Aluminum alloy thin water channel cover plate and thick vacuum cavity water channel welding technology

A technology of vacuum chamber and welding process, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the difficulty of welding aluminum alloy vacuum chamber water channels and the low success rate of aluminum alloy vacuum chamber water channel welding and other problems to achieve the effect of ensuring the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

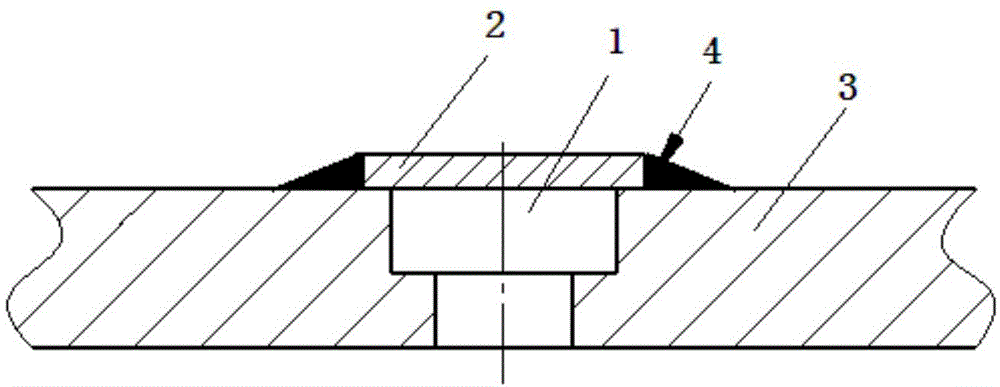

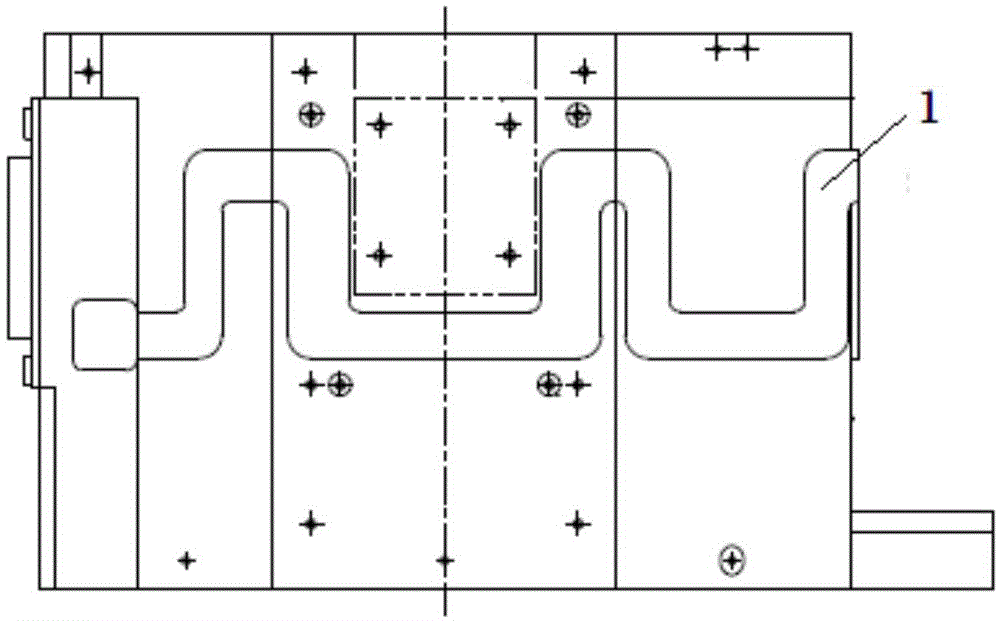

[0025] Embodiment: The aluminum alloy thin waterway cover plate and the thick vacuum cavity waterway welding process of the present invention include the following steps:

[0026] (1) Carry out the following treatment before gas shielded welding: use acetone to clean the groove of the weldment and the dirt within 30-50mm from both sides of the groove, wipe the welding wire with a stainless steel wire brush, and preheat the waterway cover and vacuum chamber 180~240℃, to ensure uniform preheating temperature, which is conducive to the full overflow of pores;

[0027] (2) During the welding process of gas shielded welding: control the line energy input, and control the welding line energy at 20-25kJ / cm to avoid burn-through; avoid arc starting and closing at corners; try to maintain symmetrical welding to control water channel deformation ;The ambient temperature is controlled above 16-25°C, the humidity is controlled at 20%-60%, and the generation of pores is controlled; the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com