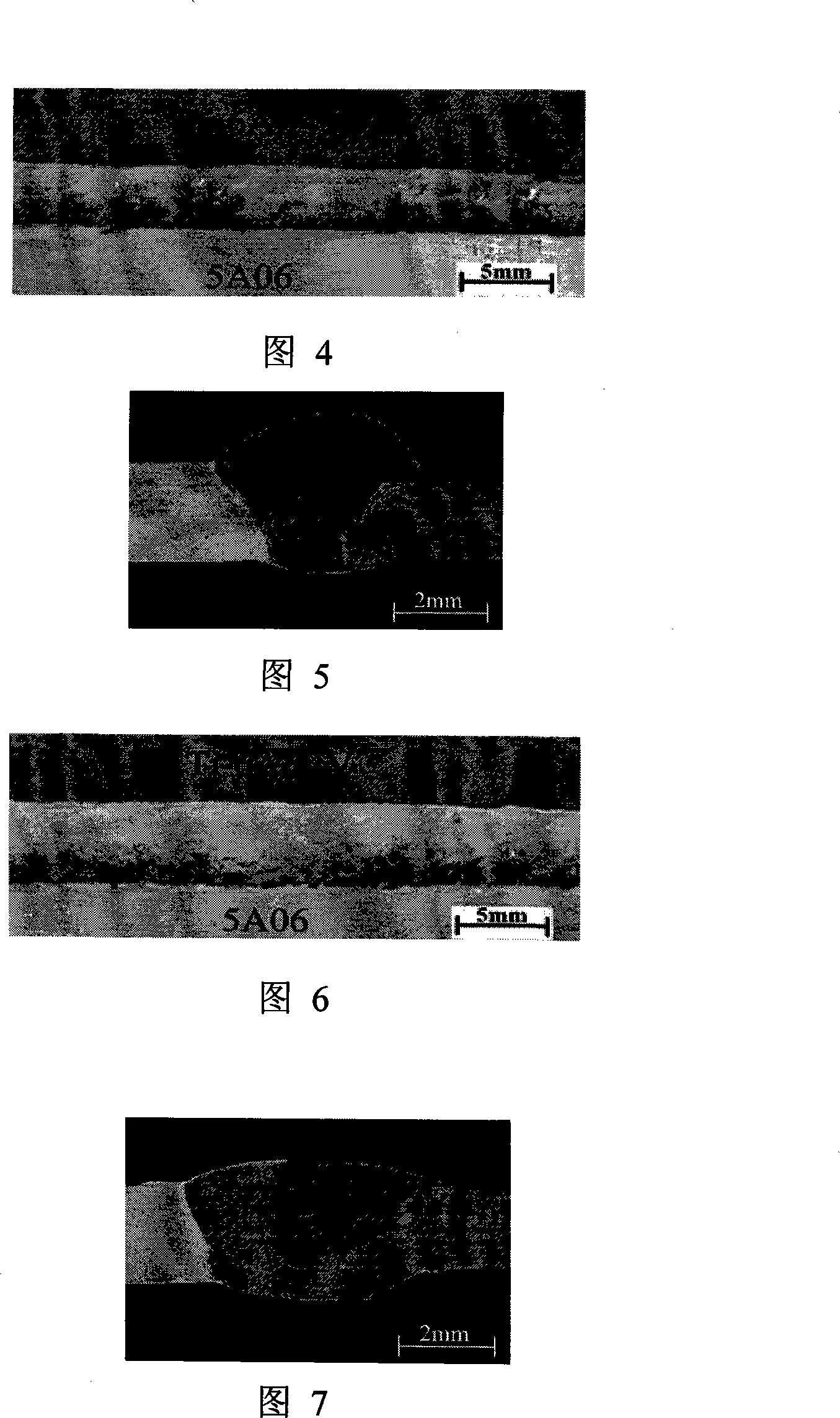

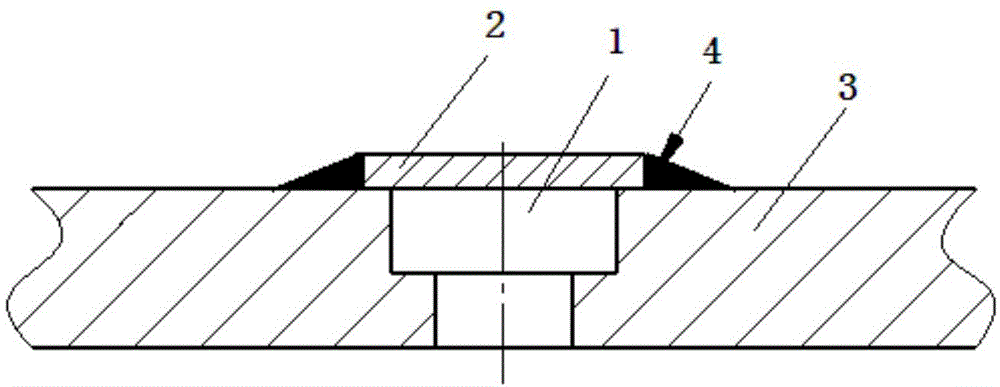

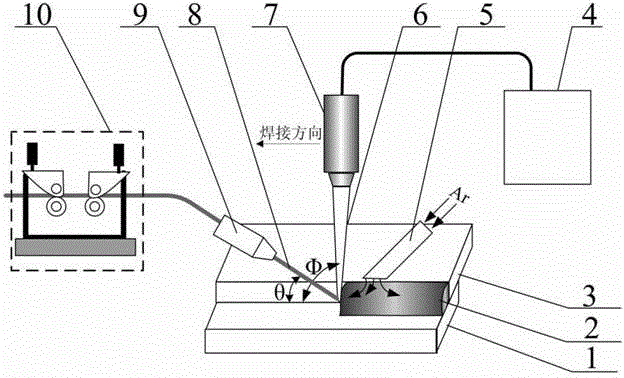

Ultrasound wave auxiliary laser braze (fuse) welding method

InactiveCN101195183AIncrease the amount of weld fillerImproved weld formationSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedWeld strength

Owner:HARBIN INST OF TECH

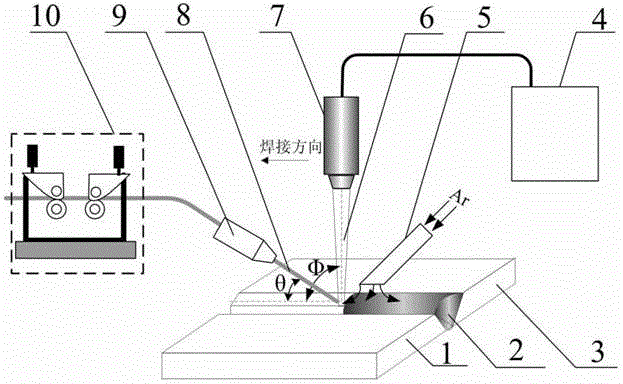

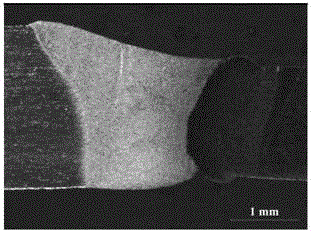

Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

ActiveCN102699535AFull overflowReduce or avoid the generation ofWelding/cutting media/materialsWelding/soldering/cutting articlesLaser beamsMaterials science

The invention provides a magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and a welding method. The welding method comprises the following steps of: forming a beveled edge on a part to be welded of a magnesium alloy and a steel workpiece, and removing oil dirt and an oxidation film from the surface of the workpiece; fixing the magnesium alloy and the steel workpiece on a welding fixture, adjusting the position and the angle of a wire feeding device, automatically feeding the welding wire at a certain angle in front of a laser beam, and protecting a welding seam through argon, wherein the welding wire comprises the following components in percentage by weight: 2 to 10 percent of Al, 0.5 to 5 percent of Zn, 0.1 to 1 percent of Sr, 0.05 to 0.2 percent of B, 0.5 to 2 percent of RE and the balance of Mg; and placing the laser beam on one side of the magnesium alloy workpiece in a slightly deviating way, and heating the welding wire and the magnesium alloy workpiece by using superaudio frequency pulse laser to form a smelting pool, wherein the steel workpiece is kept in a solid state substantially in a welding process and acts with liquid magnesium alloy to form a welding joint. The key and common problem that the improvement of the welding quality of Mg / Fe and Mg / Ti immiscible heterogeneous metal is limited is solved, and the application range of laser smelting braze-welding is expanded.

Owner:哈尔滨哈船特装科技发展有限公司

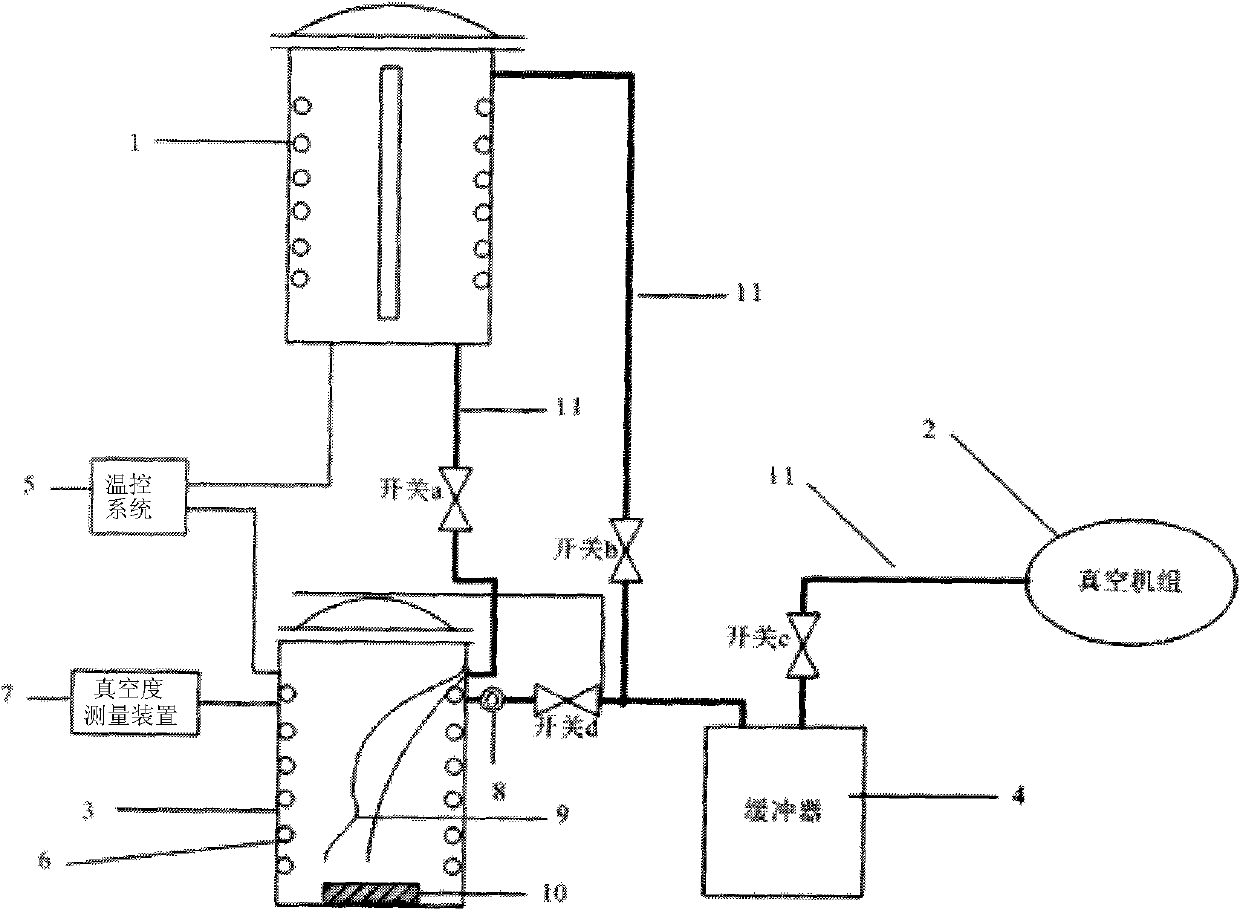

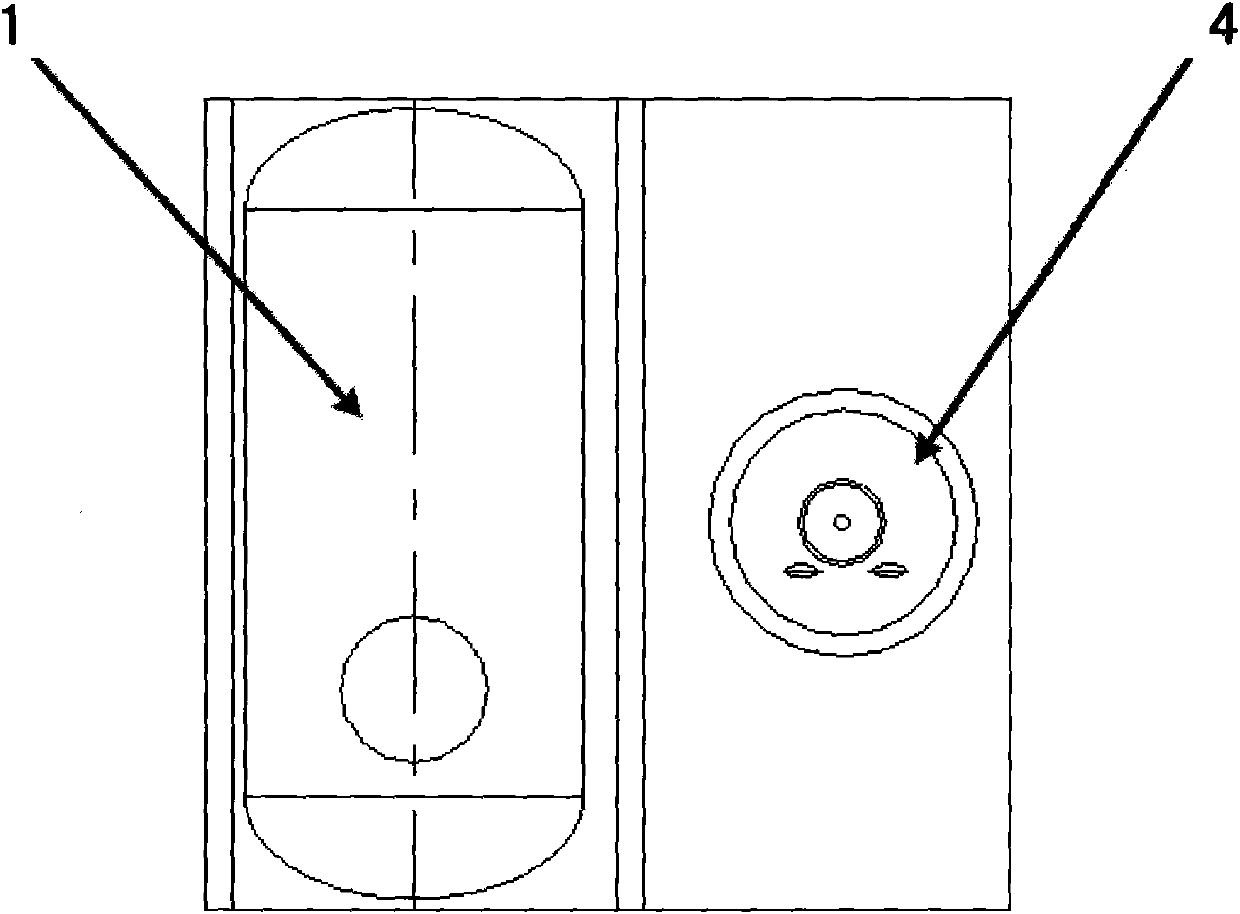

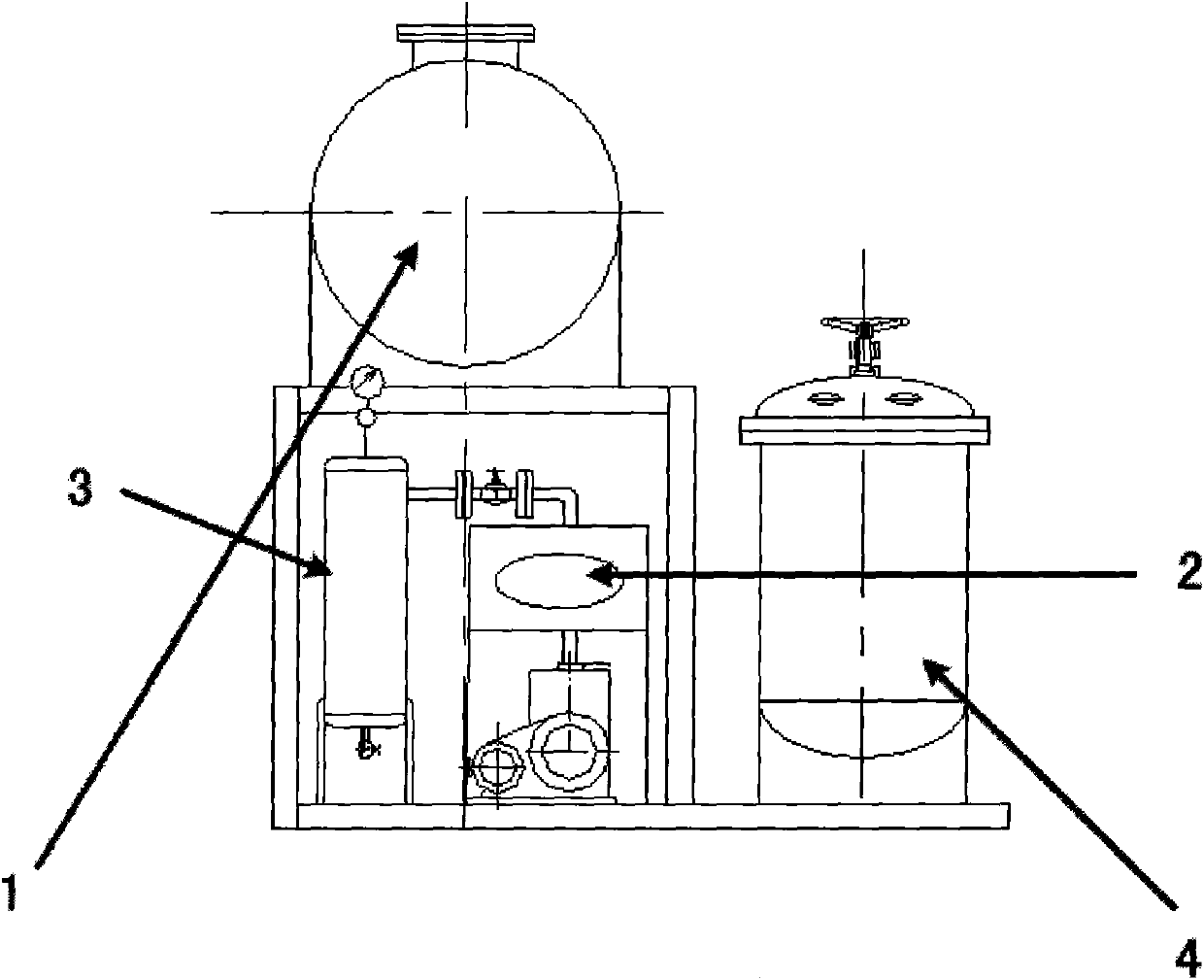

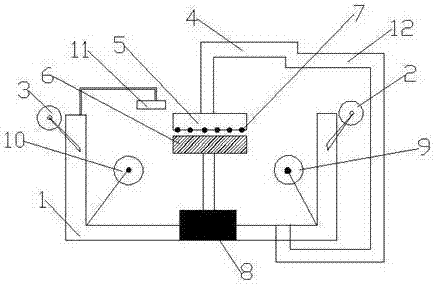

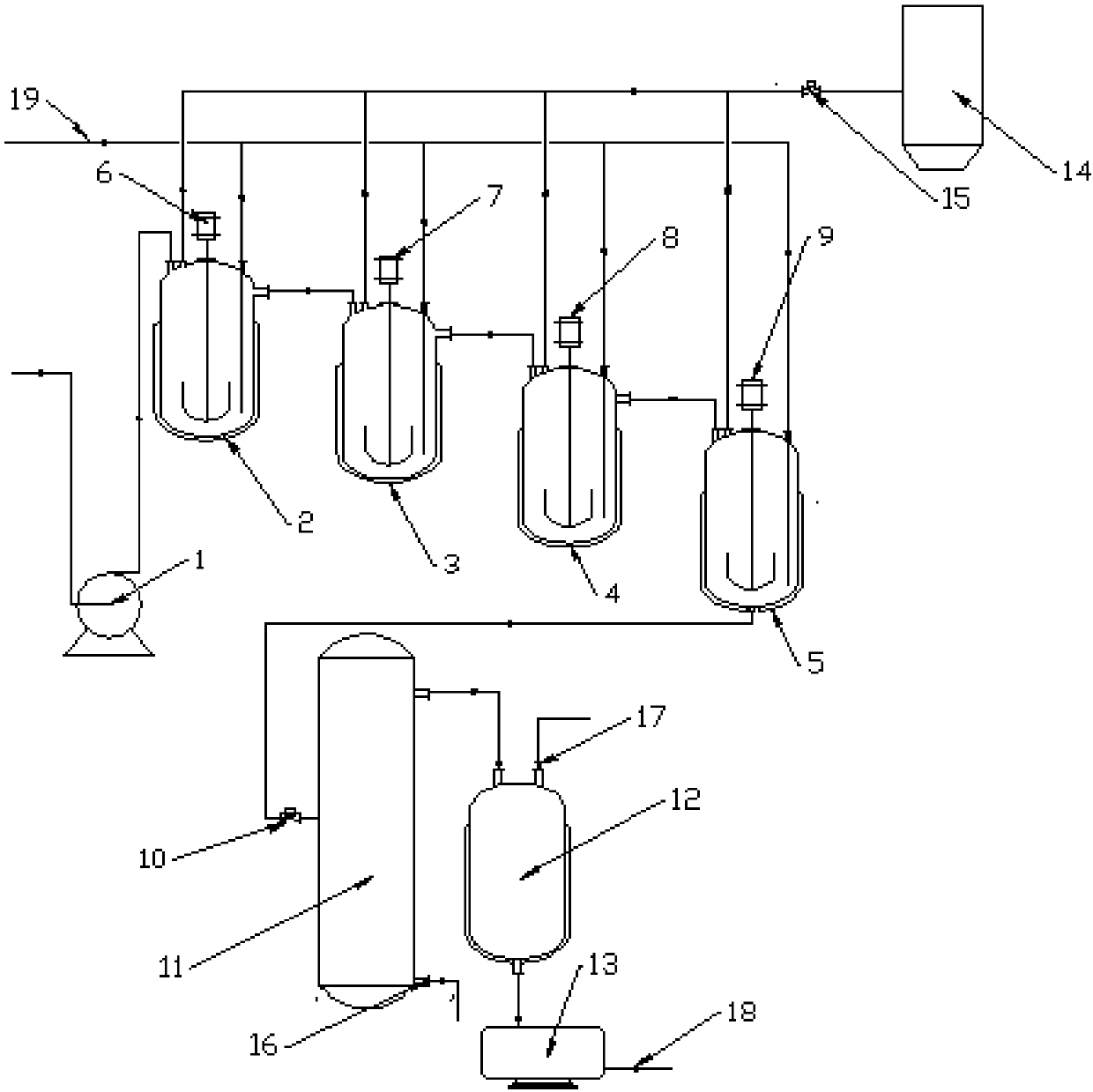

Vacuum insulation oil impregnating device and method thereof

The invention provides a vacuum insulation oil impregnation device and a method thereof. Vacuum oil impregnation is carried out by a liquid level difference method; an oil storage tank is higher than an oil impregnation tank; when the vacuum oil impregnation device works, the vacuum oil impregnation device can fully evaporate the interior of a sample in a high-temperature ultimate vacuum approaching state; after the dryness meets the requirement, a valve for connecting the oil storage tank and the oil impregnation tank is opened; and because the two tanks are all positioned in the ultimate vacuum approaching state, the insulating oil of the oil storage tank automatically flows into the oil impregnation tank under the action of gravity. The device and the method have the advantages that: the defects of the conventional air pressure difference method are avoided, the vacuum degree of the two tanks is kept unchanged, extra gas cannot enter an insulating carton and the transformer oil, oil foam cannot be generated in the oil impregnation process, the moisture inside the solid insulating material is ensured to be fully evaporated, a cavity inside the solid insulating material can be fully filled with a liquid insulating material, the insulating material treatment effect is improved, and the accuracy of the subsequent test conclusion is ensured.

Owner:CHINA ELECTRIC POWER RES INST +1

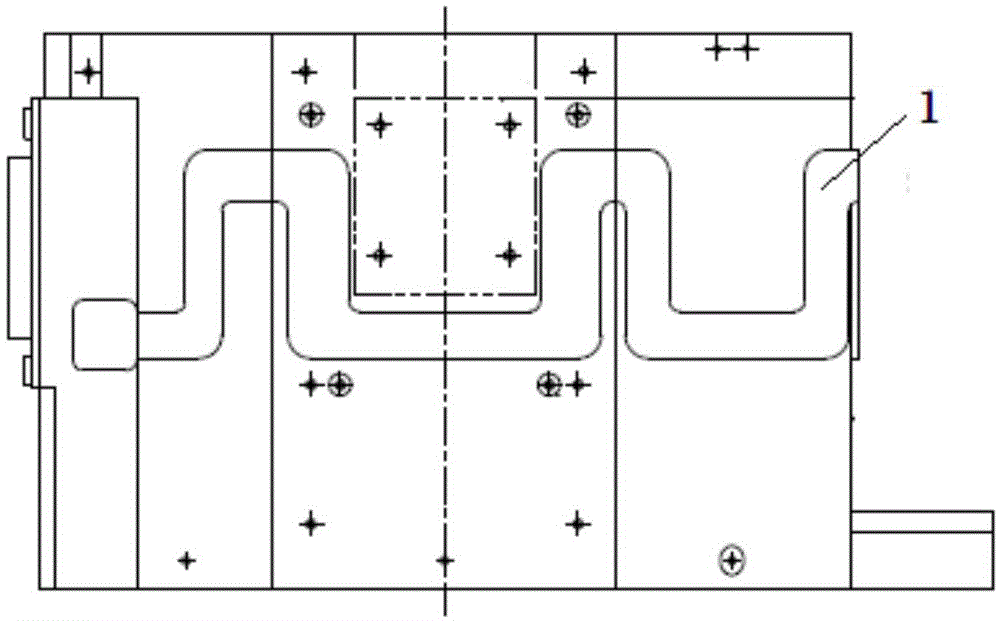

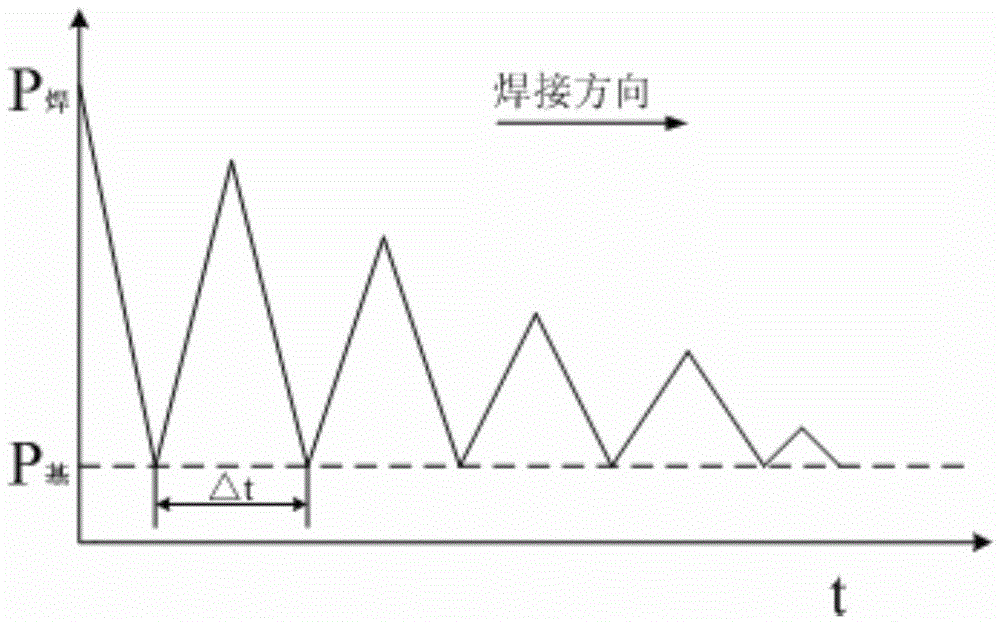

Arc ending method for high-temperature alloy laser welding

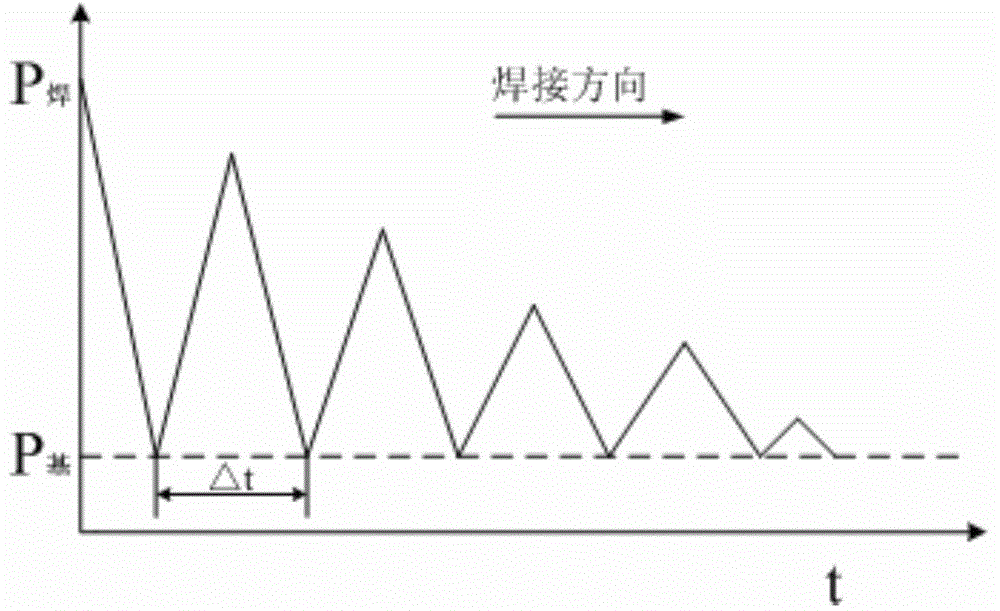

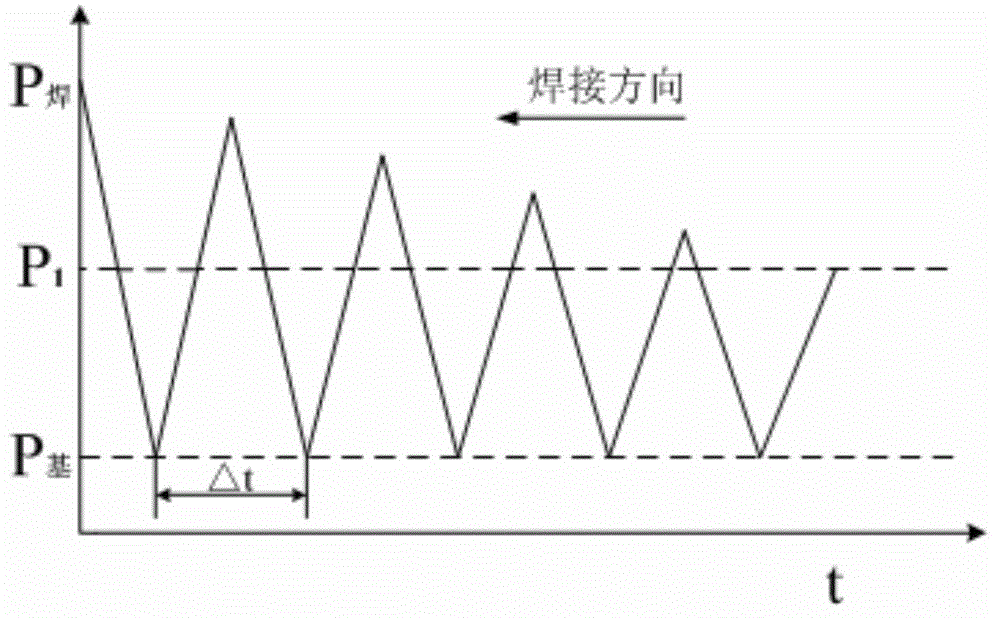

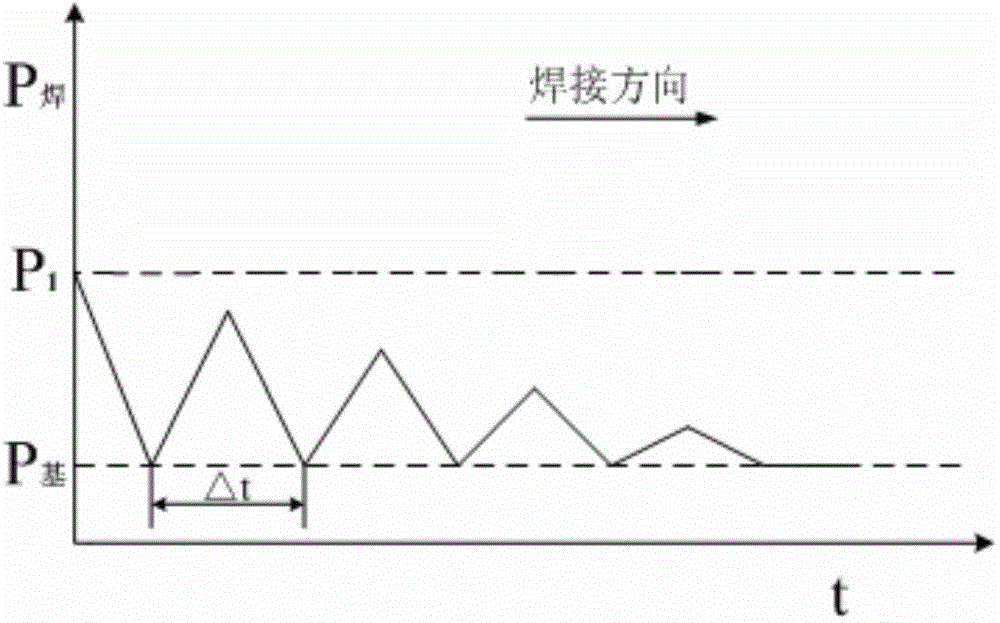

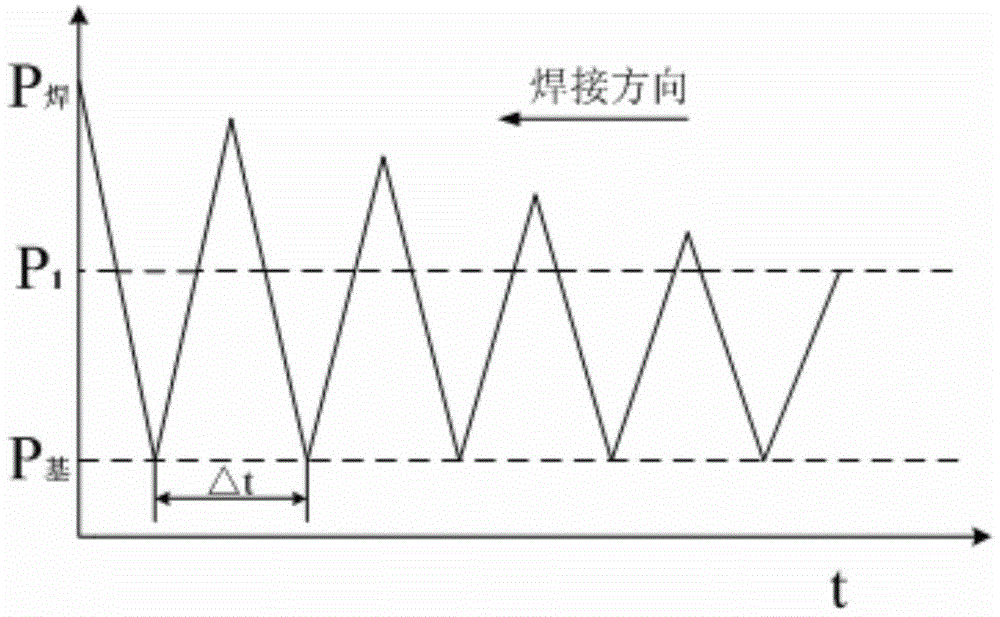

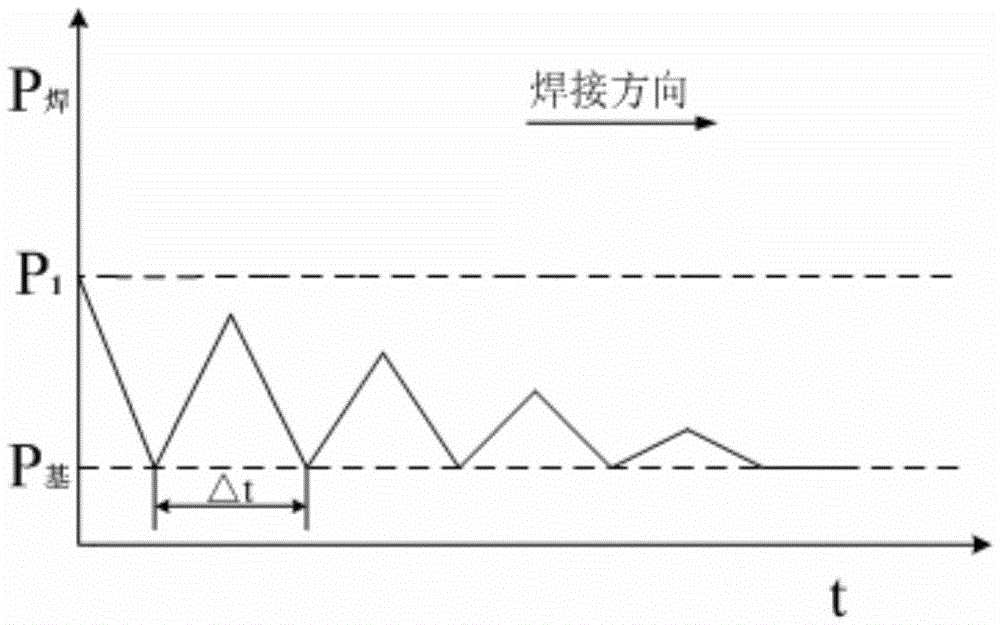

ActiveCN103817403AExtension of timeFull overflowArc welding apparatusWelding/soldering/cutting articlesWave shapeLaser scanning

The invention discloses an arc ending method for high-temperature alloy laser welding. An arc ending process of a high-temperature alloy laser weld includes three ending phases, namely first, second and third ending phases; the ending phases employ scanning directions: the first ending phase employs a regular direction, the second ending phase employs a reverse direction, and the third ending phase employs the regular direction; the ending phases successively operate to produce reciprocated laser scanning actions, and a bath at the welding arc end position is repeatedly scanned. During arc ending, laser output power waveforms of the ending phases are continuously attenuating triangular waves; laser output power attenuates into basic value in ending pulse. The method has the advantages that presence time of the ending bath is appropriately prolonged, gas in the bath is fully spilled, ending dense pores are avoided, and welding arc pits are downsized; on the premise of not using ending plates, the defects such as ending dense pores and arc pits in high-temperature alloy laser welding are avoided; the method is mainly applied to the field of laser welding.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

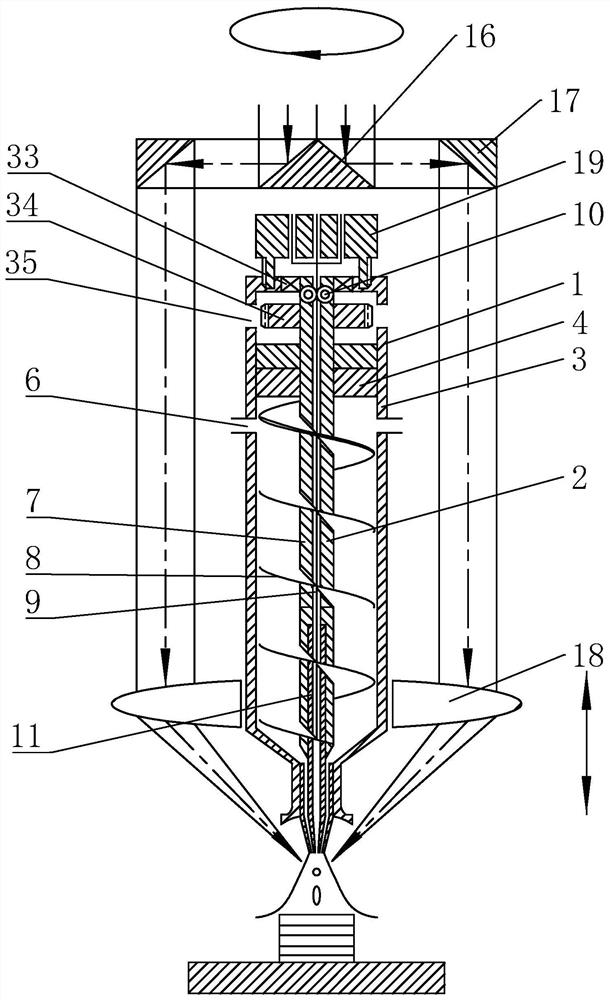

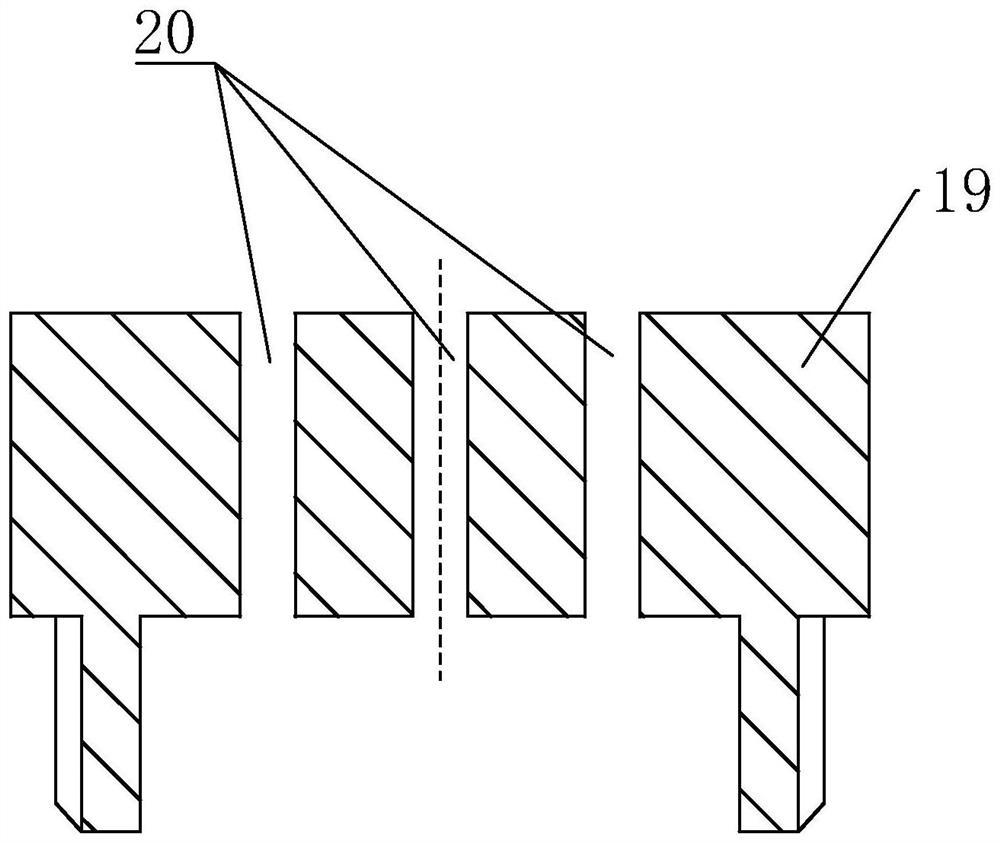

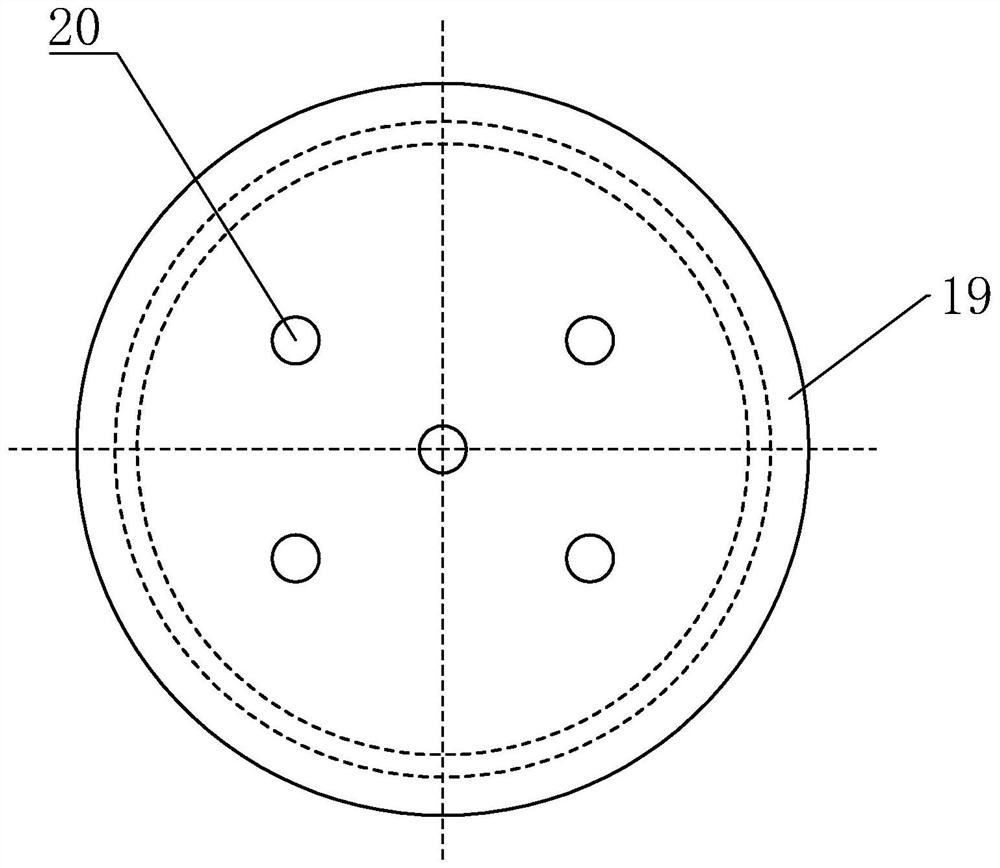

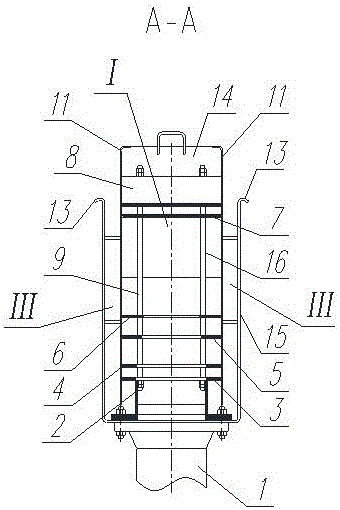

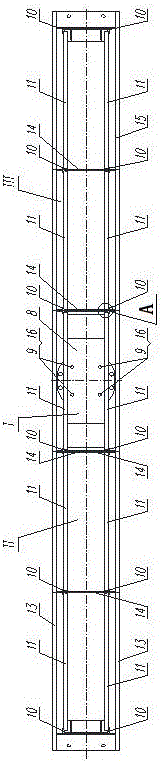

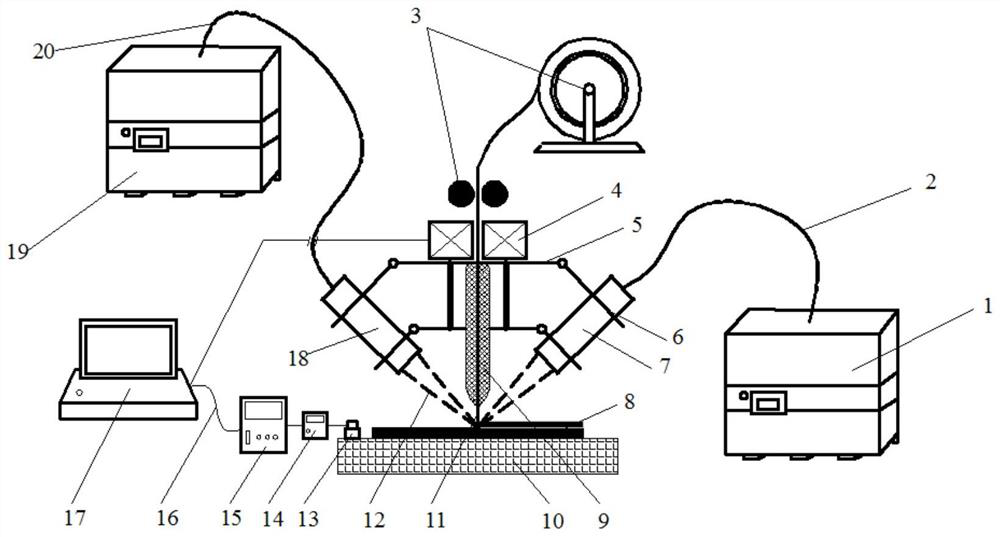

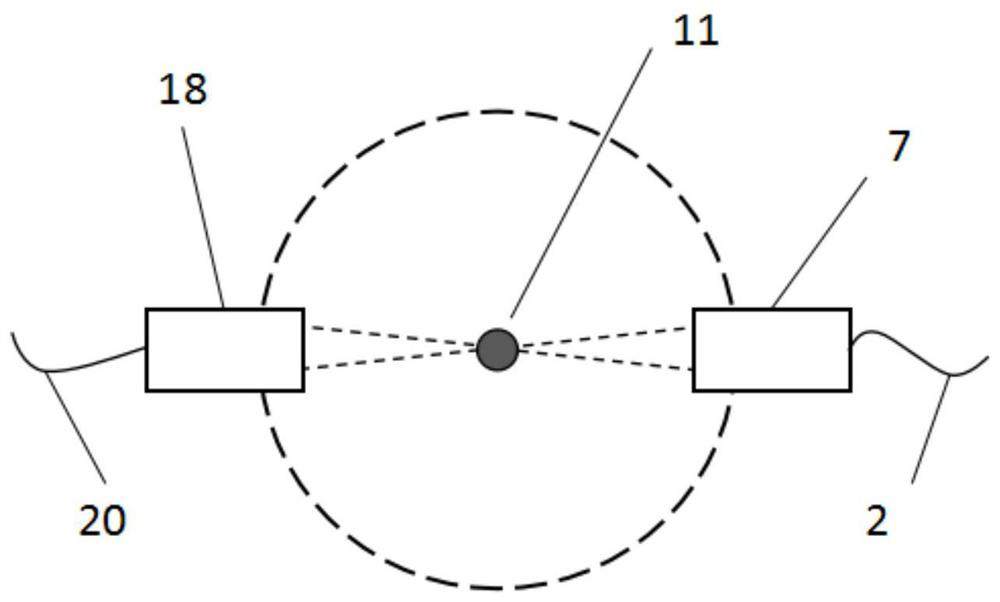

Wire-powder cooperation and laser-electric arc composite additive manufacturing device and method

ActiveCN113385821AEffective Online ProvisioningFull overflowLaser beam welding apparatusElectric arcBeam splitter

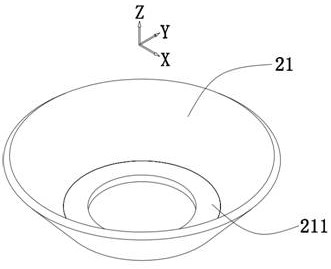

The invention discloses a wire-powder cooperation and laser-electric arc composite additive manufacturing device and method. The additive manufacturing device comprises a non-consumable electrode electric arc welding gun device for wire-powder coaxial heating feeding and a laser splitter set; the non-consumable electrode electric arc welding gun device for wire-powder coaxial heating feeding comprises an ultrasonic vibration gun body and a spiral stirring assembly, the ultrasonic vibration gun body comprises an amplitude-change pole and a transducer, the lower end of the amplitude-change pole is in a concave spherical curved surface shape, a powder feeding and air feeding combined channel is formed in the side portion of the amplitude-change pole, the spiral stirring assembly comprises a spiral stirring rod and a spiral blade, a main wire feeding and air feeding combined channel is arranged in the spiral stirring rod, and a hollow tungsten electrode is connected to the bottom of the spiral stirring rod; and the laser splitter set comprises a splitting reflector, a reflector set and a convex lens. The additive manufacturing device can achieve multi-mode additive manufacturing of field-force-heat combination and distribution, and has the advantages of being diversified in additive modes, high in additive efficiency, good in forming quality, high in material utilization rate, high in combinability and capable of adjusting alloy components flexibly.

Owner:温州竞合智造科技有限公司

Mold shell of investment casting cobalt chromium molybdenum artificial joint implant and manufacturing method of mold shell

InactiveCN108817309AImprove thermal conductivityIncreasing the thicknessFoundry mouldsFoundry coresSlurryHigh heat

The invention discloses a mold shell of an investment casting cobalt chromium molybdenum artificial joint implant and a manufacturing method of the mold shell and relates to the technical field of metal processing. A mold shell main body is provided with two layers of cobalt chromium molybdenum surface layers; each cobalt chromium molybdenum surface layer is prepared from silica sol, aluminum oxide powder, cobalt aluminate powder, a de-foaming agent, a wetting agent and latex, wherein the mass ratio of the aluminum oxide powder to the silica sol is 4.35 to 4.45 and the mass ratio of cobalt aluminate to the silica sol is 0.22 to 0.35; the mass ratio of the de-foaming agent to the silica sol is 6 to 8ml / Kg; the mass ratio of the wetting agent to the silica sol is 2 to 3ml / Kg and the mass ratio of the latex to the silica sol is 0.03 to 0.05; aluminum oxide slurry containing the cobalt aluminate and the aluminum oxide powder have very high heat conduction performance, a double-surface-layer manner ensures the thickness of a high-heat-conduction layer, the super-cooling degree of metal liquid is increased and the nucleation rate is improved, so that the aim of thinning crystal grains isfinally realized; a certain amount of the latex is added into surface-layer slurry and back-layer slurry and the latex is burnt after being baked, so that a lot of pores are formed in the mold shell,the air permeability of the mold shell is increased and the air pore rejection rate of castings is reduced.

Owner:无锡范尼韦尔工程有限公司

Automatic welding device for aluminum alloy longitudinal joints

InactiveCN106425184AHeating evenlyAvoid lostWelding/cutting auxillary devicesAuxillary welding devicesKey pressingHeat losses

The invention provides an automatic welding device for aluminum alloy longitudinal joints and relates to a structure of a welding lathe. The automatic welding device comprises a welding gun, a mandrel and two rows of key pressing finger assemblies, wherein each row of key pressing finger assemblies comprises a plurality of pressing fingers; an arc-shaped steel pipe is arranged on the upper surface of the mandrel, an electric heating pipe penetrates through the arc-shaped steel pipe, the upper surface of the arc-shaped steel pipe is connected with a liner, and the liner is arranged below a workpiece longitudinal joint; the length direction of the arc-shaped steel pipe, the length direction of the electric heating pipe and the length direction of the liner are all consistent with the length direction of the workpiece longitudinal joint; and a heat insulating plate is connected below each pressing finger, and the heat insulating plates are arranged on the outer surface of a workpiece for insulating heat. By adopting the mandrel electric heating, key pressing finger and product surface heat insulating mode, heat losses caused by heat conduction in a welding process are minimized, heat is used for fully melting aluminum materials in a concentrated manner, the cooling and condensation of a welding pool are prolonged, and oxides and gas in the pool fully overflow, so that high-quality weld joints are obtained, and the welding efficiency is increased.

Owner:JIANGSU JINXIN ELECTRIC CO LTD

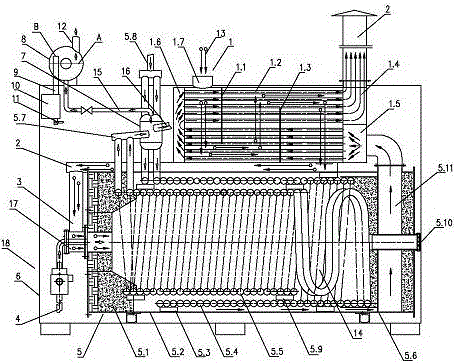

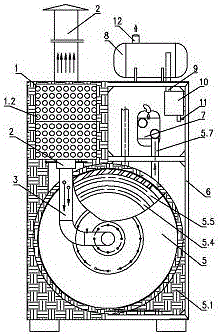

Fuel gas mold temperature controller

InactiveCN106382746ARealize automatic adjustmentEasy to controlFuel supply regulationStorage heatersOil temperatureEnergy conversion efficiency

The invention discloses a fuel gas mold temperature controller. The fuel gas mold temperature controller comprises a rack and a heat conduction oil furnace. A smoke heat recoverer is arranged on the rack which is above the heat conduction oil furnace. One end of the smoke heat recoverer is connected with a smoke chamber and a smoke guiding-in chamber in a sealed mode, and a smoke reversing chamber is arranged at the other end of the smoke heat recoverer in a sealed mode. A plurality of thread smoke tubes are arranged in the smoke heat recoverer in parallel. An oil-gas separation tank and an oil overflowing tank are arranged on the rack which is above the heat conduction oil furnace. The oil-gas separation tank is located below the oil overflowing tank. The oil-gas separation tank is communicated with a coiled tube through an oil outlet tube, the oil outlet tube is arranged on one side of the oil-gas separation tank, a separation tank oil outlet tube is arranged on the other side of the oil-gas separation tank, and the oil-gas separation tank is communicated with the oil overflowing tank. The rack is further provided with an oil temperature control device. The fuel gas mold temperature controller has the benefits that the smoke heat conversion efficiency is good, oil-gas separation is sufficient and thorough, and the oil temperature control is stable and high in precision.

Owner:DONGTAI SANCANG ENERGY SAVING BOILER

Aluminum alloy thin water channel cover plate and thick vacuum cavity water channel welding technology

ActiveCN104625349AEvenly heatedControl welding deformationArc welding apparatusWelding/soldering/cutting articlesShielding gasWeld line

The invention discloses an aluminum alloy thin water channel cover plate and thick vacuum cavity water channel welding technology and belongs to the technical field of welding technologies. The welding technology includes the following steps that first, before gas shielding welding, pollutants on a weldment groove and in the range away from the two sides of the groove by 30-50 mm are cleared away through acetone, a water channel cover plate and a vacuum cavity are preheated at the temperature of 180-240 DEG C, and it is guaranteed that the preheating temperature is uniform; second, in the welding process of gas shielding welding, the energy of a welding line is controlled within 20-25 kJ / cm; third, after gas shielding welding, arc craters are filled with matter when welding ends, time of shielding gas is prolonged, and penetration detection is performed after welding. Through the welding technology, the cooling speed of a weld pass can be reduced, hydrogen can overflow fully, and welding gas holes are effectively controlled. Due to preheating before welding, the cover plate and the cavity are heated evenly, and welding deformation is effectively controlled.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

Health-preserving special soup for peafowls and preparation method of health-preserving special soup

The invention provides health-preserving special soup for peafowls and a preparation method of the health-preserving special soup, and relates to the field of soup. The health-preserving special soupfor peafowls is mainly prepared from the following raw materials in parts by weight of 10-25 parts of peafowl meat, 10-14 parts of honey, 1-7 parts of radix astragali, 2-13 parts of radix angelicae sinensis, 3-8 parts of radix codonopsis, 5-9 parts of angelica dahurica, 3-6 parts of haws and 3-8 parts of seasoning. The health-preserving special soup for peafowls has the efficacy of strengthening the spleen and the stomach, reinforcing qi, invigorating the spleen, benefiting qi, and strengthening bodies, and besides, can treat diseases of constipation, poor appetite and the like. Based on guaranteeing the nutrients of the soup, the mouth feel of the soup is improved.

Owner:重庆菲利克思农业发展有限公司

Extracting method of phytofluene and phytoene

InactiveCN107602327AImprove securityEasy to recycleHydrocarbonsExtraction purification/separationPectinaseEdible oil

The present invention provides a method for extracting hexahydrophytoene and phytoene quickly, efficiently and safely——enzymatic hydrolysis microwave-assisted edible oil extraction method for hexahydrophytoene and phytoene, which promotes polyhydrophytoene Application of lycopene in processed food, medicine and health products. The invention uses edible oil as the extractant, has good safety, is easy to recycle and handle, and reduces equipment anticorrosion and pollution control treatment costs. The invention uses immobilized cellulase and pectinase to degrade, which is beneficial to destroy the cellulose and pectin in the tomato, so that the phytoene is fully overflowed, and combined with the microwave extraction technology, the speed of osmotic dissolution and diffusion in the extraction process is accelerated , shorten the extraction time, increase the extraction yield, and make the extraction rate of lycopene reach 5~13%, which provides a source of raw materials for the development of new products based on phytoene and phytoene.

Owner:武汉华康臣生物科技有限公司

Cloth uniform dyeing and drying device

InactiveCN107964742AReduce overflowNo wasteTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringDyeing

The invention discloses a cloth uniform dyeing and drying device. The device comprises a cloth dyeing and drying box, a cloth feeding roller and a cloth discharging roller, wherein the cloth feeding roller and the cloth discharging roller are arranged at the upper end of the outer side of the cloth dyeing and drying box separately; cloth dyeing pressing pieces and a liquid storage tube are arranged in the cloth dyeing and drying box; the dyeing cloth pressing pieces comprise the upper cloth dyeing pressing piece and the lower cloth dyeing pressing piece; the upper portion of the upper cloth dyeing piece is connected with the liquid storage tube, a plurality of liquid spraying ports are formed in the upper cloth dyeing pressing piece, and one end of the liquid storage tube is connected withan air pump. The device further comprises a cloth spreading roller and a drying roller, wherein the cloth spreading roller and the drying roller are arranged on the two sides of the cloth dyeing pressing pieces respectively; the lower cloth dyeing pressing piece moves up and down in the vertical direction. According to the device, dyeing of cloth and extrusion of redundant dye liquor are completed on the same mechanism, the redundant dye liquor can overflow to other cloth dyeing positions while extruded, the liquid spraying ports are used for spraying the liquor on the cloth on the upper cloth dyeing pressing piece, and redundant waste can not be caused; little dyeing liquor in the cloth dyeing and drying box overflows, the recycling work is simple, and the purpose of dyeing at a time isachieved.

Owner:CHENGDU JINHUI TECH

Cooked soybean milk making method

The invention concretely relates to a cooked soybean milk making method. The method comprises the following steps: 1, choosing a material; 2, cleaning; 3, immersing; 4, cleaning to remove impurities; 5, steaming or boiling the soybean raw material; 6, mixing the soybean raw material with water, and crushing; 5, detecting the concentration of the obtained soybean milk; 8, boiling the soybean milk; 9, carrying out high pressure homogenization on the soybean milk; 10, carrying out instant high temperature disinfection on the soybean milk; and 11, cooling the soybean milk to 0-15DEG C, and filling. In the above steps, steaming or boiling of the soybean raw material is carried out at a temperature of 100-121DEG C for 1-3h, the water-containing soybean raw material is crushed to above 60 meshes, and the high pressure homogenization of the soybean milk is carried out by a high pressure homogenizer. The soybean milk making method adopting the steps changes traditional uncooked soybean crushing habit, avoids the soybean residue removal step of traditional soybean milk making methods, fully reserves the nutritional components of soybeans and crude fibers and celluloses beneficial to human bodies, improves the nutrition values of the soybean milk and guarantees the mouthfeel of the soybean milk.

Owner:高天芝

Single-arc double-wire swing surfacing process

InactiveCN102909458AReduce the composition of welding consumablesFull overflowArc welding apparatusWelding/cutting media/materialsRetention timeHardness

The invention discloses a single-arc double-wire swing surfacing process. The single-arc double-wire swing surfacing process is characterized by comprising the following steps that: a single-power direct-current welding machine is adopted; two independent insulated wire feeder columns are connected with a positive electrode and a negative electrode respectively; the included angle between two wires from wire feeders is 0-15 DEG; the two wire feeders are mounted on the same welding mechanical swinger; and the swinger does the swing movement during the welding process, the swing width is 10-50mm, the swing frequency is 16-60times / min, the surfacing current is 300-500A, the voltage is 26-36V, the welding speed is 120-200mm / min, and the Rockwell hardness HRC is more than 60. The single-arc double-wire swing surfacing process has the advantages as follows: 1, the single-power double-wire welding process is adopted, so that the depth of fusion is reduced, the dilution rate is greatly reduced and is less than 20% of that in the single-wire welding process, and the depth of fusion can be controlled to be less than 0.5mm; and 2, the swing surfacing process is used, so that the weld pool retention time is long, impurities and gases can be fully overflowed, metal in a surfacing layer is pure, the mechanical performance is improved, and the surfacing efficiency is improved by 2-3 times.

Owner:HAIMEN WEILING WELDING MATERIAL MFG

Magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and welding method

ActiveCN102699535BEffect of Surface Energy StateGood wetting and spreadingWelding/cutting media/materialsWelding/soldering/cutting articlesMelting tankWeld seam

The invention provides a magnesium and steel special metal superaudio frequency pulse laser smelting braze-welding wire and a welding method. The welding method comprises the following steps of: forming a beveled edge on a part to be welded of a magnesium alloy and a steel workpiece, and removing oil dirt and an oxidation film from the surface of the workpiece; fixing the magnesium alloy and the steel workpiece on a welding fixture, adjusting the position and the angle of a wire feeding device, automatically feeding the welding wire at a certain angle in front of a laser beam, and protecting a welding seam through argon, wherein the welding wire comprises the following components in percentage by weight: 2 to 10 percent of Al, 0.5 to 5 percent of Zn, 0.1 to 1 percent of Sr, 0.05 to 0.2 percent of B, 0.5 to 2 percent of RE and the balance of Mg; and placing the laser beam on one side of the magnesium alloy workpiece in a slightly deviating way, and heating the welding wire and the magnesium alloy workpiece by using superaudio frequency pulse laser to form a smelting pool, wherein the steel workpiece is kept in a solid state substantially in a welding process and acts with liquid magnesium alloy to form a welding joint. The key and common problem that the improvement of the welding quality of Mg / Fe and Mg / Ti immiscible heterogeneous metal is limited is solved, and the application range of laser smelting braze-welding is expanded.

Owner:哈尔滨哈船特装科技发展有限公司

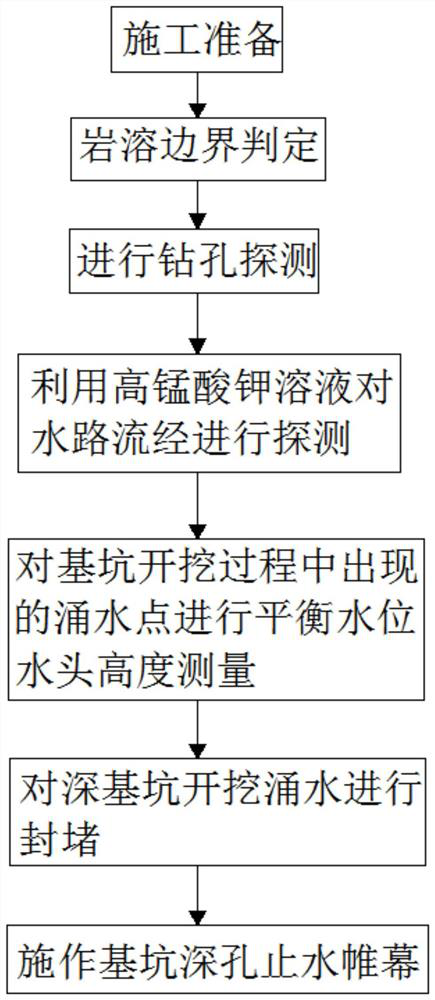

Urban underground engineering strong karst water treatment construction method

PendingCN113529683AGood treatment guidanceUnderstand comprehensivelyIn situ soil foundationLithologyPotassium manganate

The invention relates to the technical field of underground station construction, and particularly relates to an urban underground engineering strong karst water treatment construction method. The method comprises the following steps that S1, construction preparation is carried out; S2, karst boundary judgment is carried out; S3, drilling detection is carried out, a drilled grouting hole is utilized, the lithology, the geological structure and the underground water condition information of a drilling passing area are observed during drilling, and stratum, geousness and joint crack characteristics are preliminarily obtained; S4, a potassium permanganate solution is used for detecting the waterway flow; S5, the height of a balanced water level water head is measured for a water burst point appearing in the foundation pit excavation process; S6, the deep foundation pit excavation water burst is blocked; and S7, a foundation pit deep hole waterproof curtain is constructed. The construction method is complete, clear and detailed in step, construction personnel can conveniently use the method, and the construction safety and the construction efficiency can be effectively improved. The method is mainly applied to the aspect of underground engineering strong karst water treatment construction.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

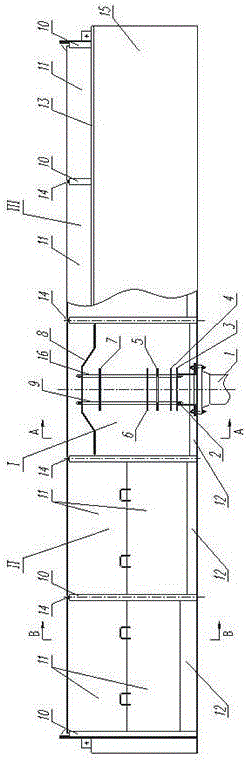

Seawater distribution system of open rack vaporizer

ActiveCN106225550AOverflow stableOverflow evenlyHeat exchanger casingsDistribution systemEngineering

The invention discloses a seawater distribution system of an open rack vaporizer. The system comprises a seawater distribution pipeline, and further comprises a buffer area, distribution areas and overflow areas; the distribution areas are positioned on two sides of the buffer area; the overflow areas are positioned on the outer sides of the length directions of the buffer area and the distribution areas, and are communicated with the two through water passing ports in the lower parts; and after seawater enters the buffer area from the seawater distribution pipeline at the bottom out of the buffer area, the seawater is guided and buffered by a buffer device in the buffer area to move in the horizontal direction to enter the distribution areas and to enter the overflow areas through the water passing ports in the lower parts to be guided out. The system effectively increases the seawater resistance fall, reduces the seawater flowing speed, prevents strong turbulence or acute fluctuation of the seawater in the overflow areas, guarantees stable and uniform distribution of the seawater in the area, and guides the seawater to the inclined lower side through an overflow weir arc to naturally, uniformly and fully overflow onto the surface of a pipe bundle heat exchange panel of the open rack vaporizer to form an effective seawater liquid film.

Owner:GANSU LANPEC TECH +2

Special peacock meat stockpot and production method thereof

InactiveCN108208607AHigh nutritional valueDelicious meatFood thermal treatmentNatural extract food ingredientsNutrientLycium chinense

The invention provides a special peacock meat stockpot and a production method thereof, and relates to the technical field of stockpots. The special peacock meat stockpot is mainly produced from, by weight, 40-54 parts of peacock meat, 1-2 parts of pig marrowbones, 10-14 parts of honey, 2-5 parts of Radix Astragali, 5-10 parts of Chinese yam, 3-8 parts of Radix Codonopsis, 4-10 parts of dahurian angelica root, 3-6 parts of wolfberry fruits, 3-8 parts of a seasoning and 1-2 parts of a dipping sauce. The special peacock peat stockpot has the efficacy of strengthening the spleen and the stomach,tonifying qi and invigorating the spleen, and tonifying qi and strengthening the physique, and can treat constipation, inappetence and other diseases. The mouthfeel of the stockpot is improved on thebasis of guaranteeing the nutrients of the stockpot.

Owner:重庆菲利克思农业发展有限公司

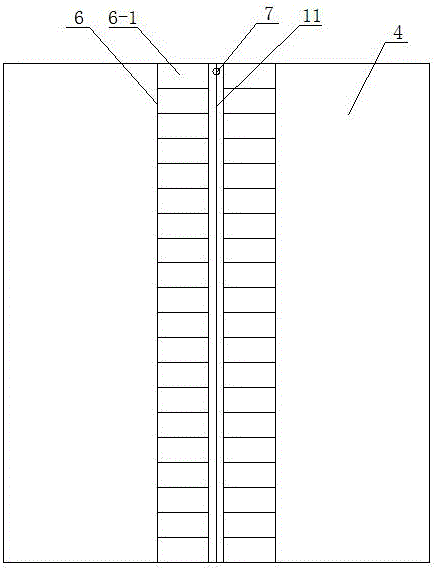

Connected anchor rod and mounting method thereof

The invention discloses a connected anchor rod and a mounting method thereof. The connected anchor rod comprises at least two rod bodies, a backing plate, a closing cover and an anchor head, wherein each rod body is of a hollow pipe shape with two open ends, the at least two rod bodies are connected together through a connecting sleeve, the diameter of the connecting sleeve is greater than that of the rod bodies, and at least one first mortar overflowing hole is formed in the middle part of the connecting sleeve; the backing plate sleeves the upper part of the uppermost rod body; the closing cover is connected with the upper end of the uppermost rod body and is used for tightly pressing the backing plate to the surface of a side slope; the anchor head is of a hollow pipe with an open upper end, and the lower end of the anchor head is tipped; the diameter of the anchor head is greater than that of the rod bodies, and the upper end of the anchor head sleeves the lower end of the lowermost rod body; at least one second mortar overflowing hole is formed in the anchor head. According to the connected anchor rod and the mounting method thereof, the structure is simple, the mounting is convenient, the pulling resistance of the anchor rod can be improved, and the rod bodies can be effectively prevented from being subjected bent damage during transportation.

Owner:GUANGXI UNIV

Arc closing method for laser welding of superalloy

ActiveCN103817403BExtension of timeFull overflowArc welding apparatusWelding/soldering/cutting articlesLaser scanningSuperalloy

The invention discloses an arc ending method for high-temperature alloy laser welding. An arc ending process of a high-temperature alloy laser weld includes three ending phases, namely first, second and third ending phases; the ending phases employ scanning directions: the first ending phase employs a regular direction, the second ending phase employs a reverse direction, and the third ending phase employs the regular direction; the ending phases successively operate to produce reciprocated laser scanning actions, and a bath at the welding arc end position is repeatedly scanned. During arc ending, laser output power waveforms of the ending phases are continuously attenuating triangular waves; laser output power attenuates into basic value in ending pulse. The method has the advantages that presence time of the ending bath is appropriately prolonged, gas in the bath is fully spilled, ending dense pores are avoided, and welding arc pits are downsized; on the premise of not using ending plates, the defects such as ending dense pores and arc pits in high-temperature alloy laser welding are avoided; the method is mainly applied to the field of laser welding.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Synthesis method of 1-methyl-4-methyl sulfonyl benzene

PendingCN107827790AFull overflowSame pressureOrganic chemistryOrganic compound preparationSynthesis methodsContact reaction

The invention discloses a synthesis method of 1-methyl-4-methyl sulfonyl benzene. The synthesis method comprises the following steps: stirring 4-methylbenzene sodium sulfinate and chloromethane for four stages of methylation, so as to obtain a 1-methyl-4-methyl sulfonyl benzene mixed solution, putting the mixed solution into a liquid separation tower for stewing separation, and then carrying out washing, crystallization and dewatering to obtain a 1-methyl-4-methyl sulfonyl benzene product. According to the synthesis method, through the adoption of self-sucking stirring, a stirrer rotates in liquid to generate negative pressure, and under the condition of the negative pressure, chloromethane gas is sucked to enhance gas-liquid contact reaction to complete the reaction; furthermore, pressures on the surfaces of four methylation kettles are kept to be equal, so that liquid in the kettles full overflows; due to the adoption of the single-stage liquid separation tower, material blockage isprevented; continuous production is realized.

Owner:浙江嘉化新材料有限公司

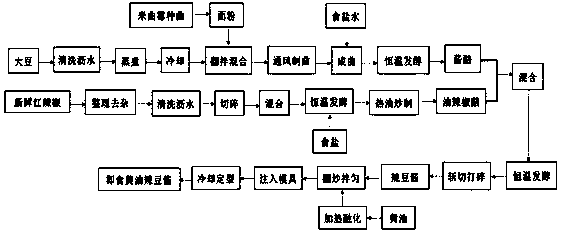

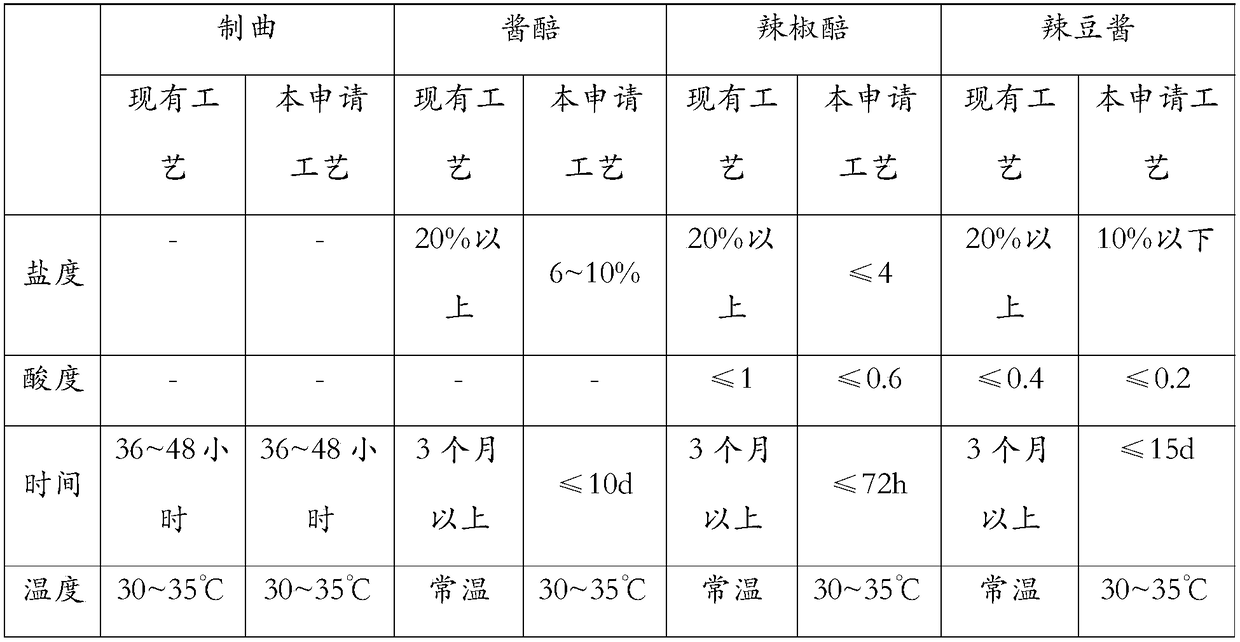

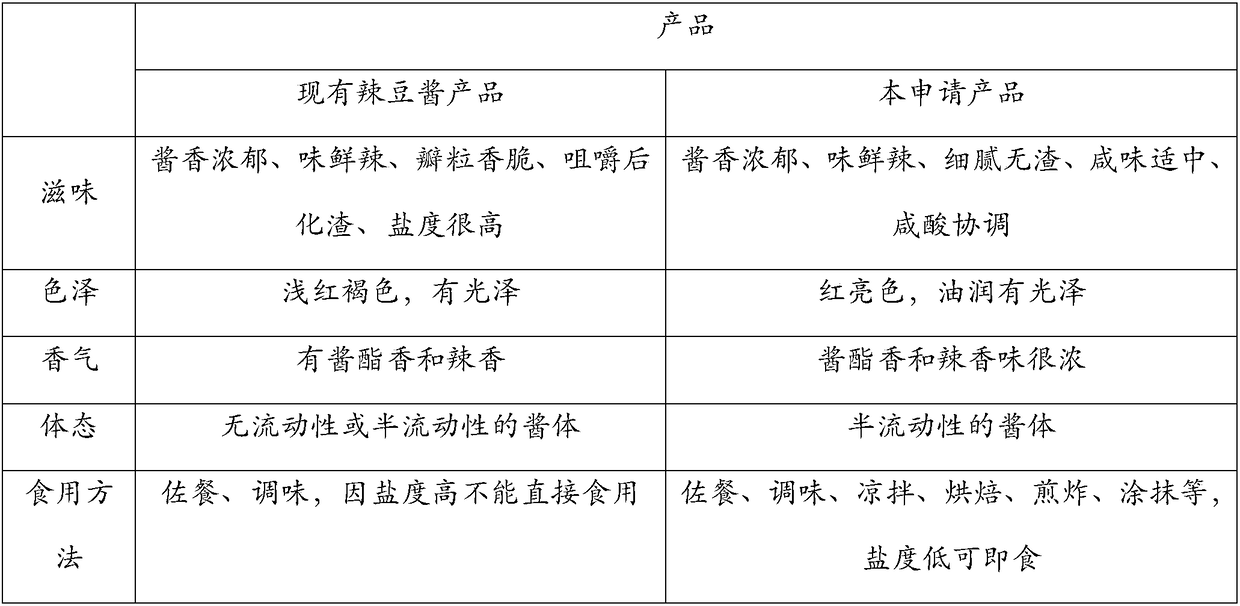

Preparation method of instant butter spicy bean sauce

The invention belongs to the field of food processing, and in particular relates to a preparation method of instant butter spicy bean sauce. According to the method, under the conditions of low salt and constant temperature, acid production of pepper mash is 0.6% or above in 36 to 48 hours, and the pepper mash is fried to eliminate the lactic acid bacteria in the pepper mash, and fully spill capsaicin pigments and spicy substances to enhance the color and taste. The obtained low-salt pepper mash and high-salt sauce mash are mixed and subjected to ventilating fermentation at a constant temperature; and when the amino state nitrogen of the sauce is equal to 0.2 or higher, the fermentation is terminated; and the sauce is broken with a tissue pulverizer. Finally, butter is weighed and melted on a pan, the butter is stir-fried and evenly mixed with the sauce; then the mixture is poured into a mold while hot, and demoulding is carried out after cooling to obtain the instant butter spicy beansauce. The method realizes the low salinization of the spicy bean sauce, maintains the unique flavor of the bean sauce, significantly reduces the salinity of the spicy sauce, shortens the fermentation cycle, reduces the production cost, improves the production efficiency of enterprises, and opens foreign markets.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

Preparation method of fleece-flower root swelling product

InactiveCN101744893AStrong fragranceLow densityNervous disorderDigestive systemFlavorBioavailability

The invention relates to a preparation method of a fleece-flower root swelling product, which comprises the following concrete steps: A, cleaning fresh fleece-flower root medicinal material, and chopping into particles with the size of 0.5-1.0 centimeter; B, heating the fleece-flower root particles of the step A at 50-60 DEG C, so that the moisture content is 10-20%; C, carrying out swelling processing on the fleece-flower root particle heated in the step B by a screw rod food extruding swelling machine, wherein the rotation speed of the swelling machine is 200-300r / min, and the swelling temperature is 120-150 DEG C, and obtaining the swelling product; and D, cooling the swelling product of the step C for 5-10 minutes, and packing. The method of the invention has simple operation and convenient processing, and the prepared fleece-flower root product has high bioavailability, loose texture, good taste, thick flavor and convenient taking.

Owner:SOUTHWEST JIAOTONG UNIV

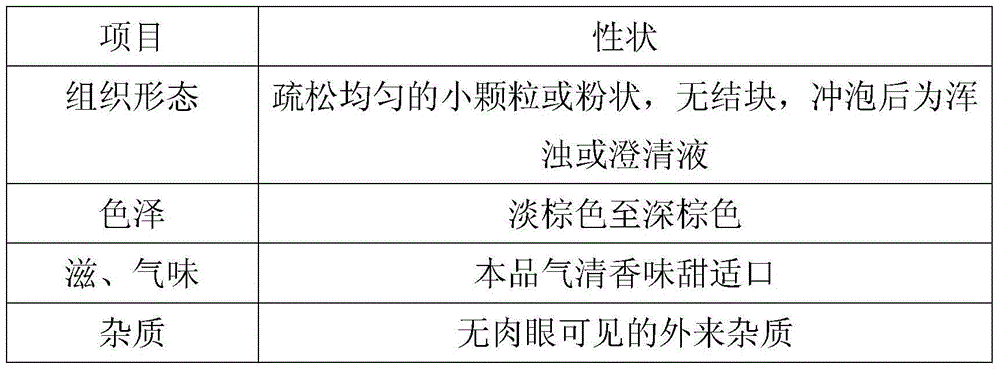

A human body sub-health improving substitutional tea and a preparation method thereof

InactiveCN104920721AEasy to carry and usePromote body absorptionTea substituesLower blood pressureDecomposition

The present invention discloses a human body sub-health improving substitutional tea and a preparation method thereof, and relates to a substitutional tea and a preparation method thereof. The substitutional tea is composed of polygonatum sibiricum, haws, cassia seeds and dried tangerine peels, and the scientific matching of the above materials can improve human immunity, relieve fatigue, lower blood pressure and improve body functions. At the same time, the soaking and extraction method used can make the beneficial substances overflow from the raw materials, increase the content of beneficial substances in the solution, improve the utilization rate of the raw materials, and reduce costs. Meanwhile, the substitutional tea also can promote the decomposition of the beneficial substances in the body to improve absorption. The substitutional tea has an appearance of loose and uniform particles or powder without caking, is turbid or clear liquid after being brewed, has refreshing fragrance, sweet taste and palatability, and can improve human body sub-health.

Owner:凉山新鑫中药饮片有限公司

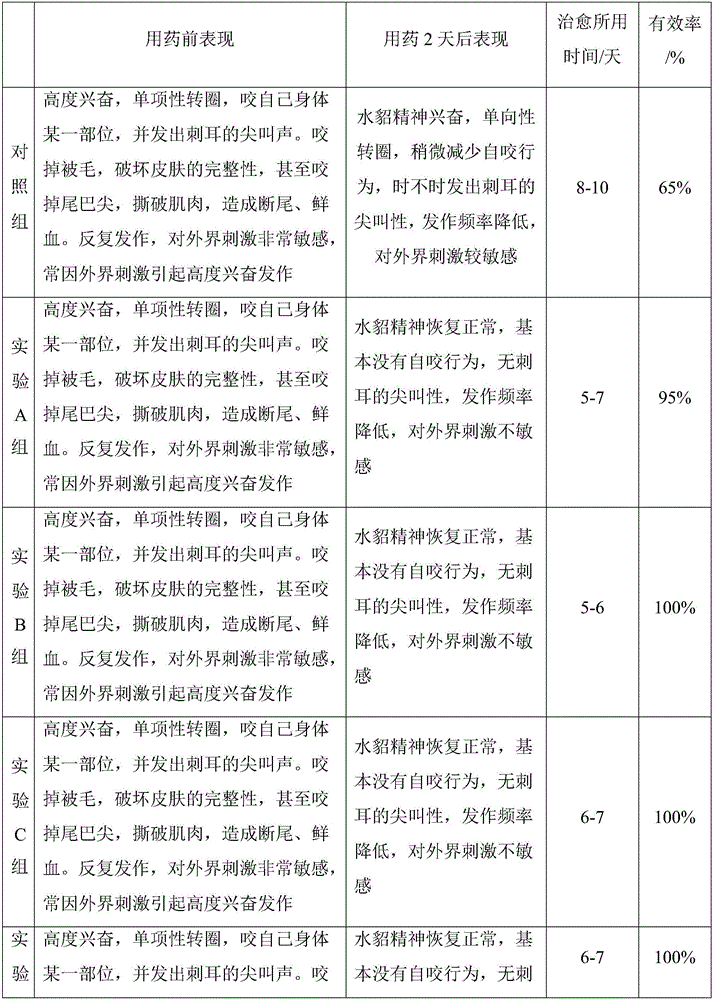

Traditional Chinese medicine tablets for treating self-biting behavior of minks and preparation method thereof

InactiveCN105748932AEasy to crushFull overflowHeavy metal active ingredientsUnknown materialsHalloysiteMink

The invention discloses traditional Chinese medicine tablets for treating the self-biting behavior of minks and a preparation method thereof.The traditional Chinese medicine tablets are prepared from radix et caulis acanthopanacis senticosi, bark or branches and leaves of melaleuca leucadendra, white quartz, cornu gorais, roots of stemmacantha carthamoides, all-grass of ludisis discolor, rhizomes of featherleaf rodgersflower, basal leaves or seeds of brassica integrifolia, radix cynanchi atrati, Chinese prickly ash, spina gleditsiae, folium eucalypti, pomelo pits, bus of citrus aurantium, rose flowers, albizia flowers, bark of Japanese pagodatree, radix astragali, red halloysite and honey.The traditional Chinese medicine tablets are an environment-friendly preparation, are nontoxic and harmless to minks and do not contain chemicals or antibiotics; in the use process, the traditional Chinese medicine tablets are mashed and mixed into basal feed of minks to feed minks; the traditional Chinese medicine tablets have a good treatment effect on milks with the self-biting behavior, are high in effective rate, and can promote rapidly recovery of minks, shorten the healing recovery period, promote regeneration of fur of the infected parts of minks, stimulate the healthy sustainable development of the mink breeding industry and increase the economic benefits of farmers.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Cuiya tea shaping technology

InactiveCN106070743AImprove integrityConsistent shape and flatnessPre-extraction tea treatmentEngineeringTea leaf

The invention discloses a Cuiya tea shaping technology in the tea processing technical field. The invention includes the steps of primary shaping, secondary shaping, tertiary shaping and fourth shaping. In the primary shaping step, tidied tea leaves are placed into a first pot of a continuous tea flatting machine, pressed for 2-2.5 min and put into a second pot, wherein the temperature is 110-115 DEG C, the tea leaf input amount is 200-250 g, and the gap between a pot body of the first pot and a pressing plate is 3-3.5 mm. In the second shaping step, the gap between a pot body of the second pot and the pressing plate is adjusted to be 2-2.5 mm, and the tea leaves are pressed for 1.5-2 min at the temperature of 95-100 DEG C and put into a third pot. In the tertiary shaping step, the gap between a pot body of the third pot and the pressing plate is 1.5-2 mm, and the tea leaves are pressed for 1.2-1.5 min at the temperature of 85-90 DEG C and put into a fourth pot. In the fourth shaping step, the gap between a pot body of the fourth pot and the pressing plate is adjusted to be 1.5 mm, the tea leaves are pressed for 1-1.5 min at the temperature of 80-85 DEG C and discharged, and shaping of Cuiya tea is finished. By means of the shaping technology, the pressing plate is stressed by tea leaves, so the tea leaves rub the pot bodies back and forth, the technology has the advantages of manual frying, quality of tea is effectively improved, Meitan Cuiya tea good in smell and mellow in taste, uniform and complete is produced, and grand positioning of Meitan Cuiya tea is expected to be improved.

Owner:GUIZHOU YANGCHUNBAIXUE TEA IND

Sour, hot and flavorful soup base of minced noodles

InactiveCN105995887AEnsure quality stabilityFully miscible and mixedFood scienceMonosodium glutamateFood flavor

The invention discloses a sour, hot and flavorful soup base of minced noodles. The soup base is prepared from the following raw materials in parts by weight: 0.45-0.55 part of sauce, 0.18-0.22 part of seasoning powder, 22.5-27.5 parts of vinegar, 6.3-7.7 parts of salt, 3.6-4.4 parts of edible oil and 2.7-3.3 parts of chili powder, wherein the source is taken from a boiling liquid prepared from the following raw materials in parts by weight: 9-11 parts of water, 0.27-0.33 part of Chinese prickly ash, 0.27-0.33 part of star anise, 0.18-0.22 part of cinnamon and 0.18-0.22 part of fennel; the seasoning powder is prepared from the following raw materials in parts by weight: 0.045-0.055 part of Chinese prickly ash powder, 0.045-0.055 part of fennel powder, 0.045-0.055 part of cinnamon powder and 0.045-0.055 part of star anise powder. The soup base also contains the following raw materials in parts by weight: 0.9-1.1 parts of fresh ginger, 3.24-3.96 parts of monosodium glutamate and 1.62-1.98 parts of essence of chicken. The sour, hot and flavorful soup base of minced noodles has aromatic flavor and stable quality and is simple in preparation method.

Owner:李伟

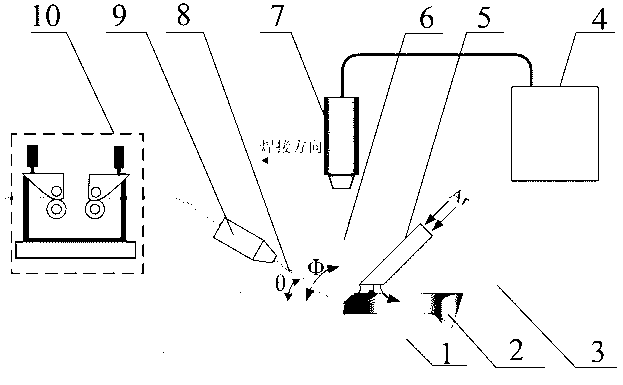

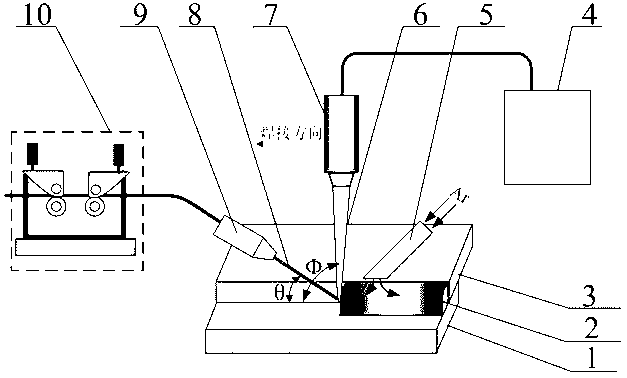

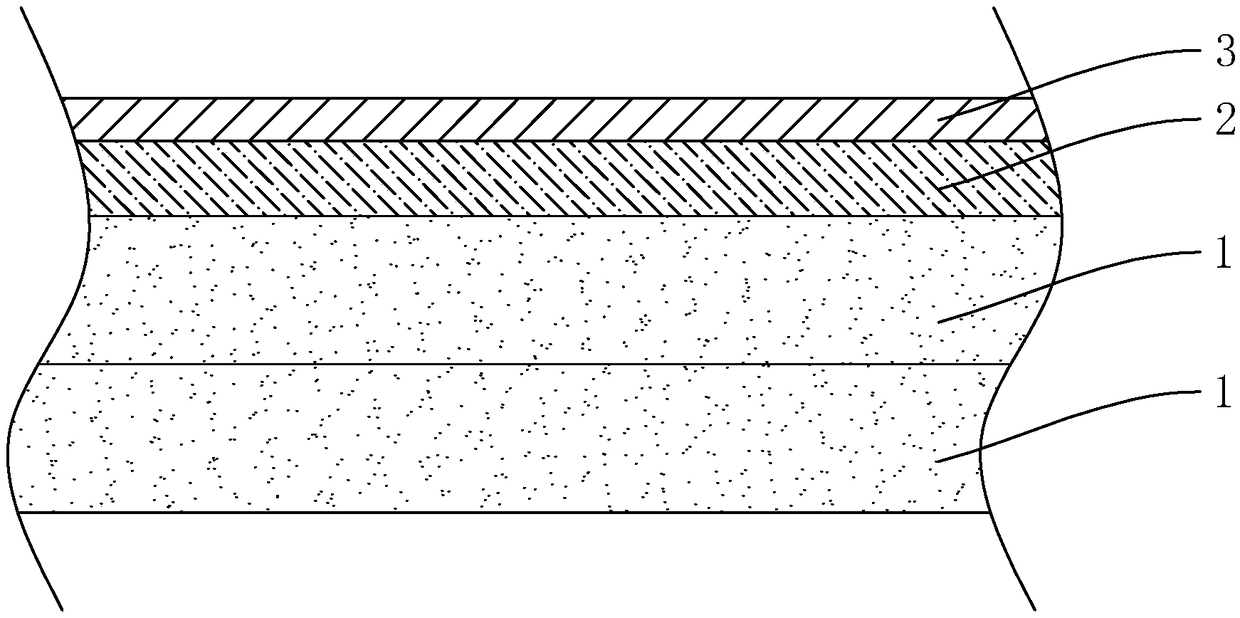

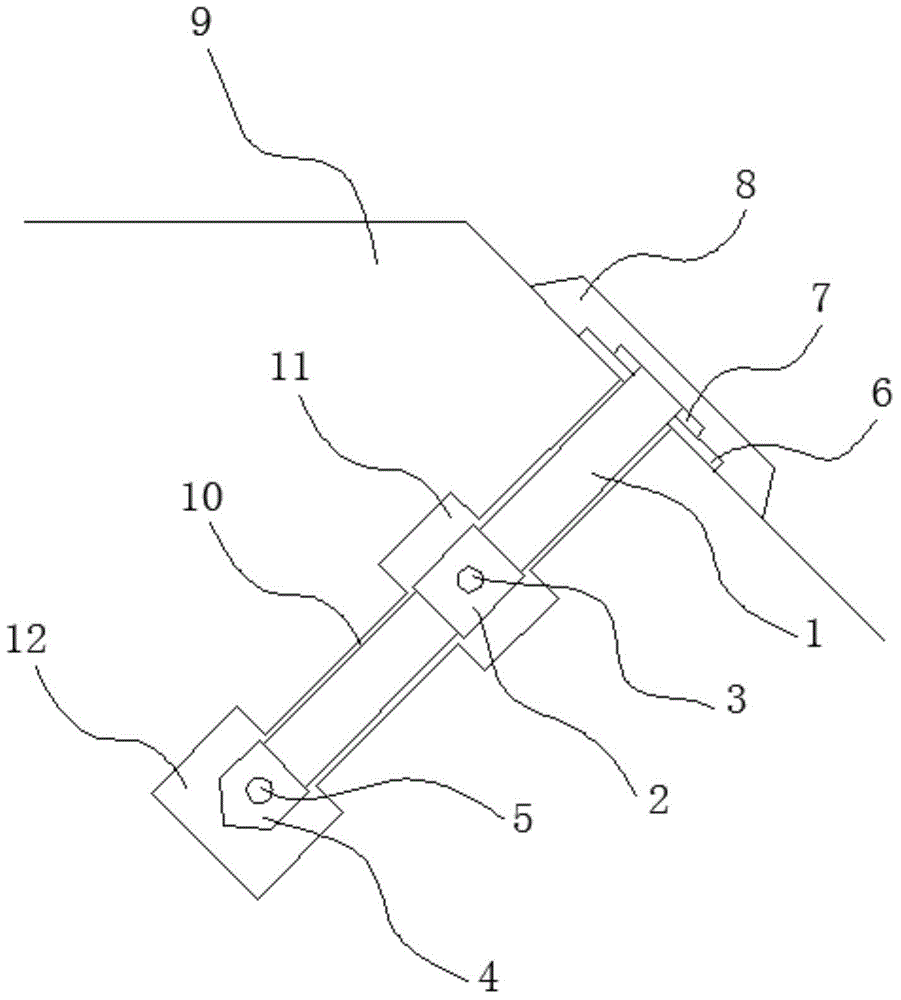

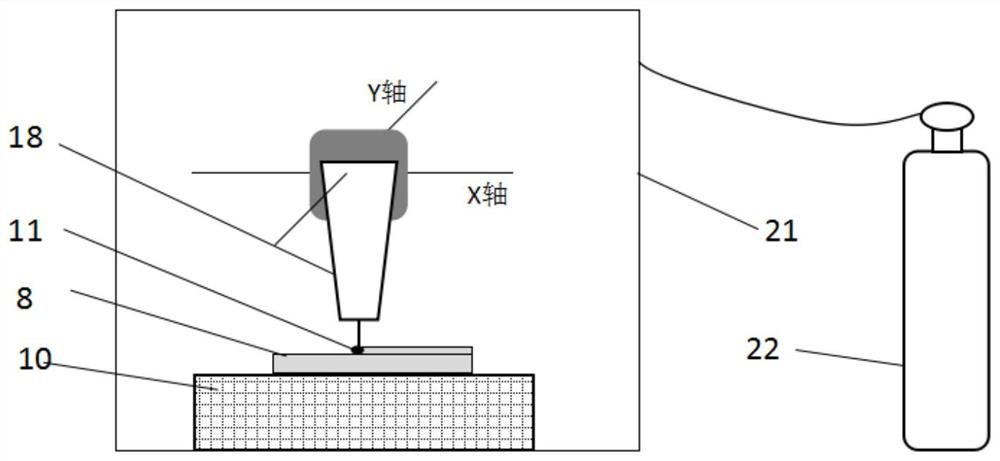

An ultrasonic-assisted multi-beam laser fuse additive manufacturing equipment and method

ActiveCN109530919BIncrease flexibilityAvoid interferenceLaser beam welding apparatusEngineeringLaser light

The invention discloses ultrasonic-assisted multi-beam laser wire-melting type additive manufacturing equipment. The equipment comprises a laser device, a wire feeding mechanism, a base plate, a wireguide head, an electromagnetic ultrasonic generator, an electromagnetic ultrasonic probe, a controller and a protective gas protection box, wherein the laser device comprises a laser light source, anoptical fiber and a laser head, the laser light source is connected with the laser head through the optical fiber, the electromagnetic ultrasonic generator is arranged at an inlet of the wire guide head, the electromagnetic ultrasonic probe is arranged on the base plate, and is used for receiving a vibration signal of an accumulated body and transmitting the vibration signal to the controller so that monitoring of a droplet transfer state in the additive manufacturing process can be realized, and the base plate, the wire guide head, the electromagnetic ultrasonic generator and the electromagnetic ultrasonic probe are all located in the protective gas protection box. According to the equipment, the flexibility of the additive manufacturing process can be greatly improved so that the accumulated layers are not prone to collapse, then the mechanical property of the accumulated body can be improved, the deformation can be inhibited, and the speed of the additive process can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

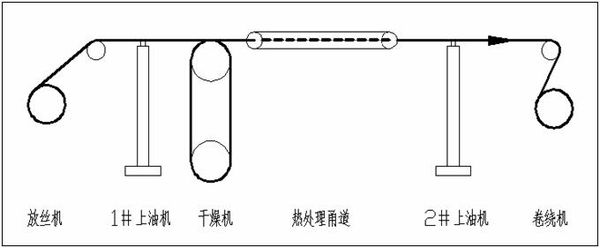

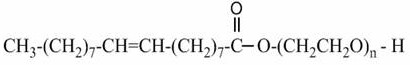

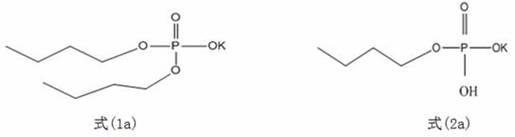

Secondary oiling agent treatment method of heterocyclic aramid

ActiveCN114075784AImprove mechanical propertiesReduce wearFibre typesHeating/cooling textile fabricsPolymer scienceSpinning

The invention discloses a secondary oiling agent treatment method for heterocyclic aramid fibers, and belongs to the technical field of chemical fibers. In a spinning process, first-stage oiling agent treatment is carried out on a heterocyclic aramid precursor, drying and heat treatment are carried out, then second-stage oiling agent treatment is carried out, and then the heterocyclic aramid fiber is wound and formed. The first-stage oiling agent is prepared from isooctyl stearate, fatty alcohol potassium phosphate, polyethylene glycol monooleate and polyoxyethylene sorbitan monooleate; and the second-stage oil agent is prepared from lauryl amine polyoxyethylene ether, dioctyl sodium sulfosuccinate and polyoxyethylene ether sorbitan monooleate. The heterocyclic aramid fiber finished silk fiber treated by two-stage different oil agents is small in mechanical property loss in the forming processing process and good in weaving performance and can be used for preparing high-quality woven cloth, meanwhile, the warp-wise tensile strength and the weft-wise tensile strength of the woven cloth reach 20.3 KN / 5cm and 21.5 KN / 5cm respectively, and the heterocyclic aramid fiber finished silk fiber is suitable for manufacturing high-tech products such as bulletproof chips, aircraft skins and linear motors.

Owner:中蓝晨光化工有限公司 +1

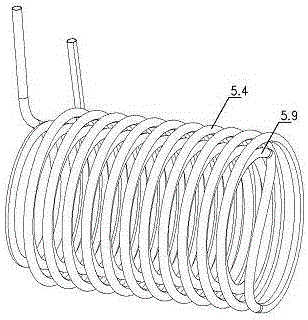

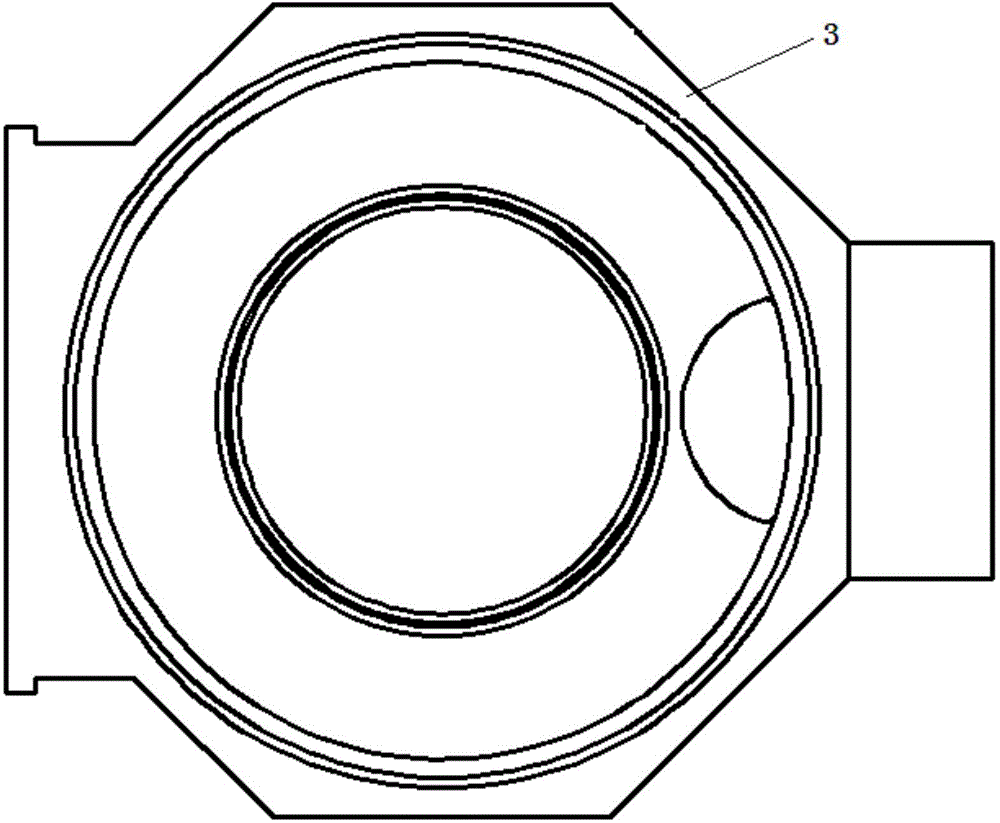

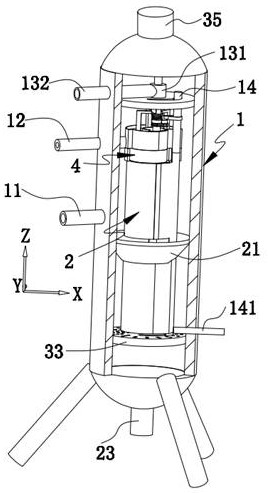

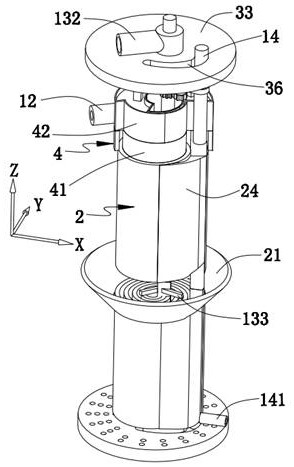

Polycondensation vacuum reaction system for flame-retardant slice production and production process

PendingCN114797732AIncrease film forming areaHigh film forming efficiencyChemical/physical/physico-chemical stationary reactorsPressure/vacuum vesselsReaction rateCoil spring

The invention relates to the technical field of flame-retardant slice production, in particular to a condensation polymerization vacuum reaction system for flame-retardant slice production and a production process. The hollow coil spring is arranged in the kettle body; the feeding pipe extends into the kettle body and is used for conveying materials to the upper end of the hollow coil spring so as to enable the materials to flow downwards along the side wall of the hollow coil spring; the first pipe and the second pipe are respectively communicated with two ends of the hollow coil spring and are matched to drive the hollow coil spring to contract and contract so as to promote heat exchange between fluid in the hollow coil spring and materials; the device has the advantages of high heat exchange efficiency, high polymerization reaction rate, high byproduct discharge rate and high product yield.

Owner:浙江安吉骏逸新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com