Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Excellent tensile strength performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

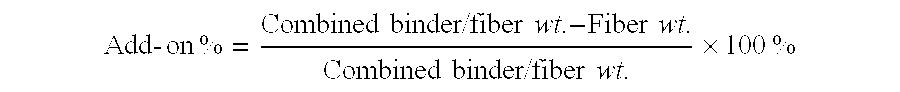

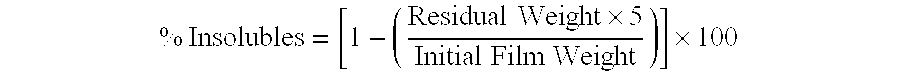

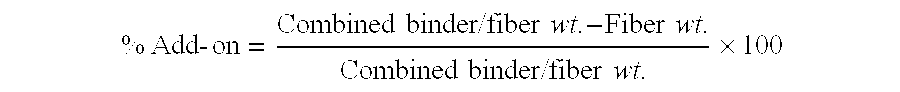

High strength polyvinyl acetate binders

InactiveUS20070184732A1Excellent tensile strength performanceEasy curingFibre treatmentSynthetic resin layered productsMonomer compositionEmulsion

A binder composition for fibrous substrates that includes a low-pressure polymerized emulsion resin comprising vinyl acetate monomer units and post-crosslinking monomer composition. The inventive compositions enable fibrous substrates with high tensile strengths and excellent curability, and are particularly useful as binders in synthetic fiberfill applications.

Owner:CELANESE INT CORP

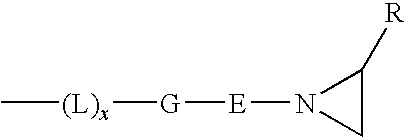

Composition containing aziridino groups, method of production and use thereof

InactiveUS8017666B2Excellent tensile strength performanceIncreasing aziridino functionalityImpression capsDental impression compositionsEquivalent weightMethods of production

The invention relates to a composition comprising a prepolymer as component (A), wherein the prepolymer comprises aziridino groups and is characterized by an equivalent weight EW1, a crosslinker as component (B), wherein the crosslinker has a structure being different from the structure of the prepolymer and comprises at least three 2-alkyl-substituted aziridino groups and is characterized by an equivalent weight EW2, an initiator as component (C) being able to start curing of the composition, optionally filler(s) as component (D) and optionally additive(s) as component (E), wherein equivalent weight is defined as (molecular mass of the molecule) / (number of aziridino groups present in the molecule) and wherein EW1>EW2. The invention also relates to the use of the composition for coating, sealing, molding, adhering, making impressions, producing a dental material.

Owner:3M INNOVATIVE PROPERTIES CO

Tube and golf club with handle made of said tube

InactiveUS6514156B1Increase elasticityReduce weightSnowboard bindingsLayered productsEngineeringGolf Ball

The tube (6) comprises a wall which is composed of a plurality of layers (2; 3; 5; 4). Longitudinally extending wires (3) are provided in the wall. At least one layer (2, 4) which is wound over the circumference of the tube (6) is present inside and / or outside with respect to the longitudinally extending wires (3).

Owner:ZORZI SILVANO

Powder metallurgy bearing material and preparation method thereof

InactiveCN103537668AImprove wear resistanceImprove the lubrication effectMicrocrystalline waxGeometric stability

The invention discloses a powder metallurgy bearing material. The powder metallurgy bearing material is characterized by being composed of, by weight, 5.2-5.5 parts of tungsten, 2.1-2.3 parts of cobalt, 5.7-5.9 parts of nickel, 1.2-1.5 parts of titanium, 0.2-0.5 part of boron, 72-75 parts of ferrum, 3.2-3.5 parts of silicon, 1.2-1.4 parts of graphite, 1.7-1.9 parts of manganese, 5.2-5.6 parts of chromium, 2.3-2.5 parts of zinc stearate, 1.2-1.4 parts of microcrystalline wax, 0.4-0.5 part of tungsten carbide, 0.2-0.4 part of titanium carbide and 1-2 parts of auxiliary agents. The graphite is added to raw materials of the powder metallurgy bearing material, so that abrasion resistance and lubricity of a bearing are enhanced, and the bearing made of the powder metallurgy bearing material is compact in structure and good in microstructure, has very few holes, and has excellent structural rigidity, hardness, fatigue resistance and tensile strength; addition of the nickel enhances toughness and the elasticity modulus of alloy, thereby playing a prominent role in guaranteeing geometric stability of the bearing.

Owner:WUHU HONGKUN AUTO PARTS

Manufacturing method for aluminum alloy air cylinder cover

InactiveCN107338387AHigh hardnessImprove wear resistanceTransportation and packagingMetal-working apparatusRare-earth elementNanoparticle

The invention discloses a manufacturing method for an aluminum alloy air cylinder cover. The manufacturing method includes the following steps that raw materials are weighed according to weight parts, then the above materials are mixed, are stirred for 10 min to 15 min under the temperature of 40 DEG C to 50 DEG C and are then loaded into a die to be pressed into a blank; then the blank is put into a sintering furnace to be sintered under the nitrogen atmosphere shield; and finally, the pressed blank is sent into a steam treatment furnace, steam is led into the furnace for 60 min to 90 min under the condition that the temperature in the furnace ranges from 200 DEG C to 300 DEG C, and then the pressed blank is obtained through air cooling. The aluminum alloy air cylinder manufactured through the method is high in hardness and good in wear resistance, rare earth elements and nano particles are matched, the metallographic phase structure is improved, the tissue is compact, the microstructure is good, pores are very few, and the structure rigidity and hardness, the fatigue resistance and the tensile strength are good.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Composition containing aziridino groups, method of production and use thereof

InactiveUS20100227945A1Improve propertyExcellent tensile strength performanceImpression capsDental impression compositionsPrepolymerChemistry

The invention relates to a composition comprising a prepolymer as component (A), wherein the prepolymer comprises aziridino groups and is characterized by an equivalent weight EW1, a crosslinker as component (B), wherein the crosslinker has a structure being different from the structure of the prepolymer and comprises at least three 2-alkyl-substituted aziridino groups and is characterized by an equivalent weight EW2, an initiator as component (C) being able to start curing of the composition, optionally filler(s) as component (D) and optionally additive(s) as component (E), wherein equivalent weight is defined as (molecular mass of the molecule) / (number of aziridino groups present in the molecule) and wherein EW1>EW2. The invention also relates to the use of the composition for coating, sealing, moulding, adhering, making impressions, producing a dental material.

Owner:3M INNOVATIVE PROPERTIES CO

High-strength adhesive

InactiveCN102020950AHigh bonding strengthImprove toughnessNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention relates to the technical field of adhesives, in particular to an adhesive used in the field of diving and boat supplies. The high-strength adhesive comprises the following constituents in percentage by mass: 60-85 percent of natural 3L rubber, 5-9 percent of accelerant, 15-20 percent of filler, 1-3 percent of vulcanizer and 0.5-1.5 percent of tackifier, wherein the accelerant is a mixture composed of a vulcanizing accelerant, an antioxidant, an antiager and polyethylene glycol. In the invention, the natural rubber is adopted to serve as a major ingredient of the adhesive, so that the adhesive has high tensile strength, protects the environment and enhances the stability; various accelerants are chosen in the formula for synergistic action to ensure that the adhesive body has the special effect of seawater resistance; and white smoke is served as the filler to ensure that the gluewater has uniform hardness degree and withstands high temperature. The tension of the adhesive is 4-6KG, and the tensile strength performance is excellent.

Owner:CHINADIVE WATERSPORTS INC

Powder metallurgy valve seat and preparation method thereof

The invention discloses a powder metallurgy valve seat, which is characterized in that the valve seat is made of the following raw materials in parts by weight: 3.1-3.2 parts of copper, 6.1-6.4 parts of molybdenum, 6.1-6.2 parts of nickel, 1.1-1.4 parts of molybdenum disulfide, 1.1-1.5 parts of graphite, 86-88 parts of iron powder, 7.2-7.4 parts of Mg, 3.5-3.8 parts of Ti, 1.2-1.5 parts of V, 0.52-0.66 parts of Ta, 0.1-0.2 parts of Pd and 2-3 parts of assistant. The graphite is added into the raw materials, so that the wear resistance and the lubricating property of a shaft sleeve are improved, and the manufactured shaft sleeve is compact in tissue, good in microstructure, very small in pore, and excellent in structural stiffness, hardness, fatigue performance and tensile strength; a process of adding lead powder is omitted, so that the pollution to the environment is reduced, the valve seat can be applied to a lead-free gasoline engine, and the service life of the valve seat is prolonged.

Owner:TONGLING GUOFANG PLUMBING TECH

Powder metallurgy antifriction bearing and preparation method thereof

InactiveCN103602909AImprove wear resistanceImprove the lubrication effectTurbinesOther manufacturing equipments/toolsBoridePorosity

The invention discloses a powder metallurgy antifriction bearing. The bearing is characterized in that: the bearing is prepared from following raw materials in parts by weight: 0.6-0.8 of graphite, 1.2-1.3 of copper, 2.1-2.3 of silicon, 5.7-5.9 of manganese, 10.2-10.7 of chromium, 0.2-0.3 of molybdenum, 1.2-1.3 of titanium, 0.2-0.3 of titanium diboride, 0.2-0.3 of niobium boride, 0.3-0.4 of V2O5, 2-3 of zinc stearate, 89-91 of waste steel powder and 1-2 of an additive; the graphite is added in the raw materials, thus enhancing the wear resistance and lubricating property of the bearing; the bearing has compact structure, good microstructure, small porosity, and excellent structural stiffness, hardness, antifatigue performance and tensile strength; and the bearing is wear resistant and corrosion resistant, and is low in noise.

Owner:江苏古沙农业科技发展有限公司

Powder-metallurgy automobile booster pump stator and manufacturing method thereof

InactiveCN103537669AImprove wear resistanceImprove the lubrication effectTurbinesOther manufacturing equipments/toolsManganeseStearic acid

The invention discloses a powder-metallurgy automobile booster pump stator. The powder-metallurgy automobile booster pump stator is characterized by being composed of, by weight, 12-13 parts of molybdenum powder, 1-2 parts of copper powder, 1-2 parts of graphite powder, 2-3 parts of zinc stearate, 1-2 parts of molybdenum disulfide, 3.1-3.4 parts of zinc, 81-82 parts of iron powder, 6.6-7.2 parts of manganese, 7.4-7.8 parts of nickel, 4.2-4.3 parts of chromium and 2-3 parts of auxiliary agents. Graphite is added to raw materials of the powder-metallurgy automobile booster pump stator, so that abrasion resistance and lubricity of the powder-metallurgy automobile booster pump stator are enhanced; besides, the structure is compact, the microstructure is good, very few holes are formed, and structural rigidity, hardness, fatigue resistance and tensile strength are excellent; in addition, the problem that the shape of the automobile booster pump stator is complex is solved.

Owner:WUHU HONGKUN AUTO PARTS

Powder metallurgy engine oil delivery pump rotor and manufacturing method thereof

The invention discloses a powder metallurgy engine oil delivery pump rotor. The powder metallurgy engine oil delivery pump rotor is characterized by being manufactured from, by weight, 0.2-0.3 part of powdered sulphur, 9-10 parts of zinc powder, 3-4 parts of molybdenum powder, 2-3 parts of copper powder, 13.5-14.5 parts of Ni, 24-25 parts of Cr, 3-4 parts of Mo, 48-51 parts of iron powder and 2-3 parts of auxiliaries. According to the powder metallurgy engine oil delivery pump rotor, the hardness of the surface of the rotor is effectively improved, a friction coefficient is lowered, abrasion resistance of the rotor is substantially improved, the rotor is excellent in structural rigidity, hardness, fatigue resistance and tensile strength performance, production cost is lowered, and quality of the product and economical benefits can be improved.

Owner:WUHU HONGKUN AUTO PARTS

High-aluminum-based composite material applied to automobile bearings

The invention discloses a high-aluminum-based composite material applied to automobile bearings. The high-aluminum-based composite material is prepared from the following raw materials in parts by weight: 85-90 parts of aluminum, 5-8 parts of zinc, 3-4 parts of bismuth, 1-2 parts of magnesium, 0.5-1 part of arsenic, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methylcellulose, 1-1.5 parts of graphite, 1.5-2 parts of benzotriazole, 1-1.2 parts of caprolactam, 0.5-0.7 part of phosphorus pentoxide and a proper amount of oleic acid. The high-aluminum-based composite material is few in holes, excellent in structural stiffness, hardness, fatigue resistance performance and tensile strength performance, free of lead, low pollution to environment and simple in production steps; the production efficiency is improved.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

Powder metallurgy bearing steel and preparation method thereof

ActiveCN103540854AImprove wear resistanceImprove the lubrication effectMicrocrystalline waxIron powder

The invention discloses powder metallurgy bearing steel and a preparation method thereof. The powder metallurgy bearing steel is prepared from 0.2-0.3 parts by weight of graphite, 0.1-0.2 parts by weight of silicon, 3.1-3.3 parts by weight of manganese, 6.7-6.9 parts by weight of chromium, 0.7-0.9 parts by weight of copper, 0.3-0.4 parts by weight of W2B, 0.1-0.2 parts by weight of SnO2, 0.4-0.45 parts by weight of V2O5, 0.1-0.2 parts by weight of Te, 0.3-0.4 parts by weight of ZrO2, 3.2-3.4 parts by weight of microcrystalline wax, 87-89 parts by weight of iron powder and 1-2 parts by weight of an assistant. Through use of graphite, bearing steel wear resistance and lubricity are improved. The powder metallurgy bearing steel has a compact and good microstructure, less apertures, good structural rigidity, good hardness, fatigue resistance and good tensile strength. The preparation method produces less pollution on the environment, has simple processes and improves production efficiency.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Rare earth-containing aluminum alloy for vacuum pump rotor and preparation method thereof

ActiveCN106480344BSmall coefficient of thermal expansionSmall expansion coefficientVacuum pumpHeat treated

The invention relates to a rare-earth-containing aluminum alloy for a rotor of a vacuum pump and a preparation method thereof, belongs to the technical field of alloy materials, and particularly provides a Dy-containing aluminum alloy for the rotor of a vacuum pump and a preparation method thereof to solve existing problems that low expansion coefficient and high tensile strength cannot be achieved at the same time. The aluminum alloy is prepared from the following components in percentage by mass: 23-26 percent of Si, 0.8-2.4 percent of Cu, 0.2-0.8 percent of Mn, 2.0-3.0 percent of Ag, 0.7-1.5 percent of Y, 0.5-1.5 percent of Dy, 1.1-1.4 percent of Ni and the balance of Al. The preparation method comprises the following steps: melting raw materials according to the proportion of the raw materials; heating and casting to obtain as-casting aluminum alloy; and heating, solutionizing, cooling and performing aging treatment. The rare-earth-containing aluminum alloy has the effects of high tensile strength and low expansion coefficient.

Owner:江苏至臻环保科技集团有限公司

Preparing method for brake pad wear-resisting material

InactiveCN107335801AHigh hardnessImprove wear resistanceTransportation and packagingMetal-working apparatusXylyleneRare-earth element

The invention discloses a preparing method for a brake pad wear-resisting material. The brake pad wear-resisting material is composed of 45-55 parts of titanium powder, 5-9 parts of molybdenum disulfide, 10-20 parts of nanometer copper oxide, 3-10 parts of micro-wax powder, 15-19 parts of aluminum powder, 10-15 parts of copper iodide, 10-20 parts of stainless steel powder, 3-8 parts of auxiliaries, 3-6 parts of potassium oxide, 4-8 parts of silicon nitride, 1-3 parts of vanadium carbide and 5-8 parts of nickel silicide. The auxiliaries are composed of phenylacetic acid lauryl alcohol, xylylene diisocynate and sodium ferrate according to the weight ratio of 1:1:2. The brake pad wear-resisting material prepared through the method has high hardness and good wear resistance, rare earth elements and nano particles are matched, the metallographic phase structure is improved, the tissue is compact, the microscopic structure is good, holes are very few, the structure rigidity, hardness, fatigue resistance and tensile strength performance are good.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Power metallurgy automobile connecting bar and production method thereof

InactiveCN103551577AEvenly dispersedImprove wear resistanceTurbinesOther manufacturing equipments/toolsIron powderAlloy

The invention discloses a power metallurgy automobile connecting bar. The power metallurgy automobile connecting bar is characterized by being made with, by weight, 81-82 parts of iron powder, 0.8-1.2 parts of yttrium, 1.8-2.2 parts of graphite, 4.1-4.5 parts of Ti, 2.1-2.3 parts of Sr, 1.0-1.4 parts of Bi, 0.3-0.5 part of Ta, 0.1-0.3 part of Nd, and 2-3 parts of aid. The aid is added, so that alloy powder disperses evenly, lengthwise and breadthwise uniformity of the inside structure of products is guaranteed, and the fatigue lives of the products are prolonged; the graphite is added, wear resistance and lubricity of the connecting bar are improved, the produced products are compact in structure and good in microstructure, have few pores, and are excellent in structural rigidity, hardness, fatigue resistance and tensile strength.

Owner:WUHU HONGKUN AUTO PARTS

Powder-metallurgy oil-pump adjusting gear ring and manufacturing method thereof

The invention discloses a powder-metallurgy oil-pump adjusting gear ring. The powder-metallurgy oil-pump adjusting gear ring is characterized by being composed of, by weight, 70-72 parts of iron powder, 2-3 parts of copper powder, 0.5-1 part of zinc stearate, 3-4 parts of machine oil, 1-2 or 2-3 parts of graphite, 4-5 parts of cobalt, 9-10 parts of nickel, 1-2 parts of tin, 2-3 parts of graphitized tungsten and 2-3 parts of auxiliary agents. The graphite is added to raw materials of the powder-metallurgy oil-pump adjusting gear ring, so that abrasion resistance and lubricity of the adjusting gear ring are enhanced, the structure is compact, the microstructure is good, very few holes are formed, and structural rigidity, hardness, fatigue resistance and tensile strength are excellent; besides, because mould pressing is adopted, equipment is simplified, production cost is reduced, and production efficiency is improved.

Owner:WUHU HONGKUN AUTO PARTS

Powder metallurgy alloy gear and manufacturing method thereof

The invention discloses a powder metallurgy alloy gear. The powder metallurgy alloy gear is characterized by being manufactured from, by weight, 5.2-5.5 parts of Mg, 2.2-2.4 parts of copper, 74-75 parts of iron powder, 5.1-5.3 parts of Ti, 3.1-3.5 parts of Co, 0.3-0.5 part of As, 0.2-0.3 part of In and 2-3 parts of auxiliaries. Due to the fact that the auxiliaries are added, alloy powder is scattered evenly, the longitudinal and transverse evenness of the internal organizational structure of the product is guaranteed, and the fatigue life of the product is prolonged. The powder metallurgy alloy gear is good in microstructure, very few in pore, and excellent in structural rigidity, hardness, fatigue resistance and tensile strength performance, simple in process and easy to obtain, and the production efficiency is improved.

Owner:WUHU HONGKUN AUTO PARTS

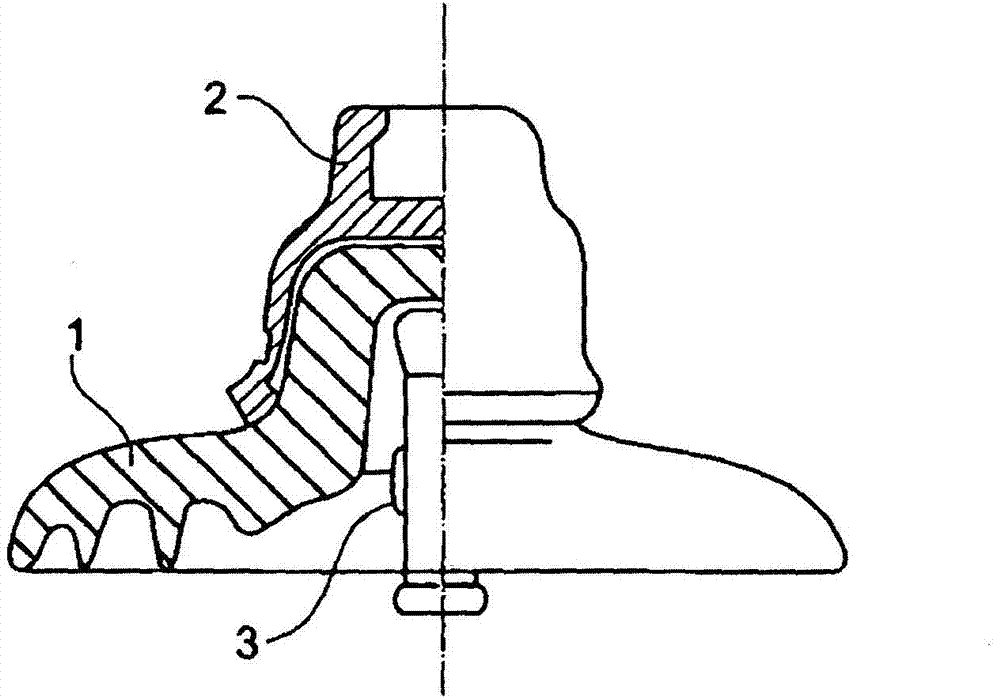

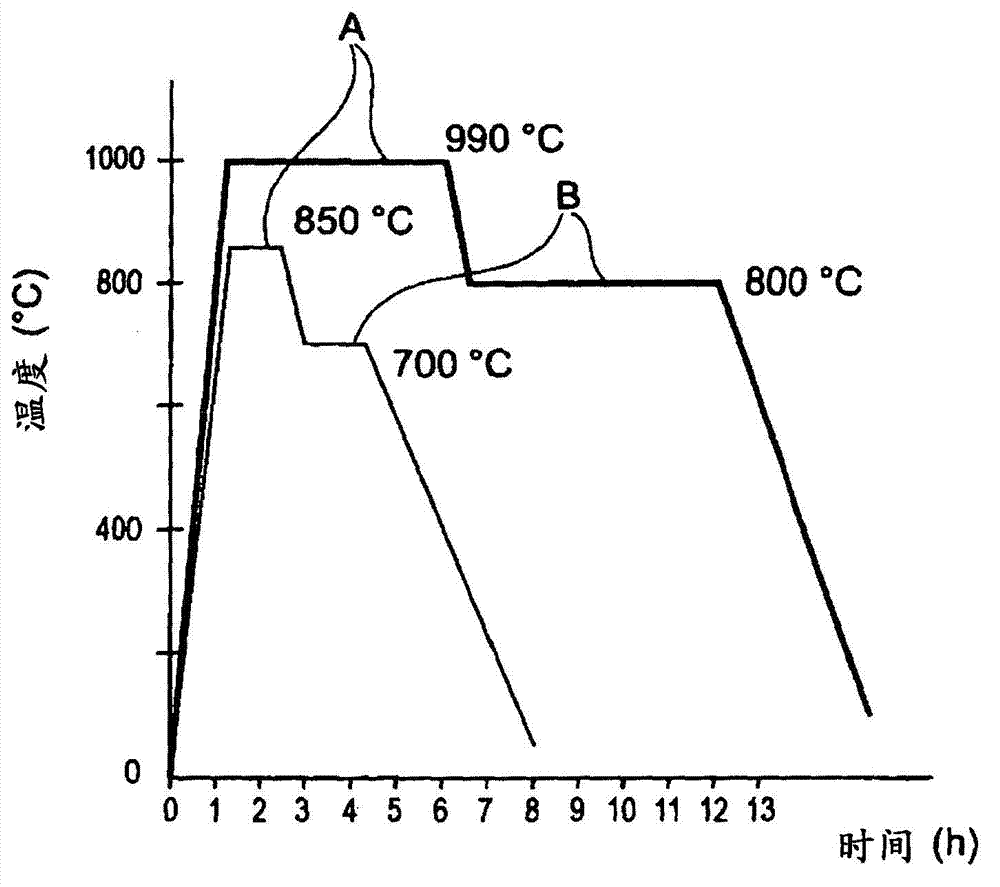

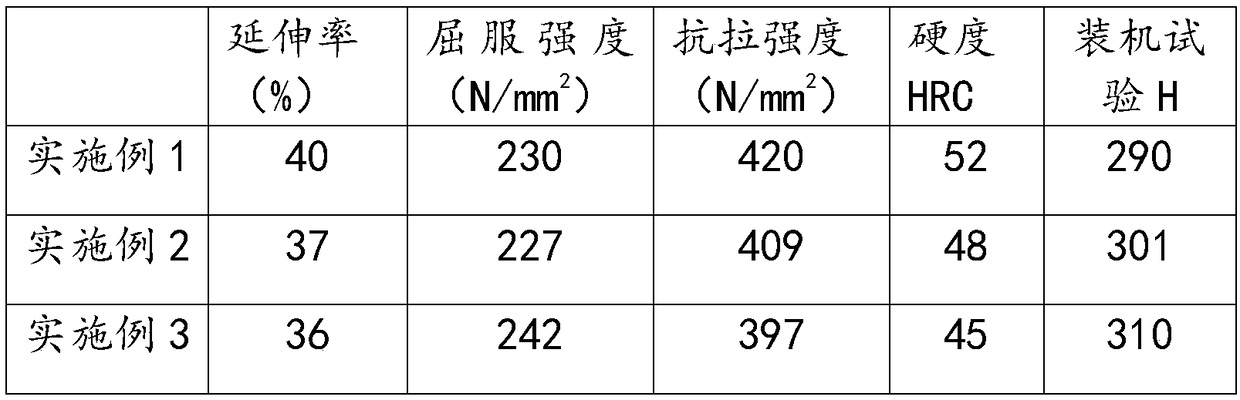

Process for manufacturing a casting made of ductile cast iron for a high-voltage insulator fitting

InactiveCN103098148AExcellent tensile strength performanceGood impact strength propertiesSuspension/strain insulatorsManganeseDuctile iron

The process for manufacturing a casting for a high-voltage insulator fitting, by casting a ductile cast iron that contains proportionally between 3.2% and 3.7% carbon, between 1.9% and 2.5% silicon, between 0.1% and 0.5% manganese and between 0.04% and 0.08% phosphorus, comprises the following steps: the casting is cast with a greater than 85% degree of nodularization in a mould; and, after removal from the mould, the casting undergoes a two-step ferritization heat treatment whereby the casting is heated at a temperature of between 850 DEG C and 990 DEG C for a time of between 1 and 5 hours and then cooled to a temperature of between 700 DEG C and 800 DEG C for a time of between 2 and 6 hours.

Owner:SEDIVER SOC EURO DISOLATEURS & VERRE & COMPOSITE

Repair method for automobile motor rotor

ActiveCN106256465AImprove wear resistanceImprove the lubrication effectFriction reductionEngineering

The invention discloses a repair method for an automobile motor rotor and belongs to the technical field of motor part repair. The repair method includes the following steps of material mixing; primary dry-pressing; secondary dry-pressing; sintering; heat treatment; shaping. Graphite is added into raw materials, so that the abrasion resistance and lubricity of the rotor are improved, friction resistance is reduced, the efficiency of a motor is improved, and the density and hardness of the rotor are improved; the motor rotor manufactured from mixed powder in the formula is dense in structure, good in micro-structure, fewer in pore and excellent in structural rigidity, hardness, fatigue resistance and tensile strength; due to the adoption of die pressing, equipment is simplified, and the production cost is reduced.

Owner:海宁市洛溪实业发展有限公司

A kind of powder metallurgy bearing steel and preparation method thereof

ActiveCN103540854BImprove wear resistanceImprove the lubrication effectMicrocrystalline waxManganese

The invention discloses a powder metallurgy bearing steel, which is characterized in that it is made of the following raw materials in parts by weight: graphite 0.2-0.3, silicon 0.1-0.2, manganese 3.1-3.3, chromium 6.7-6.9, copper 0.7-0.9, boron Ditungsten 0.3‑0.4, SnO 2 0.1‑0.2, V 2 o 5 0.4‑0.45, Te 0.1‑0.2, ZrO 2 0.3‑0.4, microcrystalline wax 3.2‑3.4, iron powder 87‑89, auxiliary agent 1‑2; graphite is added to the raw materials of the present invention, which increases the wear resistance and lubricity of bearing steel, and the manufactured bearing steel has a dense structure and microscopic The structure is good, the pores are few, and the structure rigidity, hardness, fatigue resistance and tensile strength are excellent; the invention has little environmental pollution, simple production steps and improved production efficiency.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

A powder metallurgy rolling bearing and its preparation method

InactiveCN103602909BImprove wear resistanceImprove the lubrication effectTurbinesOther manufacturing equipments/toolsBoridePorosity

The invention discloses a powder metallurgy antifriction bearing. The bearing is characterized in that: the bearing is prepared from following raw materials in parts by weight: 0.6-0.8 of graphite, 1.2-1.3 of copper, 2.1-2.3 of silicon, 5.7-5.9 of manganese, 10.2-10.7 of chromium, 0.2-0.3 of molybdenum, 1.2-1.3 of titanium, 0.2-0.3 of titanium diboride, 0.2-0.3 of niobium boride, 0.3-0.4 of V2O5, 2-3 of zinc stearate, 89-91 of waste steel powder and 1-2 of an additive; the graphite is added in the raw materials, thus enhancing the wear resistance and lubricating property of the bearing; the bearing has compact structure, good microstructure, small porosity, and excellent structural stiffness, hardness, antifatigue performance and tensile strength; and the bearing is wear resistant and corrosion resistant, and is low in noise.

Owner:江苏古沙农业科技发展有限公司

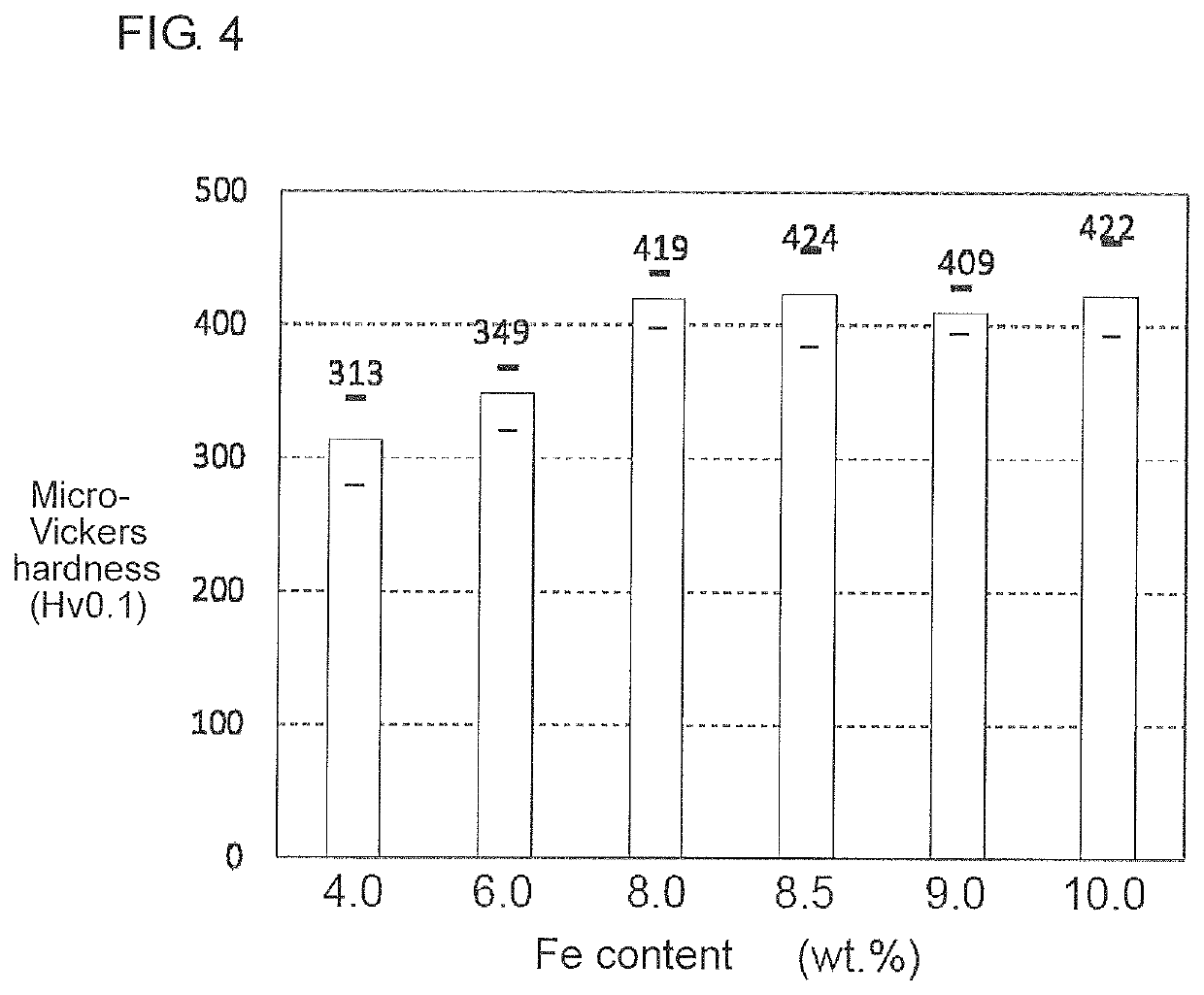

Ti—Fe-based sintered alloy material and method for producing same

ActiveUS11084093B2Excellent tensile strength performanceImprove ductilityEquiaxed crystalsCrystallite

Owner:KONDOH KATSUYOSHI +1

Nano macromolecular antistatic paint

InactiveCN107118651AImprove tear resistanceImprove puncture resistanceAntifouling/underwater paintsPaints with biocidesEpoxyDiacetone alcohol

Belonging to the technical field of building materials, the invention relates to a nano macromolecular antistatic paint. The nano macromolecular antistatic paint is prepared from the following components by weight: 15-25 parts of acetate, 50-60 parts of benzene-free epoxy resin, 20-26 parts of conductive diacetone alcohol, 2-5 parts of titanium dioxide, 8-12 parts of a conductive assistant, 2-8 parts of conductive zinc oxide, 5-10 parts of nano-antibacterial titanium dioxide, 25-27 parts of heavy calcium carbonate, 8-10 parts of filler, 0.6-0.8 part of a dispersant, 0.3-0.8 part of a defoaming agent, 0.1-0.5 part of a thickening agent, and 3-5 parts of nano carbon powder. The nano macromolecular antistatic paint provided by the invention has the advantages of stable quality, good use effect, good acid resistance, alkali resistance, strong adhesive force, and low production cost, thus having good market prospect.

Owner:张加芸

A method for repairing the rotor of an automobile motor

The invention discloses a repair method for an automobile motor rotor and belongs to the technical field of motor part repair. The repair method includes the following steps of material mixing; primary dry-pressing; secondary dry-pressing; sintering; heat treatment; shaping. Graphite is added into raw materials, so that the abrasion resistance and lubricity of the rotor are improved, friction resistance is reduced, the efficiency of a motor is improved, and the density and hardness of the rotor are improved; the motor rotor manufactured from mixed powder in the formula is dense in structure, good in micro-structure, fewer in pore and excellent in structural rigidity, hardness, fatigue resistance and tensile strength; due to the adoption of die pressing, equipment is simplified, and the production cost is reduced.

Owner:海宁市洛溪实业发展有限公司

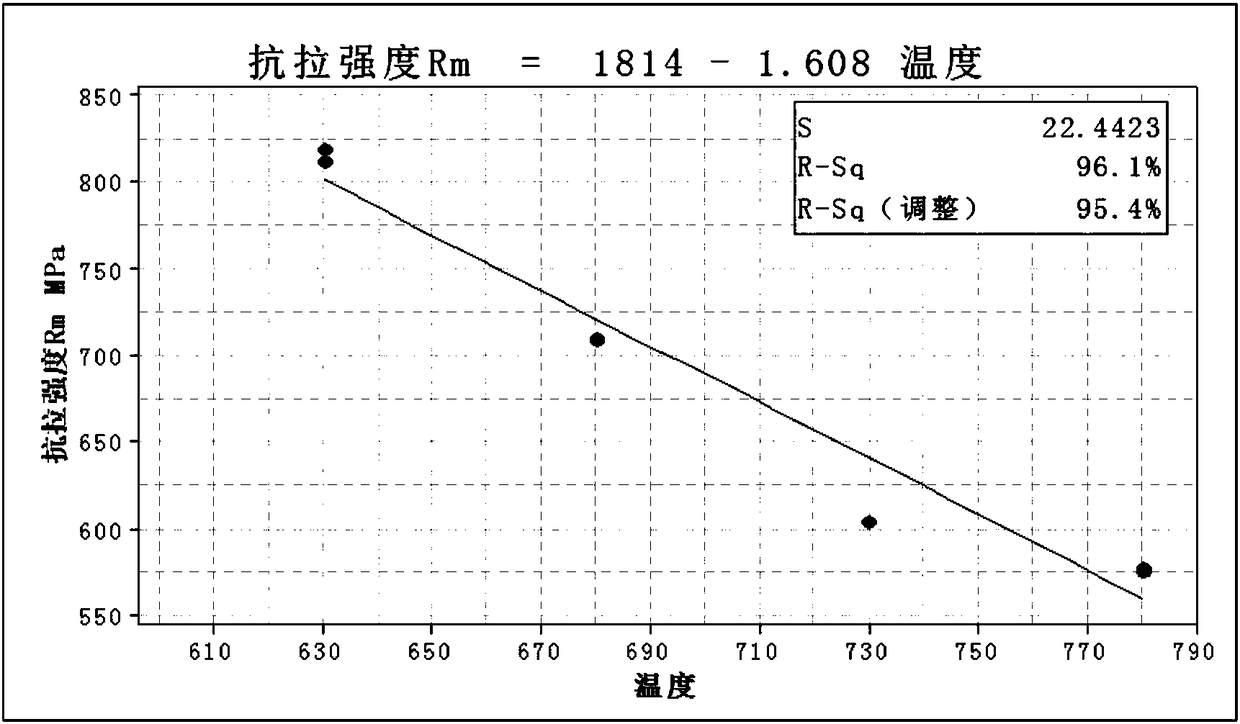

A control method of room temperature and high temperature mechanical properties of zg15cr2mo1 material

ActiveCN106947918BEffective process optimization and control of mechanical propertiesExcellent tensile strength performanceFurnace typesHeat treatment furnacesRoom temperatureMechanical property

The invention relates to the field of material mechanical property performance optimization control processes, in particular to a control method for room-temperature and high-temperature mechanical properties of a ZG15CR2Mo1 material. The control method is characterized in that the physical properties, a phase transformation point and a CCT curve of the ZG15CR2Mo1 material are carefully and deeply researched; through methods of making different thermal treatment processes, detecting and analyzing material characteristics, optimizing the thermal treatment process, researching influences, on properties, of chemical components, optimizing the chemical components and the like, a thermal treatment process and a chemical component control method, which meet the room-temperature and high-temperature mechanical properties of the ZG15Cr2Mol material, are made; a ZG15Cr2Mol material product with stable quality is produced by sampling, tempering process optimizing, annealing process optimizing, chemical component optimizing, result verifying, and finished product producing, so that stable control needs on the mechanical properties of the ZG15CR2Mo1 material are met, and therefore, the produced material can meet the use needs of the specific mechanical properties.

Owner:KOCEL EQUIP

Powder metallurgy abrasion-resistant corrosion-resistant bearing material and preparing method thereof

InactiveCN108031833AHigh temperature resistance hasHigh hardnessTransportation and packagingMetal-working apparatusTitanium carbideVanadium carbide

The invention discloses a powder metallurgy abrasion-resistant corrosion-resistant bearing material. The powder metallurgy abrasion-resistant corrosion-resistant bearing material is characterized in that the powder metallurgy abrasion-resistant corrosion-resistant bearing material is made of the following raw materials of, by weight, 0.4-0.6 part of vanadium carbide, 0.2-0.3 part of chromium carbide, 0.5-0.8 part of graphite, 2.0-3.2 parts of molybdenum powder, 9.4-9.6 parts of nickel powder, 0.15-0.25 part of silicon carbide, 0.2-0.3 part of tantalum carbide, 2-3 parts of polyethylene wax powder, 93-94 parts of iron powder and 1-2 parts of additives. The corrosion-resistant high-temperature-resistant bearing material is made by adding titanium carbide, vanadium carbide, chromium carbide,nickel, molybdenum and graphite, and has the characteristics of being high in hardness, not prone to deforming, high in corrosion resistance, resistant to high temperature, resistant to corrosion andthe like, the structural stiffness, hardness, fatigue resistance and tensile strength performance are excellent, and the powder metallurgy abrasion-resistant corrosion-resistant bearing material is suitable for the high-temperature abrasion environment.

Owner:余姚市奥祥轴承有限公司

A kind of hesperidin waterproof coating

The invention discloses a hesperidin waterproof coating, which is composed of the following raw materials in parts by weight: silicon acrylic emulsion 63-71.4, hesperidin 0.1-0.2, linoleic acid 1-2, aminopropyl triethyl Oxysilane 0.4-1, Alkanolamide 0.2-0.4, Potassium Hydrogen Sulfate 1-2, Borax 2-3, Zinc Dihydrogen Phosphate 1-2, Ethylene Glycol Dimethacrylate 2-3, Quasi-Spherical Silicon Micropowder 10-14, propylene alcohol 1-2, carboxylic acid glyceride 1-2, film-forming aid 5-8, deionized water 10-17, the waterproof coating of the present invention has excellent waterproof performance, high strength, and its bonding Good strength and tensile strength, stable coating film, strong anti-leakage, strong anti-peeling, not easy to foam and fall off, strong adhesion, friendly to the environment, and simple construction.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Ti-Fe-BASED SINTERED ALLOY MATERIAL AND METHOD FOR PRODUCING SAME

ActiveUS20190375017A1Improve ductilityExcellent tensile strength performanceEquiaxed crystalsArea ratio

A Ti—Fe-based sintered alloy material including two phases of an α phase and a β phase, in which a content of iron is 0.5% or more and 7% or less on a weight basis, a β phase containing an iron component is dispersed in an independent state in an α phase, an area ratio of the β phase containing an iron component is 60% or less of an entire area, and an equiaxed crystal grain is contained in the α phase.

Owner:KONDOH KATSUYOSHI +1

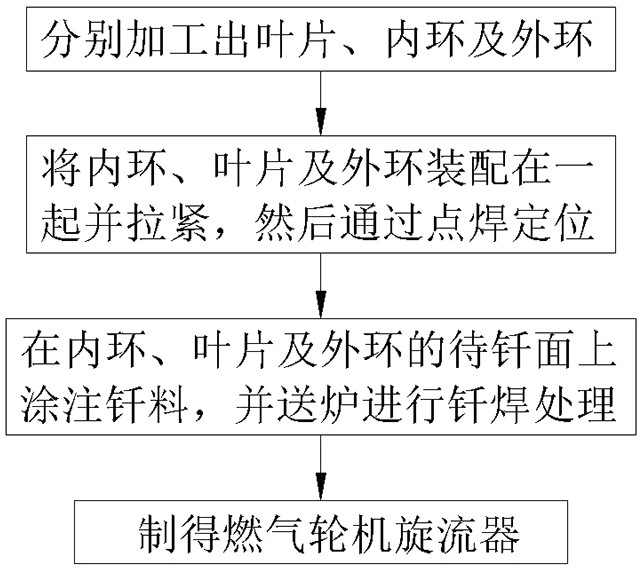

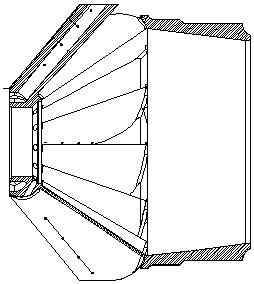

Preparation method of gas turbine swirler

ActiveCN113664466AExcellent tensile strength performanceShorten the processing cycleGas turbinesStructural engineering

The invention belongs to the technical field of precision machining, and discloses a preparation method of a gas turbine swirler, which is characterized in that the gas turbine swirler is decomposed into three parts, namely an inner ring, an outer ring and blades, then the inner ring, the outer ring and the blades are independently formed by adopting a machining method, and then the inner ring, the outer ring and the blades are connected by adopting a brazing method. In order to guarantee the brazing quality, a mounting head is machined on the heads of the blades a blade-shaped groove is correspondingly machined in the inner ring, a bayonet is correspondingly machined in the outer ring, then the outer ring, the blades and the inner ring are tensioned through an assembly tool to guarantee that brazing faces are tightly attached, spot welding is used for positioning, and the blades are conveyed into a furnace to be subjected to vacuum brazing after being completed. The roughness of the inner wall of the hollow blade is guaranteed by splitting the structure of the swirler and combining with independent machining, the tensile strength performance of brazing seams between the blades and the inner ring and the brazing seams between the blades and the outer ring is excellent under the room temperature and high temperature environment, the strength performance is better than that of base metal, the performance of the base metal cannot be lost, and the machining period is effectively shortened.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com